Melt electrospinning nanometer twisted yarn preparing device and method achieving multi-needle rotary twisting

A technology for preparing devices and melts, which is applied in textiles and papermaking, filament/thread forming, fiber processing, etc. It can solve the problems of interfering with fluid flow characteristics, difficulty in forming a uniform electric field, poor orientation and uniformity, etc., and improve mechanical properties. performance, avoid mechanical adhesion, controllable twist effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

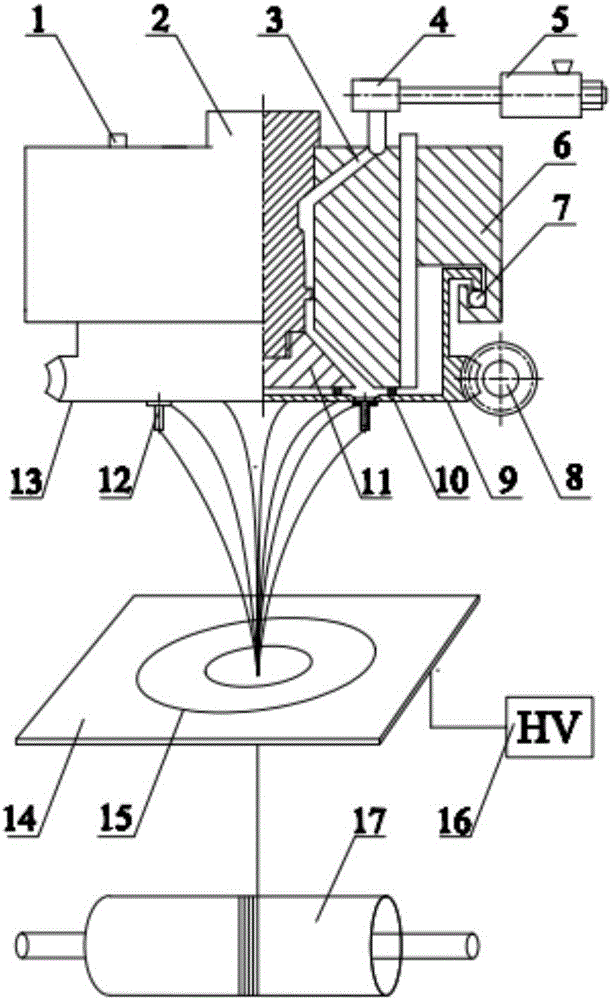

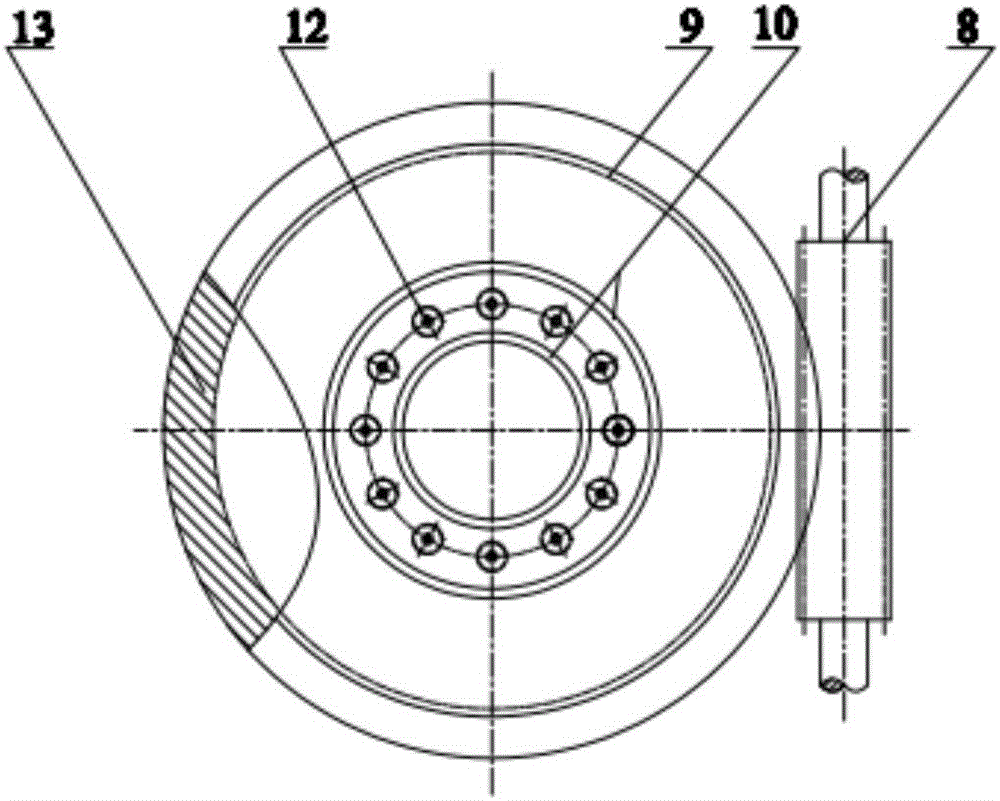

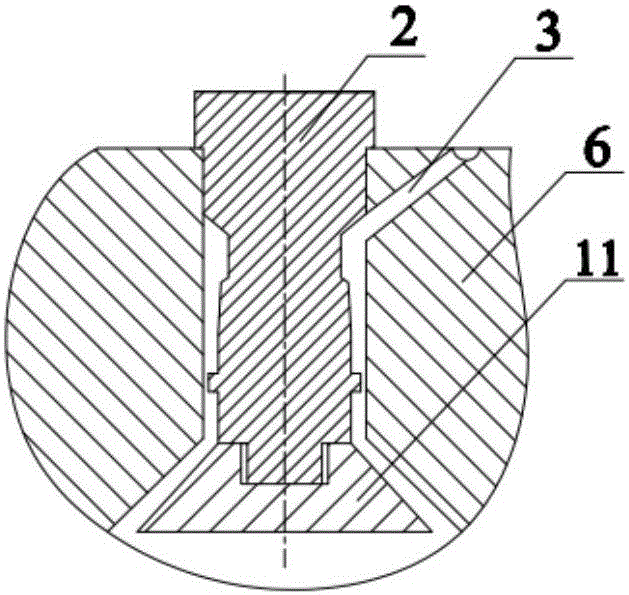

[0027] The present invention is a multi-needle rotary twisting melt electrospinning nano-twist preparation device, such as figure 1 As shown, it mainly includes: heating rod 1, central shaft 2, runner 3, corner head 4, extruder 5, diverter plate 6, ball 7, worm 8, thin-walled container 9, copper ring 10, cone deflector 11, single-needle nozzle 12, worm wheel 13, acrylic plate with holes 14, electrode plate 15, high-voltage electrostatic generator 16, receiving roller 17. The outlet at the end of the extruder 5 is connected with the inlet of the corner die 4 . The splitter plate 6 and the central shaft 2 form a flow channel 3, which gradually narrows from top to bottom and connects with the outlet of the corner head 4. A copper ring 10 is arranged between the upper part of the needle 12 and the flow channel 3 as a sealing device. The melt flows into each single-needle nozzle 12 evenly through the flow channel 3 and the conical deflector 11, ensuring the uniformity of feeding....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com