Patents

Literature

96 results about "Melt electrospinning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Melt electrospinning is a processing technique to produce fibrous structures from polymer melts for applications that include tissue engineering, textiles and filtration. In general, electrospinning can be performed using either polymer melts or polymer solutions. However, melt electrospinning is distinct in that the collection of the fiber can very focused; combined with moving collectors, melt electrospinning writing is a way to perform 3D printing. Since volatile solvents are not used, there are benefits for some applications where solvent toxicity and accumulation during manufacturing are a concern.

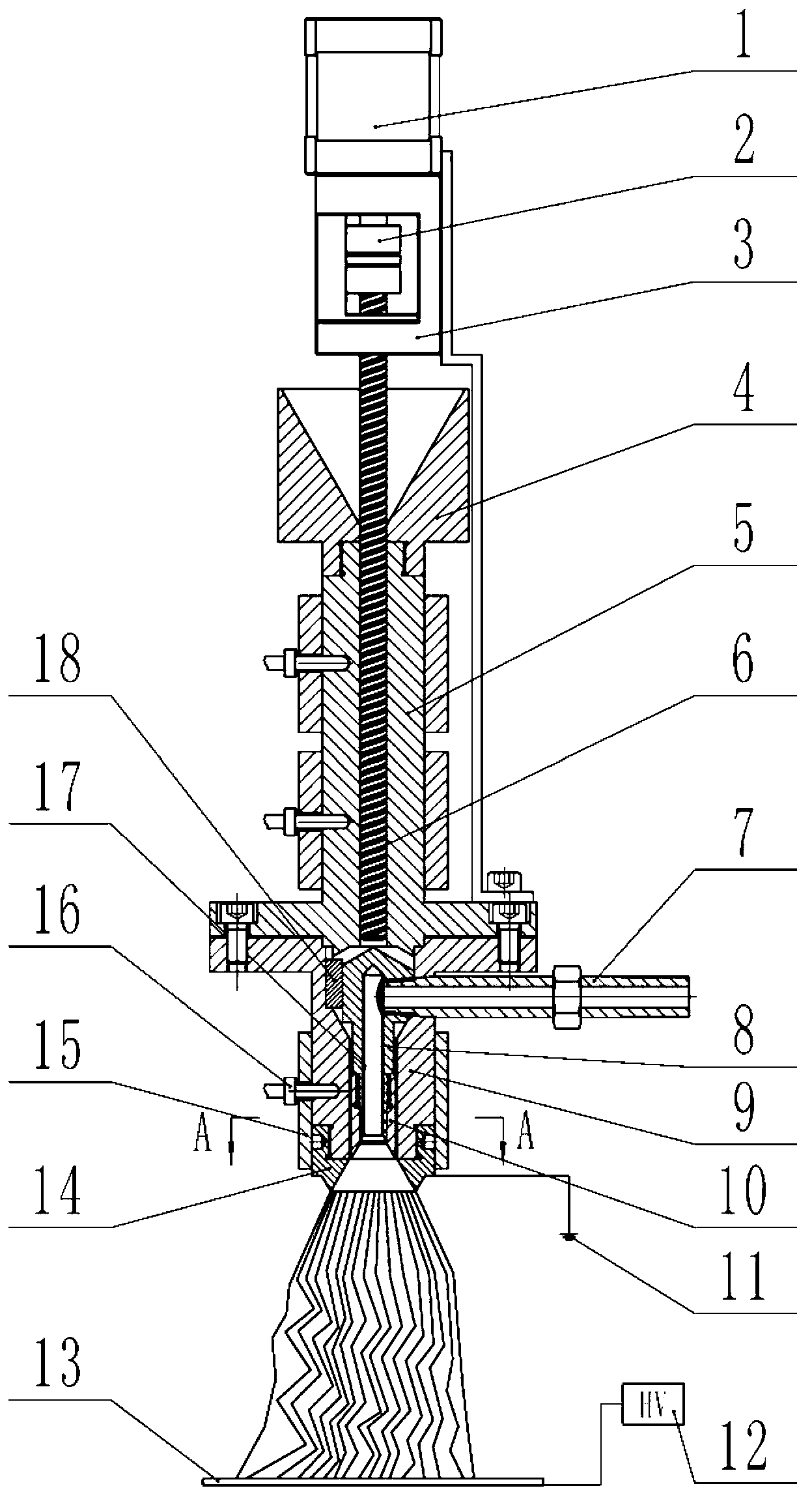

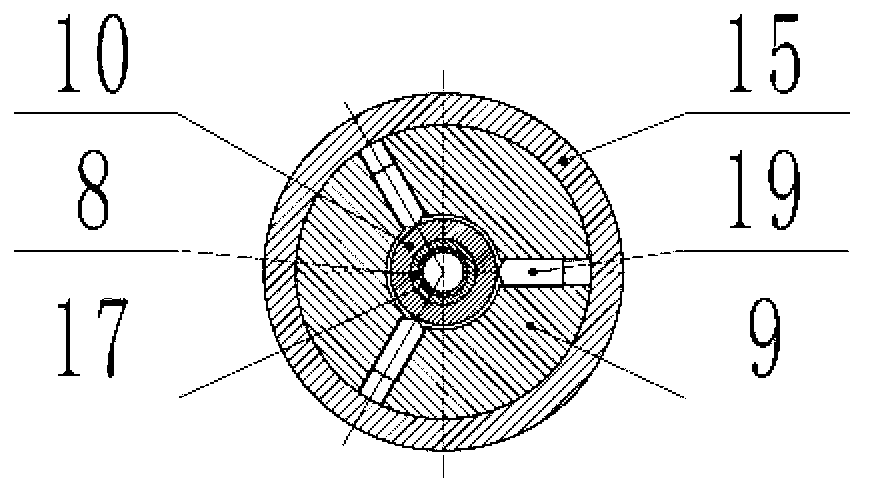

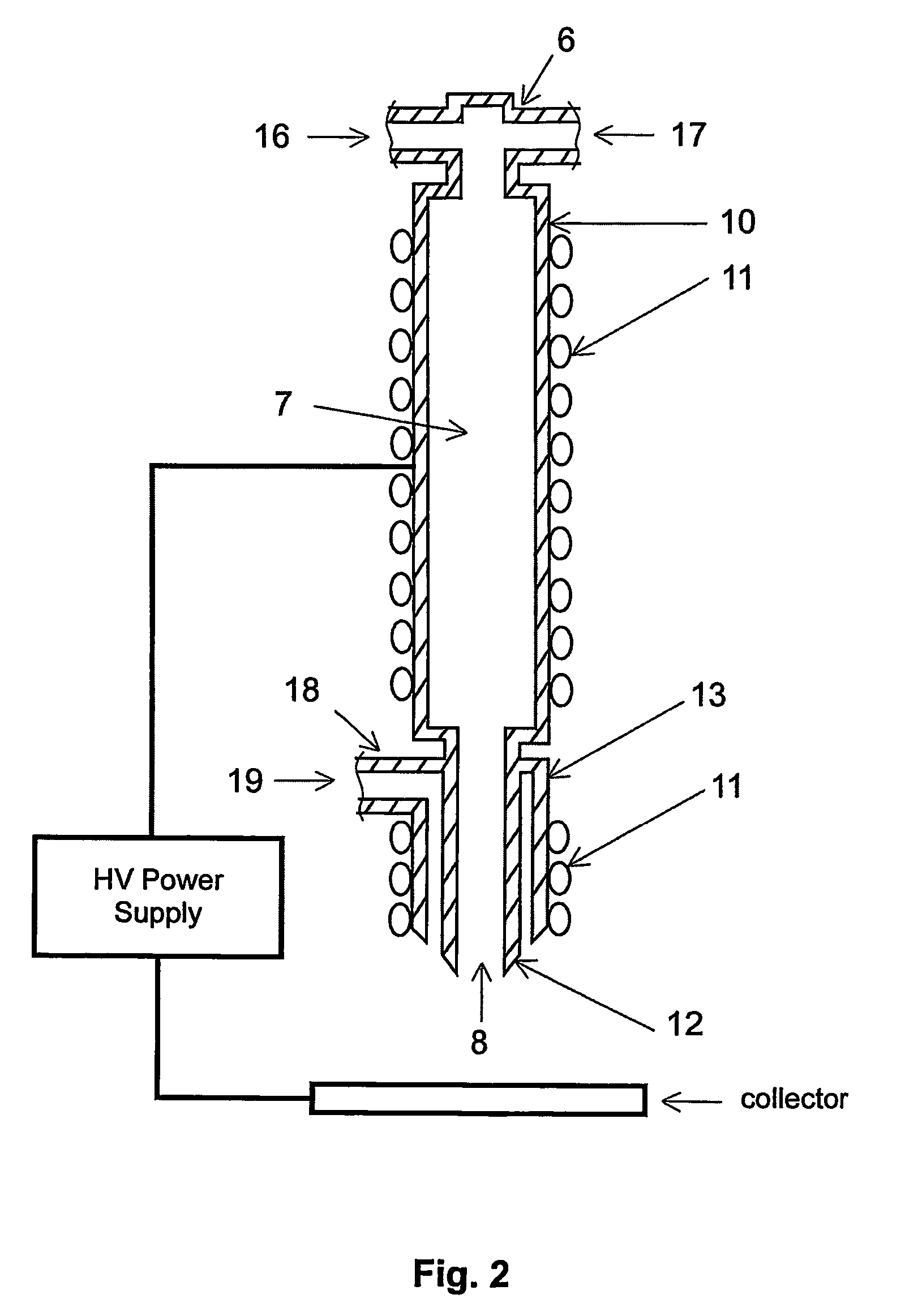

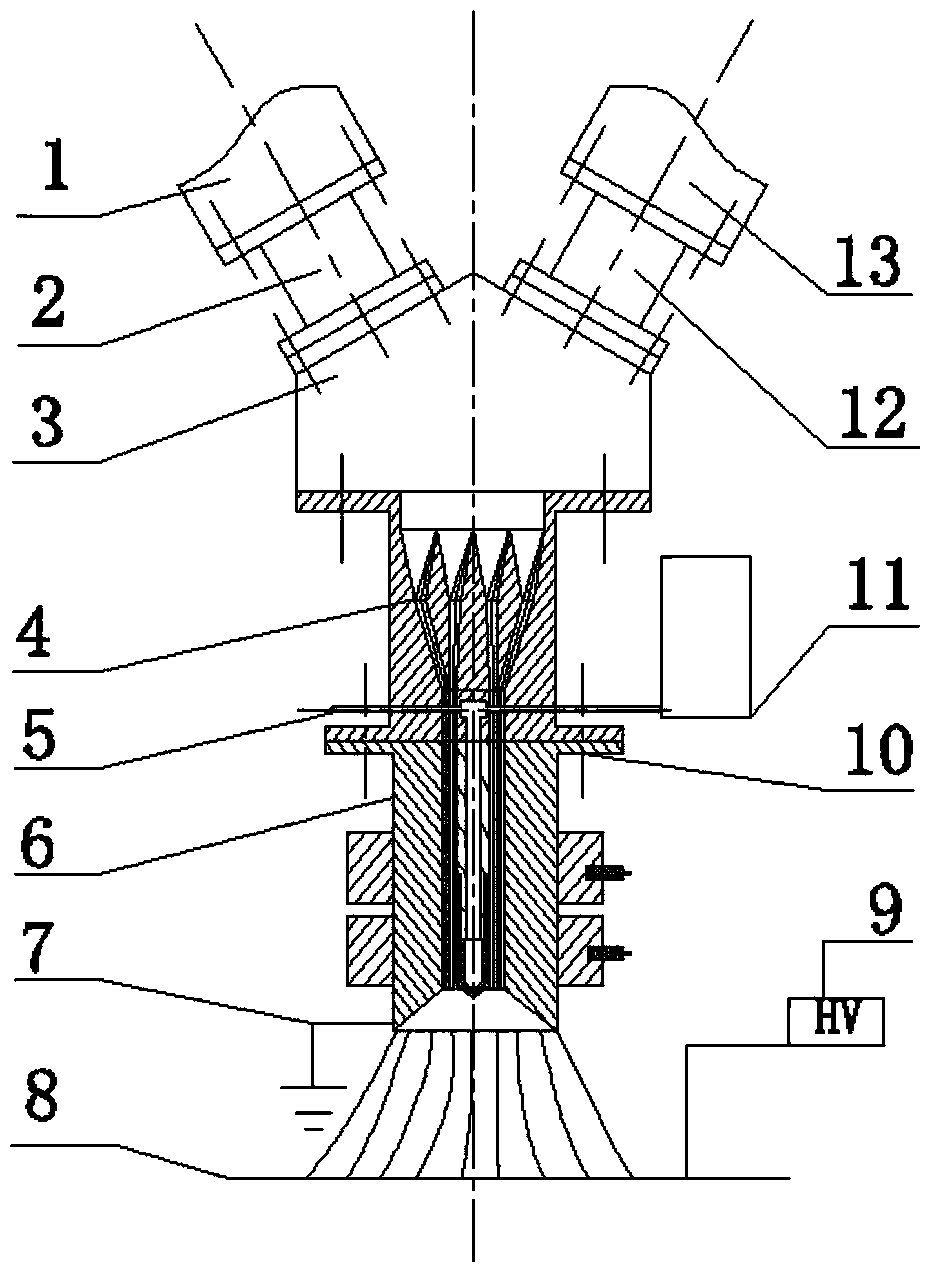

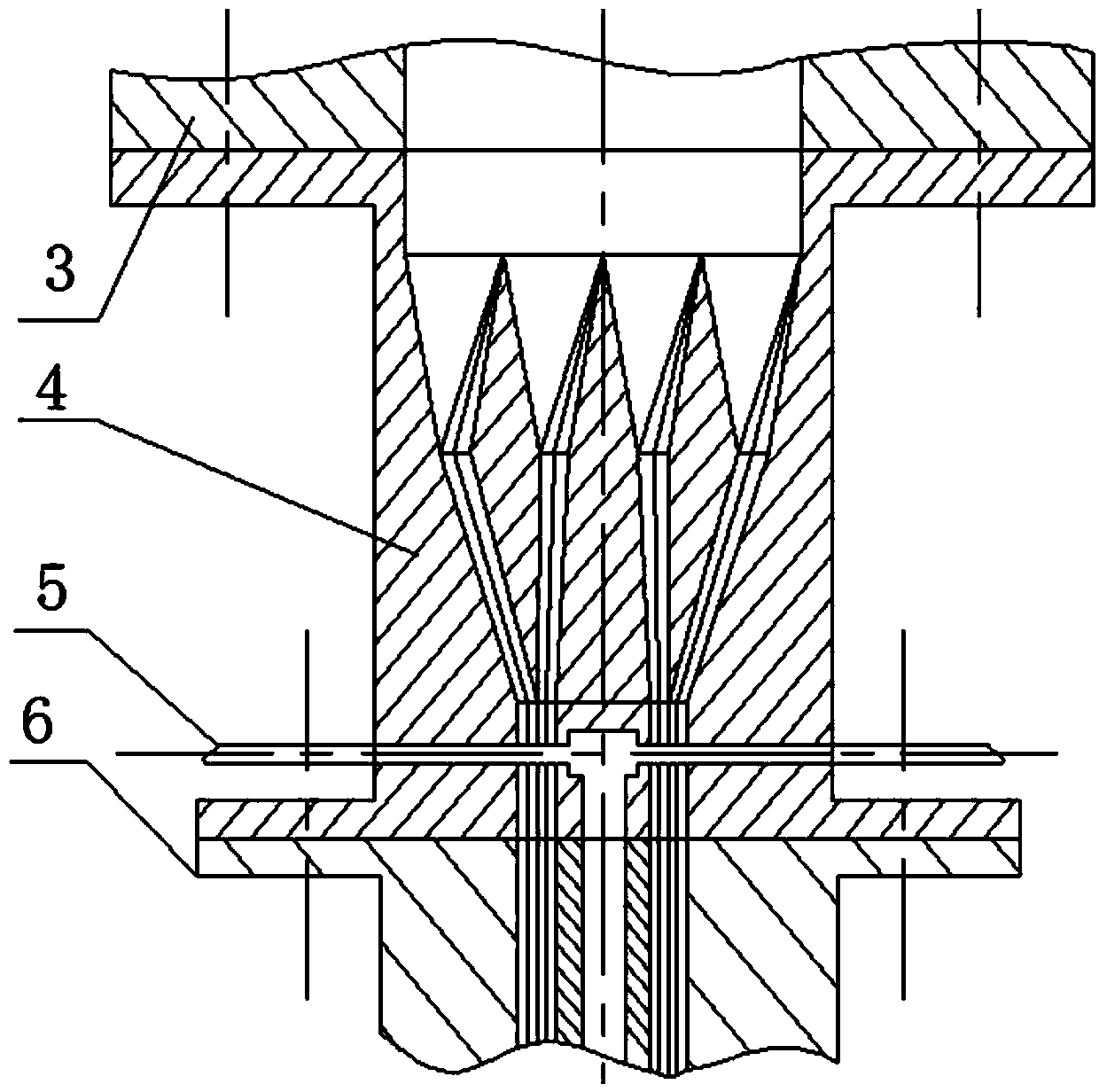

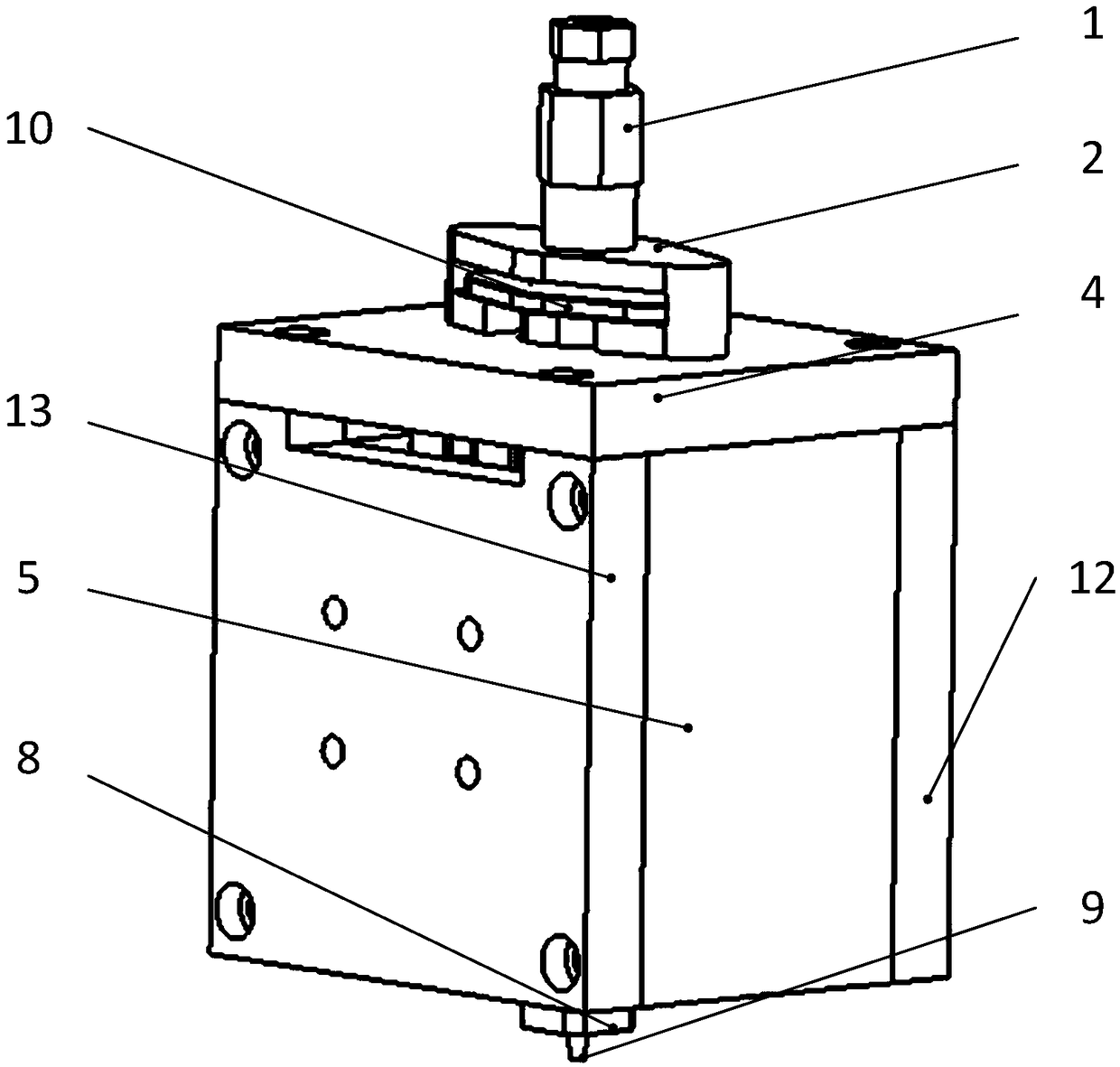

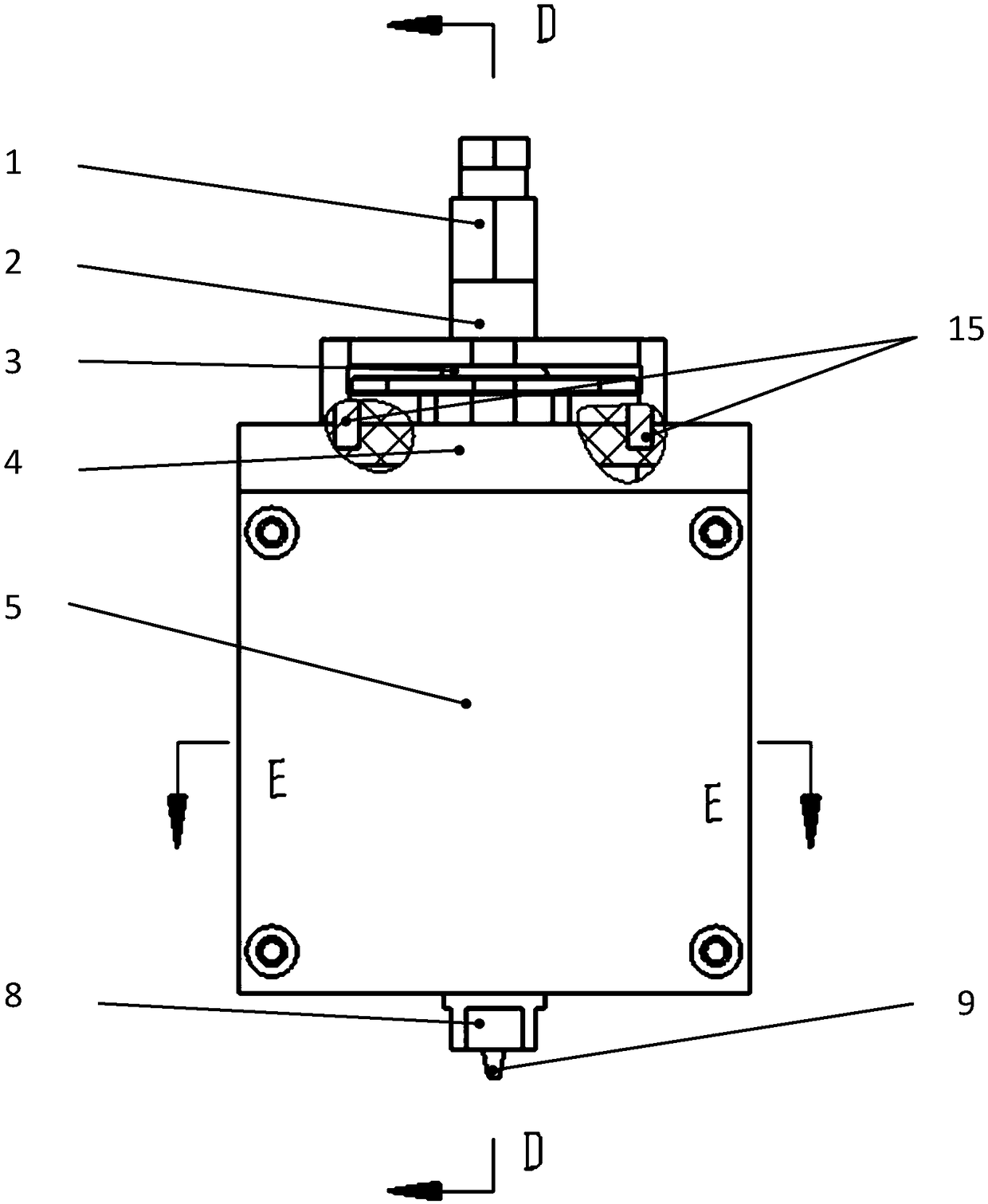

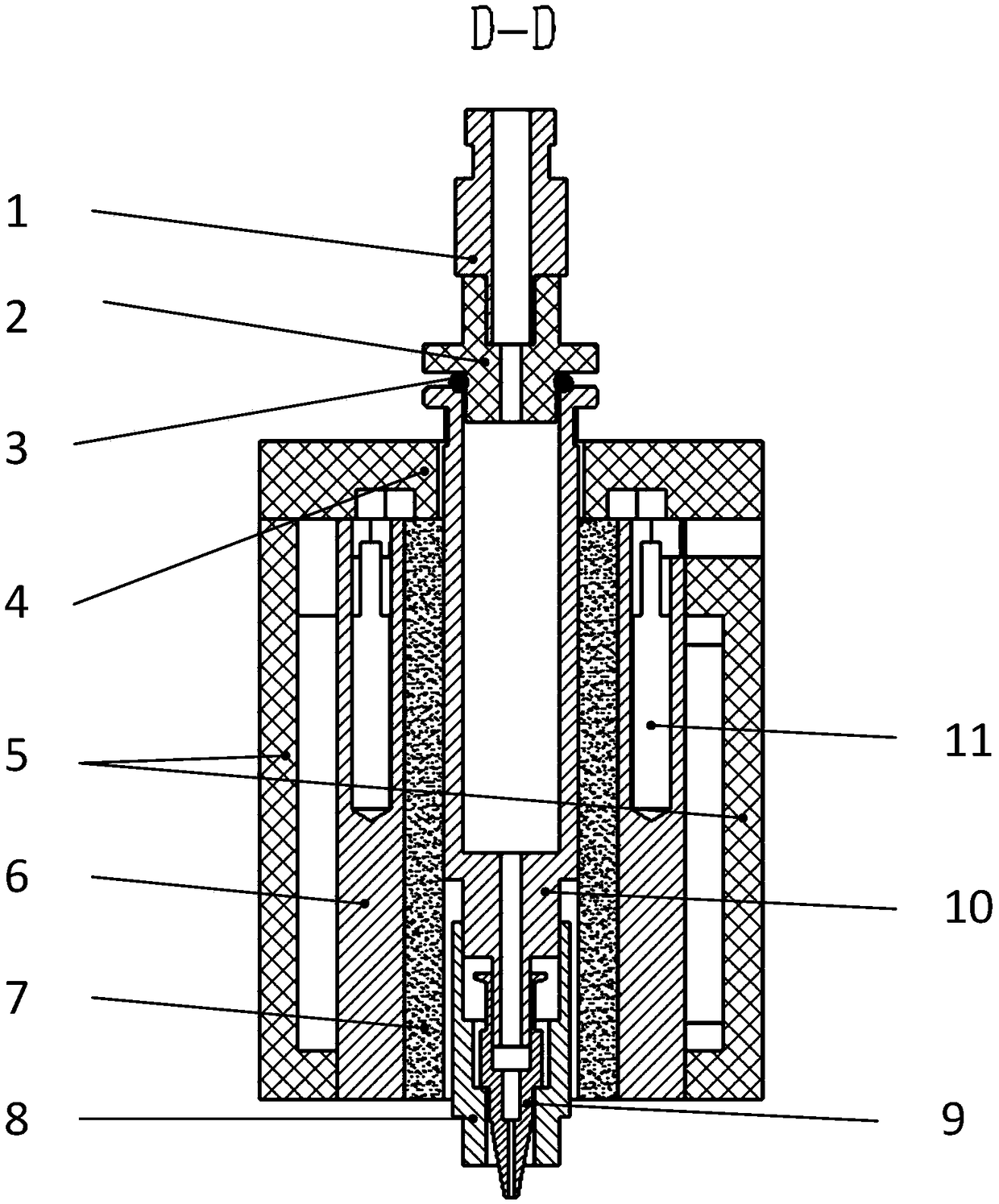

Differential melt-electrospinning jet head

The invention discloses a differential metl-electrospinning jet head and belongs to the field of electrostatic spinning. The differential metl-electrospinning jet head mainly comprises a hopper, a charging barrel, a jet head body, an internal cone-shaped jet head, an airflow channel air inlet pipe, an airflow channel standpipe, an airflow channel insulating layer, a jet head inner body, a button, a jackscrew, a heating device, a temperature sensor, a screw rod, a coupler, a servomotor, a motor support, a grounding electrode, a receiving electrode plate and a high-voltage electrostatic generator. The differential metl-electrospinning jet head adopts a center-feeding and side-air-intake manner, ensures uniform melt circumferential distribution through the adjustment of the jackscrew, adopts the inner cone-shaped jet head, and can spin dozens of filaments through a single jet head, thereby achieving high spinning efficiency; and by the aid of hot air, the melt layer on the inner cone surface can be blown thinner, the filaments can be drawn, and a heat insulation role can be played on the environmental temperature to slow down cooling of the filaments and prolong the filament drawing time. Therefore, the spun filaments are thinner. The differential metl-electrospinning jet head has the advantages of simple structure, capability of spinning thin fibers and high spinning efficiency.

Owner:BEIJING UNIV OF CHEM TECH

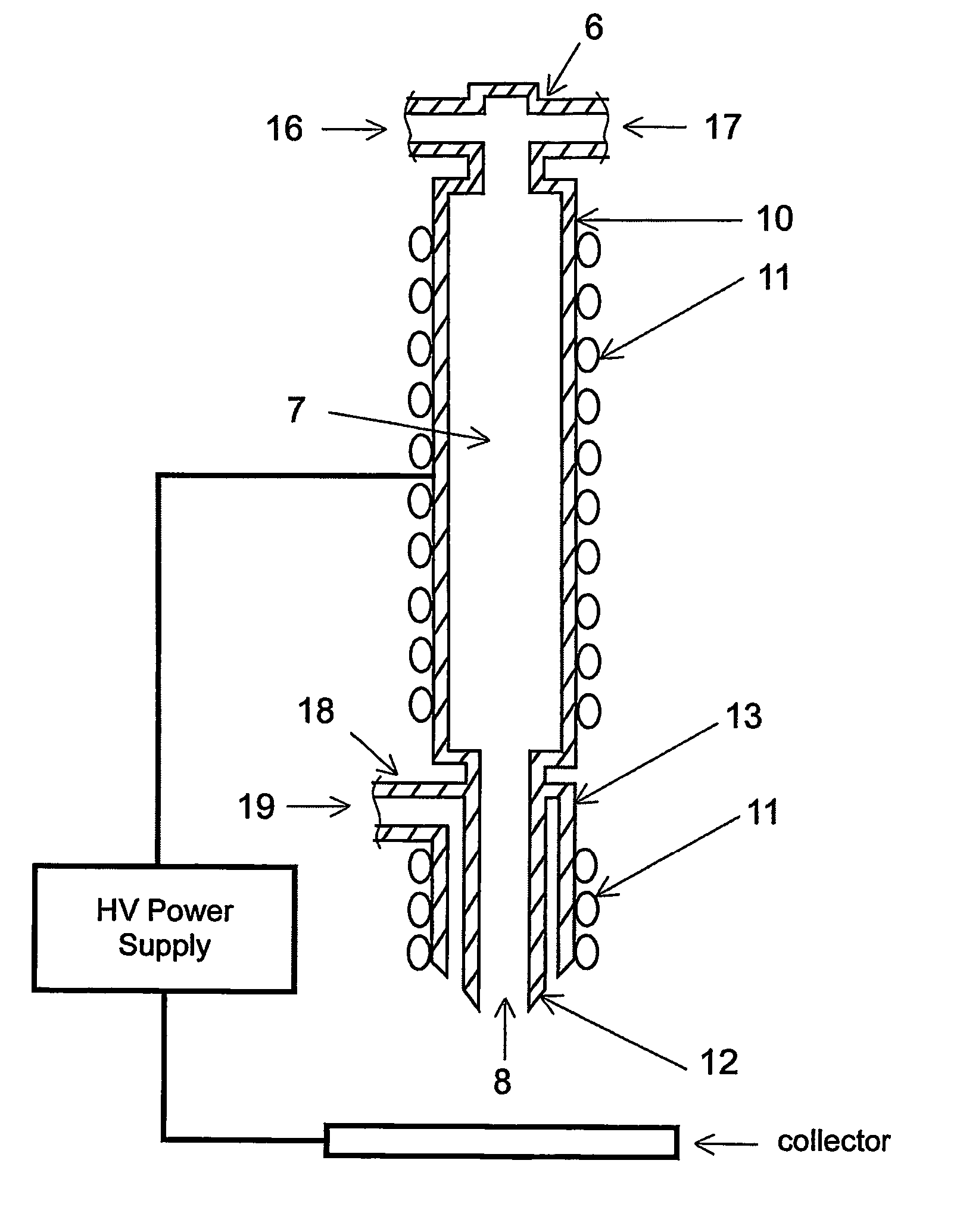

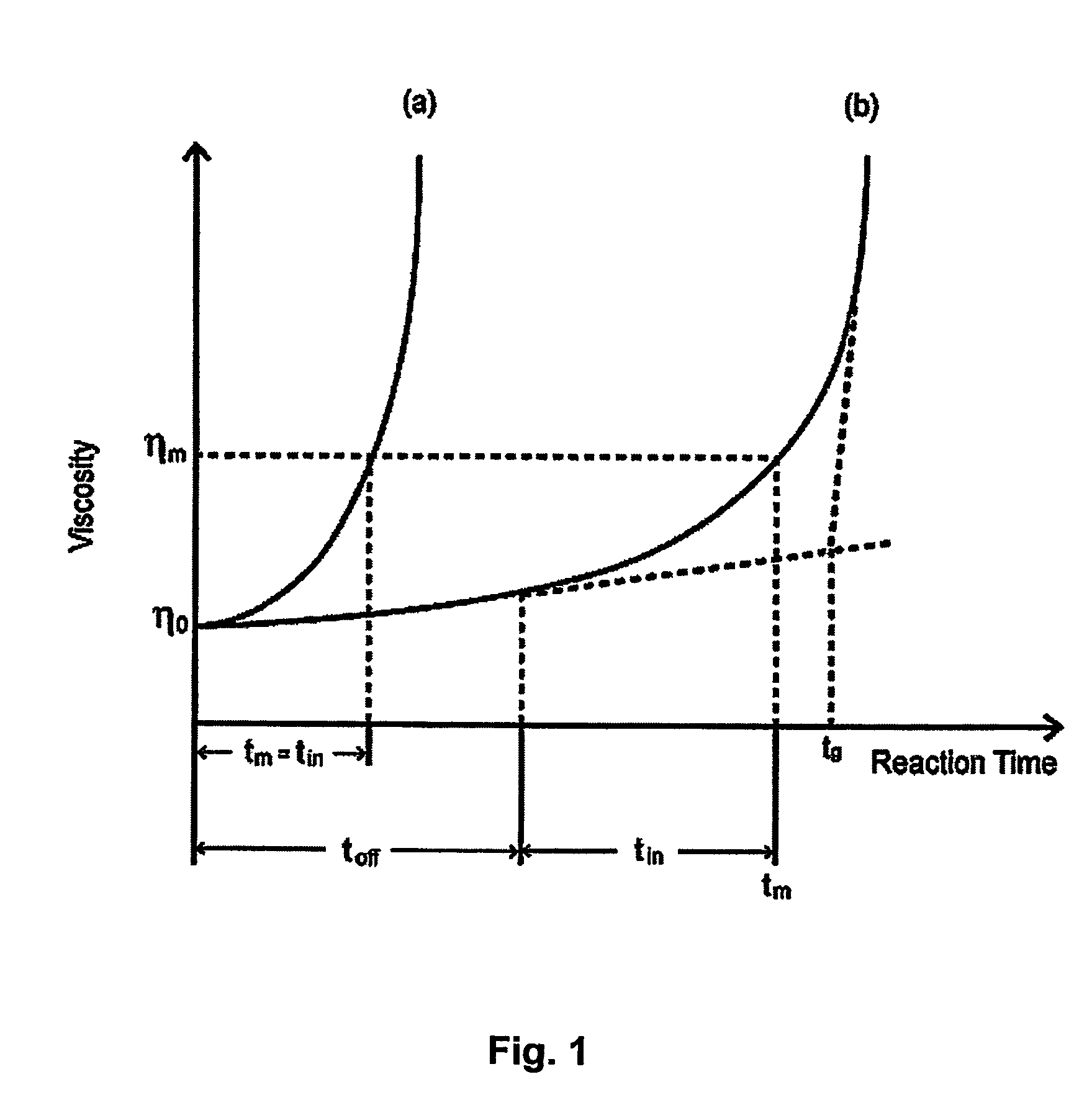

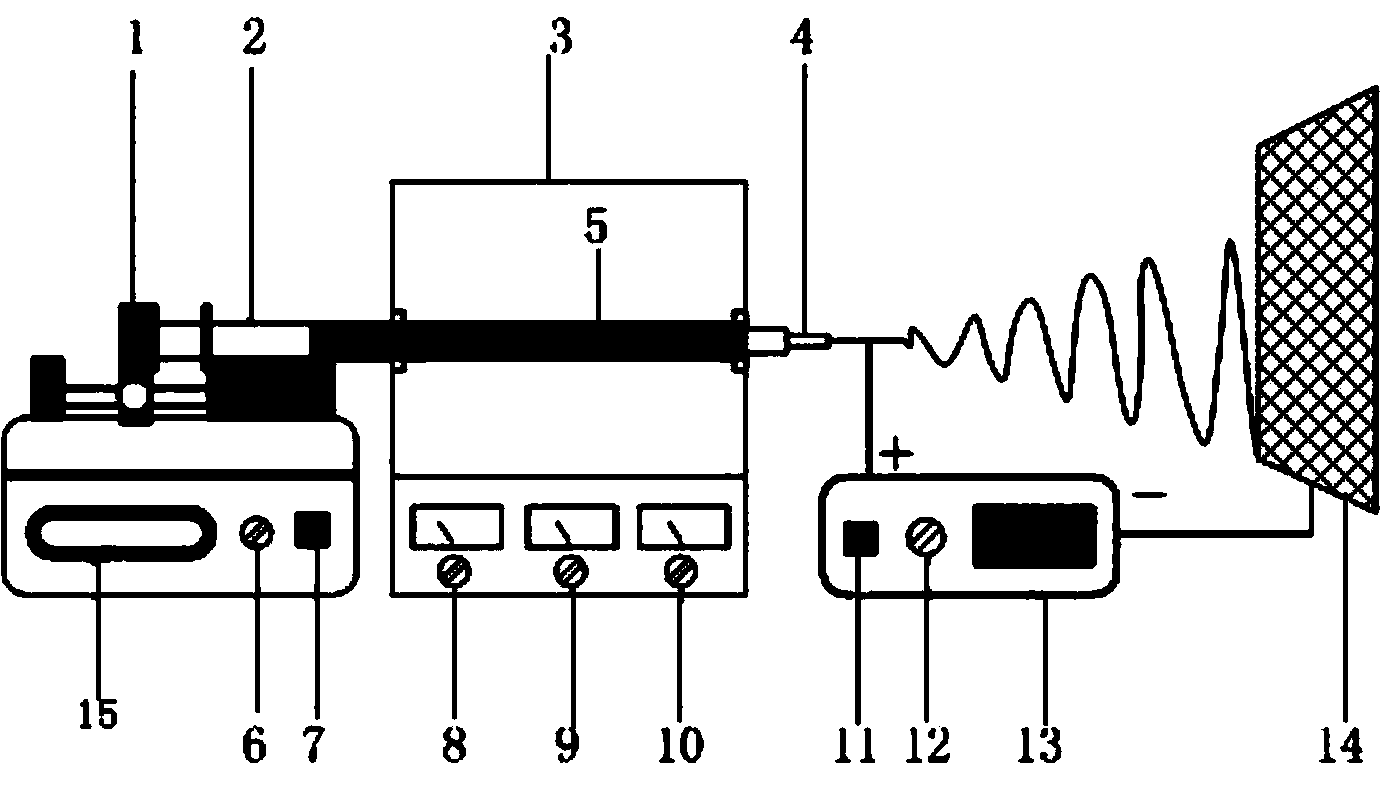

Process of fabricating nanofibers by reactive electrospinning

ActiveUS8066932B2Easy to controlHigh voltageElectric discharge heatingInorganic material artificial filamentsNanofiberCrosslinked polymers

Apparatus and methods for fabricating nanofibers by reactive electrospinning are described. An electrospinning process is coupled with an in-line reactor where chemical or photochemical reactions take place. This invention expands the application of the electrospinning and allows the production of nanofibers of crosslinked polymers and other new materials, such as gel nanofibers of ceramic precursors.

Owner:BOARD OF SUPERVISORS OF LOUISIANA STATE UNIV & AGRI & MECHANICAL COLLEGE

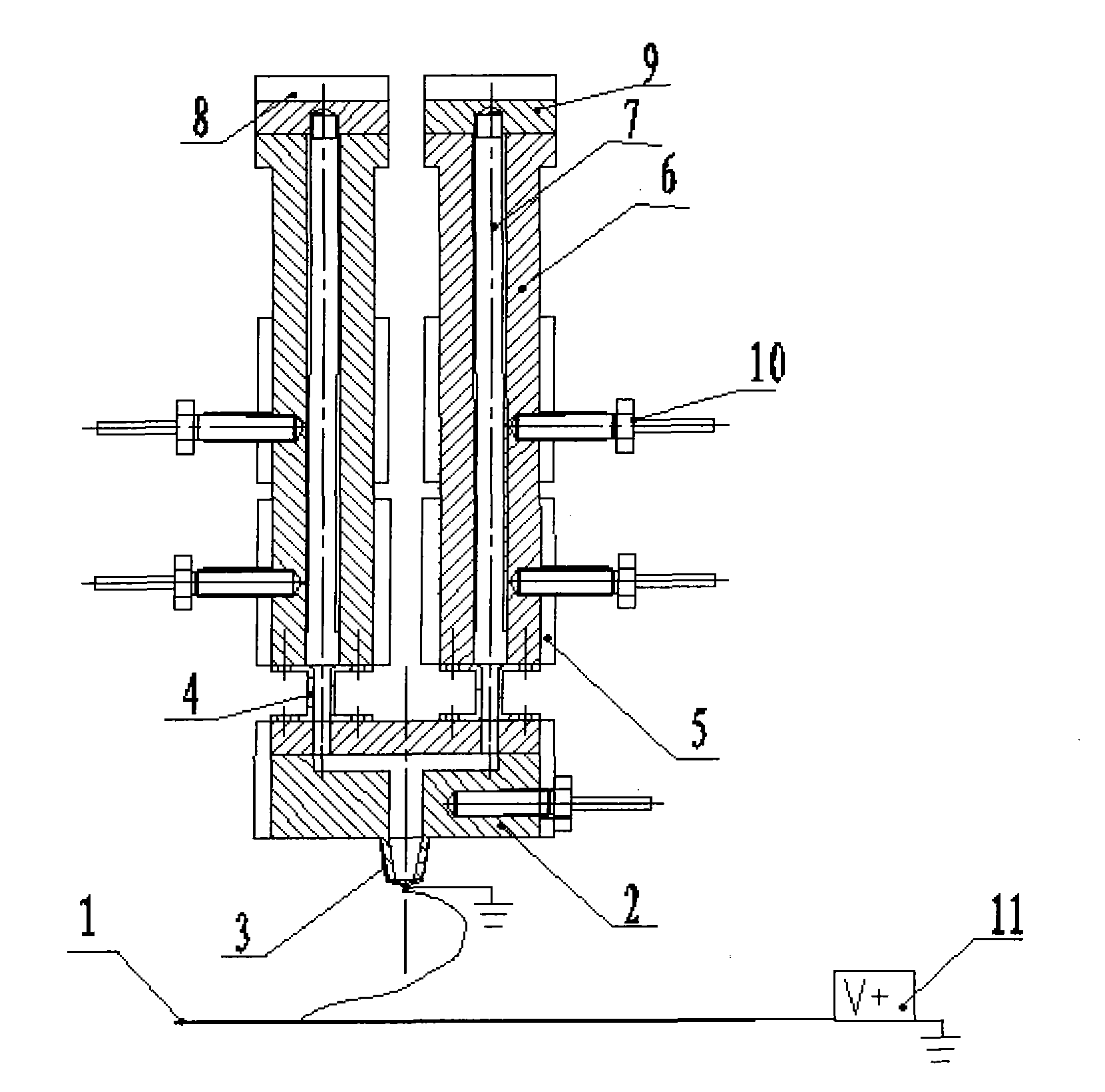

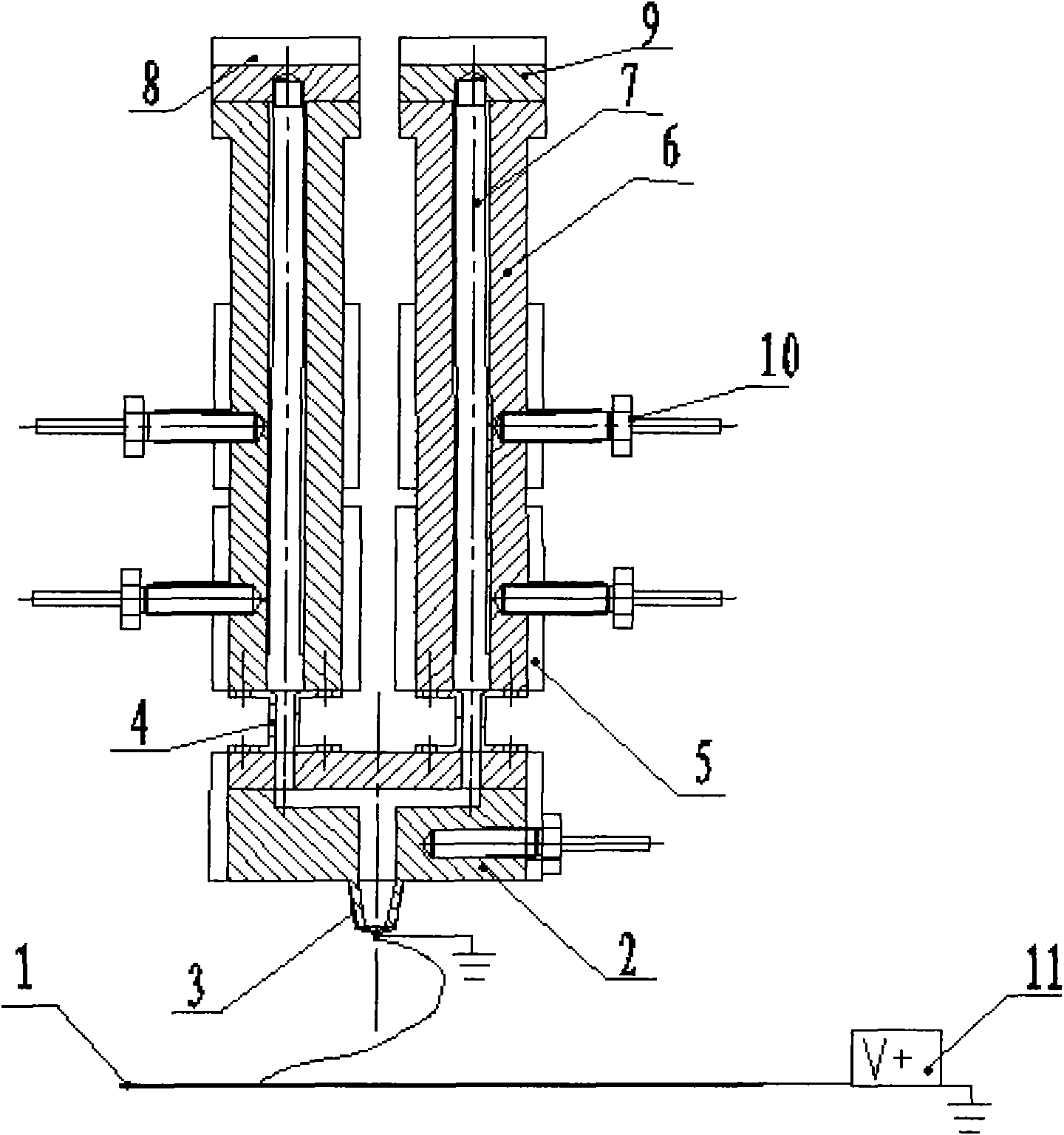

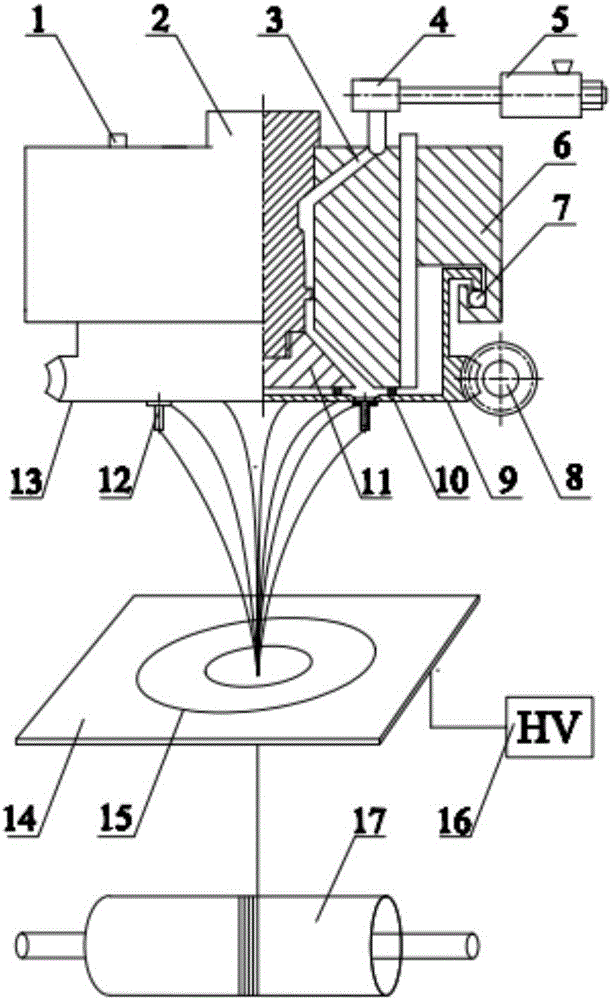

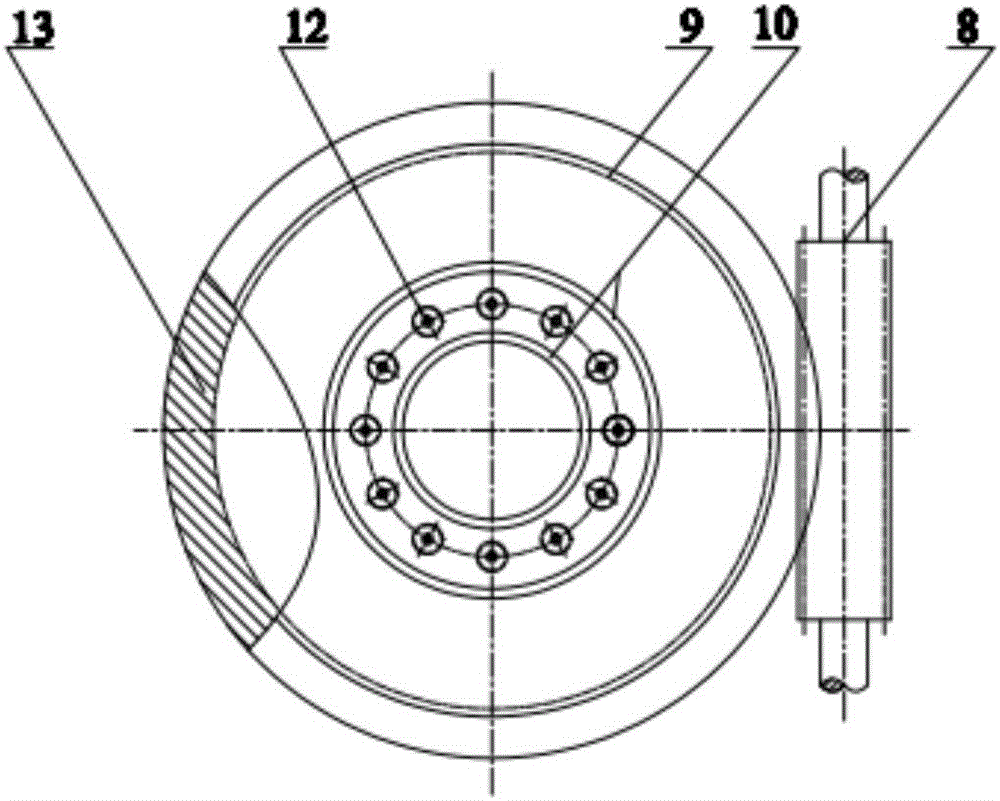

Device for producing composite fibers through melt-electrospinning

The invention discloses a device for producing composite fibers through melt-electrospinning, and belongs to the field of electrospinning. The device mainly comprises a receiving device, a converging device, a capillary tube, a nozzle, a heating ring, a charging barrel, a piston shaft, a pressure device, an end cover, a temperature sensor, a high voltage static generator and the like, wherein the receiving device is positioned under the capillary tube, and is connected with the anode of the high voltage static generator; the other electrode of the high voltage static generator is grounded; the capillary tube is in cone close fit with the converging device, and is connected with the ground through an out wire; the nozzle is in screw connection with the converging device and the charging barrel; the heating ring is coated on the surface of the charging barrel; the temperature sensor is in threaded connection with the charging barrel; the end cover is in threaded connection with the piston shaft; the pressure device is positioned on the end cover; and the distance between the smelt outlet of the capillary tube and the receiving device is more than 2cm. The device can simultaneously carry out smelt-electrospinning on two or more polymers so as to produce side-by-side or core-sheath composite fibers.

Owner:BEIJING UNIV OF CHEM TECH

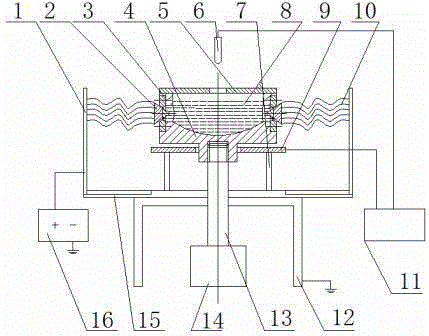

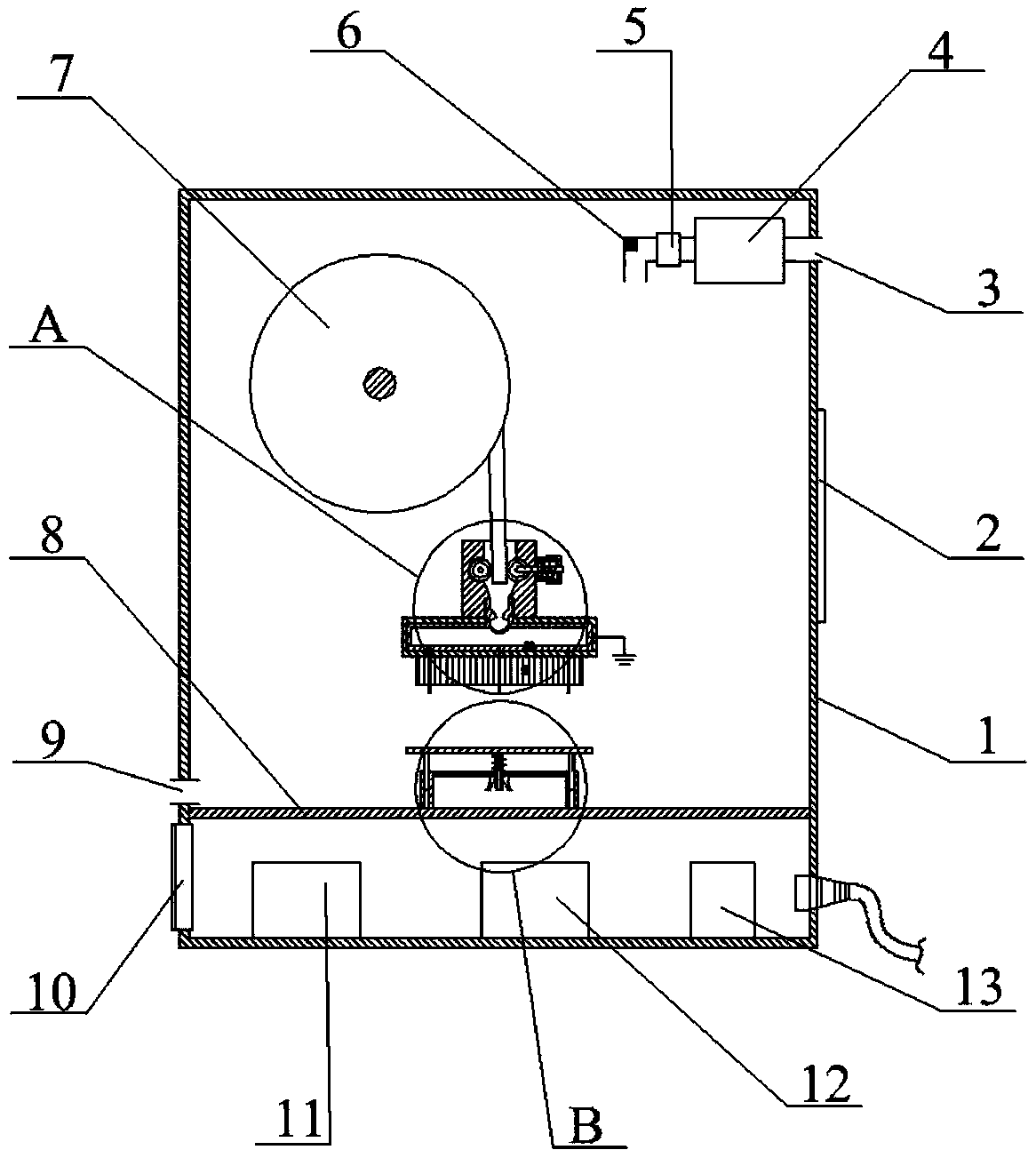

Novel centrifugal melt electrostatic spinning device

ActiveCN104088024ASolve the blockageBatch preparation in orderFilament/thread formingFiberCircular cone

The invention discloses a novel centrifugal melt electrostatic spinning device. The device mainly comprises a spinning component, a receiving component, an electromagnetic heating component, a high voltage generating component, a power-driven component and a rack. The spinning component comprises a liquid storage tank, an end cover, first circular cone frustum spray head assemblies and second circular cone frustum spray head assemblies. The receiving component comprises a plastic bottom plate made of nylon and an aluminum receiving plate which can slide on the plastic bottom plate through bolt adjusting, wherein a groove is formed in the plastic bottom plate. The electromagnetic heating component comprises an electromagnetic coil, an electromagnetic control box, an infrared thermometer and supporting rods. The electromagnetic coil is located at the lower end of the liquid storage tank. The high voltage generating component comprises a high voltage generator, wherein a positive electrode of the high voltage generation is connected with the static receiving plate of the receiving component. The power-driven component comprises a motor and a shaft, the shaft is driven by the motor to rotate so as to drive the liquid storage tank to rotate. The rack is grounded and supports the whole spinning system. Centrifugal force is introduced into a traditional melt electrostatic spinning device, by the utilization of dual functions of electrostatic force and centrifugal force, fibers are stretched and refined, and finally nanometer fibers are manufactured in order in batch.

Owner:BEIJING UNIV OF CHEM TECH

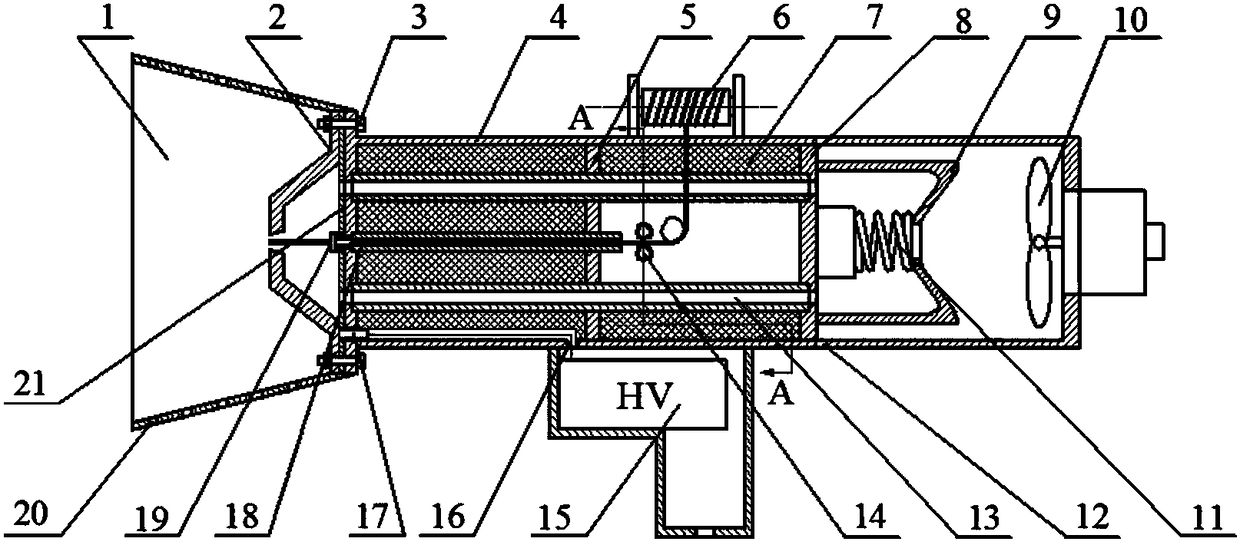

Handheld melt electrostatic spinning preparation device and method for applying same

ActiveCN108251897AAdjustable speedMeet melting requirementsFilament/thread formingTextile/flexible product manufactureFiberEngineering

The invention discloses a handheld melt electrostatic spinning preparation device and a method for applying the same. The handheld melt electrostatic spinning preparation device mainly comprises a safety shield, an end cover, fastening screws, a shell, a support plate, a rotary drum, heat preservation cotton, a partition plate, a fan, a resistance heating wire, air holes, air pipes, rollers, a miniature high-voltage electrostatic generator, a wire through hole, an electrode connector, a feed pipe, a needle, exhaust holes, a metal gasket, air pipe holes, a feed pipe hole, a conical hole and thelike. The handheld melt electrostatic spinning preparation device and the method have the advantages that materials can be continuously fed by the aid of wires, heat can be transferred by air heatedby the resistance heating wire, and accordingly the materials can be heated and molten; the needle is connected with high voltages, and electric fields are formed between the needle and grounded receiving plates; hot air can be exhausted from slits between the needle and the conical hole in the end cover after the heat is completely transferred, and accordingly fibers can be secondarily stretched;the handheld melt electrostatic spinning preparation device is simplified, is miniaturized, lightened and portable, accordingly, fibers can be conveniently and quickly prepared, and the handheld meltelectrostatic spinning preparation device can be used for preparing fibers for laboratory application, home use, clinical medical purposes and the aspect of teaching demonstration tools on a small scale.

Owner:BEIJING UNIV OF CHEM TECH

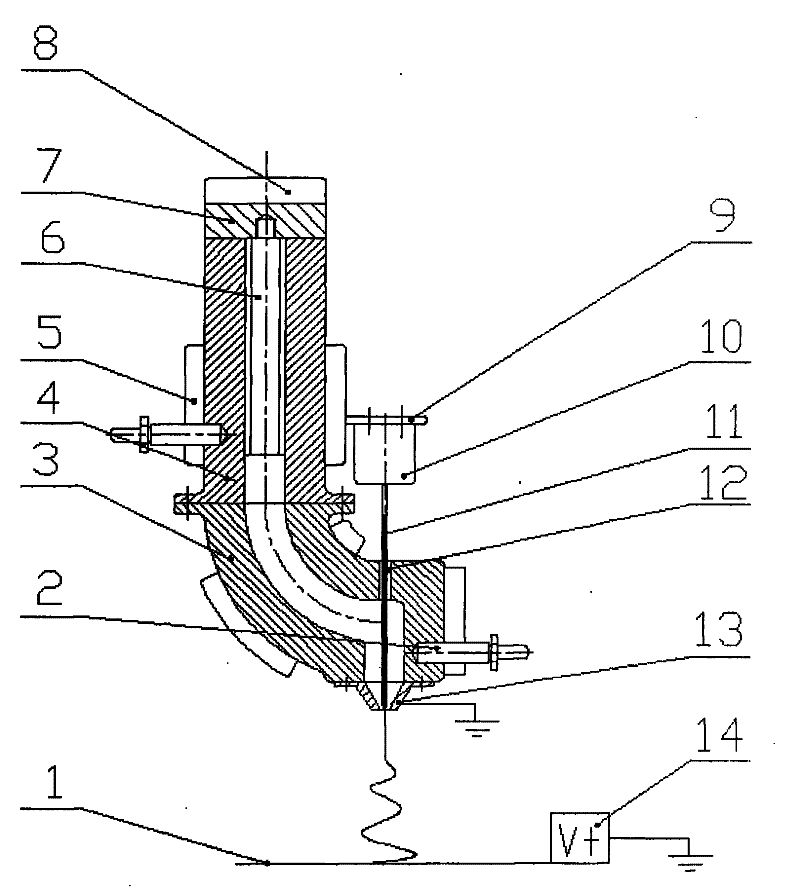

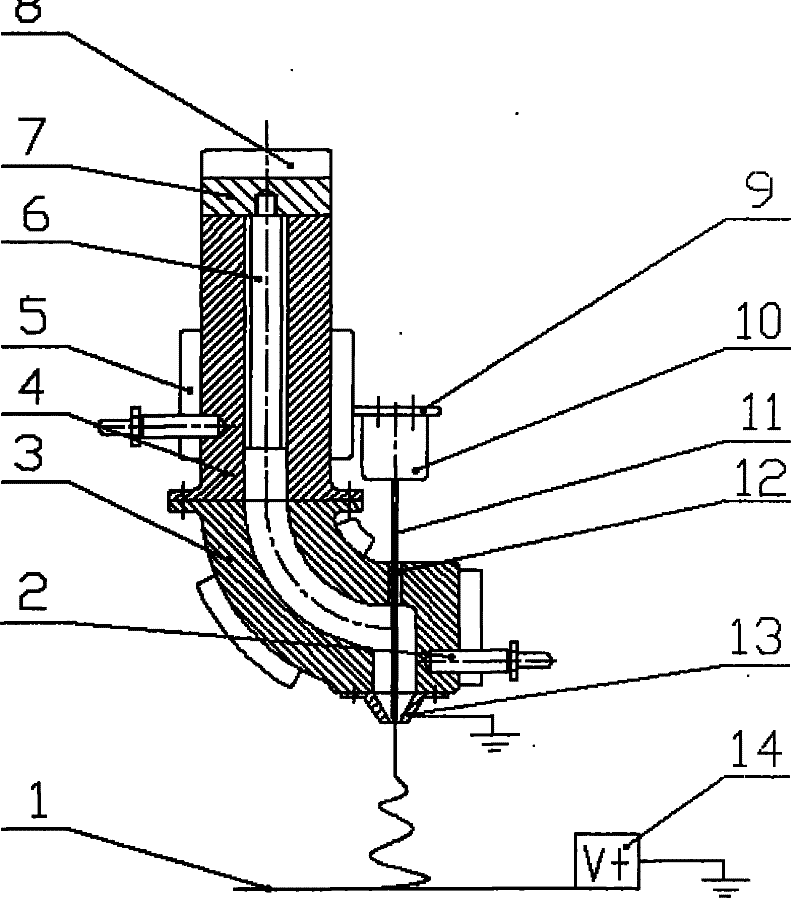

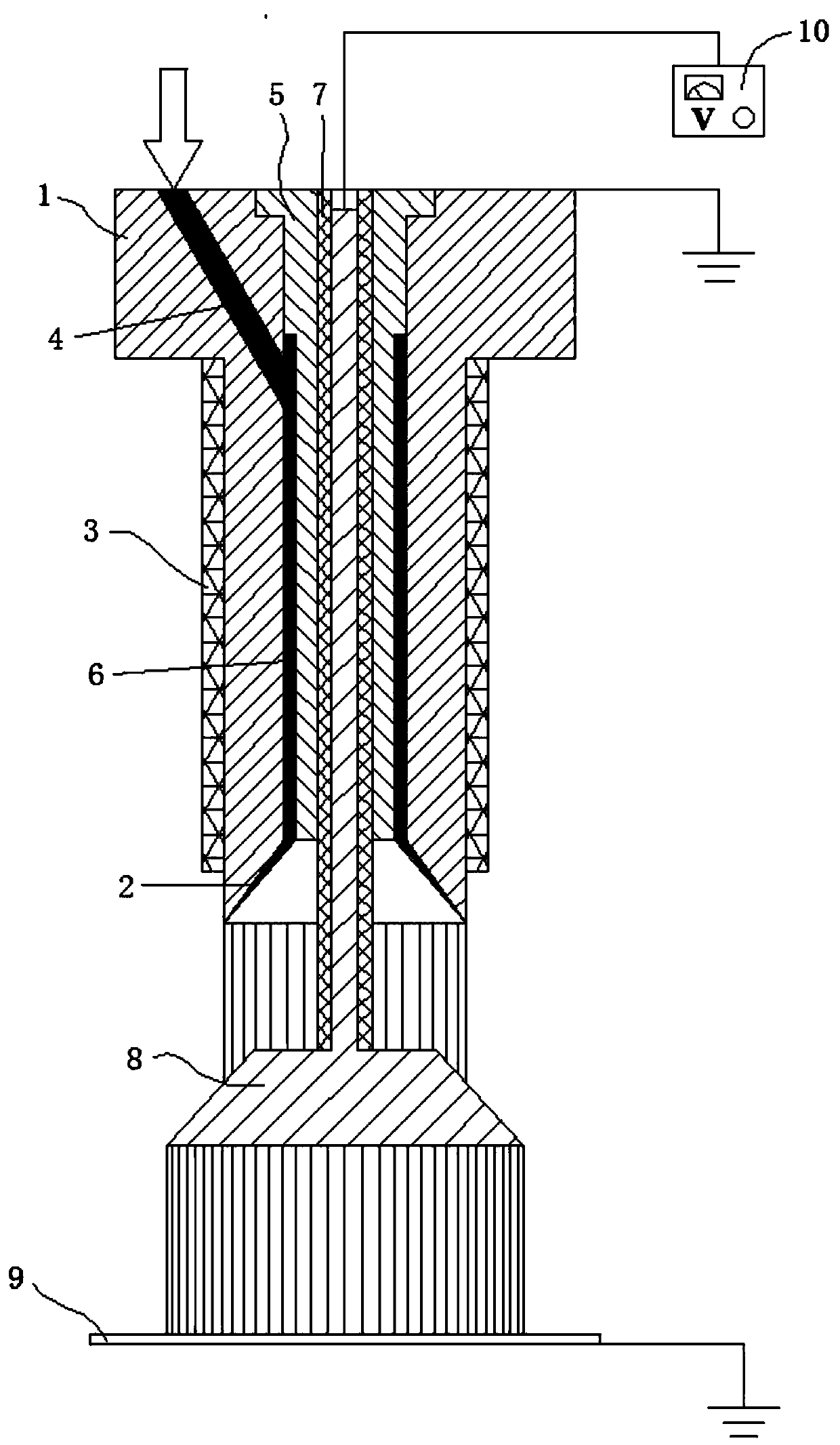

Device for promoting electrostatic spinning of high-viscosity polymer melt by using rod-climbing effect

ActiveCN102191568AReduce degradationSave energyArtificial thread manufacturing machinesFilament/thread formingFiberConductive materials

The invention discloses a device for promoting electrostatic spinning of a high-viscosity polymer melt by using a rod-climbing effect, and belongs to the field of electrostatic spinning. The device mainly comprises a receiving device, a temperature sensor, a bent material barrel, a straight material barrel, a heating ring, a piston shaft, an end cover, a pressurizing device, a motor frame, a motor, a rotary needle, a sealing ring, a spinning head and a high-voltage electrostatic generator. A spinning material can be a polymer particle, powder, a section or a melt; the receiving device adopts various modes such as a conductive flat plate, a conductive net, a roller and the like; the spinning head is made from a conductive material such as metal and the like, and the inner diameter of the spinning head is smaller than 1 millimeter; and the pressurizing device can be implemented by a weight-adding manner or adopts a micro propeller. By using the rod-climbing effect, the problem that the polymer material which is high in viscosity and easy in degradation at high temperature is poor in spinning effect; therefore, an ultrathin fiber can be prepared from the high-viscosity polymer melt by electrostatic spinning at lower temperature.

Owner:BEIJING UNIV OF CHEM TECH

Melt electrostatic spinning device

InactiveCN108823652AReduce volumeReduce weightSpinning head liquid feederArtificial thread manufacturing machinesFiberTransformer

The invention discloses a melt electrostatic spinning device. The device comprises a material supply unit, an electrostatic spinning unit, an atmosphere adjusting unit and a control unit; the materialsupply unit comprises a feeding roll, a feeding stepping motor, a material pressing roll, a spinning material roll and a spinning material heater, the feeding stepping motor is connected with the feeding roll, the material pressing roll is parallel to the feeding roll, and spinning material roll is used for supplying materials to the gap between the feeding roll and the material pressing roll; the electrostatic spinning unit comprises a grounding spraying head, an adjustable high-voltage static generation module and an electrospinning fiber collecting plate, wherein the electrospinning fibercollecting plate is in positive connection with the adjustable high-voltage static generation module; the atmosphere adjusting unit comprises a gas flow sensor, a temperature sensor, a control panel,a transformer and a controller. The melt electrostatic spinning device is high in integration degree, realizes control over the temperature and flow of the spinning materials, adjusts spinning voltageand spinning distance, can realize continuous production operation, and has good application prospects in the field of melt electrostatic spinning.

Owner:安徽东蒙环保科技有限公司

Melt electro-spinning device and technology capable of mixing supercritical gas

InactiveCN104894664AImprove uniformitySmooth feedingFilament forming substance formingArtificial thread manufacturing machinesFiberMolten state

The invention relates to a melt electro-spinning device and technology capable of mixing supercritical gas. The device comprises a power device, an extruding device, a supercritical gas generator and a melt electro-spinning device body. The technology comprises the steps that polymer is firstly added into a charging barrel, heated to a melt state, and mixed with supercritical gas conveyed by the supercritical gas generator; the mixture is conveyed to a static mixer, and the polymer and the supercritical gas form a gas / polymer homogeneous system through the static mixer; the mixture is fed to the melt electro-spinning device body, the polymer is blown, pulled and thinned under the action of high-speed hot gas flow input in an electric field between a spray nozzle and a receiving device and a gas flow channel, and finally the mixture is deposited on the receiving device to obtain fibers. According to the melt electro-spinning device and technology capable of mixing supercritical gas, the extruding device and the melt electro-spinning device body are combined, and therefore nanofibers with good uniformity can be prepared continuously and stably.

Owner:NINGBO GMF TECH

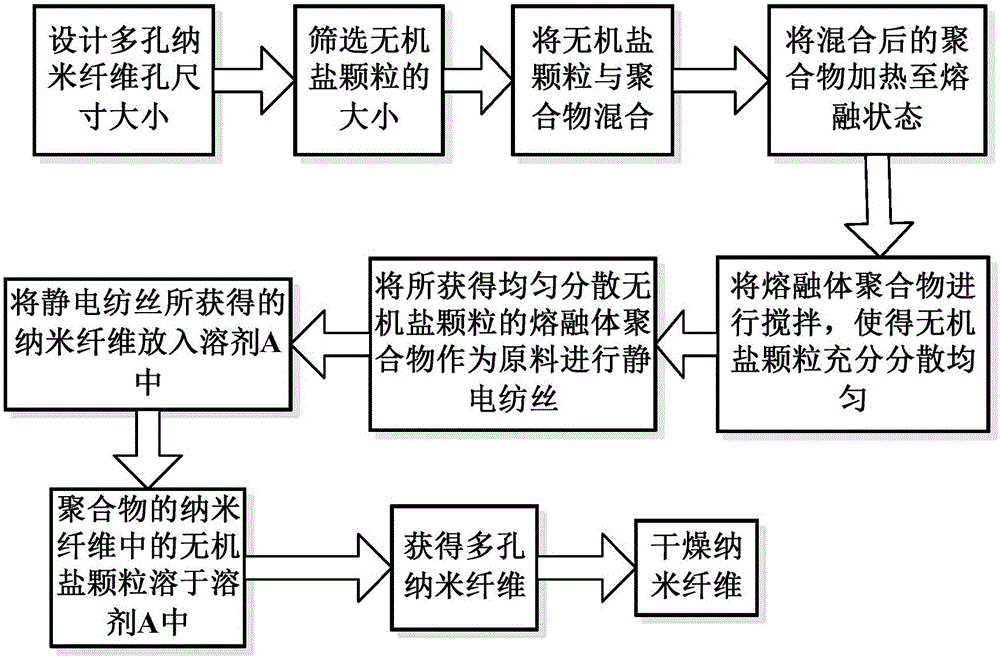

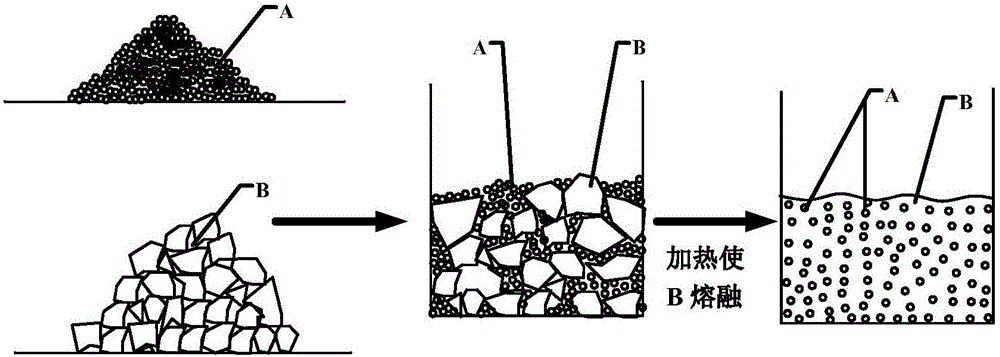

Manufacturing method of porous nanofiber with controllable aperture

ActiveCN105133067AAperture controllableSolve the problem of uncontrollable process apertureFilament/thread formingMonocomponent polyolefin artificial filamentInorganic saltsSpinning

The invention discloses a manufacturing method of porous nanofiber with a controllable aperture. The method comprises the steps of selecting inorganic particles of corresponding size according to requirement of the aperture size of the porous nanofiber; mixing polymers with inorganic salts, heating, so that the polymers are molten, while the inorganic salts are not molten, and then mixing and dispersing; performing electrostatic spinning on molten substances, so as to obtain the nanofiber, placing the nanofiber in a solvent, so as to remove the inorganic salts from the nanofiber, and drying to obtain the porous nanofiber. Thus, the porous nanofiber with the controllable aperture is manufactured. According to the manufacturing method, the inorganic salts are used as pore-foaming agents, so as to manufacture pores which are smaller and more uniform than those of a conventional process and are more economic and environmental friendly, and the conductivity of the polymers can be enhanced, and spinning is easier to realize. According to the manufacturing method, the nanofiber is manufactured by adopting melt electrospinning, and compared with a method of manufacturing the porous nanofiber by adopting solution electrospinning, more materials are applicable.

Owner:苏州佩浦再生科技有限公司

Oil-soluble temporary blocking agent and preparation method thereof

InactiveCN104831401AAdjustable lengthWidely distributedDrilling compositionMonocomponent polyolefin artificial filamentSolubilityAntioxidant

The present invention discloses an oil-soluble temporary blocking agent and a preparation method thereof, wherein a thermoplastic polymer or a mixture comprising a thermoplastic polymer and one or a plurality of materials selected from a surfactant, an antioxidant and a coupling agent is adopted as a spinning raw material and is subjected to melt electrospinning to prepare the oil-soluble temporary blocking agent. According to the present invention, the oil-soluble temporary blocking agent can be adopted as the temporary blocking agent so as to be applied in the petroleum extraction field, such that the purposes of low cost and complete petroleum extraction and no pollution are achieved; the average diameter of the obtained temporary blocking agent of the present invention is a few microns to tens of microns, even achieves the nano-scale, the distribution is wide, and the oil-soluble temporary blocking agent is suitable for various types of oil wells with complex structures, particularly the temporary blocking operation on the core with the small crack width; the oil-soluble temporary blocking agent has characteristics of high oil dissolution rate, water insolubility, acid insolubility, low residual pollution on stratum, high solubility in diesel fuel, and easy blocking releasing; and the preparation method has characteristics of easily available raw materials, simple preparation process, low cost, and good applicability.

Owner:BEIJING UNIV OF CHEM TECH

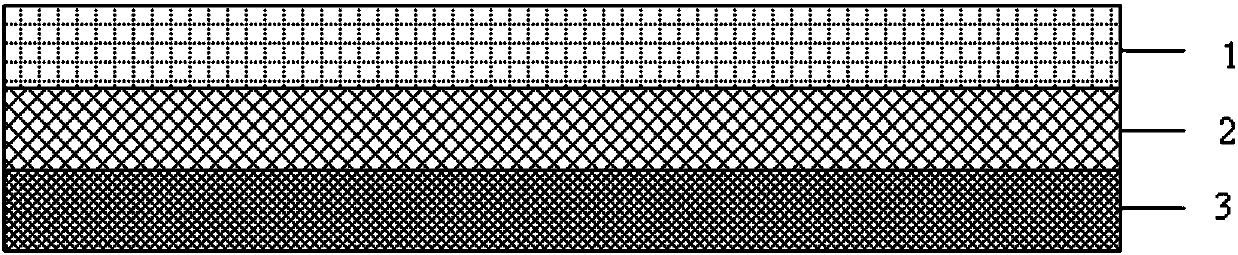

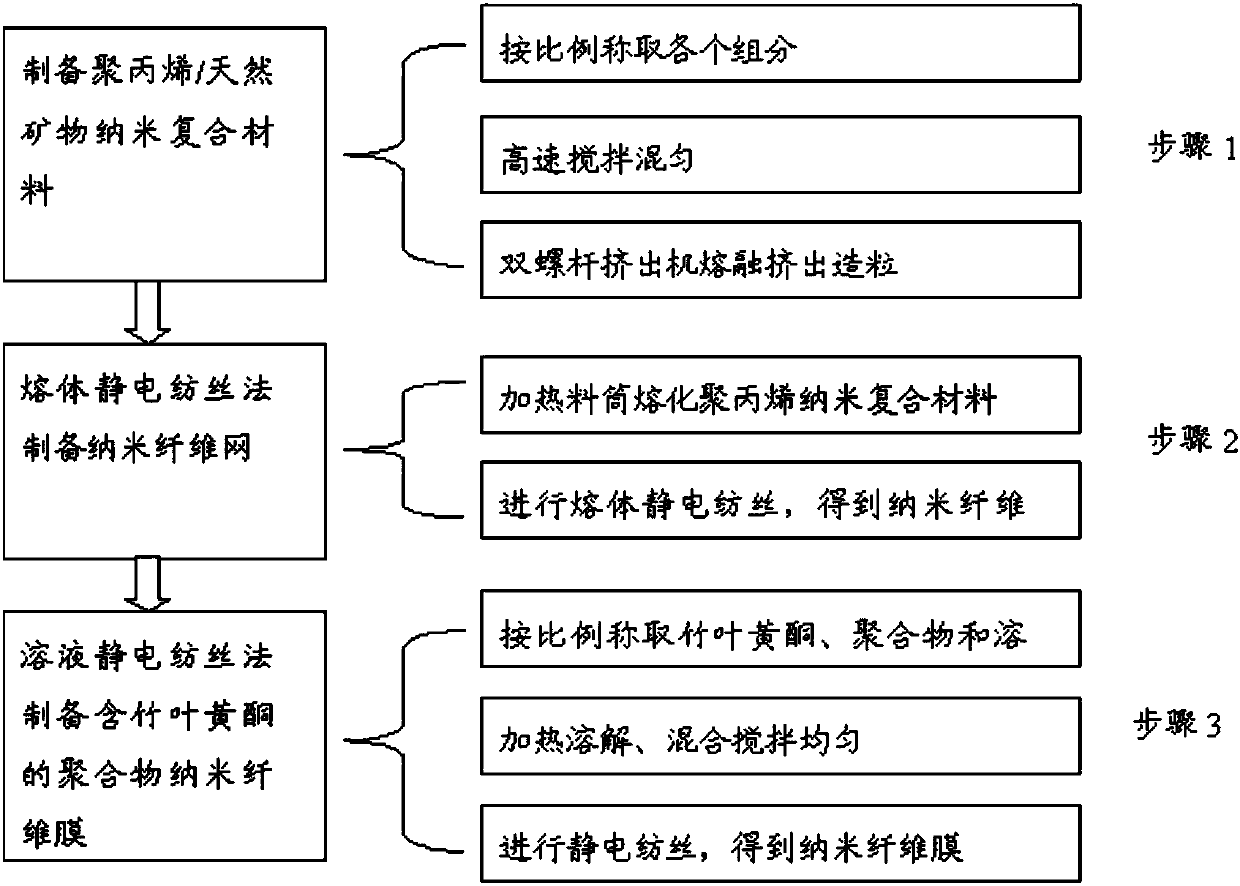

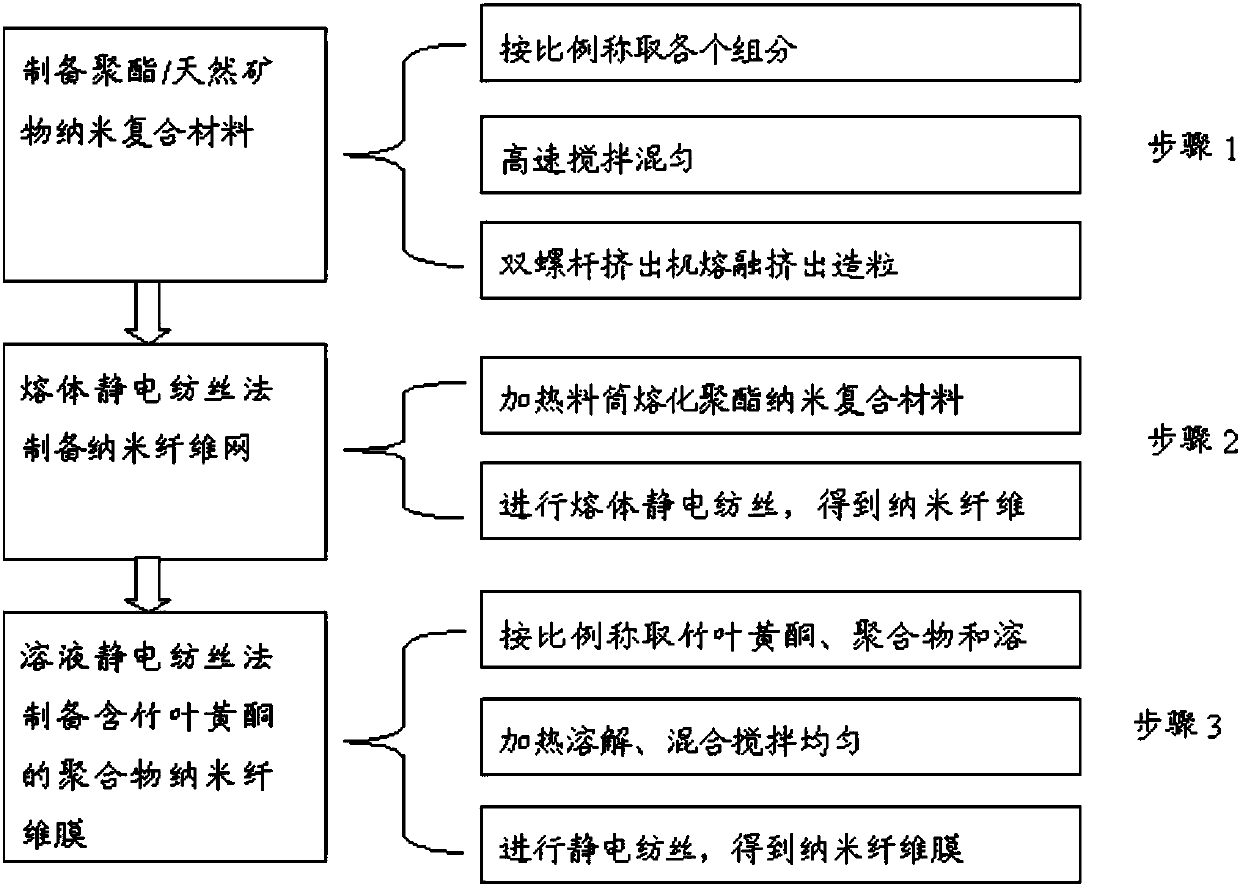

Antibacterial haze-preventing mask material containing bamboo leaf flavonoid and preparation method thereof

ActiveCN105951308AObviously high temperature resistanceImprove toughnessFilament forming substance formingFilament/thread formingFiberPolyester

Owner:国珍健康科技(北京)有限公司

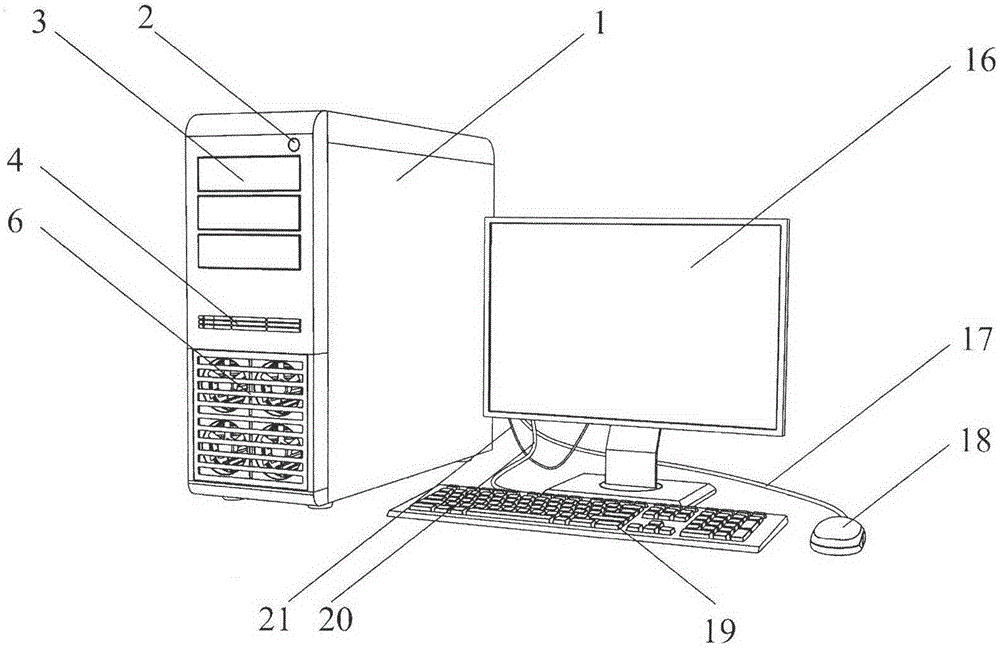

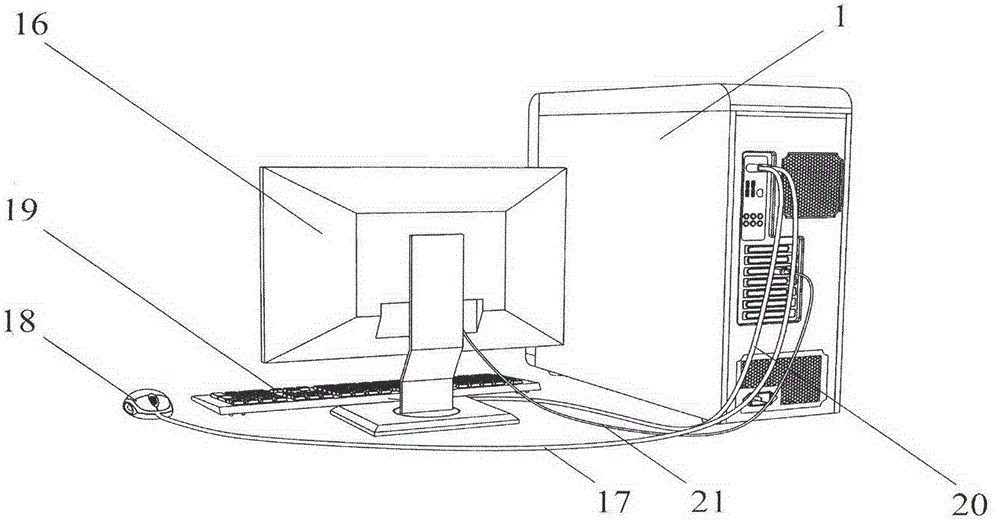

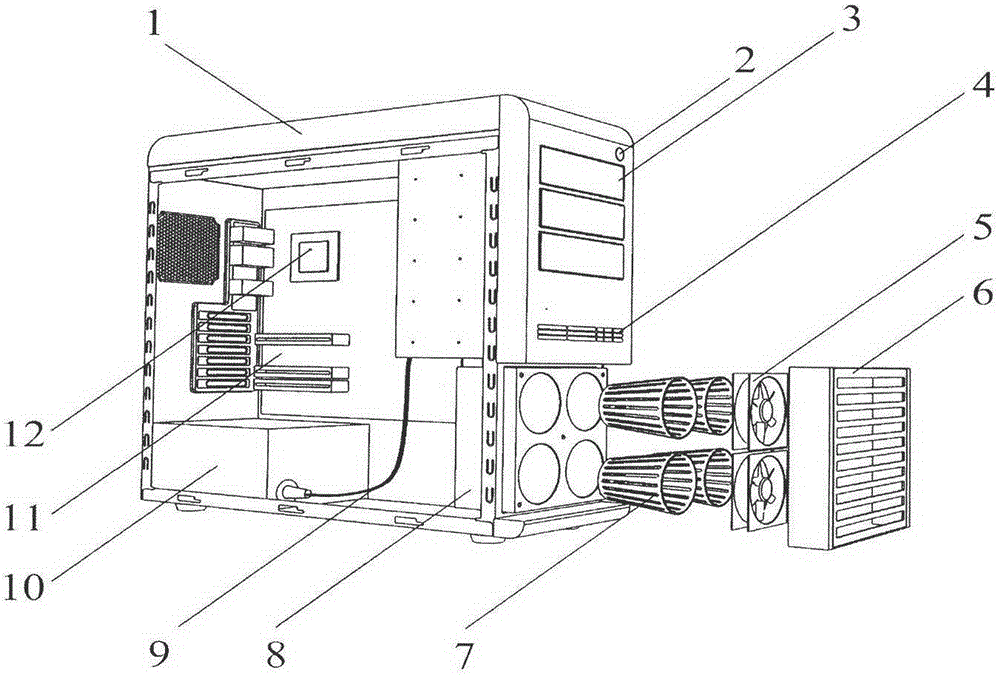

Electronic computer with air filtering and monitoring functions

InactiveCN104007790AAutomate the connectionReduce areaDispersed particle filtrationDigital data processing detailsInformation processingFiber

The invention discloses an electronic computer with air filtering and monitoring functions. Available space in a machine case is utilized for containing a component with the air filtering and monitoring functions, the air filtering and monitoring functions are organically combined by taking the electronic computer as a carrier, ultrafine filter films are adopted on the lower portion of a front panel of the machine case or / and a second side panel of the machine case to be used as air filtering media, information processing and network communication functions are utilized for performing intelligent control and humanized prompt on the air filtering function and effect, a detection head of a temperature measuring element is arranged beside a computer CPU, the computer enables the temperature change amplitude to be compared with the set value in real time, and intelligent monitoring and replacement prompt of the filter screen blocking condition can be achieved. A melt electrostatic spinning method or a water base environment-friendly solution electrostatic spinning method or other methods can be adopted for manufacturing hollow filling material ultrafine fibers of a filter screen cup and a filter screen plate, the toxic action does not exist, the hollow position of the filter plate can be directly filled with the output fibers, the product machining technological process is reduced, production time is saved, and production cost is reduced.

Owner:BEIJING UNIV OF CHEM TECH +1

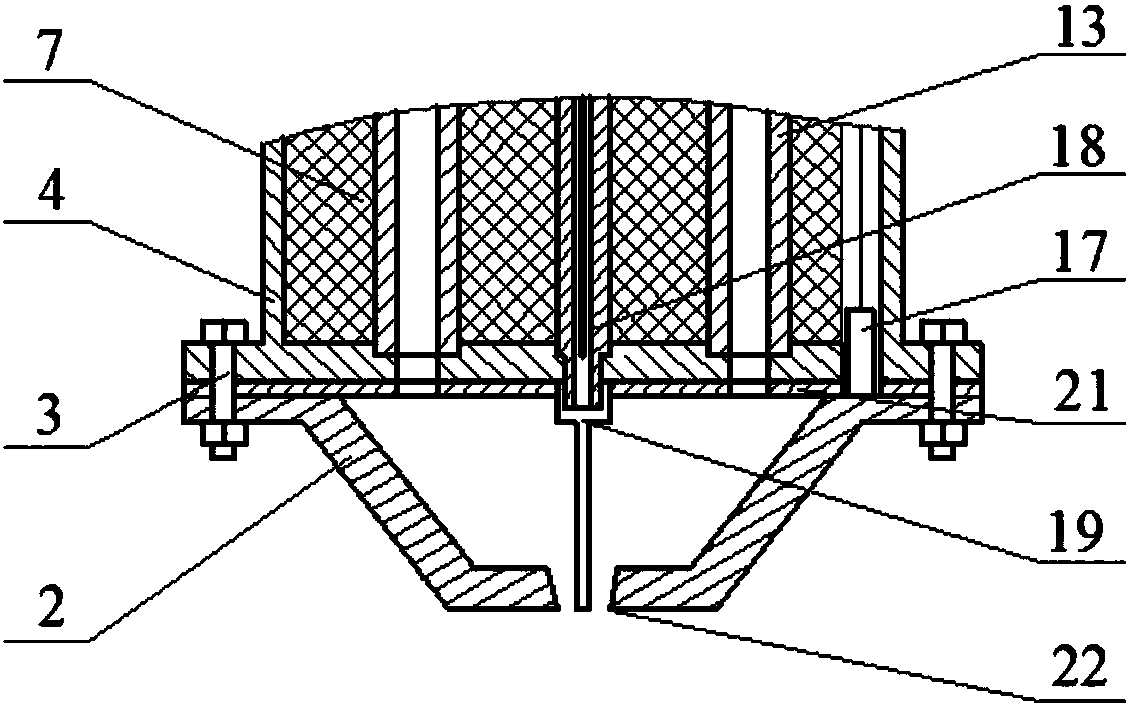

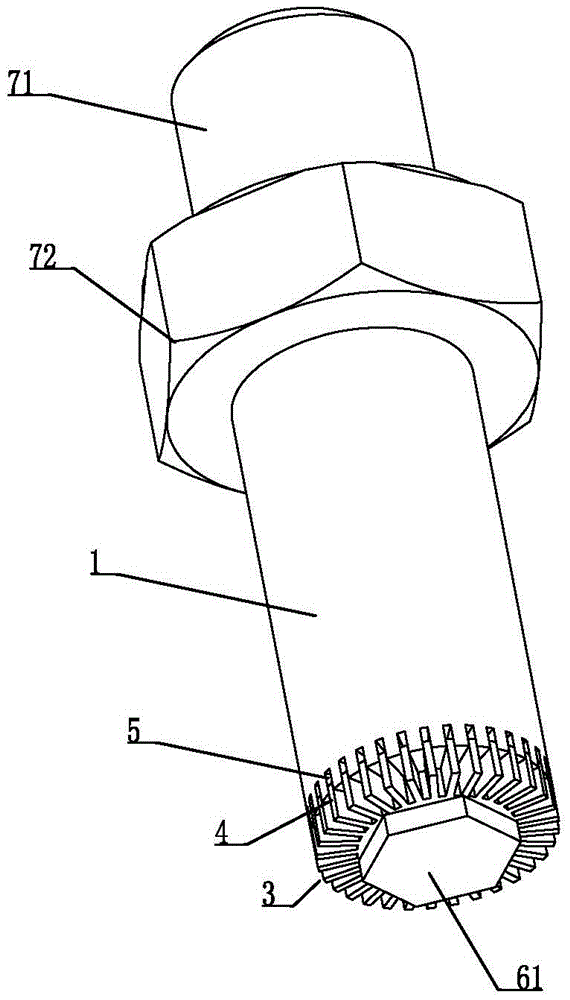

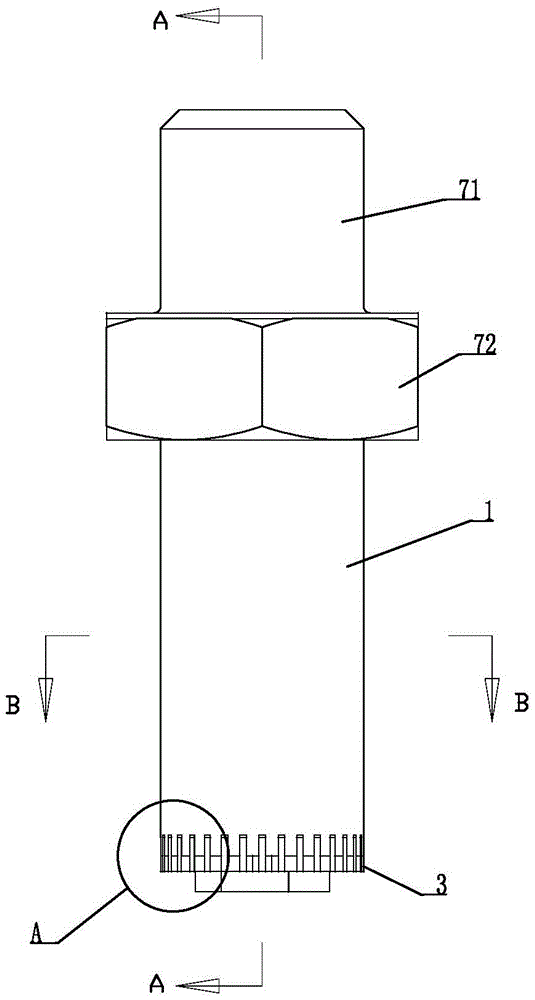

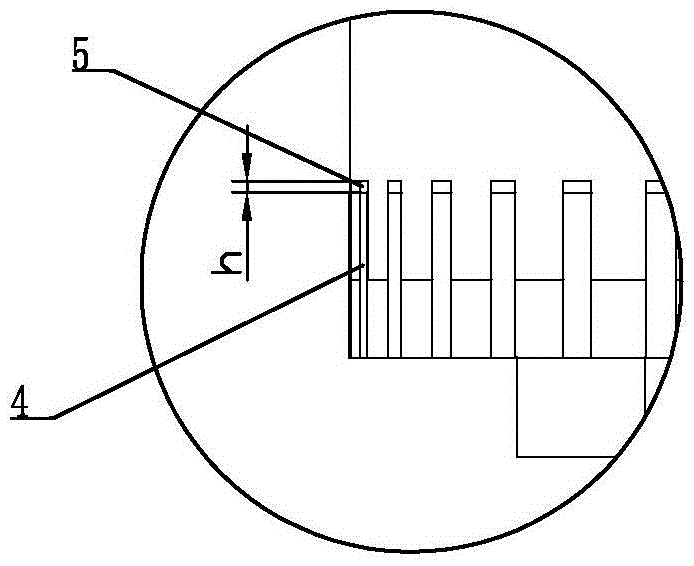

Melt electrostatic spinning device and method based on calculus cascade

ActiveCN103590122ASolving the problem of producing nanoscale fibersSimple structureFilament/thread formingFiberEngineering

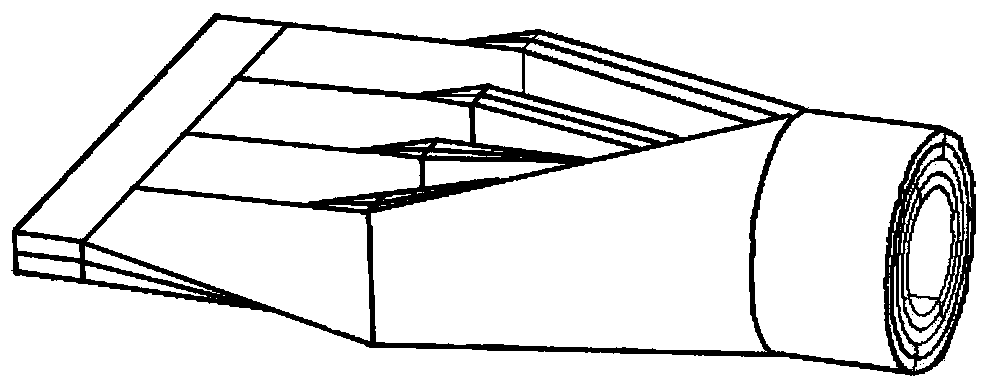

The invention discloses a melt electrostatic spinning device and method based on calculus cascade, and belongs to the field of electrostatic spinning. The melt electrostatic spinning device comprises melt conveying devices, connection flanges, a junction device, cascade devices, an inner cone shunting type nozzle, a high-voltage electrostatic generator, base cloth, a solvent tank and an air heating system. Molten polymer fluid is cascaded through the cascade devices and manufactured to be multiple layers of alternated composite materials, and therefore the thickness of each layer of composite material is decreased; the inner cone shunting type nozzle is used, and the inner cone face structure enables melts to achieve the re-shunting process naturally; the hot gas auxiliary structure is used, hot gas is shot towards the inner cone at a high speed by even spraying airflows, and the function of thinning the inner cone is achieved. The melt electrostatic spinning device is combined with the cascade devices, the thickness of the melt layers is decreased through the uniqueness of the alternated cascading of the cascade devices, and a new method is provided for producing nano-scale fiber products.

Owner:BEIJING UNIV OF CHEM TECH

Novel straight-strut electrostatic spinning spray nozzle

InactiveCN101871130AArrangement structure optimizationEasy to receiveSpinnerette packsFilament/thread formingFiberTemperature control

The invention discloses a novel straight-strut electrostatic spinning spray nozzle, which belongs to the field of electrostatic spinning. The novel straight-strut electrostatic spinning spray nozzle comprises a connecting piece, a drainage core and a straight strut, wherein the connecting piece is in threaded connection with the drainage core; the drainage core is in screw connection with the straight strut; a drainage groove for material flow and an annular balancing groove for material redistribution are formed on the drainage core; a straight strut groove surface for material flow is formed on the straight strut; and the straight strut is provided with an independent temperature control device for heating, and after molten liquid or melts are distributed on the straight strut uniformly and an electrostatic field is added, multiple strands of spraying streams are formed at the top end of the straight strut. The novel straight-strut electrostatic spinning spray nozzle improves the efficiency of melt-electrostatic spinning greatly, and optimizes the arrangement structure of spinning fibers.

Owner:BEIJING UNIV OF CHEM TECH

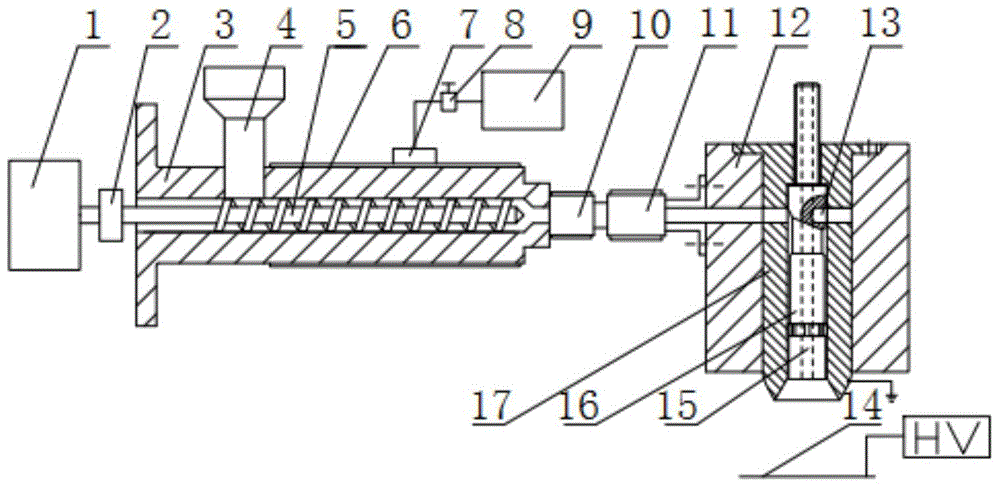

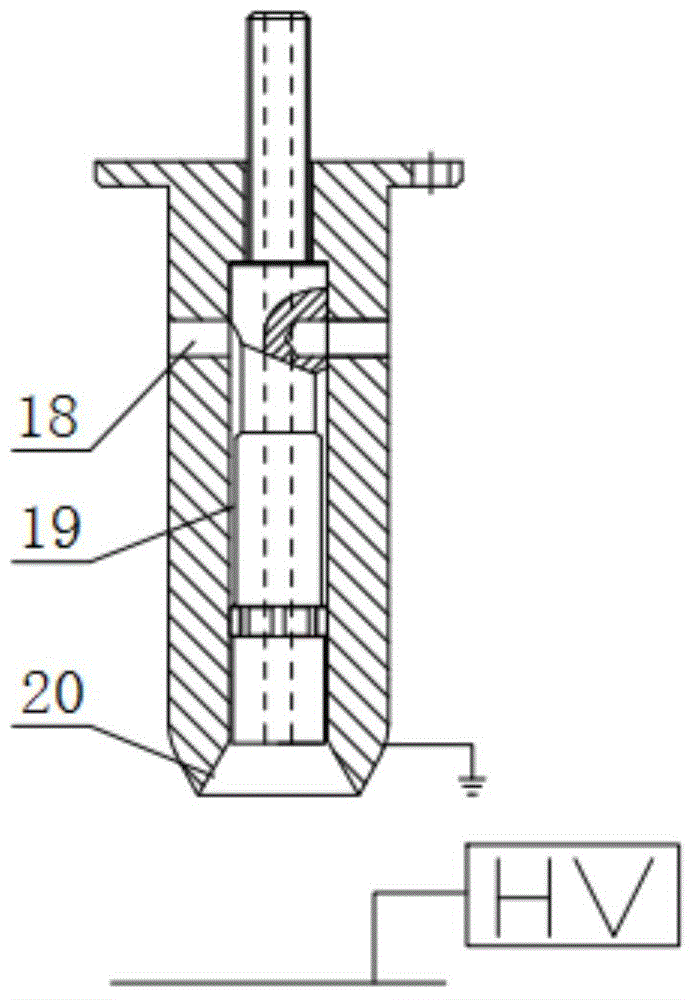

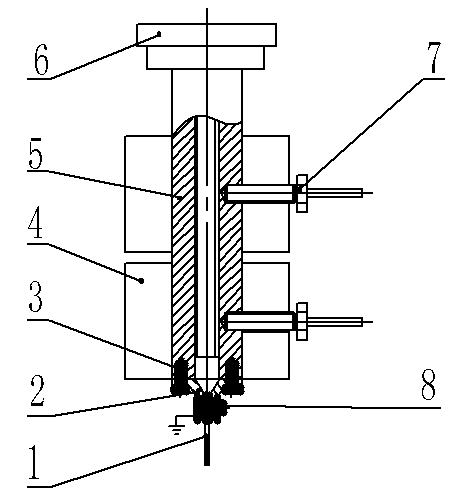

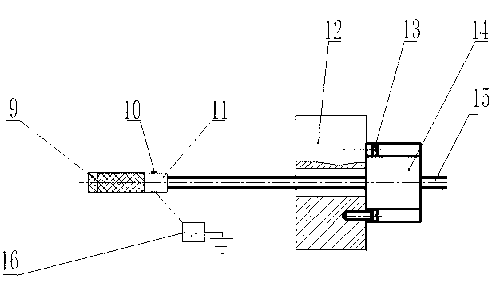

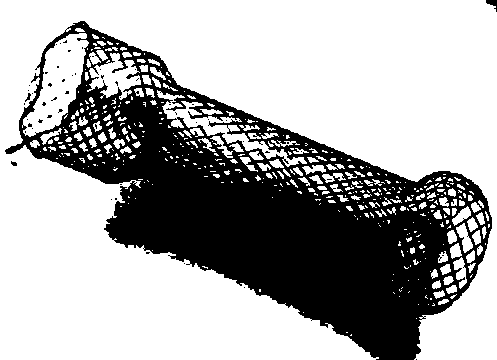

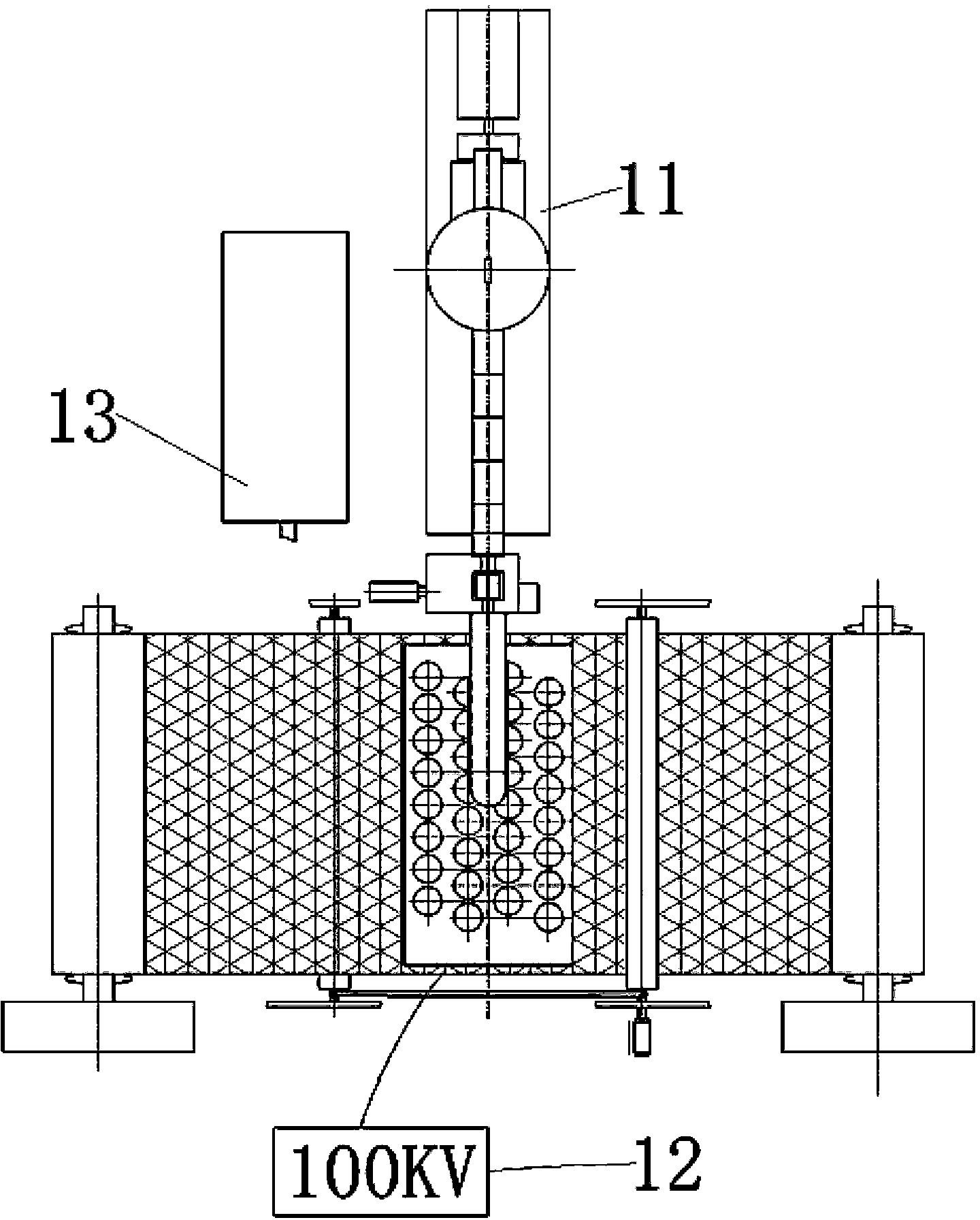

Method for coating esophageal stent through melt electrospinning

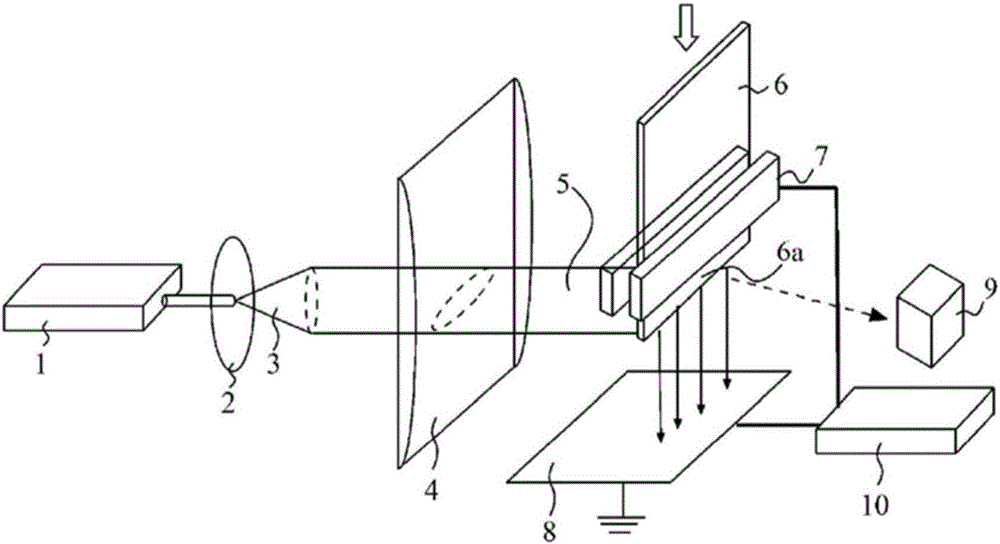

InactiveCN103225174AGood biocompatibilityLess irritatingFilament/thread formingNon-woven fabricsHigh pressureMelt electrospinning

The invention discloses a method for coating an esophageal stent through melt electrospinning and belongs to the fields of medical instruments and electrospinning. Devices adopted by the method comprise a melt-electrospinning device, a stent coating device and the like, wherein the melt-electrospinning device comprises a capillary tube, a nozzle, a heating ring, a hopper, a piston shaft with an end cover, a temperature sensor, a high-voltage electrostatic generator and the like; the stent coating device comprises a stent, a metal-coated insulating rod, a slip ring, a guide rod and a linear stepping motor; and a polymer can be thermoplastic resin used in a living body; and a spinning raw material can be polymer particles, or powder, or slices or melt. The method can be used for melt-electrospinning coating of metallic or nonmetallic stent.

Owner:BEIJING UNIV OF CHEM TECH

Metal mesh belt type electrostatic melt spinning device and technique

ActiveCN103469319AReduce processing stepsAvoid easy clogging problemsFilament/thread formingEngineeringAir compressor

The invention discloses a metal mesh belt type electrostatic melt spinning device and technique, belonging to the field of electrostatic spinning. The device mainly comprises an extruder, a filter mesh, a melt metering pump, a feeding machine head, an infrared heater, an air knife, an airflow regulating valve, an air compressor, a metal mesh belt, a pored electrode plate, a high-pressure electrostatic generator, a mesh paving belt, a wind chamber, an exhaust fan, a hot rolling device and a winding device. According to the metal mesh belt type electrostatic melt spinning device and technique, even and thin-layer melts are directly coated on the surface of the metal mesh belt by adopting non-nozzle mesh belt design through a wide film or a plate machine head, the melts can form bulges on each fine mesh hole under the turbulence of auxiliary airflow, jet flow is formed under the drafting of lower high-pressure electric field force, single-layer non-woven fabric with the diameter of 500nm below can be manufactured, and multi-layer non-woven fabric with different diameters can also be prepared simultaneously in an online manner.

Owner:JIANGSU NEW HORIZON ADVANCED FUNCTIONAL FIBER INNOVATION CENT CO LTD

Microwave heating melt electrostatic spinning device

InactiveCN104131358AFast heatingImprove thermal efficiencyFilament forming substance formingArtificial thread manufacturing machinesFiberEngineering

The invention belongs to the technical field of melt electrostatic spinning equipment, and relates to a microwave heating melt electrostatic spinning device. A boost pump button, a boot pump switch and an electronic display screen are arranged on the front side face of a boost pump, and a charging barrel is fixedly mounted at the upper end of the boost pump. One end of the charging barrel is connected with a propeller, the other end of the charging barrel is connected with a material tube, and the material tube is arranged in a microwave heating cavity. The material tube penetrates through microwave heating cavity to be connected with a fusion nozzle, and a microwave frequency adjusting rotary knob, a heating time setting rotary knob and a temperature control rotary knob are arranged on the front side face of the microwave heating cavity. The positive electrode of a high-voltage power source is connected with the fusion nozzle, and the negative electrode of the high-voltage power source is connected with a collecting device which is vertically arranged. The distance between the fusion nozzle and the collecting device is 10-20 cm. A high-voltage power switch and a voltage adjusting rotary knob are arranged on the high-voltage power source. The microwave heating melt electrostatic spinning device is simple in structure, convenient to operate, safe to use, low in cost, high in spinning efficiency, high in automation degree, environmentally friendly, and beneficial to industrial large-scale nano-fiber preparation.

Owner:QINGDAO UNIV

Preparation method of dielectric material for high energy storage capacitor

The invention discloses a preparation method of a dielectric material for a high energy storage capacitor, the invention relates to the technical field of dielectric materials, the preparation methoduses polyaniline coated with inorganic nanoparticles as a filler, polyvinylidene fluoride as polymer matrix, metal Ni as the load. Firstly, the surface of inorganic nanoparticles is modified by physical ball milling and chemical surfactant, a supercritical fluid reaction is adopted to coat polyaniline on the surface of the inorganic nanoparticles, so that a composite fill is prepared, the composite fill and the polyvinylidene fluoride are spun into a fibrous membrane by melt electrospinning, at last, the metal Ni load and the polyvinylidene fluoride are composited on the fiber membrane by magnetron sputter, the load of the metal Ni not only helps to fill the high porosity of the electrospun fiber film, but also helps to maintain high breakdown field strength, high energy storage density, high dielectric constant and low dielectric loss of the dielectric material, and the composite dielectric material has high energy storage performance.

Owner:滨州高新高端装备制造产业园有限公司

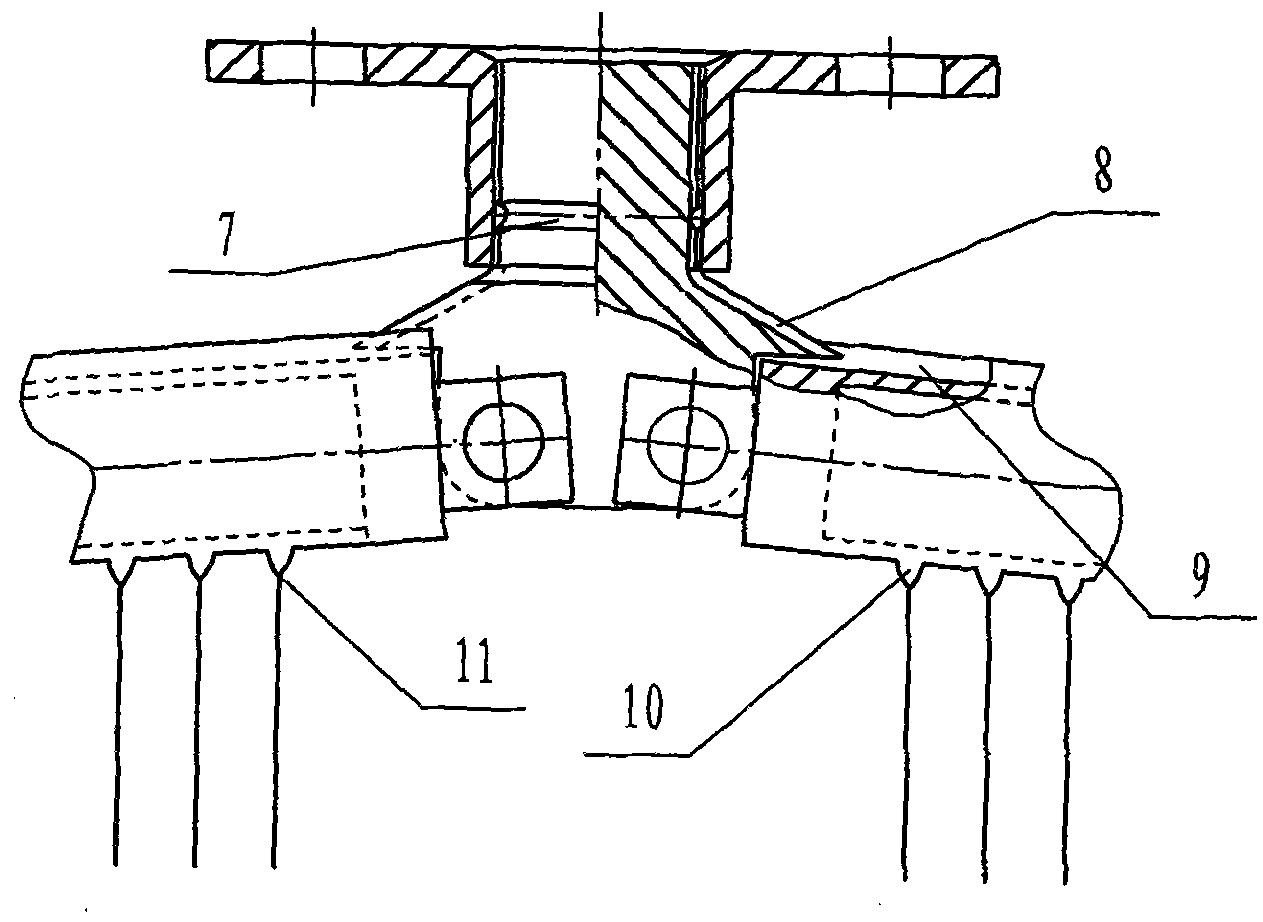

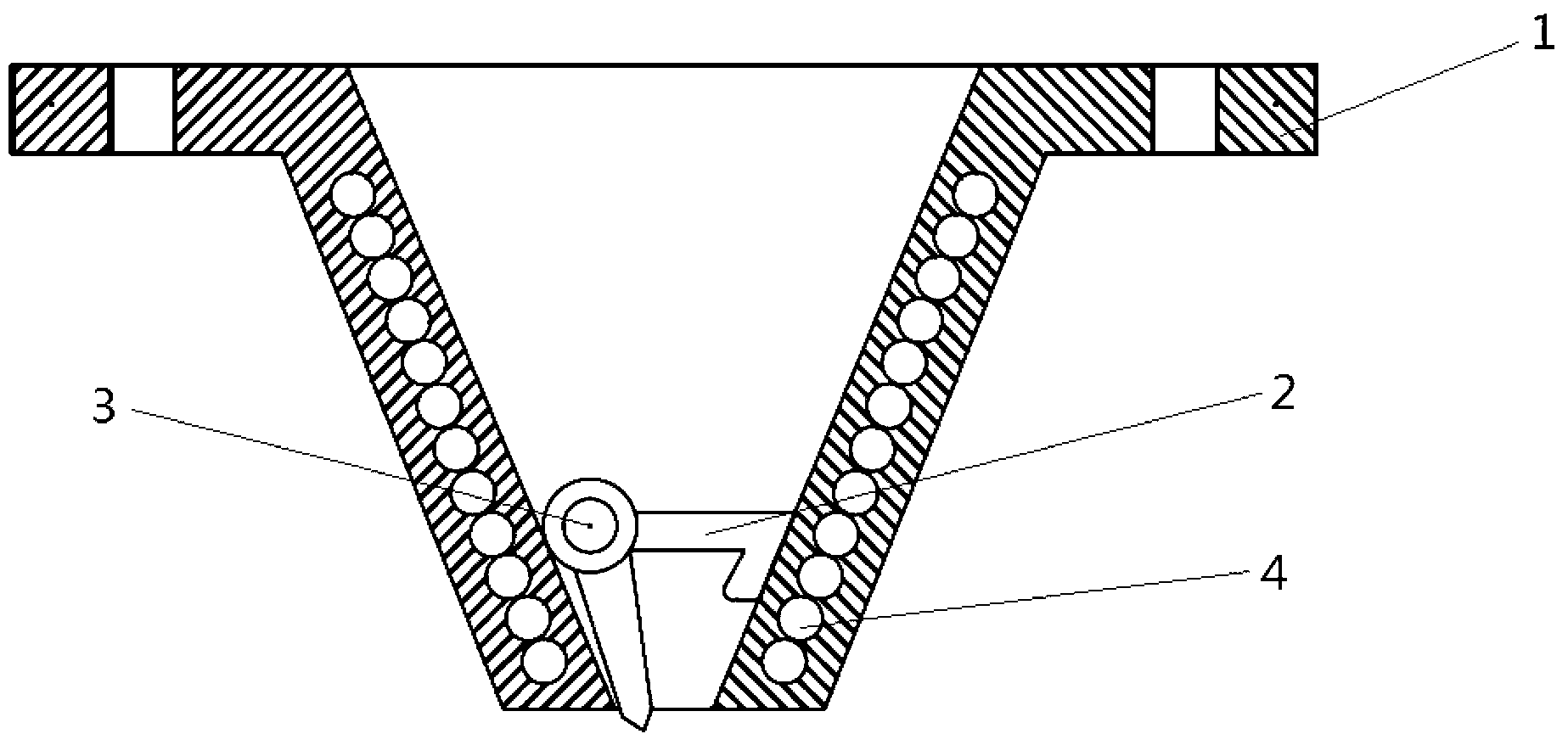

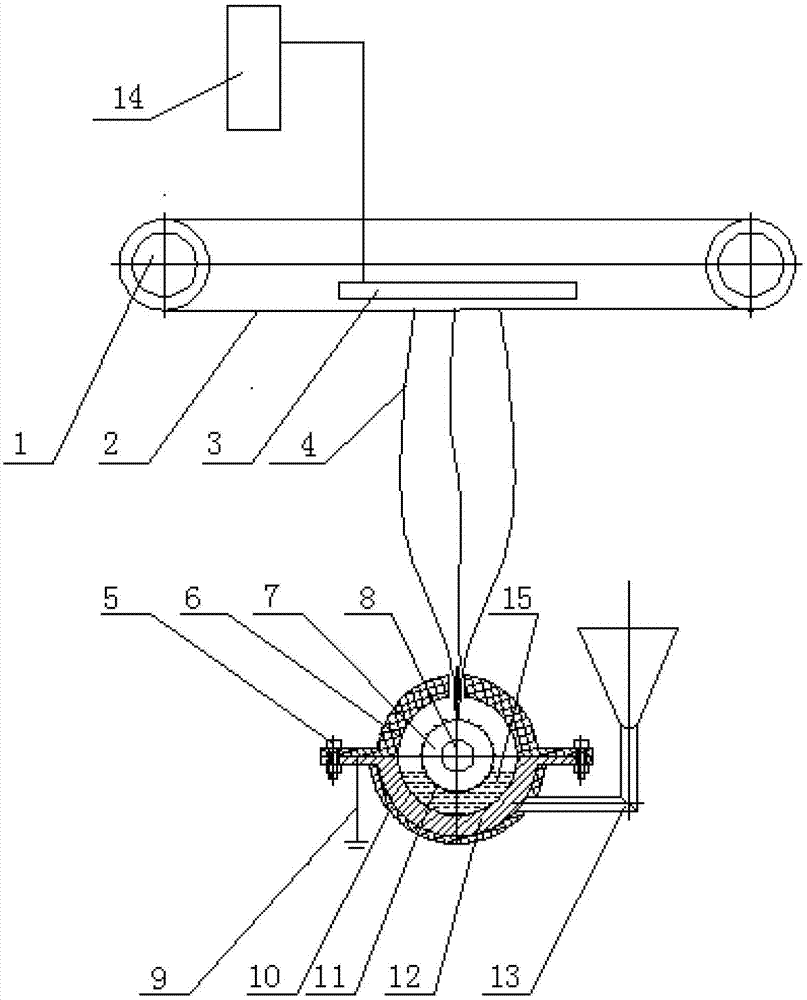

Continuously-producing high-efficiency melt electrostatic spinning device

ActiveCN101812733AImprove efficiencyPromote the pace of industrializationFilament/thread formingEngineeringHigh pressure

The invention discloses a continuously-producing high-efficiency melt electrostatic spinning device, and belongs to the field of spinning. The continuously-producing high-efficiency melt electrostatic spinning device comprises a precision extruder, a spinning die head, a high-efficiency nozzle, a static generator and a receiving device, wherein the precision extruder and the spinning die head are in bolt connection; the high-efficiency nozzle is grounded; a reel of the receiving device is connected with the anode of the high pressure static generator through a metal bearing, and is made of a conducting material; a bracket of the reel is made of an insulating material; a belt used by a belt drive mechanism of the reel is made of an insulating material; the reel of the receiving device is provided with a lifting device; the spinning die head is in cone close fit with the high-efficiency nozzle; and several planes are uniformly cut off on the cone of the high-efficiency nozzle. Through the melt electrostatic spinning, a problem caused by using a solvent is avoided, and the efficiency of the electrostatic spinning is greatly improved by using the high-efficiency spinning nozzle.

Owner:BEIJING UNIV OF CHEM TECH

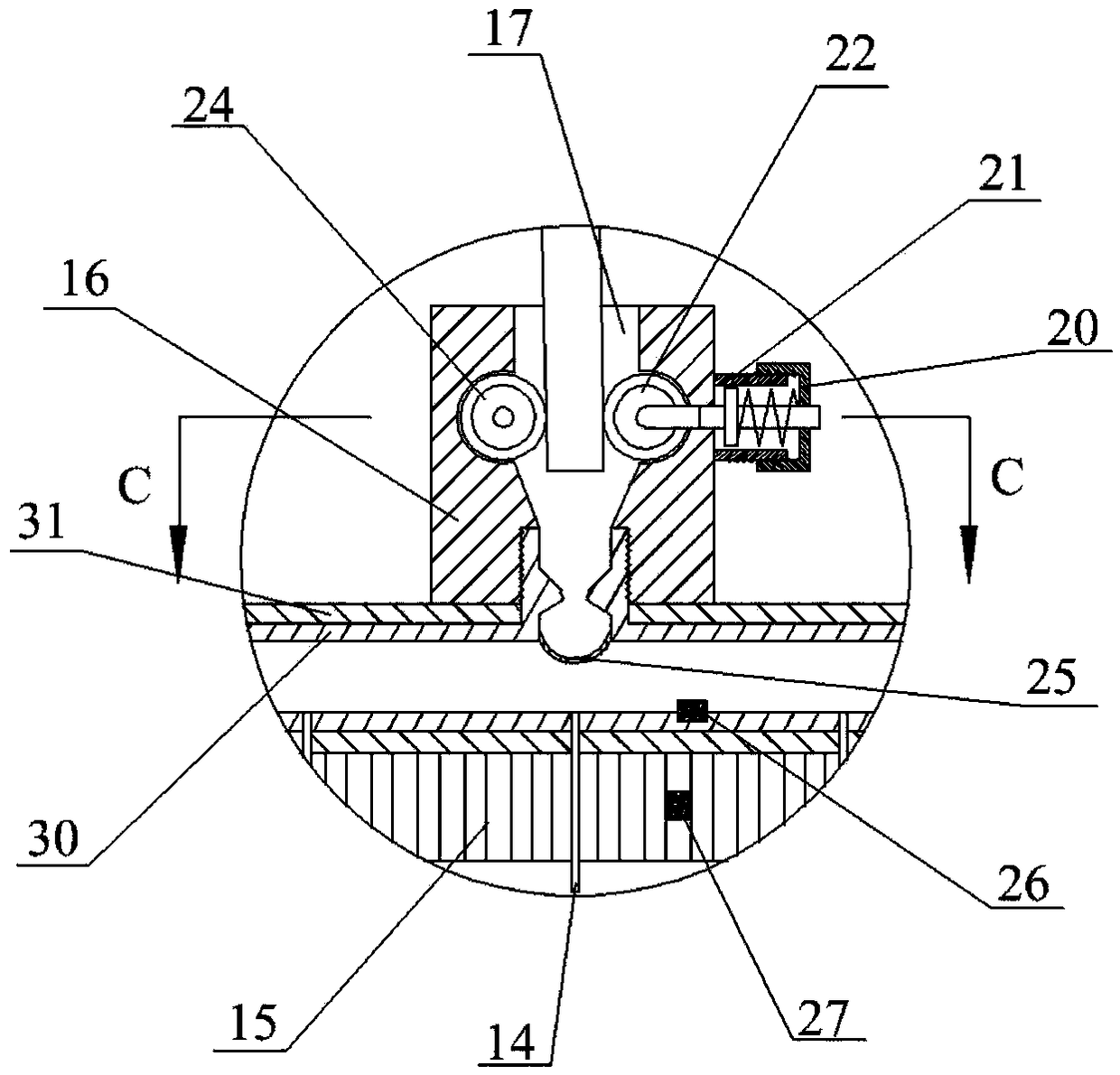

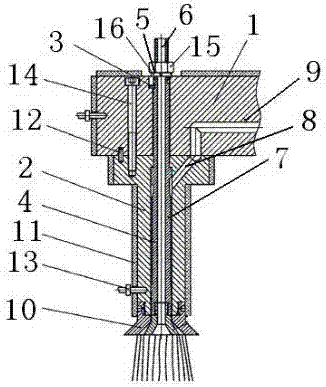

Melt electrospinning nanometer twisted yarn preparing device and method achieving multi-needle rotary twisting

ActiveCN106283219AImprove mechanical propertiesControllable twistFilament/thread formingYarnEngineering

The invention relates to a melt electrospinning nanometer twisted yarn preparing device and method achieving multi-needle rotary twisting, and belongs to the field of electrostatic spinning. The device mainly comprises a heating rod, a center shaft, a flowing channel, a corner handpiece, an extruding machine, a spreader plate, a rolling ball, a worm rod, a thin-walled container, a copper ring, a conical flow guider, multiple single-needle spray heads, a worm wheel, an acrylic board with a hole, an electrode plate, a high-voltage electrostatic generator, a receiving roller and the like. According to the device and method, the conical flow guider is in threaded connection with the center shaft and is arranged to be coaxial with the thin-walled container; the copper ring is arranged between the upper portions of needle heads and the flowing channel to serve as a sealing device; the single-needle spray heads are annularly arranged, so that the spinning efficiency is improved, and the spinning yield is increased; the single-needle spray heads are in threaded connection with a bottom plate of the thin-walled container, and therefore replacing and cleaning are convenient; by replacing the single-needle spray heads with needle head plugs, the fiber number can be controlled; a worm wheel and worm rod transmission device drives the single-needle spray heads to rotate, the twisting degree and the fiber number are controllable, the fiber diameter is uniform, the applicability of nanometer twisted yarn can be improved, and therefore the requirements in different fields are met.

Owner:BEIJING UNIV OF CHEM TECH

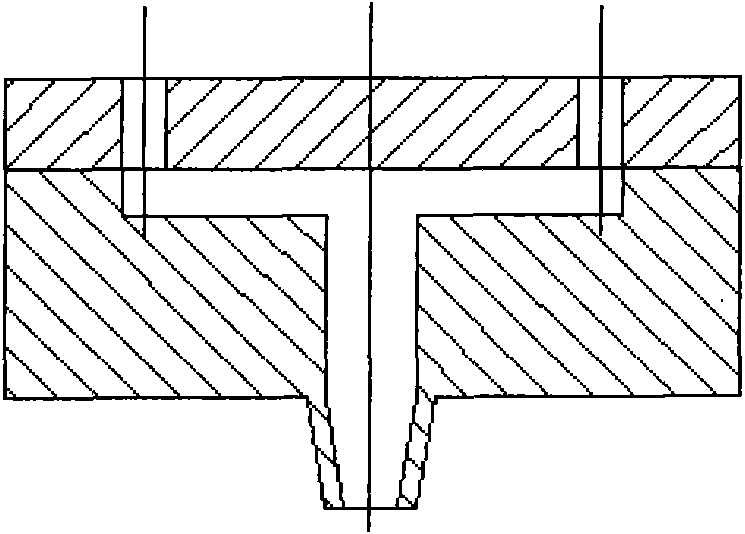

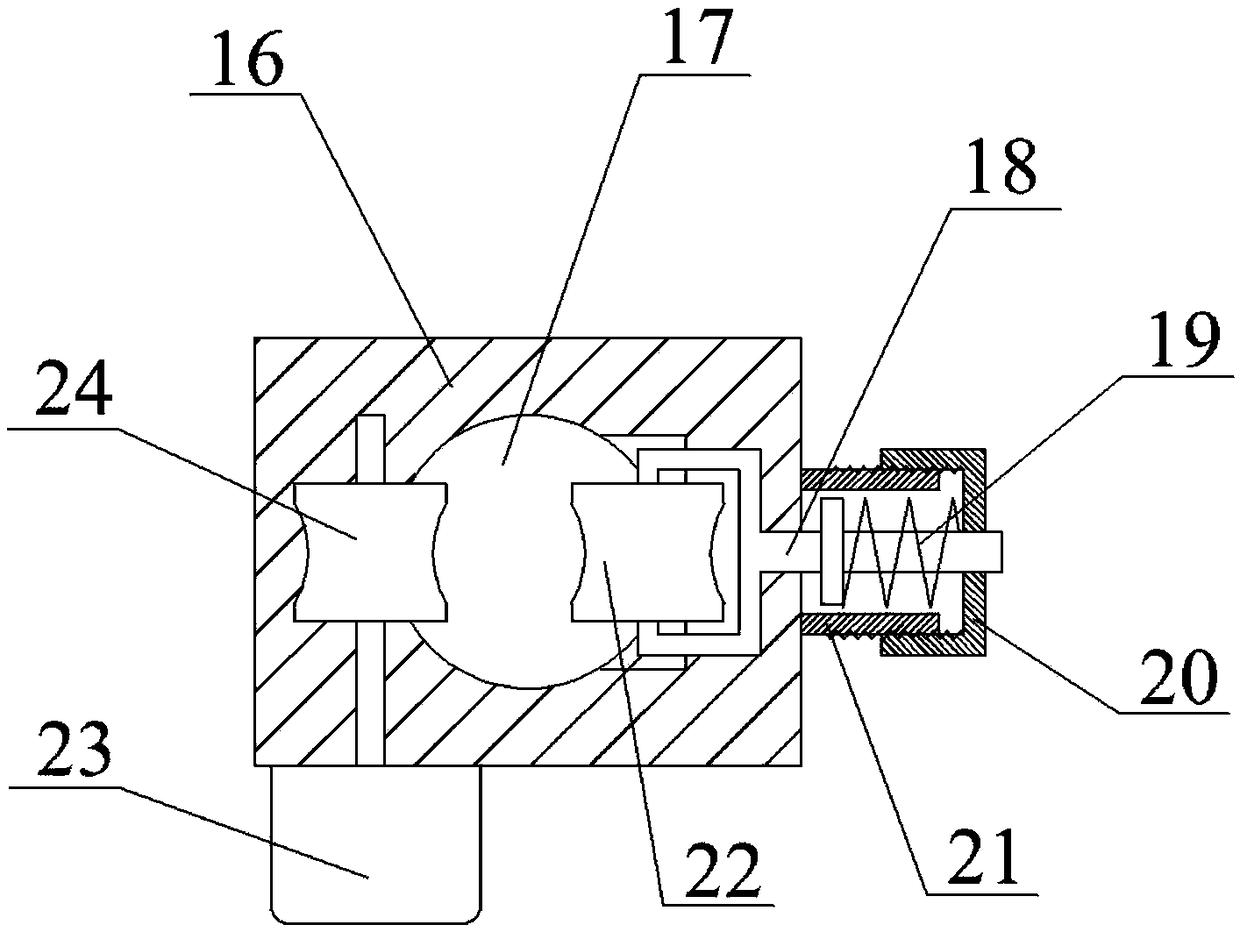

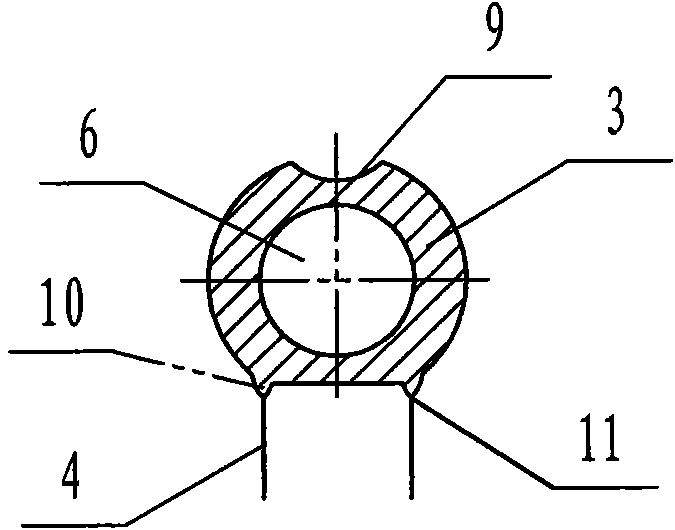

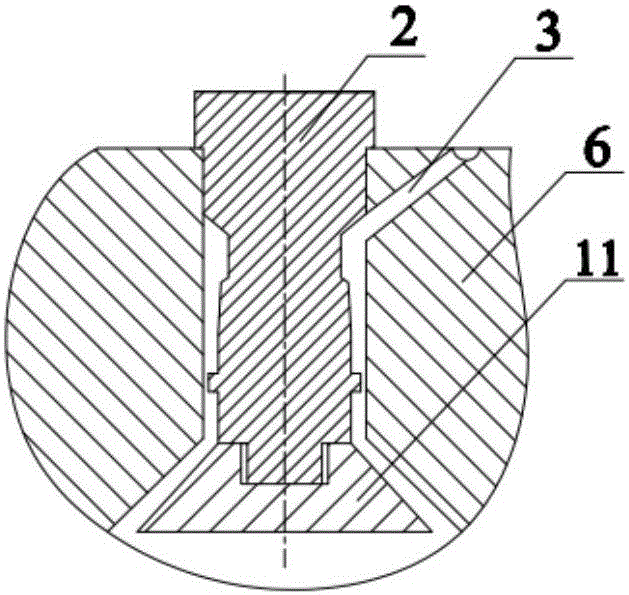

Two-stage differential melt electrostatic spinning device

The invention belongs to the technical field of melt electrostatic spinning equipment, and particularly relates to a two-stage differential melt electrostatic spinning device. A main structure comprises a primary nozzle outer sleeve, an inner conical surface, an electric heating ring, a melt channel, a primary nozzle inner sleeve, an annular cavity, an insulating ring, a secondary nozzle, a fibercollecting plate and a high-voltage electrostatic generator. The two-stage nozzle structure is adopted; a polymer melt forms a jet at the bottom of the primary nozzle outer sleeve, and a second jet isformed at the bottom of the secondary nozzle; the polymer melt subjected to secondary distribution is more evenly distributed along the conical surface of the secondary nozzle; since the circumference of the bottom edge of the secondary nozzle is greater than the perimeter of the bottom of the primary nozzle outer sleeve, the number of secondary jets is increased, and the diameter is more uniform; fibers with smaller diameter and more uniform distribution are formed under the condition that the quality of the polymer melt is unchanged; and batch continuous uniform preparation of nanofibers isachieved.

Owner:QINGDAO UNIV OF SCI & TECH

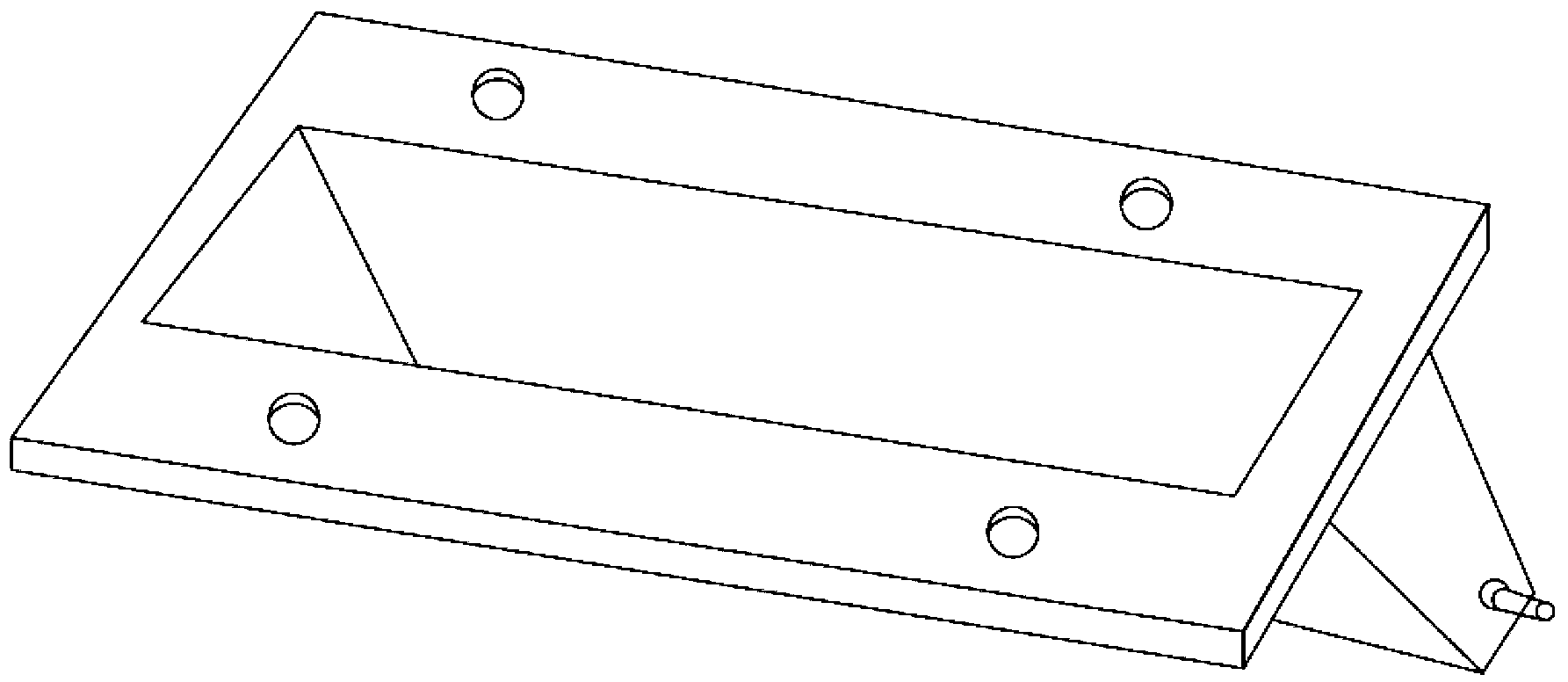

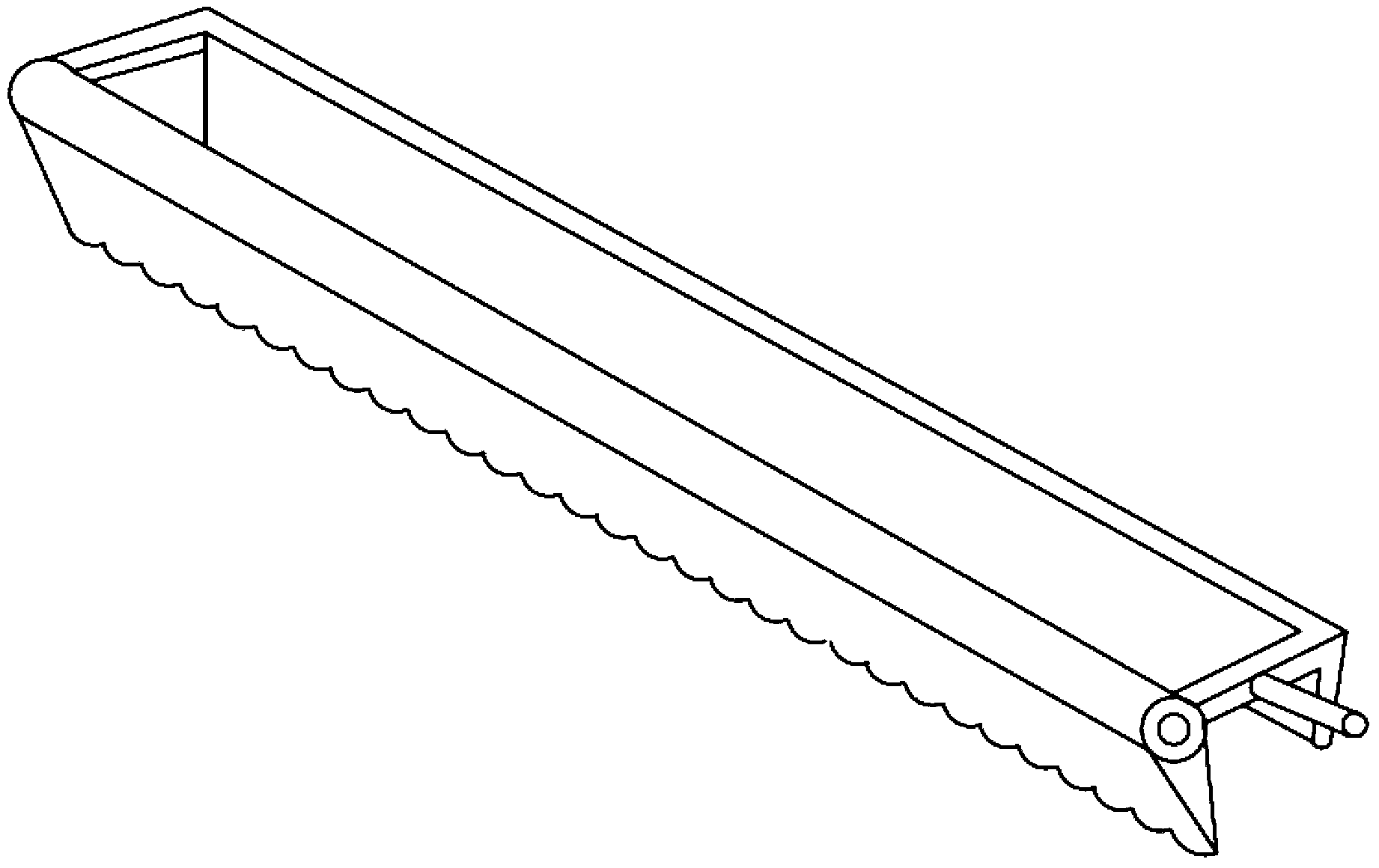

Novel efficient linear nozzle for electrostatic spinning

InactiveCN103320876ASolve heatingSolve the problem of difficult pressurizationFilament/thread formingTemperature controlHeat control

The invention discloses a novel efficient linear nozzle for electrostatic spinning. The novel efficient linear nozzle is characterized by comprising a heat control device and a conducting device; the heat control device is of a long cavity and a high-voltage electrostatic receiving end and is provided with a heating and temperature control device, and a linear nozzle is arranged at the bottom of the cavity; the conducting device is elongated and disposed in a cavity of the heat control device, connected with the high-voltage electrostatic receiving end of the heat control device and disposed at the linear nozzle of the bottom of the cavity, and saw-toothed protrusions are formed at the edge of the bottom of the conducting device. The novel efficient linear nozzle for electrostatic spinning has the advantages that the difficulty in synchronous heating and pressurizing of the nozzle of melt electrostatic spinning is overcome; the novel efficient linear nozzle is in the shape of a triangular prism, the mode of stacking single-hole or multi-hole nozzles is omitted, so that multiple spinning jet flows can be generated, productivity of electrostatic spinning is improved greatly on the premise of reducing processing difficulty; and the aperture of the nozzle is convenient to regulate so that outflow speed of spinning solution is convenient to control.

Owner:JIANGNAN UNIV +1

Gap-adjustable electrostatic-spinning nozzle and array-type spinning system

ActiveCN105543985AIncrease spinning speedAvoid high cost, difficult maintenance, easy blockage and other problemsElectro-spinningInlet channelAnnular array

The invention discloses a gap-adjustable electrostatic-spinning nozzle and an array-type spinning system. The gap-adjustable electrostatic-spinning nozzle comprises a liquid inlet pipe, an end cover and an adjuster, wherein a plurality of tiny grooves are formed in the end face of one end of the liquid inlet pipe in an annular array mode, and the tiny grooves penetrate through the inner wall and the outer wall of the liquid inlet pipe to be communicated with a liquid inlet channel inside the liquid inlet pipe and the outside; a plurality of convex ribs are arranged on the end cover in an annular array mode, the tiny grooves are filled with all the convex ribs one by one, the convex ribs are equal to the tiny grooves in thickness, and liquid outlet gaps are formed between the opposite end faces of the convex ribs and the tiny grooves; the adjuster is used for driving the liquid inlet pipe and the end cover to get close to each other or get away from each other, the distance between the liquid outlet gaps is changed accordingly, and the adjuster is connected with the liquid inlet pipe and the end cover. According to the gap-adjustable electrostatic-spinning nozzle and the array-type spinning system, the spinning diameter can be adjusted, and spinning efficiency can be improved. The gap-adjustable electrostatic-spinning nozzle and the array-type spinning system can be applied to the field of melt electrostatic spinning or the field of solution electrostatic spinning.

Owner:FOSHAN QINGZI PRECISION MEASUREMENT & CONTROL TECH

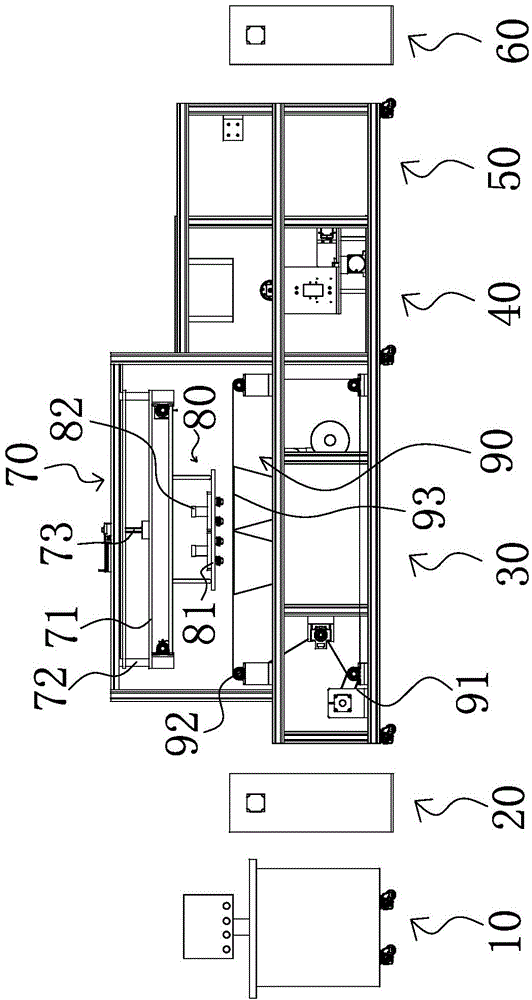

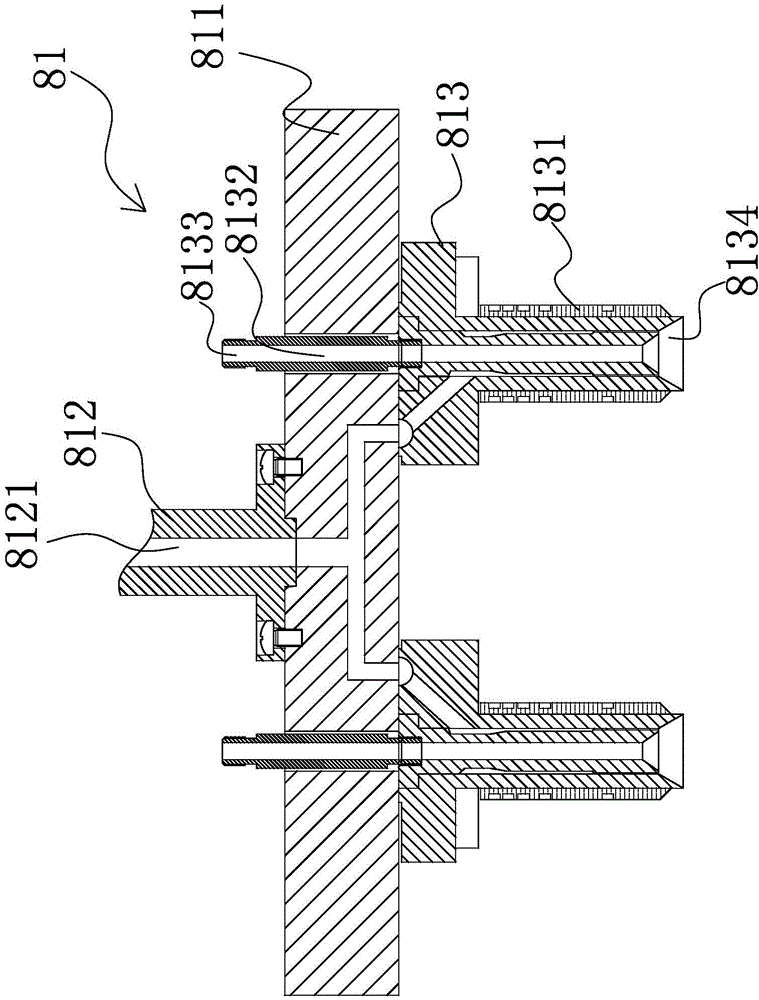

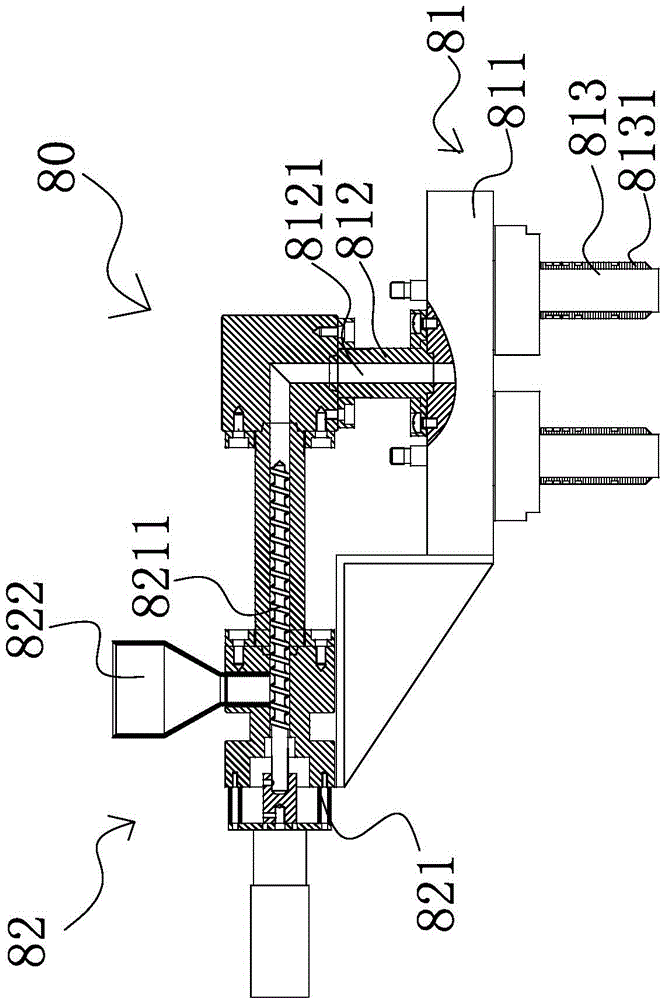

Automatic efficient melt electrostatic spinning device

InactiveCN104894659AImprove efficiencyImprove stabilityFilament forming substance formingFilament/thread formingYarnEngineering

The invention provides an automatic efficient melt electrostatic spinning device, and belongs to the technical field of electrostatic spinning. The automatic efficient melt electrostatic spinning device comprises a circuit control device, an unwinding device, a spinning device body, a compound device, a rolling device and a winding device, the spinning device body comprises a movement device, a spinning mechanism and a receiving device, the spinning mechanism comprises a plurality of yarn spraying machines and a plurality of feeding mechanisms mounted on the corresponding yarn spraying machines, each yarn spraying machine comprises a flow distribution plate, a main injection nozzle and a plurality of heating nozzles, the main injection nozzles are mounted on the upper end faces of the flow distribution plates, the heating nozzles are mounted on the lower end faces of the flow distribution plates, main injection heating rings are arranged on the outer side faces of the main injection nozzles, material pipes are arranged in the middles of the main injection nozzles and connected with the heating nozzles through flow distribution material pipes, a nozzle heating ring is wound on the outer side face of each heating nozzle, and an air flow duct is inserted into the middle of each heating nozzle and penetrates the corresponding flow distribution plate and the corresponding heating nozzle. The automatic efficient melt electrostatic spinning device has the advantages of simple structure and high efficiency.

Owner:NINGBO GMF TECH

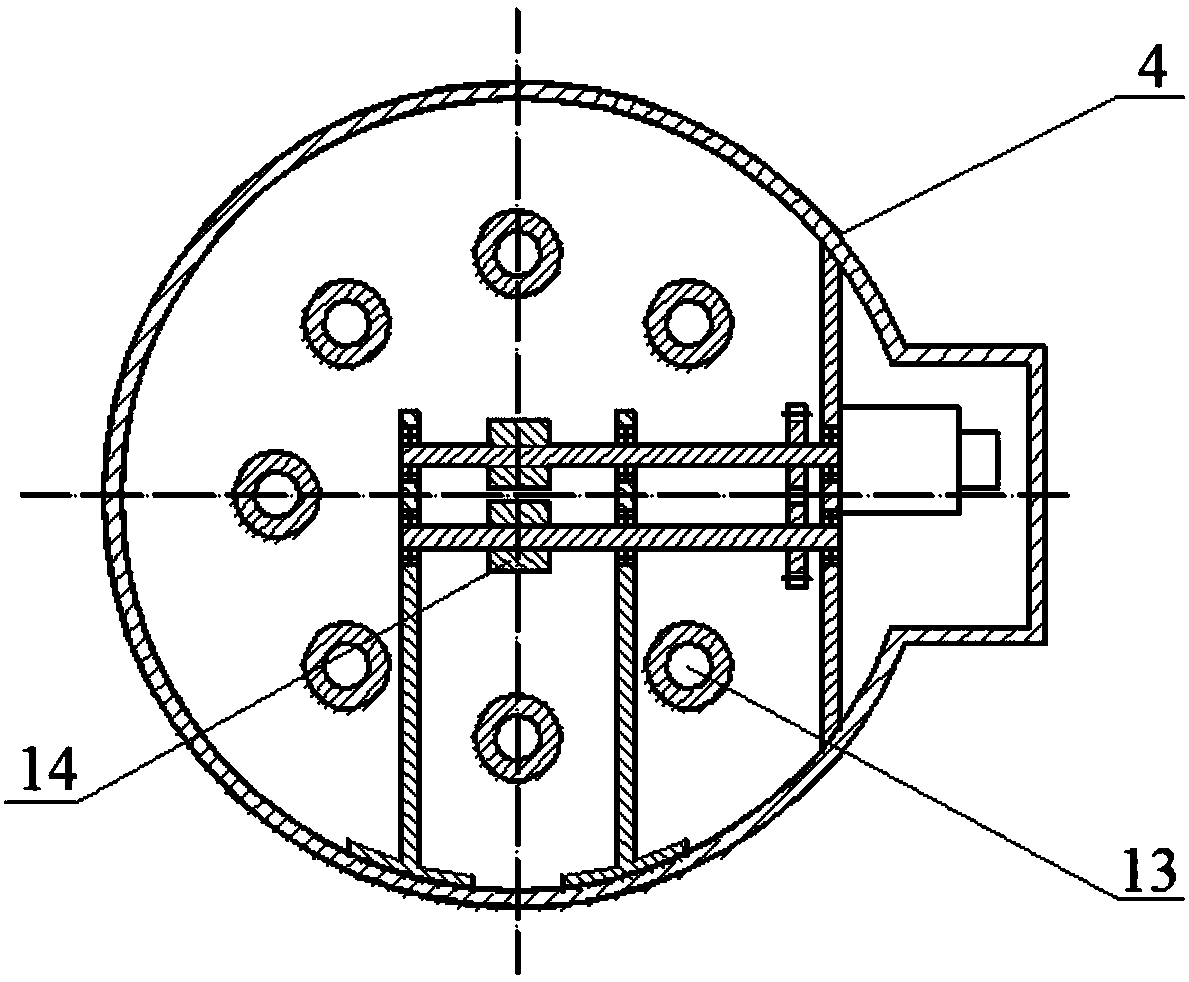

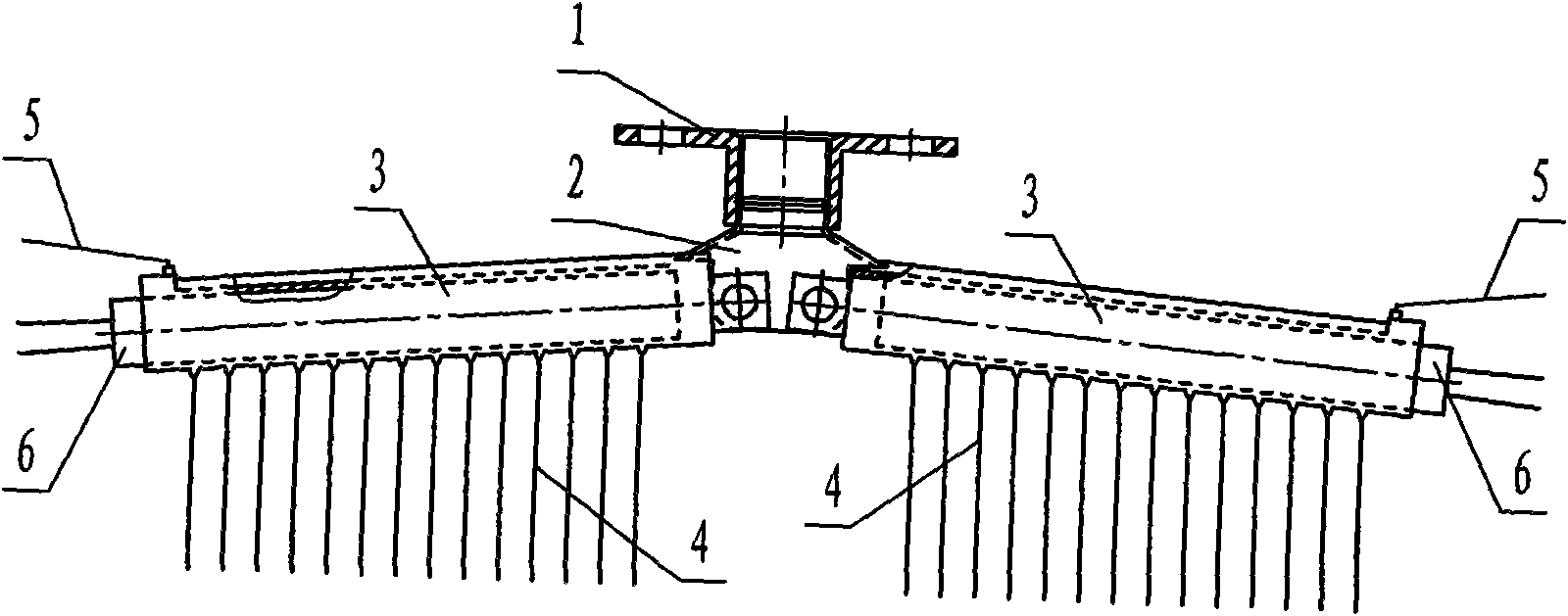

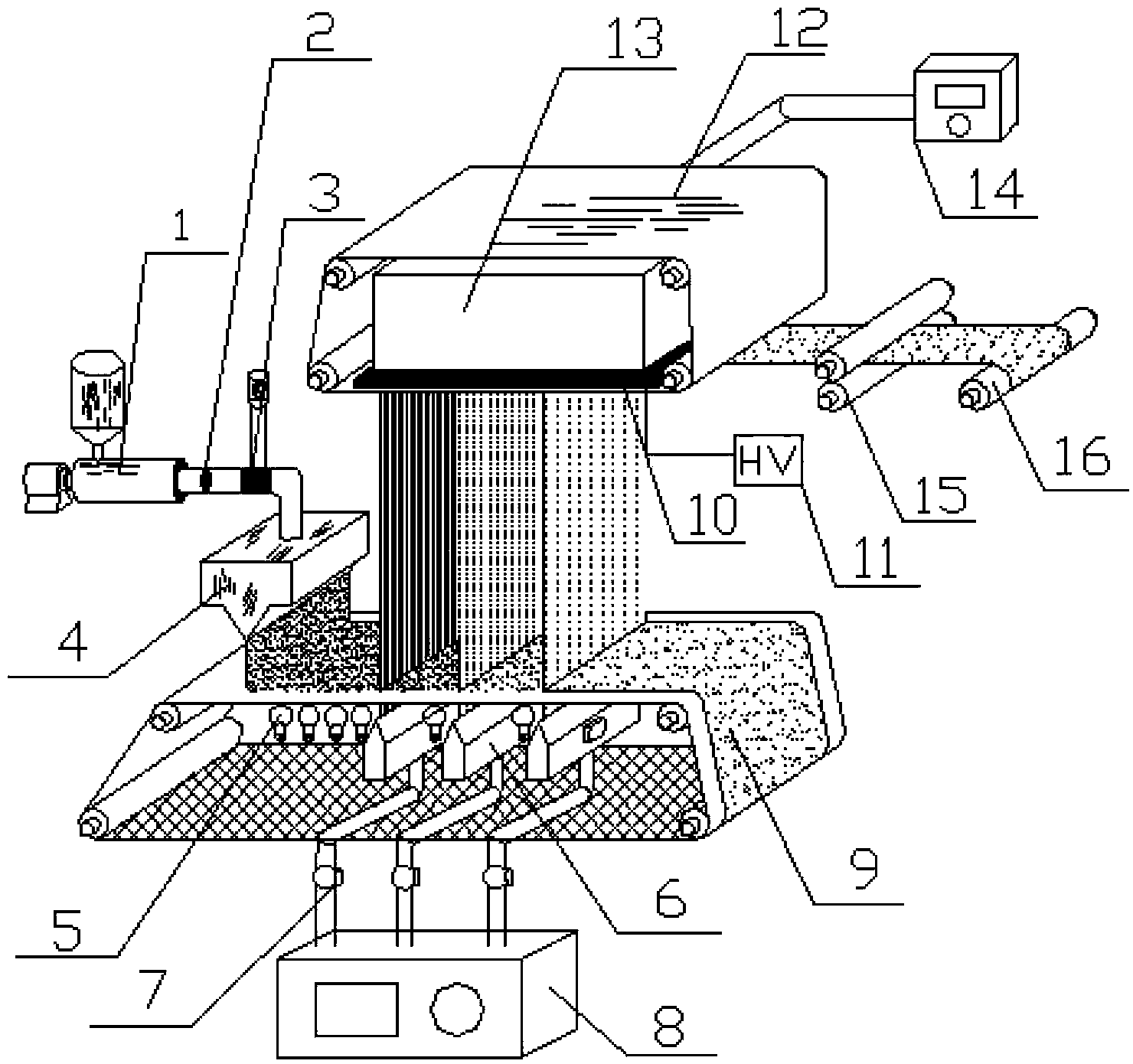

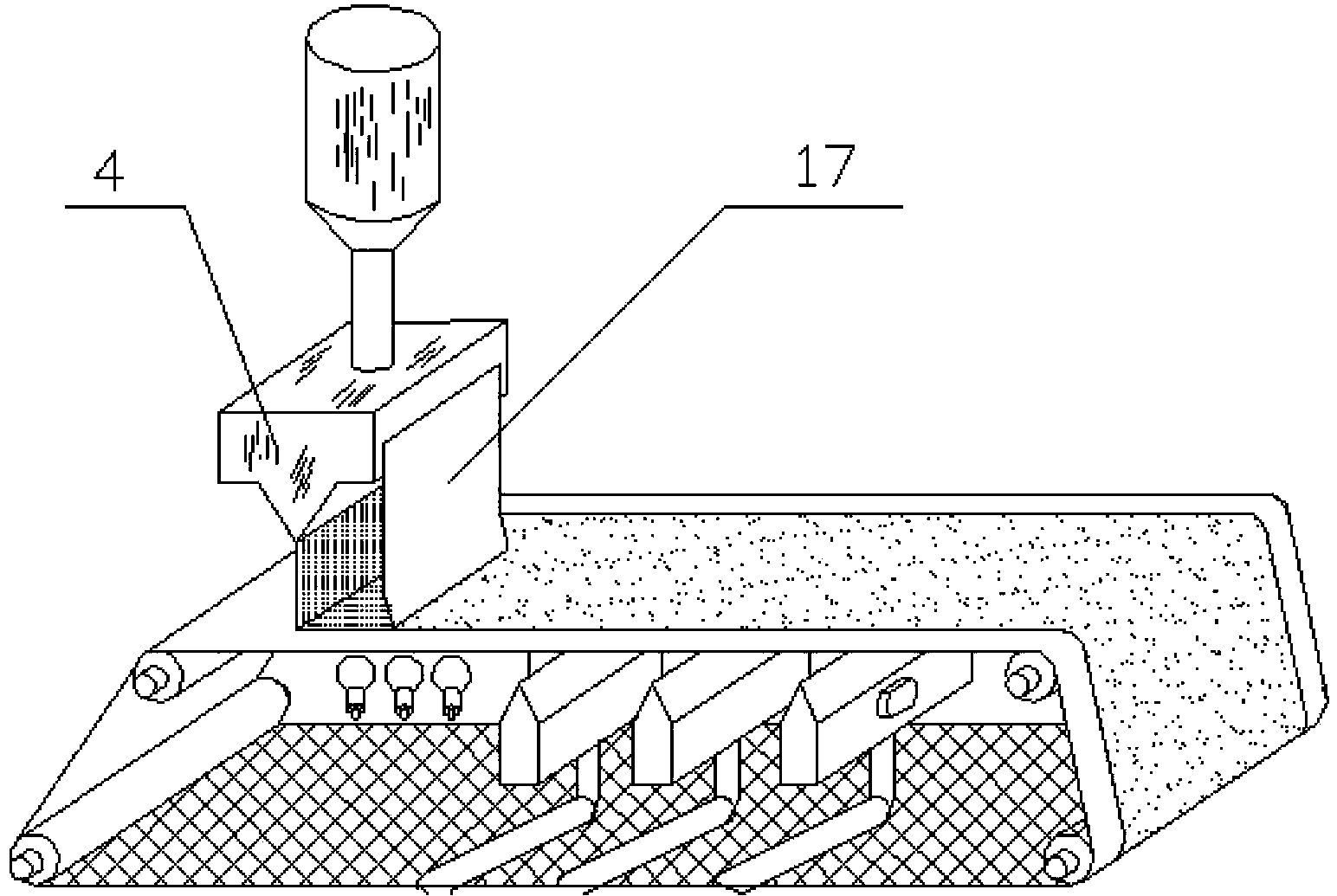

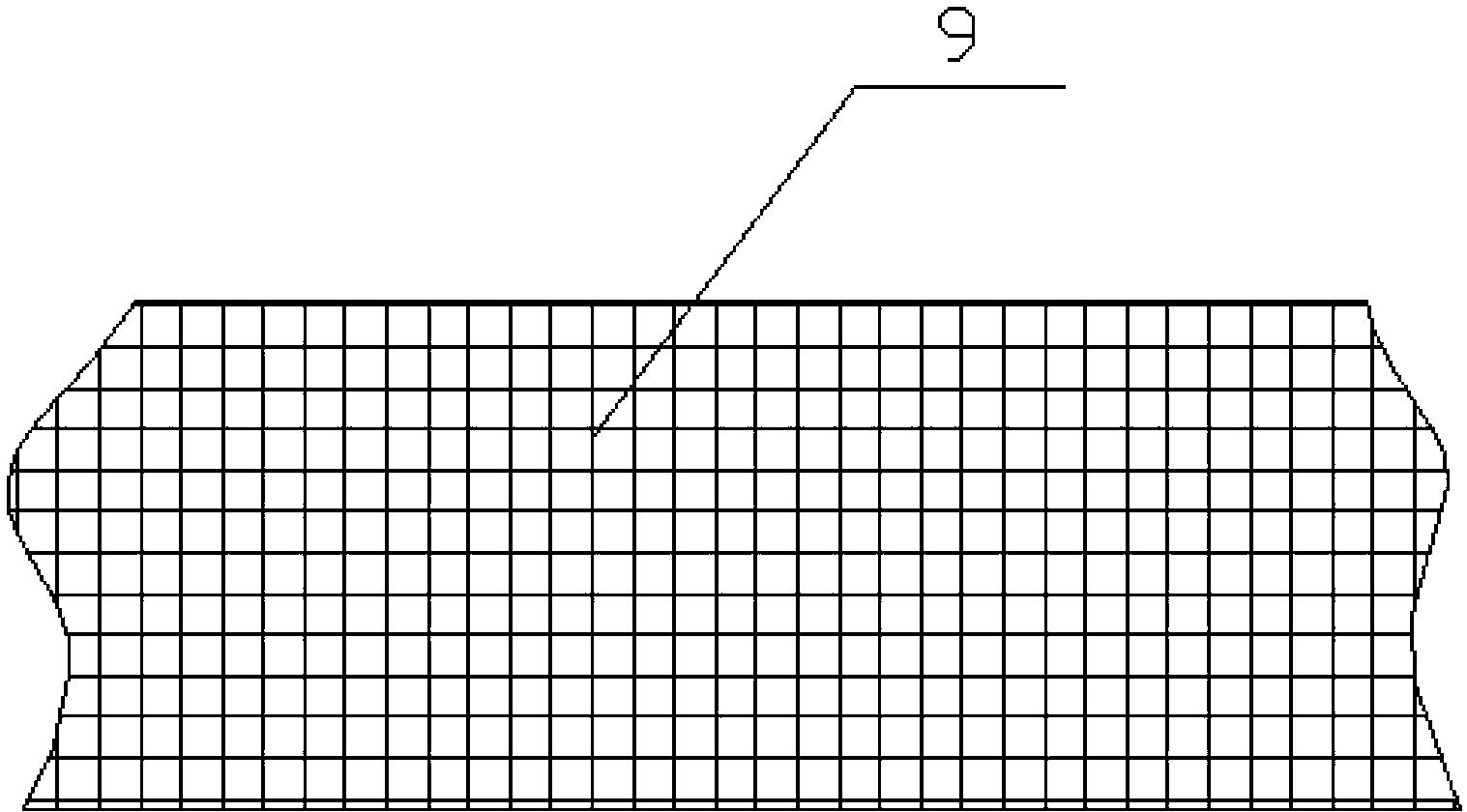

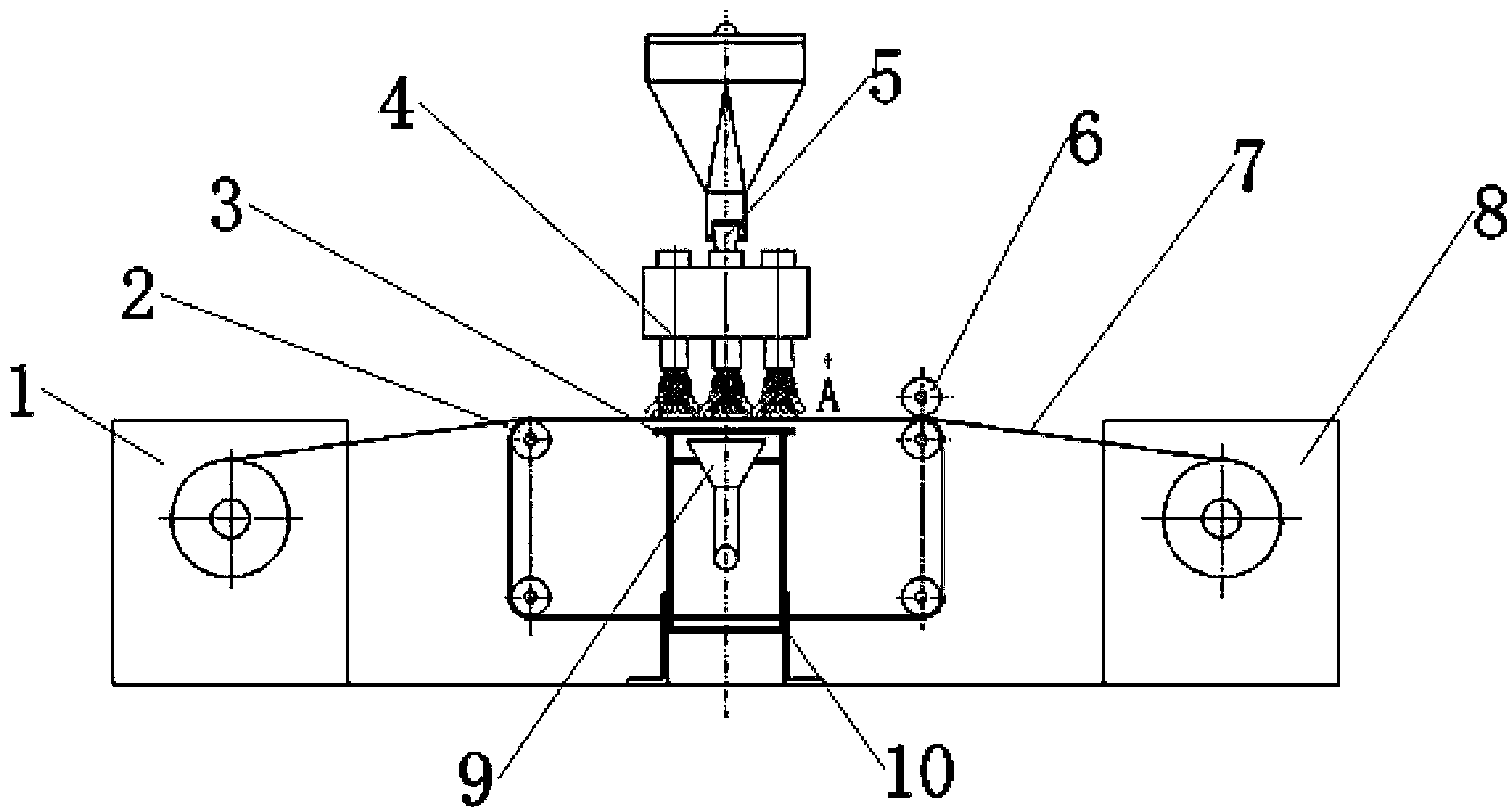

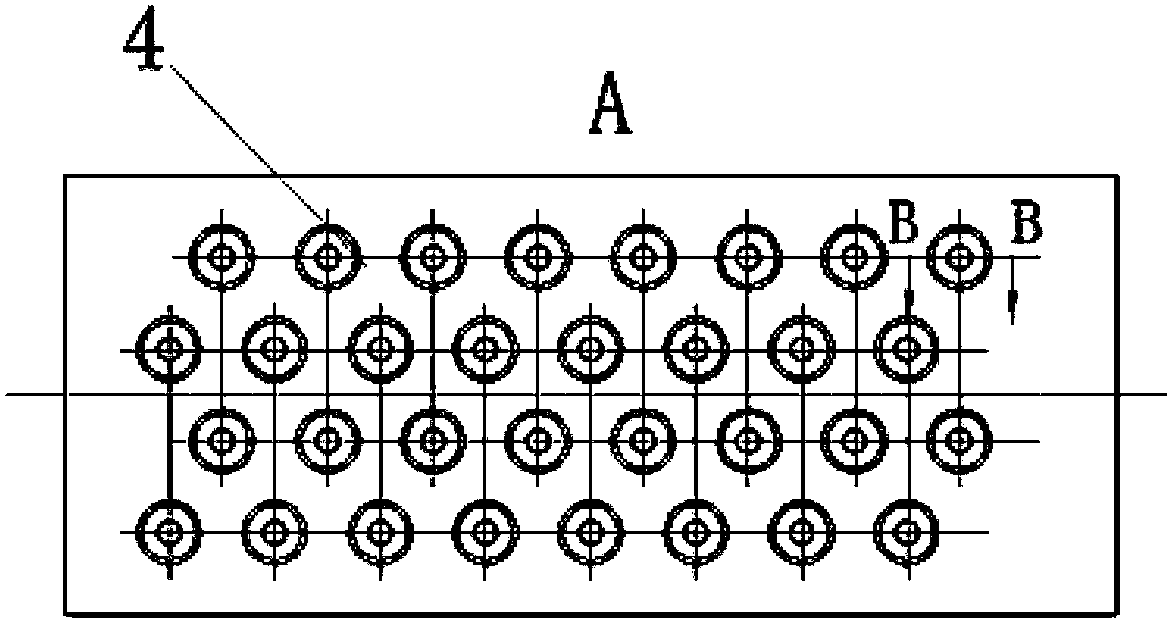

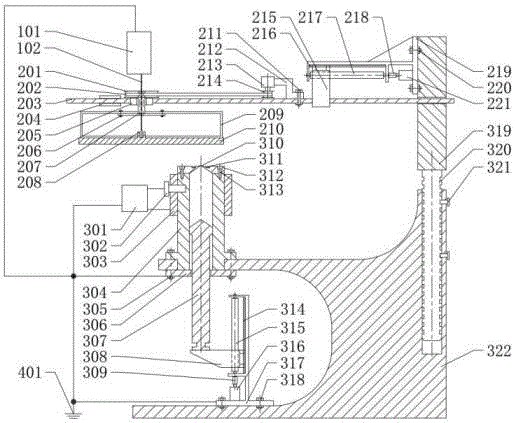

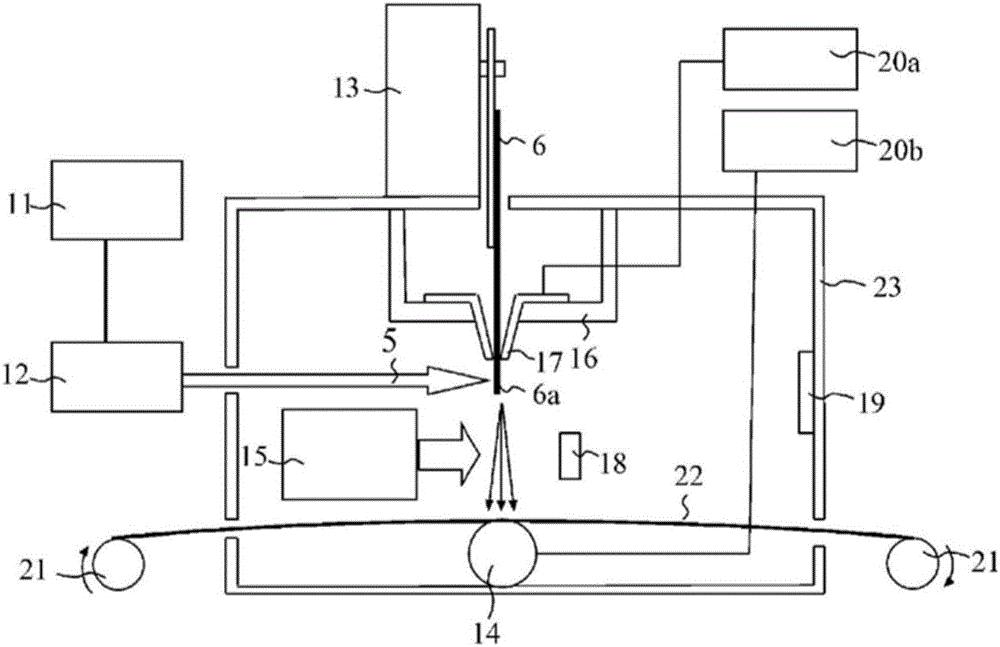

Device and process for mass production of nanometer fiber by melt electro-spinning method

ActiveCN102839431BUniform diameterJet Accelerated ThinningSpinnerette packsFilament/thread formingSpinningEngineering

The invention relates to a device and a process for mass production of nanometer fiber by a melt electro-spinning method, belonging to the field of electro-spinning. The device mainly comprises a base fabric unwinding device, a conveyor belt device, a high-voltage electrode net, a spinning die head assembly, a melt body metering pump, a static removal roller, base fabric, a base fabric winding device, a hot wind return path, an electrode net insulation support, a melt body transmission device, a high-voltage static generator and an air heating system, wherein by the application of a primary division runner in the spinning die head assembly, primary division and accurate partition temperature control of a melt body can be realized; with the creation of a nozzle on an airflow-assisted inner conical face and the assistance of high-speed hot air, secondary division thinning of a melt body layer is realized; by the whole device and the corresponding process, the problems of thick fiber and low yield of the traditional melt body spinning device and process are solved, the device and the process can substitute a melt blowing method to be the main production device and process for production of non-woven materials, and a new path is provided for the production of hundred-nanometer fiber products.

Owner:BEIJING UNIV OF CHEM TECH

A flow controlled type reciprocating circling melt electrostatic spinning machine

InactiveCN105696091ARealization of melt electrospinning technologyNew-spun product collectionFilament/thread formingTemperature controlFiber

The invention provides a flow controlled type reciprocating circling melt electrostatic spinning machine and belongs to the field of electrostatic spinning and the mechanical field. The flow controlled type reciprocating circling melt electrostatic spinning machine comprises an electrostatic generator, a flow controlled type melt electrostatic spinning device and a reciprocating circling receiving device. The flow controlled type melt electrostatic spinning device mainly comprises a device pedestal, a material barrel, a plunger rod, a spinneret disc, a material barrel bottom plate, a heating element, a temperature sensor, a temperature control instrument, a guide rail frame, a propelling slider, a screw shaft, a guide rail, a coupler and a motor. The reciprocating circling receiving device mainly comprises a motor, a driving belt wheel, a driven belt wheel, a belt, a bearing, a hollow shaft, a reciprocating lever, a reciprocating rail, a collection board, a motor rack, a collection board support, a device rack, a height adjusting pillar, a guide rail frame, a propelling slider, a screw shaft, a guide rail, a coupler and a motor. The machine has the advantages that flow of melt electrostatic spinning is controllable, upward collection is realized and fiber films with uniform thickness can be prepared.

Owner:BEIJING UNIV OF CHEM TECH

Upward spinning type melt electrostatic spinning device using rotary shaft with embossment as emitter

InactiveCN102965742AIncrease productivityLower threshold voltageFilament/thread formingFiberMotor drive

The invention discloses an upward spinning type melt electrostatic spinning device using a rotary shaft with an embossment as an emitter, and belongs to the field of electrostatic spinning. The melt electrostatic spinning device comprises an emission device, a receiving device and an electrostatic generator, wherein the emission device mainly comprises the rotary shaft with the embossment, a sealing cover and a heating rod; a rectangular hole is formed in the top of the sealing cover; the heating rod is arranged in the rotary shaft with the embossment; the receiving device is positioned above the emission device and mainly comprises a nonmetal net belt; and the net belt is driven by a motor-driven shaft to rotate so as to continuously receive spinning fibers. According to the melt electrostatic spinning device, superfine fibers with the diameters of less than 500 nm can be subjected to large-scale preparation.

Owner:BEIJING UNIV OF CHEM TECH

High melting point resin fibers and nonwoven fabric

ActiveCN106661773AEasy to processImprove heat resistanceMonocomponent synthetic polymer artificial filamentMelt spinning methodsPolymer scienceHeat resistance

A purpose of the present invention is to provide: high melting point resin fibers which have heat resistance, solvent resistance and excellent processability / formability, while having a diameter of 4 [mu]m or less; and a nonwoven fabric which is formed from the high melting point resin fibers. Another purpose of the present invention is to provide a method for efficiently producing high melting point resin fibers having a diameter of 4 [mu]m or less with use of a laser melt electrospinning method. High melting point resin fibers according to the present invention are formed from a resin having a melting point of 250 DEG C or more, and have a diameter of 4 [mu]m or less. It is preferable for the high melting point resin fibers according to the present invention that the resin having a melting point of 250 DEG C or more is PEEK and the crystallization degree thereof is 30% or less.

Owner:DAICEL CHEM IND LTD

Electrofluid spray nozzle device for melt electrospinning

PendingCN109440201AEasy temperature adjustmentFast deliveryFilament/thread formingSpray nozzleElectric breakdown

The invention discloses an electrofluid spray nozzle device for melt electrospinning. The electrofluid spray nozzle device for melt electrospinning comprises a material cylinder, an aluminium oxide ceramic pipe, heating blocks, heat insulation side plates, a heat insulation cover plate and a conical spray nozzle; the aluminium oxide ceramic pipe sleeves the material cylinder, and the heating blocks are arranged on the periphery of the aluminium oxide ceramic pipe; the heat insulation side plates are arranged at the outer sides of the heating blocks, and the heat insulation cover plate is arranged on the upper ends of the material cylinder, the aluminium oxide ceramic pipe and the heating blocks; the spray nozzle is connected to an opening of the lower end of the material cylinder, and an opening of the upper end of the material cylinder is used as an air supply port. By adopting direct heating, the electrofluid spray nozzle device is simple, an insulation ceramic structure is introduced, and the electric breakdown problem is solved. By applying the device, a solution composed of polymers and metal, polymers and metal melts can be subjected to spray printing, and the device is suitable for a wide range of spray printing materials.

Owner:WUHAN HUAWEIKE INTELLIGENT TECH

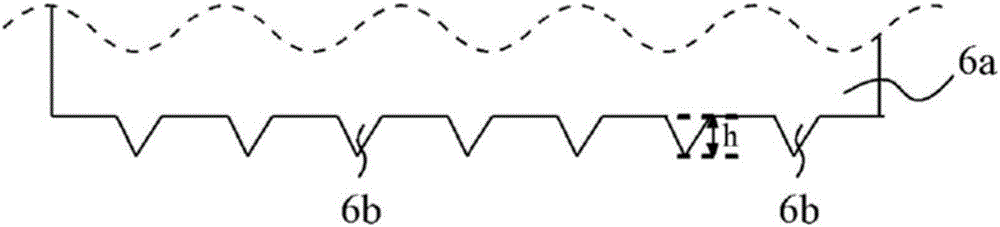

Electrostatic melt spinning device

InactiveCN107574483AAchieve anti-adhesion effectReduce direct contactFilament/thread formingLiquid coreHigh pressure

An electrostatic melt spinning device comprises an upper nozzle and a lower nozzle. An upper-nozzle inner barrel is formed in the upper nozzle, a lower-nozzle inner barrel is formed in the lower nozzle, and a liquid core pipeline penetrates the upper nozzle and the lower nozzle; a concave and convex anti-adhesion structure is arranged on inner walls of parts connected with a molten polymer in spinning, and an anti-adhesion function of a polymer melt in spinning assemblies can be achieved; the function mechanism of the concave and convex anti-adhesion structure lies in that the concave and convex anti-adhesion structure includes concave parts and convex parts, the convex parts are arranged in a manner of protruding internal surfaces of the parts, direct contact of the polymer melt with highadhesion and internal walls of the parts is reduced by the aid of supporting among points, a gas suspension function is formed under the action of the high-temperature high-pressure melt, and self-separated anti-adhesion is achieved.

Owner:TONGXIANG YIZHIJIANNENG INFORMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com