A flow controlled type reciprocating circling melt electrostatic spinning machine

A melt electrospinning, melt electrospinning technology, applied in textile and papermaking, filament/thread forming, bundling of newly blown filaments, etc., can solve problems such as uniform distribution, unfavorable fibers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below with reference to the accompanying drawings. Those skilled in the art should understand that the embodiments described here are only examples, and other features that can achieve the same effect can be conceived, and the features drawn in the drawings can be reduced or enlarged according to specific situations. The connection method, the number and type of its connecting parts can vary according to specific conditions.

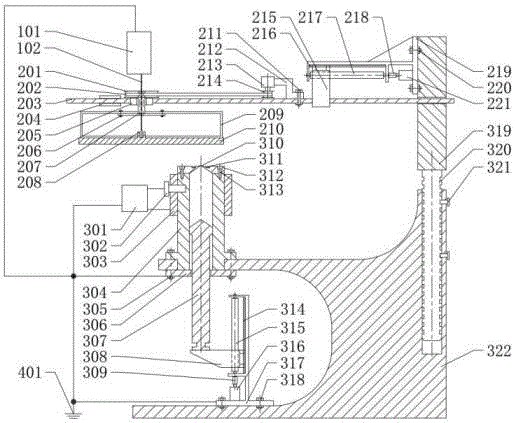

[0010] The invention provides a flow-controlled reciprocating rotary melt electrospinning machine, such as figure 1 As shown, the flow-controlled reciprocating rotary melt electrospinning machine includes an electrostatic generator 101, a flow-controlled melt electrospinning device and a reciprocating rotary receiving device. The flow-controlled melt electrospinning device mainly includes a device base 322, a barrel 304, a plunger rod 307, a spinneret 312, a barrel chassis 306, a heating e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com