Metal mesh belt type electrostatic melt spinning device and technique

A melt electrospinning, metal mesh belt technology, used in textiles and papermaking, filament/thread forming, fiber processing, etc., to avoid dangers and limitations, simple composition, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

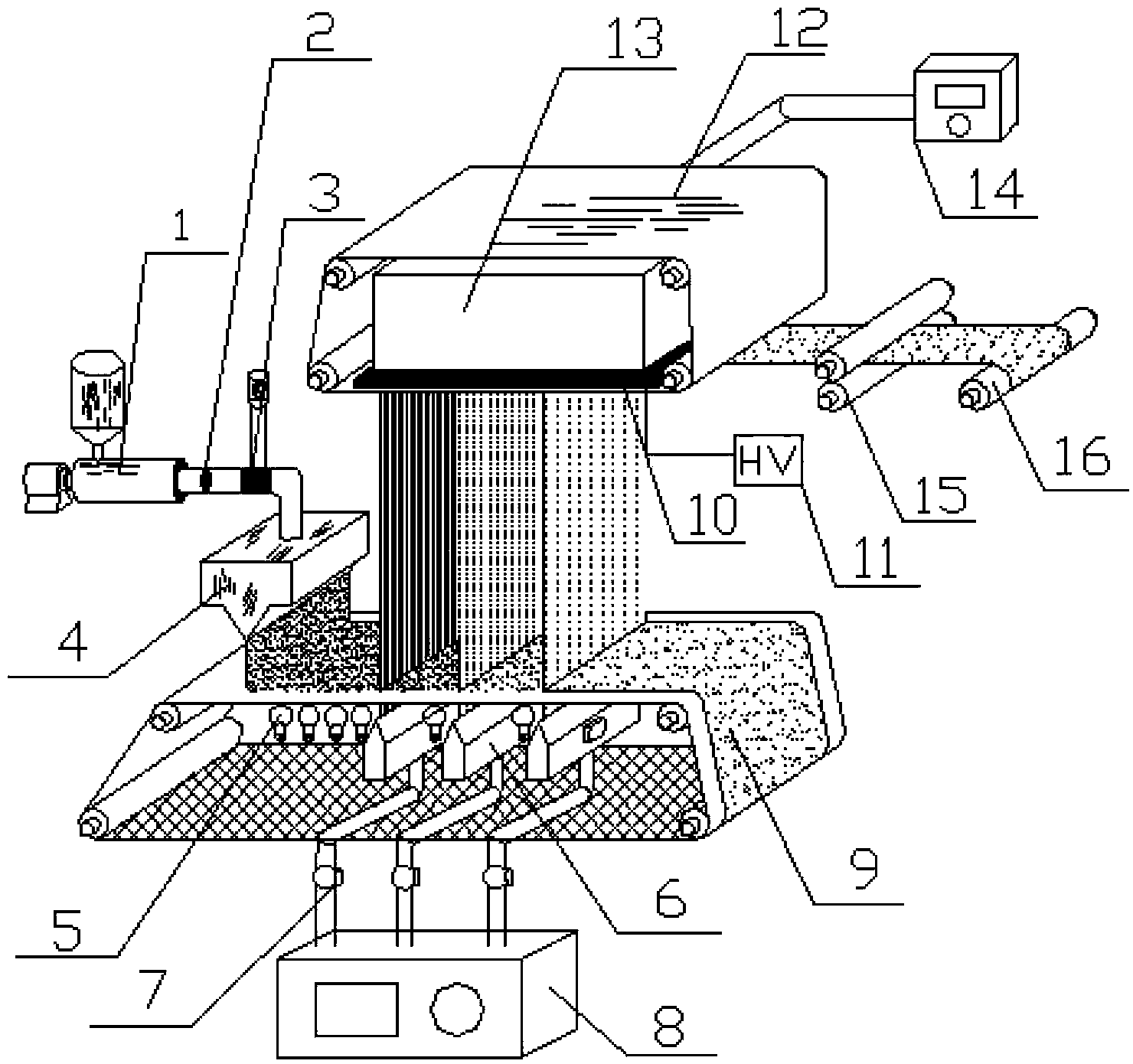

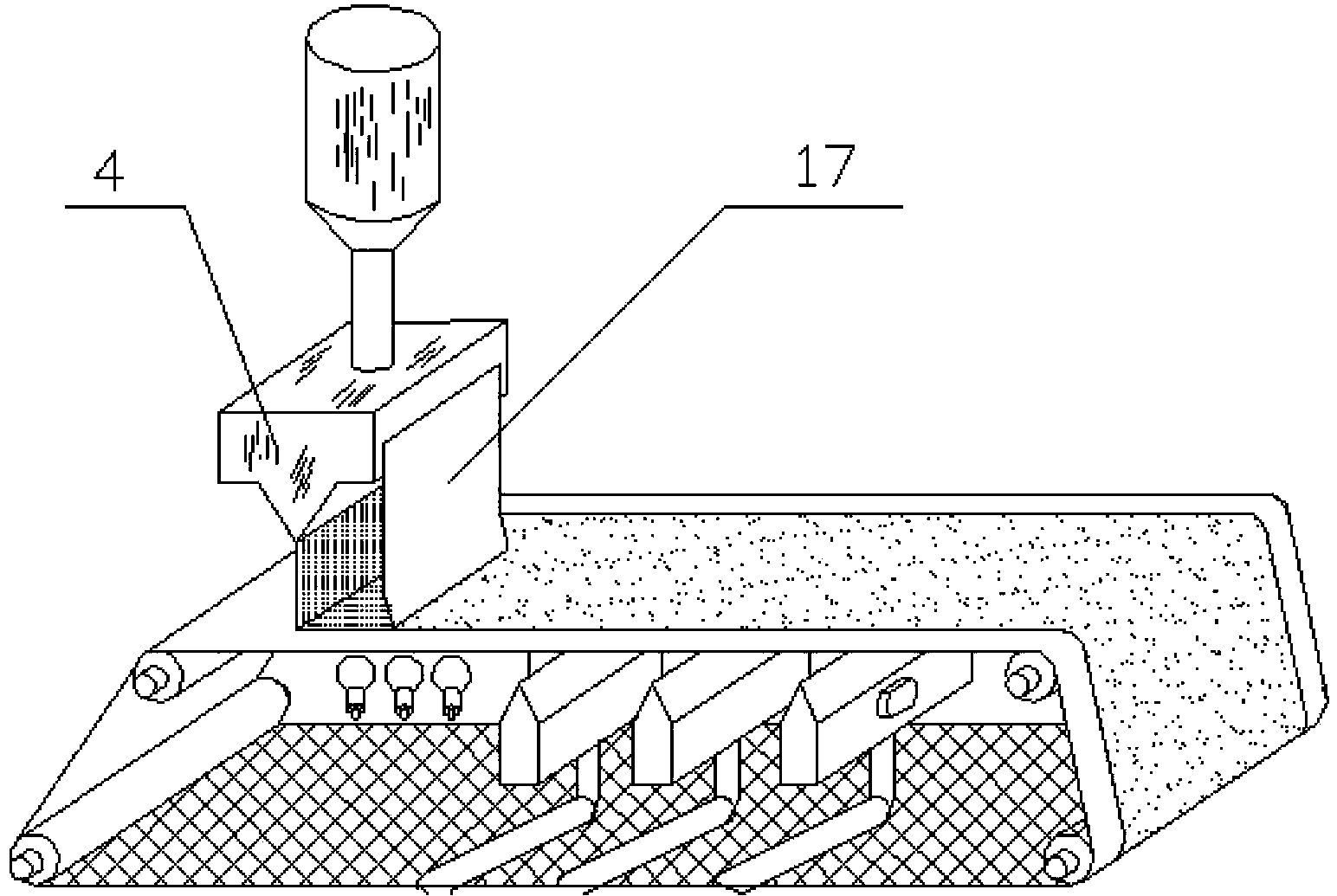

[0022] The present invention is a metal mesh belt type melt electrostatic spinning device. The schematic diagram of the device is as follows Figure 1-4 As shown, it mainly includes extruder 1, filter screen 2, melt metering pump 3, feeding head 4, infrared heater 5, air knife 6, air flow regulating valve 7, air compressor 8, metal mesh belt 9 , Perforated electrode plate 10, high voltage electrostatic generator 11, mesh belt 12, exhaust box 13, exhaust fan 14, hot rolling device 15, winding device 16 and powder uniform brush 17, extruder 1 and melt metering A filter screen 2 is installed between the pump 3, the melt metering pump 3 is connected to the feeder head 4, and the metal mesh belt 9 is placed under the feeder head 4, and its left end corresponds to the position of the feeder head. The infrared heater 5 and the gas The knives 6 are all arranged inside the metal mesh belt 9 and close to the upper metal mesh belt. The air knives 6 are arranged in parallel and evenly dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com