Patents

Literature

421 results about "Melt blowing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

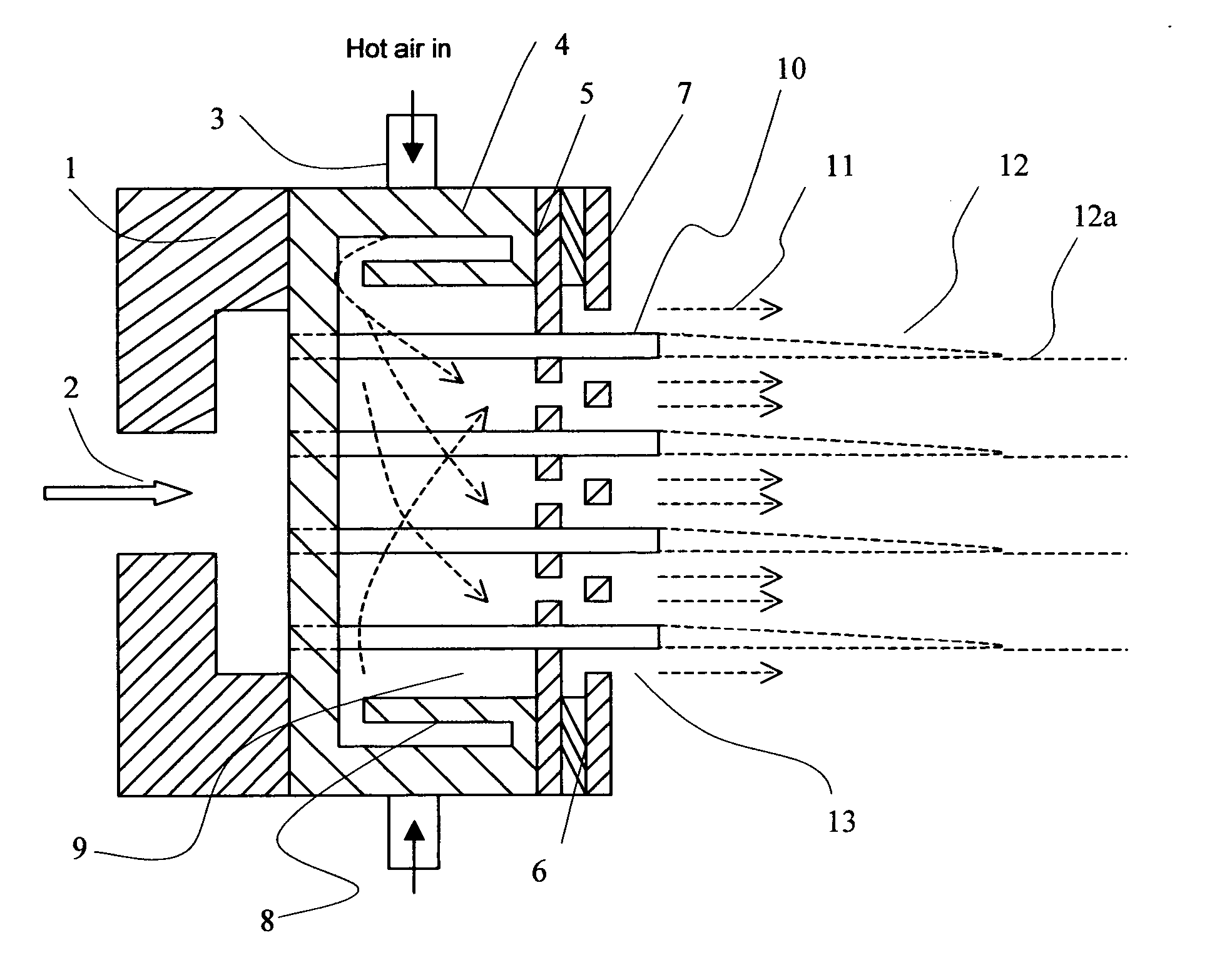

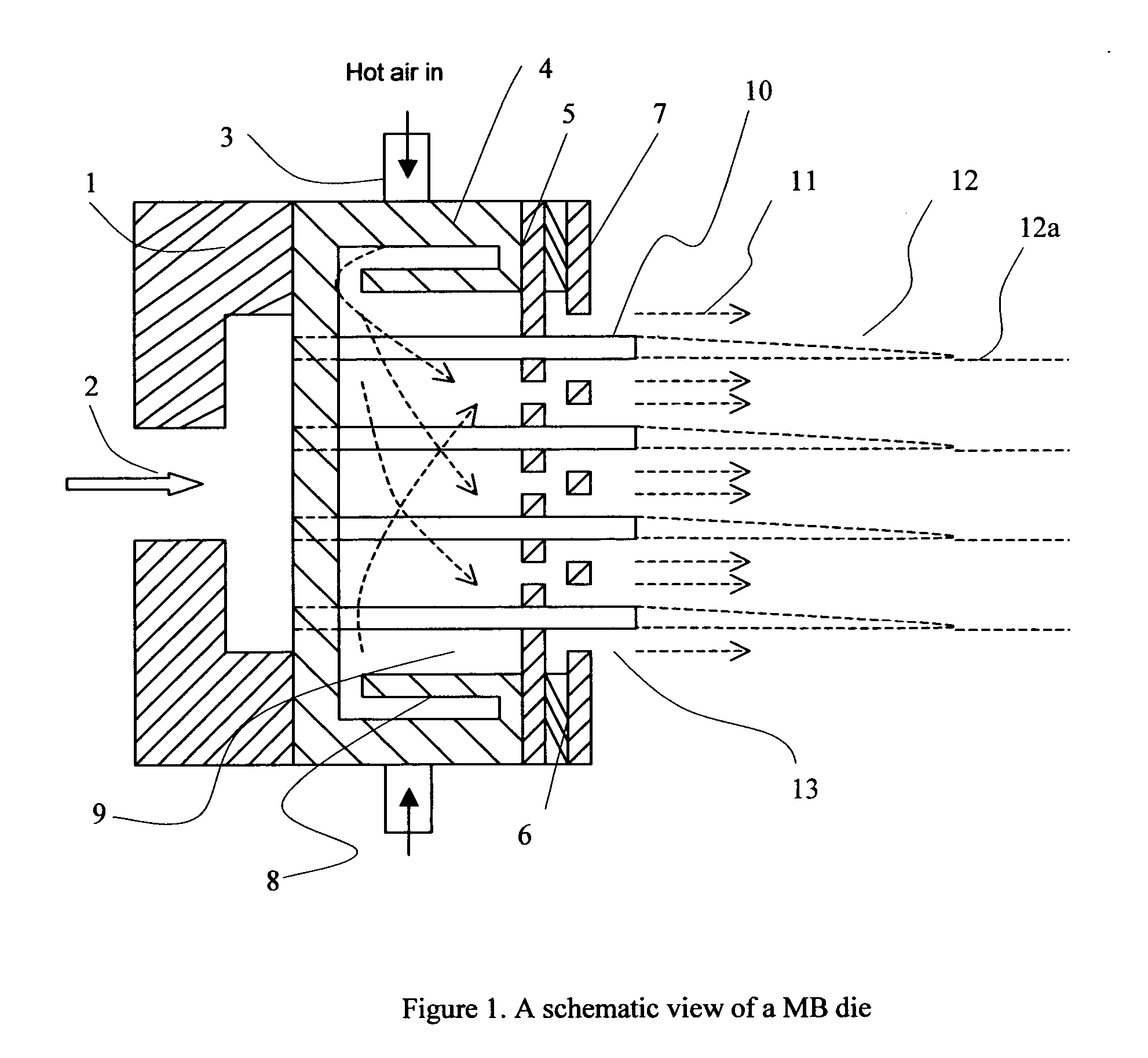

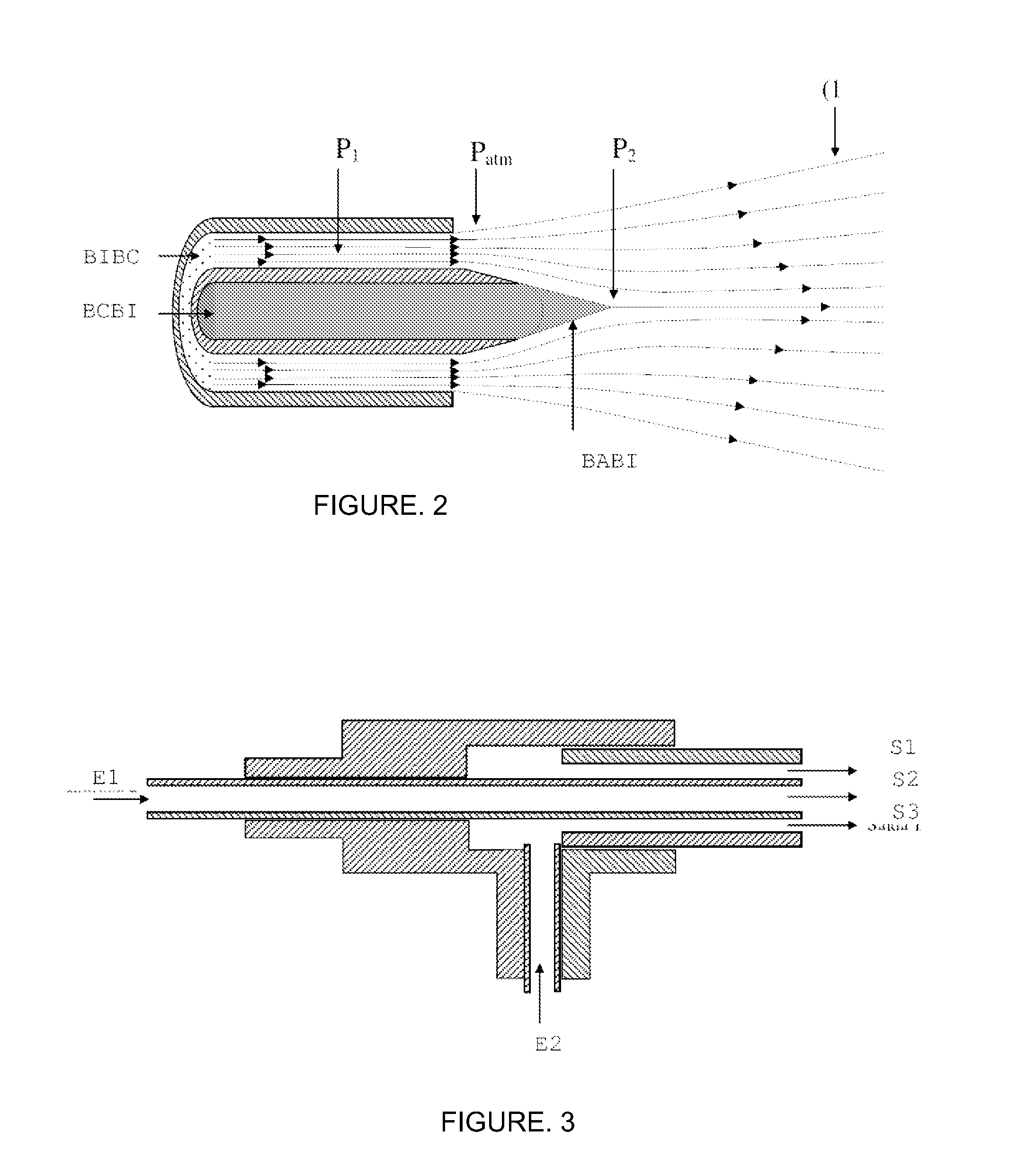

Melt blowing is a conventional fabrication method of micro- and nanofibers where a polymer melt is extruded through small nozzles surrounded by high speed blowing gas. The randomly deposited fibers form a nonwoven sheet product applicable for filtration, sorbents, apparels and drug delivery systems. The substantial benefits of melt blowing are simplicity, high specific productivity and solvent-free operation. Choosing an appropriate combination of polymers with optimized rheological and surface properties, scientists have been able to produce melt-blown fibers with an average diameter of down to 36nm.

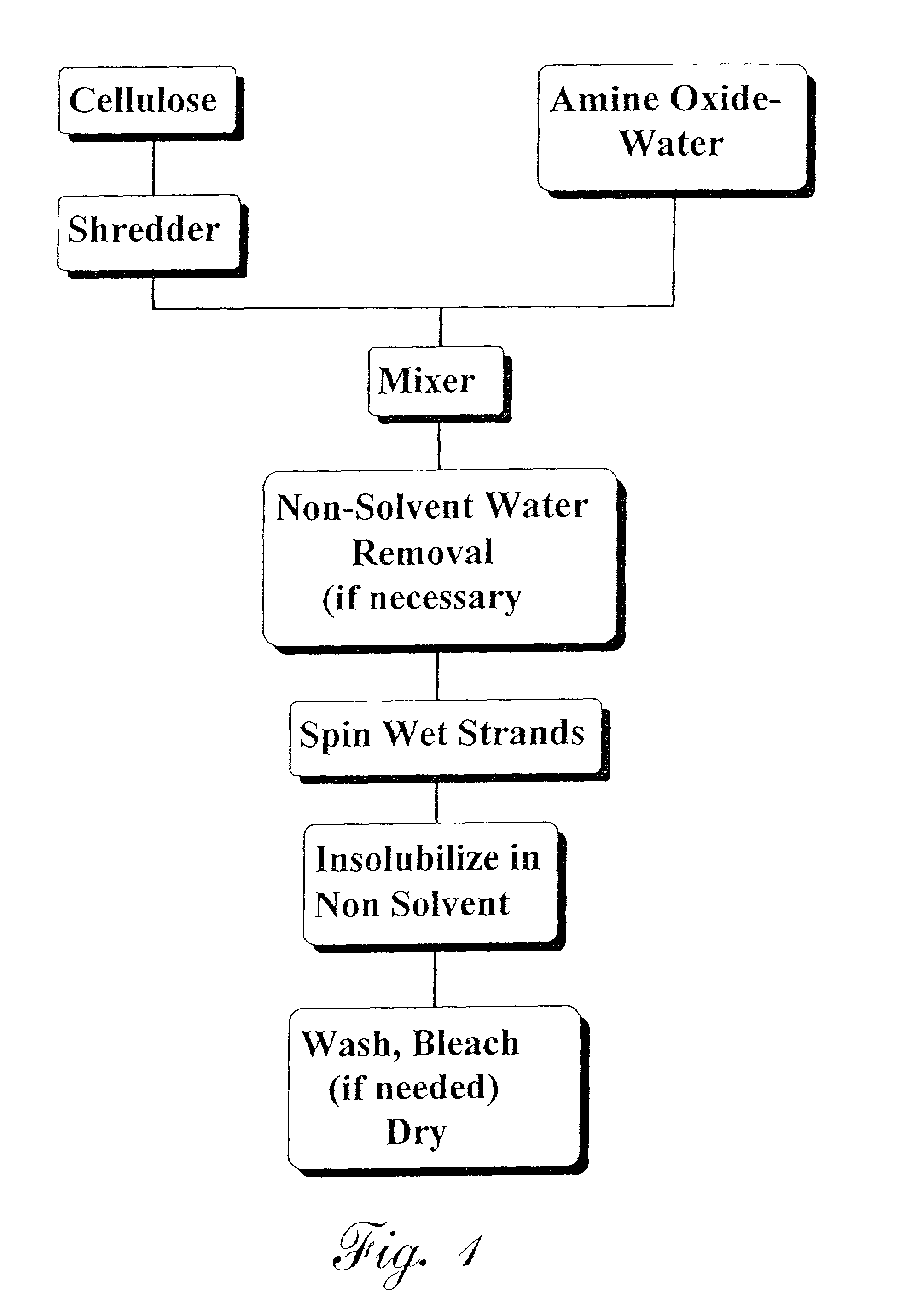

Process for forming micro-fiber cellulosic nonwoven webs from a cellulose solution by melt blown technology and the products made thereby

InactiveUS20050056956A1Artificial filament washing/dryingLoose filtering material filtersNon solventEngineering

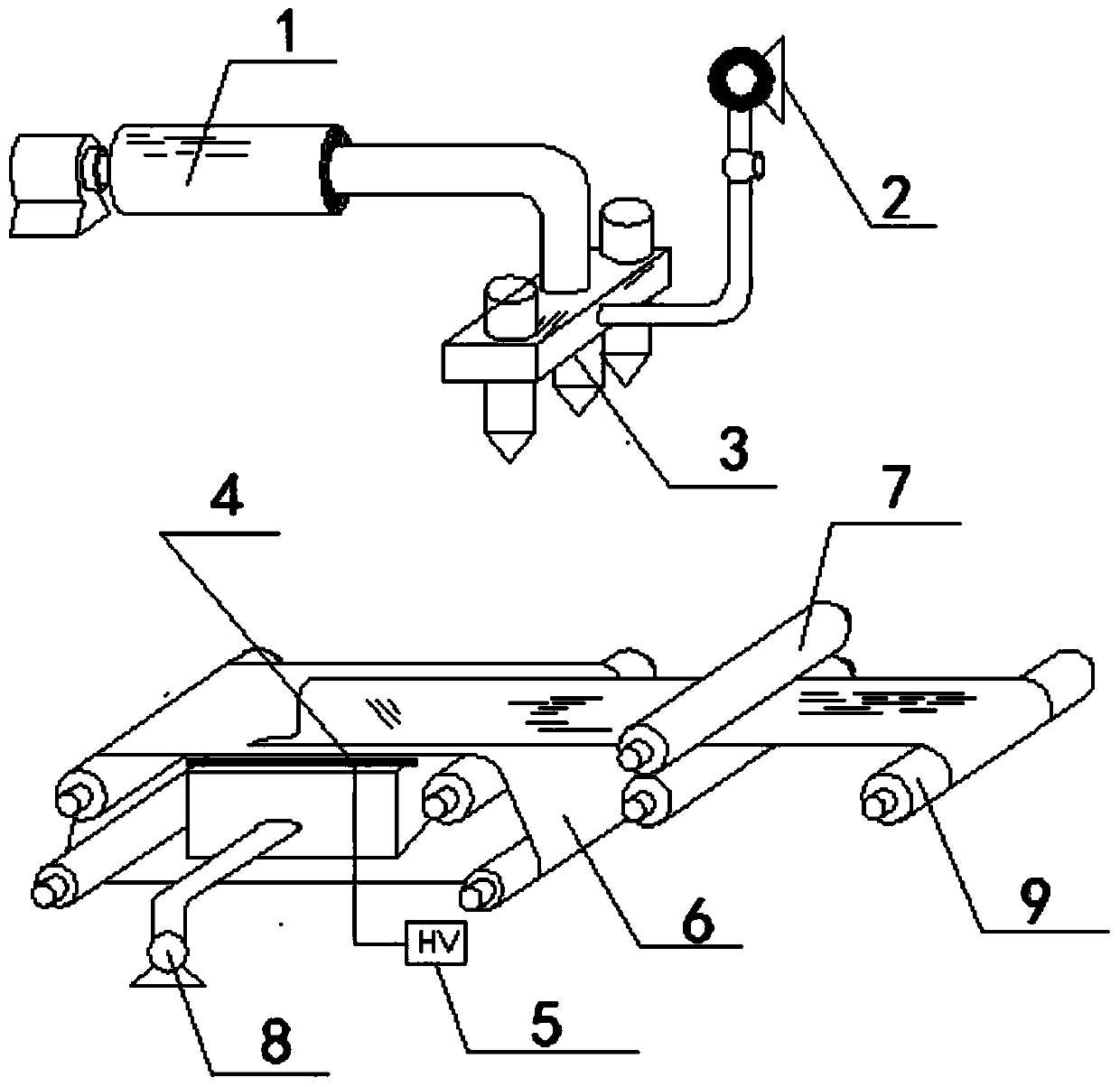

This invention relates to a process of melt blowing a cellulose solution through a concentric melt blown die with multiple rows of spinning nozzles to form cellulosic microfiber webs with different web structures. The process comprises the steps of (a) extruding a cellulose solution (dope) through a melt blown spinneret with multiple rows of spinning nozzles; (b) drawing each individual extrudate filament to fine fiber diameter by its own air jet; (c) coagulating and entangling the fine fibers with a series of pressured hydro needling jets of recycling solution of the mixture of cellulose solvent and non-solvent in the spin-line; (d) collecting the stream of microfibers, air and needling jets on a moving collecting surface to form cellulosic fiber web; (e) hydro-entangling the said pre-bonded web downstream with at least one set of hydro needling jets of recycling solvent / non-solvent solution for forming well bonded nonwoven web; (f) regenerating the fine fibers in at least one bath for at least 5 seconds; (g) further regenerating and washing the fine fibers in another bath for at least 5 seconds; (h) pinching the well bonded melt blown cellulosic nonwoven with pressure rollers to remove major portions of the non-solvent; (i) drying the nonwoven web by heat, or vacuum or both, and (j) winding the nonwoven web into rolls.

Owner:BIAX FIBERFILM CORP

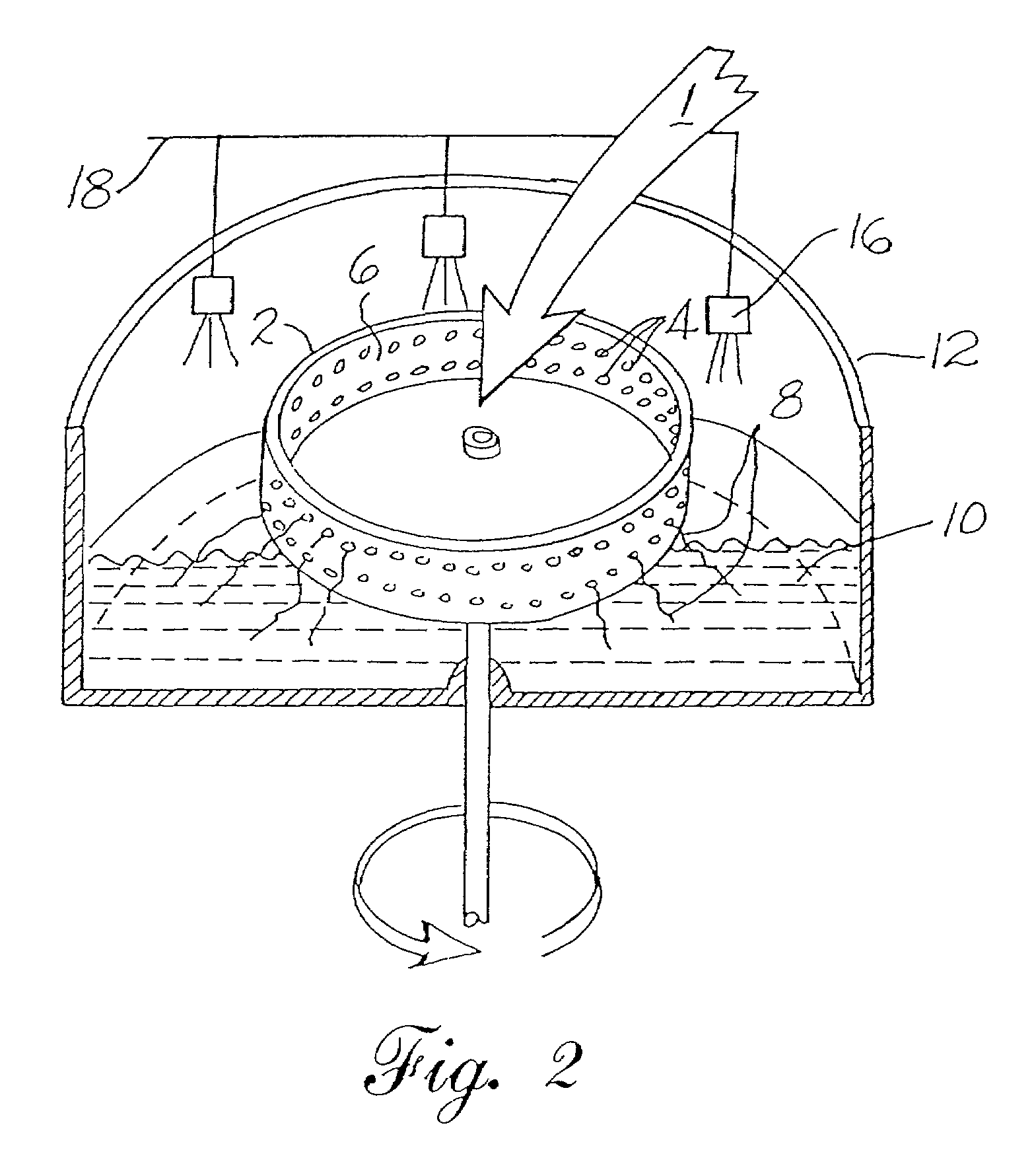

Lyocell nonwoven fabric

InactiveUS7067444B2Powerful solventLow tendency to fibrillatePulp properties modificationMonocomponent cellulose artificial filamentMelt blowingNonwoven fabric

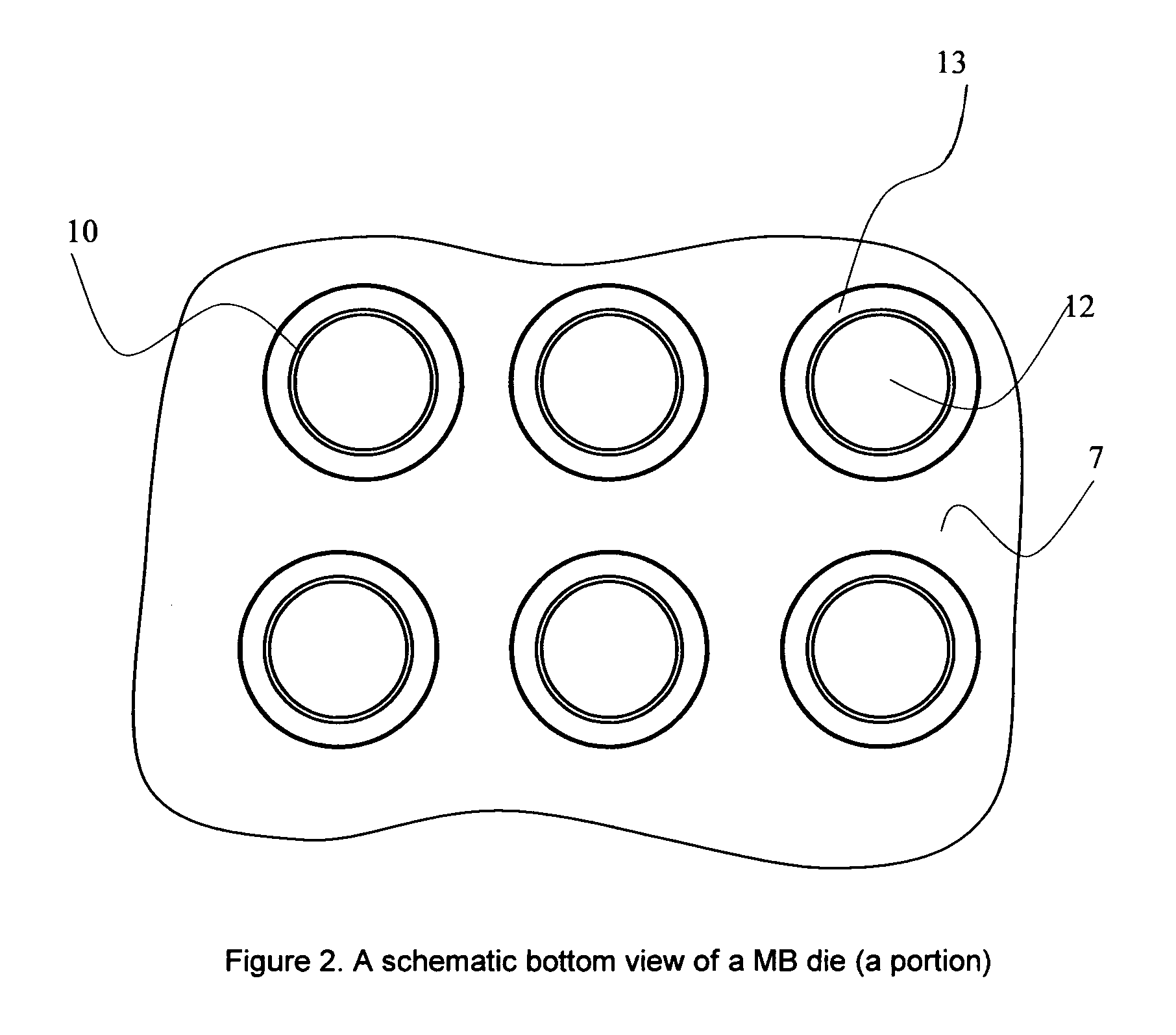

A lyocell nonwoven fabric having fibers characterized by pebbled surfaces and variable cross sections and diameters along the fibers and from fiber to fiber, is disclosed. The lyocell nonwoven fabric is produced by centrifugal spinning, melt blowing or spunbonding. The lyocell nonwoven fabric has fibers that can be made in the microdenier range with average weights as low as one denier or less. The lyocell nonwoven fabric has fibers with low gloss, a reduced tendency to fibrillate and have enhanced dye receptivity.

Owner:INT PAPER CO

Process for preparing a non-woven fibrous web

Disclosed is a process for preparing a fibrous web. The fibrous web includes a microencapsulated material, such as a microencapsulated phase change material, adhered to the web. Preferably, the web is prepared in a melt-blowing or spun-bonding process. In the melt-blowing process, cooling water containing the microcapsules is used to cool melt blown fibers prior to collection on a collector. In the spun-bonding process, microcapsules are applied in liquid suspension or in dry form to a heated web, for instance, after the web has been calendared. The fibrous webs thus prepared have numerous uses, and are particularly suited to the manufacture of clothing.

Owner:ENCAPSYS LLC

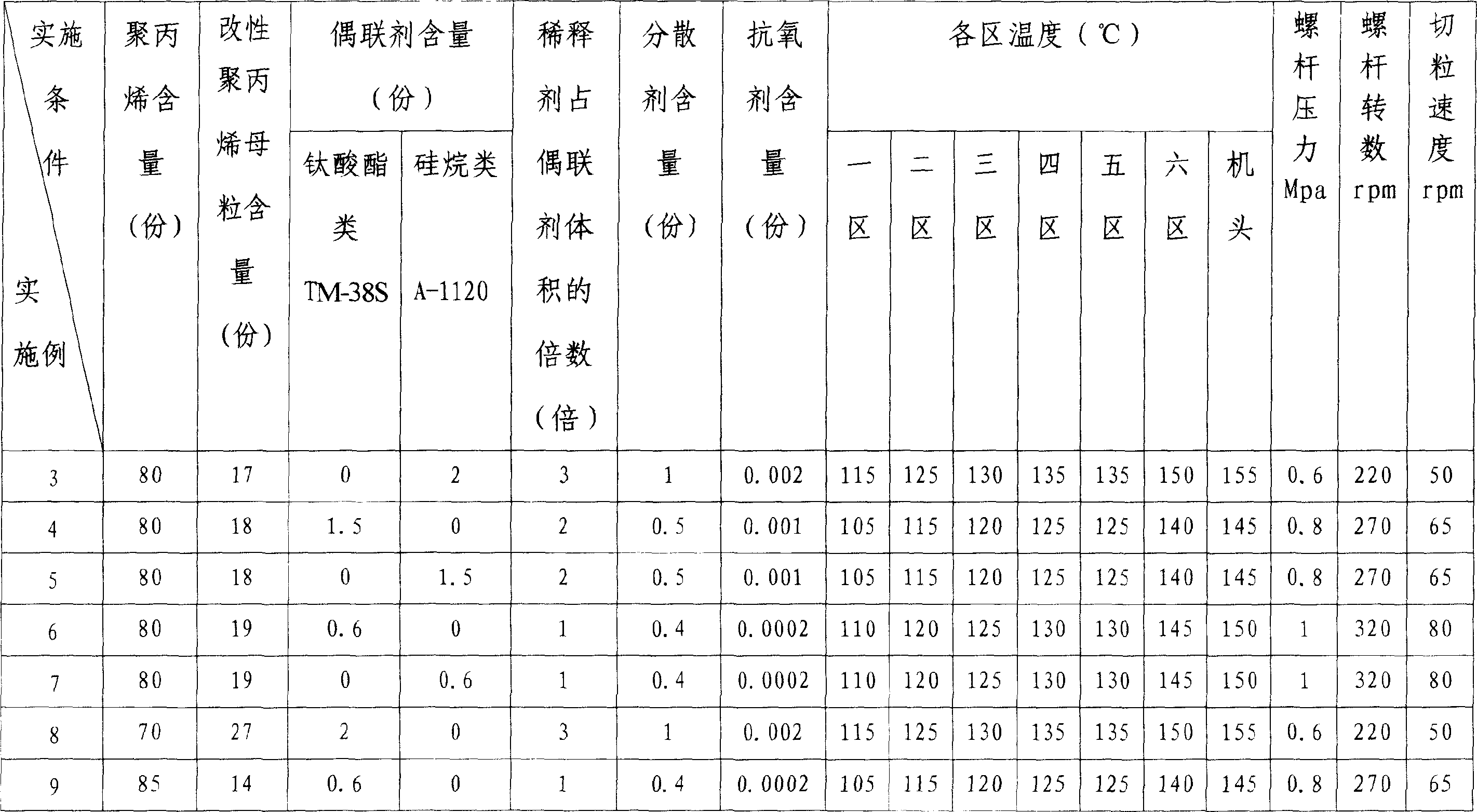

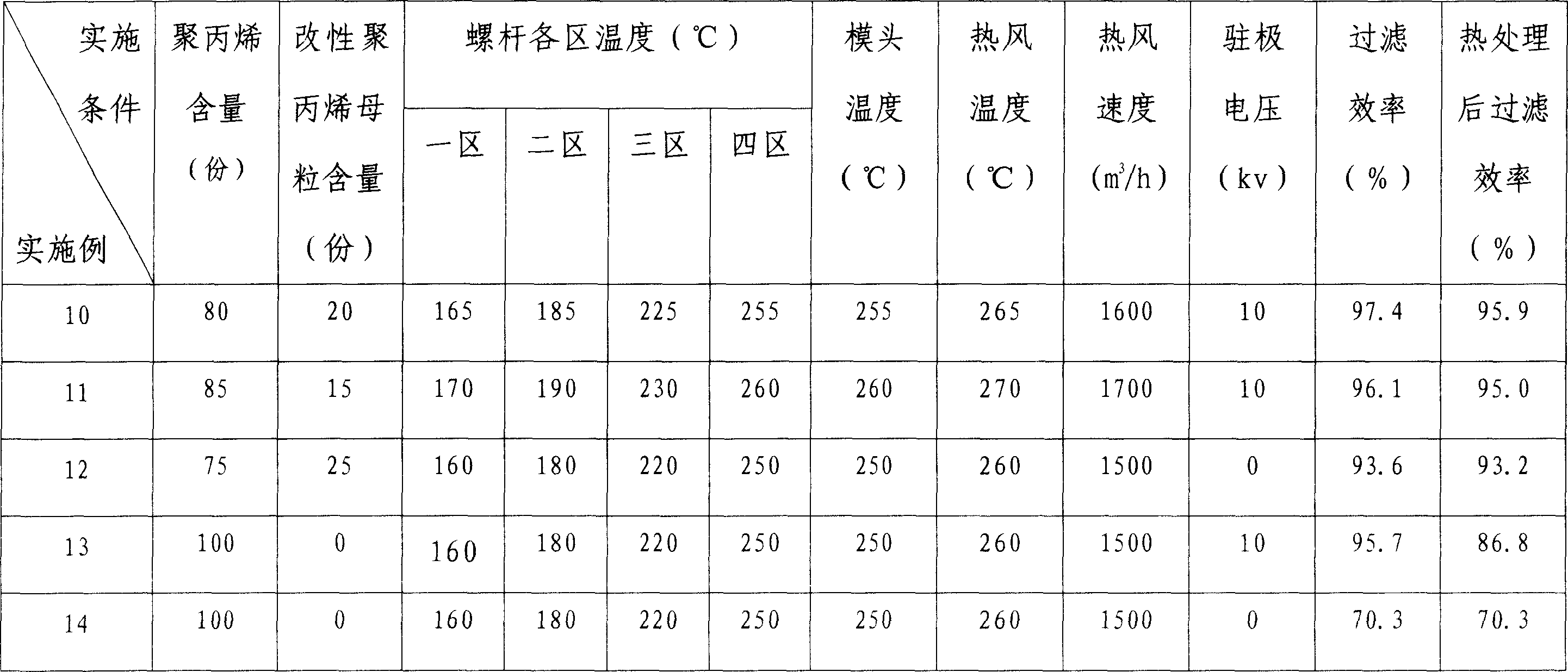

Modified polypropylene mother particle for melt spray, its preparation method and use

The present invention relates to a modified polypropylene mother granule for melt-blowing process, its preparation method and application technique. Its composition contains (by wt %) 70-85% of polypropylene, 14-27% of tourmaline and 1-3% of adjuvant. The described polypropylene is a low molecular weight melt-blowing polypropylene resin, the average grain size of tourmaline is less than 0.5 microns, and the adjuvant includes coupling agent, dispersing agent and antioxidant. Its preparation method includes the steps of surface modification of tourmaline, vacuum drying and meltblending and granulating, etc.

Owner:TIANJIN POLYTECHNIC UNIV

Fully-degradable polylactic acid fiber melt-blowing nonwoven and preparation method thereof

InactiveCN101824708APromote degradationPromote growthMelt spinning methodsNon-woven fabricsVolumetric Mass DensityMelt blowing

The invention discloses fully-degradable polylactic acid fiber melt-blowing nonwoven and a preparation method thereof. The nonwoven is characterized in that polylactic acid slices are spinned at a melting temperature; and fiber filaments stretched by hot air is formed by self-adhesion and hot rolling, wherein, the even fineness of the nonwoven fiber filaments is 0.52-5mu m, the surface density is 5-50g / m2, the thickness is 0.1-0.9mm, the ratio of longitudinal strength to transverse strength is 0.9-1.2, and the filtering efficiency to bacteria is above 95%. The filtering efficiency of the melt-blowing nonwoven product of the invention to bacteria reaches up to 95% which is far higher than that of the existing similar products. The invention solves the problem of low and uneven longitudinal strength and transverse strength of the existing melt-blowing nonwoven. The invention lowers the melt-blowing die head temperature to 180-185 DEG C and brings optimal spinning effect. The technology of the invention is easy to operate and control, has favorable technical stability and can carry out industrial production.

Owner:豆丁乐园(南京)婴儿用品有限公司

Antibiotic fiber and preparation method of fiber product

InactiveCN102337602AGood compatibilityAntibacterial long-acting and fastFibre treatmentArtifical filament manufactureAntibiotic AgentsMelt blowing

The invention discloses antibiotic fiber and a preparation method of fiber product. According to the invention, an aqueous nano-grade silver antibiotic agent is prepared into organic nano-grade silver sol by using a chemical phase transferring method, such that the antibiotic agent has a good compatibility with a high polymer substrate; the sol is directly mixed with high polymer, and the mixture is dried, such that an antibiotic high polymer is prepared. The obtained antibiotic high polymer has characteristics of good versatility, good dispensability, simple technology, good processability, good temperature tolerance, and no environmental pollution. With methods of spinning or melt blowing, the antibiotic high polymer can be directly used for preparing antibiotic fibers and antibiotic fiber products. The obtained antibiotic fibers and antibiotic fiber products have excellent performances of rapid and long-lasting antibiotic effect. The physical properties of the antibiotic fibers and the antibiotic fiber products are not changed with additional antibiotic agents.

Owner:周刚

Converting process for converter low-silicon molten iron

ActiveCN101117651AOxygen blowing time shortenedGood foamingManufacturing convertersProcess efficiency improvementMelting tankSlag

The present invention provides a siliconeisen iron melt blowing and refining method in a converter, and the method includes the steps as follows: (1) waste steel and iron melt are loaded into the converter, and oxygen blowing and steel making begin, the oxygen flux is 900Nm3 / min to 1050Nm3 / min, the height that the oxygen gun spraying head departs the metal liquid surface in the melt pond is 1.8-3.0m; (2) a first batch of slag charge is added after oxygen is blown in the first batch of the slag charge is 60-80 percent of the total slag charge, and the rest slag charge can be charged in 2-3 batches after the first batch of the slag charge is melted. The consumption of the slag charge: the lime 18-28kg / t steel, the light calcined dolomite 15-25kg / t steel, the ironstone 5-10kg / t steel, the carbonaceous heat generating agent 0-7kg / t steel, the compound slag 0-6kg / t steel; and the rest process are same as the prior art. The oxygen blowing duration of the present invention decreases 1.8min per furnace averagely, and the problem that the heat quantity is short and the slag forming is difficult can be solved simultaneously, and the present invention can make the converter steel-making to produce efficiently.

Owner:BAOSHAN IRON & STEEL CO LTD +1

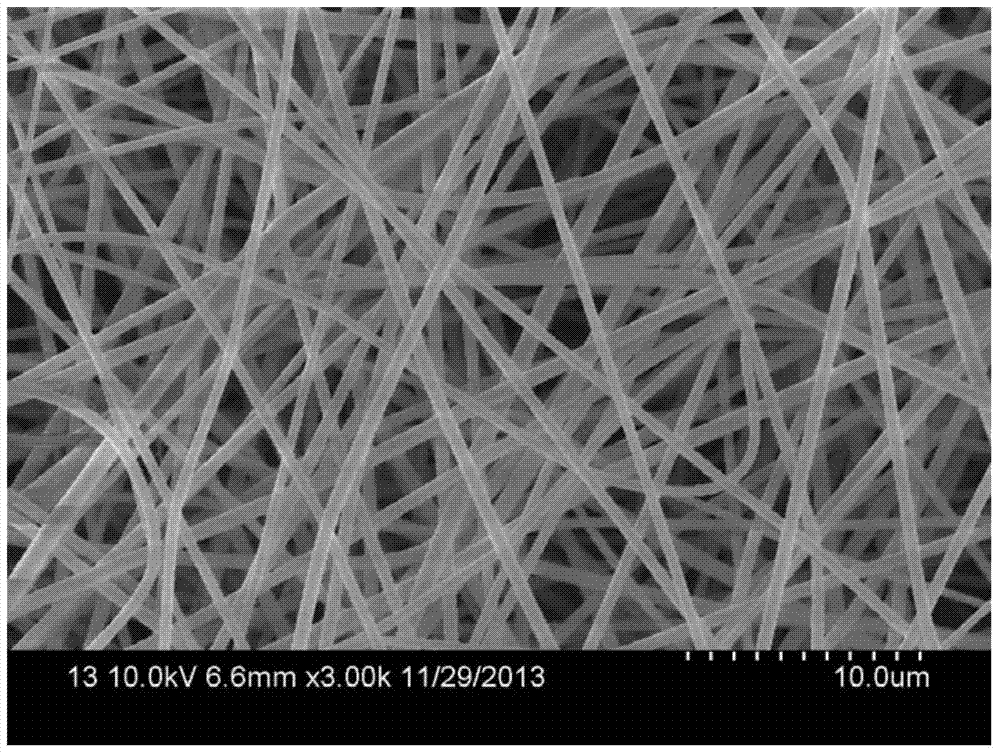

Nanofiber composite membrane and preparation method thereof

InactiveCN104727016AWide range of usesHigh hydrostatic pressure resistanceNon-woven fabricsAdhesivesPolymer scienceNanofiber

The invention provides a preparation method of a nanofiber composite membrane. The method includes the steps that a spinning solution and melt of a high-melting-point polymer are provided, a spinning solution and melt of a low-melting-point polymer are provided, and the melting point difference of the high-melting-point polymer and the low-melting-point polymer is not smaller than 10 DEG C; the spinning solution of the high-melting-point polymer and the spinning solution of the low-melting-point polymer are subjected to electrostatic spinning, and accordingly an electrostatic spinning high-melting-point polymer fiber membrane and an electrostatic spinning low-melting-point polymer fiber membrane are obtained; the low-melting-point polymer melt and the high-melting-point polymer melt are subjected to melt-blowing spinning, so that a melt-blowing spinning low-melting-point polymer fiber membrane and a melt-blowing spinning high-melting-point polymer fiber membrane are obtained; the melt-blowing spinning high-melting-point polymer fiber membrane and the electrostatic spinning low-melting-point polymer fiber membrane undergo composite hot pressing, or the melt-blowing spinning low-melting-point polymer fiber membrane and the electrostatic spinning high-melting-point polymer fiber membrane undergo composite hot pressing, and thus the nanofiber composite membrane is obtained. The nanofiber composite membrane has high tensile strength which reaches up to 22 MPa-32 MPa.

Owner:ZHEJIANG WEIXING IND DEV

Mould-proof mothproof non-woven fabric and preparation method thereof

InactiveCN103696142AHigh tensile strengthImprove adhesionSynthetic resin layered productsNon-woven fabricsPentachlorophenolJojoba oil

The invention provides a mould-proof mothproof non-woven fabric, which comprises a top surface layer, a back surface layer, and a fiber cotton layer sandwiched between the top surface layer and the back surface layer, wherein the top surface layer and the back surface layer are made of non-woven fabric materials; the non-woven fabric is prepared by the following active ingredients in parts by weight through adopting a melt-blowing method: 100 parts of isotactic polypropylene, 2-3 parts of molybdenum disulfide, 1-2 parts of copper sulfate, 1-2 parts of jojoba oil, 1-2 parts of pentachlorophenol, 3-4 parts of zinc stearate, 1-2 parts of antioxidant 168, 12-15 parts of dioctyl terephthalate, 10-12 parts of rice hulls, 2-3 parts of bamboo charcoals, 2-3 parts of coptidis rhizome, 1-2 parts of cogongrass rhizome, 1-2 parts of rust-coloured crotalaria herb with root, and 4-5 parts of auxiliaries. The non-woven fabric has the mould-proof mothproof properties, as well as aromatic fragrance and health-care function, can adsorb harmful gas and peculiar smell, is heat-resistant, corrosion-resistant, non-toxic and odorless, large in tensile strength, good in binding power and free from dust and chips.

Owner:MAANSHAN HUBIN NONWOVEN CLOTH TECH

Biologically and photochemically degradable polymeric compositions and film

The present invention is directed to mineral-filled polyester compounds and films which are produced by melt blowing polyester resins containing 10 to 50 wt % fillers. The fillers are selected from two different groups: the first consisting of block type fillers including inorganic carbonates, synthetic carbonates, feldspar, nepheline syenite, magnesium oxide, magnesium hydroxide, aluminum trihydrate, and diatomaceous earth; the second consisting of platy fillers including talc, mica, or calcined clays, all having a particle size less than 150 mesh. These fillers may be employed in mixtures to yield films and molded articles characterized by improved stiffness, handling, and end-use characteristics, increased rates of environmental degradation in biological and photochemical processes, and reduced cost.

Owner:HERITAGE PLASTICS

Montmorillonite/isotactic polypropylene/polylactic acid composite sound absorbing cotton and preparation method thereof

InactiveCN103696127ASimple production processRaw materials are cheap and easy to getSynthetic resin layered productsNon-woven fabricsAdditive ingredientPolypropylene

The invention discloses montmorillonite / isotactic polypropylene / polylactic acid composite sound absorbing cotton, which consists of a top surface layer, a back surface layer and a fiber cotton layer, wherein the fiber cotton layer is clamped and arranged between the top surface layer and the back surface layer, and the top surface layer and the back surface layer are made of non-woven fabric materials. The montmorillonite / isotactic polypropylene / polylactic acid composite sound absorbing cotton is characterized in that the non-woven fabric is prepared form the following ingredients in parts by weight by a melt blowing method: 100 parts of isotactic polypropylene, 10 to 12 parts of polylactic acid, 10 to 12 parts of montmorillonite powder, 5 to 7 parts of dilauryl thiodipropionate, 2 to 3 parts of zinc oxide, 12 to 15 parts of diethylene glycol dibenzoate, 4 to 6 parts of triethyl citrate, 2 to 3 parts of zinc chloride, 5 to 7 parts of chitosan, 2 to 3 parts of molecular sieves, 12 to 15 parts of yellow cinnamon leaf, 2 to 3 parts of rhizoma gastrodiae, 2 to 3 parts of mint, 2 to 3 parts of radix angelicae pubescentis and 4 to 5 parts of auxiliary agents. The montmorillonite / isotactic polypropylene / polylactic acid composite sound absorbing cotton has the advantages that the montmorillonite, the isotactic polypropylene and the polylactic acid are compounded for preparing the sound absorbing cotton by the melt blowing method, the production process is simple, the raw materials are easy to obtain, the cost is low, and the prepared product has the advantages that the air permeability and the oxygen permeability are good, the tensile strength and the extension degree are high, the sound absorbing effect is obvious, and the like.

Owner:芜湖跃飞新型吸音材料股份有限公司

Modified polypropylene fiber and preparation method thereof

InactiveCN104499089AReduce stretchDecreased spinnabilityFlame-proof filament manufactureFilament/thread formingHindered amine light stabilizersMelt blowing

The invention relates to a modified polypropylene fiber and a preparation method thereof. The invention is characterized in that the fiber has a skin-core structure, wherein the core layer is composed of pure polypropylene; and the skin layer is composed of 0.5-60 parts of functional material, 0-5 parts of compatilizer and the balance of polypropylene, totaling 100 parts. The viscosity-average molecular weight of the polypropylene is 0.18-0.3 million, and the degree of isotacticity is greater than 95%. The functional material is a functional polypropylene fiber master batch prepared by blending and granulating inorganic or organic functional micropowder, a compatilizer and polypropylene, wherein the functional micropowder is composed of one or more of nano silicon dioxide, nano titanium dioxide, nano silicon dioxide, an anti-mite agent and an N-substituted alkoxy hindered amine flame retardant. The polypropylene fiber can be subjected to skin-core conjugate spinning according to the skin-core formula, and can be further processed into a polypropylene fiber spunbonded nonwoven fabric or melt-blown nonwoven fabric by spunbonding or melt-blowing. The method has the advantages of simple production technique and small modification for equipment, and is easy for practical popularization and application.

Owner:BINZHOU COC CARPET

Inorganic-organic hybrid micro-/nanofibers

InactiveUS20070112115A1Material nanotechnologyMonocomponent polyetheresters artificial filamentElectrospinningMelt blowing

Inorganic-organic hybrid micro- / nanofibers having a cross-sectional area not exceeding 140μ2 include micro- / nanoparticulate inorganic components dispersed in an organic, absorbable or non-absorbable polymeric matrix at a weight concentration of at least about 4 percent by weight and are produced by electrostatic spinning or melt-blowing.

Owner:POLY MED

Far infrared negative ion functional non-woven fabric and preparation method thereof

InactiveCN103757820AHeat resistantCorrosion resistanceSynthetic resin layered productsNon-woven fabricsPolyethylene glycolCis-Butenedioic Acid

The invention discloses a far infrared negative ion functional non-woven fabric. The far infrared negative ion functional non-woven fabric consists of a top surface layer, a back face layer and a fiber cotton layer clamped between the top surface layer and the back face layer, wherein the top surface layer and the back face layer are made of a non-woven fabric material. The non-woven fabric is prepared from the following raw materials in parts by weight through a melt blowing method: 100 parts of isotactic polypropylene, 3-4 parts of tourmaline, 2-3 parts of aluminum oxide, 1-2 parts of zinc oxide, 12-15 parts of tributyl phosphate, 1-2 parts of titanium dioxide, 6-8 parts of dibutyl maleate, 2-3 parts of 3-aminopropyltrimethoxysilane, 2-3 parts of polyethylene glycol, 3-4 parts of urea, 2-3 parts of grassleaf sweelflag rhizome, 1-2 parts of lily, 2-3 parts of kudzuvine root and 4-5 parts of aid. The non-woven fabric has far infrared, negative ions, antibacterial and deodorization functions. Due to the adoption of the isotactic polypropylene, the non-woven fabric has the characteristics of heat resistance, corrosion resistance, nontoxicity and no odor, is high in tensile strength and bonding property, does not produce dust or scrap, and has the functions of perfuming and health care.

Owner:芜湖跃飞新型吸音材料股份有限公司

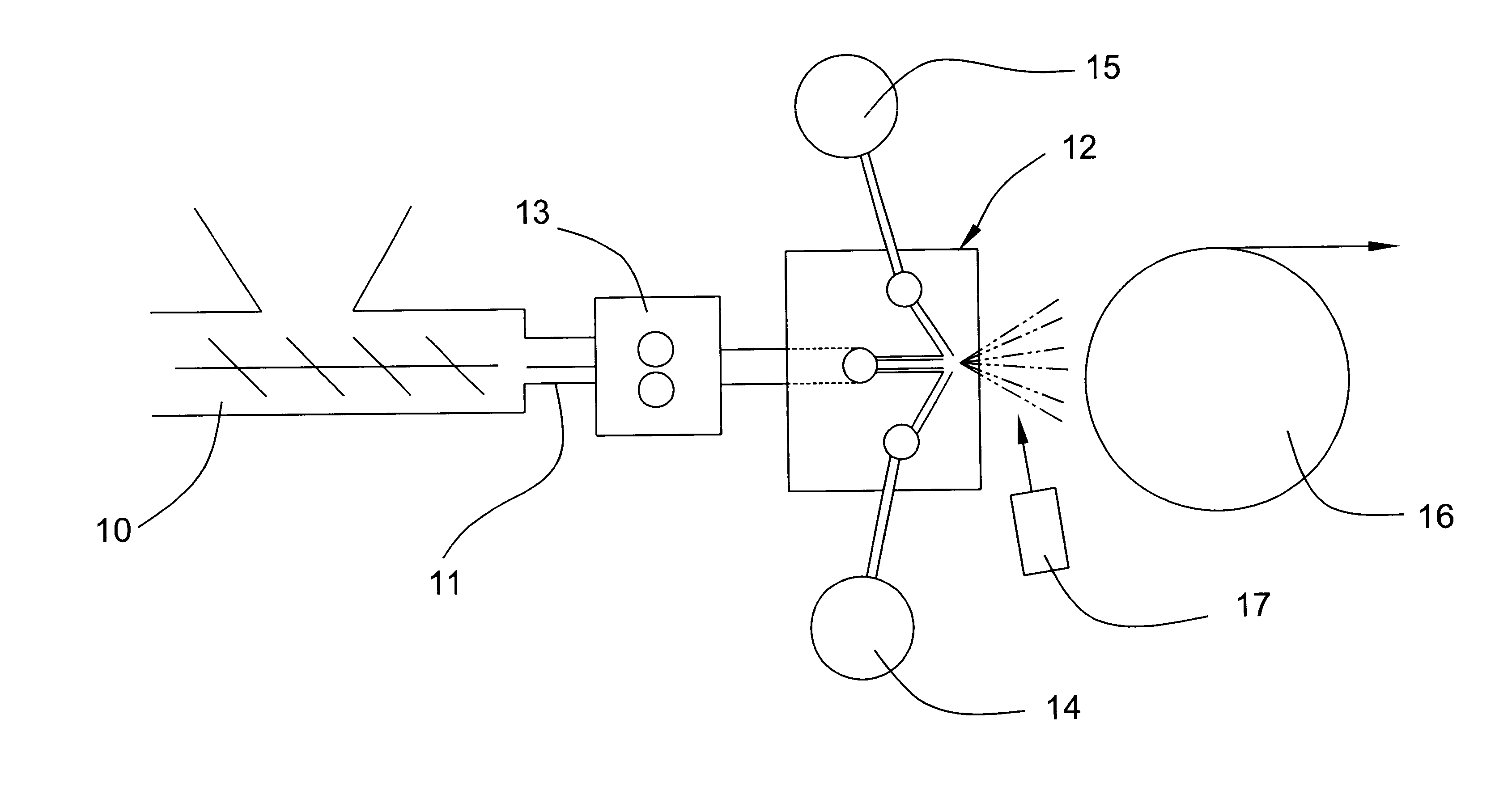

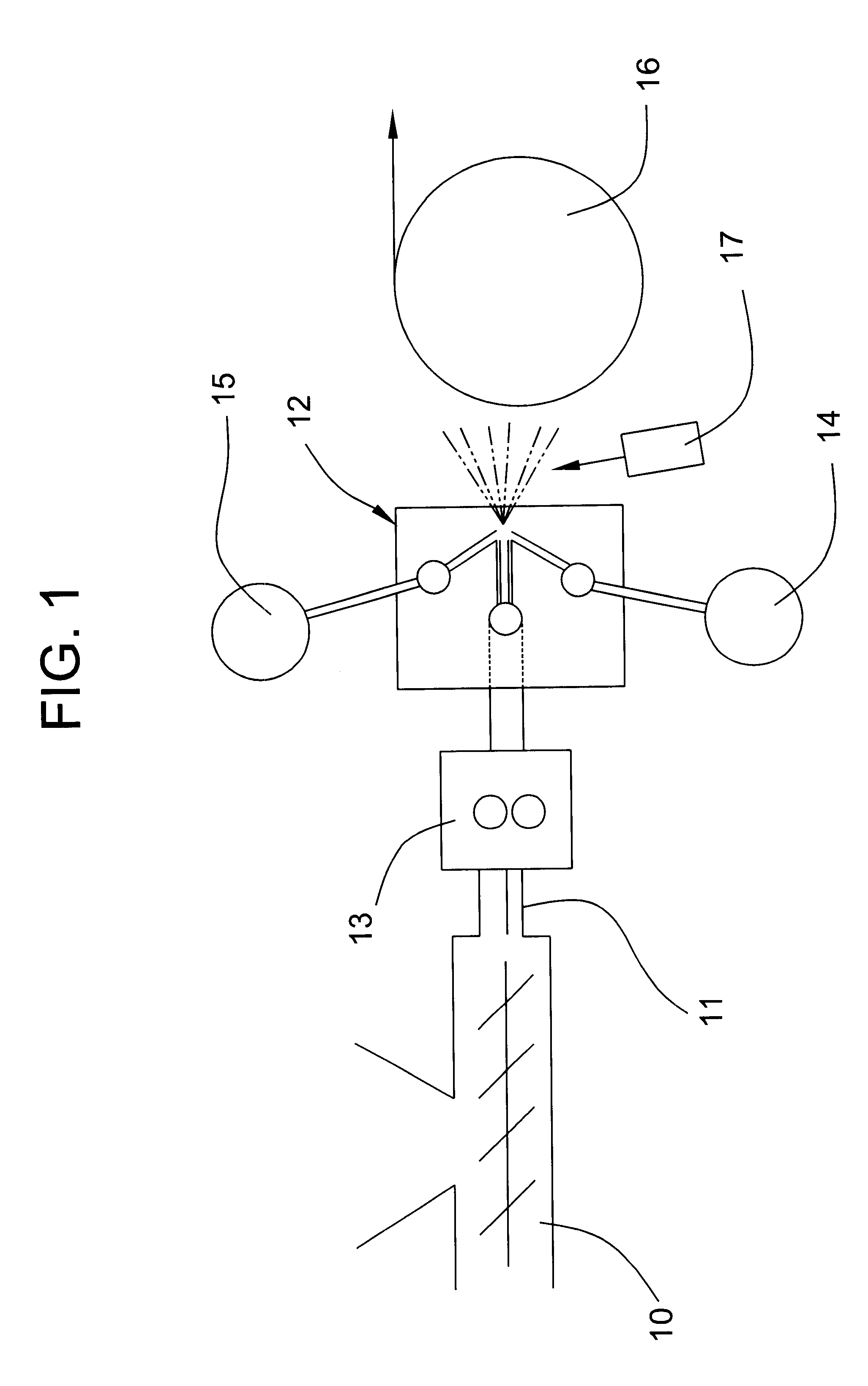

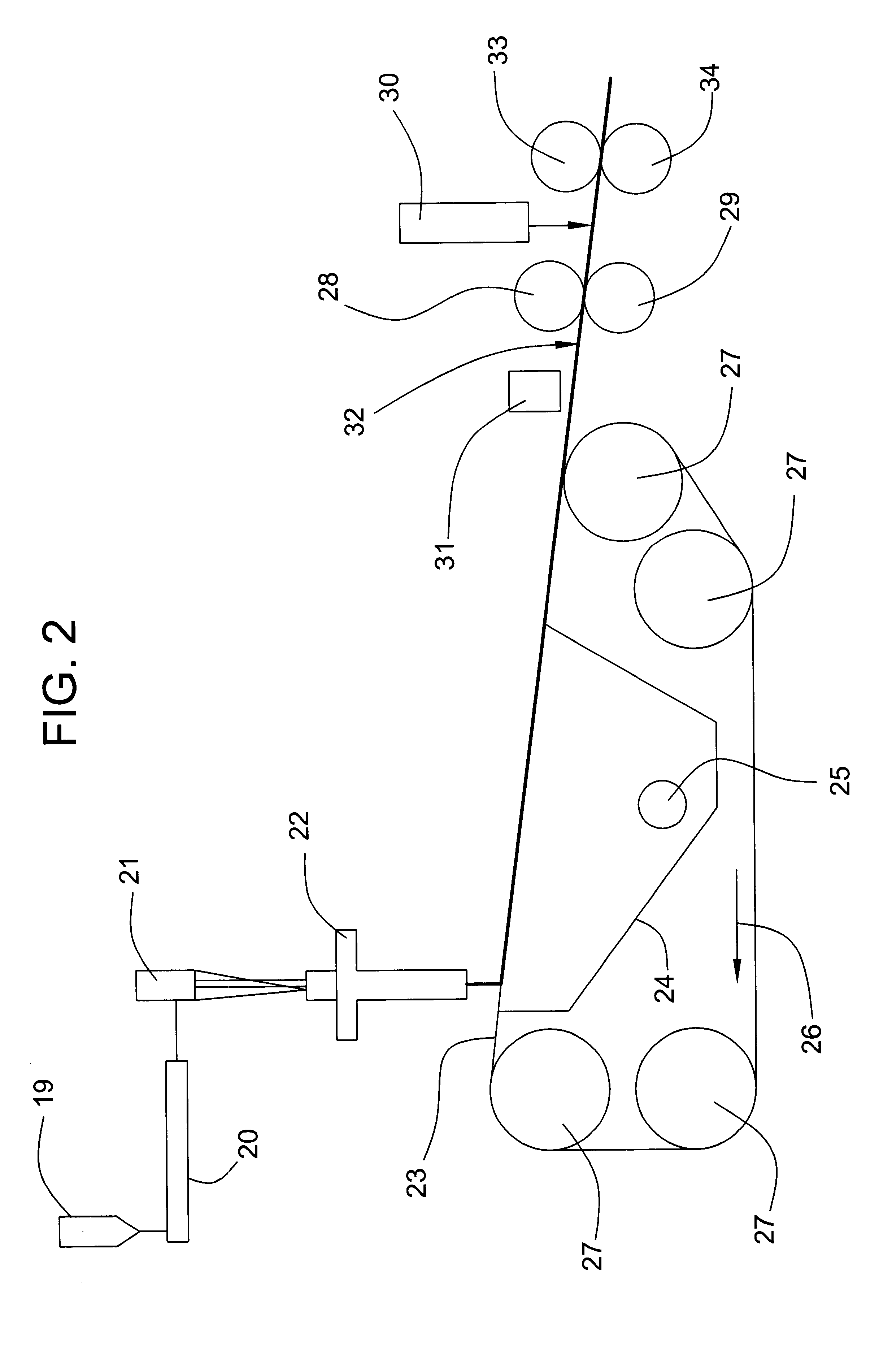

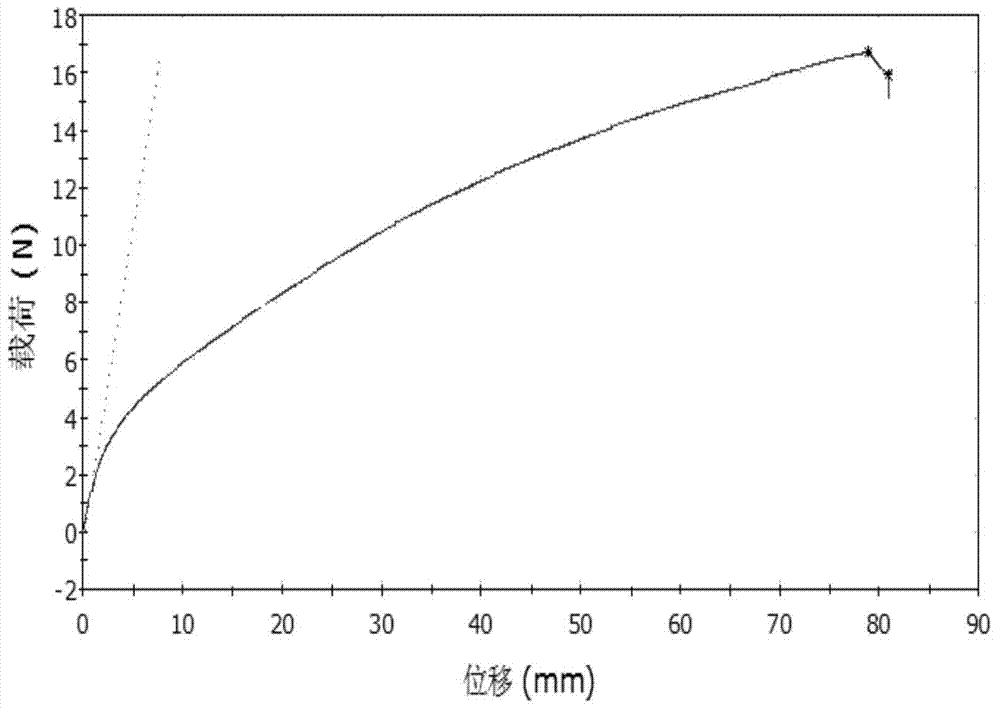

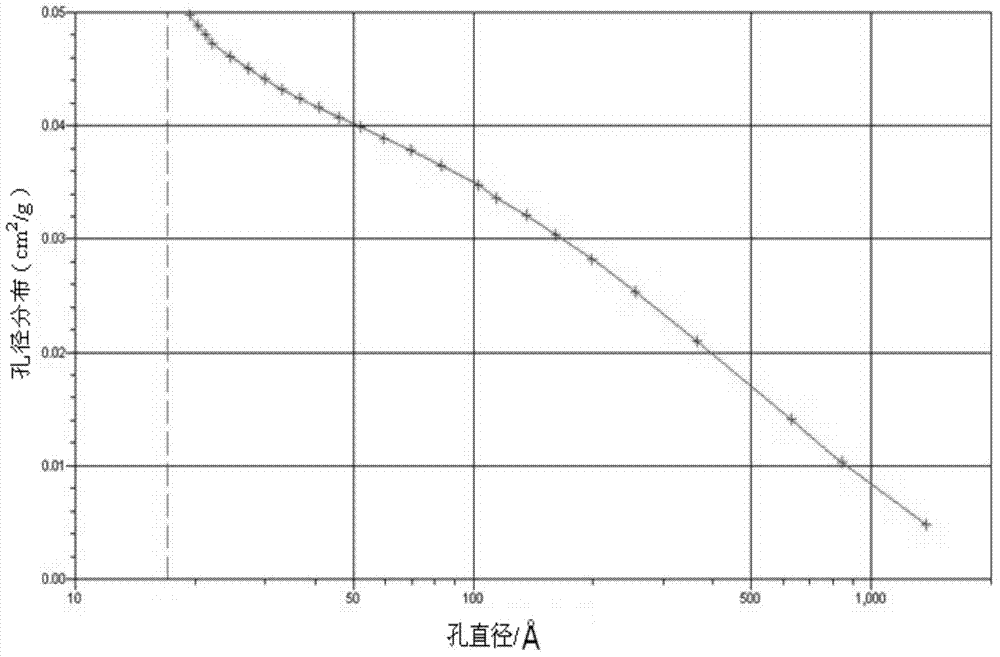

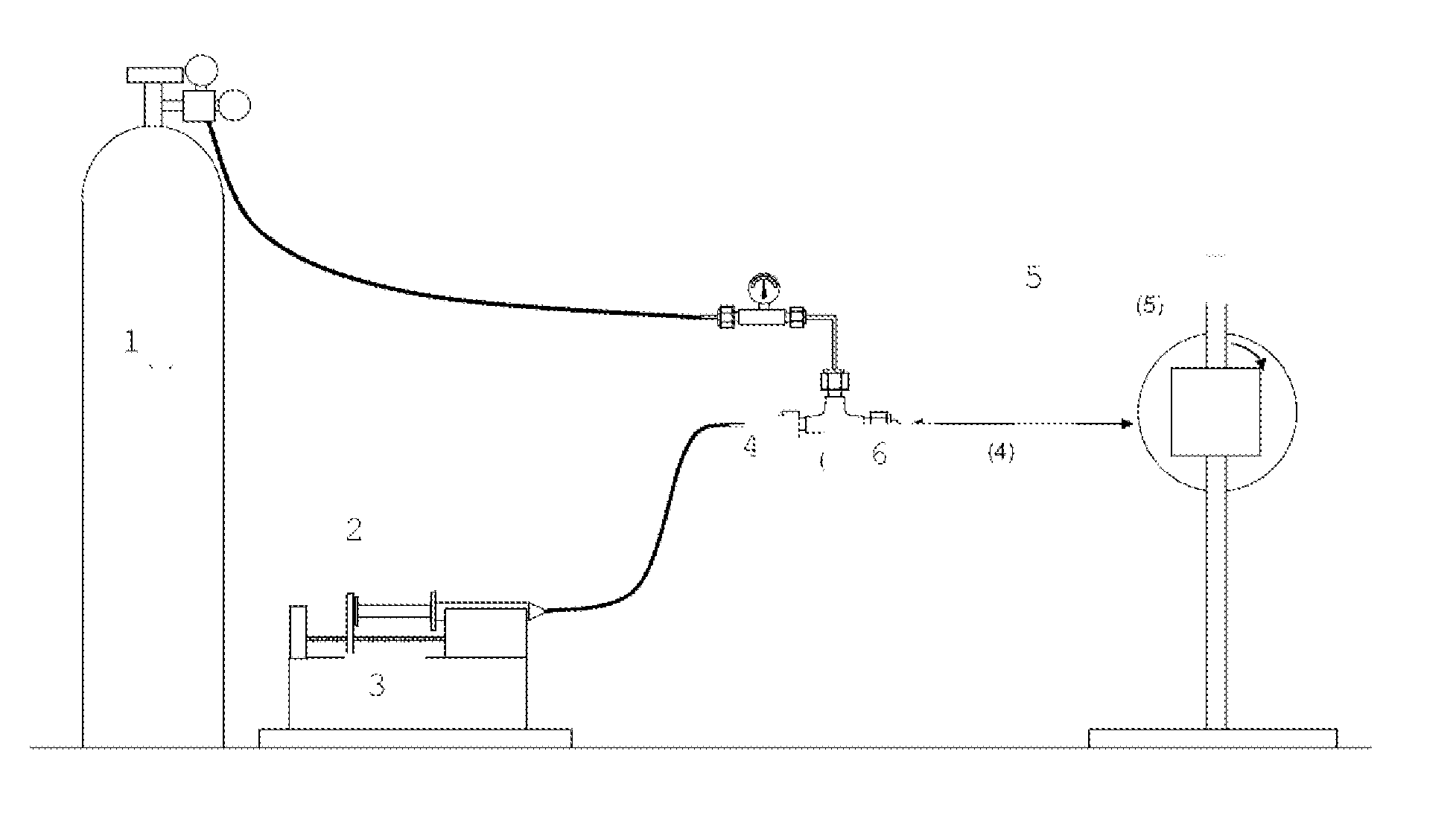

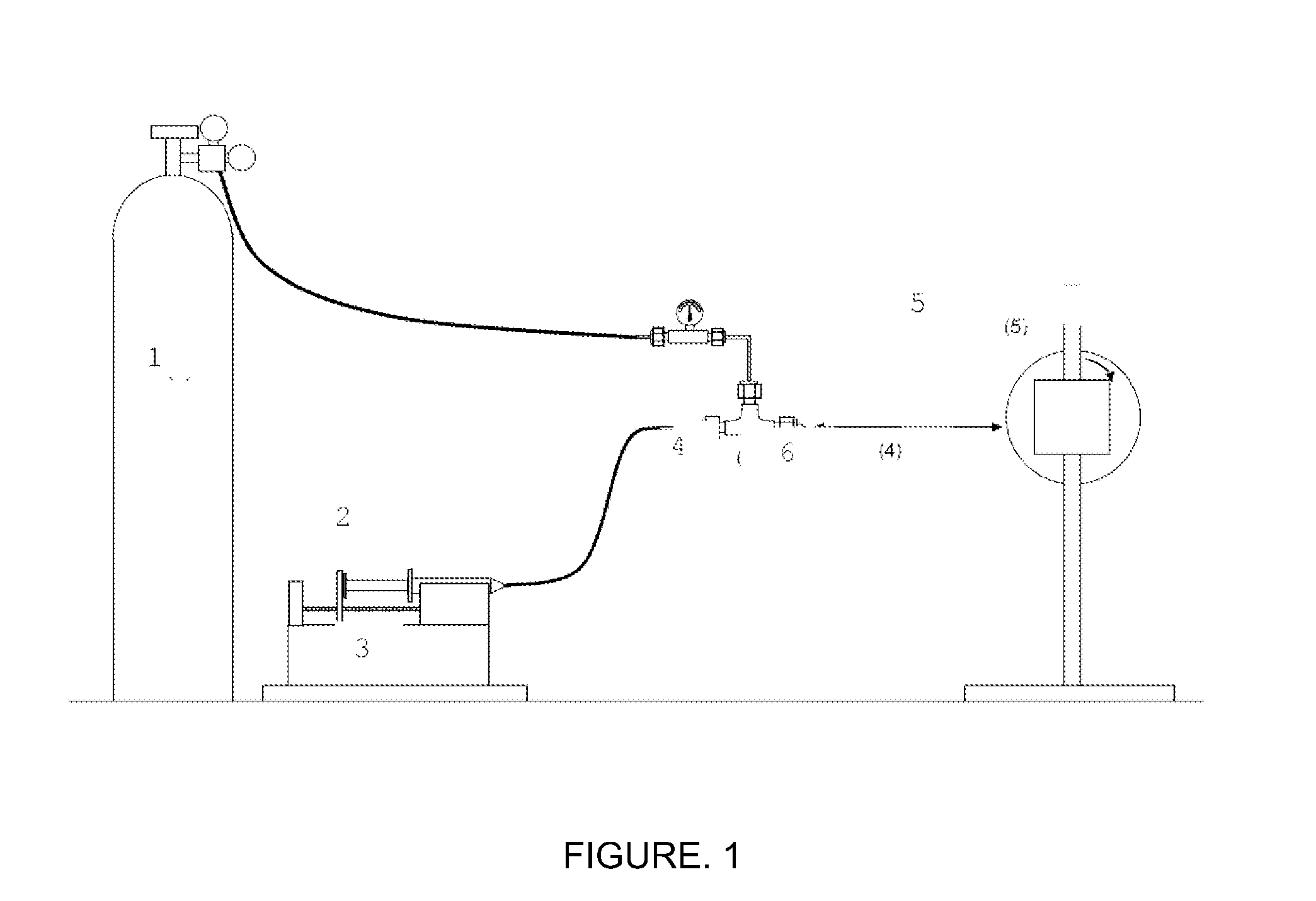

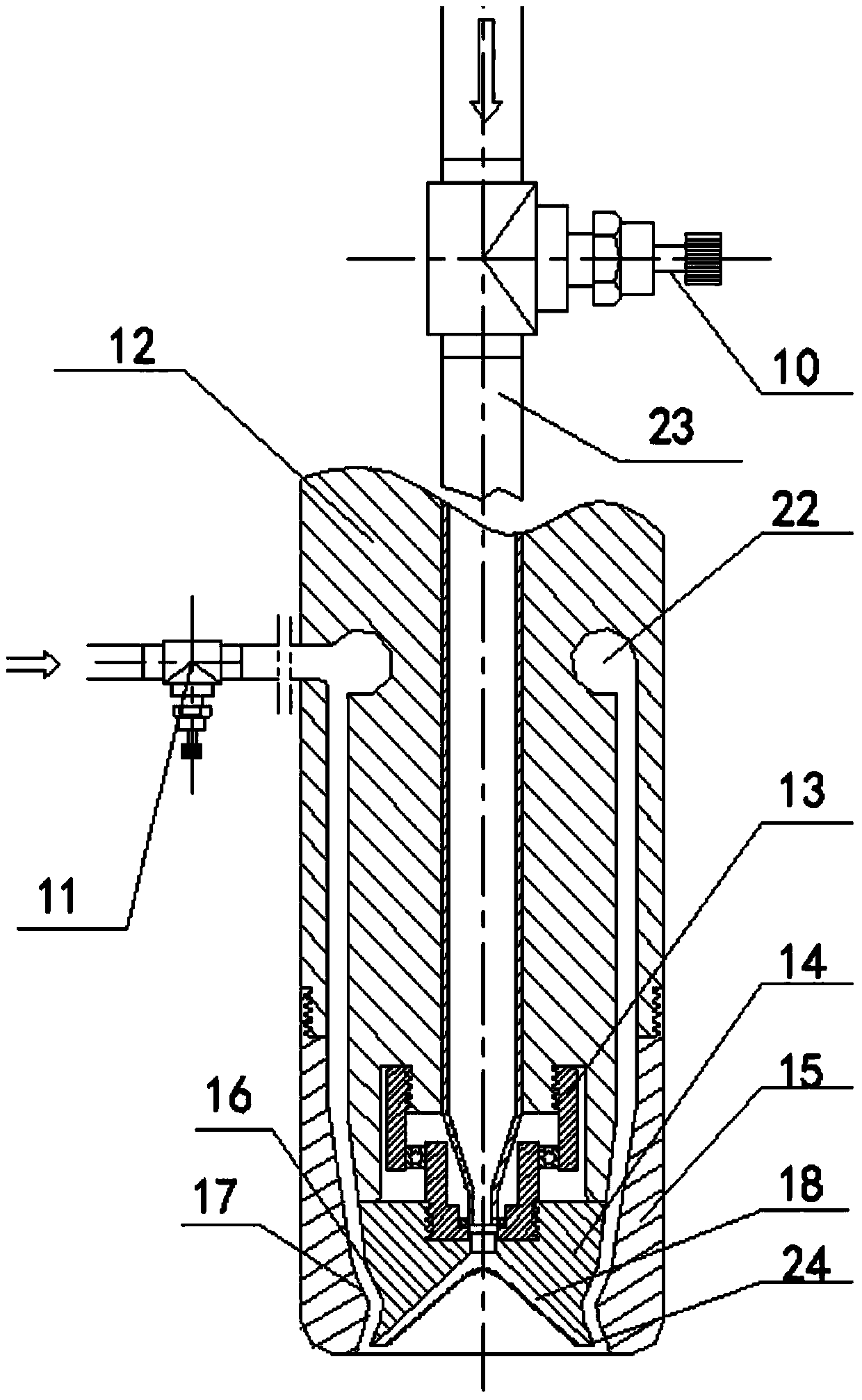

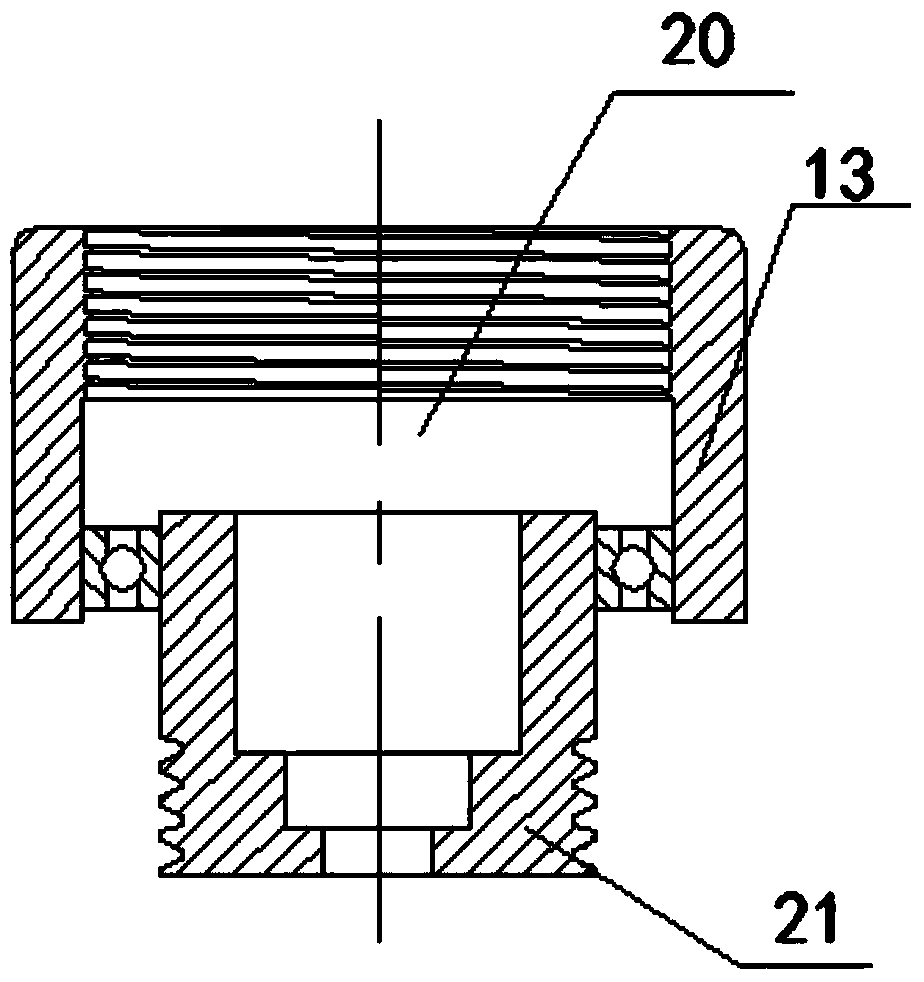

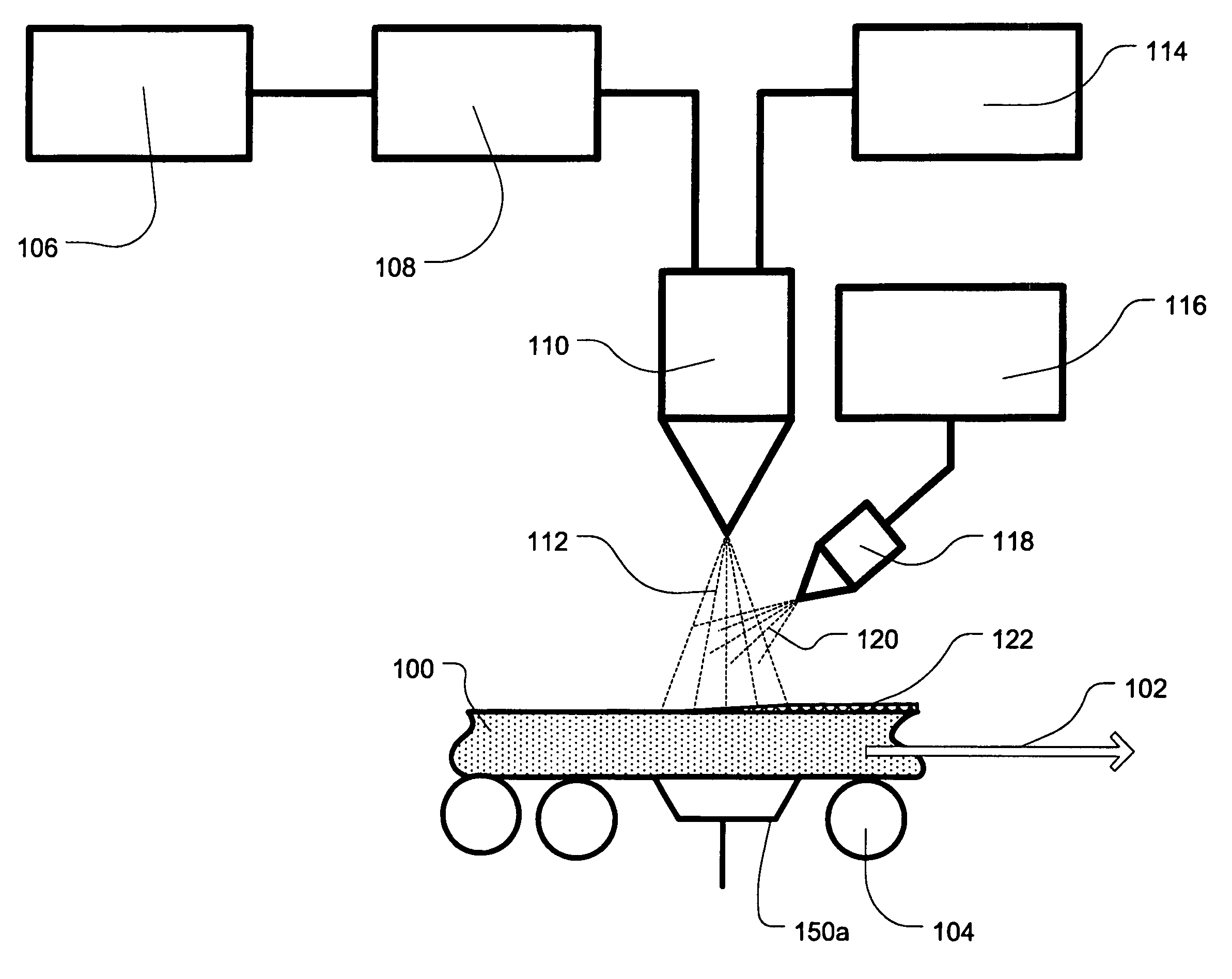

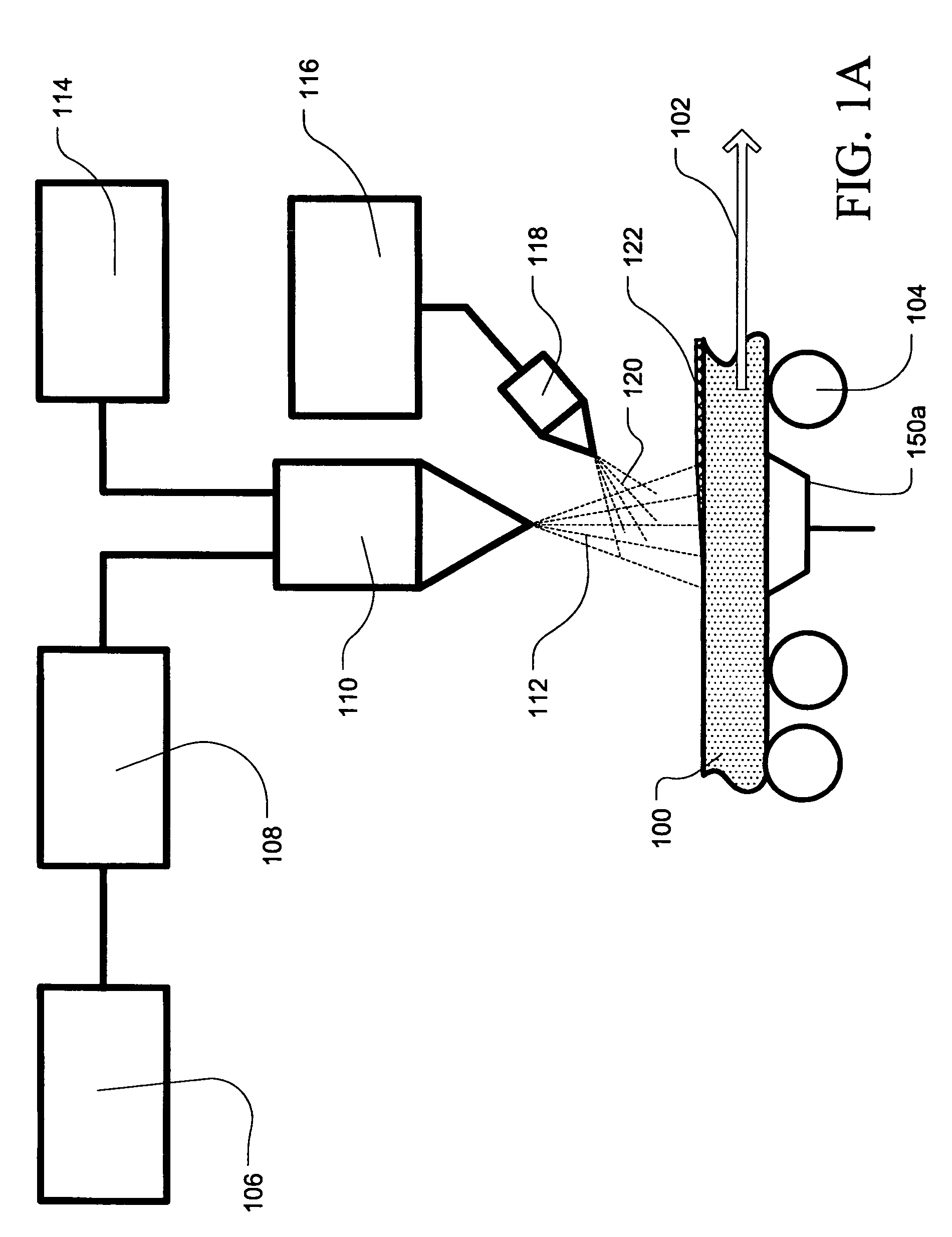

Method and apparatus to produce micro and/or nanofiber webs from polymers, uses thereof and coating method

The present invention refers to an apparatus and method for producing non-woven nanofibers from polymers. The method for producing non-woven micro nanofibers from polymers comprises the use of electrospinning and melt blowing elements. The apparatus presented for producing non-woven micro and / or nanofibers from polymers comprises a source of compressed gas, a pressure gauge, a hypodermic syringe with a pump for controlling the injection rate of the polymeric solutions, a pulverizing apparatus and a collector preferably with controlled rotation speed. The technology presented for producing non-woven micro and / or nanofibers is capable of producing micro and nanofibers having diameters similar to those produced by electrospinning, also on an industrial scale. The invention also comprises the use of non-woven nanofibers in pulverizing live tissues and as coating for materials.

Owner:EMPRESA BRASILEIRA DE PESQUISA AGROPECUARIA EMBRAPA

Activated carbon-EVA composite emulsion coated polypropylene-based non-woven sound absorbing material for automobile interior decoration

InactiveCN104553172AHigh strengthIncrease the areaFlame-proof filament manufactureFibre typesNoise reductionYarn strength

The invention relates to a non-woven sound absorbing material and in particular relates to an activated carbon-EVA composite emulsion coated polypropylene-based non-woven sound absorbing material for automobile interior decoration. The material is prepared from the following raw materials in parts by weight: 20-24 parts of polypropylene, 10-14 parts of polyurethane, 0.2-0.3 part of an antioxidant DLTP, 5-8 parts of mineral cotton fibers, 0.5-0.8 part of activated carbon micro powder with the granularity being 400-600 meshes, 1-2 parts of rosin, 1-2 parts of silicone oil, 14-18 parts of tetrapod-like zinc oxide whiskers, 0.1-0.2 part of ammonium polyphosphate, 10-12 parts of EVA emulsion with the solid content being 10-12 percent and 1-2 parts of aids. The surface of fiber yarns formed by performing melt-blowing on modified polypropylene-based master batch is coated by the EVA composite emulsion, the prepared material has the advantages of the traditional polypropylene non-woven material, the mechanical property is improved, the scour and wear resistance, fiber yarn strength and specific surface area are improved, the sound absorption and noise reduction effects are obvious, the odor in an automobile can be eliminated, and the material is fireproof, flame-retardant, light, environmentally friendly, tough and tight and is a novel and practical sound absorbing material for vehicles.

Owner:WUHU HUANRUI AUTO INTERIOR DECORATION

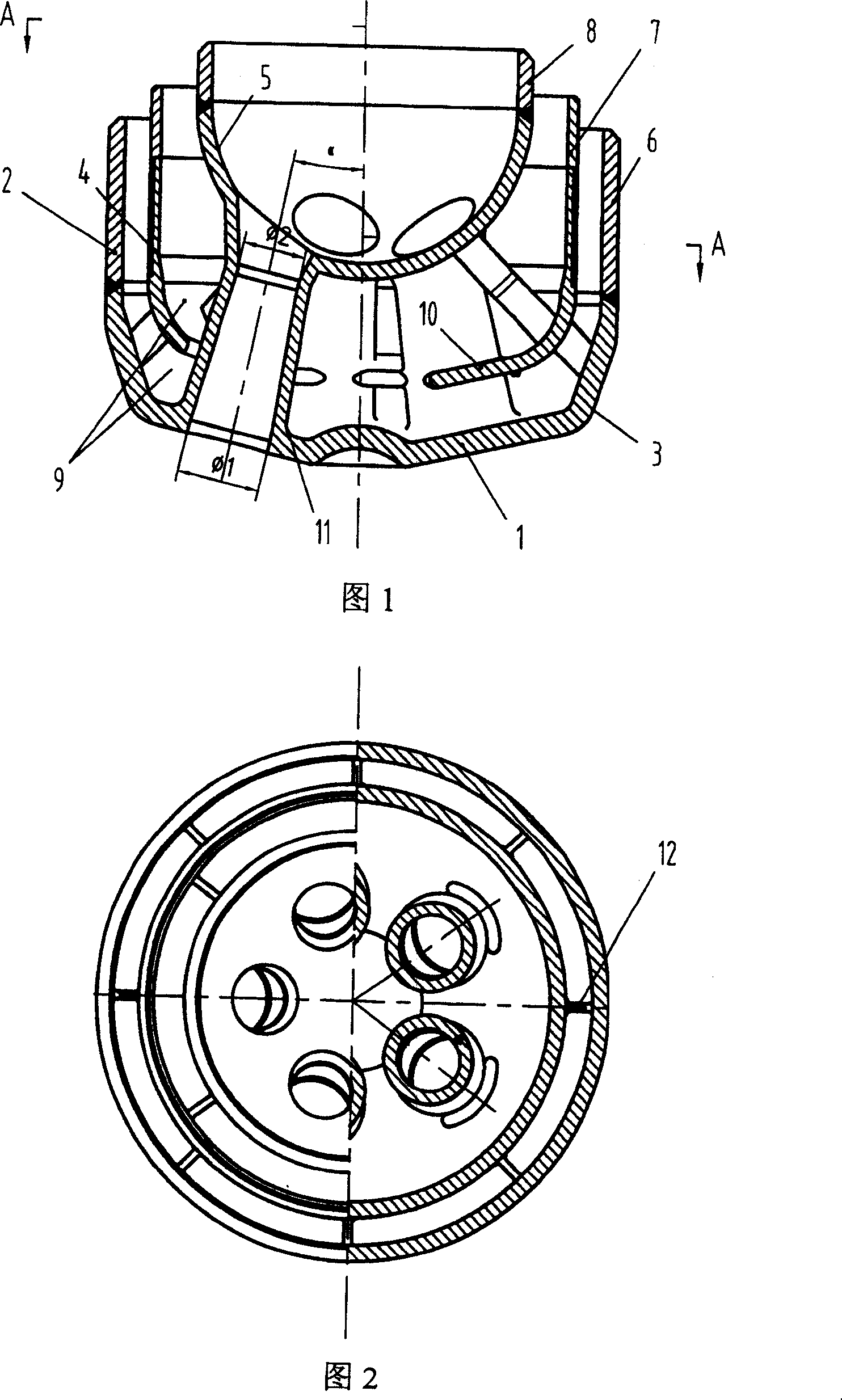

Automatic-rotating electrostatic spinning device assisted by high-pressure airflow and provided with nozzle

ActiveCN103628149AEnsure quality and efficiencyEnsure spinning efficiencyFilament/thread formingAir pumpEngineering

Owner:JIANGSU NEW HORIZON ADVANCED FUNCTIONAL FIBER INNOVATION CENT CO LTD

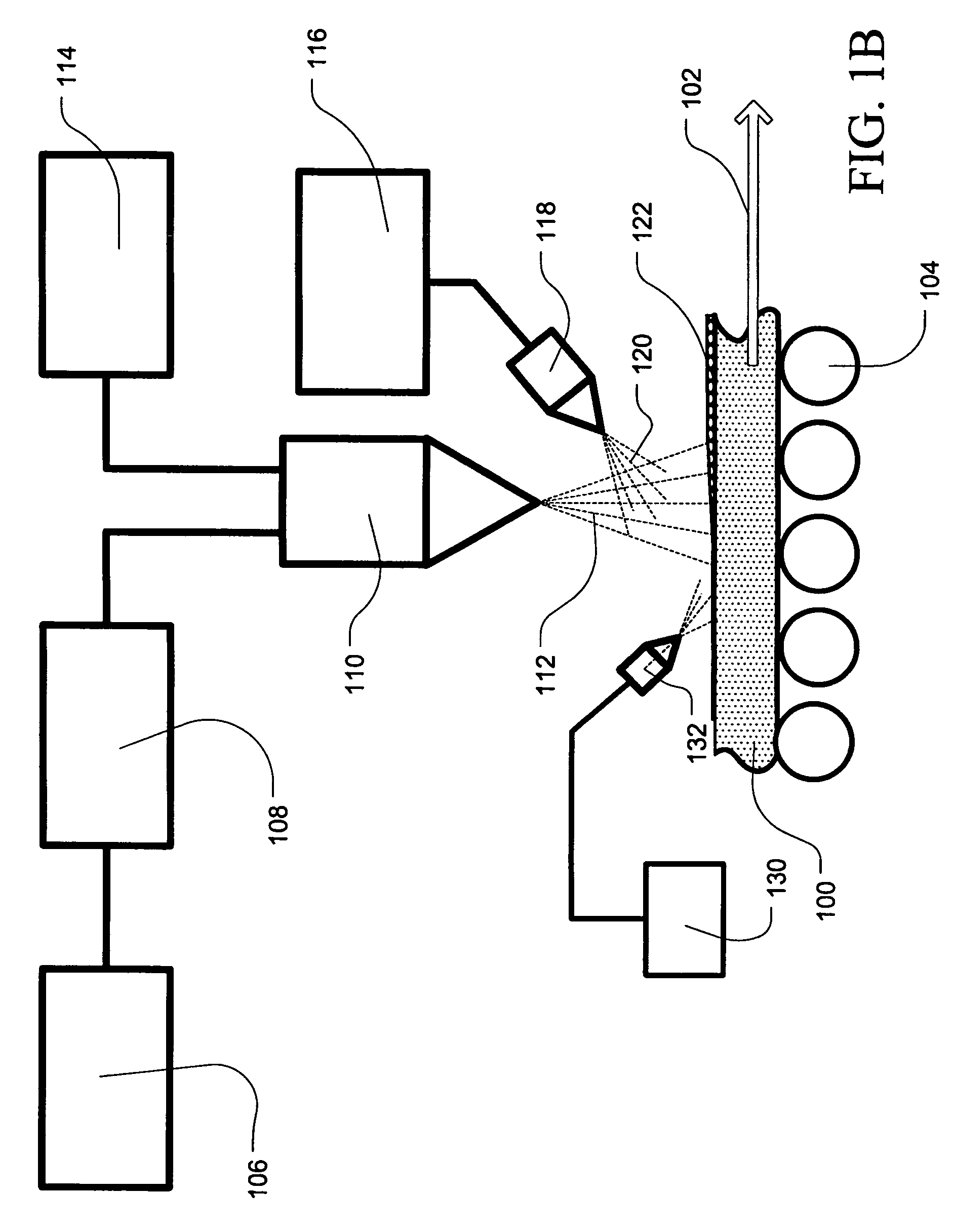

Method and apparatus for melt-blown fiber encapsulation

Owner:OWENS CORNING FIBERGLAS TECH INC

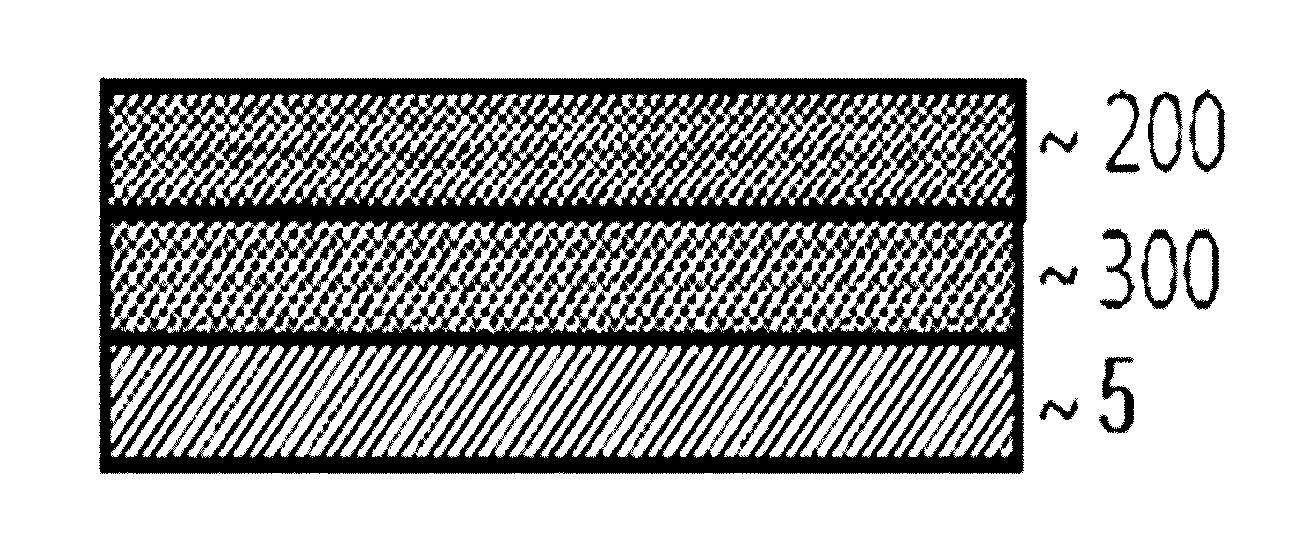

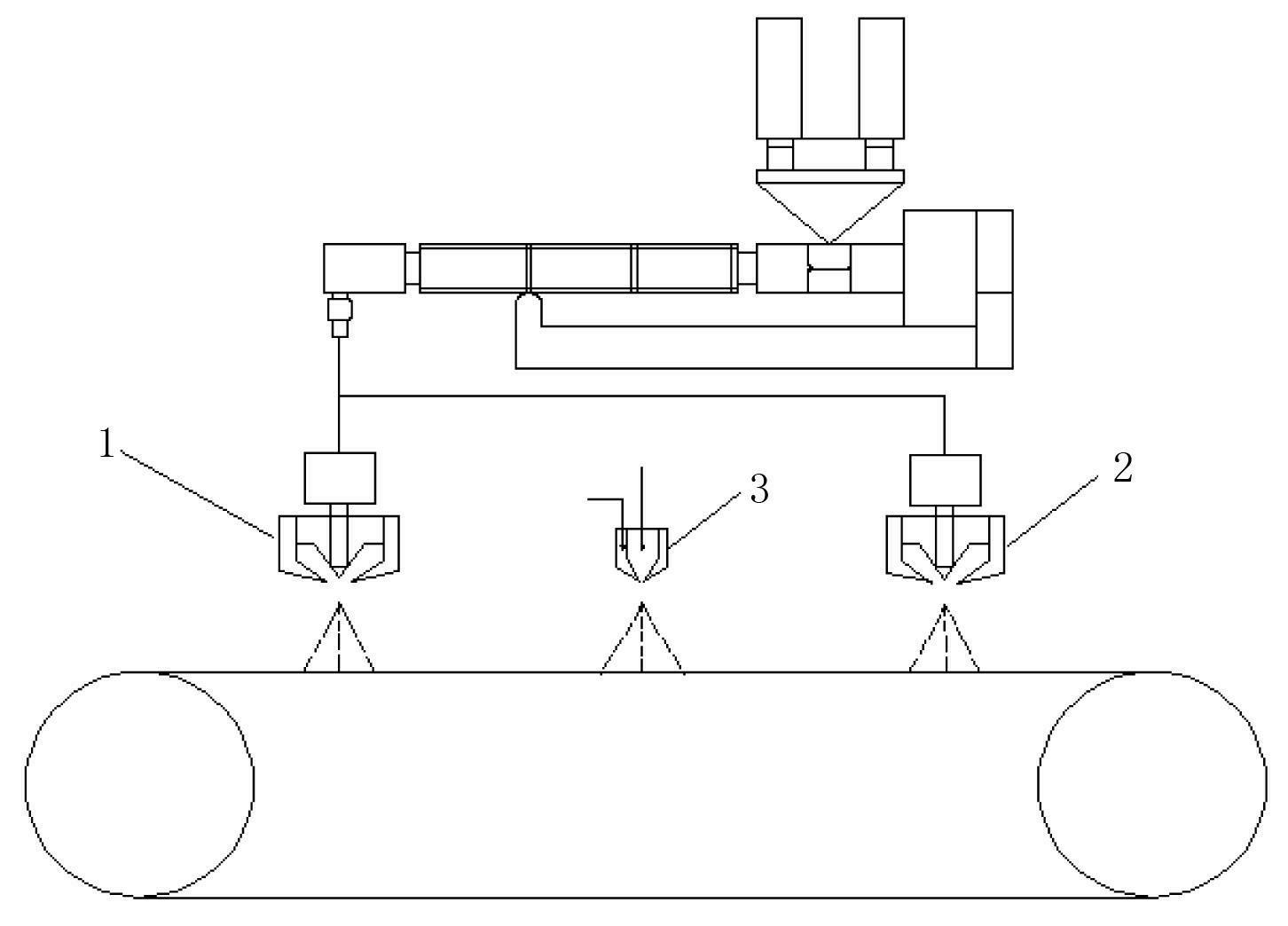

Multi-layered nanofiber medium using electro-blowing, melt-blowing or electrospinning, and method for manufacturing same

InactiveUS20160193555A1Efficient processingStrong heat resistanceCombination devicesCellulosic plastic layered productsCelluloseHeat resistance

The present invention, aimed to enhance low heat-resistant ability of the current filters, relates to multi-layered nanofiber filter media and its manufacturing method, laminating nanofiber using electro-blown and electro-spinning subsequently on a cellulose substrate. In addition, the present invention relates to multi-layered nanofiber filter media and its manufacturing method, laminating nanofiber using melt-blown and electro-spinning subsequently on a cellulose substrate.

Owner:FINETEX ENE

Antistatic sound-absorbing cotton and preparation method thereof

InactiveCN103692706AAntistaticImprove flatnessLayered productsSound producing devicesGlycerolPhosphoric acid

The invention discloses an antistatic sound-absorbing cotton. The antistatic sound-absorbing cotton comprises a top layer, a back layer and a cellucotton layer sandwiched between the top layer and the back layer, wherein the top layer and the back layer are made of a non-woven fabric material. The antistatic sound-absorbing cotton is characterized in that the non-woven fabric is prepared from the following raw materials by weight through melt-blowing: 100 parts of isotatic polypropylene, 7 to 9 parts of fatty alcohol-polyoxyethylene ether, 2 to 3 parts of alkyl ethyl ether polysiloxane polysilicone, 2 to 3 parts of aluminum phosphate, 1 to 2 parts of tin oxide, 13 to 16 parts of glycerol triacetate, 1 to 2 parts of magnesium silicate, 1 to 2 parts of nanometer silica, 2 to 3 parts of calcium alginate, 1 to 2 parts of sodium silicate, 20 to 24 parts of twigs, 1 to 2 parts of mint leaves, 2 to 3 parts of licorice, 3 to 4 parts of gynostemma pentaphylla and 4 to 5 parts of an auxiliary agent. According to the invention, a melt-blowing process is used for preparation of the non-woven fabric and has the advantages of easiness, good controllability and high production efficiency; and the prepared sound-absorbing cotton provided by the invention has the advantages of an antistatic property, soft hand feel, smoothness, good surface flatness, strong adsorptivity, a good sound-absorbing effect, etc.

Owner:芜湖跃飞新型吸音材料股份有限公司

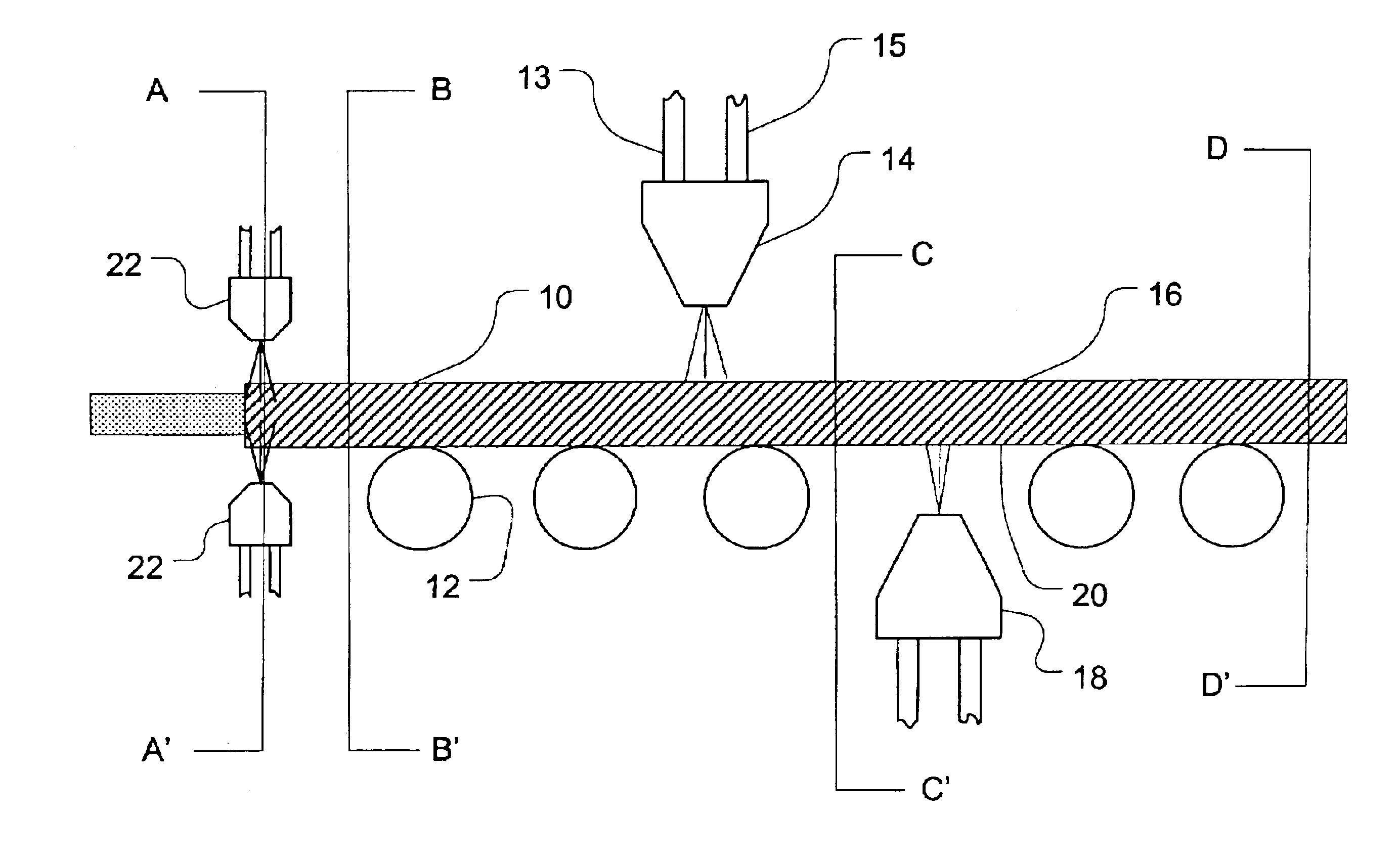

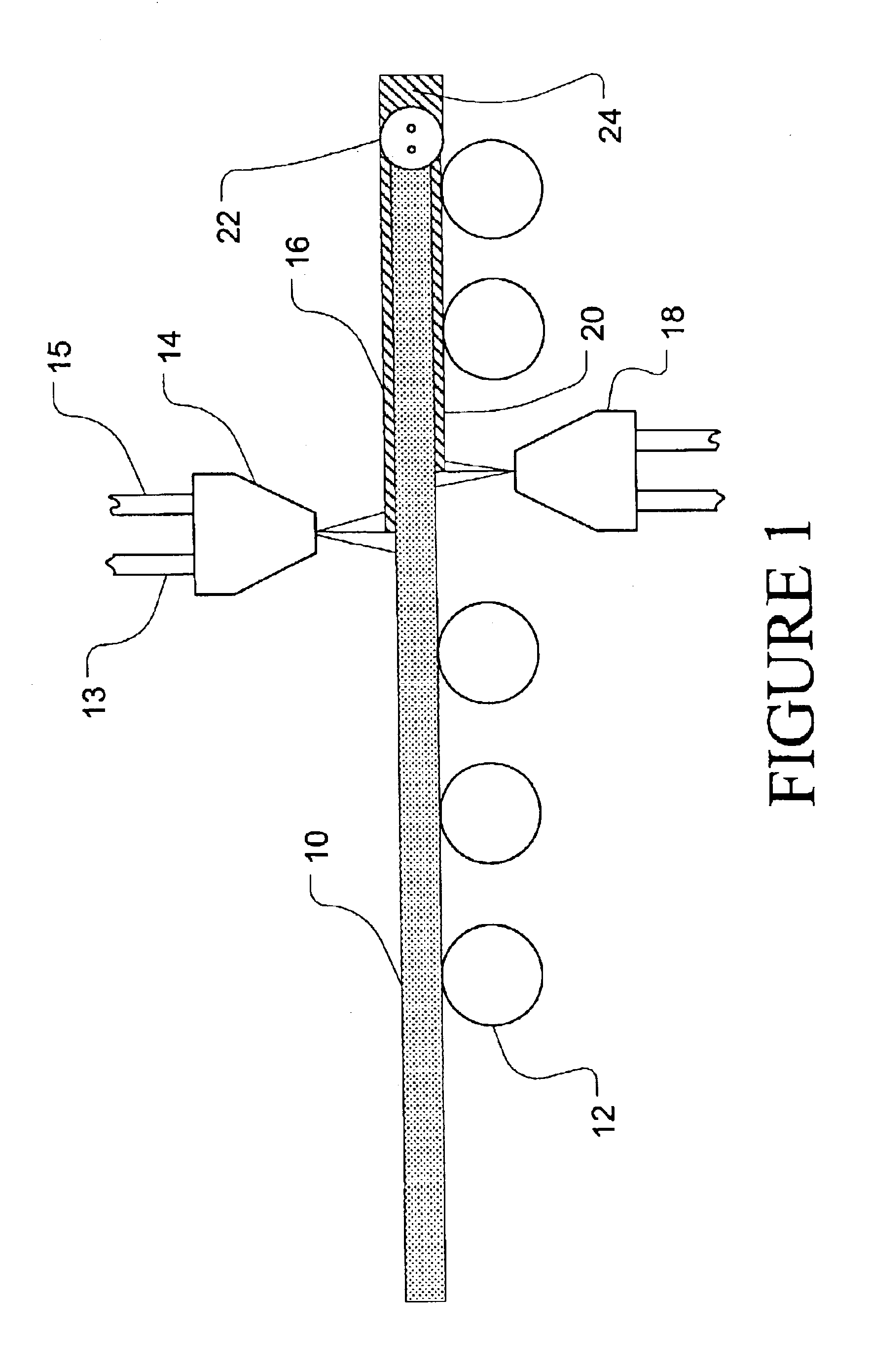

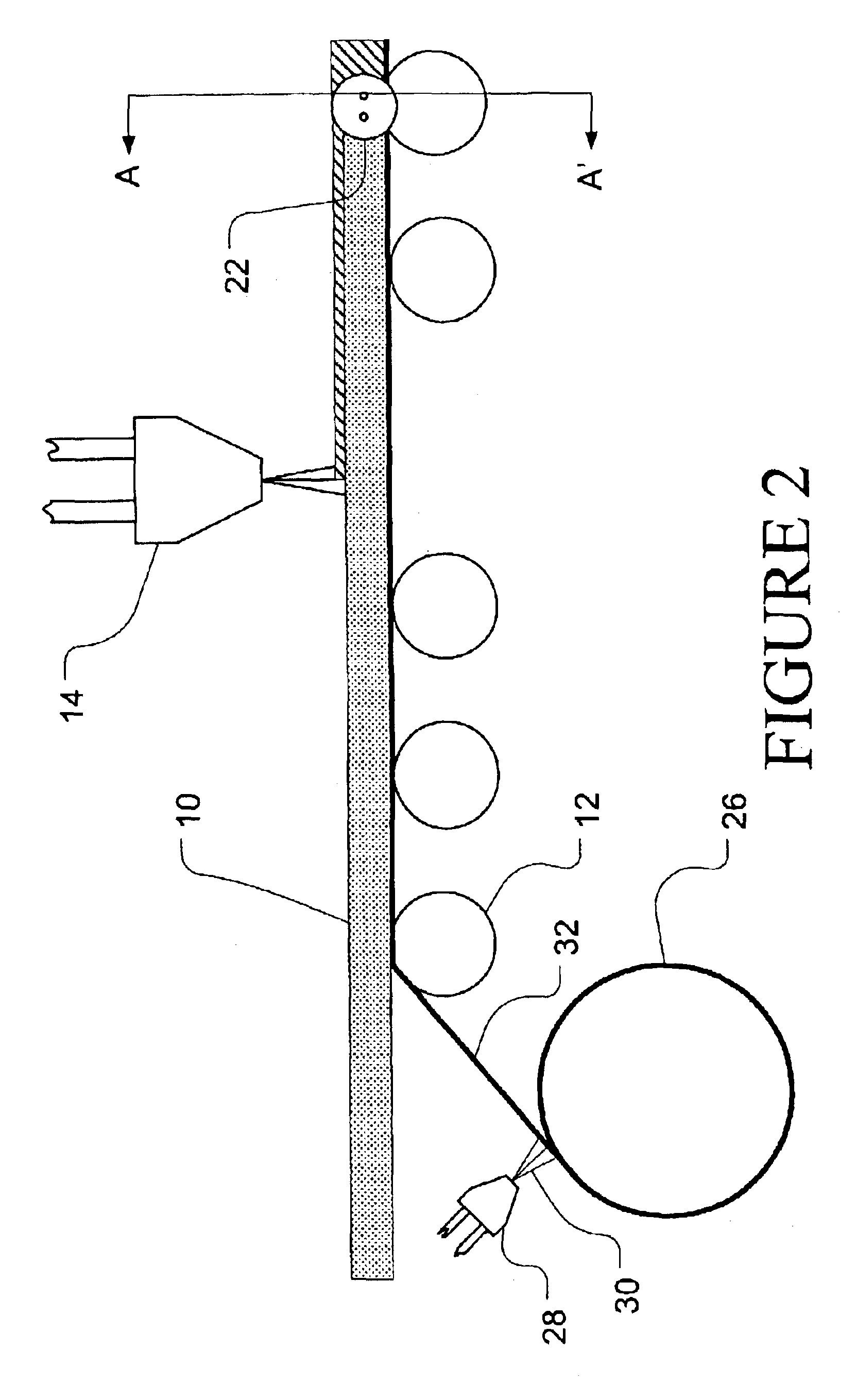

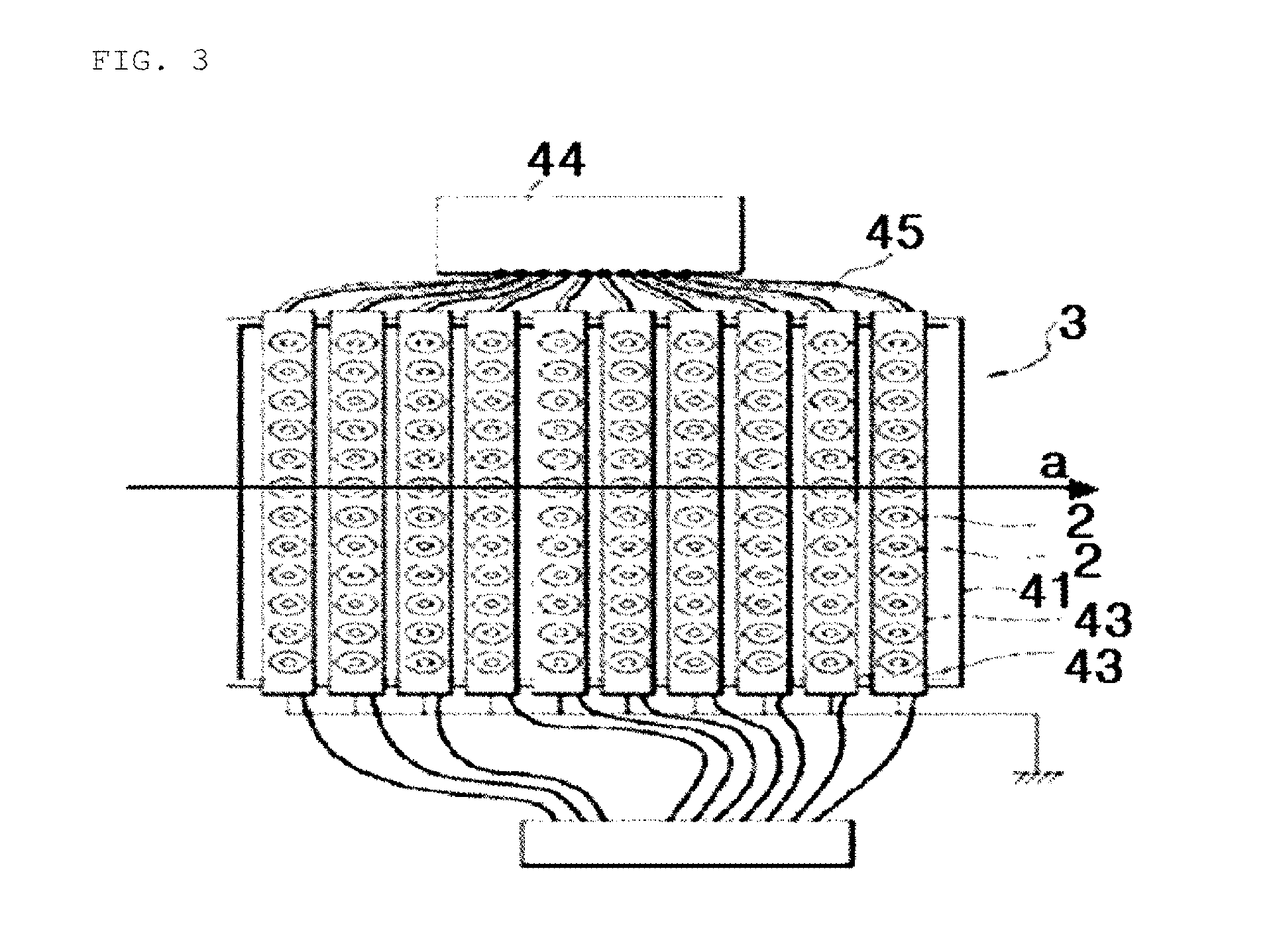

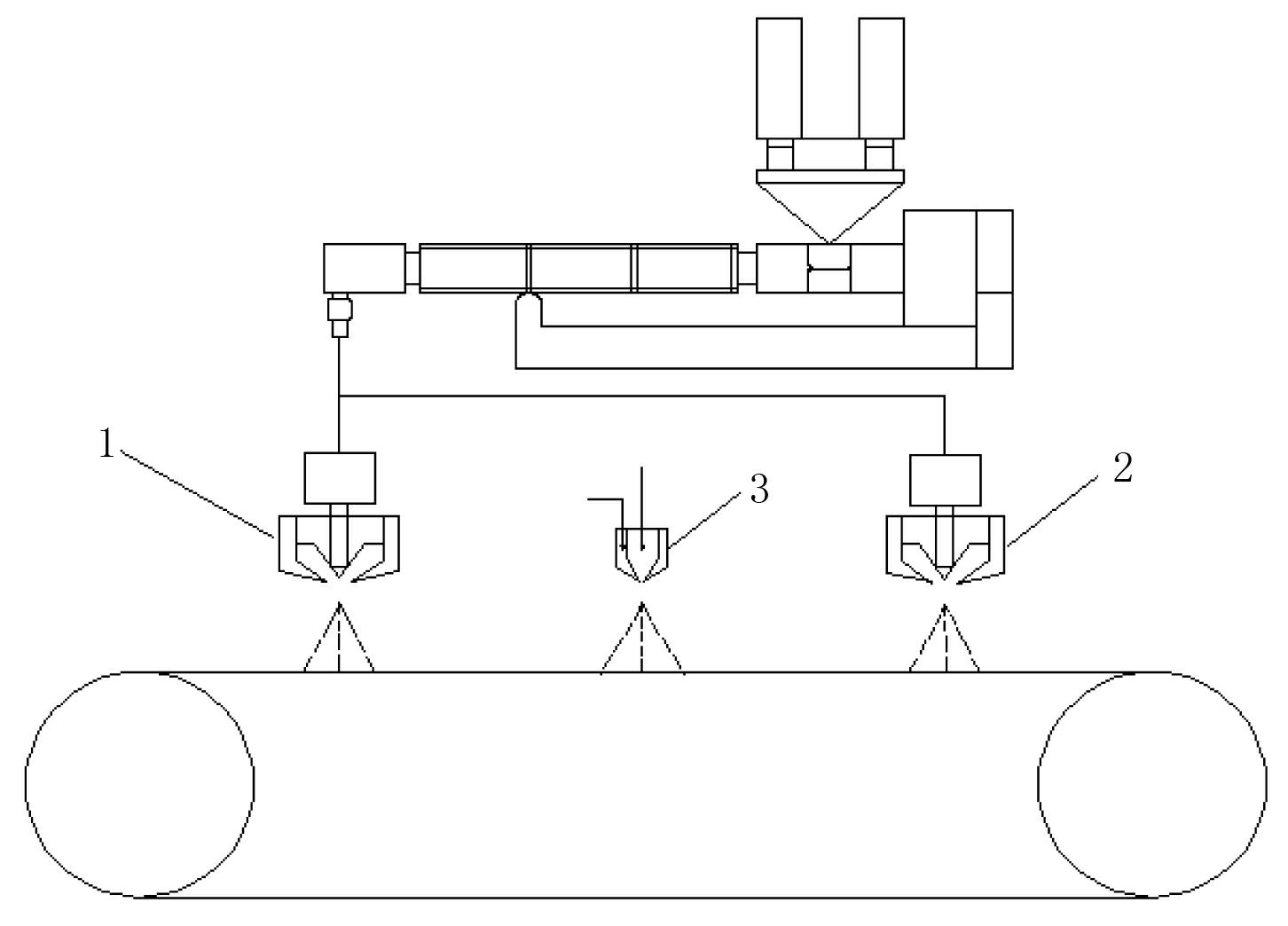

Apparatus and method for fiber batt encapsulation

Disclosed is an apparatus and a method for at least partially encapsulating a fiber batt or other substrate by applying a polymer fiber layer to one or more surfaces of the fiber batt or substrate by melt-blowing. The melt-blowing assemblies are arranged and configured to extrude both a polymer melt and a hot gas stream whereby the hot gas stream attenuates the polymer melt to form polymer melt fibers and to direct the polymer melt fibers toward a surface to be coated. The melt-blowing assemblies are further of the fiber batt. A combination of melt-blowing assemblies may be provided in either fixed or moveable configurations for coating one or more sides of the fiber batt.

Owner:OWENS CORNING FIBERGLAS TECH INC

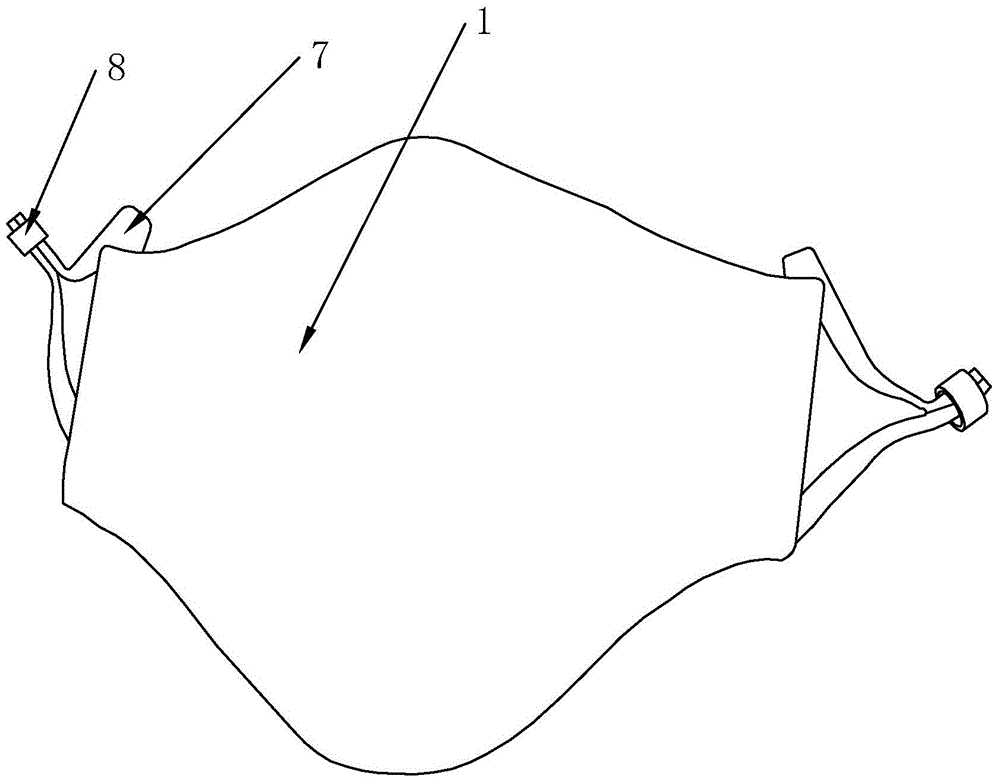

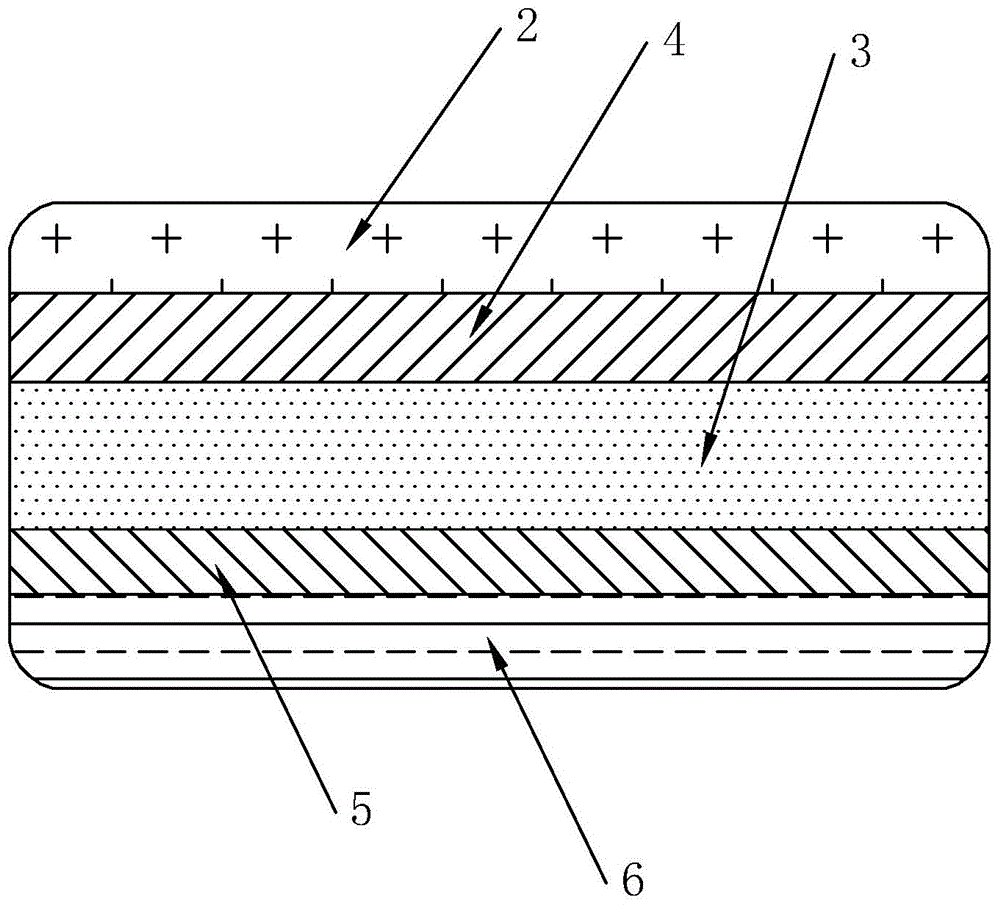

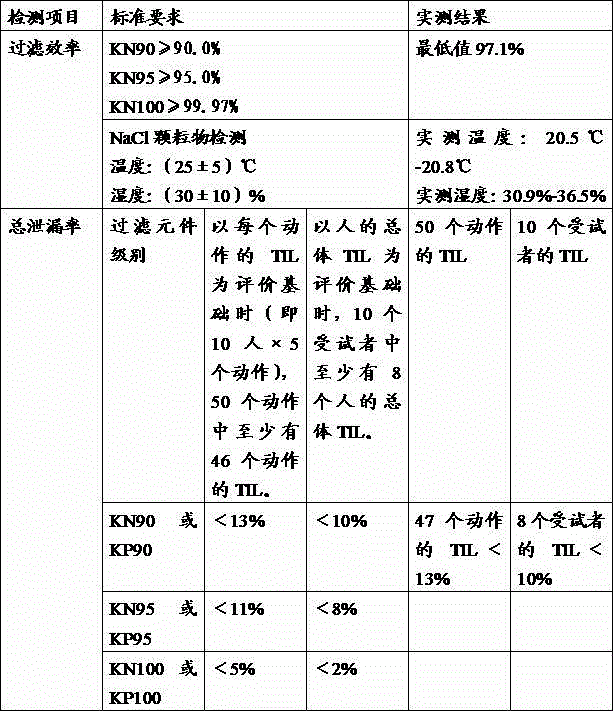

Mask capable of preventing PM2.5 and manufacture method thereof

ActiveCN104921345AAdjustable lengthEasy to manufactureLayered productsProtective garmentInter layerSurface layer

The invention provides a mask capable of preventing PM2.5 and a manufacture method thereof. According to the technical scheme, the mask comprises a mask body, the mask body comprises a surface layer, an interlayer and an inner layer, the surface layer is provided with first comprehensive fabric, the interlayer is provided with melt-blowing non-woven fabric which is 50 g per square meter in weight, and the inner layer is provided with second cotton fabric; a filtering layer is arranged between the first comprehensive fabric and the melt-blowing non-woven fabric, an insulating layer is arranged between the second cotton fabric and the melt-blowing non-woven fabric, and the first comprehensive fabric is connected with the second cotton fabric through covered edges. By means of the mask capable of preventing the PM2.5 and the manufacture method, the technical effect of poisonous gas filtering during going out in hazy weather is achieved.

Owner:好梦来家纺有限公司

X-ray and gamma-ray shielding non-woven fabric and preparation method thereof

ActiveCN102560900AHigh shielding efficiencyIncrease productivityNon-woven fabricsMonocomponent polyolefin artificial filamentSkin contactX-ray

The invention discloses an X-ray and gamma-ray shielding non-woven fabric and a preparation method thereof. The X-ray and gamma-ray shielding non-woven fabric is formed by uniformly doping tantalum, tungsten and strontium or a compound thereof in a polypropylene non-woven fabric. The metals or compounds in the non-woven fabric account for 60wt%-70wt% of the non-woven fabric; and tantalum accounts for 30%-40% of the metals, tungsten accounts for 40%-50% of the metals and strontium accounts for 10%-30% of the metals. The preparation method of the X-ray and gamma-ray shielding non-woven fabric adopts a melt blowing and spraying composite technology; and the X-ray and gamma-ray shielding non-woven fabric provided by the invention has the characteristics of no skin contact toxicity, no shielding weak-absorption zone and high shielding efficiency.

Owner:HUBEI HUAQIANG HIGH TECH CO LTD

Absorbable copolyesters of poly(ethoxyethylene diglycolate) and glycolide

A semi-crystalline, absorbable copolyester composition comprising the reaction product of a polycondensation polyester and at least one lactone, wherein the polycondensation polyester comprises the reaction product of diglycolic acid and / or a derivative thereof and diethylene glycol; and the copolyester comprises about 30 to 60% by weight of the polycondensation polyester based on the total weight of the copolyester. Also medical devices such as absorbable sutures comprising such copolyesters and absorbable microspheres comprising such copolyesters and methods of making of such absorbable microspheres. Additionally, a method of melt blowing an absorbable copolyester composition and a nonwoven construct are disclosed.

Owner:ETHICON INC

Anti-static nonwoven fabric and preparing method thereof

InactiveCN102505354AAntistaticFlexibleElectroconductive/antistatic filament manufactureNon-woven fabricsPolymer scienceNonwoven fabric

The invention discloses an anti-static nonwoven fabric, which is a composite fiber of a skin and core structure. A core layer is made of polypropylene, a skin layer is made of mixture of polypropylene and conductive filling materials, wherein the skin layer takes 40%-80% of the total mass fraction of the composite fiber, and the conductive filling materials take 1.5%-10% of the total mass fraction of the skin layer. The preparation method includes steps: 1) the polypropylene and the conductive filling materials are mixed by a fusion manner so as to obtain the anti-static mixture; 2) polypropylene melt is extruded via a round hole on the inner side of a mold head, the anti-static mixture is extruded via a ring on the outer side of the mold head, so that the composite fiber of the skin and core structure is formed, and the anti-static nonwoven fabric is obtained by means of melt blowing. The anti-static nonwoven fabric has good flexibility while having an anti-static performance.

Owner:ZHEJIANG UNIV

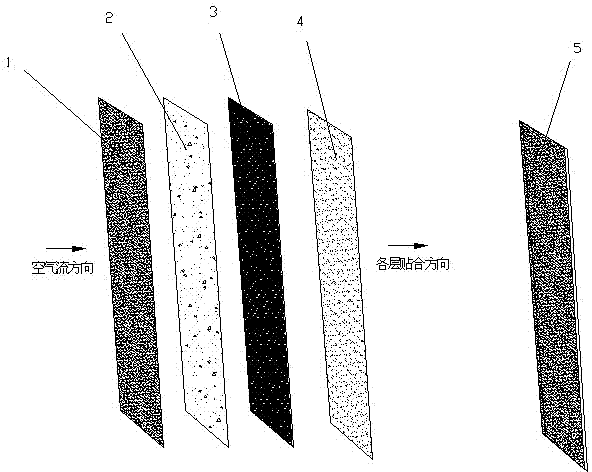

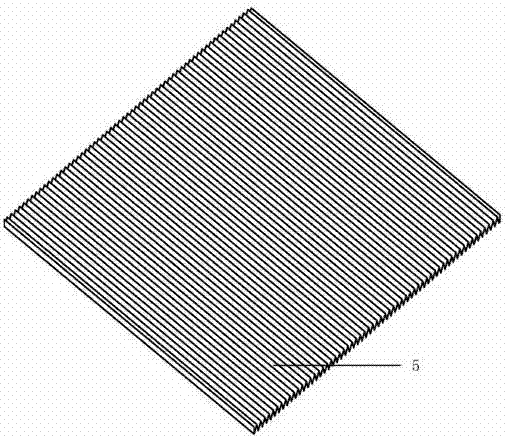

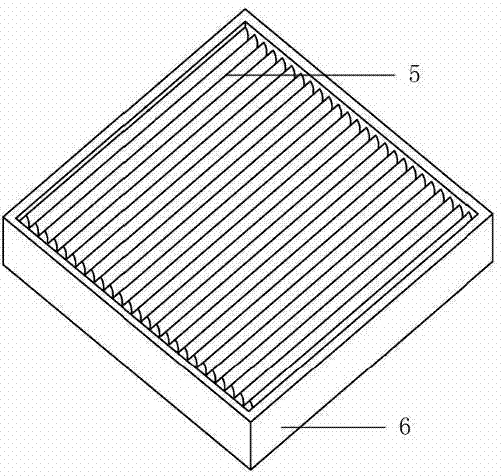

Multilayer-structure antibiotic automobile air conditioner filter capable of filtering PM2.5

The invention discloses a multilayer-structure antibiotic automobile air conditioner filter capable of filtering PM2.5. The multilayer-structure antibiotic automobile air conditioner filter capable of filtering PM2.5 comprises a frame body and a filter element, wherein the filter element is made of melt-blown non-woven fabric, preferably an antibiotic melt-blown non-woven fabric which is prepared by adding antibacterial master batches into a melt-blown non-woven fabric polymer and then performing melt-blowing extrusion. According to the multilayer-structure antibiotic automobile air conditioner filter, multiple times of screening are performed, so that the technical problems of low filtration efficiency, wind resistance and the like are overcome; the melt-blown non-woven fabric is applied to the automobile air conditioner filter for the first time, and a static electricity technology is combined, so that the PM2.5 problem is effectively solved. Meanwhile, by virtue of a mode of adding the antibacterial master batches into the melt-blown non-woven fabric or compounding an antibiotic non-woven fabric with the melt-blown non-woven fabric, the bacterium problem is solved; an active carbon layer is arranged for solving the problems of smell and organic matters. Correspondingly, the multilayer-structure automobile air conditioner filter can be used for various problems of purification of an automobile air conditioner, is capable of resisting PM2.5, bacteria, organic matters, peculiar smell and the like, and has quite wide application prospect.

Owner:HUIZHOU AGPLUS ENVIRONMENTAL PROTECTION TECH CO LTD

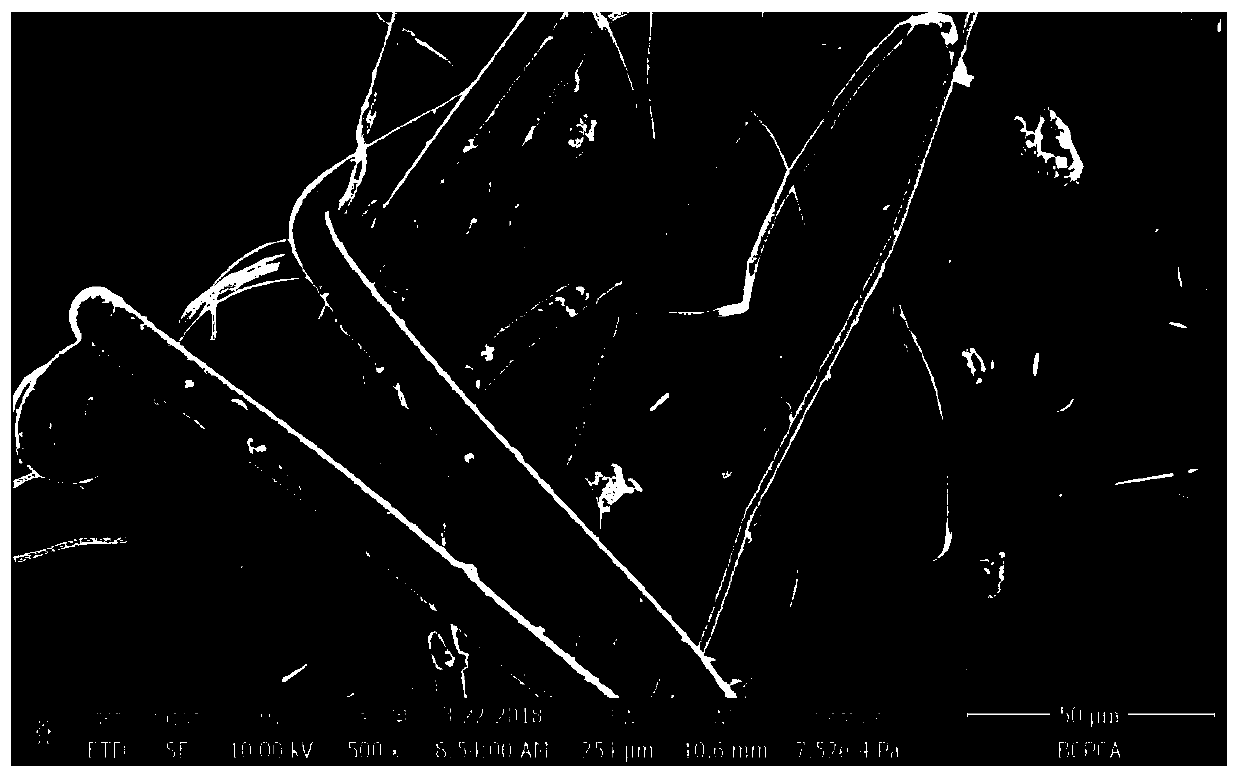

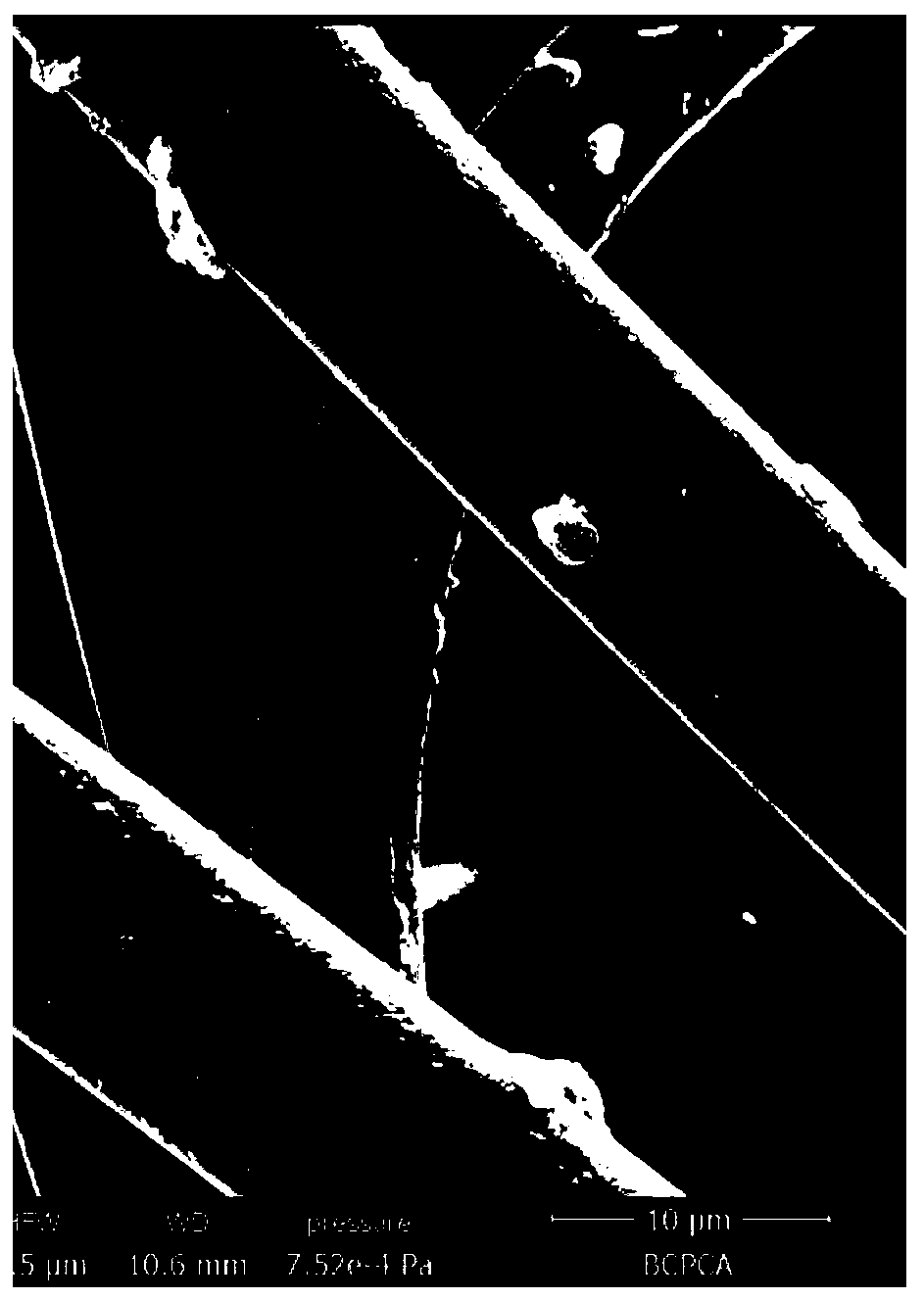

Graphene antibacterial mask filter material and preparation method and application thereof

InactiveCN109701504AExert mechanical propertiesHigh thermal conductivityOther chemical processesProtective garmentAdditive ingredientMechanical property

The invention provides a graphene antibacterial mask filter material and a preparation method and application thereof. According to the method, antibacterial primary masterbatches are prepared by a method for producing masterbatches through ingredient mixing by a double-screw extruder; and agglomeration of graphene nanosheets is effectively weakened by a melt-blowing process. A macro-structure with certain morphology is formed by graphene through superposition or overlapping of sheet layers. After macroscopic fibers are assembled by the graphene, the structural strength of the material is enhanced, furthermore, an effect of a flexible supporting body is achieved between graphene sheet layer structures, aggregation of graphene sheet layers is relieved, and mechanical properties, high thermal conductivity, high-speed electron mobility and good adsorption capacity of the graphene are played well, and the prepared material has excellent antibacterial effect and wide application prospect.

Owner:宿迁市美达净化科技有限公司

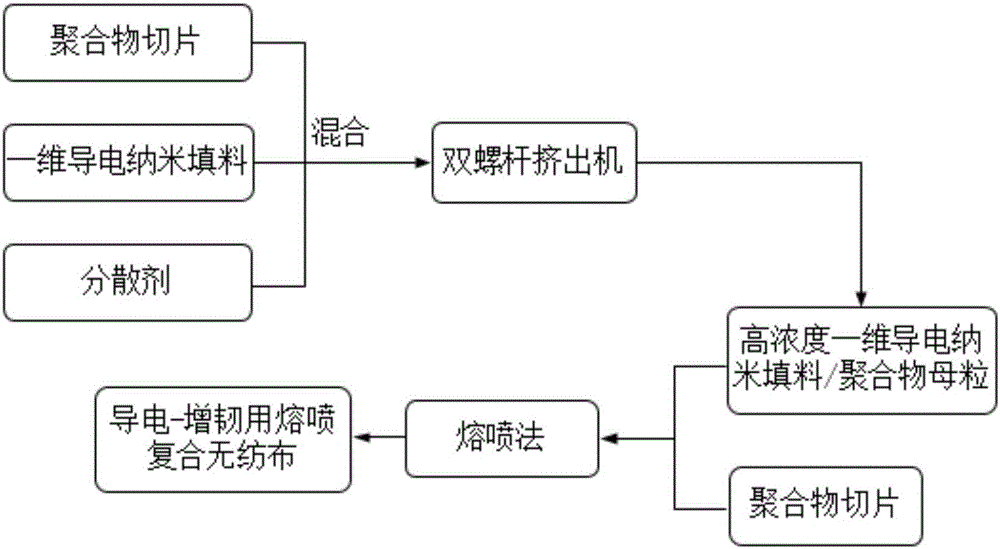

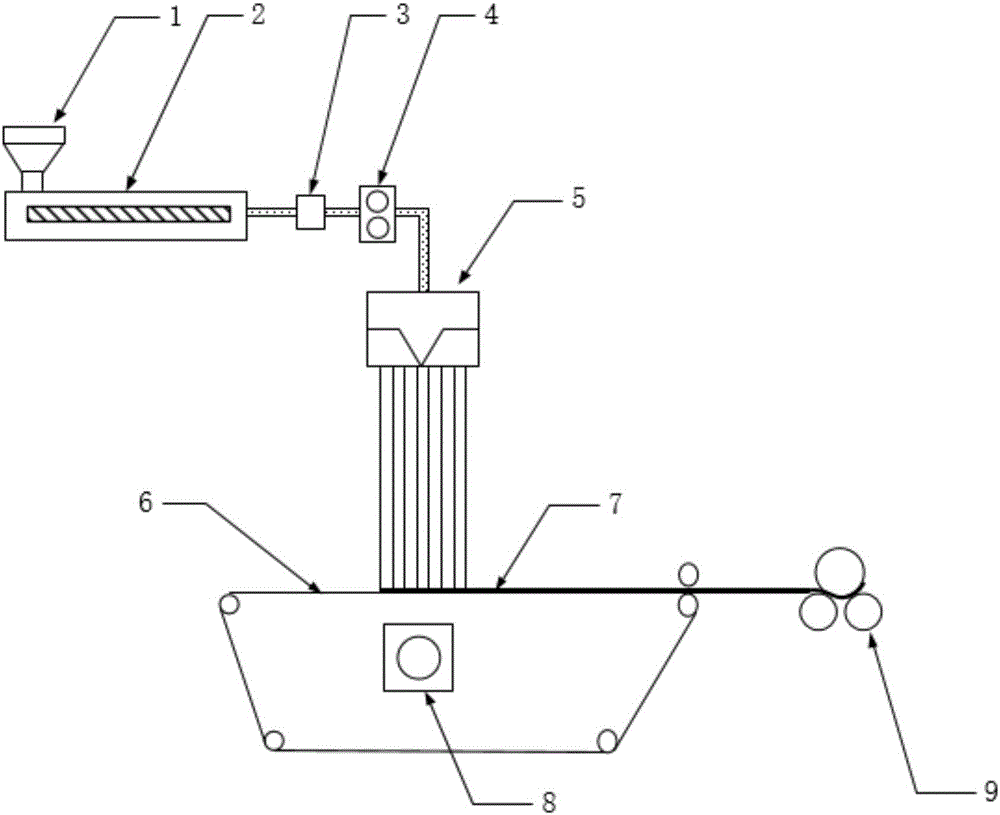

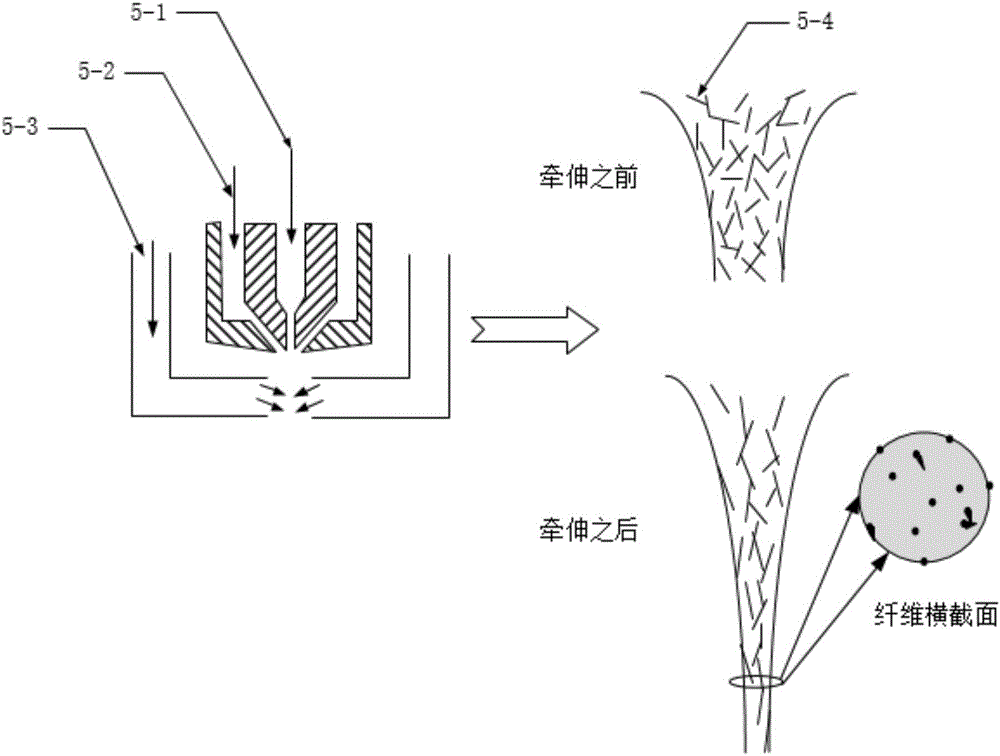

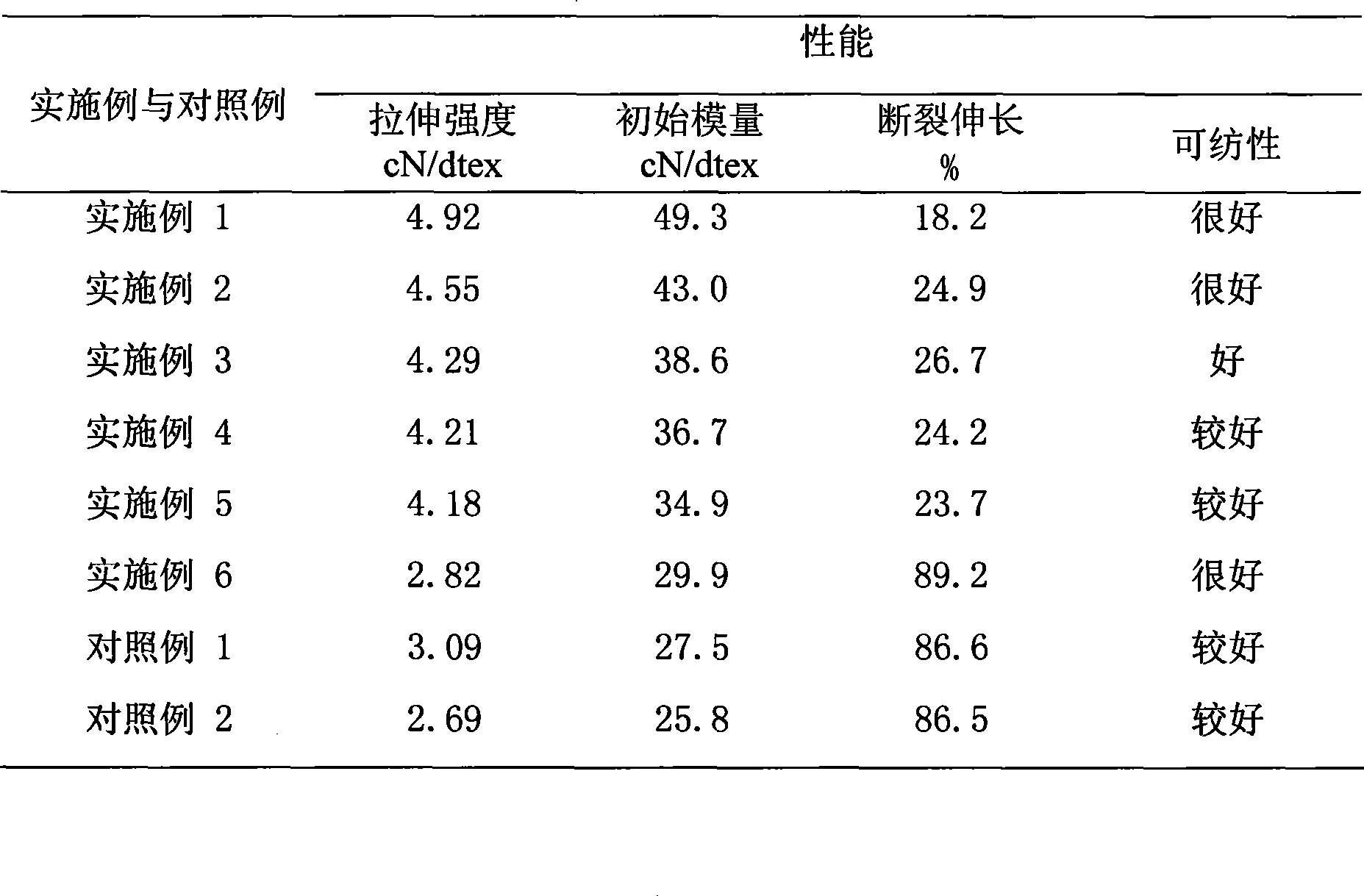

Production method of conductive-toughening melt-blown composite nonwoven fabric

ActiveCN106521805ARaise the ratioWell mixedElectroconductive/antistatic filament manufactureMelt spinning methodsStructure functionIntegrated design

The invention provides a production method of conductive-toughening melt-blown composite nonwoven fabric. The nonwoven fabric is produced by polymer chips, one-dimensional conductive nano filler and a dispersing agent. The production method specifically includes the steps of firstly, preparing conductive master batch; secondly, producing the conductive-toughening melt-blown composite nonwoven fabric. The production method has the advantages that the synergic effect of shear and collision during high-speed mixing and the dispersing agent is utilized, and extrusion by a double-screw extruder is used to allow the one-dimensional conductive nano filler to be evenly dispersed in the polymer; the traction effect of the high-speed hot air in a melt-blowing method to allow the one-dimensional conductive nano filler to oriented along the axial directions of fibers in the fibers and on the surfaces of the fibers, and the building of a conductive network is guaranteed while the conductivity threshold of the composite material is lowered evidently; the conductive-toughening melt-blown composite nonwoven fabric can effectively achieve the effect of structure-function modification integrated design of the composite material; the method is simple in step, convenient to operate and high in practicality.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS +1

Method for preparing polyester/nano calcium carbonate mixture

The invention relates to a preparation method for a mixed material of polyester / nanometer calcium carbonate, which includes the steps as follows: when polyester chips, nanometer calcium carbonate particles, a reactive monomer and other additives are mixed at a high speed in a high-speed mixing machine simultaneously, the temperature of a mixed system is raised to the temperature of 145 DEG C by utilizing a method of mixed heating or added heating to soften the polyester chips and to lead the nanometer calcium carbonate as well as the other additives to be uniformly stuck on the polyester chips; while no serious conglutination exists between the particles of the polyester chips. The mixed material of polyester / nanometer calcium carbonate prepared by the invention has excellent processing properties and can be used for manufacturing fibers, films or reinforced plastics used for weaving by melt blowing or melt spinning.

Owner:DONGHUA UNIV +1

Absorbable copolyesters of poly(ethoxyethylene diglycolate) and glycolide

A semi-crystalline, absorbable copolyester composition comprising the reaction product of a polycondensation polyester and at least one lactone, wherein the polycondensation polyester comprises the reaction product of diglycolic acid and / or a derivative thereof and diethylene glycol; and the copolyester comprises about 30 to 60% by weight of the polycondensation polyester based on the total weight of the copolyester. Also medical devices such as absorbable sutures comprising such copolyesters and absorbable microspheres comprising such copolyesters and methods of making of such absorbable microspheres. Additionally, a method of melt blowing an absorbable copolyester composition and a nonwoven construct are disclosed.

Owner:ETHICON INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com