Patents

Literature

97 results about "Cellulose microfibril" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A microfibril composed of cellulose arranged in orthogonal layers. Cellulose is a straight chain polysaccharide composed of B(14) linked glucose subunits. It is a major component of plant cell walls. Higher plant microfibrils are about 10nm in diameter and extremely long in relation to their width. The cellulose molecules are oriented parallel to the long axis of the microfibril in a paracrystalline array, which provides great tensile strength. The microfibrils are held in place by the wall matrix and their orientation is closely controlled by the cell. [GOC:jid, ISBN:0943088399]

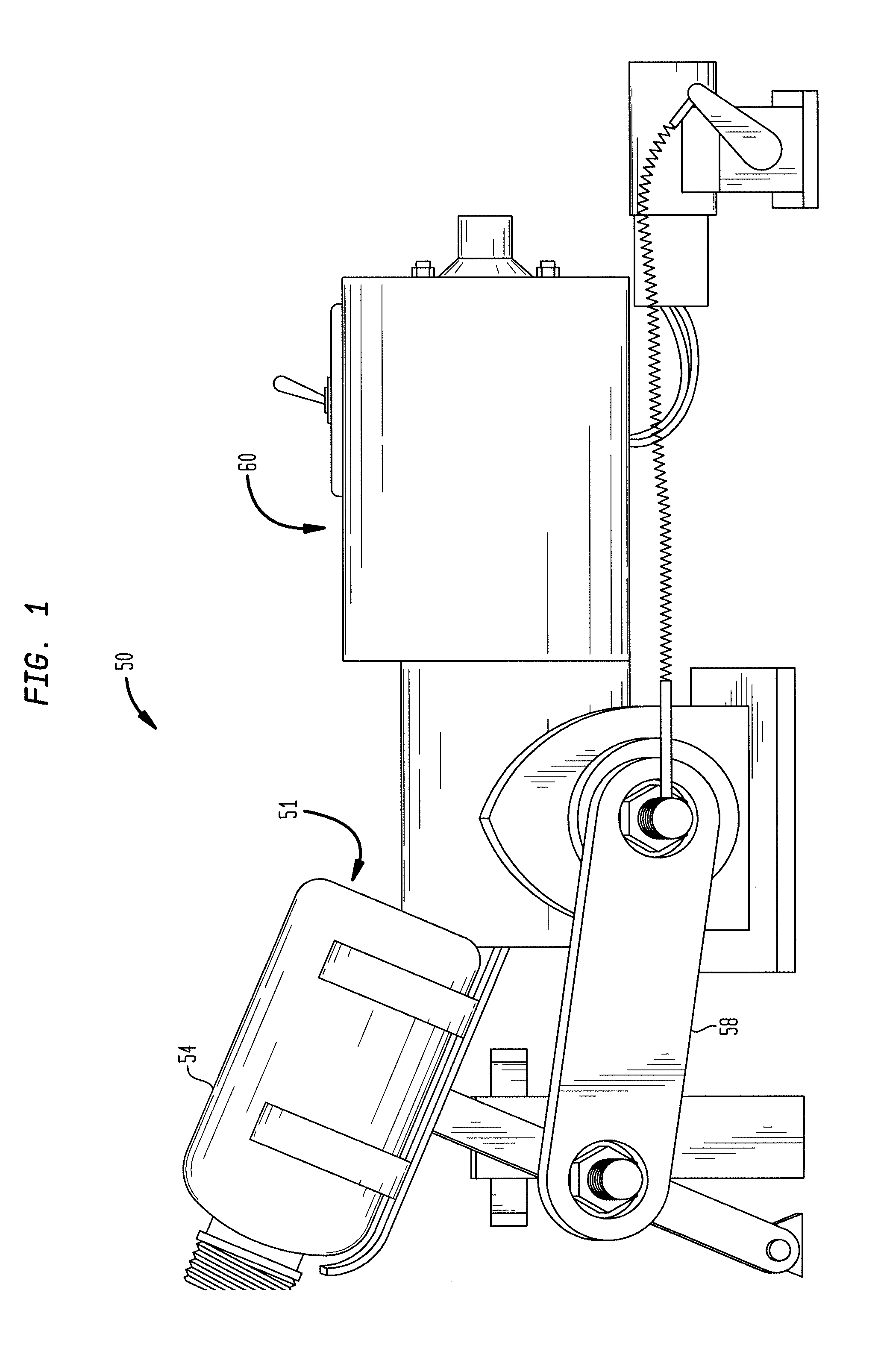

Process for forming micro-fiber cellulosic nonwoven webs from a cellulose solution by melt blown technology and the products made thereby

InactiveUS20050056956A1Artificial filament washing/dryingLoose filtering material filtersNon solventEngineering

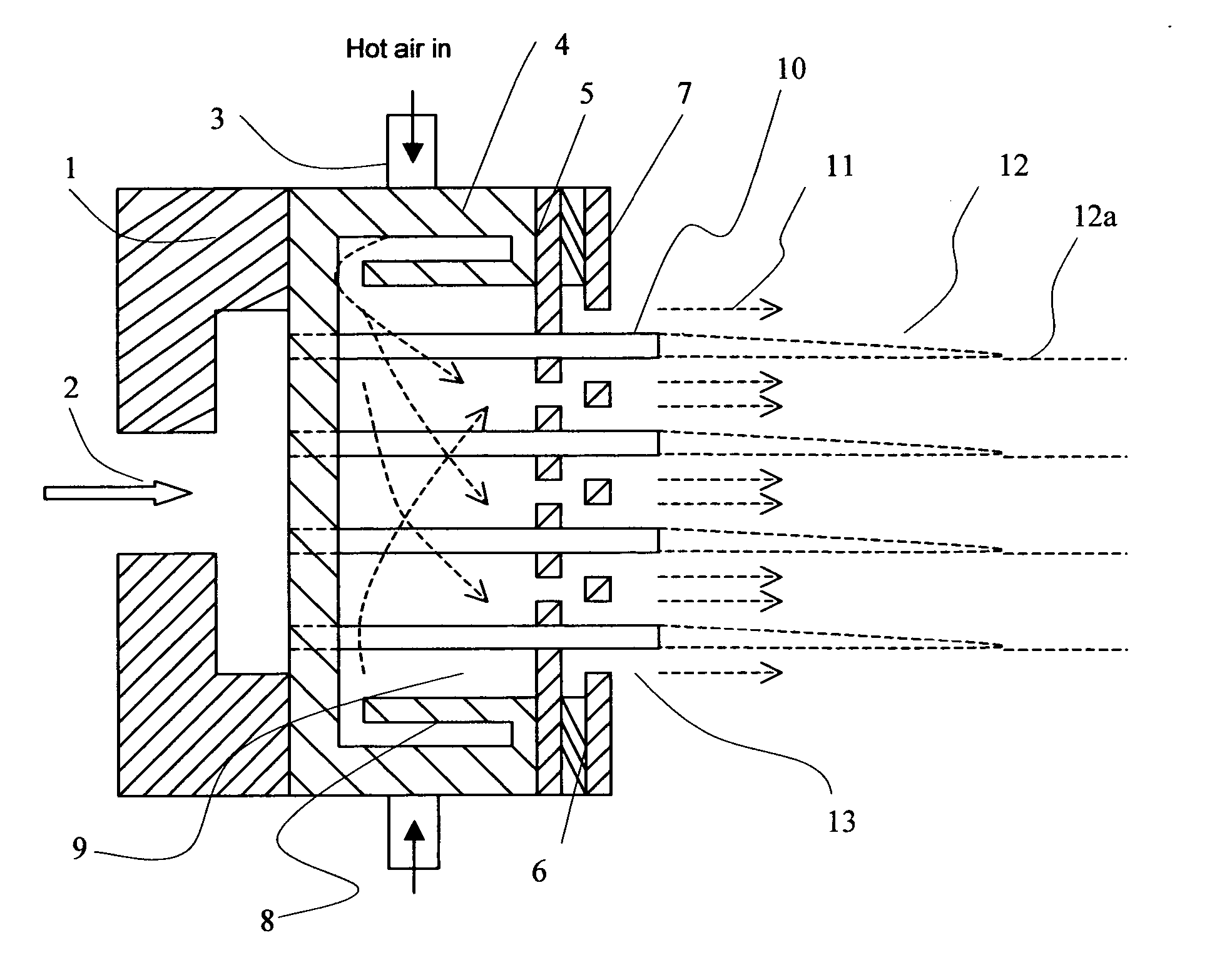

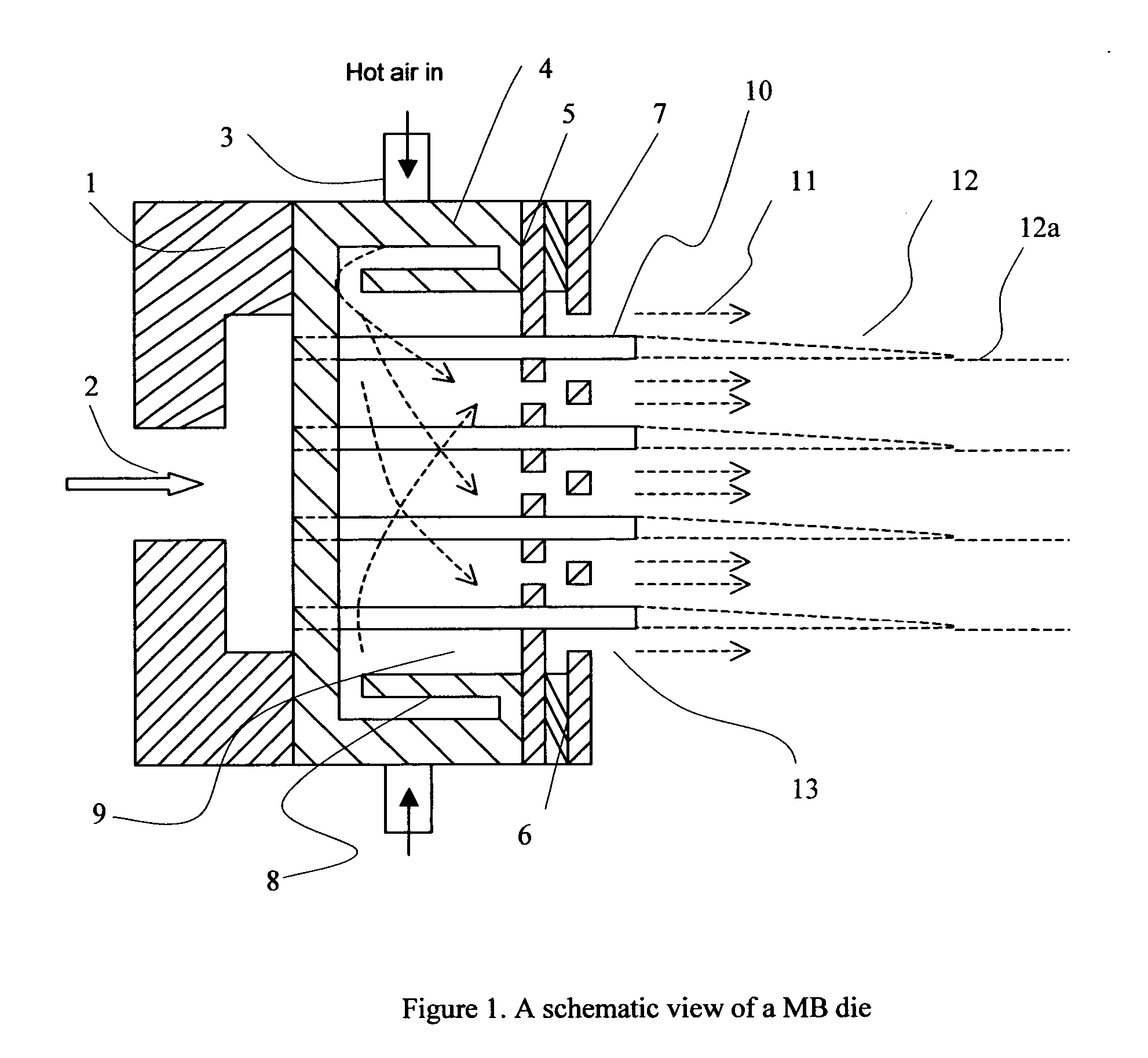

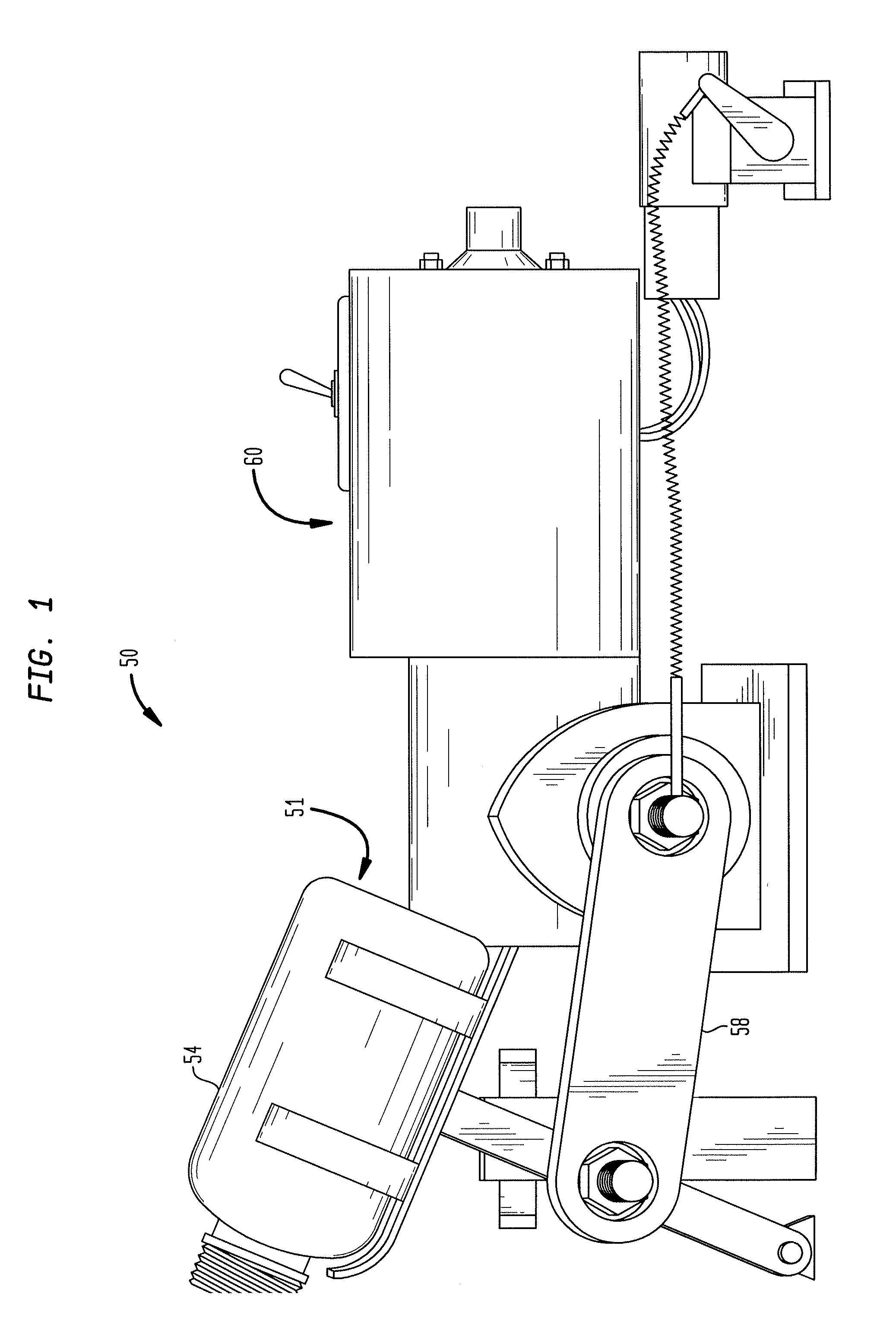

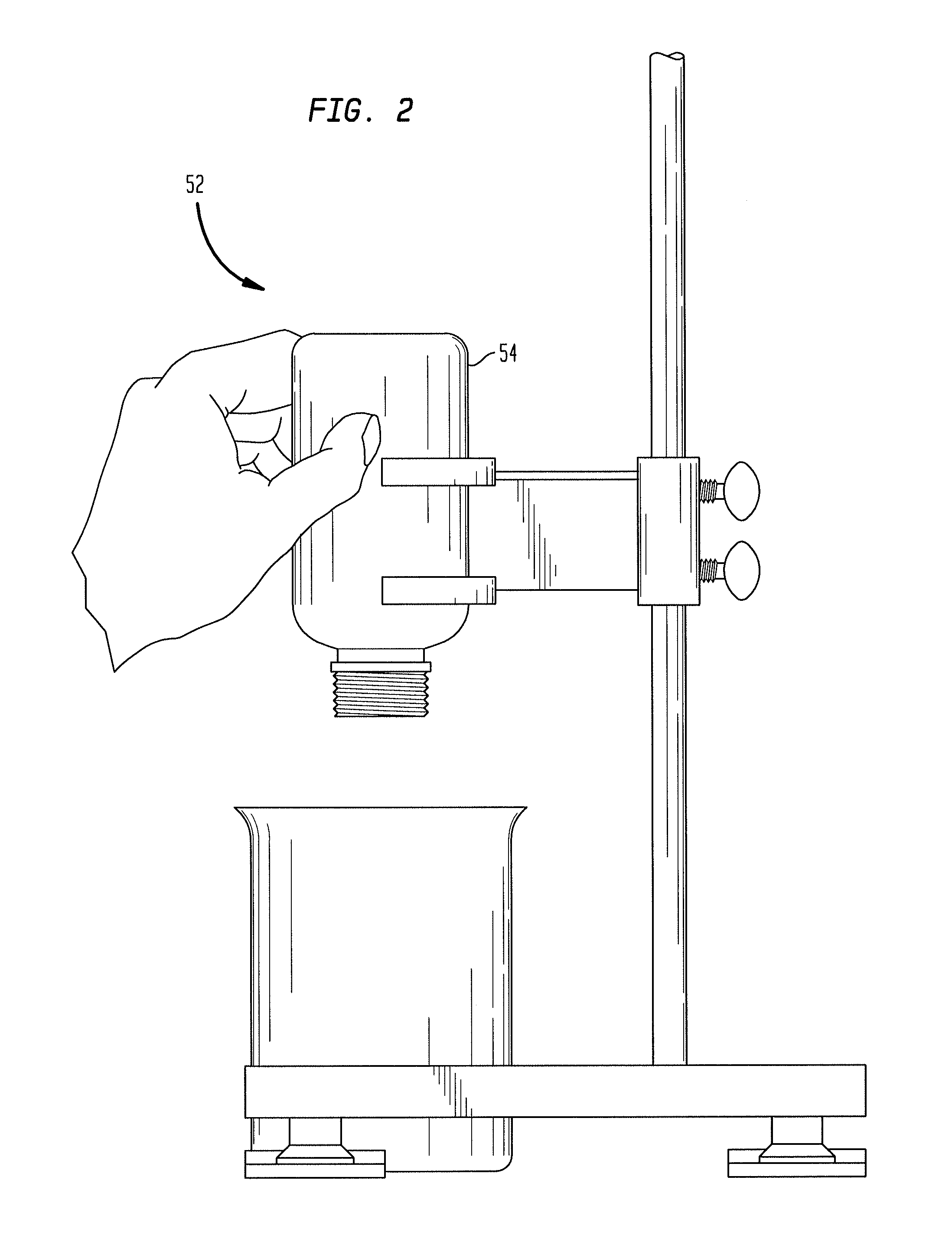

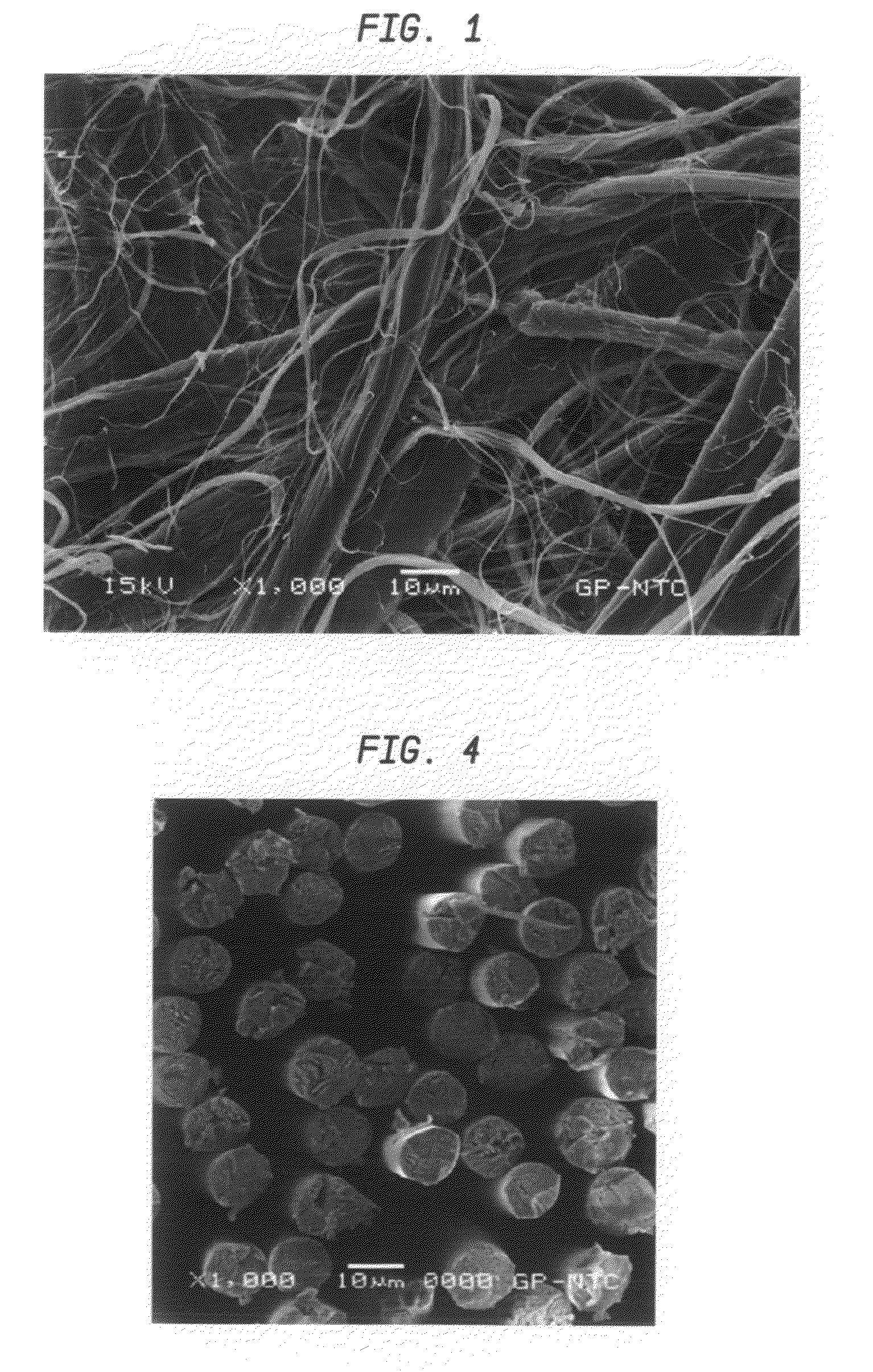

This invention relates to a process of melt blowing a cellulose solution through a concentric melt blown die with multiple rows of spinning nozzles to form cellulosic microfiber webs with different web structures. The process comprises the steps of (a) extruding a cellulose solution (dope) through a melt blown spinneret with multiple rows of spinning nozzles; (b) drawing each individual extrudate filament to fine fiber diameter by its own air jet; (c) coagulating and entangling the fine fibers with a series of pressured hydro needling jets of recycling solution of the mixture of cellulose solvent and non-solvent in the spin-line; (d) collecting the stream of microfibers, air and needling jets on a moving collecting surface to form cellulosic fiber web; (e) hydro-entangling the said pre-bonded web downstream with at least one set of hydro needling jets of recycling solvent / non-solvent solution for forming well bonded nonwoven web; (f) regenerating the fine fibers in at least one bath for at least 5 seconds; (g) further regenerating and washing the fine fibers in another bath for at least 5 seconds; (h) pinching the well bonded melt blown cellulosic nonwoven with pressure rollers to remove major portions of the non-solvent; (i) drying the nonwoven web by heat, or vacuum or both, and (j) winding the nonwoven web into rolls.

Owner:BIAX FIBERFILM CORP

High Softness, High Durability Bath Tissues With Temporary Wet Strength

ActiveUS20130029105A1Improve tissue performanceGood flexibilityPersonal careReinforcing agents additionWet strengthCalipers

Owner:GPCP IP HLDG LLC

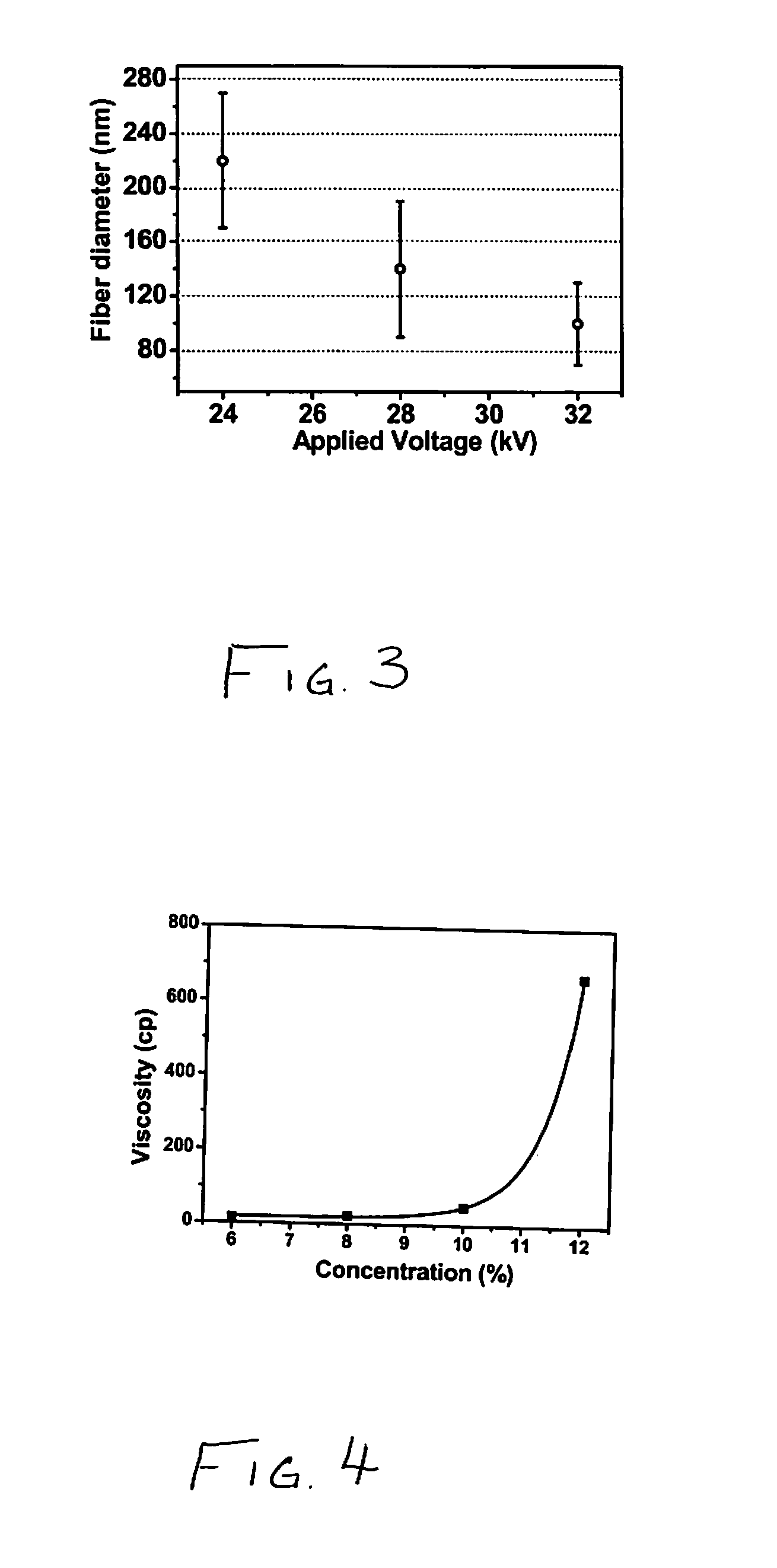

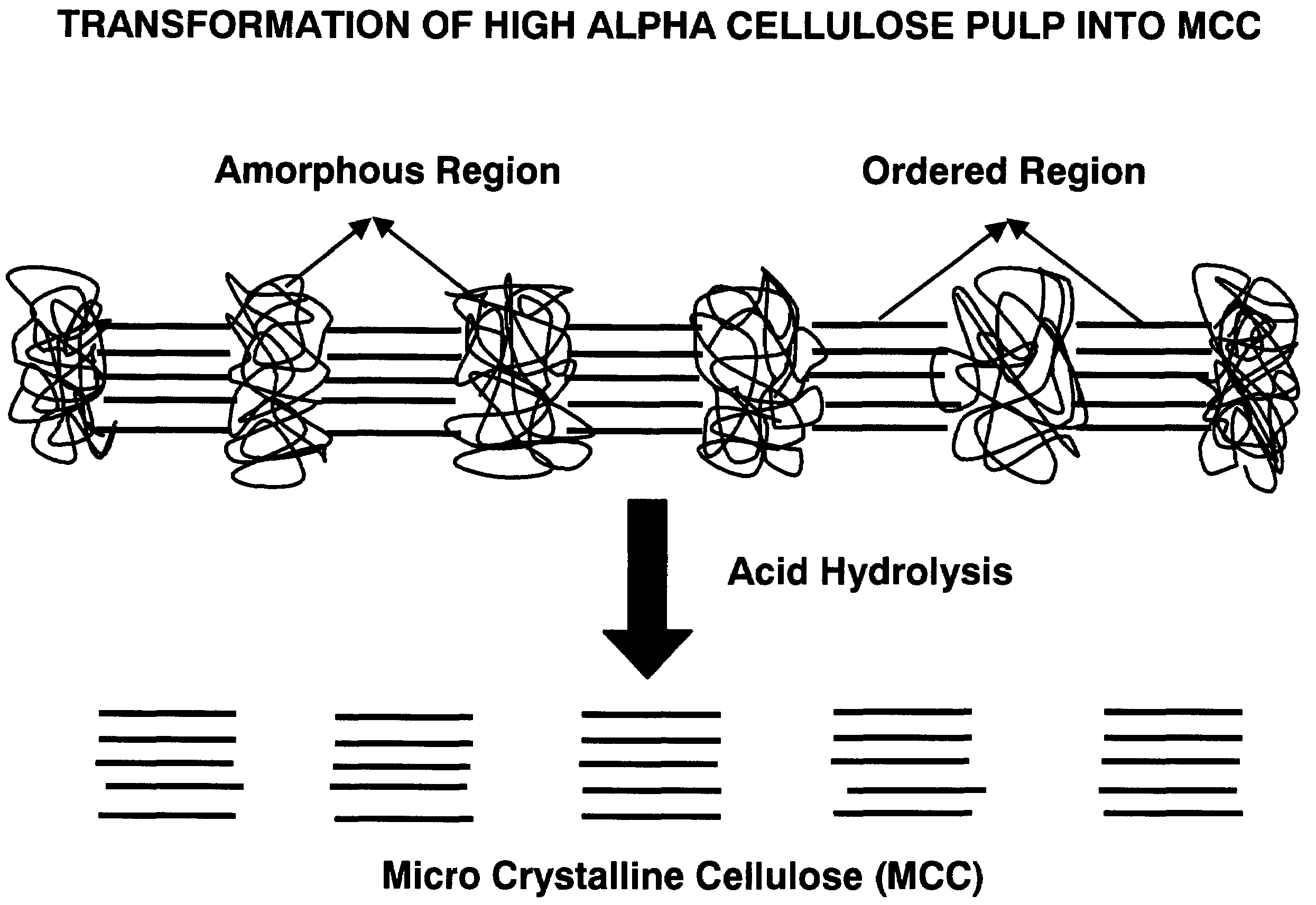

High flux high efficiency nanofiber membranes and methods of production thereof

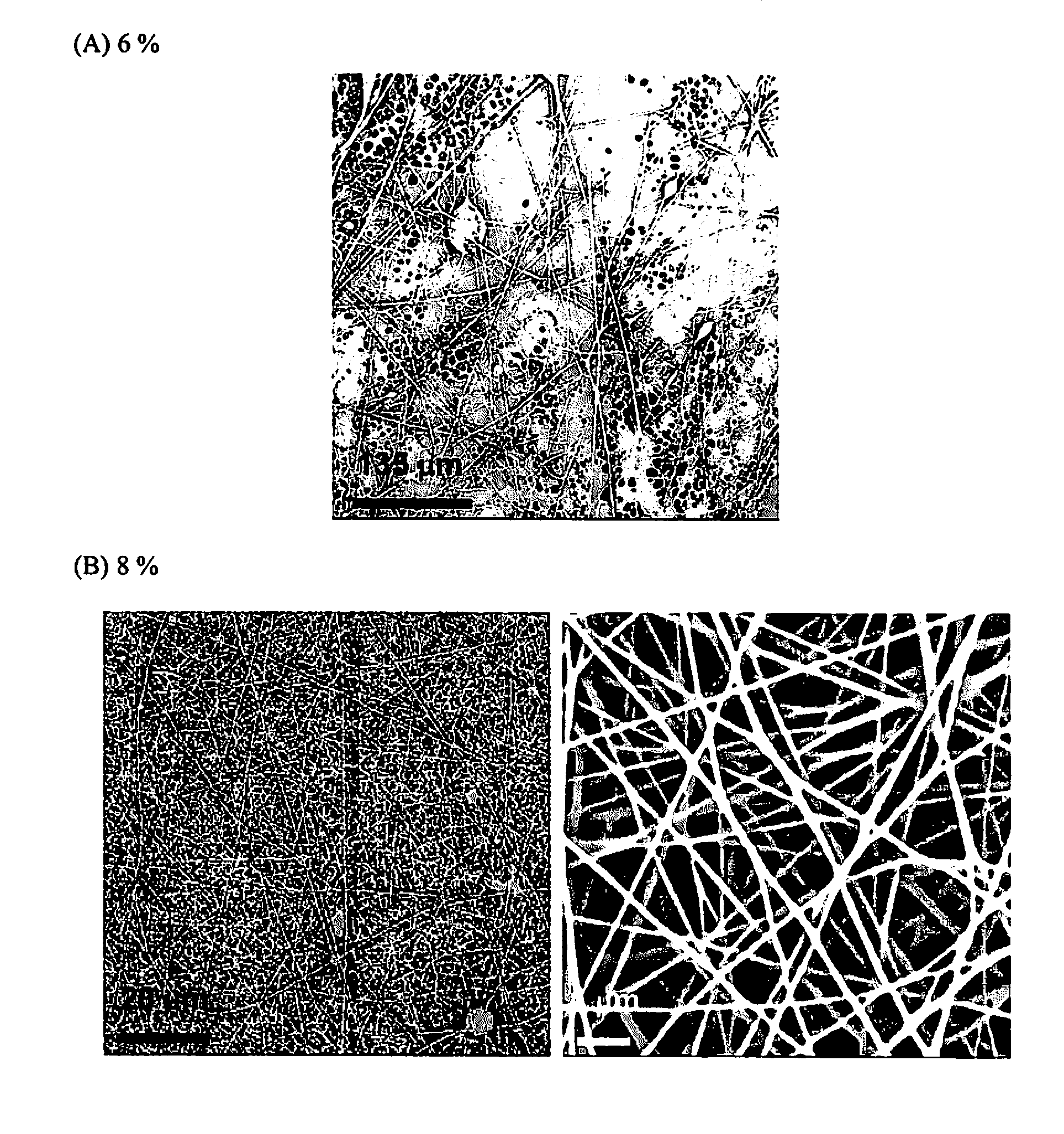

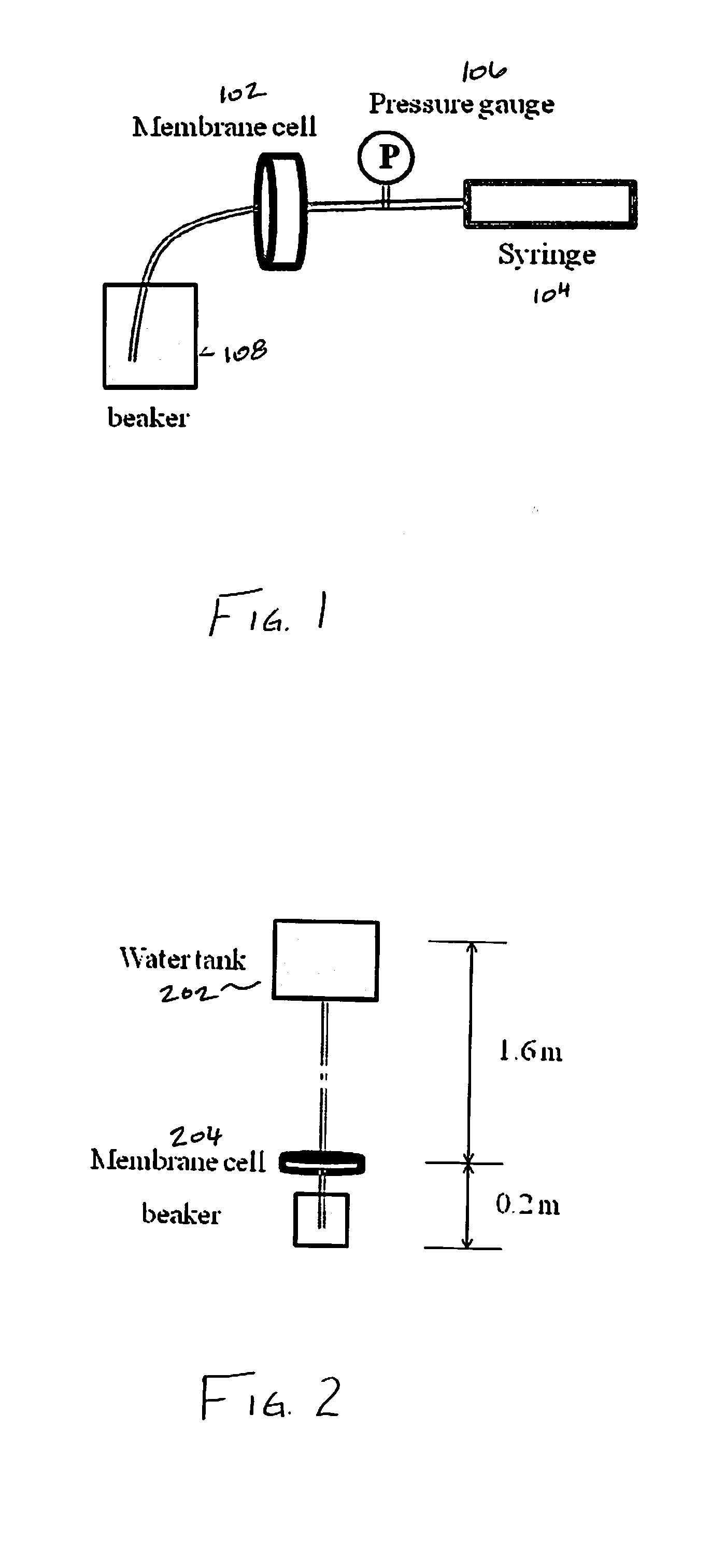

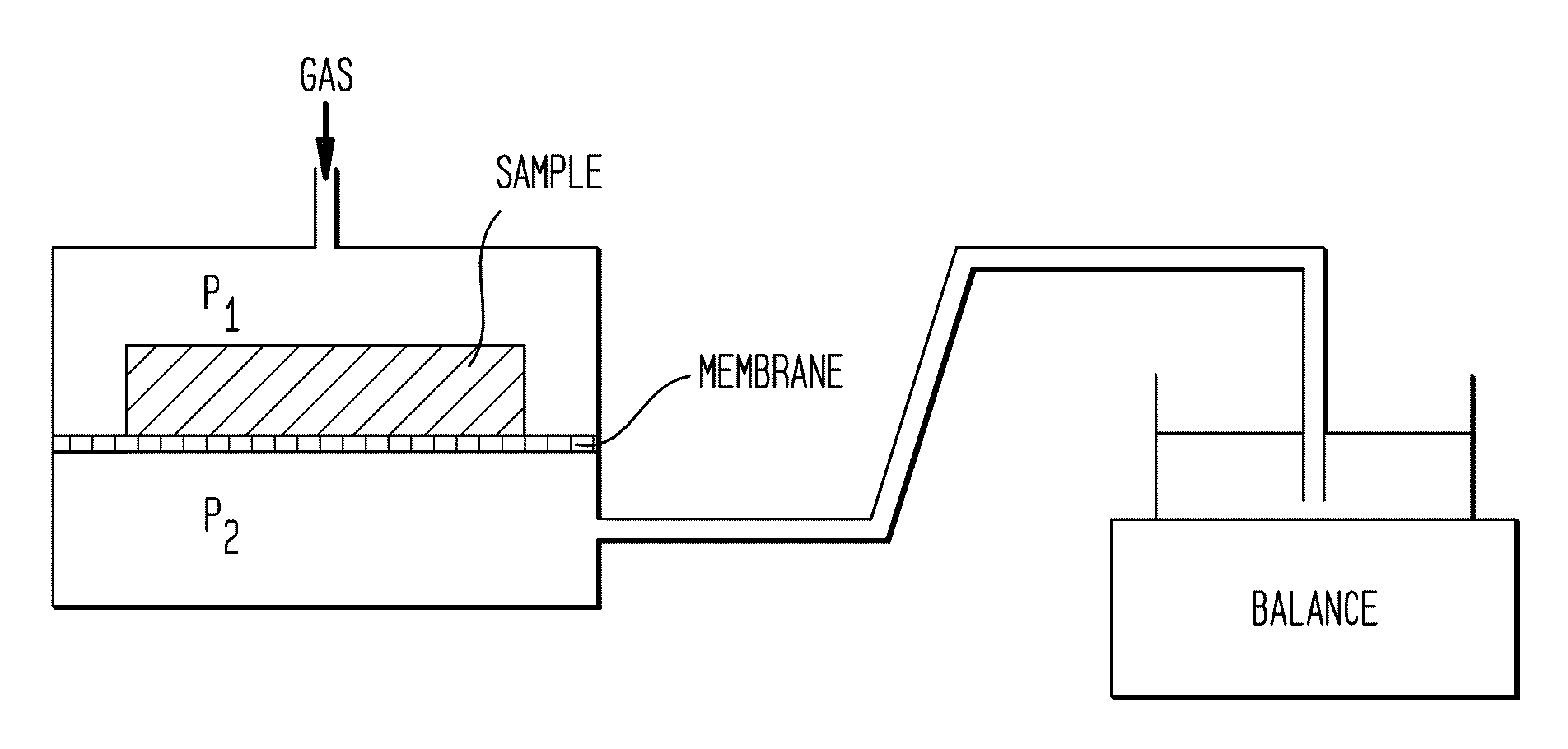

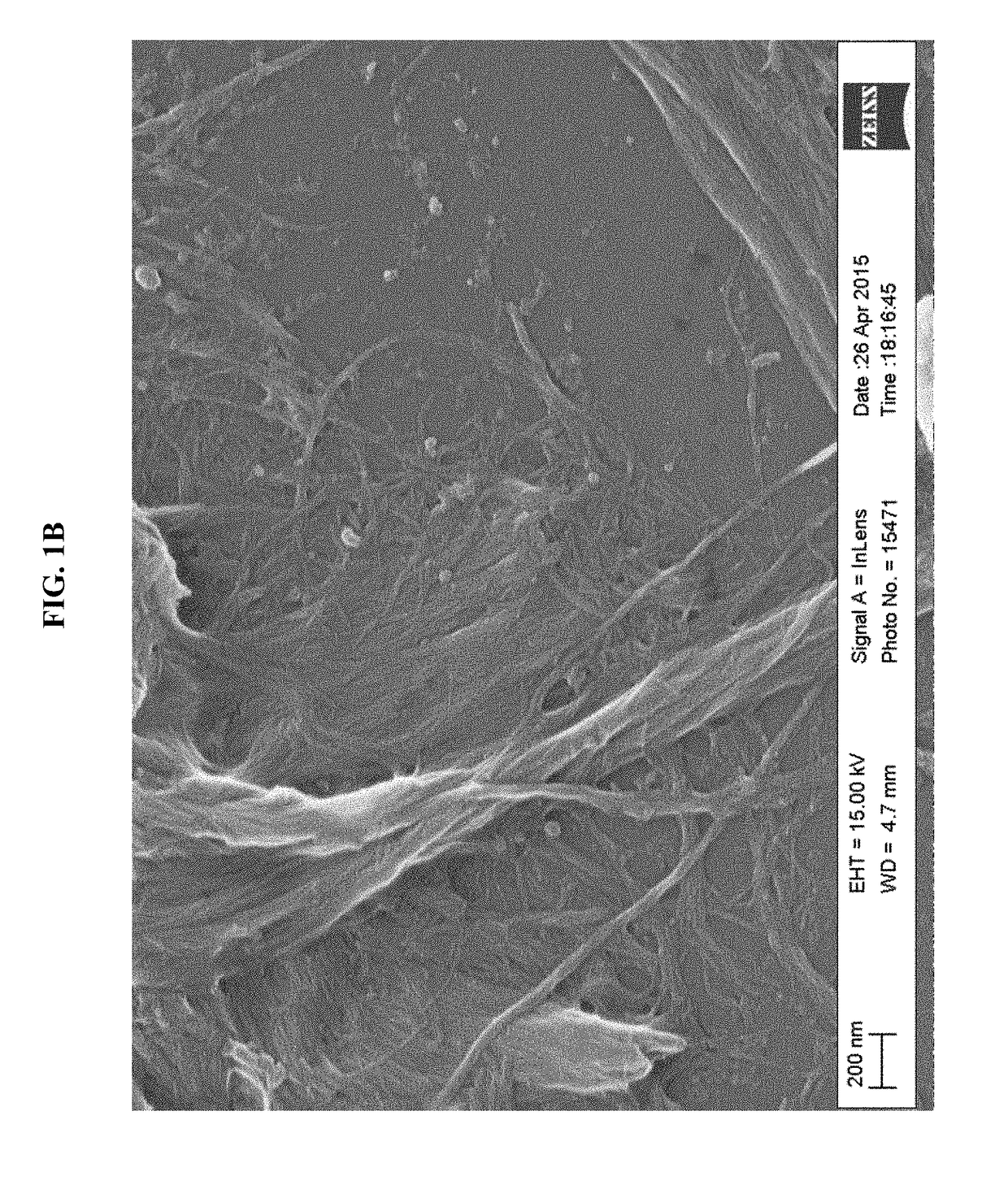

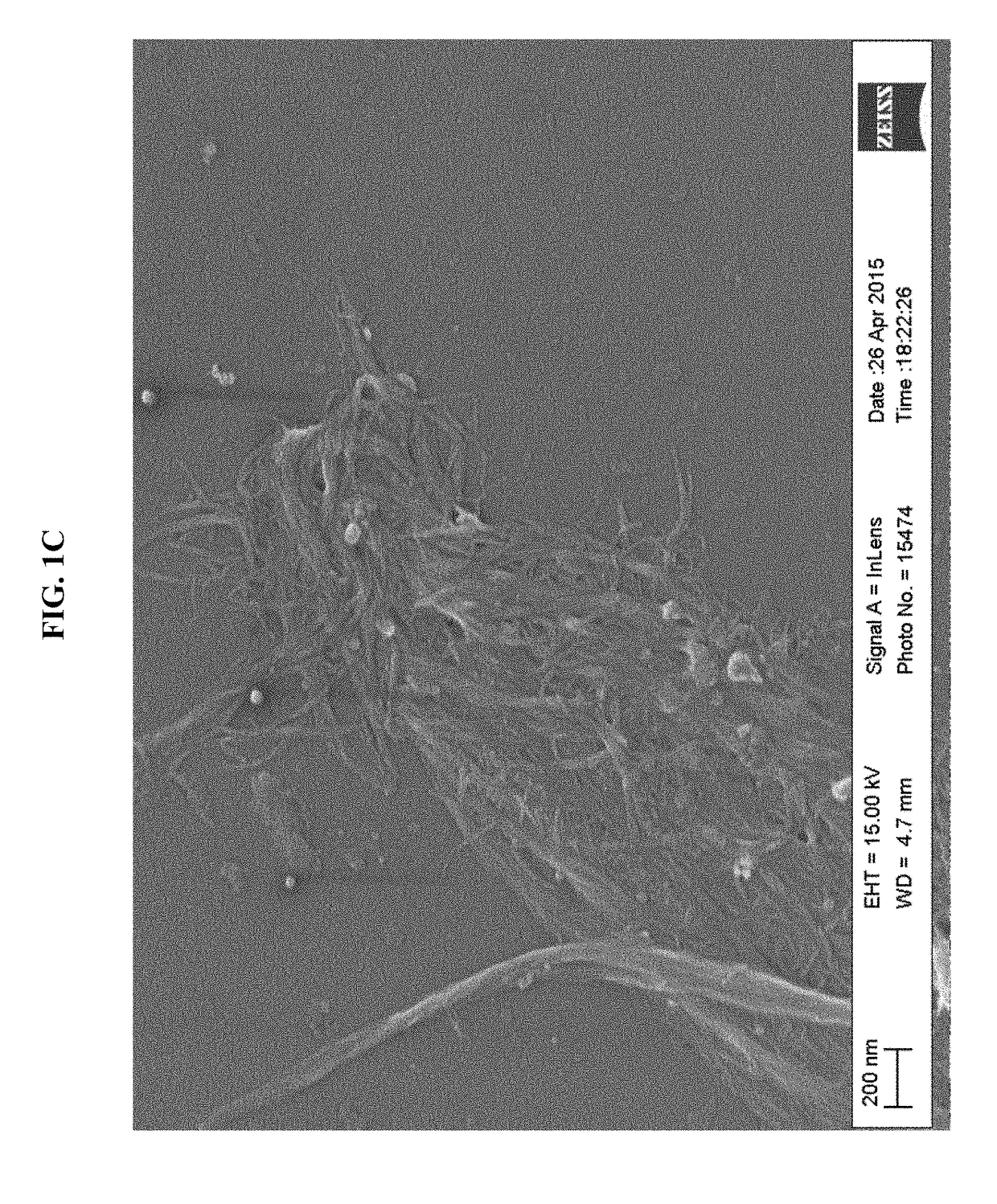

A membrane is provided including a coating layer having cellulose nanofibers produced from oxidized cellulose microfibers and an electrospun substrate upon which the coating layer is applied. The nanofibers of the electrospun substrate have a diameter greater than that of the cellulose nanofibers. The membrane also has non-woven support upon which the electrospun substrate is disposed. Microfibers of the non-woven support have a diameter greater than that of the nanofibers of the electrospun substrate. Application of electrospun membrane is in microfiltration area, while the cellulose nanofiber membrane serves in ultra-filtration, nanofiltration, and reverse osmosis after chemical modification.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

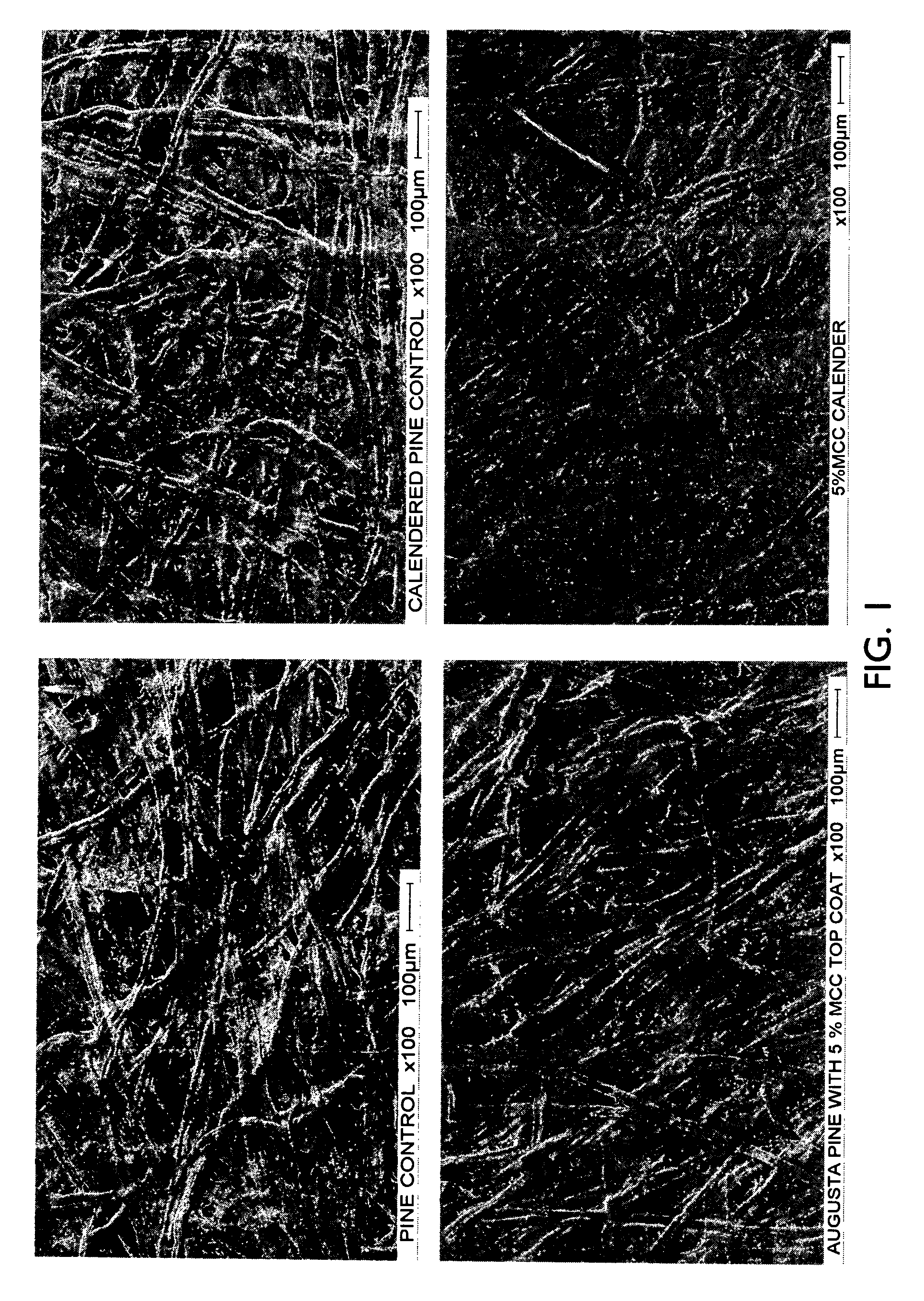

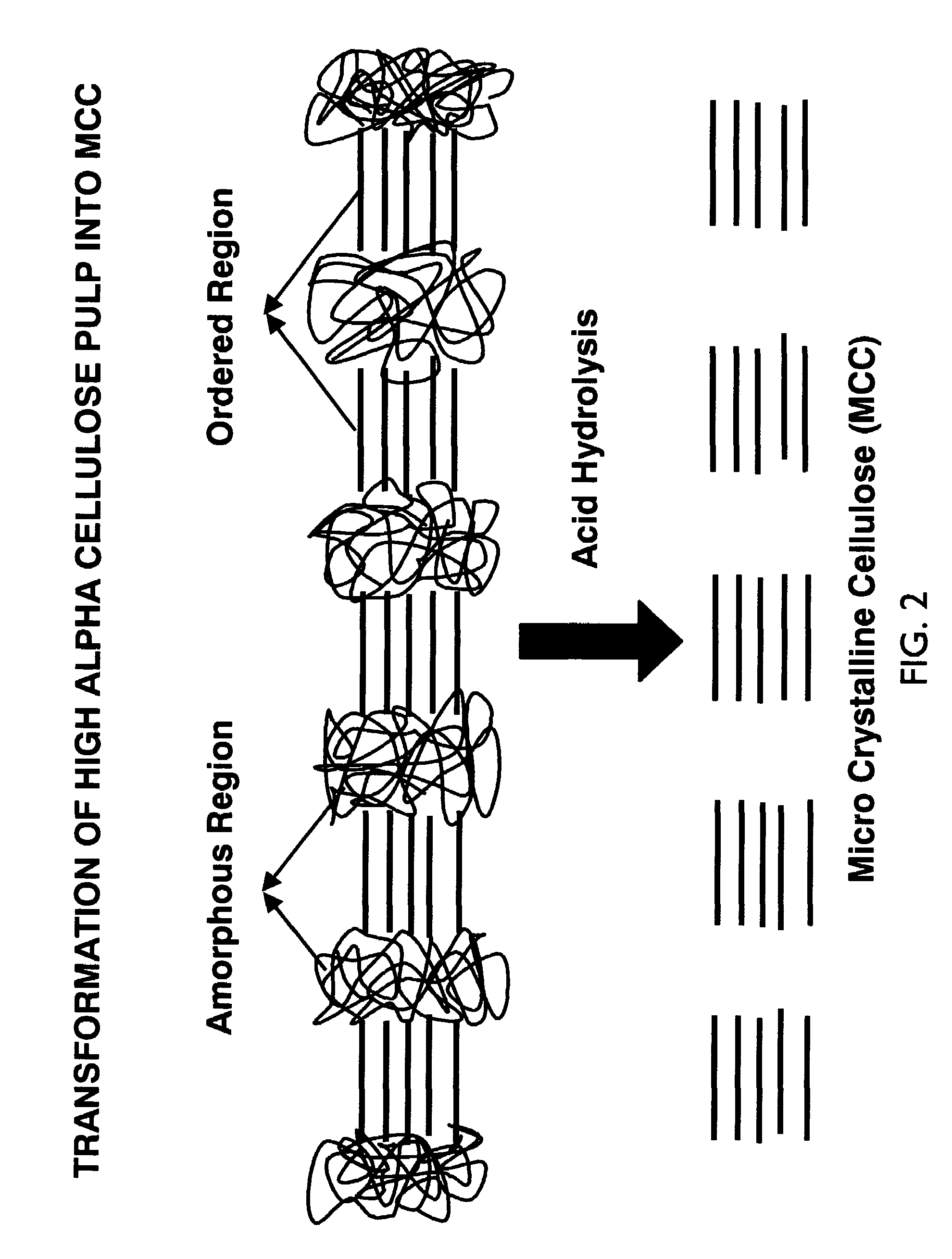

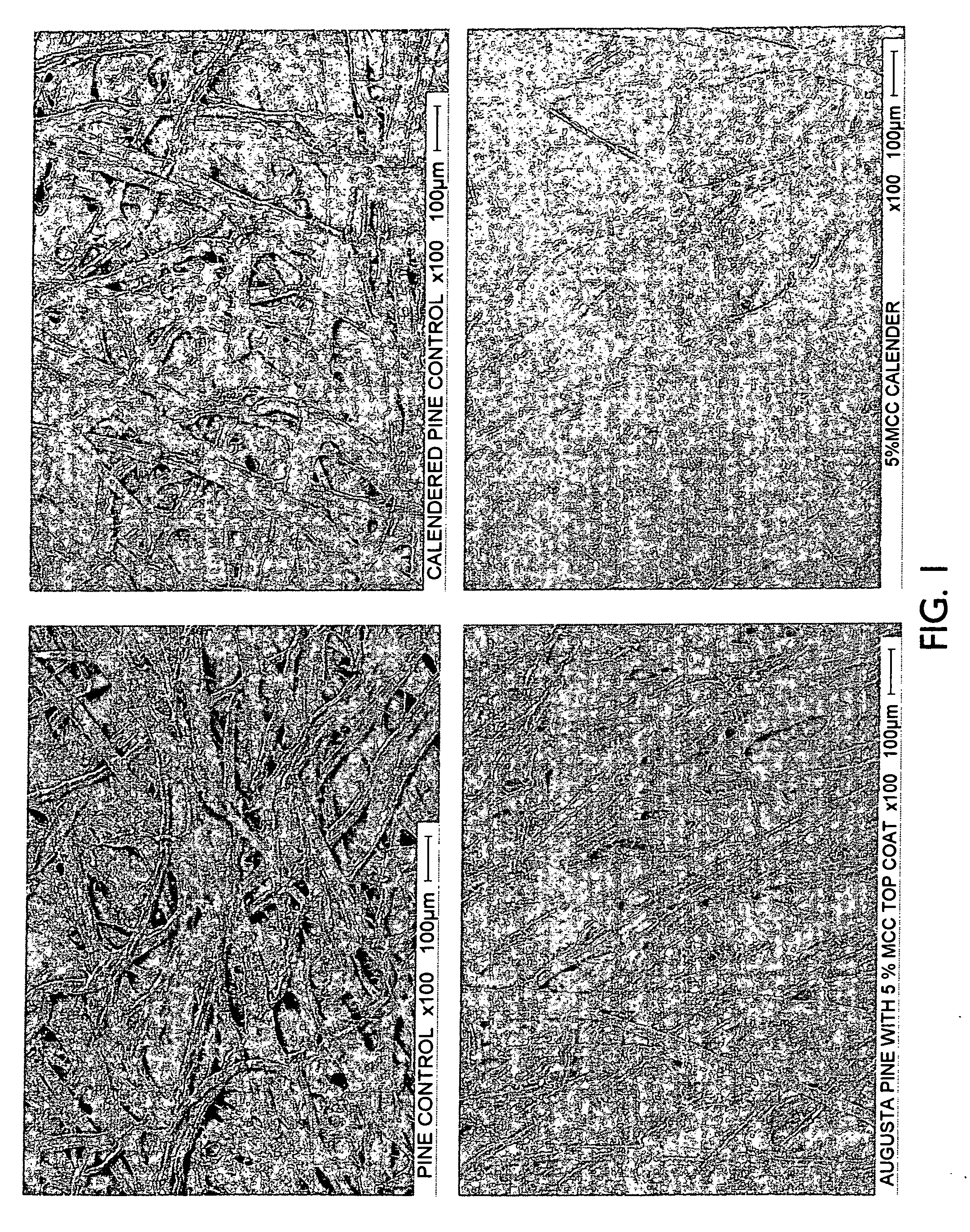

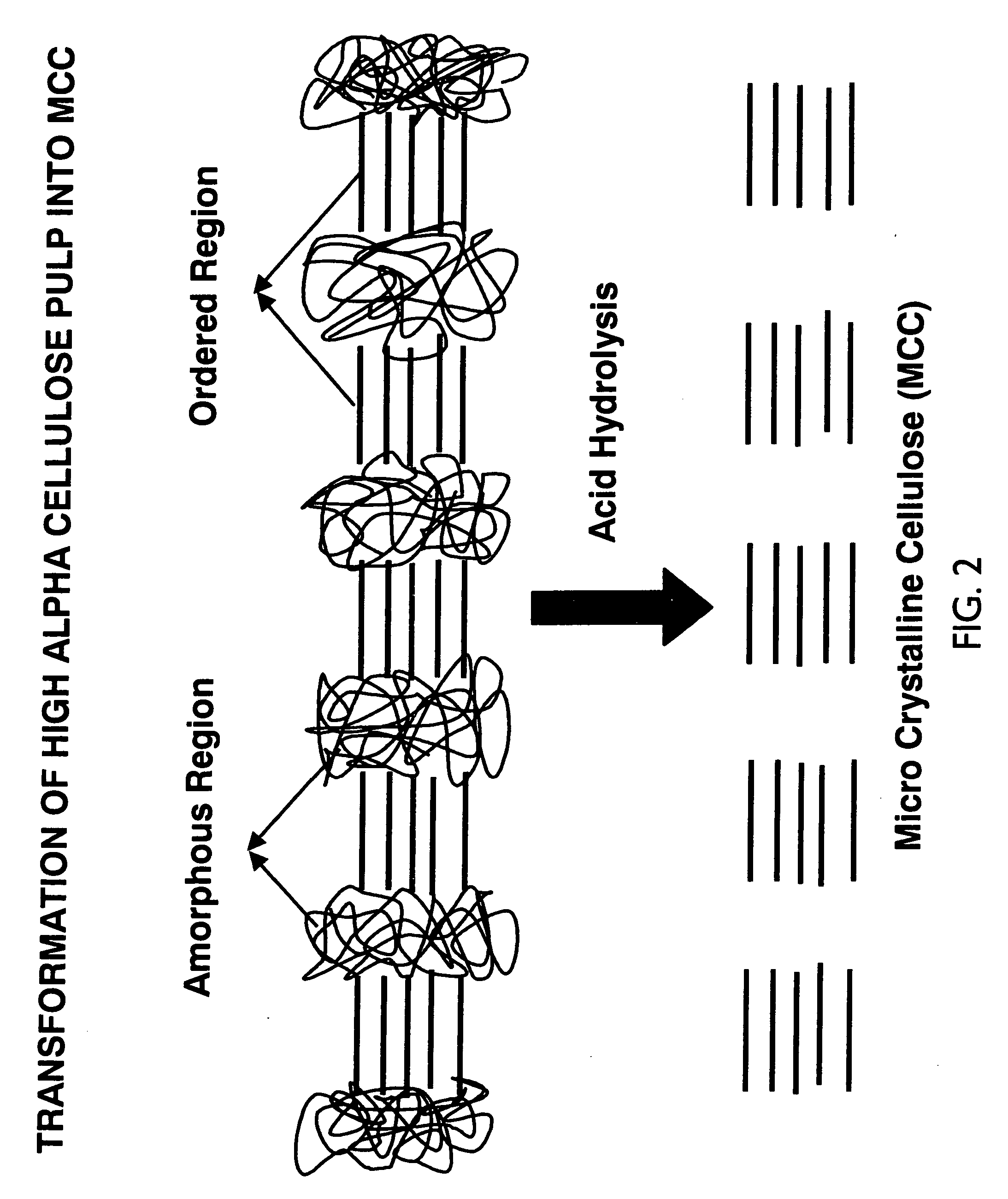

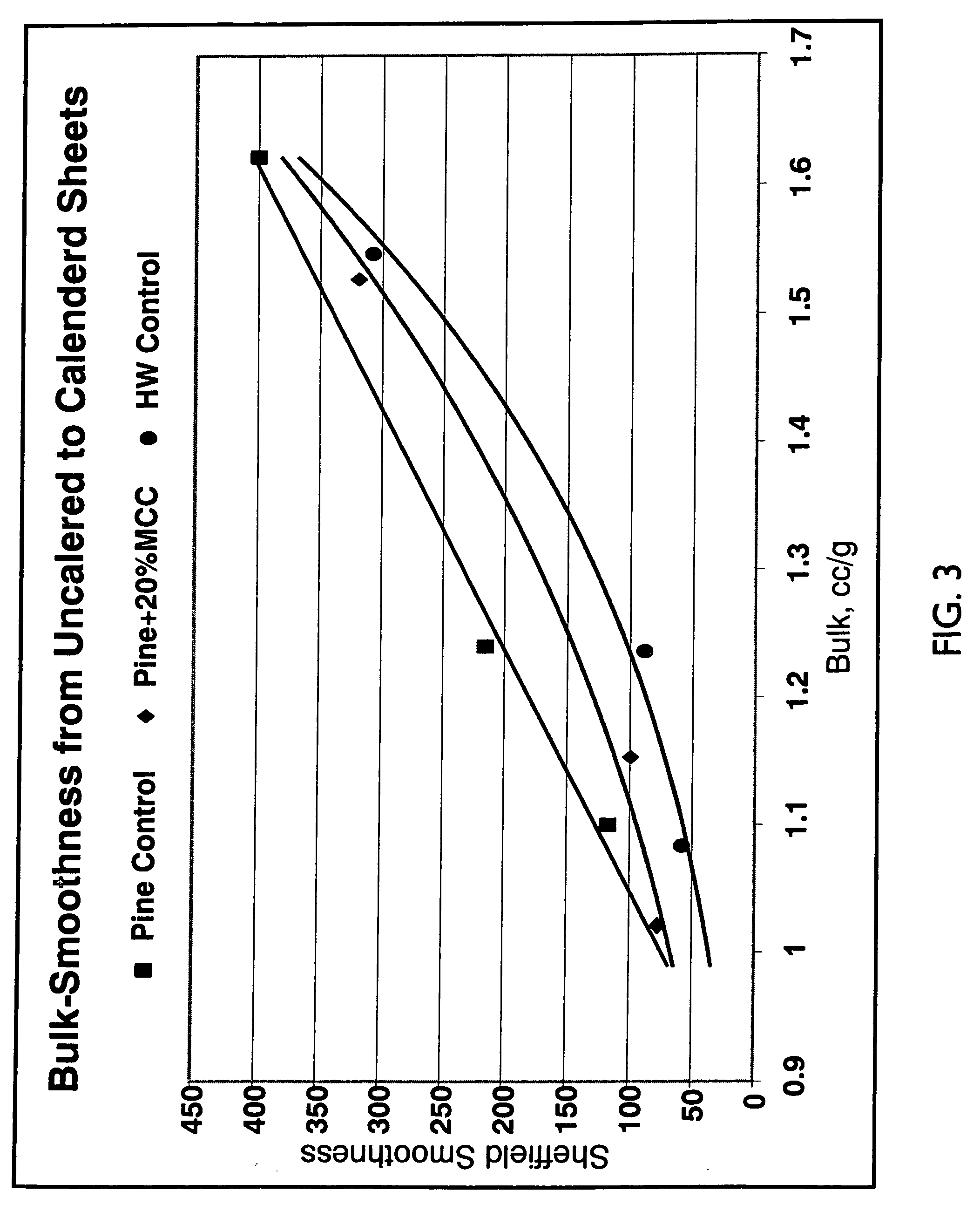

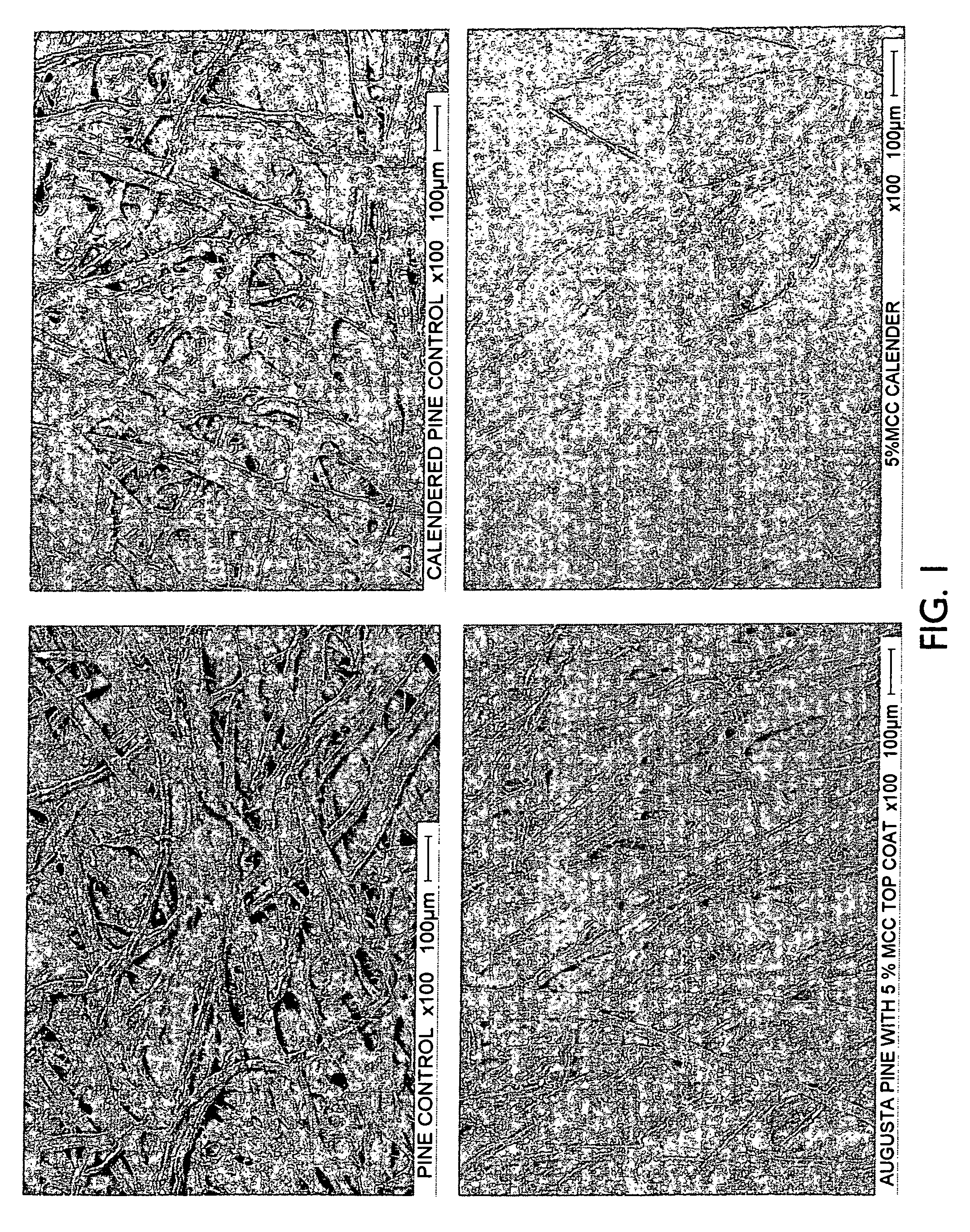

Surface treatment with texturized microcrystalline cellulose microfibrils for improved paper and paper board

InactiveUS7037405B2High binding capacityImprove abilitiesNon-fibrous pulp additionNatural cellulose pulp/paperFiberPaperboard

The present invention relates to the production of texturized microcrystalline cellulose from raw pulp material. This texturized microcrystalline cellulose can then be used for surface treatment of paper or paper board. Additionally, the texturized microcrystalline cellulose may be used as a starting material for production of paper or paper board.

Owner:INT PAPER CO

Surface treatment with texturized microcrystalline cellulose microfibrils for improved paper and paper board

InactiveUS20060144535A1High binding capacityImprove abilitiesNon-fibrous pulp additionSpecial paperFiberCardboard

The present invention relates to the production of texturized microcrystalline cellulose from raw pulp material. This texturized microcrystalline cellulose can then be used for surface treatment of paper or paper board. Additionally, the texturized microcrystalline cellulose may be used as a starting material for production of paper or paper board.

Owner:INT PAPER CO

Rapidly Dehydrating Lost Circulation Material (LCM)

A rapidly dehydrating lost circulation material (LCM) composition is provided. The LCM composition may include a carrier fluid, volcanic ash, a viscosifier, and date tree rachis fibers. The carrier fluid may be water and the viscosifier may be a cellulosic microfiber. The LCM composition may form a rapidly dehydrating loss control slurry (RDLCS). The LCM composition may be formed by mixing the carrier fluid, the volcanic ash, the viscosifier, and the date tree rachis fibers in a mixer to form a homogenous mixture. Methods of lost circulation control and manufacture of a rapidly dehydrating LCM are also provided.

Owner:SAUDI ARABIAN OIL CO

Method for preparing seaweed cellulose aerogel oil absorption material

ActiveCN103980530AEnsure thoroughnessFast oil absorptionOther chemical processesCelluloseUltimate tensile strength

The invention discloses a method for preparing a seaweed cellulose aerogel oil absorption material and relates to a method for preparing an oil absorption material. The method comprises the following steps: I, purifying seaweed cellulose; II, preparing seaweed nano cellulose microfibril in a mechanical colloid milling mode; III, preparing seaweed cellulose aerogel; and IV, performing hydrophobic modification on the seaweed cellulose aerogel. The seaweed cellulose aerogel oil absorption material prepared by using the method is natural and pollution-free and has the advantages of high oil absorption efficiency, , good strength, simple secondary treatment and the like, and is an important development direction of novel aerogel oil absorption materials.

Owner:HARBIN INST OF TECH

High strength material using cellulose micro-fibril

InactiveUS20050067730A1Reduce amountHigh strengthFibreboardCellulosic pulp after-treatmentFiberPolymer science

The present invention relates to a high strength material and a high strength molded article comprising 65 to 100 wt. % of cellulose microfibrils; and products comprising these. The material, which is lightweight and has a very high strength, can be used for various purposes and can be produced by recycling wastepaper, used cloth and the like. Furthermore, by appropriately selecting the type and / or amount of binder, the material comprising microfibrils as a main component can be decomposed by microbes or the like after being dumped as waste, and is thus friendly to the global environment.

Owner:KYOTO UNIV

Surface treatment with texturized microcrystalline cellulose microfibrils for improved paper and paper board

The present invention relates to the production of texturized microcrystalline cellulose from raw pulp material. This texturized microcrystalline cellulose can then be used for surface treatment of paper or paper board. Additionally, the texturized microcrystalline cellulose may be used as a starting material for production of paper or paper board.

Owner:INT PAPER CO

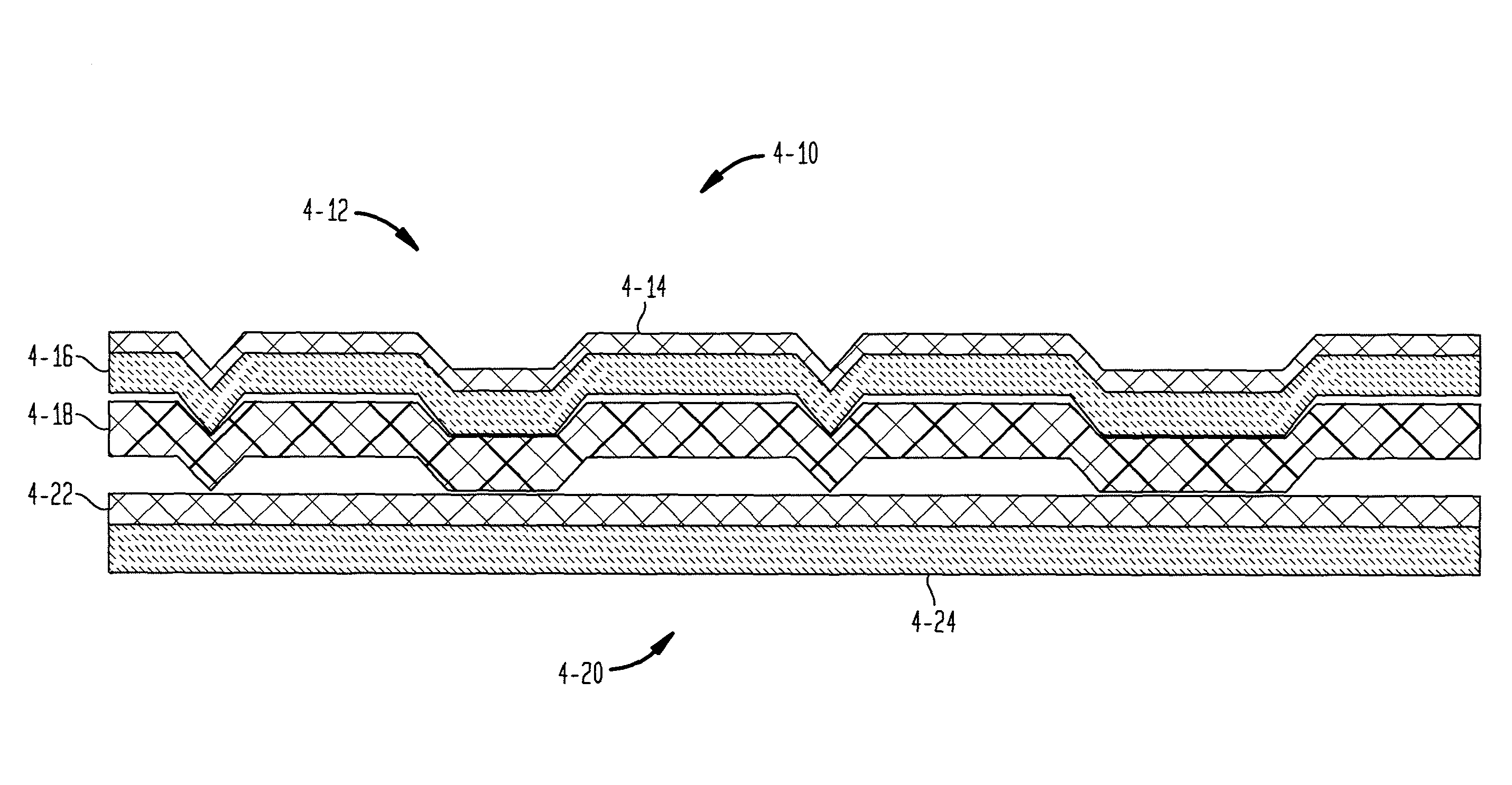

Belt-creped, variable local basis weight multi-ply sheet with cellulose microfiber prepared with perforated polymeric belt

ActiveUS20120021178A1High absorbency (SAT)Eliminate needMechanical working/deformationLayered productsPaper towelEngineering

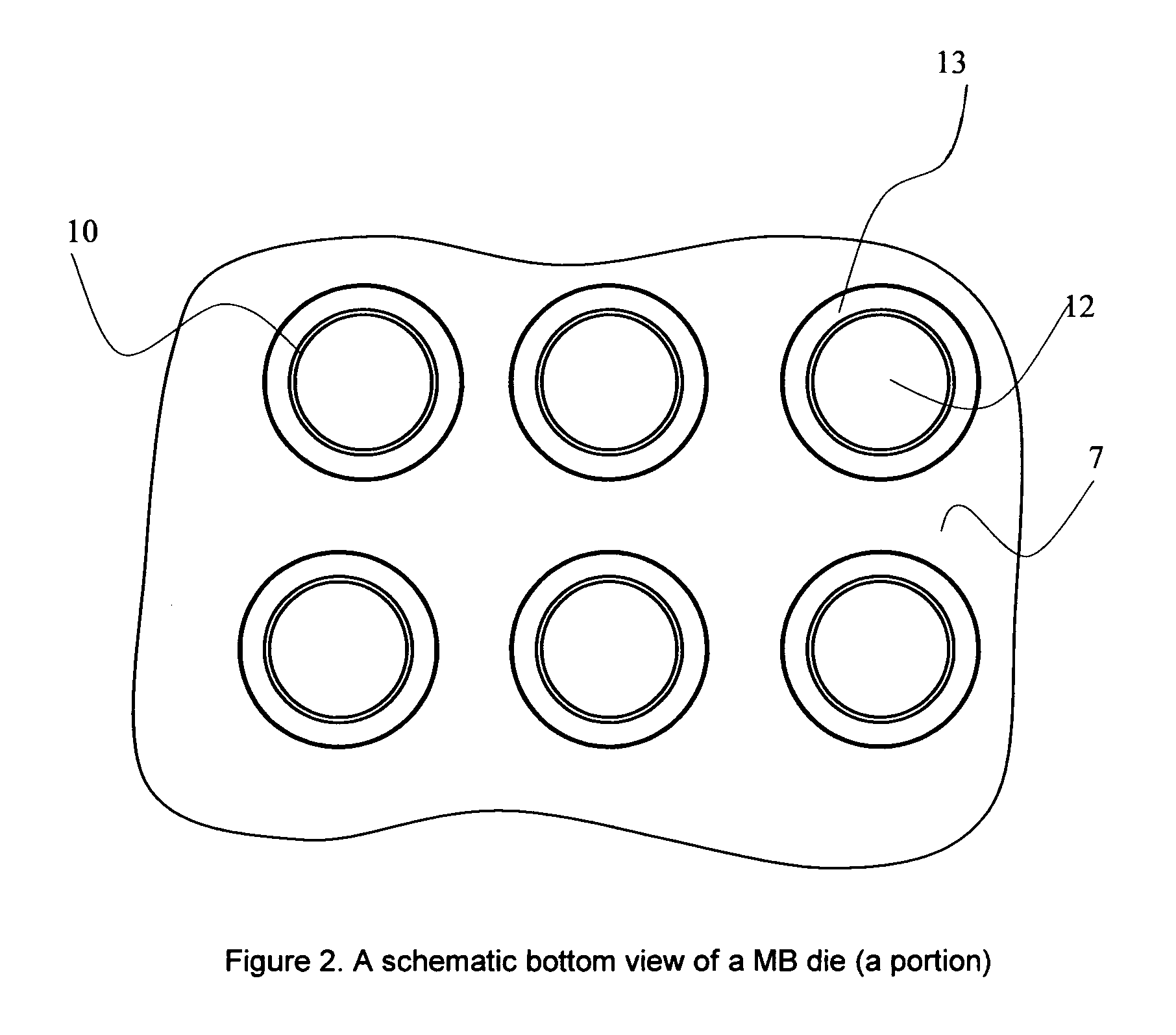

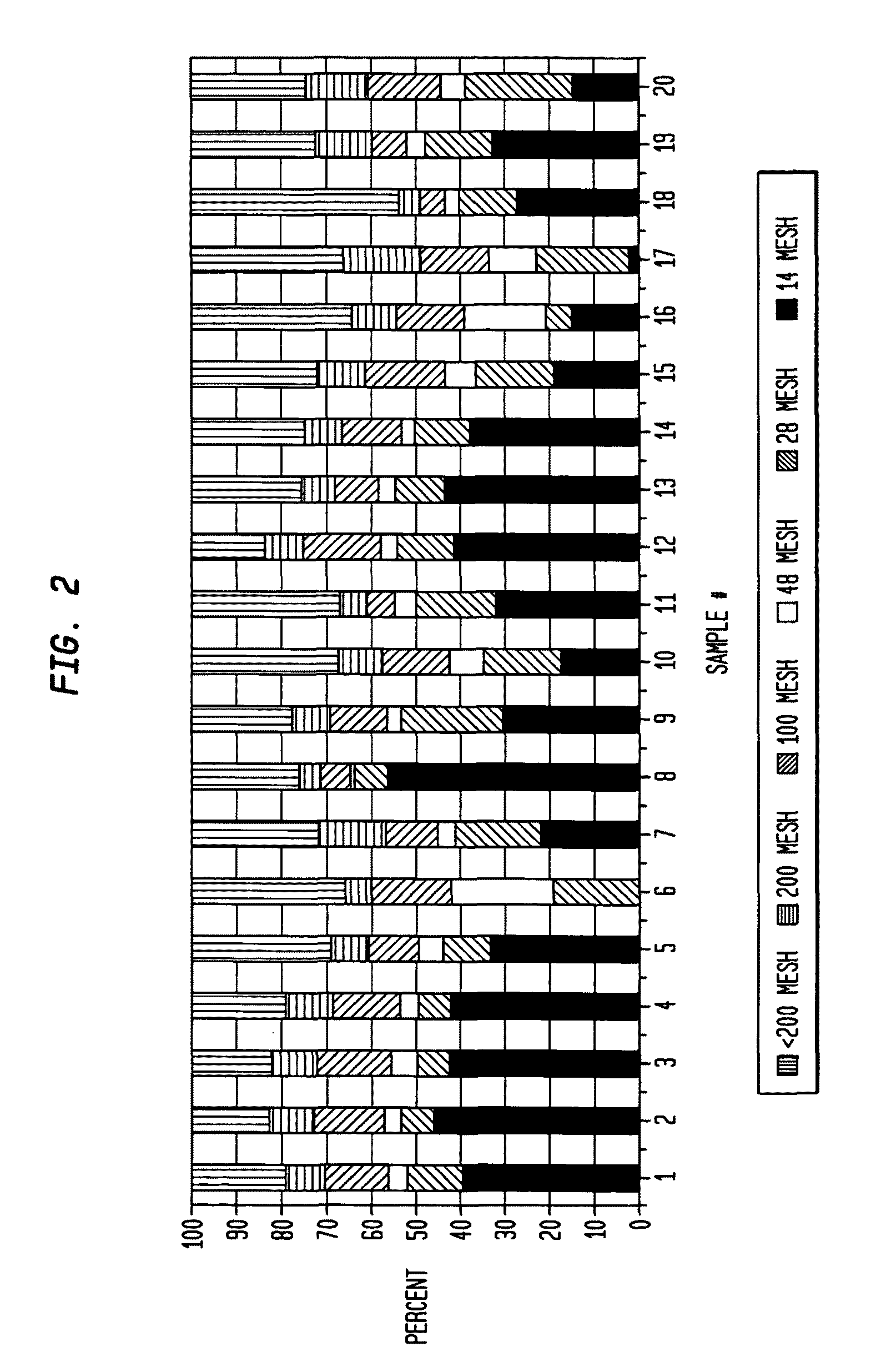

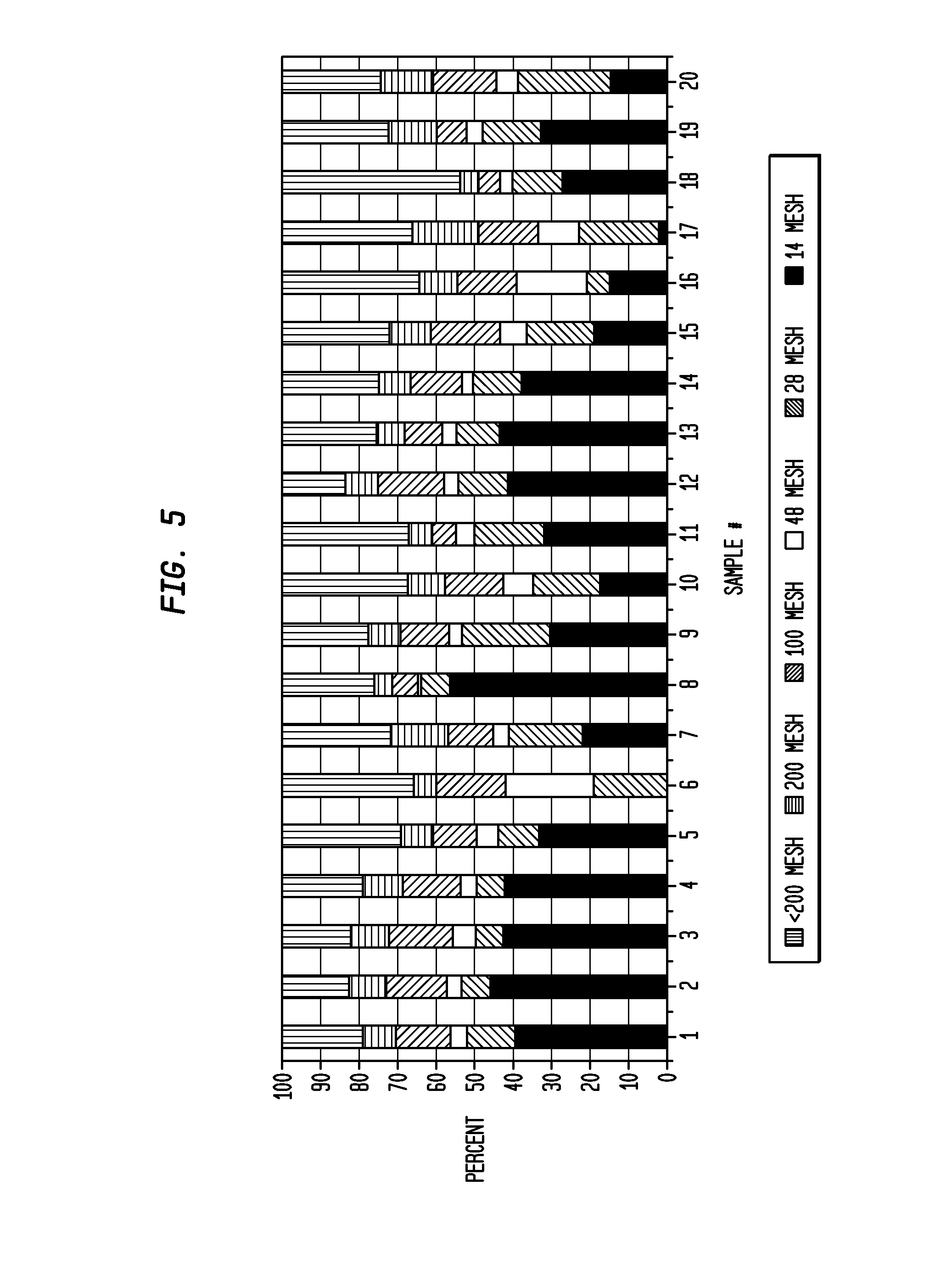

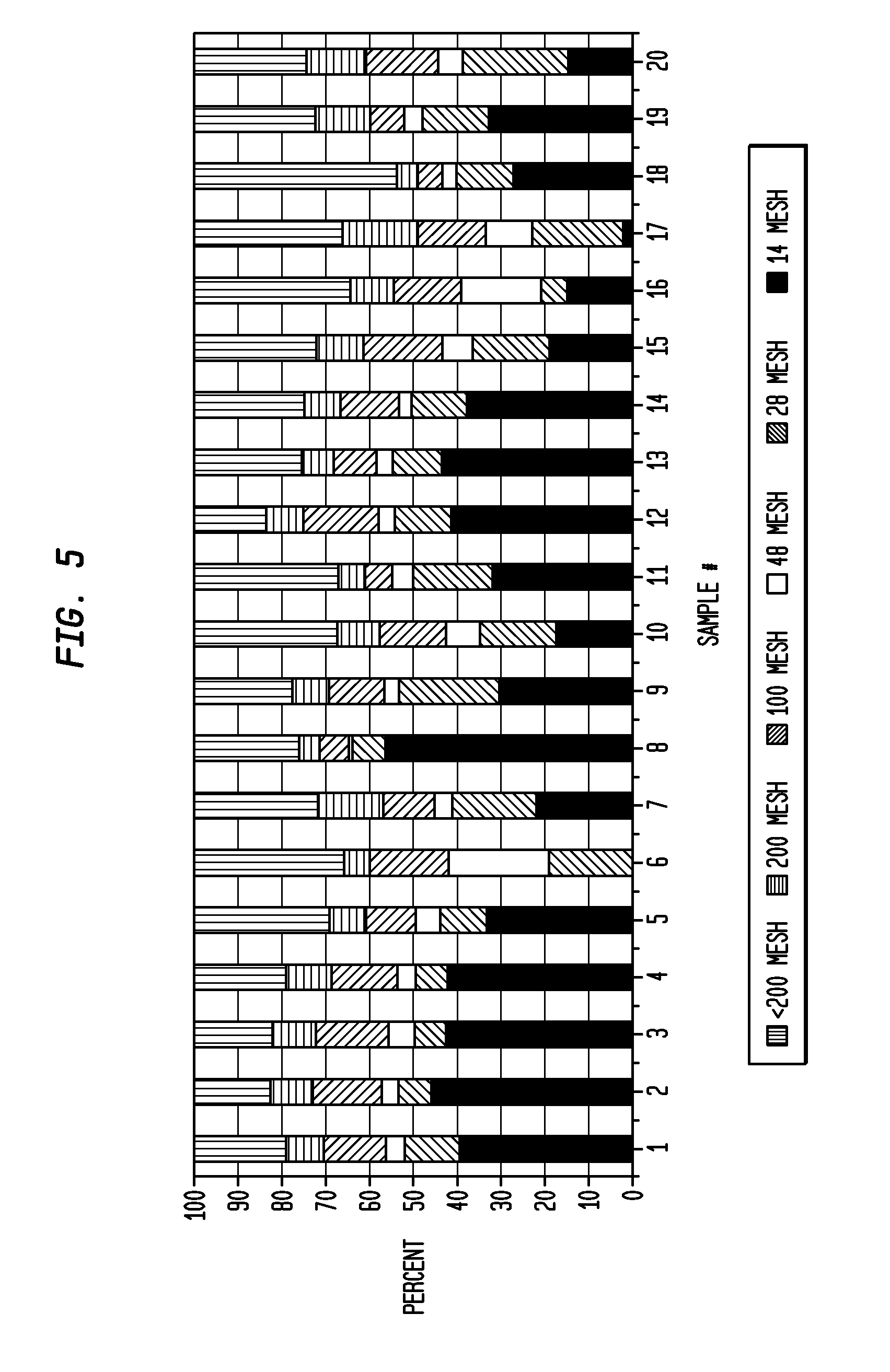

A multi-ply absorbent sheet includes at least a first and second ply bonded together. In one construction, the first and second ply are provided with from about 90% by weight to about 25% by weight pulp-derived papermaking fiber and from about 10% to about 75% by weight fibrillated regenerated cellulosic microfiber having a characteristic CSF value of less than 175 ml; the sheet having a caliper of from 180-250 mils / 8 sheets and exhibiting a wipe-dry time of less than 20 seconds, an SAT capacity in the range of 350-500 g / m2, an SAT rate in the range of 0.05-0.25 g / s0.5, a CD wet tensile in the range of 400-2500 g / 3″ and a wet / dry CD tensile ratio of from 35% to 60%. The multi-ply sheets are efficient, high capacity wipers and have enough absorbent capacity to be used as ordinary paper towels. Preferred wiper towel products exhibit a differential pore volume for pores under 5 microns in diameter of at least about 75 mm3 / g / micron.

Owner:GPCP IP HLDG LLC

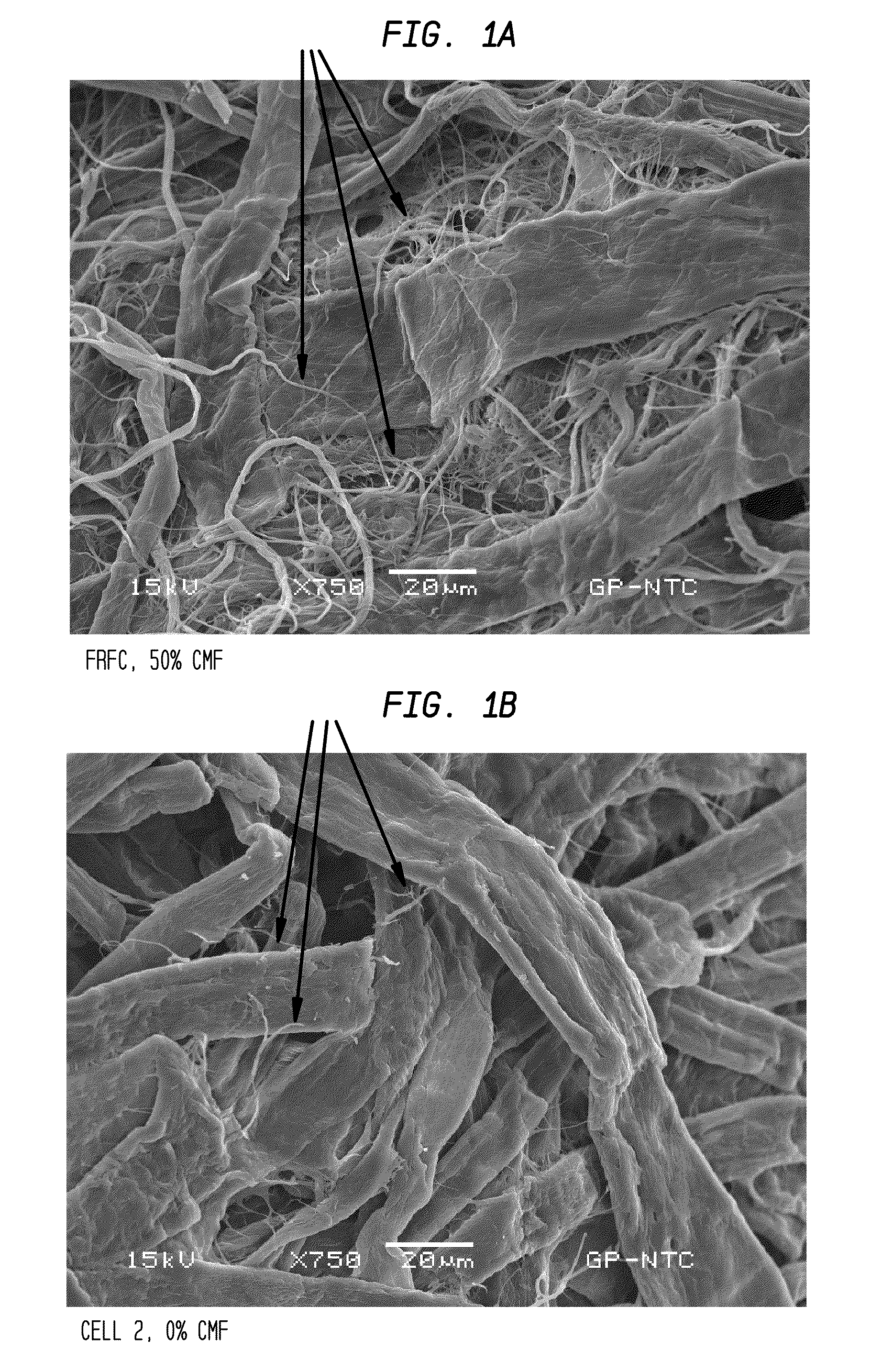

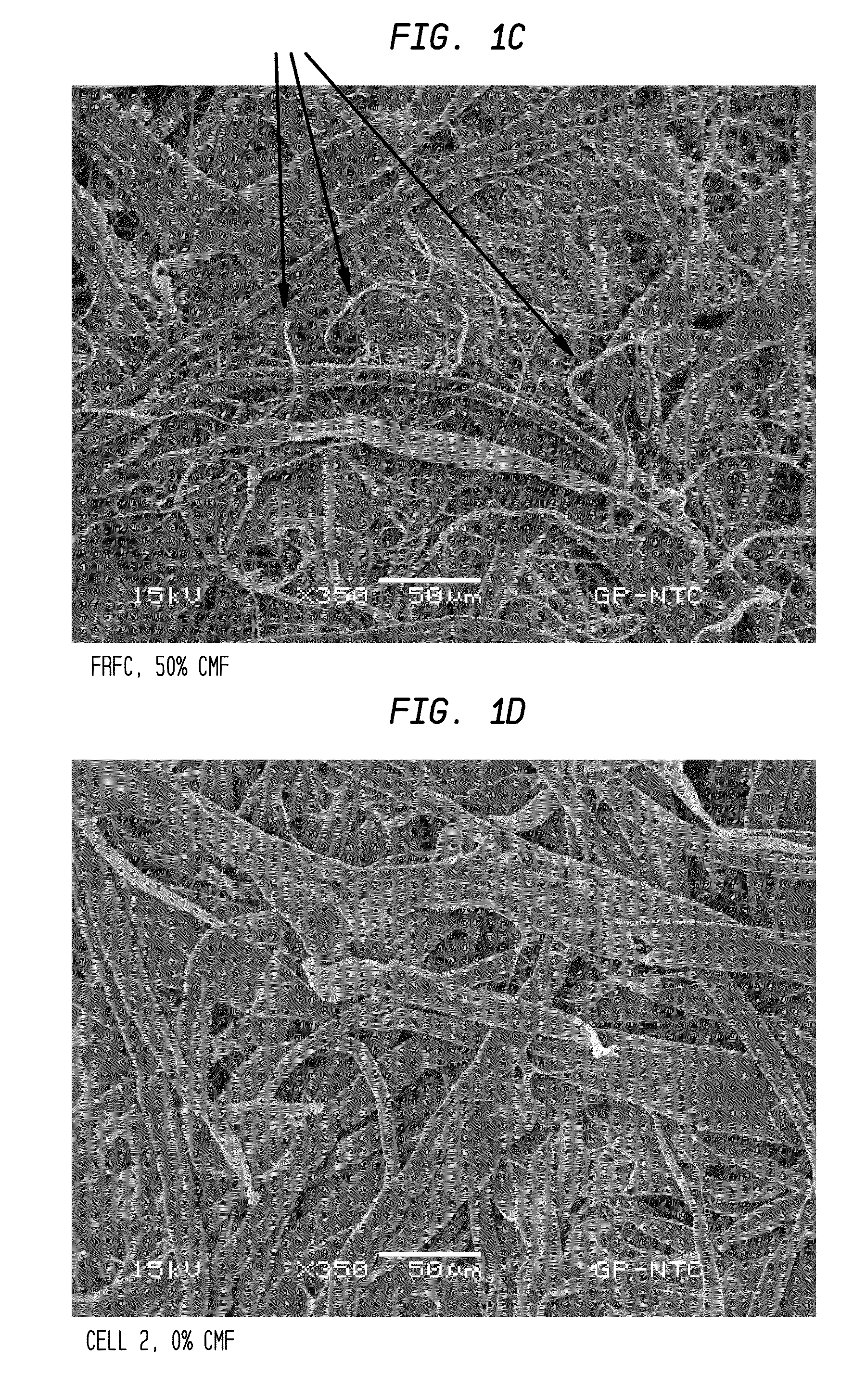

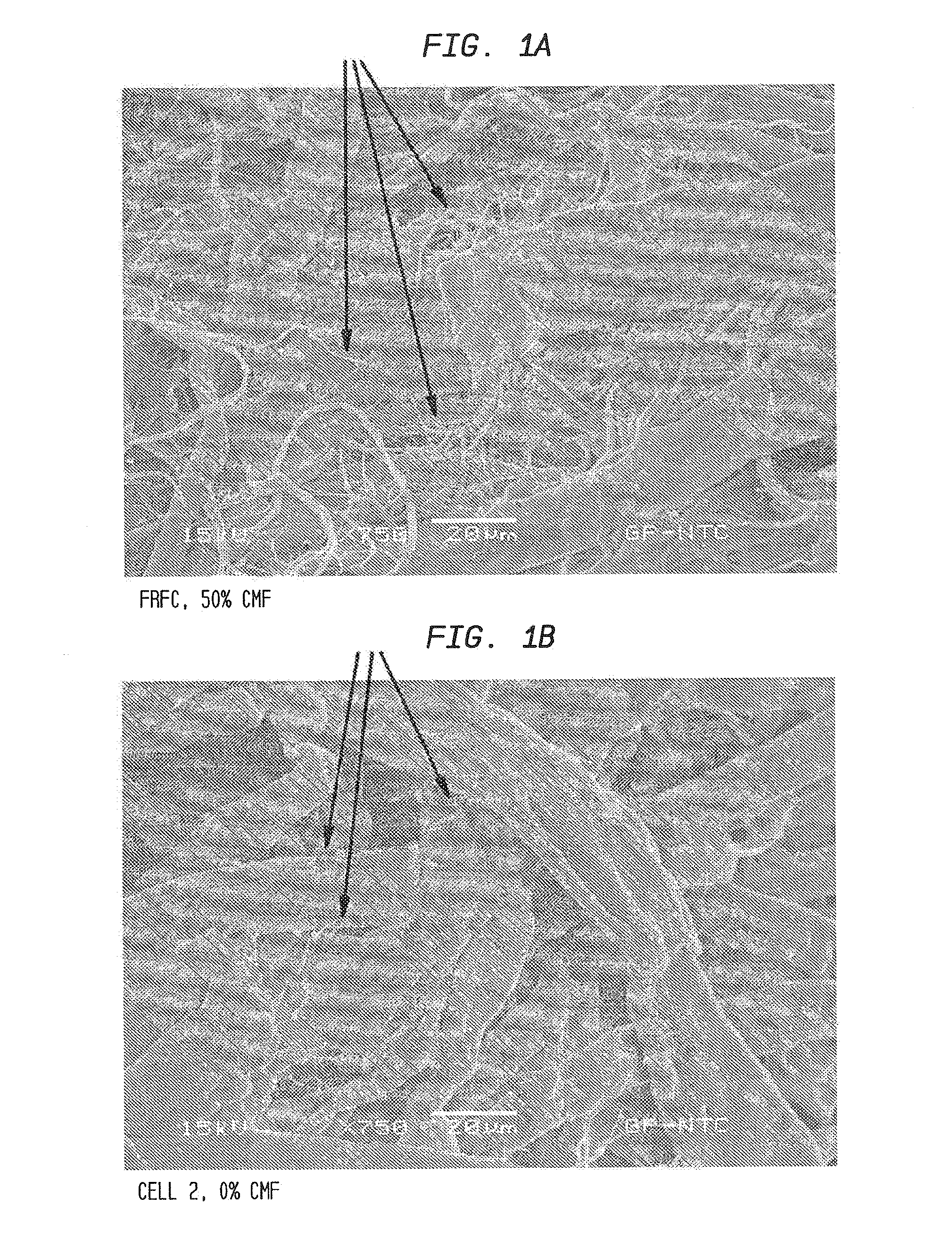

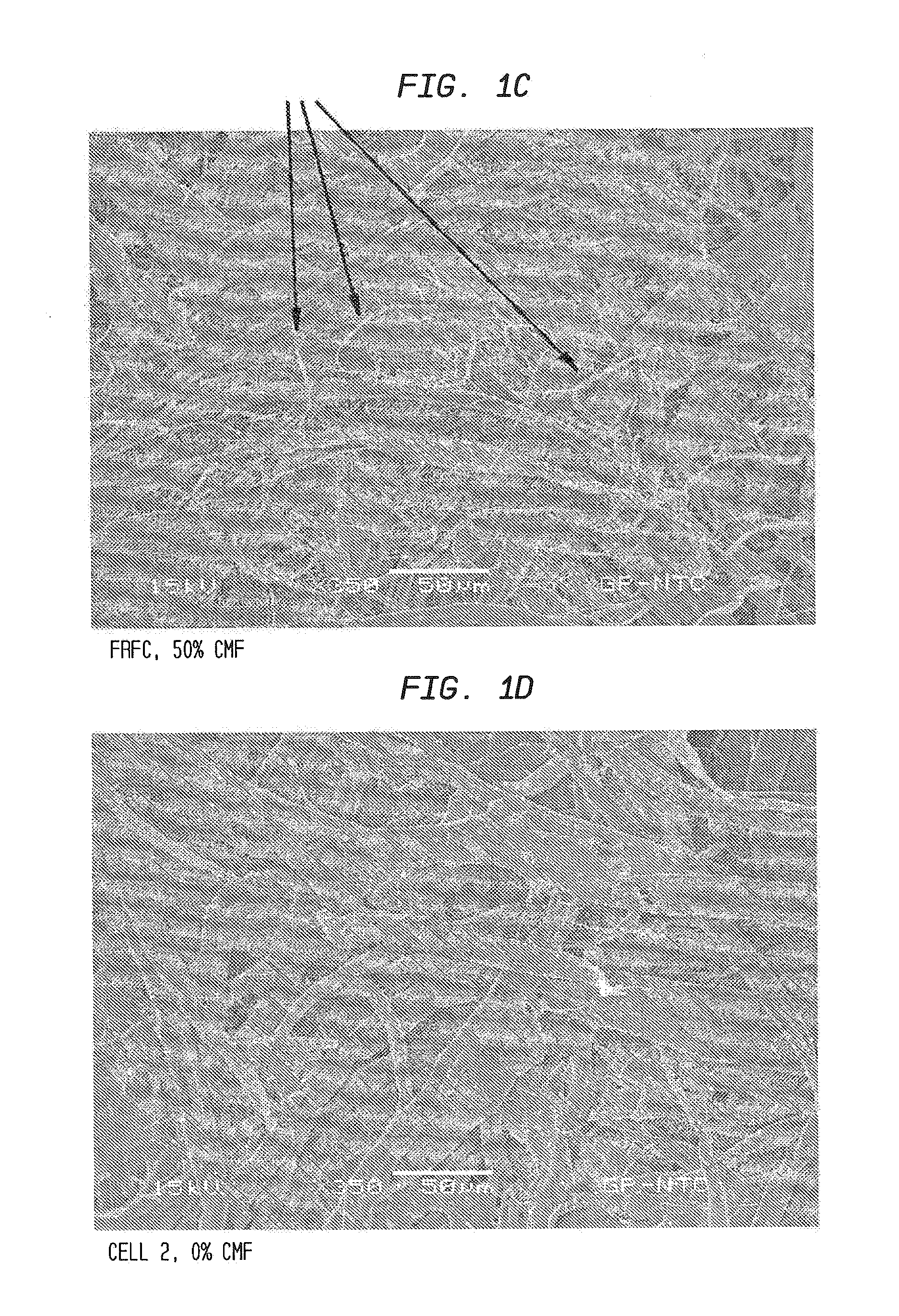

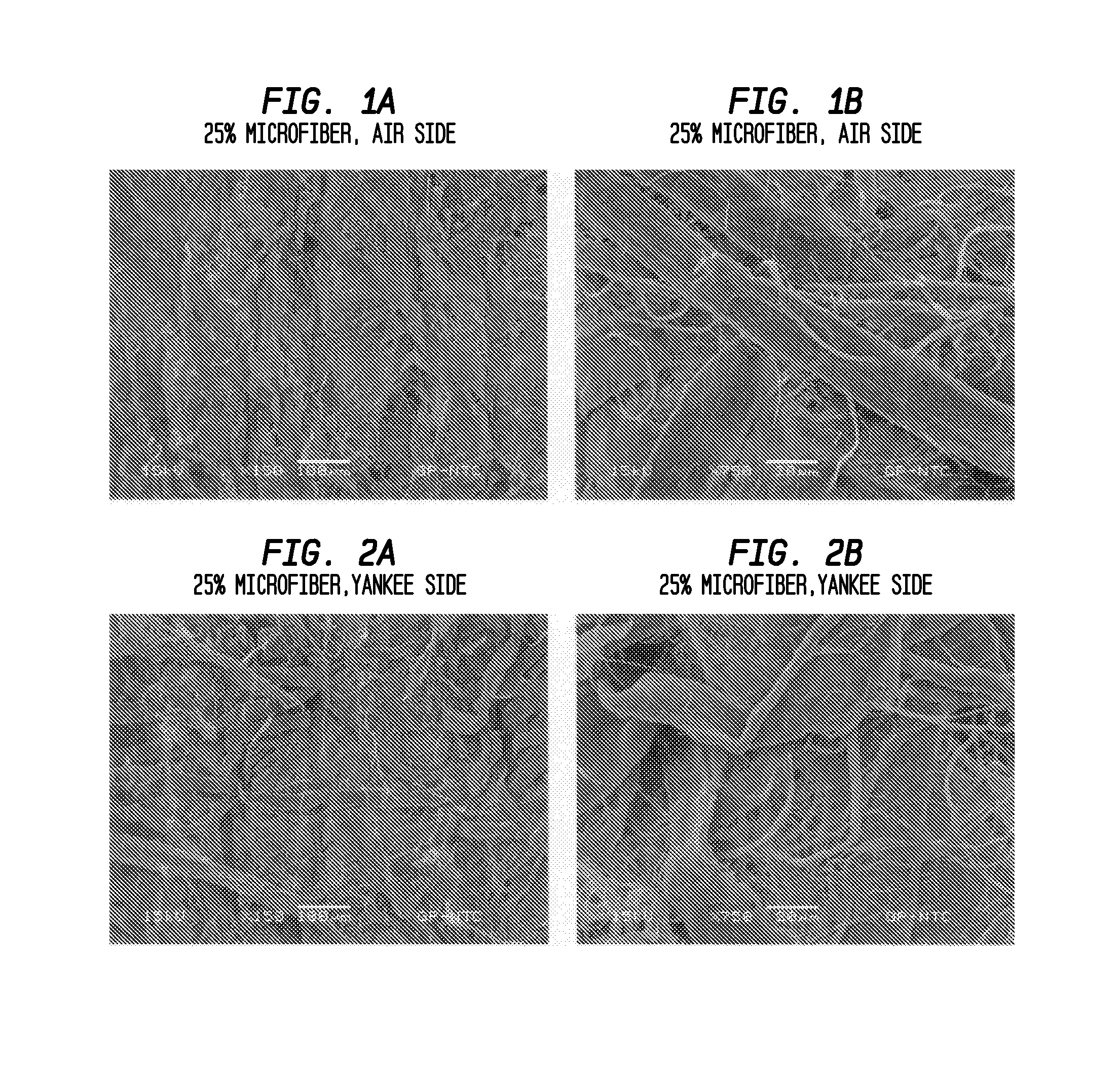

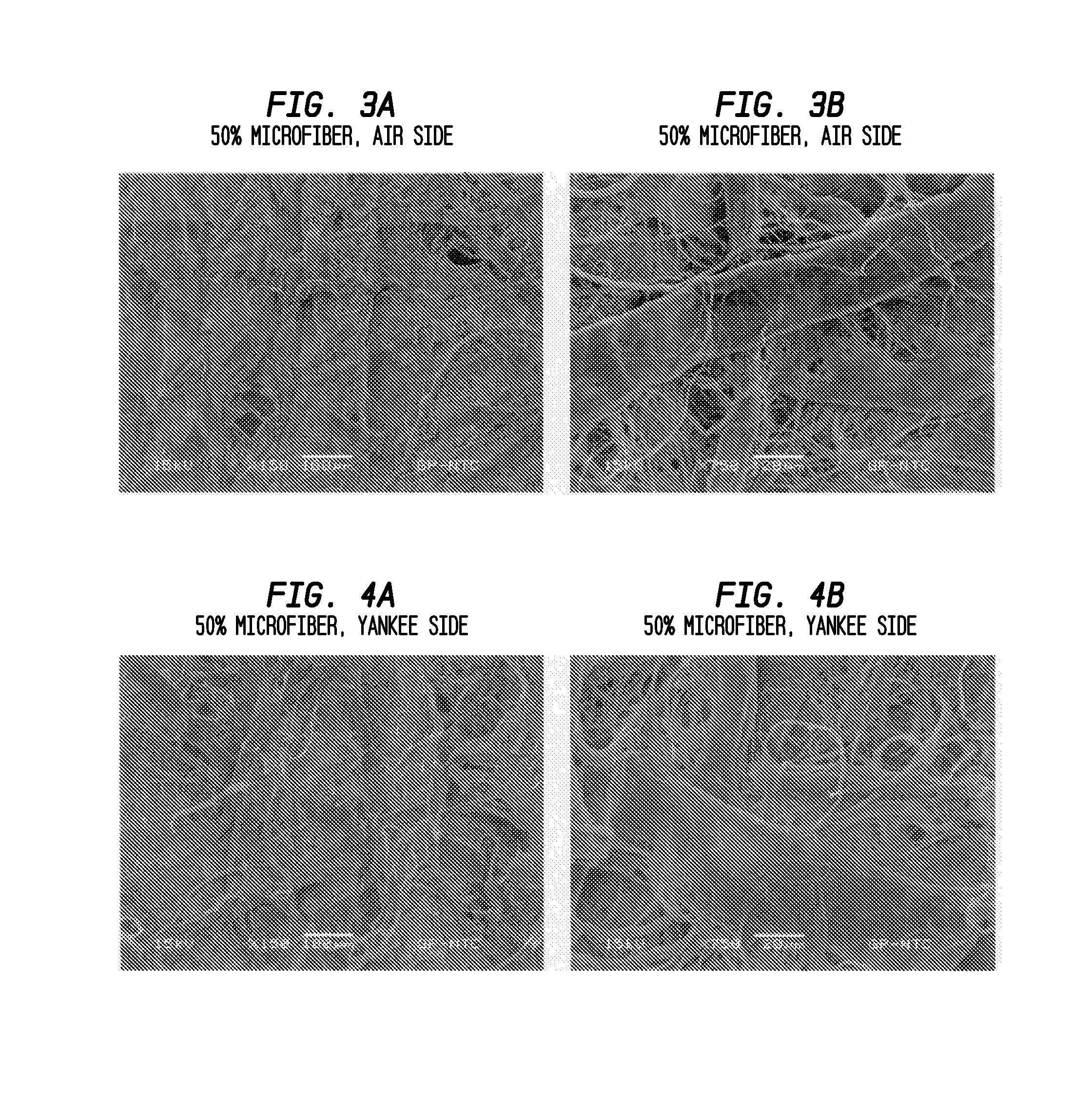

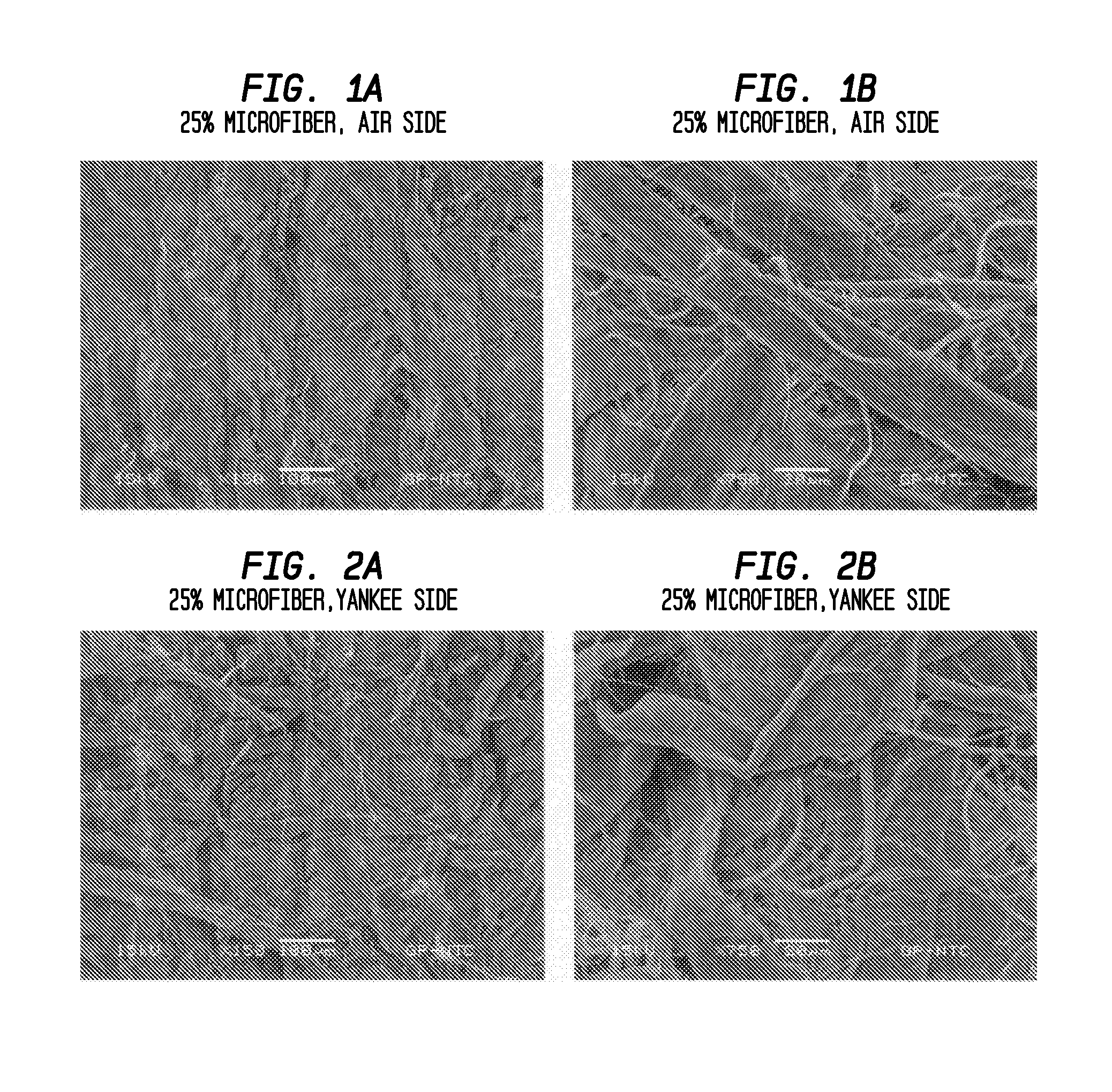

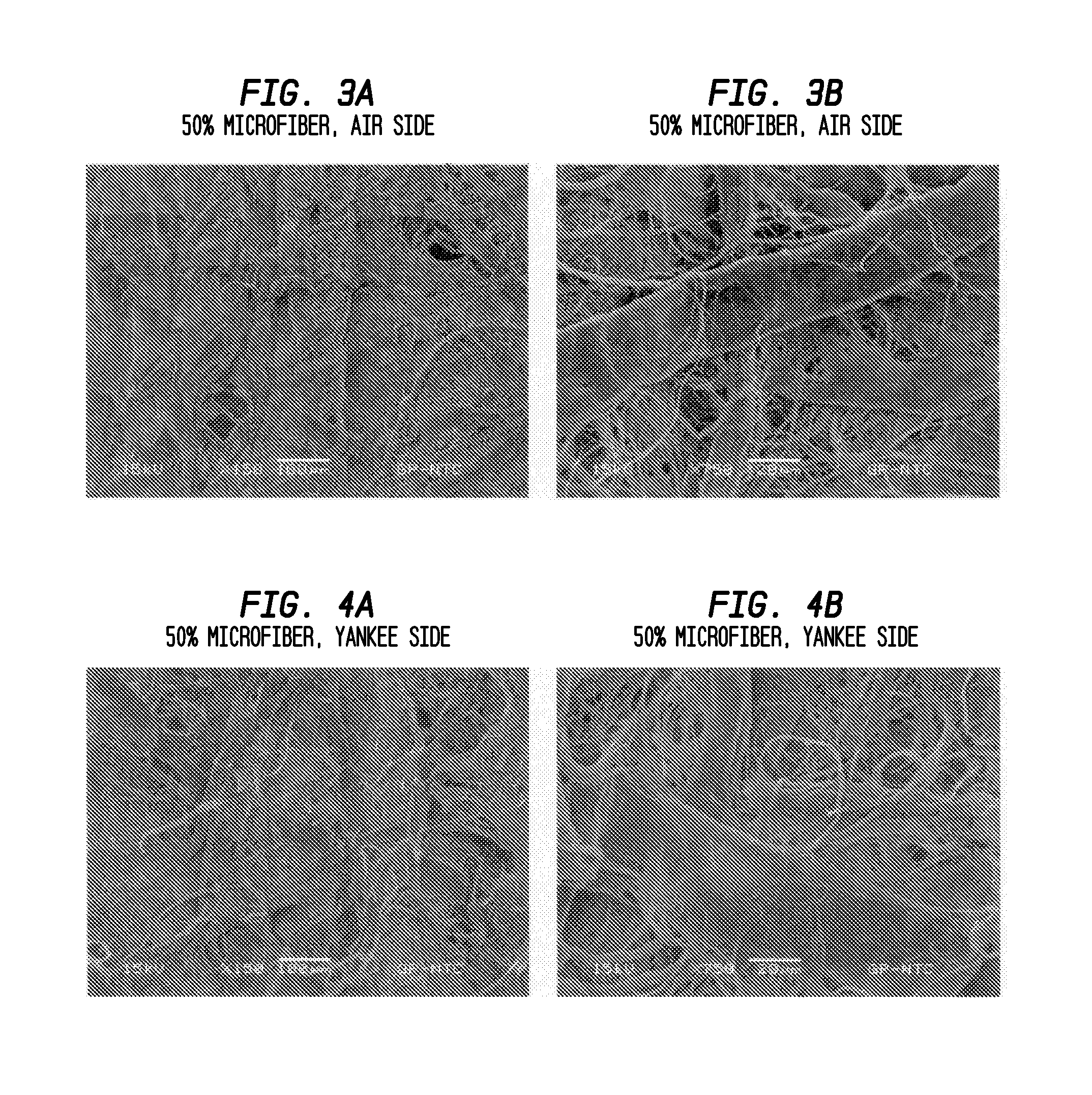

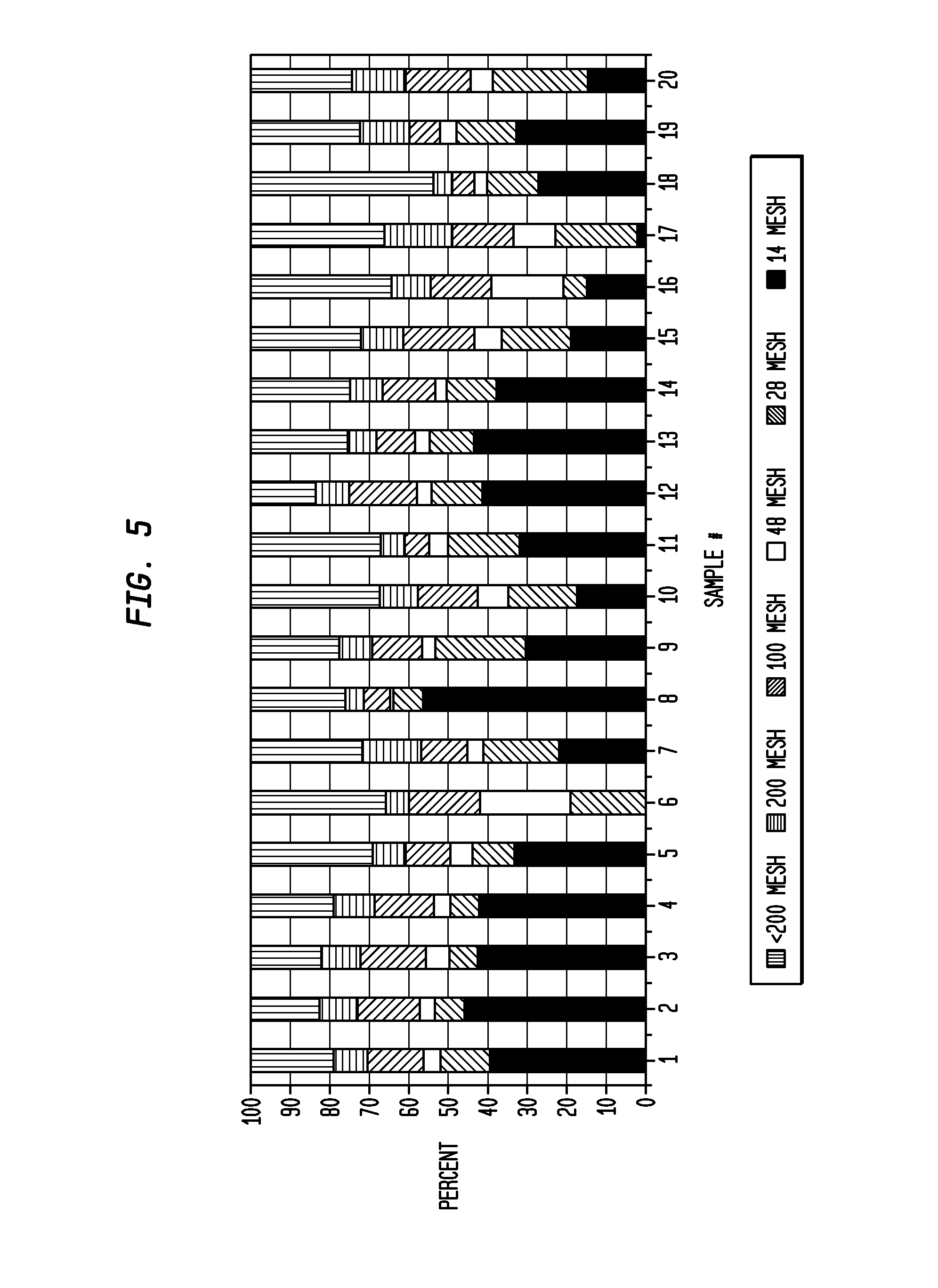

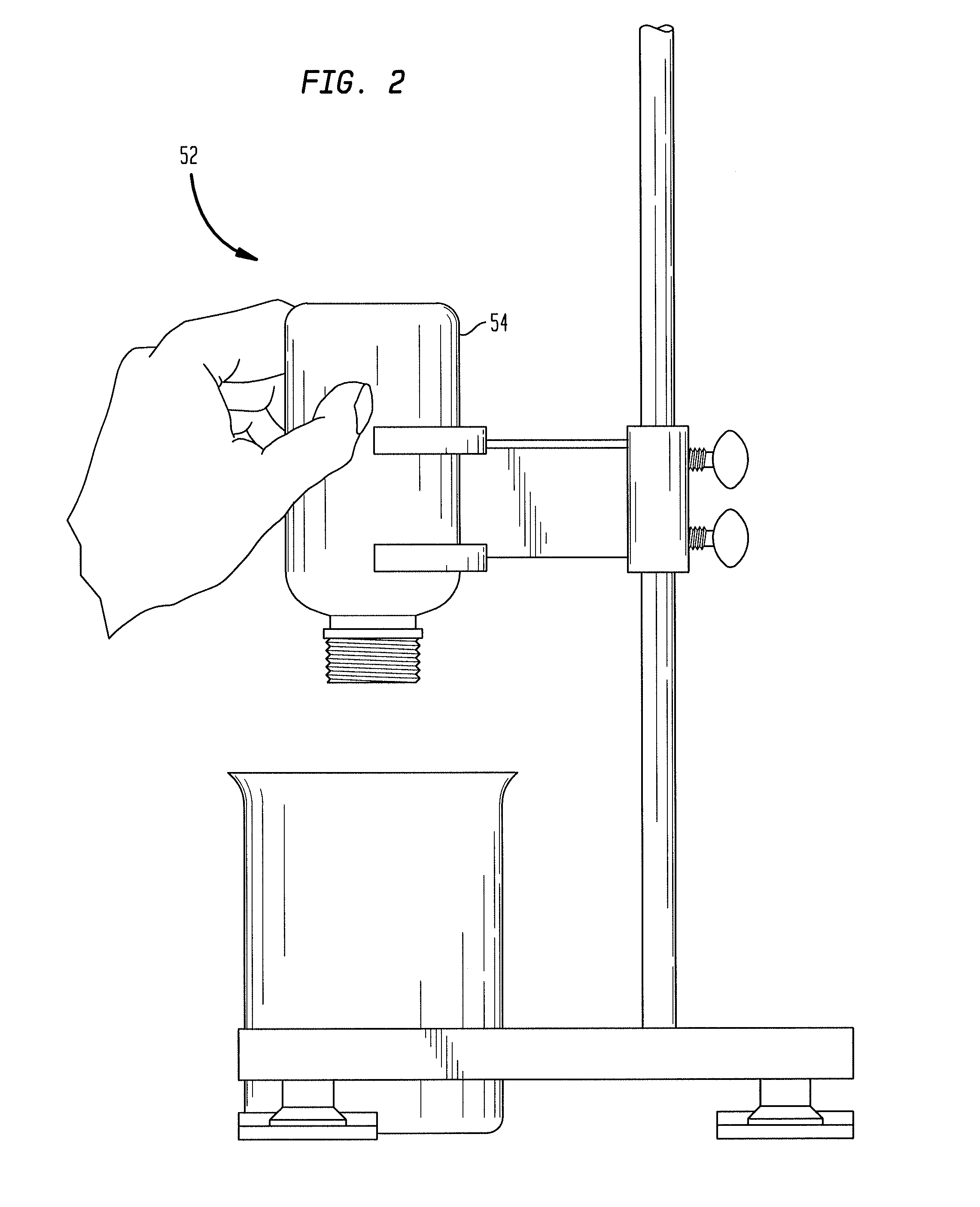

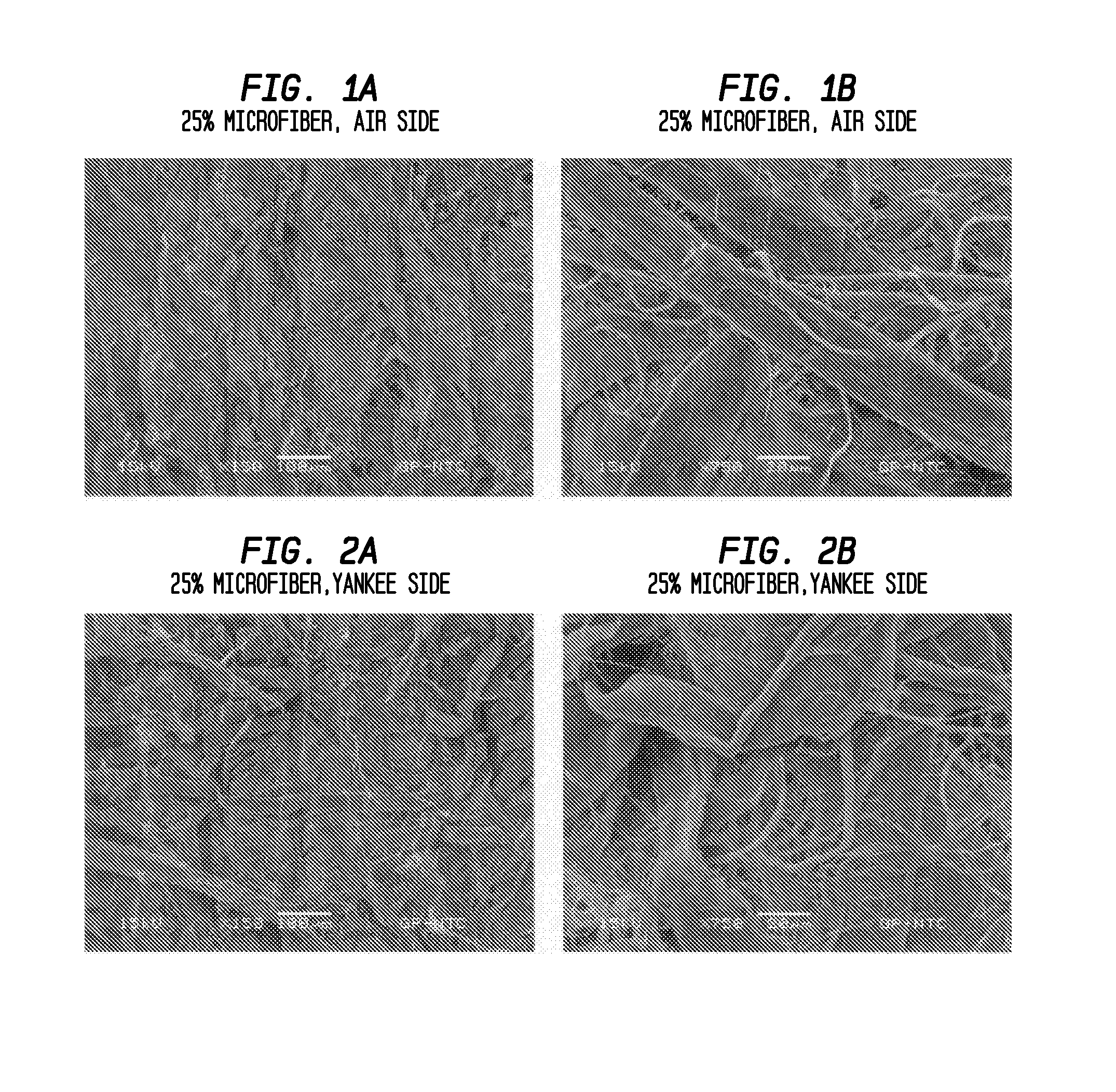

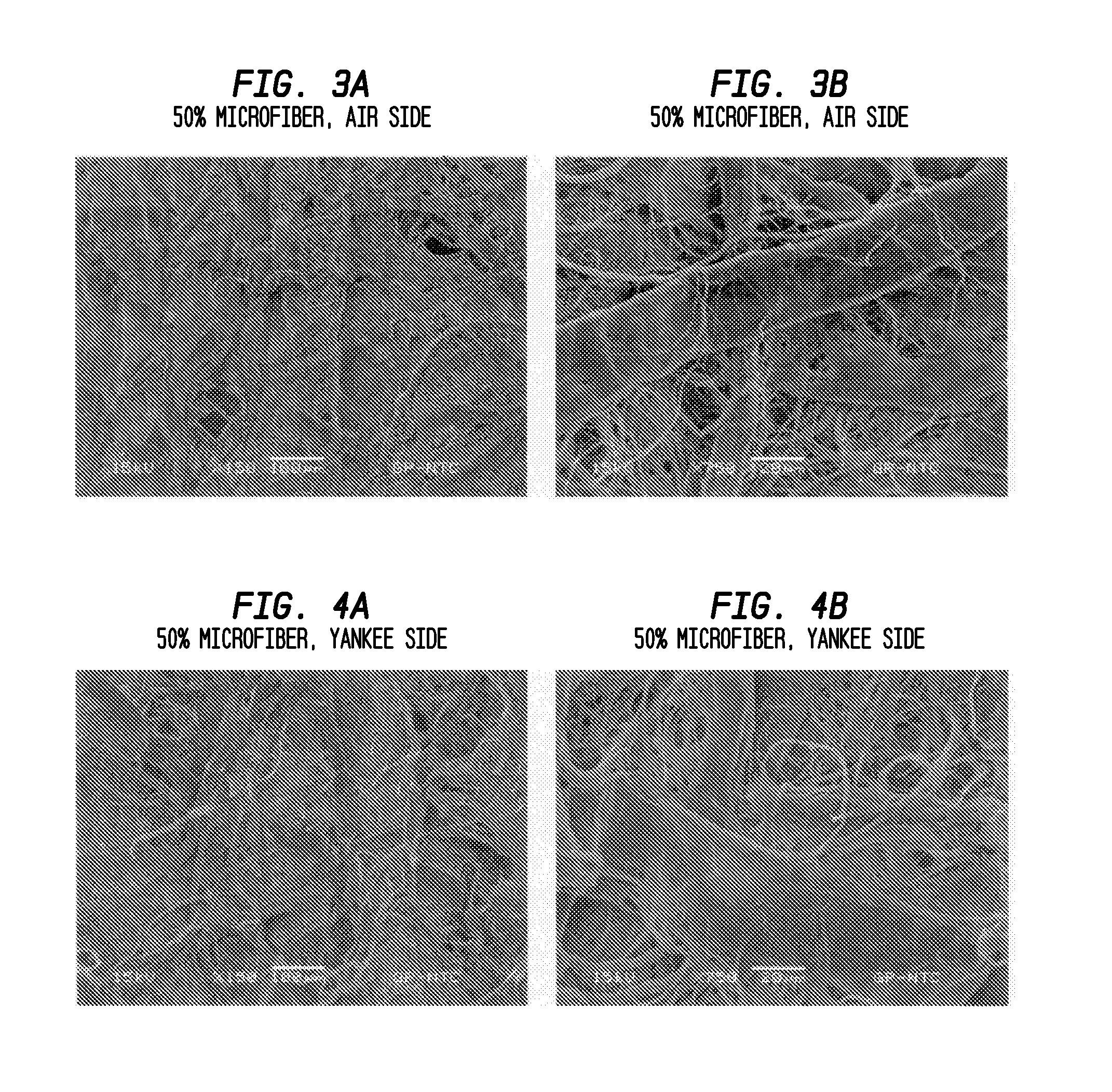

Absorbent sheet incorporating regenerated cellulose microfiber

ActiveUS8187421B2Good flexibilityHigh strengthCellulosic pulp after-treatmentNon-fibrous pulp additionPolymer sciencePapermaking

An absorbent paper sheet includes cellulosic papermaking fiber and up to about 75 percent by weight fibrillated regenerated cellulose microfiber which may be regenerated from a cellulosic dope utilizing a tertiary amine N-oxide solvent or selected ionic liquids. Fibrillation of the microfiber is controlled such that it has a reduced coarseness and a reduced freeness as compared with unfibrillated regenerated cellulose microfiber from which it is made and provides at least one of the following attributes to the absorbent sheet: (a) the absorbent sheet exhibits an elevated SAT value and an elevated wet tensile value as compared with a like sheet prepared without fibrillated regenerated cellulose microfiber; (b) the absorbent sheet exhibits an elevated wet / dry CD tensile ratio as compared with a like sheet prepared without fibrillated regenerated cellulose microfiber; (c) the absorbent sheet exhibits a lower GM Break Modulus than a like sheet having like tensile values prepared without fibrillated regenerated cellulose microfiber; or (d) the absorbent sheet exhibits an elevated bulk as compared with a like sheet having like tensile values prepared without fibrillated regenerated cellulose microfiber.

Owner:GPCP IP HLDG LLC

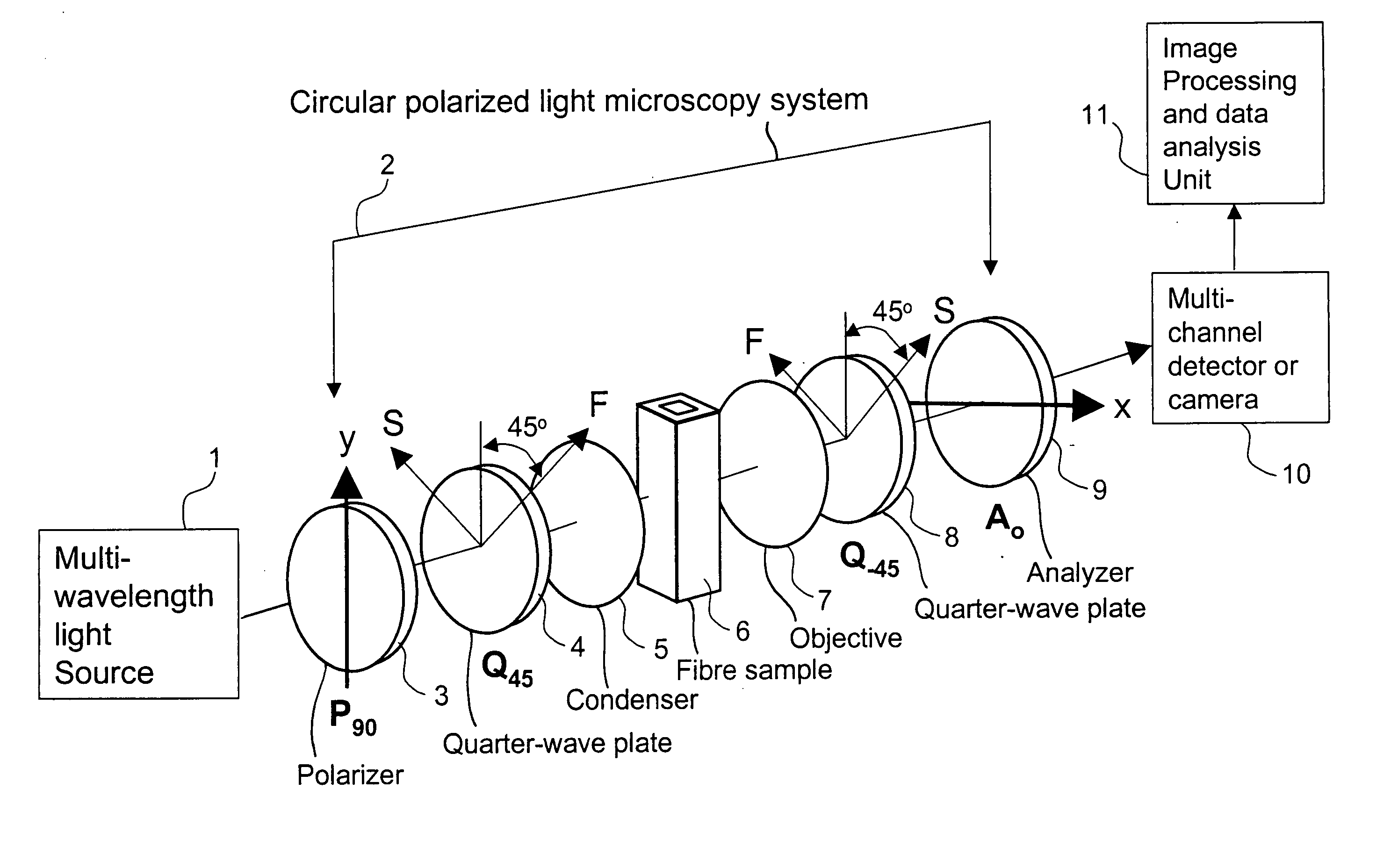

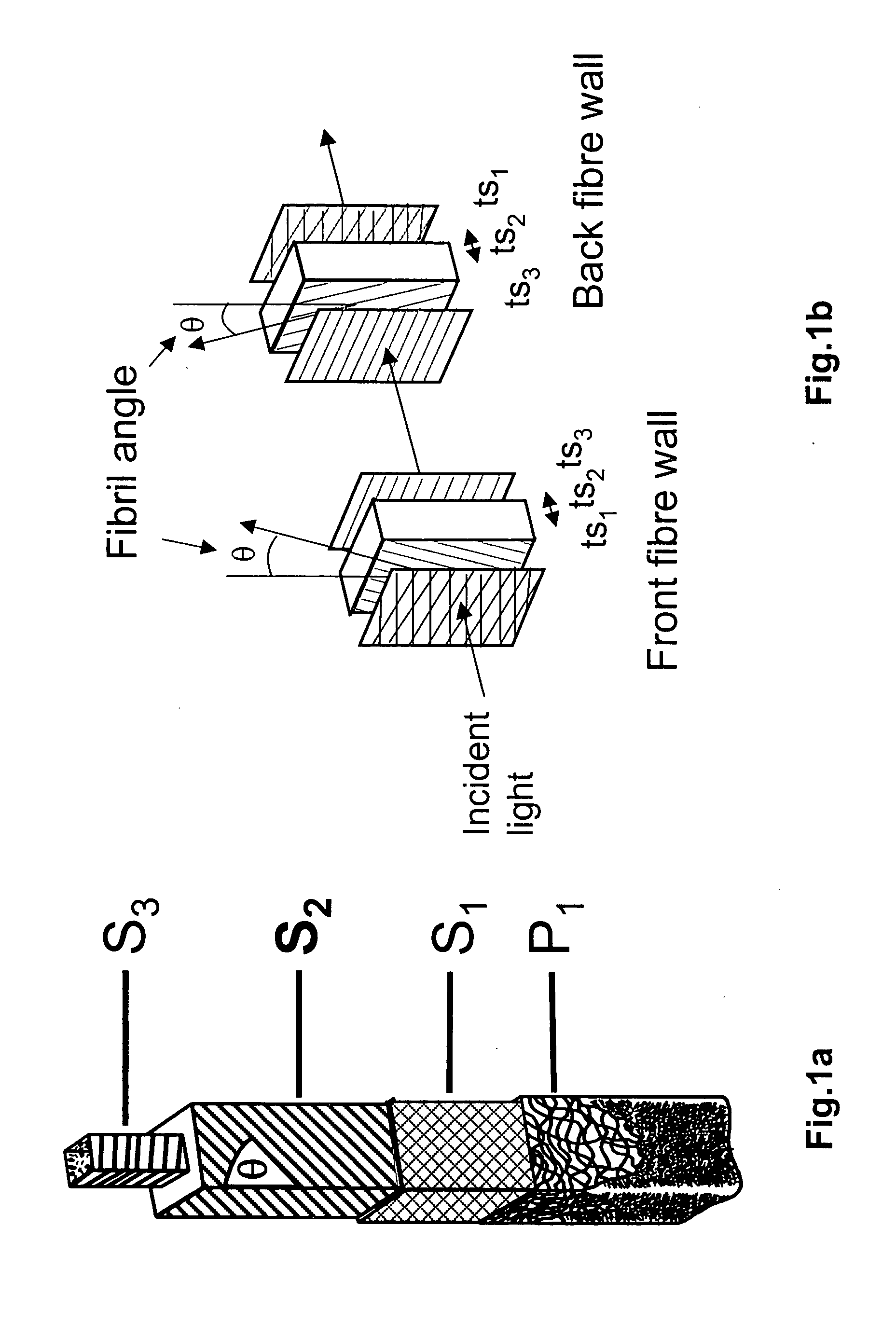

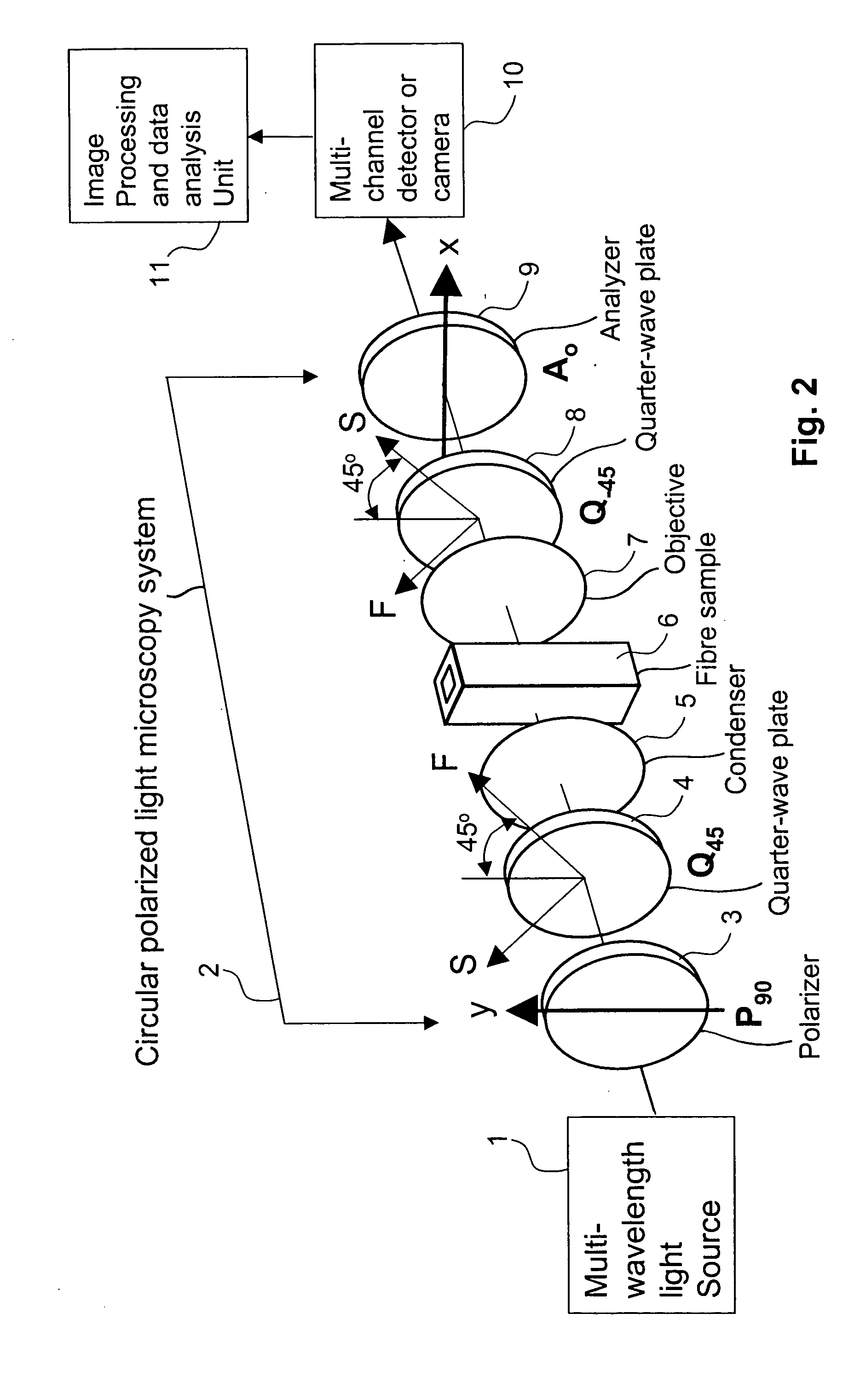

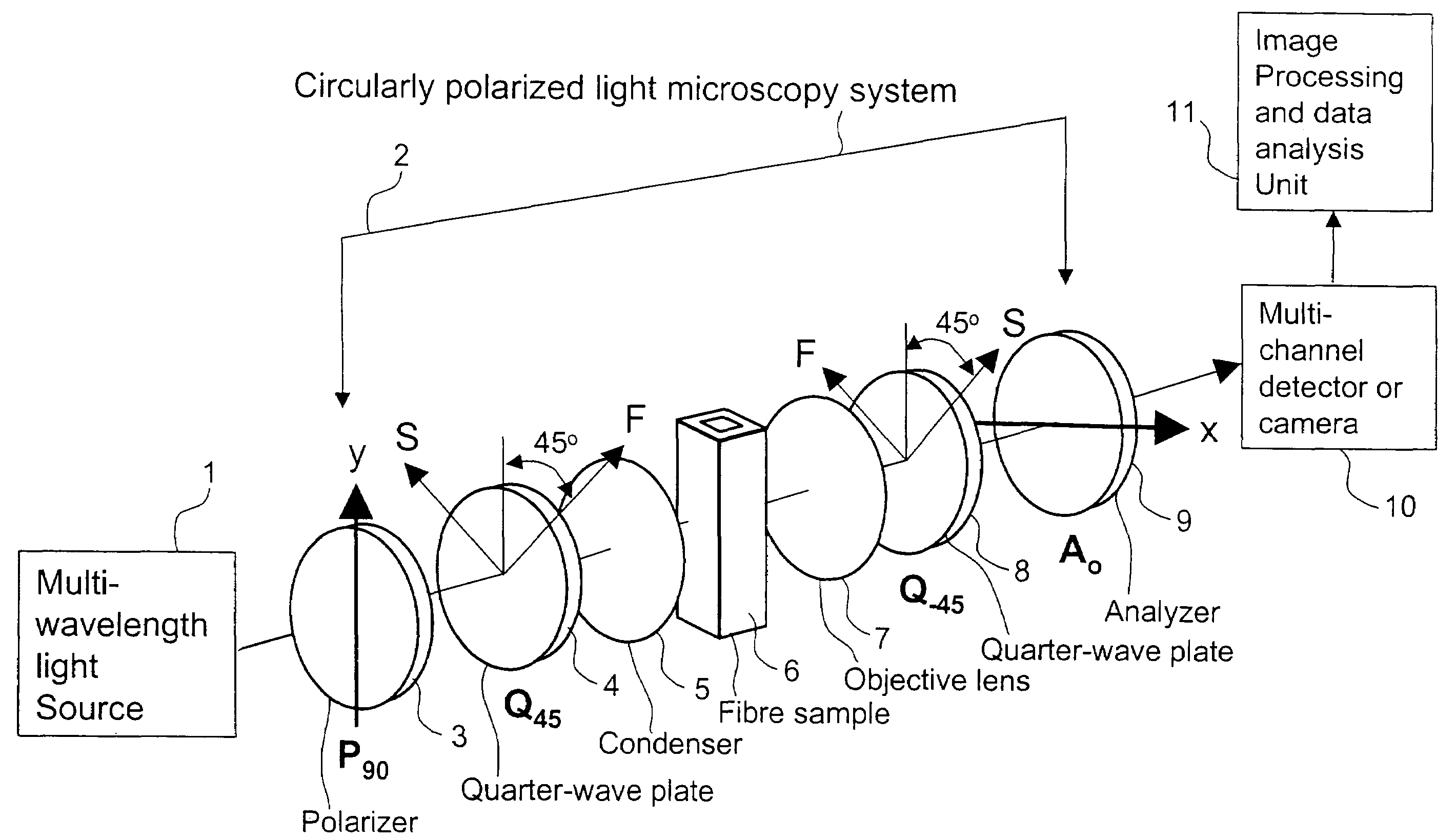

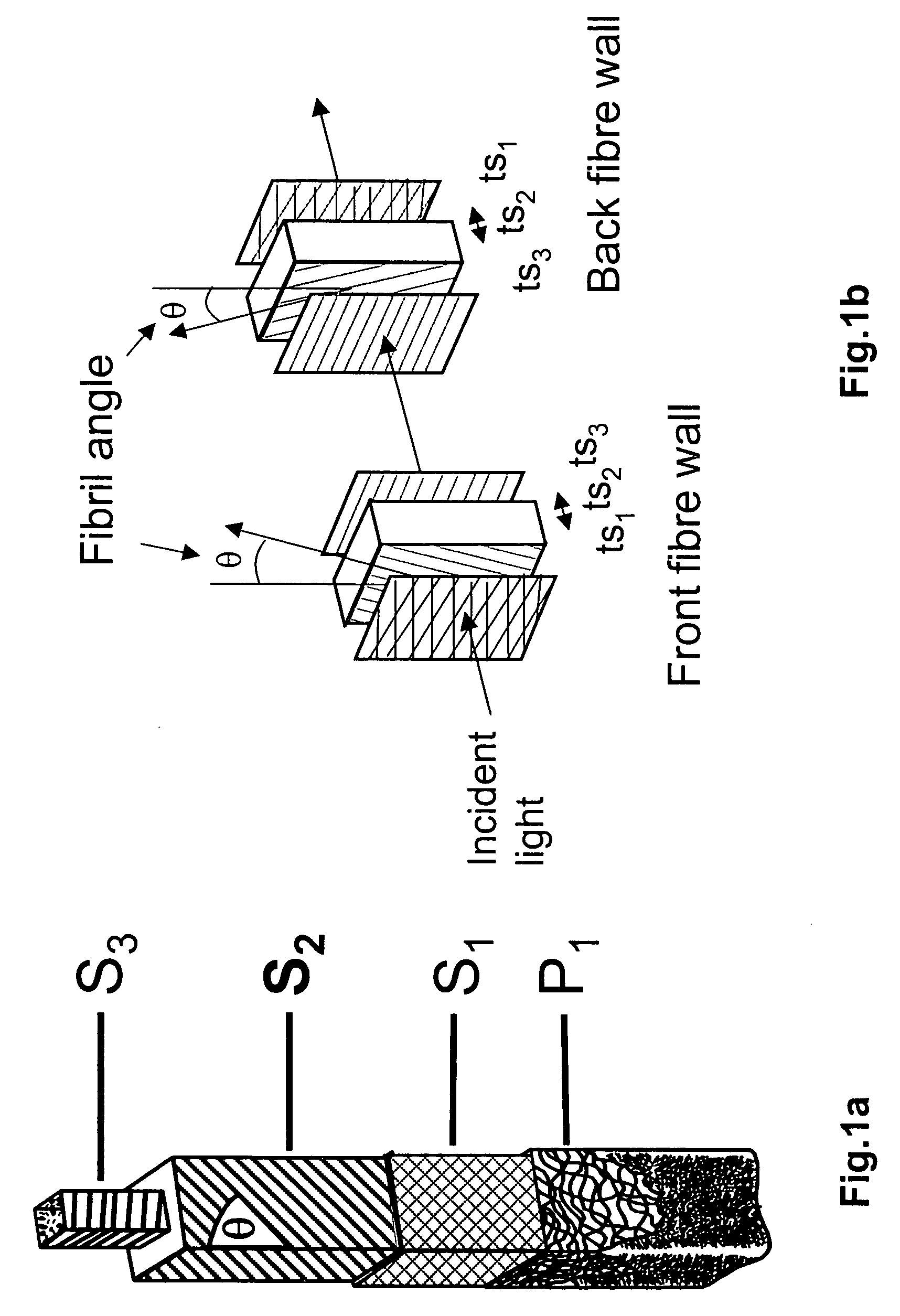

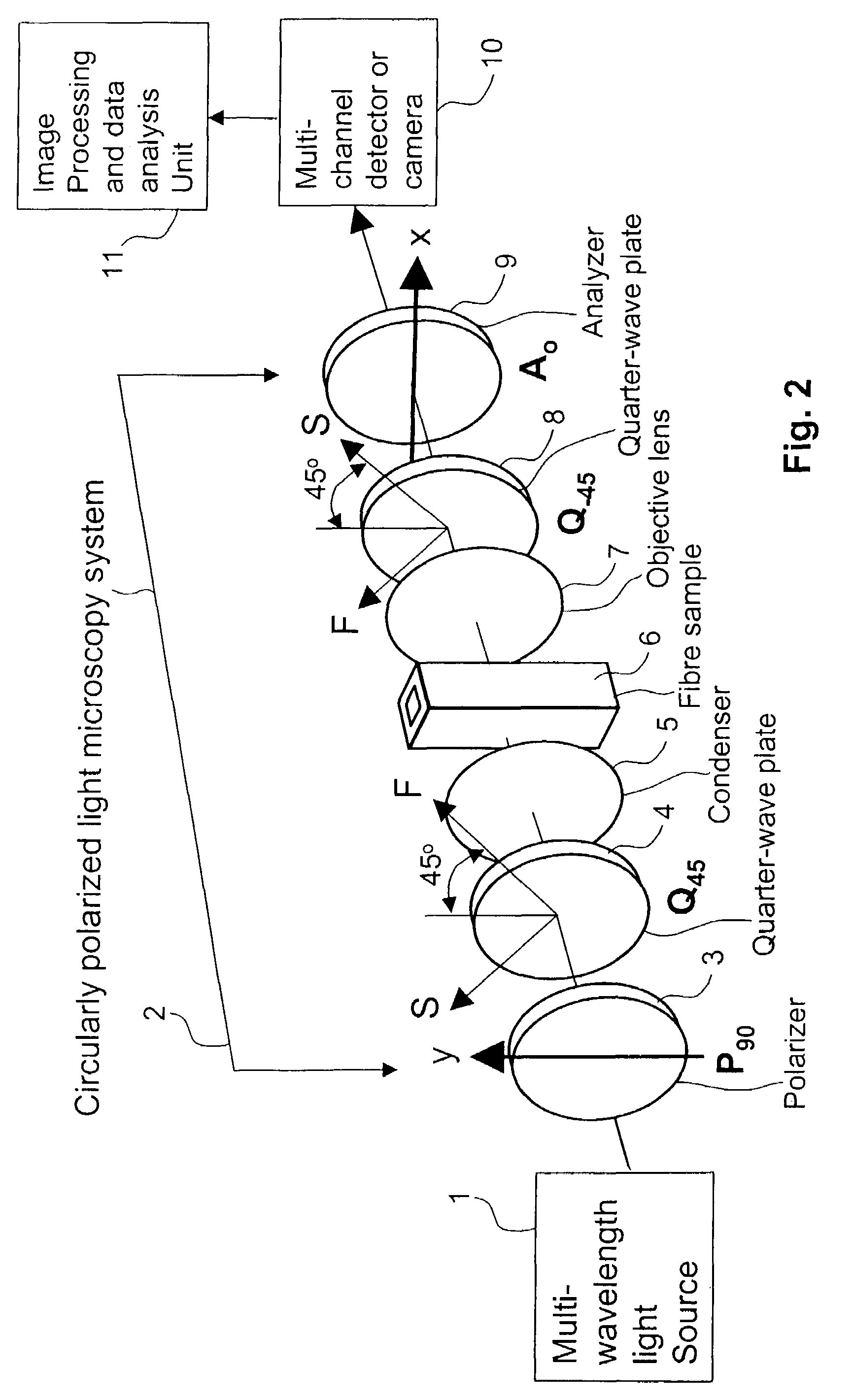

Circular polarized light method and device for determining wall thickness and orientations of fibrils of cellulosic fibres

ActiveUS20050122514A1Polarisation-affecting propertiesPhase-affecting property measurementsFibrilData analysis system

This invention provides a novel, rapid method and device for determining the relative phase retardation of a multi-layered specimen, which is related to the thicknesses of its layers and walls, and the orientations of its optical axes. An intact wood pulp fibre is a typical multi-layered birefringent specimen. This new method is based on the change of polarization of polarized light that passes through a specimen composed of birefringent layers with different optical axis orientations, such as directions of cellulosic microfibrils oriented differently in various layers of wood fibres. In particular, a novel solution is found to relate the emerging light intensity from an intact wood fibre to the incident light intensity, the wavelength of the light, and the relative phase retardations of various layers and orientations of their cellulosic microfibrils, such as fibril angle, in a circular polarized light system. This new method evaluates the transmitted light intensities of multiple predetermined wavelengths simultaneously to determine the optical and physical properties of a multi-layered specimen being measured. A device for determining the relative phase retardation (retardance) of fibre walls and the fibril angle of intact wood fibres in accordance with the presented invention comprises a light source with well defined multi-wavelengths, an achromatic circular polarized light system, appropriate imaging optics, a multi-channel camera such as a digital color camera that has two or more wavelength (color) detection channels, and an image processing and data analysis system. The measurements take advantage of the birefringence of cellulosic microfibrils, and thus require neither sample preparation nor high resolution optics. Specimen alignment is not required as specimens such as wood fibres are evaluated under circular polarized light. Compared with other methods, this invention is more rapid, accurate, and robust. This method can be automated, and implemented in a fibre flow-through system, thus allowing a rapid assessment of wood pulp fibre properties (on-line in real time).

Owner:FPINNOVATIONS INC

Multi-Ply Wiper/Towel Product With Cellulosic Microfibers

ActiveUS20130153164A1High absorbency (SAT)Improve efficiencyMechanical working/deformationCreping adhesives additionCelluloseEngineering

Owner:GPCP IP HLDG LLC

Method of cleaning residue from a surface using a high efficiency disposable cellulosic wiper

A method of cleaning residue from a surface includes providing a disposable cellulosic wiper including a percentage by weight of pulp-derived papermaking fibers. The pulp-derived papermaking fibers have a characteristic scattering coefficient of less than 50 m2 / kg. The wiper also includes a percentage by weight of fibrillated regenerated independent cellulosic microfibers having a number average diameter of less than about 2 microns, and a characteristic Canadian Standard Freeness (CSF) value of less than 175 ml. The microfibers are selected and present in amounts such that the wiper exhibits a scattering coefficient of greater than 50 m2 / kg. The wiper is applied, with a predetermined amount of pressure, to a residue-bearing surface, and the surface is wiped, while applying the predetermined amount of pressure, to remove residue from the surface, such that the surface has less than 1 g / m2 of residue after being wiped under the predetermined amount of pressure.

Owner:GPCP IP HLDG LLC

Method of cleaning residue from a surface using a high efficiency disposable cellulosic wiper

A method of cleaning residue from a surface includes providing a disposable cellulosic wiper including a percentage by weight of pulp-derived papermaking fibers. The pulp-derived papermaking fibers have a characteristic scattering coefficient of less than 50 m2 / kg. The wiper also includes a percentage by weight of fibrillated regenerated independent cellulosic microfibers having a number average diameter of less than about 2 microns, and a characteristic Canadian Standard Freeness (CSF) value of less than 175 ml. The microfibers are selected and present in amounts such that the wiper exhibits a scattering coefficient of greater than 50 m2 / kg. The wiper is applied, with a predetermined amount of pressure, to a residue-bearing surface, and the surface is wiped, while applying the predetermined amount of pressure, to remove residue from the surface, such that the surface has less than 1 g / m2 of residue after being wiped under the predetermined amount of pressure.

Owner:GPCP IP HLDG LLC

High softness, high durability bath tissues with temporary wet strength

ActiveUS9309627B2Improve tissue performanceGood flexibilityPersonal careReinforcing agents additionWet strengthCalipers

A multi-ply bath tissue having no more than three plies and no fewer than two plies. The multi-ply tissue has a basis weight of from about 20 to about 35 lbs per 3000 sq foot ream and includes from about 3% to about 50% cellulosic microfiber, from about 50% to about 97% wood pulp fibers, has a geometric mean (GM) dry tensile of from about 17 to 80 g / 3 in. per pound of basis weight, a cross-machine direction (CD) dry tensile of between about 30 to about 60 g / 3 in. per pound of basis weight, and sufficient temporary wet strength resin to provide an initial Finch Cup CD wet tensile of from about 2.5 to about 20 g / 3 in. per pound of basis weight. The initial Finch Cup CD wet tensile decays to less than 65% of the initial value in less than fifteen minutes after immersion in water. The product has a caliper of at least 5 mils per 8 sheets per pound of basis weight.

Owner:GPCP IP HLDG LLC

High efficiency disposable cellulosic wiper

A disposable cellulosic wiper includes a percentage by weight of pulp-derived papermaking fibers, and a percentage by weight of regenerated independent cellulosic microfibers having a number average diameter of less than about 2 microns and a characteristic Canadian Standard Freeness (CSF) value of less than 175 ml. The microfibers are selected and present in amounts such that the wiper exhibits a relative water residue removal efficiency of at least 150% as compared with a like sheet without regenerated independent cellulosic microfibers.

Owner:GPCP IP HLDG LLC

High strength material using cellulose microfibrils

The present invention relates to a high strength material and a high strength molded article including 65 to 100 wt. % of cellulose microfibrils; and products comprising these. The material, which is lightweight and has a very high strength, can be used for various purposes and can be produced by recycling wastepaper, used cloth and the like. Furthermore, by appropriately selecting the type and / or amount of binder, the material comprising microfibrils as a main component can be decomposed by microbes or the like after being dumped as waste, and is thus friendly to the global environment.

Owner:KYOTO UNIV

Rapidly dehydrating lost circulation material (LCM)

A rapidly dehydrating lost circulation material (LCM) composition is provided. The LCM composition may include a carrier fluid, volcanic ash, a viscosifier, and date tree rachis fibers. The carrier fluid may be water and the viscosifier may be a cellulosic microfiber. The LCM composition may form a rapidly dehydrating loss control slurry (RDLCS). The LCM composition may be formed by mixing the carrier fluid, the volcanic ash, the viscosifier, and the date tree rachis fibers in a mixer to form a homogenous mixture. Methods of lost circulation control and manufacture of a rapidly dehydrating LCM are also provided.

Owner:SAUDI ARABIAN OIL CO

Circularly polarized light method and device for determining wall thickness and orientations of fibrils of cellulosic fibres

ActiveUS7289210B2Polarisation-affecting propertiesPhase-affecting property measurementsFibrilData analysis system

This invention provides a novel, rapid method and device for determining the relative phase retardation of different layers of a multi-layered specimen, which is related to the thicknesses of its layers and walls, and the orientations of its optical axes. An intact wood pulp fibre is a typical multi-layered birefringent specimen. This new method is based on the change of polarization of polarized light that passes through a specimen composed of birefringent layers with different optical axis orientations, such as directions of cellulosic microfibrils oriented differently in various layers of wood fibres. In particular, a novel solution is found to relate the emerging light intensity from an intact wood fibre to the incident light intensity, the wavelength of the light, and the relative phase retardations of various layers and orientations of their cellulosic microfibrils, such as fibril angle, in a circularly polarized light system. This new method evaluates the transmitted light intensities of multiple predetermined wavelengths simultaneously to determine the optical and physical properties of a multi-layered specimen being measured. A device for determining the relative phase retardation (retardance) of fibre walls and the fibril angle of intact wood fibres in accordance with the presented invention comprises a light source with well defined multi-wavelengths, an achromatic circularly polarized light system, appropriate imaging optics, a multi-channel camera such as a digital color camera that has two or more wavelength (color) detection channels, and an image processing and data analysis system. The measurements take advantage of the birefringence of cellulosic microfibrils, and thus require neither sample preparation nor high resolution optics. Specimen alignment is not required as specimens such as wood fibres are evaluated under circularly polarized light. Compared with other methods, this invention is more rapid, accurate, and robust. This method can be automated, and implemented in a fibre flow-through system, thus allowing a rapid assessment of wood pulp fibre properties (on-line in real time).

Owner:FPINNOVATIONS INC

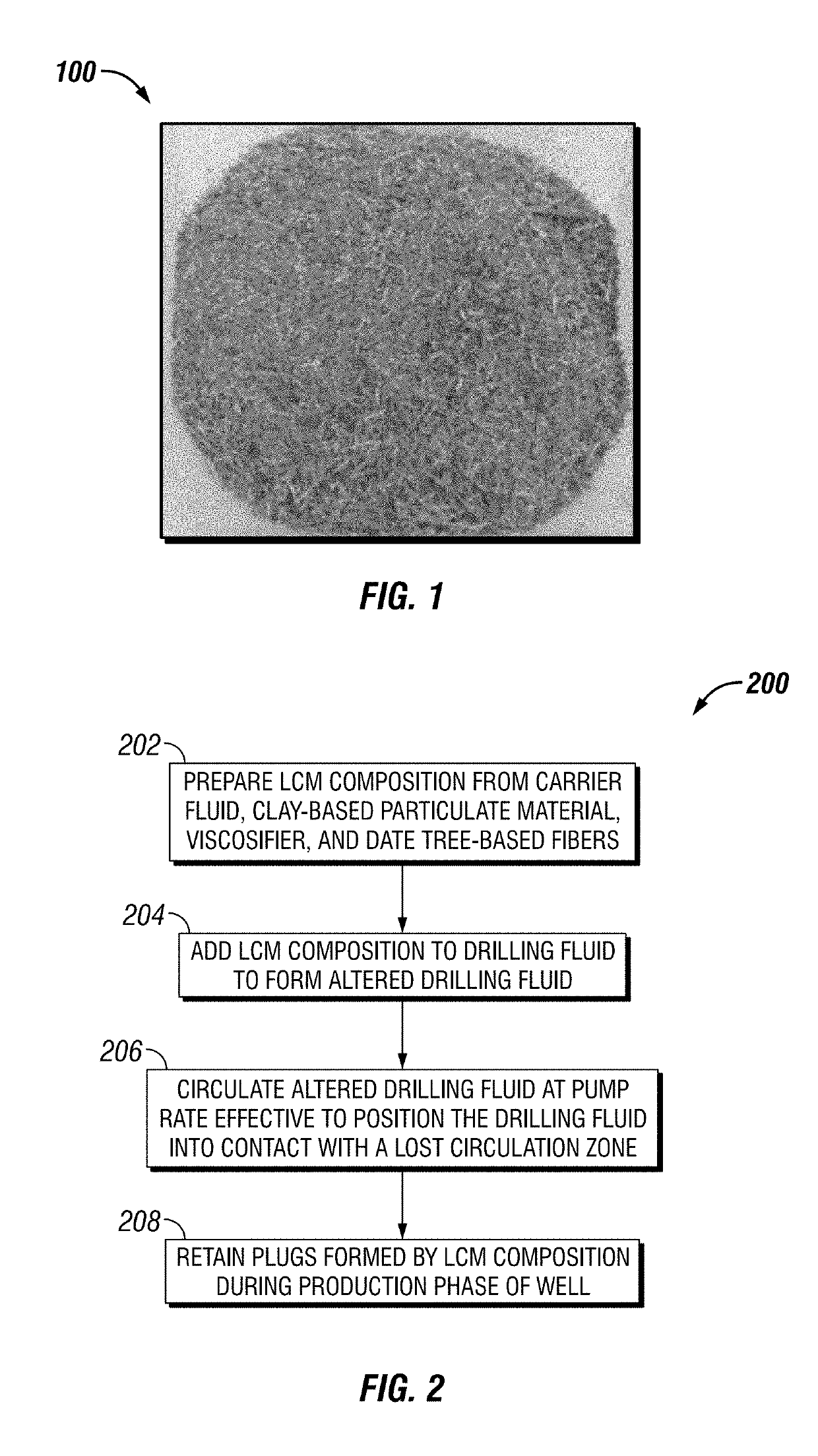

Synchronization method for preparing microfibrillated cellulose and application of microfibrillated cellulose in strengthening of paper

The invention provides a manufacturing process for an MFC (Microfibrillated Cellulose) product, which can complete the swelling of ZnCl2 and the mechanical dissociation of microfibril synchronously. The manufacturing process has the basic characteristics that the swelling and the mechanical dissociation of the cellulose microfibril in cell walls of plant fibers are completed synchronously by combining moderate mechanical pulping treatment when pulp fibers are subjected to swelling treatment by taking various types of bleaching chemical pulp, mechanical pulp and the plant fibers, such as cotton, hemp and crop straw as main treatment objects and utilizing the ZnCl2 which has a good fiber swelling effect as a main pretreatment agent; the purposes of saving energy, reducing consumption and simplifying a product preparation process flow are achieved; the MFC product can be obtained by performing subsequent treatment, such as high pressure homogenizing, on the cellulose microfibril which are subjected to the dissociation. When the product is applied to a paper production process in pulp and paper making industry, a plurality of quality indexes, such as paper strength and paper optical performance, can be effectively improved, so that the product has a good application prospect.

Owner:JILIN CHENMING PAPER IND

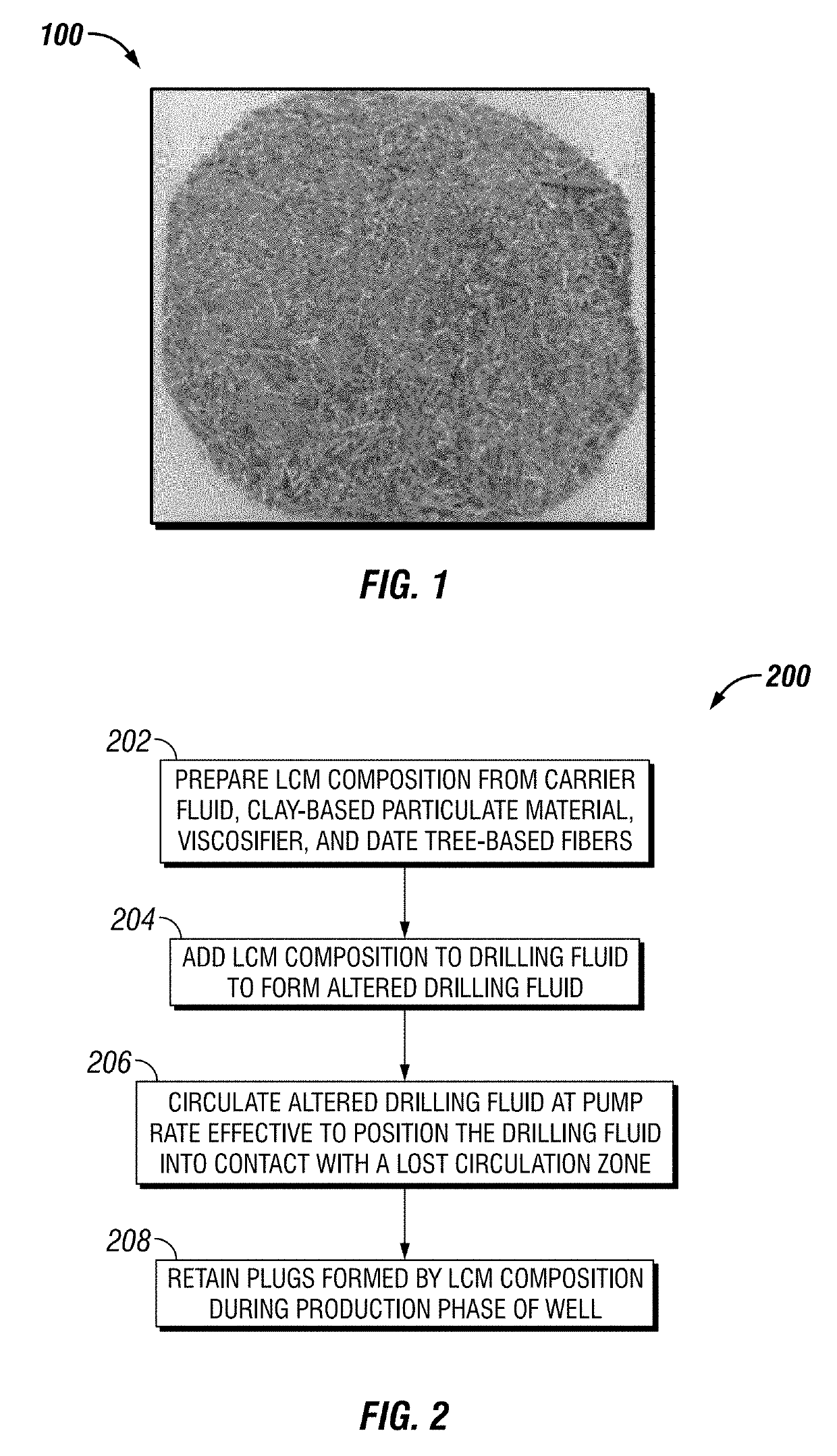

ARC Perm-Squeeze RDF - A Permeable Plug Forming Rapidly Dehydrating Fluid

A rapidly dehydrating lost circulation material (LCM) composition that forms a permeable plug is provided. The LCM composition may include a carrier fluid, a clay particulate material, a viscosifier, and date tree waste fibers. The carrier fluid may be water and the viscosifier may be a cellulosic microfiber. The LCM composition may mitigate or prevent lost circulation by forming a plug in a fracture of the lost circulation zone and may also enable the production of hydrocarbons from the zone without removal of the plug via an acid treatment. Methods of lost circulation control and manufacture of the rapidly dehydrating LCM are also provided

Owner:SAUDI ARABIAN OIL CO

ARC Perm-Squeeze RDF - A Permeable Plug Forming Rapidly Dehydrating Fluid

A rapidly dehydrating lost circulation material (LCM) composition that forms a permeable plug is provided. The LCM composition may include a carrier fluid, a clay particulate material, a viscosifier, and date tree waste fibers. The carrier fluid may be water and the viscosifier may be a cellulosic microfiber. The LCM composition may mitigate or prevent lost circulation by forming a plug in a fracture of the lost circulation zone and may also enable the production of hydrocarbons from the zone without removal of the plug via an acid treatment. Methods of lost circulation control and manufacture of the rapidly dehydrating LCM are also provided

Owner:SAUDI ARABIAN OIL CO

Rubber composition for tire, method of preparing the same, and pneumatic tire

InactiveUS20130197132A1Improve compatibilityImprove fuel economySpecial tyresRolling resistance optimizationFiberCellulose

Provided are a rubber composition for a tire, in which while the use of petroleum resources is reduced as much as possible, the compatibility of microfibrillated plant fibers with the rubber component is enhanced by a simple method, which can lead to a balanced improvement in tensile properties, handling stability, and fuel economy; a method of preparing the rubber composition; and a pneumatic tire formed from the rubber composition. The present invention relates to a rubber composition for a tire, containing a rubber component, microfibrillated plant fibers, and an industrial lignin. It is preferable that the rubber component should contain at least one selected from the group consisting of natural rubber, modified natural rubber, synthetic rubber, and modified synthetic rubber, and it is preferable that the microfibrillated plant fibers should be cellulose microfibrils.

Owner:SUMITOMO RUBBER IND LTD

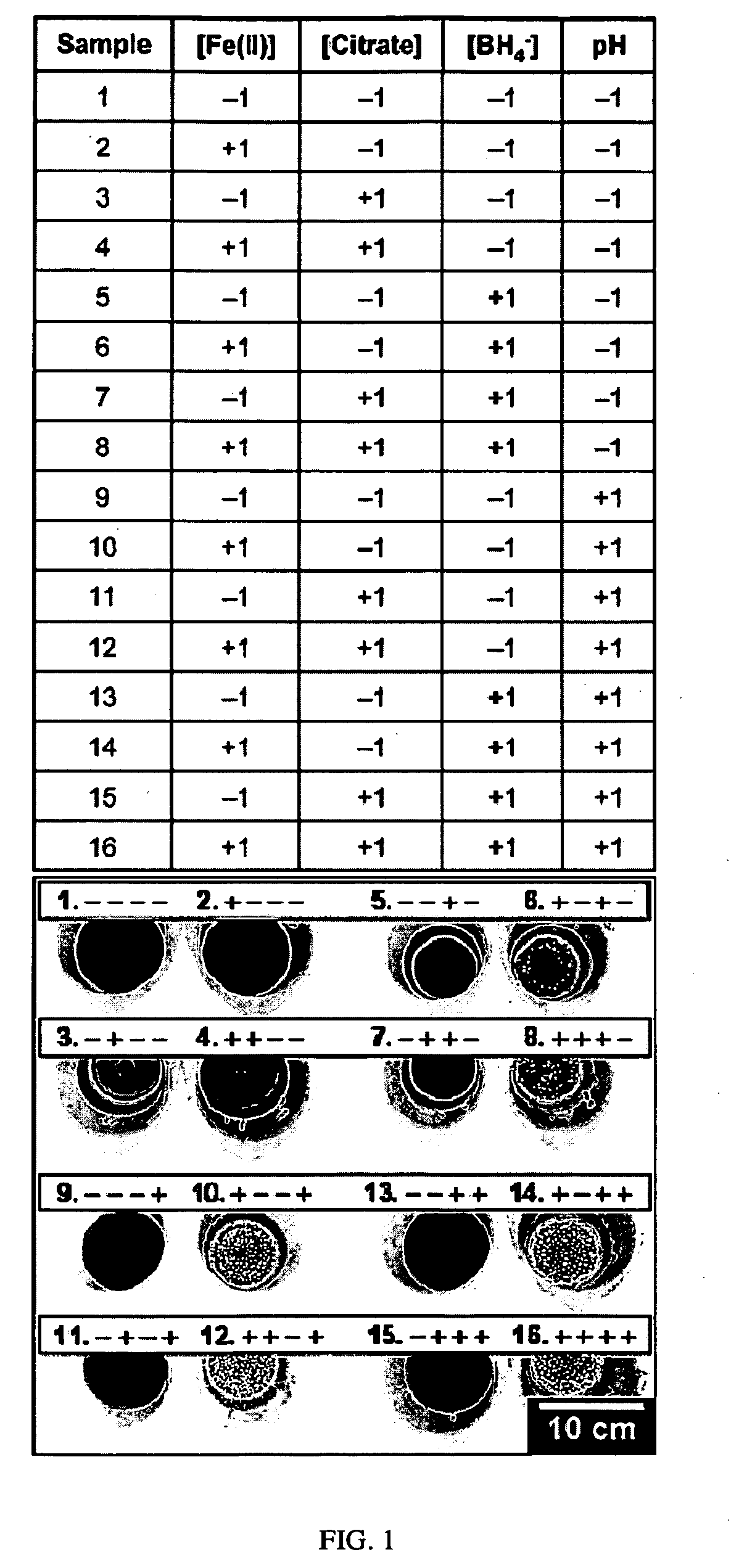

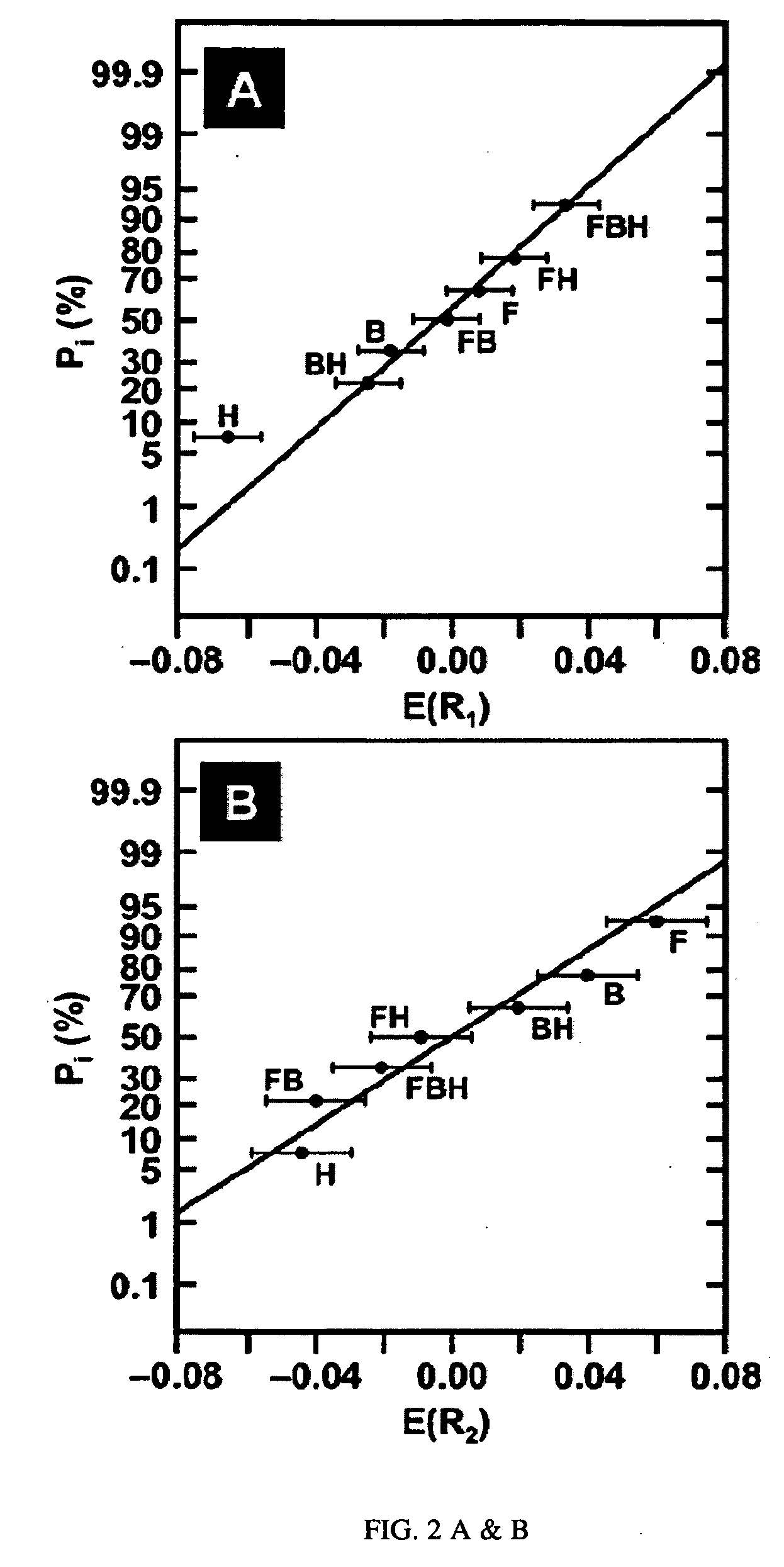

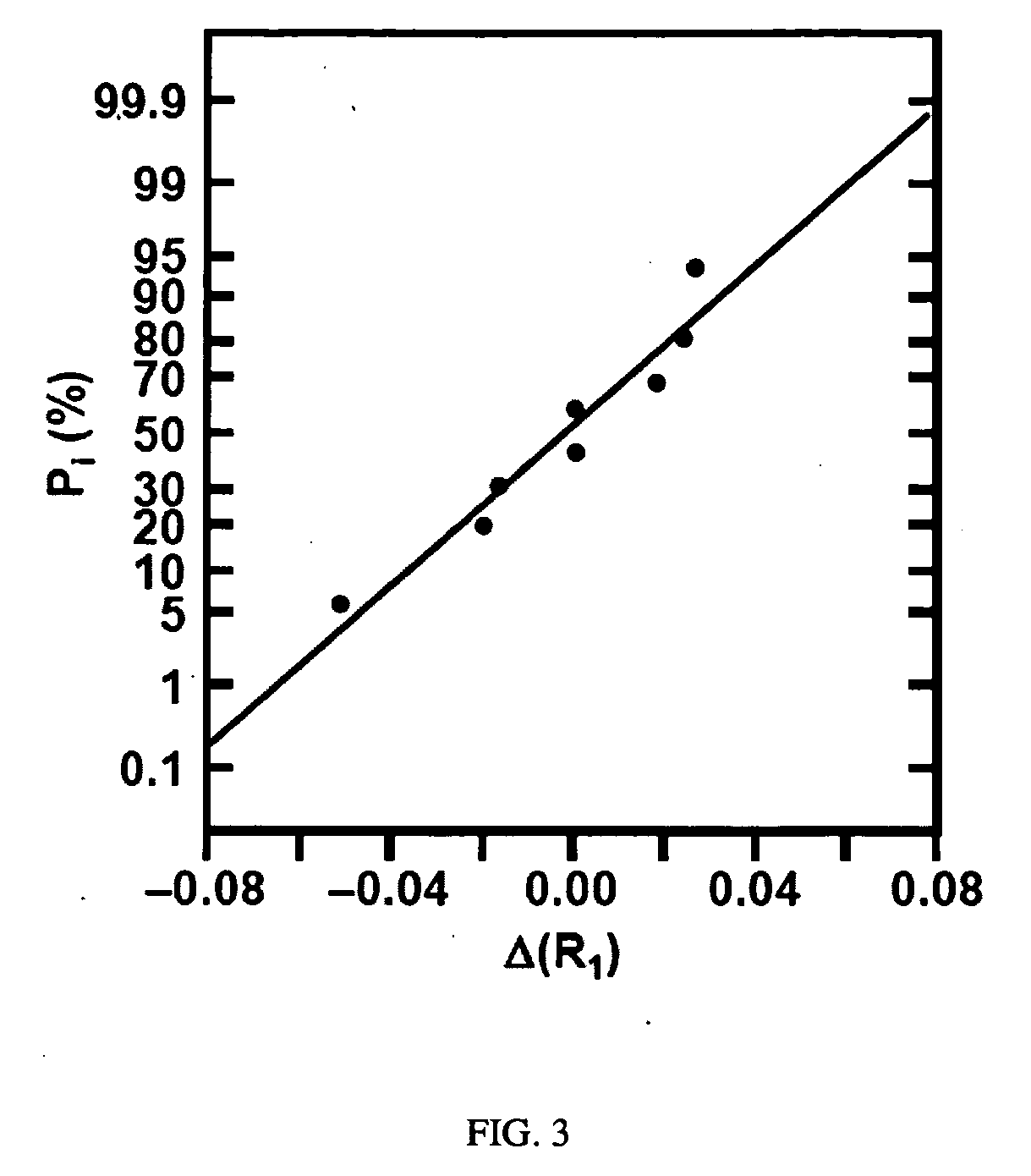

ROOM TEMPERATURE ELECTROLESS IRON BATH OPERATING WITHOUT A GALVANIC COUPLE FOR DEPOSITION OF FERROMAGNETIC AMORPHOUS FeB FILMS

Provided is an electroless iron bath capable of depositing a ferromagnetic FeB coating onto Pd / Sn-catalyzed substrates at room temperature without the need for an accompanying galvanic couple. The new electroless iron bath is comprised of Fe2+ as the metal source, citrate as the metal chelator, boric acid buffer as the pH controller, and borohydride as the reductant. Surface analysis following plating confirms the deposition of an amorphous FeB coating onto the surface of Pd / Sn-catalyzed cellulose microfibers.

Owner:UNITED STATES OF AMERICA

Cellulose microfibrils as air release agent

InactiveUS20120100367A1High porosityImpact porosityLayered productsRecord information storageCelluloseFiber

The present invention relates to the use of microfibrillated cellulose (MFC) as an air release agent in viscous compositions that are subjected to a hardening step. The air release agent according to the invention is added prior to or during said hardening step, in particular drying, cooling and / or curing process. The present invention also relates to such viscous compositions in an article comprising the MFC as further specified in the description as an air release agent.

Owner:BORREGAARD INDS

Nanolignocellulose compositions and processes to produce these compositions

Some variations provide a new nanolignocellulose composition comprising, on a bone-dry, ash-free, and acetyl-free basis, from 35 wt % to 80 wt % cellulose nanofibrils, cellulose microfibrils, or a combination thereof, from 15 wt % to 45 wt % lignin, and from 5 wt % to 20 wt % hemicelluloses. The hemicelluloses may contain xylan or mannan as the major component. Novel properties arise from the hemicellulose content that is intermediate between high hemicellulose content of raw biomass and low hemicellulose content of conventional nanocellulose. The nanolignocellulose composition is hydrophobic due to the presence of lignin. Processes for making and using the nanolignocellulose compositions are also described.

Owner:GRANBIO INTELLECTUAL PROPERTY HOLDINGS LLC

Polyolefin resin composition, molded article, and outer panel for a vehicle

ActiveUS20170218188A1Reduction factorImprove liquiditySynthetic resin layered productsVehicle sub-unit featuresFiberCellulose

A polyolefin resin composition, containing: a polyolefin resin; and cellulose microfibrils, in which a content of the cellulose microfibrils is 0.5 to 20 parts by mass, with respect to 100 parts by mass of an entire resin component in the polyolefin resin composition, a molded article and a back door for a vehicle.

Owner:FURUKAWA ELECTRIC CO LTD

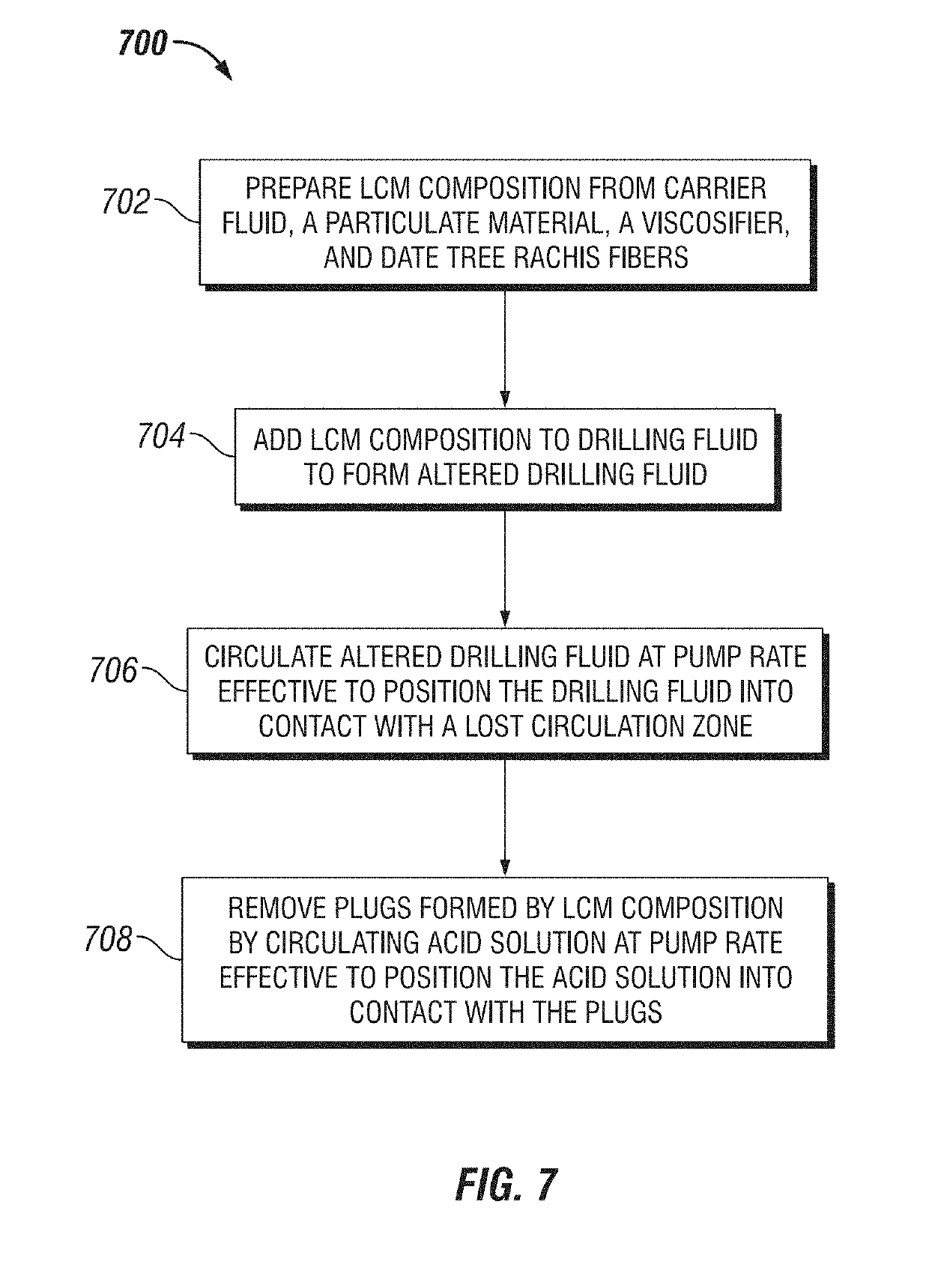

Acid-soluble plug forming rapidly dehydrating loss control slurry

ActiveUS20190177597A1Loss of well productivityAvoid productivityFlushingDrilling compositionEngineeringCarrier fluid

A rapidly dehydrating lost circulation material (LCM) composition that forms an acid-soluble plug is provided. The LCM composition may include a carrier fluid, an acid-soluble-particulate material, a viscosifier, and date tree rachis fibers. The carrier fluid may be water and the viscosifier may be a cellulosic microfiber. The LCM composition may alter a lost circulation zone by forming an acid-soluble plug in a fracture of the lost circulation zone. The acid-soluble plug may be removed via an acid solution, such as a hydrochloric acid solution. Methods of lost circulation control and manufacture of a rapidly dehydrating LCM are also provided.

Owner:SAUDI ARABIAN OIL CO

Rubber composition for tire, and pneumatic tire

InactiveUS20130190426A1Improve fuel economyImprove handling stabilitySpecial tyresRolling resistance optimizationCellulose microfibrilSurface finishing

Provided are a rubber composition for a tire which makes it possible to improve the handling stability and fuel economy in a well-balanced manner by a simple method without requiring any chemical reaction process for surface treatment of microfibrillated plant fibers; and a pneumatic tire formed from the rubber composition. The rubber composition for a tire contains: a rubber component; microfibrillated plant fibers; a phenol resin; and a curing agent. It is preferable that the rubber component should include at least one selected from the group consisting of natural rubber, modified natural rubber, synthetic rubber, and modified synthetic rubber, and it is preferable that the microfibrillated plant fibers should be cellulose microfibrils.

Owner:SUMITOMO RUBBER IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com