Nanolignocellulose compositions and processes to produce these compositions

a technology of nanolignocellulose and compositions, applied in the field of nanocellulose, can solve the problems of large fibril diameter and length distribution, high energy consumption, and damage to fibers and particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

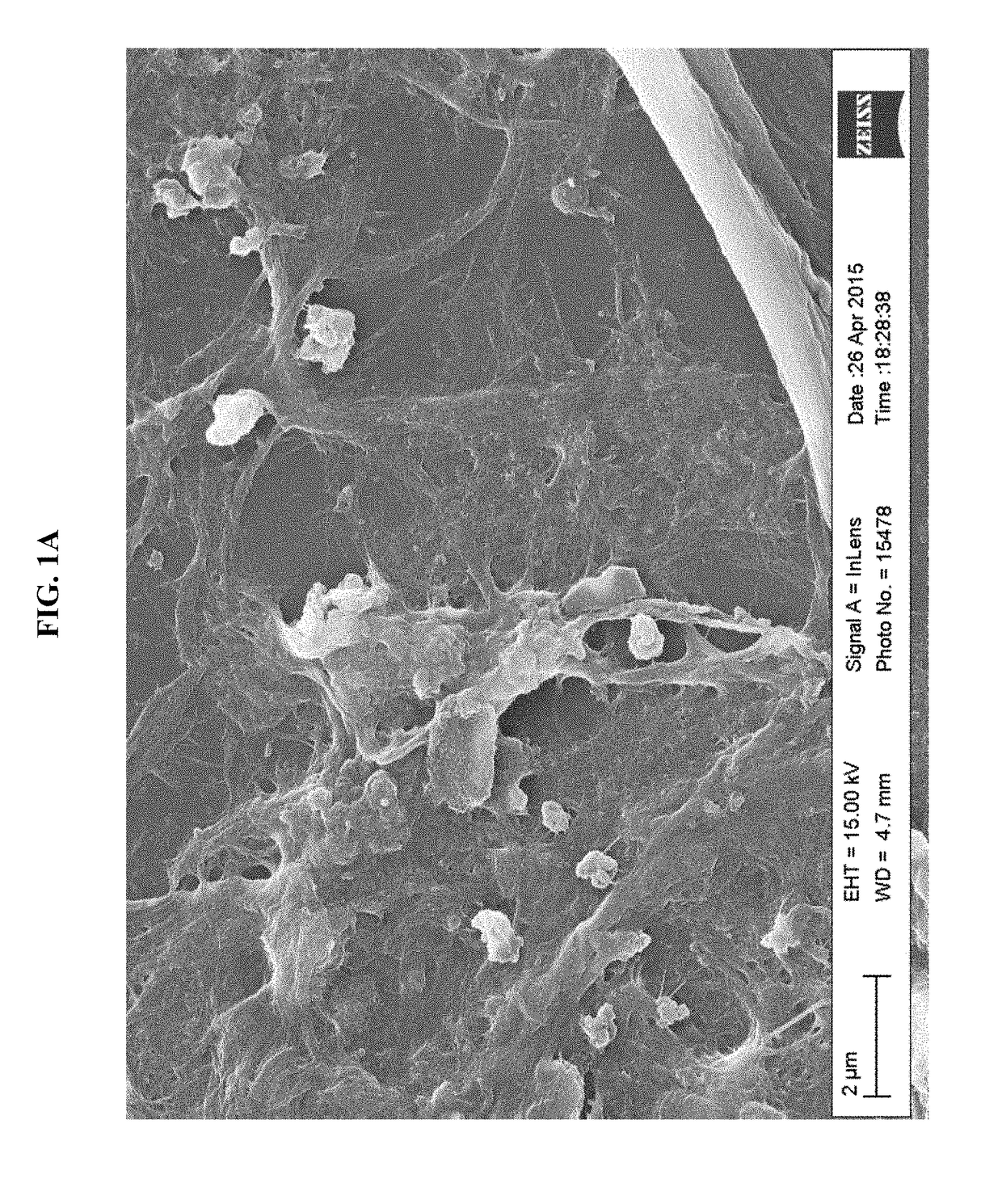

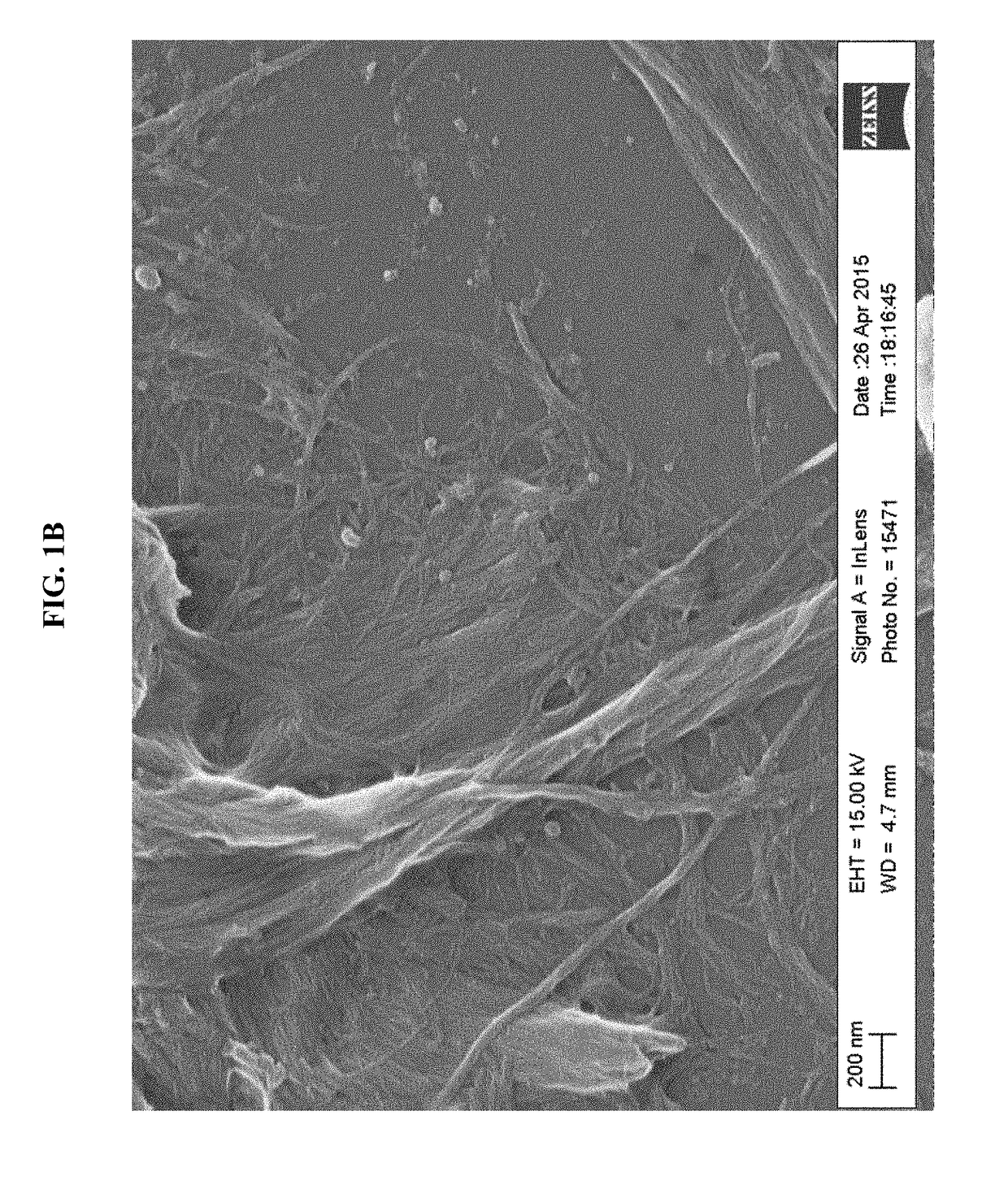

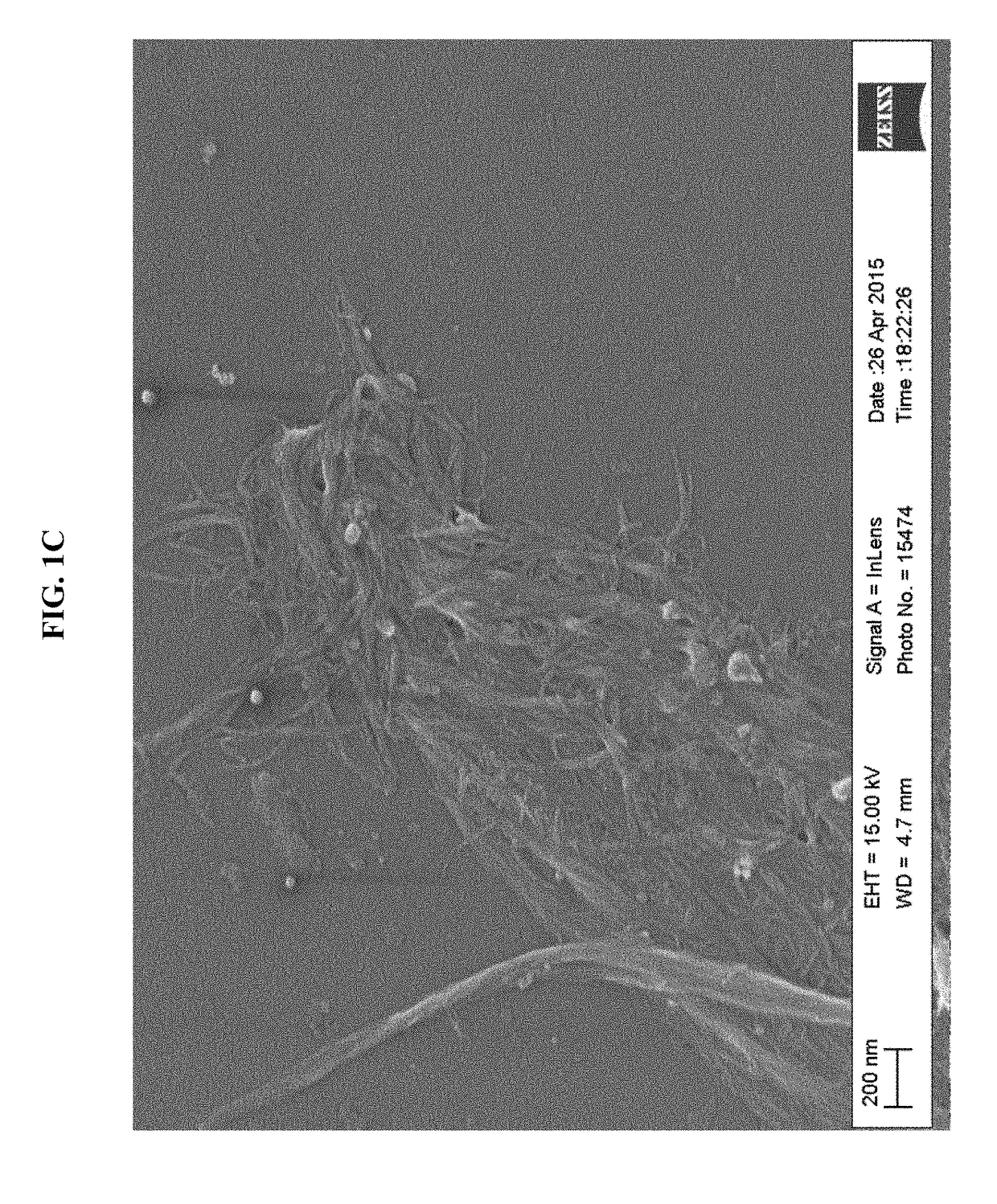

Image

Examples

example 1

cellulose Produced from Softwood

[0264]Softwood (pine) chips are processed in a pilot steam gun digester at a temperature of 185° C. and 20 minutes, resulting in a pulp yield of about 80%. The pulp is passed through a pilot plant disk refiner to defiberize the cooked chips to about 100 freeness. The freeness of pulp gives a measure of the rate at which a dilute suspension of pulp may be drained (see TAPPI T221 “Drainage Time of Pulp”). The pulp is then passed through a lab-scale homogenizer three times for a target of 80-85% fines, to produce unwashed nanolignocellulose. The percentage of fines (refined material) can be increased with more homogenizer passes. The unwashed nanolignocellulose is washed with water three times at 60° C. for 30 min at about 2, 1, and 1 kg water per kg pulp, to produce washed nanolignocellulose.

[0265]FIG. 2 shows an optical micrograph at 40× magnification of the washed nanolignocellulose produced in this example.

[0266]The nanolignocellulose in this example...

example 2

cellulose Produced from Hardwood

[0269]Hardwood chips are processed in a pilot steam gun digester at a temperature temperature of 185° C. and 15 minutes, resulting in a pulp yield of about 80%. The pulp is passed through a pilot plant disk refiner to defiberize the cooked chips to about 100 freeness. The pulp is then passed through a lab-scale homogenizer three times for a target of 80-85% fines, to produce unwashed nanolignocellulose. The percentage of fines (refined material) can be increased with more homogenizer passes. The unwashed nanolignocellulose is washed with water three times at 60° C. for 30 min at about 2, 1, and 1 kg water per kg pulp, to produce washed nanolignocellulose.

[0270]FIG. 3 shows an optical micrograph at 40× magnification of the washed nanolignocellulose produced in this example.

[0271]The pulp produced in this example is also passed through the homogenizer 7 times, resulting in 92% fines. This is compared to bleached softwood Kraft pulp, Masuko refined, 14 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com