Patents

Literature

199 results about "Lignin degradation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

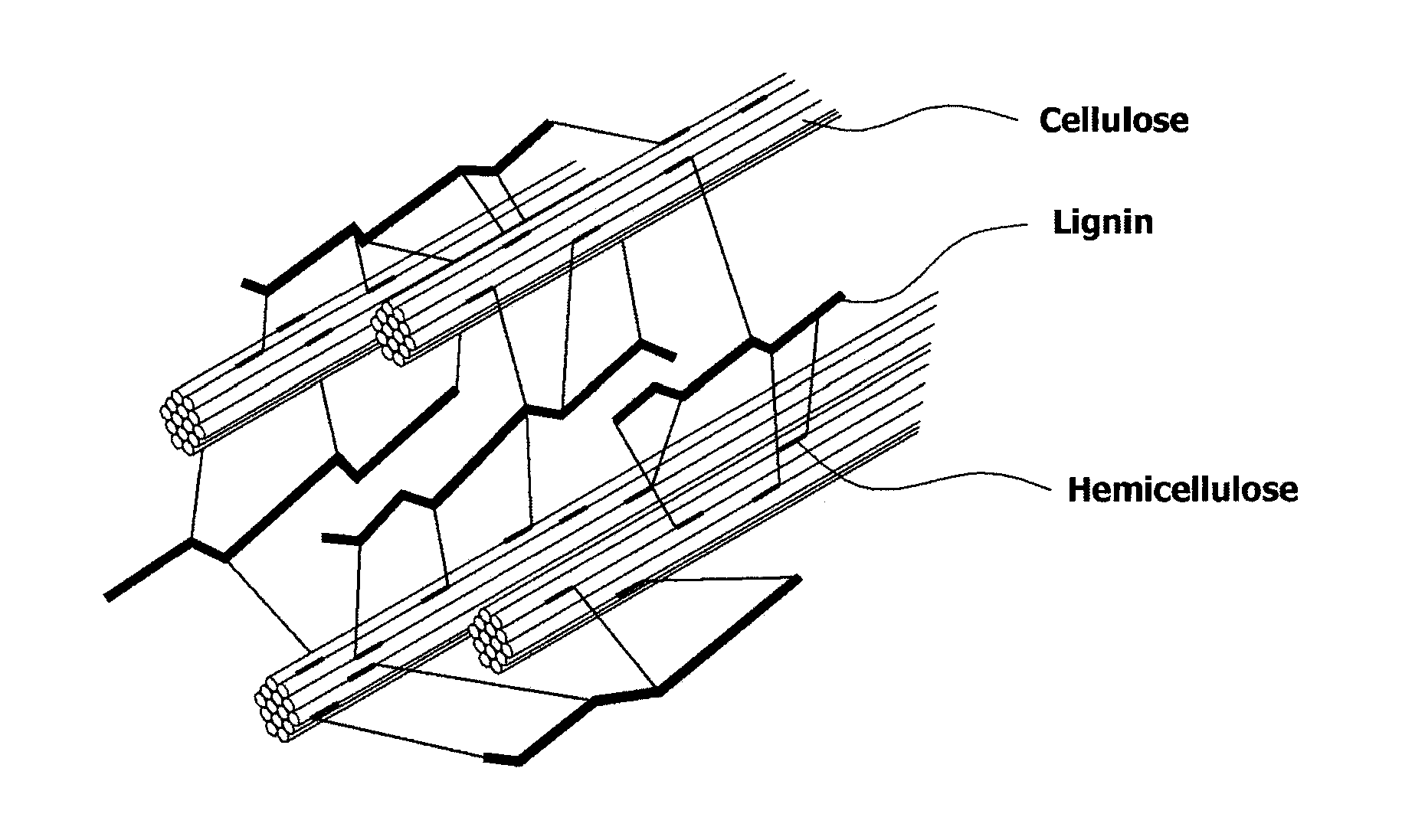

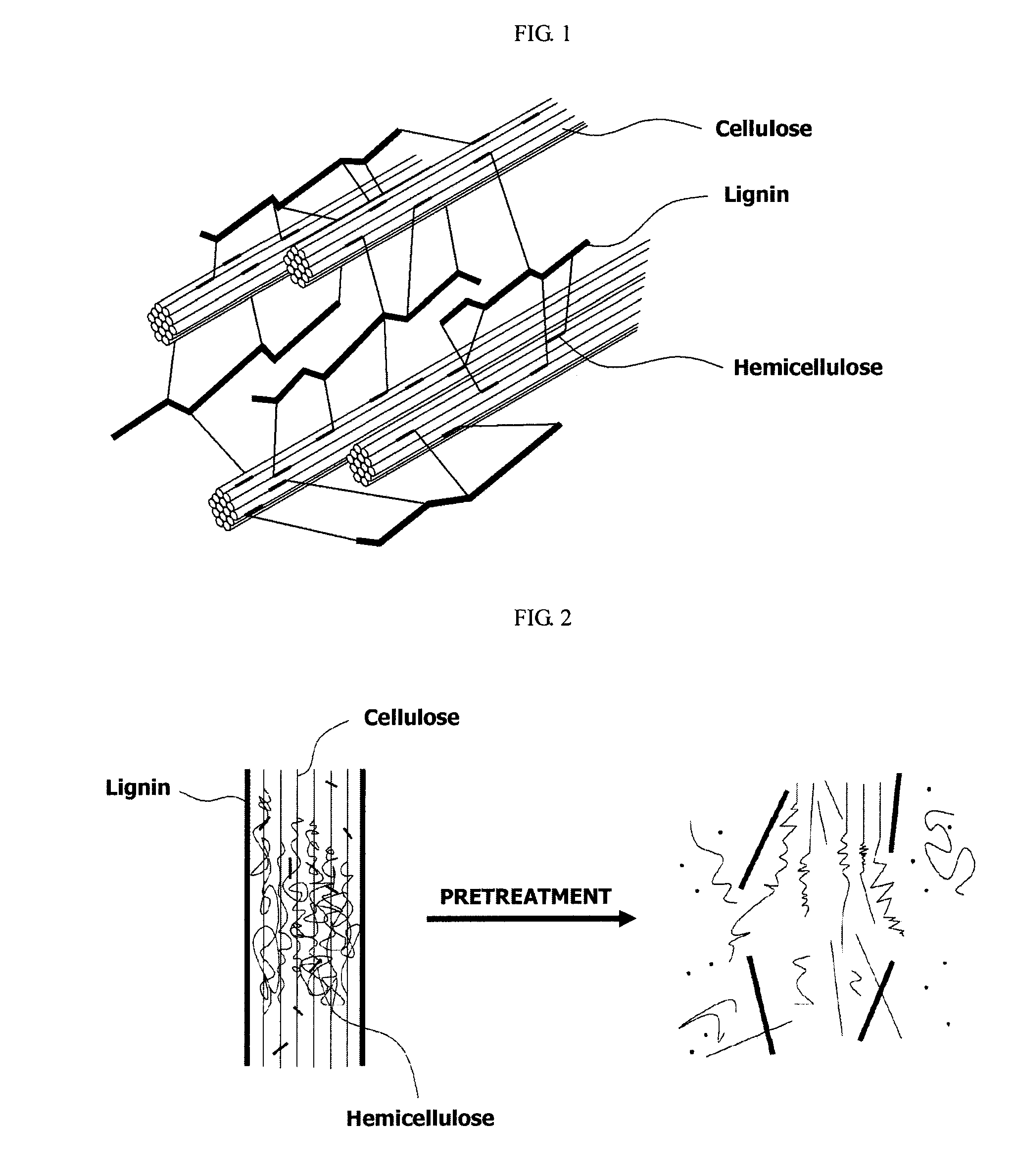

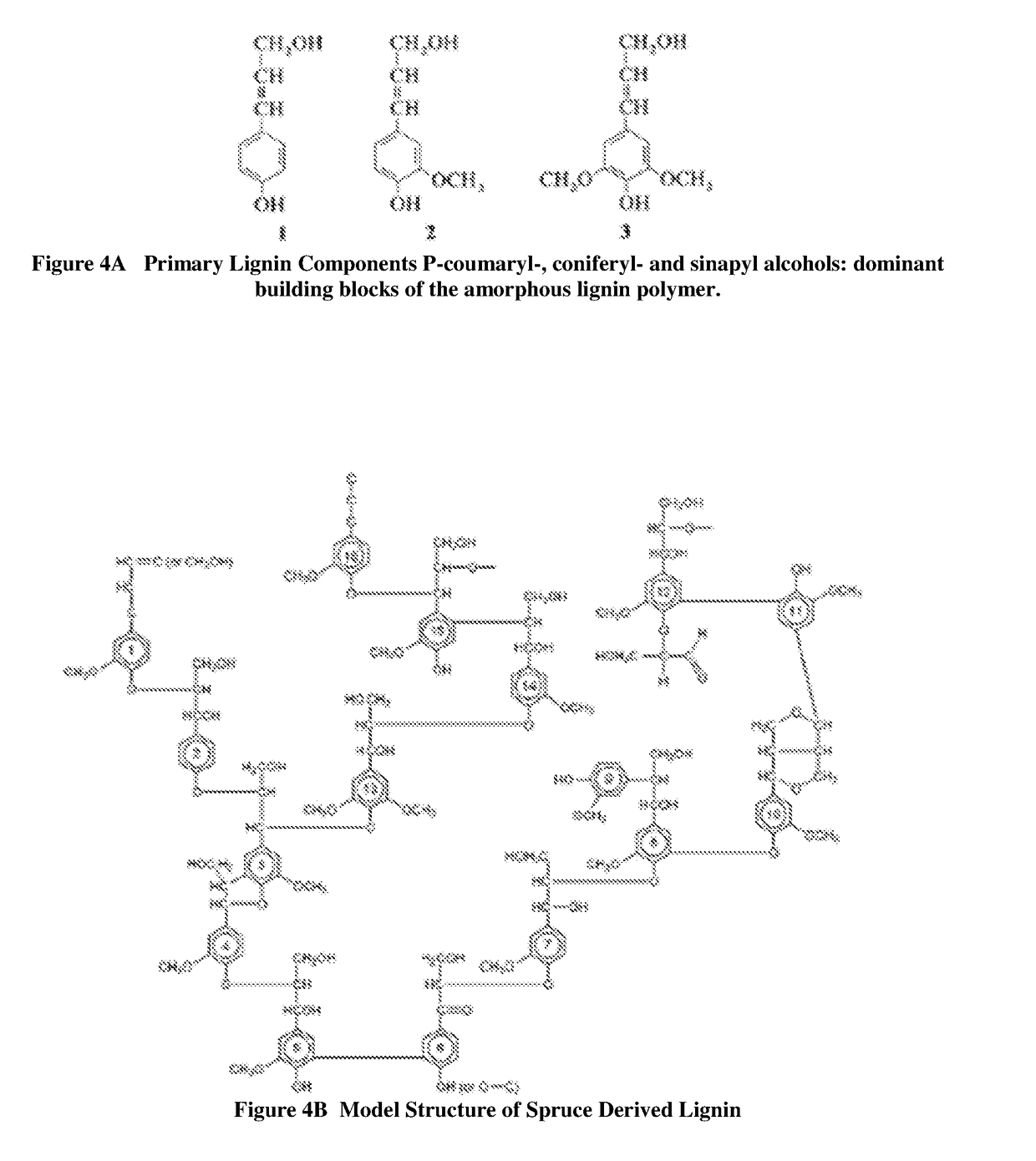

Lignin is a recalcitrant biopolymer, meaning that it resists degradation. Recalcitrance is manifested in resistance to acid- and base-catalyzed hydrolysis. In contrast, other biopolymers - proteins, DNA, and even cellulose - degrade when treated with aqueous acids or bases.

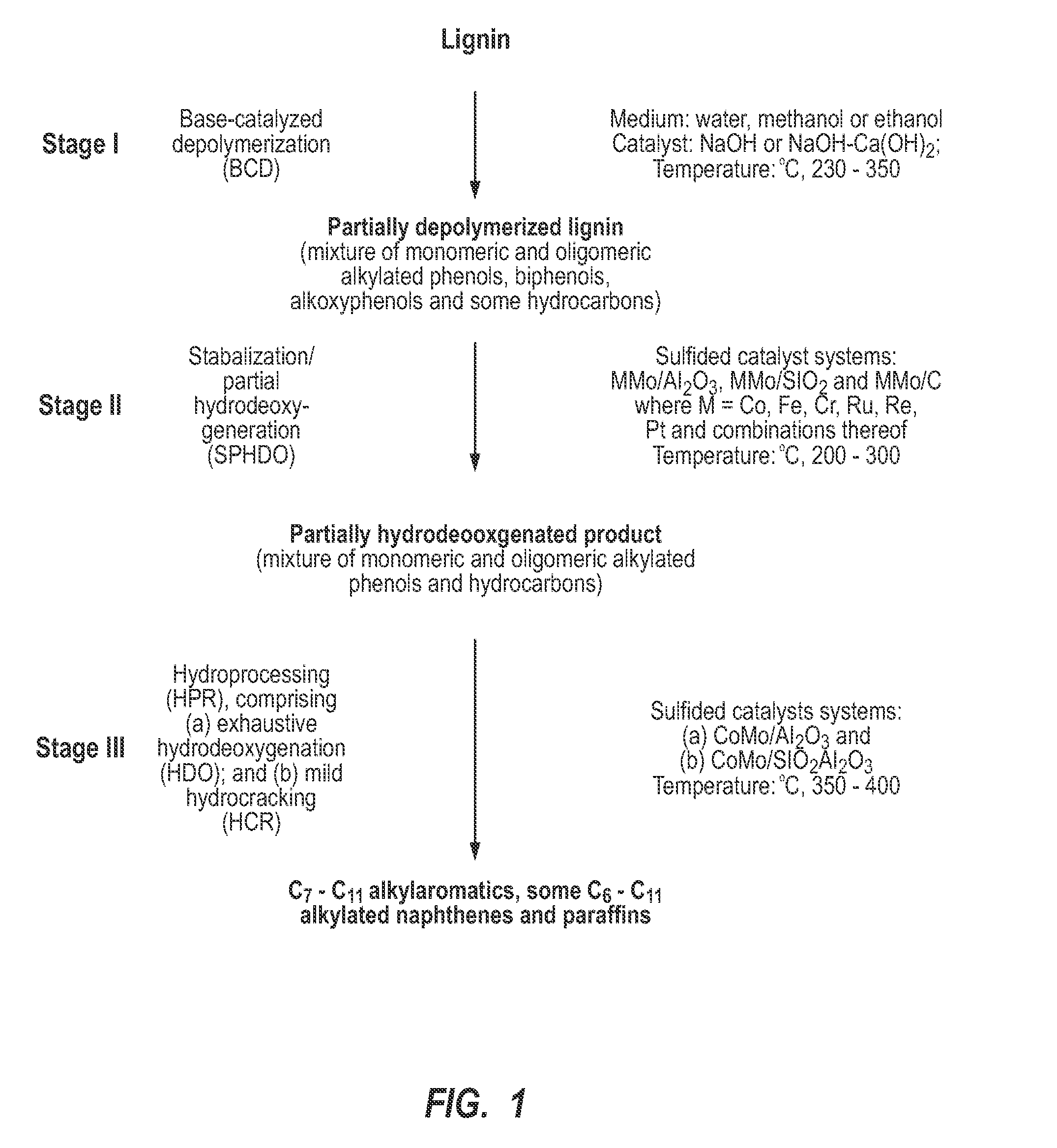

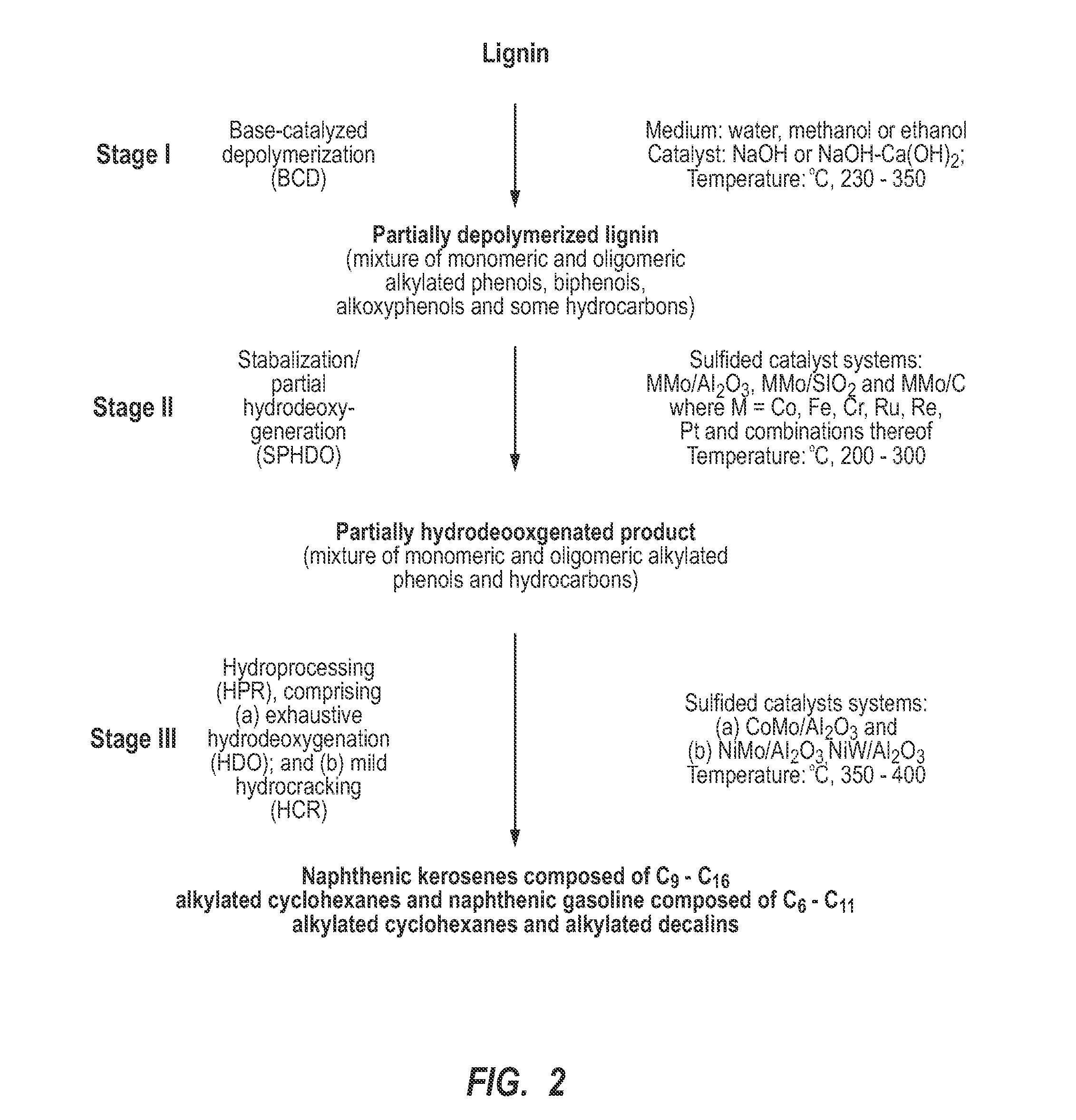

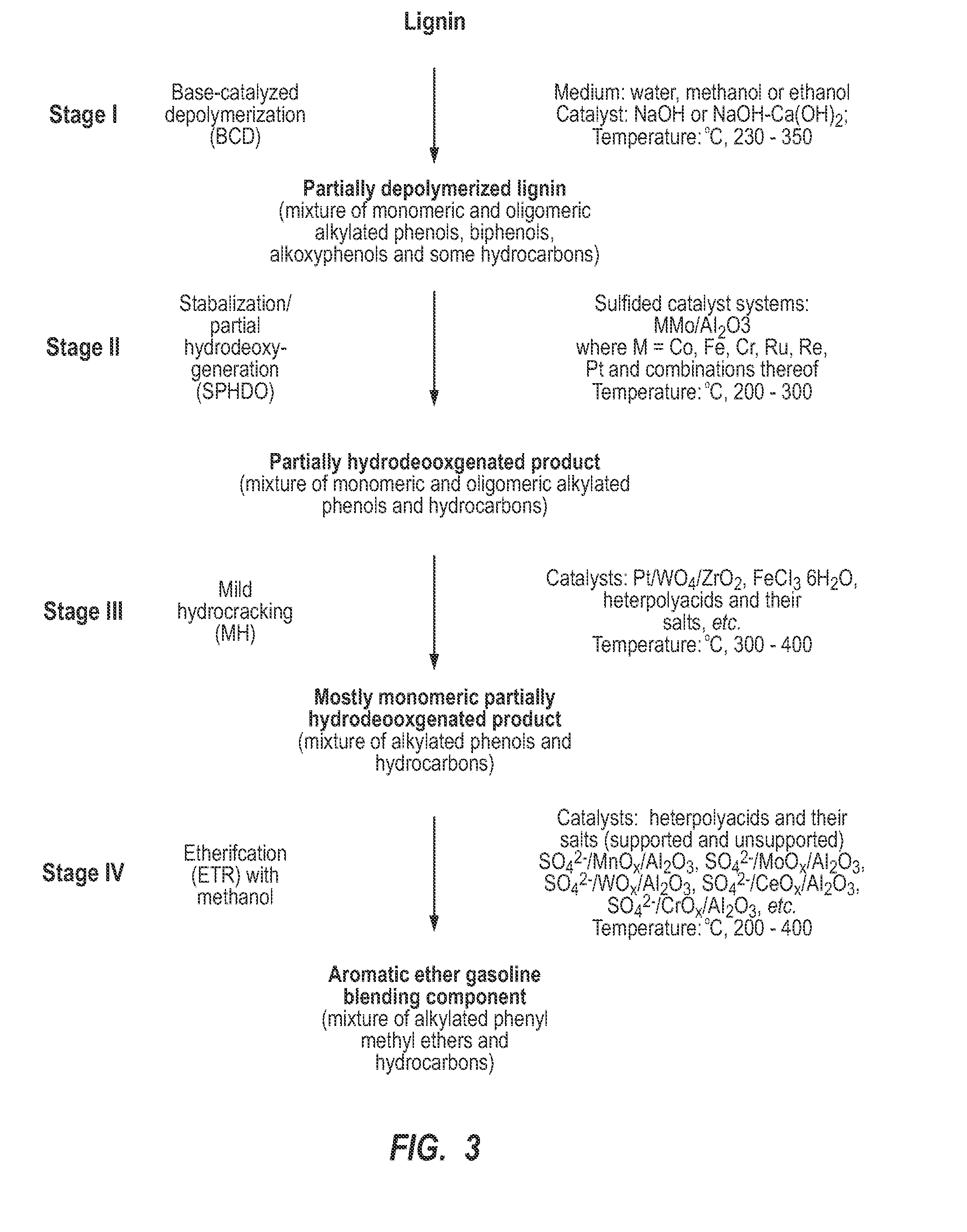

Processes for catalytic conversion of lignin to liquid bio-fuels and novel bio-fuels

InactiveUS20080050792A1Increase productionAcceptable processing conditionBiofuelsSolid fuelsLiquid productLignin degradation

Processes for conversion of lignin to liquid products such as bio-fuels and fuel additives are disclosed and described. A process for conversion of a lignin material to bio-fuels can include subjecting the lignin material to a base catalyzed depolymerization reaction to produce a partially depolymerized lignin. The partially depolymerized lignin can then be subjected to a stabilization / partial hydrodeoxygenation reaction to form a partially hydrodeoxygenated product. Following partial hydrodeoxygenation, the partially hydrodeoxygenated product can be reacted in a hydroprocessing step to form a bio-fuel. Each of these reaction steps can be performed in single or multiple steps, depending on the design of the process. The production of an intermediate partially hydrodeoxygenation product and subsequent reaction thereof can significantly reduce or eliminate reactor plugging and catalyst coking. A variety of useful bio-fuels such as fuels, fuel additives, and the like, including gasoline and jet or rocket fuels are describe which can be readily produced from renewable lignin materials in an improved conversion process.

Owner:UNIV OF UTAH RES FOUND

Lignin blockers and uses thereof

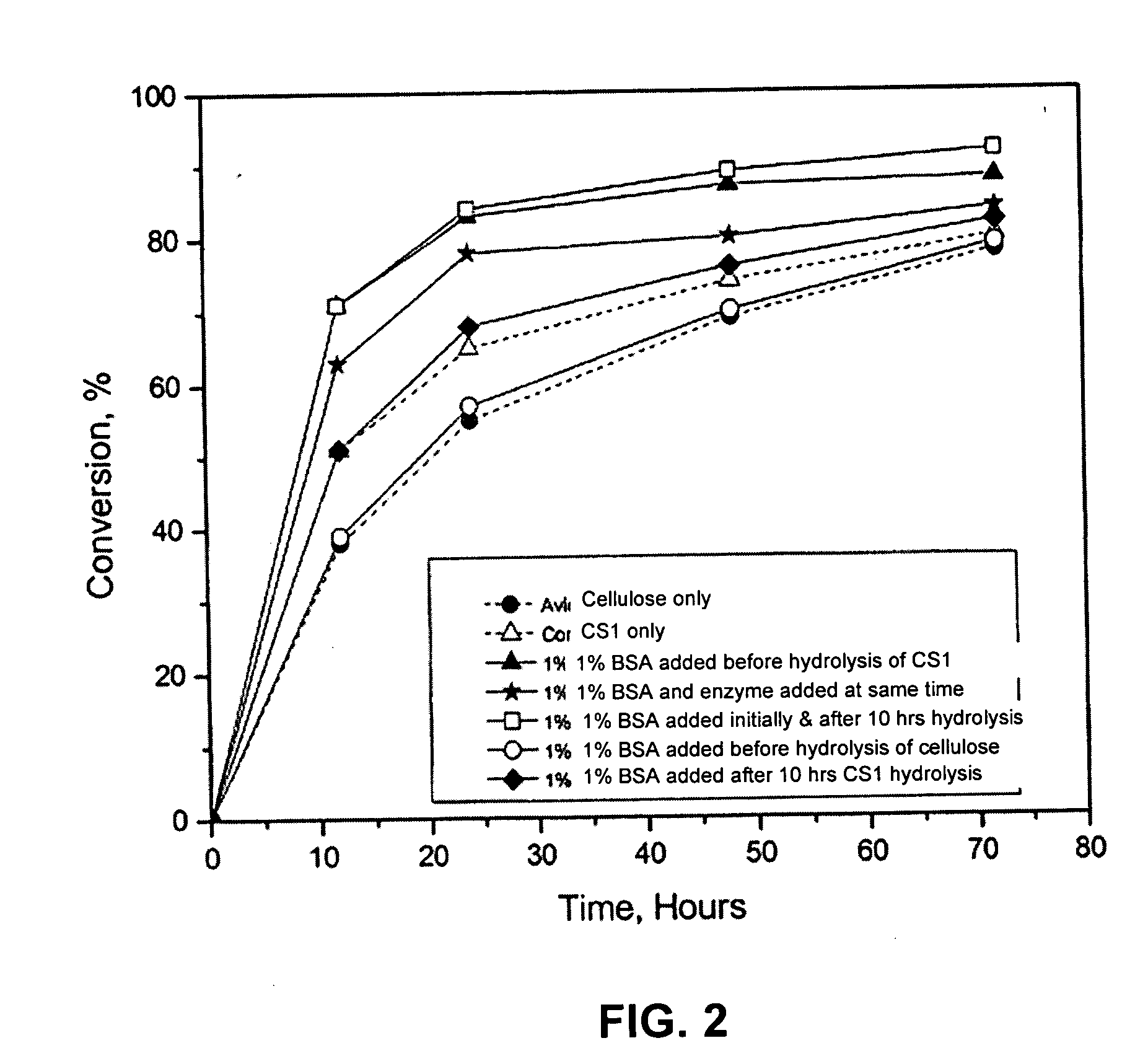

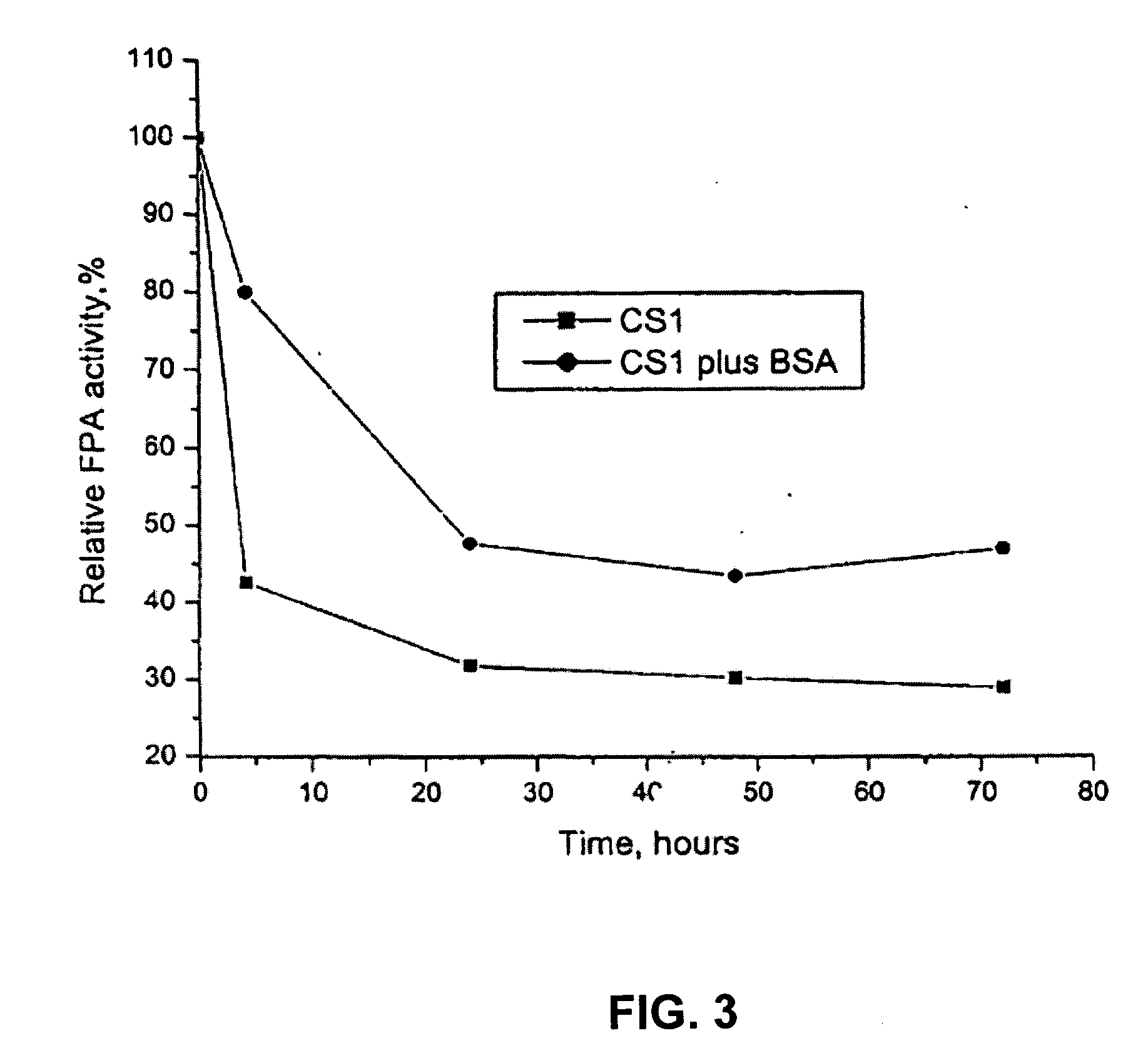

InactiveUS20060088922A1High efficiency in cellulose conversionLess of advantageProtein composition from vegetable seedsBiofuelsLignin degradationLignocellulosic biomass

Disclosed is a method for converting cellulose in a lignocellulosic biomass. The method provides for a lignin-blocking polypeptide and / or protein treatment of high lignin solids. The treatment enhances cellulase availability in cellulose conversion and allows for the determination of optimized pretreatment conditions. Additionally, ethanol yields from a Simultaneous Saccharification and Fermentation process are improved 5-25% by treatment with a lignin-blocking polypeptide and / or protein. Thus, a more efficient and economical method of processing lignin containing biomass materials utilizes a polypeptide / protein treatment step that effectively blocks lignin binding of cellulase.

Owner:TRUSTEES OF DARTMOUTH COLLEGE THE

Cyclosporin compositions

A composition is disclosed herein comprising from about 0.001% to about 0.4% cyclosporin A, castor oil, and a surfactant selected from the group consisting of alcohol ethoxylates, alcohols, alkyl glycosides, alkyl polyglycosides, alkylphenol ethoxylates, amine oxides, block polymers, carboxylated alcohol or alkylphenol ethoxylates, carboxylic acids / fatty acids, cellulose derivatives, ethoxylated alcohols, ethoxylated alkylphenols, ethoxylated aryl phenols, ethoxylated fatty acids, ethoxylated fatty acids, ethoxylated fatty esters and oils, fatty alcohols, fatty esters, glycol esters, lanolin-based derivatives, lecithin and lecithin derivatives, lignin and lignin derivatives, methyl esters, monoglycerides and derivatives , phosphalipids, polyacrylic acids, polyethylene glycols, polyethylene oxide-polypropylene oxide copolymers, polyethylene oxides, polymeric surfactants, polypropylene oxides, propoxylated alcohols, propoxylated alkyl phenols, propoxylated fatty acids, protein-based surfactants, sarcosine derivatives, silicone-based surfactants, sorbitan derivatives, stearates, sucrose and glucose esters and derivatives, and combinations thereof.

Owner:SAINT REGIS MOHAWK TRIBE

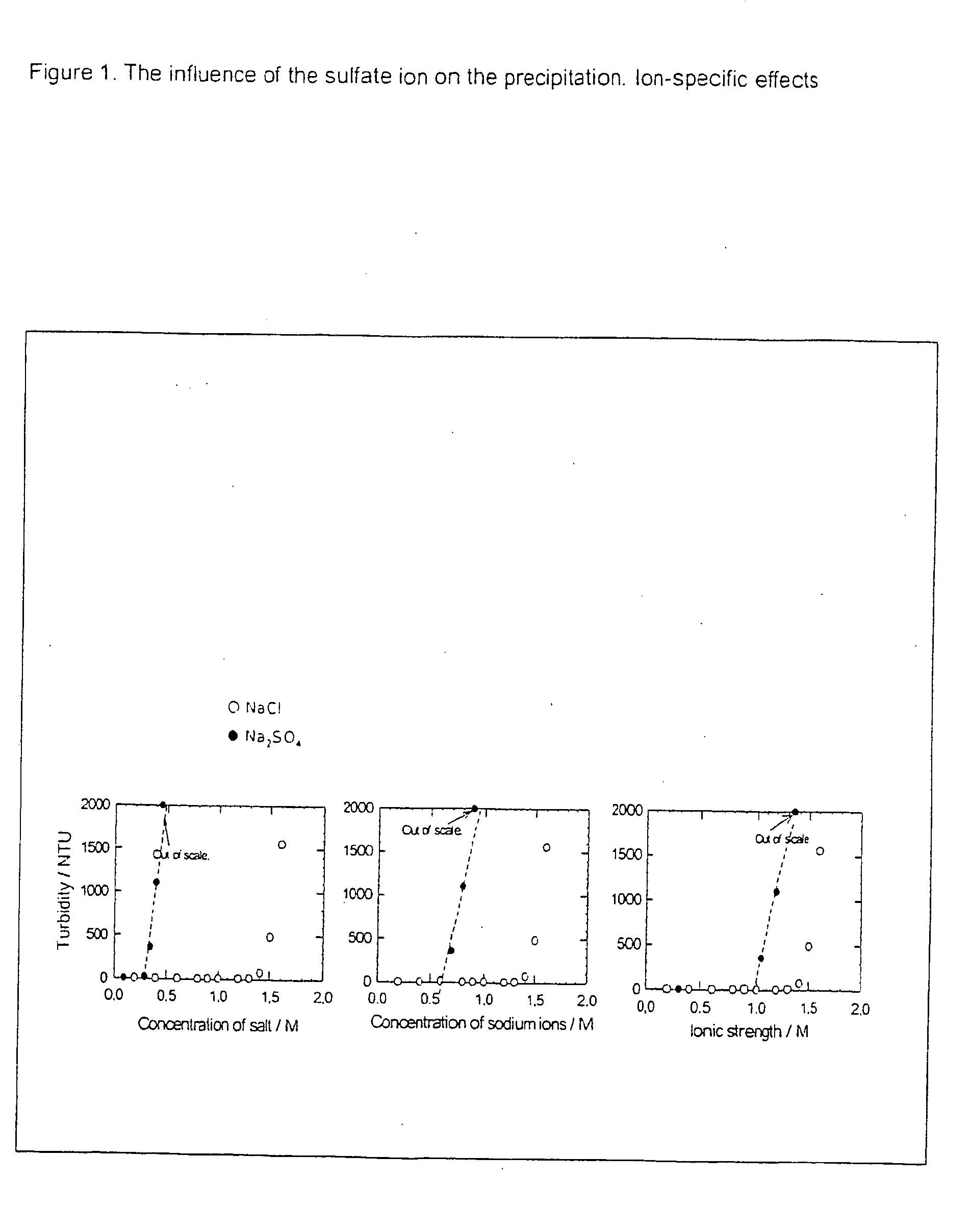

Method For Separating Lignin From A Lignin Containing Liquid/Slurry

InactiveUS20080051566A1Efficient separationImprove filtering effectLignin derivativesPulp by-products recoveryLignin degradationBlack liquor

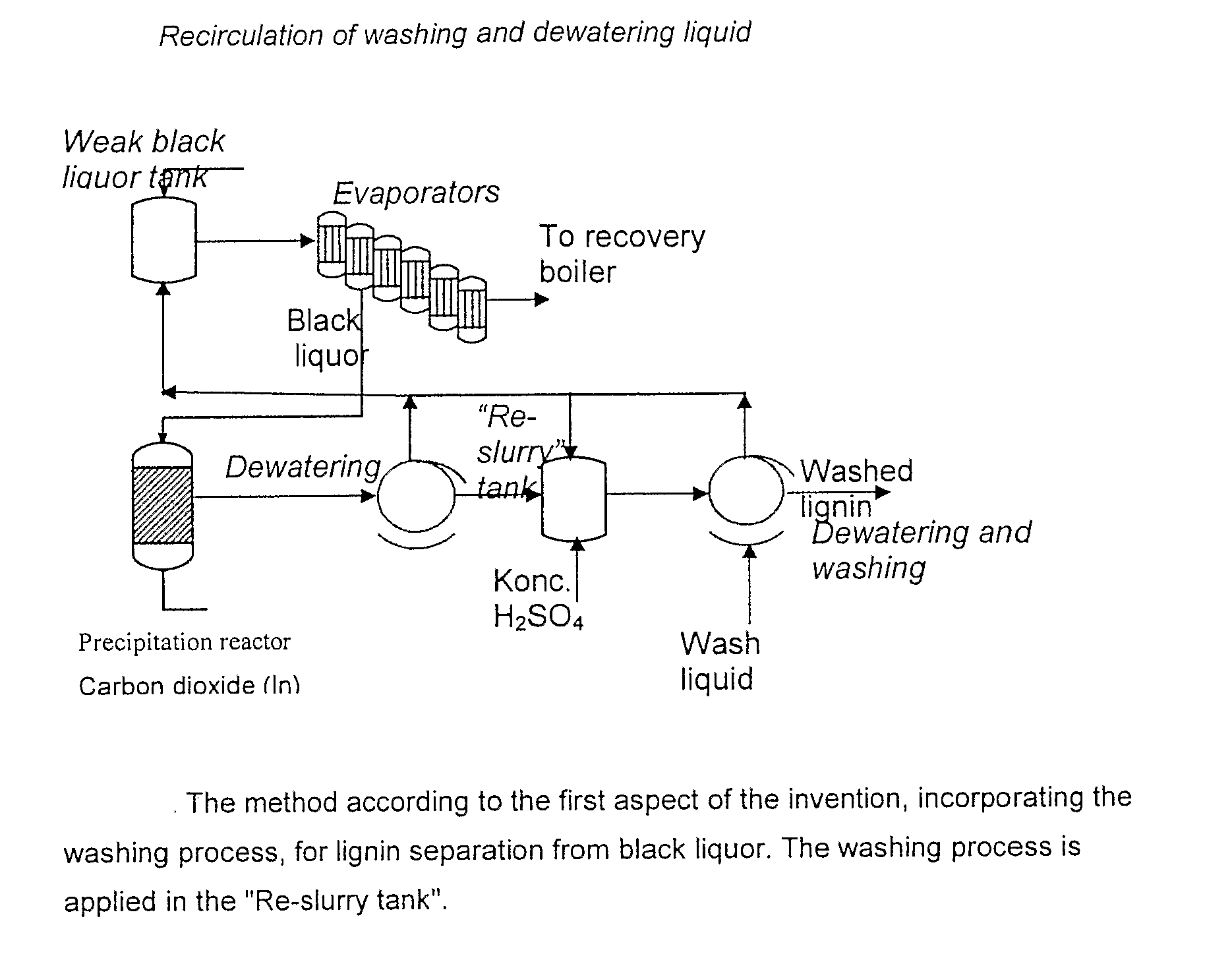

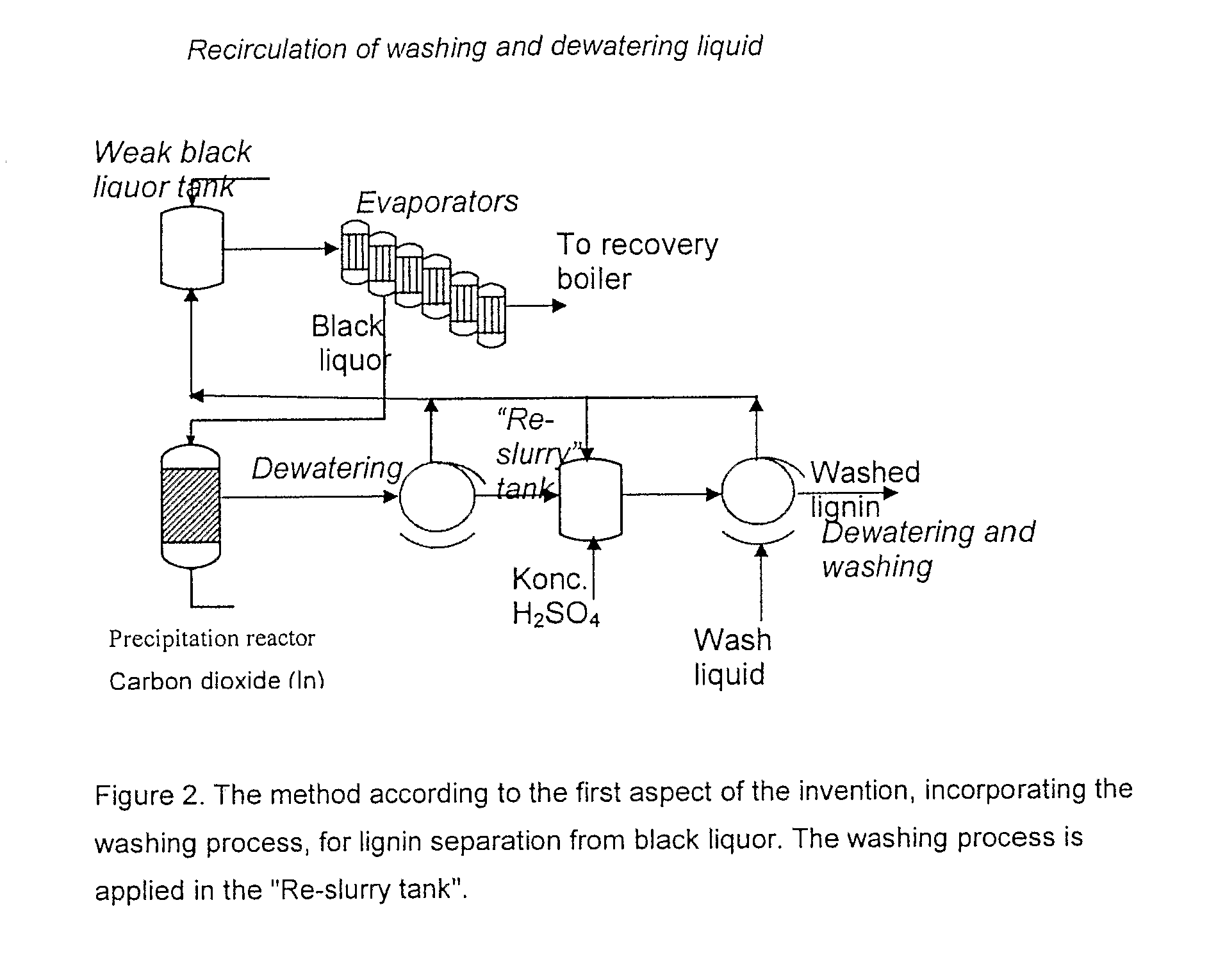

A method for precipitating (separation) of lignin, using small amounts of acidifying agents, whereby a lignin product or an intermediate lignin product is obtained which can be used as fuel or chemical feed stock (or as a chemical or a raw material for further refining), from a lignin containing liquid / slurry, such as black liquor. A method for separation of lignin from a lignin containing liquid / slurry, such as black liquor, whereby a more pure lignin is obtained, a lignin product or an intermediate lignin product obtainable by the above methods, and use, preferably for the production of heat or for use as chemical, of the lignin product or intermediate lignin product are also disclosed.

Owner:LIGNOBOOST

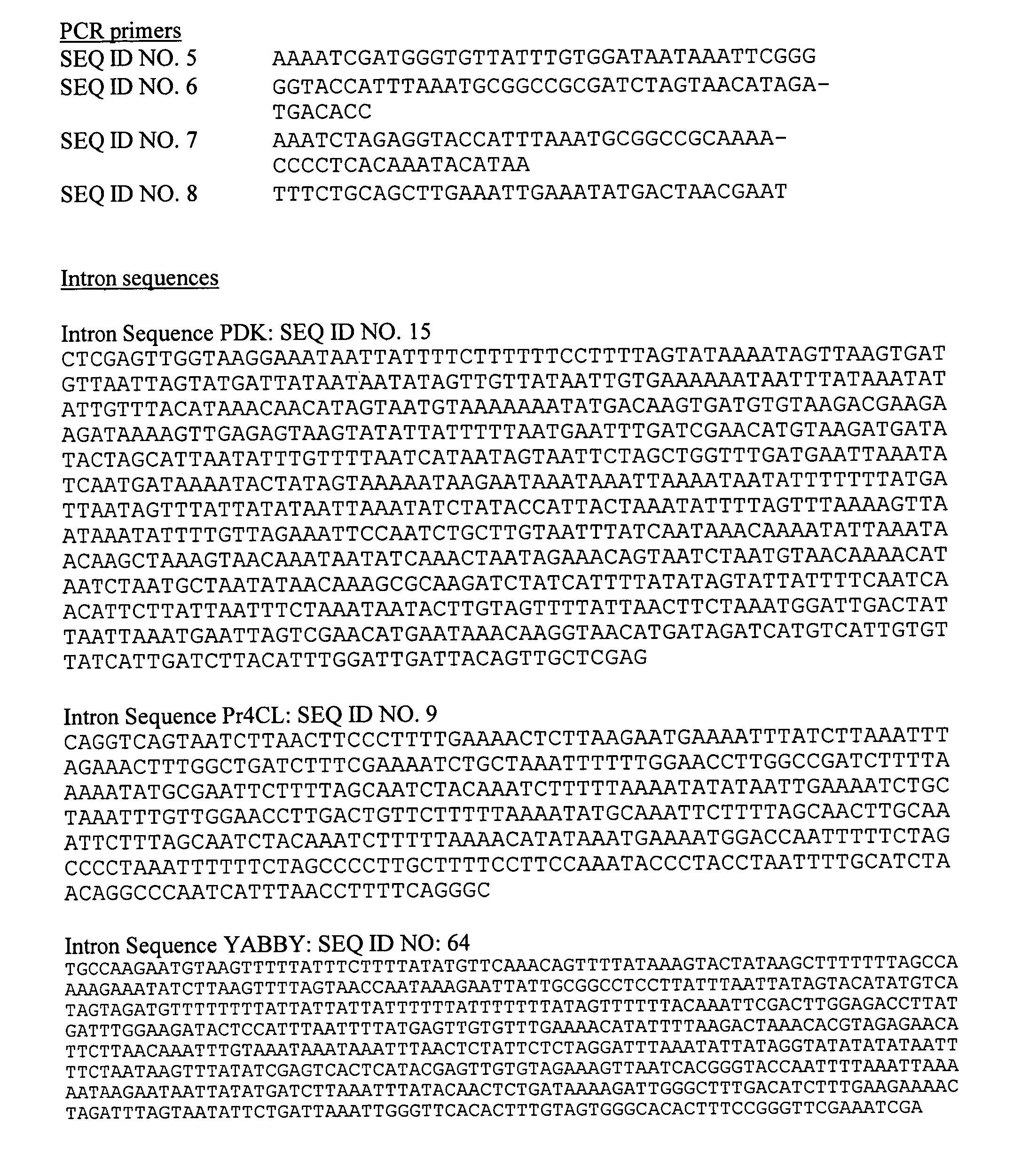

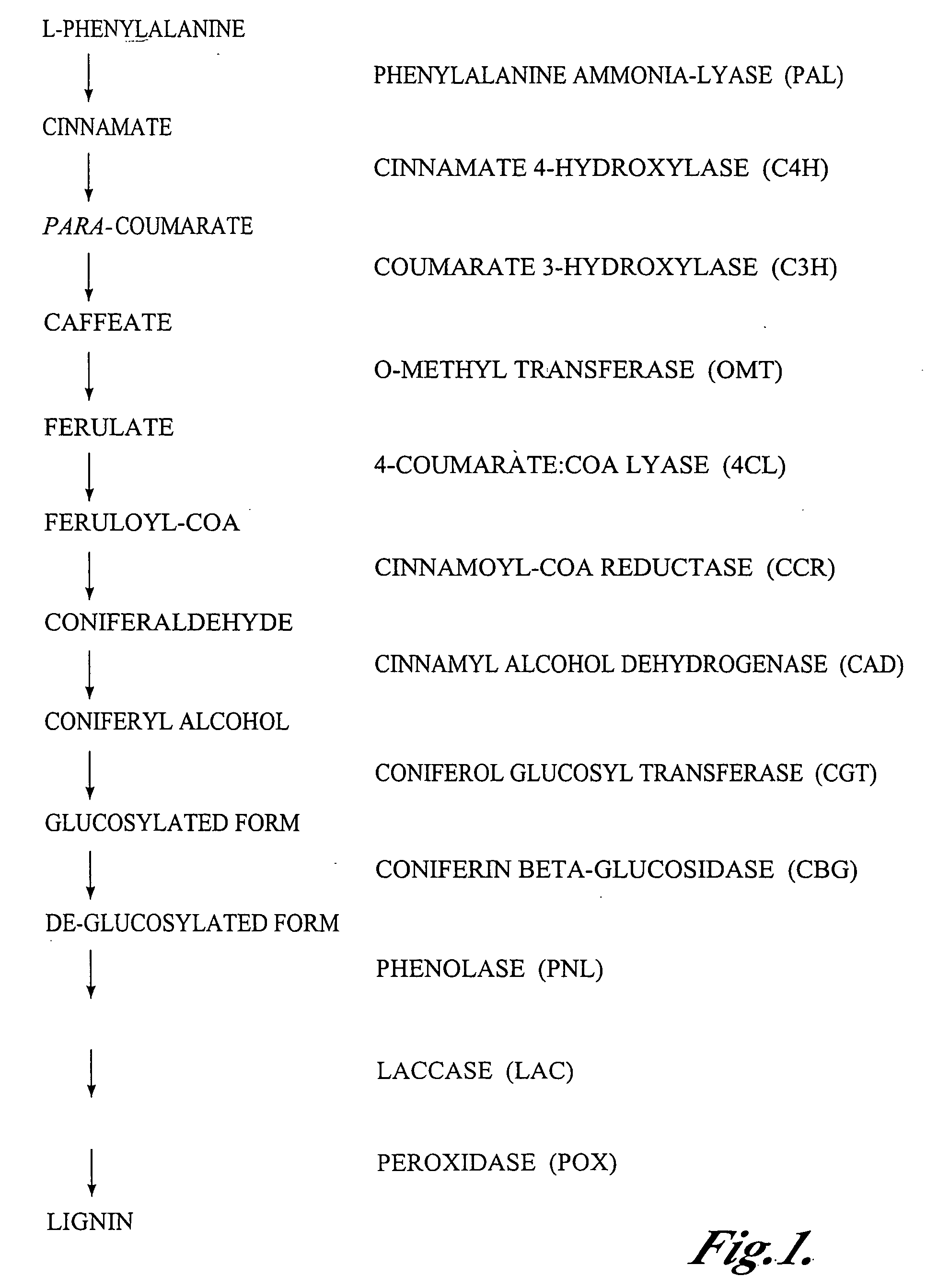

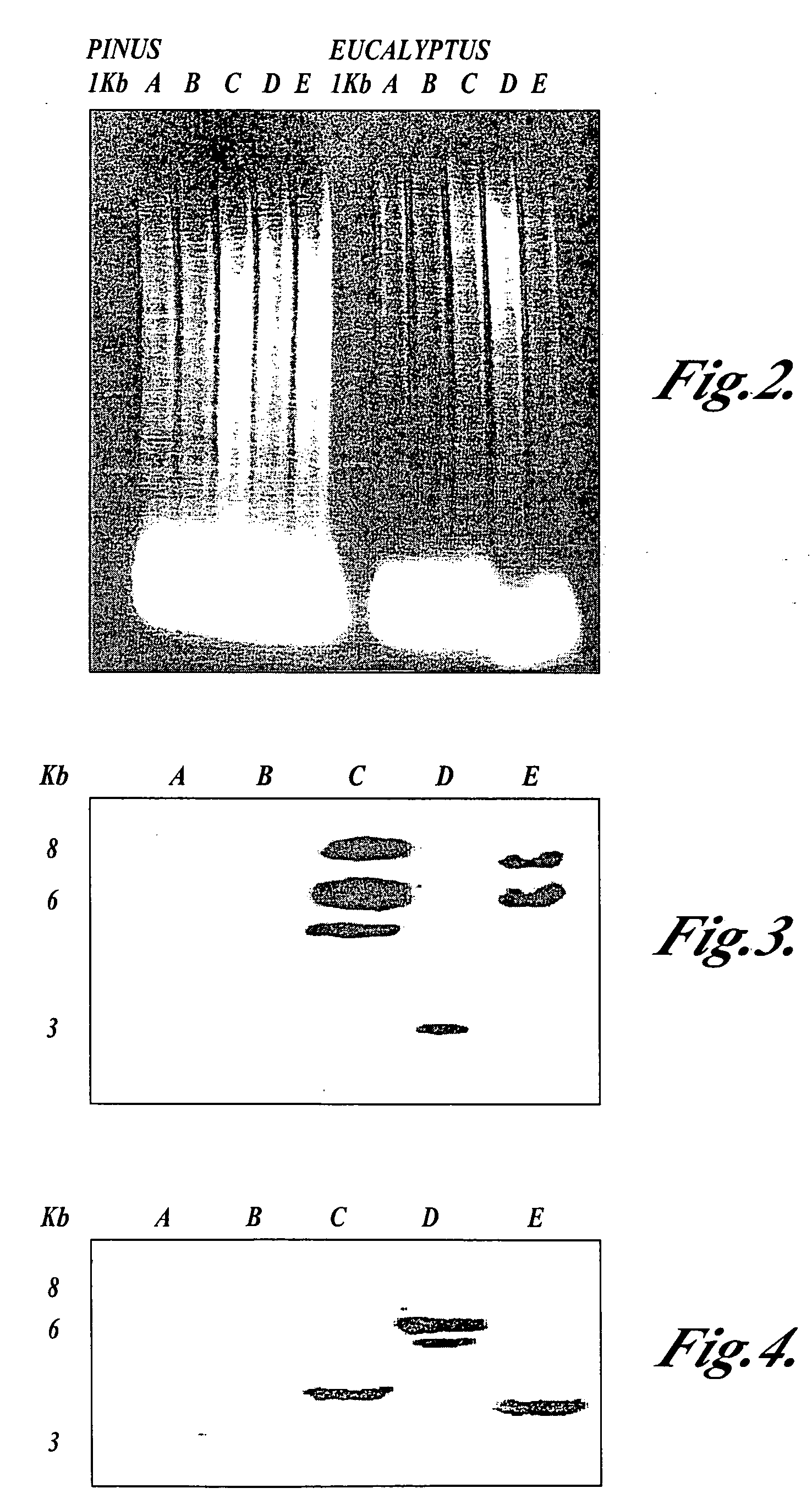

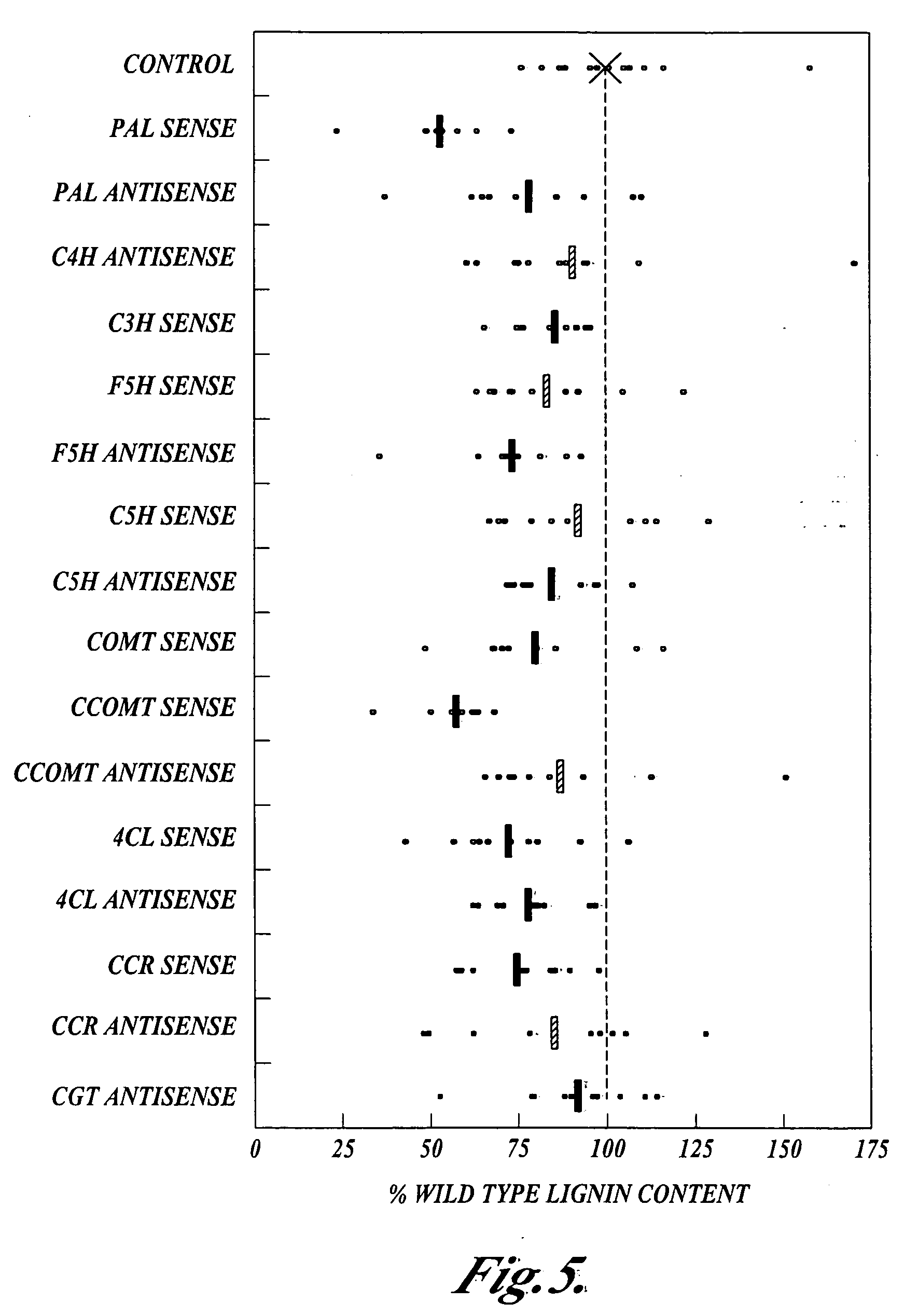

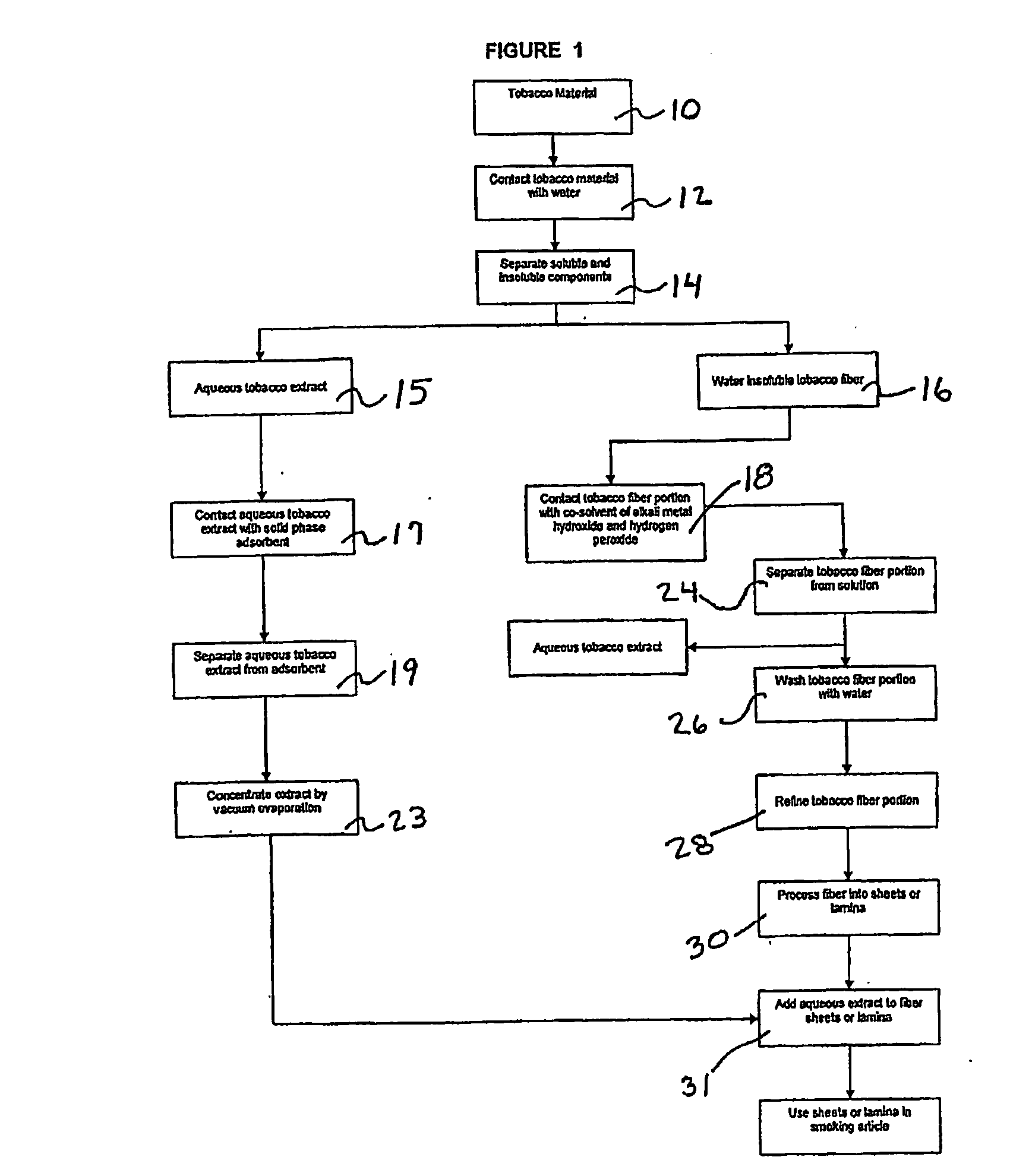

Modification of plant lignin content

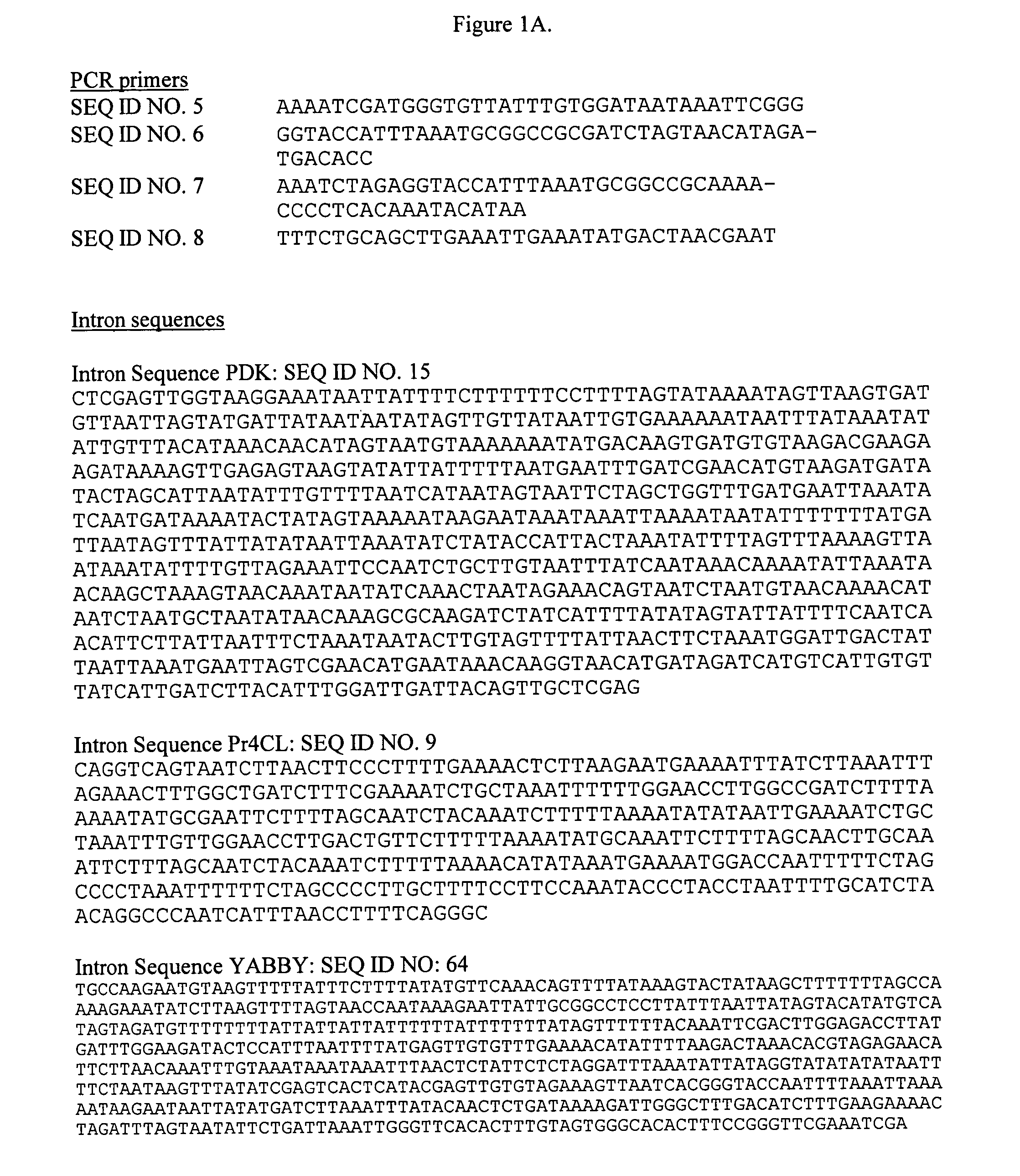

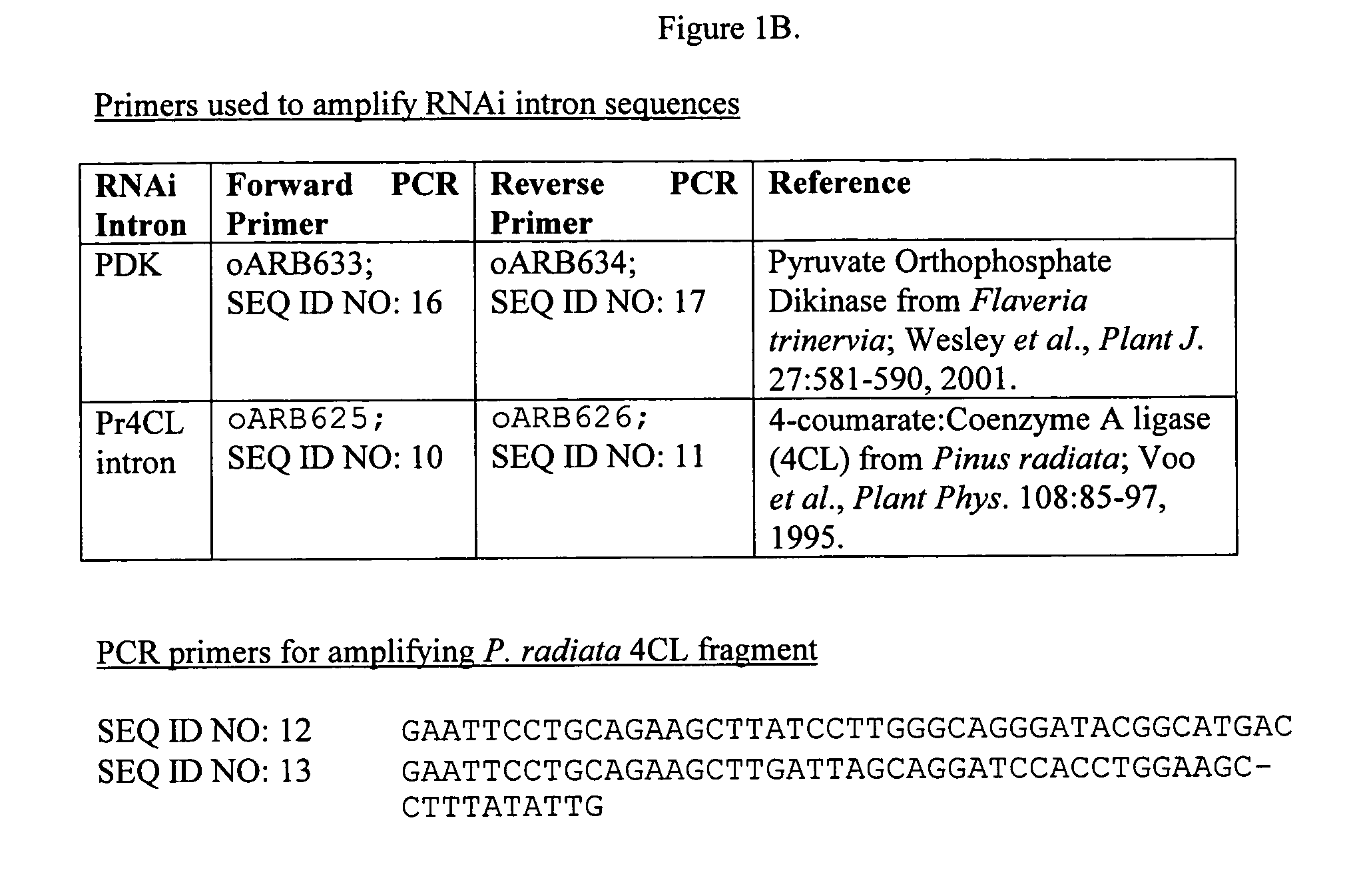

DNA constructs comprising a first DNA segment that corresponds to at least a portion of a gene in the monolignol biosynthetic pathway, a spacer DNA segment, and a second DNA segment that is complementary to the first DNA segment can be used to reduce or modulate the lignin content in plants. In some embodiments, DNA constructs comprise at a least a portion of a gene for 4CL, C3H, CCR, C4H or CCoAOMT. Vascular-preferred and constitutive promoters can be used to drive expression of the constructs.

Owner:ARBORGEN

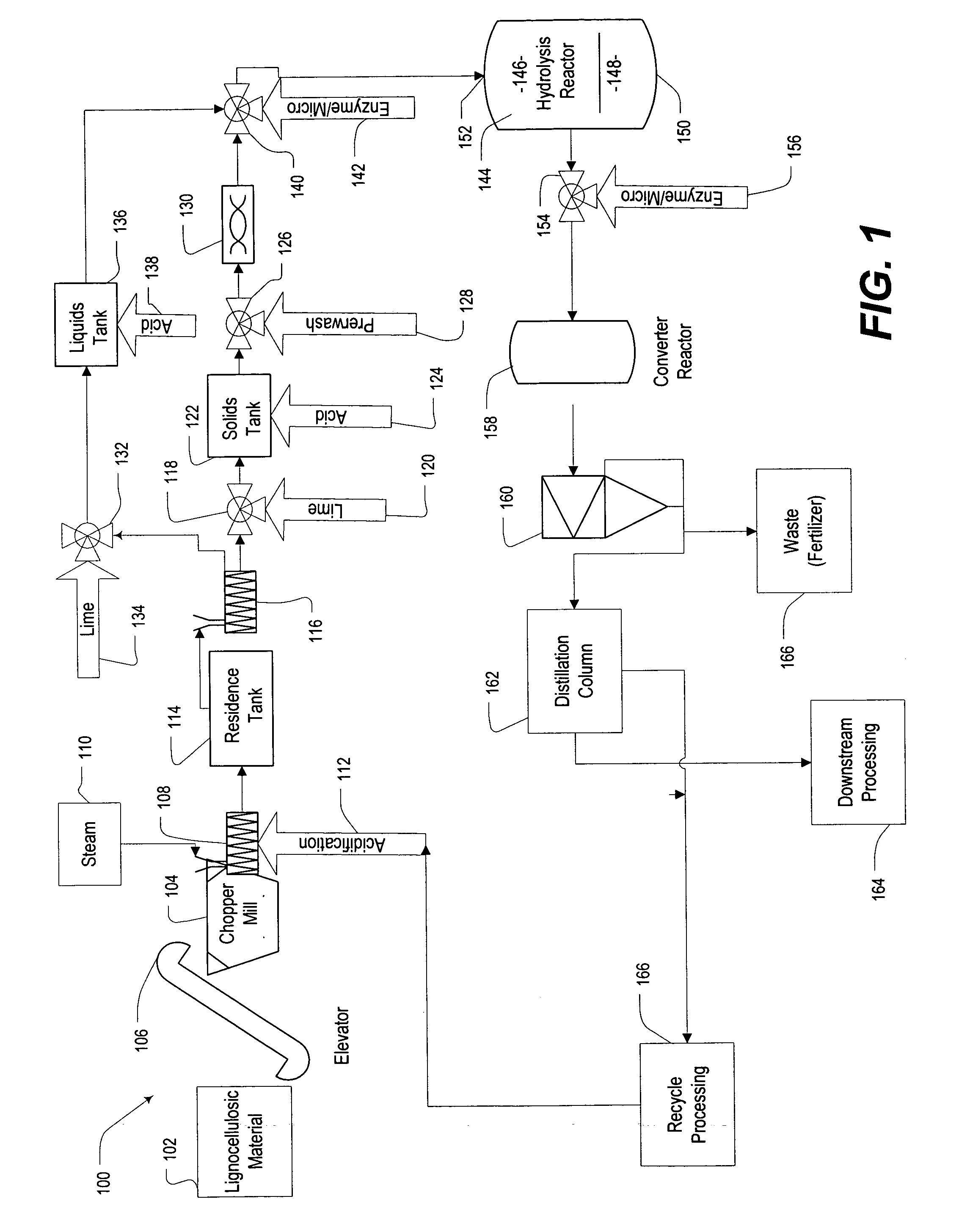

Method and apparatus for fractionating lignocellulose-based biomass

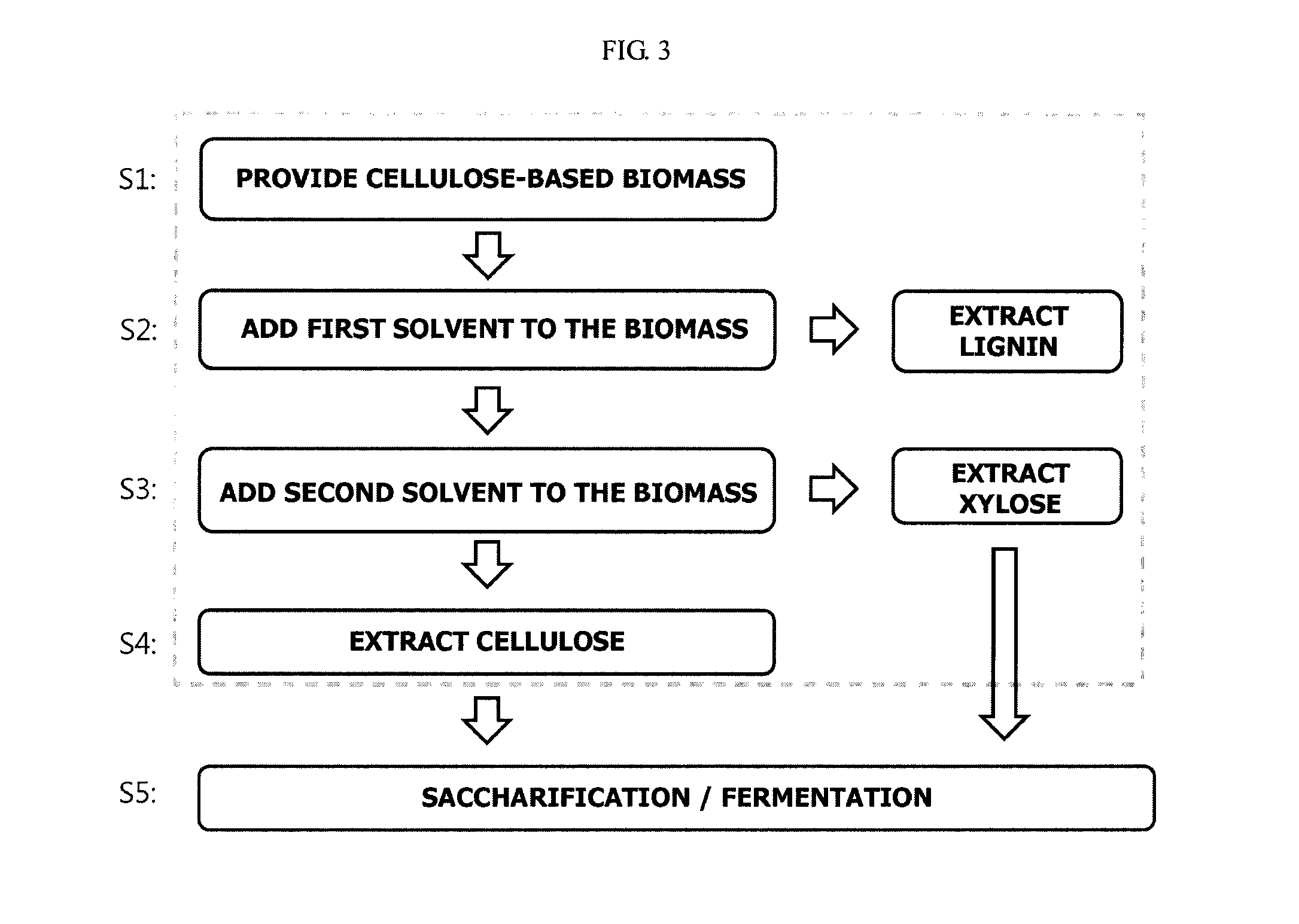

ActiveUS20100203605A1Improve processing efficiencyEnhanced interactionPressurized chemical processBiological substance pretreatmentsCelluloseLignin degradation

A method and apparatus for fractionating a lignocellulose-based biomass are provided. The method includes providing a lignocellulose-based biomass, extracting lignin from the biomass by adding a first solvent capable of dissolving the lignin, extracting xylose by adding a second solvent capable of dissolving hemicellulose to the biomass treated with the first solvent, and extracting the cellulose remaining in the biomass. In this method, a continuous process can be performed instead of a low efficiency batch-type process and components of the biomass can be obtained at high yield.

Owner:SAMSUNG ELECTRONICS CO LTD

Method for Separating Lignin from Black Liquor

ActiveUS20080047674A1Smoother resultAvoid cloggingLignin derivativesPulp by-products recoveryLignin degradationBlack liquor

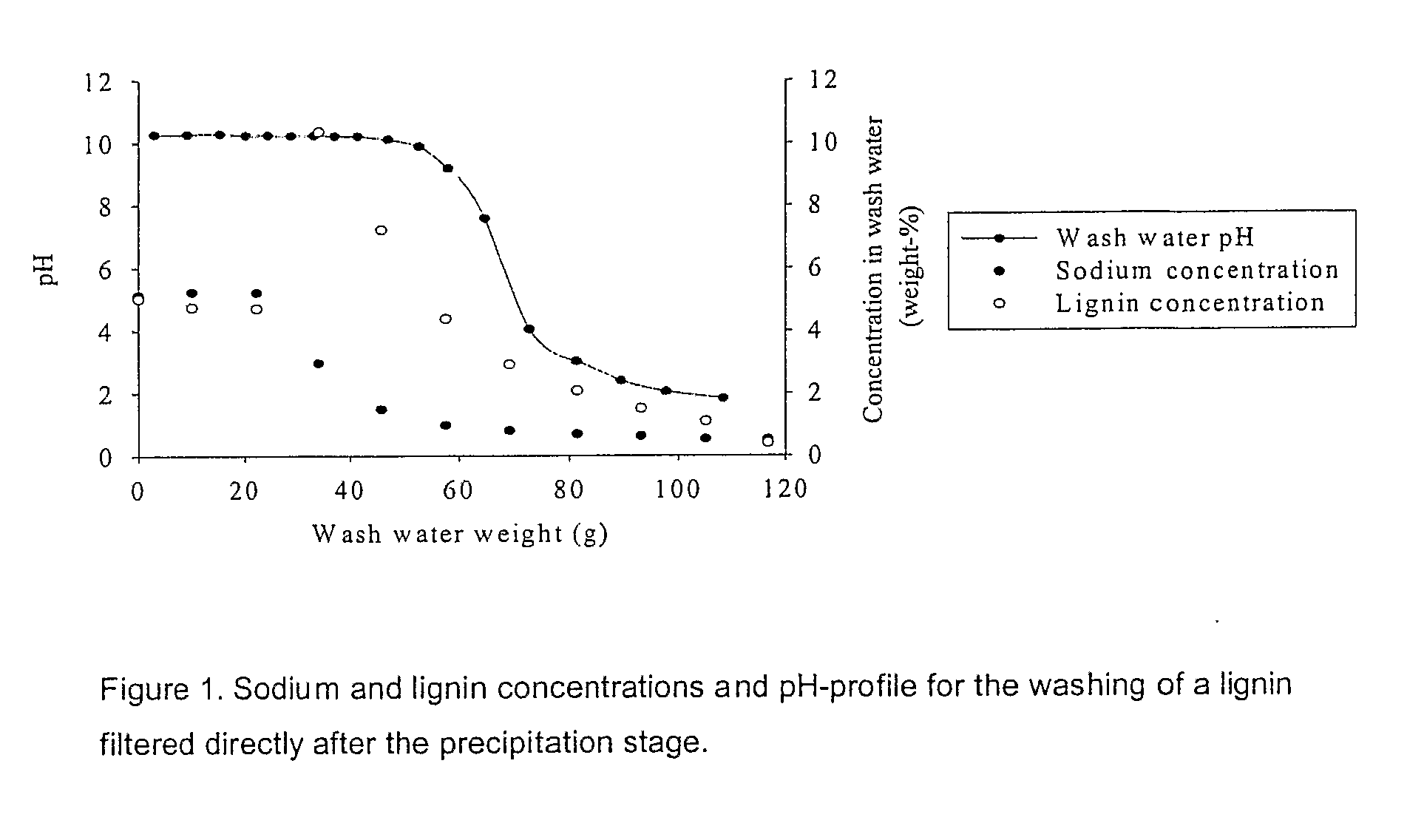

Method for separating lignin from black liquor includes the following steps: a) precipitating lignin by acidifying black liquor and thereupon dewatering, b) suspending the lignin filter cake obtained in step a) to obtain a second lignin suspension and adjusting the pH level to approximately that of the washing water of step d) below, c) dewatering of the second lignin suspension, d) adding washing water and performing a displacement washing at substantially constant conditions without any dramatic gradients in the pH, and e) dewatering the lignin cake produced in step d) into a high dryness and displacing the remaining washing liquid in the filter cake, whereby a lignin product is obtained which has an even higher dryness after the displacement washing of step d). The lignin product or an intermediate lignin product obtained by the method, and its use, preferably for the production of heat or chemicals is also disclosed.

Owner:LIGNOBOOST

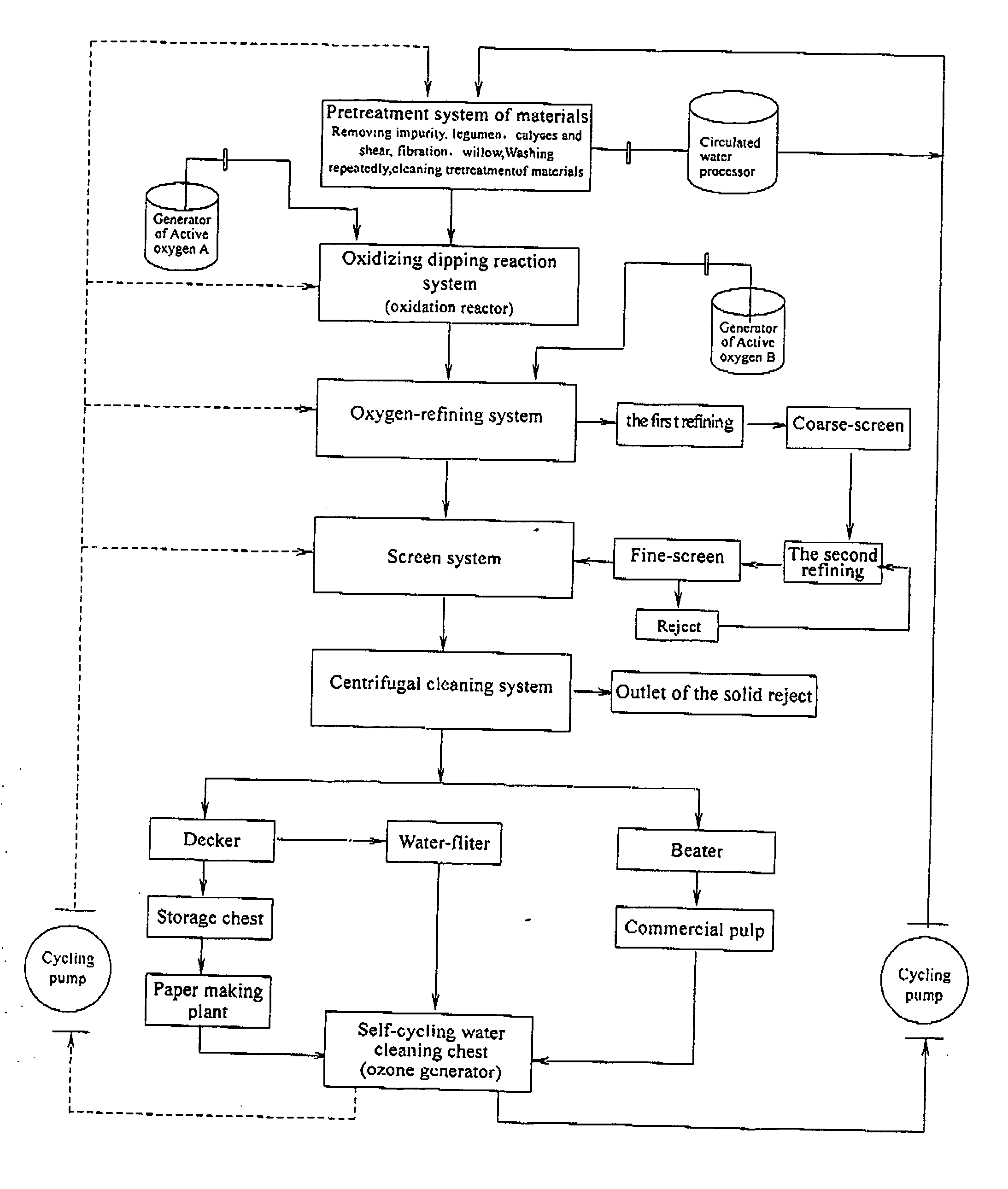

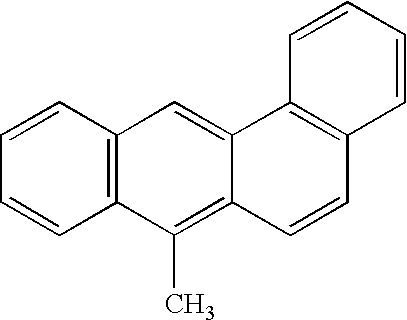

Fully Closed, Zero Discharge, Clean Oxidizing Pulping Technology and Process

InactiveUS20070272377A1Avoid pollutionSave energyPulp properties modificationPulp bleachingFiberLignin degradation

The aim of the present invention is to provide a close-loop, zero discharge and clean oxidation pulping method and technology. In accordance with present invention, it takes advantage of active oxygen free radical generated by reduction reaction of molecular oxygen in process reactor to transform and separate lignin to change chromophoric group in the intercellular space and obtain paper pulp. The conventional pulping technologies which use harmful polluting chemicals such as acid, alkaline, chlorine, anthraquinone and so on are basically changed in the present invention. The cooking and bleaching process, generating severe pollution, can be avoided. The abundant yearly grown fiber materials can be utilized in this process, and water and energy can be saved. The present invention can cut down production cost and have excellent social, economic and environmental performance.

Owner:MEI XIUQUAN

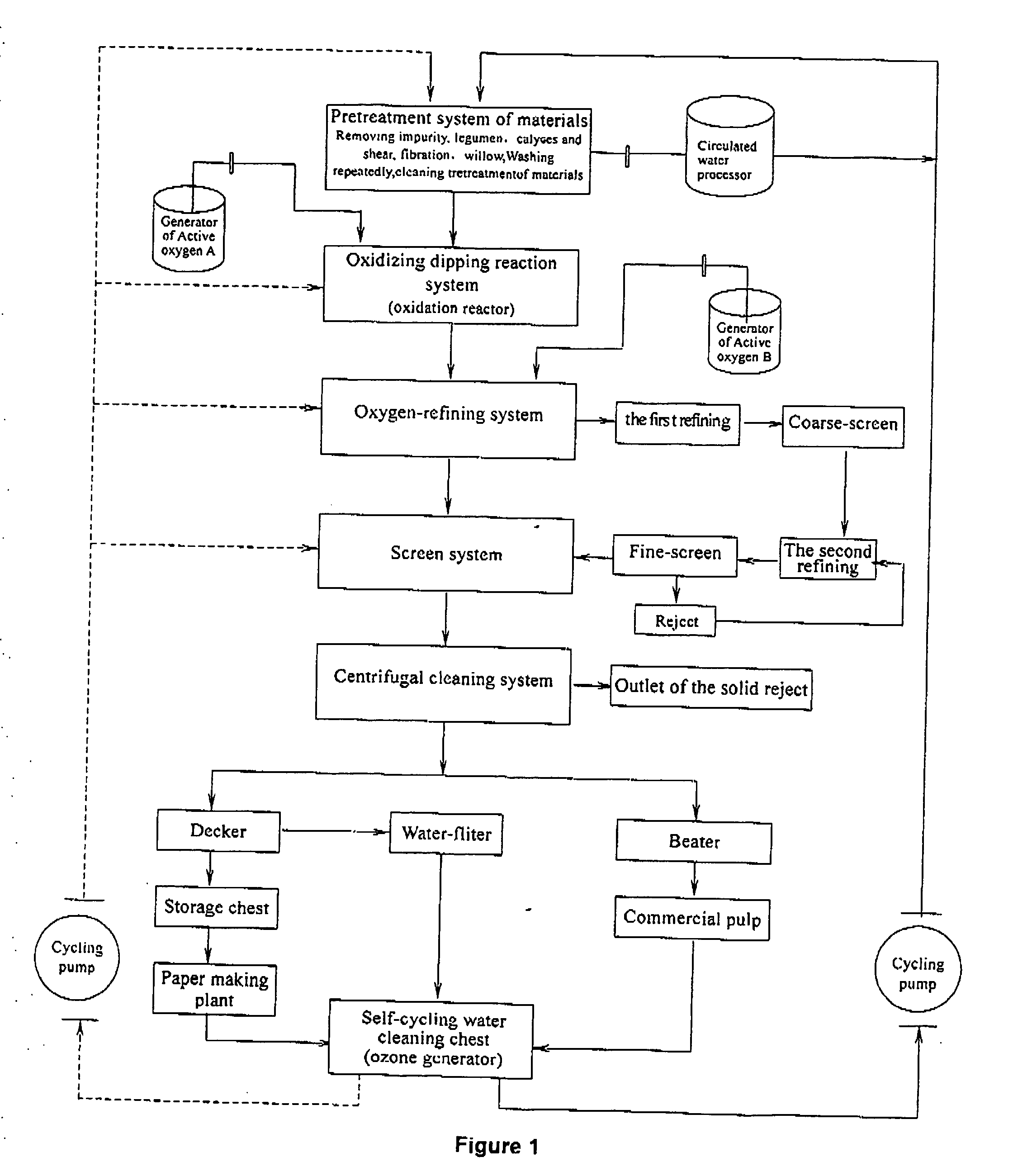

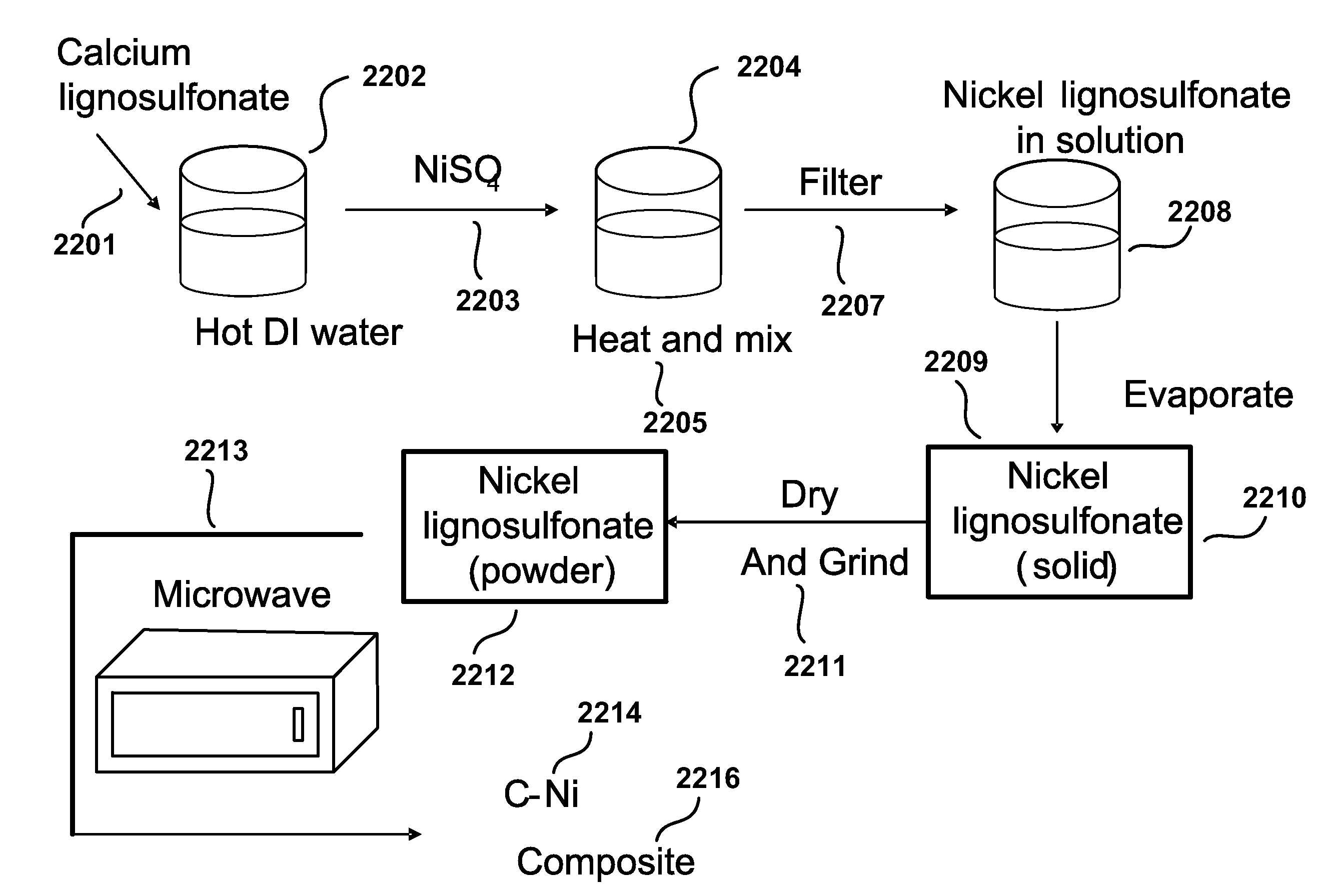

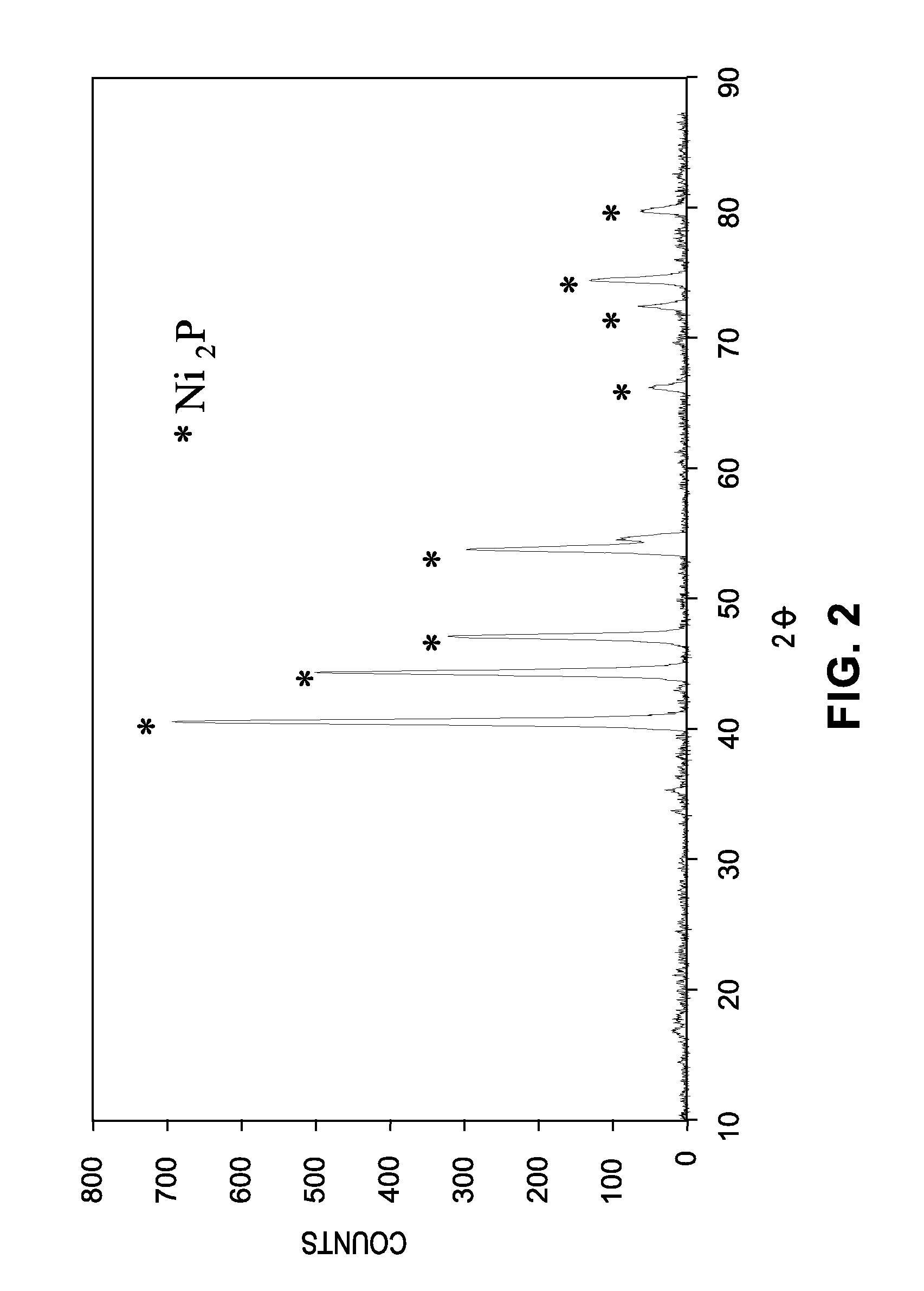

Microwave-assisted synthesis of carbon and carbon-metal composites from lignin, tannin and asphalt derivatives and applications of same

InactiveUS20100035775A1Quick and inexpensiveLarge specific surface areaNanotechConductive materialNanocompositeMicrowave irradiation

A plurality of carbon-metal nanocomposites. In one embodiment, the plurality of carbon-metal nanocomposites includes a plurality of carbons with a molecular structure that shows a first peak in the range of 1585 to 1565 cm−1 in a corresponding Raman spectrum, and a second peak in the range of 1325 to 1355 cm−1 in the corresponding Raman spectrum, wherein the first peak represents carbons with a graphitic nature and the second peak represents nanodiamonds, and wherein the plurality of carbon-metal nanocomposites is made from a metal derivative or metal chelated derivative of a carbon-containing precursor in solid form that is subjected to microwave radiation at a frequency in the range of 900 MHz to 5.8 GHz, for a period of time effective to allow the plurality of carbon-metal nanocomposites to be formed.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS

Method for improving separation of carbohydrates from wood pulping and wood or biomass hydrolysis liquors

A method for separating carbohydrates from pulping liquors includes the steps of providing a wood pulping or wood or biomass hydrolysis pulping liquor having lignin therein, and mixing the liquor with an acid or a gas which forms an acid upon contact with water to initiate precipitation of carbohydrate to begin formation of a precipitate. During precipitation, at least one long chain carboxylated carbohydrate and at least one cationic polymer, such as a polyamine or polyimine are added, wherein the precipitate aggregates into larger precipitate structures. Carbohydrate gel precipitates are then selectively removed from the larger precipitate structures. The method process yields both a carbohydrate precipitate and a high purity lignin.

Owner:UT BATTELLE LLC

Lignin-based polyurethane and process for producing the same

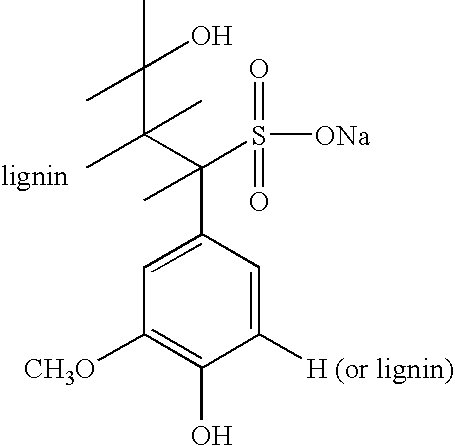

Provided is a polyurethane which is inexpensive and excellent in physical properties and which contains a lignin sulfonic acid component incorporated into the molecular chain of the polyurethane. The polyurethane is obtainable by polycondensation of a polyol solution containing dissolved therein lignin sulfonic acid or a partially neutralized salt thereof with a polyisocyanate, wherein the content of said lignin sulfonic acid is 1-40% based on a total weight of said polyurethane.

Owner:NAT INST OF ADVANCED IND SCI & TECH +2

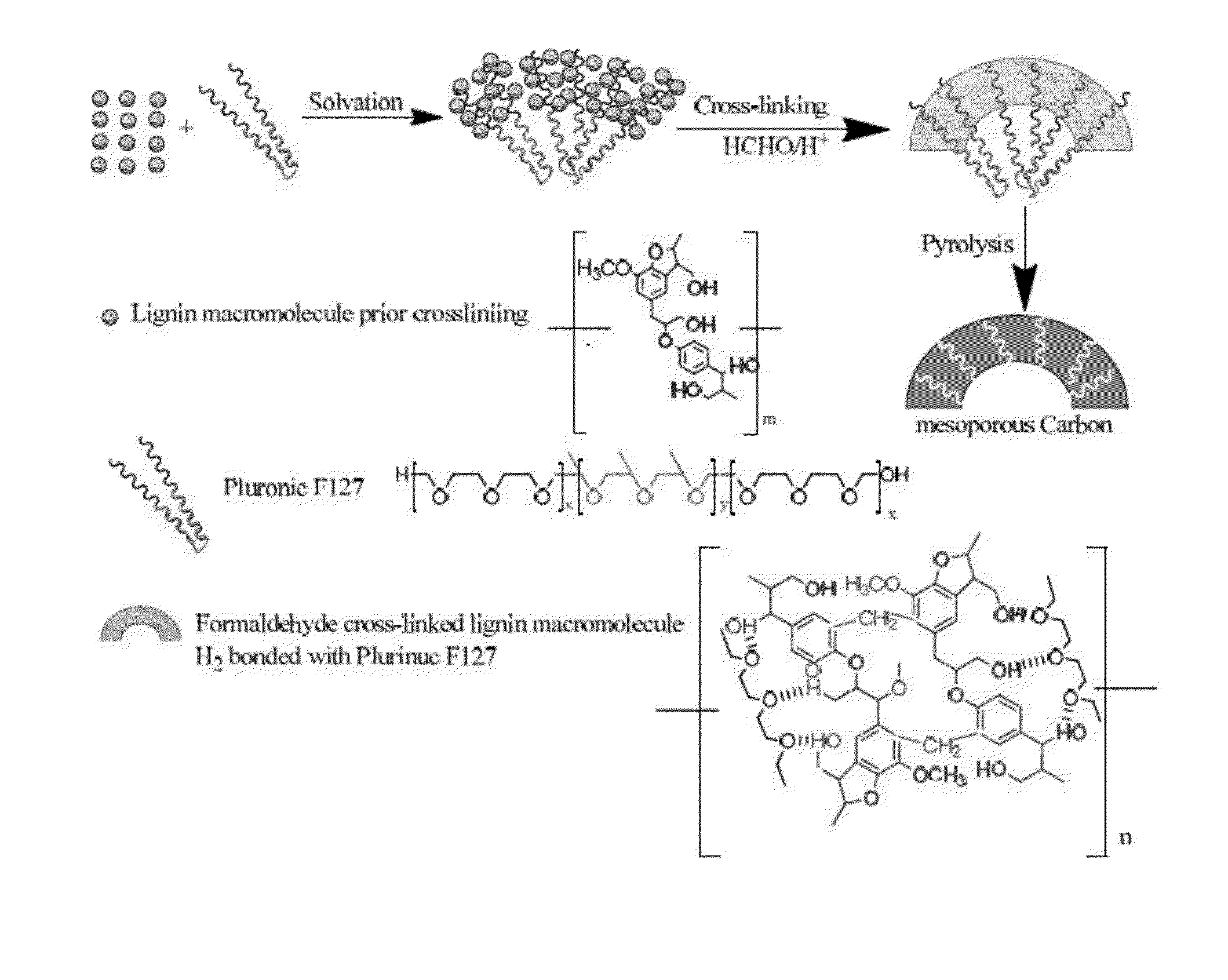

Lignin-derived porous carbon composition, methods of preparation, and use thereof

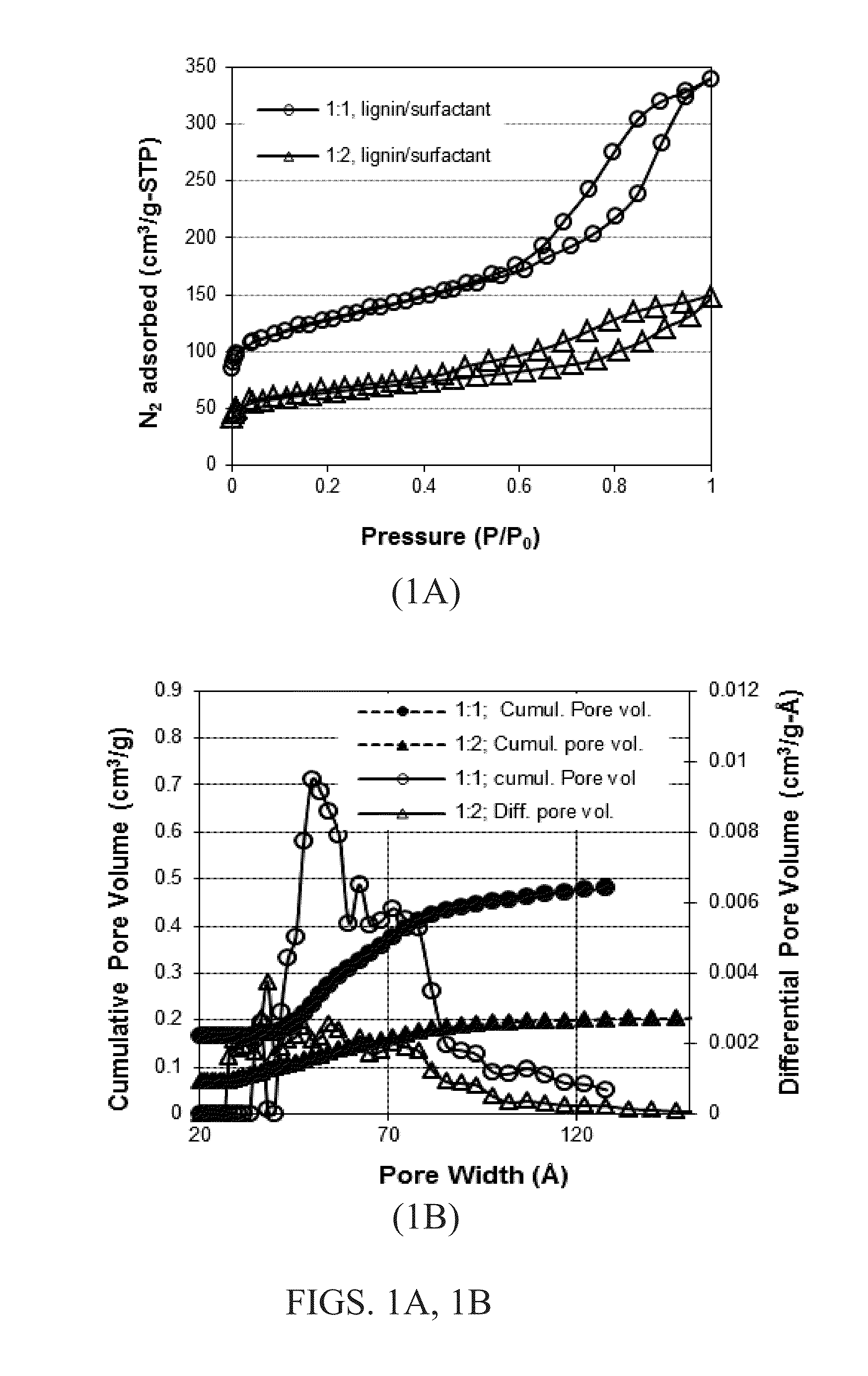

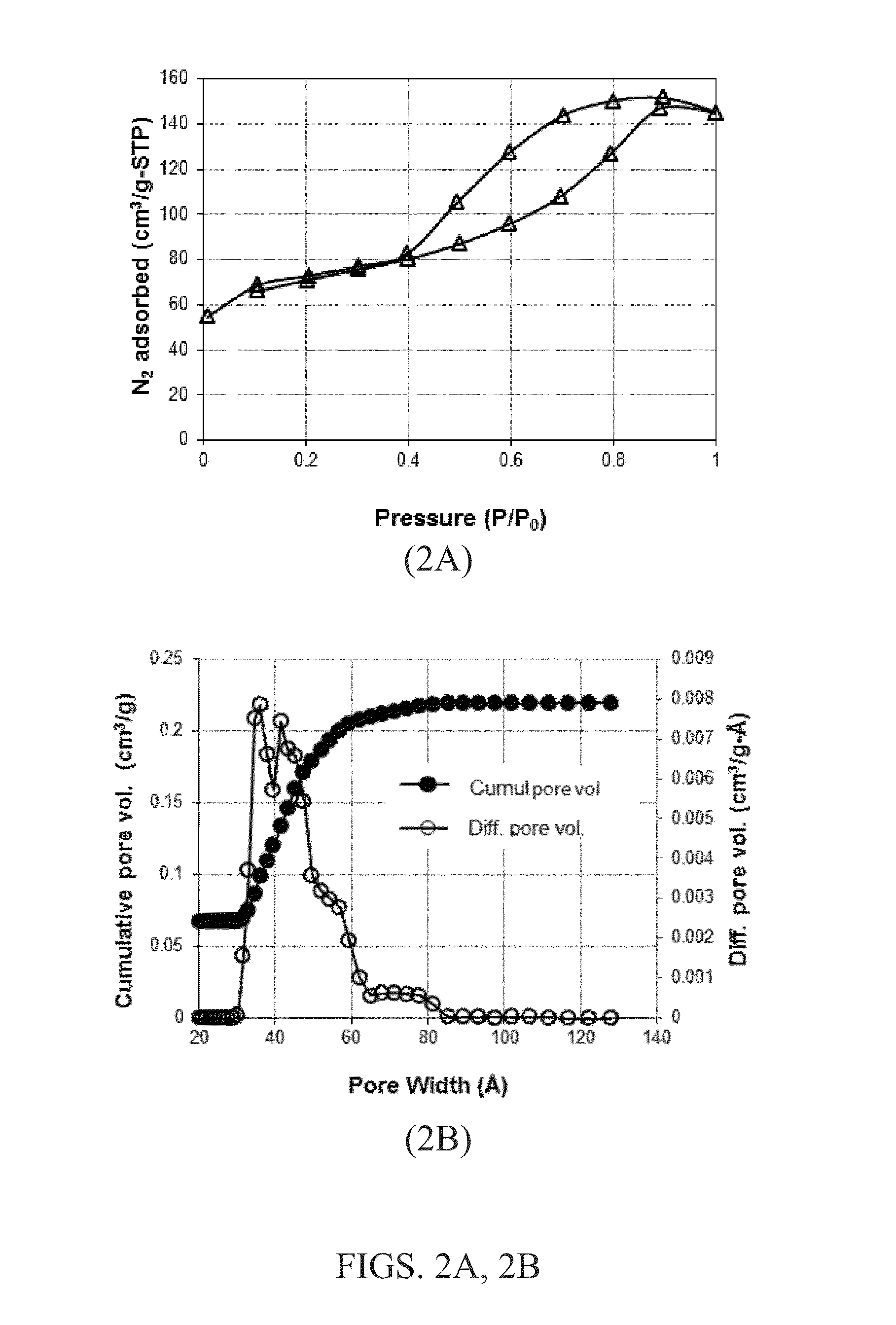

InactiveUS20140227325A1Reduce carbon footprintOther chemical processesCarbon active ingredientsLignin degradationSufficient time

A method of fabricating a porous carbon composition, the method comprising subjecting a precursor composition to a thermal annealing step followed by a carbonization step, the precursor composition comprising: (i) a templating component comprised of a block copolymer and (ii) a lignin component, wherein said carbonization step comprises heating the precursor composition at a carbonizing temperature for sufficient time to convert the precursor composition to a carbon material comprising a carbon structure in which is included mesopores having a diameter within a range of 2 to 50 nm, wherein said porous carbon composition possesses a mesopore volume of at least 50% with respect to a total of mesopore and micropore volumes. Also described are the resulting mesoporous carbon composition, a composite of the mesoporous carbon material and at least one pharmaceutical agent, and the administration of the carbon-pharmaceutical dosage form to a subject.

Owner:UT BATTELLE LLC

Charge-based water filtration systems

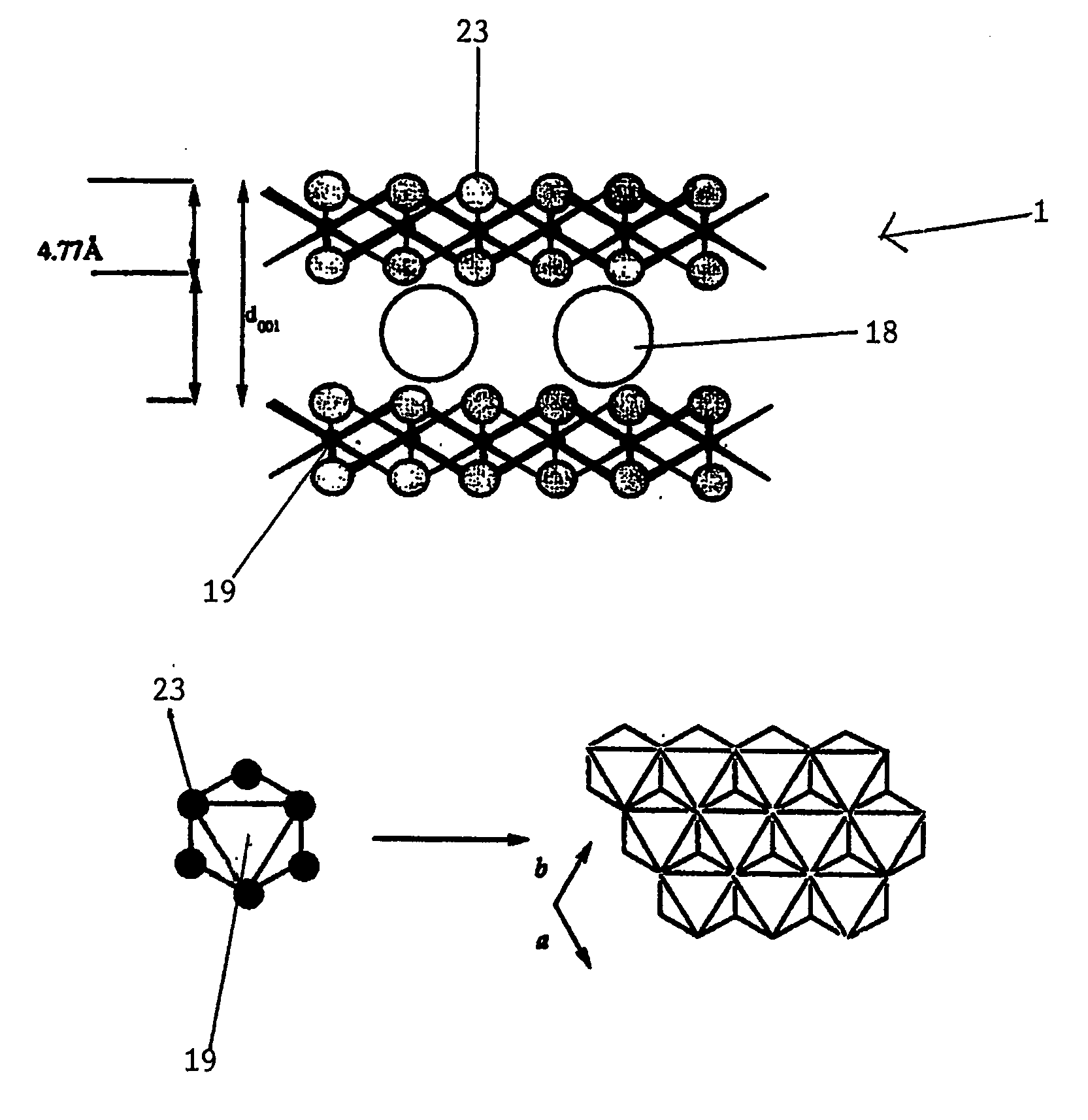

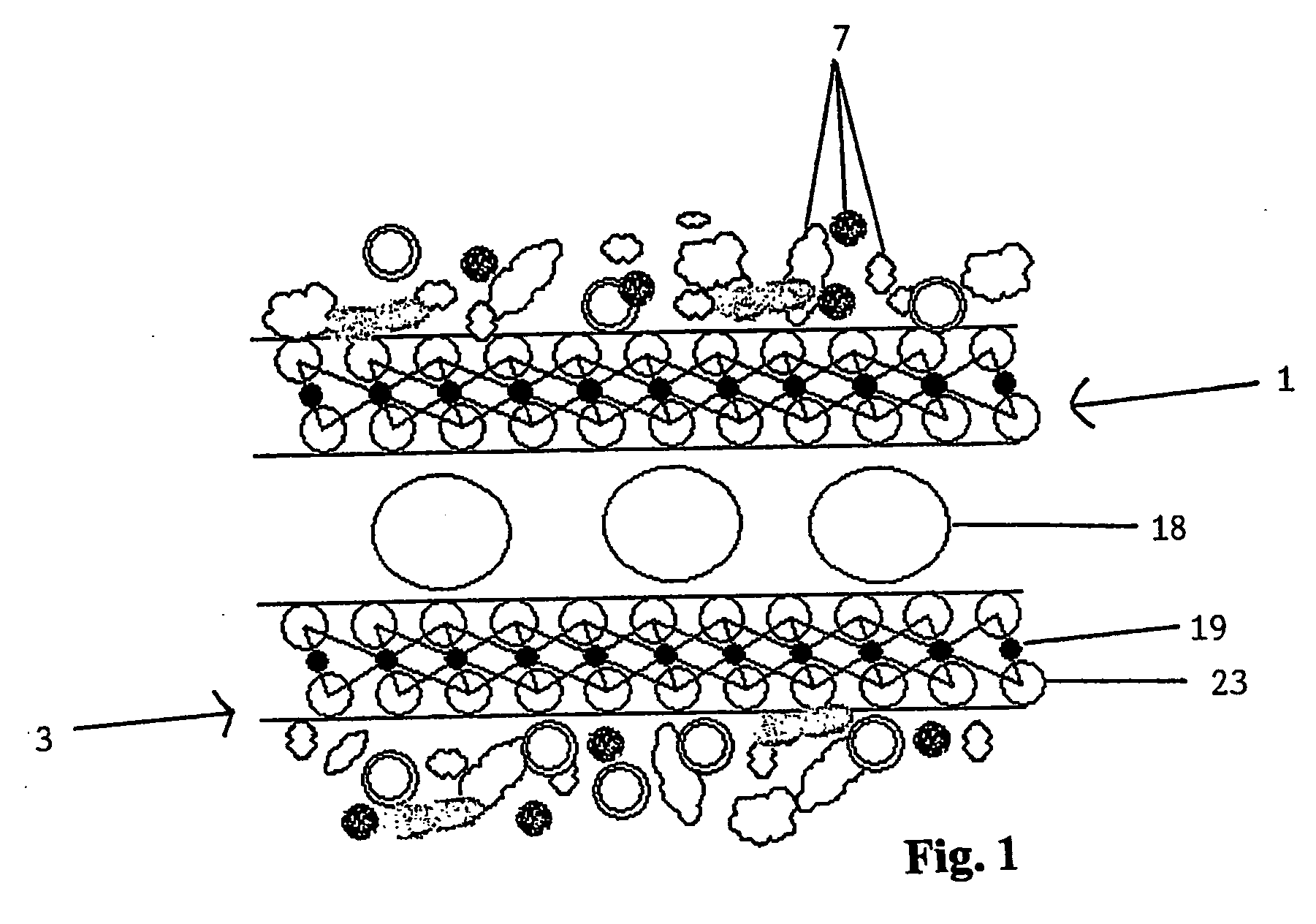

InactiveUS20060070952A1Liquid separation by electricityVolume/mass flow measurementLignin degradationFiltration

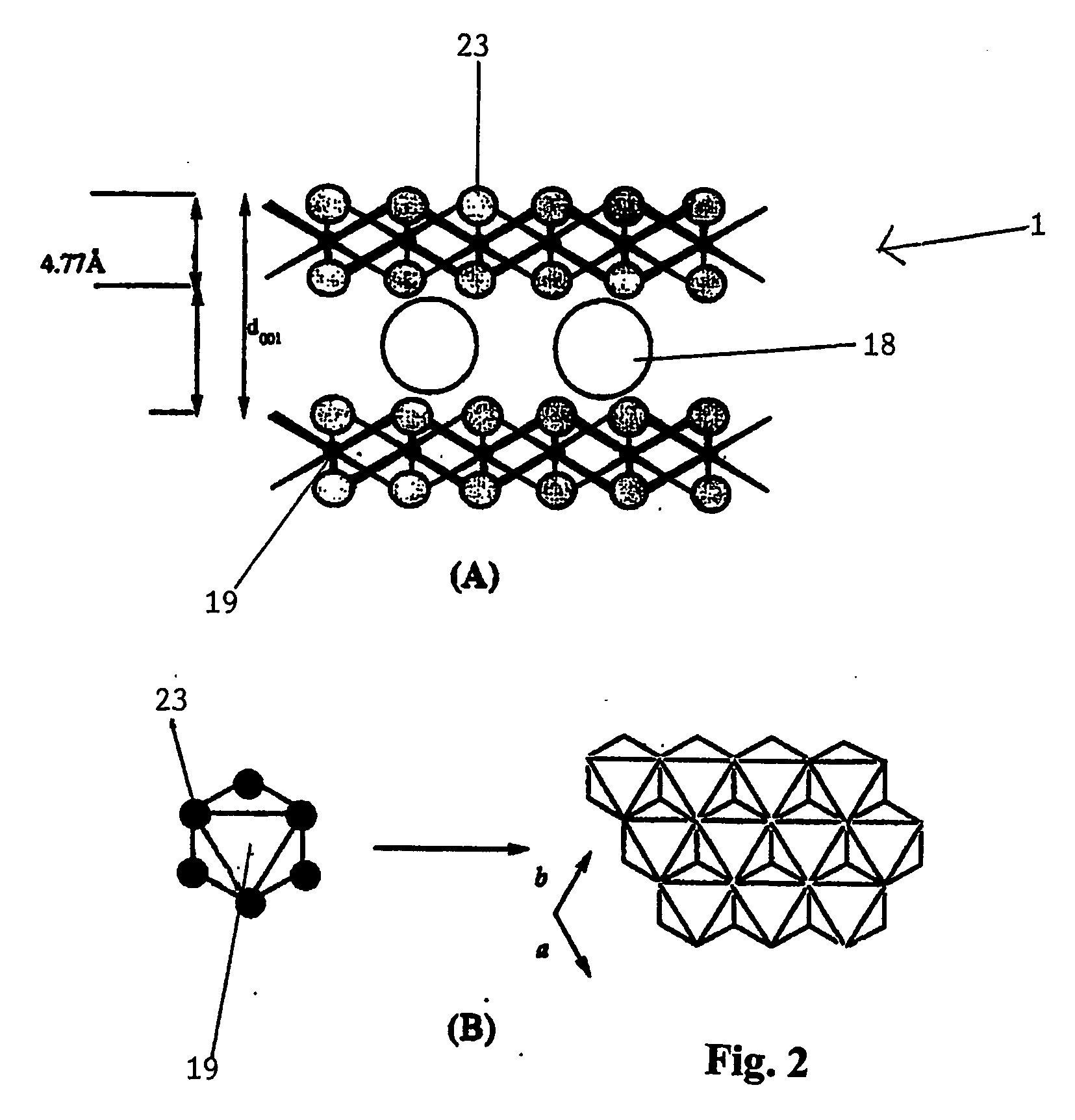

Generally, systems for air and water purification using unpowered charged sorbent mediums (3) which may include layered double hydroxide (LDH) (1) compositions, lignin (2), and methods of sorbing inorganic or organic material(s) onto such mediums, including anionic contaminants (10), cationic contaminants (11), non ionic organic contaminants (20), and even biological agents (7) such as bacteria or viruses present in liquids or gases.

Owner:WESTERN RES INST INC

Production methods for solubilized lignin, saccharide raw material and monosaccharide raw material, and solubilized lignin

A new lignin degradation product, a method for producing the same, and methods for producing a saccharide raw material and a monosaccharide raw material are provided.The method for producing the new lignin degradation product includes: (a first step) mixing 100 parts by mass of a powder, obtained by pulverizing a lignocellulosic raw material and defatting the resulting powder with an organic solvent, with aqueous hydrogen peroxide in an amount of 20 to 400 parts by mass in terms of hydrogen peroxide and heating the mixture for 5 to 120 minutes at a pressure of 0.1 to 1.5 MPa and a temperature of 80 to 200° C. while irradiating the mixture with microwaves; (a second step) separating insoluble matter from the aqueous hydrogen peroxide; (a third step) extracting the insoluble matter with a solvent to produce an extract; and (a fourth step) distilling the solvent away from the extract to yield a solubilized lignin as a residue. Further, a saccharide raw material composed mainly of a polysaccharide or a monosaccharide raw material is obtained by subjecting the liquid portion or the insoluble matter, respectively, obtained in the first step to a predetermined treatment.

Owner:NIPPON STEEL AND SUMIKIN CHEMICAL CO LTD

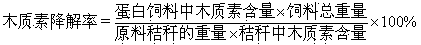

Technology for extracting bran dietary fibers by combining ultrasonic-assisted enzymolysis and microbial fermentation

ActiveCN104921149AImprove functionalityHigh nutritional valueFood ingredientsFood ultrasonic treatmentBiotechnologyCellulose

The invention discloses a technology for extracting bran dietary fibers by combining ultrasonic-assisted enzymolysis and microbial fermentation. The gloss of a dietary fiber product is ivory, the function index of the dietary fiber product is far higher than the standard of dietary fibers commonly used in the western countries, and the dietary fiber product can serve as high-quality dietary fibers and an ideal food additive. The technology has the advantages that the dietary fibers in bran are extracted through the technology of combining ultrasonic-assisted enzymolysis protein starch removal, microbial fermentation and ultrasonic-assisted enzymolysis, the product yield and the function are obviously improved; the bran dietary fibers obtained after ultrasonic-assisted enzymolysis and microbial fermentation are carried out and the lignin degradation rate reach 70% or higher, part of thallus dietary fibers are included, and the nutrient value of the bran dietary fibers is obviously improved; the production cost of the technology is low, industrialization production is facilitated, and a set of bran dietary fiber developing and utilizing approach which is high in efficiency, low in cost, safe and feasible is established.

Owner:HENAN KUANGHUA FOOD CO LTD

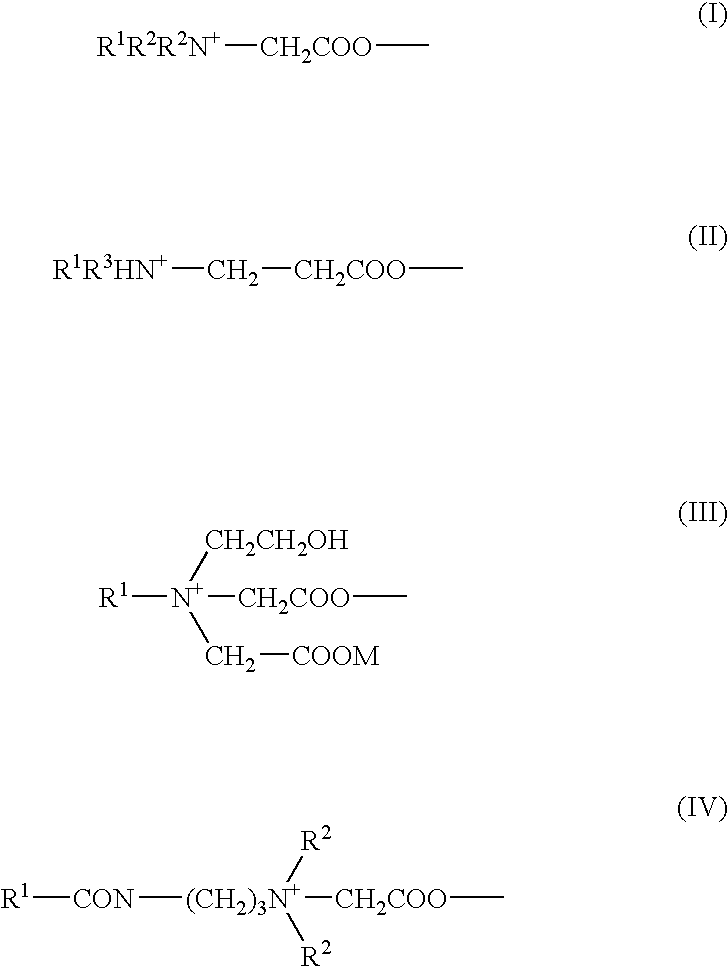

Use of polymers in dishwashing compositions for the removal of grease and oil from plastic dishware, and dishwashing compositions

InactiveUS20070272277A1Easy to cleanHigh molecular weightOrganic detergent compounding agentsAnionic surface-active compoundsAdditive ingredientPyridine-N-oxide

Owner:THE PROCTER & GAMBLE COMPANY

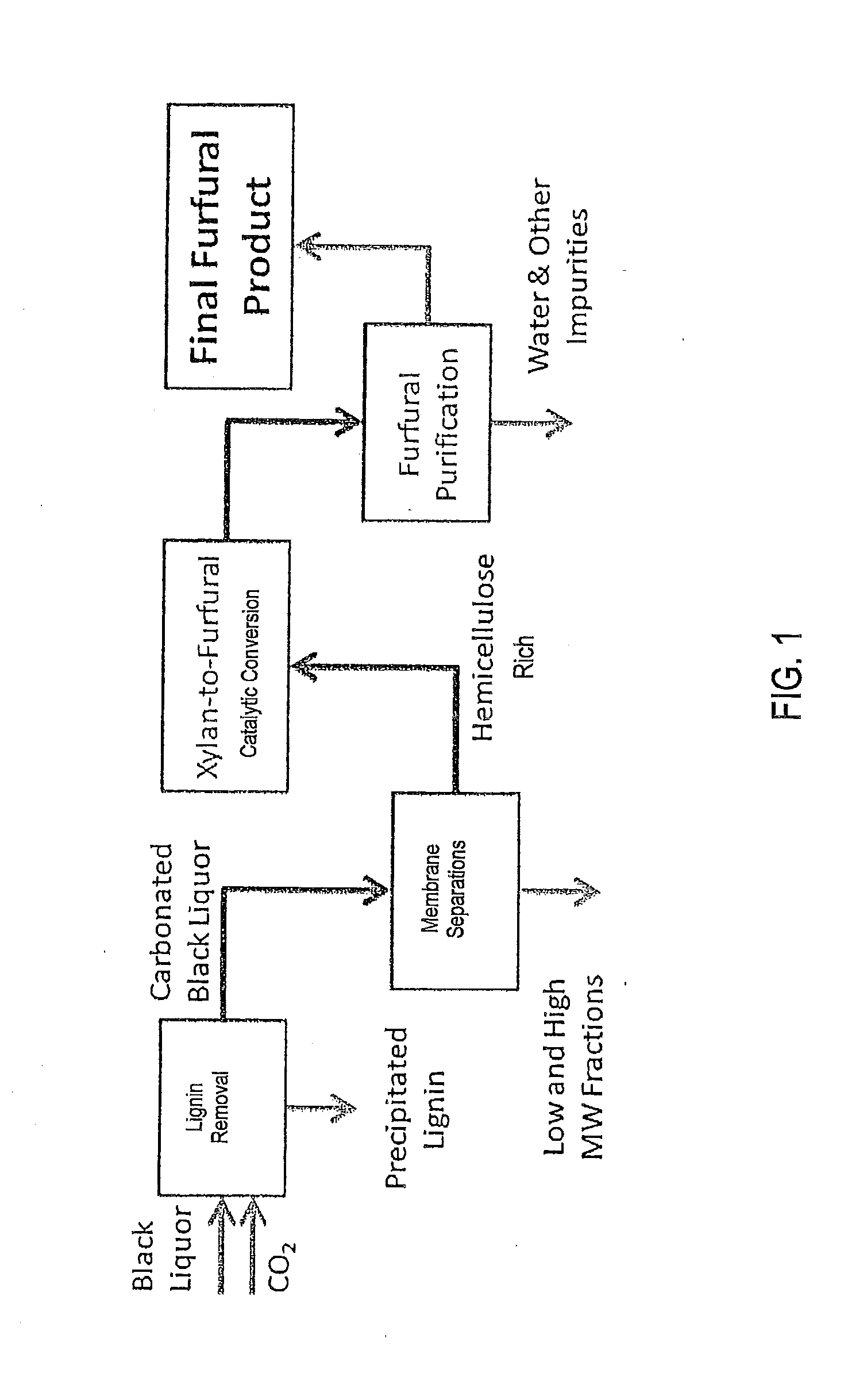

Process for producing furfural from black liquor

A process for making furfural using papermaking black liquor from the kraft pulping process as a feed material. First, the lignin is removed from the black liquor by carbonizing the black liquor to a pH below pH 10 to insolubilize the lignin, neutralize NaOH and other inorganic components of the black liquor. The next step is to treat the carbonated black liquor that contains the hemicellulose to remove the high molecular weight components. In a preferred embodiment the treatment uses multiple sequential steps. The first step of the treatment is to use ultrafiltration, centrifugation or dissolved-air floatation to separate the high molecular weight components. The second filtration is to pass the hemicellulose containing black liquor stream through a nanofilter to remove low molecular weight components. The conversion of xylans in the hemicellulose-containing mixture to furfural is accomplished using a catalytic process. The xylans are converted to pentose sugars and then converted to furfural. The furfural is formed at a low concentration and then further concentrated.

Owner:LIQUID LIGNIN

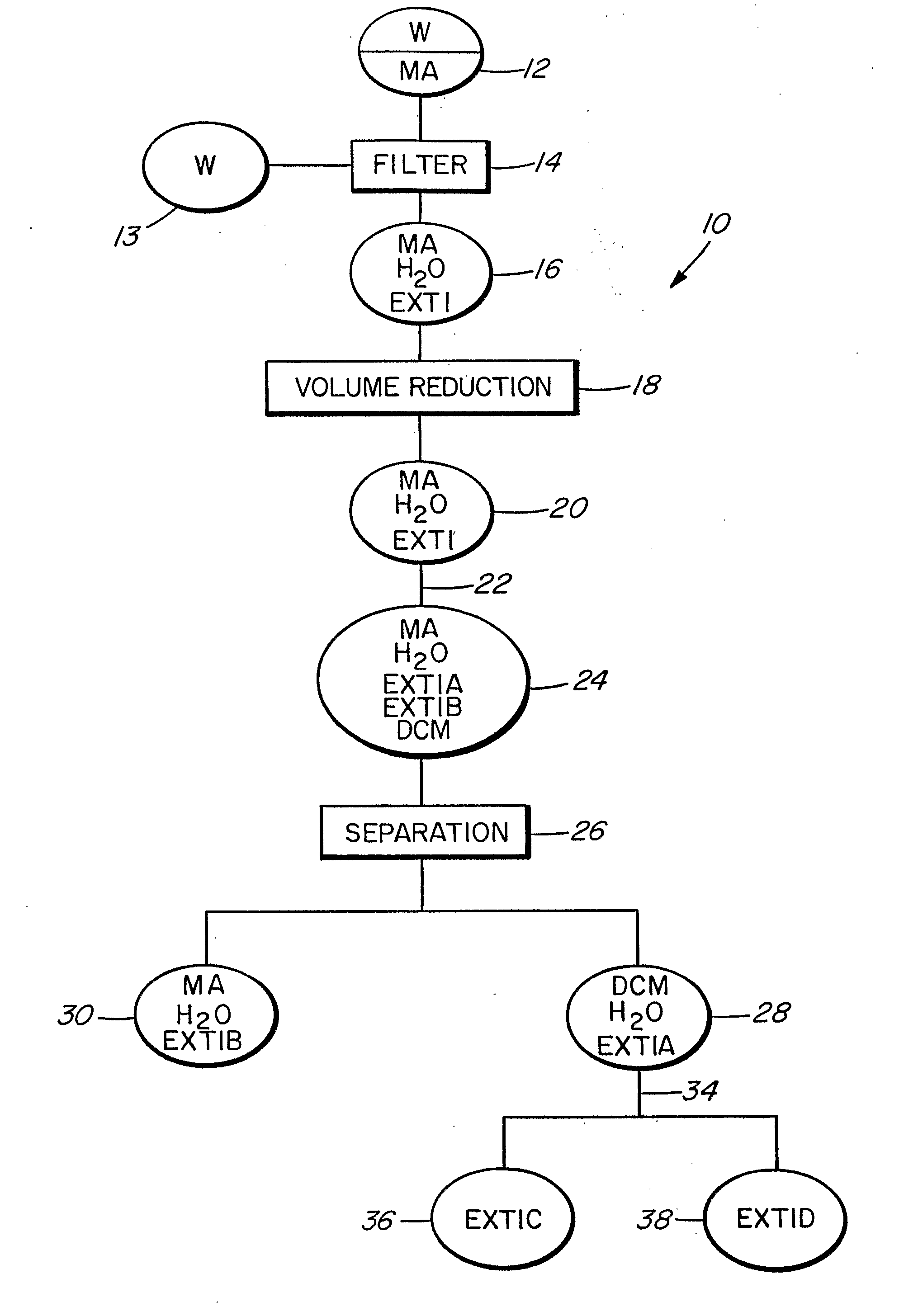

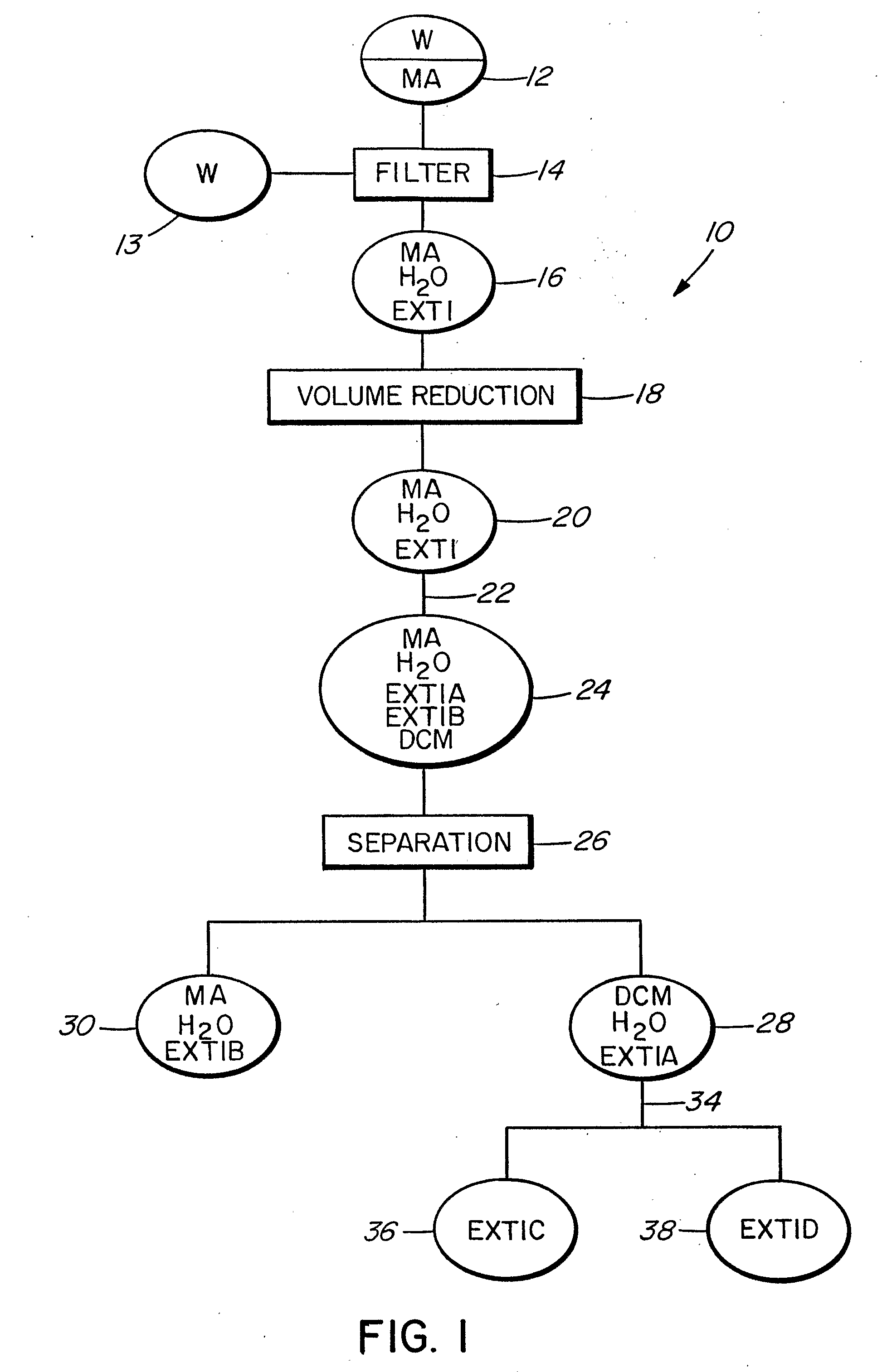

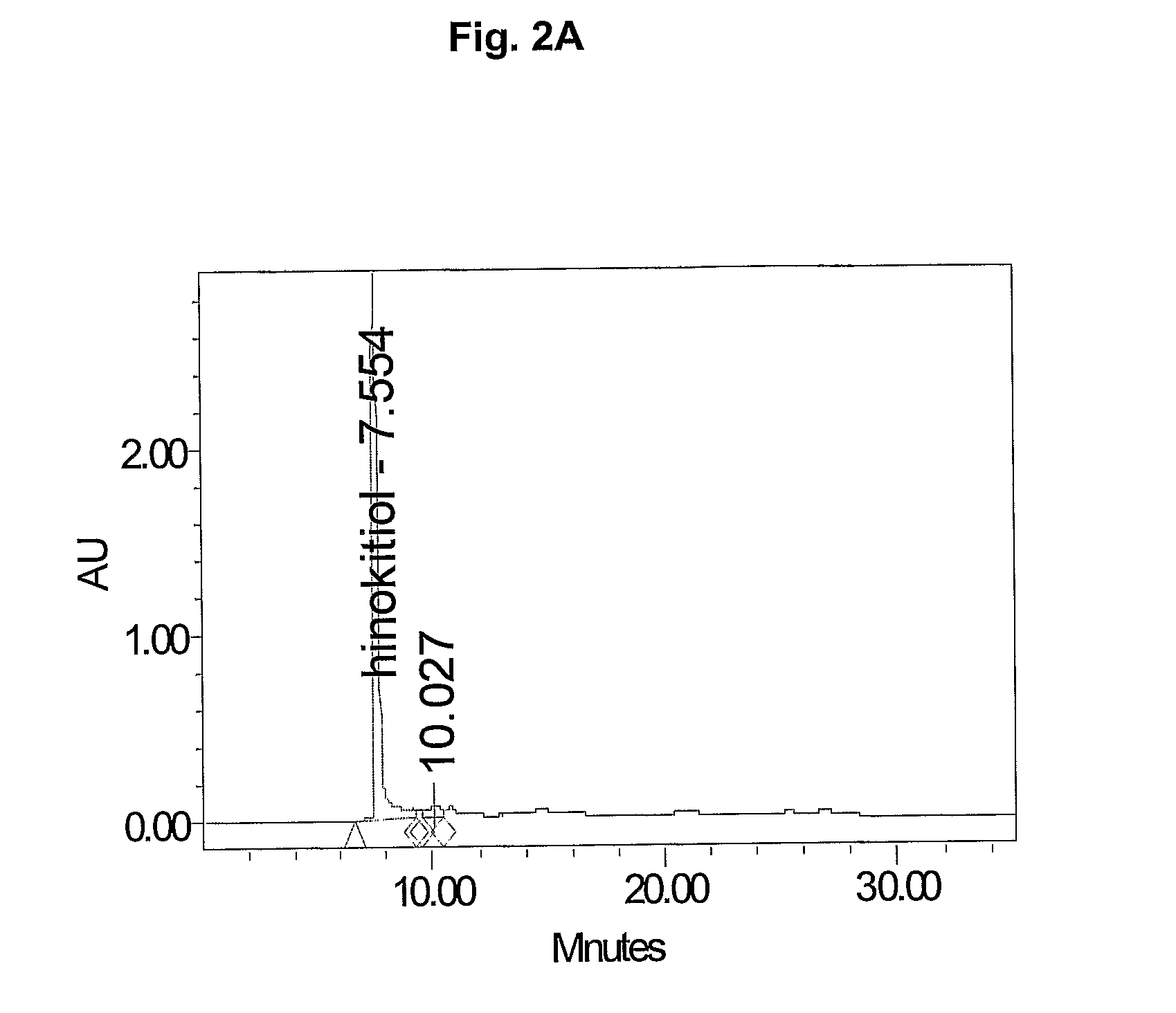

Plant Materials Extraction Method

A process for preparing plant extracts is provided. Plant materials, including tropolones, lignins and polar molecules, are mixed with a liquid polar solvent to form an extraction mixture, which is maintained under extraction conditions effective to extract lignins, polar molecules and at least 50% of the tropolones into the polar solvent to form a pregnant polar solvent liquid phase. The pregnant polar solvent phase is separated from the solid plant materials, and mixed with a substantially immiscible nonpolar solvent under conditions effective to partition the tropolones and lignins substantially into the nonpolar solvent and to partition the polar molecules substantially into the polar solvent to form a partitioned nonpolar solvent phase comprising lignins and tropolones, and a partitioned polar solvent phase comprising the polar molecules, and separating the polar solvent phase from the nonpolar solvent phase to obtain a polar plant extract and a nonpolar plant extract.

Owner:JONES DAVID +1

Agricultural pesticide compositions

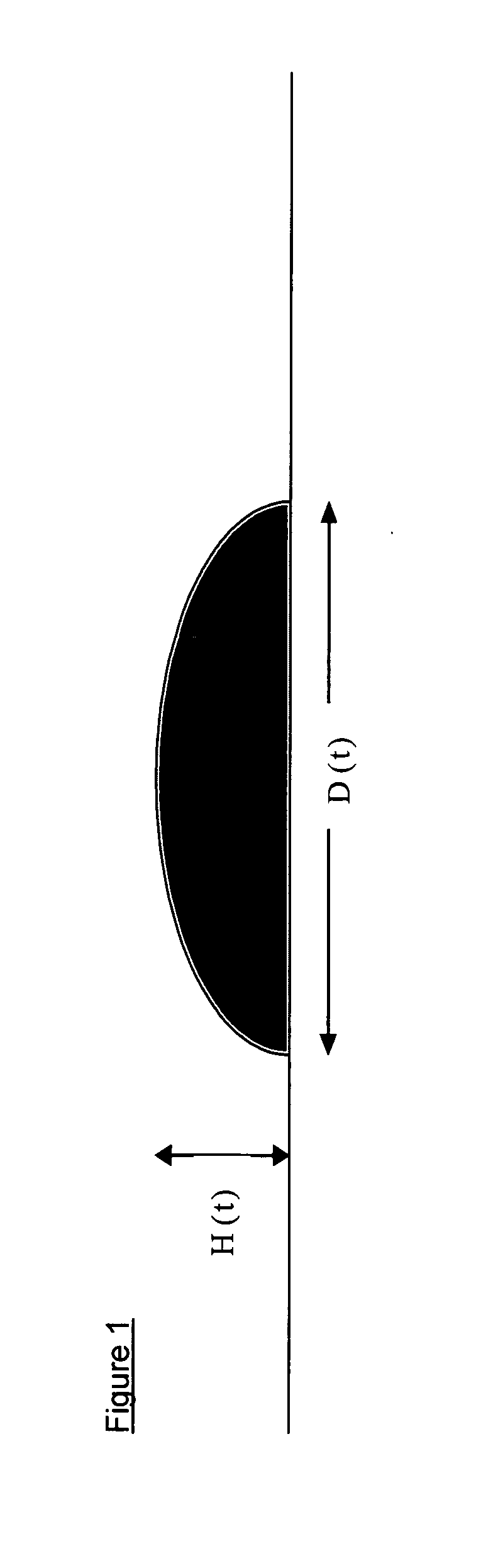

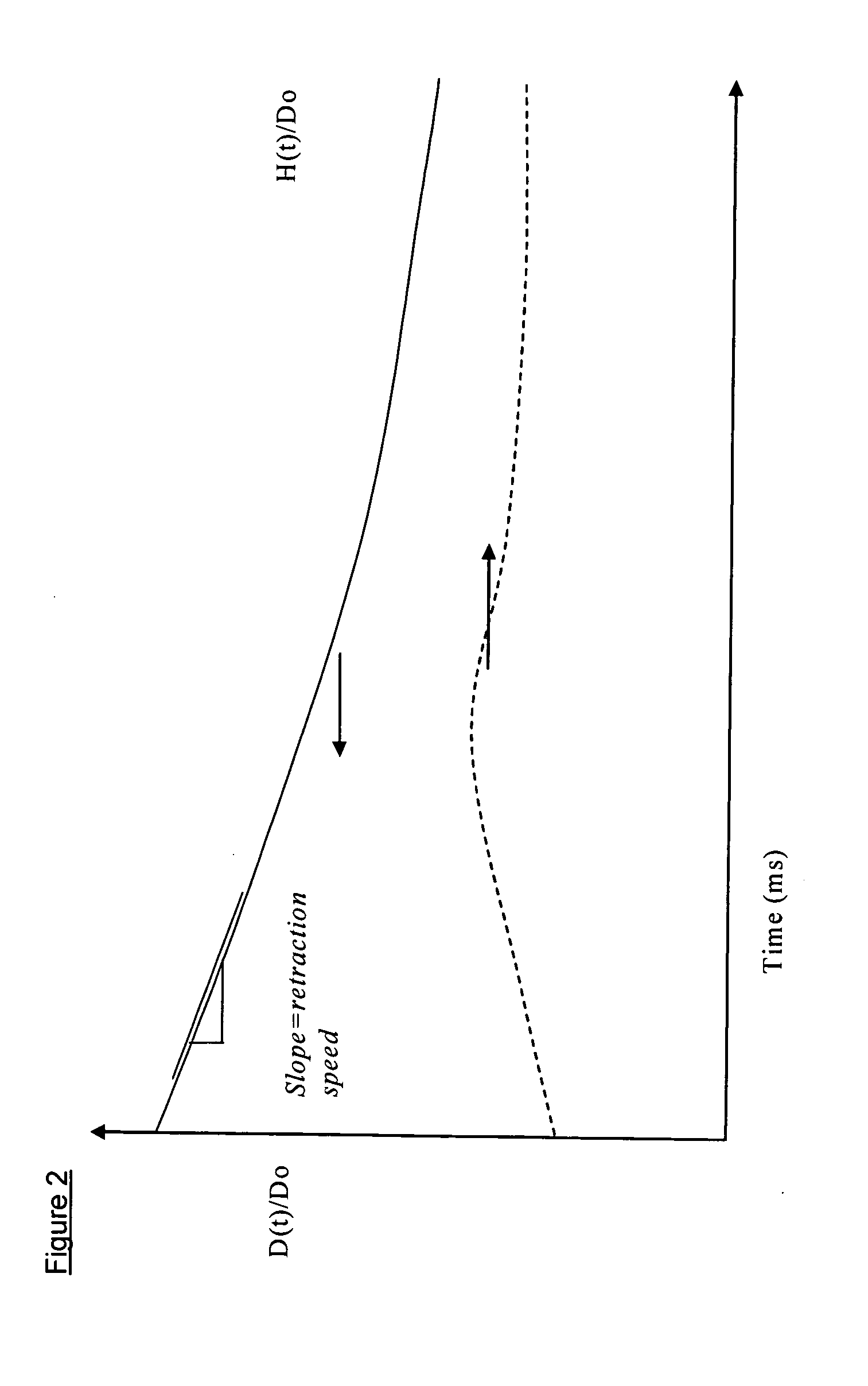

InactiveUS20070161512A1Improved anti-rebound propertySlow down the retraction speedBiocideAnimal repellantsLipid formationWater dispersible

An aqueous agricultural pesticide composition contains: (a) a water soluble or water dispersible deposition control agent, in an amount effective to provide improved anti-rebound properties and selected from: (i) dextrins and tamarind gums, (ii) derivatized polysaccharide hydrocolloids, except derivatized guars, having a molecular substitution of greater than or equal to about 0.1, (iii) proteinaceous hydrocolloids, (iv) lignins and lignin derivatives, except alkali metal, alkaline earth metal or ammonium lignosulphonates, and (v) lipid polymers, and (b) an effective amount of a pesticide.

Owner:RHODIA OPERATIONS SAS

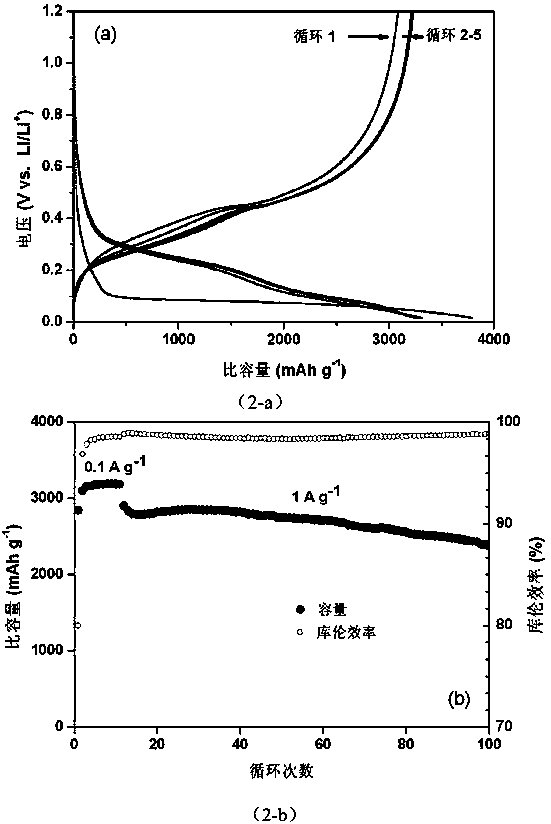

Lithium ion battery anode piece preparation method, anode piece and lithium battery

PendingCN107732158AEasy to useImprove cycle performanceMaterial nanotechnologyCell electrodesLithium electrodePOLYOXYETHYLENE ETHER

The invention discloses a preparation method of a lithium ion battery anode piece. The preparation method comprises the following steps: S01, uniformly mixing lignin, polyoxyethylene and dimethyl formamide; S02, putting nano silicon powder into a precursor solution obtained in the step S01, maintaining constant temperature, and continuously stirring in the heating process till the viscosity of a mixture is 2000-3000cp; S03, coating an anode current collector by the precursor solution obtained in the step S02, and naturally drying in an atmosphere environment; and S04, sintering the anode current collector obtained in the step S03 in the presence of an inert atmosphere. The invention provides a preparation method for a novel carbon-covering silicon material as the lithium ion battery anodepiece, and a novel lithium ion battery anode piece and a lithium ion battery with the lithium ion battery anode piece are prepared by using the preparation method. By adopting the preparation method,the circulation property of the lithium ion battery anode piece is improved due to a nano silicon covering carbon structure, and the overall use performance of the lithium ion battery is improved.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

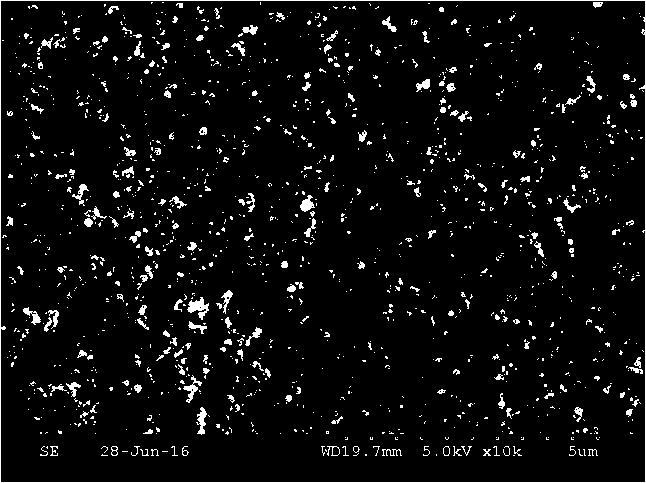

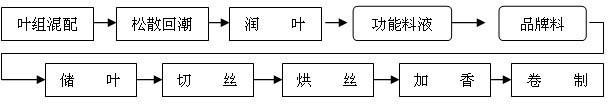

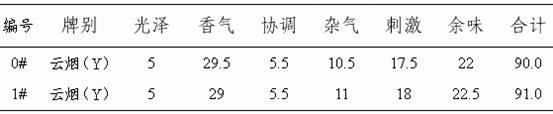

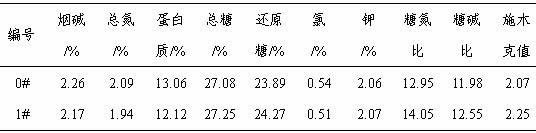

Functional material liquid for improving cigarette quality and preparation and application thereof

InactiveCN102318892AComponents are highly targetedUnique secondary feeding technologyTobacco preparationPectinaseLignin degradation

The invention discloses a functional material liquid for improving the cigarette quality and a preparation method and application thereof. The functional material liquid is obtained by uniformly mixing 40-50 parts of bacillus subtilis zymotic fluid, 20-25 parts of aroma-producing yeast zymotic fluid, 10-20 parts of lignin degradation complex enzyme, 10 parts of cellulose and 5-10 parts of pectase. When tobacco flakes become loose and wet during cigarette throwing, the functional material liquid is added onto the tobacco flakes in an amount of 0.01-0.07 percent by mass based on the total mass of the tobacco flakes. Components in the functional material liquid have high specificity, so that a substrate shared by tobacco leaf raw materials of different levels and varieties can be degraded specifically. A brand material is added, so that the style characteristic is improved, combination of inner and outside is realized, and the cigarette quality can be better improved. The functional material liquid is added on the basis of not changing the original throwing process, and has the advantages of simple process, convenience for operating, and the like.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Materials and methods for the modification of plant lignin content

Novel isolated polynucleotides and polypeptides associated with the lignin biosynthetic pathway are provided, together with genetic constructs including such sequences. Methods for the modulation of lignin content, lignin structure and lignin composition in target organisms are also disclosed, the methods comprising incorporating one or more of the polynucleotides of the present invention into the genome of a target organism.

Owner:ARBORGEN

Process for reducing nitrogen containing compounds and lignin in tobacco

InactiveUS20060130859A1Reduced ligninReduced nitrogenous contentTobacco preparationTobacco treatmentFiberLignin degradation

A process for reducing lignin and nitrogenous content in tobacco lamina and tobacco fiber material, including whole leaf, stems, scraps, fines and lamina, as well as burley leaf and stem, in an extraction with a solution containing hydrogen peroxide and an alkali metal hydroxide. The treated tobacco may then be further processed for use in cigarettes and other smoking articles.

Owner:MUA JOHN PAUL +2

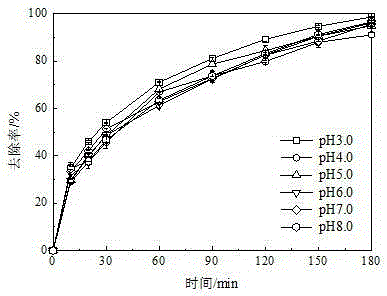

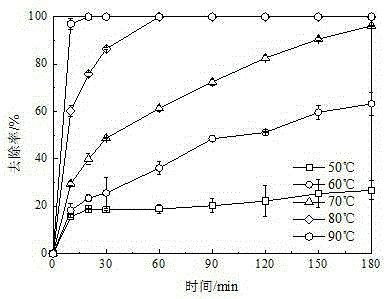

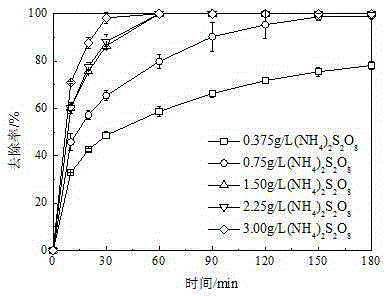

Lignin degradation product removing method

The present invention discloses a lignin degradation product removing method. According to the method, the lignin degradation products are adopted as the substrate, and the way that the persulfate is activated to generate the sulfate free radical is used to carry out oxidation removal on the lignin degradation products, wherein the activating way selects the thermal activating, and the persulfate selects ammonium persulfate as the oxidant. According to the present invention, the thermal activating way is used to activate the ammonium persulfate so as to perform the oxidation removal of the lignin degradation products, and the results show that the removal rates of vanillin, 4-hydroxybenzaldehyde, vanillic acid, 4-hydroxy benzoic acid and syringic acid achieve 100% within 1 h, and the syringic aldehyde removal rate achieves 100% within 2 h.

Owner:NANJING FORESTRY UNIV

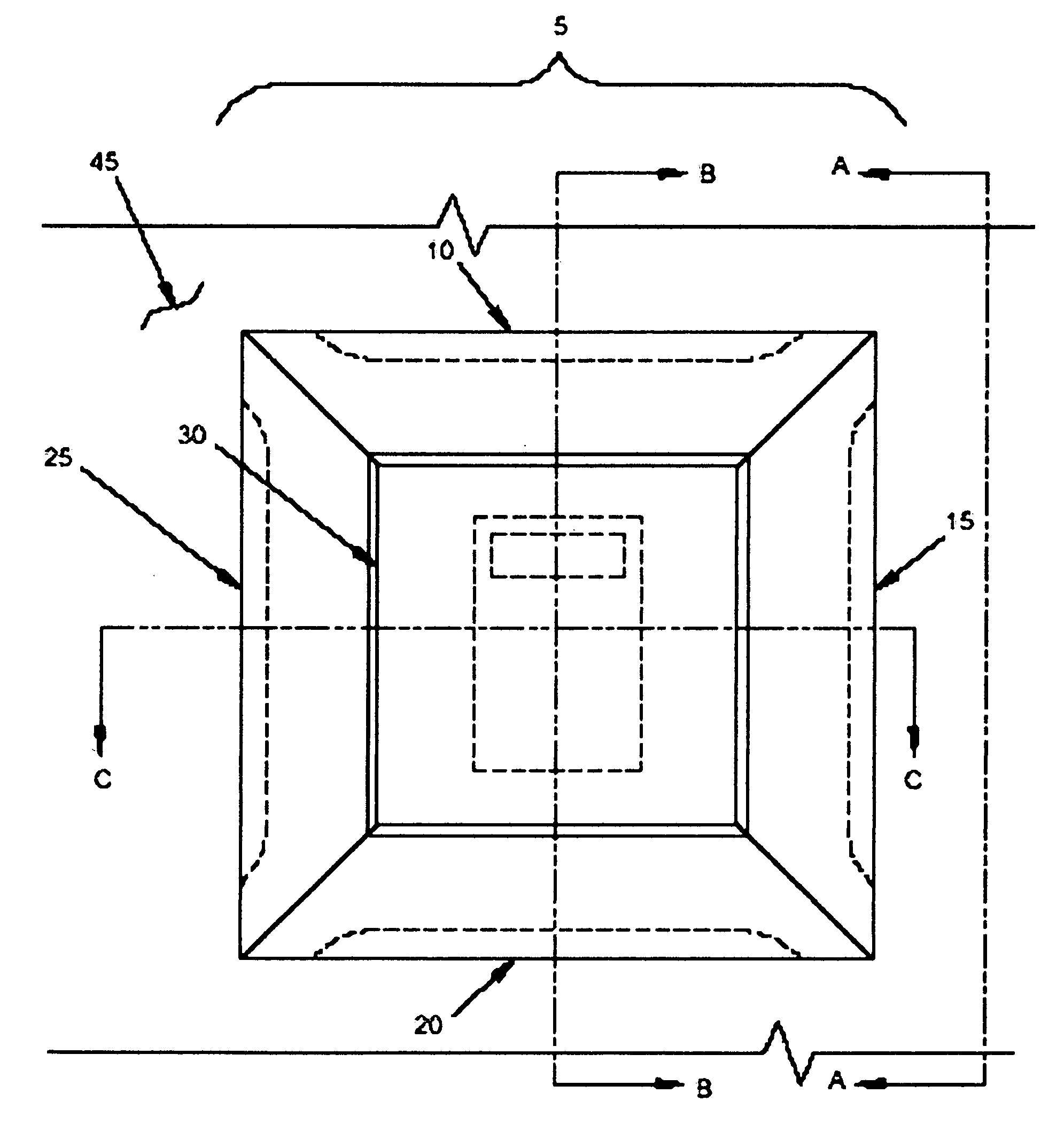

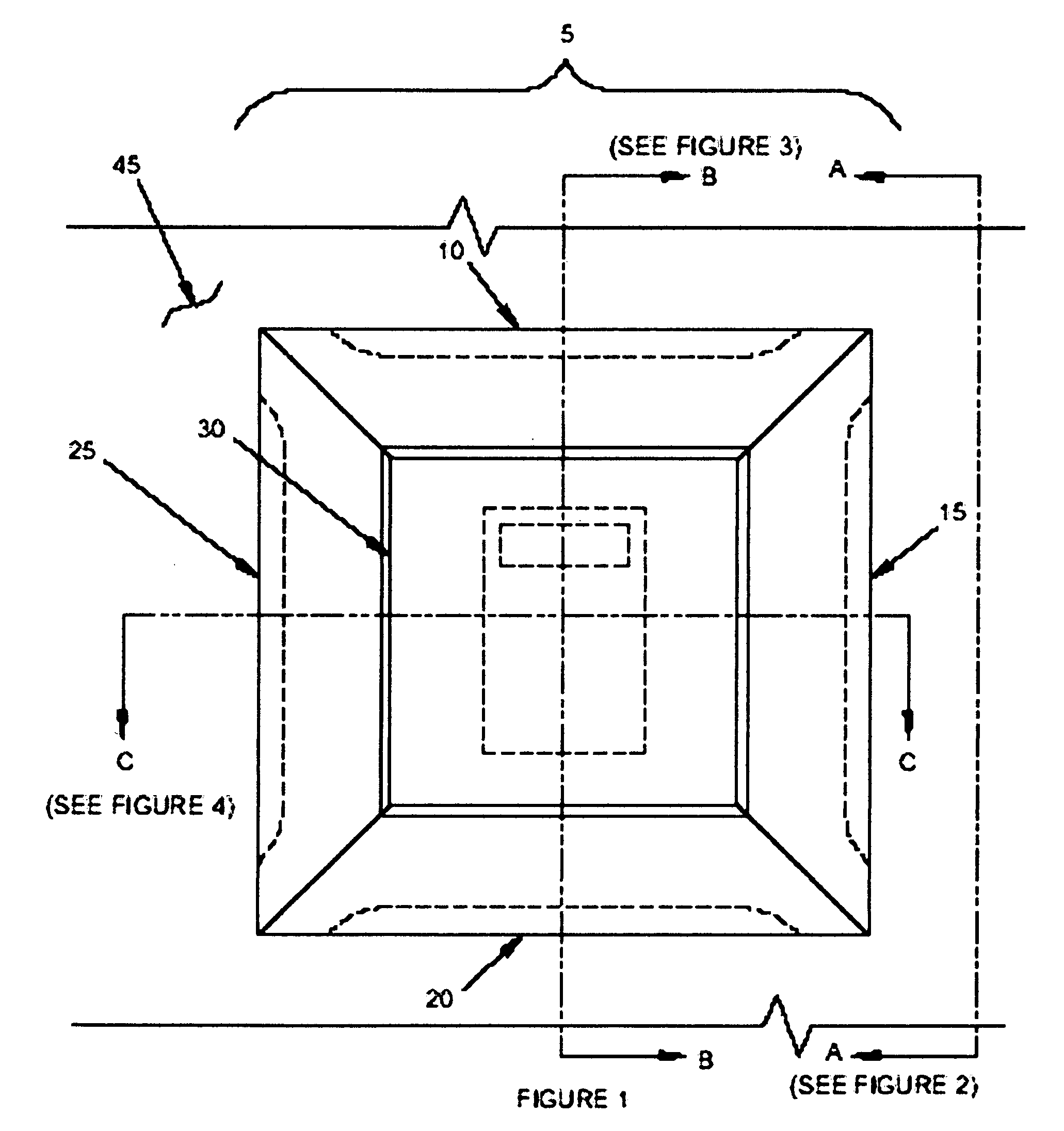

Wall mounted cover

InactiveUS20060207146A1Improve aestheticsPicture framesDomestic mirrorsLignin degradationSpace environment

A cover for a a wall mounted control device that is both functional and decorative. A hollow is formed by this invention that is orientated over the device that is desired to be ornamented. It is attached to the wall surrounding the device and allowed to rest over the device. It may be made from ferrous, nonferrous, polymeric, or lignin reinforced celluose materials to create a three dimensional Euclidean-space environment that has an enhancing effect wherever placed.

Owner:EL NANCY L +1

Carbon foam from metallic salts of lignosulfonates

ActiveUS20050085372A1Improve selected propertyAvoid crackingCarbon compoundsLayered productsLignin degradationCarbonization

A process for the production of an open-cell carbon foam from a metallic salt of a lignosulfonate is described. The process includes heating the metallic salt of a lignosulfonate from ambient temperature to a maximum temperature, greater than about 250° C., at a rate sufficiently slow as to provide for essentially uniform heating of the lignin derived material. Heating of the lignin derived material is performed in a non-oxidizing atmosphere having a pressure greater than about 100 psig. The resultant carbon foam can subsequently be optionally subjected to carbonization or graphitization temperatures as desired. The resultant carbon foam has a regular open-cell structure. Densities of the carbon foam products are commonly in the range of about 0.1 g / cm3 to 0.2 g / cm3. The carbon foams may also exhibit compressive strengths of up to about 200 psi. The carbon foam materials potentially have utility as lightweight thermal barriers and in many other of the applications associated with carbon foams.

Owner:CFOAM LLC

Shaped nanoporous bodies

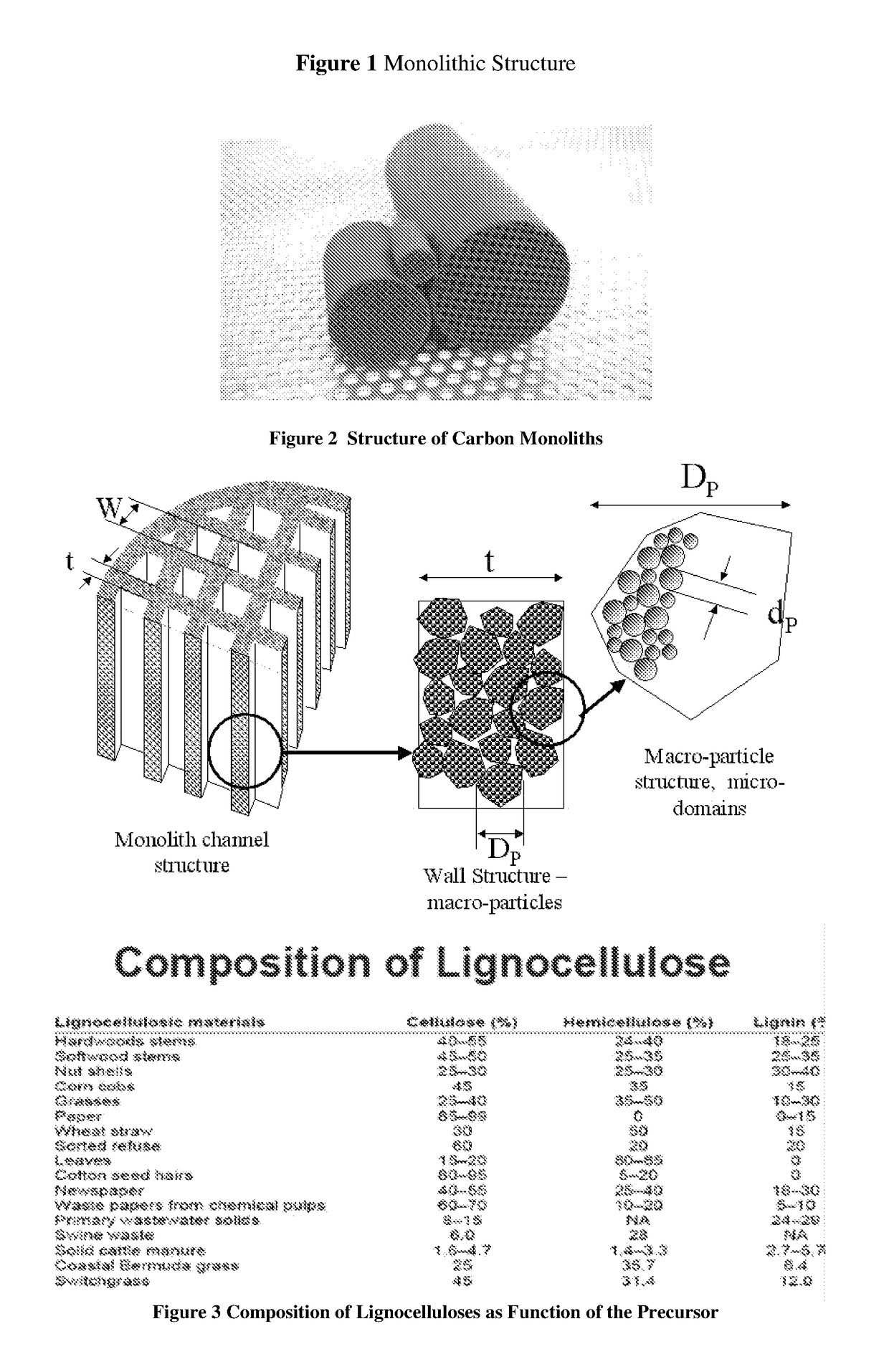

ActiveUS20190022623A1Preventing in use leakagePrevent escapeCarbon compoundsOther chemical processesCellulosePorous carbon

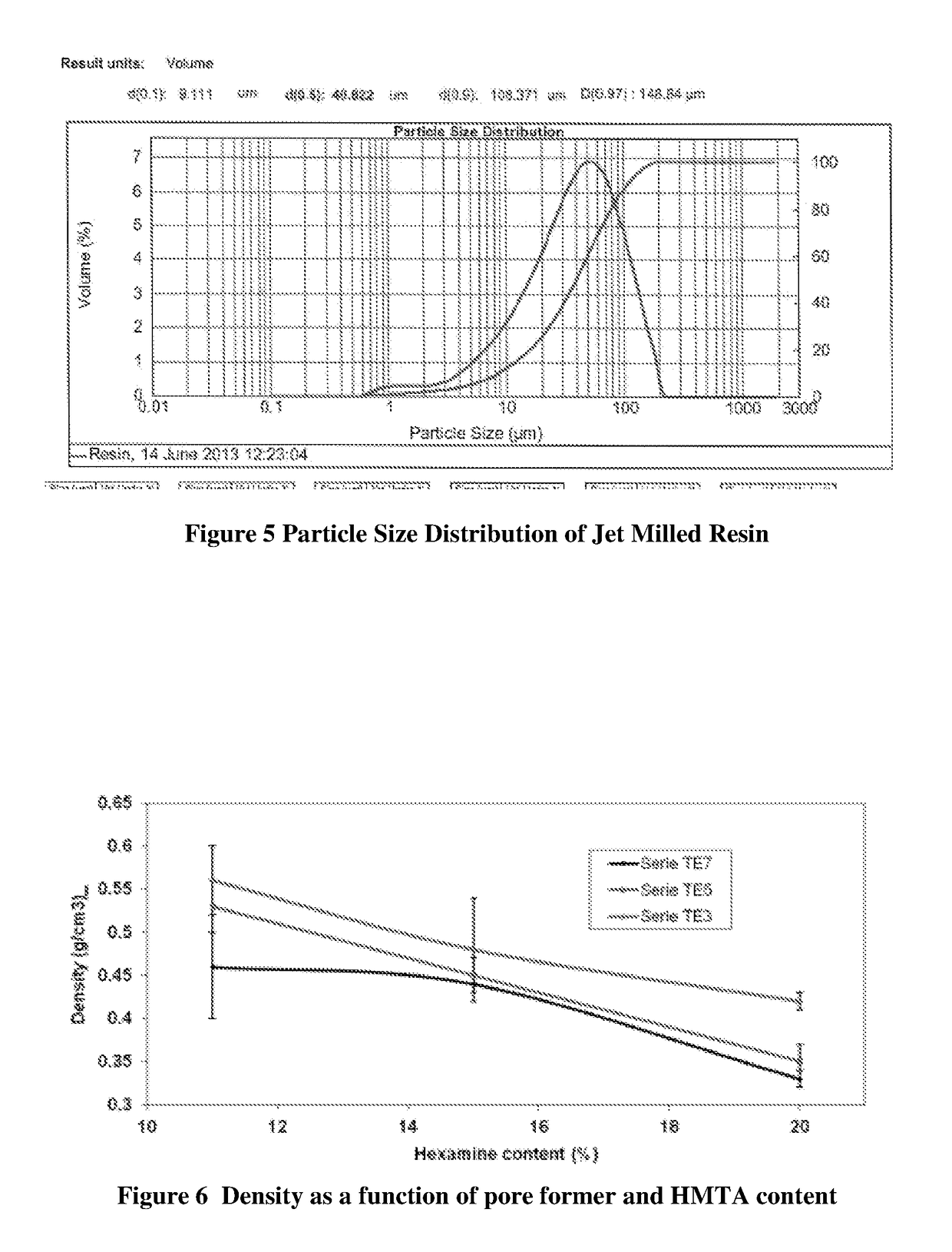

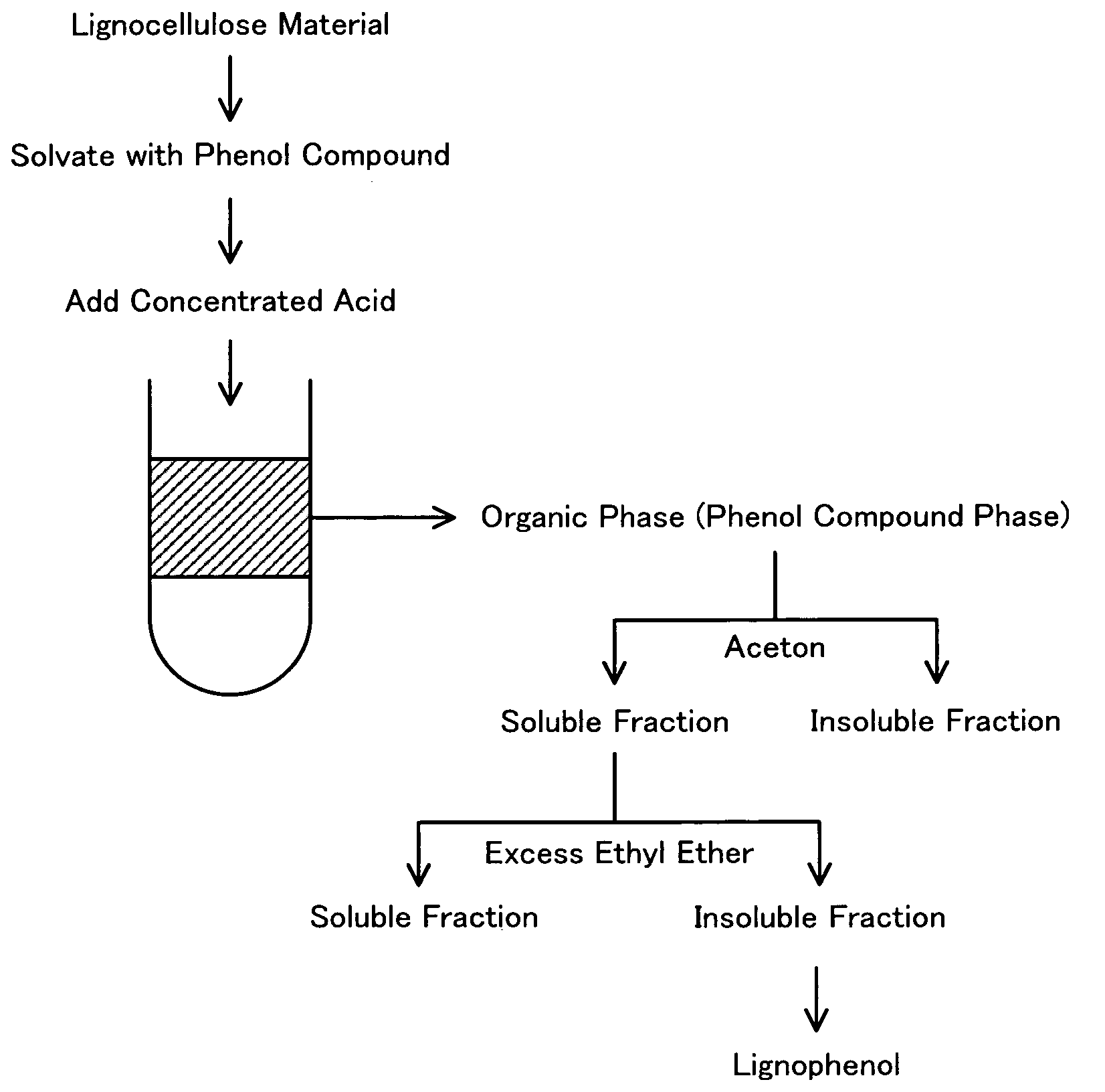

A range of carbon materials can be produced using lignin in combination with synthetic phenolic resins or naturally occurring lingo-cellulosic materials. The lignin, which is essentially a naturally occurring phenolic resin, has a carbon yield on pyrolysis similar to that of the synthetic resins, which aids processing. The lignin can be used as a binder phase for synthetic resin or lignocellulosic materials allowing the production of monolithic carbons from a wide range of precursors, as the primary structural material where the thermal processing is modified by the addition of small quantities of synthetic resin materials or as structure modified in the production of meso / macro porous carbons in either bead, granular or monolithic form. A carbonised monolith is provided comprising mesoporous and / or macroporous carbon particles dispersed in a matrix of microporous carbon particles with voids between the particles defining paths for fluid to flow into and through the structure. The monolith may take the form of a shaped body having walls defining a multiplicity of internal transport channels for fluid flow, the transport channels being directed along the extrusion direction. The monolith may be made by carbonising a shaped phenolic body based on phenolic resin precursors. In a method for producing such a carbonisable shaped resin body solid particles of a first phenolic resin are provided which is partially cured so that the particles are sinterable but do not melt on carbonisation. The particles of the first phenolic resin are mixed with particles of a second phenolic resin that has a greater degree of cure than said first phenolic resin and has a mesoporous and / or macroporous microstructure that is preserved on carbonisation. The resulting mixture is formed into a dough e.g. by mixing the resin particles with methyl cellulose, PEO and water, after which the dough is extruded to form a shaped product and stabilising in its shape by sintering.

Owner:NEOTERYX

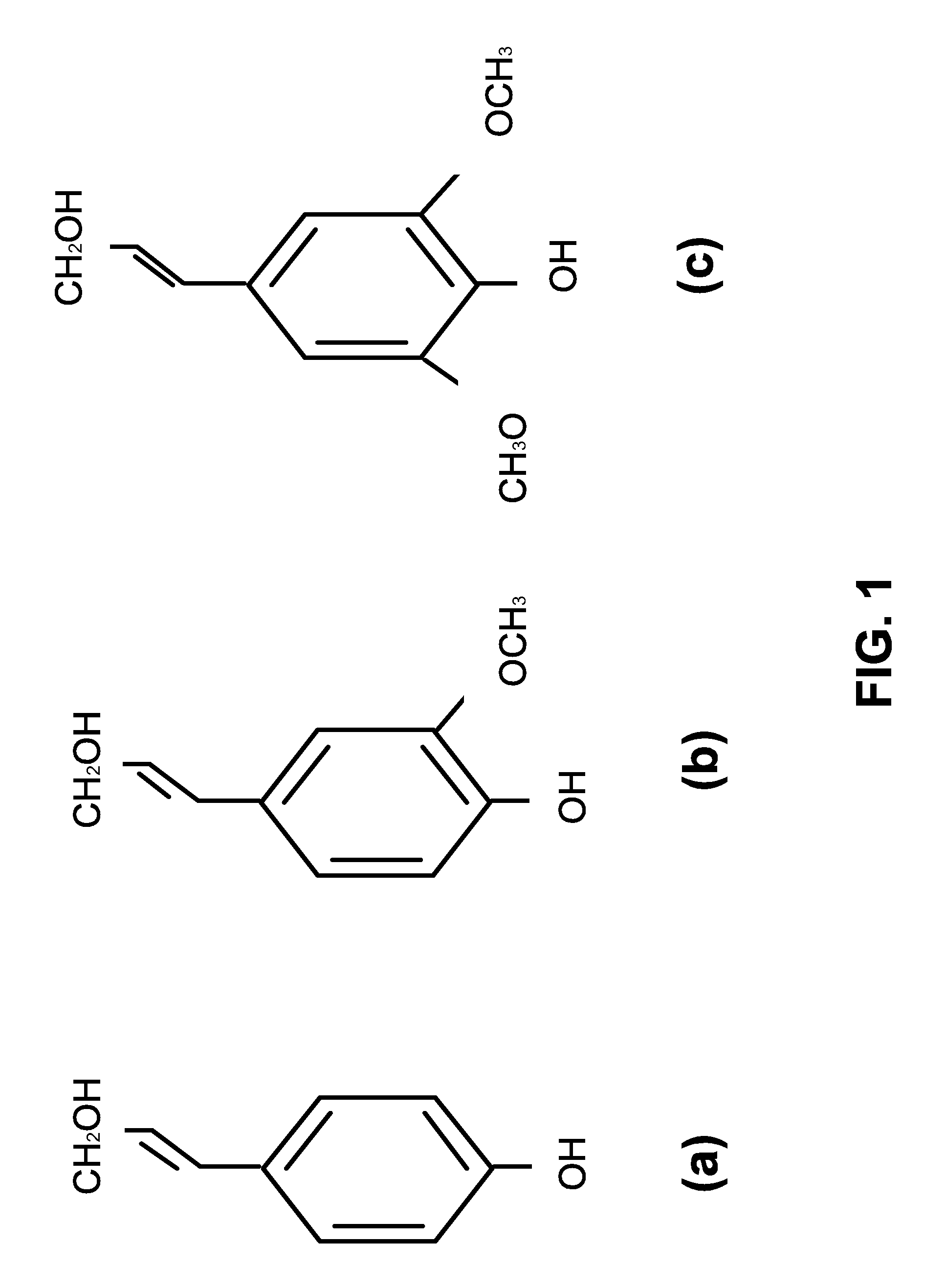

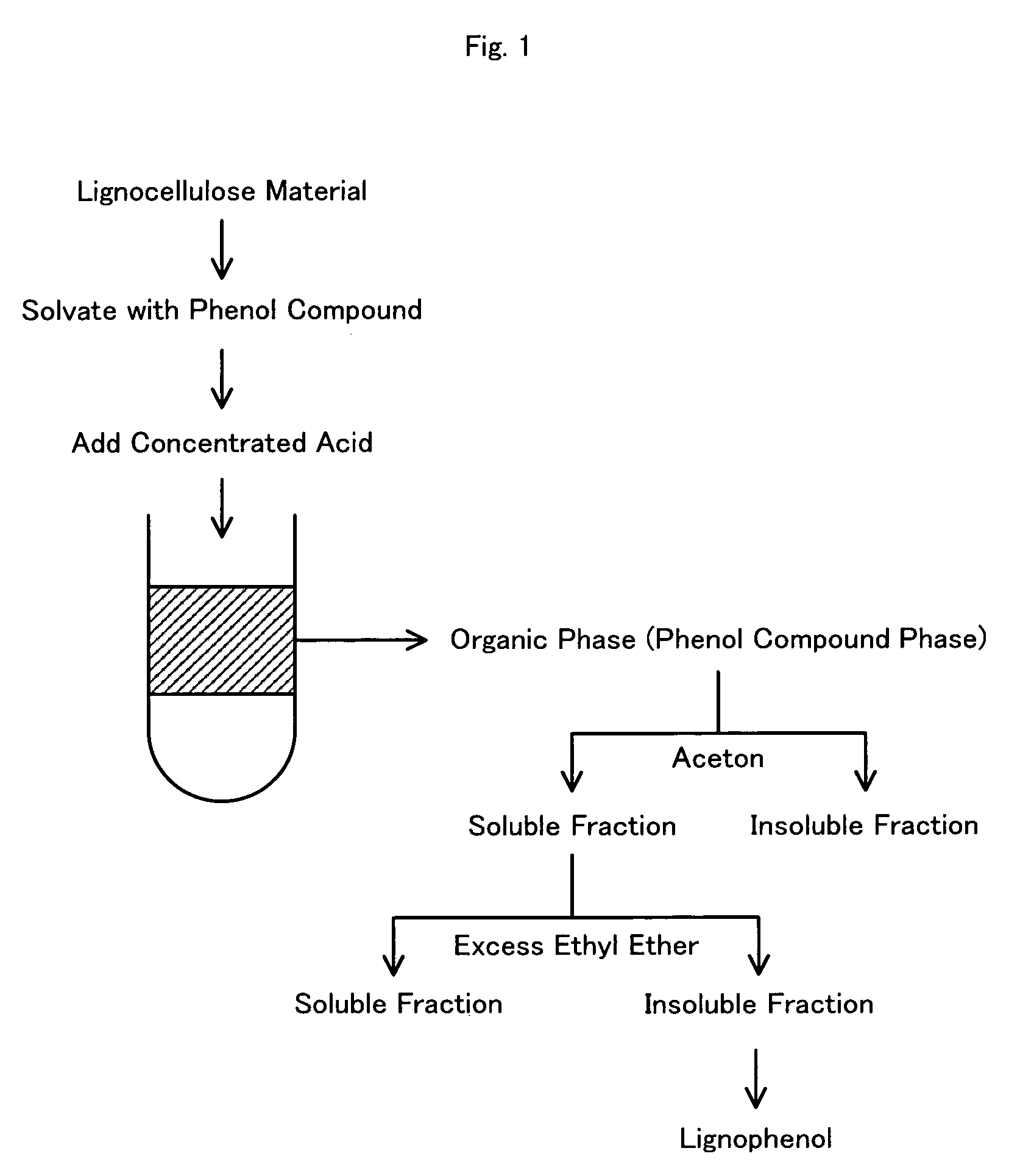

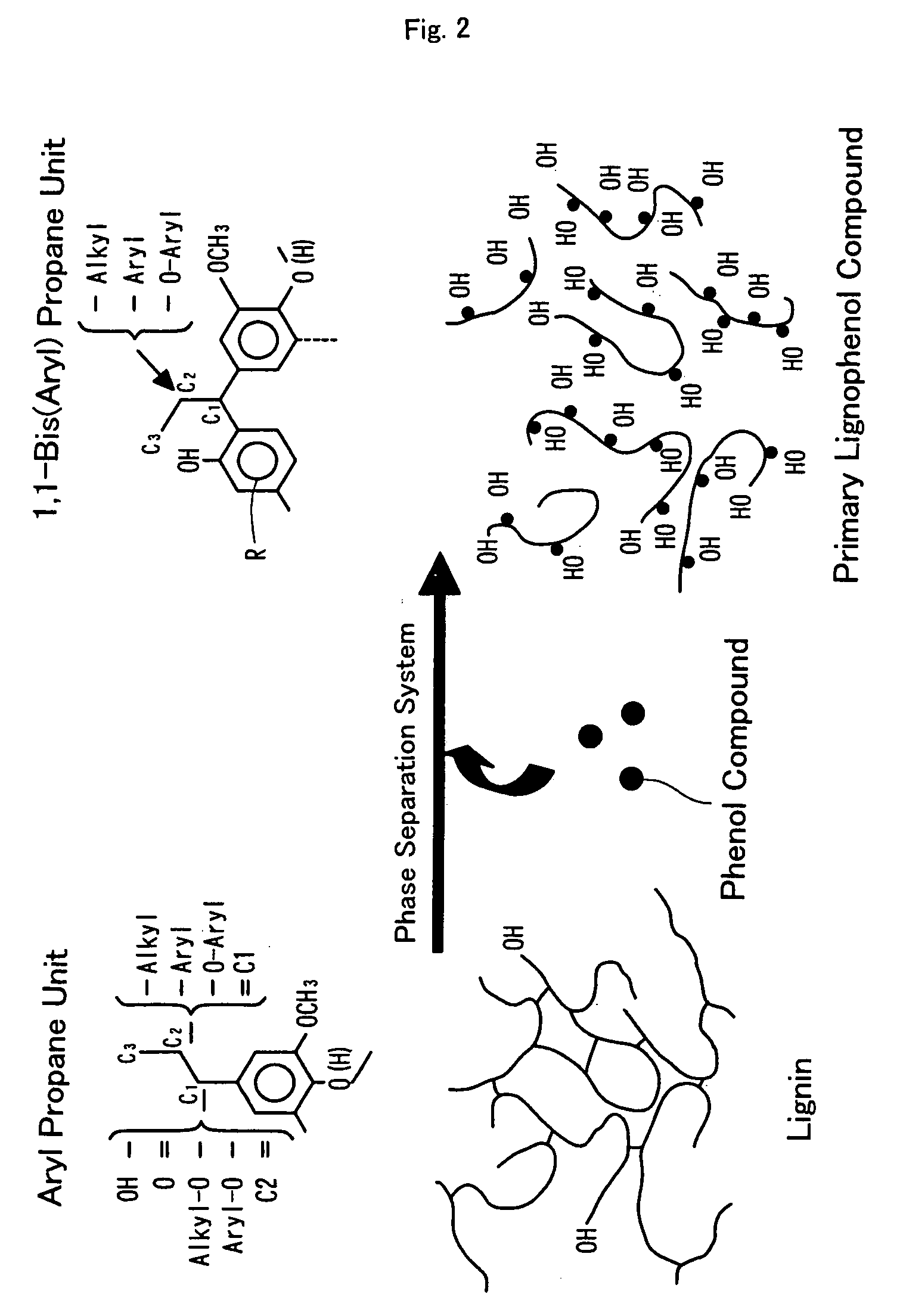

Application of lignin derivatives to photoelectric transducer and photoelectrochemical cell

ActiveUS20060035392A1Easy to recycleLight-sensitive devicesFinal product manufacturePhenol derivativePhotochemistry

The invention regards application of lignin derivatives to a photoelectric transducer. The photoelectric transducer of the invention includes a semiconductor film as a thin film electrode, that is photosensitized by one or multiple lignin derivatives selected from the group consisting of: (a) a lignophenol derivative or a phenol derivative of lignin that is prepared by solvating a lignin-containing material with a phenol compound and adding an acid to the solvate; (b) a secondary derivative that is prepared by one reaction of the lignophenol derivative (a) selected among acylation, carboxylation, amidation, introduction of a crosslinking group, and alkali treatment; (c) a higher-order derivative that is prepared by at least two reactions of the lignophenol derivative (a) selected among acylation, carboxylation, amidation, introduction of the crosslinking group, and alkali treatment; (d) a crosslinked secondary derivative that is prepared by crosslinking the secondary derivative (b) obtained by the introduction of the crosslinking group; and (e) a crosslinked higher-order derivative that is prepared by crosslinking the higher-order derivative (c) obtained by the introduction of the crosslinking group.

Owner:JAPAN SCI & TECH CORP

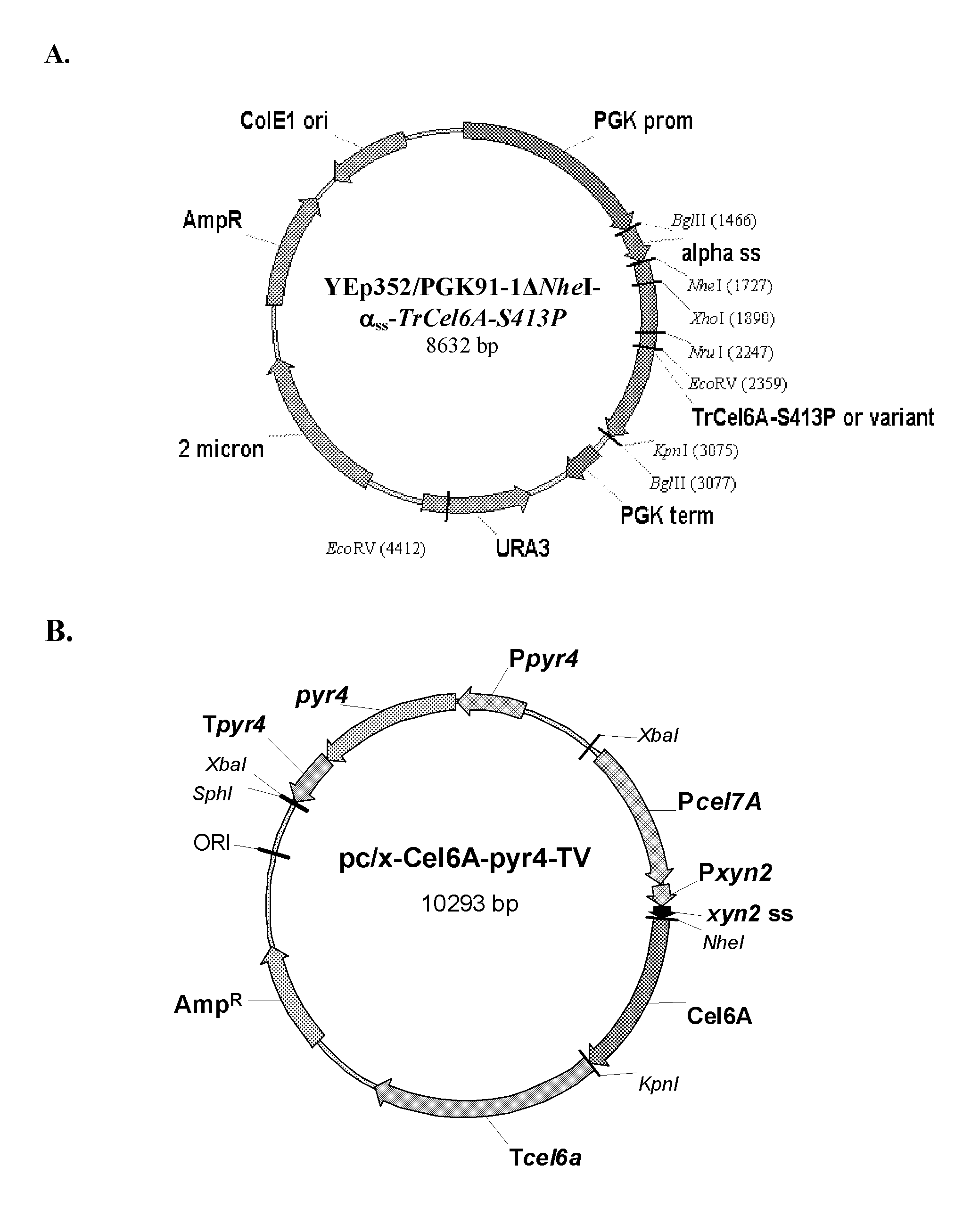

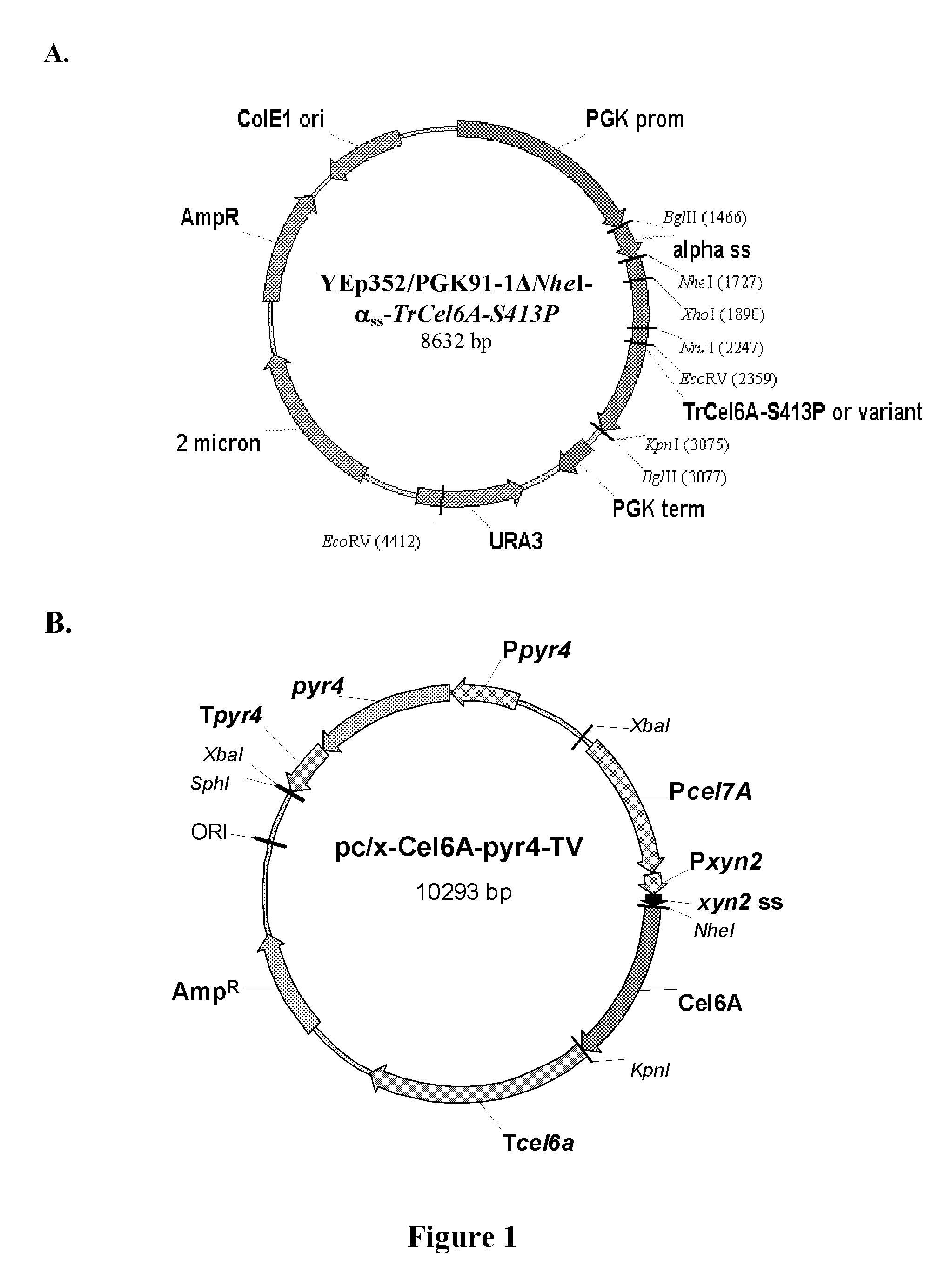

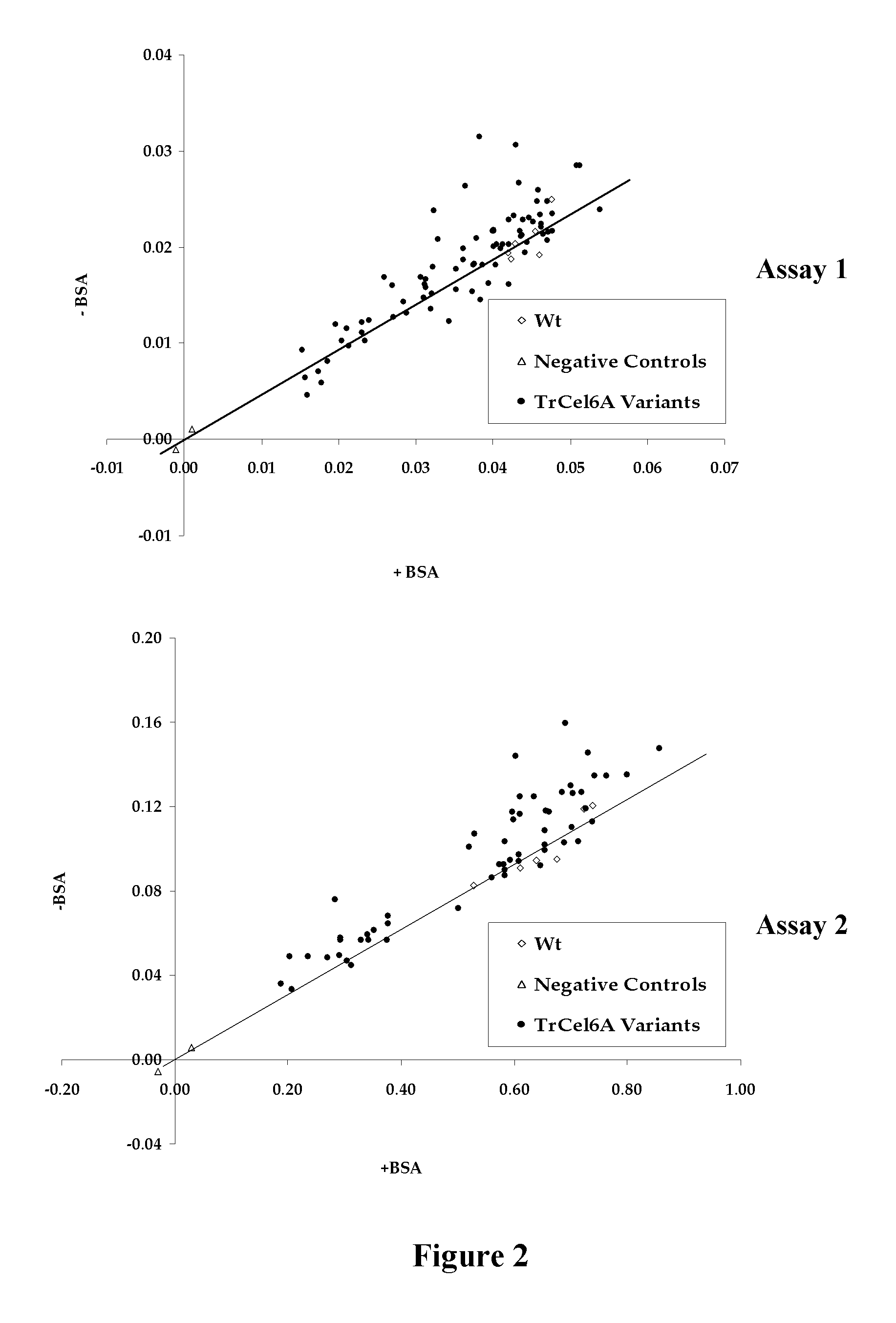

Novel lignin-resistant cellulase enzymes

ActiveUS20100221778A1Increase in cellulose-hydrolyzing activityDecrease in lignin bindingFungiEnzymesLignin degradationAmino acid substitution

Provided are modified cellulase enzymes exhibiting increase cellulose-hydrolyzing activity in the presence of lignin and / or reduced binding to lignin comprising modified linker peptides comprising one or more amino acid substitutions, insertions, or deletions that result in (a) a decrease in the calculated isoelectric point of the linker peptide and / or (b) an increase in the ratio of threonine:serine in the linker peptide relative to a parental linker peptide from which said modified linker peptide is derived. Also provided are genetic constructs comprising nucleic acidsequences encoding for modified cellulase enzymes, methods for the production of the modified cellulase enzymes from host strains and a process for hydrolysing cellulose with the modified cellulases in the presence of lignin.

Owner:IOGEN ENERGY CORP

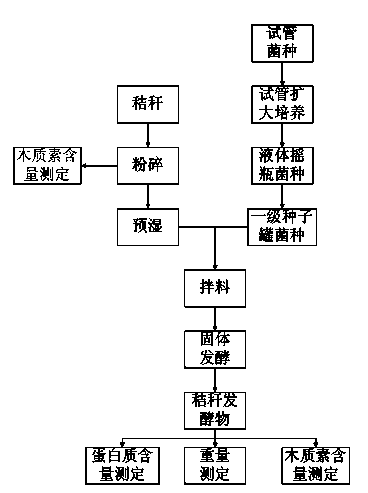

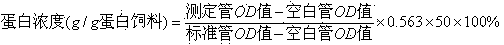

Method for Aspergillus oryzae to degrade straw to produce protein feed

Relating to the field of biological engineering, the invention provides a method for Aspergillus oryzae to degrade straw to produce protein feed. The method uses straw as a main raw material to produce protein feed by Aspergillus oryzae fermentation. The production process includes: subjecting the straw to crushing, pre-wetting and other pre-treatment technologies, and subjecting the Aspergillus oryzae to liquid shaking culture, first class seed culture, and mixing with straw to undergo solid state fermentation, thus obtaining fermented straw protein feed. The fermentation process is simple, has no pollution to the environment, and also causes no resource waste. The feed prepared by the method has a protein content of 15-30%, a lignin degradation rate of 34-76%, and a feed yield of 45-60%. Because of the effects of Aspergillus oryzae, the feed can degrade lignin and cellulose, thus improving the utilization rate of straw.

Owner:沂源翰林农业发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com