Patents

Literature

74 results about "Monolignol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

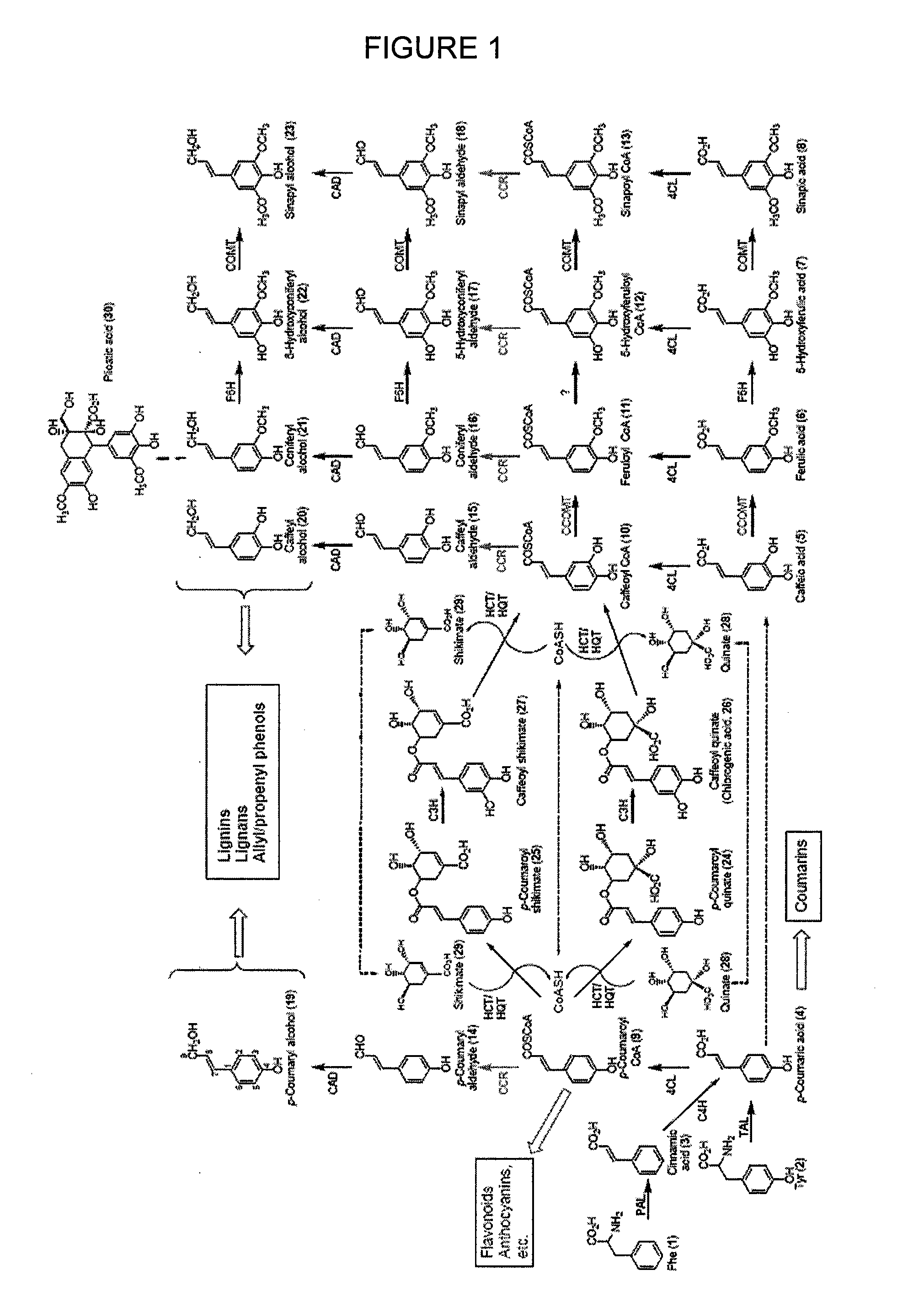

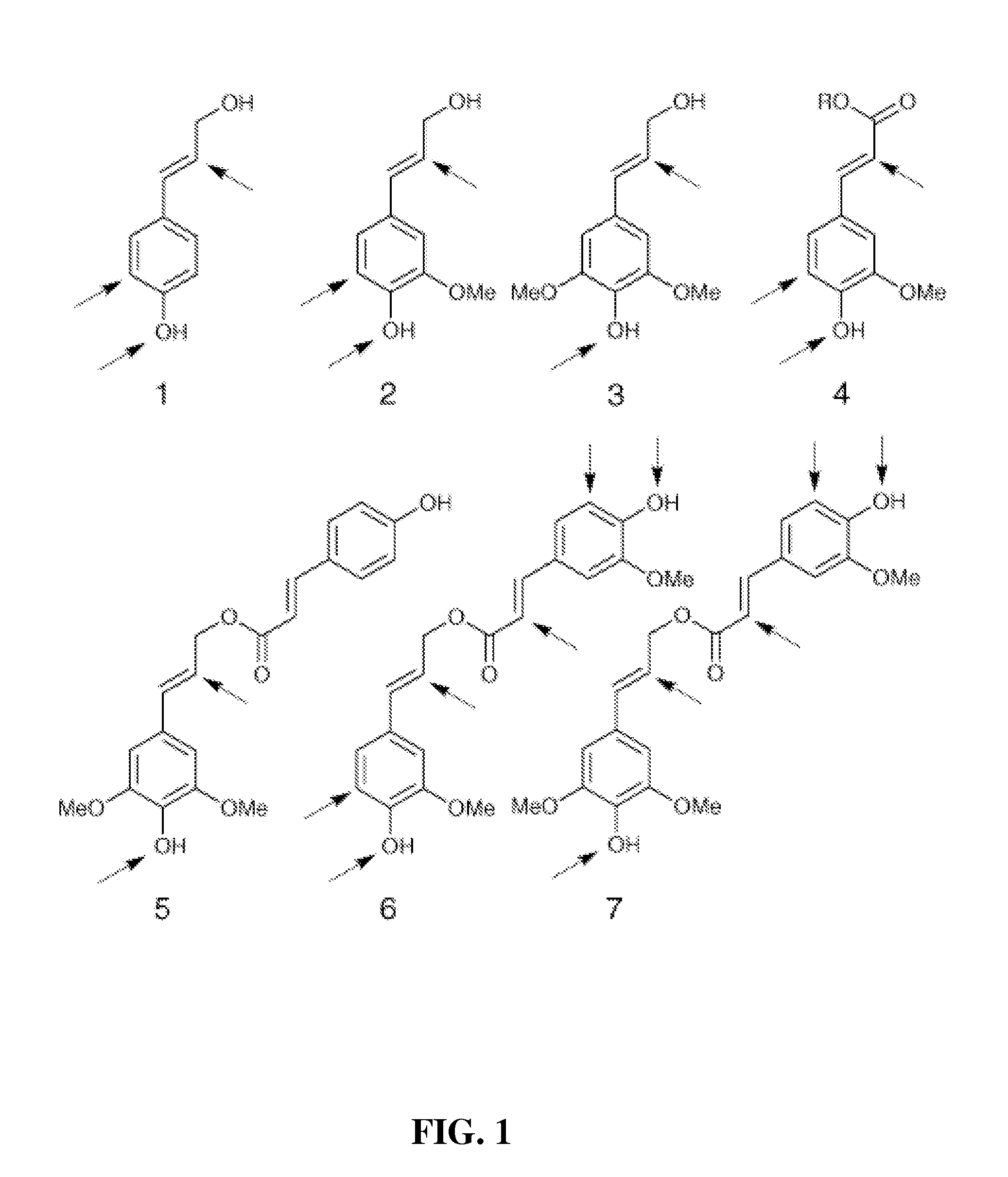

Monolignols are phytochemicals acting as source materials for biosynthesis of both lignans and lignin. The starting material for production of monolignols is the amino acid phenylalanine. The first reactions in the biosynthesis are shared with the phenylpropanoid pathway, and monolignols are considered to be a part of this group of compounds. Three monolignols predominate: coniferyl alcohol, sinapyl alcohol, and paracoumaryl alcohol. The ratio of these components varies with plant species. For example, Norway spruce lignin is almost entirely coniferyl alcohol, whereas paracoumaryl alcohol is found almost exclusively in grasses.

Modification of plant lignin content

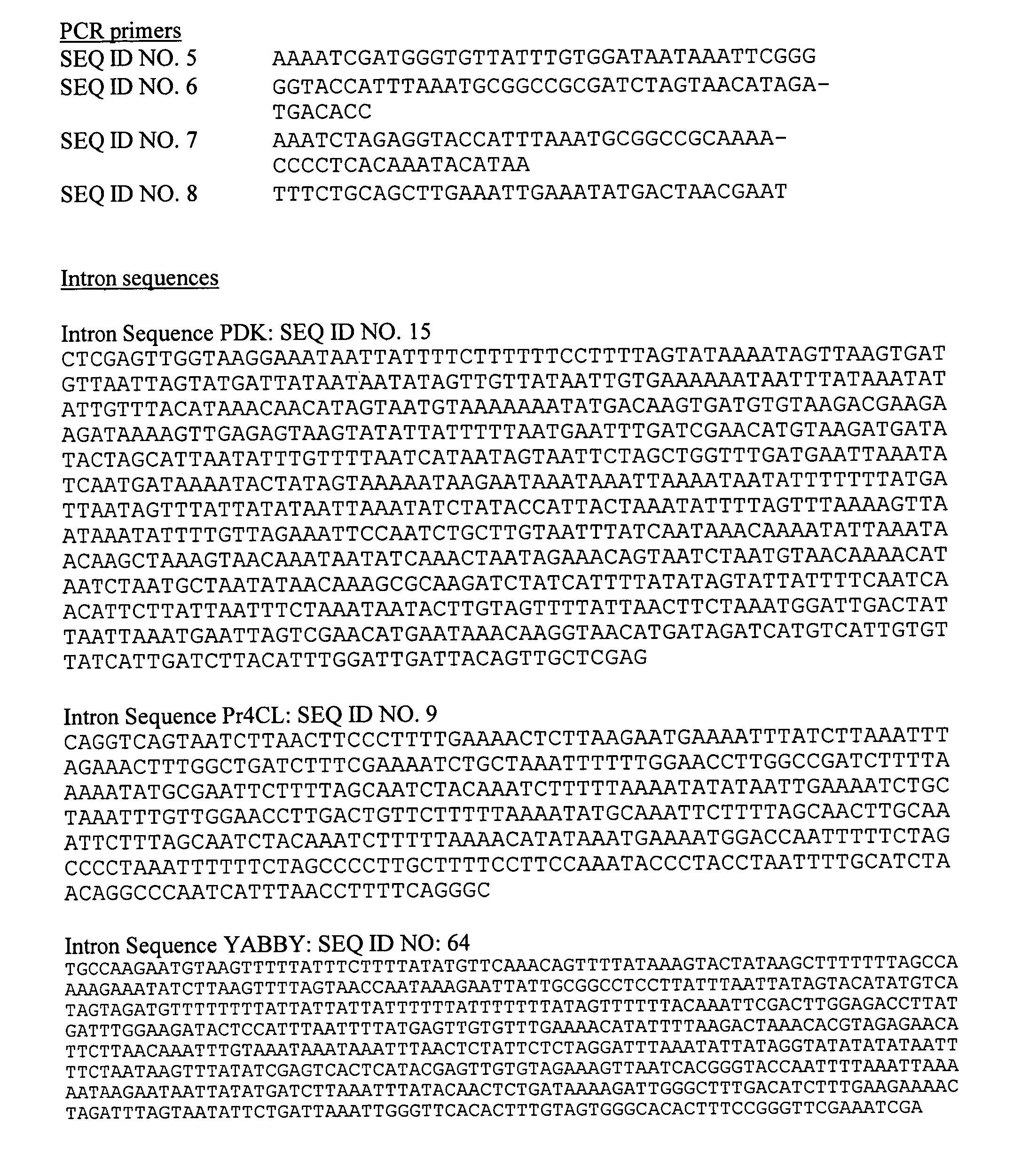

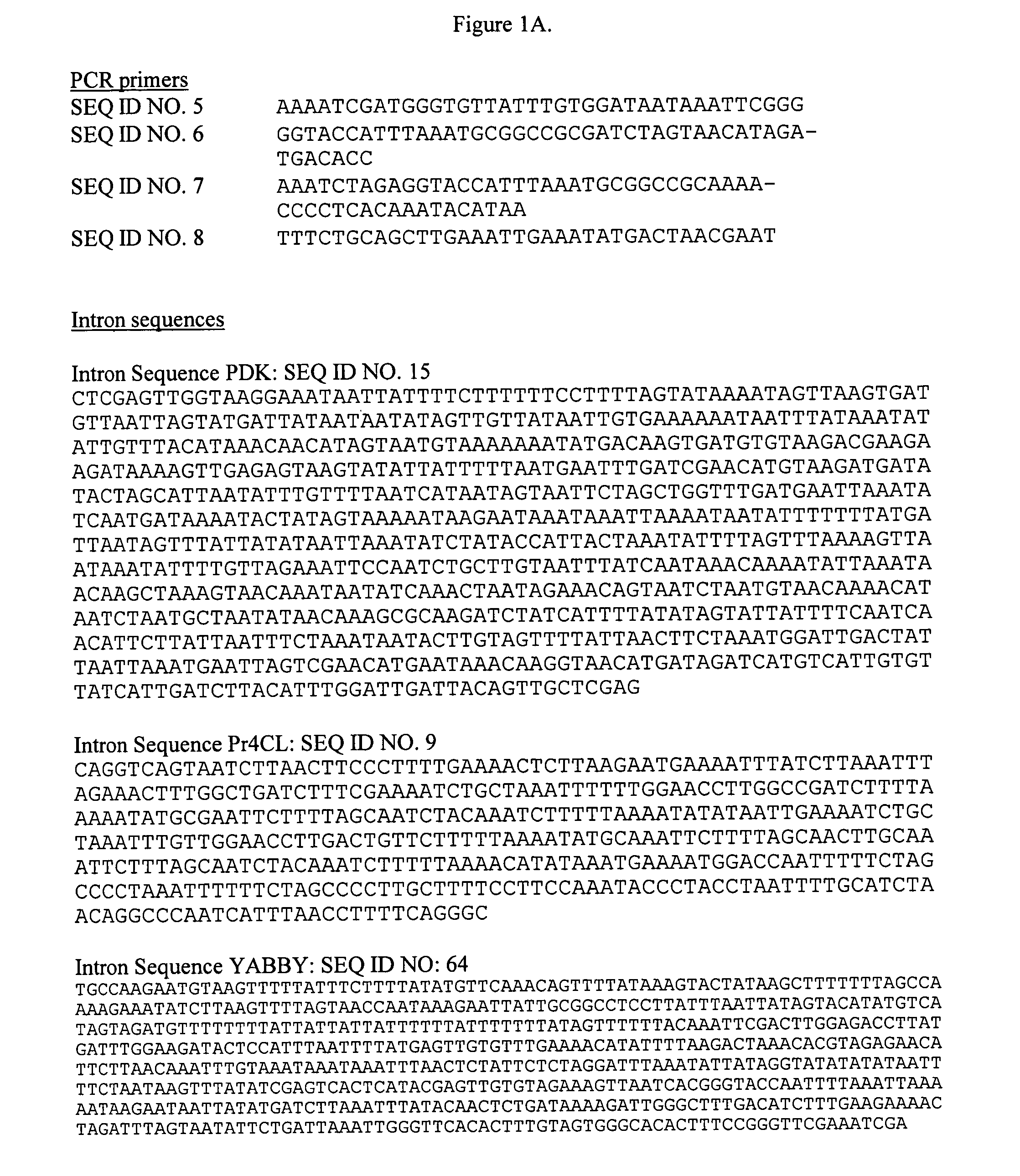

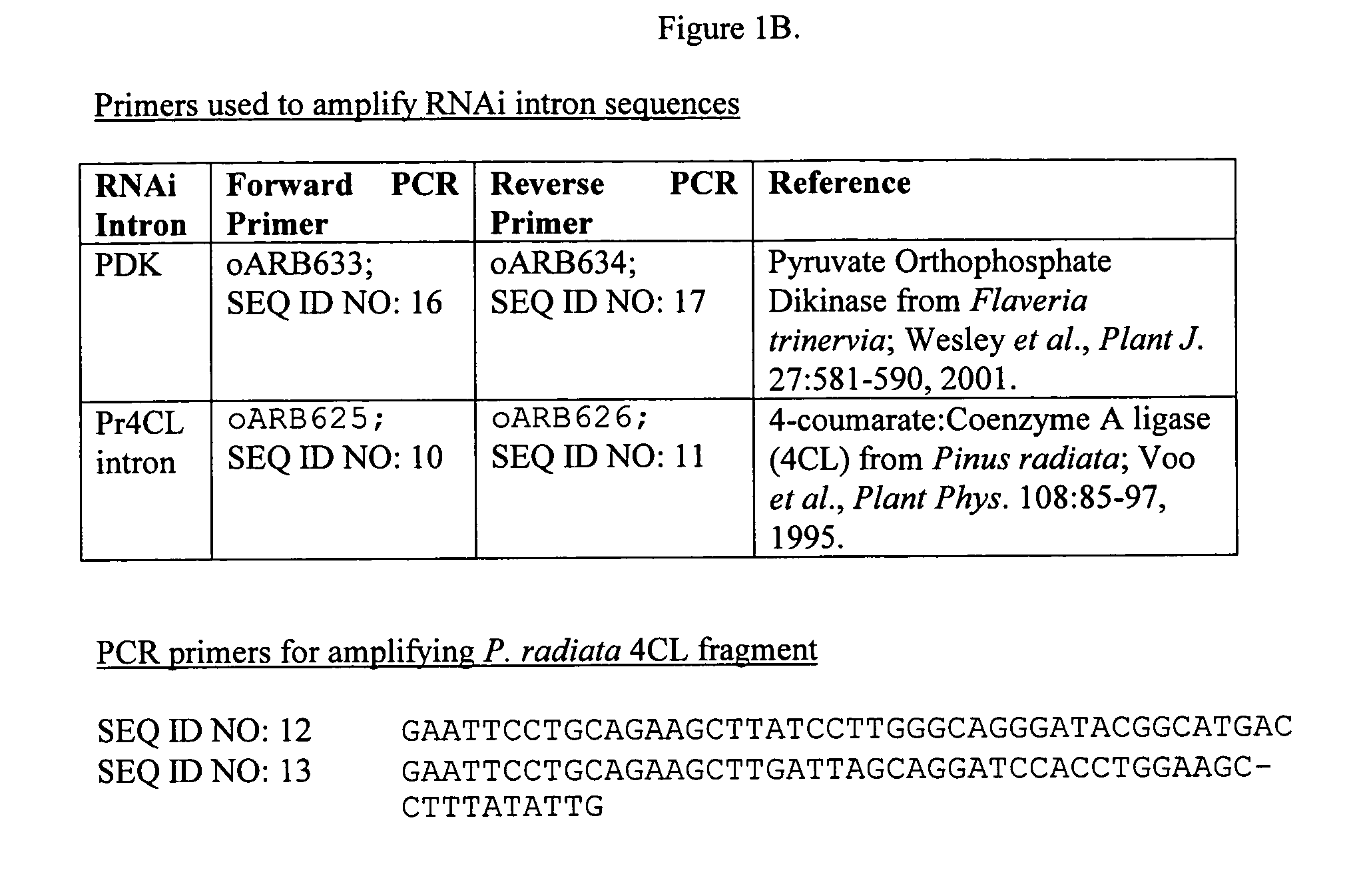

DNA constructs comprising a first DNA segment that corresponds to at least a portion of a gene in the monolignol biosynthetic pathway, a spacer DNA segment, and a second DNA segment that is complementary to the first DNA segment can be used to reduce or modulate the lignin content in plants. In some embodiments, DNA constructs comprise at a least a portion of a gene for 4CL, C3H, CCR, C4H or CCoAOMT. Vascular-preferred and constitutive promoters can be used to drive expression of the constructs.

Owner:ARBORGEN

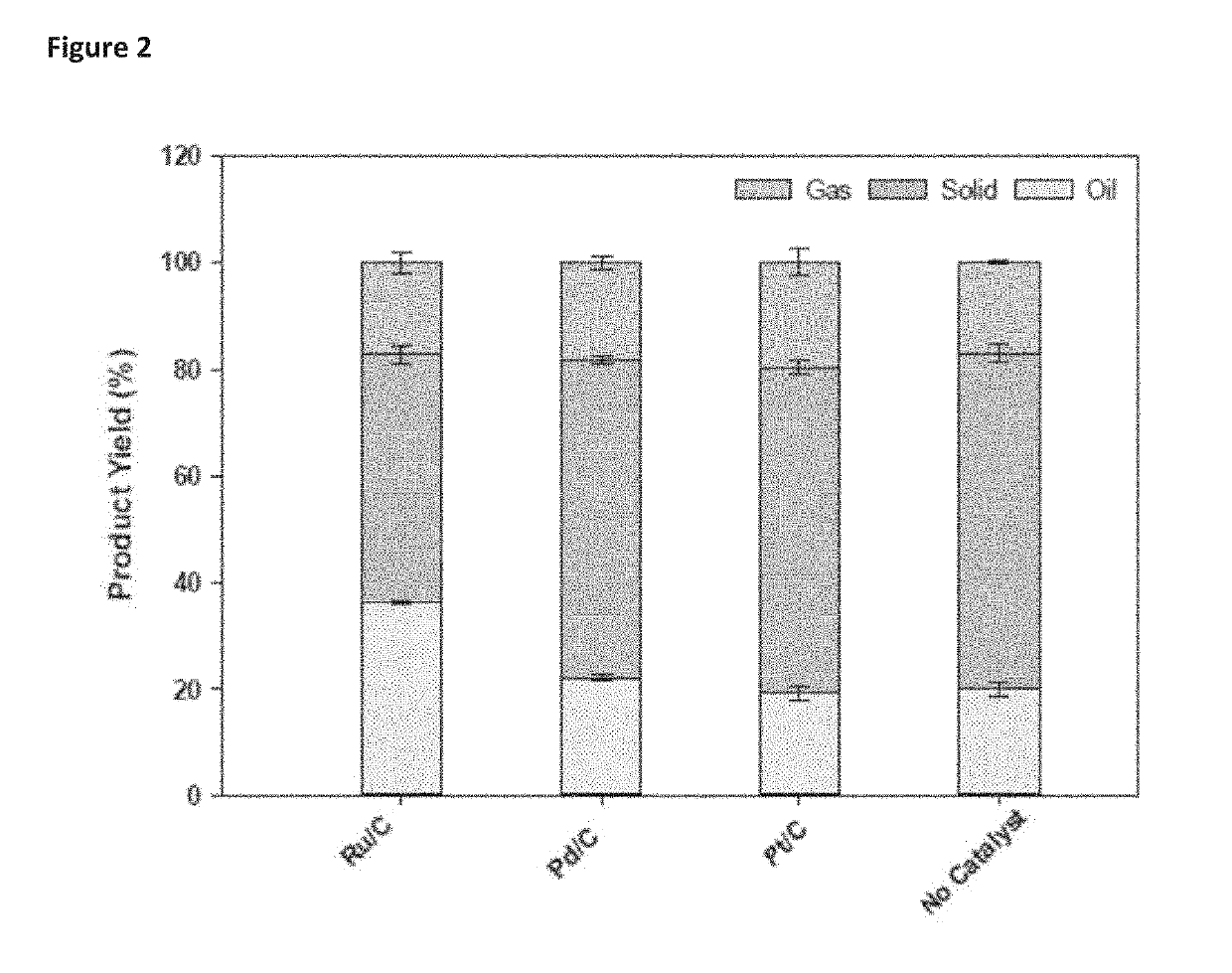

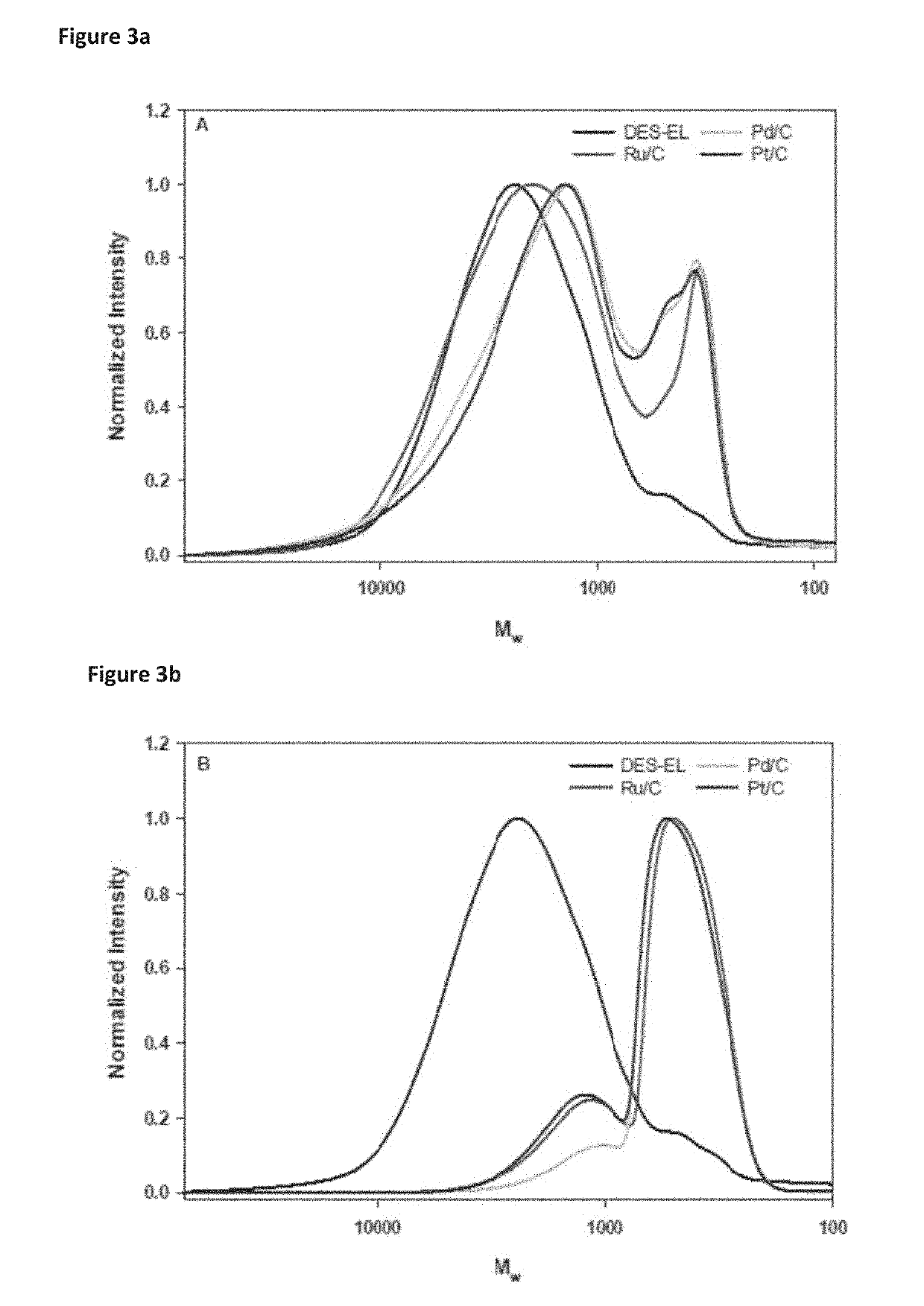

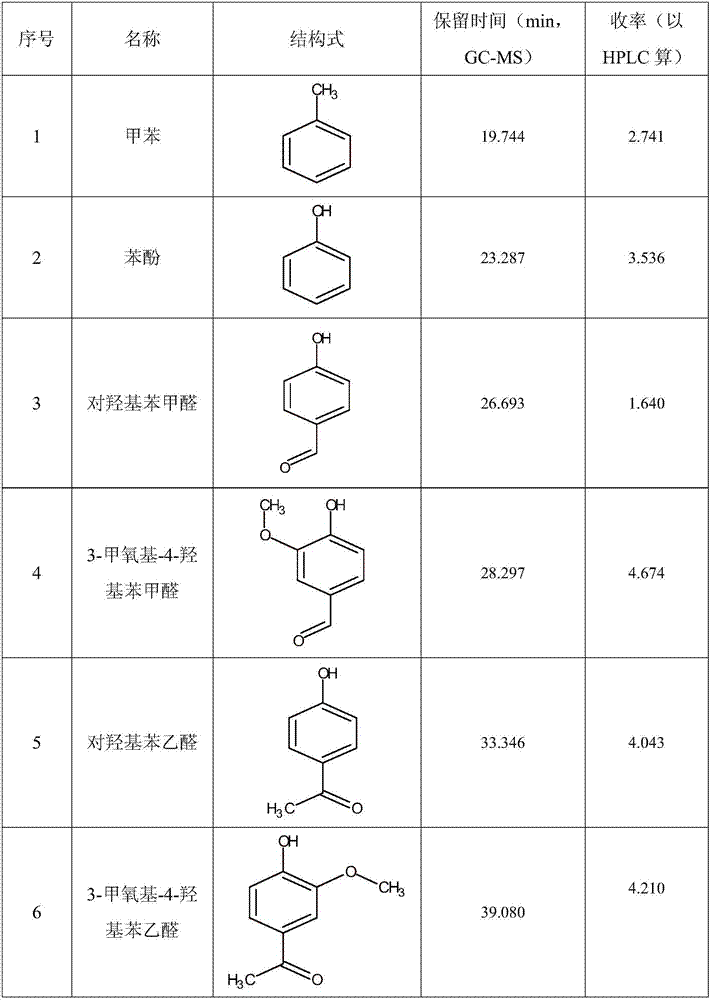

Lignin valorization in ionic liquids and deep eutectic solvent via catalysis and biocatalysis

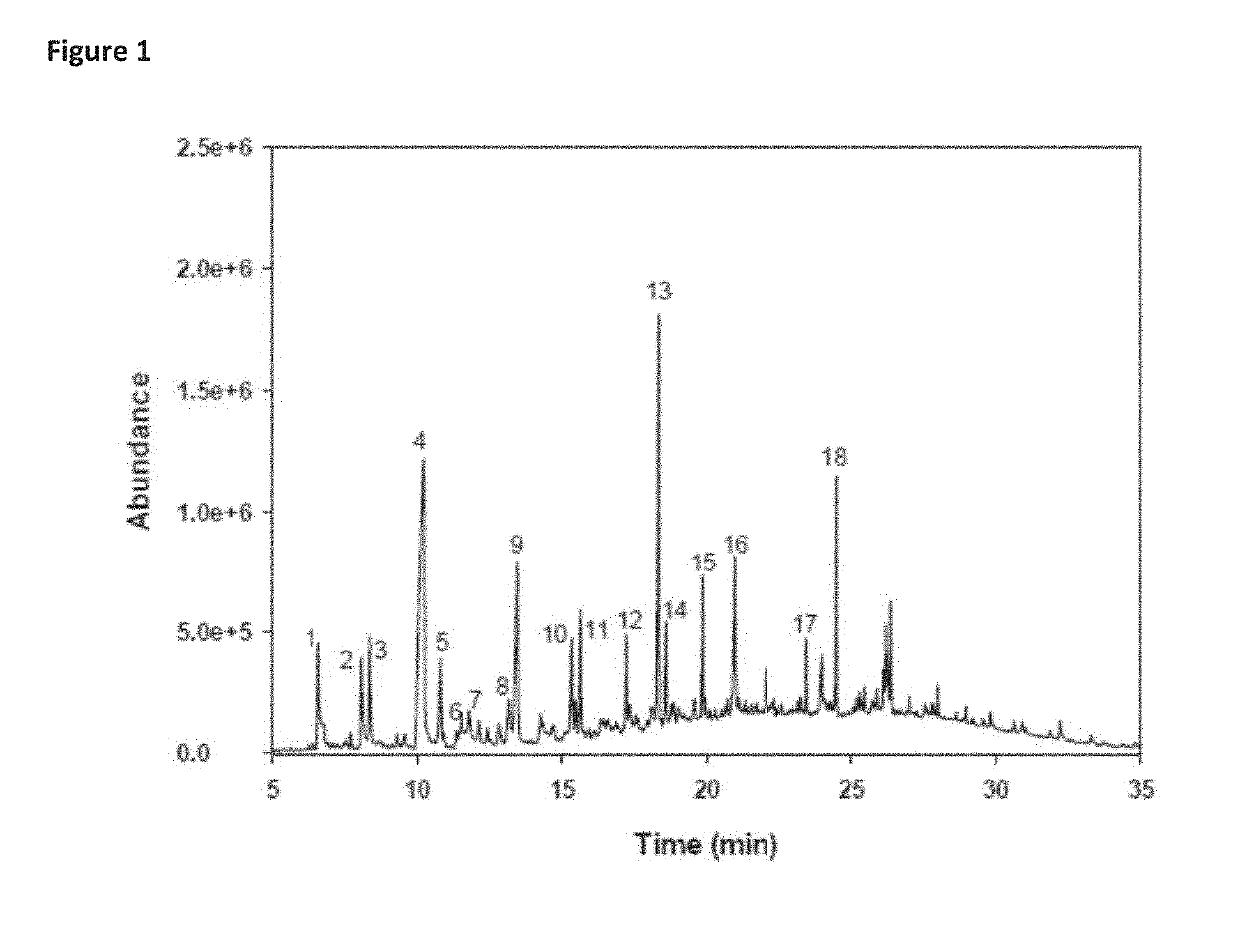

This invention relates to a method for extracting valorized compounds from lignin by contacting lignins with an ionic liquid and / or a deep eutectic solvent and adding a catalyst and / or a biocatalyst to assist in breaking down the source material. Converting lignin into high value chemicals adds revenues for a bio-refinery and helps to improve the economic viability of biofuel production.

Owner:UNIV OF KENTUCKY RES FOUND

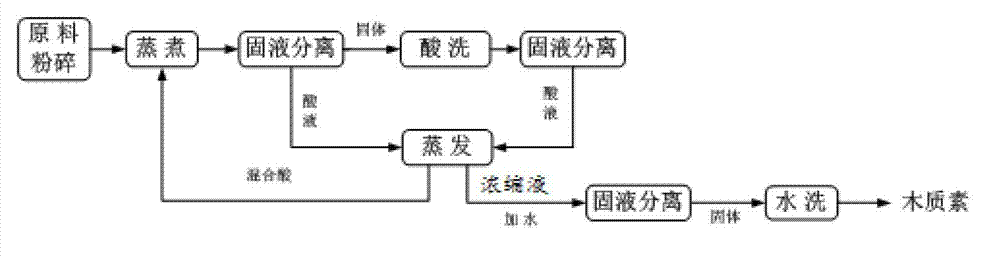

Technique for extracting lignin from biomass raw materials

The invention relates to a technique for extracting lignin, in particular to a technique of utilizing organic acid to extract the lignin from biomass raw materials by a catalytic action of hydrogen peroxide. According to the method, the lignin is obtained by extracting the biomass raw materials boiled by organic acid formed by methanoic acid and acetic acid by the catalytic action of hydrogen peroxide; a whole technique route is simple; the energy consumption is lower; and an extraction ratio of the lignin reaches 80-90%.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

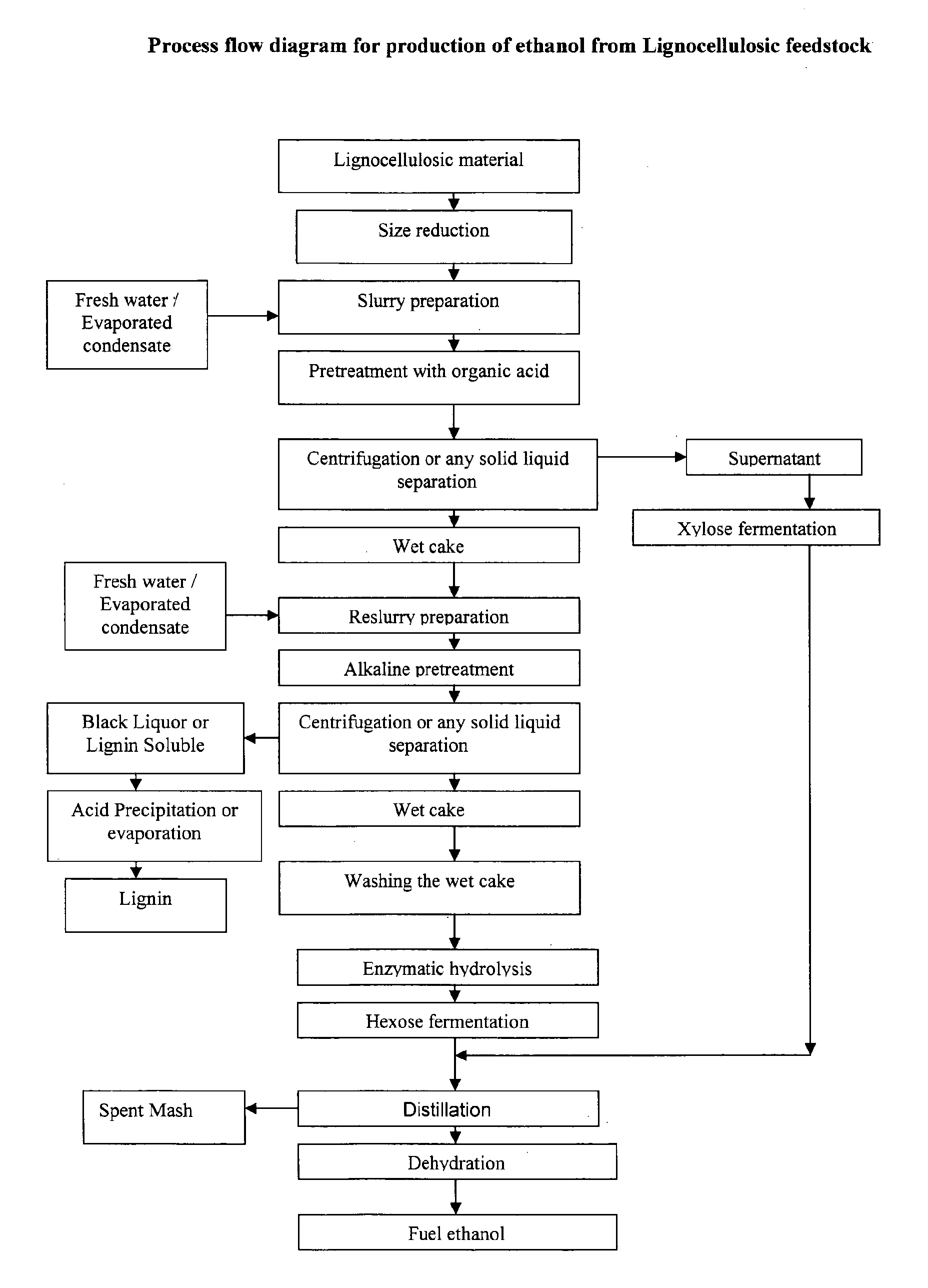

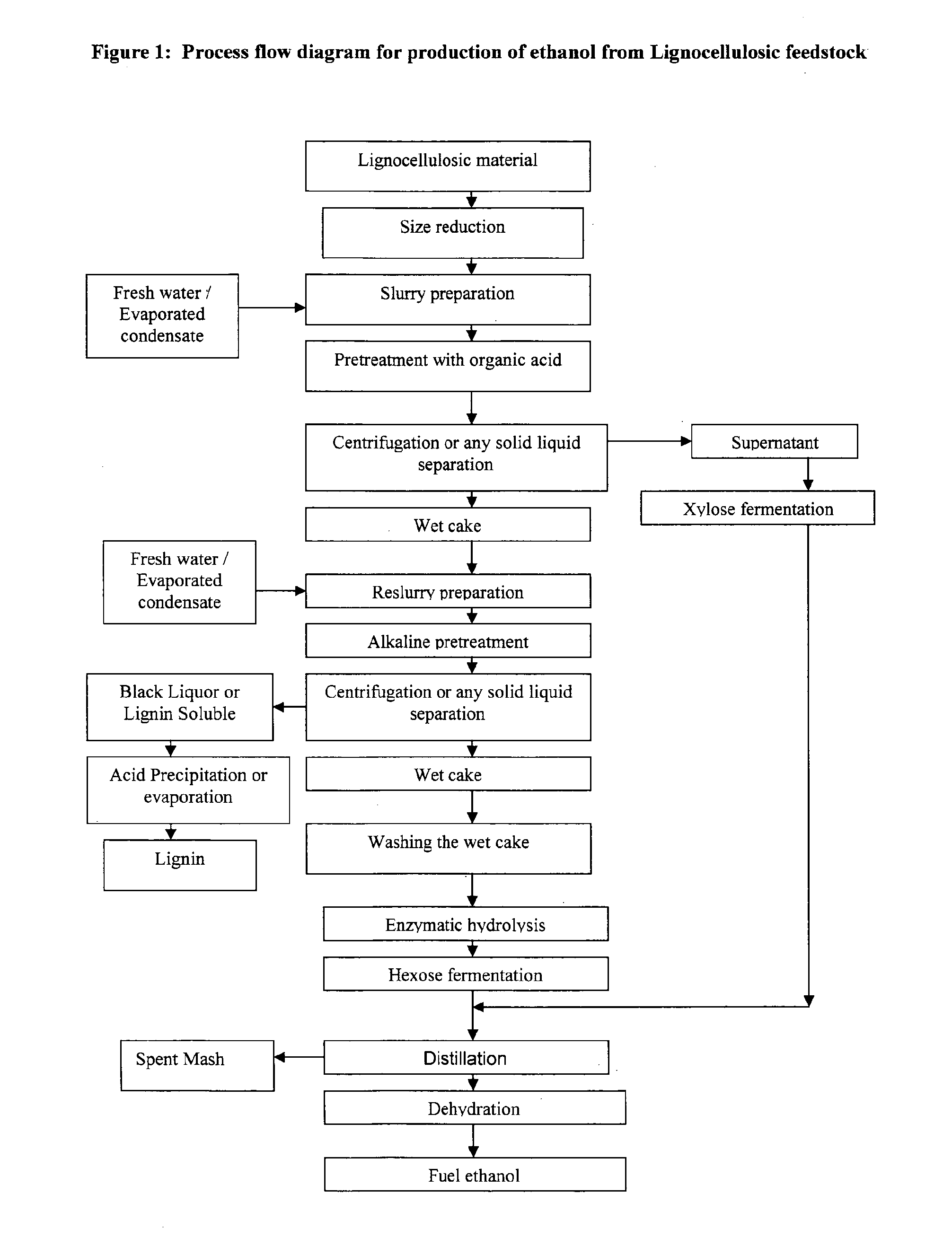

Process for Production of Ethanol from Lignocellulosic Material

InactiveUS20110129889A1Process is effective and economicalSpeed up the processBiofuelsFermentationDistillationFermentation

This invention relates to a process for production of ethanol from lignocellulosic material. Lignocellulosic material treated with a dicarboxylic acid, preferably with oxalic acid, separating a hemicellulosic fraction to ferment pentose sugar. The lignin is dissolved in alkali, preferably with NaOH, separating a cellulose fraction for further enzymatic treatment with one or more than one cellulytic enzymes capable of hydrolyzing cellulose. The enzyme hydrolyasate is further subjected to fermentation in the presence of ethanol-producing yeast, preferably Sacchoromyces cerevisiae. The fermented broth is further subjected to distillation followed by dehydration to yield ethanol.

Owner:PRAJ IND LTD

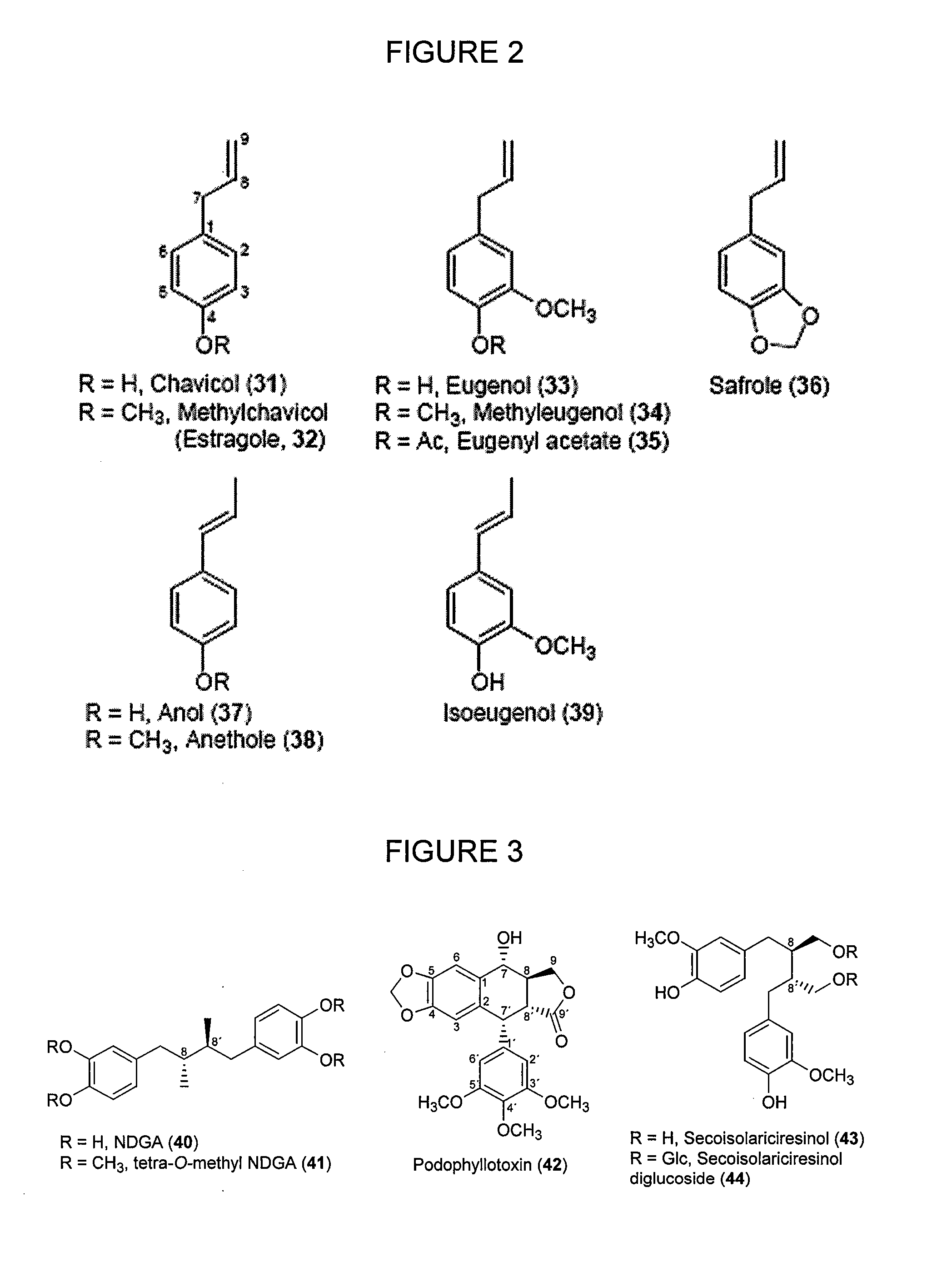

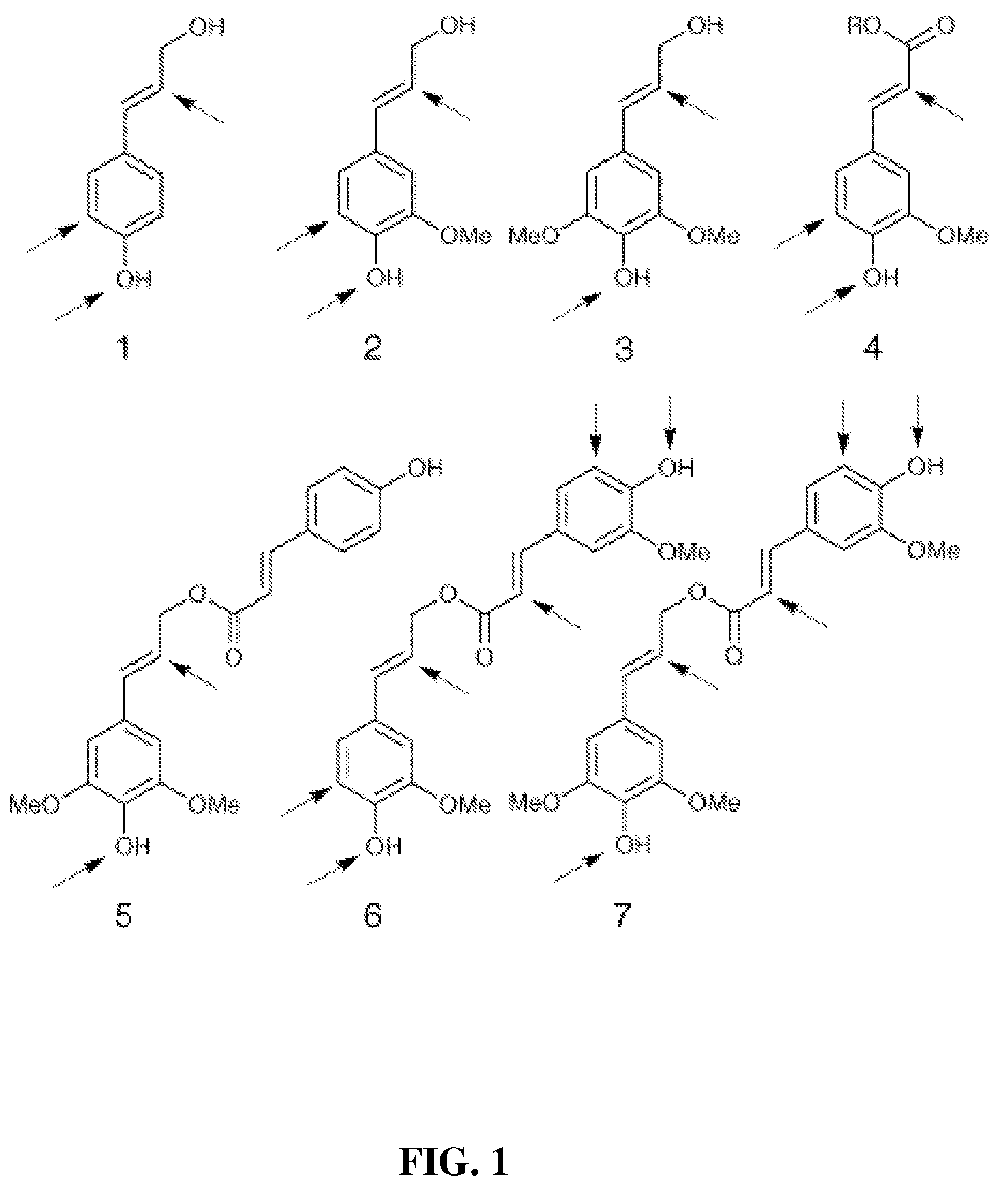

Genes encoding chavicol/eugenol synthase from the creosote bush larrea tridentata

Particular aspects provide novel methods for redirecting carbon allocation in plants or cell culture from lignification to inherently more useful and tractable materials, and to facilitate the generation of, e.g., biofuels from the remaining plant roculture biomass. Particular aspects provided novel methods for converting monolignols into allyl / propenyl phenols, and for chavicol / eugenol formation or production. Additional aspects relate to the discovery of novel chavicol / eugenol synthases that convert p-coumaryl / coniferyl alcohol esters into chavicol / eugenol, and to novel compositions (e.g., novel proteins and nucleic acids encoding same), and novel methods using same for producing or forming chavicol / eugenol and other derivatives in cell culture and / or genetically modified plants, and for re-engineering the composition of plant biomass. Particular aspects provide novel methods for generation in culture or in planta of liquid / combustible allyl / propenyl phenols, and these phenolic products are utilized for (non-ethanol) biofuel / bioenergy purposes, while the remaining plant biomass facilitates the generation of other biofuels.

Owner:WASHINGTON STATE UNIVERSITY

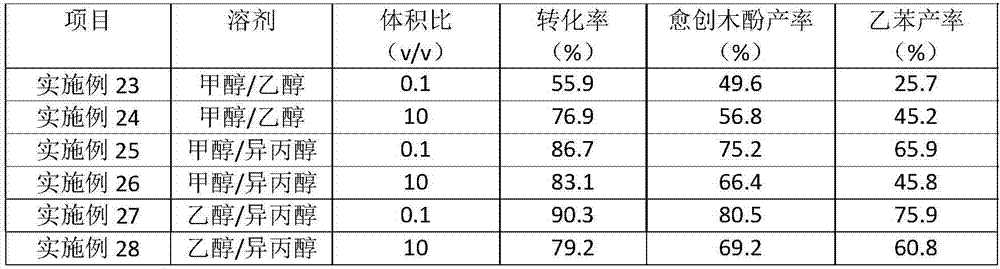

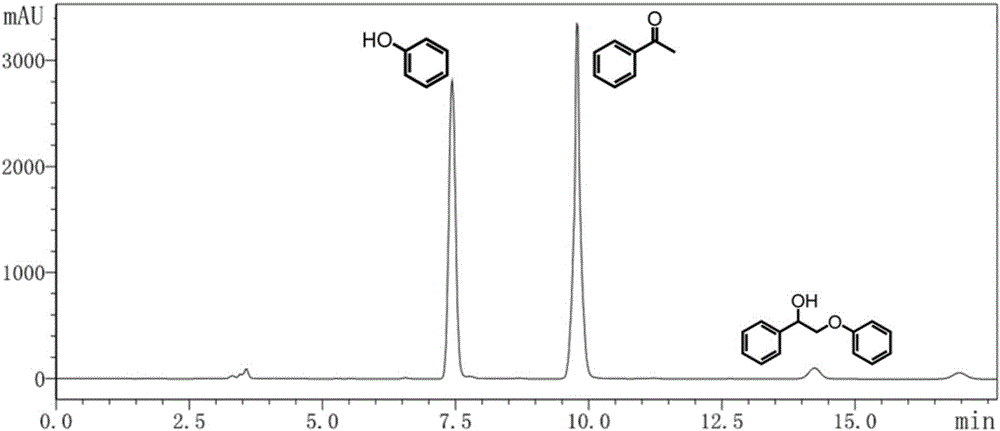

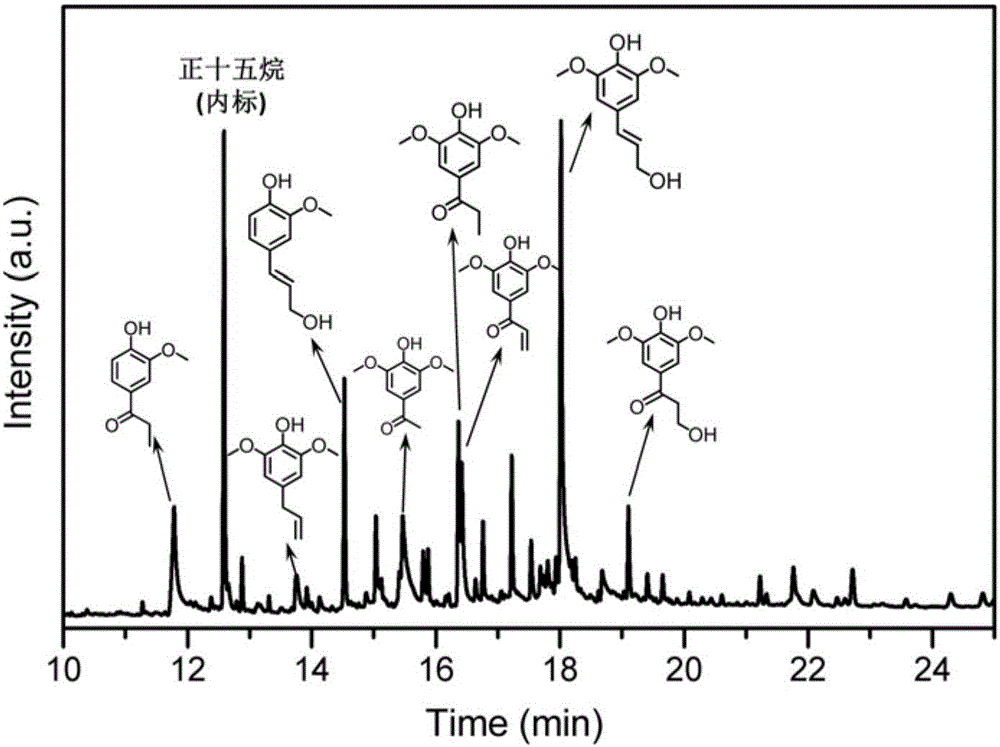

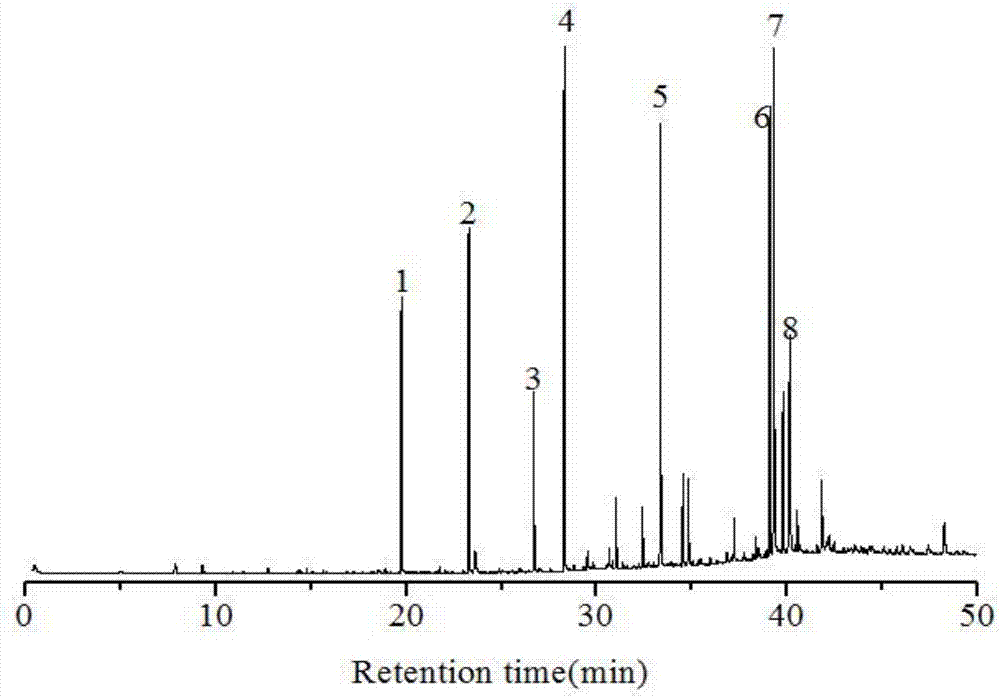

Method for lignin aryl-ether bond catalytic pyrolysis with ReO<x>/AC

ActiveCN107473944ABreak through dependenceAvoid it happening againOrganic compound preparationCatalystsRecyclable catalystCatalytic pyrolysis

The invention provides a new method for converting a lignin model compound dimer and a lignin raw material to a corresponding aromatic compound through a hydrogen transfer reaction by taking ReO<x> / AC as a catalyst. According to the method, one or two micromolecular alcohol is taken as a reaction regent, ReO<x> / AC is taken as a catalyst, and the lignin model compound and the lignin raw material are catalyzed and converted to a micromolecular aromatic chemical in a mild condition. Compared with a traditional lignin depolymerization method, the method has distinct features: no addition of hydrogen and oxygen sources, mild reaction conditions, high selectivity of monophenol products, fast reaction speed, recyclable catalyst, and simple operation. The aromatic chemicals can be prepared from renewable lignin sources, a mild depolymerization strategy without consuming hydrogen sources is developed, and a new approach is developed for producing an aromatic compound in a non-petroleum route.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

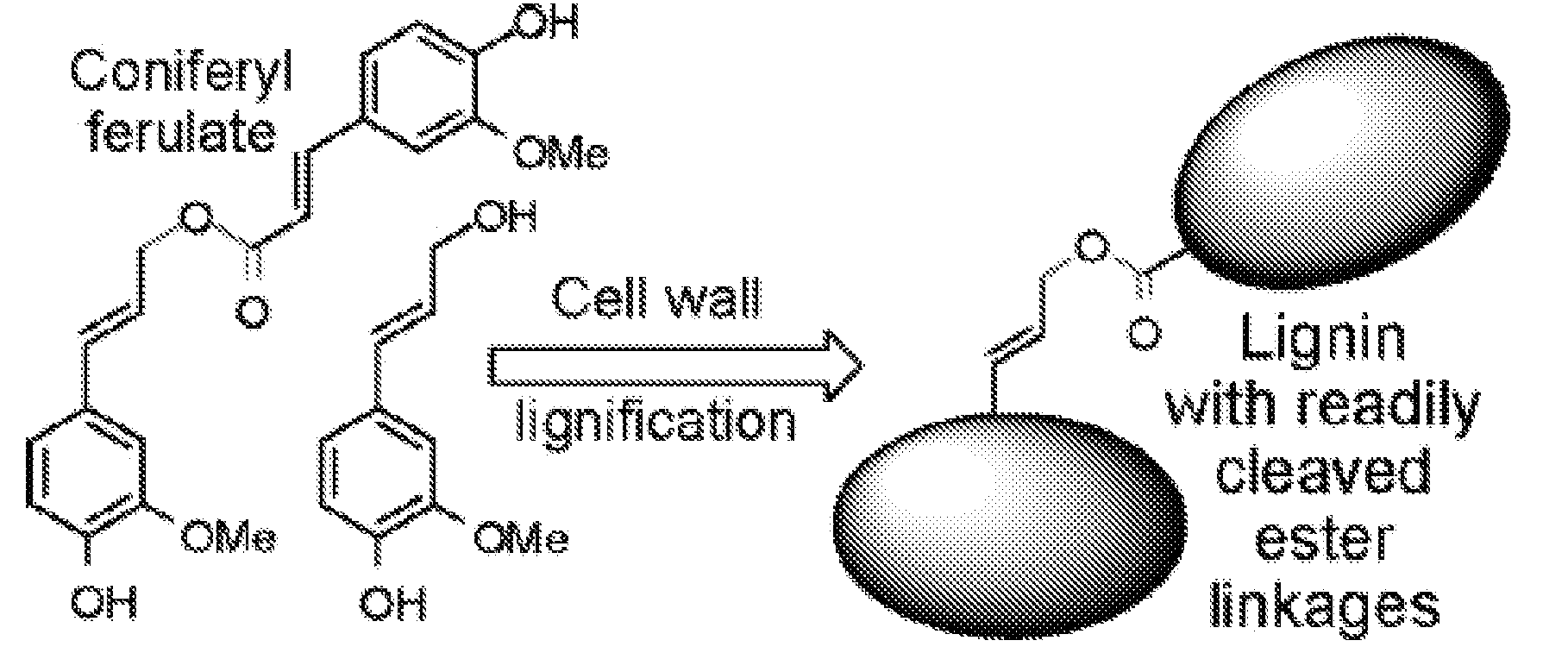

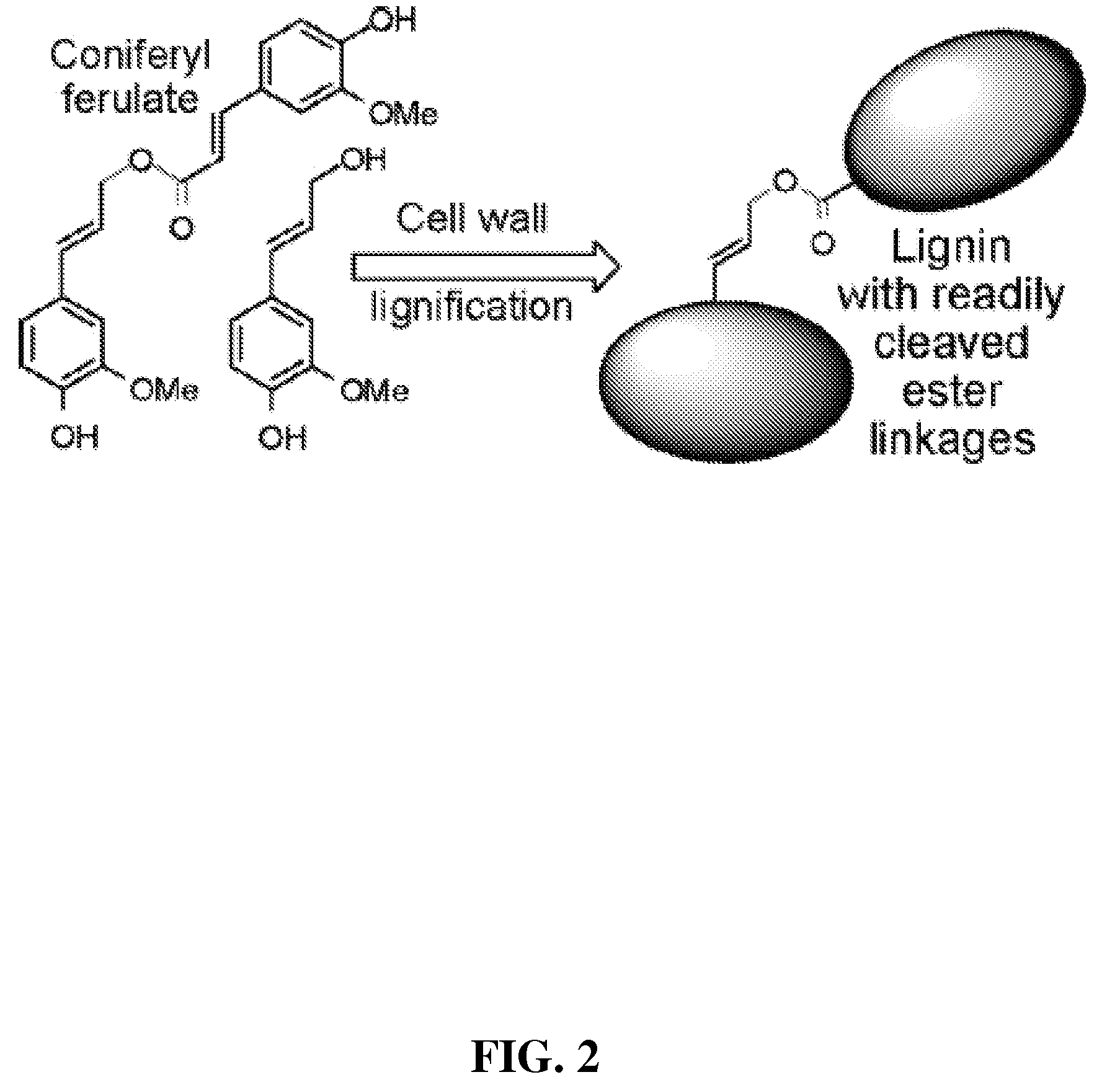

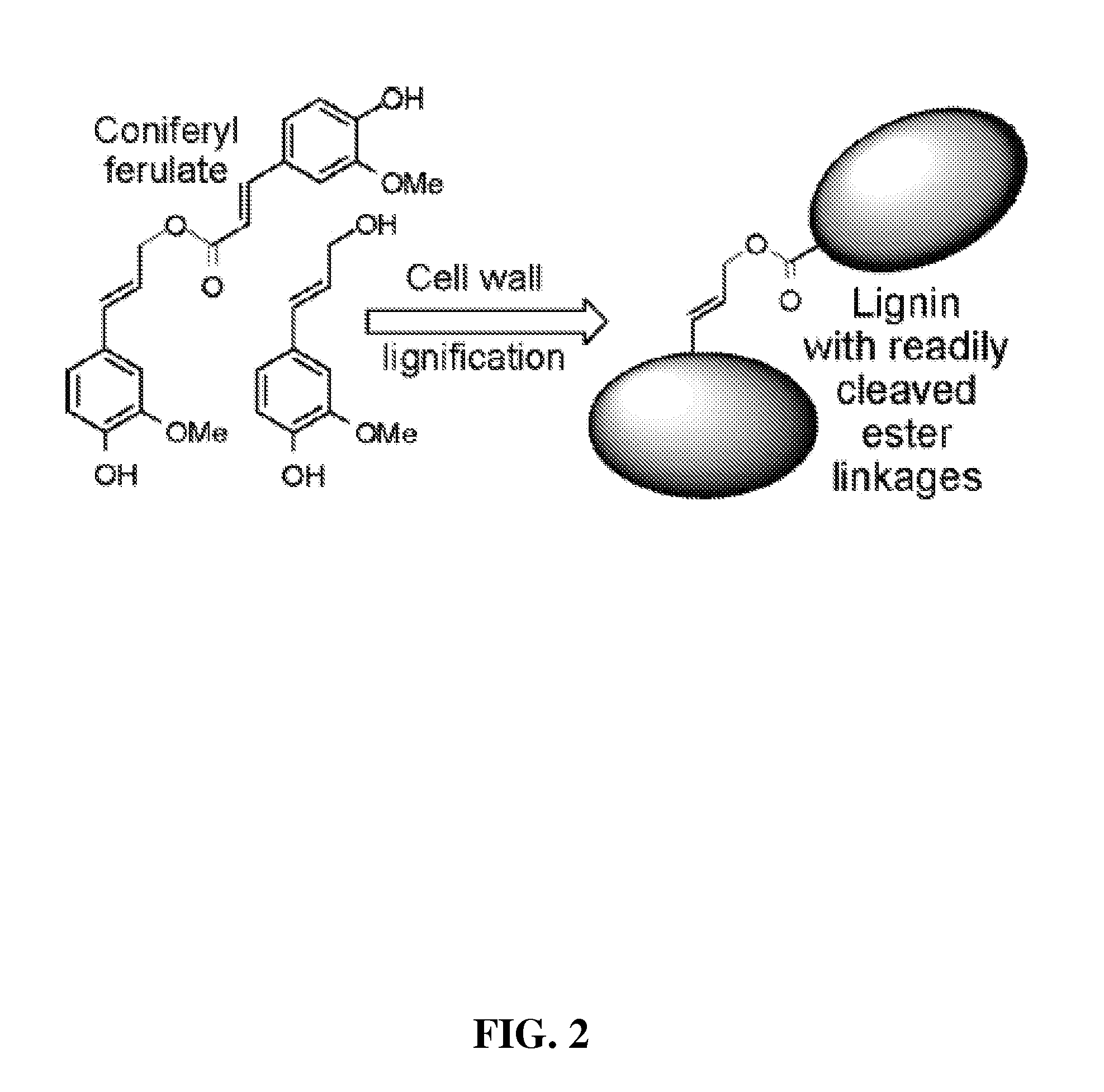

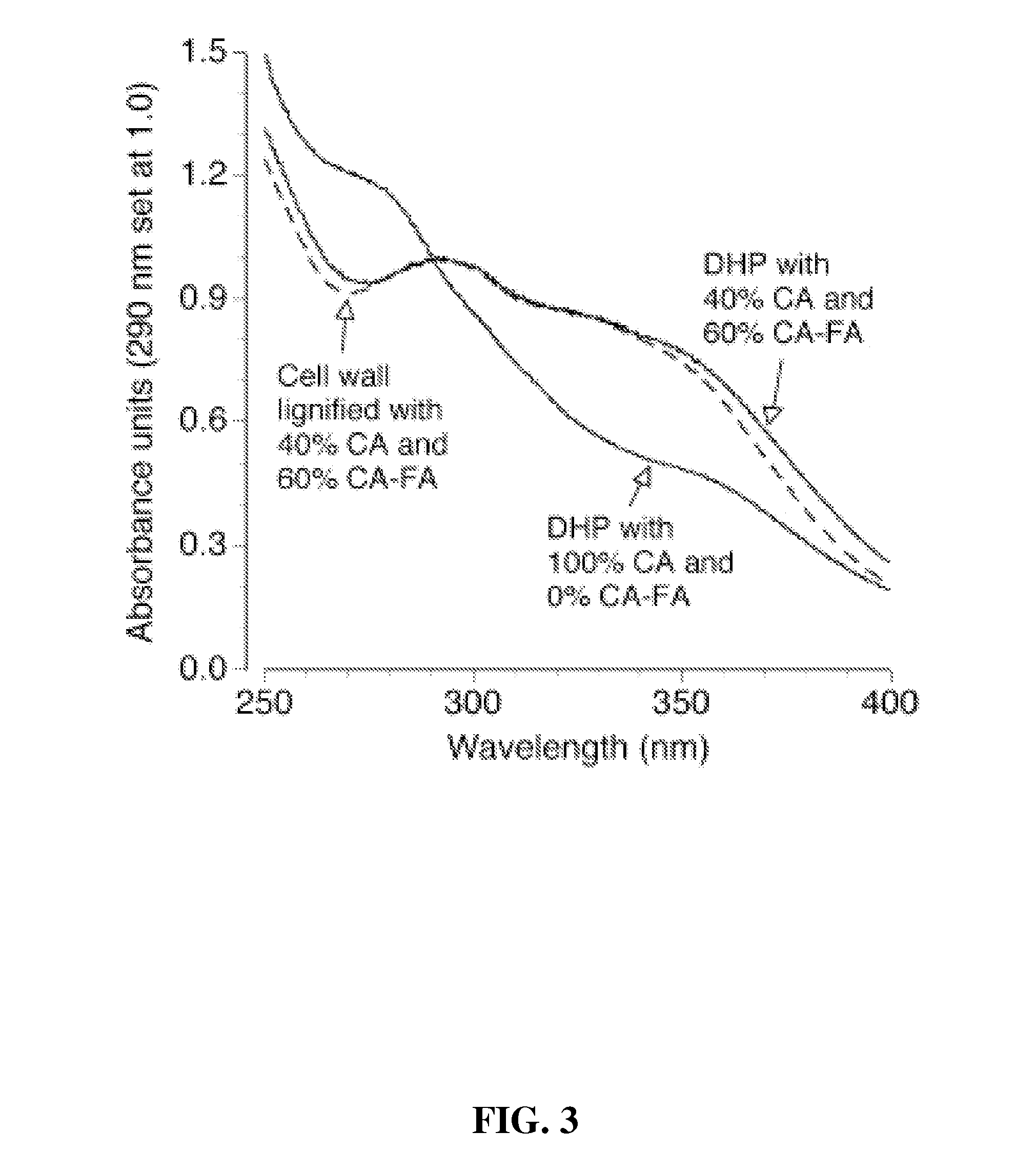

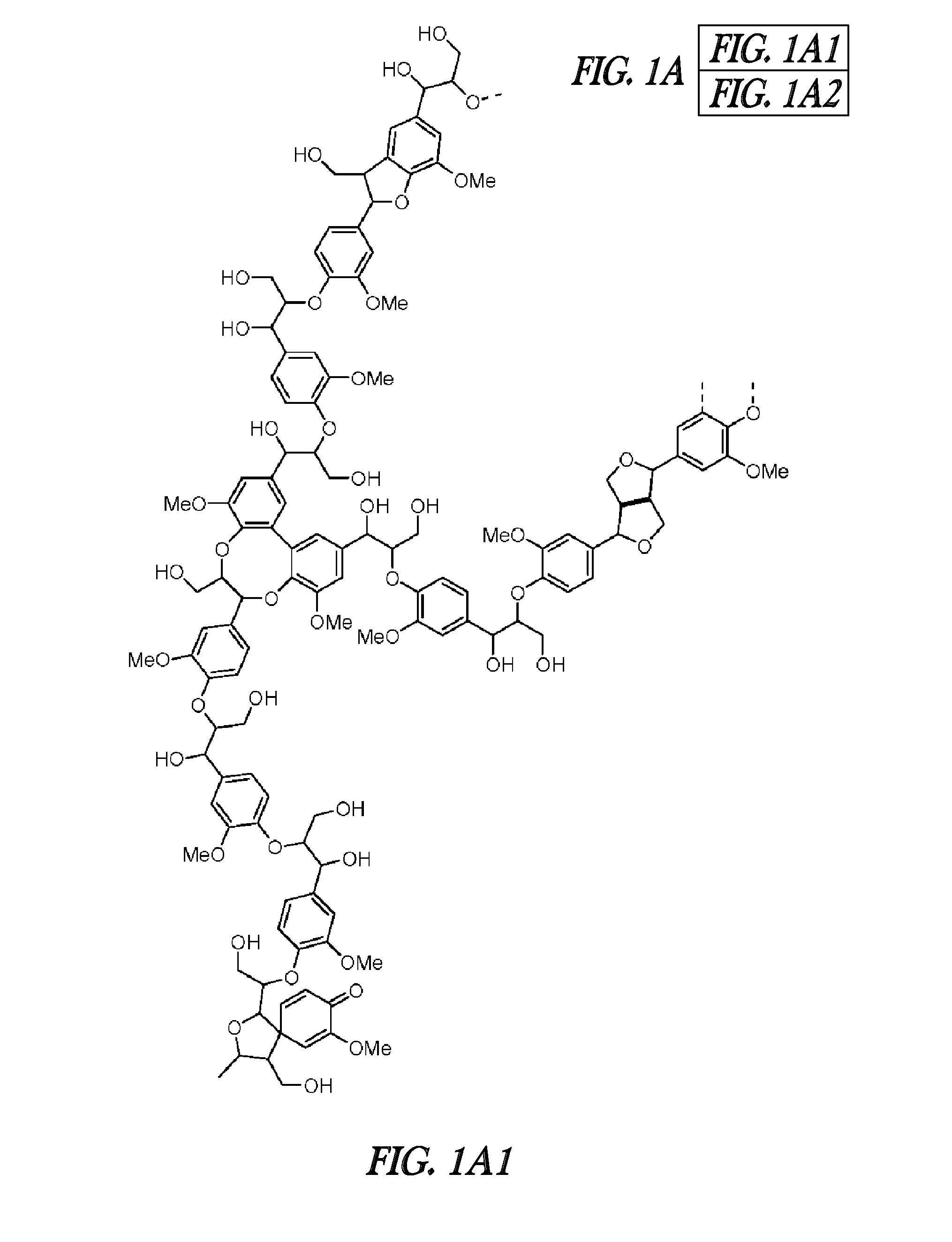

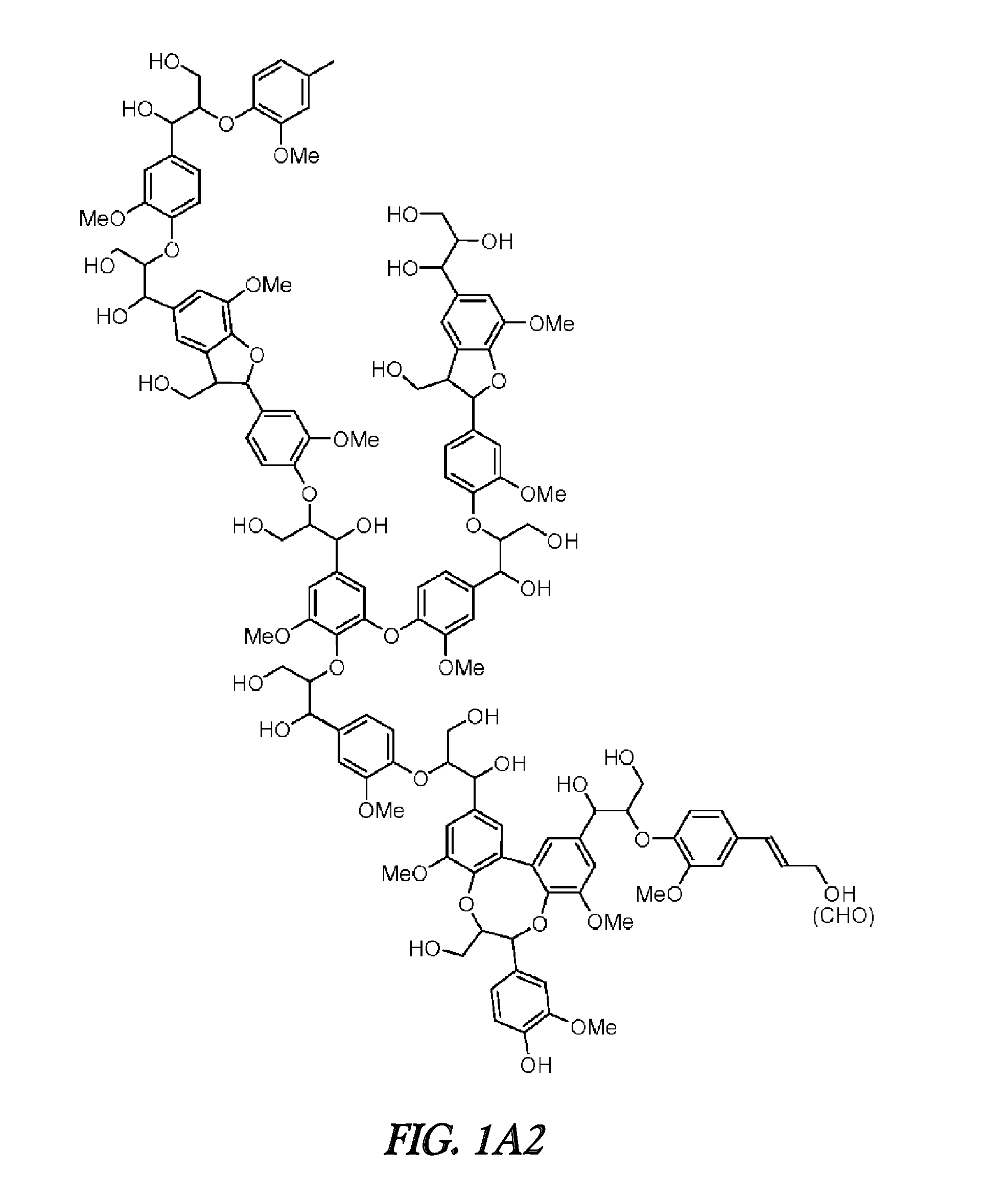

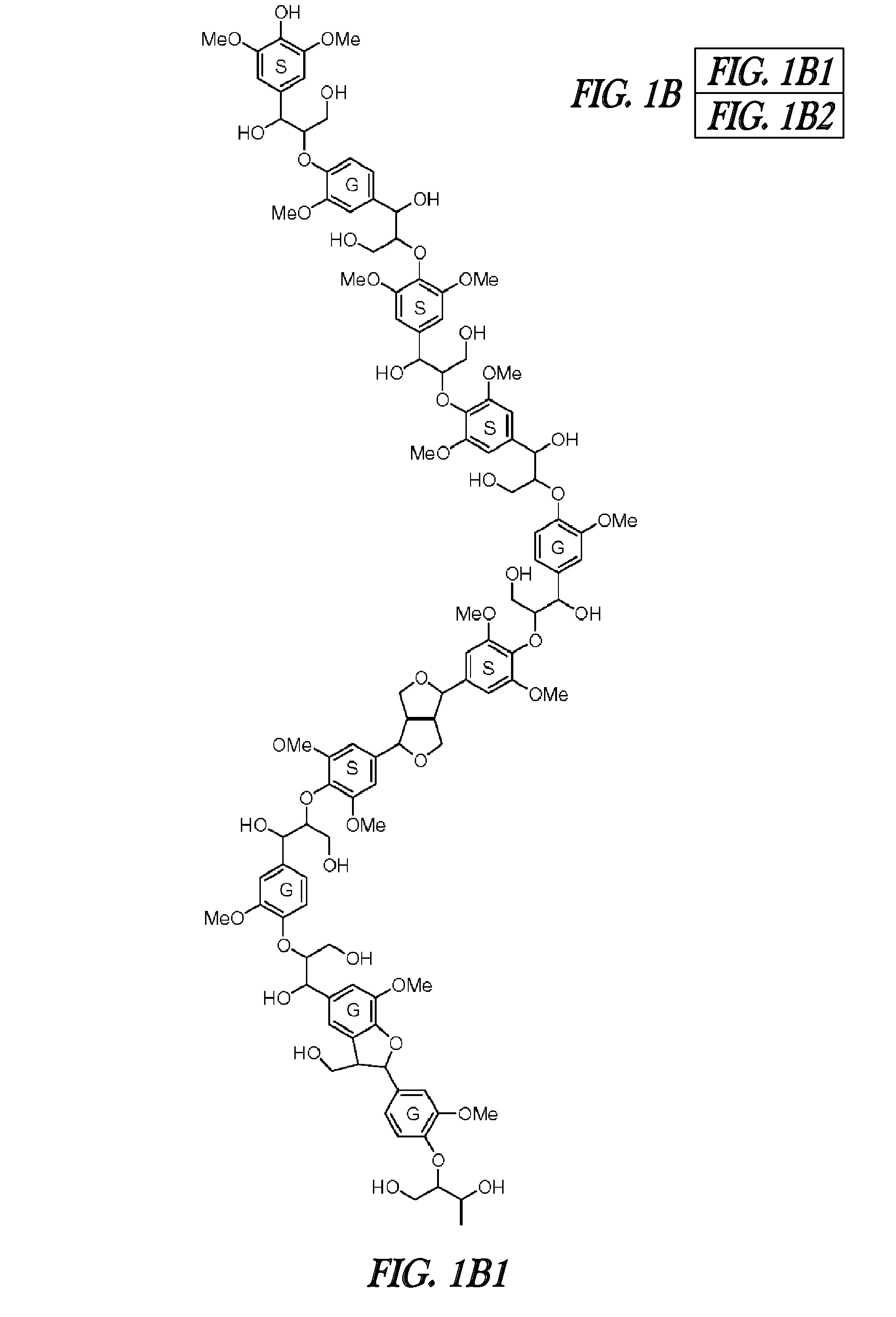

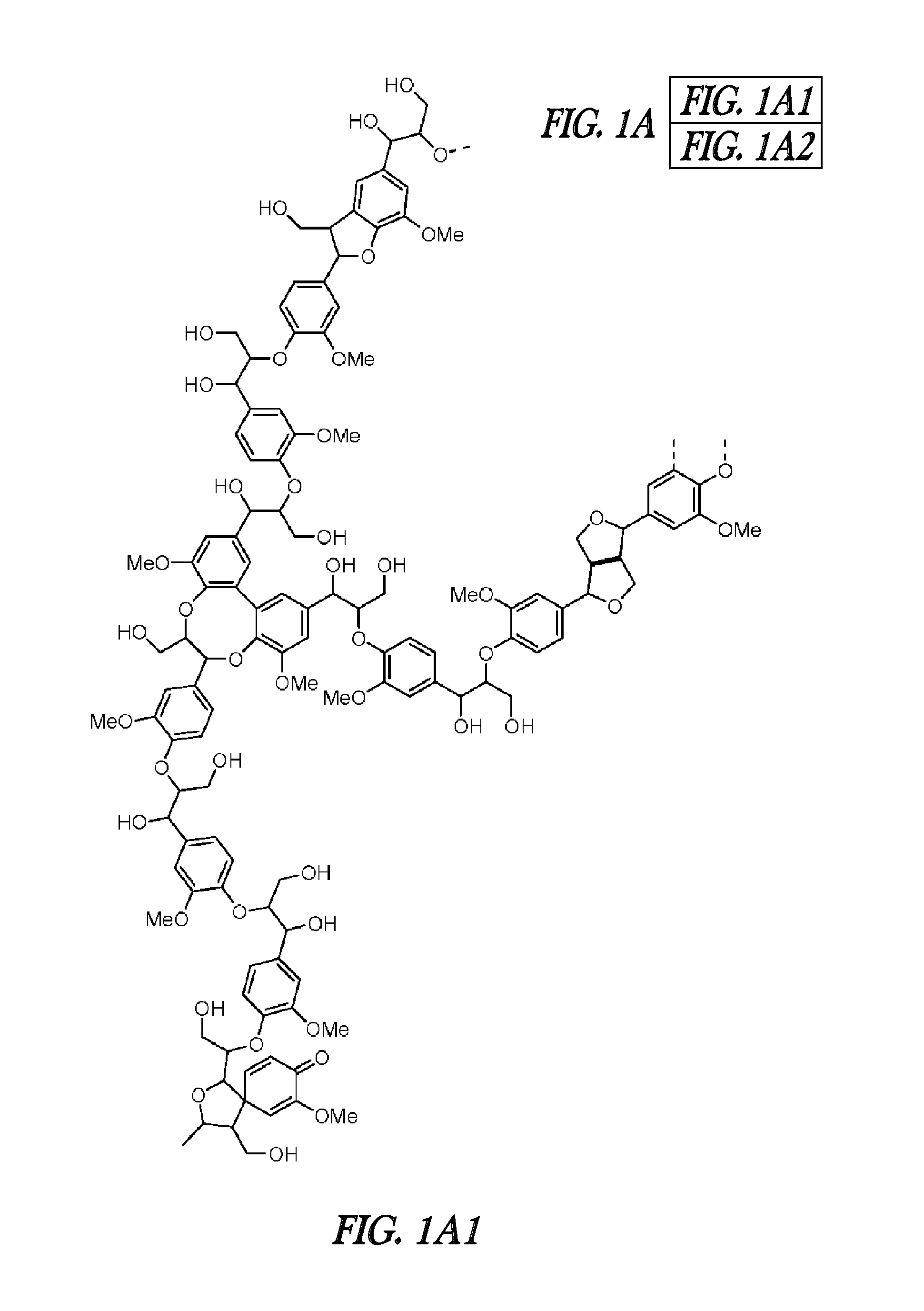

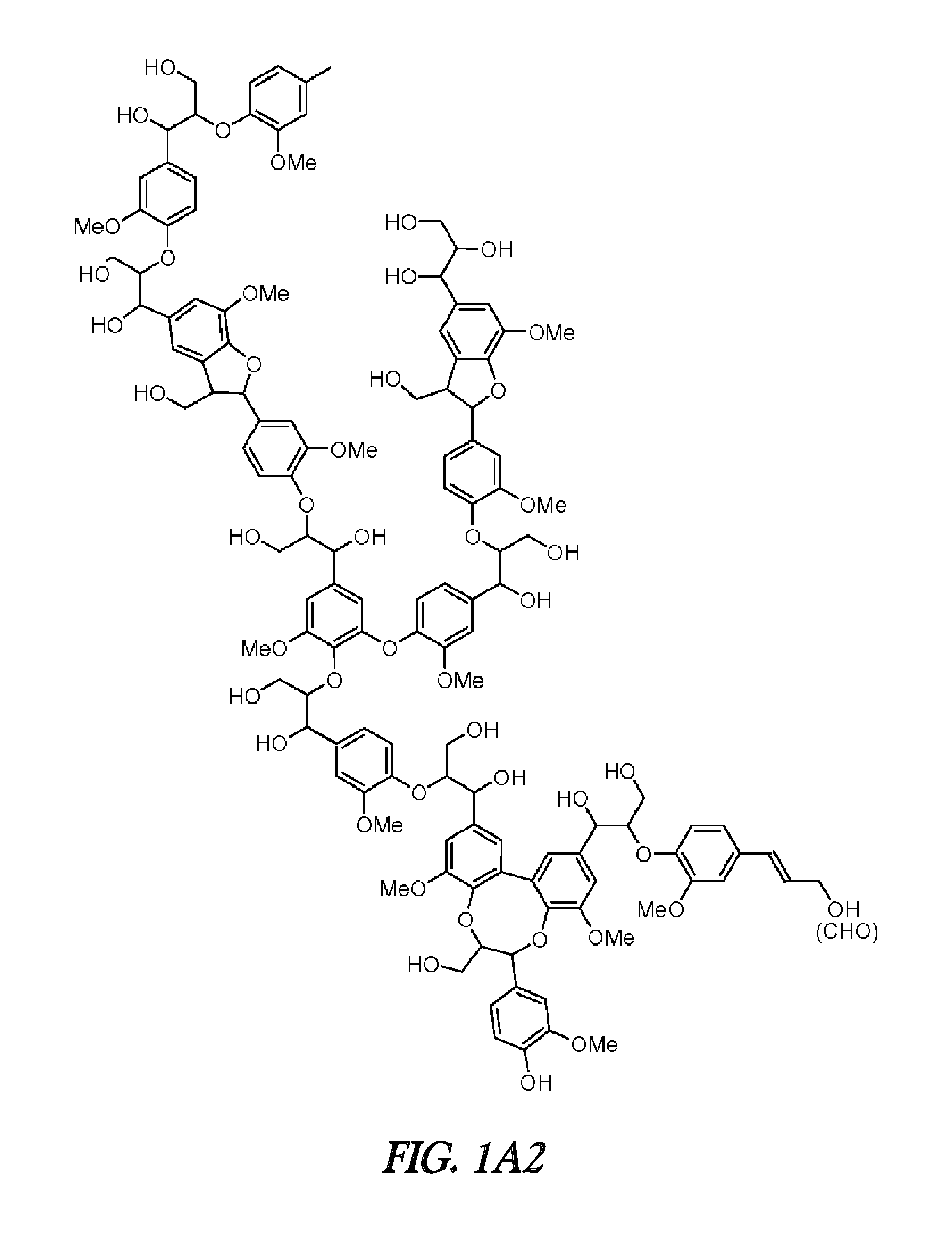

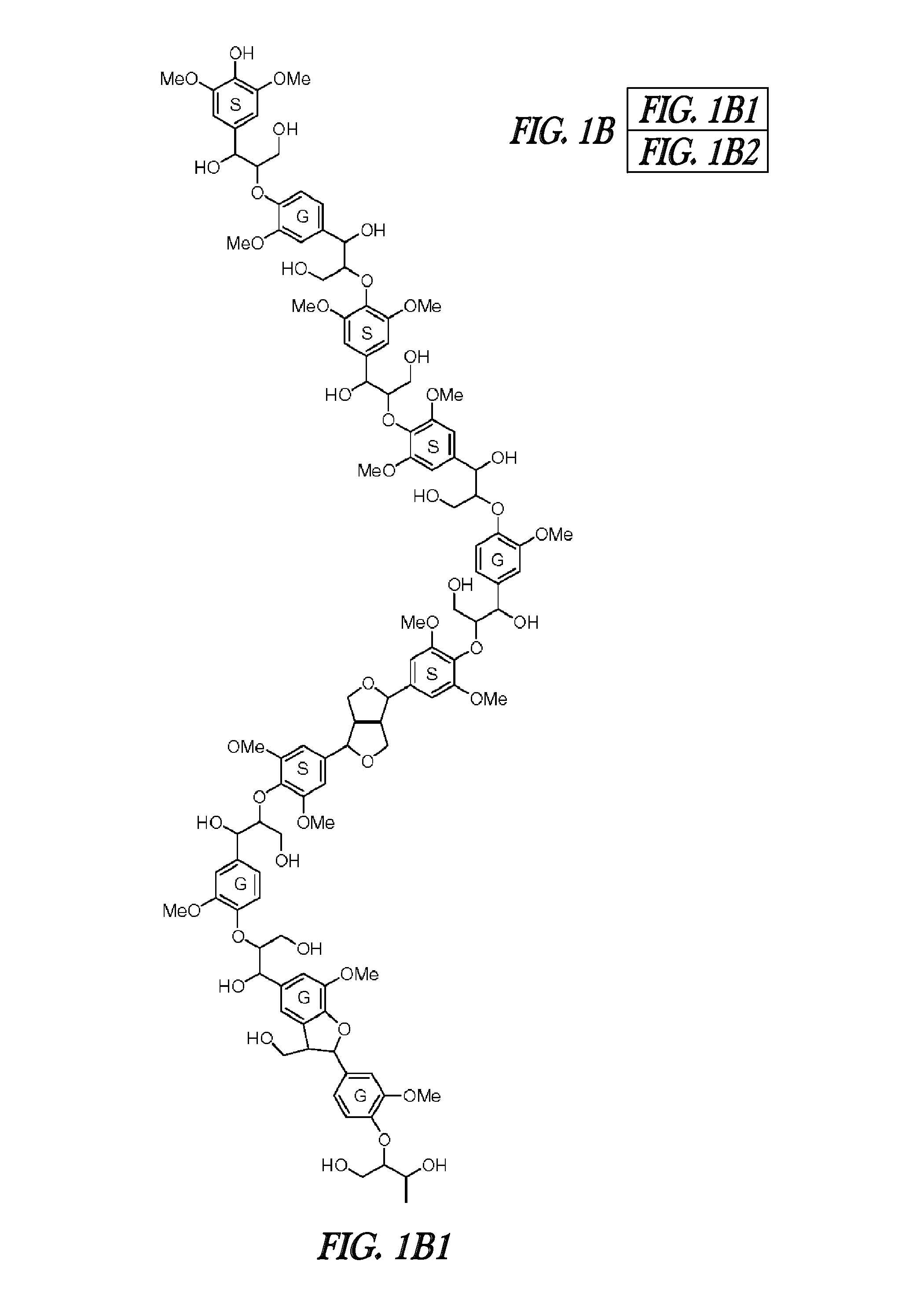

Method for modifying lignin structure using monolignol ferulate conjugates

ActiveUS8569465B2Limit enzyme accessImproves digestibility/fermentabilityMicroorganismsLignin derivativesPlant cellCell wall

Described is an isolated lignified plant cell wall including lignin, wherein the lignin includes a ferulate residue incorporated therein, such as from coniferyl ferulate and / or sinapyl ferulate. Also described is a method to make the isolated lignified plant cell wall, and the lignin produced by the method.

Owner:WISCONSIN ALUMNI RES FOUND +1

Method for modifying lignin structure using monolignol ferulate conjugates

ActiveUS20110003978A1Limit enzyme accessImproves digestibility/fermentabilityMicroorganismsLignin derivativesSinapic acidMonolignol

Described is an isolated lignified plant cell wall including lignin, wherein the lignin includes a ferulate residue incorporated therein, such as from coniferyl ferulate and / or sinapyl ferulate. Also described is a method to make the isolated lignified plant cell wall, and the lignin produced by the method.

Owner:WISCONSIN ALUMNI RES FOUND +1

Feruloyl-CoA:monolignol transferase

ActiveUS9441235B2Readily cleavableSimple processLignin derivativesPulping with inorganic basesFeruloyl-CoAConiferyl ferulate

The invention relates to nucleic acids encoding a feruloyl-CoA:monolignol transferase and the feruloyl-CoA:monolignol transferase enzyme that enables incorporation of monolignol ferulates, for example, including p-coumaryl ferulate, coniferyl ferulate, and sinapyl ferulate, into the lignin of plants.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV +2

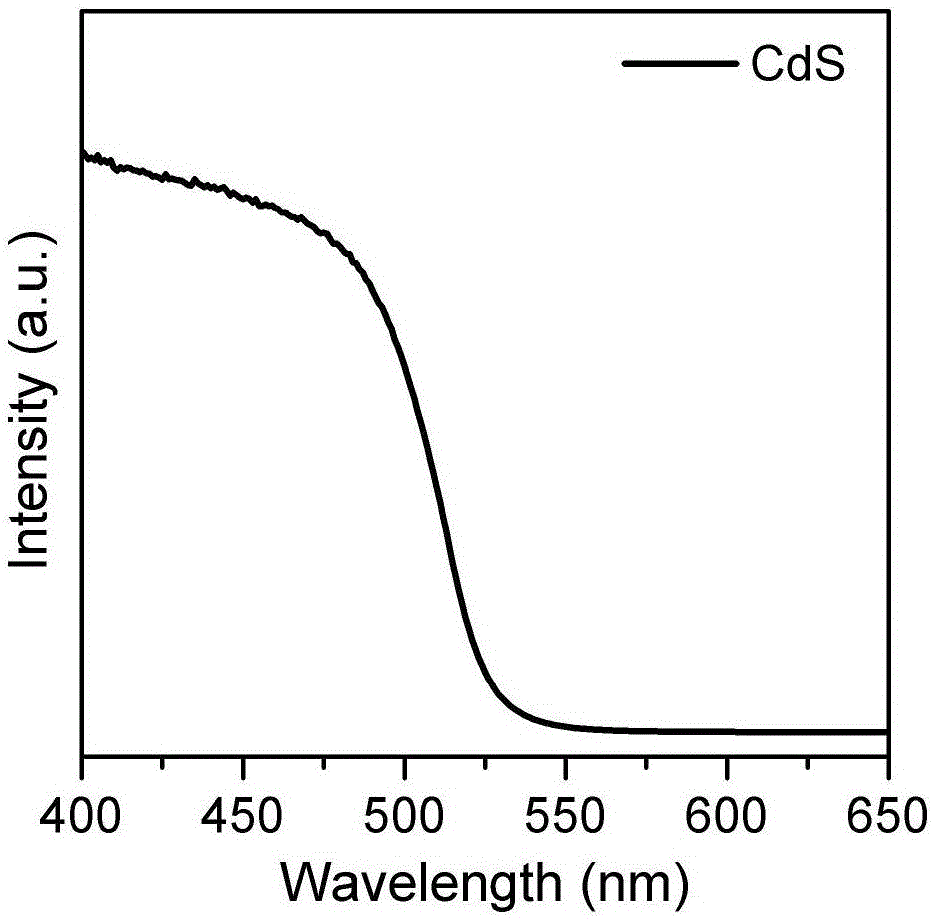

Method for preparing aromatic compound through photocatalytic conversion of lignin and lignin-derived aryl ether

ActiveCN106748640AGreenMild reaction conditionsOxygen-containing compound preparationOrganic compound preparationArylPhotocatalytic reaction

The invention discloses a method for preparing an aromatic compound through photocatalytic conversion of lignin and lignin-derived aryl ether, and relates to the aromatic compound. A photocatalytic reaction is performed under a visible light condition so as to convert the lignin and the lignin-derived aryl ether into the aromatic compound. A sulfide semiconductor catalyst is added into a solution with the lignin or the lignin-derived aryl ether as a raw material, and after oxygen in a system is removed, a light source is turned on for the photocatalytic reaction so as to obtain the aromatic compound product. In visible light, preparation of the aromatic compound from the lignin and the lignin-derived aryl ether is achieved. According to the method, the visible light is used for the photocatalytic reaction, so that the method has the characteristics of environment friendliness, a mild reaction condition and the like. The method has the advantages as follows: the technical process is simple, the use of a sacrificial agent is avoided, the reaction is performed in an inert atmosphere, the catalyst is high in activity and stability, the aromatic compound product is unlikely to be excessively oxidized and is high in selectivity, the raw materials are low in price, and environment friendliness is ensured.

Owner:XIAMEN UNIV

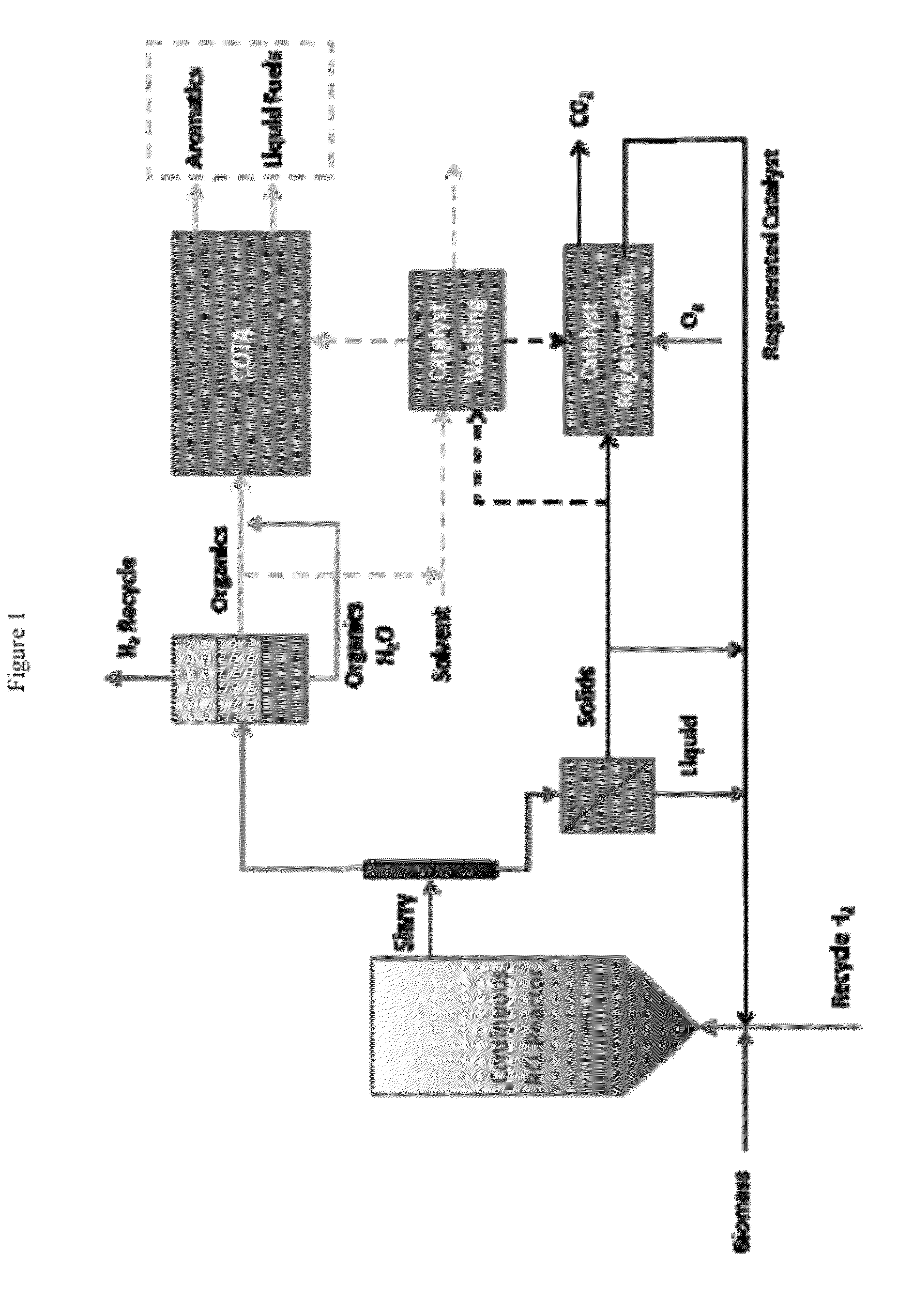

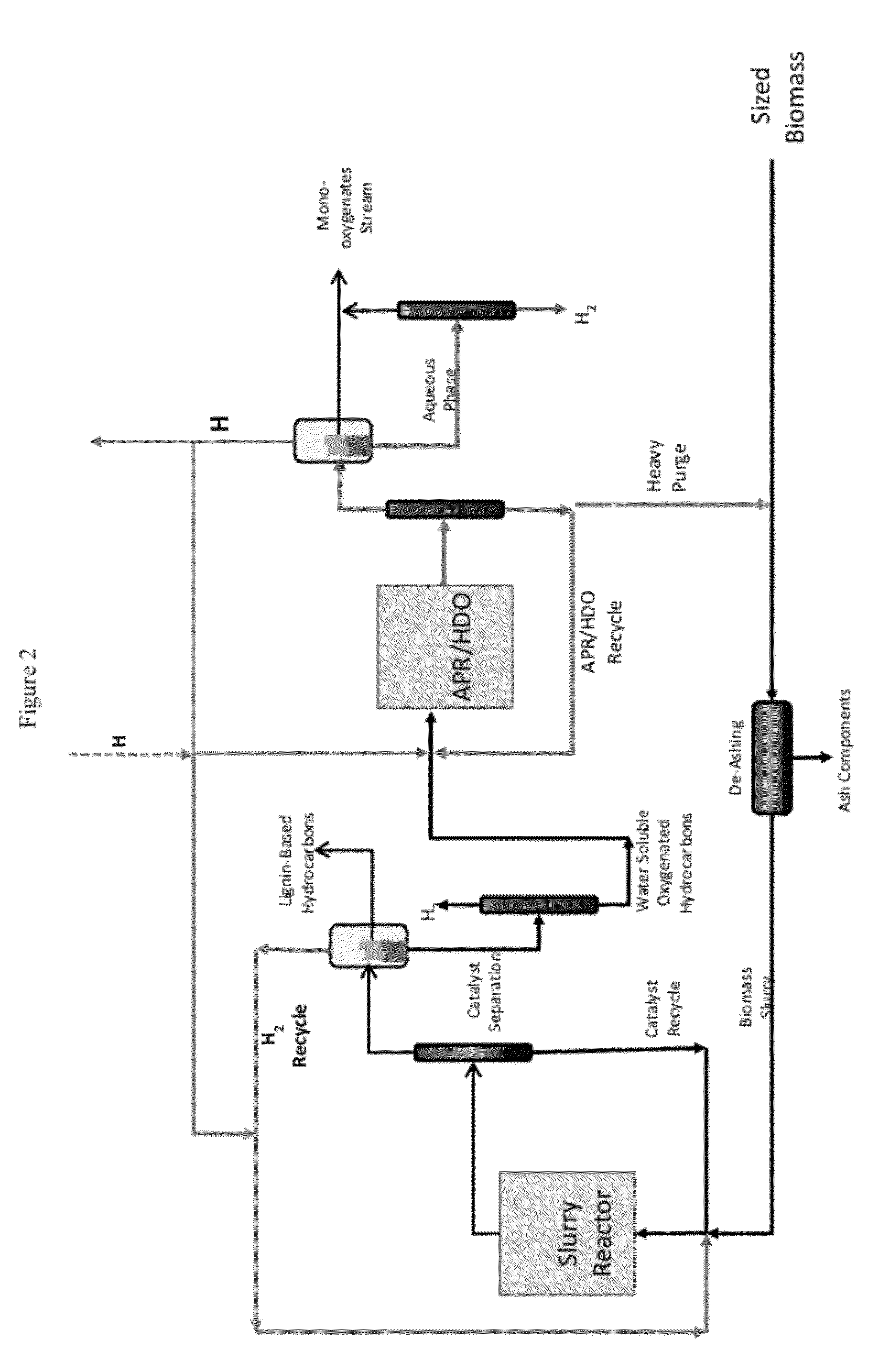

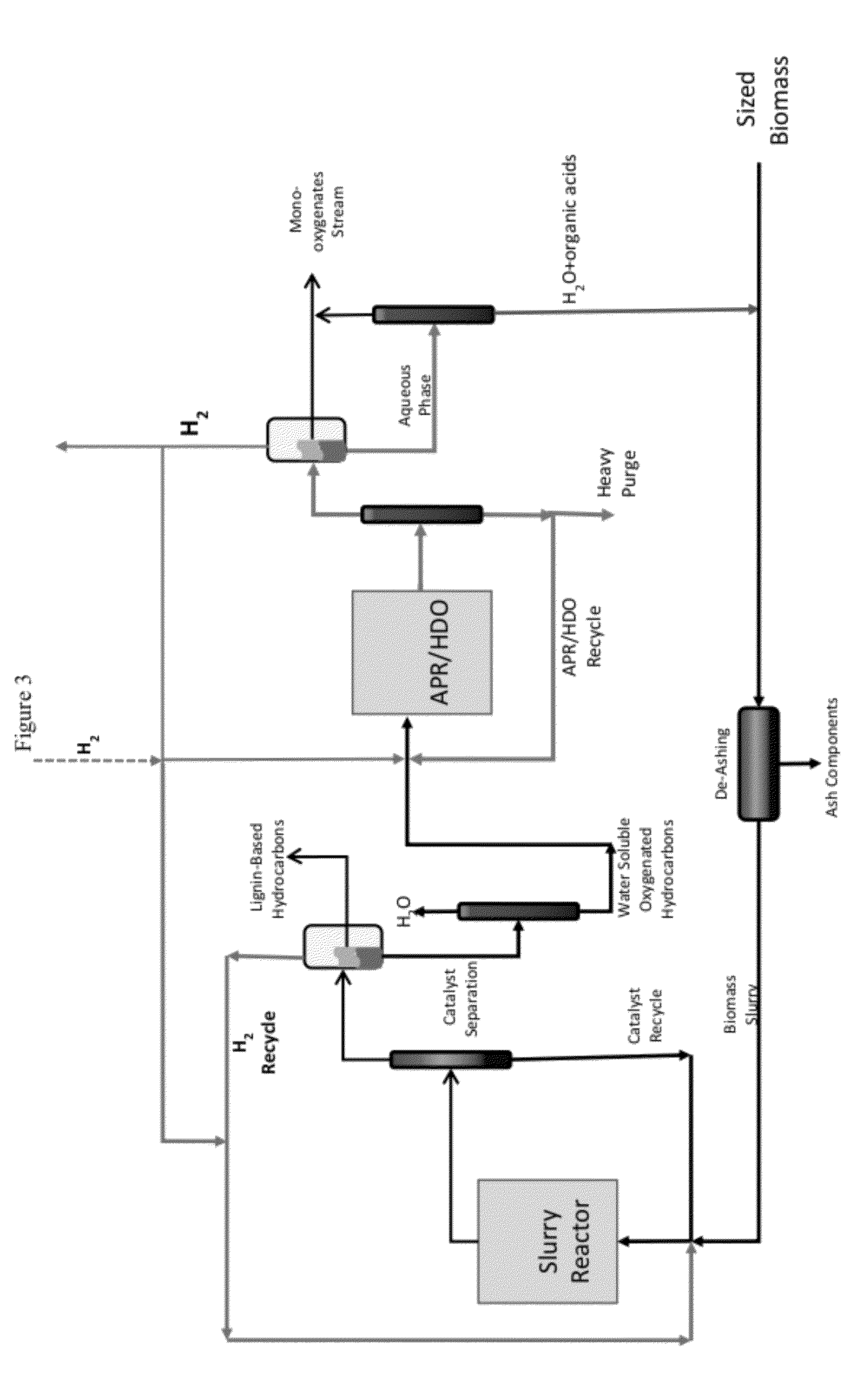

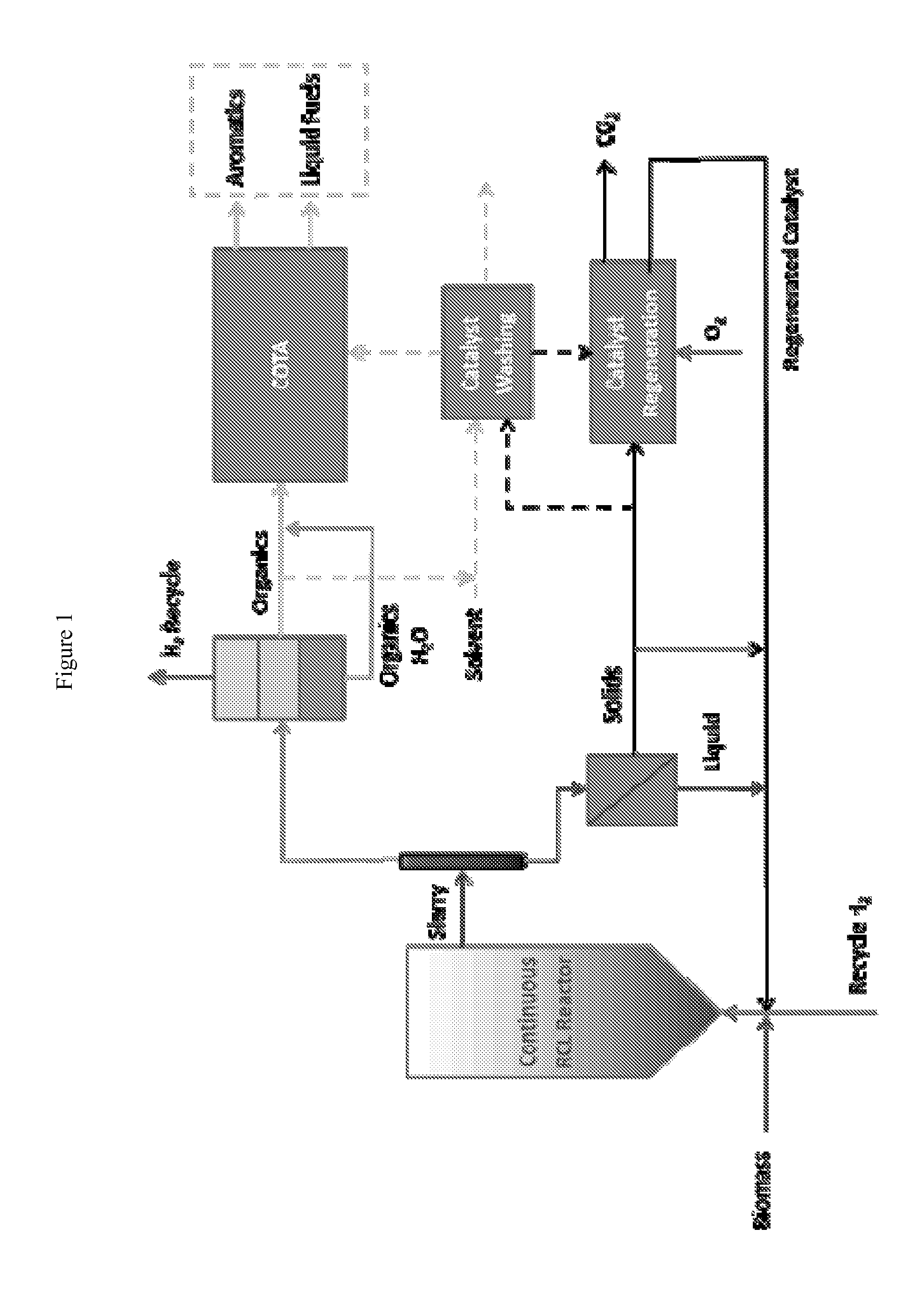

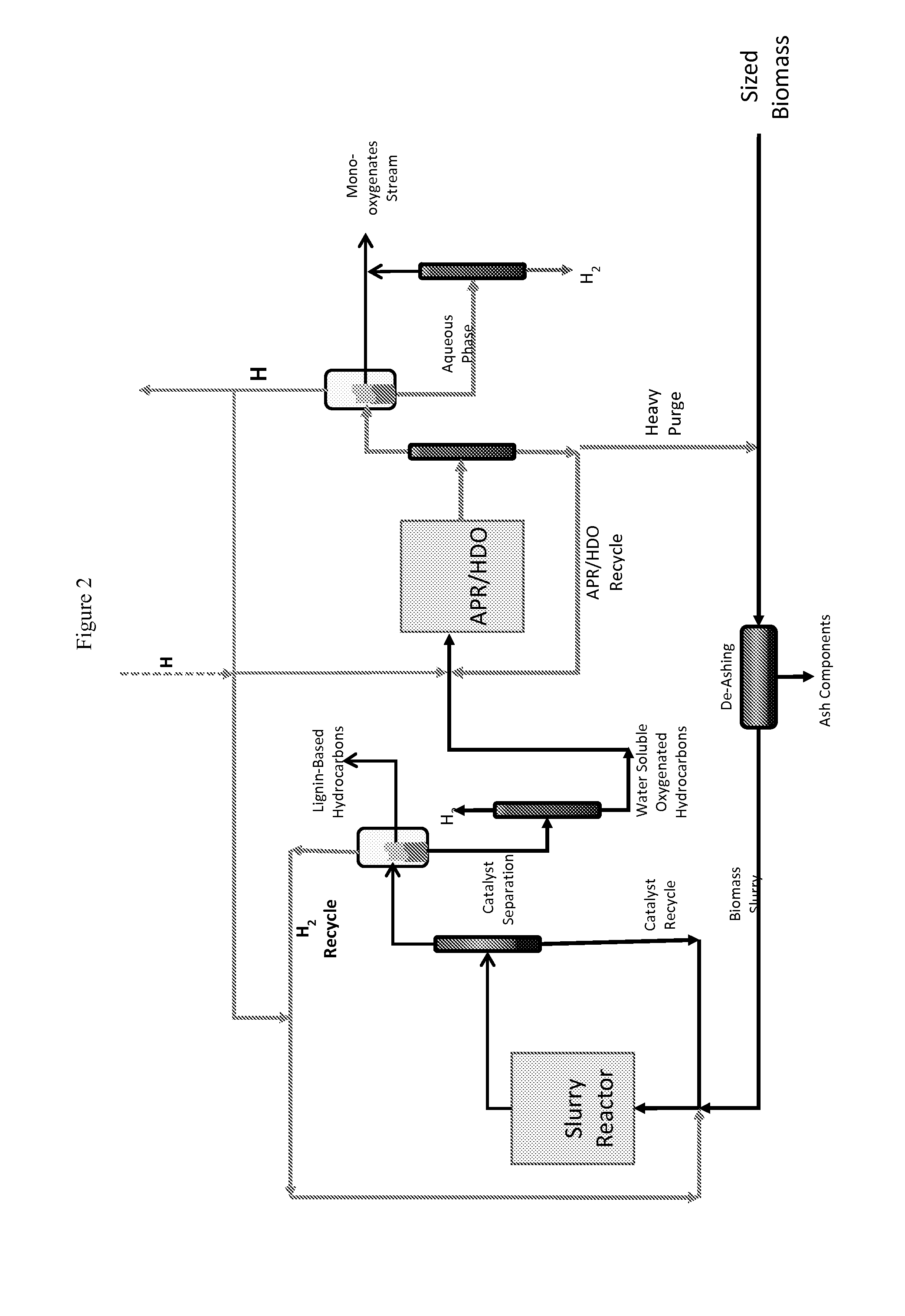

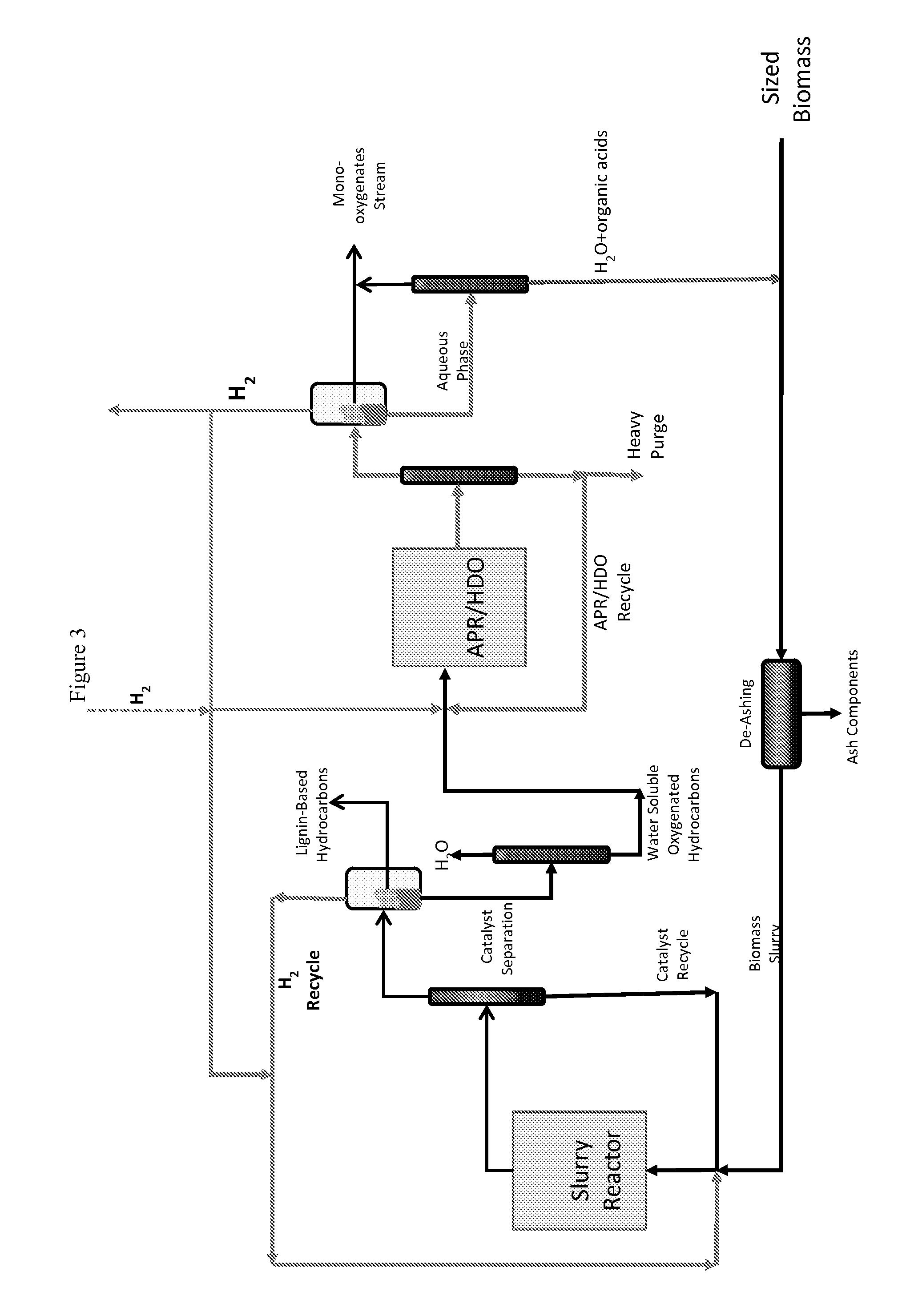

Reductive biomass liquefaction

The present invention provides methods, reactor systems, and catalysts for converting in a continuous process biomass to less complex oxygenated compounds for use in downstream processes to produce biofuels and chemicals. The invention includes methods of converting the components of biomass, such as hemicellulose, cellulose and lignin, to water-soluble materials, including lignocellulosic derivatives, cellulosic derivatives, hemicellulosic derivatives, carbohydrates, starches, polysaccharides, disaccharides, monosaccharides, sugars, sugar alcohols, alditols, polyols, diols, alcohols, ketones, cyclic ethers, esters, carboxylic acids, aldehydes, and mixtures thereof, using hydrogen and a heterogeneous liquefaction catalyst.

Owner:VIRENT

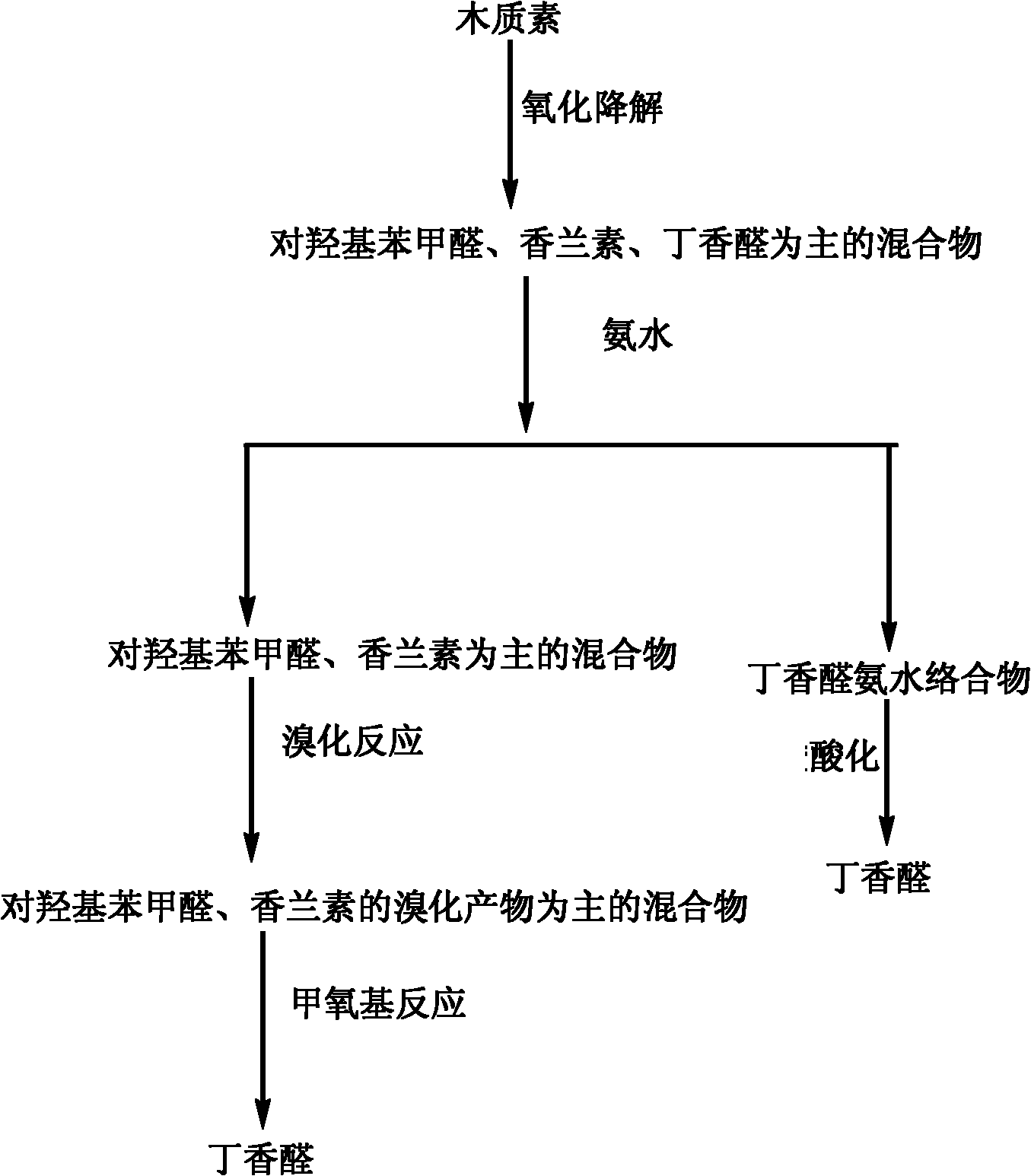

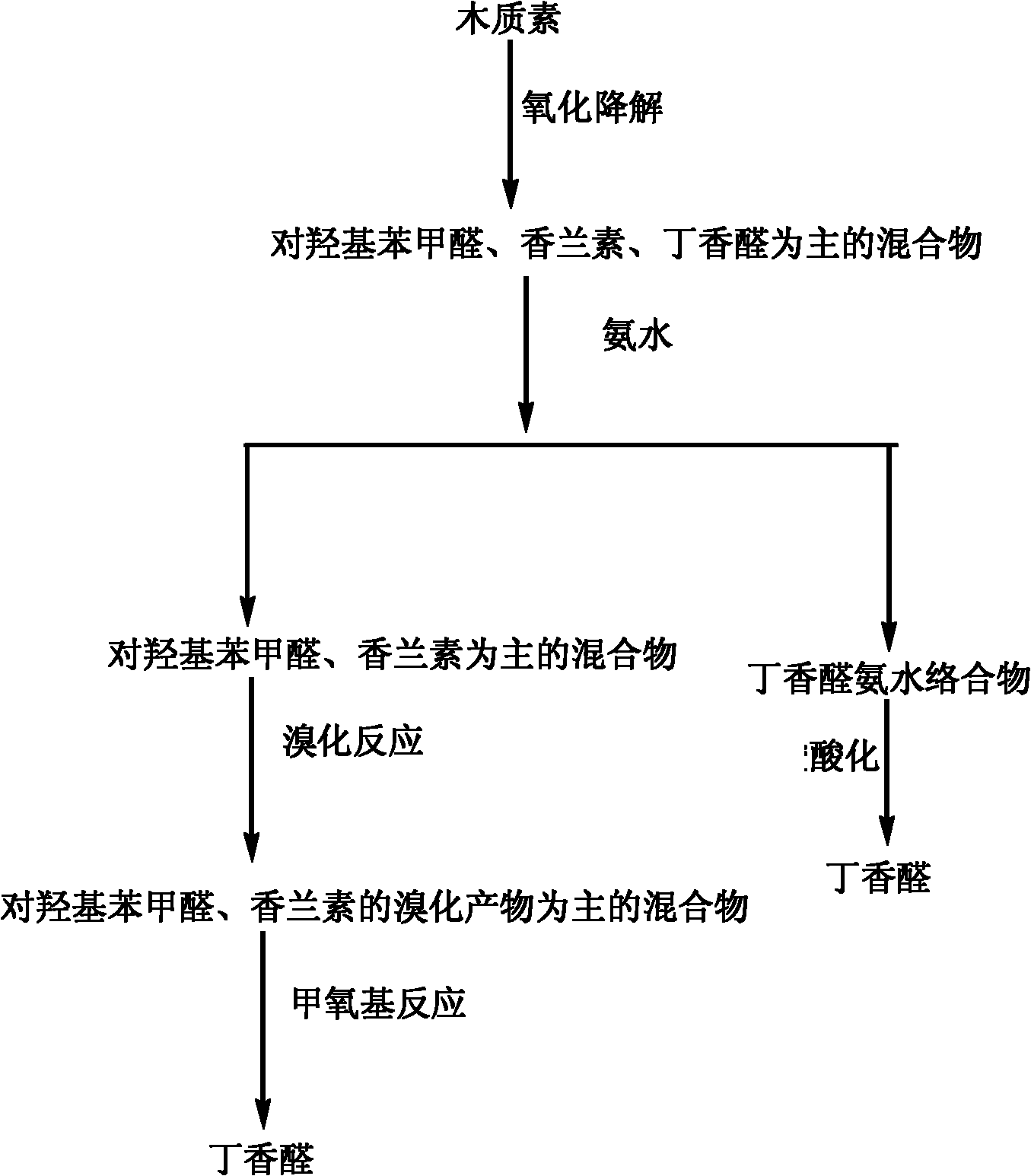

Method for preparing syringaldehyde by oxidative degradation of lignin

InactiveCN102146025AIncrease profitLow costOrganic compound preparationCarbonyl compound separation/purificationSodium methoxideFiber

The invention relates to a method for preparing syringaldehyde by oxidative degradation of lignin, which comprises the following steps of: 1) dissolving an oxidative degradation product solid of the lignin by using an organic solvent, adding ammonia water to obtain a syringaldehyde and ammonia water complex precipitate, performing centrifugal separation, and acidifying the complex precipitate to obtain syringaldehyde; and 2) evaporating to dryness under reduced pressure and centrifuging to obtain ammonia water mixed solution, performing bromination on the obtained solid substance and elemental bromine or bromine hydride solution, and performing methoxylation reaction on the bromination product and sodium methoxide under the catalysis of cuprous salt to obtain the syringaldehyde. By the steps, the oxidative degradation product of the lignin is all converted into the same product, namely the syringaldehyde, the yield of the syringaldehyde is 50-60 percent, the utilization rate of lignocellulosic materials is improved, the cost of cellulose alcohol and papermaking industry is reduced, and the method has important meaning for realizing high value-added industrial development of the lignin and industrialization of cellulose ethanol and promoting agricultural sustainable development.

Owner:JIANGNAN UNIV

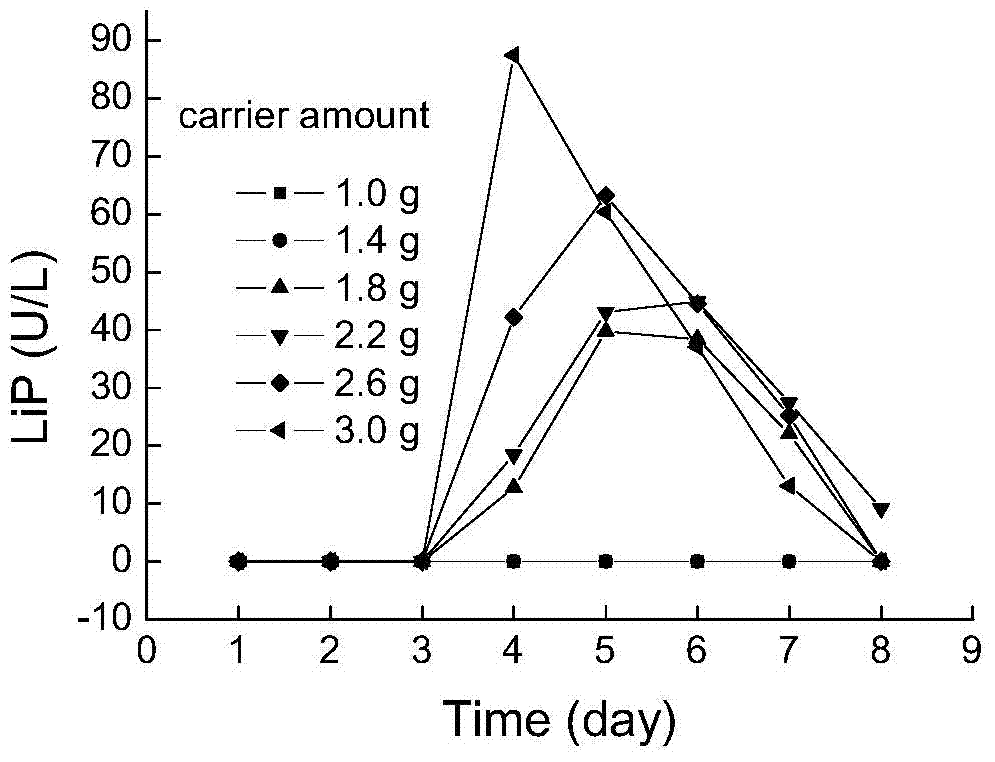

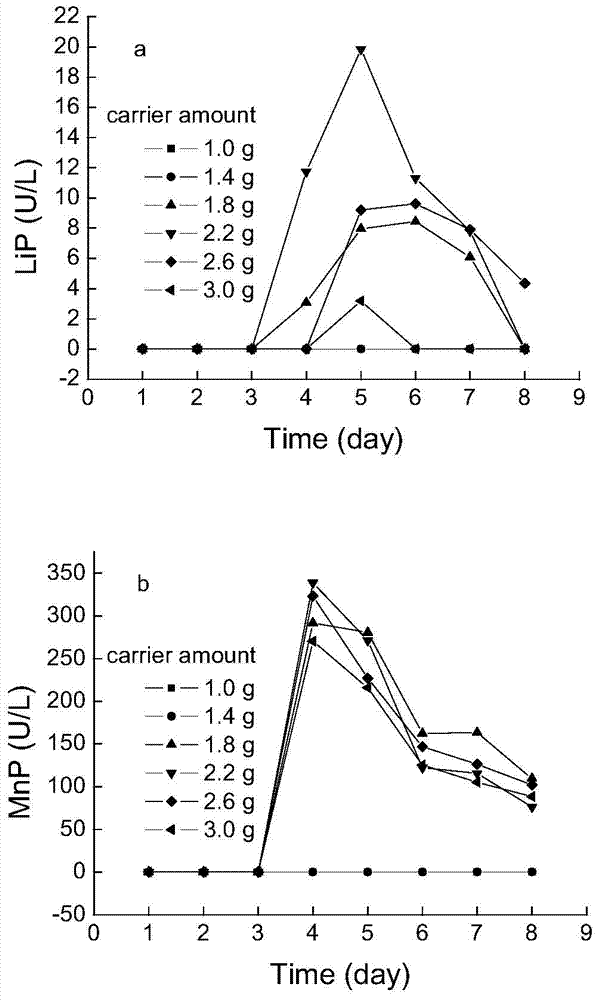

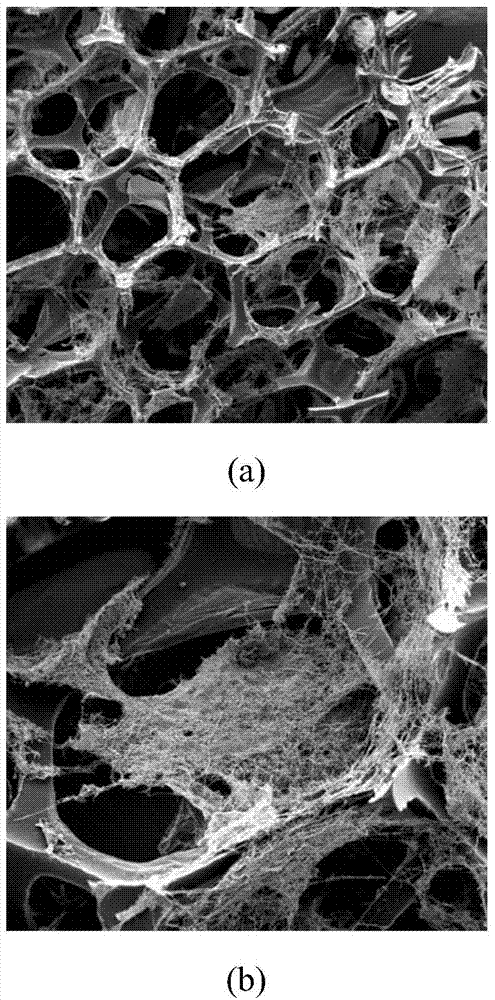

Method for selectively producing lignin-degrading enzymes by using phanerochaete chrysosporium

The invention relates to a method for selectively producing lignin-degrading enzymes by using phanerochaete chrysosporium. The invention provides a method for selectively producing lignin-degrading enzymes by using phanerochaete chrysosporium, which comprises the following steps: fermenting phanerochaete chrysosporium in a culture medium containing an immobilized culture carrier in a non-immersed state, and collecting a fermentation product, namely, a lignin-degrading enzyme. Experiments show that when the method is adopted for carrying out fermentation on a lignin-degrading enzyme, the lignin-degrading enzyme can be selectively obtained under air conditions without feeding pure oxygen or air containing high-concentration oxygen in the process of culturing but just by controlling the concentration of a carbon and nitrogen source in the culture medium and adding a carrier in a non-immersed state. The method disclosed by the invention is simple in condition control, and the obtained lignin-degrading enzyme is strong in selectivity.

Owner:TSINGHUA UNIV

hibiscus cannabinus feruloyl-coa:monolignol transferase

The invention relates to isolated nucleic acids encoding a feruloyl-CoA:monolignol transferase and feruloyl-CoA:monolignol transferase enzymes. The isolated nucleic acids and / or the enzymes enable incorporation of monolignol ferulates into the lignin of plants, where such monolignol ferulates include, for example, p-coumaryl ferulate, coniferyl ferulate, and / or sinapyl ferulate. The invention also includes methods and plants that include nucleic acids encoding a feruloyl-CoA:monolignol transferase enzyme and / or feruloyl-CoA:monolignol transferase enzymes.

Owner:THE UNIV OF BRITISH COLUMBIA +2

Method for oxidative degradation of lignin into aromatic monomers through molybdenum catalysis

ActiveCN108947783AHigh yieldMild operating conditionsOrganic compound preparationCarboxylic acid esters preparationCelluloseCatalytic oxidation

The invention relates to a method for oxidative degradation of lignin into aromatic monomers through molybdenum catalysis. According to the method, the oxidative degradation of the lignin is catalyzedby taking molecular oxygen as an oxygen supply and taking a non-noble metal molybdenum compound as a catalyst. According to the method, the catalytic oxidation system is simple in composition and isenvironmentally friendly, the operating conditions are moderate, and the yield of the aromatic monomers (mainly aromatic aldehyde, aromatic ketone and aromatic acid ester) in a degradation product ishigh; and possibility is provided for the high-value utilization of native lignin and even lignocellulose.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Process for the isolation of lignin from black liquor and modification of the lignin for plastic applications

A process for the isolation of lignin from black liquor and modification of lignin for use in many plastic applications is disclosed. The isolation of lignin consists of removing all of the non-lignin components from black liquor solution. The non-lignin components including but not limited to organic acids, sugars, and inorganic materials can be removed using either solvent extraction or ion-exchange resin or a combination of both methods. The isolated lignin is water soluble. The non-lignin components can be further isolated and sold or reused in the pulping or lignin isolation processes. The isolated lignin can be further modified in order to meet the needs of the desired plastic application.

Owner:ORGANIC CHEM

Method for preparing lignin-based polyhydric alcohol and polyurethane from solid-super-acid-catalyzed lignin or sulfonated lignin

InactiveCN105399962ALiquefaction conversion process greenEfficient use ofChemical recyclingEvaporationPolyethylene glycol

The invention discloses a method for preparing lignin-based polyhydric alcohol and polyurethane from solid-super-acid-catalyzed lignin or sulfonated lignin. The method comprises: under the normal pressure, putting a certain amount of solid super acid, glycerin, and polyethylene glycol-400 (PFG-40) into a reactor, performing pre-heating at a certain temperature, adding industrial lignin or sulfonated lignin, or wheat straw lignin, and performing mechanical stirring and cooling; and adding a dioxane aqueous solution into the obtained product according to a certain solid-to-liquid ratio, fully dissolving the obtained mixture, and performing centrifugation, filtering, and rotary evaporation of the obtained filtrate. The obtained dioxane aqueous solution can be reused after purification, and the obtained lignin-based polyhydric alcohol is subjected to index measurement. The filtered residue is washed and centrifuged to recycle solid super-acid for reuse. Then, a material of lignin-based polyurethane is prepared by taking lignin-based polyhydric alcohol as a raw material and reacting the lignin-based polyhydric alcohol with isocyanate. According to the method, solid super-acid is firstly used for catalyzing transformation of industrial lignin or sulfonated lignin to prepare polyhydric alcohol and polyurethane foam (PUF).

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

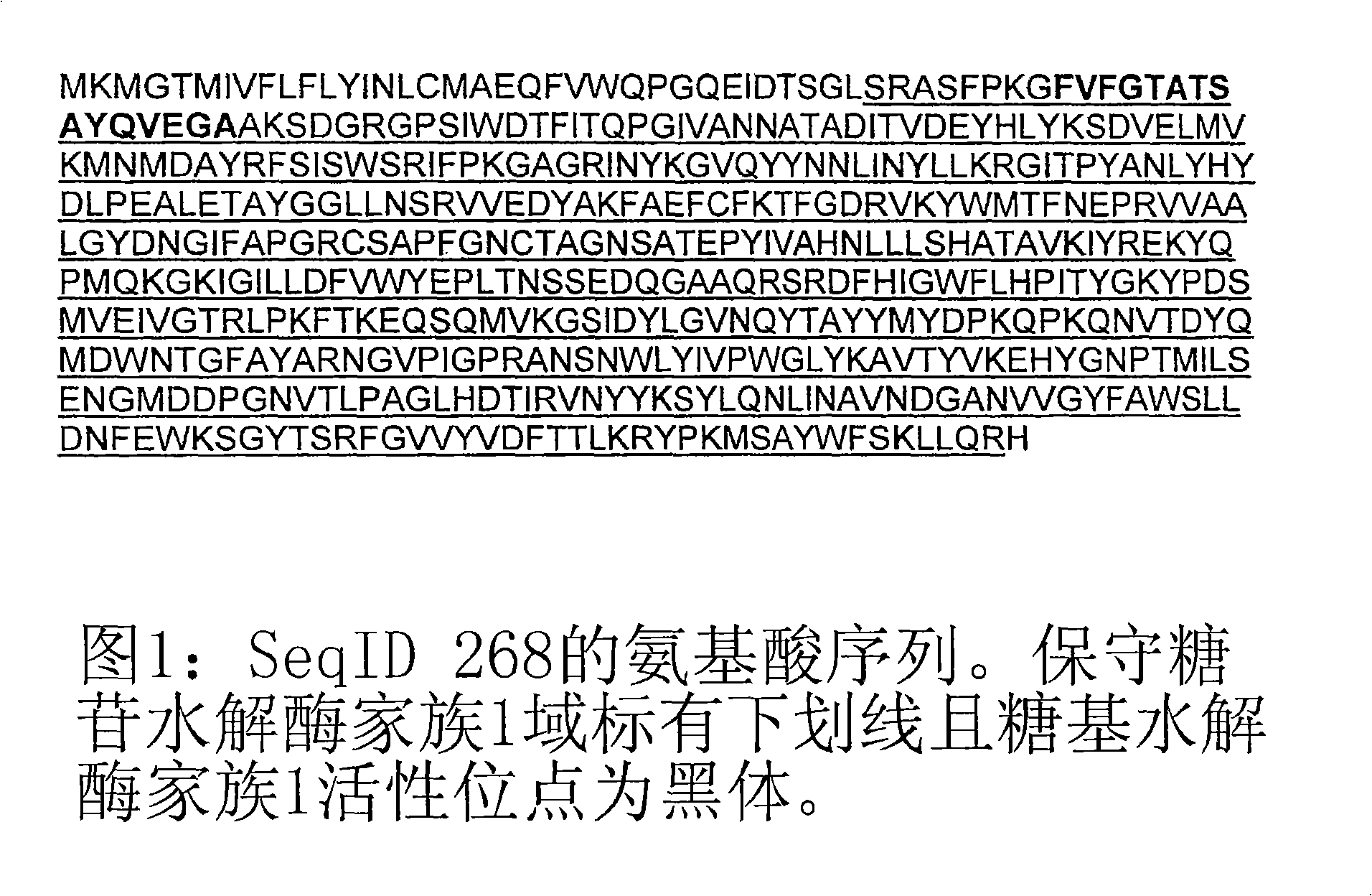

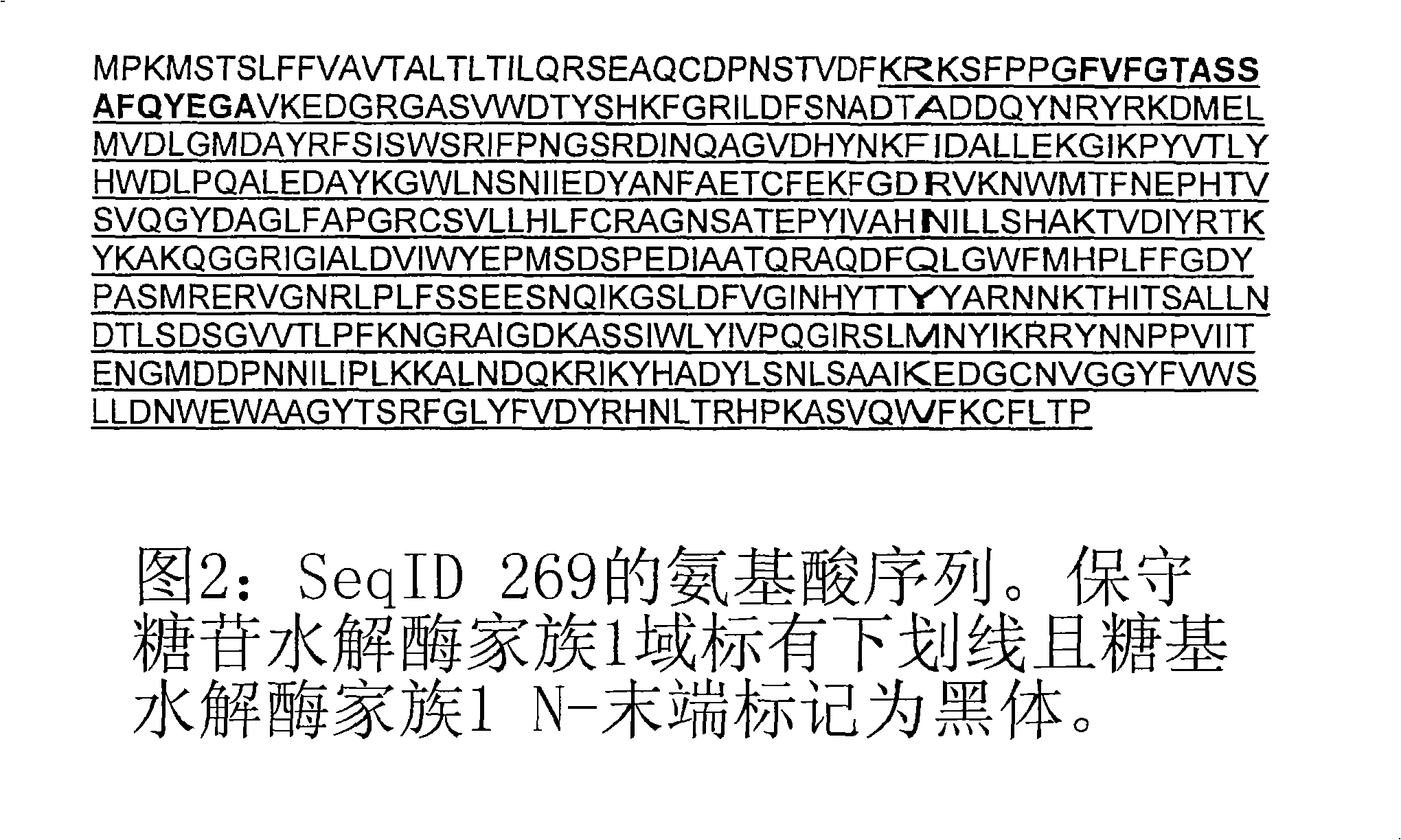

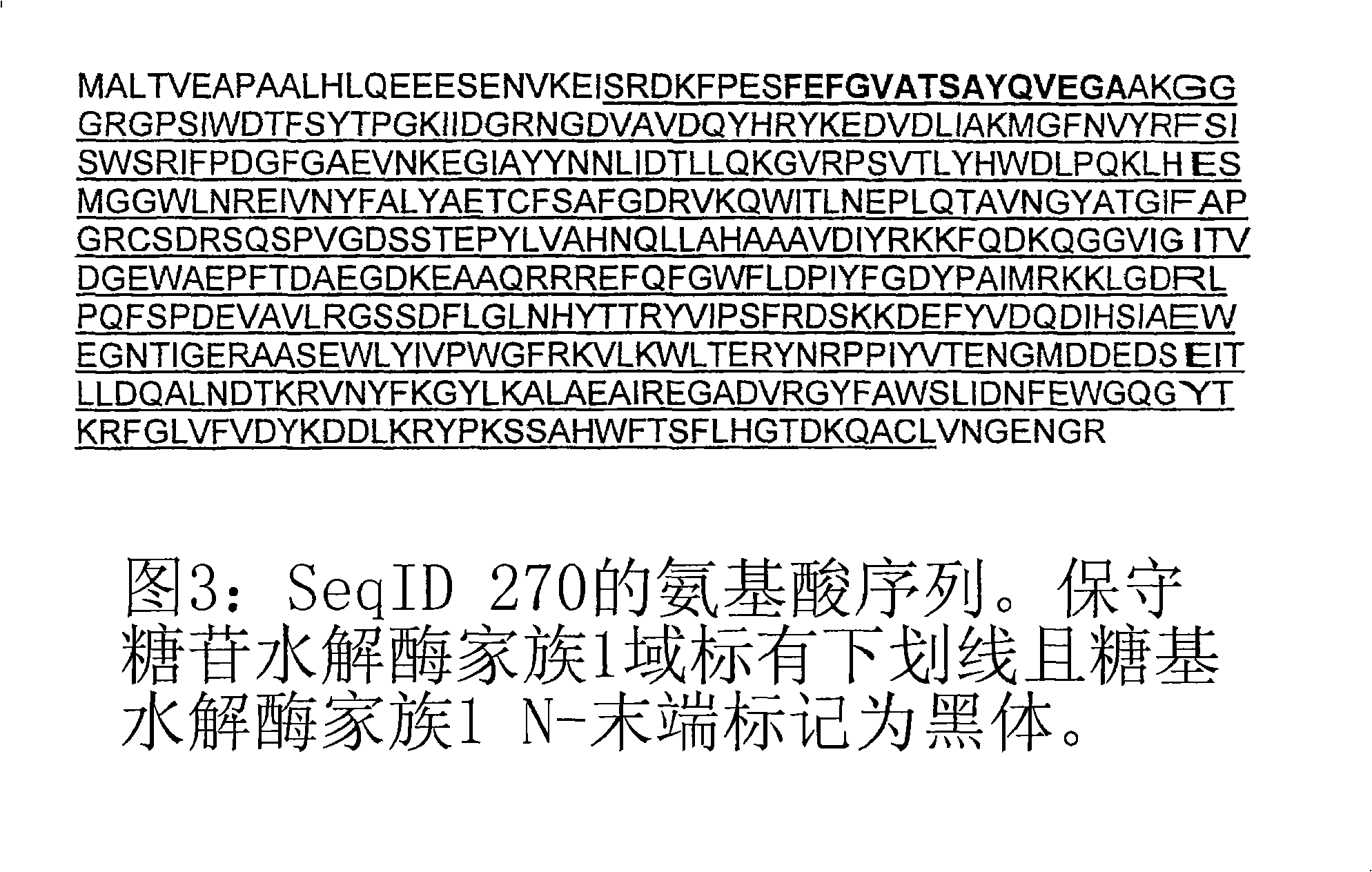

Compositions and methods for modulating lignin of a plant

Novel plant monolignol synthesis, monolignol transport, and lignin polymerization genes and polypeptides encoded by such genes are provided. These genes and polynucleotide sequences are useful regulating the lignification process and plant phenotype. Moreover, these genes are useful for expression profiling of plant monolignol synthesis, monolignol transport, and lignin polymerization genes. The invention specifically provides polynucleotide and polypeptide sequences isolated from Eucalyptus and Pinus.

Owner:ARBORGEN

Method for preparing phenolic chemicals by catalyzing degradation of lignin with carbon-based solid acid

ActiveCN104177447ASimple preparation processSimple preparation process compared to the preparation process of other sulfonated solid acidsPhysical/chemical process catalystsOrganic compound preparationEnvironmental resistanceGuaiacol

The invention provides a method for preparing phenolic chemicals by catalyzing degradation of lignin with carbon-based solid acid. The method comprises the following steps: by taking lignin as a raw material, a carbon-based solid acid as a catalyst and a water phase as a reaction solvent, putting lignin, carbon-based solid acid and water into a high-pressure reaction kettle; and carrying out warming reaction under the protection of an inert gas, and then extracting by using ethyl acetate, and performing vacuum evaporation so as to obtain the phenolic chemicals, wherein used carbon-based solid acid is prepared by using the lignin as the raw material in an inorganic acid environment; and the lignin raw material for carbon-based solid acid is alkali lignin, organic lignin, zymolytic lignin residue or hydrolytic lignin residue. The phenol yield can be up to 53%, the relative selectivity of guaiacol aromatic products can be up to 70%, the technique disclosed by the invention is simple and environmental friendly, available in raw materials and low in demands on equipment, and does not need to use a concentrated acid with strong corrosivity, and compared with the prior art, the method has outstanding advantages.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

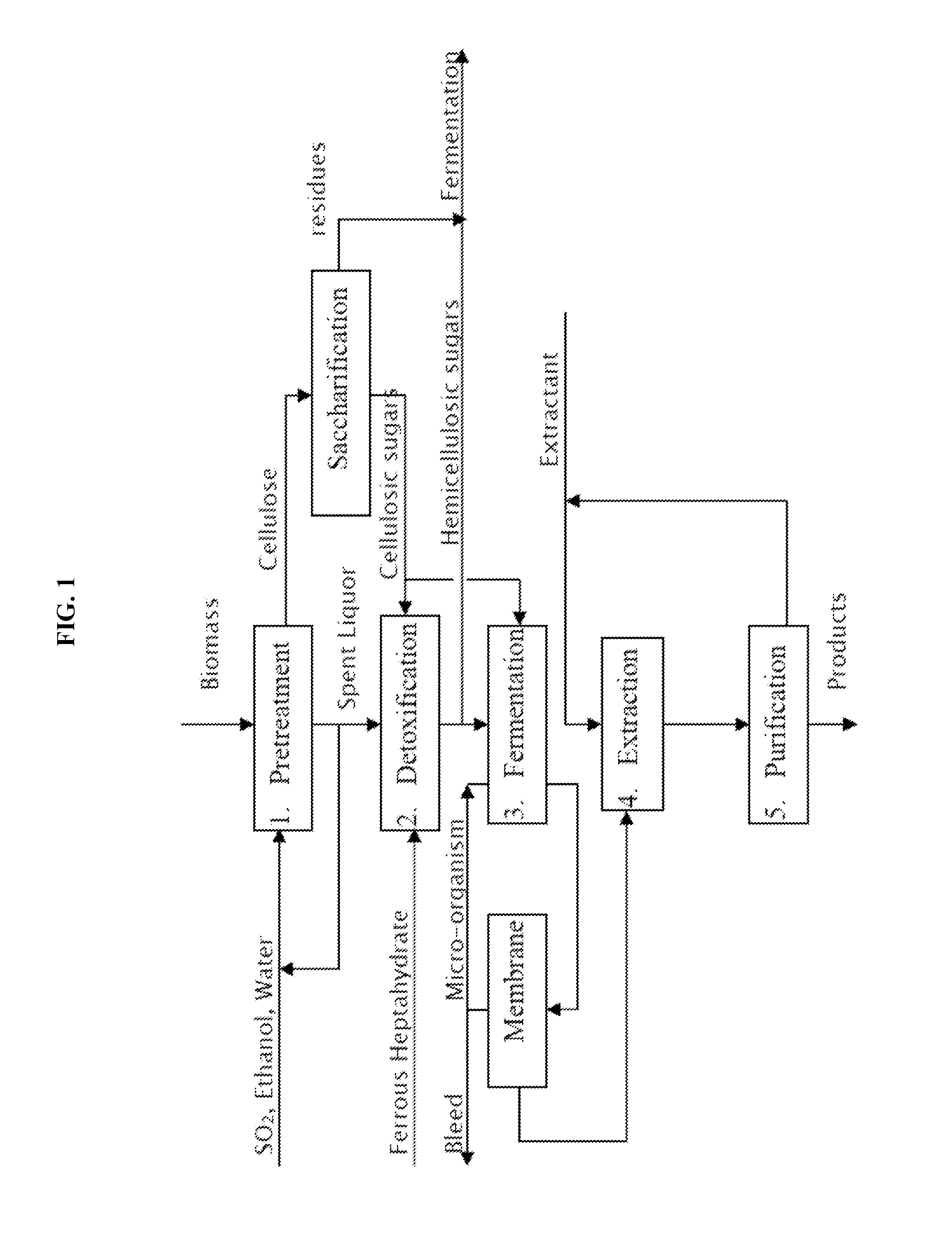

Processes for fermentation of lignocellulosic glucose to aliphatic alcohols or acids

A process for producing an organic aliphatic product (such as butanol) from lignocellulosic biomass is provided, comprising: (a) fractionating lignocellulosic biomass in the presence of a solvent for lignin, a hydrolysis catalyst, and water, to produce a liquor containing hemicellulose, cellulose-rich solids, and lignin; (b) washing the cellulose-rich solids and separating the cellulose-rich solids from the liquor; (c) enzymatically hydrolyzing the cellulose-rich solids to generate a hydrolysate comprising glucose; (d) detoxifying the hydrolysate by neutralizing the hydrolysate, removing insoluble solids, and removing or oxidizing residual hydrolysis catalyst, thereby generating a purified hydrolysate; (e) fermenting the purified hydrolysate using a suitable microorganism to produce a dilute organic aliphatic product, wherein the microorganism is recycled with a membrane; (f) extracting the dilute organic aliphatic product into a water-immiscible extractant, to generate an intermediate material; and (g) distilling the intermediate material to generate a concentrated organic aliphatic product.

Owner:GRANBIO INTELLECTUAL PROPERTY HOLDINGS LLC

Reductive Biomass Liquefaction

The present invention provides methods, reactor systems, and catalysts for converting in a continuous process biomass to less complex oxygenated compounds for use in downstream processes to produce biofuels and chemicals. The invention includes methods of converting the components of biomass, such as hemicellulose, cellulose and lignin, to water-soluble materials, including lignocellulosic derivatives, cellulosic derivatives, hemicellulosic derivatives, carbohydrates, starches, polysaccharides, disaccharides, monosaccharides, sugars, sugar alcohols, alditols, polyols, diols, alcohols, ketones, cyclic ethers, esters, carboxylic acids, aldehydes, and mixtures thereof, using hydrogen and a heterogeneous liquefaction catalyst.

Owner:VIRENT

Method for preparing monophenol compound through catalyzing degradation of lignin by using ammino-complex

ActiveCN106946660AImprove degradation rateIncrease contact pointsOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsFiltrationHigh pressure

The invention discloses a method for preparing a monophenol compound through catalyzing degradation of lignin by using an ammino-complex. The method comprises the steps: adding the lignin, a metal salt, ammonia water, a peroxidant, an alkali and deionized water into a high-pressure reaction vessel, and carrying out stirring to form a uniform solution; carrying out a reaction for 100 to 240 minutes at the temperature of 120 DEG C to 180 DEG C, and carrying out cooling; and adjusting the pH value of a reaction solution to 2 to 3 with an acid, then, carrying out a reaction for 10 to 20 minutes at the temperature of 100 DEG C to 120 DEG C, carrying out cooling, then, carrying out filtration to collect filtrate, carrying out extraction on the filtrate with dichloromethane, separating an organic phase, and carrying out drying with anhydrous calcium chloride, thereby obtaining a monophenol compound mixed solution. According to the method, a stable ammino-complex solution is formed by using the metal salt and the ammonia water under alkaline conditions, so that the number of sites of contact between a catalyst and the lignin can be effectively increased compared with that in the conventional lignin oxidative degradation method; the degradation of the lignin can be efficiently catalyzed in an aqueous solution under moderate reaction conditions; and the method has the characteristics of high efficiency and low cost and is applicable to large-scale industrial production.

Owner:GUANGXI ACAD OF SCI

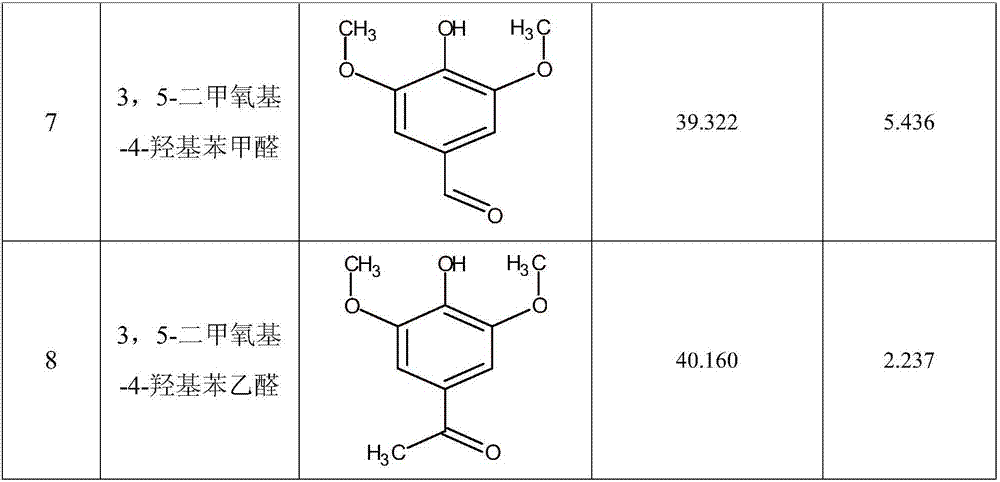

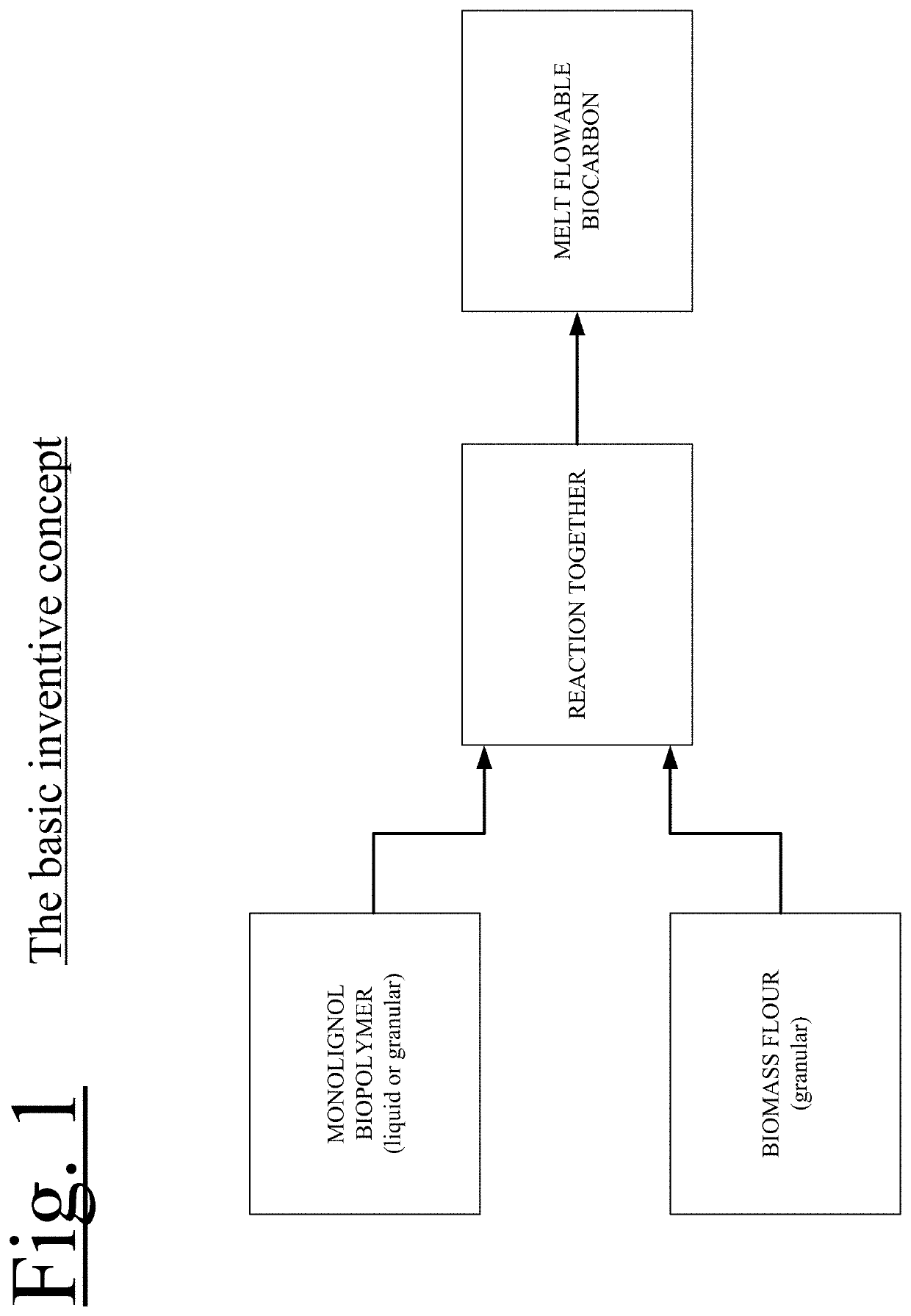

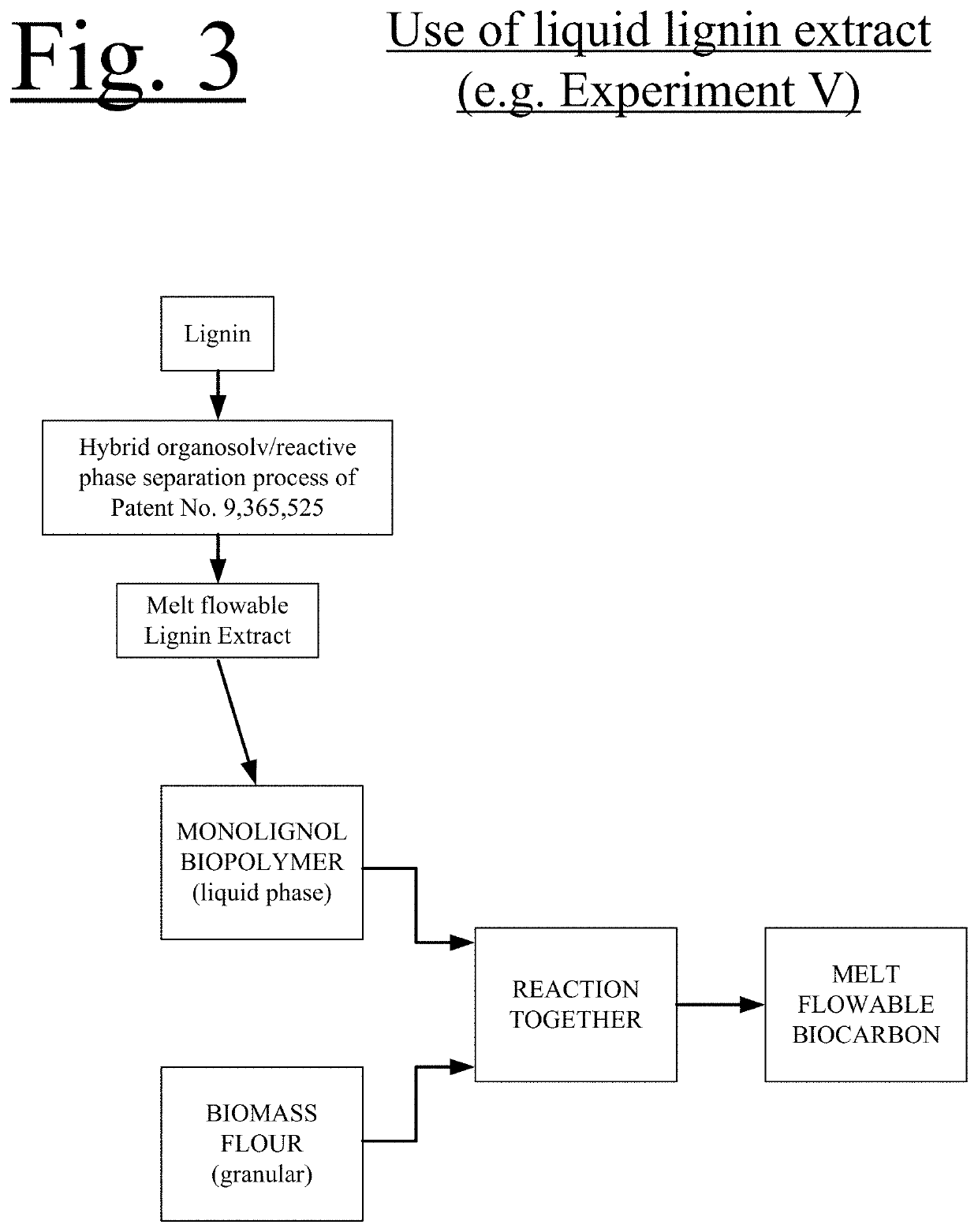

Melt flowable biocarbon and method of making same

The following invention generally relates to a melt flowable biocarbon polymeric material derived from a cellulosic ethanol refining co-product, monolignol biopolymer, and a heat processed or thermally modified biomass flour, both of which are reacted together to create a melt flowable biopolymer which has melt flowable properties, process-ability and rheology similar to that of standard petrochemical based thermoplastics.

Owner:PLAIN SIGHT INNOVATIONS LLC

Method for degrading oxidation lignin into small molecular aromatic compound

InactiveCN106928053AMild reaction conditionsImprove conversion rateOxygen-containing compound preparationOrganic compound preparationBenzoic acidBiomass degradation

Belonging to the technical field of biomass degradation, the invention relates to a method for degrading oxidation lignin into a small molecular aromatic compound, and in particular relates to a method of breaking C-C bond by nontransition metal catalysis to degrade oxidation lignin into a small molecular aromatic compound. The method includes: firstly oxidizing oxidation lignin in an organic solvent with an oxidizing agent, then subjecting the obtained intermediate product to alcoholysis or hydrolysis under the action of a catalyst so as to obtain a small molecular aromatic compound, like methoxy substituted benzoic acid, methoxy substituted phenol, methoxy substituted benzoate and chain alcohol, etc. The method provided by the invention has the advantages of simple steps, mild reaction conditions, high conversion rate (up to 100%), no need for transition metals and the like, has effect on multiple connection modes of oxidation lignin, can reach the purpose of high selectivity and efficient degradation of lignin, and is conducive to large-scale industrial application.

Owner:JILIN UNIV

Genes and enzymes for degradation of ferulic acid crosslinks

Novel genes that code for a family of feruloyl esterases that break down ferulic acid crosslinks between polysaccharide chains and between polysaccharides and lignins in plant cell walls are described herein as well as a method of rapid gene discovery.

Owner:UNITED STATES OF AMERICA

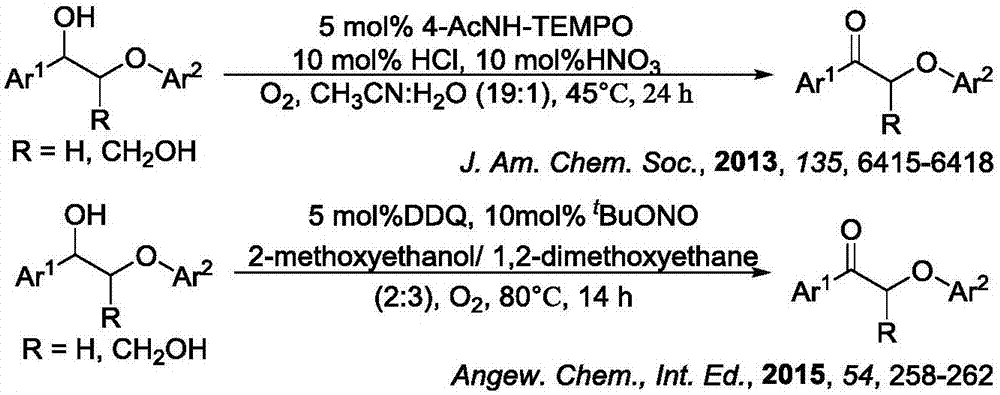

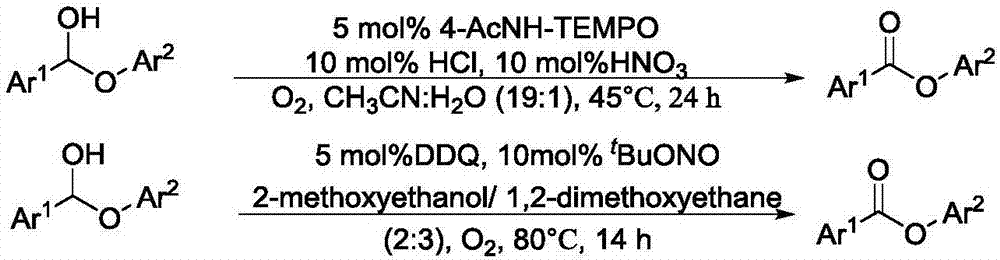

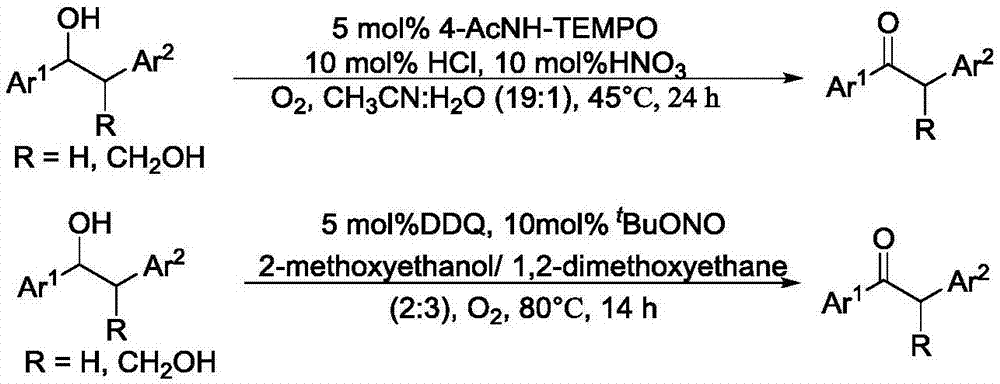

Method for catalyzing oxicracking of aryl ethers of lignin model

ActiveCN108947776AReduce dosageMild reaction conditionsOrganic chemistryOrganic compound preparationArylNitrate

The invention relates to a method for catalyzing oxicracking of aryl ethers of a lignin model. The method is characterized by comprising the step of catalyzing the oxicracking of the aryl ethers of the lignin model by taking two components, i.e., a simple inorganic oxovanadium compound and nitrate as a composite catalyst system and taking molecular oxygen as an oxygen supply. According to the method, the catalyst is simple, cheap and readily available, the reaction conditions are mild, the efficiency of oxicracking is high, and the aryl ethers in lignin can be efficiently cracked by a catalyzed oxidation method.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

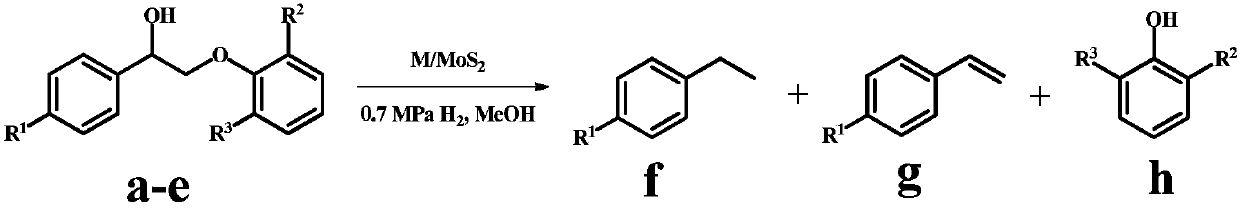

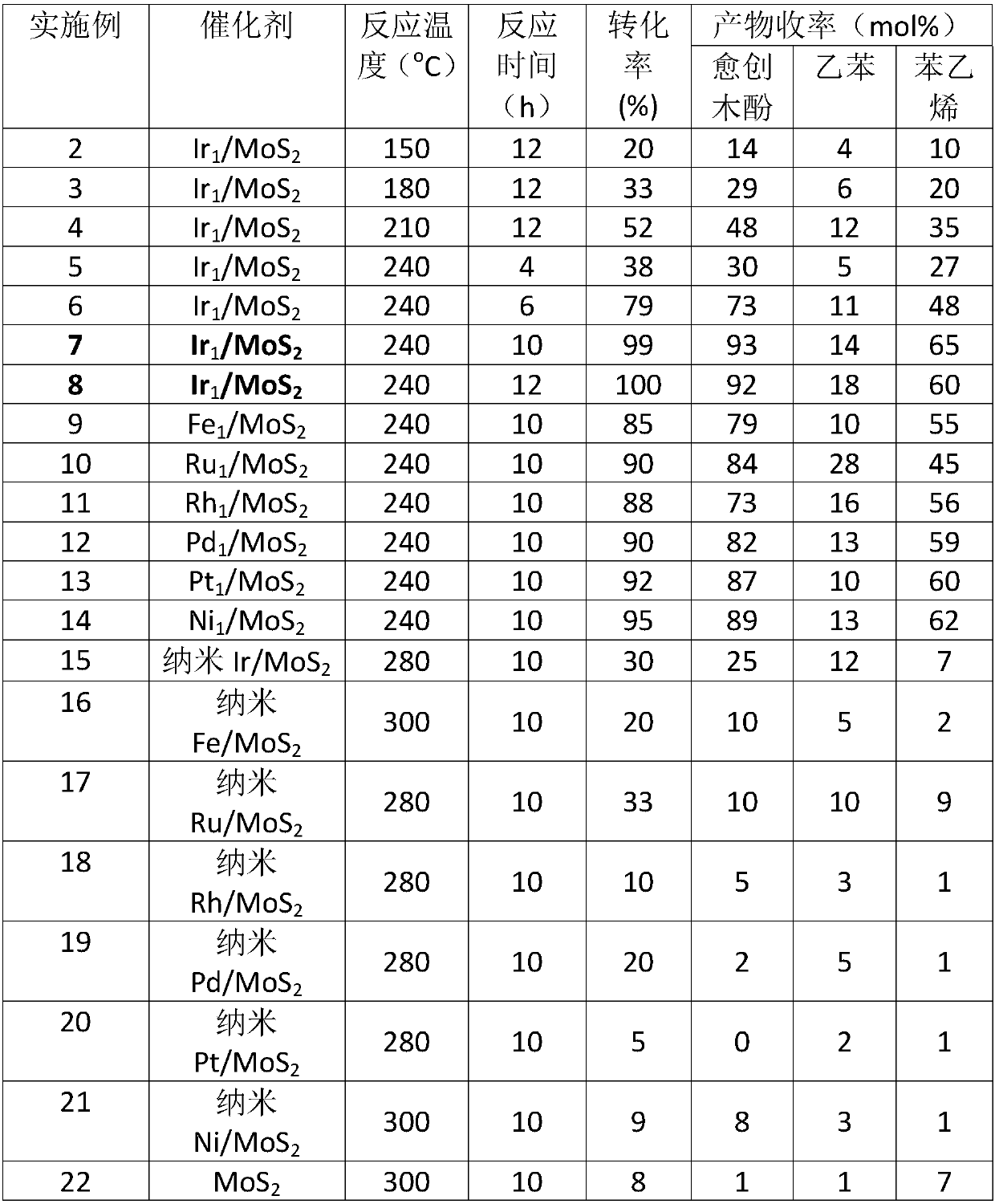

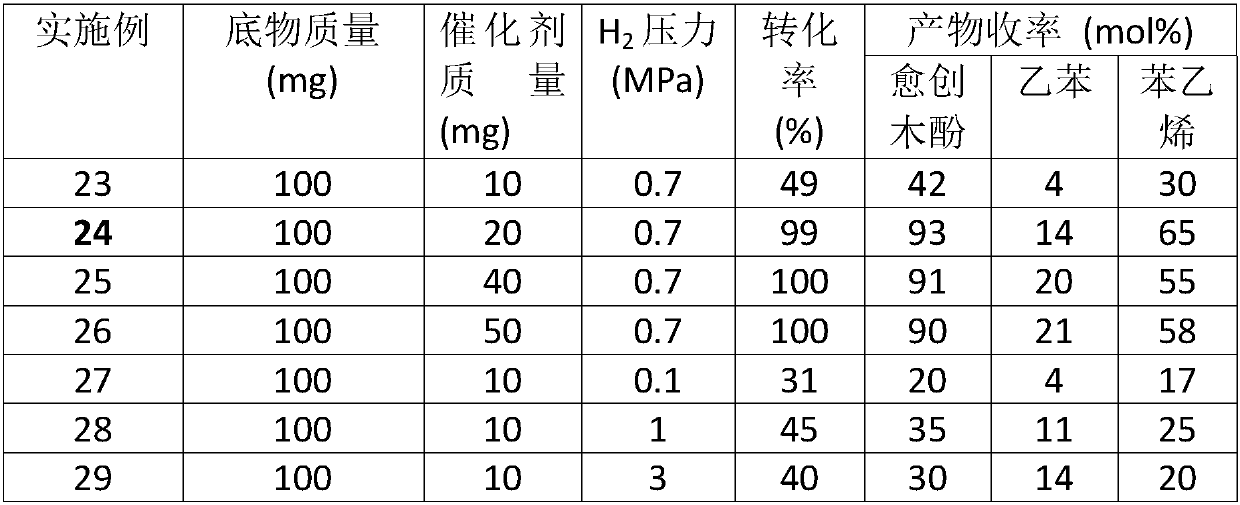

Application of monatomic catalyst in catalytic hydrogenation of lignin to aromatic compounds

ActiveCN109647441AWide variety of sourcesLow costOrganic compound preparationCatalystsDepolymerizationHydrogen atmosphere

The invention relates to selective depolymerization of lignin hydrogenation, in particular to application of a monatomic catalyst in the catalytic hydrogenation of lignin to an aromatic compound. According to the method, a plurality of beta-O-4 model molecules and organic lignin, lignosulfonate and alkali lignin are used as raw materials, and the aromatic compound is obtained by highly selective cracking of an aryl ether bond in the hydrogen atmosphere of 150-240 DEG C and 0.7-3.0 MPa. The conversion rate of the beta-O-4 model molecules reaches up to 99%, the yield of guaiacol reaches up to 93%, and the yield of styrene reaches up to 65%. When different lignins are used as the raw materials for conversion, the yield of aromatic bio-oil is 38-70%. Renewable natural biomass is as the raw material, and the raw material is cheap and has a wide source; there is no need to use inorganic acid and alkali in the reaction process, and a lot of alkali lye by traditional lignin catalysis is avoided; and the reaction condition is mild, activity and selectivity are high, and the reaction process is environmentally-friendly.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Transgenic sweet sorghum with altered lignin composition and process of preparation thereof

The present invention provides a sweet sorghum plant characterized by altered lignin content and / or altered lignin composition compared to a wild plant and this is achieved by manipulating the expression of caffeoylCoA-O-methyltransferae (CCoAOMT) in particular and optionally caffeic acid-O-methyltranferase (COMT) in sweet sorghum by incorporation of a construct comprising an isolated DNA sequence represented by SEQ ID NO 2 and optionally SEQ ID NO 1.

Owner:NAGARJUNA ENERGY

Method for separating and extracting cellulose nanocrystals and lignin from poplar powder

InactiveCN110552224AMild method conditionsReduce energy consumptionPulping with organic compoundsPulping with acid salts/anhydridesFiberOrganic acid

The invention provides a method for separating and extracting cellulose nanocrystals and lignin from poplar powder, and belongs to the field of natural polymer material separation and extraction. According to the method, 1-6 parts by mass of the poplar powder is treated by a mixed acid system which is prepared from the components in parts by mass: 60-90 parts of organic acid, 40 parts of distilledwater and 5-20 parts of concentrated sulfuric acid with mass fraction being 98%, the reaction temperature is 70 DEG C-80 DEG C and the reaction time is 6h-8h, the organic acid is one of oxalic acid,formic acid and acetic acid, after the reaction is completed, the obtained lignin-containing cellulose nanocrystals are subjected to alkali treatment, and the cellulose nanocrystals and the lignin areseparated. The method omits the step of preparing the cellulose nanocrystals to perform pretreatment and delignification on fiber raw materials, and simultaneously obtains two products of the cellulose nanocrystals and the lignin. The process is simple and the cost is reduced.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

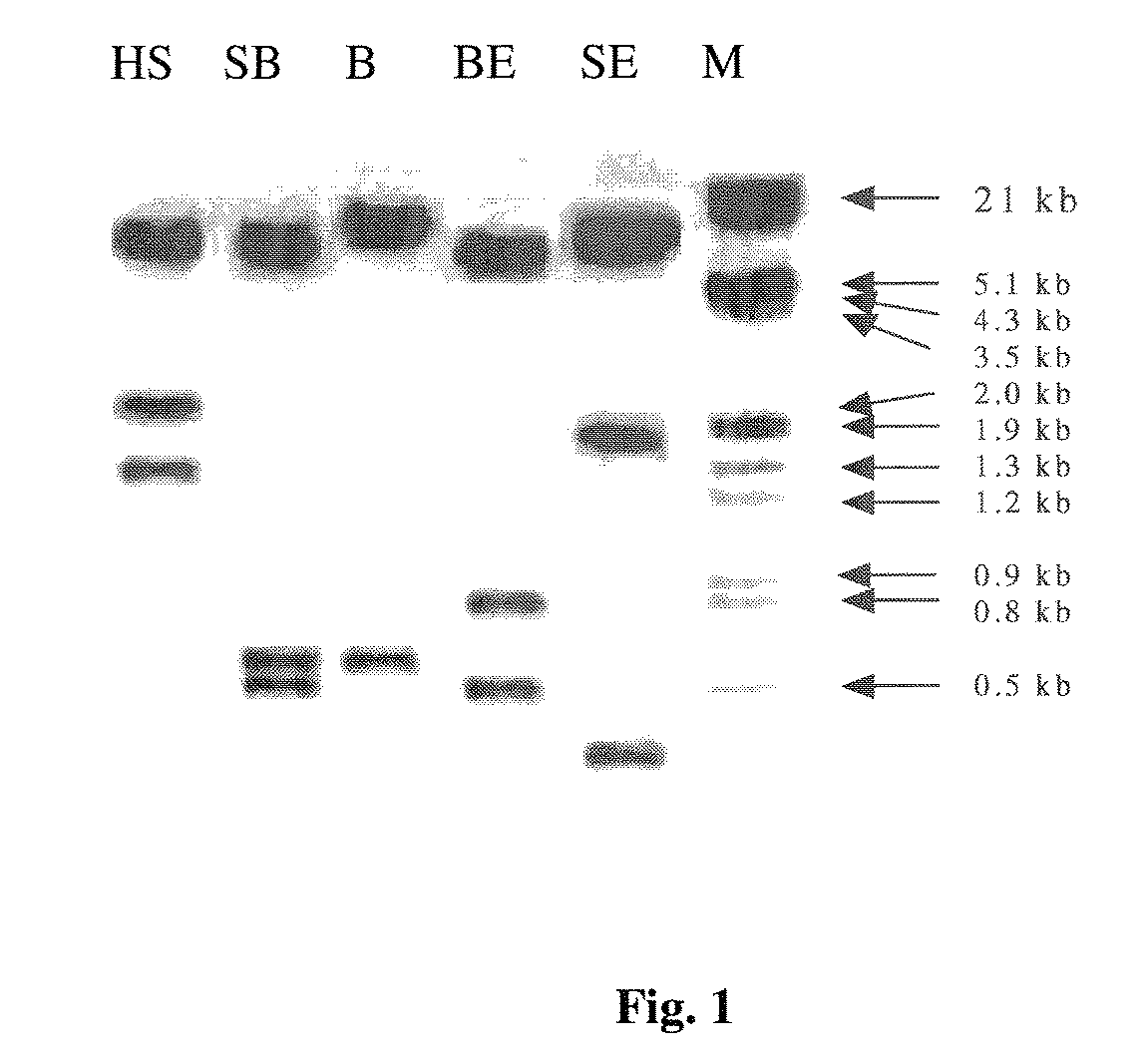

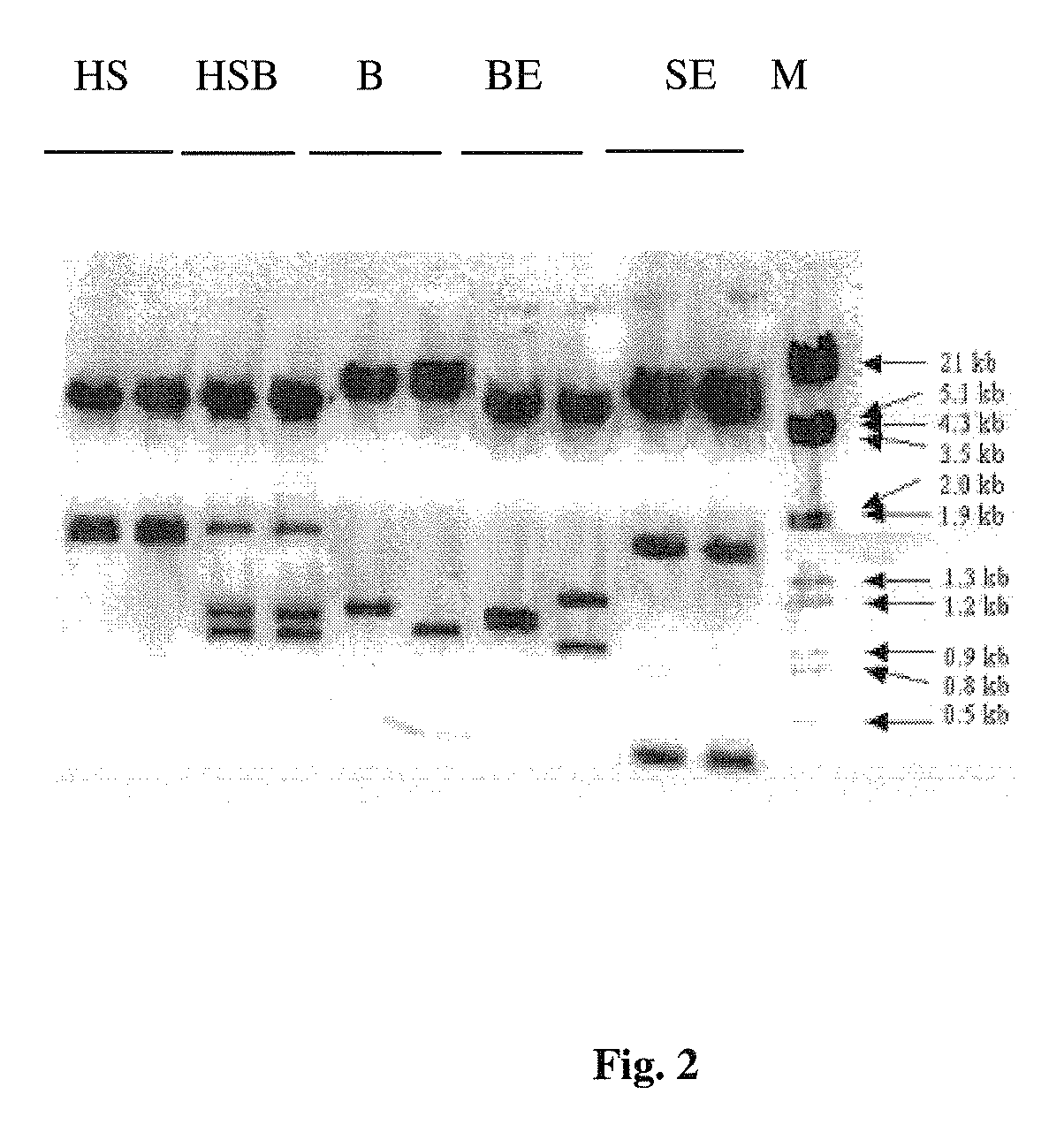

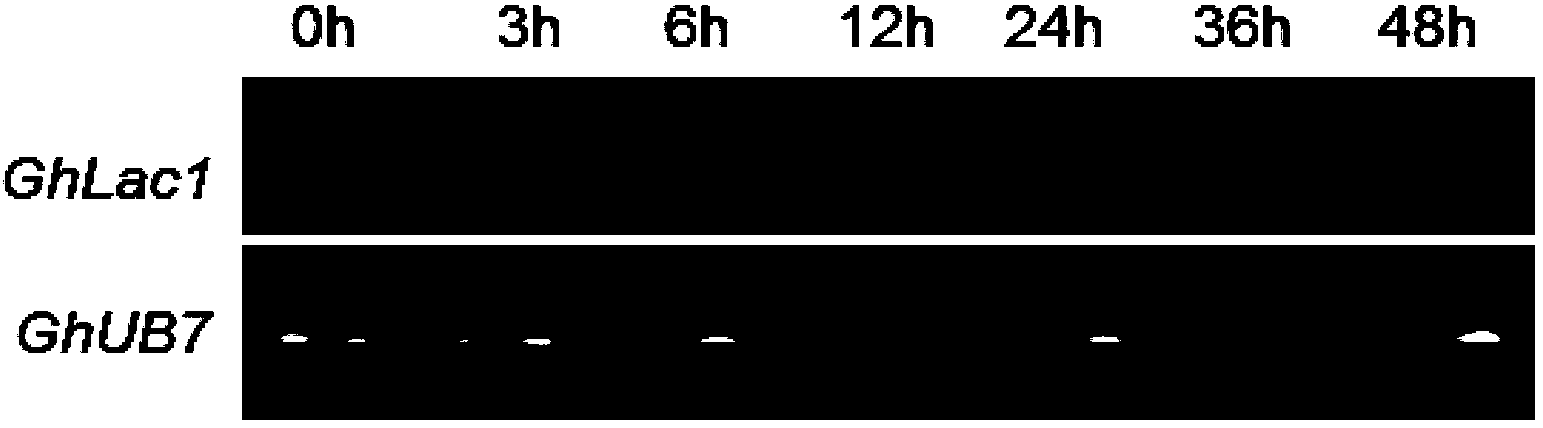

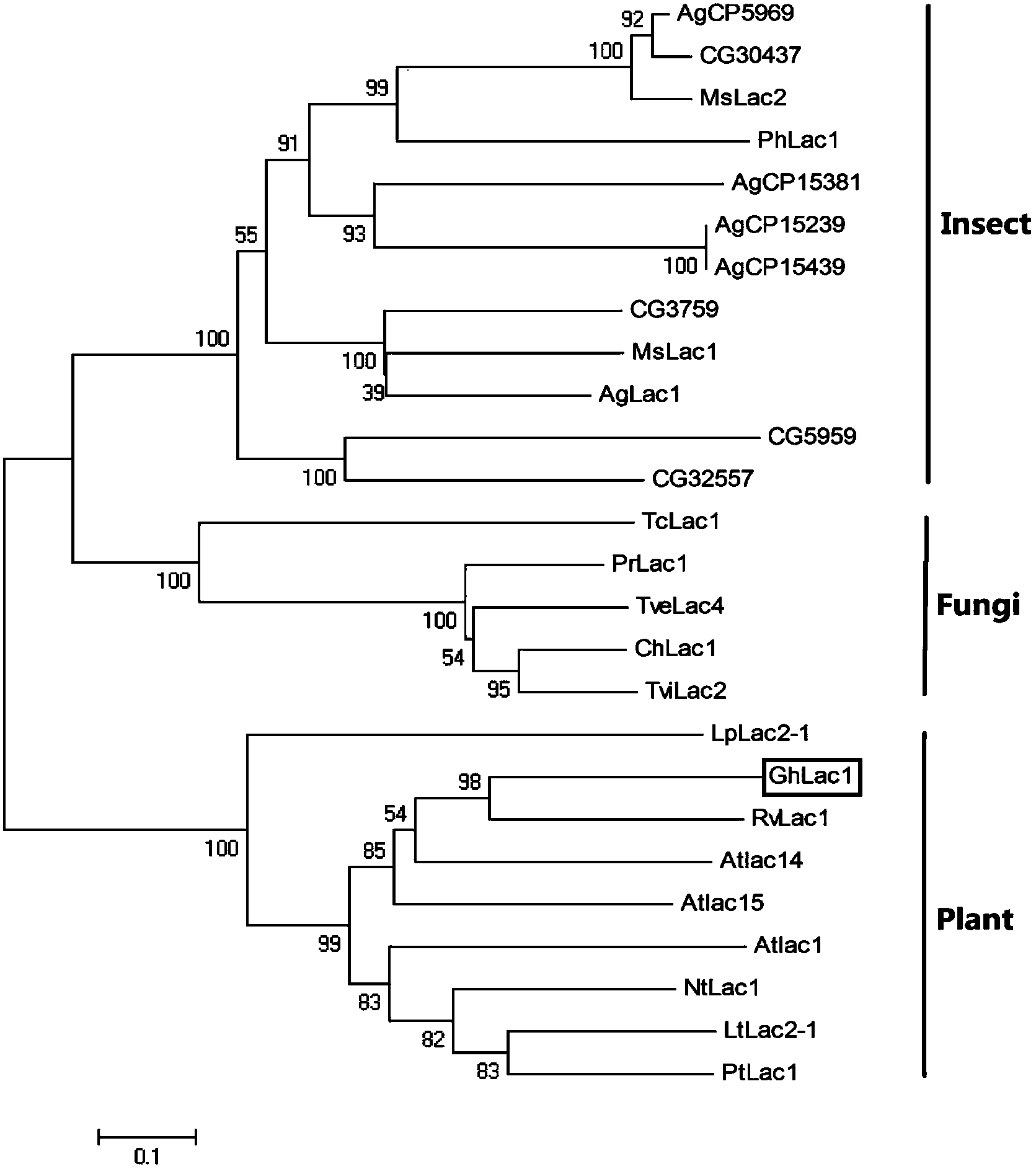

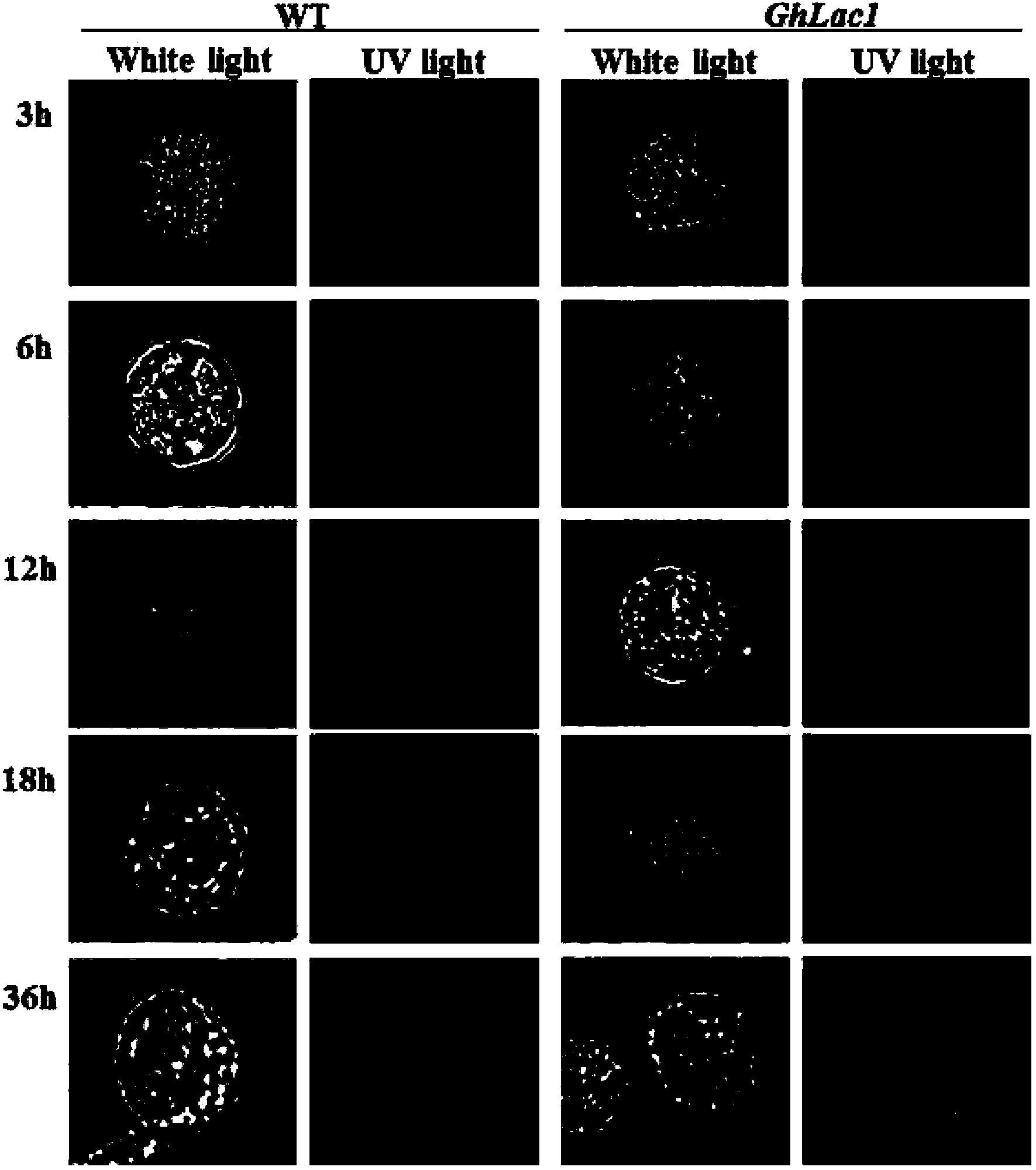

GhLac1 gene of broad-spectrum resistance of mediated cotton and application thereof

ActiveCN103421822ABroad spectrum resistantEasy to buildOxidoreductasesFermentationDiseaseAgricultural science

The invention belongs to the technical field of plant gene engineering, and particularly relates to GhLac1 gene of broad-spectrum resistance of mediated cotton. According to the invention, the nucleotide sequence of the GhLac1 gene is as shown by SEQ ID NO:1, the sequence of amino acid of coded protein thereof is as shown by SEQ ID NO:2, and an open reading frame thereof is the sequence corresponding to 20-1720th basic group shown by the SEQ ID NO:1. The invention also discloses an application of the gene in cotton heredity and transformation. Through excessive expression of the gene, the synthesis of lignose in the plant can be promoted, so as to accelerate lignification process, and meanwhile, to accelerate reconstruction of cell walls of damaged cells. The cloned gene provided by the invention can be applied to the select breeding of broad-spectrum disease resistance or insect-resistant novel varieties through heredity and transformation.

Owner:HUAZHONG AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com