Technique for extracting lignin from biomass raw materials

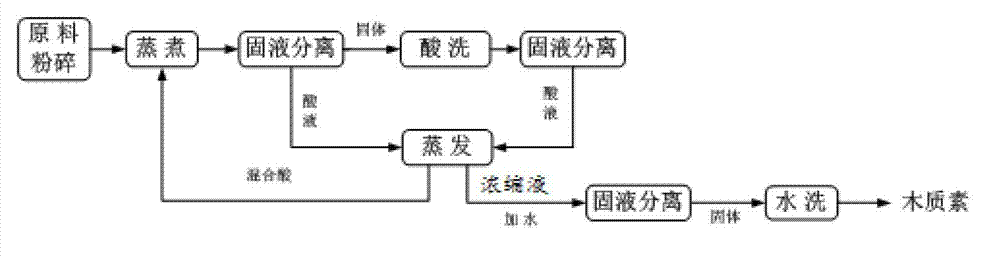

A technology of biomass raw material and lignin, which is applied in the field of lignin extraction technology, can solve problems such as difficult separation, unsuitable lignin extraction, and affecting processing efficiency, and achieve the effects of intensified degradation and dissolution, shortened cooking time, and simple process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In this embodiment, the reeds (with a lignin content of 25.10%) are first crushed to a particle size of 2-10 cm.

[0040] The present embodiment extracts the technique of lignin from described reed, comprises the steps:

[0041] (1) After the reeds are pulverized and pretreated, use the organic acid liquid whose total acid concentration is 70% formic acid and acetic acid to cook the treated reeds. The mass ratio of acetic acid and formic acid in the organic acid liquid of the present embodiment is 1: 1, and before adding the reed raw material, add 3% hydrogen peroxide (H 2 o 2 ) as a catalyst, control the reaction temperature at 115°C, react for 55min, and have a solid-liquid mass ratio of 1:5, and carry out the first solid-liquid separation of the obtained reaction solution;

[0042] (2) adding the solid obtained from the above separation to the same acid solution as the organic acid solution described in step (1) for acid washing, wherein the amount of hydrogen pero...

Embodiment 2

[0046] In this embodiment, firstly, corn stalks (with a lignin content of 24.09%) were crushed to a particle size of 2-10 cm.

[0047] The present embodiment extracts the technology of lignin from described corn stalk, comprises the steps:

[0048] (1) After the corn stalks are pulverized and pretreated, use the organic acid liquid whose total acid concentration is 75% formic acid and acetic acid to cook the treated corn stalks, the quality of acetic acid and formic acid in the organic acid liquid of the present embodiment The ratio is 1:2, and before adding corn stalks, add 2% hydrogen peroxide (H 2 o 2 ) as a catalyst, control the reaction temperature at 90°C, react for 40min, and have a solid-liquid mass ratio of 1:15, and carry out the first solid-liquid separation of the obtained reaction solution;

[0049] (2) Add the solid obtained from the above separation into the same acid solution as the organic acid solution described in step (1) for acid washing, wherein the amo...

Embodiment 3

[0053] In this embodiment, the rice straw (19.07% lignin content) is first crushed to a particle size of 2-10 cm.

[0054] The present embodiment extracts the technique of lignin from described rice straw, comprises the steps:

[0055] (1) After the rice straw is pulverized and pretreated, the organic acid solution of formic acid and acetic acid with a total acid concentration of 80% is used to cook the treated rice straw. The mass ratio of acetic acid and formic acid in the organic acid solution of the present embodiment is 1: 6, and add before adding the straw raw material and account for 4% hydrogen peroxide (H 2 o 2 ) as a catalyst, the reaction temperature is controlled at 135° C., the reaction is 70 minutes, the solid-liquid mass ratio is 1:10, and the obtained reaction solution is subjected to solid-liquid separation for the first time;

[0056] (2) adding the solid obtained from the above separation into the same acid solution as the organic acid solution described i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com