Patents

Literature

256results about How to "Uniform molecular weight distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of graft copolymerization carboxylate high-performance dehydragent

InactiveCN101041570ANo pollution in the processLow conversion rate of esterificationNitrogen gasAqueous solution

The invention discloses a preparing method of graft copolymerization carboxylate high-performance dehydragent belonging to dehydragent domain, which comprises the following steps: choosing methoxy carbowax with molecular weight distributing between 1000-2000 and acroleic acid or methacrylic acid as main raw material; adopting total acid method esterified priority method; preparing intermediate (big monomer) with polymerization activity; adding third monomer into polymerization reaction; adjusting polymerization activity of copolymerization system; proceeding technique route synthesis of main chain polymerization in the water solution. The getting big monomer possesses merits of high conversion rate, short reacting time, simple process flow and strong controlling property.

Owner:BEIJING UNIV OF TECH

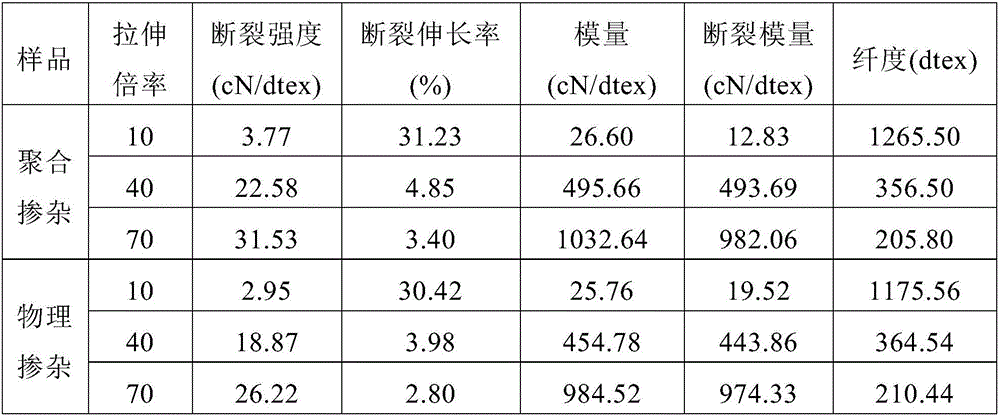

Method for preparing polyaramide resin modified by aromatic heterocycle and chloromonomer

InactiveCN101165078AGood molecular weightHigh molecular weightPolyamide coatingsMonocomponent polyamides artificial filamentTwo stepMonomer

The present invention discloses process of producing aromatic heterocycle and chlorated monomer modified polyaramide resin. Monomers including paraphthaloyl chloride and p-phenylene diamine in the calculated equivalents and 2-(4-aminophenyl)-5(6) aminophenyl benzimidazole in 20-80 % the calculated equivalent are synthesized inside NMP / CaCl2 solvent system into high molecular weight resin through one two-step process including the first reaction between partial paraphthaloyl chloride and all the p-phenylene diamine to form amido group terminated low molecular weight oligomer and the subsequent reaction between the rest paraphthaloyl chloride and the amido group terminated low molecular weight oligomer to form the high molecular weight resin. The aromatic heterocycle and chlorated monomer modified polyaramide resin has the advantages of high fireproof performance, high mechanical strength and low cost.

Owner:四川华通特种工程塑料研究中心有限公司

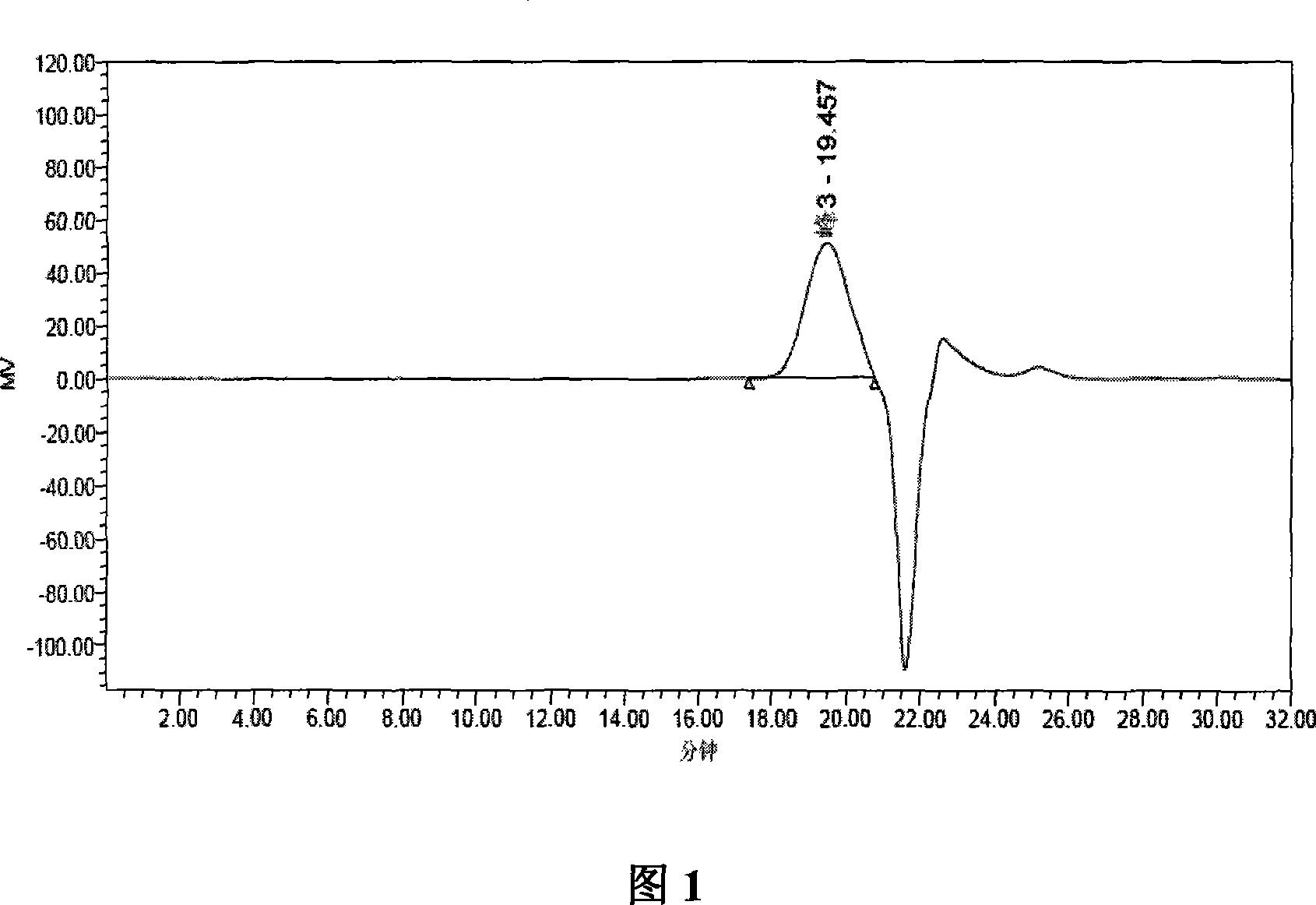

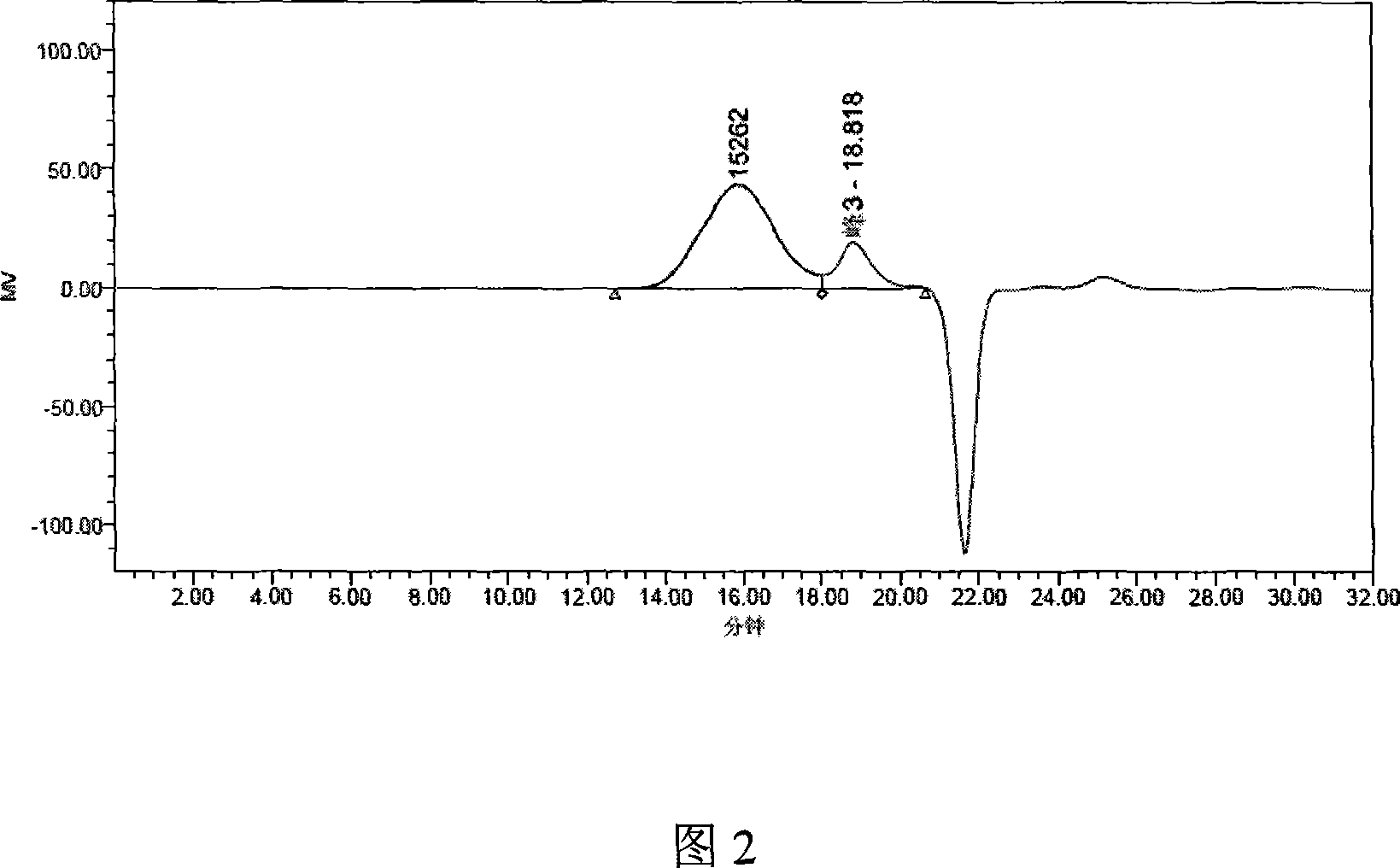

Authentication system and method

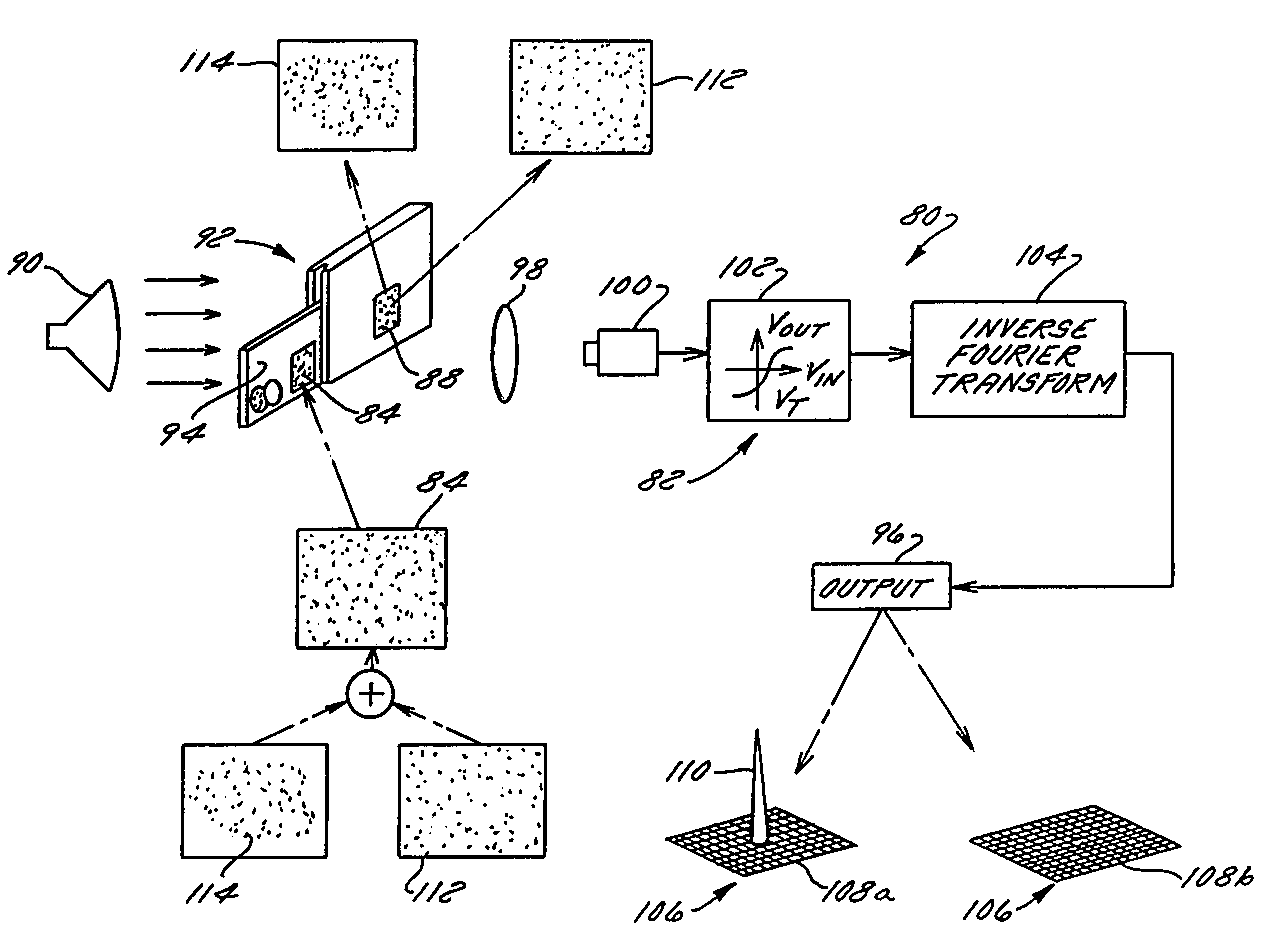

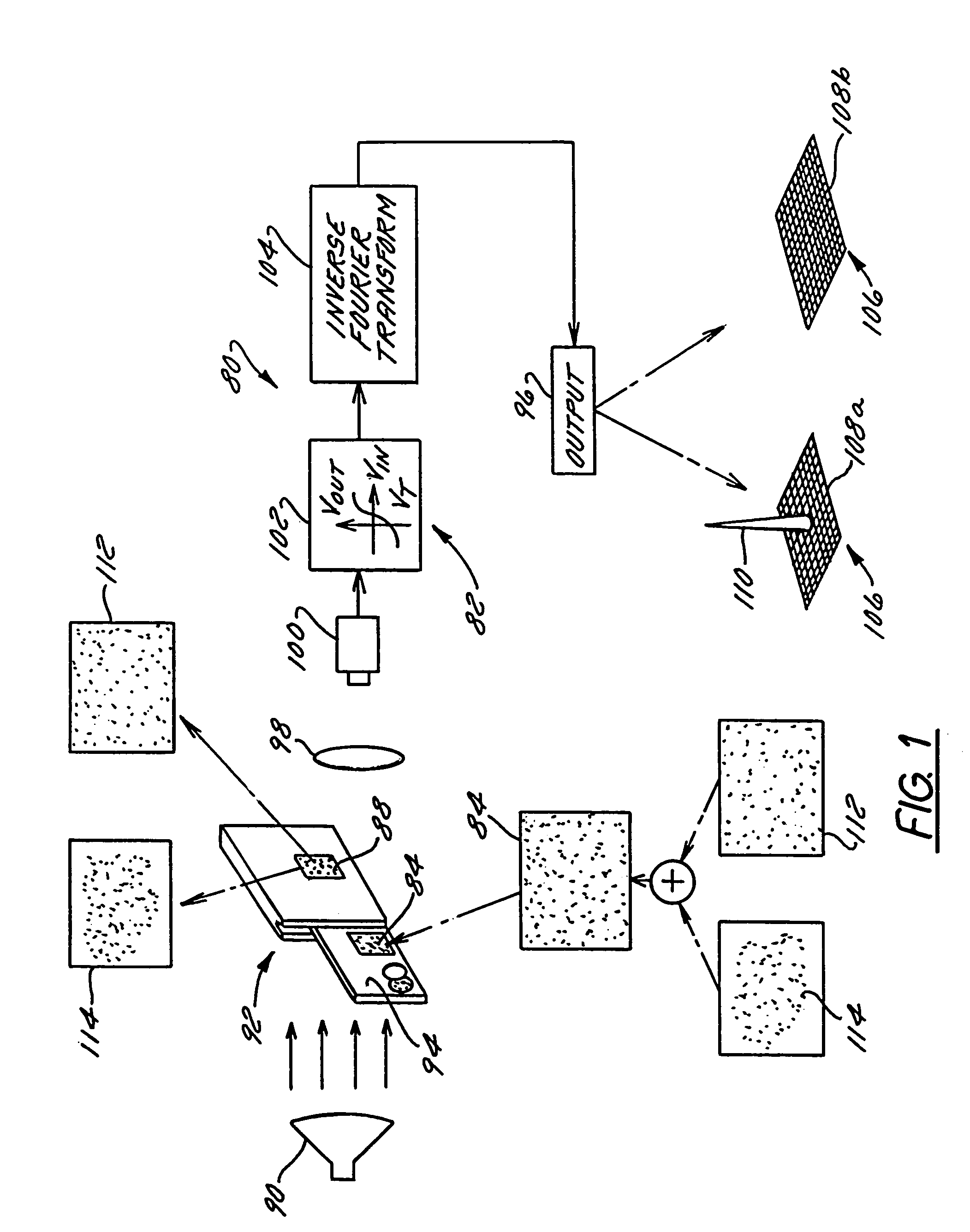

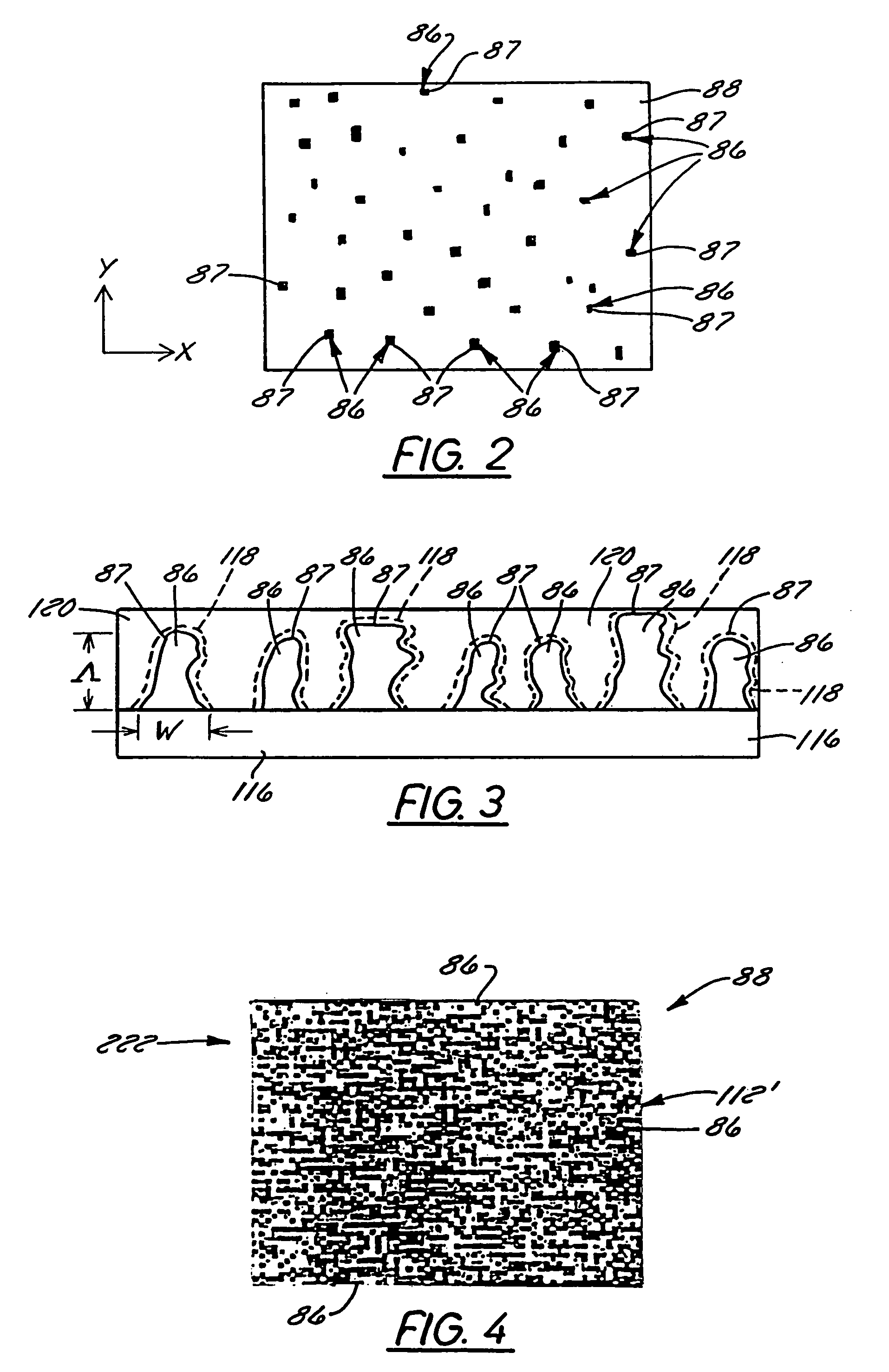

InactiveUS7317814B2Cheaply replicatedRaise security concernsRadiation pyrometryCo-operative working arrangementsSpatial light modulatorFourier transform on finite groups

An authentication system using a correlator that correlates an input with a reference wherein at least one of the input and reference comprises a phase volume mask having structures, preferably points, that are each less than about six microns in size and can have an aspect ratio (AR) greater than 1:1 so as to produce a phase encoded random pattern having millions of combinations in a mask that is as small as one square millimeter. The random pattern can be convolved with a second pattern, such as a biometric pattern, to produce a phase convolved mask. The correlator preferably is a nonlinear joint transform correlator that can use “chirp” encoding to permit the input to be located in a different plane than the reference. The correlator optically Fourier transforms images of the reference and input that are thereafter nonlinearly transformed and inverse Fourier transformed by a processor to determine the presence or absence of a correlation spike indicative of authenticity. A spatial light modulator (SLM) can be used as an input or reference and preferably is a liquid crystal panel having pixels or elements whose phase or grey scale intensity can be selectively controlled by a processor. The SLM can be used to display a biometric pattern, preferably scanned in real time from a person, that is correlated against an input or reference that can comprise a label on a card, a tag, or another object.

Owner:PHYSICAL OPTICS CORP

Method for preparing fluorine-containing acrylate emulsion

The invention discloses a method for preparing fluorine-containing acrylate emulsion. The fluorine-containing acrylate emulsion is prepared from perfluoroalkyl ethyl acrylate and acrylic monomers which are used as main materials, persulfate which is used as the initiator, and a compound emulsifier by adopting the semi-continuous titration polymerization process. The titration mode is adopted in the whole reaction process, the heat is preserved after finishing titrating, the reaction process is convenient to control, and the finally prepared fluorine-containing acrylate emulsion has excellent performance and high performance-price ratio, is environmental friendly and safe and can be cured at normal temperature to form a film. The detection on the emulsion paint prepared from the fluorine-containing acrylate emulsion shows that the emulsion paint can resist scrubbing of 10,000 times without changing, can resist both acid and base for 120 hours without blistering and powder falling in addition to slight loss of gloss and color and can resist ageing for 5,000 hours without blistering, stripping and cracking. The content of solid (the mass percent of non-volatile matters) in the fluorine-containing acrylate emulsion is more than 45%, and the water repellent angle of the coating of the fluorine-containing acrylate emulsion is more than 100 degrees.

Owner:JINZHOU DPF TH CHEM CO LTD

Glycolide preparation method

InactiveCN105272958ALow impurity contentImprove conversion rateOrganic chemistryDepolymerizationReaction temperature

The present invention relates to a glycolide preparation method. A purpose of the present invention is mainly to solve the problems of low purity and low yield of the prepared glycolide in the prior art. The technical scheme comprises: (1) melt condensation polymerization: a) normal pressure condensation polymerization, wherein a glycolic acid crystal is subjected to sectional reaction under a normal pressure in the presence of a condensation catalyst or a transesterification catalyst, the reaction is performed for 0.5-10 h by maintaining the reaction temperature between the glycolic acid melting point and the glycolic acid boiling point at the first stage normal pressure prepolymerization, and at the second stage normal pressure condensation polymerization, the condensation reaction or the transesterification reaction is performed at a reaction temperature of 112-220 DEG C until no water is distilled to obtain the molten glycolic acid oligomer, b) pressure reducing condensation polymerization, and c) strengthened condensation polymerization; and (2) high temperature depolymerization, wherein a depolymerization reaction is performed at a reaction temperature of 230-290 DEG C under a reaction pressure of 0.1-1 KPa so as to obtain the glycolide crude product. With the technical scheme of the present invention, the problems in the prior art are well solved, and the method can be used in the industrial glycolide production.

Owner:CHINA PETROLEUM & CHEM CORP +1

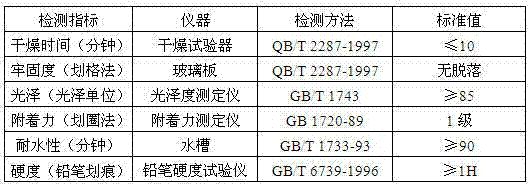

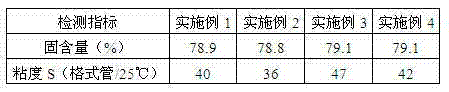

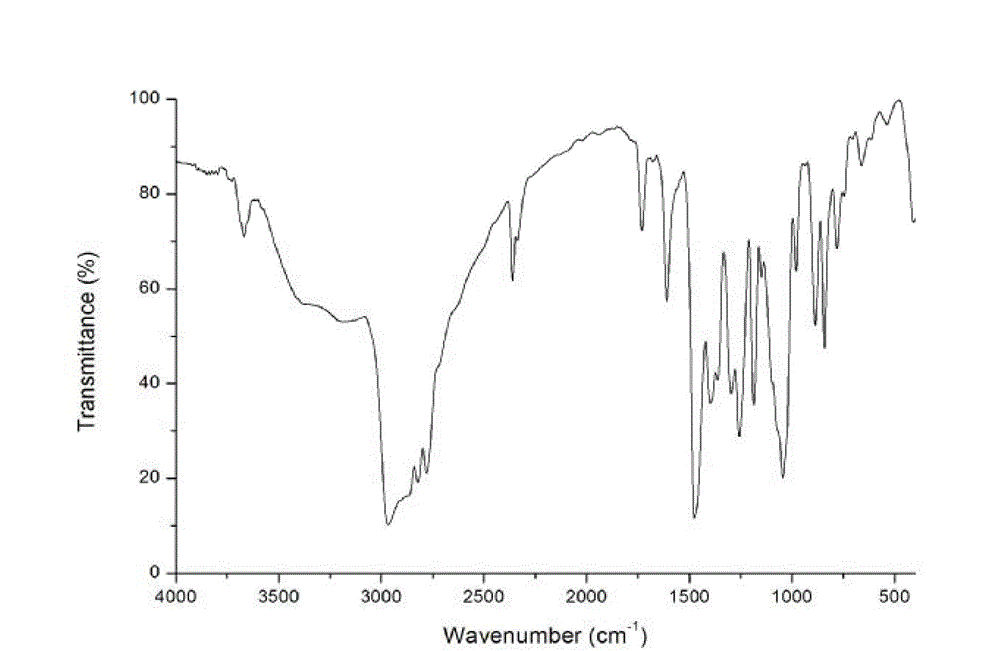

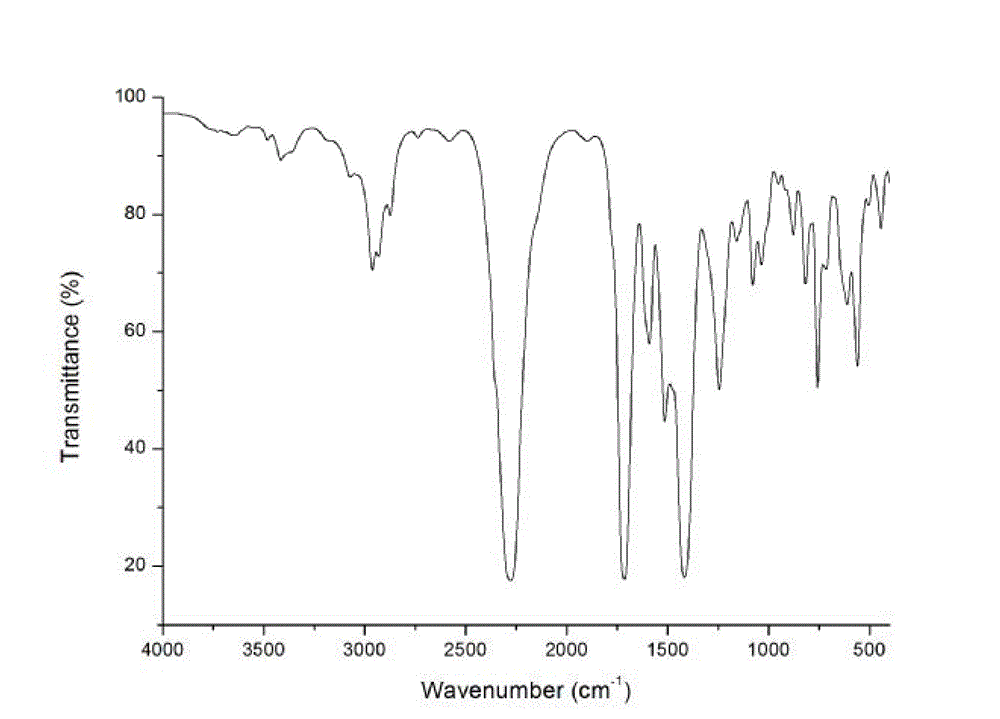

Preparation method of alkyd resin

InactiveCN102408551AImprove adhesionFullnessCosmetic preparationsToilet preparationsPolymer scienceNitrocellulose

The invention relates to a preparation method of alkyd resin. The preparation method comprises the following specific steps: (1) adding neopentyl glycol, trihydroxymethyl propane, phthalic anhydride, hydrogenated phthalic anhydride and antioxidant to a reaction container, and heating to carry out melt esterification on the materials at the temperature of 200-240 DEG C; (2) when esterification is carried out to an acid value being 40-45 mgKOH / g, cooling to 120-160 DEG C, and adding short-chain synthetic fatty acid and an aliphatic hydrocarbon solvent; (3) heating to carry out reflux esterification at the temperature of 180-200 DEG C, and diluting with acetic acid ester organic solvent when the acid value is smaller than or equal to 8 mgKOH / g; and (4) cooling to 100 DEG C and filtering to obtain alkyd resin. The paint prepared from the alkyd resin obtained in the invention and nitrocellulose has the characteristics of rapid drying, high hardness, good fullness, good adhesion force, and good water resistance.

Owner:JIANGSU SANMU GROUP CORPORATION

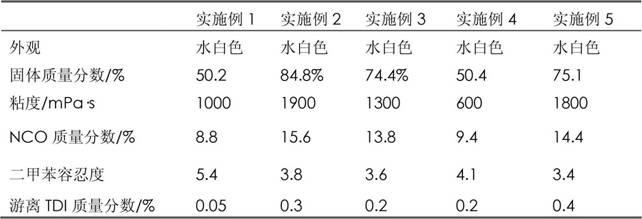

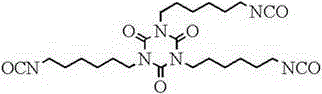

Preparation method of polyurethane trimer curing agent of low free isocyanate monomer

ActiveCN102718944AGood compatibilityRapid curing at room temperatureOrganic chemistryPolyurea/polyurethane coatingsPolymer scienceNitrogen

The invention discloses a preparation method of a polyurethane trimer curing agent of a low free isocyanate monomer, comprising the following steps of: under the protection of nitrogen, firstly putting an isocyanate monomer and an esters solvent into a reaction container to evenly stir, wherein the temperature is kept at 50-90DEG C; dropwise adding diamine into the reaction container under the condition of stirring, wherein the dropwise adding time is 1-1.5 hours; and after dropwise adding, adding a catalyst of which the mass is 0.1-0.5% of that of the isocyanate monomer once, continuing stirring and reacting at the temperature of 70-100DEG C for 3-6hours, when the NCO base content is 20%-25%, immediately adding the polymerization inhibitor of which the mass is 0.1-1% of that of the isocyanate monomer, keeping the temperature for 1-2hours, and discharging in a cooling way. The polyurethane trimer curing agent prepared by the preparation method can be better compatible with the resin, can be quickly solidified under normal temperature, and has the advantages of being higher in mechanical strength, modulus, adhesion, etc.

Owner:SOUTH CHINA UNIV OF TECH +1

Preparation method for poly-2-olefine drag reducer of pipe oil transporting product

A process for preparing the alpha-olefine as the drag reduce used for delivering oil in pipeline includes such steps as loading monomers into reactor, adding catalyst while stirring in the condition of isolating air, adding the oil-soluble polyester, polyether or ester-ether copolymer solution to which the alpha-olefine polymer is not dissolved, and reacting at -50-20 deg.C for 3-10 days. Its advantages are simple process, and high molecular weight, high effect, high stability and low viscosity of product.

Owner:PIPECHINA SOUTH CHINA CO

Preparation method of cationic polyacrylamide

ActiveCN102603970AReduce dosageHigh puritySludge treatment by de-watering/drying/thickeningWater/sewage treatment by flocculation/precipitationUltraviolet lightsSewage treatment

The invention relates to a preparation method of cationic polyacrylamide. The cationic polyacrylamide is prepared by the following steps of: adding a certain amount of solubilizing agent and complexing agent into acrylamide (AM) and aqueous solution of two cationic monomers; regulating the pH value of a reaction system; then adding a certain amount of initiator; and performing the polymerization reaction under the ultraviolet light with a certain wavelength. The preparation method has the advantages that the polymerization reaction time is short; few types of auxiliaries are added; and the prepared product has high purity and is non-toxic and harmless. The cationic polyacrylamide obtained by the preparation method has multifunctionality, has the molecular weight of 1 million to 12 million, has ultralow concentration of a residual acrylamide monomer, is suitable for treatment of drinking water and sewage treatment and dehydration treatment of sludge and has excellent application prospect.

Owner:贾高锋 +1

High-solid and averaged-molecular weight non-toxic polyurethane curing agent for sub-gloss varnish and preparation method thereof

The invention belongs to the technical field of curing agents and discloses a high-solid and averaged-molecular weight non-toxic polyurethane curing agent for a sub-gloss varnish and a preparation method thereof. The method comprises the steps of (1) in the nitrogen protection environment, adding a catalyst drop by drop in a reaction vessel filled with a solvent and toluene diisocynate during the stirring process, reacting at the temperature of 40-55 DEG C, cooling on the condition that the content of NCO is lowered to be 13%-23%, and adding an acidic polymerization inhibitor to obtain a toluene diisocyanate trimer; (2) mixing a polyhydroxy compound with a dehydrating agent, adding the obtained mixture in the toluene diisocyanate drop by drop, reacting and cooling to obtain a polyurethane addition product; (3) stirring and mixing the toluene diisocyanate trimer with the polyurethane addition product, separating in a film evaporator, adding a dilution solvent and stirring evenly to obtain the high-solid and averaged-molecular weight non-toxic polyurethane curing agent. The curing agent is centralized in the distribution of molecular weight, low in viscosity, and high in content of effective isocyanate groups. After a varnish is prepared by the curing agent, a paint film is fast in drying speed, good in levelability and high in fullness.

Owner:SOUTH CHINA UNIV OF TECH

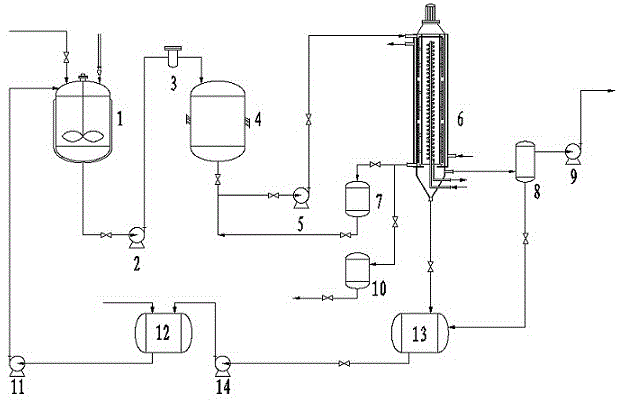

Preparation method for low-color number environment-friendly polyurethane curing agent

ActiveCN103848954ALow viscosityUniform molecular weight distributionChemical industryThermal energyAlcohol

The invention discloses a preparation method for a low-color number environment-friendly polyurethane curing agent. The method comprises the following steps of 1, continuously reacting dihydric alcohol, trimethylolpropane and toluene diisocynate to generate prepolymer reaction liquid by using a continuous reaction device, wherein the trimethylolpropane is fed in a batch addition way; 2, separating the prepolymer reaction liquid by using two stages of film evaporators, pumping evaporation residues obtained by separation into a diluting tank by using a pump, and performing diluting to obtain low-free isocyanate monomer content polyurethane curing agent. The method has the advantages that the whole production process is continuous, the use of a solvent is avoided, reaction heat is maximally utilized, the method is energy-saving and environmentally friendly, the color of a product is improved, and the quality of the curing agent product is improved.

Owner:WANHUA CHEM GRP CO LTD +1

Preparation method of toluene diisocyanate trimer curing agent

ActiveCN102911343AEasy to operateLow equipment requirementsOrganic chemistryPolyurea/polyurethane coatingsAlcoholToluene diisocyanate

The invention discloses a preparation method of a polyurethane trimer curing agent. The method comprises the steps of adding toluene diisocyanate and a polar solvent into a reaction vessel under the protection of introduced N2, dripping a catalyst solution containing alkyl amine methyl phenol for trimerization of isocyanate, and performing heat preservation and stirring for reaction for 2-12 hours; detecting the weight percentage of free NCO group, adding isocyanate trimerization inhibitor and performing heat preservation, then stirring for reaction for 0.5-1 hour when the NCO content is 9.5-8.5%; dripping a polar solvent solution of monobasic alcohol, and continuously performing heat preservation, then stirring for reaction for 1-2 hours; stopping the reaction when the weight percentage of NCO reduces to be 8.0-7.0%, and cooling to room temperature, and discharging to obtain a transparent and near water-white product. The preparation method has the beneficial effects that the curing agent is well matched with the resin, is rapidly cured at room temperature, and has the advantages of high compatibility, low viscosity, high mechanical strength and the like.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing chitosan oligosaccharide by applying complex enzyme

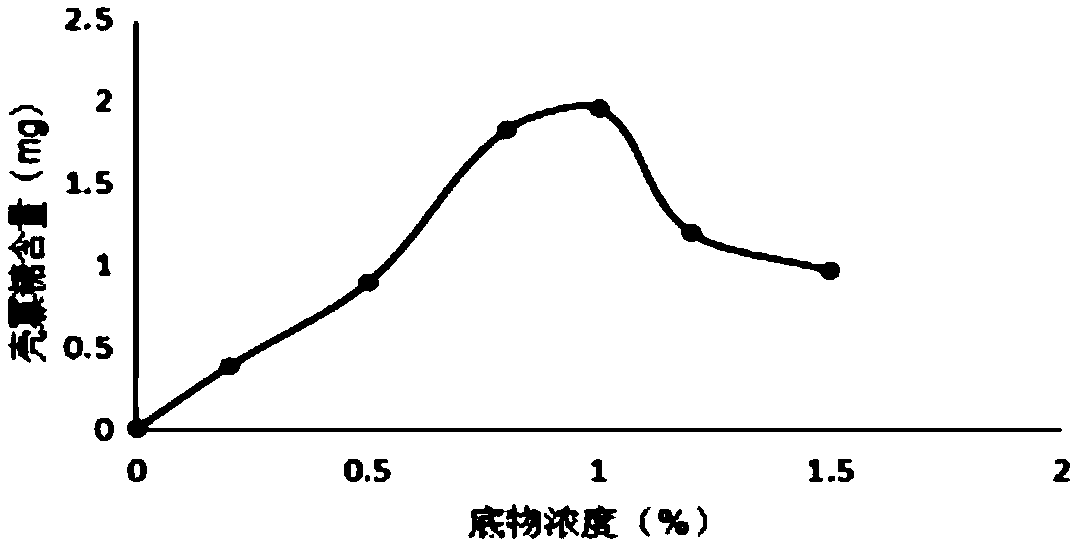

ActiveCN102492664AEfficient degradationAvoid Degradation DefectsHydrolasesFermentationCellulaseCHITOSAN OLIGOSACCHARIDE

The invention relates to a method for preparing a chitosan oligosaccharide by applying a complex enzyme. The complex enzyme comprises cellulose, lysozyme, amylase, lipase, glucolase and papain. The invention further provides a method for preparing a chitosan oligosaccharide by applying the complex enzyme. The method comprises the following step of: adding the complex enzyme into a reaction buffersolution of chitosan, wherein the mass ratio of the complex enzyme to the chitosan is (1-20):100, and is preferably (5-15):100. The complex enzyme and the chitosan oligosaccharide prepared from the complex enzyme have uniform molecular weight distribution and high yields.

Owner:HAINAN ZHENGYE ZHONGNONG HIGH TECH

Preparation method of functionalized ultra-high molecular weight polyethylene resin

ActiveCN105906748AMolecular weight controllableUniform molecular weight distributionElectroconductive/antistatic filament manufactureMonocomponent polyolefin artificial filamentPolymer scienceHydrogen

The invention relates to a preparation method of functionalized ultra-high molecular weight polyethylene resin. In the method, a modifying additive is added to solvent oil, and with ethylene as a raw material and under the effects of a catalyst and hydrogen, a low-pressure slurry method is employed to prepare the functionalized ultra-high molecular weight polyethylene resin. The method, compared with the prior art, is simple and is suitable for large-scale production. The resin is controllable in molecular weight and has uniform distribution in molecular weight. The modifying additive in the resin is uniformly mixed.

Owner:SHANGHAI RES INST OF CHEM IND +1

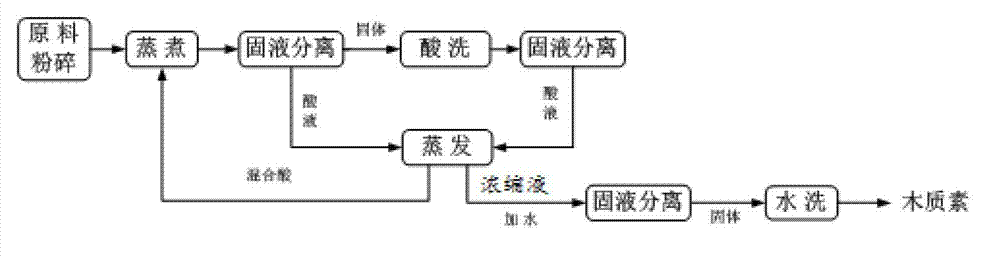

Technique for extracting lignin from biomass raw materials

The invention relates to a technique for extracting lignin, in particular to a technique of utilizing organic acid to extract the lignin from biomass raw materials by a catalytic action of hydrogen peroxide. According to the method, the lignin is obtained by extracting the biomass raw materials boiled by organic acid formed by methanoic acid and acetic acid by the catalytic action of hydrogen peroxide; a whole technique route is simple; the energy consumption is lower; and an extraction ratio of the lignin reaches 80-90%.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

Preparation method of polyurethane prepolymer with low free isocyanate monomer

The invention discloses a preparation method of polyurethane prepolymer with low free isocyanate monomer. The preparation method comprises the following steps of: forming into mixed alcohol by trihydric alcohol and dihydric alcohol under the temperature of 120-150DEG C, and carrying out vacuum dehydration; putting isocyanate monomer and ester solvents into a reactor to keep the temperature at 30-70DEG C, and dropwise adding the mixed alcohol into the reactor; after dropwise adding, continuously reacting for 3-6h under the temperature of 40-70DEG C under stirring, and discharging in a cooling way to obtain polyurethane prepolymer; and separating the obtained polyurethane prepolymer, and adjusting the solid content of polyurethane prepolymer solid and the content of free isocyanate monomer in the separated heavy components by diluted solvent. According to the preparation method, the real continuous production can be realized, all the recovered solvent and isocyanate monomer can be recycled, the zero emission can be realized, and the real clean production can be realized; and the product has the characteristics of being low in viscosity, high and adjustable in NCO value content, low in the content of the free isocyanate monomer, high in solid content, good in compatibility, etc.

Owner:SOUTH CHINA UNIV OF TECH +1

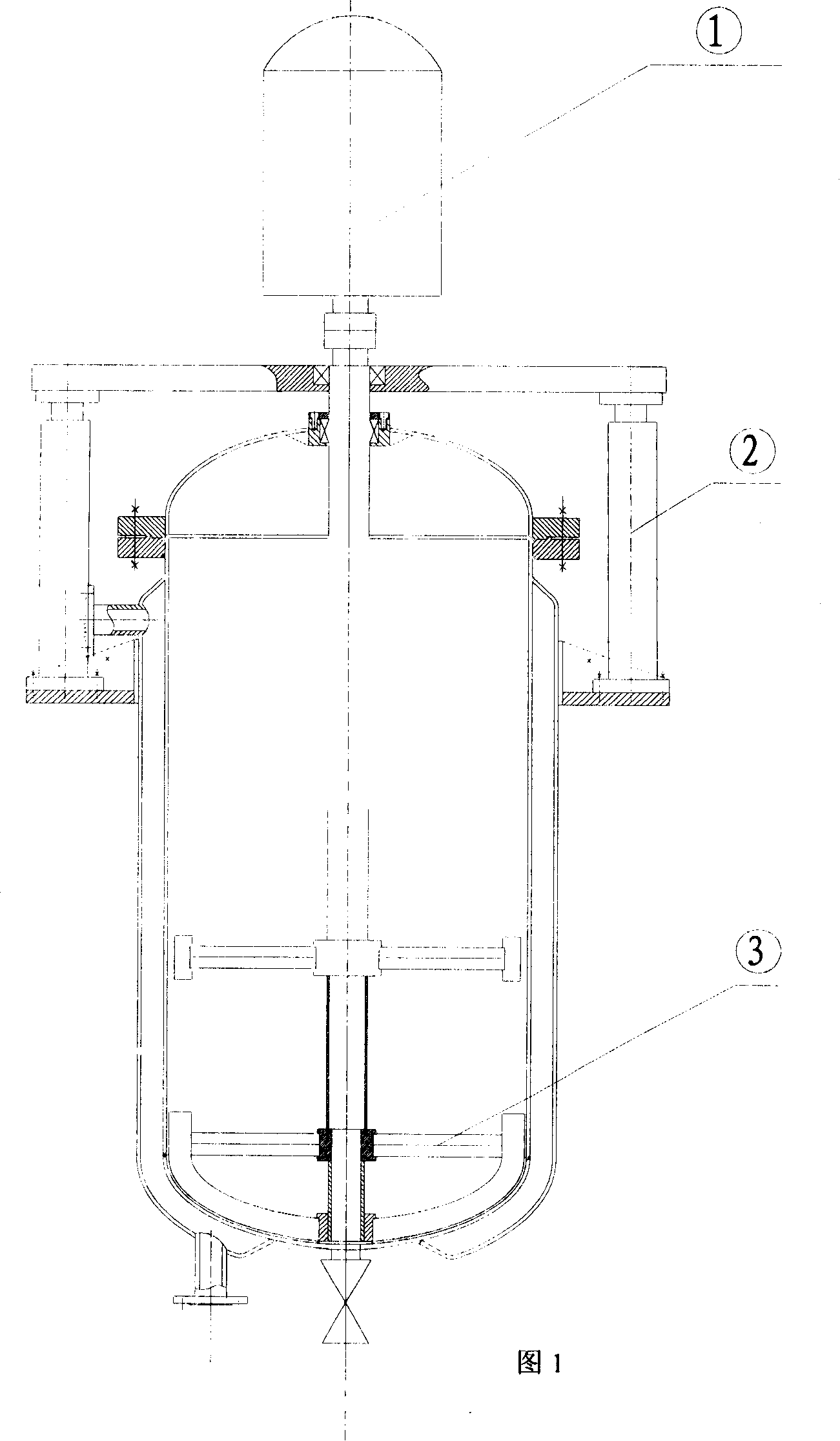

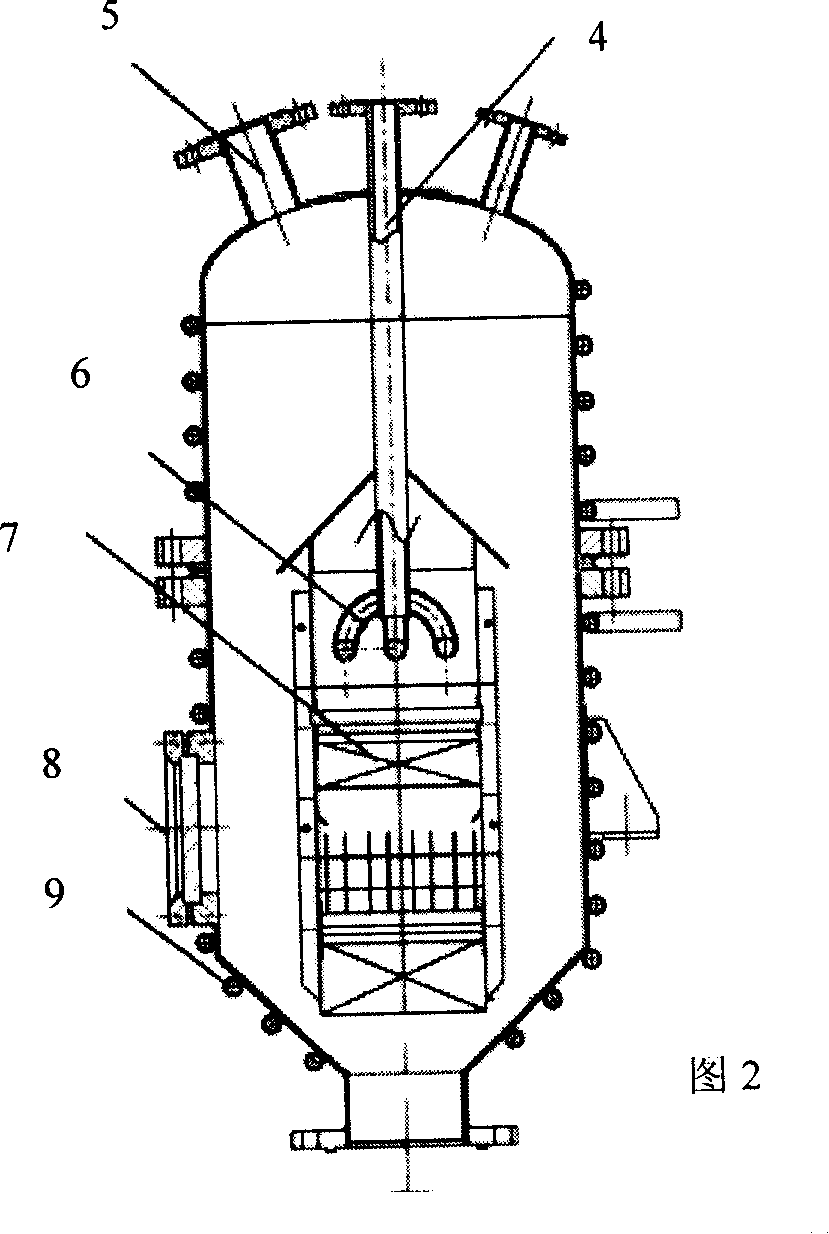

Polymerization method for crude rubber of fluorinated silicone rubber

The invention relates to a method for aggregation of hydrofluorosilicic crude rubber. The hydrofluorosilicic crude rubber prepared by this invention is of even molecular weight distribution and superior performance, and can exactly control the average molecular weight of the product. The method includes the following steps: first preparing the polymeric materials, in which the polymeric materials can be fluosilicic monomer D3F, vinyl silicon monomer or alkaline agent, mixing and dewatering the raw materials, then inputting the materials into the polymerization kettle, after the polymerization, the materials entering the devolatilization kettle because of pressure differences, then entering the out-feed extrusion machine, and the polymer blendedly discharging by the extrusion machine. The hydrofluorosilicic crude rubber prepared by this invention is of even molecular weight distribution and can exactly control and adjust the average molecular weight of the product, so it can improve the homogeneity of the product.

Owner:GUANGDONG SUNLITE MATERIAL SCI & TECH

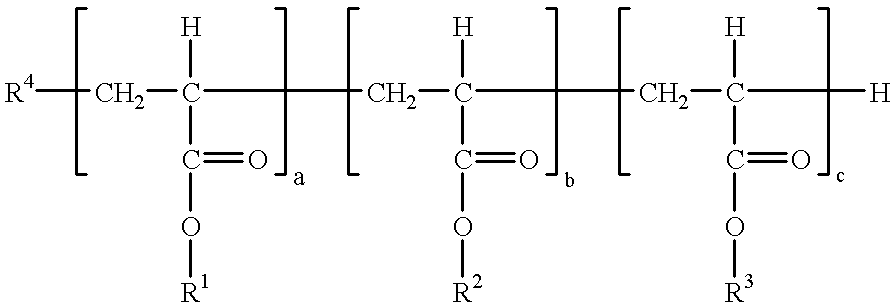

Polyacrylates and their use as degassing agents for paints and coatings

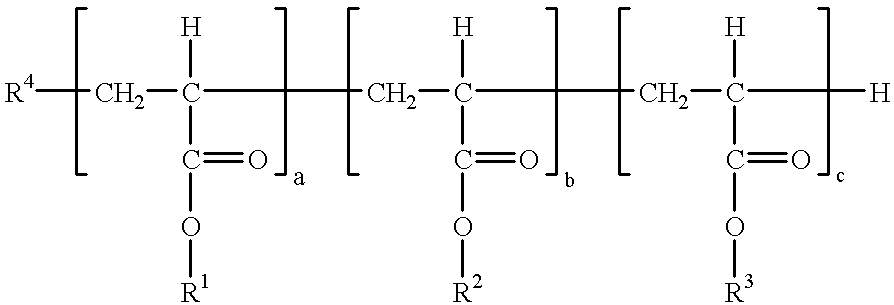

InactiveUS6353068B1Minimizing presenceMinimizing risksLiquid degasificationConductive materialMeth-Hydrocarbon

Polyacrylates having an average molecular weight of from about 1000 to about 10,000 and the general formulawhereR4 is the radical of a known chain regulator or initiator,R1 is identical or different and is an alkyl radical, preferably of 1 to 4 carbon atoms,R2 is identical or different and is a saturated or unsaturated alkyl radical of 12 to 22 carbon atoms,R3 is a hydrocarbon radical which carries at least one (meth)acryloxy group,a is from 10 to 50,b is from 3 to 20,c is from 0 to 10,and the ratio a:b+c is from 0.25 to 4 and the ratio b:c is from 1:0 to 1:0.7 as degassing agents for paints and coatings.

Owner:EVONIK DEGUSSA GMBH

Hydrolyzed sericin peptide preparation method

ActiveCN107937460AReduce manufacturing costEasy to operatePeptide preparation methodsFermentationChemical industryPeptide

The invention relates to a hydrolyzed sericin peptide preparation method, and belongs to the technical field of protein separation and purification. According to the present invention, tasar silkwormcocoon shell or waste mulberry silk is used as a raw material, the tasar silkworm cocoon shell is washed, a sericin solution is prepared, a hydrolyzed sericin peptide solution is prepared, an activated macroporous resin decolorization system is assembled, a hydrolyzed sericin peptide decolorization solution is prepared, an activated MCI GEL resin system is assembled, a hydrolyzed sericin peptide grading separation solution is prepared, a hydrolyzed sericin peptide grading separation concentration solution is prepared, a hydrolyzed sericin peptide grading separation ethanol removing concentration solution is prepared, and hydrolyzed sericin peptide freeze-drying powder is prepared so as to obtain the product; by using multi-enzyme combined hydrolysis, ultra-filtration, nano-filtration separation, macroporous resin decolorization, MCI GEL resin grading separation, low-temperature concentration, freeze drying, and other modern chemical industry technologies and equipment, such that the preparation method has characteristics of convenient operation, mild condition, high efficiency, energy saving, low production cost and the like; and the product prepared by using the preparation methodcan be widely used in the fields of nutritious daily chemicals, fiber modification, and the like.

Owner:YIBIN PINGSHAN HUIRUI OIL CO LTD

Poly(m-phenylene isophthalamide) resin liquid, preparation method thereof, poly(m-phenylene isophthalamide) resin and poly(m-phenylene isophthalamide) fibrid

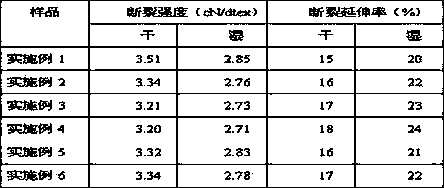

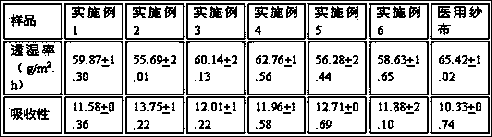

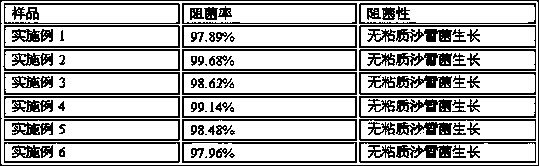

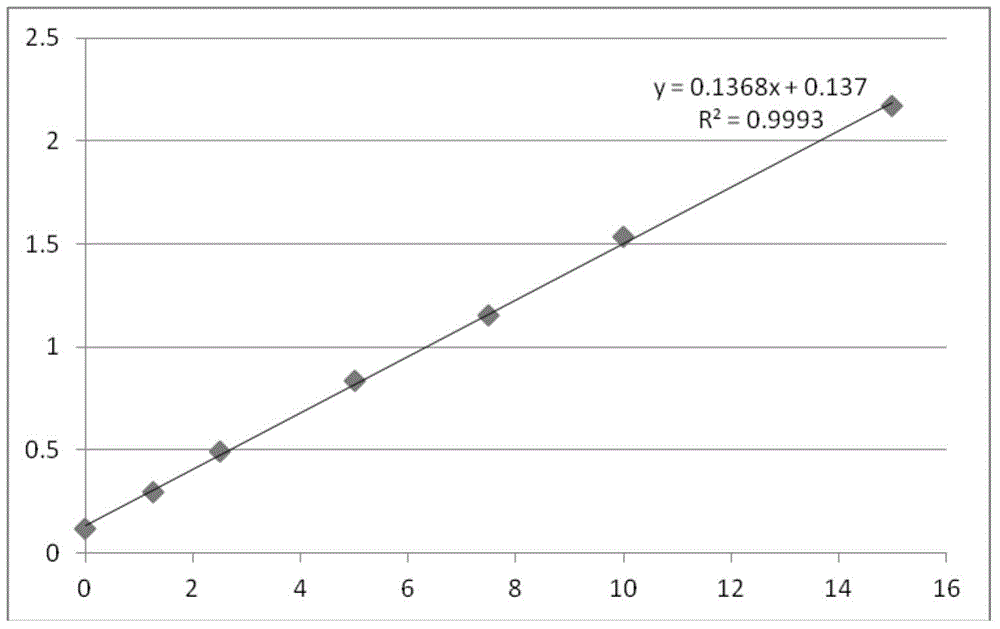

InactiveCN107522858AGood dispersionImprove liquidityMonocomponent polyamides artificial filamentBreaking strengthMoisture absorption

The invention discloses a poly(m-phenylene isophthalamide) resin liquid, a preparation method thereof, a poly(m-phenylene isophthalamide) resin and a poly(m-phenylene isophthalamide) fibrid. The preparation method of the poly(m-phenylene isophthalamide) resin liquid comprises (1) preparing m-phenylenediamine solution and m-phthaloyl dichloride organic solution; (2) mixing the m-phenylenediamine solution and a part of the m-phthaloyl dichloride organic solution for pre-polymerization; (3) mixing pre-polymerized mixture solution with the rest part of the m-phthaloyl dichloride for polymerization to obtain the poly(m-phenylene isophthalamide) resin liquid. The poly(m-phenylene isophthalamide) resin and the poly(m-phenylene isophthalamide) fibrid are both prepared through precipitation of the poly(m-phenylene isophthalamide) resin liquid. The preparation method of the poly(m-phenylene isophthalamide) resin liquid has the advantages of being controllable in reaction heat, small in influence of by-products, free from of neutralization of acid-binding agent, capable of avoiding moisture absorption of m-phthaloyl dichloride and formation of intermediates, and low in content of low-molecular polymers during reaction. Therefore, the prepared poly(m-phenylene isophthalamide) resin is high and stable in logarithmic viscosity number, and the prepared poly(m-phenylene isophthalamide) fibrid is uniform in fiber structure and high in tensile breaking strength.

Owner:HUNAN CHEM RES INST +1

Method for preparing chitosan oligosaccharide from papain through freeze drying

InactiveCN107739418AUniform molecular weight distributionIncrease productionSodium acetateAcetic acid

The invention belongs to the field of an oligosaccharide preparation method, and particularly relates to a method for preparing chitosan oligosaccharide from papain through freeze drying. The method for preparing the chitosan oligosaccharide from the papain through freeze drying provided by the invention comprises the following steps of dissolving chitosan into an acetic acid-sodium acetate buffersolution for preparing a chitosan solution; adding the papain into the chitosan solution for enzymolysis; after the enzymolysis is completed, dialyzing filter liquid by a dialyzing method; then, performing heating concentration on the collected dialyzing liquid; next, performing freeze drying and the like. The method for preparing the chitosan oligosaccharide from the papain through freeze dryingprovided by the invention has the advantages that simplicity, convenience, high speed and high efficiency are realized; the method is suitable for industrialized production; good industrial popularization practicability and values can be realized.

Owner:GUANGDONG PHARMA UNIV

Preparation method of aliphatic diisocyanate tripolymer curing agent

InactiveCN105566239AEvenly loadedSpeed up evaporationOrganic chemistryPolyurea/polyurethane coatingsMonomerPolymerization

The invention discloses a preparation method of an aliphatic diisocyanate tripolymer curing agent. The preparation method is characterized by comprising the following steps of adding aliphatic diisocyanate monomers into a reactor under the protection of inert gas; adding homemade trimerization catalysts for performing self-polymerization to generate aliphatic diisocyanate tripolymers; adding terminating agents to terminate the reaction after the proper conversion rate is reached; filtering and collecting clear filtering liquid to be used as raw products; using a short-process evaporator to perform twice separation on the crude product; recovering and reusing unreacted free monomers, wherein the content of the free monomers in the separated aliphatic diisocyanate tripolymers is reduced to be lower than 0.4 percent. The aliphatic diisocyanate tripolymers prepared by the preparation method can be prepared into super fast-drying paint; good anti-yellowing performance is realized; the aliphatic diisocyanate tripolymers can be widely applied to high-grade paint.

Owner:QINGDAO UNIV OF SCI & TECH +2

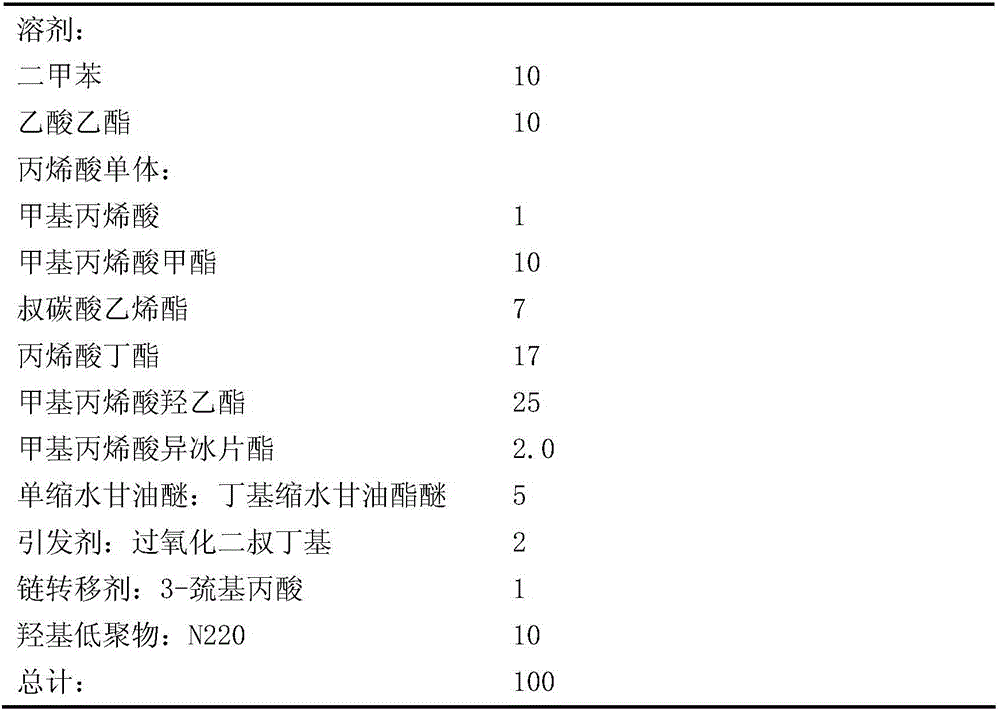

High-solid low-viscosity hydroxy acrylic resin as well as preparation method and application thereof

ActiveCN106009454ALow viscosityHigh cost performancePolyurea/polyurethane coatingsPolymer scienceOligomer

The invention discloses high-solid low-viscosity hydroxy acrylic resin as well as a preparation method and application thereof. During preparation, a first part of solvent and mono-glycidyl ether are added into a reaction kettle, stirred and heated to 140-180 DEG C; a first part of initiator and a chain transfer agent are added into an acrylic monomer mixture, the obtained mixture is dropwise added into a reaction kettle within 3-6 h, and the temperature is kept for 0.5-1h after dropwise addition; the residual initiator and the residual solvent are mixed uniformly and added into the reaction kettle within 20-40 min, the temperature is kept for 1-2 h after the addition is completed, a hydroxyl oligomer is added, stirring is performed for 30-60 min, the temperature is lowered for material discharge, and the high-solid low-viscosity hydroxy acrylic resin is obtained. The resin solid accounts for 70% or higher, the viscosity is as low as 300mPa*s. The technology for preparing the hydroxy acrylic resin is simple, the cost is low, and a bi-component polyurethane coating film has excellent water resistance, acid and alkali resistance and mechanical properties.

Owner:英德市佐桐化学品有限公司

A kind of method for graft copolymerization of starch and vinyl monomer

InactiveCN102276772AOvercome the disadvantage of difficult to obtain high solid content graft copolymerHigh solid contentBulk chemical productionOrganic solventEmulsion polymerization

The invention is relates to a method for grafting copolymerization of starch and a vinyl monomer. The invention is characterized in that the starch is taken as a substrate, vinyl monomer acrylamide, acrylic acid, acrylic acid ester, N,N-dimethyl diallyl ammonium chloride and the like are taken as a grafting copolymerization monomer, the graft copolymer of the starch and vinyl monomer can be obtained by adding an initiator to perform a grafting copolymerization reaction in a supercritical carbon dioxide system. Compared with the traditional technology of grafting copolymerization, the technology of the present invention overcomes the defect of low effective concentration of a traditional solution and obtains the high solid content, on the other hand, the defect of environmental pollution caused by using an anti-phase emulsion polymerization method can be overcome due to no organic solvent employed in the reaction process. The obtained grafting copolymerization product is in a looseningporous structure due to the existence of the supercritical carbon dioxide, the grafting copolymerization product is capable of easily dissolving which brings great convenience when the grafting copolymerization product is taken as a flocculating agent, and the grafting copolymerization product provides the materials with large adsorption potential due to the existence of a plurality of pores whenthe grafting copolymerization product is taken as a material for absorbing water and oil.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Preparation method of fish collagen combined chitosan biological dressing

ActiveCN103386144AUniform molecular weight distributionLess impuritiesAbsorbent padsFermentationBiological dressingSlurry

The invention discloses a preparation method of a fish collagen combined chitosan biological dressing. The preparation method comprises the following steps: cutting clean fish wastes, from which surface impurities are removed, into fish meal of 50-200 meshes; putting the fish meal in an airtight container and then adding distilled water and a reaction enzyme into the airtight container, and stirring to form slurry; reacting the slurry under high pressure and ultrasonic treatment; after the reaction is finished, subjecting the slurry to purification treatment; adding chitosan to the purified slurry, heating until the temperature is in a range from 80 DEG C to 90 DEG C and stirring for 20-30 minutes; and finally, carrying out dialysis, concentration and drying, thereby obtaining the fish collagen combined chitosan biological dressing. The preparation method disclosed by the invention is simple in process, easy to implement, convenient to operate, and low in cost; the quickly extracted fish collagen is even in molecular weight distribution and few in impurities; the prepared biological dressing is good in mechanical strength, and has the effects of stopping bleeding and promoting wound healing, and also has the effect of antibiosis.

Owner:HAINAN GUANGYU BIOTECH

Galactomannan antigen and preparation method thereof

InactiveCN104945527AHigh antigen purityEliminate distractionsAspergillus fumigatus AntibodyIon exchange

The invention relates to a preparation method of a galactomannan antigen. The method comprises the steps that breaking, centrifugation, alcohol precipitation, washing and drying are carried out on a living body rich in galactomannan, and galactomannan crude extract is obtained through separation; hydrazinolysis and hydrolysis are carried out on the obtained galactomannan crude extract in sequence; an enzyme is added to a hydrolysis product for enzymolysis, and the enzyme and small molecular substances in an enzymolysis product are removed; a product is purified through an ion exchange column, an affinity column and gel chromatography, and the pure galactomannan antigen is obtained; the obtained pure galactomannan antigen is identified. The galactomannan antigen obtained through the preparation method is high in purity, the inference of galactosamine, protein, miscellaneous sugar possibly included in the galactomannan crude extract is eliminated, and the preparation method can be used for preparing aspergillus fumigatus antibodies.

Owner:DYNAMIKER BIOTECH TIANJIN

Gelatin preparation process for acid process bone element gelatin

ActiveCN102827550ASave resourcesIncrease added valueGlue/gelatin preparationWater dischargePhosphoric acid

The invention relates to a gelatin preparation process for acid process bone element gelatin. The process is characterized in that animal bones are sequentially subjected to steps of crushing, degreasing, acid soaking, ash soaking, water washing, gelatin extraction, purification, concentration, sterilization, forming and drying to obtain the bone element gelatin; the ash soaking step comprises the processes that bone particles obtained after the acid soaking are soaked for 15 to 20 hours in lime emulsion with the concentration being 3 to 8 baume degree, then, the lime emulsion is completely discharged, 35-percent phosphoric acid water solution is added for treatment for 3 to 5 hours, and 5L of phosphoric acid water solution is added for each ton of bone grains. Through the optimized control and innovation on the gelatin preparation process, the material selection and the parameters, the technical problems of poor product performance stability and low yield in the gelatin preparation process for the acid process bone element gelatin are solved, the production period is shortened to 3 to 5 days, the waste water discharge quantity is low, the cost is low, in addition, the yield is as high as more than 90 percent, and good foundation is laid for the industrial scale production.

Owner:嘉兴佳斯贝特新材料有限公司

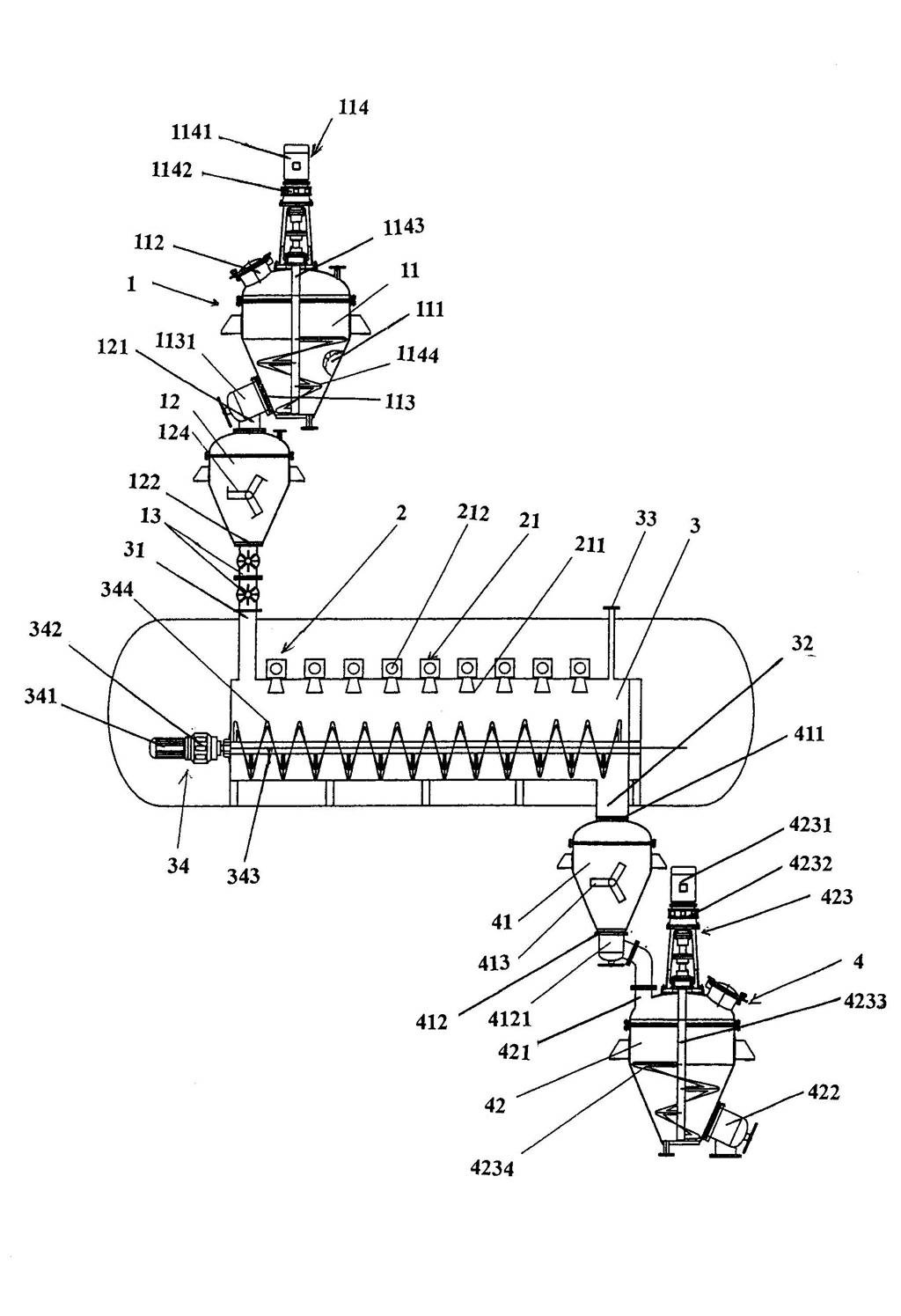

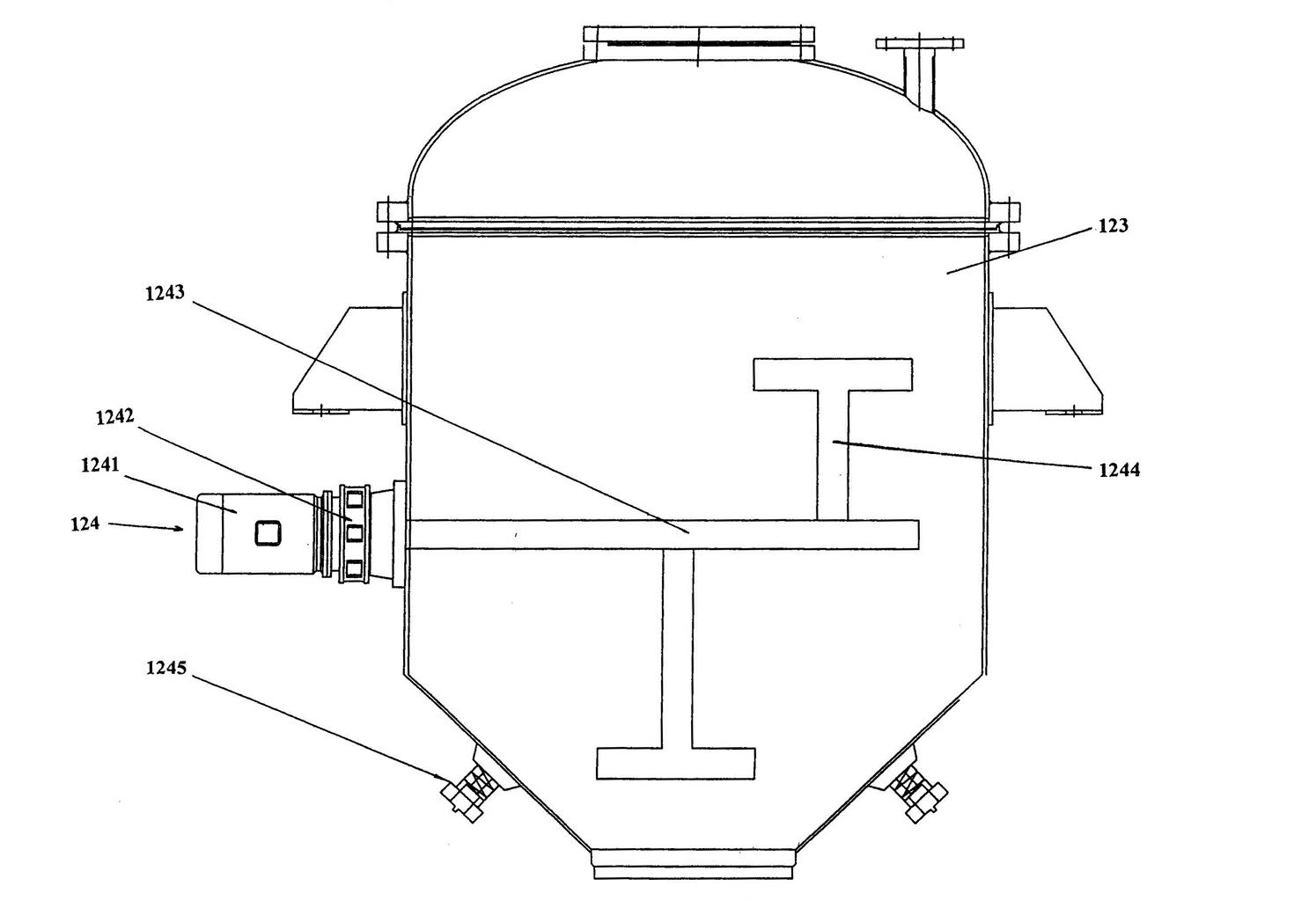

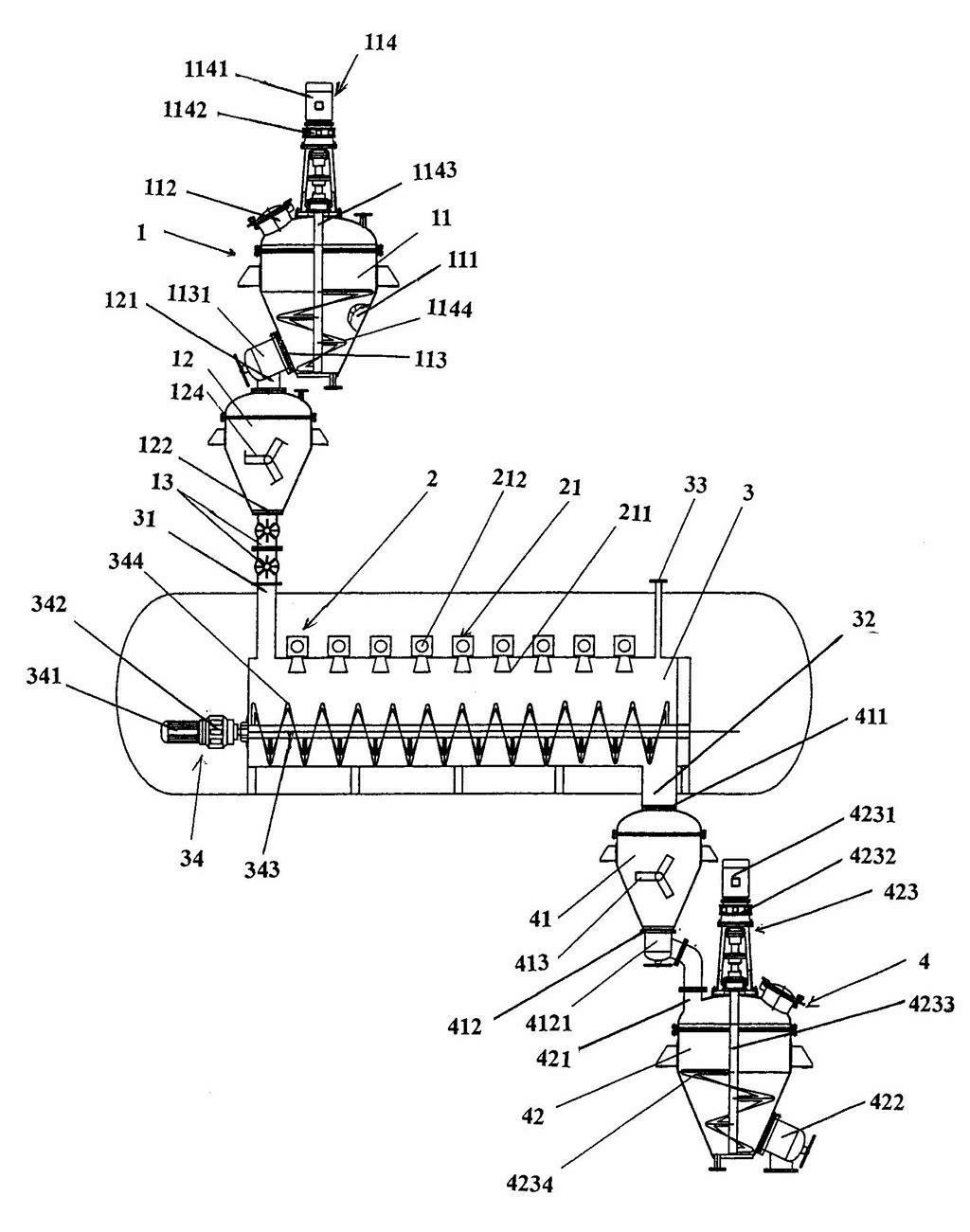

Continuous vacuum microwave drying device

ActiveCN102538425ADry fastHeating up fastDrying using combination processesDrying machinesVacuum dryingCopolymer

The invention discloses a continuous vacuum microwave drying device, and belongs to the technical field of drying devices. The device comprises a vacuum continuous feeding mechanism, a vacuum microwave dryer, a vacuum drying chamber and a vacuum continuous discharge mechanism, wherein the vacuum microwave dryer is arranged on the vacuum drying chamber and used for vacuum microwave drying of a material introduced into the vacuum drying chamber; the vacuum continuous feeding mechanism is connected with the feeding hole of the vacuum drying chamber; and the vacuum continuous discharge mechanism is connected with the discharge hole of the vacuum drying chamber. The device has the advantages that: the material is dried and processed by using microwave under the vacuum condition, the vacuum drying ensures that the material can be dried under the low-temperature condition, and the microwave drying of the material has instantaneous high efficiency, so that quick and continuous low-temperature drying of the material can be realized, the energy is saved and the drying efficiency is improved; and decomposition of alkaline-earth metal chlorides is reduced, so that the polymerization requirements of poly-p-phenylene terephthamide and copolymer thereof are met, and the molecular weight of the obtained polymer is distributed uniformly.

Owner:SINOCHEM HIGH PERFORMANCE FIBER MATERIALS CO LTD

Preparation method polyglycolic acid oligomer

The invention relates to a preparation method of a polyglycolic acid oligomer. The preparation method is mainly used for solving problems of the prior art that the content of impurities is large when the polyglycolic acid oligomer prepared via a conventional method is used for producing glycolide, and glycolide yield and purity are low. The preparation method comprises following steps: (1) normal pressure condensation polymerization, wherein glycollic acid crystals are subjected to staged reaction at normal pressure in the presence of a condensation catalyst or an ester exchange catalyst, wherein normal pressure prepolymerization is carried out for 0.5 to 10h at a temperature maintained to be higher than the melting point of glycollic acid and lower than the boiling point of glycollic acid at a step of first stage prepolymerization, and condensation reaction or ester exchange is carried out at 112 to 220 DEG C until no water is evaporated for a step of second stage condensation polymerization so as to obtain a molten glycollic acid oligomer; and (2) decompression polycondensation; and (3) strengthened polycondensation. The preparation method is capable of solving the problems above preferably, and can be applied to industrial production of glycolide.

Owner:CHINA PETROLEUM & CHEM CORP +1

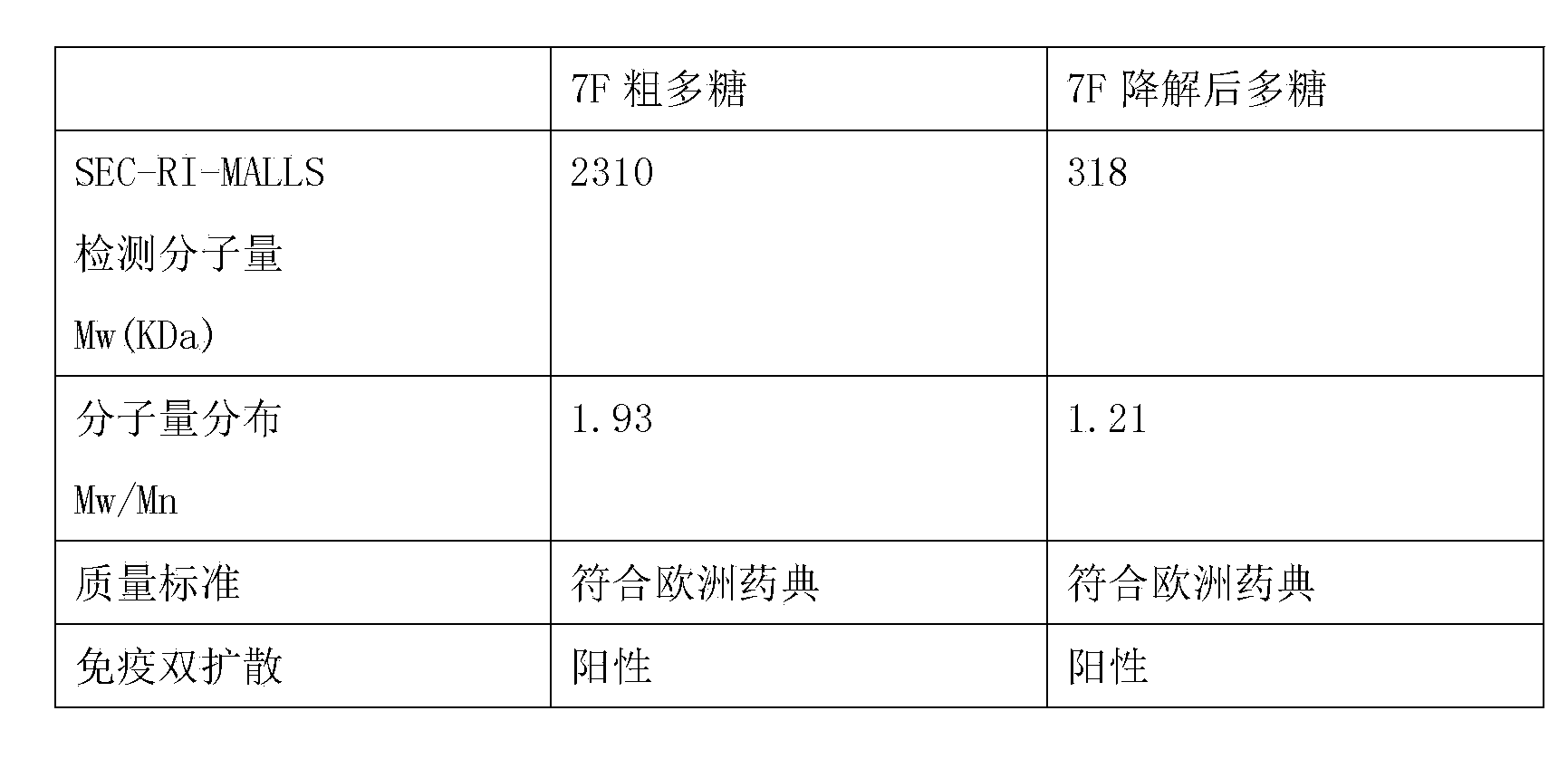

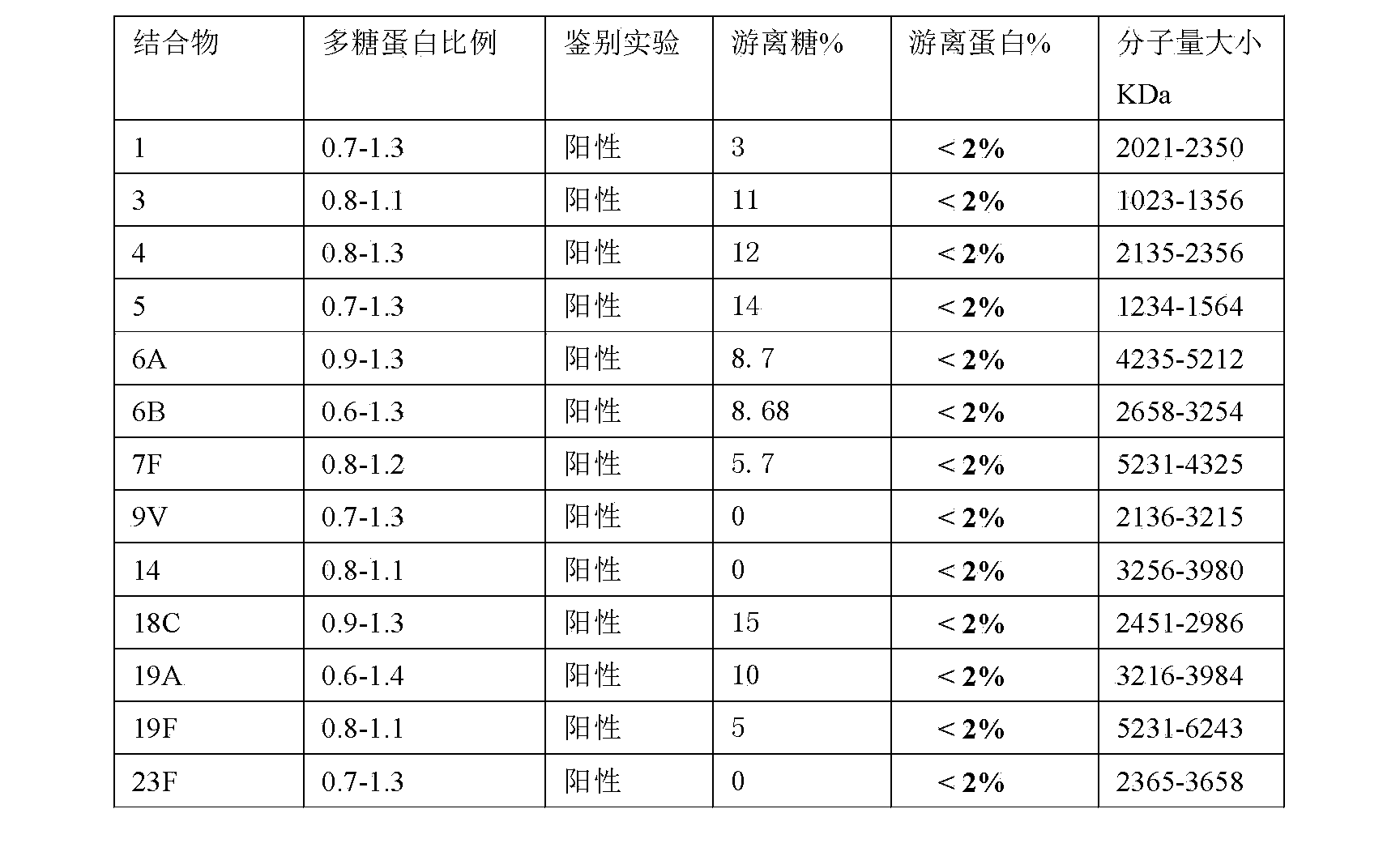

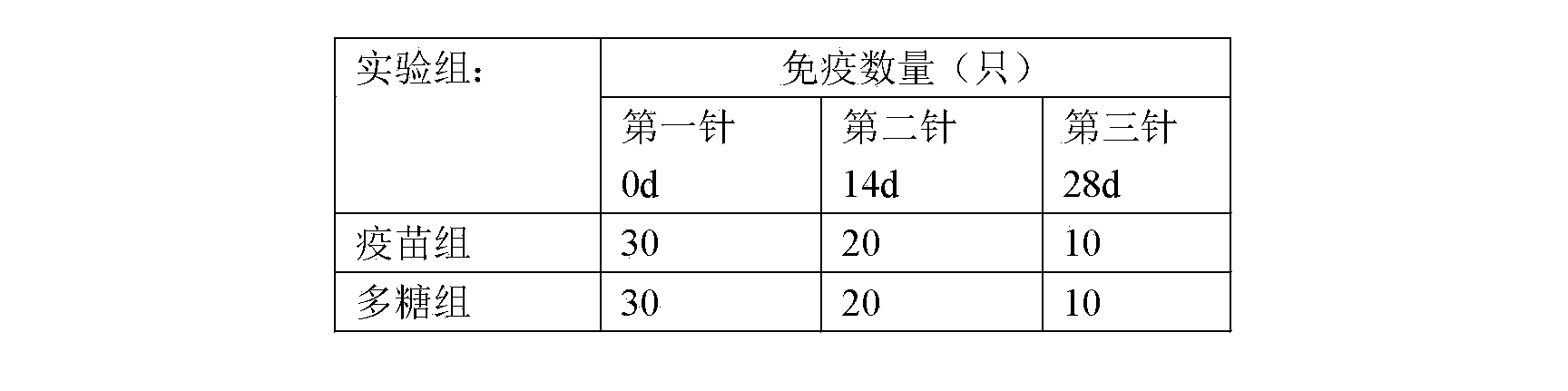

Preparation method of streptococcus pneumoniae capsular polysaccharide protein conjugate vaccine

InactiveCN103830723AIncrease coverageImprove cross protectionAntibacterial agentsBacterial antigen ingredientsConjugate vaccineStreptococcus pneumoniae capsular polysaccharide

The invention discloses a preparation method of a streptococcus pneumoniae capsular polysaccharide protein conjugate vaccine, which comprises the following steps: degrading extracted streptococcus pneumoniae capsular polysaccharide; and conjugating the degraded streptococcus pneumoniae capsular polysaccharide with a carrier protein, and preparing the vaccine preparation.

Owner:TIANJIN TASLY PHARMA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com