High-solid low-viscosity hydroxy acrylic resin as well as preparation method and application thereof

A technology of sticky hydroxyl acrylic acid and hydroxyl acrylic acid, which is applied in the field of organic polymer synthesis, can solve the problems of increasing the complexity and difficulty of resin synthesis process, which is not conducive to the promotion and application of industrialization, and the high VOC content of coatings, and achieves excellent weather resistance and energy saving Effect of low cost and molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

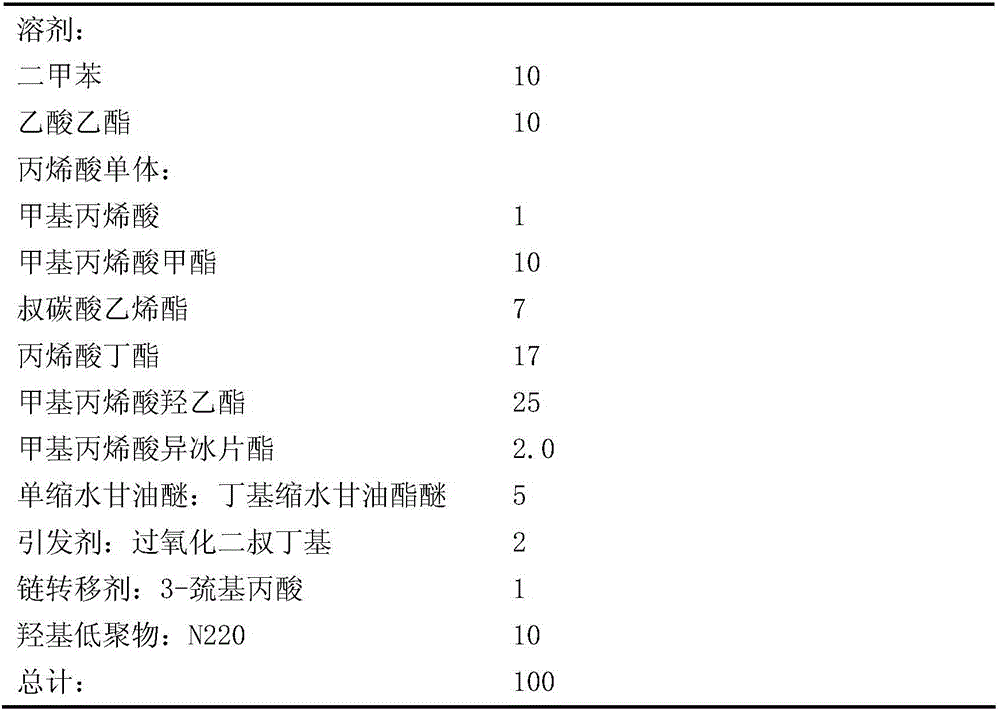

[0035] A high-solid low-viscosity hydroxyl acrylic resin, comprising the following formula components in parts by weight as shown in the table:

[0036] Table 1

[0037]

[0038] The preparation method of the high-solid low-viscosity hydroxyl acrylic resin comprises the following steps:

[0039] (1) Synthesis of hydroxyacrylic resin: add the first part of solvent and butyl glycidyl ether into the reaction kettle, stir and heat up to 140°C; add the first part of initiator and chain transfer agent into the acrylic monomer mixture, Add dropwise to the reaction kettle within 6 hours, and keep warm for 0.5h after dropping; mix the remaining initiator and solvent and add it to the reaction kettle within 40 minutes, and keep warm for 1 hour after dropping. The first solvent was a mixture of xylene and ethyl acetate. The first solvent accounts for 50% of the total mass of the solvent; the first initiator accounts for 80% of the total mass of the initiator. Acrylic monomers inclu...

Embodiment 2

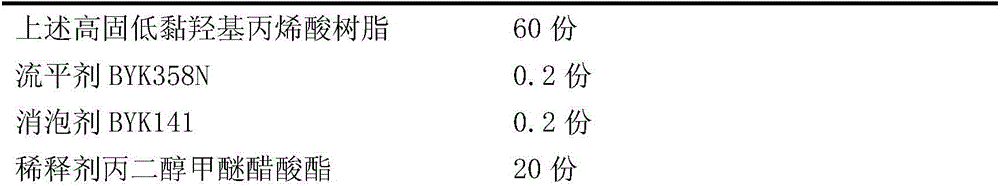

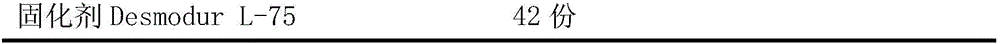

[0052] A kind of high-solid low-viscosity hydroxyl acrylic resin, comprises the raw material formulation component such as table 4 parts by weight:

[0053] Table 4

[0054]

[0055]

[0056] The preparation method of the high-solid low-viscosity hydroxyl acrylic resin specifically comprises the following steps:

[0057] (1) Synthesis of hydroxyacrylic resin: the first part of solvent and C 12-14 Add glycidyl ether (commercialized substance) into the reaction kettle, stir and heat up to 150°C; add 5 parts of the first initiator and chain transfer agent 2-mercaptoethanol to the acrylic acid monomer mixture, and add it dropwise to the reaction kettle within 3 hours. Kettle, keep warm for 1h after dropping; mix the remaining initiator and solvent and add it to the reaction kettle within 40min, keep warm for 2h after dropping. The first part of solvent accounts for 30% of the total mass of solvent; the first part of initiator accounts for 50% of the total mass of initiator...

Embodiment 3

[0069] A high-solid low-viscosity hydroxyl acrylic resin, comprising the raw material formulation components of the following table 7 parts by weight:

[0070] Table 7

[0071]

[0072] The preparation method of the high-solid low-viscosity hydroxyl acrylic resin comprises the following steps:

[0073] (1) Synthesis of hydroxyacrylic resin: 40% solvent and glycidyl tertiary carbonate are added to the reaction kettle, stirred and heated to 180°C; 70% initiator and chain transfer agent are added to the acrylic acid monomer mixture, Add dropwise to the reaction kettle within 3 hours, and keep warm for 0.5h after dropping; mix the remaining initiator and solvent and add it to the reaction kettle within 20 minutes, keep warm for 2 hours after dropping.

[0074] (2) Preparation of high-solid and low-viscosity hydroxyl acrylic resin: Add hydroxyl oligomers to the above resin, stir for 60 minutes, cool down and discharge to obtain high-solid and low-viscosity hydroxyl acrylic resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com