Preparation method of functionalized ultra-high molecular weight polyethylene resin

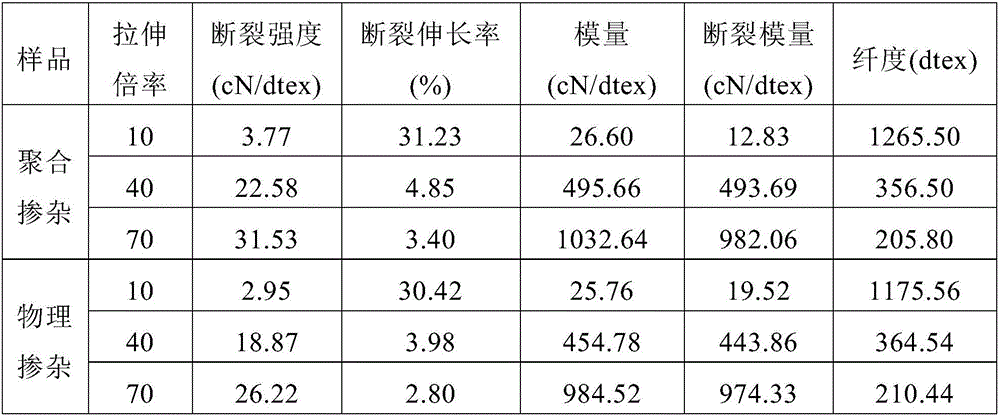

An ultra-high molecular weight, polyethylene resin technology, applied in the manufacture of single-component polyolefin rayon, conductive/antistatic filament, etc. The molecular weight is controllable, the production process is simple, and the molecular weight distribution is uniform.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for preparing a functional ultra-high molecular weight polyethylene resin, which adopts a low-pressure slurry method. The mass ratio of raw materials is 80-100 parts of ethylene, 80-200 parts of solvent oil, and 1-10 parts of modified additives. Heat the reactor to 50-100°C and vacuumize it for 1 hour, replace it with clean and dry nitrogen, add a certain amount of dried solvent oil and catalyst, start stirring, add a certain amount of nitrogen and hydrogen, and finally add ethylene to the reactor continuously to control Pressure 0.1-1.5MPa, temperature 50-100°C for 2-4 hours, after polymerization, quickly cool the reactor to 40°C, filter off solvent oil to obtain slurry, dry the slurry to obtain functional ultra-high molecular weight polyethylene resin. The molecular weight of functional ultra-high molecular weight polyethylene resin is between 80 and 10 million, the resin particles are uniform, the average particle size ranges from 100 to 300 μm, the particle ...

Embodiment 2

[0027] A kind of preparation method of functional ultra-high molecular weight polyethylene resin, ethylene 2750L (volume under standard conditions), solvent naphtha hexane 3800g, SiO 2 Mass 30g, using aluminum alkyl / TiCl 4 Catalyst, the temperature of the reaction kettle is set at 65-66°C, the stirring speed is 800r / min, and the reaction is 2h. Diameter distribution width (d90-d10) / d50: 0.966, bulk density (g / cm 3 ): 0.467.

Embodiment 3

[0029] This embodiment is basically the same as Example 1, the difference being that ethylene 2750L (volume under standard conditions), solvent naphtha hexane 3800g, TiO 2 Mass 103g, using aluminum alkyl / TiCl 4 Catalyst, set the temperature of the reactor at 65-66°C, rotate at 800r / min, react for 2 hours, and finally obtain a resin with a molecular weight of 5.38 million, a volume average particle size of 198.713 μm, a particle size distribution width (d90-d10) / d50: 1.214, and accumulation Density (g / cm 3 ): 0.497.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com