Fluorine-containing waterproofing agent for textiles and method for preparing same

A water repellent and fabric technology, applied in textiles, papermaking, fiber processing, etc., can solve the problems of large amount of fluorine-containing monomers and high cost, and achieve the effects of low cost, improved performance and good waterproof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

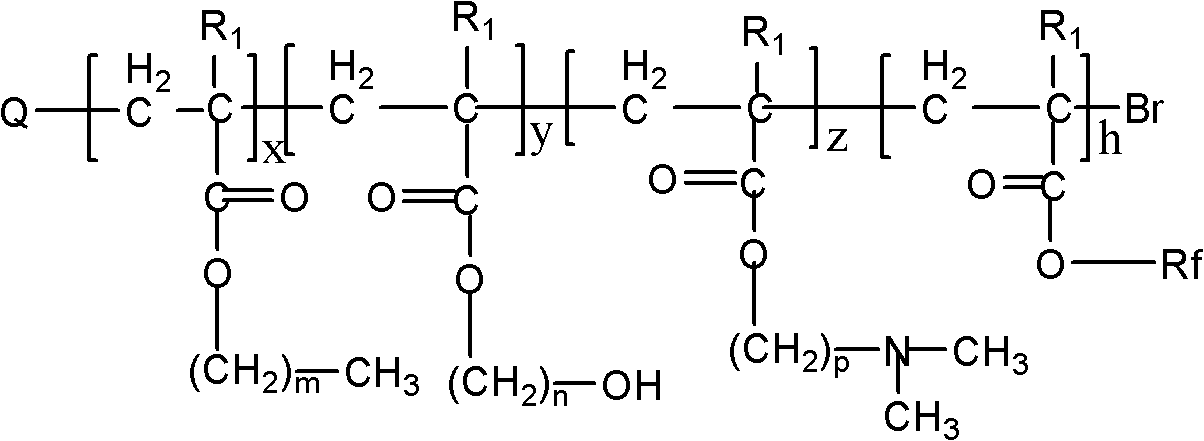

[0039] Embodiment 1: the molecular weight of fluorine-containing block copolymer is 10000, and the structure is:

[0040]

[0041] A. Preparation of fluorine-containing block copolymer:

[0042] In a 500ml four-necked flask, add 78g (0.5485mol) of butyl methacrylate, 10g (0.06360mol) of dimethylaminoethyl methacrylate, 2g (0.01537mol) of hydroxyethyl methacrylate, and the initiator α-bromo Ethyl isobutyrate 1.948g (0.01mol), CuBr 2 0.03504g (0.1569mmol) and PMDETA 0.2714g (1.569mmol) catalyst complex, reducing agent Sn(EH) 2 5.0961g (0.01256mol), solvent toluene 45g (50% of the monomer mass), after mixing evenly, nitrogen gas was passed for 1h, and reacted in an oil bath at 85°C for 4h. After the conversion rate reached 85%, a light yellow viscous product was obtained . Then, 10 g of trifluoroethyl acrylate and 5 g of toluene were added to the reaction vessel, and the reaction was continued for 3 h. After the reaction, a yellow viscous substance was obtained, and the c...

Embodiment 2

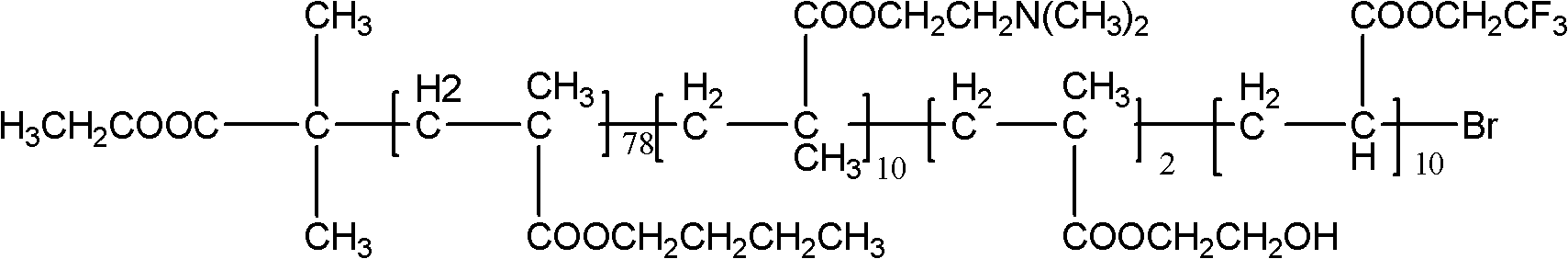

[0047] Embodiment 2: the molecular weight of fluorine-containing block copolymer is 10000, and the structure is:

[0048]

[0049] A. Preparation of fluorine-containing block copolymer:

[0050] Add 73g (0.8488mol) of butyl acrylate to a 500ml four-necked flask, 10g (0.06360mol) of dimethylaminoethyl methacrylate, 2g (0.01537mol) of hydroxyethyl methacrylate, and the initiator α-bromoisobutyl Ethyl acetate 1.948g (0.01mol), CuBr 2 0.04740g (0.2122mmol) and PMDETA 0.3671g (2.122mmol) catalyst complex, reducing agent Sn(EH) 2 3.4437g (0.008488mol), solvent toluene 45g (50% of the monomer mass), after mixing evenly, nitrogen gas was passed for 1h, and then reacted in an oil bath at 85°C for 4h. After the conversion rate reached 85%, a light yellow viscous product was obtained . Then, 15 g of hexafluorobutyl methacrylate and 7.5 g of toluene were added to the reaction vessel, and the reaction was continued for 3 h. After the reaction, a yellow viscous substance was obtain...

Embodiment 3

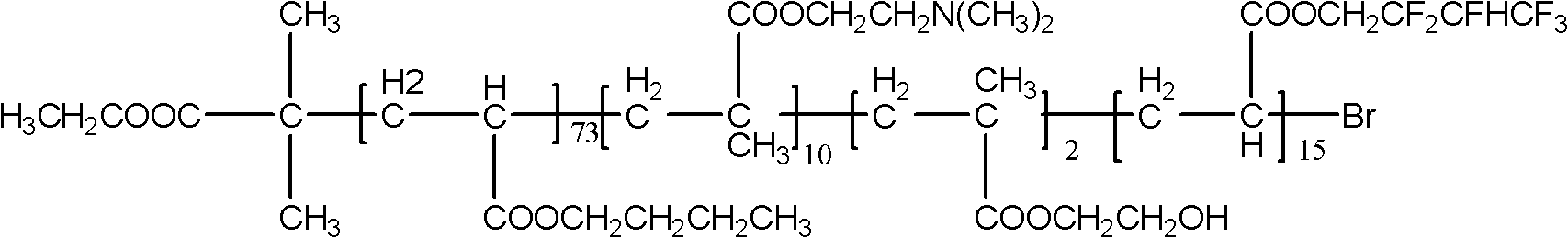

[0055] Embodiment 3: the molecular weight of fluorine-containing block copolymer is 10000, and the structure is:

[0056]

[0057] A. Preparation of fluorine-containing block copolymer:

[0058] In a 500ml four-necked flask, add 68g (0.7907mol) of methyl acrylate, 10g (0.06360mol) of dimethylaminoethyl methacrylate, 2g (0.01537mol) of hydroxyethyl methacrylate, and the initiator α-bromoisobutyl Ethyl acetate 1.948g (0.01mol), CuBr 2 0.03792g (0.1698mmol) and PMDETA 0.2937g (1.698mmol) catalyst complex, reducing agent Sn(EH) 2 2.7554g (0.00679mol), solvent toluene 45g (50% of the monomer mass), after mixing evenly, nitrogen gas was passed for 1h, and then reacted in an oil bath at 85°C for 4h. After the conversion rate reached 85%, a light yellow viscous product was obtained . Then, 5 g of dodecafluoroheptyl methacrylate and 2.5 g of toluene were added to the reaction vessel, and the reaction was continued for 3 h. After the reaction, a yellow viscous substance was obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com