Patents

Literature

320results about How to "Composition is easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Load type non-metallocene catalyst, preparation method and application thereof

ActiveCN102039186AThe load is easy to controlSimple processOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationChemistryAlkene

The invention relates to a load type non-metallocene catalyst and a preparation method thereof. The load type non-metallocene catalyst has the characteristics of simple preparation method, flexible and adjustable polymerization activity and the like. The invention also relates to the application of the load type non-metallocene catalyst in olefin homopolymerization / copolymerization. Compared withthe prior art, the application has the characteristic of less cocatalyst amount.

Owner:CHINA PETROLEUM & CHEM CORP +1

Supported non-metallocene catalyst as well as preparation method and application thereof

ActiveCN102039184AComposition is easy to controlThe content is easy to controlOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationChemical treatmentAlkene

The invention relates to a supported non-metallocene catalyst and a preparation method thereof. The catalyst has the characteristics of simple and practical preparation method, flexible and adjustable polymerization activity and the like, and the non-metallocene compound in the catalyst and the chemical treatment agent have synergy beneficial to giving play to activity. The invention also relatesto an application of the supported non-metallocene catalyst in olefin homopolymerization / copolymerization. Compared with the prior art, the catalyst is characterized in that the dosage of the promoter is less in the application.

Owner:CHINA PETROLEUM & CHEM CORP +1

Supported non-metallocene catalyst, its preparation method and uses

ActiveCN102039185AThe load is easy to controlSimple processOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationChemistryAlkene

The invention relates to a supported non-metallocene catalyst and its preparation method. The preparation method of the supported non-metallocene catalyst is characterized by simple and convenient preparation method, flexible and adjustable polymerization activity etc. The invention also relates to use of the supported non-metallocene catalyst in homopolymerization / copolymerization of alkenes, and less co-catalysts are required compared with the prior art.

Owner:CHINA PETROLEUM & CHEM CORP +1

Supported non-metallocene catalyst, its preparation method and uses

ActiveCN102039188AThe load is easy to controlSimple processOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationChemical treatmentCompound (substance)

The invention relates to a supported non-metallocene catalyst and its preparation method. The supported non-metallocene catalyst is characterized by simple preparation method, flexible polymerization activity etc. In addition, non-metallocene complexes in the catalyst cooperate with the chemical disposal agent to enhance the activity. The invention also relates to the application of the supportednon-metallocene catalyst in alkene homopolymerization / copolymerization. Less amount of co-catalyst is required in use compared with the prior art.

Owner:CHINA PETROLEUM & CHEM CORP +1

Load type non-metallocene catalyst, preparation method and application thereof

ActiveCN102039191AComposition is easy to controlThe content is easy to controlOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationChemical treatmentOrganic chemistry

The invention relates to a load type non-metallocene catalyst and a preparation method thereof. The load type non-metallocene catalyst has the characteristics of simple preparation method, flexible and adjustable polymerization activity and the like, and synergistic reaction which is beneficial to activity development is formed between non-metallocene complexes and chemical conditioning agents inthe catalyst. The invention also relates to the application of the load type non-metallocene catalyst in olefin homopolymerization / copolymerization. Compared with the prior art, the application has the characteristic of less cocatalyst amount.

Owner:CHINA PETROLEUM & CHEM CORP +1

Loaded non-metallocene catalyst and preparation method and application thereof

ActiveCN102059153AThe load is easy to controlAdjust molecular weightOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationMetalloceneChemistry

The invention relates to a loaded non-metallocene catalyst and a preparation method and application thereof. The loaded non-metallocene catalyst has the characteristics of simple and practicable preparation method, flexible and adjustable polymerization activity and the like. The invention also relates to the application of the loaded non-metallocene catalyst to the homopolymerisation / copolymerization of olefin. Compared with the prior art, the application has the characteristic of small using amount of a cocatalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Loaded non-metallocene catalyst and preparation method and application thereof

ActiveCN102059151AThe load is easy to controlEvenly distributedOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationChemistryMetallocene

The invention relates to a loaded non-metallocene catalyst and a preparation method and application thereof. The loaded non-metallocene catalyst has the characteristics of simple and practicable preparation method, flexible and adjustable polymerization activity and the like. The invention also relates to the application of the loaded non-metallocene catalyst to the homopolymerisation / copolymerization of olefin. Compared with the prior art, the application has the characteristic of small using amount of a cocatalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Lubricity coatings preparation method on the medical catheter polymers surface

InactiveCN101455861AImprove surface physicochemical propertiesChange adsorption stateCatheterCoatingsPolymer scienceGraft reaction

The invention discloses a method for preparing a lubricant coating on the surface of polymer materials of a medical catheter, which comprises the following steps: (A), pretreating the surface of the polymer materials of the medical catheter, so as to obtain hydrophilic adsorption active sites; (B), soaking the pretreated polymer materials of the medical catheter in step (A) into a prepared precursor solution of the lubricant coating for adsorption; and (C), performing grafting reaction on the soaked polymer materials of the medical catheter in step (B), and washing and drying the polymer materials of the medical catheter. The method can be widely used for preparing medical polymer materials and coating materials on the surface of a medical apparatus.

Owner:SOUTHEAST UNIV

Block poly-carboxylic acid concrete high-efficiency water reducing agent and preparation method thereof

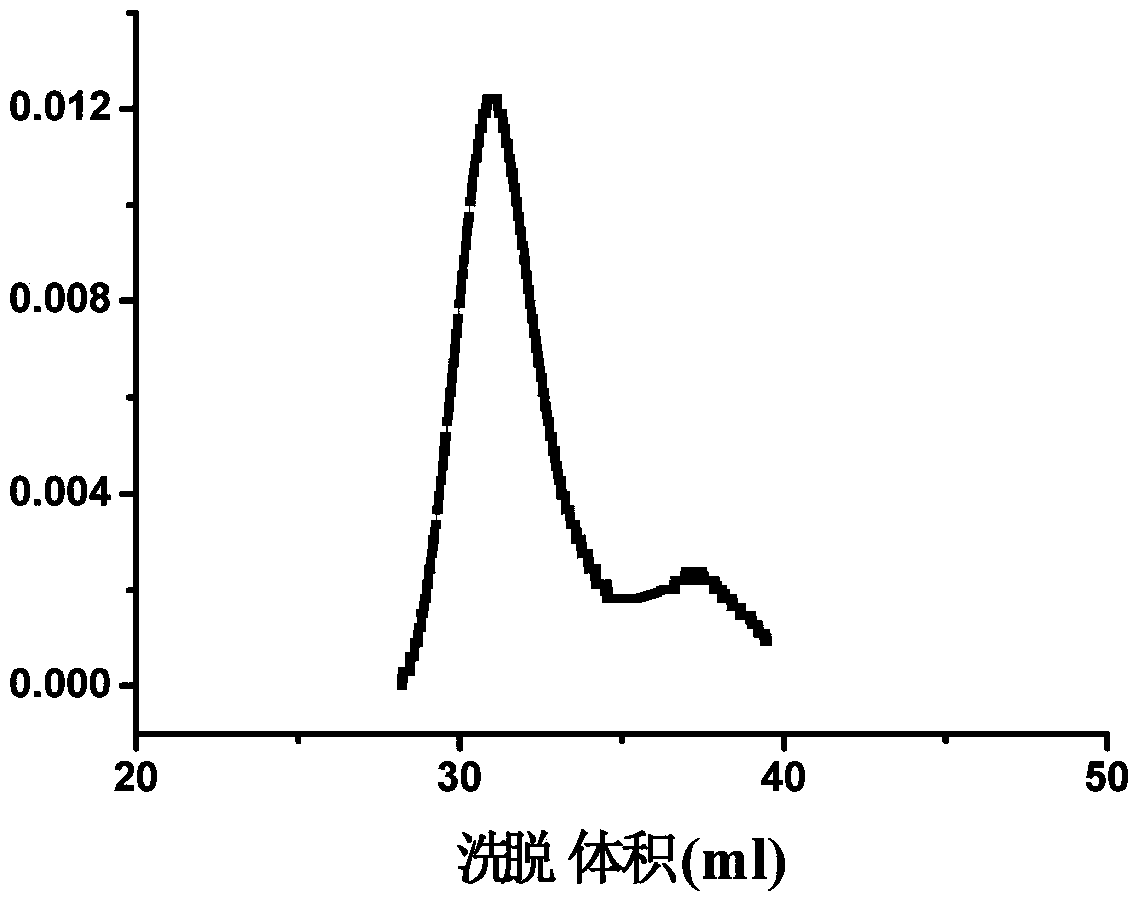

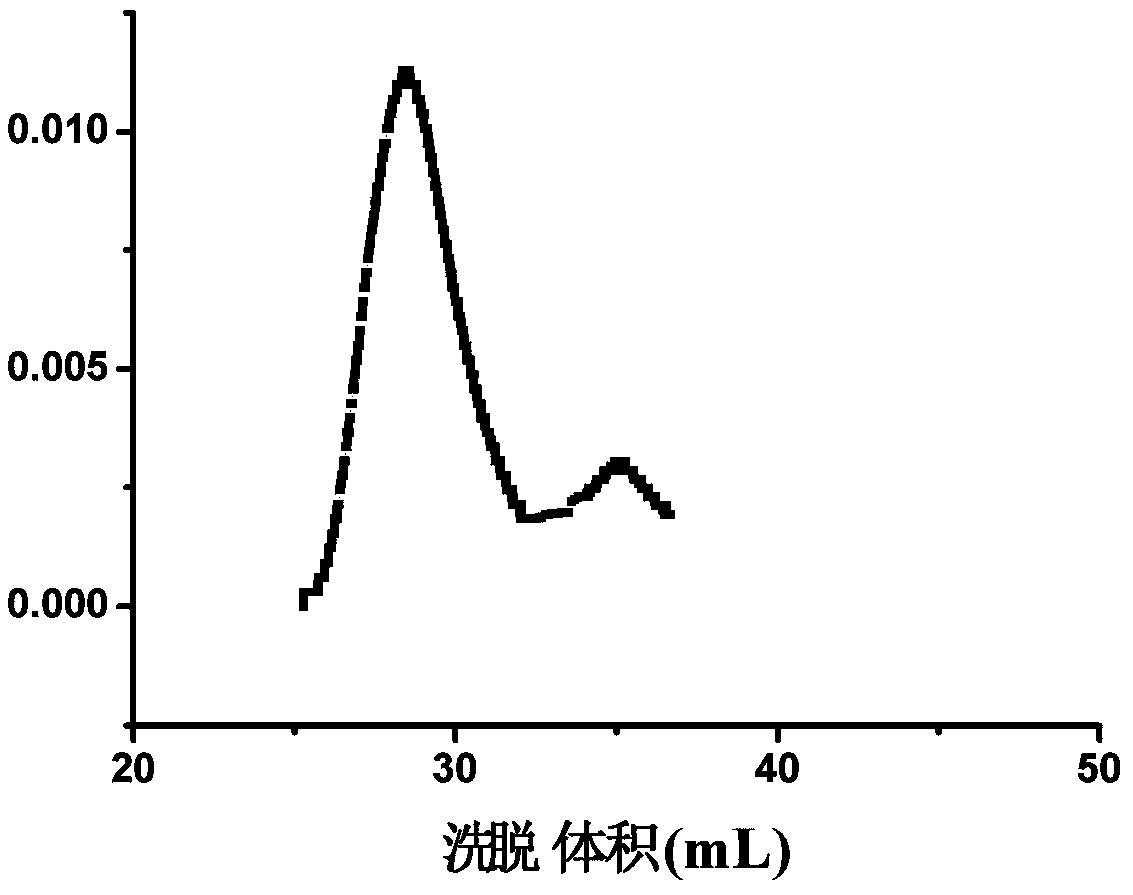

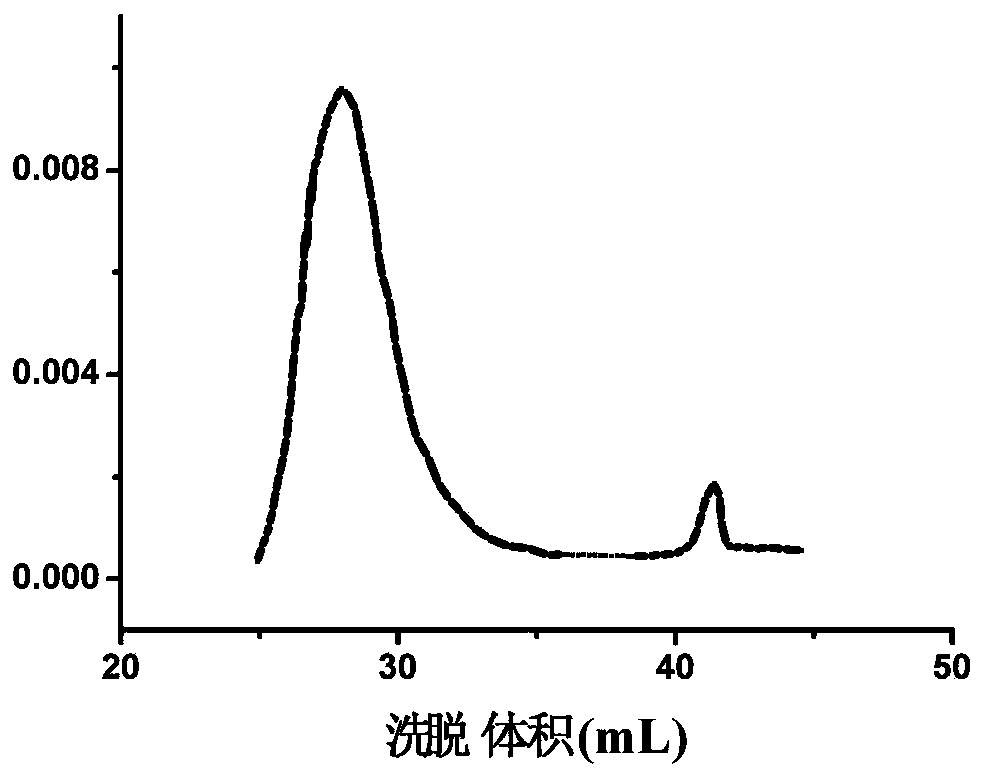

ActiveCN103482897AControl structureControl its molecular weight distributionStructural regularityPolymer science

The invention provides a block poly-carboxylic acid concrete high-efficiency water reducing agent with an ordered structure and a preparation method thereof. The block poly-carboxylic acid is prepared by using atom transfer radical polymerization, the structural regularity and the molecular weight distribution of the poly-carboxylic acid are controlled effectively, and the water reducing agent is used in a cement dispersing process. By adoption of the block poly-carboxylic acid concrete high-efficiency water reducing agent and the preparation method thereof, the problems of uncontrollable molecular weight of the poly-carboxylic acid, wider molecular weight distribution, un-designable molecular structure and the like are solved.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

Loaded non-metallocene catalyst and preparation method and application thereof

ActiveCN102059152AThe load is easy to controlAdjust molecular weightOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationAlkeneMetallocene

The invention relates to a loaded non-metallocene catalyst and a preparation method and application thereof. The loaded non-metallocene catalyst has the characteristics of simple and practicable preparation method, flexible and adjustable polymerization activity and the like. The invention also relates to the application of the loaded non-metallocene catalyst to the homopolymerisation / copolymerization of olefin. Compared with the prior art, the application has the characteristic of small using amount of a cocatalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

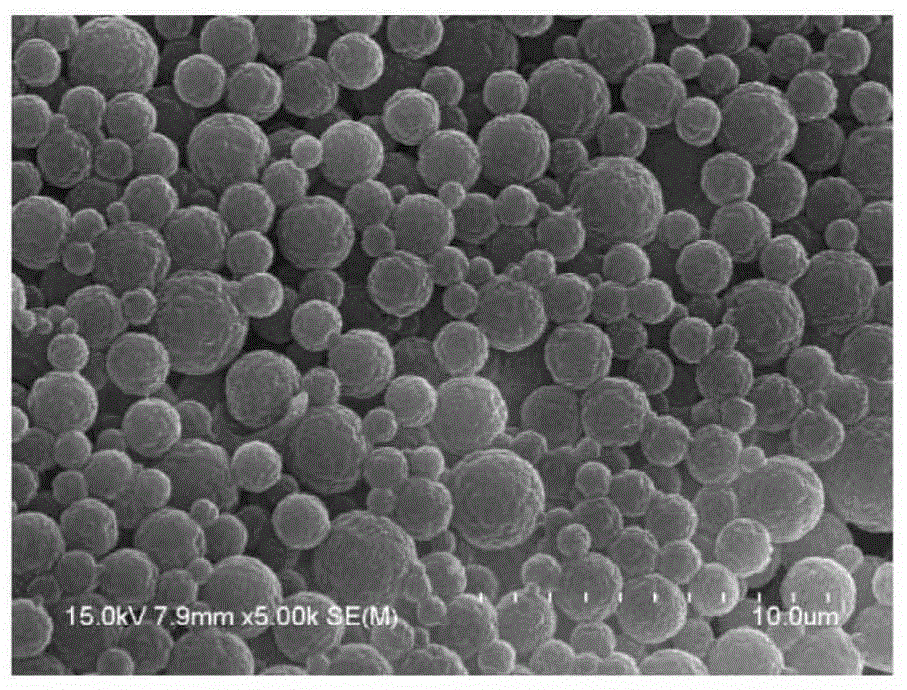

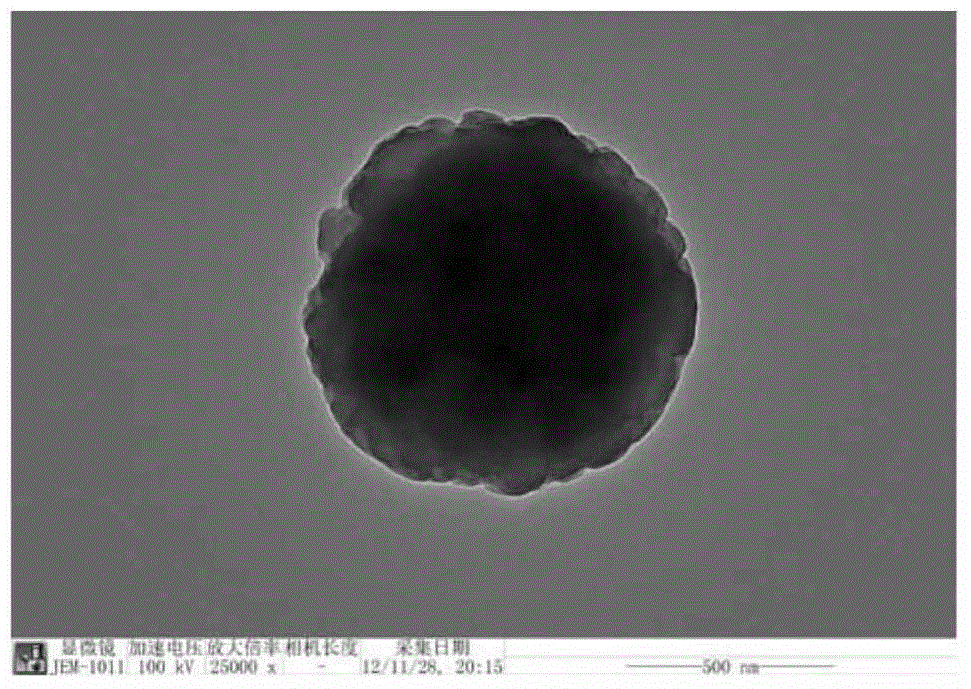

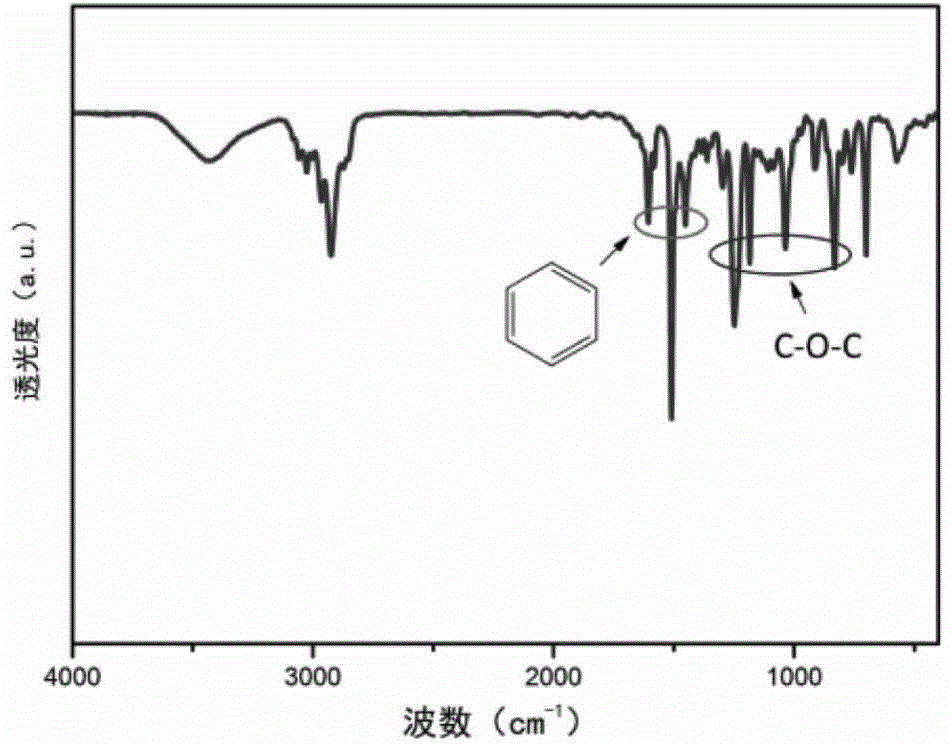

Epoxy resin self-repairing microcapsule and preparation method thereof

InactiveCN104624132AComposition is easy to controlImprove stabilityMicroballoon preparationMicrocapsule preparationEpoxyEmulsion polymerization

The invention provides an epoxy resin self-repairing microcapsule and a preparation method thereof. The method comprises the following steps: mixing a water phase containing inorganic nanoparticles and water with an oil phase containing epoxy resin, monoolefin monomer, a polyene cross-linking agent and an initiator to form a stable oil-in-water emulsion; and heating the emulsion to realize emulsion polymerization in order to form the epoxy resin self-repairing microcapsule. The epoxy resin self-repairing microcapsule is prepared by adopting the inorganic nanoparticles as an emulsifier through an emulsion polymerization process via the method; and compared with methods adopting molecular emulsifiers, the method provided by the invention has the advantages of no need of subsequent emulsifier removal, simple process, and no pollution to environment. The epoxy resin self-repairing microcapsule prepared in the invention has the advantages of excellent stability, excellent leakproofness and high cladding rate.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Method for preparing poly organic polysulfide/sulfonated graphene conductive composite material

The invention relates to a method for preparing poly organic polysulfide / graphene conductive composite material, which is characterized by taking water-soluble sulfonated graphene as a carrier and adopting an in-situ oxidation polymerization method to deposit poly organic polysulfide on the surface of the grapheme so as to prepare the poly organic polysulfide / graphene conductive composite material. The composite material has high conductivity and excellent electrochemical properties and can be used as anode material of lithium secondary batteries.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for preparing MgAlON transparent ceramic in pressureless sintering way

ActiveCN101817683AAccelerate the reaction processReduce energy consumptionFluoride saltPressureless sintering

The invention relates to a method for preparing MgAlON transparent ceramic, in particular to a method for preparing MgAlON transparent ceramic in a pressureless sintering way. The method is characterized by comprising the following steps of: (1) preparing MgAlON transparent ceramic powder; (2) mixing 95 to 99 percent by weight of MgAlON transparent ceramic powder and 0.1 to 5 percent by weight of fluoride, dispersing in absolute ethanol, and ball-milling to obtain slurry B; (3) drying the slurry B to obtain a mixture B; (4) carrying out pressing molding on the mixture B under the normal temperature by adopting axial mould pressing and then carrying out cold isostatic pressing to obtain a ceramic bisque; and (5) sintering to obtain the MgAlON transparent ceramic. The MgAlON transparent ceramic can obtain high-density (more than 99.5 percent) and excellent optical property without the processes of hot isostatic sintering, and the like; the optimal linear transmissivity of a flat material with the thickness of 2 mm within the wavelength range of 0.25 to 6mu m is more than 70 percent; and the material can be widely applied to various windows, shades, transparent safeguards, lamp tubes, optical devices, and the like.

Owner:WUHAN UNIV OF TECH

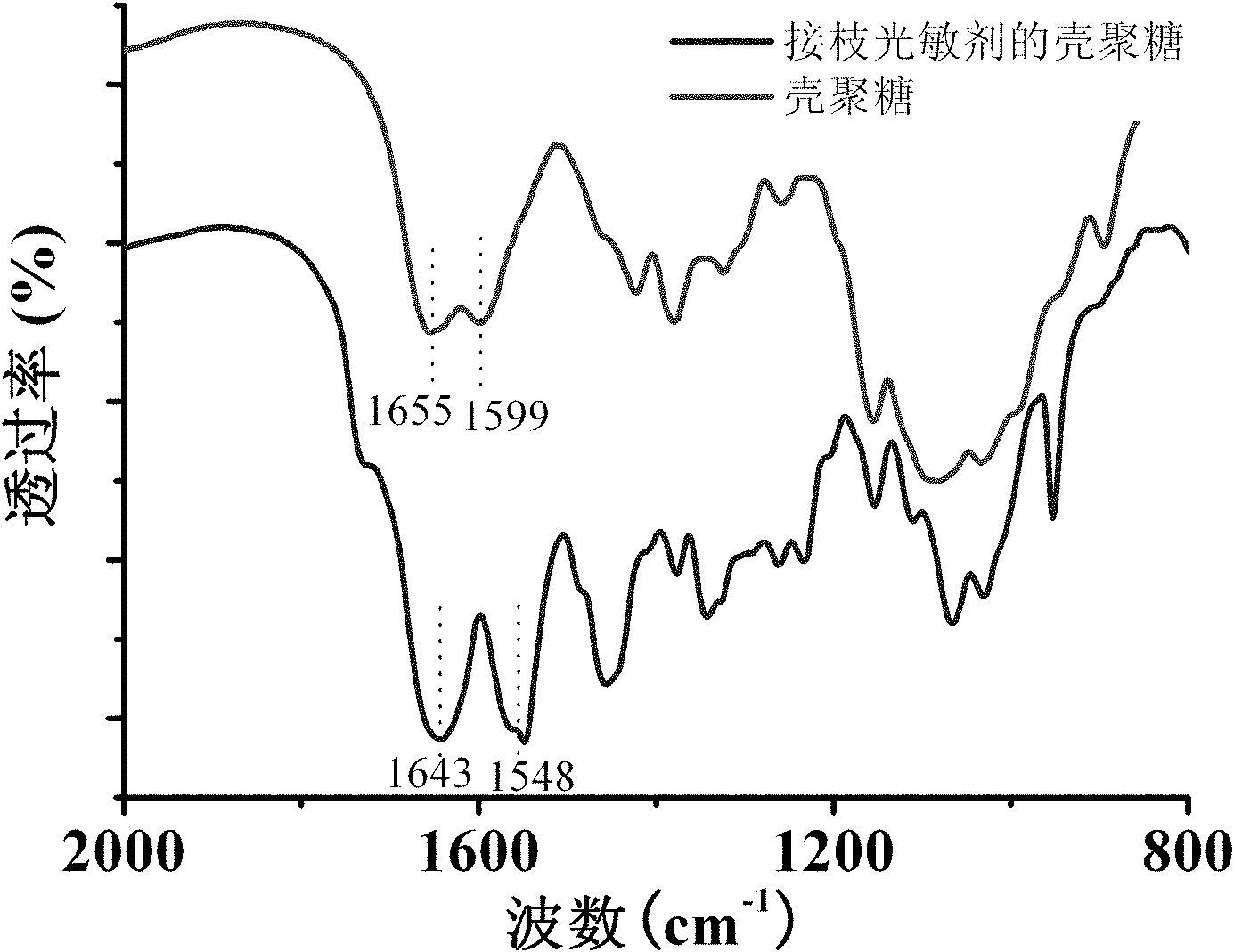

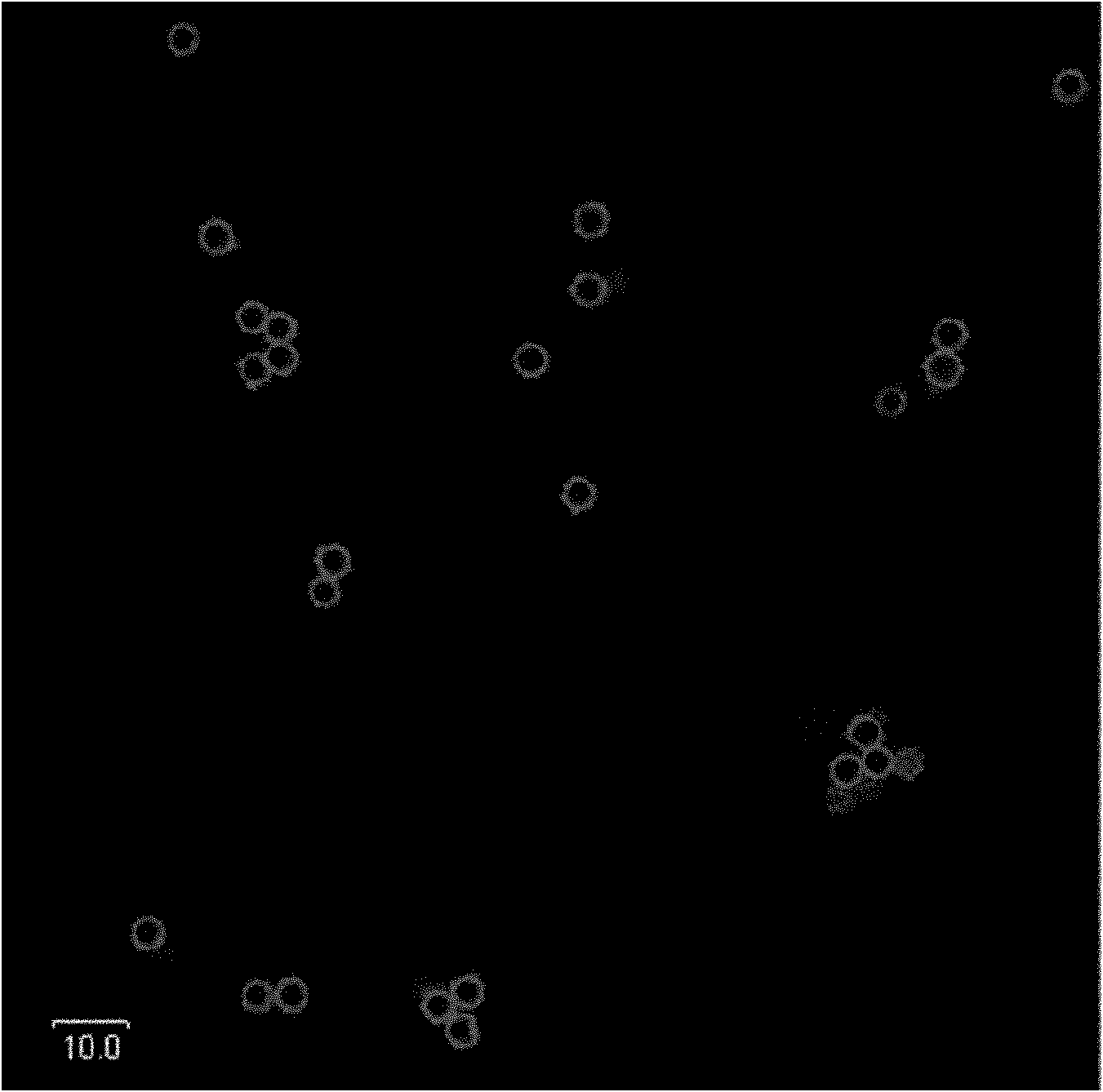

Photosensitive microcapsule used for photodynamic therapy and preparation method thereof

InactiveCN102133208AIncrease surface chargeEasy to assembleEnergy modified materialsPharmaceutical non-active ingredientsCancer cellMicrosphere

The invention discloses a photosensitive microcapsule used for photodynamic therapy and a preparation method thereof, belonging to the technical field of photosensitive polymer thin film materials. The photosensitive microcapsule is prepared by the following steps: firstly, preparing photosensitive polymer materials of photosensitizer molecule graft polymer, and then adopting the layer self assembly technology, assembling polyelectrolyte materials with opposite charges on a microballoon template, and preparing a hollow capsule assembled by a plurality of capsule walls, wherein materials of the capsule walls include natural polymer glycan (CHI) or glucan directly grafted with photosensitizer by chemical bonds. The photosensitive microcapsule has good biocompatibility, fixes photosensitive molecules, can kill cancer cells effectively, can be applied to (Photodynamic Therapy) PDT, and is good in water dispersion and uniform in particle size, high in single-state oxygen content yield under the illumination of beams with specific wavelength, simple in process and easy in operation.

Owner:BEIJING UNIV OF CHEM TECH

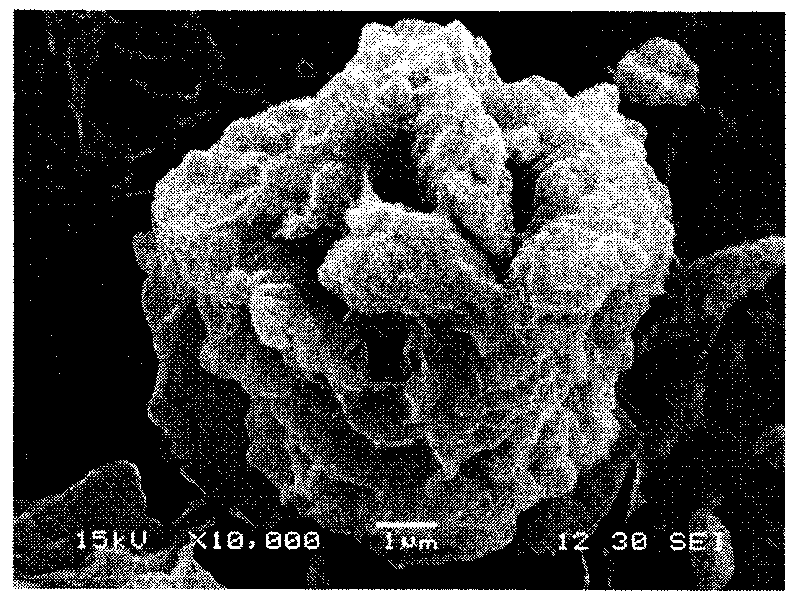

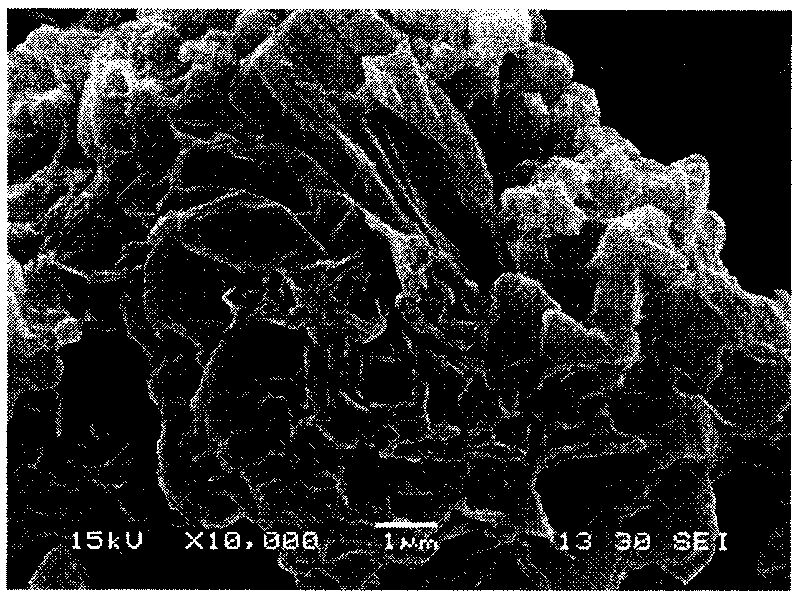

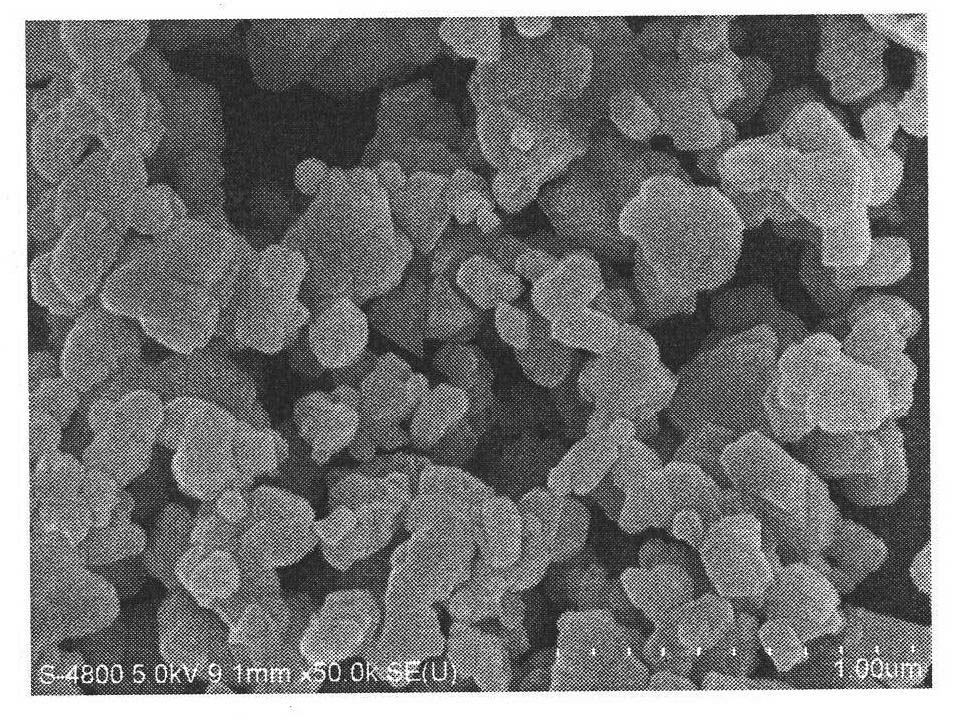

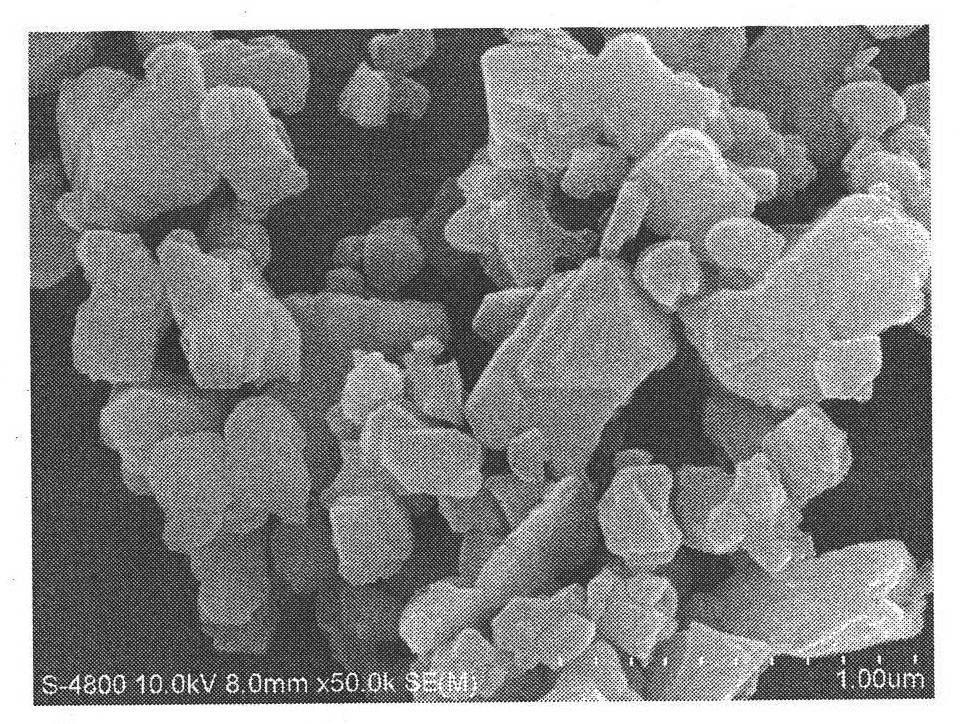

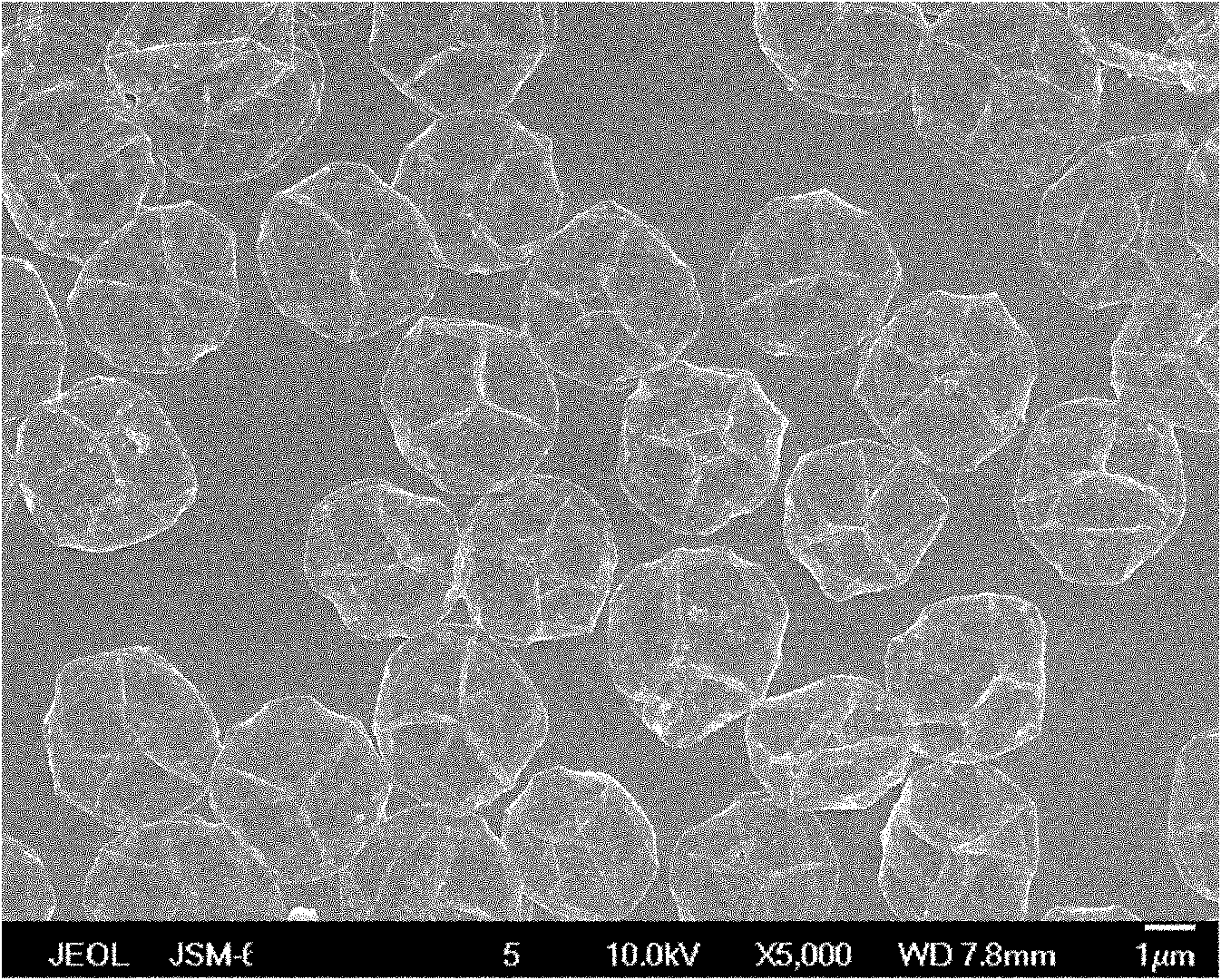

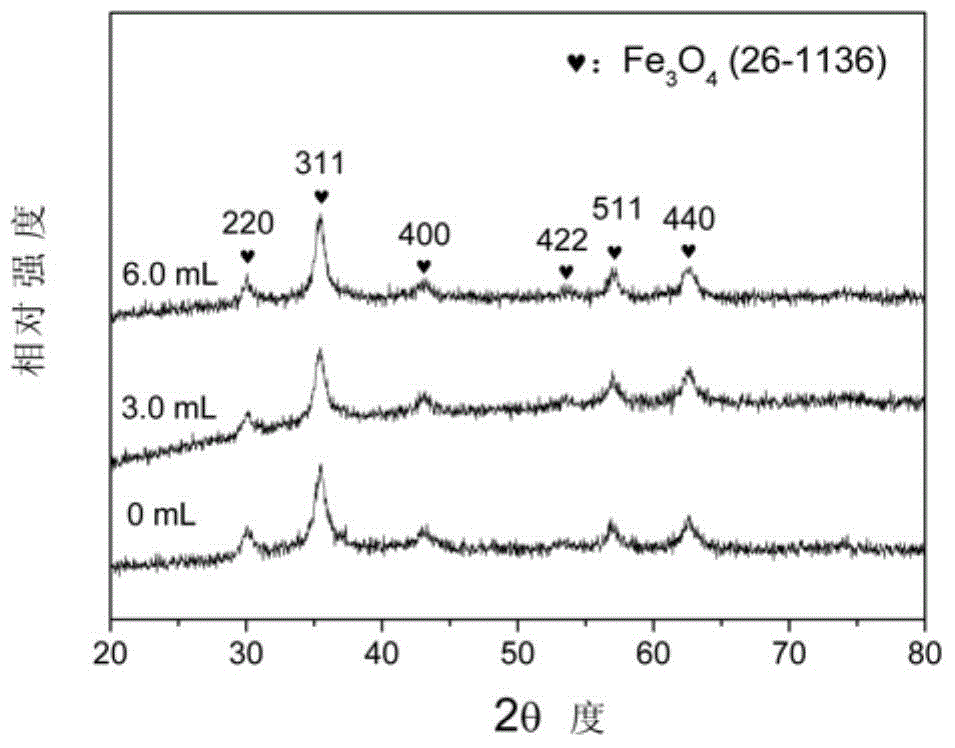

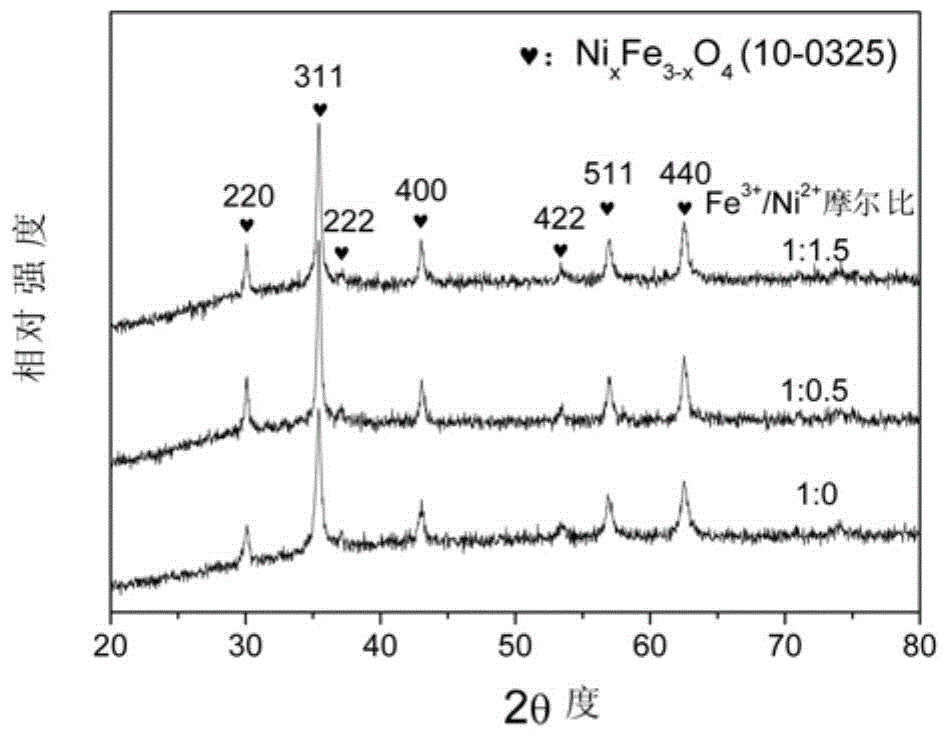

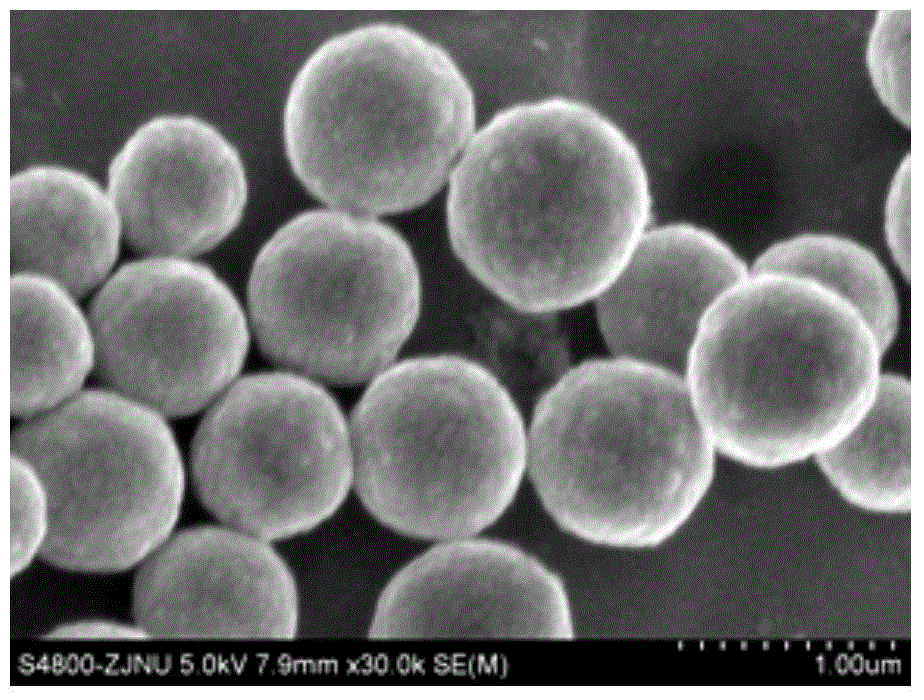

Multi-scale uniform and single-dispersion magnetic microsphere and preparation method thereof

ActiveCN104538145AEasy to prepareGood repeatabilityInorganic material magnetismMicroballoon preparationMicrometerMetal

The invention discloses a multi-scale uniform and single-dispersion magnetic microsphere and a preparation method of the multi-scale uniform and single-dispersion magnetic microsphere. The multi-scale uniform and single-dispersion magnetic microsphere comprises spinel structure ferrite doped with transition metal elements, the microsphere is a polycrystal micro-nano sphere which is formed by nanocrystalline in an aggregation mode, the diameter of the microsphere ranges from 20nm to 1.23 micrometers, the specific surface area of the microsphere ranges from 0.94 m<2>*g<-1> to 17.31 m<2>*g<-1>, and the size of the nanocrystalline ranges from 9.2nm to 25.8nm. A mixed solvothermal method is adopted, and the size and the composition of particles can be adjusted through adjustment of the volume fraction of water or the ratio of iron to other transition metal salt. According to the preparation method, raw materials are low in price, and can be easily obtained, the cost is low, the technology is simple, the requirement for equipment is low, efficiency is high, and popularization is easy; the multi-scale uniform and single-dispersion magnetic microsphere has the advantages that single dispersion and uniformity are good, and the size and the composition can be adjusted; the multi-scale uniform and single-dispersion magnetic microsphere can have the broad application prospect in the fields such as the magneto-rheological field, the magnetic separation field, the catalysis field, the electrode material field, the pigment field, the high-density magnetic recording material field and the medical diagnosis field.

Owner:ZHEJIANG NORMAL UNIVERSITY

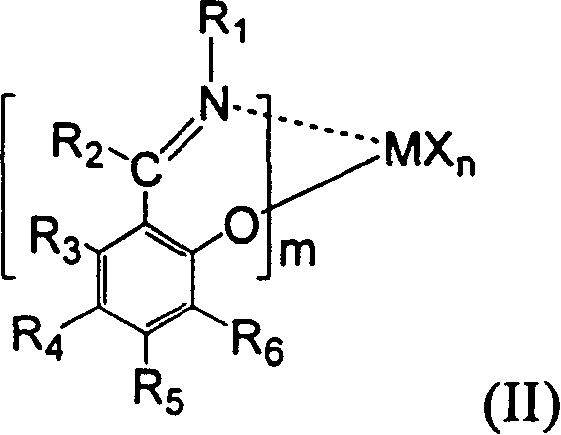

Olefin/polar alpha-olefin copolymer and preparation method and uses

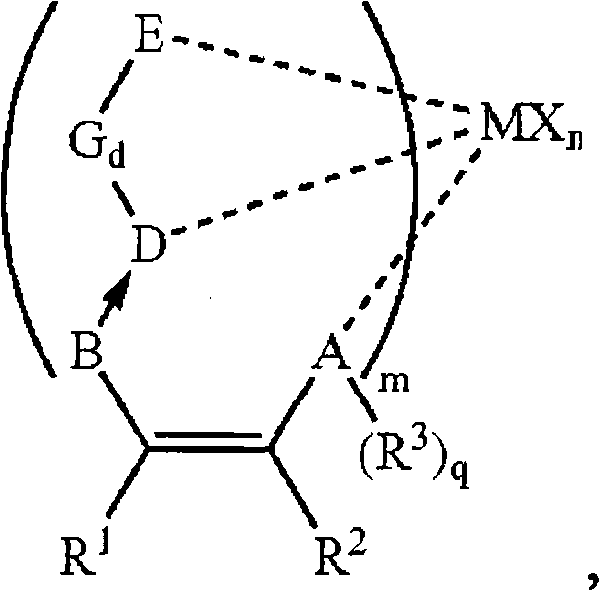

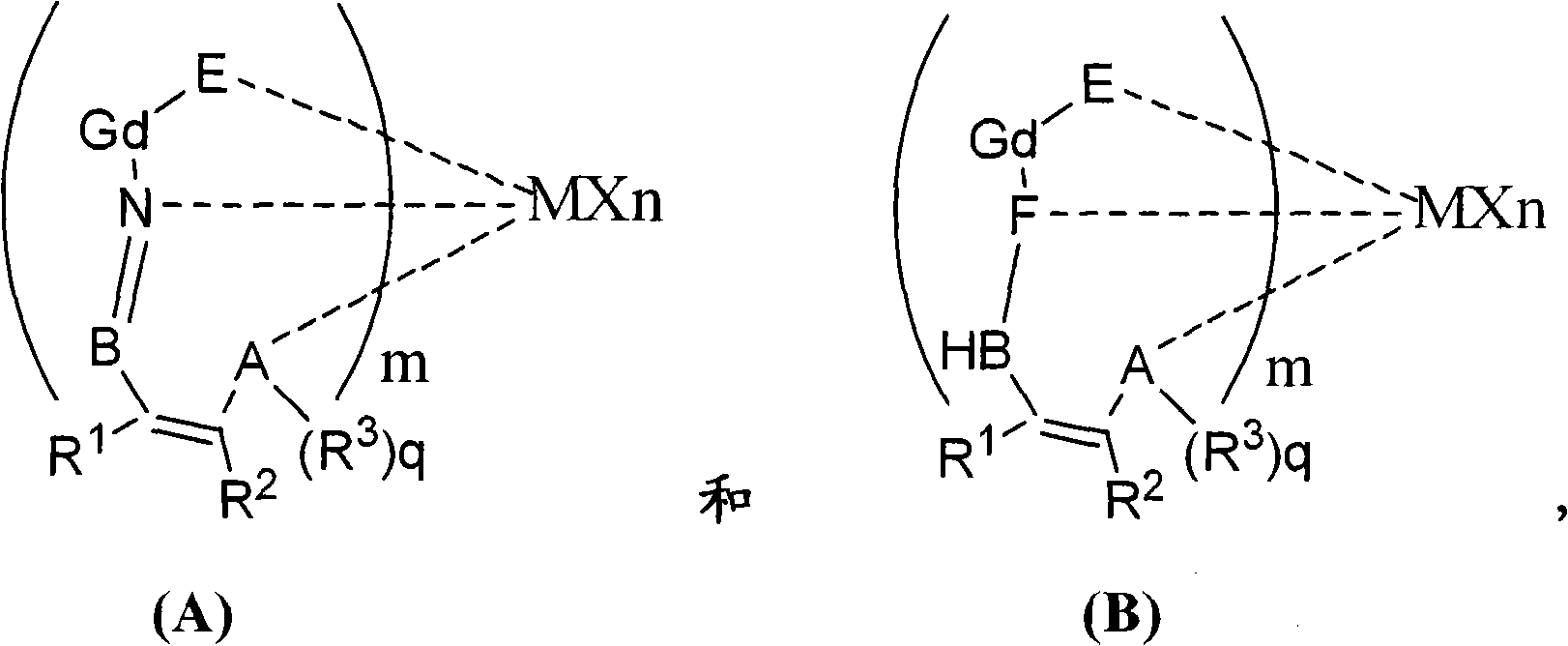

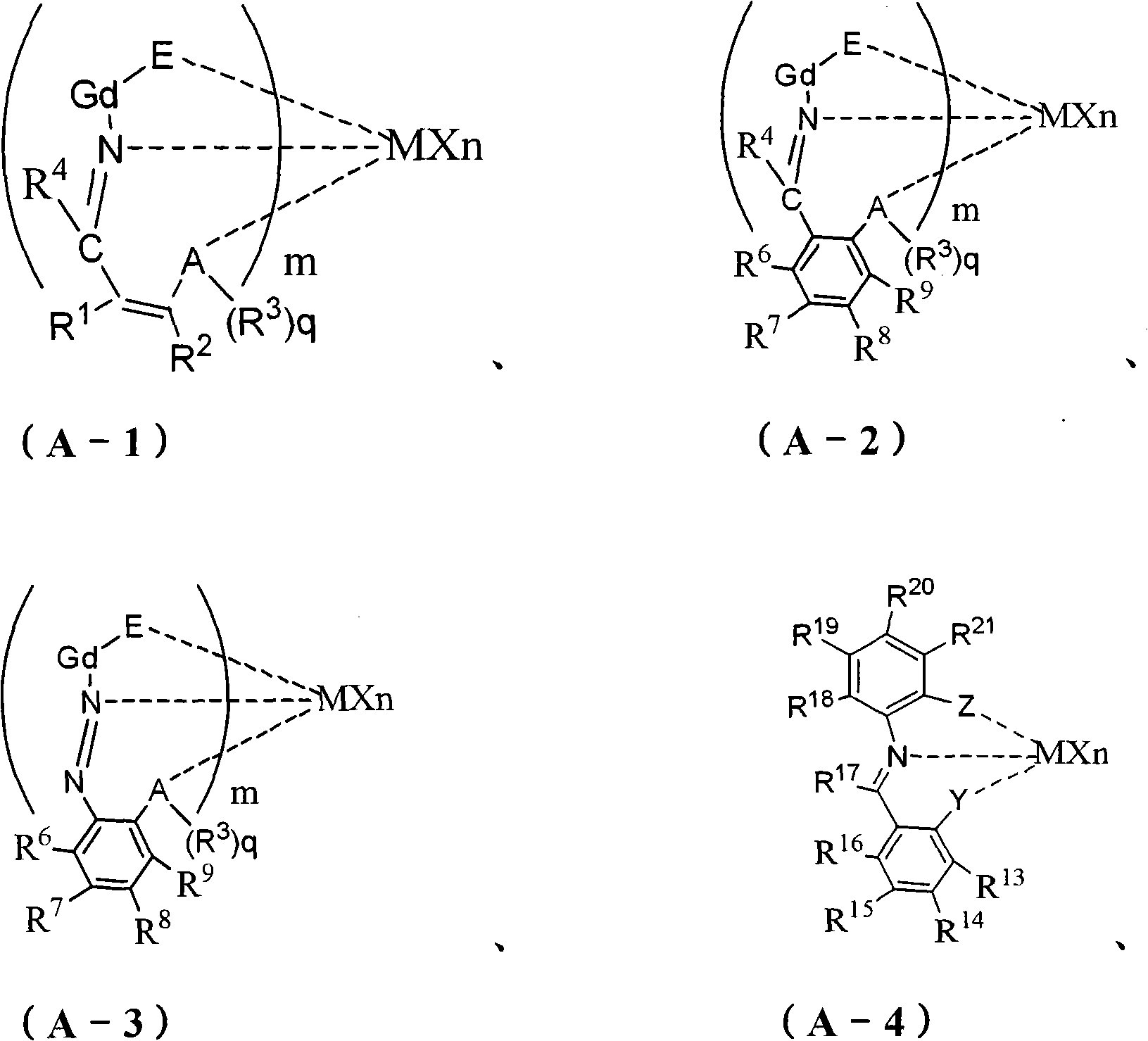

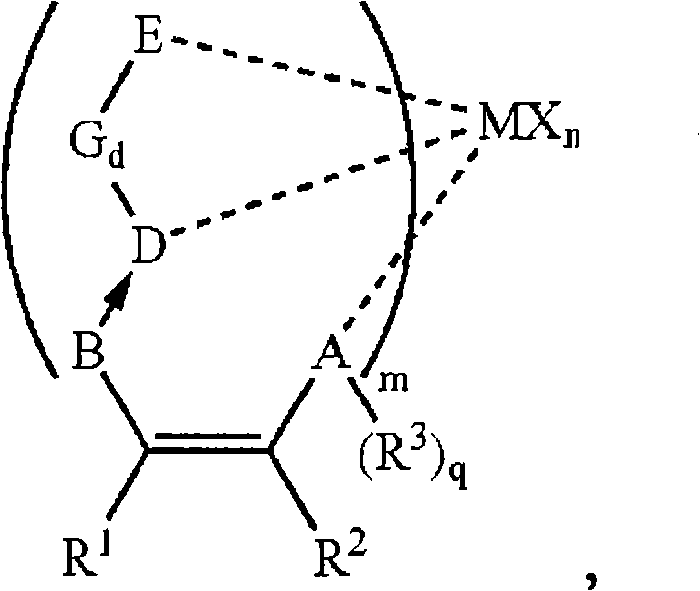

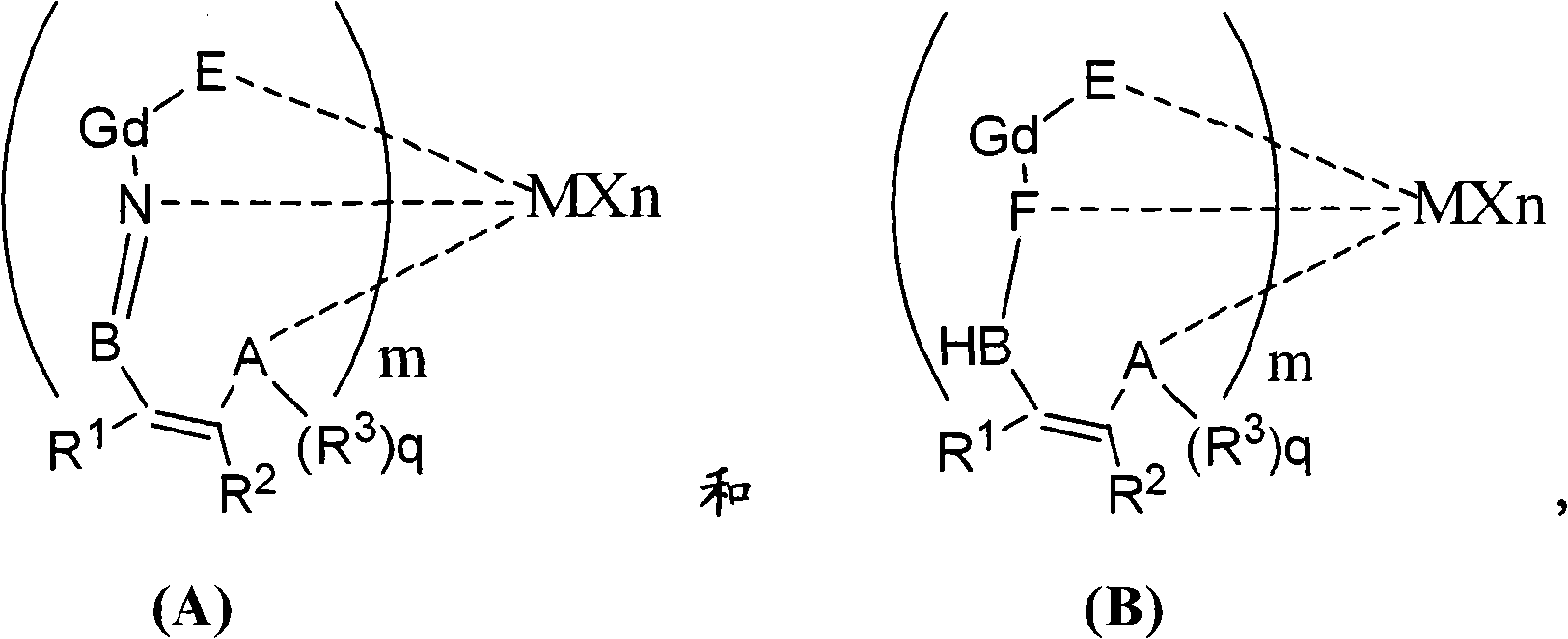

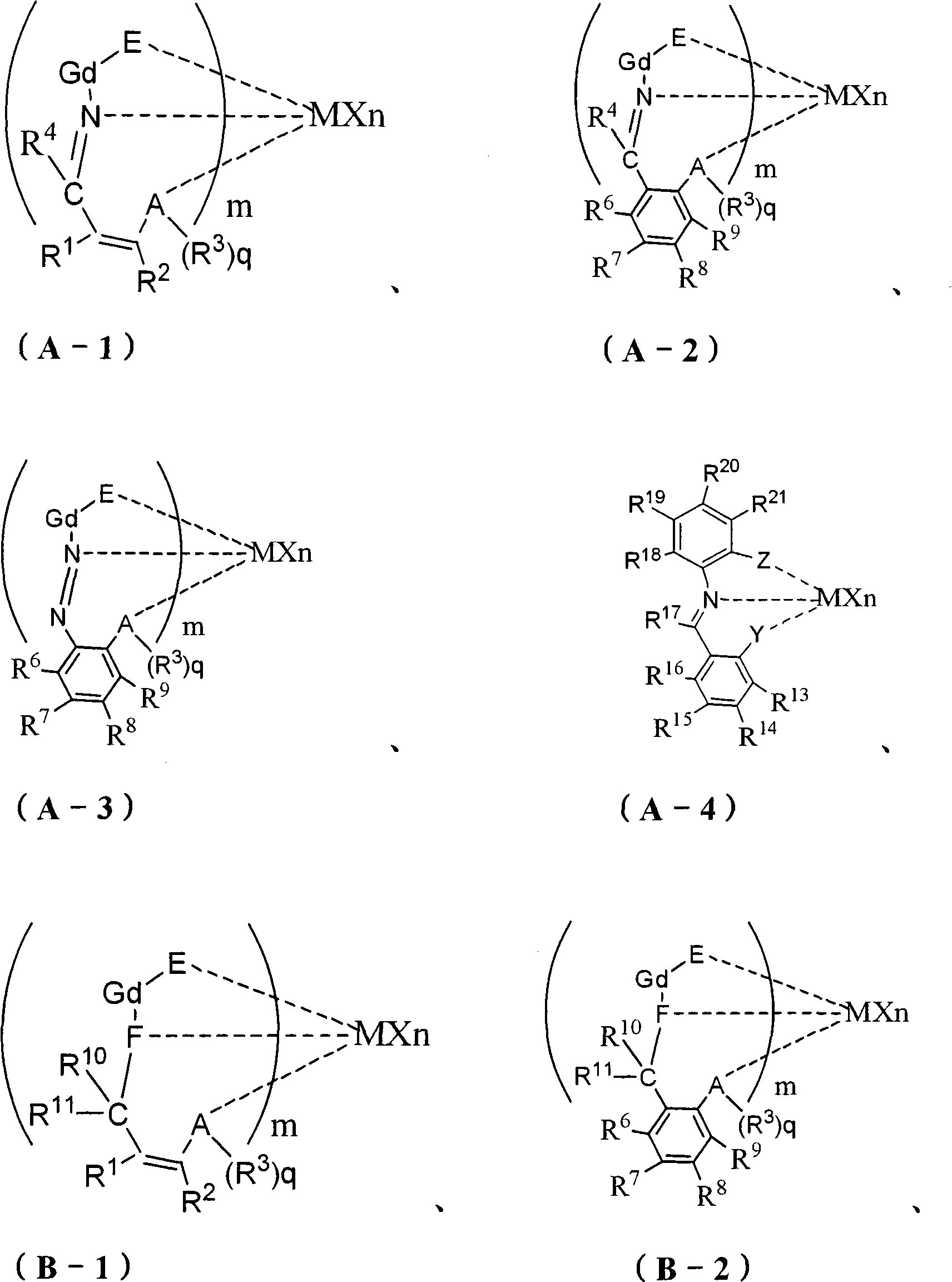

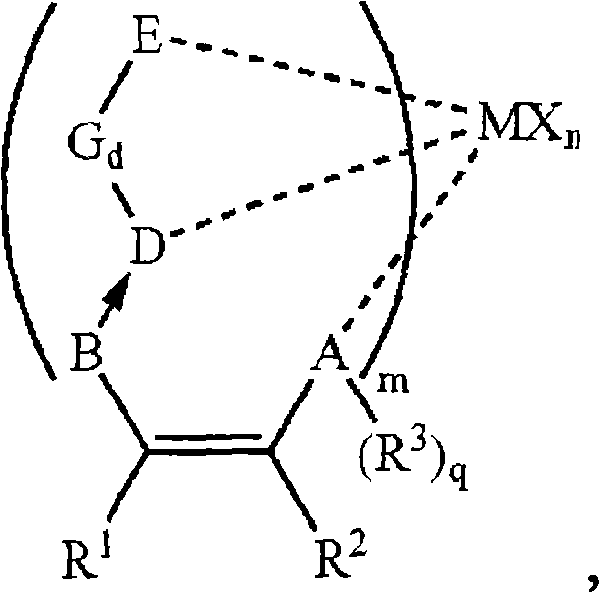

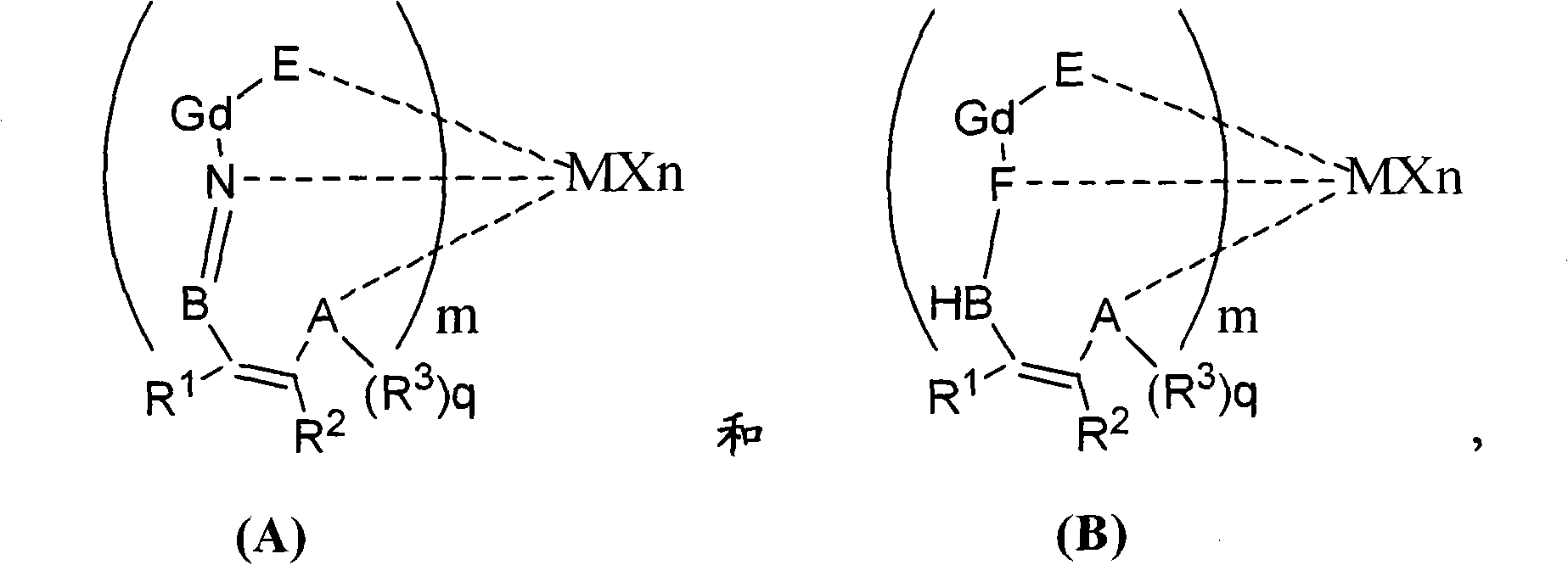

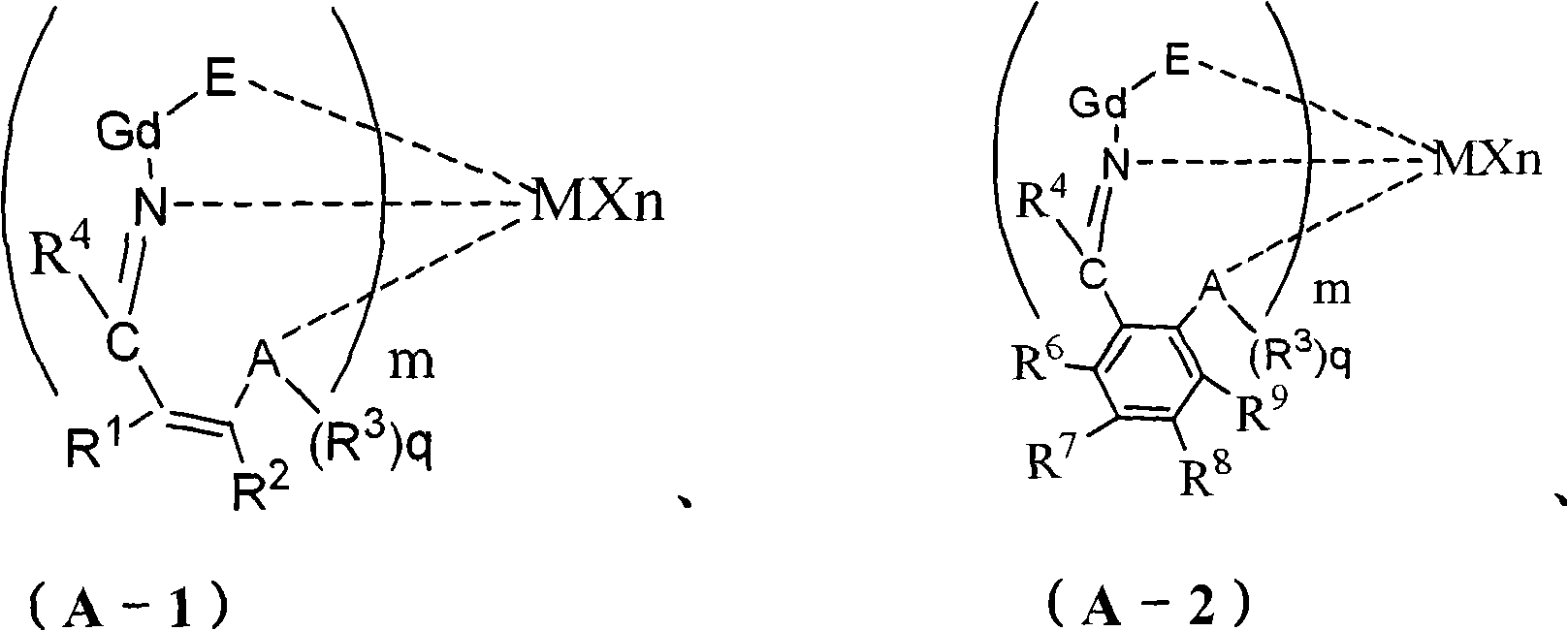

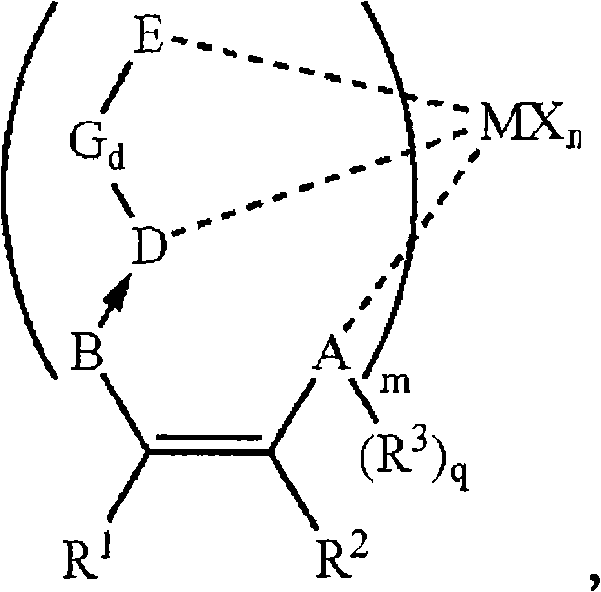

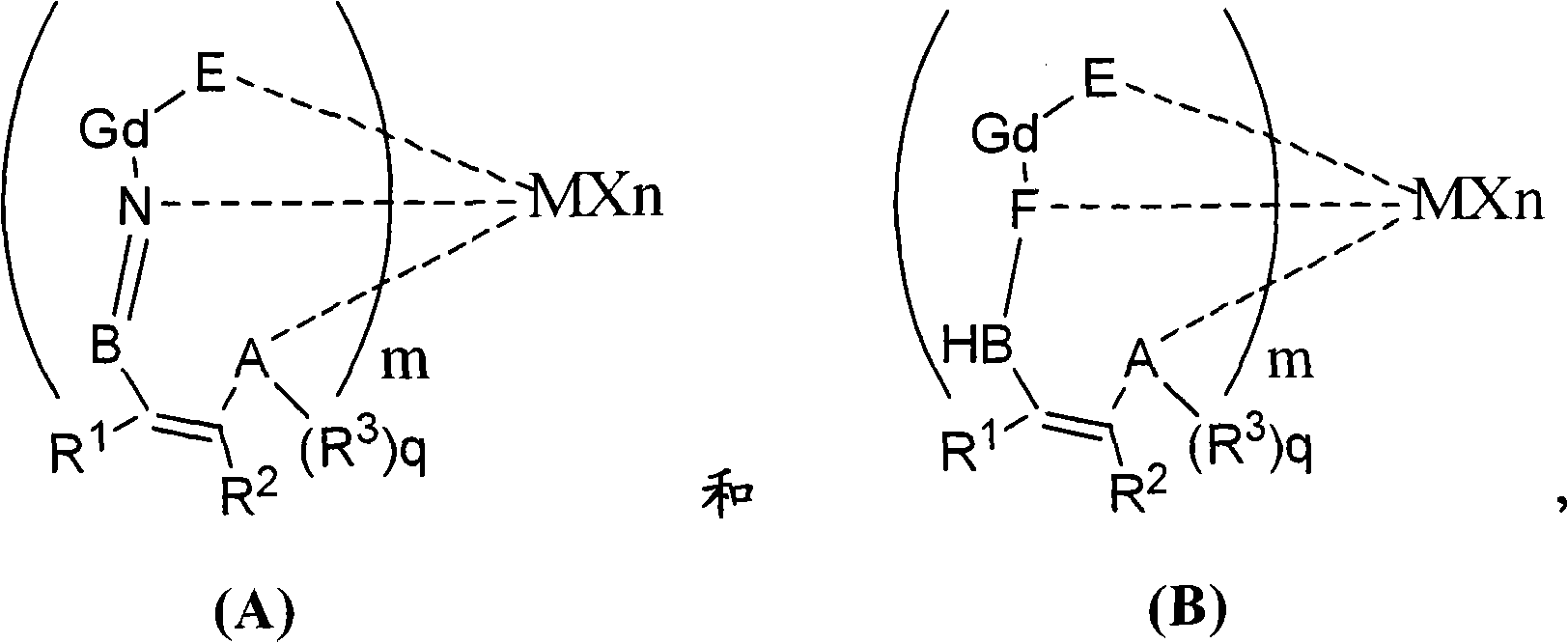

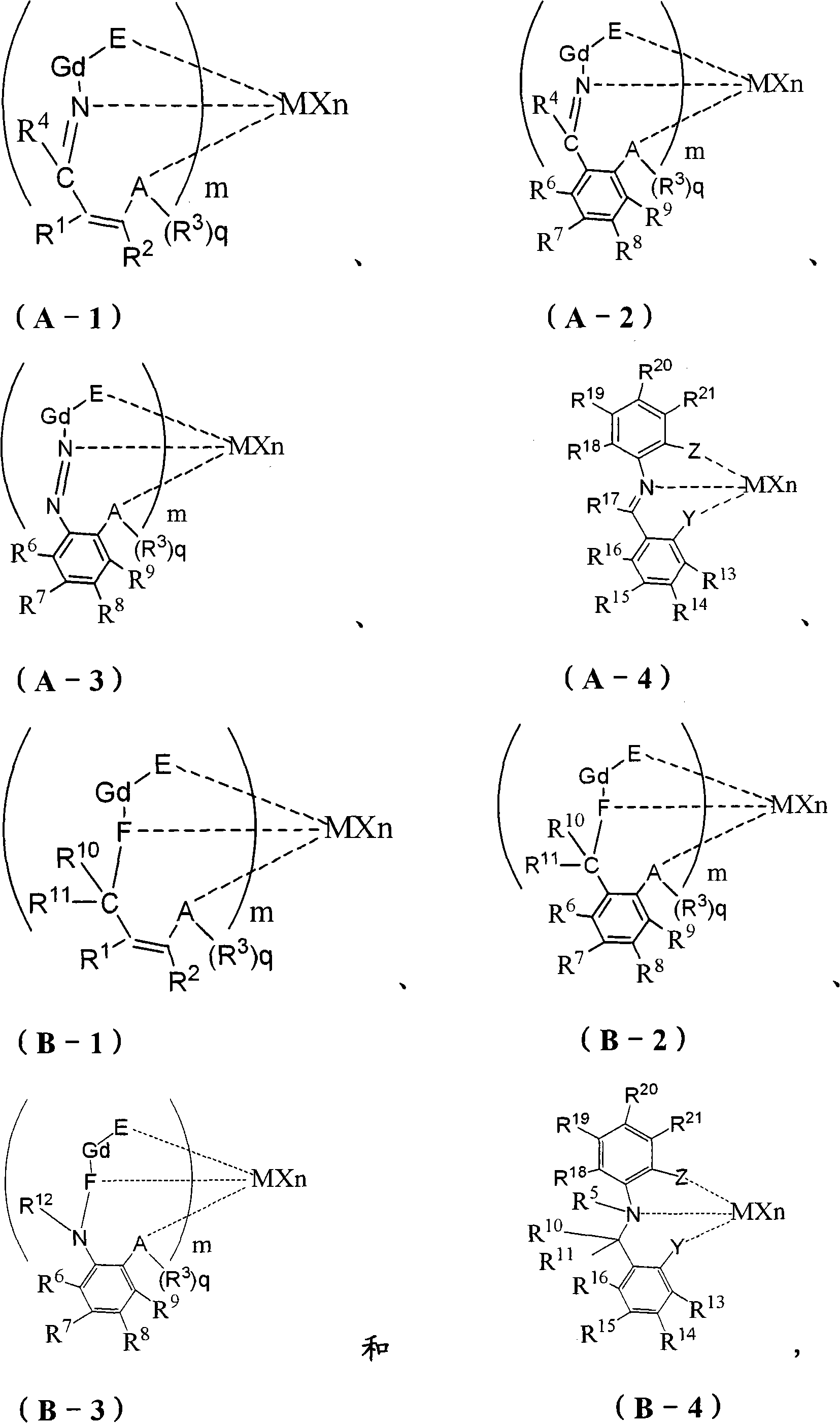

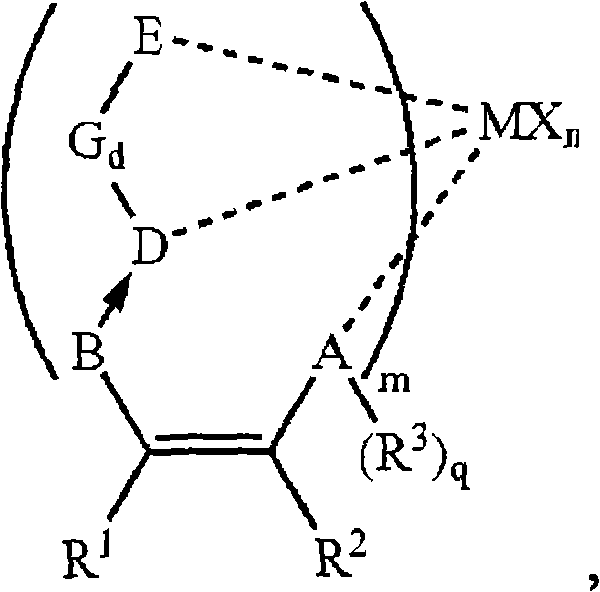

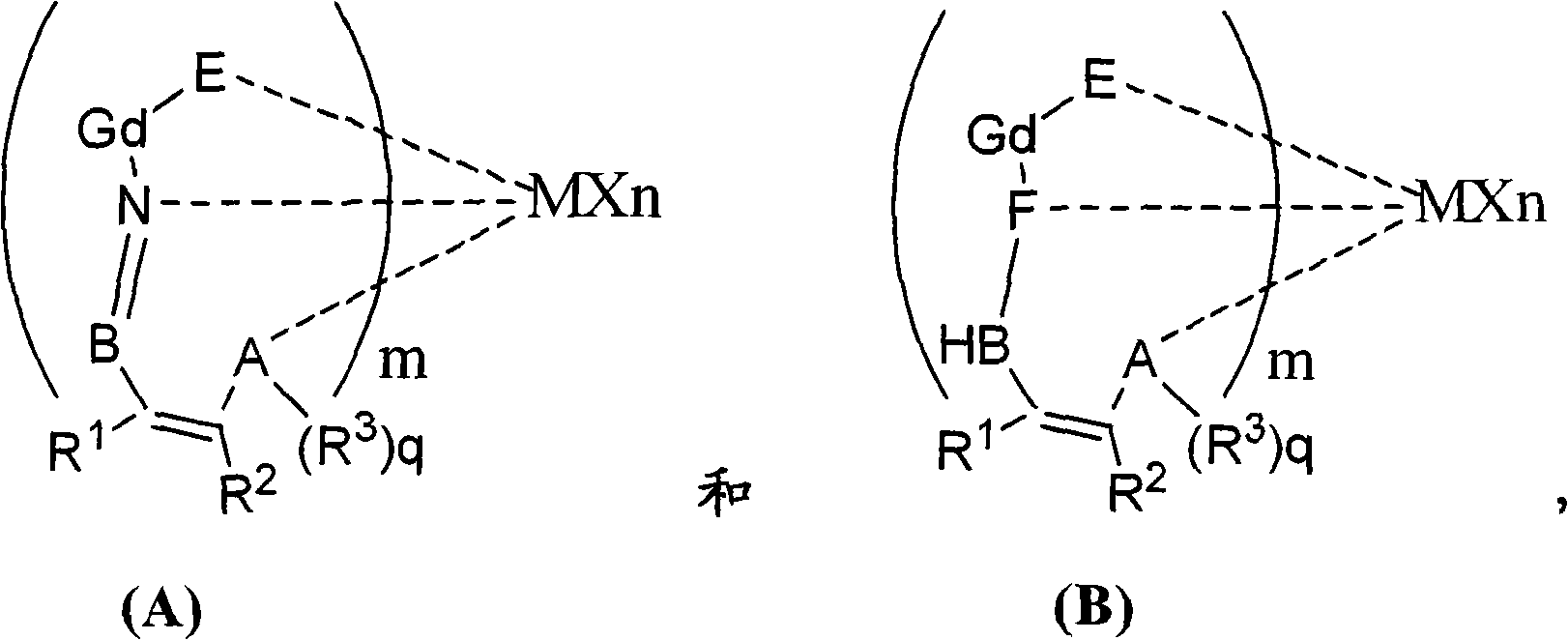

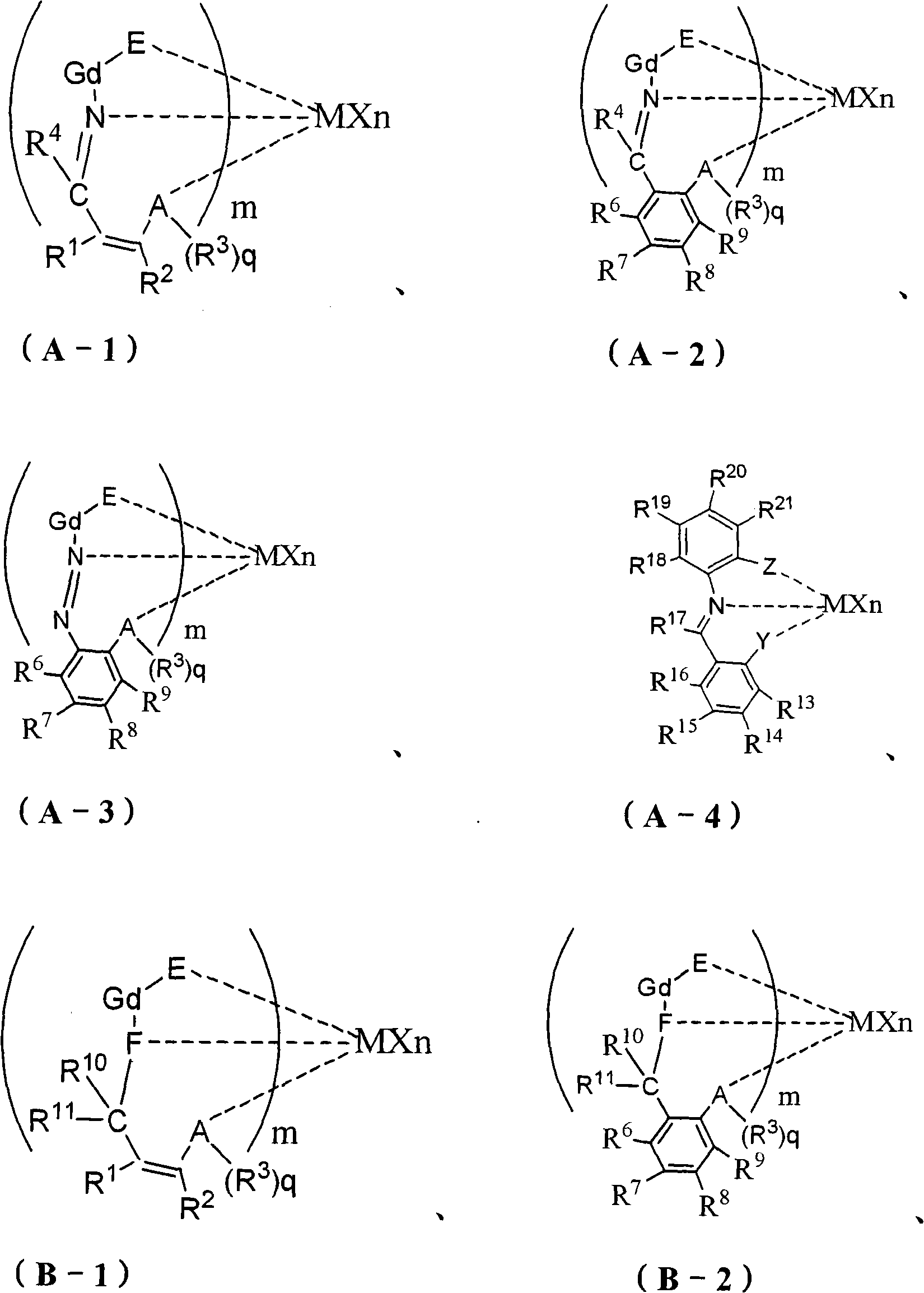

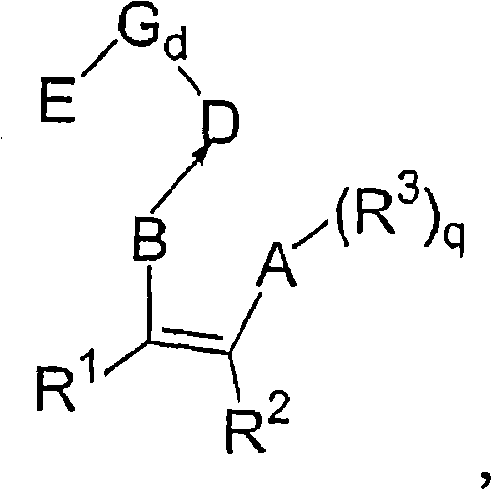

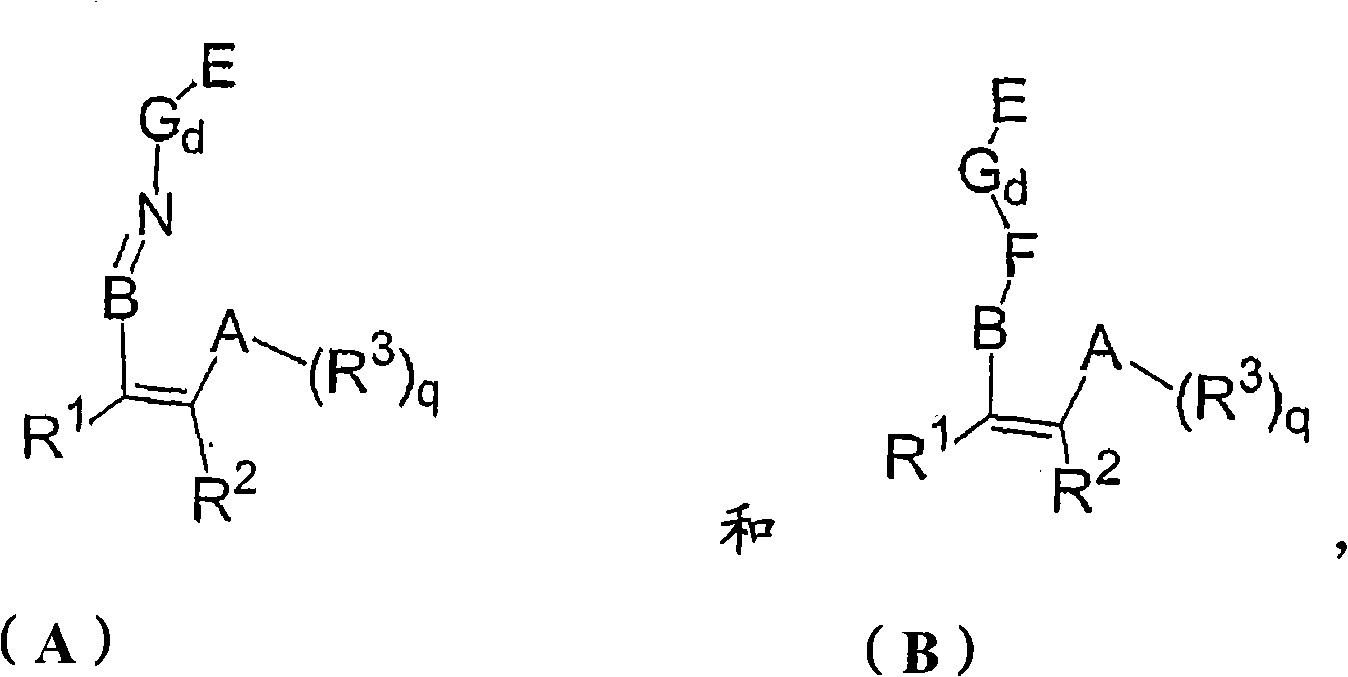

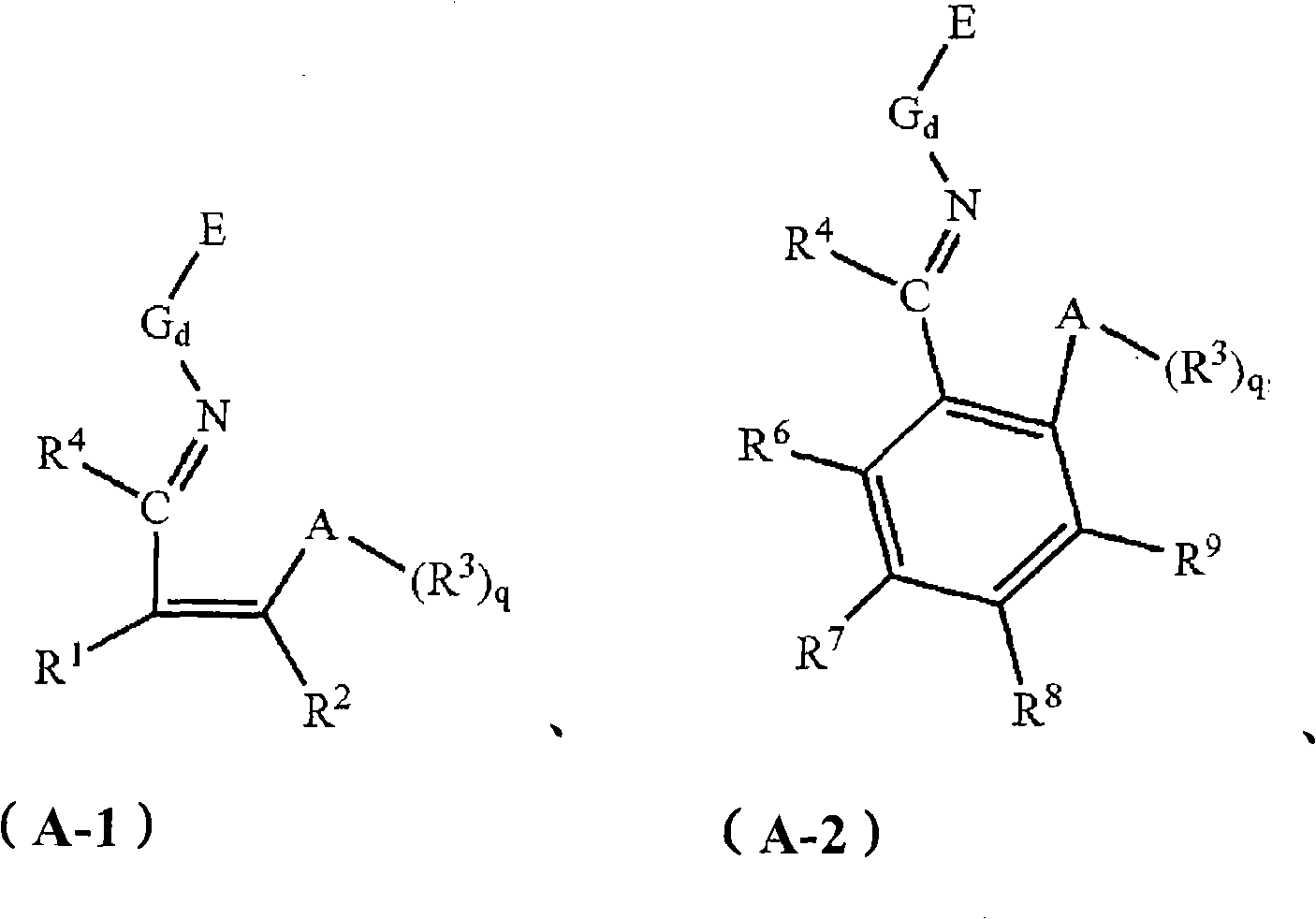

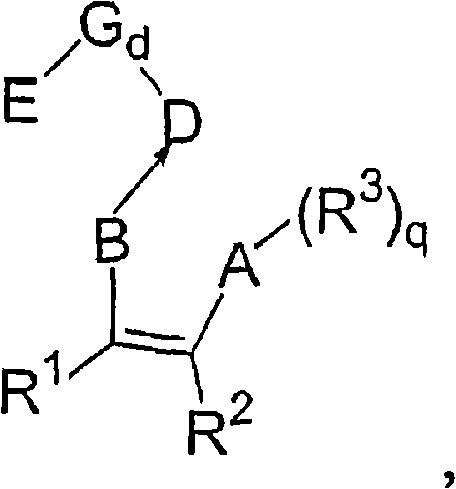

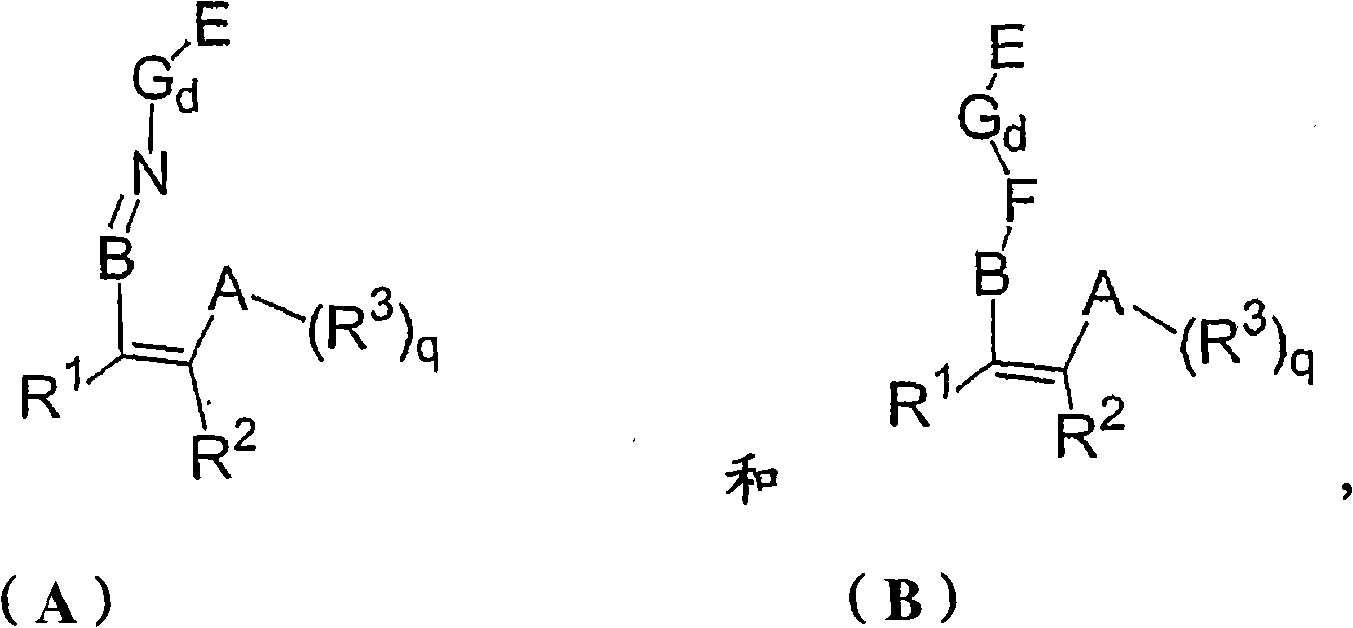

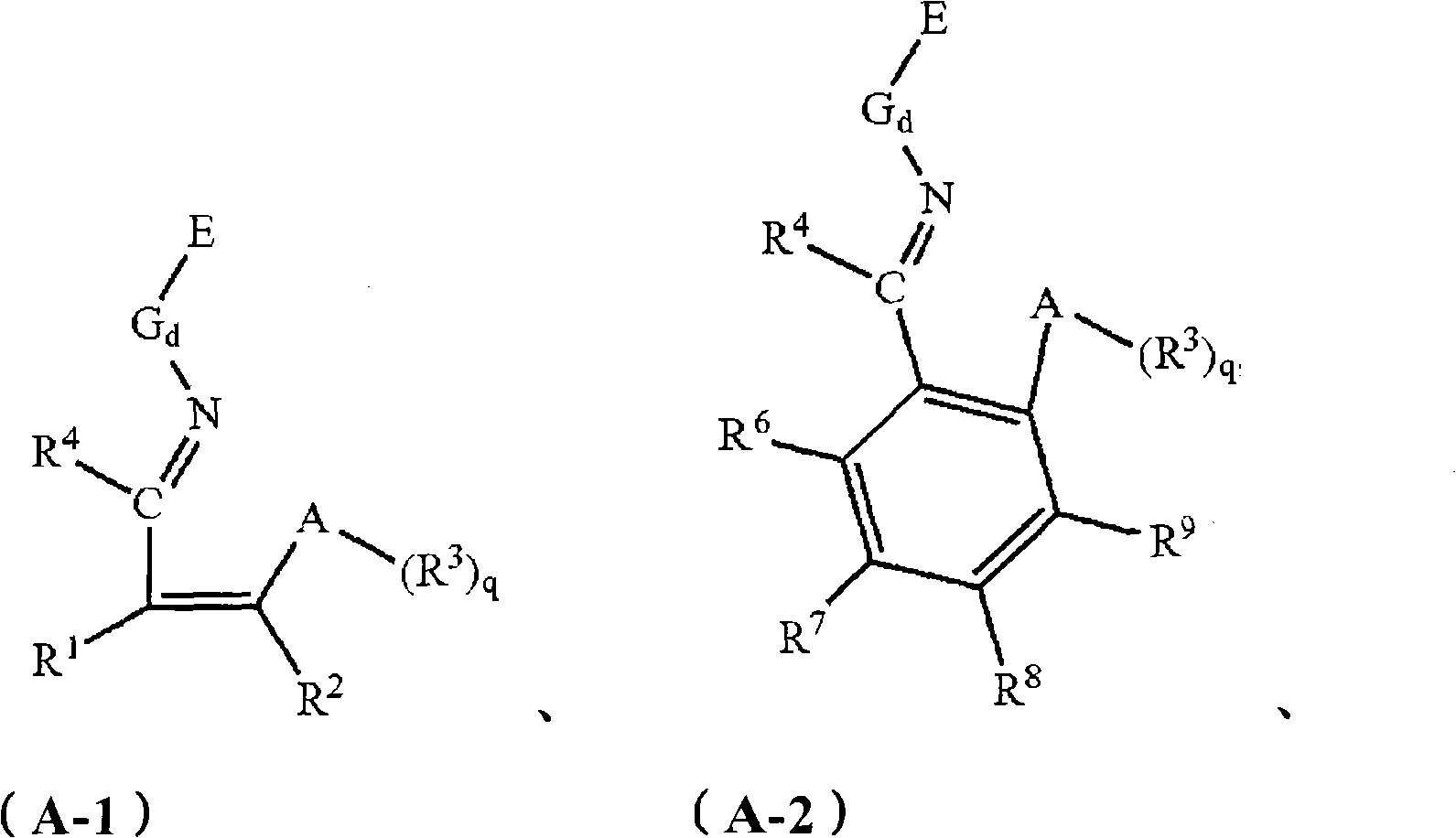

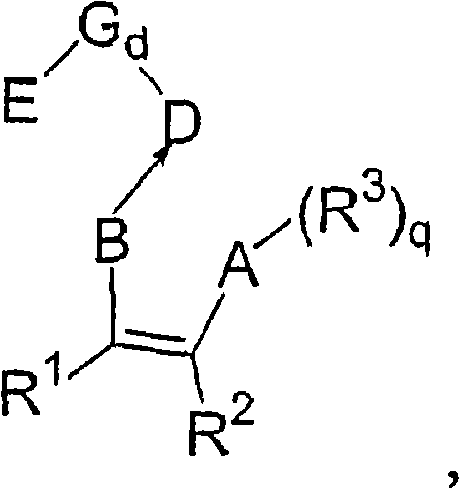

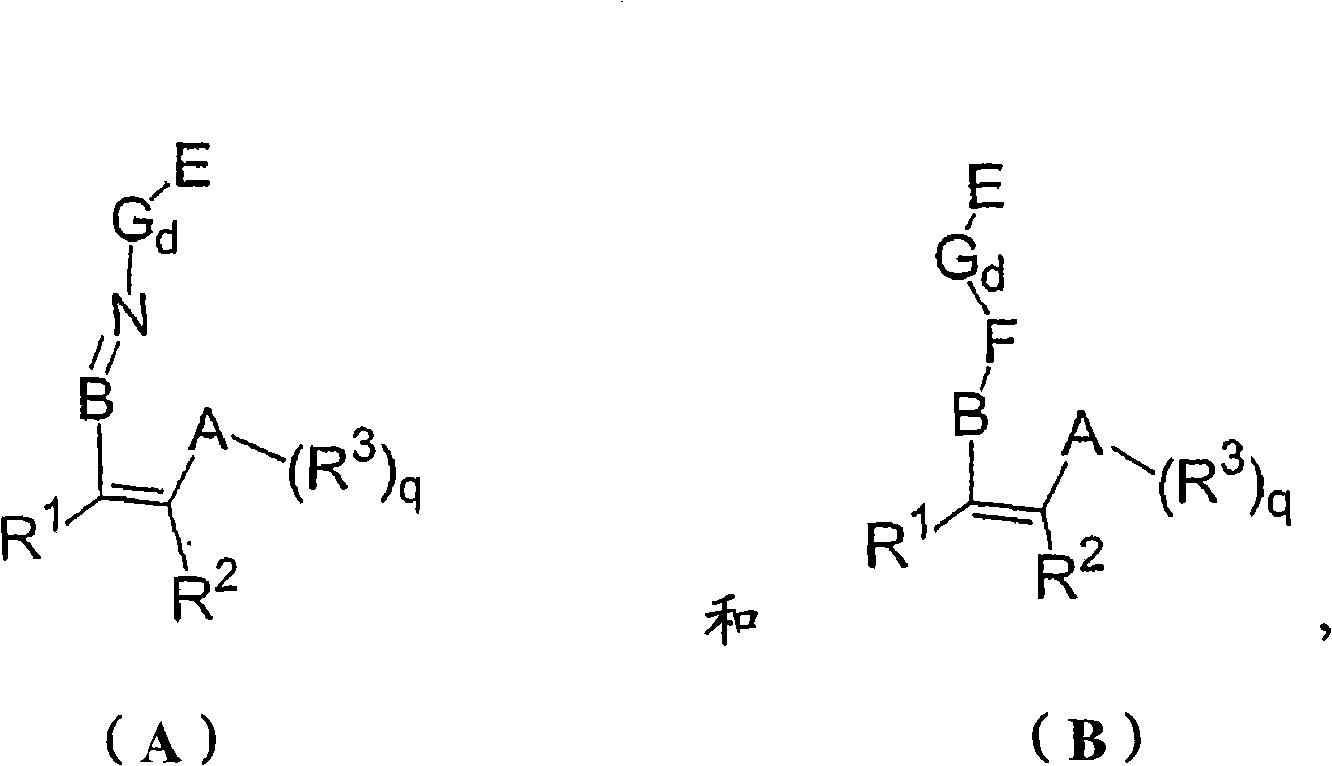

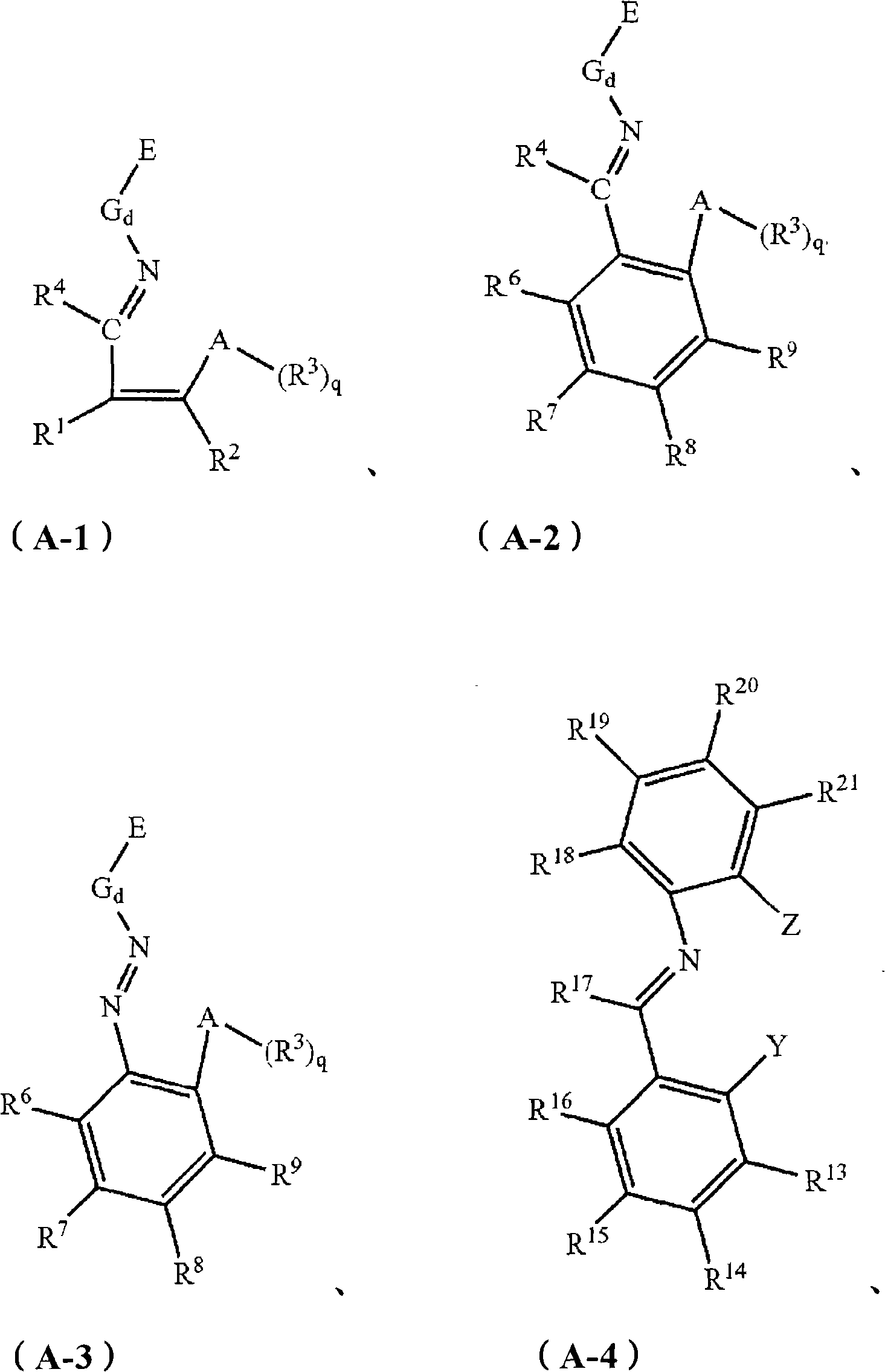

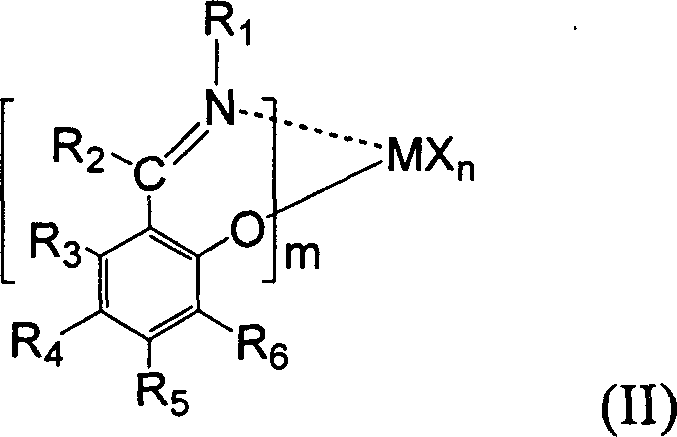

InactiveCN1769313AComposition is easy to controlImprovement of compatibilizerAluminoxaneAlpha-olefin

The invention provides the alkene polymerization catalyst which possesses high polymerization activity and the method of preparing alkene polar monomer copolymer by using the said catalyst. The catalyst comprises (A) and (B). The (A) comprises transition metal compound whose general formula is (I), and the (B) comprises the metal organic compound or organic aluminoxane compound or ionized ionic compound. In the transition metal compound of general formula (I), the M is at the ó¾B or ó¶B in the periodic table of elements, m is a integer between 1 and 3, R1 is alkene, R2 - R5 are H, halogen, hydrocarbon radical and so on, R6 is halogen or hydrocarbon radical and so on, and X is halogen or hydrocarbon radical and so on. The alkene used in combined polymerization comprises the all alkene which can coordinate and polymerize, the polar monomer comprises the ª‡-alkene polar monomer which can coordinate and polymerize and includes NíóOíóPíóSíóBíóSi, halogen and so on.

Owner:CHINA PETROLEUM & CHEM CORP +1

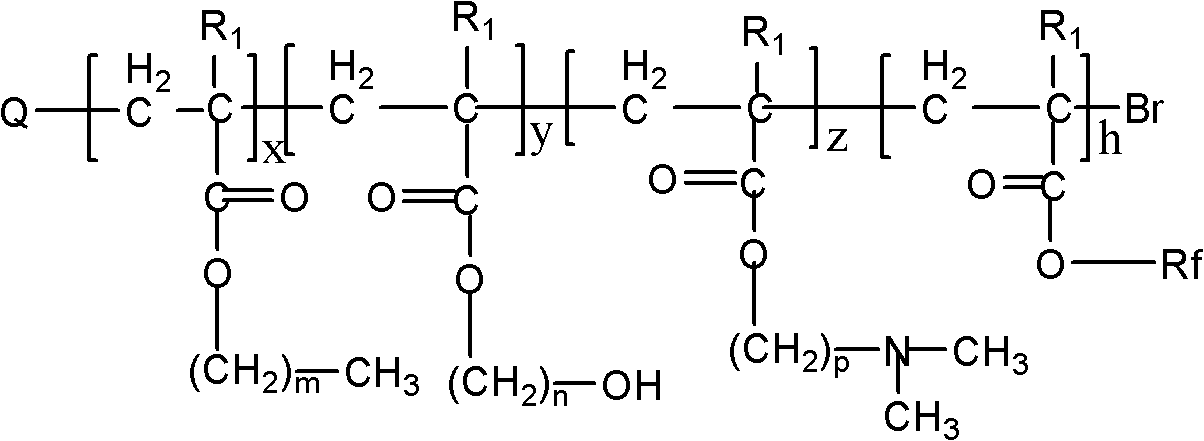

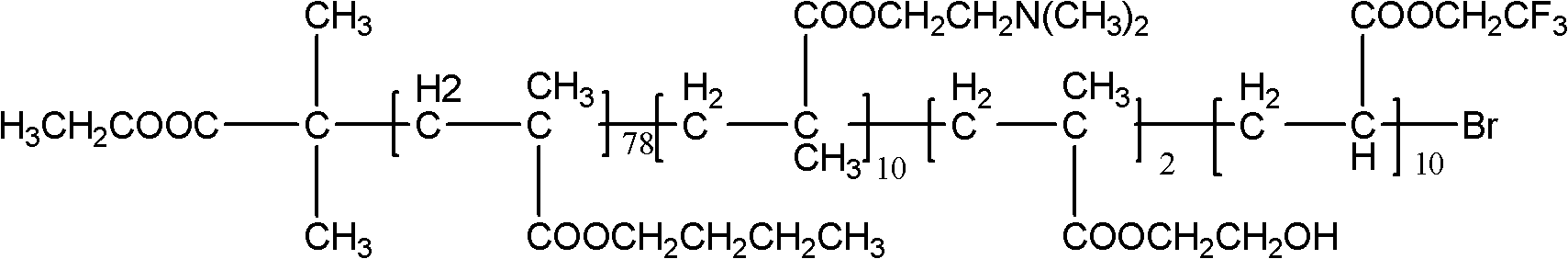

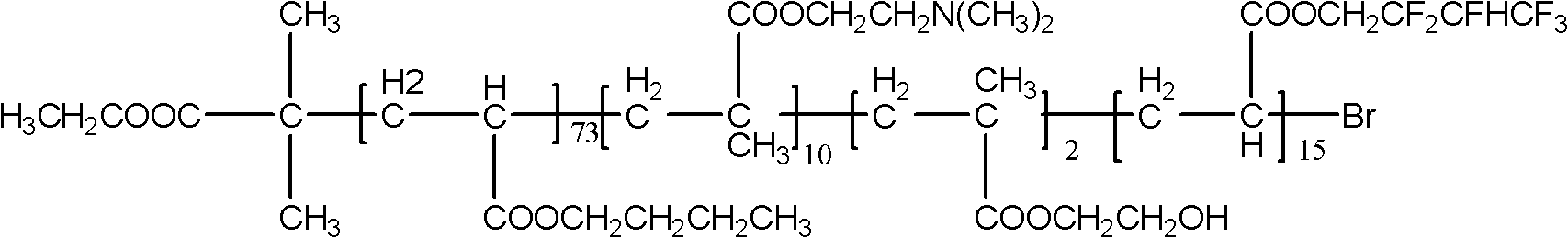

Fluorine-containing waterproofing agent for textiles and method for preparing same

ActiveCN102634980AImprove regularityImprove performanceFibre treatmentAtom-transfer radical-polymerizationFluorocarbon

The invention provides a fluorine-containing waterproofing agent for textiles and a method for preparing the same, belonging to the chemical material field. A self-emulsifying fluorine-containing acrylate block copolymer is synthesized by means of ARGETATRP (Activators Regenerated by Electron Transfer for Atom Transfer Radical Polymerization); and the self-emulsifying fluorine-containing acrylate block copolymer can be directly used after being emulsified and diluted. The self-emulsifying fluorine-containing acrylate block copolymer prepared by the method has excellent pH stability, chemical stability, diluting stability and storage stability; and the fluorine-containing structure units are distributed in form of blocks on the polymeric chain of the fluorine-containing acrylate block copolymer so that the fluorine-containing chain segments can be effectively utilized. Compared with a random fluorocarbon resin, the fluorine-containing acrylate block copolymer is capable of achieving the same performance and the usable amount of fluorine-containing monomers is very low. Moreover, textiles finished by the fluorine-containing waterproofing agent have excellent waterproofness; and compared with the similar products, the fluorine efficiency is improved and the cost is reduced.

Owner:京准化工技术(上海)有限公司

Nb-doped nano indium tin oxide powder and method for preparing high density sputtering coating target thereof

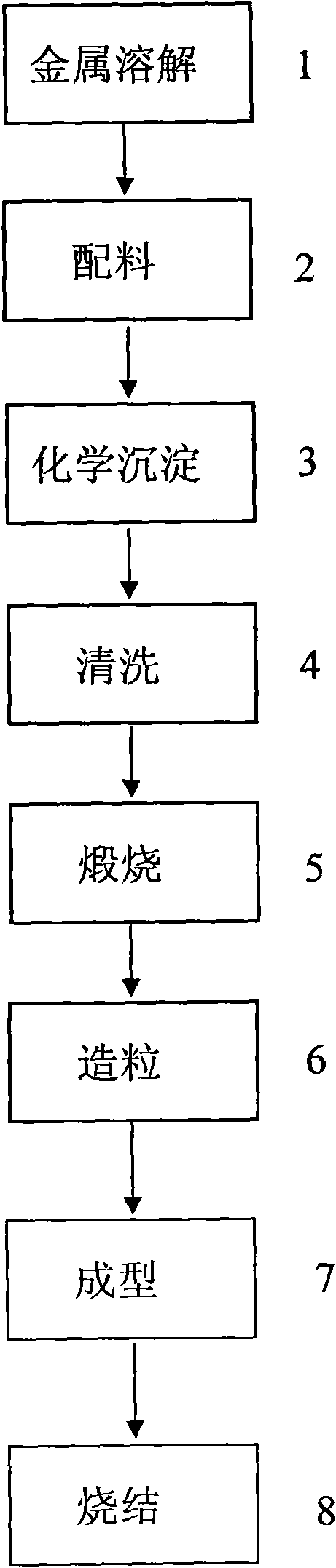

InactiveCN101580379AHigh puritySmall granularityVacuum evaporation coatingSputtering coatingIndiumNiobium

The invention relates to an Nb-doped nano indium tin oxide powder and a method for preparing high density sputtering coating target thereof. The method comprising the following steps: (1) dissolving high pure metals: high pure metal niobium, high pure metal indium and high pure metal tin are respectively dissolved into transparent solutions by inorganic acid; (2) mixing: the obtained transparent solutions are respectively filled into containers according to the proportion; (3) chemical precipitation: the three transparent solutions are made into Nb-doped and heavily tin-doped indium hydroxide nano-powder; (4) washing: the Nb-doped and heavily tin-doped tin indium hydroxide nano-powder is washed by de-ionized water and then precipitated; (5) calcinating: the nano-powder is calcined, and the Nb-doped nano indium tin oxide powder is prepared; (6) granulation: the Nb-doped nano indium tin oxide powder is added with a bonding agent and then dried, so that Nb-doped nano indium tin oxide powder before molding can be prepared; (7) molding: the Nb-doped nano indium tin oxide powder before molding is pressed into early embryo; (8) sintering: the early embryo is sintered under the normal pressure, and the high density sputtering coating target of the Nb-doped indium tin oxide can be prepared; in addition, pressure sintering can be adopted to further improve the density of the target.

Owner:BEIHANG UNIV +1

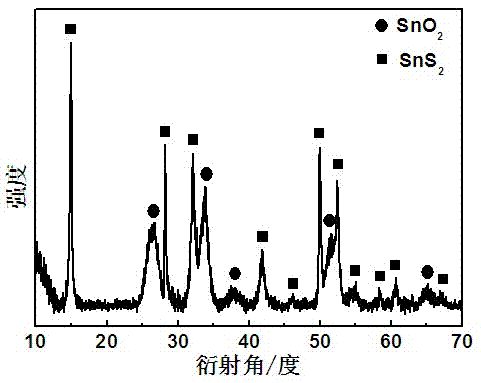

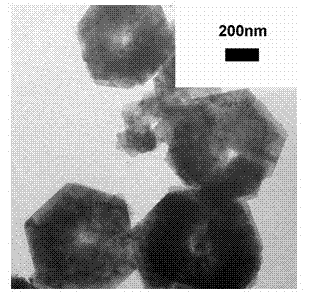

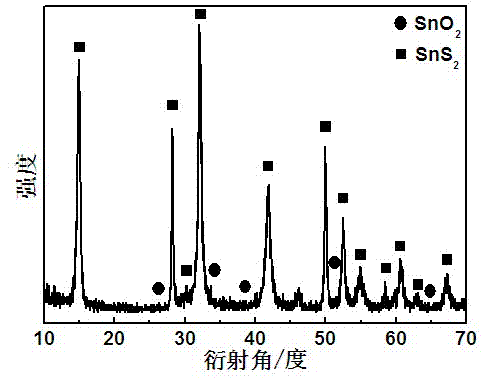

Method for preparing SnS2/SnO2 composite photocatalyst material of numismatics-shaped hollow structure

The invention discloses a method for preparing SnS2 / SnO2 composite photocatalyst material of a numismatics-shaped hollow structure, and belongs to the technical field of novel photocatalyst material production. The method comprises the following steps of: adding thiourea powder into a stannic chloride acetic acid water solution, and stirring for dissolving the powder so as to prepare a reaction liquid; subsequently putting the reaction liquid into a high pressure kettle in which the polytetrafluoroethylene is used as a lining, sealing and reacting at an environmental temperature not less than 180 DEG C; after the reaction is ended, cooling naturally to room temperature so as to obtain the sediment; and finally extracting and filtering the sediment, washing with deionized water and drying in vacuum so as to obtain the composite photocatalyst material of the numismatics-shaped hollow structure. The raw material is low in price and easy to obtain; the toxic gas H2S, the vacuum environment and the inert gas shielding are unnecessary; a template and a surface active agent are not needed to be added; the production equipment, the process condition and steps are relatively simple; and moreover a product is used for making the controllable SnS2 / SnO2 composite material which is of a numismatics-shaped hollow structure and has the advantages of larger specific surface area and heterojunction structure and excellent visible light catalysis property.

Owner:YANGZHOU UNIV

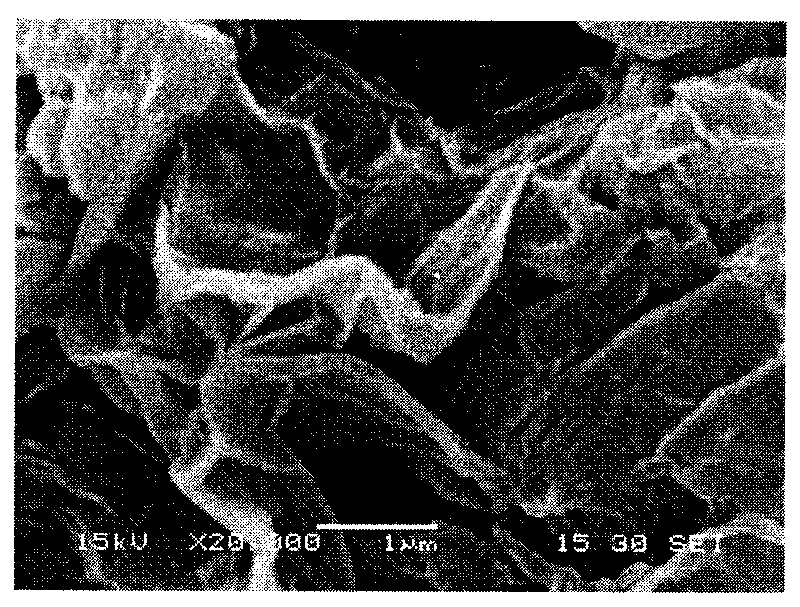

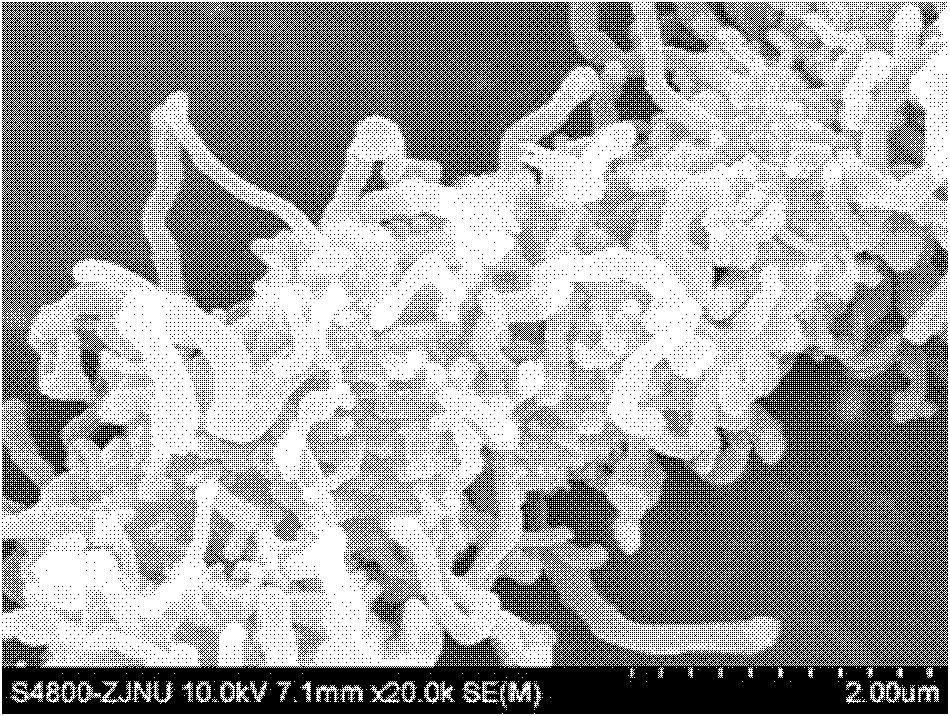

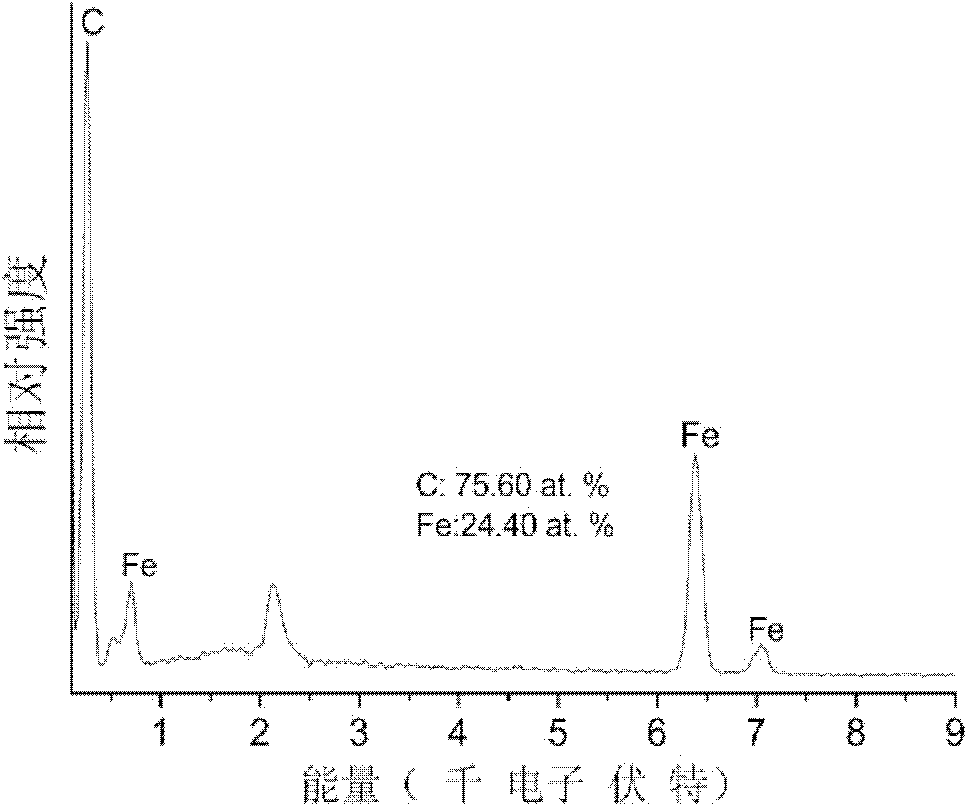

In situ preparation method for novel iron/carbon nano-tube grading nano-composite material

InactiveCN102423671ASimple processGood repeatabilityInorganic material magnetismMicroballoon preparationTube furnaceCarbon nanotube

The invention relates to a preparation method for a novel iron / carbon nano-tube grading nano-composite material. The method comprises the following concrete steps: adopting ceramic arks to respectively load a precursor of iron and an organic compound of carbon source; placing the ceramic arks in a tube furnace, heating to a temperature of 300-450 DEG C under the protection of inert gas, and holding the temperature for 30 minutes; continuously heating to the temperature of 450-900 DEG C, and holding the temperature for 1-4 hours; after completing the reaction, cooling to the room temperature along with the furnace under the protection of inert gas to obtain the novel iron / carbon nano-tube grading nano-composite material. According to the present invention, the preparation process is simple, and the forming mechanism is unique; the addition of any templates, any surfactants or any structural guideline agents during the reaction process is not required; the method has characteristics of low cost and high efficiency, and is easy to industrially apply and popularize; the prepared novel iron / carbon nano-tube grading nano-composite material has strong magnetic responsibility; the morphology and the composition of the iron / carbon nano-tubes can be controlled by the reaction temperature, the reaction time and the feed ratio.

Owner:ZHEJIANG NORMAL UNIVERSITY

System and method for treatment of organic matters in industrial waste salt by fractional gas stripping by use of hot fluid

ActiveCN108408744AAvoid cloggingHarmless treatment time is shortAlkali metal chloridesAlkali metal halide purificationExhaust gasIndustrial waste

The invention discloses a system and a method for treatment of organic matters in an industrial waste salt by fractional gas stripping by use of a hot fluid, and the system comprises a hot fluid generating device, a fractionating gas stripping device and a tail gas treating device. The industrial waste salt is continuously fed in from a secondary gas stripping device. The material is preliminarilygas-stripped and dried by the hot fluid, then enters an intermediate salt silo through a secondary cyclone separator, then enters a first gas stripping device through a conveying device, and is gas-stripped by the high-temperature hot fluid to a first cyclone separator to discharge, the temperature in the hot fluid generating device is 700-1000 DEG C, the temperature of the first gas stripping device is 400-800 DEG C, and the temperature of the secondary gas stripping device is 150-400 DEG C, the retaining time of the material is 2 to 5 seconds, the organic matters in the industrial waste salt are decomposed into a volatile tail gas under the action of first-stage hot fluid heating, and the tail gas is discharged to a high altitude after being dusted by a cloth bag. The system can rapidlydecompose the organic matters in the industrial waste salt, the tail gas is recycled and utilized, and the treated industrial salt is used as a high quality raw material of a chloralkali device.

Owner:LIAOCHENG LUXI POLYCARBONATE CO LTD

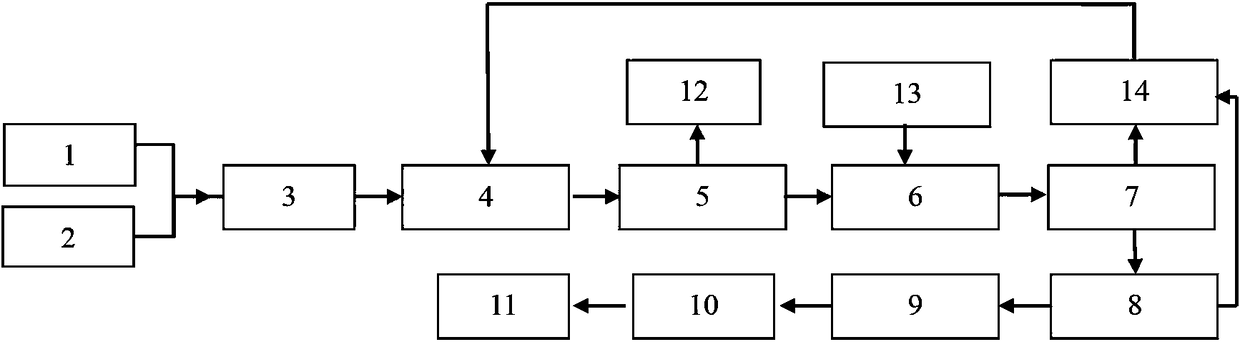

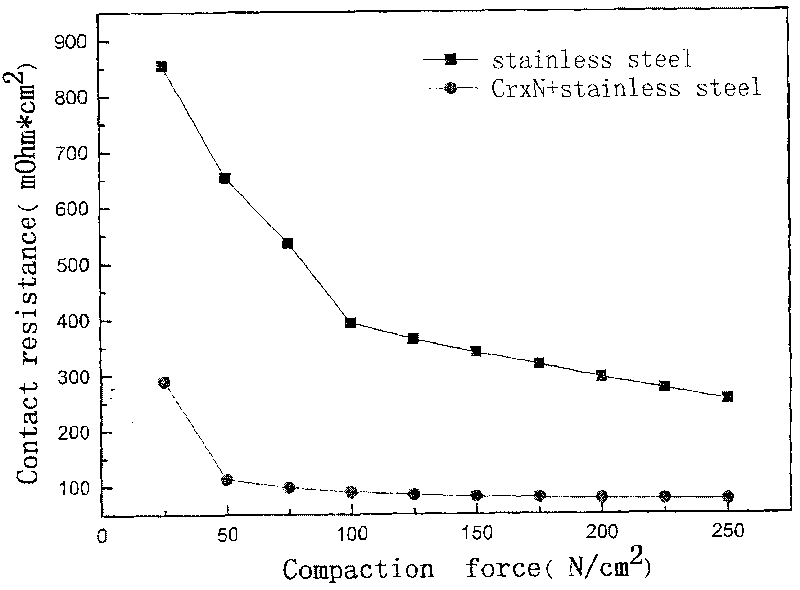

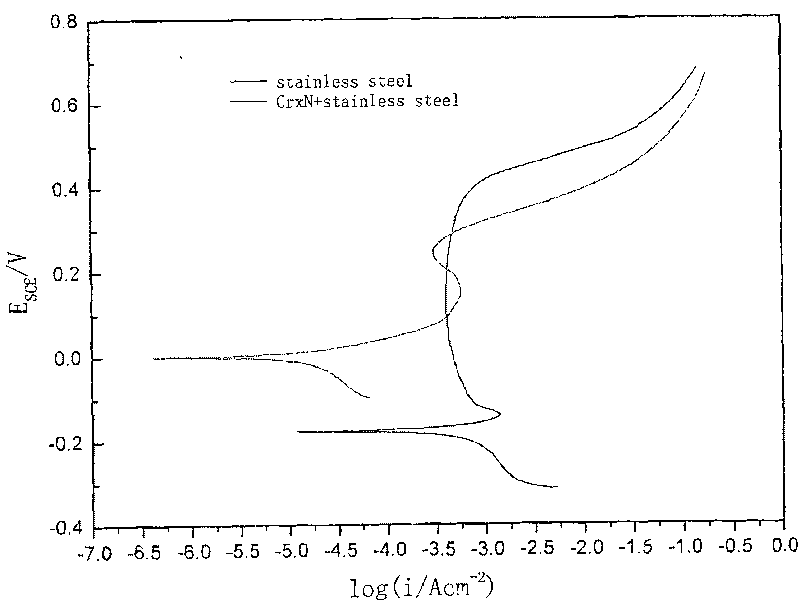

Proton exchange membrane fuel cell stainless steel bipolar plate and method for preparing same

InactiveCN101710621AReduce contact resistanceImprove corrosion resistanceFinal product manufactureCell electrodesCorrosionOhm

The invention relates to an improvement on a proton exchange membrane fuel cell stainless steel bipolar plate and a preparation method thereof. The invention is characterized in that: a CrxN plating layer is formed on the surface of a stainless steel bipolar plate by adopting ion injection, wherein x is between 0.06 and 10. The obtained bipolar plate has lower contact resistance and higher corrosion resistance; the contact resistance is only between 20 and 30 ohm cm2 under a condition of 150N / cm2 pressure; corrosion current is between 2 and 3 muA / cm2 under a simulation PEMFC corrosive environment; the corrosion resistance is higher than that of a pure metal plating layer and a nitride plating layer; and the properties are similar to those of electric arc ion nickel plating, chromium nitride and the like. The improvement adopts Cr ion and N ion injection, has the advantages of lower equipment requirement, simple process and low modification cost, is easy to control components and depth of the plating layer, can accurately control surface CrxN type and is suitable for commercial production of the bipolar plate. The injection temperature is only between 100 and 250 DEG C, so low energy consumption is required, high-temperature thermal treatment is saved, and influence on the size of a flow channel formed by stamping stainless steel plates is less.

Owner:江苏新源动力有限公司

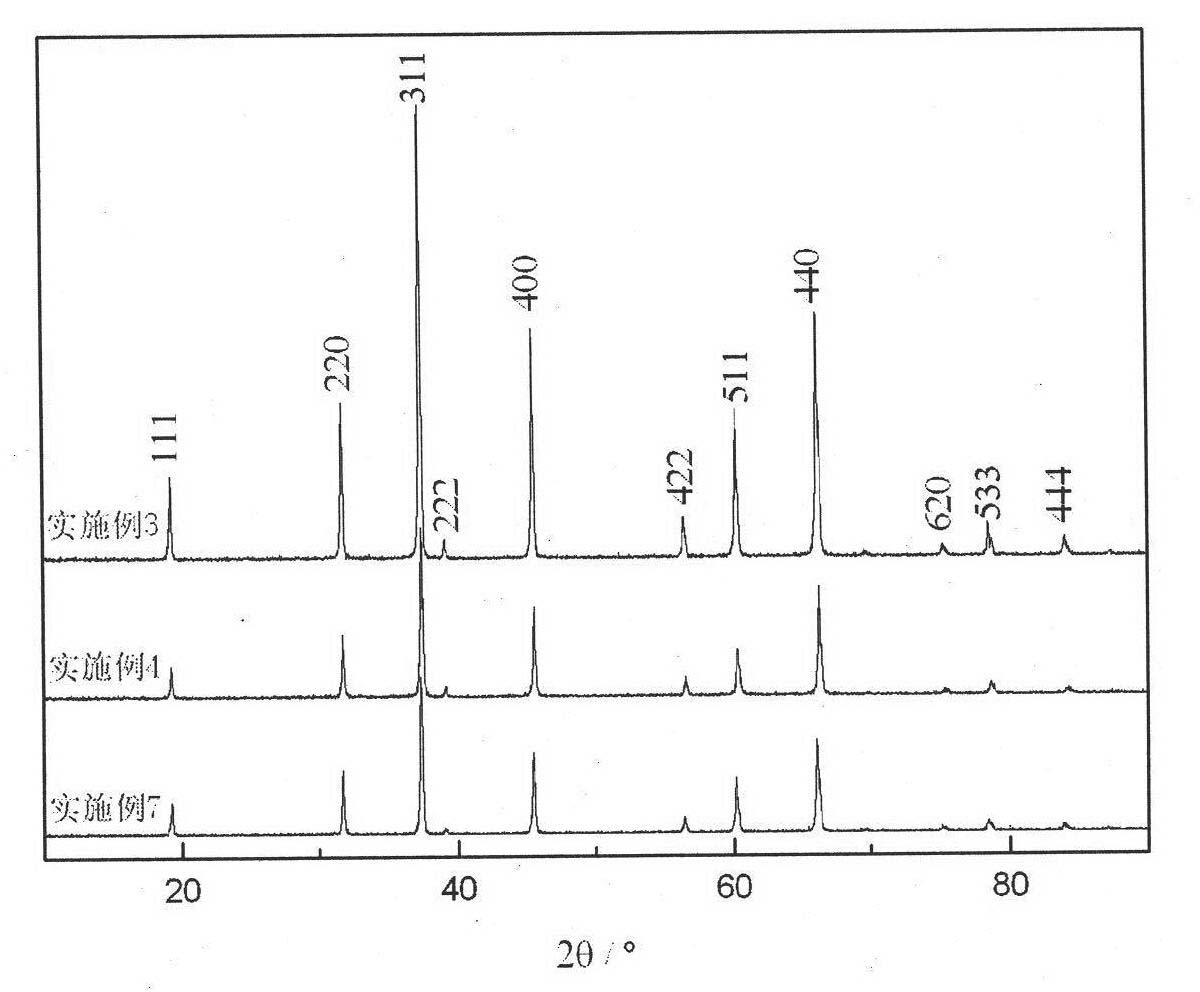

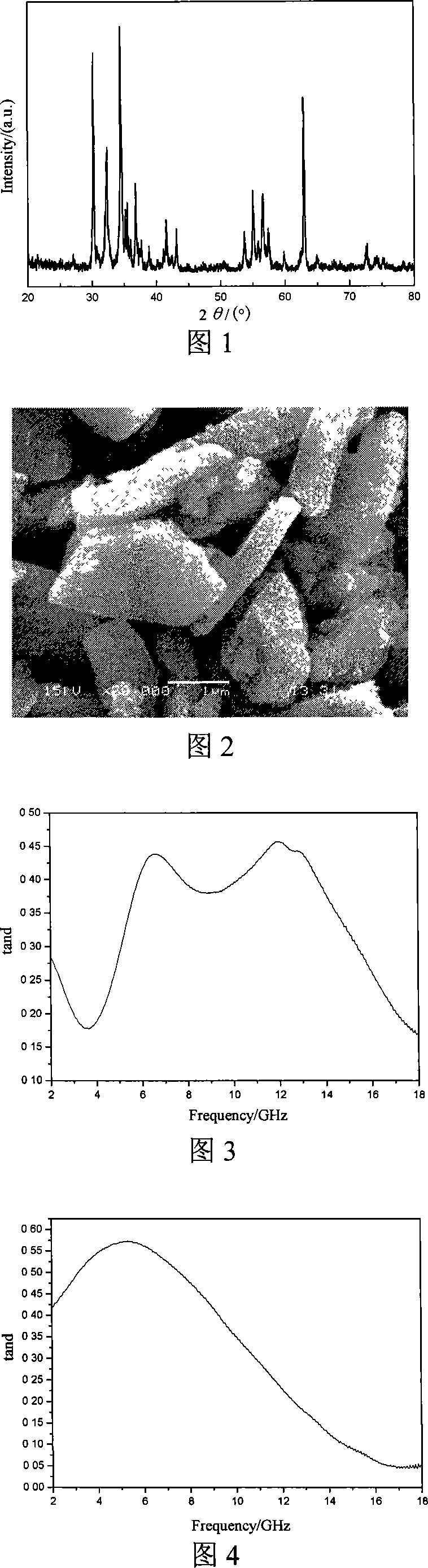

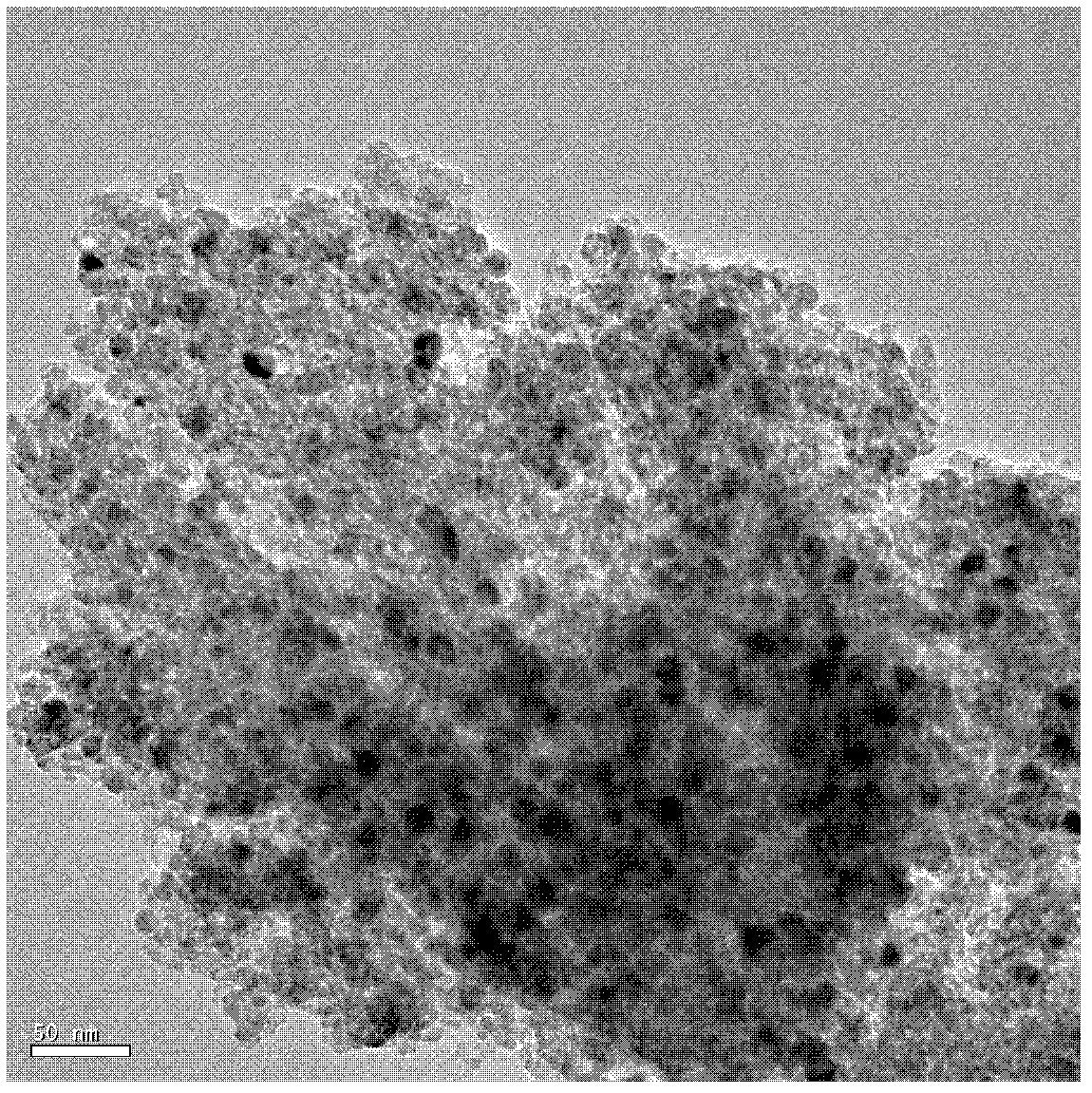

A W-type ferrite electromagnetic-wave absorbent and the corresponding preparation method

ActiveCN101217861ASmall powder particlesHigh powder particlesOther chemical processesMagnetic/electric field screeningCeriumManganese

The invention discloses a W-typed ferrite electromagnetic absorbing material and the preparation method thereof, which takes barium, cobalt, the iron nitrate of iron, organic acid, saturated lower alcohol and water as main raw materials with the molar ratio that Ba / Fe is equal to 1:14-17, Ba / Co is equal to 1:1-2, the organic acid / Ba is equal to 10-40:1 and the saturated lower alcohol / organic acid is equal to 0-3:1; the raw material can be mixed by transition metal elements such as lanthanum, nickel, titanium, manganese, copper and cerium; the invention is prepared by a sol-gel process and roasting under pre-roasting and high temperature conditions; the invention takes the organic acid as a complexing agent and takes the saturated small molecular alcohol as a dispersant; the invention has the advantages of uniform and complete crystallization, excellent electromagnetic performance, high dielectric constant, high absorbing efficiency, thin coating, wide frequency band, etc. The invention is easy for processing and batch production and is an ideal method for preparing the ferrite.

Owner:溧阳常大技术转移中心有限公司

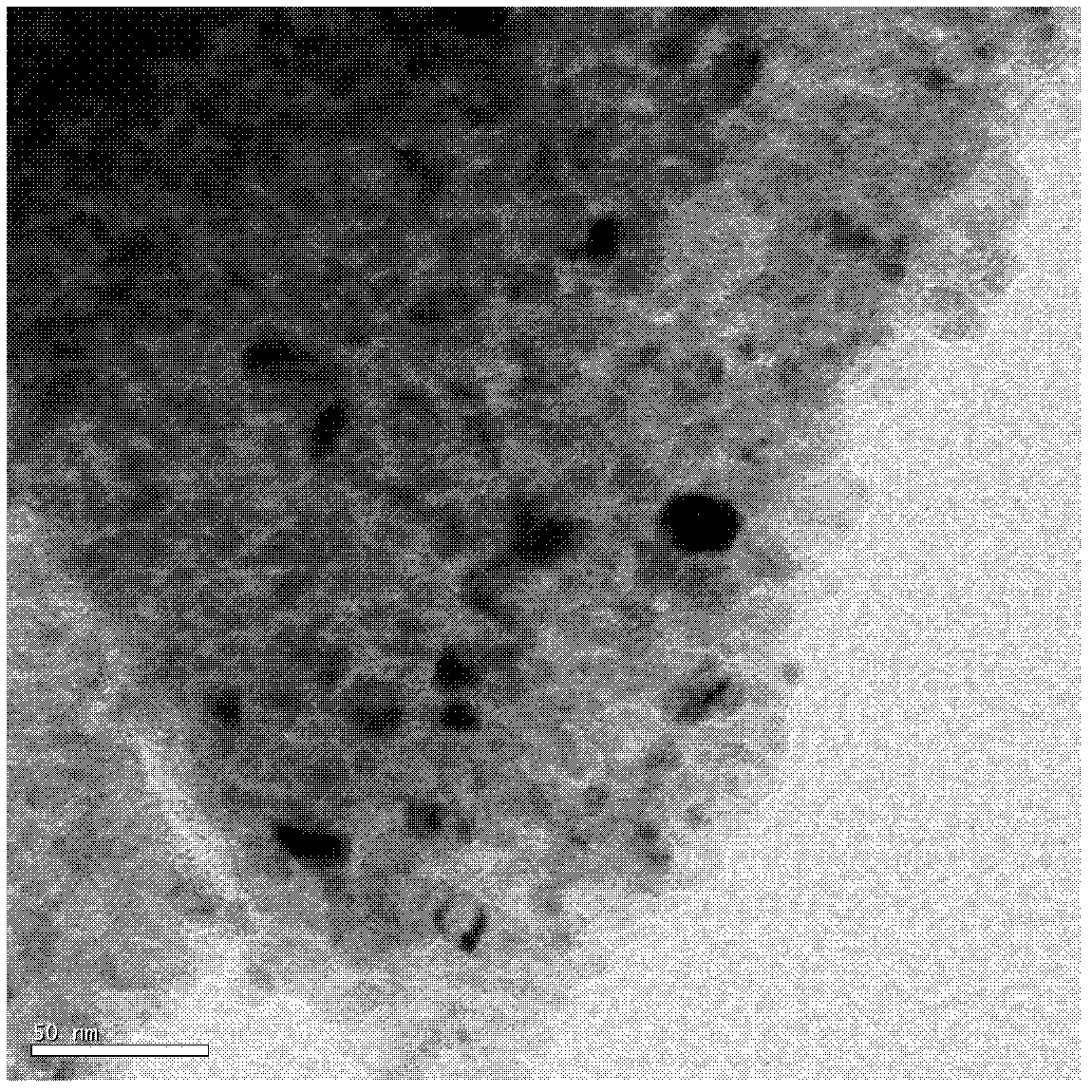

Nano-composite catalyst and preparation method thereof

ActiveCN102626641AHigh degree of compoundReduce dosageMetal/metal-oxides/metal-hydroxide catalystsDecompositionSurface-active agents

The invention provides a nano-composite catalyst and a preparation method thereof, belongs to the technical field of catalyzing, and solves the problem that the conventional load nano-composite oxide catalyst is low in nano-composite degree, and poor in catalyzing performance. The nano-composite catalyst is obtained by the flowing steps based on the condition that a surface-active agent is not used: firstly, reducing composite oxide crystal lattices or first metal ions mixed in the crystal lattices so as to obtain nano-metal granules containing first metal; and then introducing second metal into the surface of the first metal by Galvanic substitution reaction so as to obtain the nano-composite catalyst. Compared with the conventional catalyst, the nano-composite catalyst has more efficient catalyzing performance when being used for catalytic reaction of VOC (volatile organic compound) removal, automobile tail gas purification, formaldehyde removal, methane combustion, hydrogenation, hydrogenolysis, ammonia synthesis, ammonia decomposition, hydrocarbon synthesis, hydroformylation and the like.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

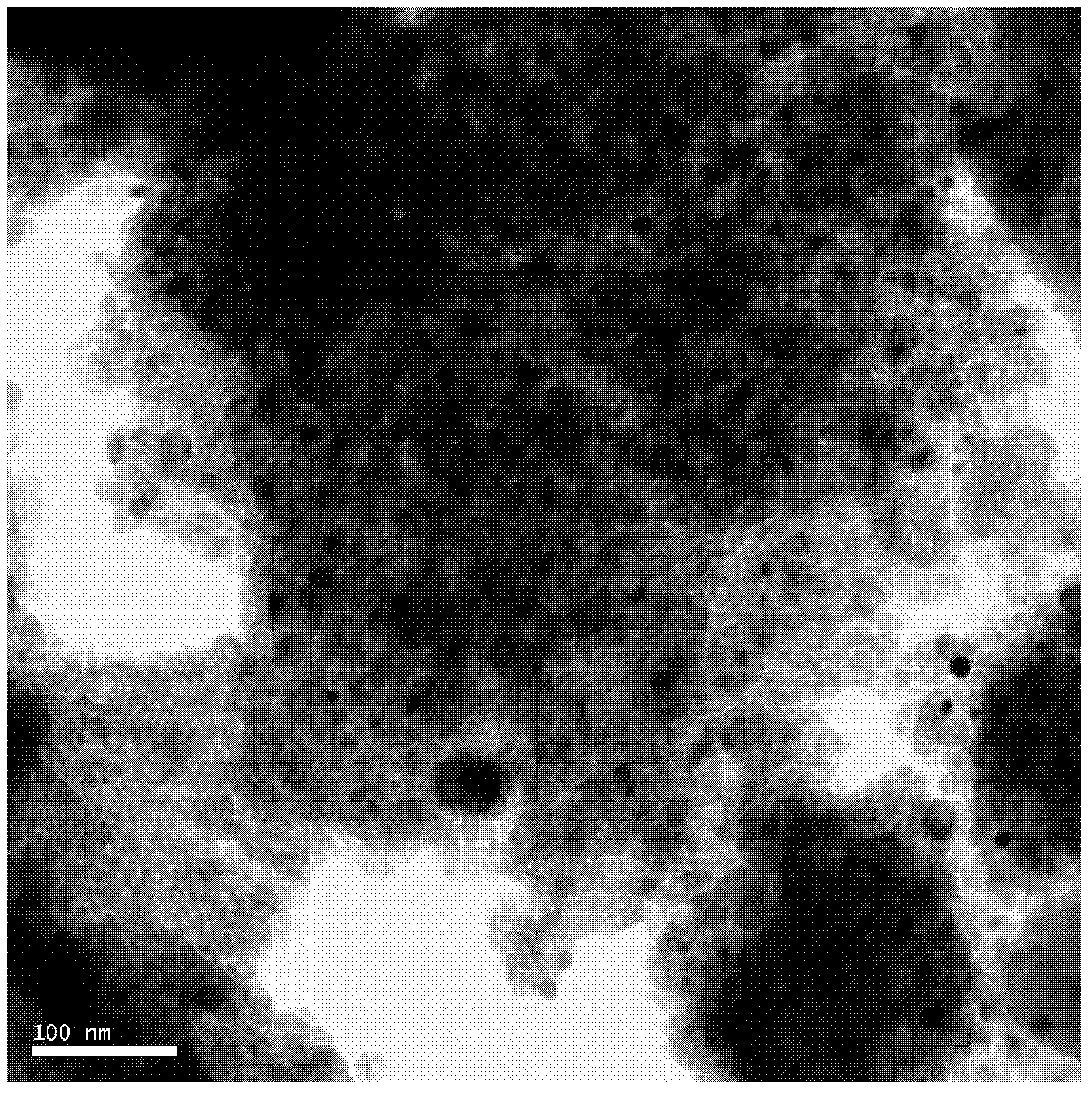

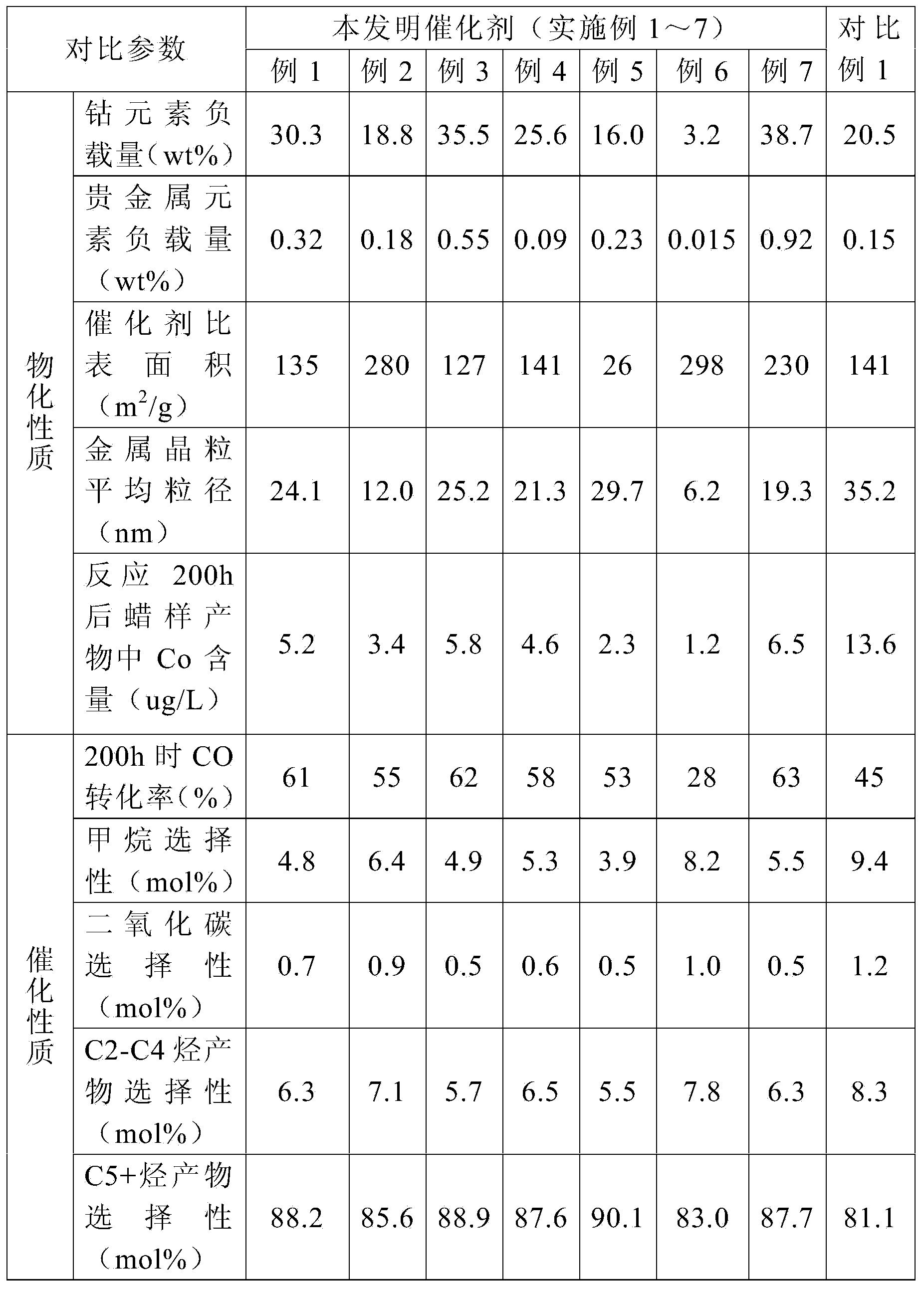

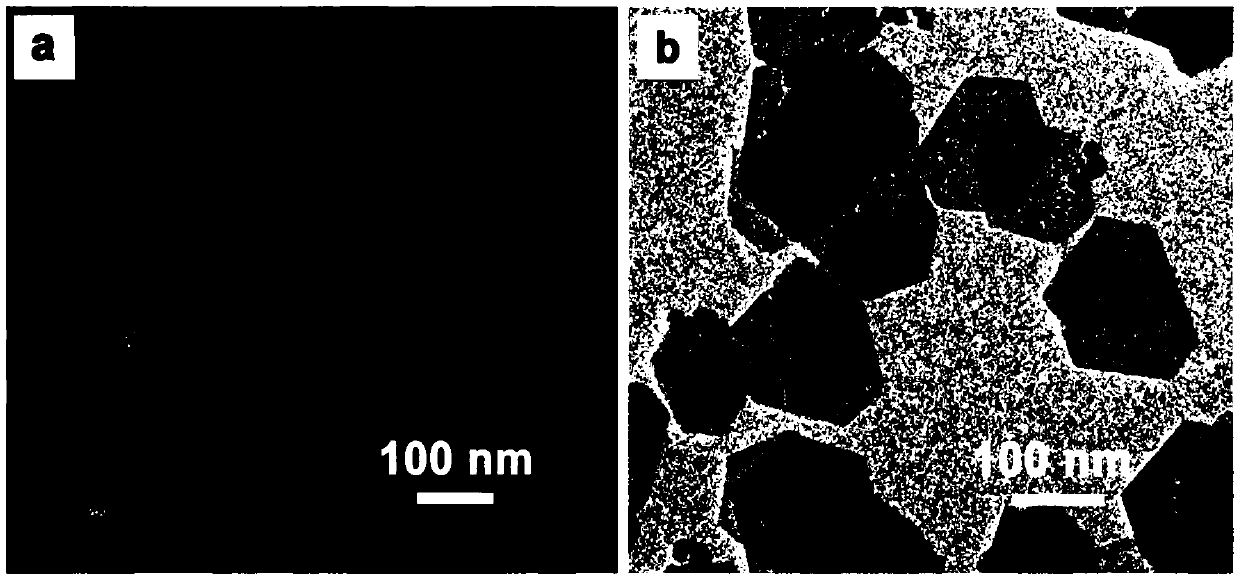

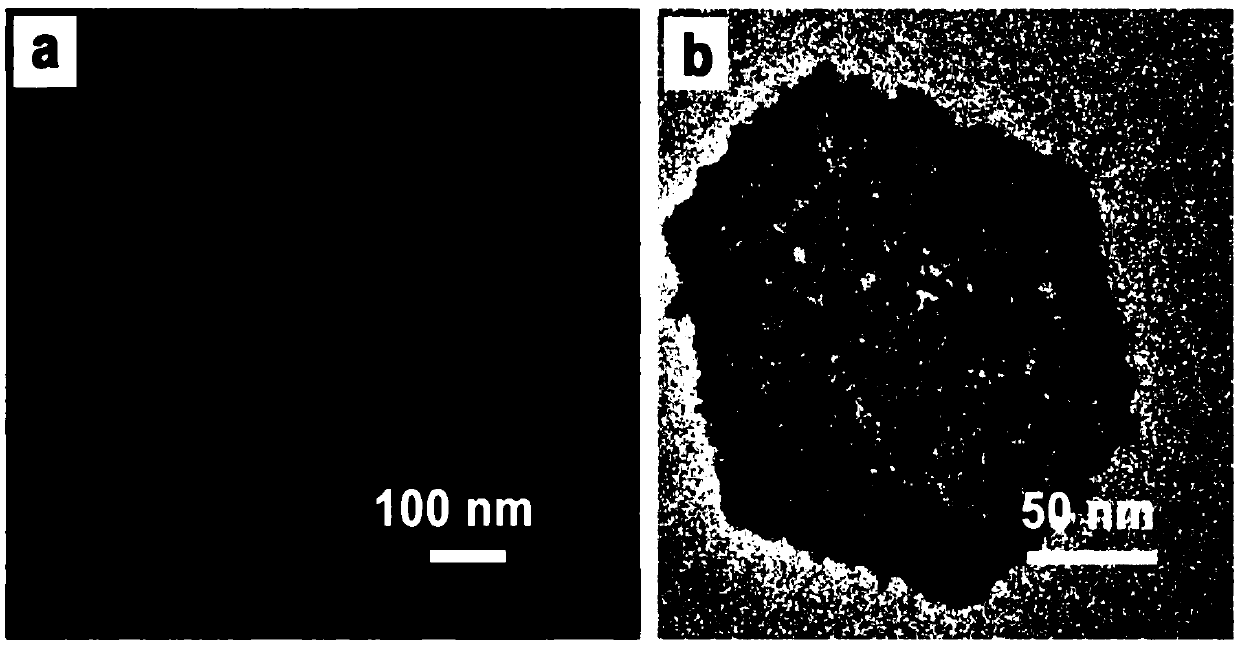

High-dispersity cobalt-based Fischer-Tropsch synthesis catalyst as well as preparation method and application thereof

ActiveCN104289231AInhibition of dissolutionHigh mechanical strengthLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsDispersityHydrazine compound

The invention discloses a high-dispersity cobalt-based Fischer-Tropsch synthesis catalyst as well as a preparation method and an application thereof. The catalyst comprises an oxide carrier, wherein an active component cobalt and a noble metal addition agent are loaded on the surface of the oxide carrier; the active component cobalt accounts for 3%-40% of the total weight of the catalyst, the noble metal addition agent accounts for 0.01%-1% of the total weight of the catalyst and the oxide carrier accounts for 59%-96.99% of the total weight of the catalyst; and the specific surface area of the catalyst is 20m<2> / g-300m<2> / g. According to the high-dispersity cobalt-based Fischer-Tropsch synthesis catalyst, a high-pH-value complexing metal salt carrier is selected to provide a metal element loading environment; hydrazine hydrate and a heavy metal salt are respectively used as a reducing agent and an induction agent of a reduction reaction; the active component cobalt is obtained by reduction at low temperature, and a water-phase reaction environment and ultrasonic vibration are additionally adopted so that the dispersity and the reduction degree of active grains are improved; the reduction of the mechanical intensity of the carrier and the loss of the active component are effectively avoided; the service life is prolonged; and the catalyst can be directly used for a Fischer-Tropsch synthesis reaction without high-temperature roasting and activation reduction.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

Preparation method and application of hollow porous transition metal chalcogenide nanosheets

InactiveCN106698365AAdjustable microscopic morphologyComposition is easy to controlMaterial nanotechnologyCobalt sulfidesSulfurIon exchange

The invention discloses a preparation method and application of hollow porous transition metal chalcogenide nanosheets. The preparation method comprises the following steps: performing a reaction on an alkaline solution of transition metal salt and water to obtain solid nanosheets of transition metal hydroxide, using the transition metal hydroxide as a precursor, performing a reaction on the transition metal hydroxide and chalcogenide anion X<2->, and performing anion exchange on the X<2-> and OH<-> to obtain the hollow porous nanosheets. The preparation method provided by the invention is an anion exchange and hydrothermal synthesis method, and is simple in process, low in cost and environment-friendly; and through adoption of different transition metal elements, the preparation method can be used for preparing a variety of transition metal chalcogen compound hollow porous nano-tablets, so that the preparation method is high in universality.

Owner:TIANJIN UNIV

Preparation method of zinc silicate nanometer material

InactiveCN102976344ALow reaction temperatureMild reaction conditionsMaterial nanotechnologySilicon compoundsAqueous solutionCatalytic degradation

The invention discloses a preparation method of a zinc silicate nanometer material. Amorphous nanometer silicon dioxide and soluble zinc salt are used as raw materials. The preparation method comprises the following steps: (A) weighing the amorphous nanometer silicon dioxide and the soluble zinc salt according to a stoichiometric ratio so as to prepare a suspended aqueous solution, regulating pH value of the suspended aqueous solution to 5-13, and stirring the suspended aqueous solution; (B) transferring the suspended aqueous solution in the step A into a hydrothermal reaction kettle and reacting the suspended aqueous solution at 160-230 DEG C for 2-24 hours; and (C) cooling a reaction system after the reaction is finished, and washing and drying a reaction product so as to obtain the zinc silicate nanometer material. The preparation method disclosed by the invention has the advantages of mild reaction, good reproducibility, simplicity in operation and the like; and the prepared Zn2SiO4 can be widely applied to the fields of fluorescent materials, catalytic degradation, adsorbing materials and so on.

Owner:SHIJIAZHUANG UNIVERSITY

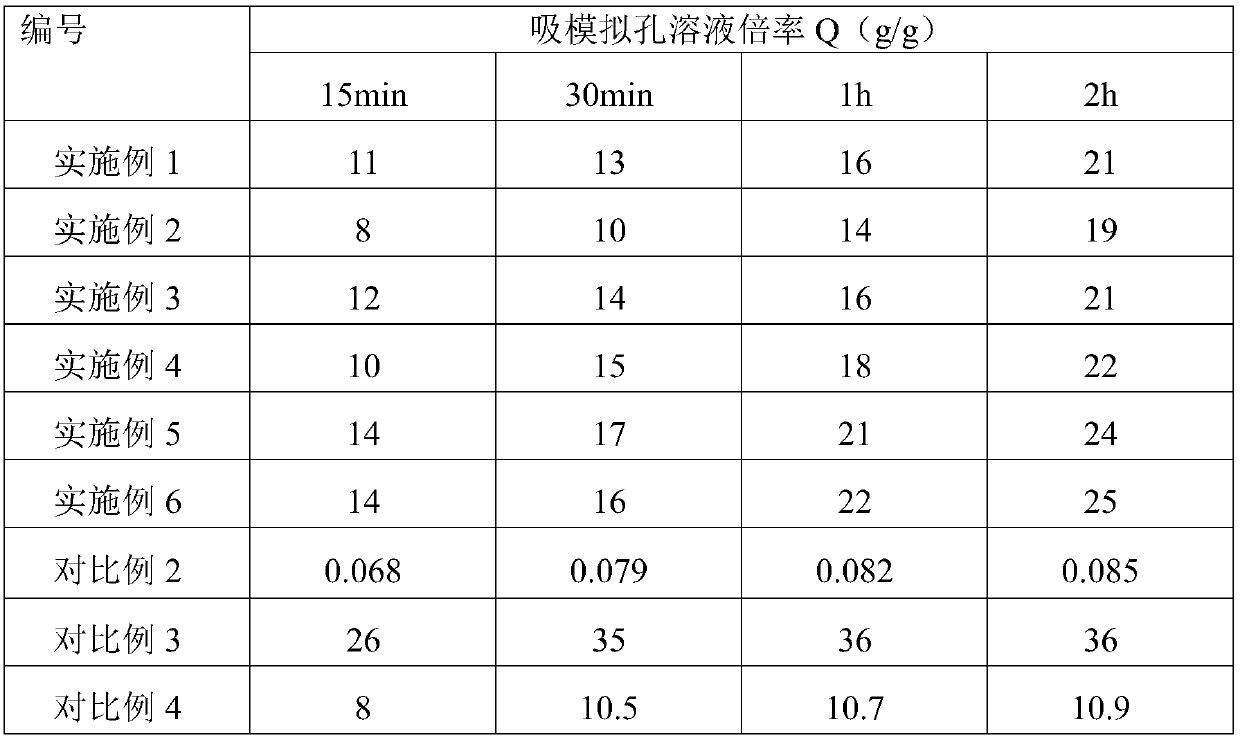

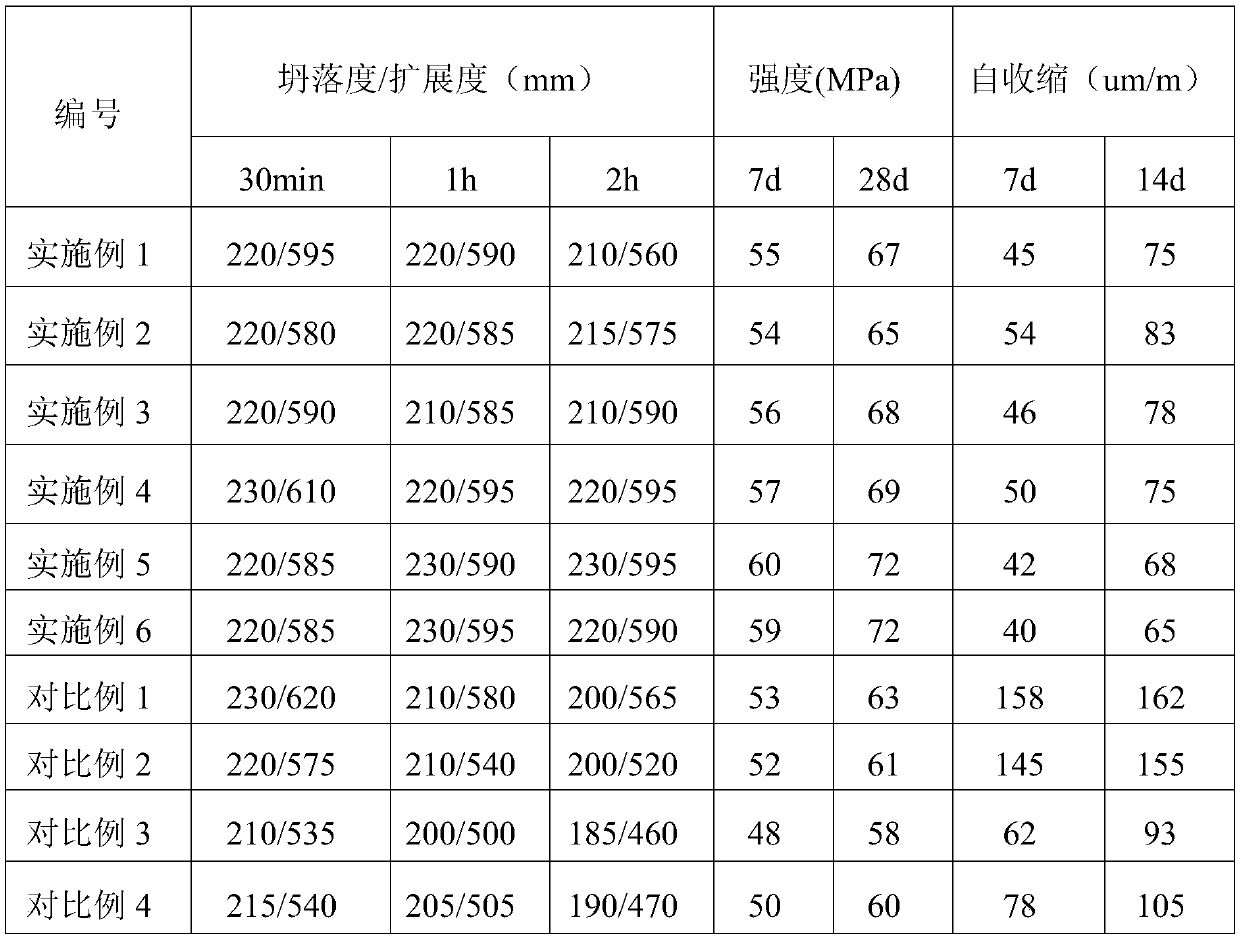

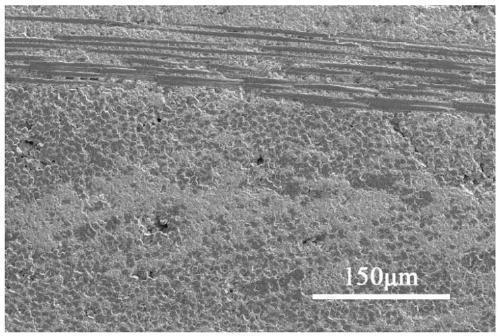

Curing agent in ceramsite carrier concrete and preparation method thereof

ActiveCN109516714AImprove water absorptionEasy to cause loss of work performanceExpanded clay aggregateAbsorption rate

The invention discloses a curing agent in ceramsite carrier concrete. A preparation method of the curing agent comprises the following steps that an acrylic acid solution, 2-acrylamide-2-methacrylic acid, initiators and crosslinking agents are uniformly mixed to prepare a reaction solution a; an etherificated sodium alginate solution, an acrylamide solution, initiators and crosslinking agents areuniformly mixed to prepare a reaction solution b; ceramsite is sequentially soaked in the reaction solution a and the reaction solution b, and is sequentially subjected to microwave treatment. Firstly, the ceramsite is used as a carrier; the polymerization of water absorption resin is performed inside and outside the ceramsite; meanwhile, a hole-inside hole-outside two-step method is used; the building of polymers with different water absorption rates inside and outside holes is realized; the prepared curing agent in the ceramsite carrier concrete can greatly improve the humidity inside the concrete; the early-period reduction and shrinkage effect of the concrete is obvious; meanwhile, the curing agent in the ceramsite carrier concrete has the advantages that the water absorption and waterrelease rate is slow; the use performance such as concrete strength is favorably guaranteed; important application and promotion values are realized.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD

Preparation method of high-performance polyelectrolyte-carbon nanotube nanocomposite pervaporation membrane

ActiveCN101695632AEasy to separateImprove throughputDistillationCationic polyelectrolytesCarbon nanotube

The invention discloses a preparation method of a polyelectrolyte-carbon nanotube nanocomposite separation membrane. The preparation method comprises the following steps of: drying anionic polyelectrolyte and cationic polyelectrolyte in vacuum, then respectively dissolving into water, and adding hydrochloric acid; dispersing a carbon nanotube in a cationic polyelectrolyte solution under the stirring and ultrasonic conditions; dripping the cationic polyelectrolyte solution dispersed with the carbon nanotube into an anionic polyelectrolyte solution under the stirring and ultrasonic conditions to obtain a series of polyelectrolyte-silicon dioxide nanocomposites; drying the polyelectrolyte-silicon dioxide nanocomposites in vacuum and then adding into water together with sodium hydroxide, stirring, dissolving, standing, defoaming and then obtaining a membrane casting solution; evenly scraping the membrane casting solution of the sodium polyelectrolyte-silicon dioxide nanocomposites onto a polyacrylonitrile porous membrane, and drying to obtain the polyelectrolyte-carbon nanotube nanocomposite separation membrane. The invention has cheap and easily-obtained raw materials, simple preparation method and excellent mechanical and separation properties.

Owner:ZHEJIANG UNIV

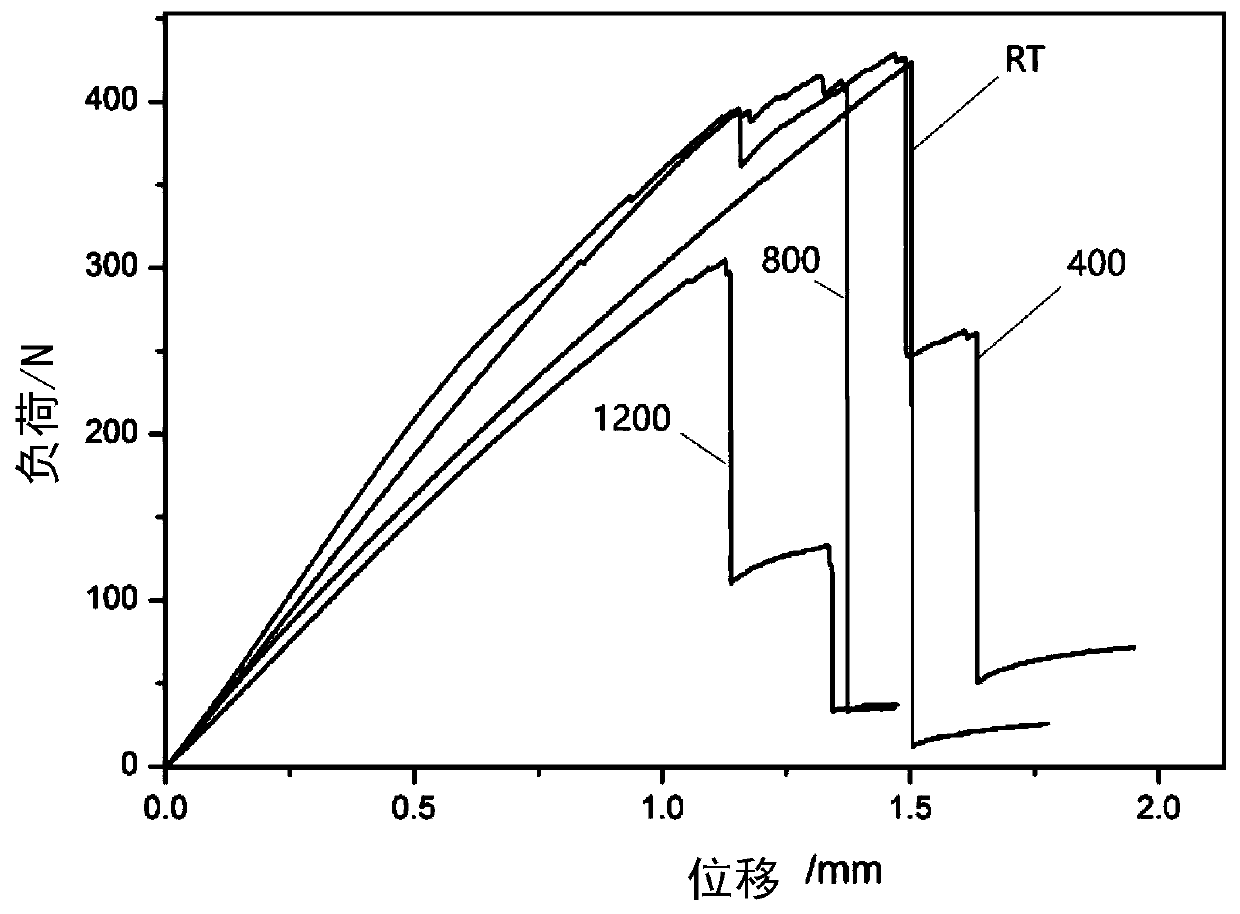

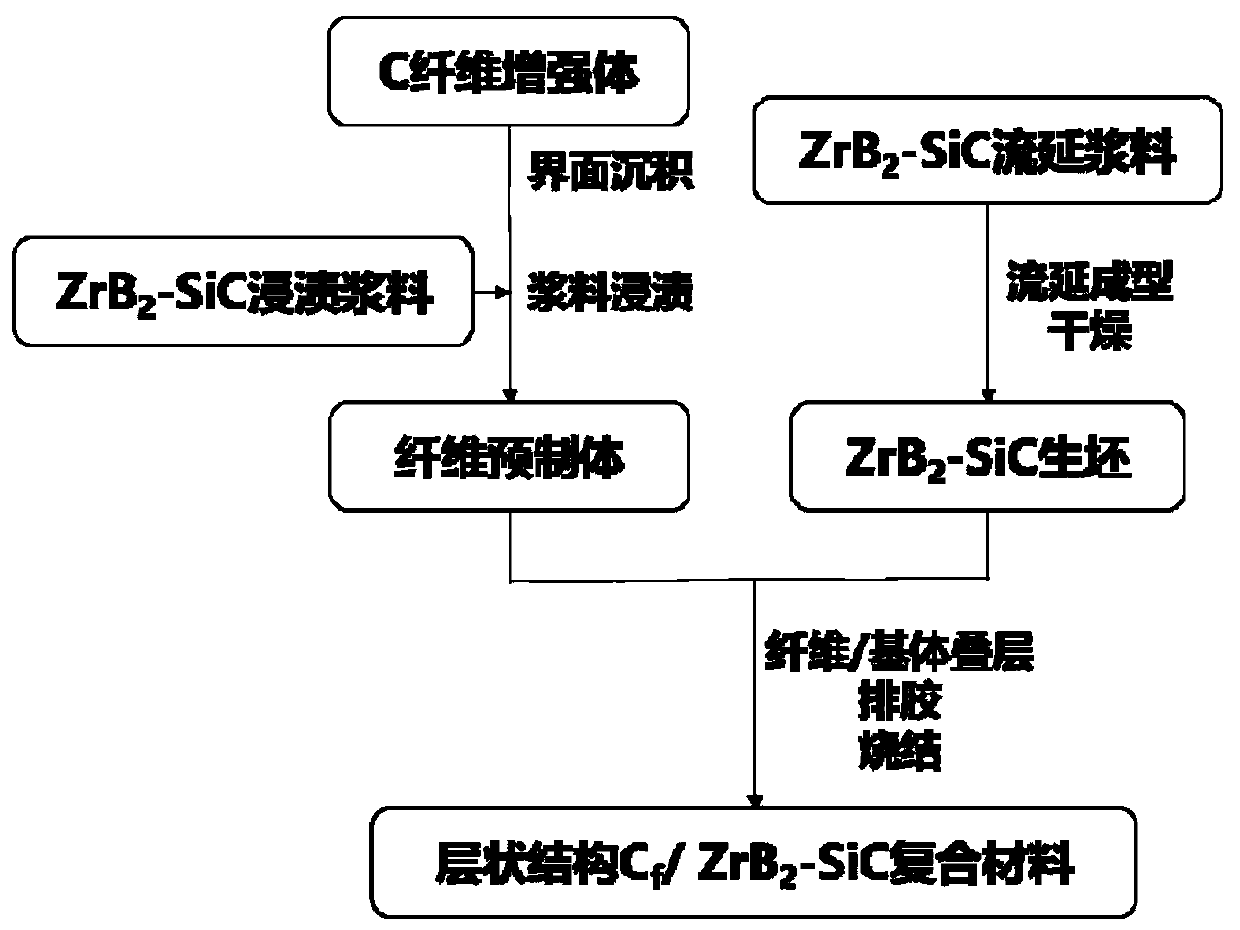

Cf/ZrB2-SiC ultrahigh-temperature ceramic matrix composite material of laminated structure and preparing method thereof

The invention relates to a Cf / ZrB2-SiC ultrahigh-temperature ceramic matrix composite material of a laminated structure and a preparing method thereof. The preparing method comprises the steps of 1, adding ZrB2 powder, SiC powder, a dispersing agent and a binder into a solvent, and mixing the materials to obtain ZrB2-SiC slurry; 2, adopting a casting forming method for preparing the ZrB2-SiC slurry into ZrB2-SiC biscuits; 3, impregnating a carbon fiber fabric body with the ZrB2-SiC slurry to obtain carbon fiber preforms; 4, alternatively laminating the obtained ZrB2-SiC biscuits and the carbonfiber preforms at least once, and then conducting glue discharge and sintering to obtain the Cf / ZrB2-SiC ultrahigh-temperature ceramic matrix composite material of the laminated structure.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com