Preparation method and application of hollow porous transition metal chalcogenide nanosheets

A technology of chalcogenides and transition metals, applied in metal selenide/telluride, cobalt compounds, chemical instruments and methods, etc., can solve the problems of two-dimensional nanosheet research that have not been reported, and achieve large specific surface area, microscopic Adjustable topography and predictable macro topography

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] 1. Raw materials: analytically pure cobalt nitrate hexahydrate, triethylamine, thioacetamide, ethanol

[0046] 2. Accurately weigh 0.1091g (0.37mmol) cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) Dissolve in 15 mL of water and stir at room temperature until a pink homogeneous solution is formed.

[0047] 3. Slowly add 0.375mL triethylamine solution dropwise to the mixture under constant stirring, the pink solution will immediately turn dark blue.

[0048] 4. Add 14.625mL of water to the mixture at one time. The resulting solution was transferred to an autoclave with a total volume of 50 mL, then the autoclave was sealed, and placed in a constant temperature oven at 180° C. for 24 h to obtain an aqueous solution containing cobalt hydroxide (ie cobalt hydroxide solution).

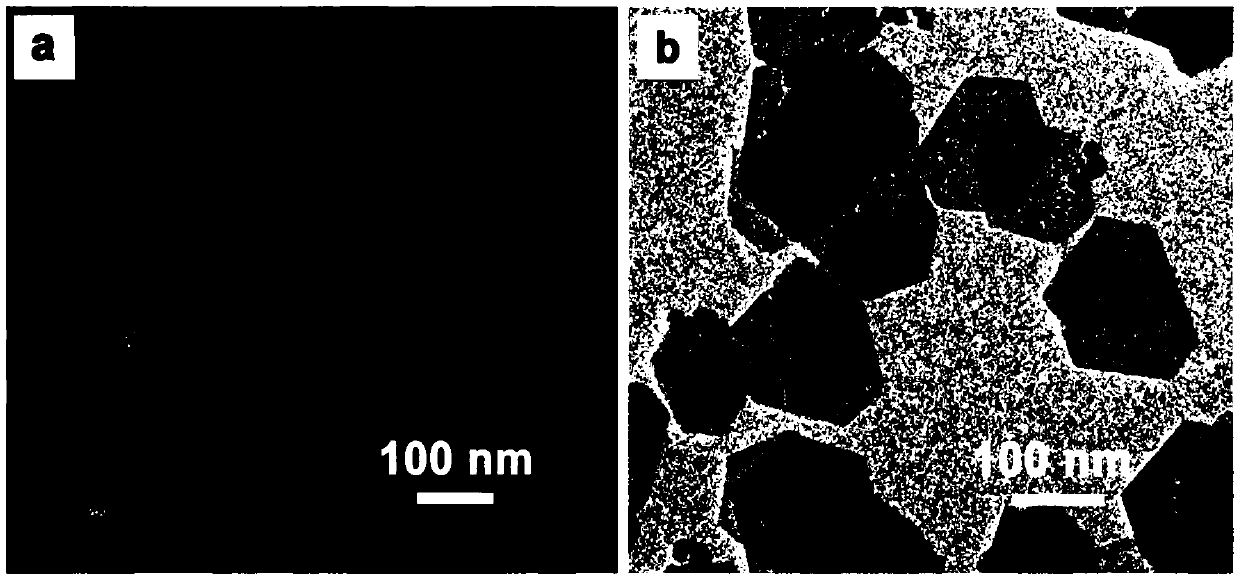

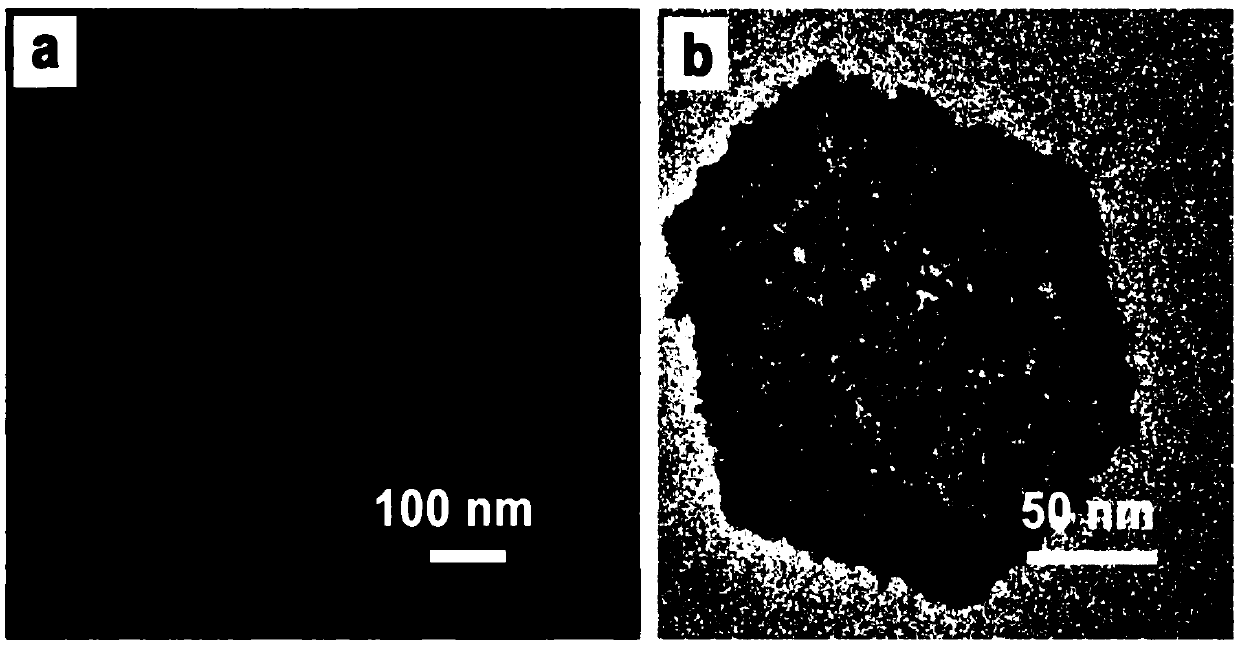

[0049] 5. Weigh 0.0423g (0.563×10 -3 mmol) thioacetamide (TAA) was placed in 7.5 mL of water, and after stirring at room temperature to form a homogeneous solution, 4.5 mL of cobalt hydroxide s...

Embodiment 2

[0054] The steps are the same as in Example 1, except that in the sixth step, the autoclave is placed in an oven at 140° C. for 6 hours, then taken out and cooled to room temperature. Other reaction conditions remain unchanged, and the obtained results are basically consistent with the results obtained in Example 1.

Embodiment 3

[0056] The steps are the same as in Example 1, except that in the sixth step, the autoclave is placed in an oven at 160° C. for 6 hours, then taken out and cooled to room temperature. Other reaction conditions remain unchanged, and the obtained results are basically consistent with those obtained in Example 1. .

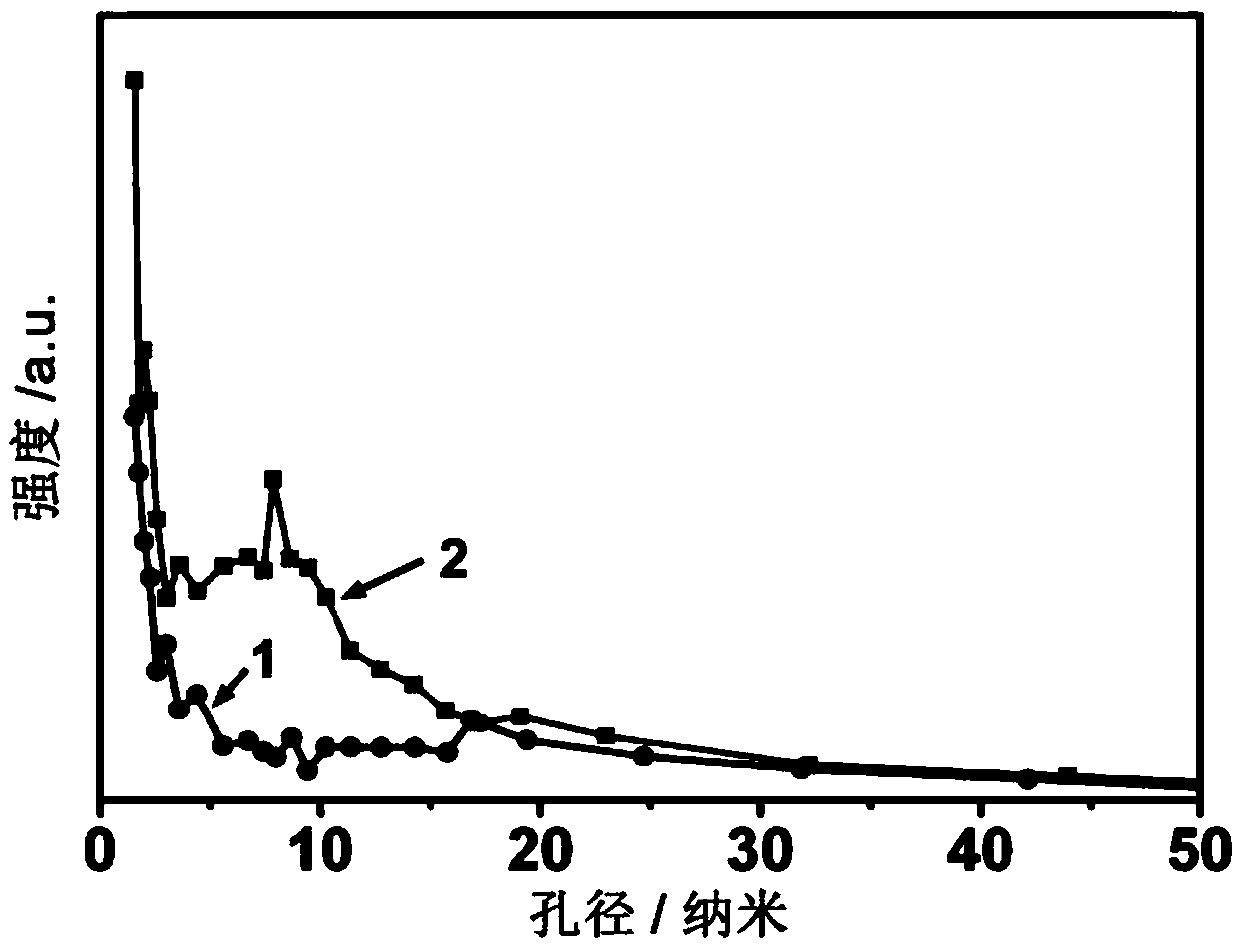

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com