A kind of preparation method of zno hemispherical micro-nano structure and obtained product

A micro-nanostructure, hemispherical technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of poor size control effect, poor morphology uniformity, poor repeatability, etc. Good market application prospect, good appearance, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1.1 Add 0.439 g of zinc acetate to a mixed solvent of 30 mL of ethylene glycol and 1 mL of water and stir until clear;

[0034] 1.2 Add 3 mL of ethanolamine dropwise to the above solution and stir evenly;

[0035] 1.3 Transfer the above solution to the reactor and react at 150 °C for 12 h;

[0036] 1.4 After the reaction, the product was obtained after centrifugation and washing.

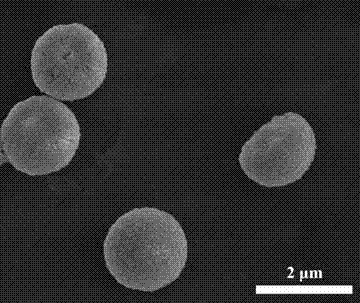

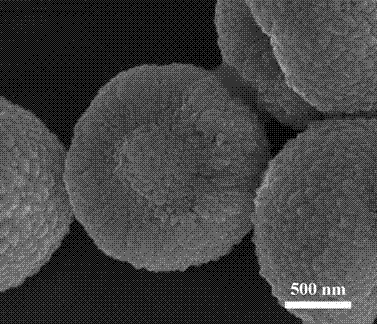

[0037] SEM of the product as figure 1 with figure 2 It can be seen from the figure that the obtained product is a solid hemispherical structure formed by the close arrangement of ZnO particles and ZnO rods. The diameter of the ZnO hemispherical structure is 1.5-1.7 μm, and the diameter of the central part is 0.9-1.1 μm , consisting of ZnO particles with a size of 0.04-0.06 μm, the outer layer part is composed of ZnO rods with a diameter of 0.04-0.06 μm and a length of 0.27-0.30 μm, and the ZnO rods are closely arranged along the diameter of the ball.

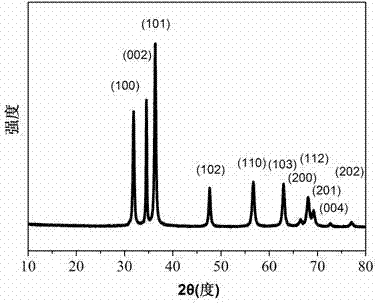

[0038] The XRD pattern of the produ...

Embodiment 2

[0041] 2.1 Add 0.525 g of zinc nitrate hexahydrate to a mixed solvent of 30 mL of ethylene glycol and 0.8 mL of water and stir until clear;

[0042] 2.2 Add 3.6 mL of ethanolamine dropwise to the above solution and stir evenly;

[0043] 2.3 Transfer the above solution to the reactor and react at 130 °C for 2 h;

[0044] 2.4 After the reaction is over, the product is obtained after centrifugation and washing.

[0045]The obtained product is a solid hemispherical structure formed by the close arrangement of ZnO particles and ZnO rods. The diameter of the ZnO hemispherical structure is 0.23-0.26 μm, and the diameter of the central part is 0.14-0.16 μm. The outer layer is composed of ZnO rods with a diameter of 0.02-0.03 μm and a length of 0.04-0.06 μm, and the ZnO rods are closely arranged along the diameter of the ball.

[0046] The product is irradiated by a 365 nm ultraviolet lamp, and the illuminated area is 1.5cm 2 Under the condition, its photocurrent intensity can reach...

Embodiment 3

[0048] 3.1 Add 0.875 g of zinc nitrate hexahydrate to a mixed solvent of 30 mL of ethylene glycol and 1.2 mL of water and stir until clear;

[0049] 3.2 Add 4.5 mL of ethanolamine dropwise to the above solution and stir evenly;

[0050] 3.3 Transfer the above solution to the reactor and react at 170 °C for 26 h;

[0051] 3.4 After the reaction is over, the product is obtained after centrifugation and washing.

[0052] The obtained product is a solid hemispherical structure formed by the close arrangement of ZnO particles and ZnO rods. The diameter of the ZnO hemispherical structure is 9.2-9.6 μm, and the diameter of the central part is 3.6-3.8 μm. The outer part is composed of ZnO rods with a diameter of 0.25-0.28 μm and a length of 2.7-2.9 μm, and the ZnO rods are closely arranged along the diameter direction of the ball.

[0053] The product is irradiated by a 365 nm ultraviolet lamp, and the illuminated area is 1.5cm 2 Under the condition, its photocurrent intensity can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com