Transparent nanofiber membrane, preparation thereof and application of transparent nanofiber membrane to transparent mask

A nanofiber membrane, transparent technology, applied in the field of masks, can solve the problems of reducing the thickness of the electrospun fiber membrane, poor mechanical properties, long preparation time, etc., to achieve the maintenance of fiber morphology, excellent air permeability and filtration performance, method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

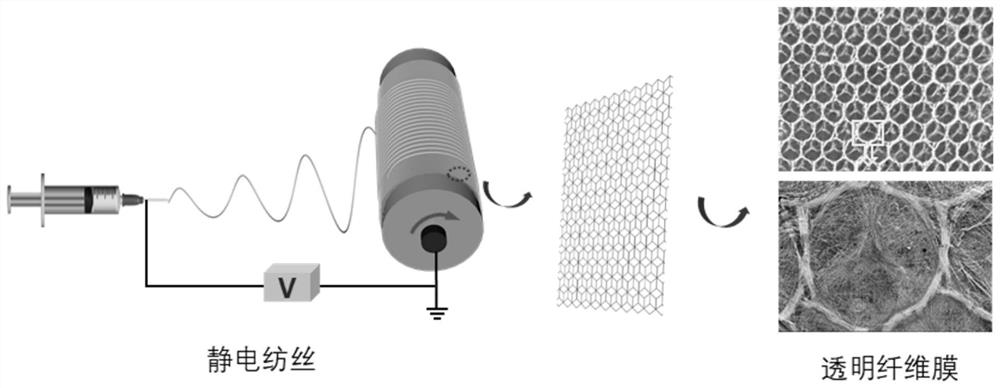

[0054] A preparation method of a transparent nanofiber film, which uses an electrospinning process and a special receiving substrate to make a transparent nanofiber film from a high molecular polymer (polyurethane);

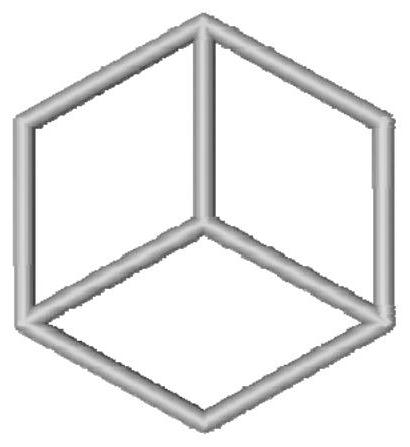

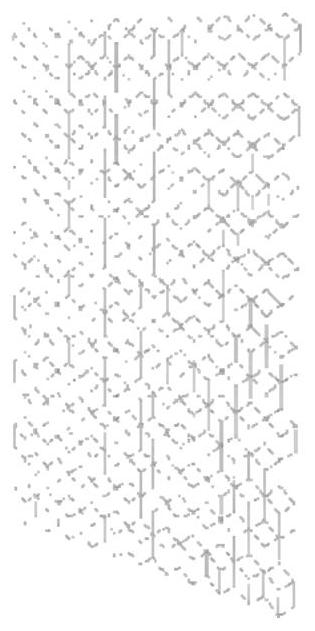

[0055] The special receiving base material refers to an insulating base material with a planar network structure as a whole, and the basic unit I constituting the planar network structure is a planar structure connected by a regular hexagonal bracket and three inline brackets. One end of an inline bracket converges at the center of the regular hexagonal bracket, and the other end is connected to three vertices of the regular hexagonal bracket respectively, and the three vertices are mutually non-adjacent vertices on the regular hexagonal bracket ; The side length of the regular hexagon is 1 mm; the thickness of the regular hexagonal bracket and the inline bracket are both 100 μm;

[0056] The special receiving base material is covered on the peripheral surface of...

Embodiment 2

[0068] A method for preparing a transparent nanofiber film, using an electrospinning process and a special receiving substrate to make a transparent nanofiber film from a high molecular polymer (polyacrylonitrile);

[0069] The special receiving base material refers to an insulating base material with a planar network structure as a whole, and the basic unit I constituting the planar network structure is a planar structure connected by a regular hexagonal bracket and three inline brackets. One end of an inline bracket converges at the center of the regular hexagonal bracket, and the other end is connected to three vertices of the regular hexagonal bracket respectively, and the three vertices are mutually non-adjacent vertices on the regular hexagonal bracket ; The side length of the regular hexagon is 1.5 mm; the thickness of the regular hexagonal bracket and the inline bracket are both 150 μm;

[0070] The special receiving base material is covered on the peripheral surface o...

Embodiment 3

[0078] A method for preparing a transparent nanofiber film, using an electrospinning process and a special receiving substrate to make a transparent nanofiber film from a high molecular polymer (polyvinylidene fluoride);

[0079] The special receiving base material refers to an insulating base material with a planar network structure as a whole, and the basic unit I constituting the planar network structure is a planar structure connected by a regular hexagonal bracket and three inline brackets. One end of an inline bracket converges at the center of the regular hexagonal bracket, and the other end is connected to three vertices of the regular hexagonal bracket respectively, and the three vertices are mutually non-adjacent vertices on the regular hexagonal bracket ; The side length of the regular hexagon is 2mm; the thickness of the regular hexagonal bracket and the inline bracket is 150 μm;

[0080] The special receiving base material is covered on the peripheral surface of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com