Patents

Literature

36 results about "Planar network" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

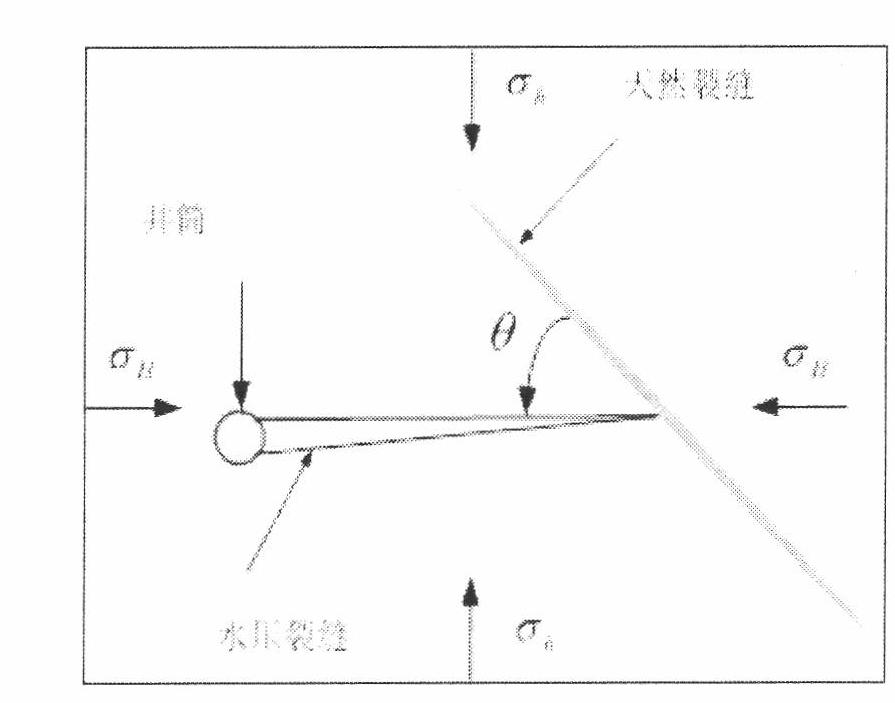

Non-planar network fracturing control method for fractured reservoir

The invention discloses a non-planar network fracturing construction control method for a fractured reservoir, which includes the step: firstly, performing pre-fracturing evaluation by (1) obtaining the intrinsic fracture development degree and directions according to FMI (formation micro-scanner image) logging and conventional logging data, (2) determining man-made fracture directions, (3) judging the angle relation between man-made fractures and intrinsic fractures, and (4) judging the non-planar network fracturing formation adequacy; secondly, establishing a stress field inversion constrained optimization model by utilizing a numerical value inversion method combining multi-well constrained optimization and finite elements so as to obtain numerical simulation of three-dimensional geostress states and rock mechanical parameters of a fractured reservoir area; thirdly, selecting corresponding construction parameters, and fracturing strata so as to force the intrinsic fractures and holes to open as large as possible; and fourthly, according to the opened equivalent number and openness of the intrinsic fractures explained by test fracturing, selecting grain sizes and use amount of propping agents matched with the intrinsic fractures or the holes, and leading fracturing fluid carrying the propping agents to enter the intrinsic fractures or the holes.

Owner:ORIENT BAOLIN TECH DEV BEIJING

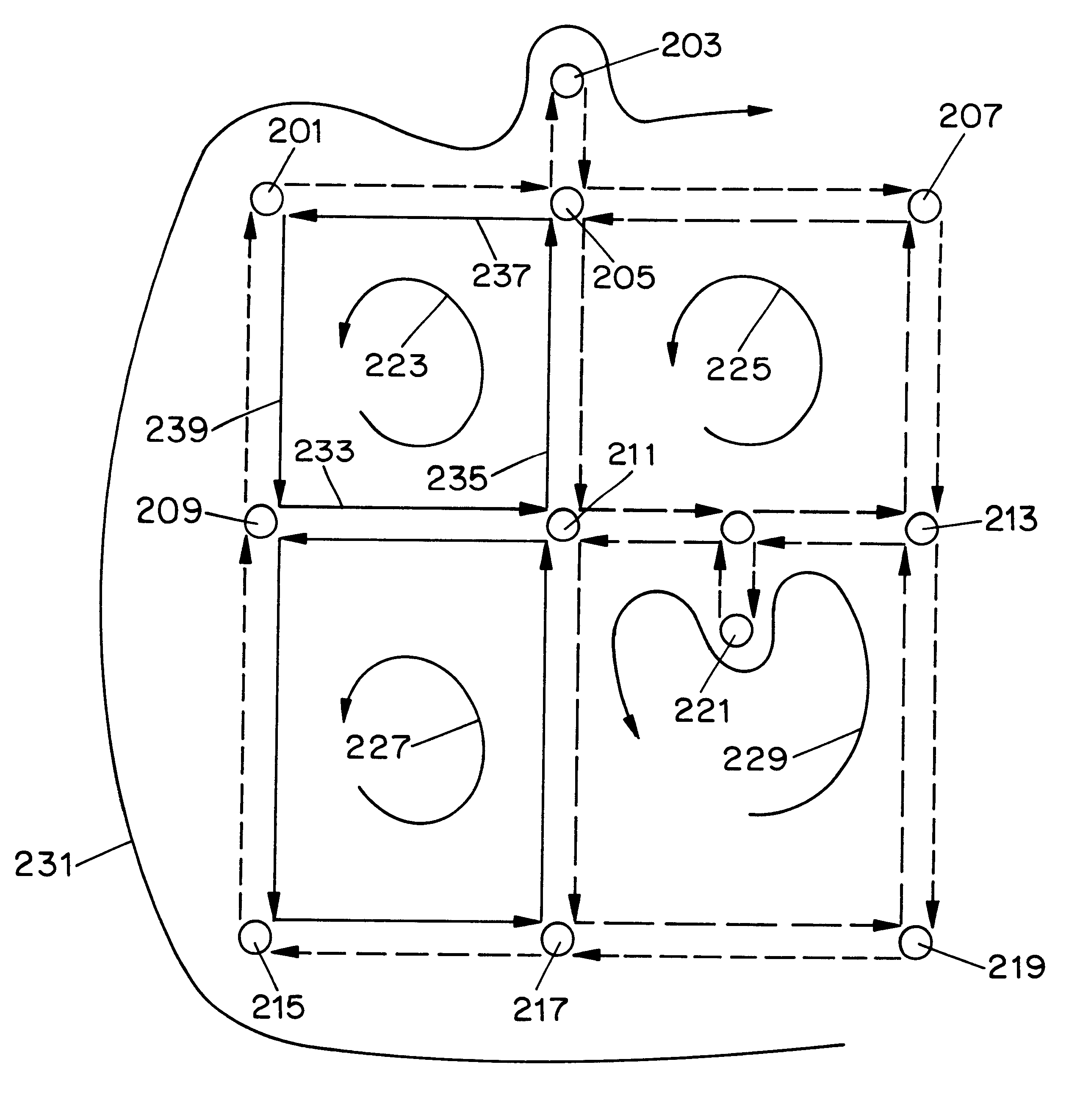

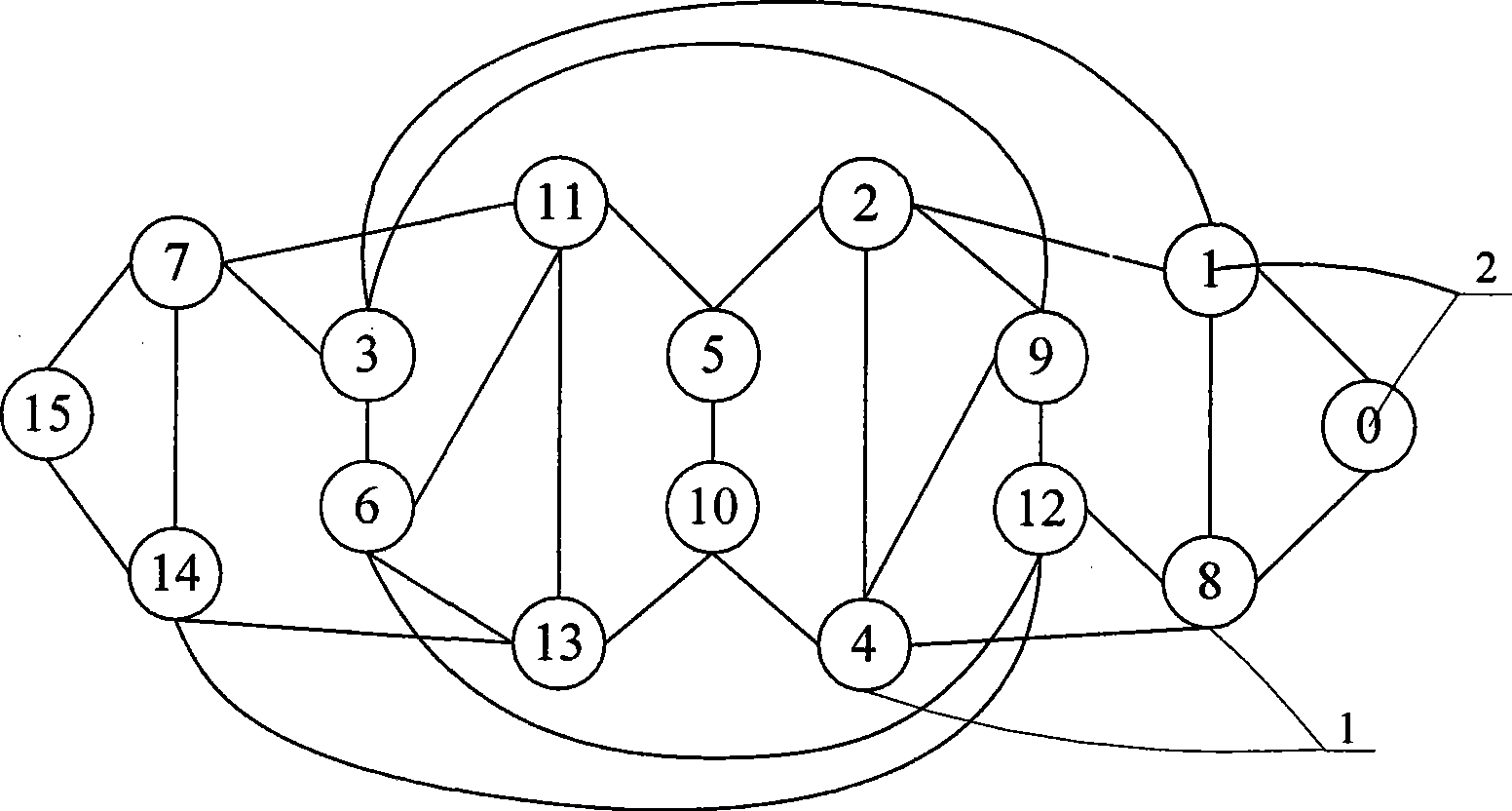

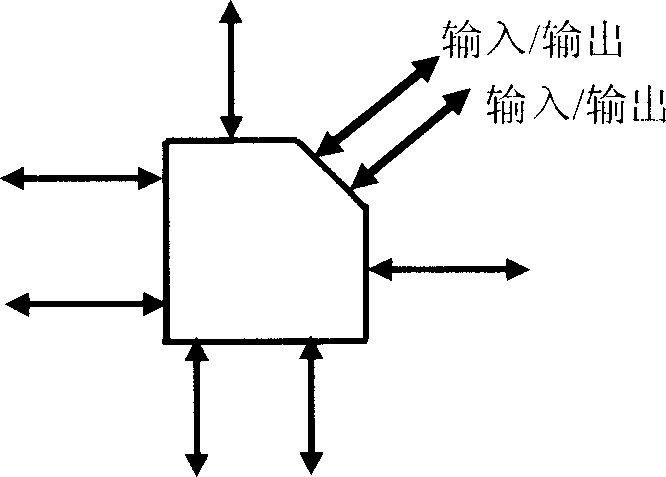

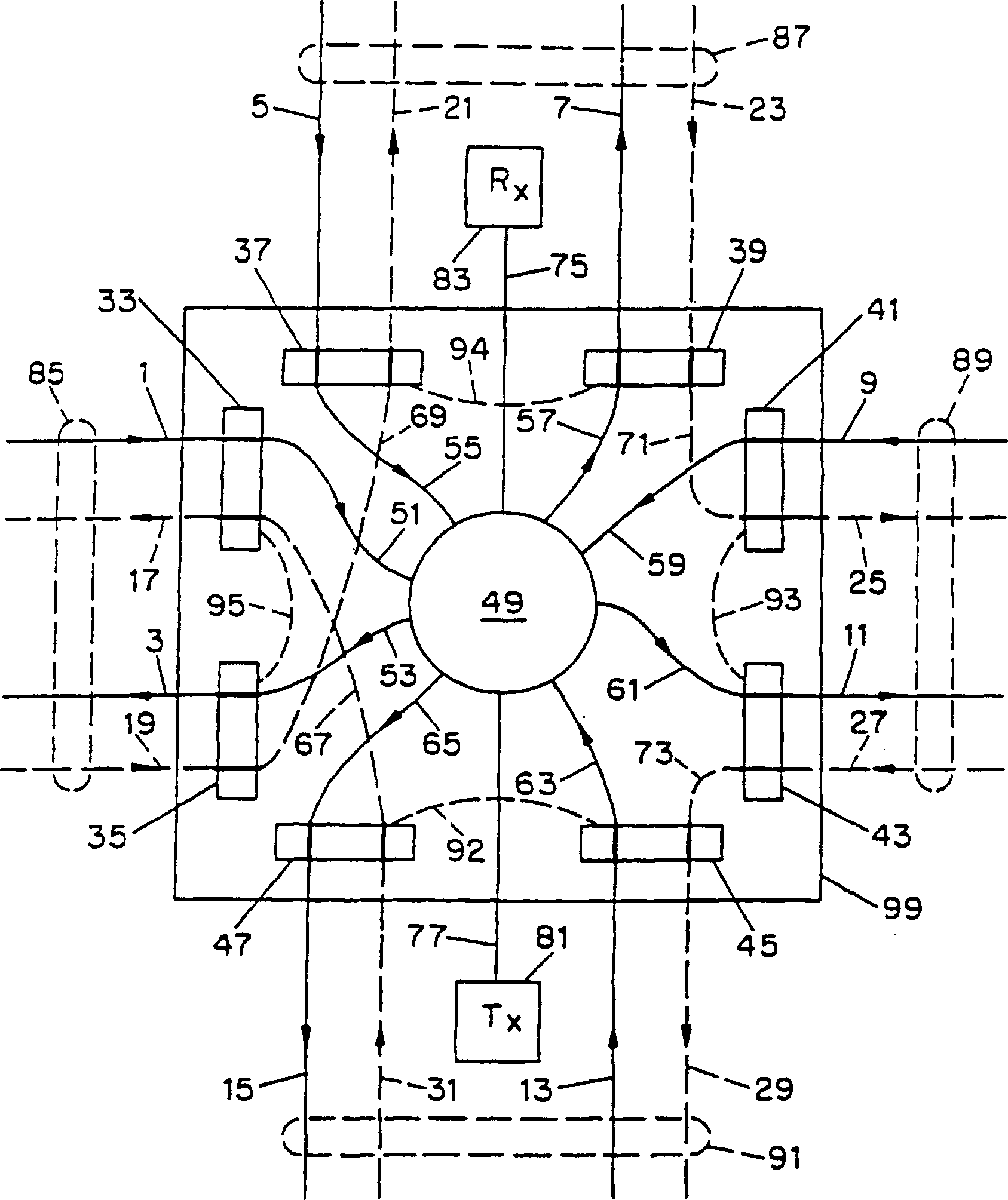

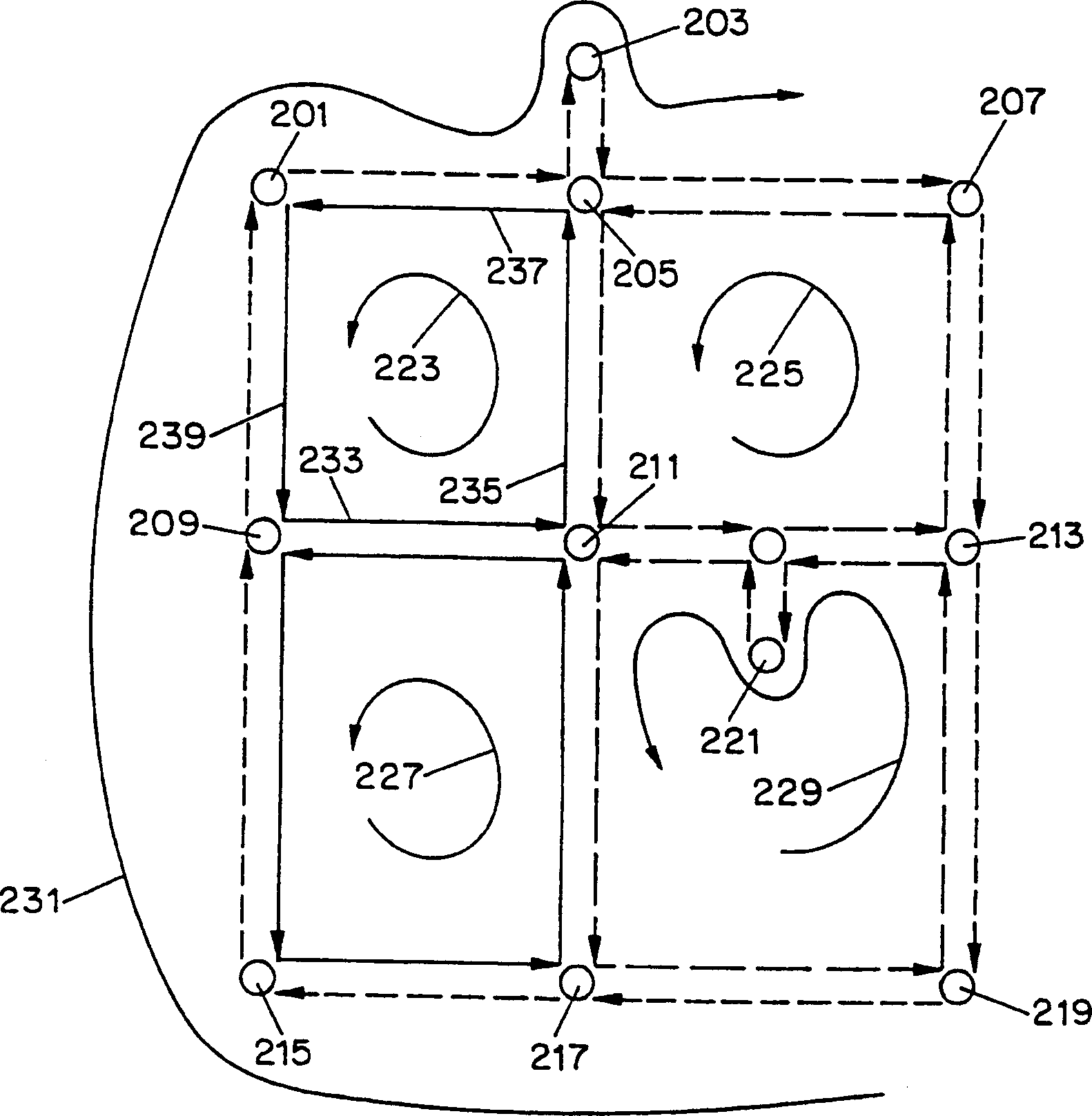

Network switch failure restoration

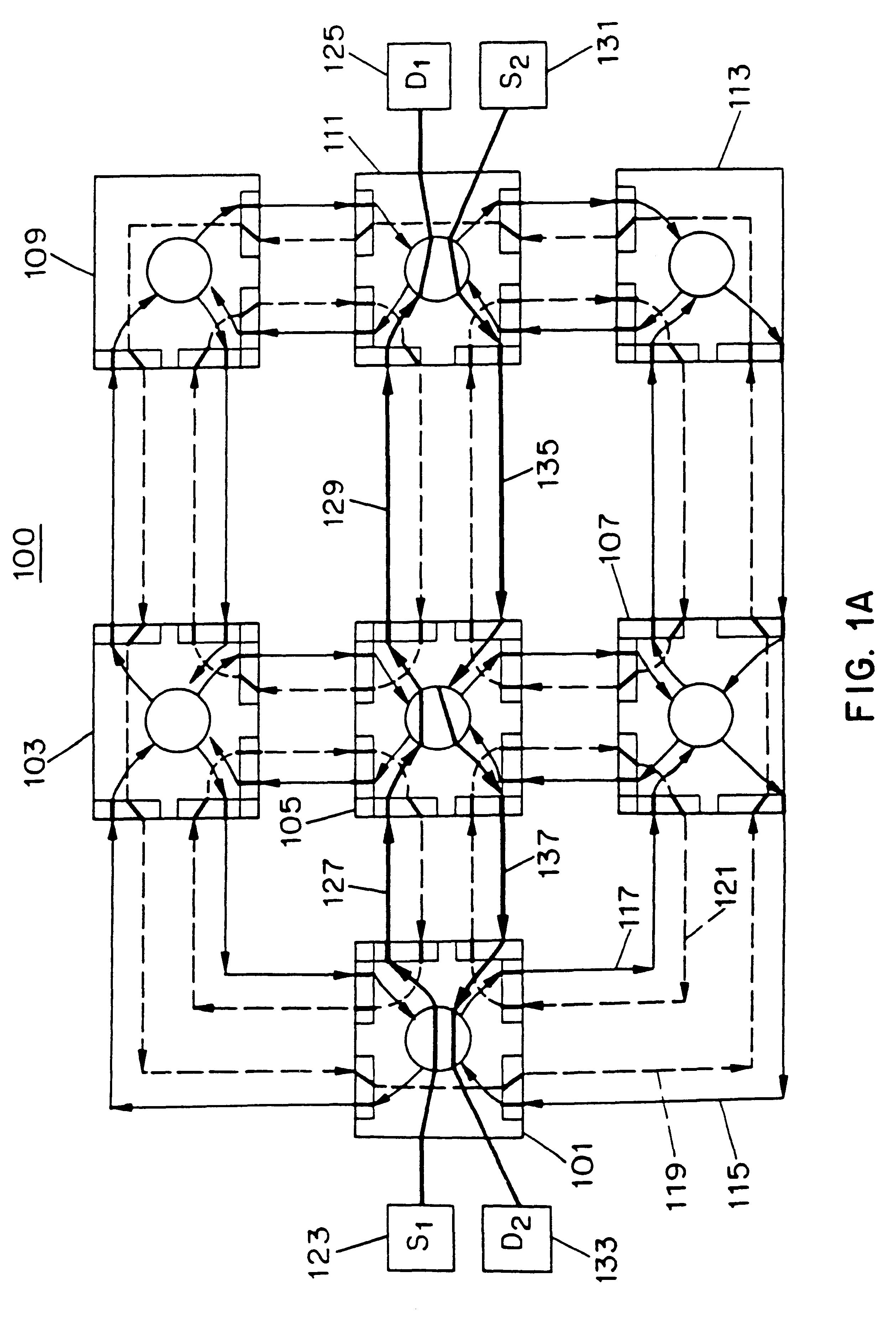

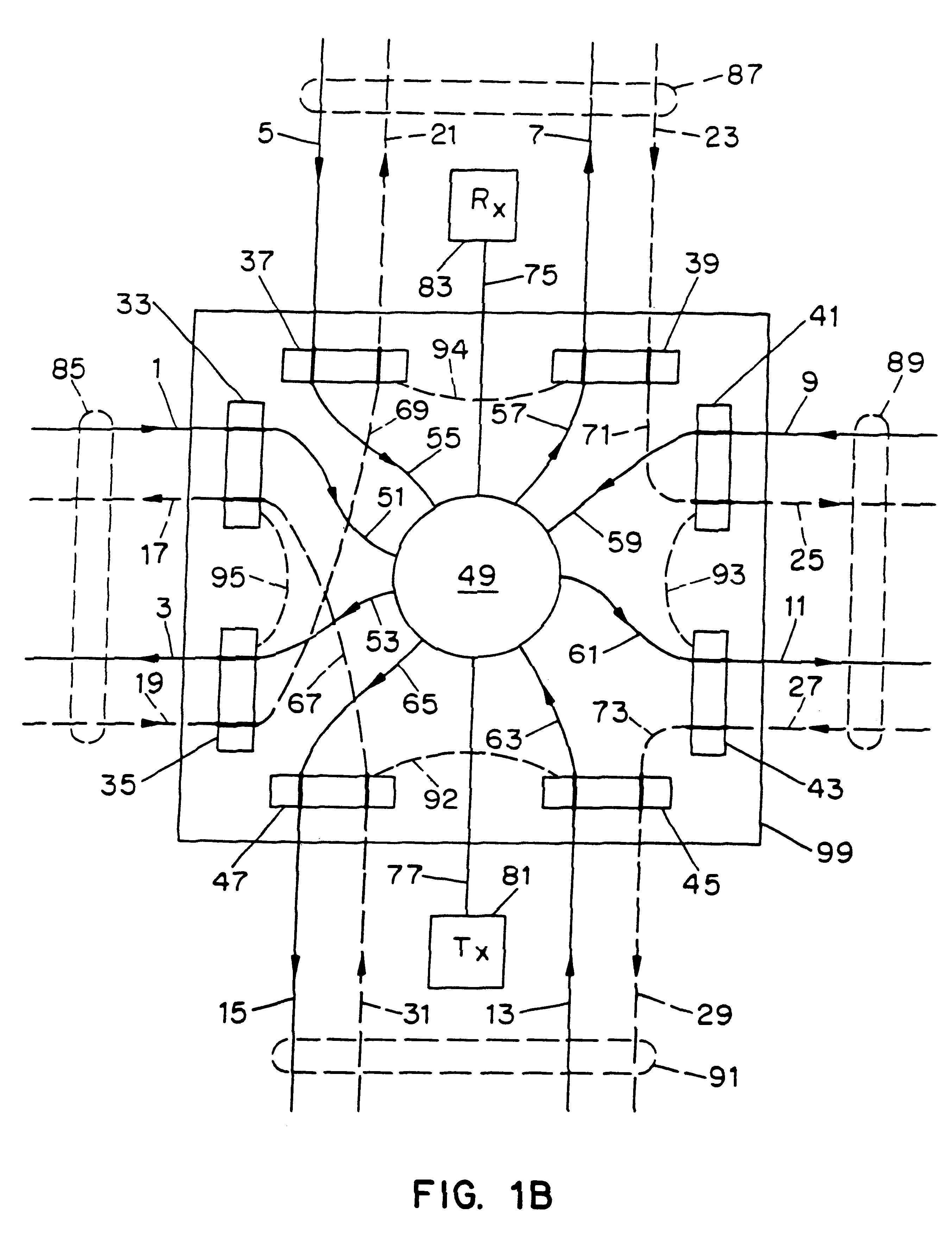

A system and method for automatically restoring a network which contains a node with a failed switch. Protection cycles are generated for the network to be restored and cyclegroups are generated from the protection cycles. Each node is provided with protection switches which internally interconnect the input / output ports to connecting links via interconnecting protection fibers. The selection of which internal protection fibers upon which to switch transmitted information onto allows the node to be configured to create merged cyclegroups. Thus if a failure in the central switch is detected, the transmitted information is diverted to a selected protection fiber corresponding to a merged cyclegroup so that the information can be automatically passed around the failed switch via the protection fibers. Each protection switch has associated mapping data which defines which protection fiber will be switched to based upon the input and output link for the transmission that is required to be sent through the node. The system and method applies to non-planar networks as well as planar networks.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

Cut set-based risk and reliability analysis for arbitrarily interconnected networks

InactiveUS6125453AError detection/correctionMultiple digital computer combinationsNODALPlanar network

Method for computing all-terminal reliability for arbitrarily interconnected networks such as the United States public switched telephone network. The method includes an efficient search algorithm to generate minimal cut sets for nonhierarchical networks directly from the network connectivity diagram. Efficiency of the search algorithm stems in part from its basis on only link failures. The method also includes a novel quantification scheme that likewise reduces computational effort associated with assessing network reliability based on traditional risk importance measures. Vast reductions in computational effort are realized since combinatorial expansion and subsequent Boolean reduction steps are eliminated through analysis of network segmentations using a technique of assuming node failures to occur on only one side of a break in the network, and repeating the technique for all minimal cut sets generated with the search algorithm. The method functions equally well for planar and non-planar networks.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

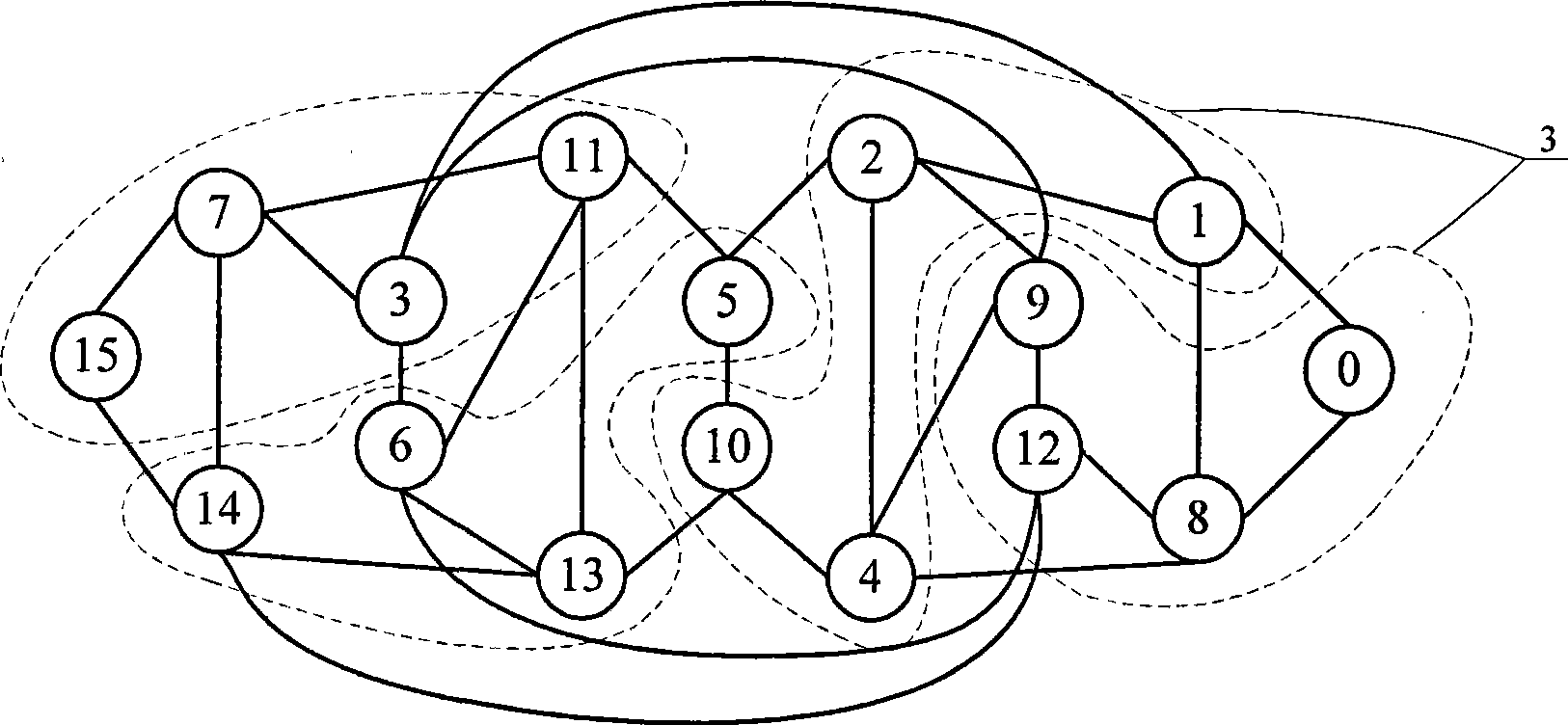

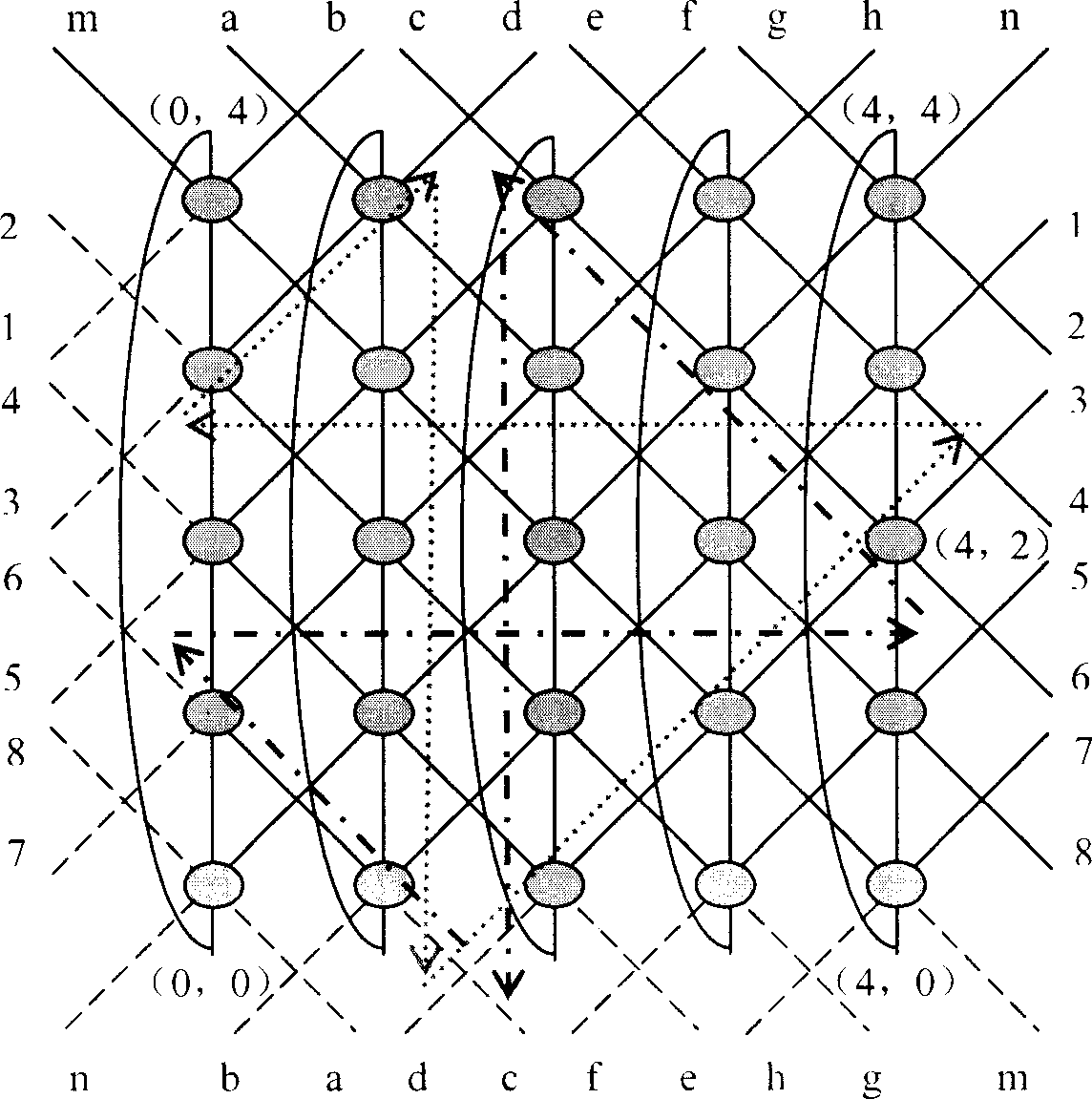

Method for constructing network on three-dimensional chip

InactiveCN101483614AImprove performanceSmall diameterData switching networksVertical planeRound complexity

The invention provides a three-dimensional network on chip (NoC) structuring method by using a horizontal-plane network structure and a flexible imaginary-plane network structure, wherein, the horizontal-plane network of which the network topology adopts a De Bruijn picture is a plane extending along the X direction and the Y direction; while the imaginary-plane network is a curved surface extending along the three directions of X, Y and Z, the network can be formed by connecting certain nodes of each layer of the horizontal-plane network according to the requirement for solving certain problems such as reducing the wiring complexity or improving the fault-tolerant character, namely, the nodes are not necessarily in a vertical plane. The invention also provides two kinds of imaginary-plane structuring methods comprising a De Bruijn picture structure and a double-ring structure. The first method fully utilizing that the De Bruijn picture allows shorter routing algorithm reduces average hop times in the data transmission, provides a small network delay and has a better fault-tolerant character; the second method improves the transmission efficiency by using the characteristics of low wiring complexity of a ring structure and high data transmission speed and by combining the horizontal-plane network utilizing the advantage of small network diameter of the De Bruijn picture.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

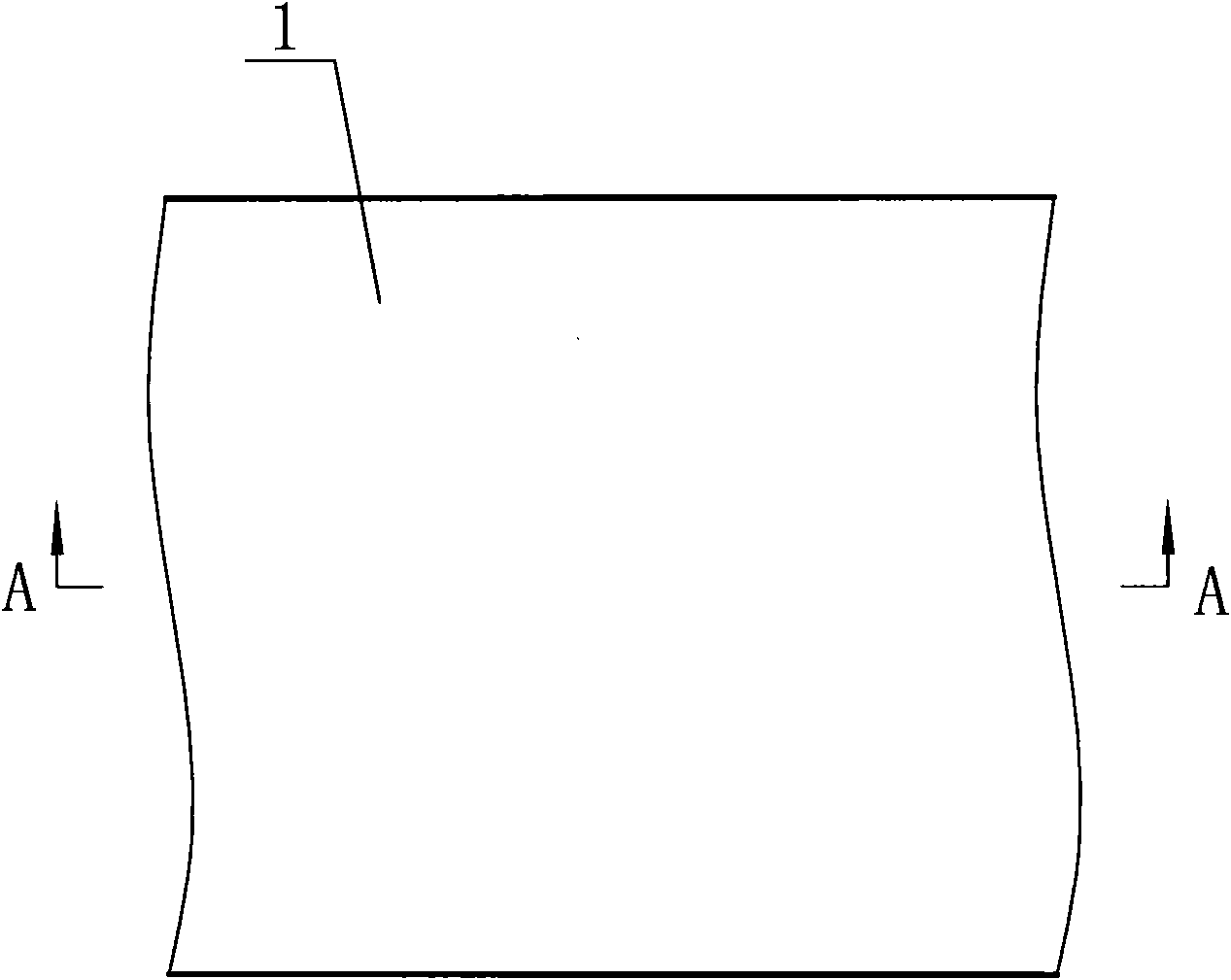

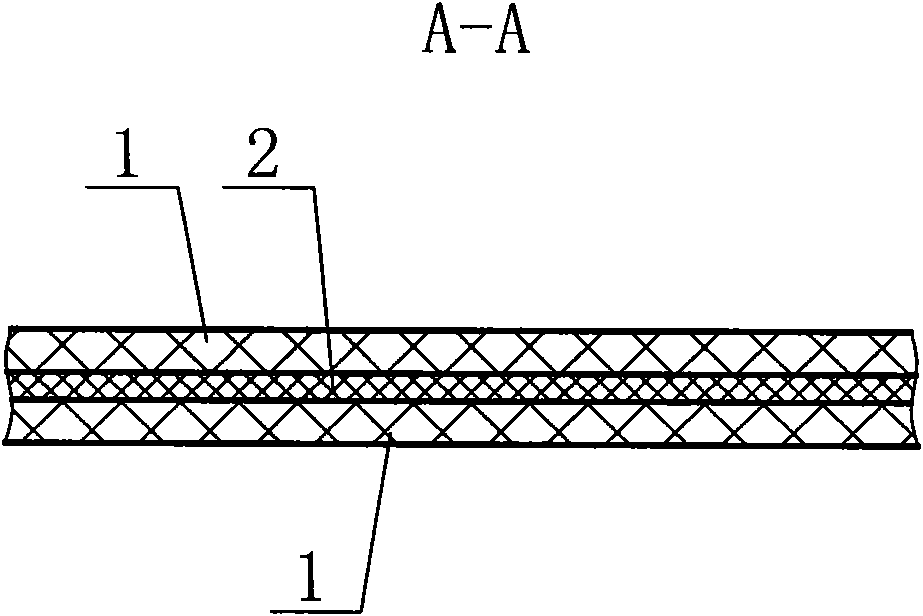

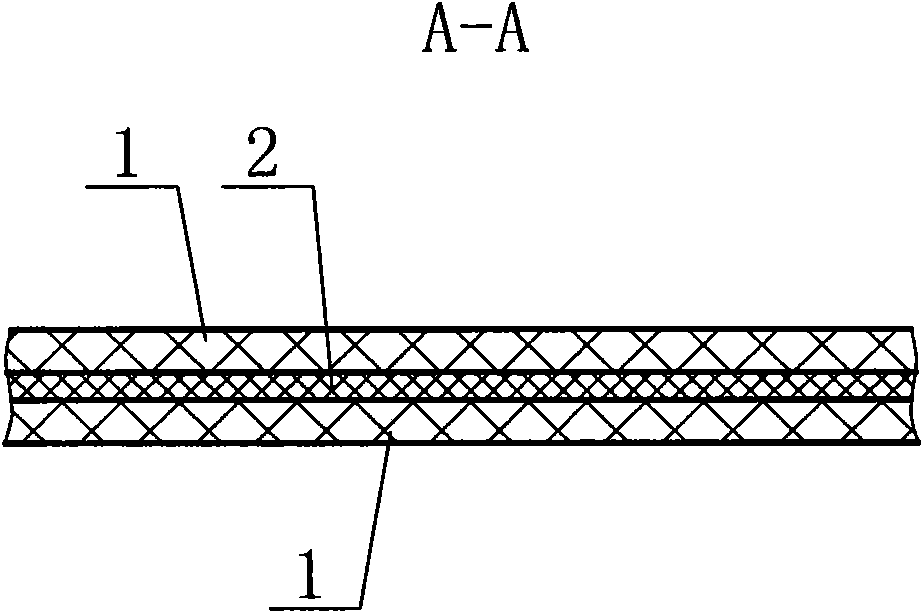

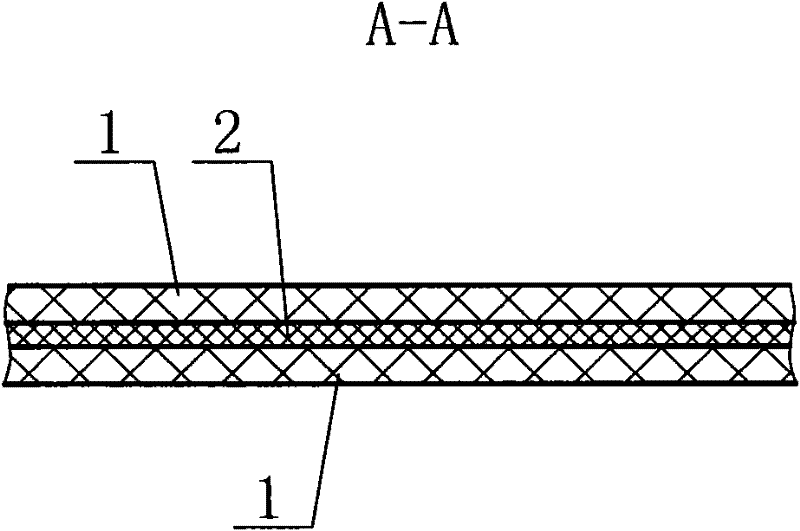

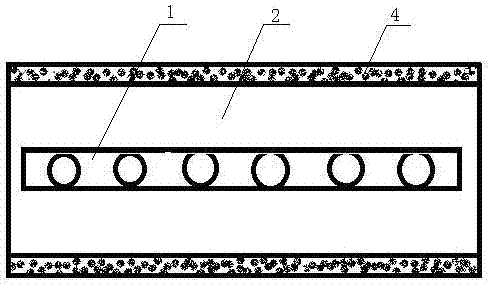

High-temperature resistant fiber layer composite filter material and method for preparing same

ActiveCN101862567AImprove thermal stabilityGood chemical stabilityCellulosic plastic layered productsFiltration separationPlanar networkMixed materials

The invention discloses a high-temperature resistant fiber layer composite filter material and a method for preparing the same. The cross section of the material adopts a triple-layer structure, the upper layer and the lower layer are both a mixed fiber layer, and the middle layer is the PTFE base fabric layer. The preparation comprises the following steps of: preparing PPS fibers and PTFE fibers for later use; mixing two kinds of raw materials in a cotton-mixing box to obtain a preliminary mixed material; loosening the preliminary mixed material in a loosening machine; performing refined mixing of the loosened material in the cotton-mixing box; carding the refined mixing material into planar network fibers by a carding machine; spreading the planar network fibers by a lapping machine to make the mixed fiber layers; adding the PTFE base fabric layer between the two mixed fiber layers; preparing the composite fiber material by a needling machine; and putting the composite fiber material in shaping equipment for shaping, putting the composite fiber material in coating equipment for coating, and then performing surface singeing treatment to obtain the filter material. The filter material of the invention possesses high thermal stability, chemical stability, corrosion resistance and electrical property, and compared with the conventional materials, the oxidation resistance and the corrosion resistance of the filter material are greatly improved.

Owner:张延青

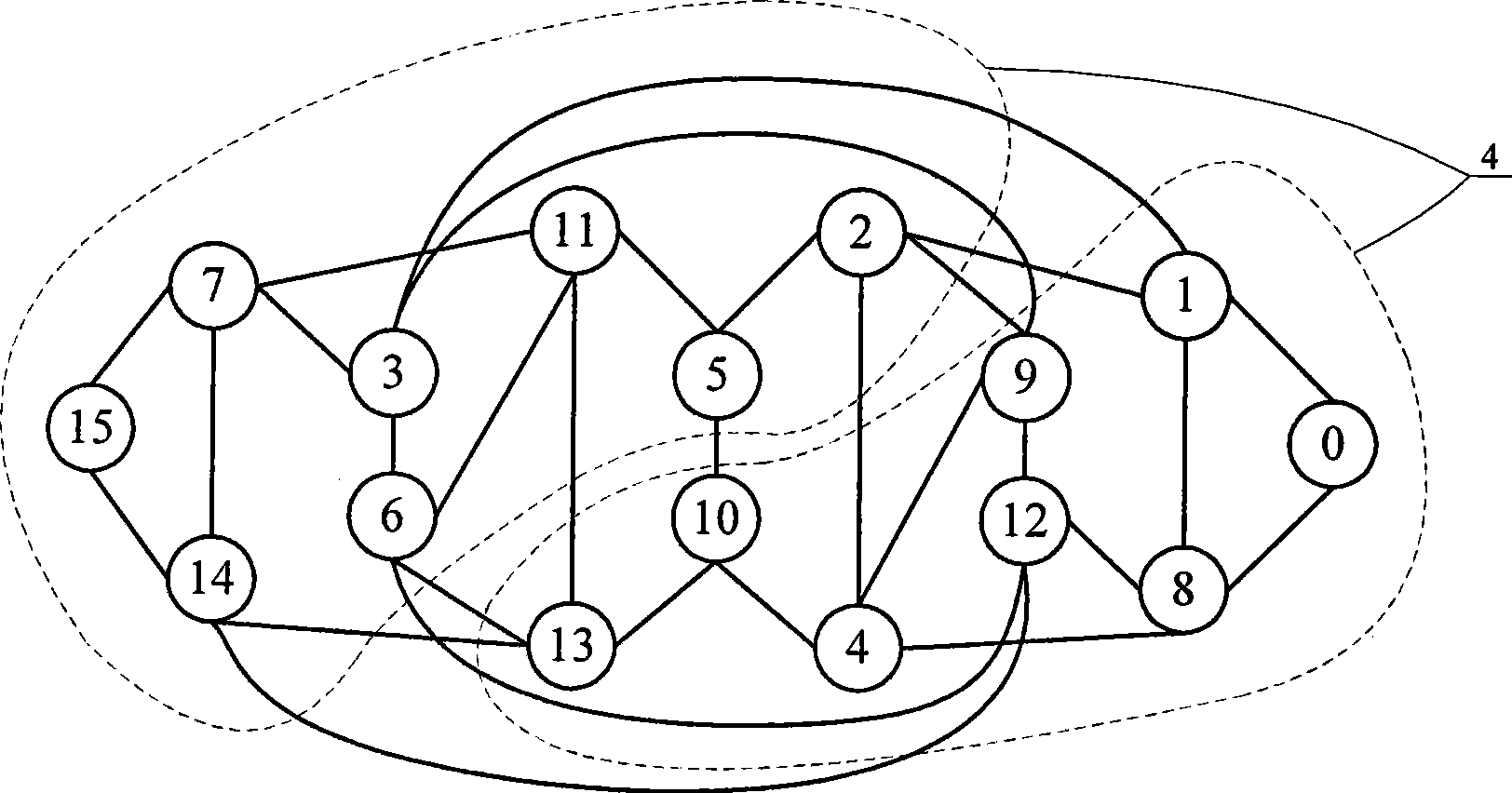

Large capacity and expandable packet switching network structure

InactiveCN1431808ASmall diameterSmall average distanceData switching networksSelection arrangementsExtensibilityComputer architecture

The network structure is composed of multiple switching nodes connected each other directly. Each switching node possesses the input, the output and the transmit port in order to realize the functions of inputting, outputting and transmitting traffic flow. Each switching node is connected to adjacent nodes through multiple paths of chain. The 3D loop circuits connect these switching node, forminga planar network structure. This structure not only is in favor of designing backboard and PBC, simplifying the structure design of the switching system and the specific engineering implementation, but also has the good network performances, the fault tolerant capacities and the expansibility. Thus, the exchange capacity can be expanded from G bits level to T bits level applicable to the switching network structure utilized by the Internet kernel router.

Owner:XIDIAN UNIV +1

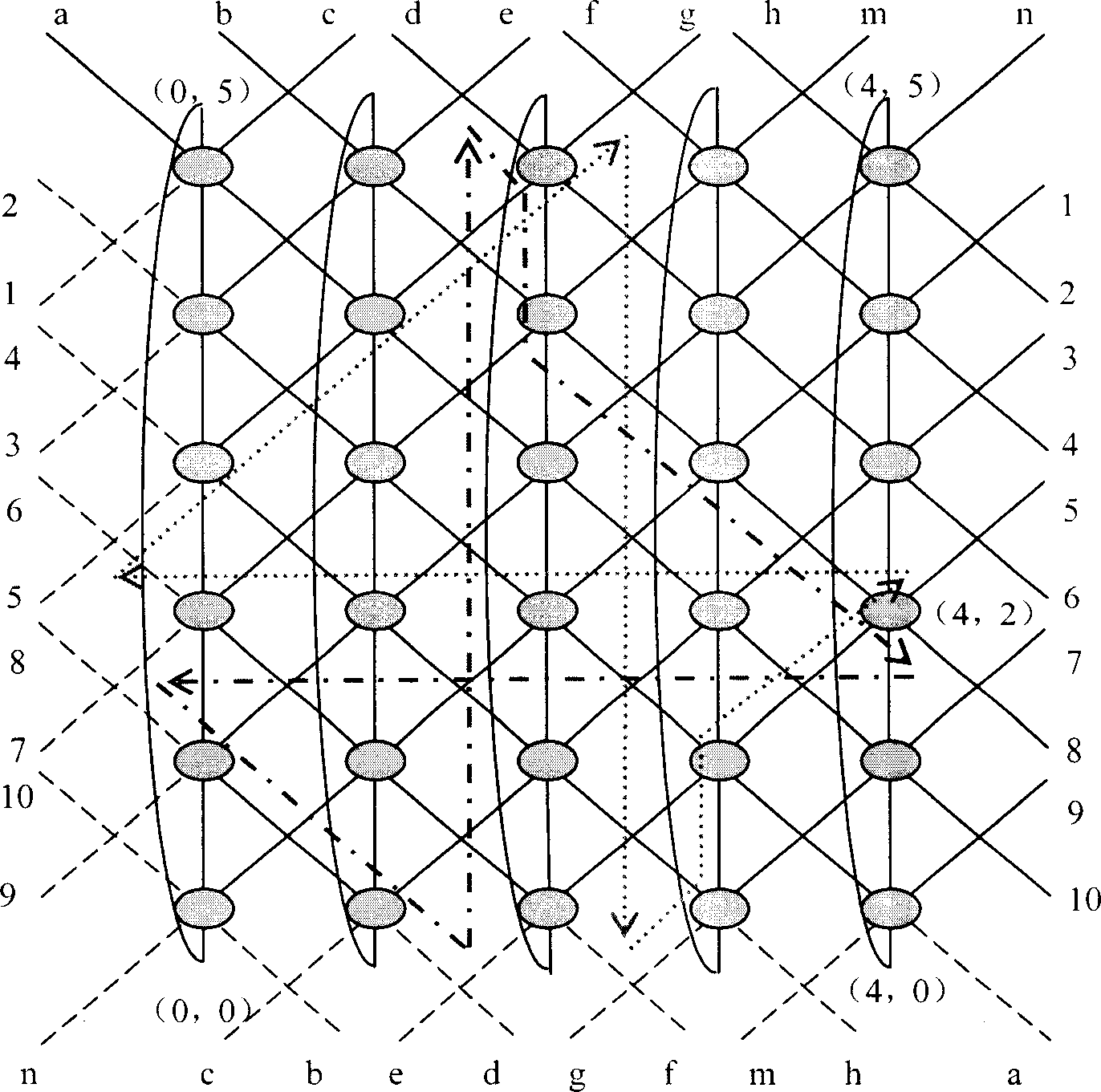

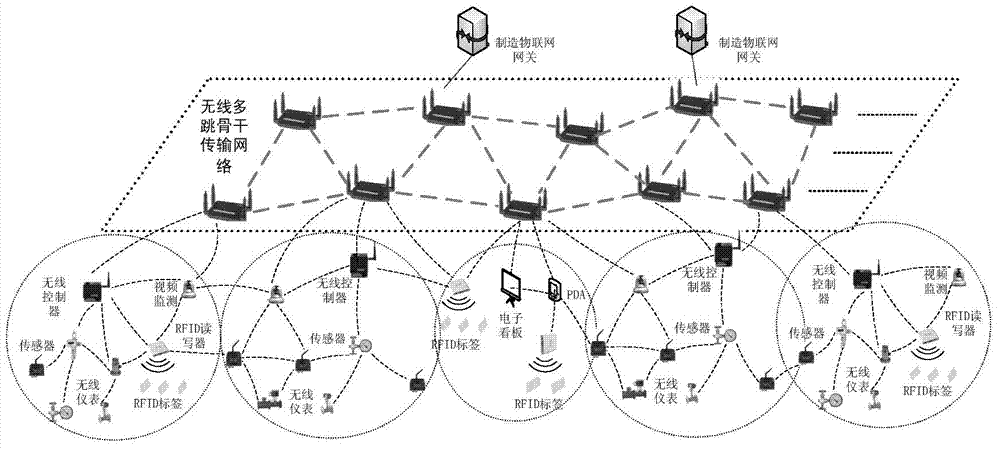

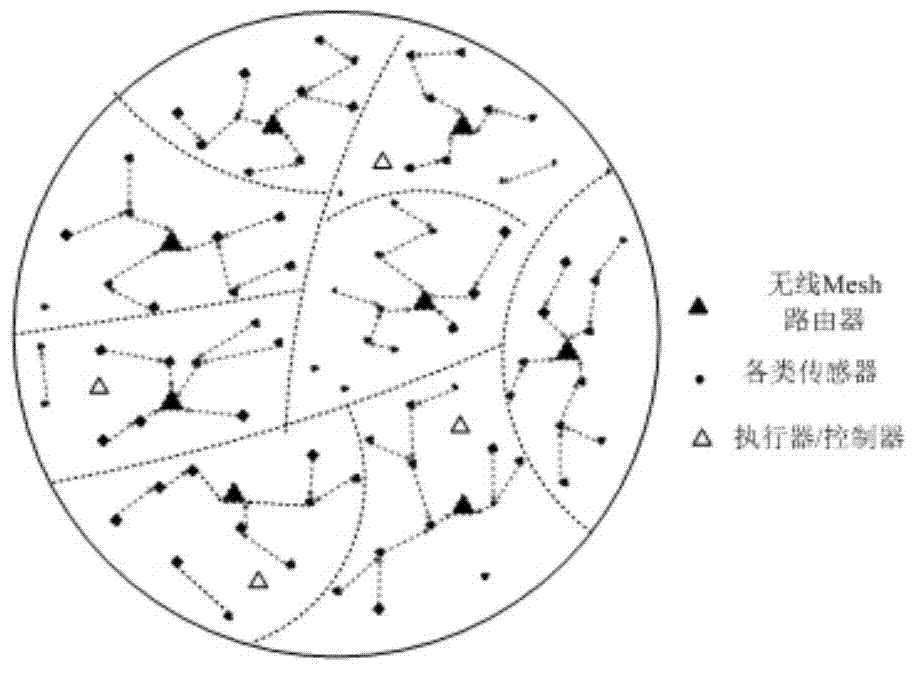

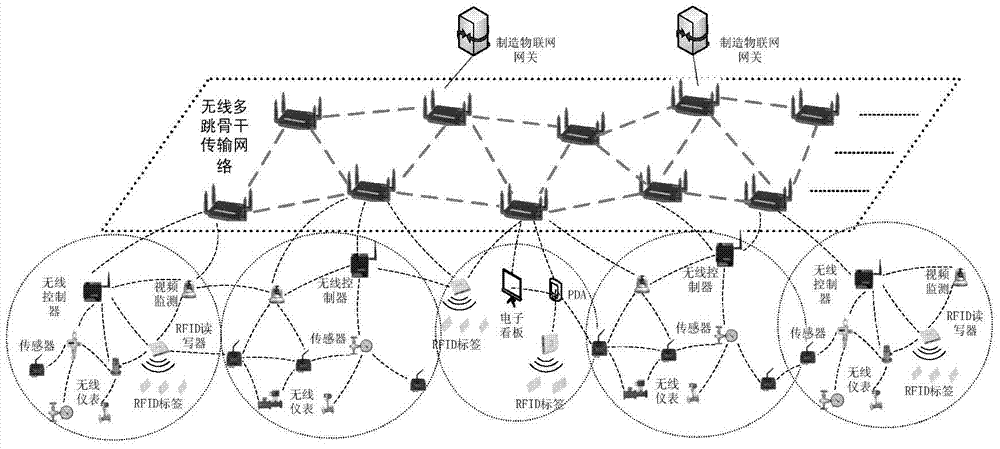

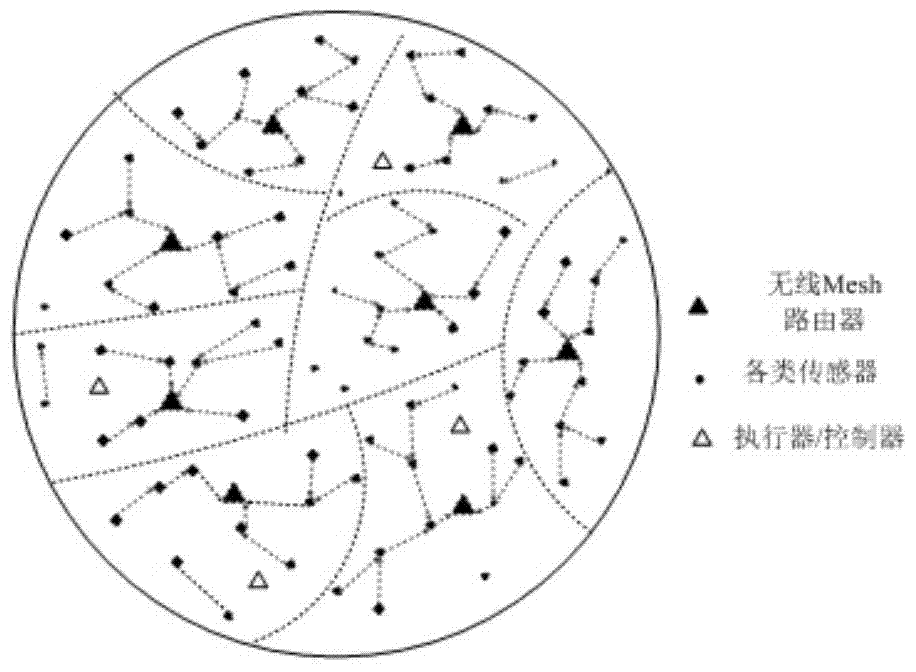

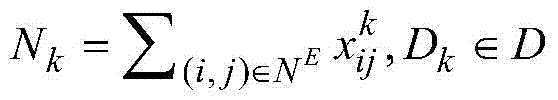

Sensing network topological optimization method in manufacturing internet of things

The invention discloses a sensing network topological optimization method in manufacturing internet of things. Combining the characteristics of sensing nodes of massive distribution, limited wireless communication distance and energy limitation, and considering that the large-scale wireless sensing network cannot directly adopt a planar network topology structure, a large-scale distribution node clustered network topology structure with wireless Mesh routers as the cluster head is adopted, two factors, namely load balancing and energy efficiency, need comprehensive considering during clustering, reasonable optimization is performed, the cluster range of each wireless Mesh router is divided, and a minimum energy consumption data forwarding tree with the wireless Mesh routers as the root nodes is built on the premise of guaranteeing that all the wireless Mesh routers have balanced loads.

Owner:GUANGDONG UNIV OF TECH

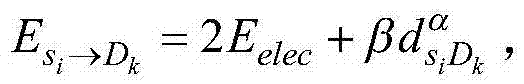

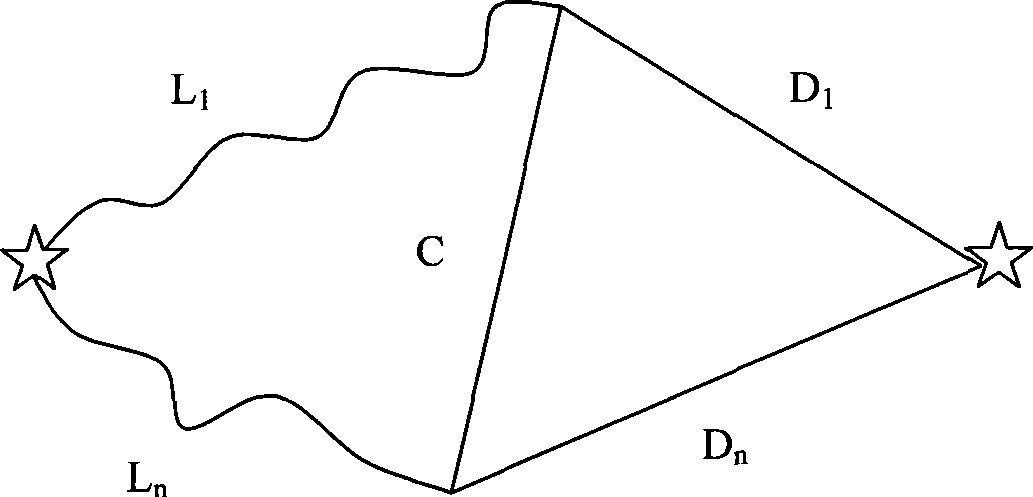

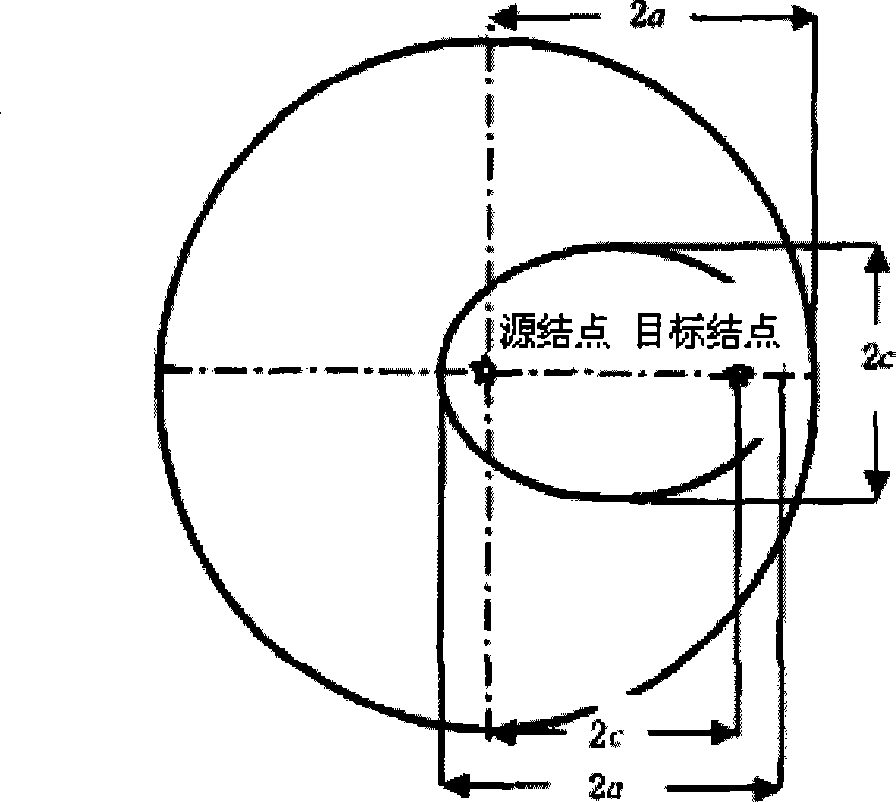

Linear optimal shortest path search method

ActiveCN101447947AReduce the number of nodesImprove search speedData switching networksSpecial data processing applicationsPermanent markerShortest path search

The invention relates to a linear optimal shortest path search method. In the method, the shortest path distance between a marked temporary node and a source node and the linear distance between the temporary node and a target node are used as the basis for selecting a permanent marker node from a temporary node set under the conditions that a researched network can be seen as a planar network. The provided shortest path search method reduces the number of traversing nodes in search, thereby increasing the searching speed.

Owner:BEIJING RES CENT FOR INFORMATION TECH & AGRI

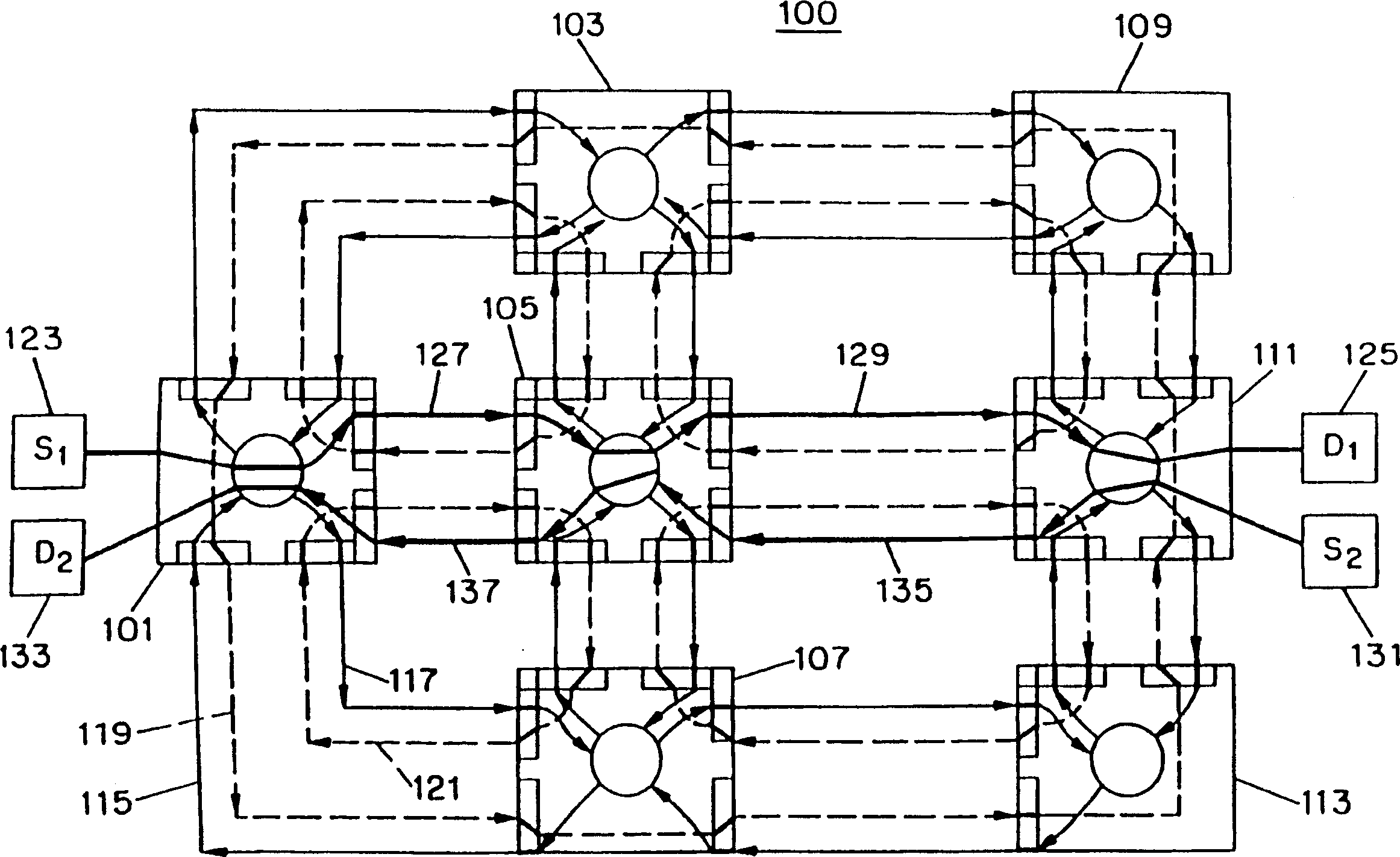

Network switch for failure restoration

InactiveCN1379936AMultiplex system selection arrangementsSupervisory/monitoring/testing arrangementsFiberPlanar network

A system and method for automatically restoring a network containing failed converter nodes. A protection ring is generated for network restoration, and a ring group is generated from the protection ring. Each node is equipped with a protection switch (105) internally interconnecting the input / output to the connection link through the interconnecting protection fiber. The selection of which inner protection fiber to switch traffic on allows configuration of nodes to create merged ring groups. In this way, if a failure of the central converter is detected, the transmission information is diverted to the selected protection fiber of the corresponding merged ring group, so that the information can automatically pass through the protection fiber bypassing the faulty node. Each protection switch has associated with it mapping data that defines which protection fiber should be switched to in terms of input and output links for transmissions that need to be sent through the node. The system and method are applicable to both non-planar and planar networks.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

Composite grafting method for trees and special device

ActiveCN102217489AIncrease success rateImprove the survival rate of graftingCultivating equipmentsForestryGratingPlanar network

The invention provides a composite grafting method for trees and a special device, belonging to the technical field of tree grafting. According to the invention, an auxiliary grafting technology and a composite grating technology are simultaneously adopted; according to the auxiliary grafting, an auxiliary stock special for supplying nutrition to a main grafted fragment is additionally grafted on the main grafted fragment, the root of the auxiliary stock is cultured in nutrient matrix, and the tip of the auxiliary stock is directly grafted to the main grafted fragment which does not belong to the same main grafted unit as a main root stock; and according to the composite grating, more than two intermediate stocks grafted on one main grafted fragment are grafted to different main grafted fragments, and / or more than two intermediate stocks grafted from different main grafted fragments are grafted to the same main grafted fragment. The special device for tree grafting can realize auxiliary grafting and composite grating. According to the composite grafting method and the special device, multiplicity of multiple grafting and limitation of form are overcome, planar networking grafting and three-dimensional cross grafting of the grafted trees can be realized, and diversification is realized in the tree grafting form.

Owner:赵化友

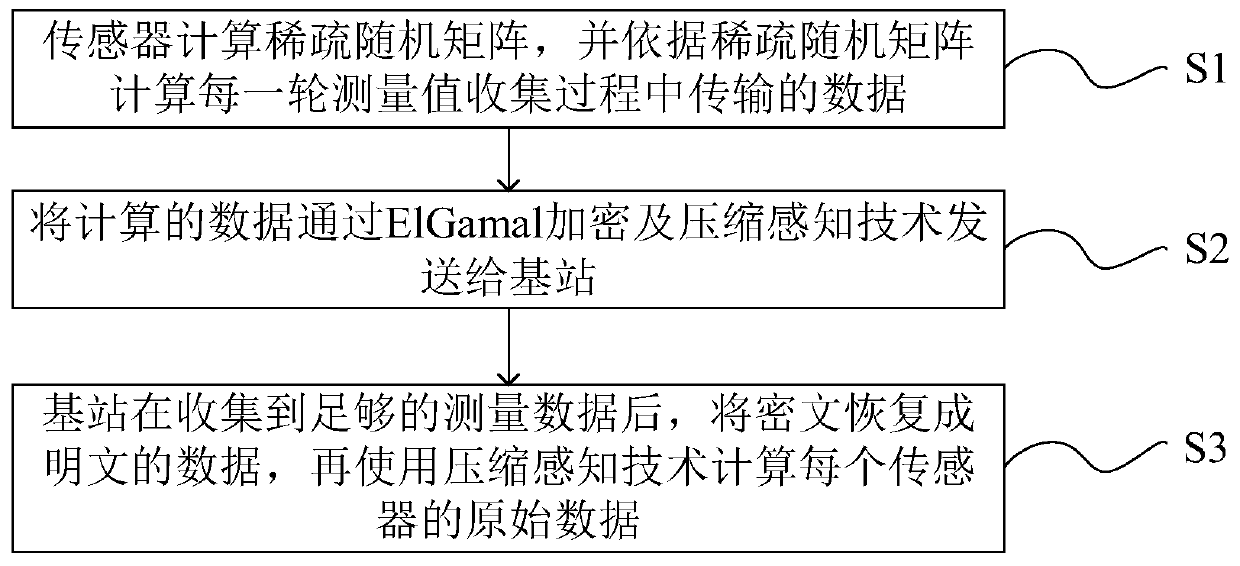

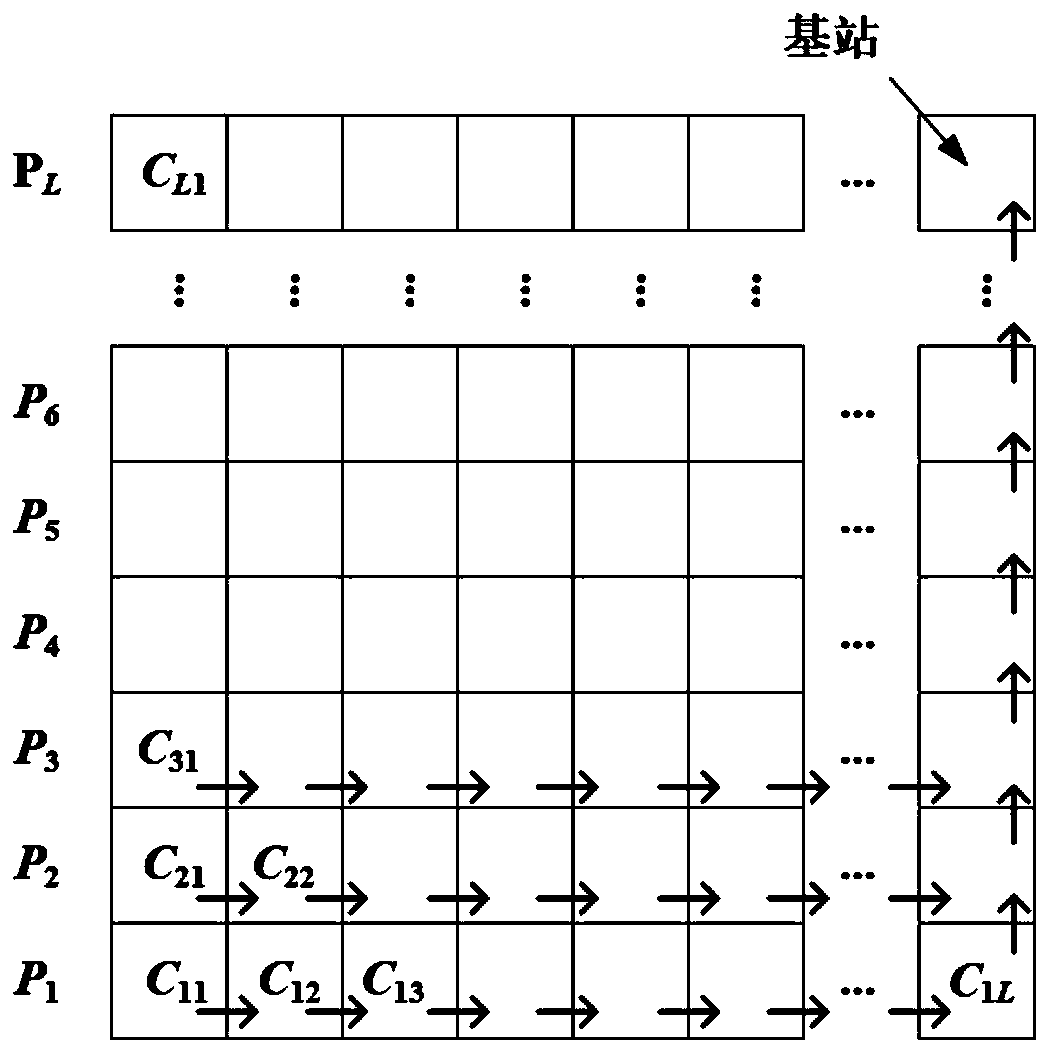

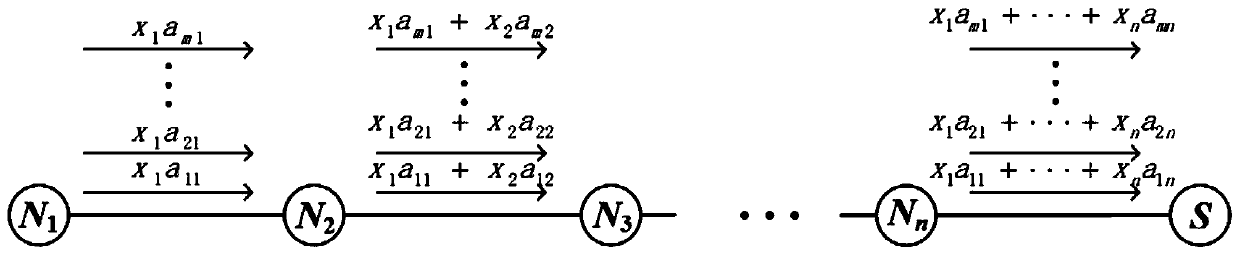

Wireless sensor data collection method based on ElGamal algorithm

ActiveCN110267225AReduce energy consumptionLower latencyParticular environment based servicesSecurity arrangementPlaintextLine sensor

The invention discloses a wireless sensor data collection method based on an ElGamal algorithm, and the method comprises the steps: S1, enabling a sensor to calculate a sparse random matrix, and calculating the data transmitted in the collection process of each round of measurement value according to the sparse random matrix; S2, sending the calculated data to a base station through an El Gammal encryption and compressed sensing technology; and S3, after the base station collects enough measurement data, recovering the ciphertext into plaintext data, and calculating the original data of each sensor by using a compressed sensing technology. According to the method, a sparse sub-Gaussian random matrix is used for replacing a traditional Gaussian random matrix to serve as a sensing matrix, the characteristics of a planar network are comprehensively considered, and in the data collection process, a pipeline technology is used for collecting measurement values, so that the energy consumption of the network is reduced, and the data collection time is shortened.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

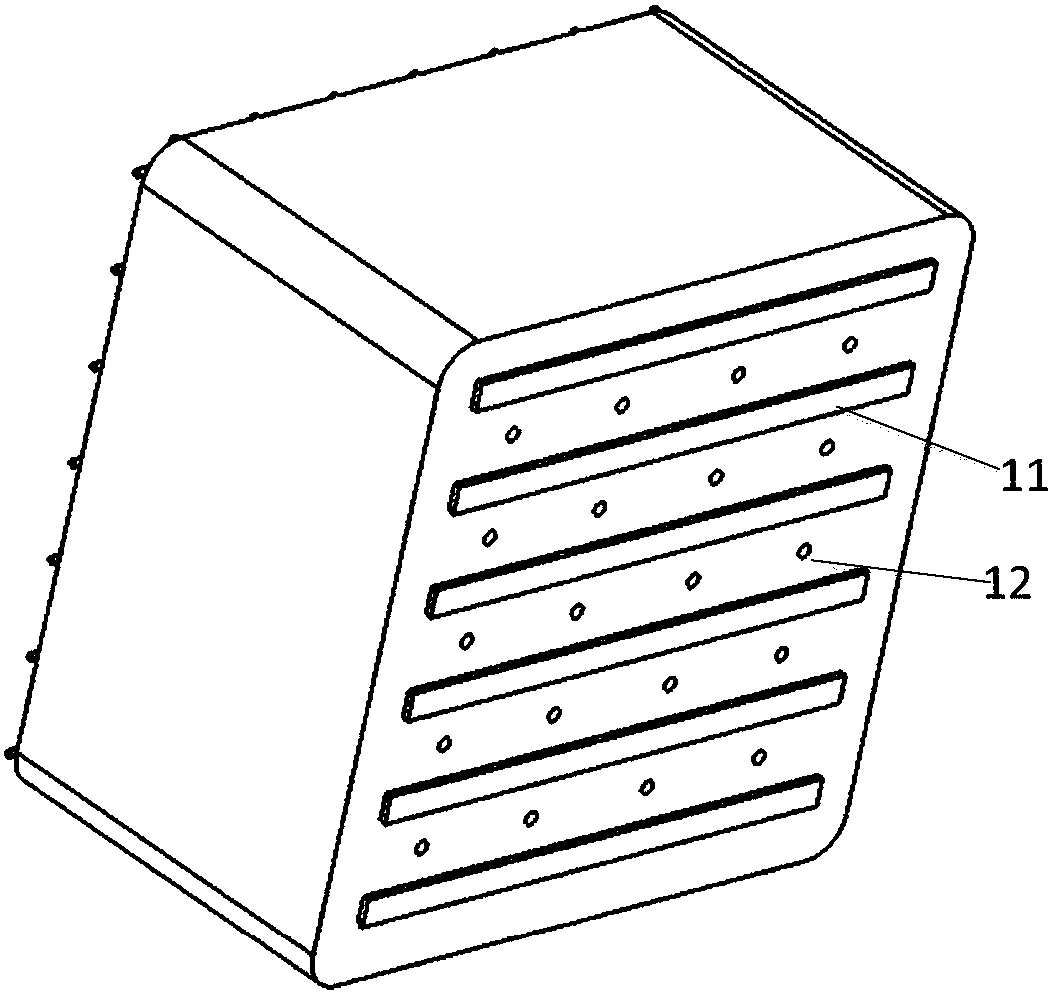

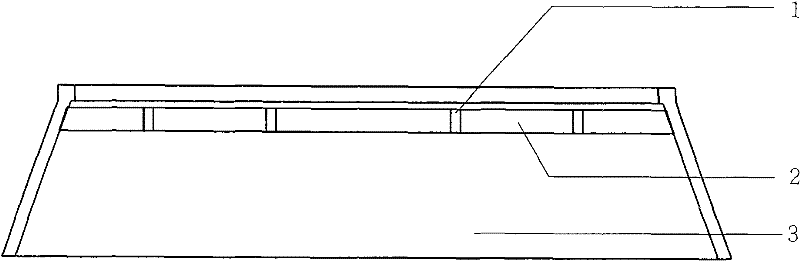

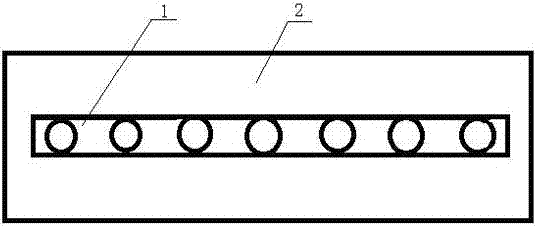

Solar cell production process using net-knot-free printing

ActiveCN106683741AGood printabilitySolve bad problems such as printing disconnectionScreen printersNon-conductive material with dispersed conductive materialSilver pastePlanar network

The invention discloses a solar cell production process using net-knot-free printing and relates to the technical field of solar cell production. An anode is printed by a net-knot-free printing manner. The solar cell production process specifically includes the steps of firstly, preparing silver paste, to be more specific, stirring, by weight percentage, 70-75% of silver powder, 10-15% of graphene powder, 2-4% of glass powder and 12-15% of organic carrier in a stirring device at 85 DEG C for 10-12 hours; secondly, producing a screen, to be more specific, using a planar network structure integrally formed by 3D printing, and reserving printing down alignment space at positions needing line printing to obtain the printing screen; thirdly, printing, to be more specific, placing the printing screen obtained in the second step on a moving mechanism which parallelly moves relative to a printing bearing table, allowing a plane where the screen is located to be parallel with a plane where the printing bearing table is located, and printing with the silver paste obtained in the first step. The solar cell production process has the advantages that the production process is good in printing effect, and the problems that the printing paste is severely affected by net knots formed warps and wefts on screen cloth, and defects such as printing line breaking are caused in the prior art are solved.

Owner:TONGWEI SOLAR ENERGY CHENGDU CO LID

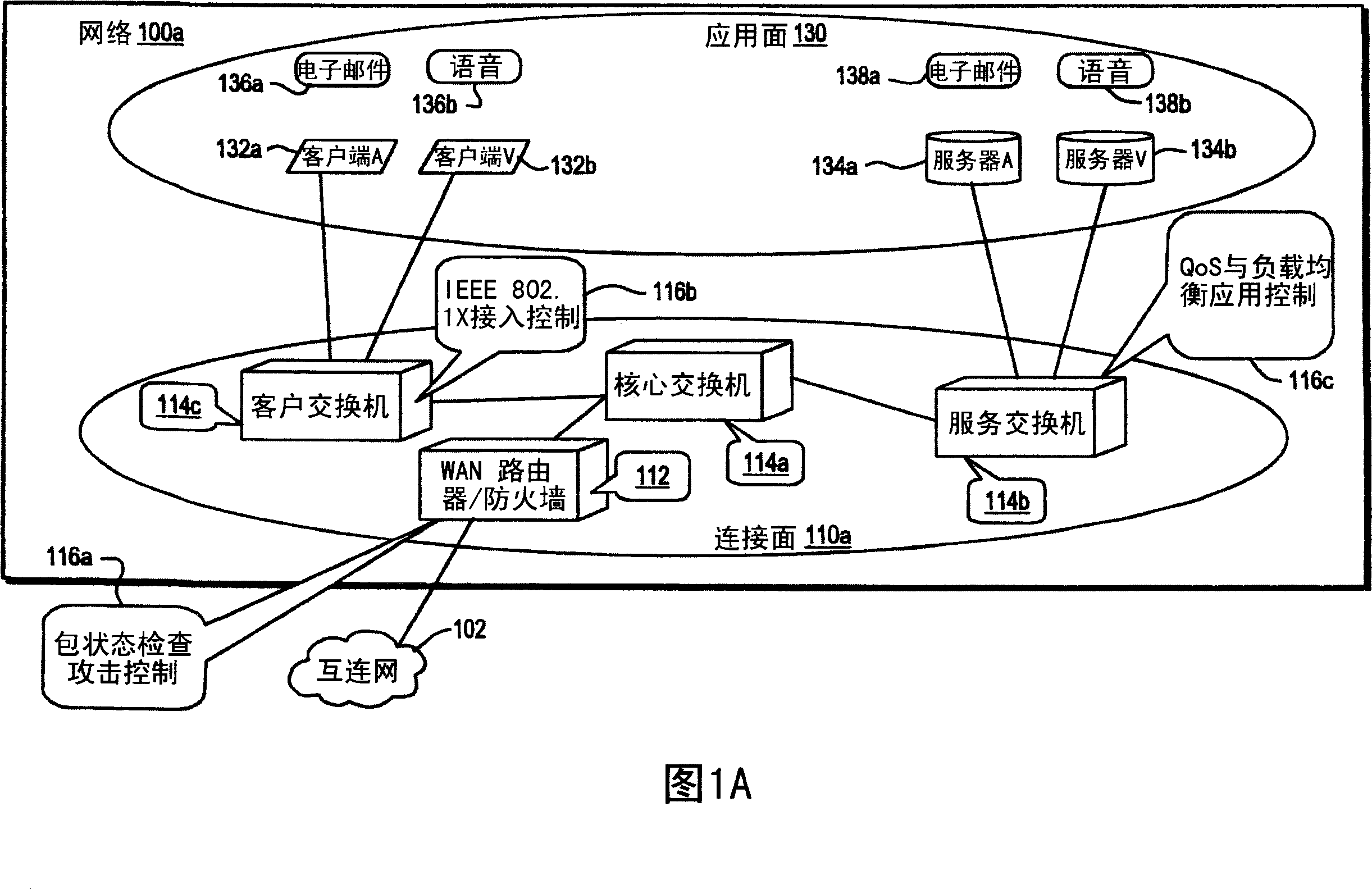

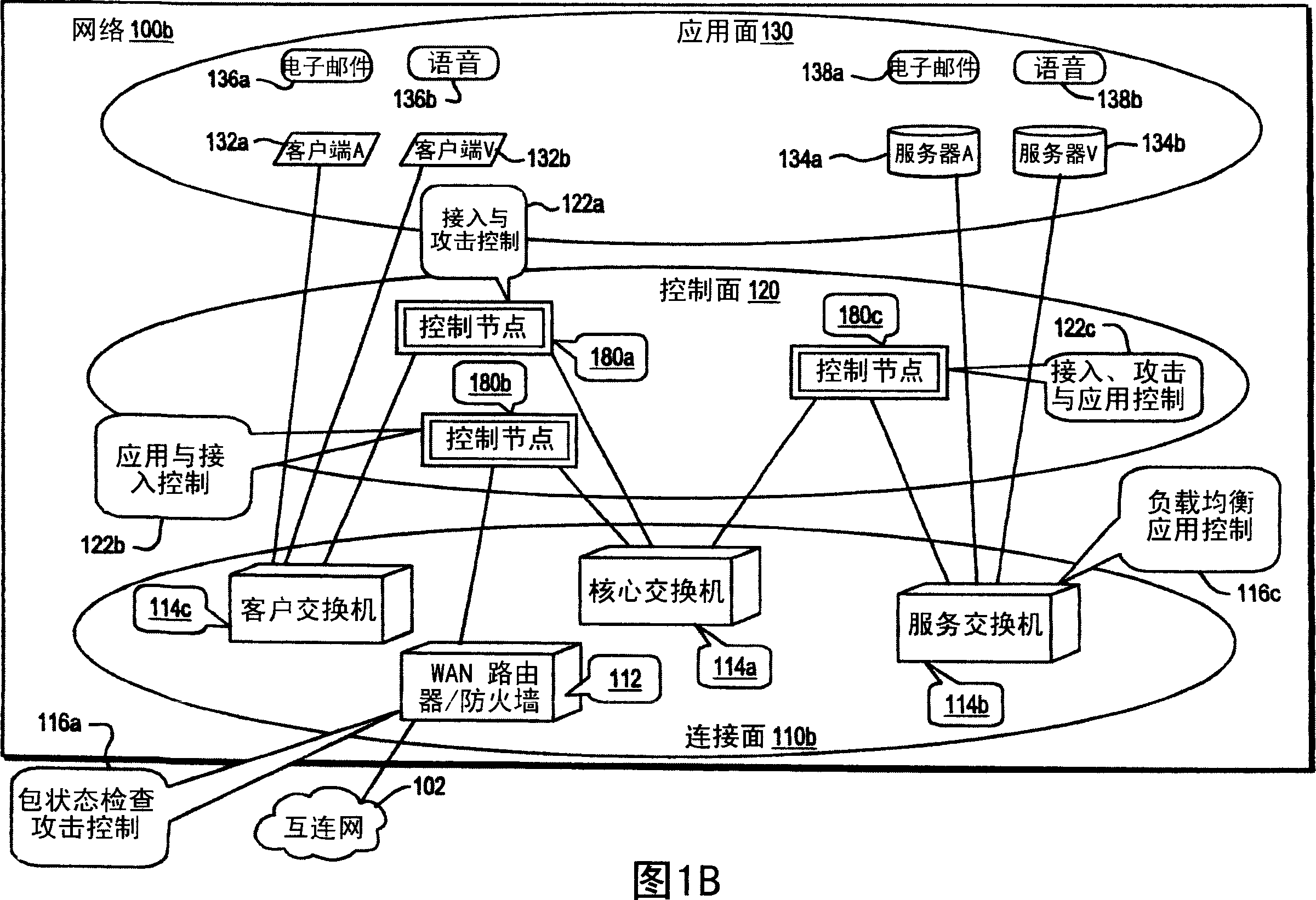

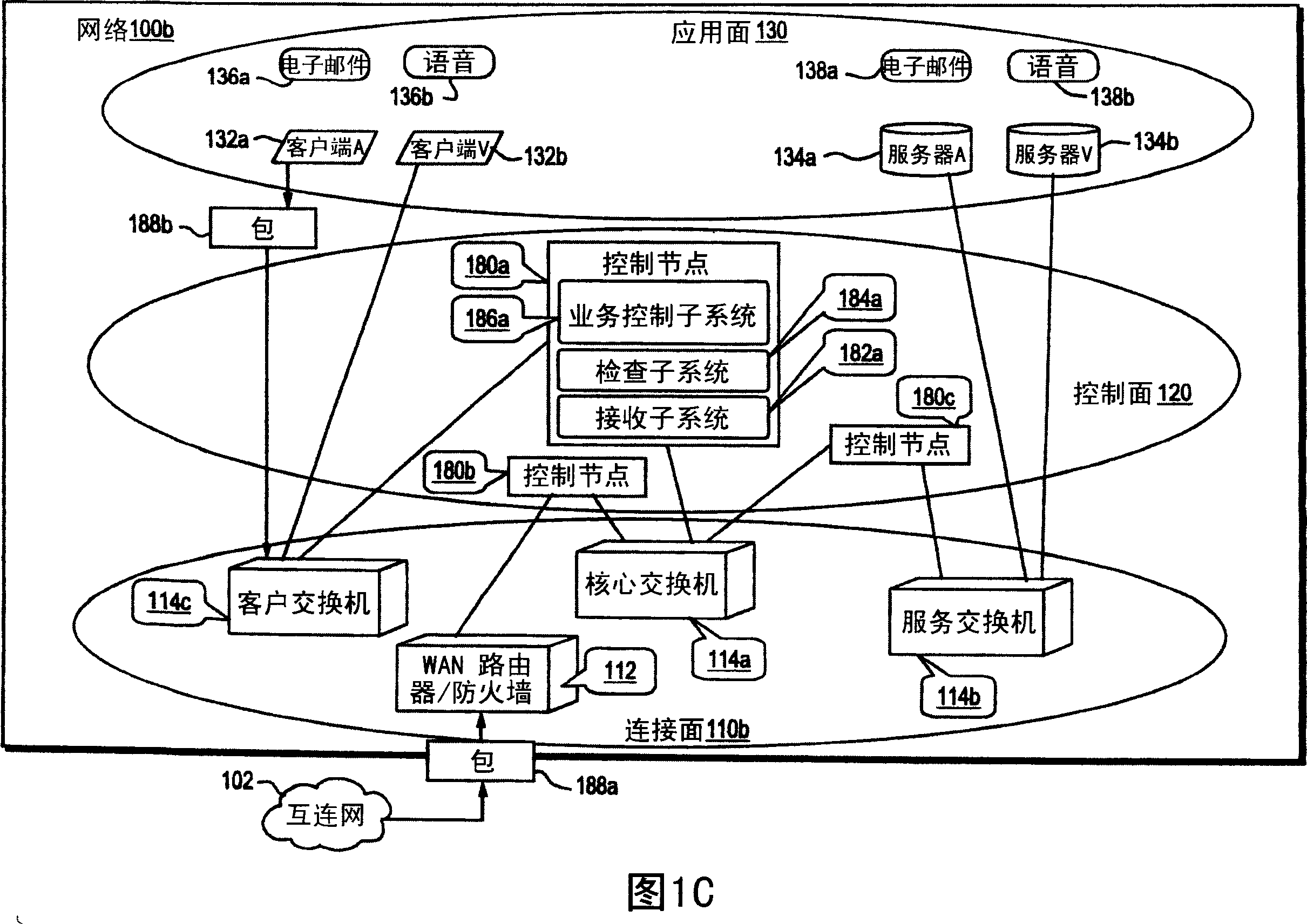

Bi-planar network architecture

InactiveCN101018200AMultiplex system selection arrangementsData switching networksNetwork architecturePlanar network

Owner:HEWLETT PACKARD CO

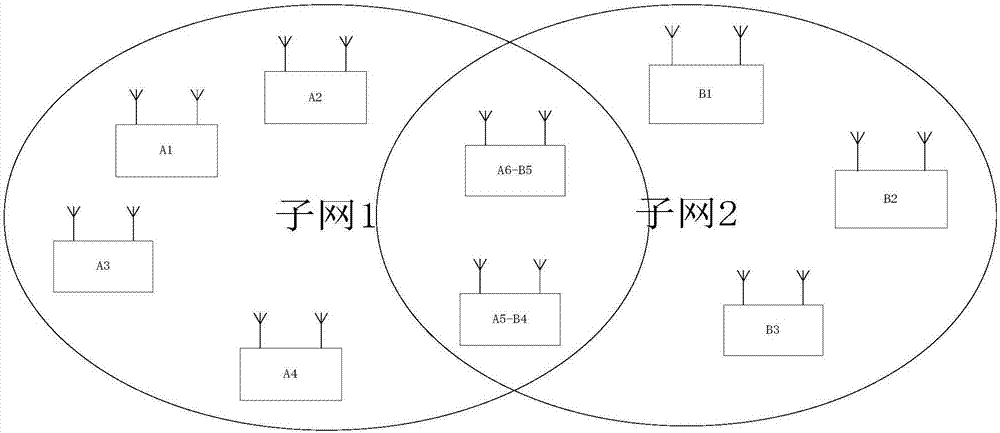

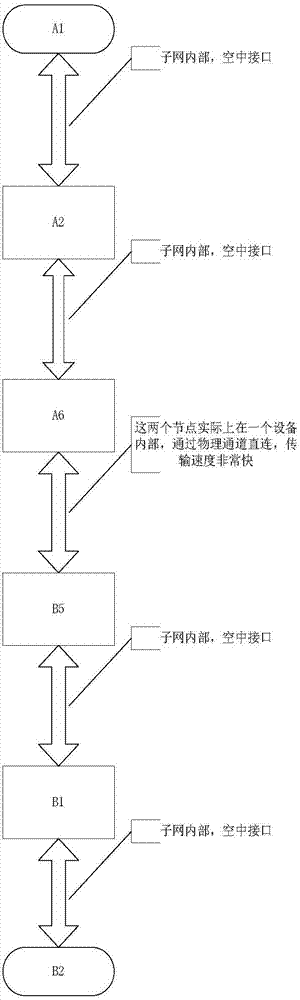

TDMA ad hoc network expansion method and node gateway

InactiveCN107027192AAvoid the problem of too long development cycleImprove data transfer efficiencyNetwork topologiesPlanar networkData exchange

The invention discloses a TDMA ad hoc network expansion method, comprising the following steps: performing data exchange through a first node gateway between a first sub-network and a second sub-network in a TDMA ad hoc network, wherein the first node gateway is registered in the first sub-network as a node of the first sub-network and is also registered in the second sub-network as a node of the second sub-network; and in addition to the first node gateway, also enabling a second node gateway to perform data exchange between the first sub-network and the second sub-network, and ensuring that the second node gateway is registered in the first sub-network as a node of the first sub-network and is also registered in the second sub-network as a node of the second sub-network. According to the TDMA ad hoc network expansion method disclosed by the invention, existing planar network protocols can be upgraded with relatively low cost, and the problem of too long development cycle existing in the process of implementing a multi-layer ad hoc network protocol can be avoided; and the data transmission between the sub-networks adopts a multi-gateway mode, and thus the data transmission efficiency can also be greatly increased.

Owner:SHANGHAI FUDAN COMM

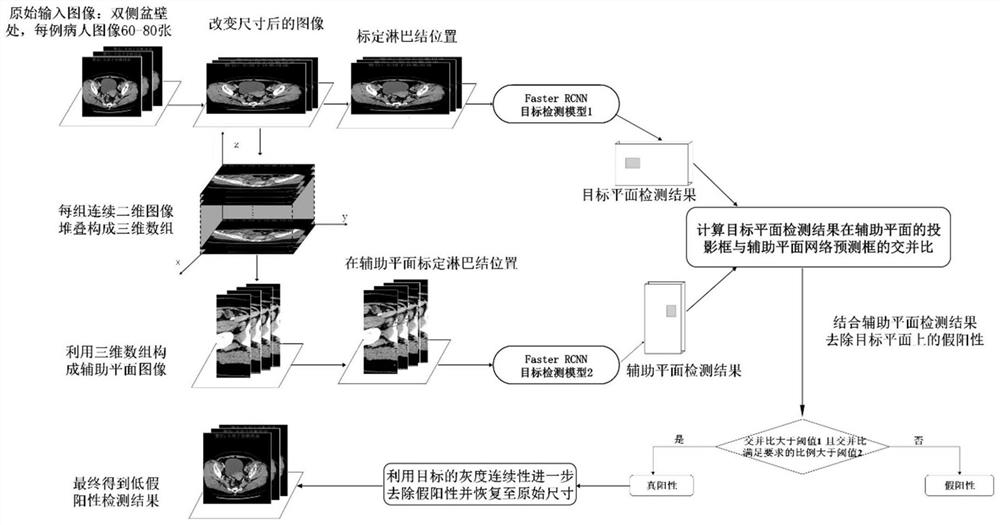

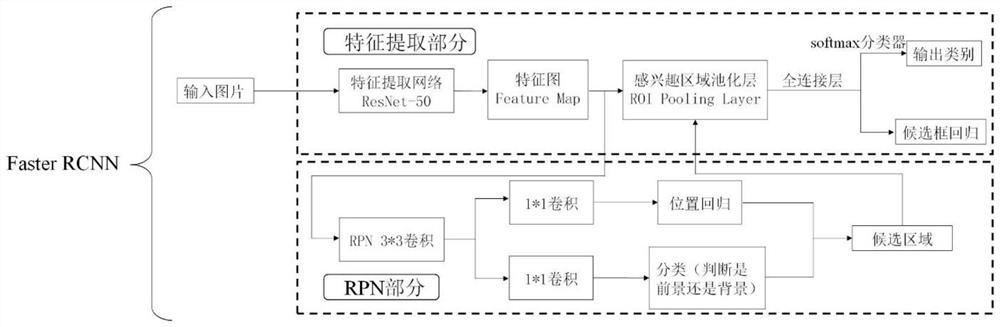

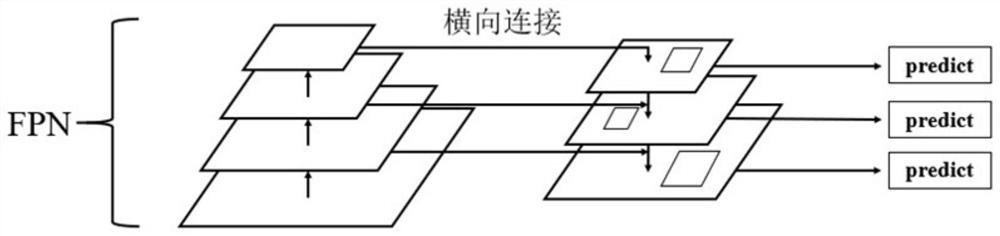

Automatic detection method for multi-scale polymorphic target in two-dimensional image sequence

PendingCN112365498AEfficient removalImprove accuracyImage enhancementImage analysisPattern recognitionData set

The invention discloses an automatic detection method for a multi-scale polymorphic target in a two-dimensional image sequence. The method comprises the following steps: changing the size of an original two-dimensional image and calibrating a target; forming a three-dimensional array according to stacking of the two-dimensional image sequence, and then an image of another plane being obtained anda target of the image being calibrated; respectively training data sets of two planes by using a target detection neural network, ensuring a relatively high recall rate as much as possible, and obtaining a detection result of two-dimensional image prediction; projecting a detection result on the target plane to the auxiliary plane to obtain a frame position, comparing the frame position with a detection frame predicted by the auxiliary plane network, judging an intersection degree of the frame position and the detection frame, and removing a false positive example appearing in two-dimensionalimage prediction detection according to a prediction detection result of the auxiliary plane; and finally, further removing false positive examples by using the gray continuity of the target in the image, recovering the image to the original size, and synthesizing the information of the two planes through the steps to obtain a target detection result with relatively high accuracy.

Owner:NANJING UNIV

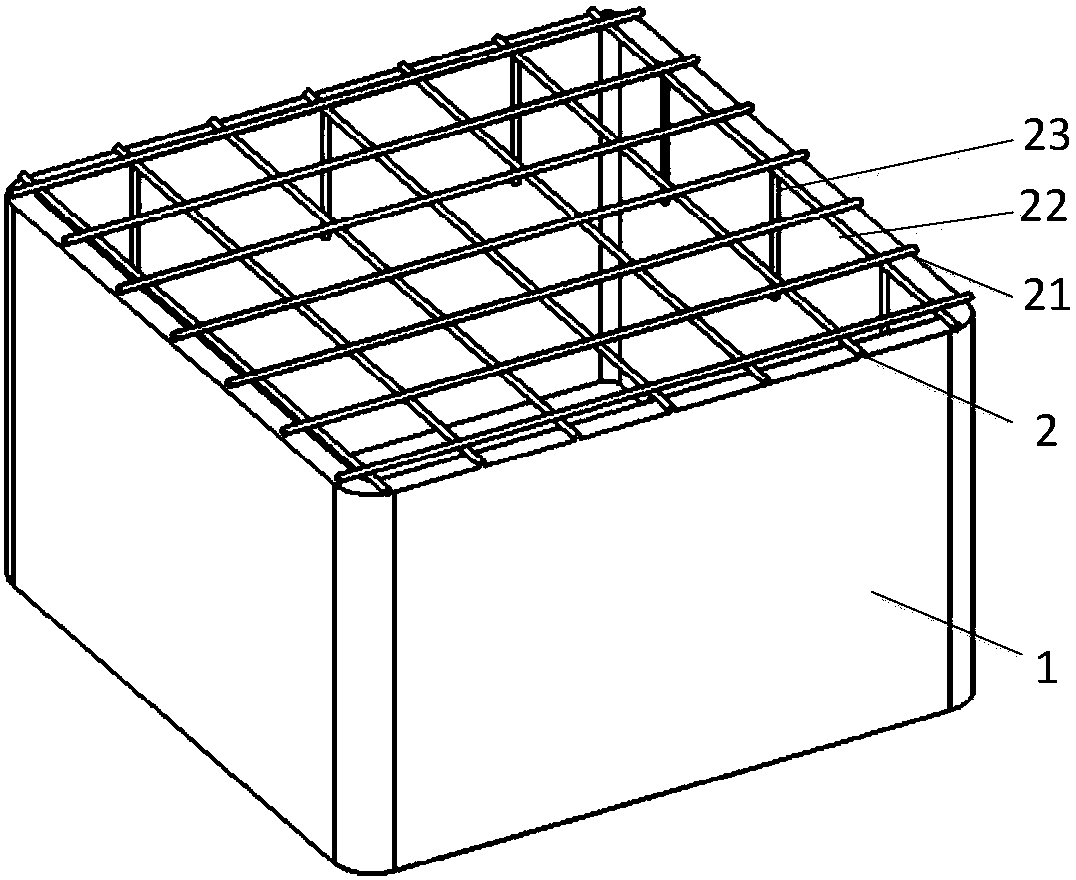

Movable pitaya seedling cultivation box and preservation method

PendingCN108207414AFlexible moving processSmall footprintGrowth substratesCulture mediaWater dischargePlanar network

The invention discloses a movable pitaya seedling cultivation box and preservation method, and belongs to the technical field of pitaya cultivation. The movable cultivation box comprises a square boxbody and a cultivation frame, an opening is formed in the upper portion of the box body, a water discharging port is formed in the bottom of the box body, the length of the box body is 30-60cm, the width of the box body is 20-45cm, the height of the box body is 20-50cm, the cultivation frame is arranged on the upper end surface of the opening of the box body and comprises a plurality of horizontalrods and a plurality of vertical rods, the horizontal rods and the vertical rods form a planar network structure, the length and the width of the cultivation frame are slightly larger than those of the box body, and the cultivation frame is of a hard structure and not easily corroded and deformed. The pitaya seedling preservation method includes the steps: box filling with substrates; seedling treatment and planting; seedling pruning; new female stem selection and the like. According to the cultivation box and the preservation method, pitaya seedlings are simply preserved, occupied land is less, management is convenient, and retrieval, update and destruction are facilitated.

Owner:广西壮族自治区农业科学院园艺研究所

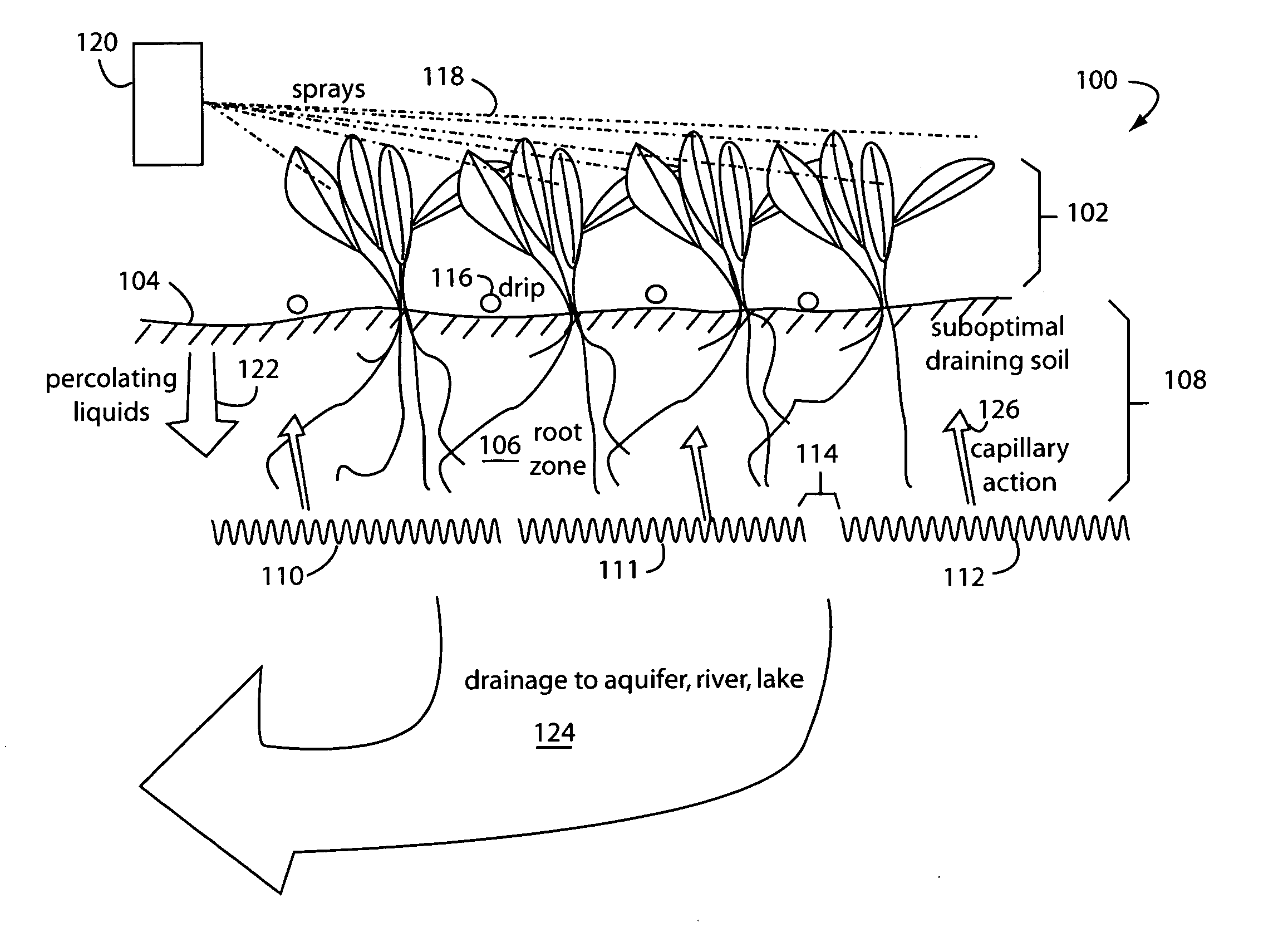

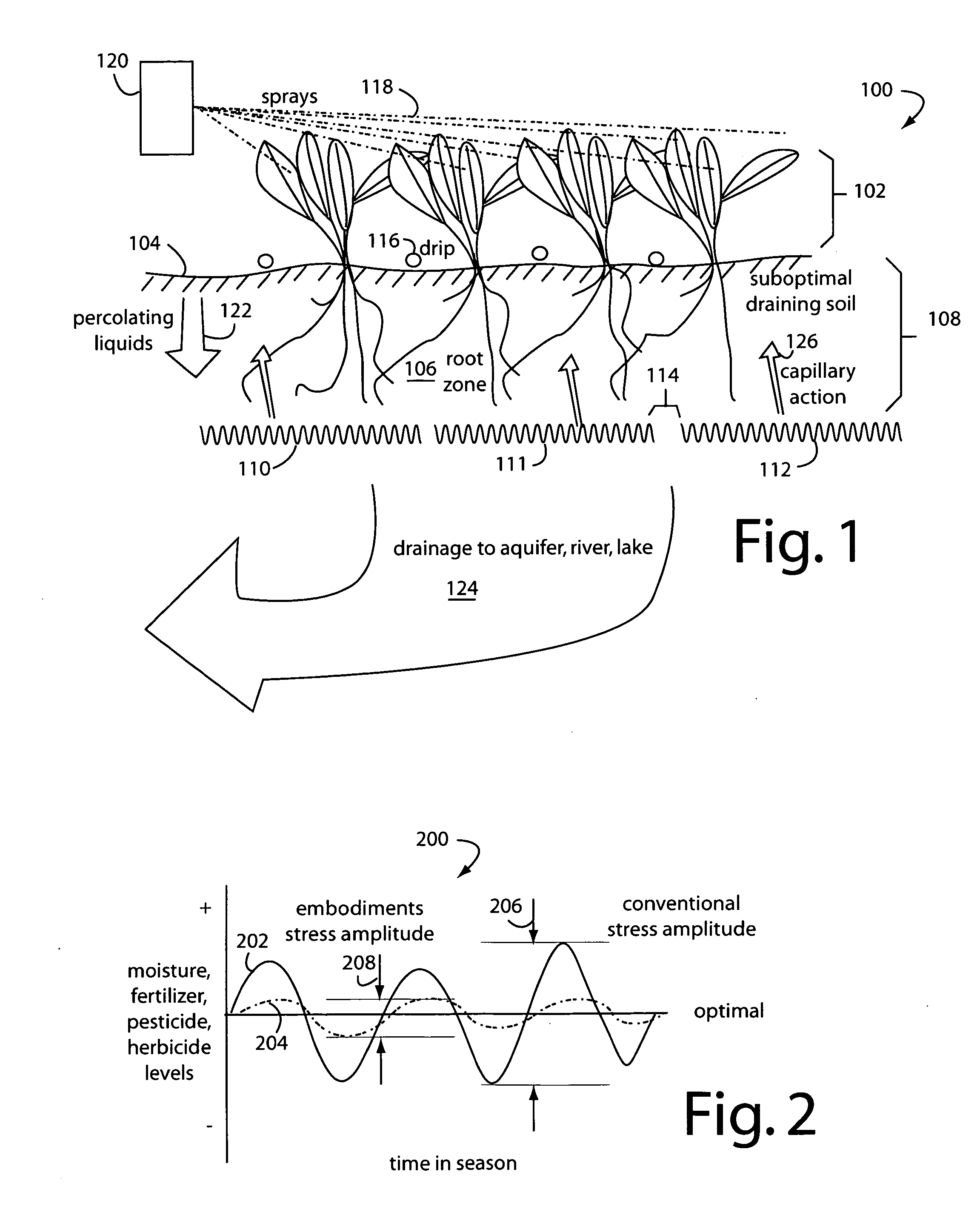

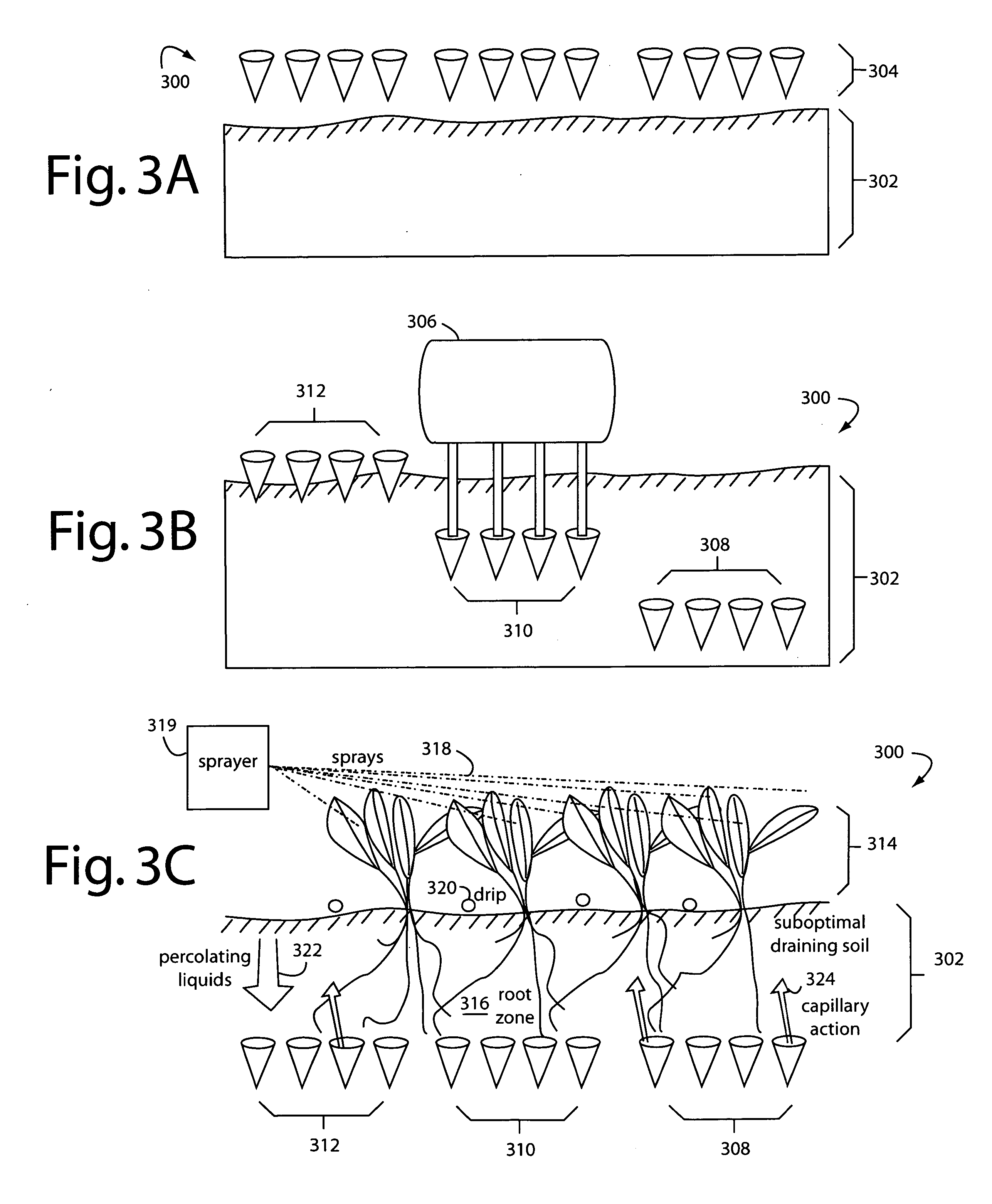

Irrigation water, herbicide, pesticide, and fertilizer conservation system for farming

InactiveUS20050193935A1Reduces volume of watering and fertilizing and applicationRelieve pressureSeed and root treatmentFertiliser distributersPlanar networkEngineering

A farming system compensates for soils that drain too well by underlaying the crop fields with a planar network of liquid reserve matrices. These are placed at the bottom of the root zone, below the level that ordinary seasonal tilling will reach. In one version, the top soil is laid open and the underlayment is patterned out like carpet tiles. The top soil is then back filled to bury the liquid reserve matrices at a predetermined depth. In another version, individual cone shaped cups are forcibly driven deep into the ground below the seasonal tilling depth. Both versions can then enable reductions in the necessary volumes of watering, fertilizing, and application of herbicides and pesticides because the individual buried wells will catch some of the drainage and keep it near the root zone.

Owner:SCHNEIDER STEVEN A

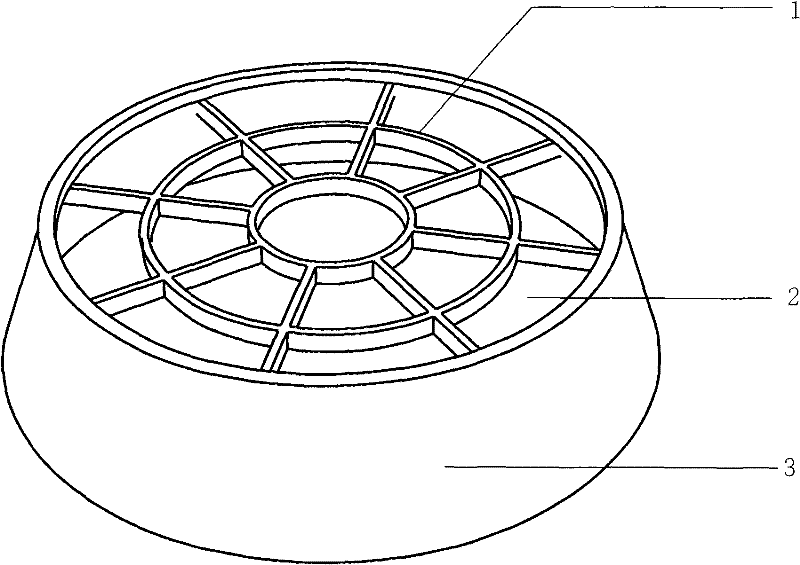

pomegranate seed extractor

InactiveCN102283562ASimple structureEasy to useKitchen fruit stoningPeelersLife qualityPlanar network

The invention discloses a seed extractor for pomegranate, which is used for separating pomegranate seeds from a diaphragm and a hull of the pomegranate. The seed extractor consists of a hollow cylindrical body and a supporting structure positioned above inside the cylindrical body; a supporting frame structure is a planar network structure and is positioned at the position of 1-7mm sunken from the top end of the cylindrical body; the thickness of the supporting frame structure is 5-7mm; the size of the mesh hole of the support frame structure is 1.5-3cm; the width of a grid support frame of the support structure is 1-2mm; and the supporting frame with holes is used for separating the pomegranate seeds from the diaphragm. When the seed extractor is in use, the section of the cut pomegranate is downwards placed on the supporting frame; the pomegranate hull is lightly pressed and knocked from the upper part of the pomegranate; the pomegranate seeds penetrate through the holes on the support frame due to vibration and fall off; and meanwhile, the diaphragm and the hull of the pomegranate can be stopped by the supporting frame and are separated from the pomegranate seeds. The seed extractor has the beneficial effects that the seed extractor with a simple structure and convenience in use for pomegranate is provided, is convenient to eat the pomegranate seeds and can be used for preventing the contacted pollution between hands and the pomegranate seeds and improving the quality of modern home life.

Owner:吴志宣

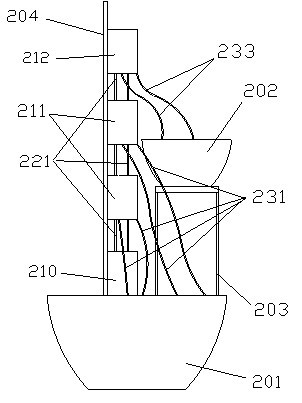

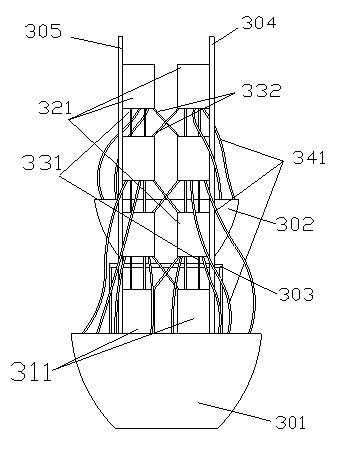

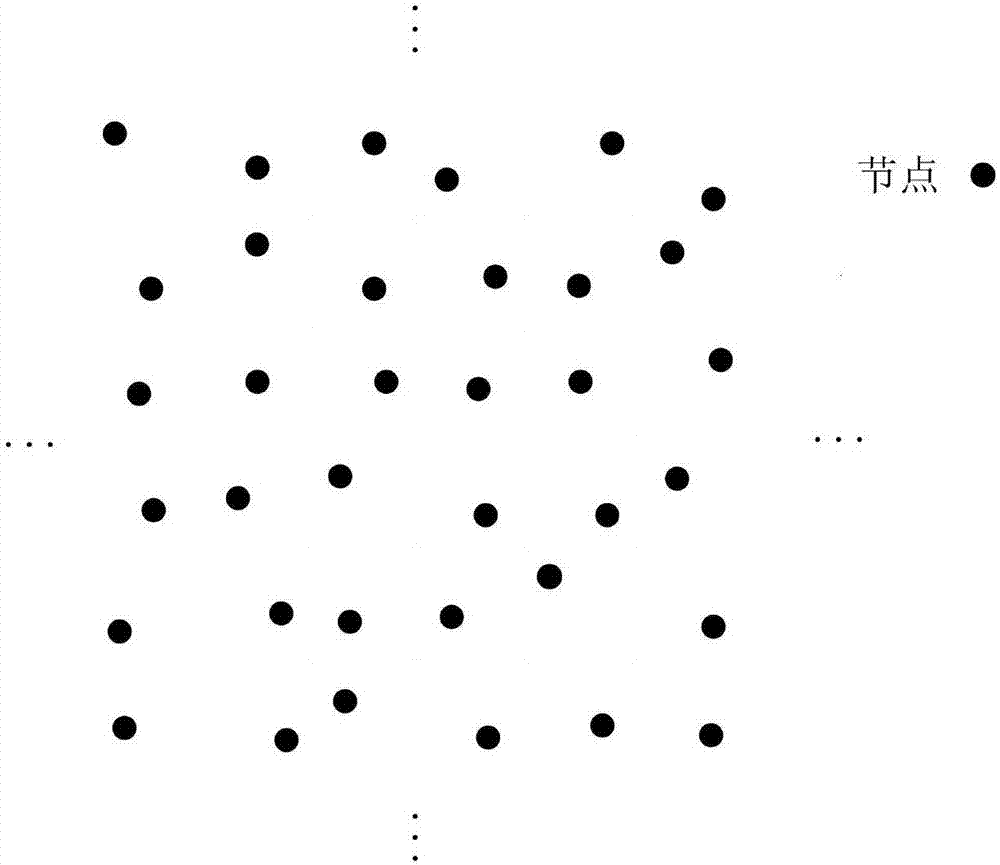

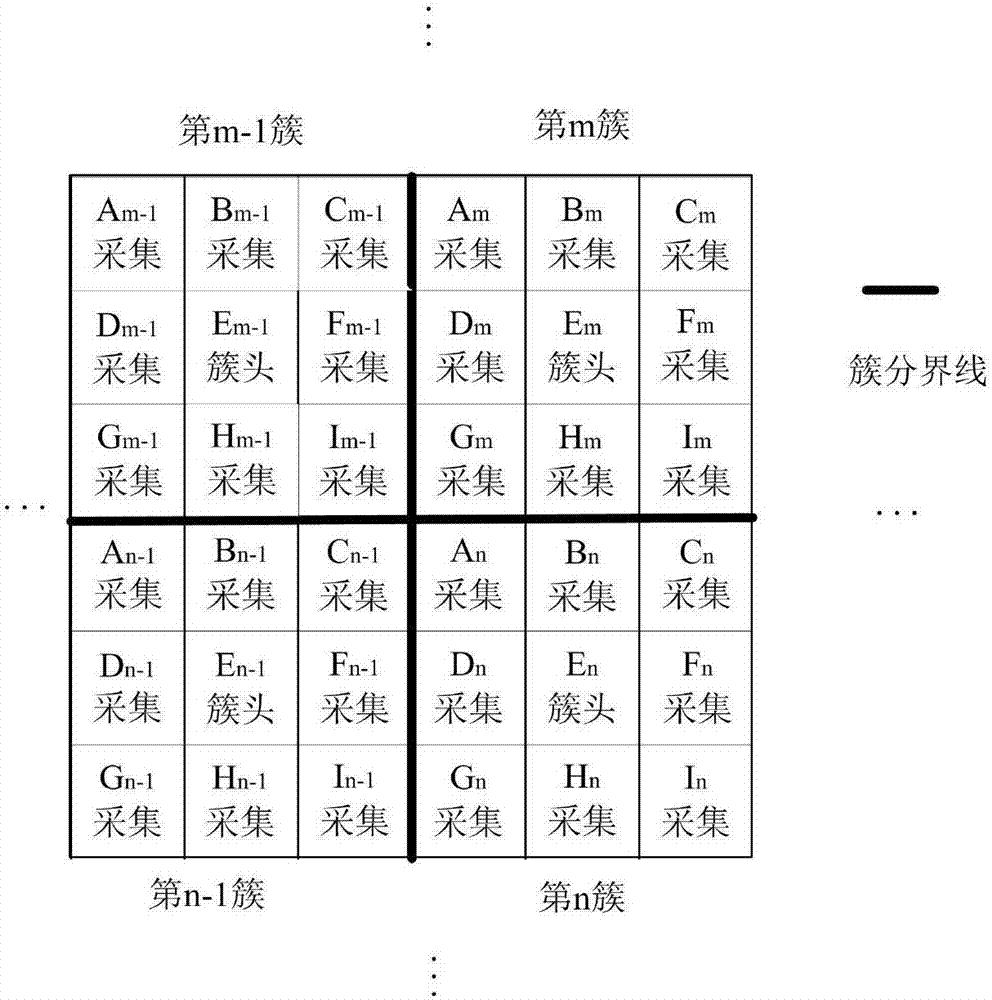

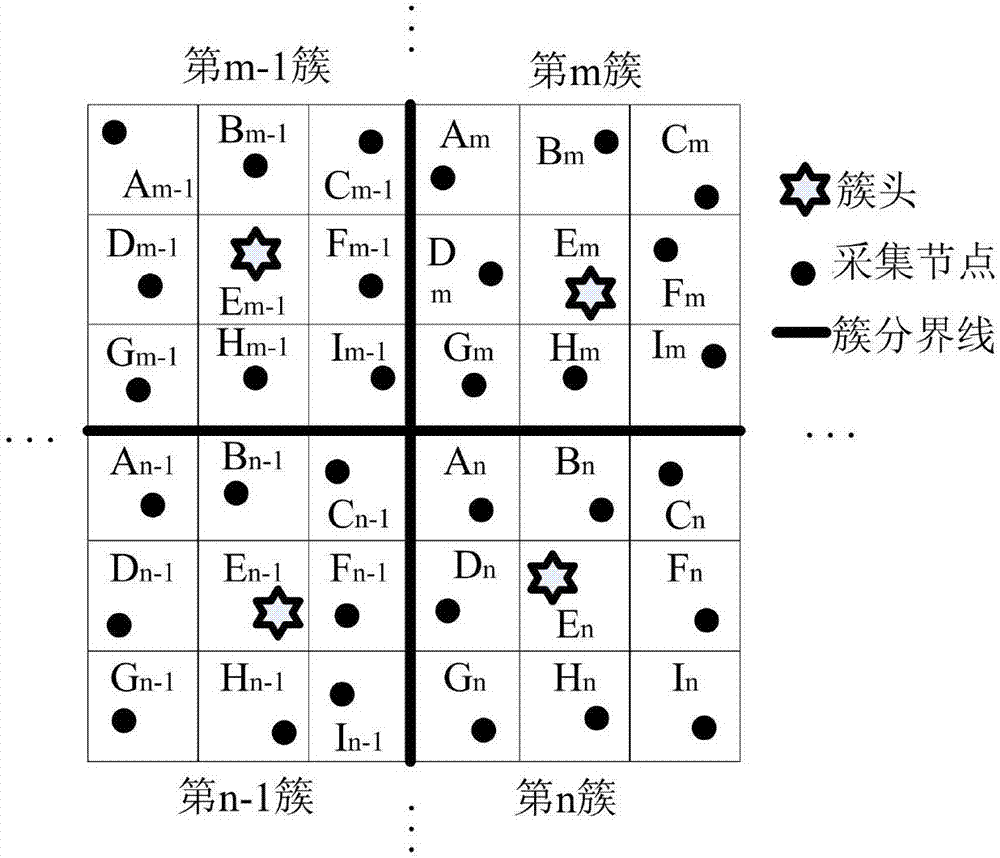

Dynamic clustering underwater acoustic network routing method based on two-dimensional virtual grids

For a planar network composed of underwater isomorphic sensor nodes, the invention provides energy balanced underwater acoustic communication that sensor network clustering is planned by Sink nodes in a unified manner. An algorithm is as follows: on the basis of the mutual positions of the underwater sensor nodes, a grid system capable of covering the whole sensor network and composed of small grids is fictitious; some small grids in the grid system are defined as acquisition grids; some small grids in the grid system are defined as cluster head grids; a sensor node network is covered by the grid system; the nodes under different grids perform different functions; and the Sink nodes perform residual energy calculation of the nodes based on received data, appoint the moving direction of the grid system, and change the functions of the nodes. By means of the method disclosed by the invention, the node energy consumption can be effectively saved; energy balance can be realized; and thus, the network survival time is prolonged.

Owner:HARBIN INST OF TECH AT WEIHAI

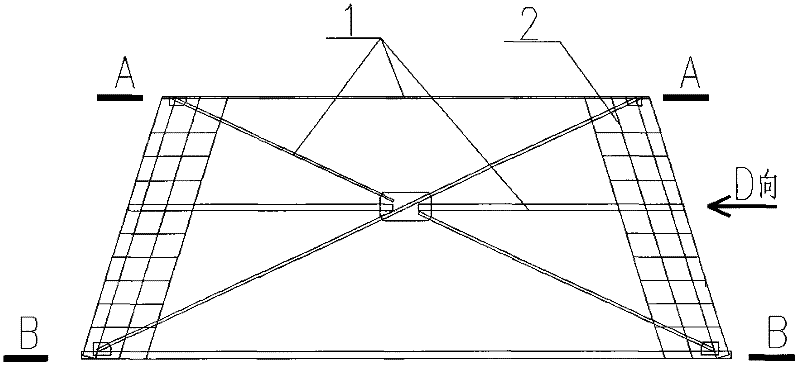

Cage and method for closing closure gap by combining cage with filler

InactiveCN102206935ASolve the problem of difficult closureReduce widthBarrages/weirsReinforced concretePlanar network

The invention relates to a cage and a method for closing a closure gap by combining the cage with filler. The technical scheme adopted in the invention is as follows: the cage is in a spatial hexahedron cage structure and is formed by connecting a spatial skeleton with a planar network structure, the cage is rectangular or is in a combined shape of rectangle and trapezoid, the skeleton is a steel structure or reinforced concrete structure, and the planar network structure is one or combination of more than one of a structural steel network, a reinforcement fabric, a steel wire mesh and a nylon mesh; and the method for closing closure by combining the cage with filler comprises the following steps of: firstly, arranging the cage on a fenced area closure river bottom protection structure; secondly, throwing and filling the filler used for river closure into the cage so as to realize the river closure on the closure gap; and thirdly, strengthening and choking inside and outside the cage so as to realize choking and closing on the closure gap. The invention has the technical effects that the cage and the method provided by the invention are used for closing a large fenced area high-flow rate closure gap by virtue of the river closure, the problem that the large fenced area high-flow rate closure gap is difficult to close by virtue of the river closure is effectively solved, the width of the closure gap is reduced, subarea dike separation is reduced or even eliminated, investment is saved, and construction period is shortened.

Owner:马兴华

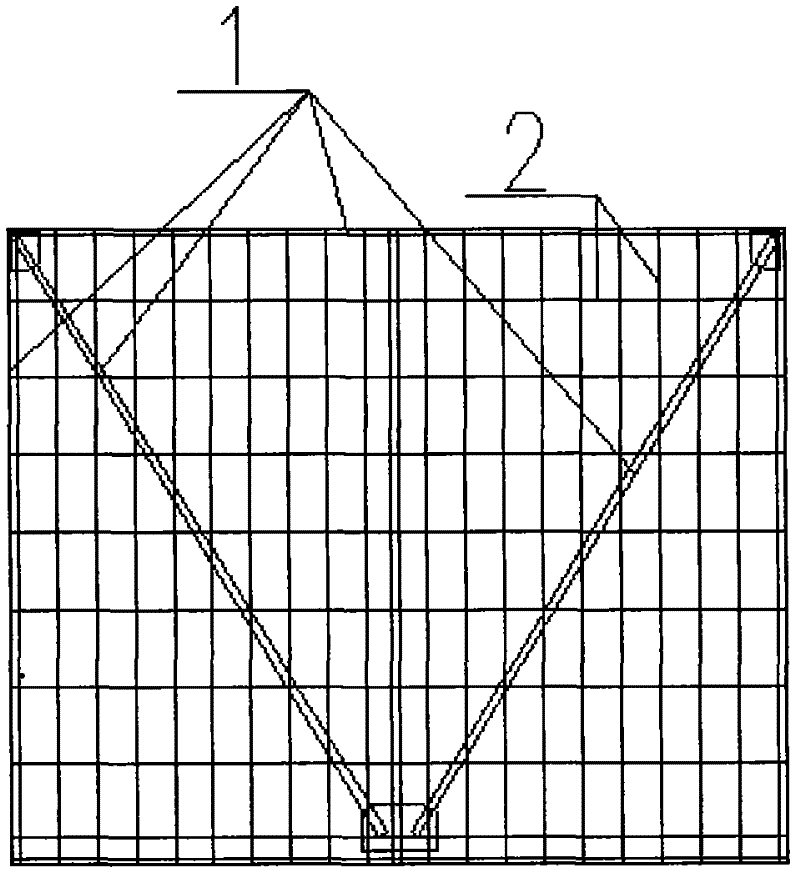

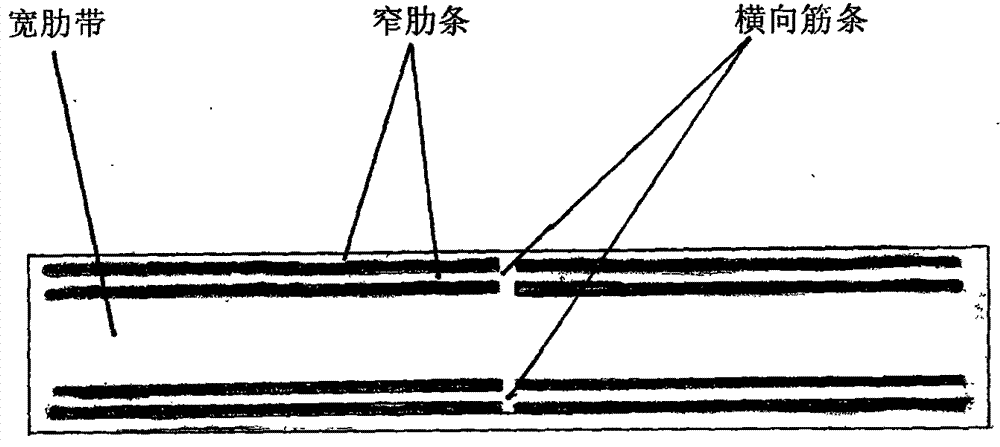

A kind of manufacturing method of sheet material and three-dimensional structure made therefrom

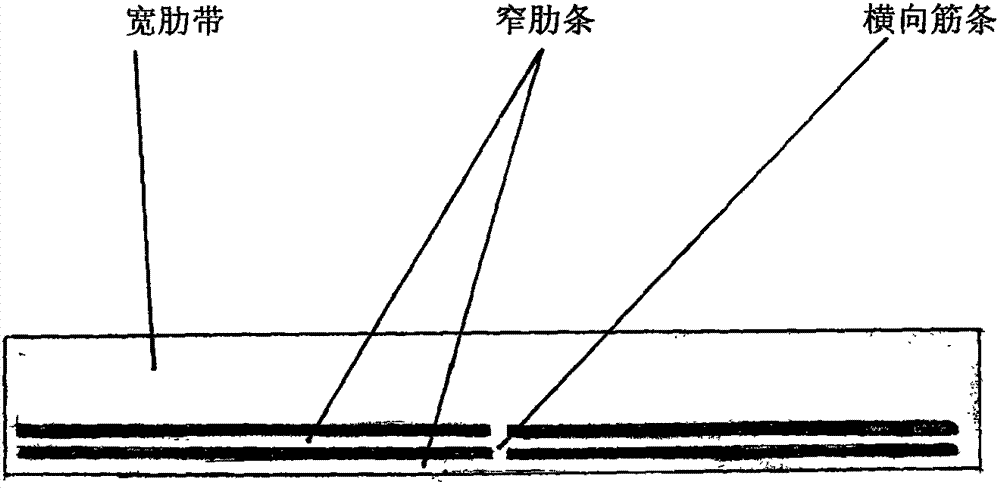

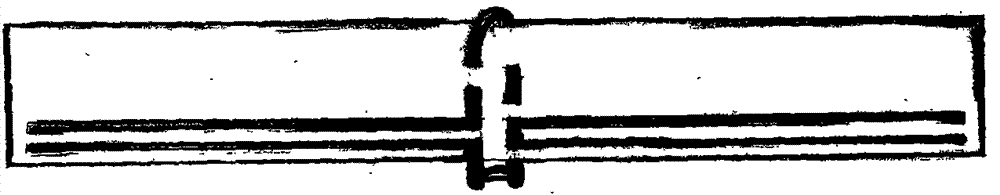

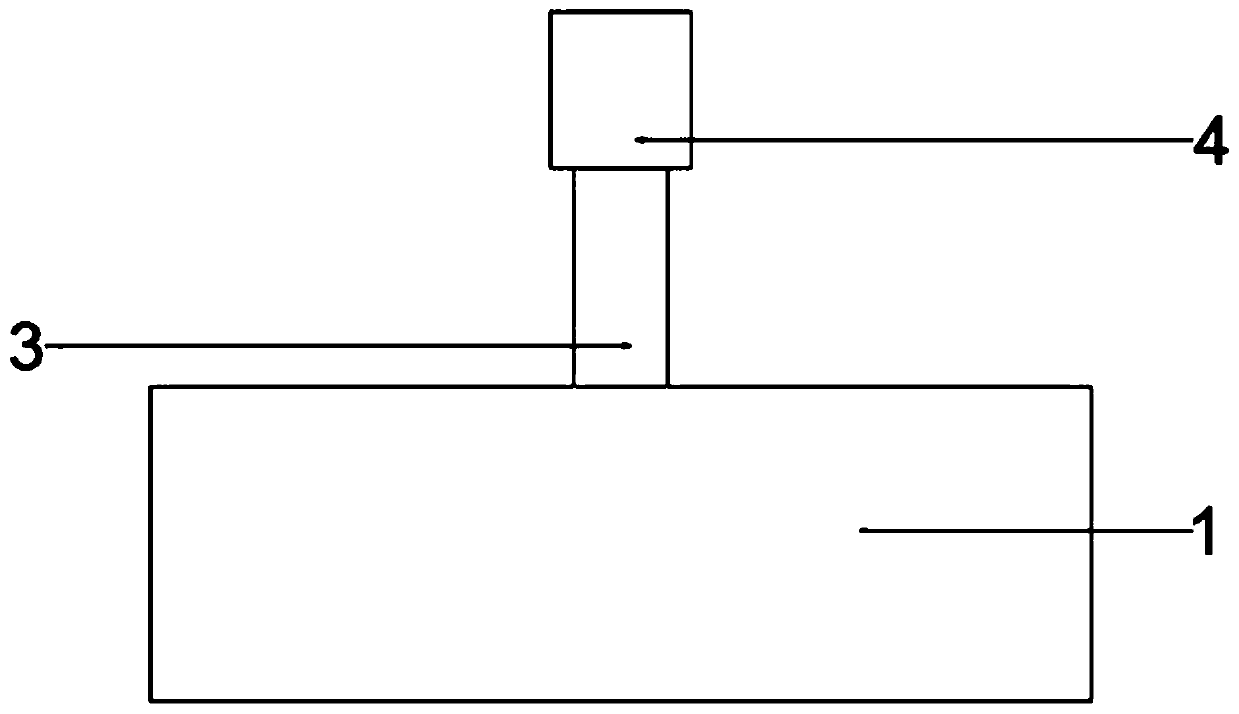

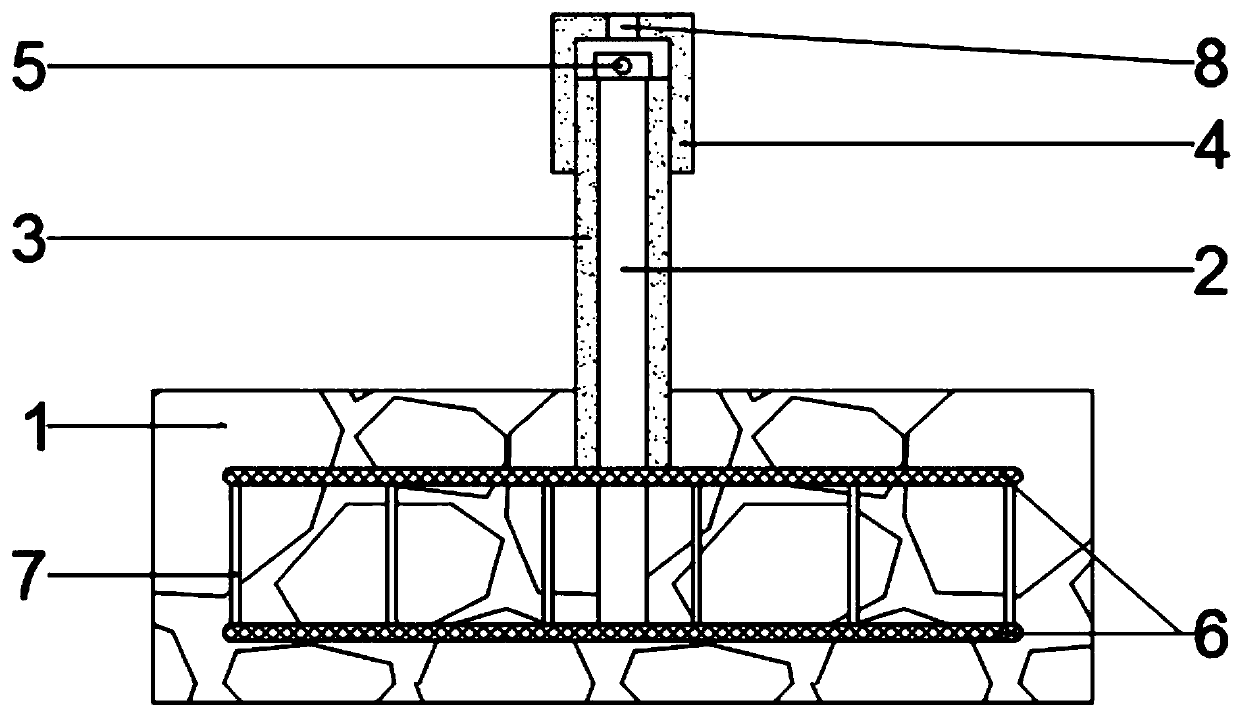

ActiveCN103850238BAvoid local subsidencePrevent sideways movementSoil preservationHoneycombPlanar network

The invention discloses a manufacturing method of a sheet material and a three-dimensional structure made thereof. The sheet comprises wide ribs, repeated longitudinal narrow ribs and repeated transverse ribs, and the repeated transverse ribs include the entire ribs running through the transverse direction of the sheet or the part of the edge of the sheet Ribs. The manufacturing method of the sheet is to heat and stretch an orifice plate with a specific hole spacing; or to directly punch or cut holes on the plate. Through the connection between the sheets and the narrow ribs in the sheets, they are grouped, and after unfolding, a three-dimensional structure including a honeycomb facade structure and a planar network structure is formed. The invention has dual functions of preventing local settlement of the soil body and sideways movement of the soil body, and is an ideal reinforcement material for civil engineering.

Owner:何晓婷

Conductive concrete grounding peg

PendingCN110323584AHigh strengthReliable electrical connectionMulticonductor cable end piecesConnection contact member materialPlanar networkElectrical connection

The present invention discloses a conductive concrete grounding peg, which comprises a cylindrical conductive column. The bottom of the conductive column is provided with two parallel conductive meshes in a planar network form. A plurality of connecting rods are vertically connected between the two conductive meshes. The conductive meshes and the connecting rods are wrapped with a rectangular blocky conductive base. The conductive column extends vertically to the upper part of the conductive base. The inside of the conductive base of the invention is wrapped with the conductive column, the conductive meshes and the connecting rods, so the strength of the conductive base is improved; the inner electrical connection ability of the conductive base is also increased; and the conductive performance of the conductive base is improved.

Owner:ECONOMIC RES INST OF STATE GRID GANSU ELECTRIC POWER +2

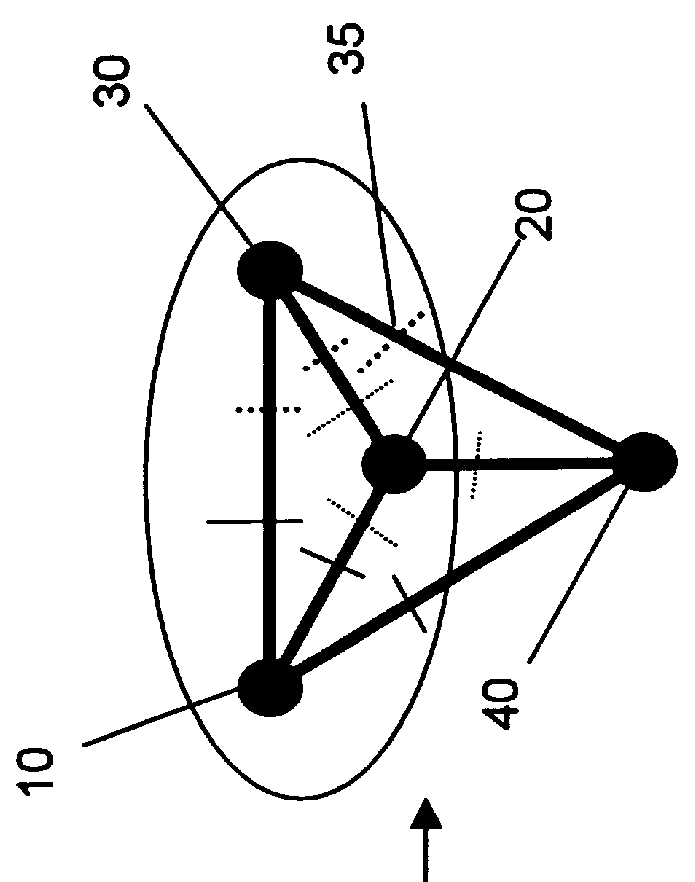

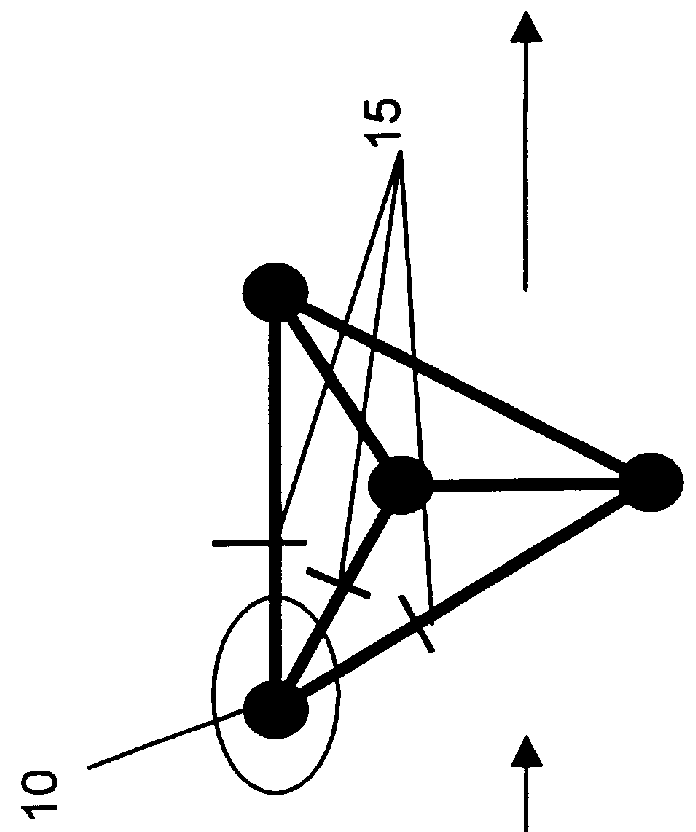

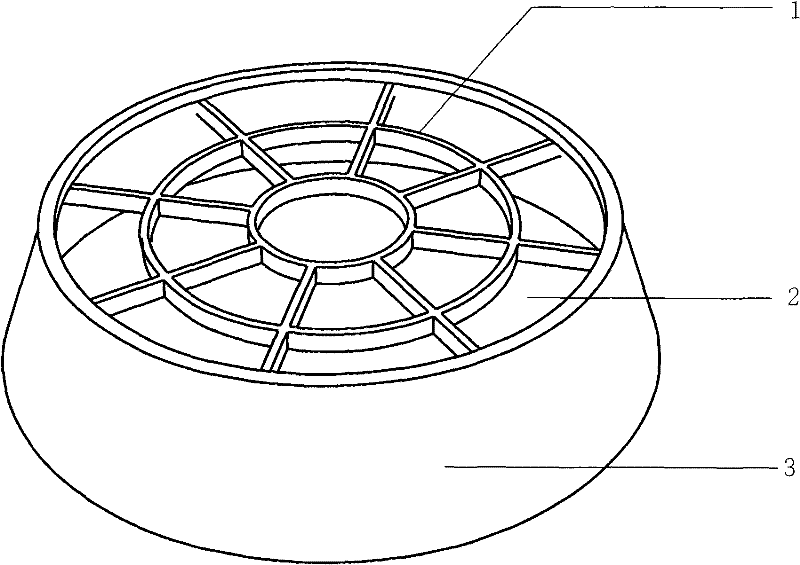

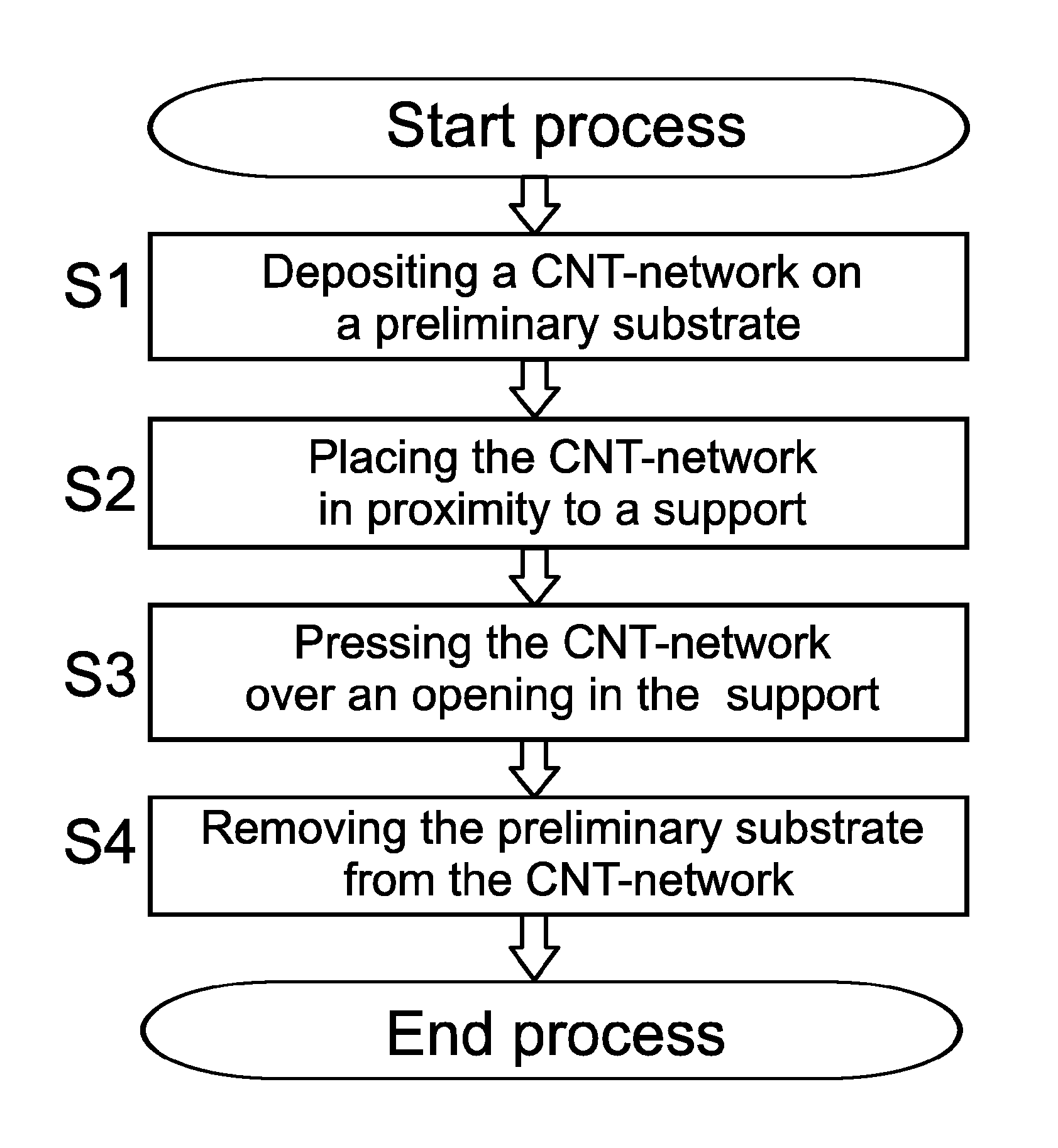

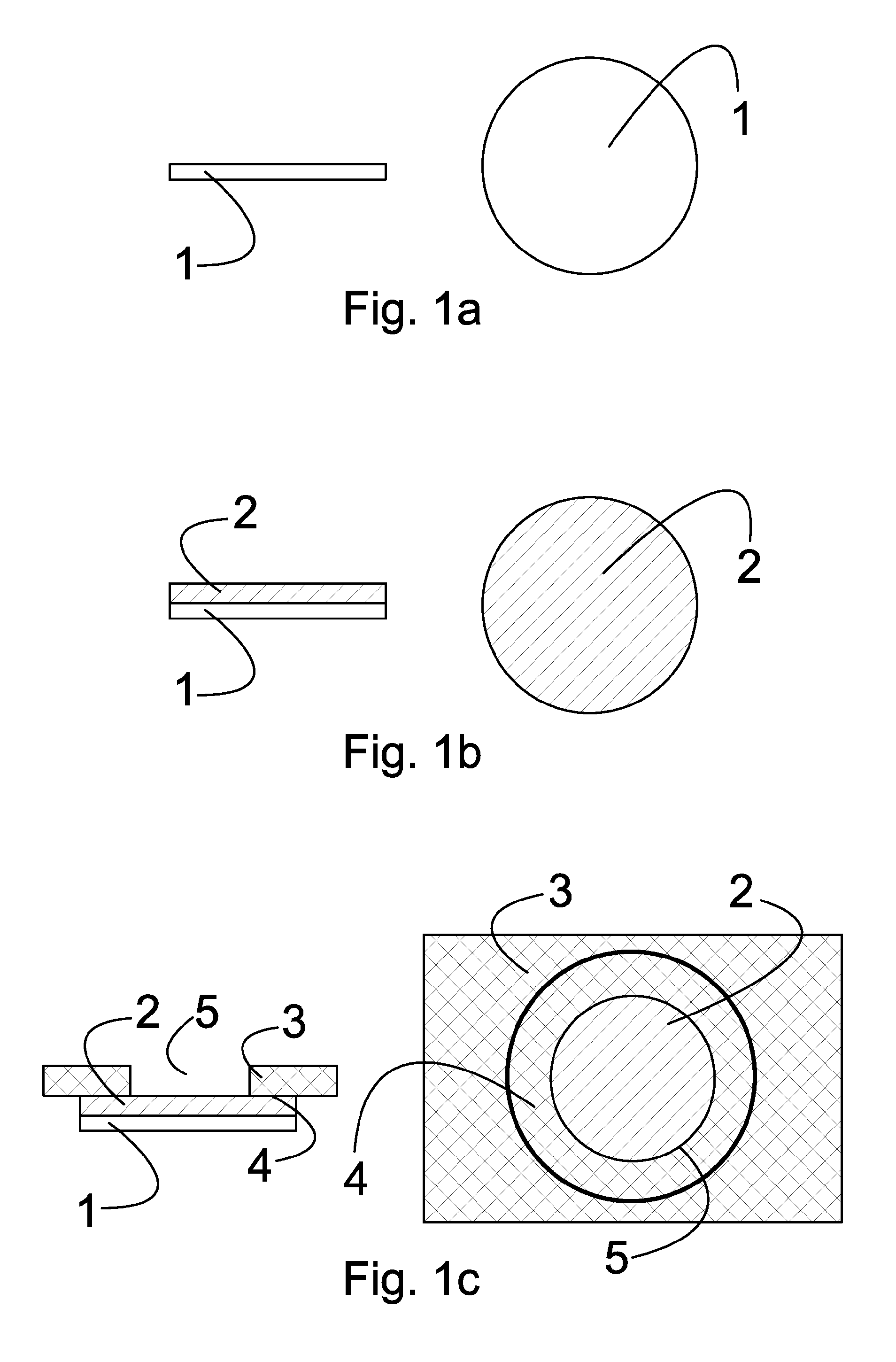

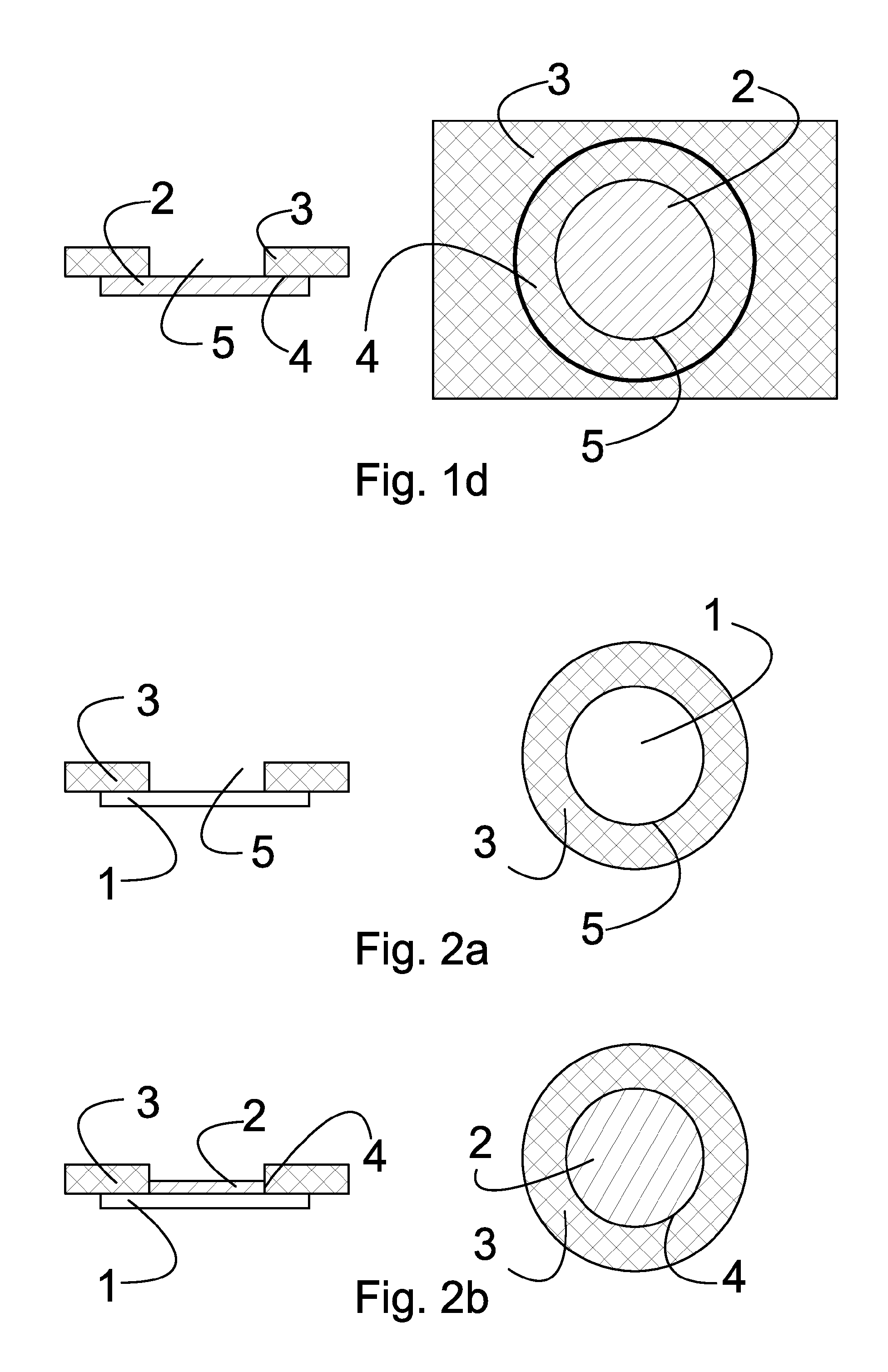

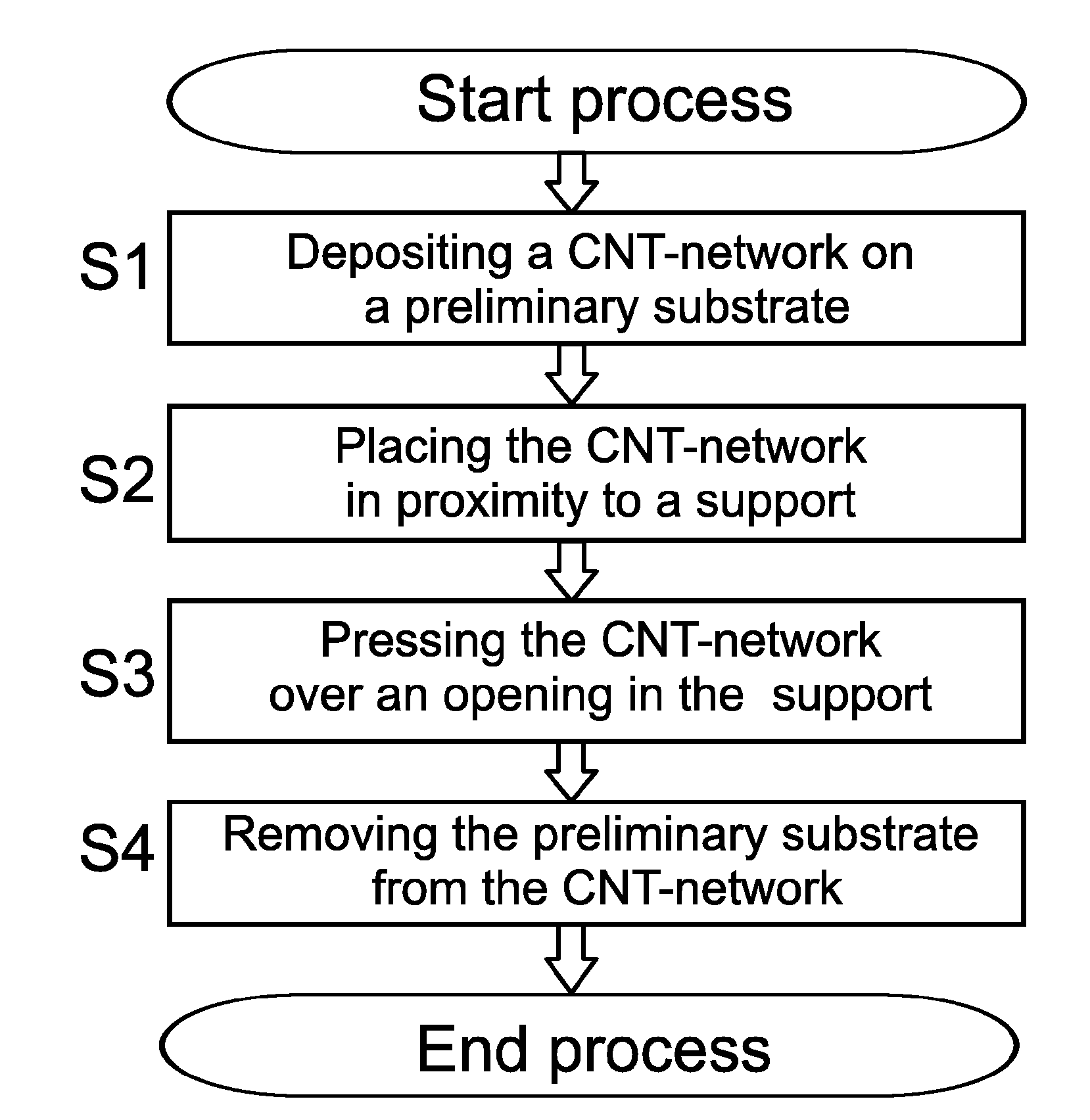

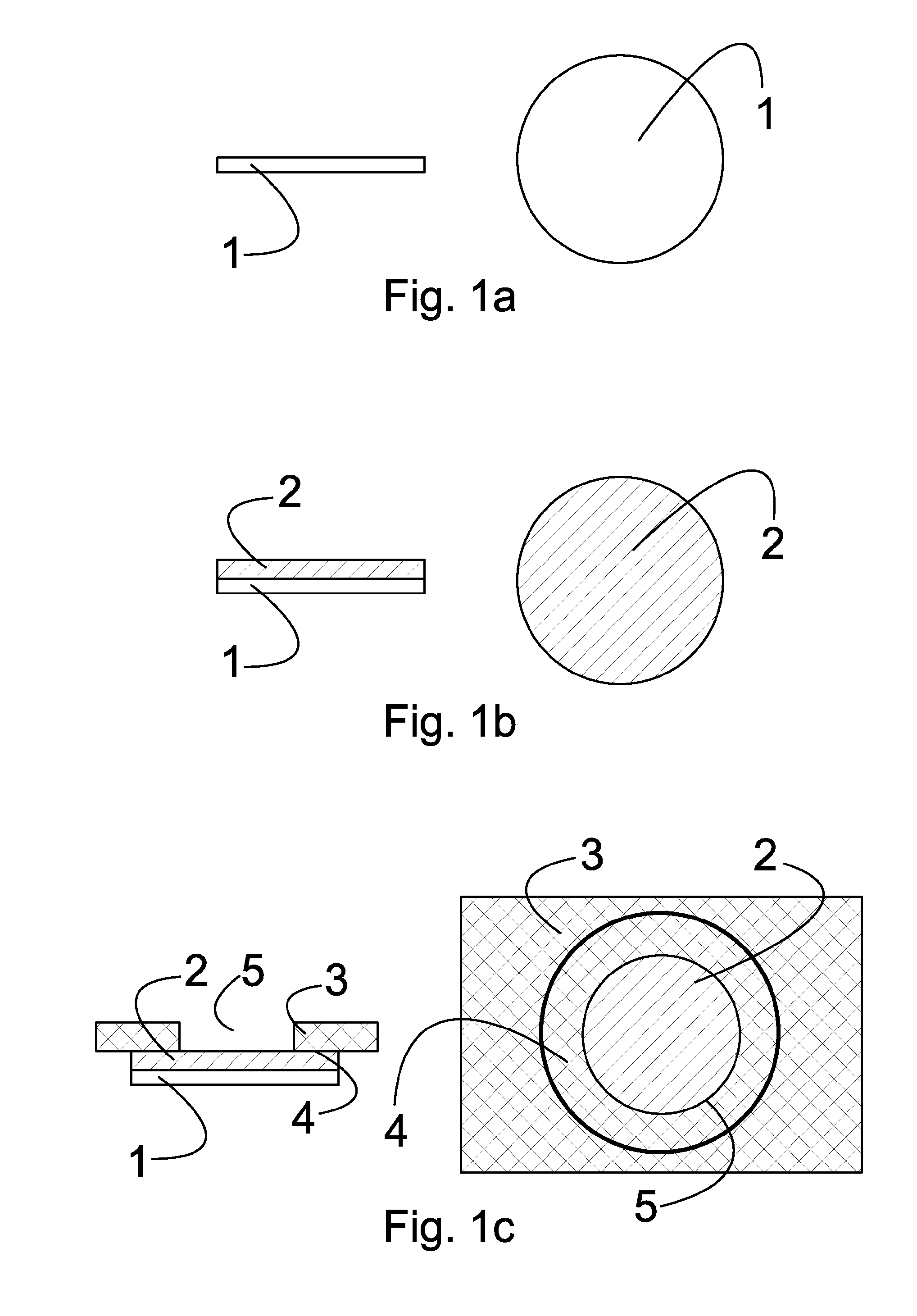

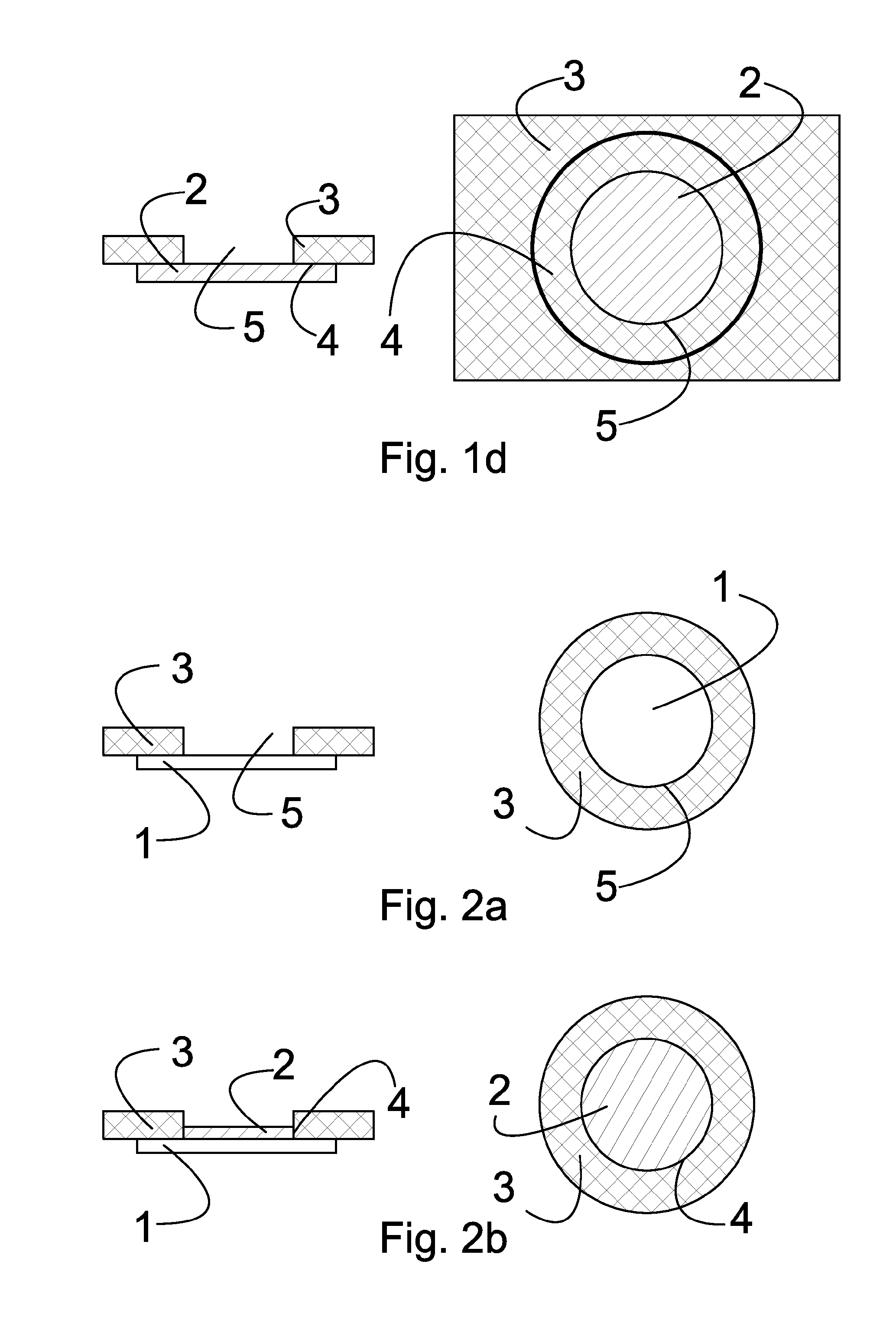

Structures comprising high aspect ratio molecular structures and methods of fabrication

ActiveUS9133022B2Improve thermal conductivityIncreased durabilityMaterial nanotechnologyNanostructure manufacturePlanar networkEngineering

A structure comprising high aspect ratio molecular structures (HARM-structures), wherein the structure comprises an essentially planar network (2) of HARM-structures, and a support (3) in contact with the network (2). The support (3) has an opening (5) therein, at the peripheral region (4) of which opening (5) the network (2) is in contact with the support (3), such that the middle part of the network (2) is unsupported by the support (3). The network (2) comprises essentially randomly oriented HARM-structures.

Owner:CANATU OY

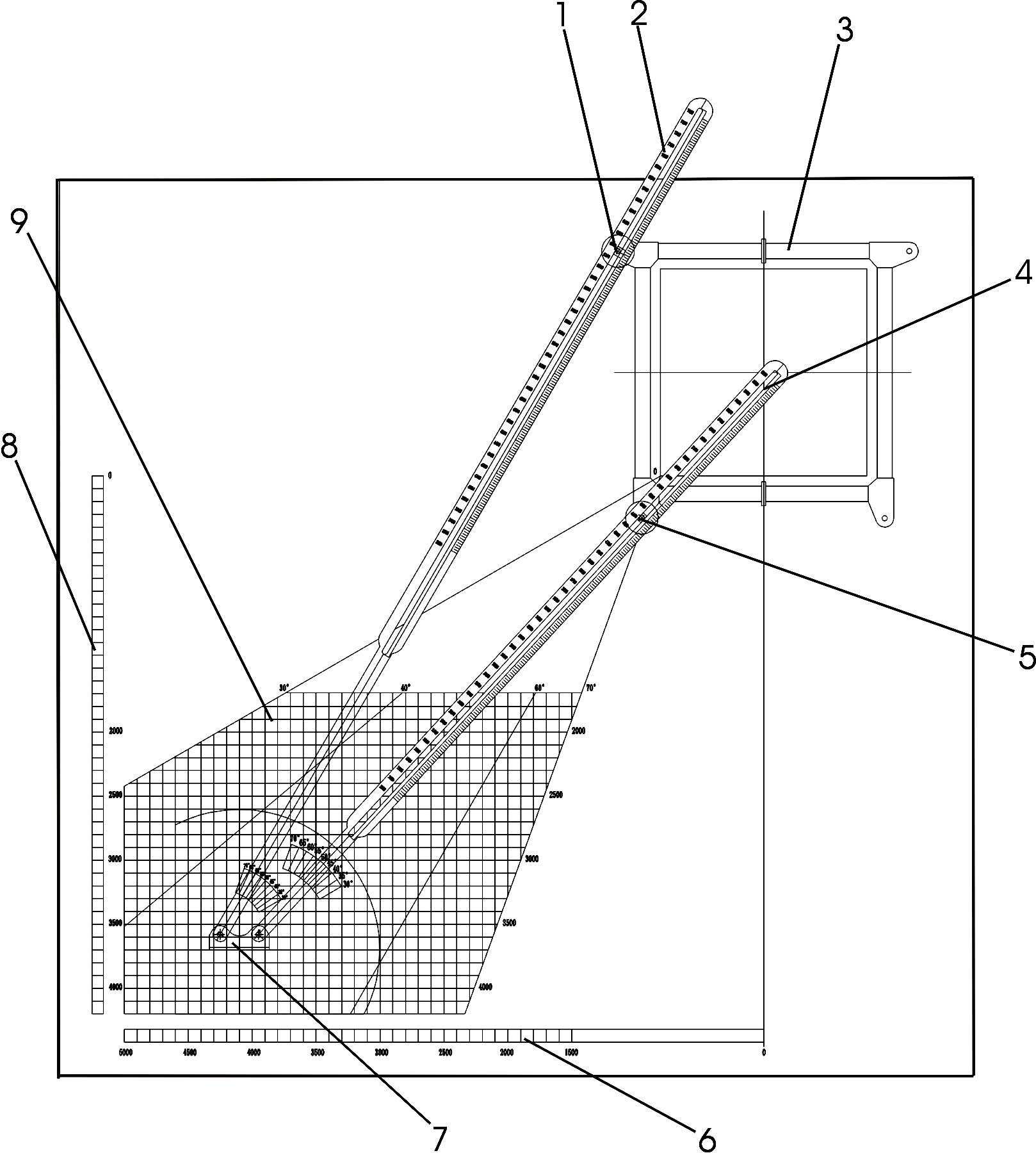

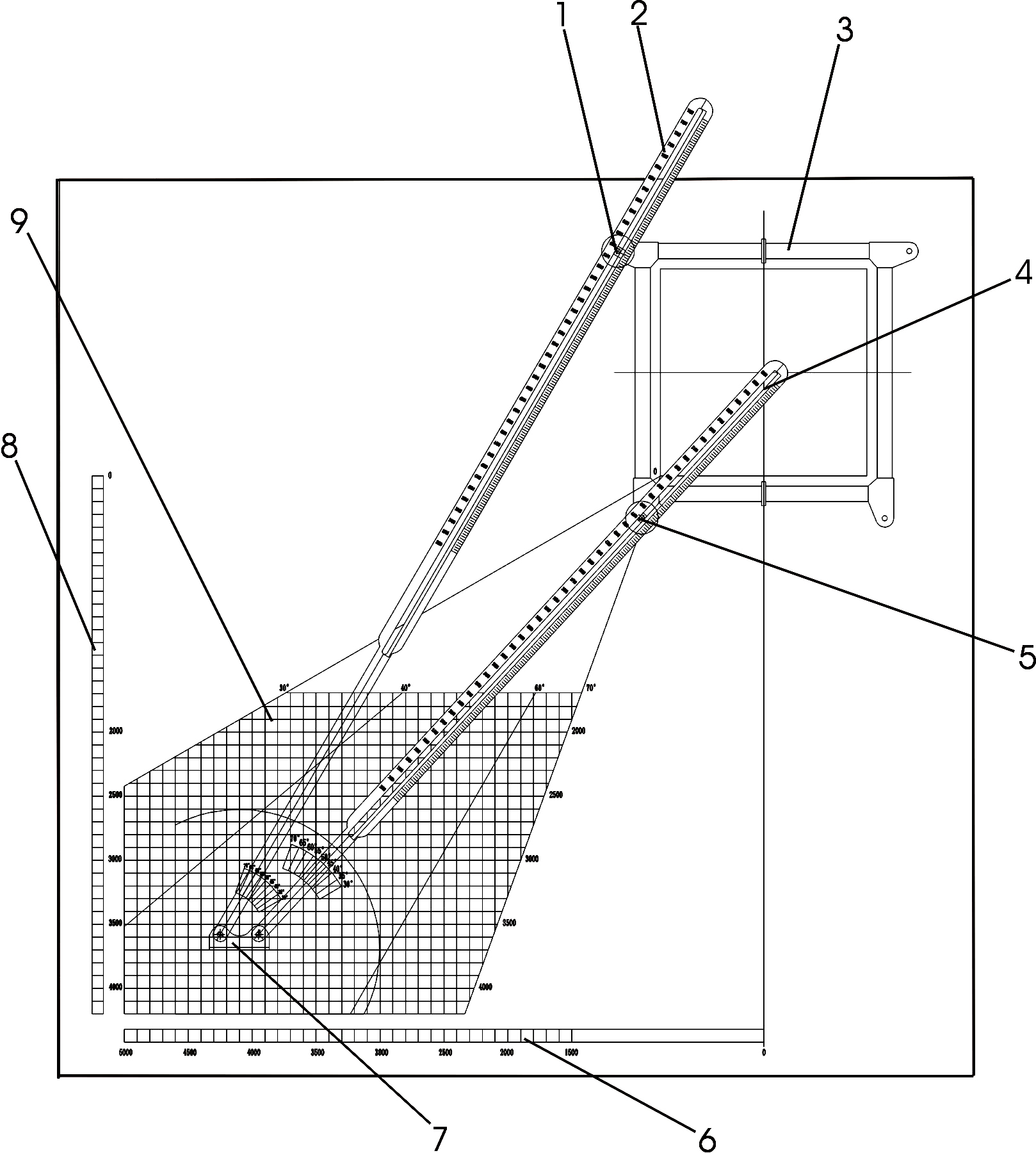

Attached parameter measuring instrument of tower crane

InactiveCN102506643ASimple structureEasy to useMechanical measuring arrangementsMeasuring instrumentPlanar network

The invention discloses an attached parameter measuring instrument of a tower crane, which includes an external rod pinhole, an external attached rod scale, an attached frame, an internal attached rod scale, an internal rod pinhole, an attached wall base central distance scale, an attached wall base positioning plate, a tower body and building horizontal distance scale, and a planar network graph board, wherein the planar network graph board is a main body piece and adopts an integrally square board structure; the vertical tower body and building horizontal distance scale is arranged on the left side of the lower part of the planar network graph board; the horizontal attached wall base central distance scale is arranged below the planar network graph board; the attached wall base positioning plate is arranged at the left lower corner of the planar network graph board; the external attached rod scale and the internal attached rod scale are rotatably arranged on the attached wall base positioning plate, namely, the lower ends of the external attached rod scale and the internal attached rod scale are both connected onto the attached wall base positioning plate; and graduation lines, the angle index lines and sliding chutes are marked and formed on both the external attached rod scale and the internal attached rod scale. The attached parameter measuring instrument of the tower crane has the simple structure, is highly stable and reliable, and is convenient to operate and use.

Owner:SHANDONG NINGJIAN CONSTR GRP

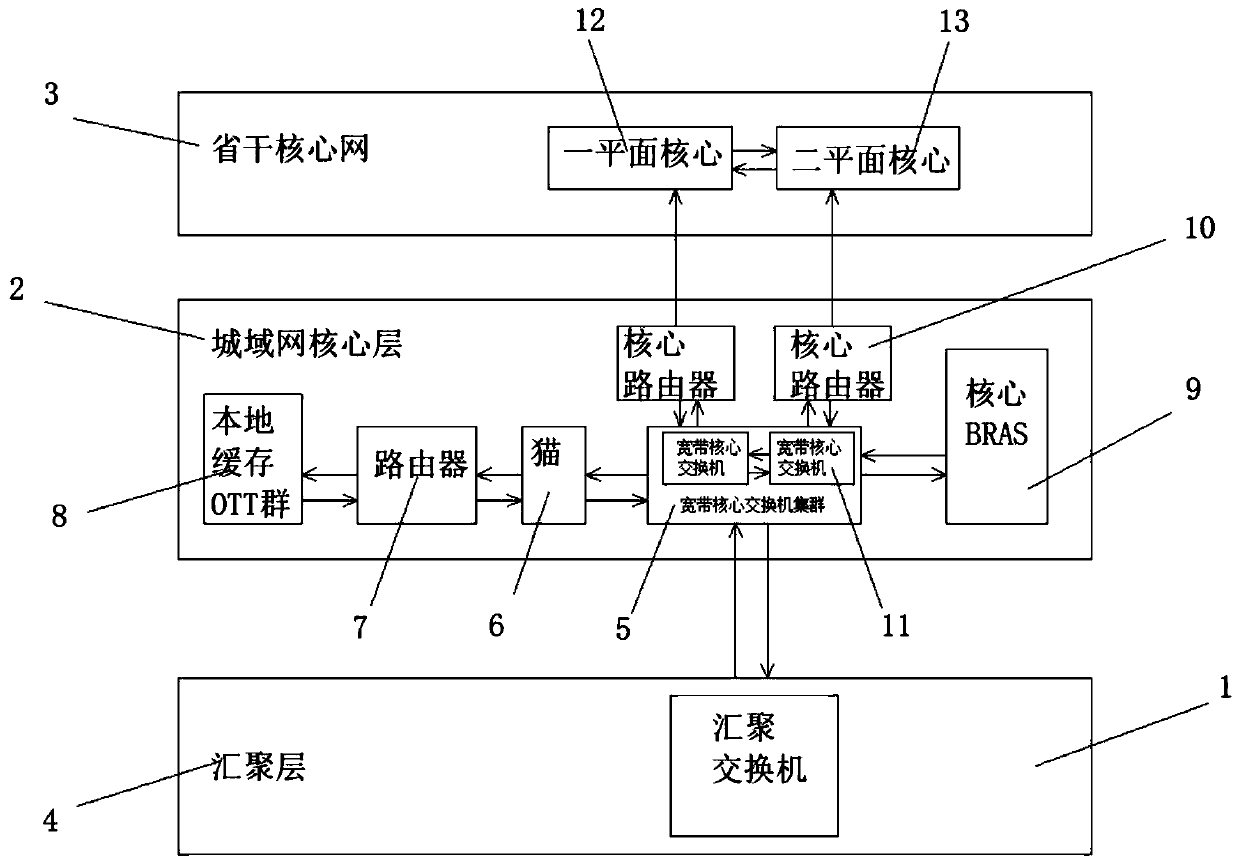

Biplanar network architecture

InactiveCN109688015AUse will not affectReasonable structural designData switching networksData synchronizationModem device

The invention discloses a biplanar network architecture, and belongs to the technical field of the communication equipment. The network architecture comprises a convergence layer, a metropolitan areanetwork core layer and a provincial core network; the convergence layer comprises a convergence switch; the metropolitan area network core layer comprises a bandwidth core switch cluster, a modem, a router, a local cache OTT group, a core BRAS and two core routers; the convergence switch is electrically and bidirectionally connected with the bandwidth core switch cluster; the bandwidth core switchcluster is electrically and bidirectionally connected with the core BRAS machine, the bandwidth core switch cluster is electrically and bidirectionally connected with the modem. The arrangement of the biplanar network architecture is reasonable in structure design, two bandwidth core switches and two core routers are cooperatively used to form a biplanar network so as to realize the data synchronization; when one set of planar network equipment is in trouble, the other set of planar network equipment can run as normal, the internet surfing and the use of the OTT service cannot be influenced.

Owner:武汉市九晖通讯技术有限公司

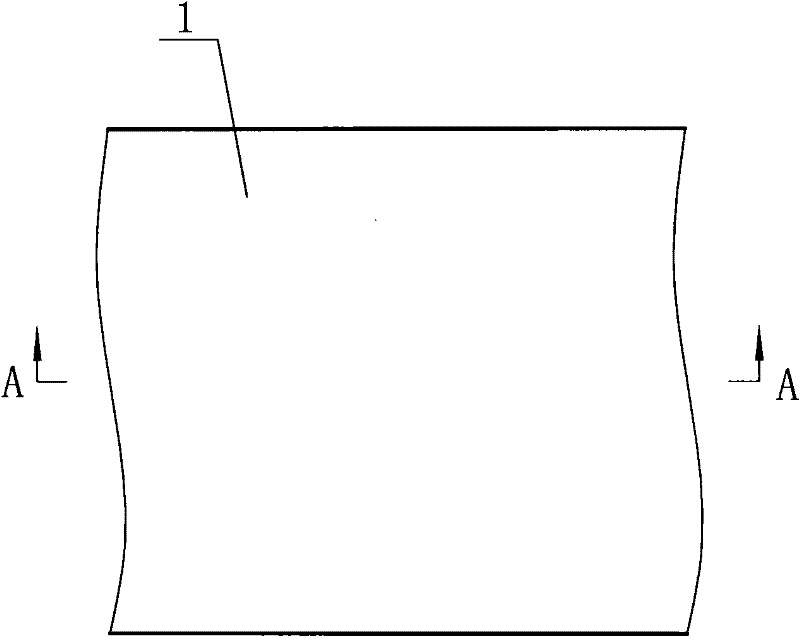

High-temperature resistant fiber layer composite filter material and method for preparing same

ActiveCN101862567BImprove thermal stabilityGood chemical stabilityCellulosic plastic layered productsFiltration separationPlanar networkMixed materials

The invention discloses a high-temperature resistant fiber layer composite filter material and a method for preparing the same. The cross section of the material adopts a triple-layer structure, the upper layer and the lower layer are both a mixed fiber layer, and the middle layer is the PTFE base fabric layer. The preparation comprises the following steps of: preparing PPS fibers and PTFE fibersfor later use; mixing two kinds of raw materials in a cotton-mixing box to obtain a preliminary mixed material; loosening the preliminary mixed material in a loosening machine; performing refined mixing of the loosened material in the cotton-mixing box; carding the refined mixing material into planar network fibers by a carding machine; spreading the planar network fibers by a lapping machine to make the mixed fiber layers; adding the PTFE base fabric layer between the two mixed fiber layers; preparing the composite fiber material by a needling machine; and putting the composite fiber material in shaping equipment for shaping, putting the composite fiber material in coating equipment for coating, and then performing surface singeing treatment to obtain the filter material. The filter material of the invention possesses high thermal stability, chemical stability, corrosion resistance and electrical property, and compared with the conventional materials, the oxidation resistance and thecorrosion resistance of the filter material are greatly improved.

Owner:张延青

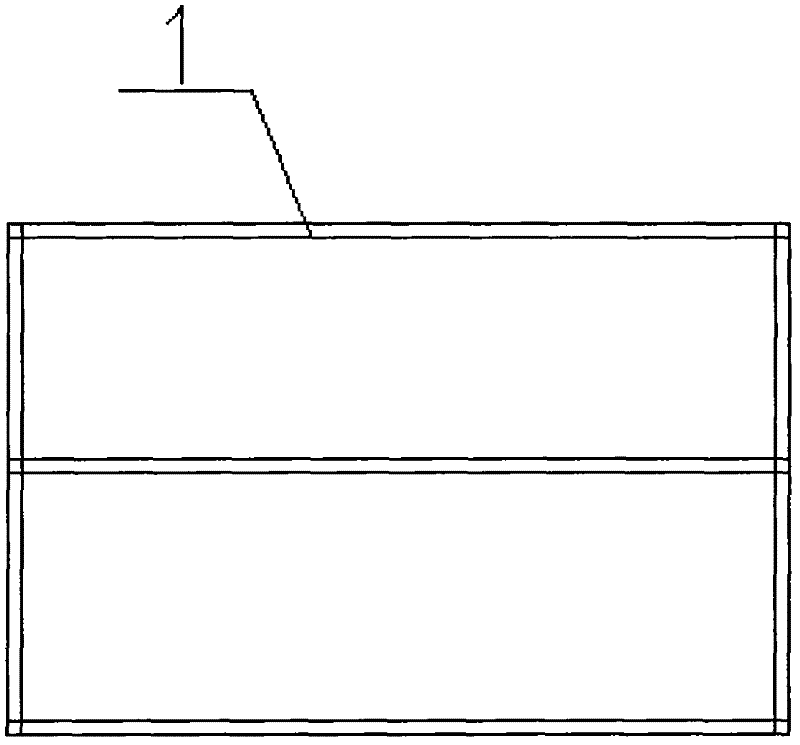

A solar cell preparation process without mesh printing

ActiveCN106683741BGood printabilitySolve bad problems such as printing disconnectionScreen printersNon-conductive material with dispersed conductive materialSilver pastePlanar network

The invention discloses a solar cell production process using net-knot-free printing and relates to the technical field of solar cell production. An anode is printed by a net-knot-free printing manner. The solar cell production process specifically includes the steps of firstly, preparing silver paste, to be more specific, stirring, by weight percentage, 70-75% of silver powder, 10-15% of graphene powder, 2-4% of glass powder and 12-15% of organic carrier in a stirring device at 85 DEG C for 10-12 hours; secondly, producing a screen, to be more specific, using a planar network structure integrally formed by 3D printing, and reserving printing down alignment space at positions needing line printing to obtain the printing screen; thirdly, printing, to be more specific, placing the printing screen obtained in the second step on a moving mechanism which parallelly moves relative to a printing bearing table, allowing a plane where the screen is located to be parallel with a plane where the printing bearing table is located, and printing with the silver paste obtained in the first step. The solar cell production process has the advantages that the production process is good in printing effect, and the problems that the printing paste is severely affected by net knots formed warps and wefts on screen cloth, and defects such as printing line breaking are caused in the prior art are solved.

Owner:TONGWEI SOLAR ENERGY (CHENGDU) CO LID

Structures comprising high aspect ratio molecular structures and methods of fabrication

ActiveUS20120021191A1Easy to manufactureHigh mechanical strengthMaterial nanotechnologyNanostructure manufacturePlanar networkBiomedical engineering

A structure comprising high aspect ratio molecular structures (HARM-structures), wherein the structure comprises an essentially planar network (2) of HARM-structures, and a support (3) in contact with the network (2). The support (3) has an opening (5) therein, at the peripheral region (4) of which opening (5) the network (2) is in contact with the support (3), such that the middle part of the network (2) is unsupported by the support (3). The network (2) comprises essentially randomly oriented HARM-structures.

Owner:CANATU OY

A sensor network topology optimization method in the manufacturing Internet of things

The invention discloses a sensing network topological optimization method in manufacturing internet of things. Combining the characteristics of sensing nodes of massive distribution, limited wireless communication distance and energy limitation, and considering that the large-scale wireless sensing network cannot directly adopt a planar network topology structure, a large-scale distribution node clustered network topology structure with wireless Mesh routers as the cluster head is adopted, two factors, namely load balancing and energy efficiency, need comprehensive considering during clustering, reasonable optimization is performed, the cluster range of each wireless Mesh router is divided, and a minimum energy consumption data forwarding tree with the wireless Mesh routers as the root nodes is built on the premise of guaranteeing that all the wireless Mesh routers have balanced loads.

Owner:GUANGDONG UNIV OF TECH

A surgical organ isolation pad

ActiveCN105193505BPlastic elasticEffective isolationInstruments for stereotaxic surgeryElastomerNiobium

The invention provides a surgical organ isolation pad, which includes an isolation pad body made of a polymer elastomer, and is characterized in that: a sheet metal mesh is arranged in the middle of the isolation pad body as a skeleton, and the material of the sheet metal mesh is Medical stainless steel, cobalt-based alloys, nickel-titanium alloys, tantalum, niobium or zirconium metals. The thickness of the sheet metal mesh is 0.2mm‑2mm; the structure of the sheet metal mesh is a woven mesh or a molded mesh formed on a plane, the edge of the sheet metal mesh is smooth, and the mesh shape of the sheet metal mesh is square, rectangular, Circle, oval, triangle or hexagon. The shape of the isolation pad can be changed by hand according to the needs, and the abdominal organs can be effectively isolated or retracted after being placed at the desired position in the abdominal cavity, without the use of metal retractors to fix and protect the organ tissue; the isolation pad can be tracked under X-ray, eliminating the need hidden dangers in the body. Moreover, it is easy to use and greatly shortens the preparation time for surgery.

Owner:QINGDAO HUAREN MEDICAL PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com