High-temperature resistant fiber layer composite filter material and method for preparing same

A technology of high-temperature resistant fibers and filter materials, applied in the field of filter materials, can solve problems such as inability to meet production needs, and achieve the effects of improved oxidation resistance and corrosion resistance, good thermal stability, and prolonged corrosion resistance life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

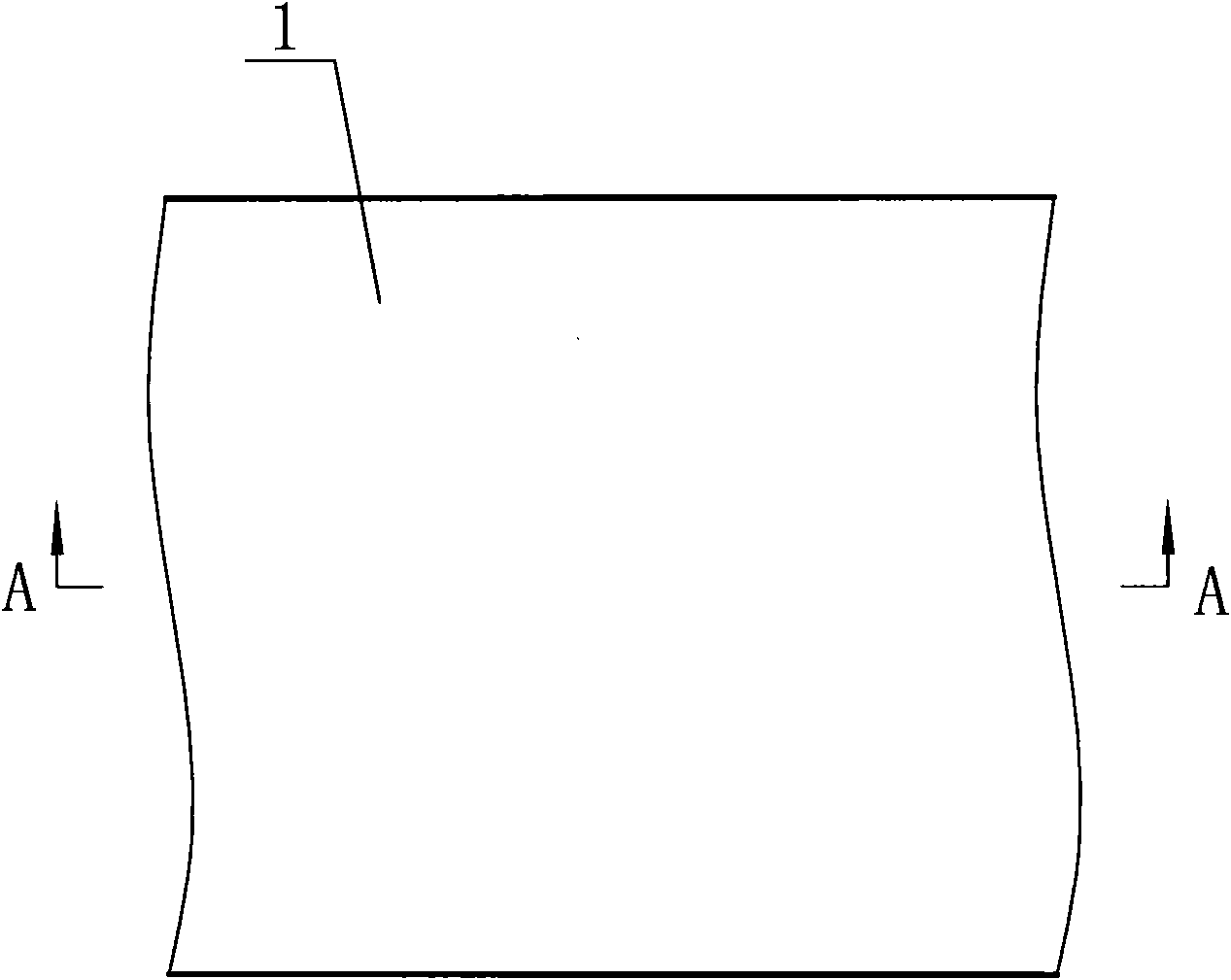

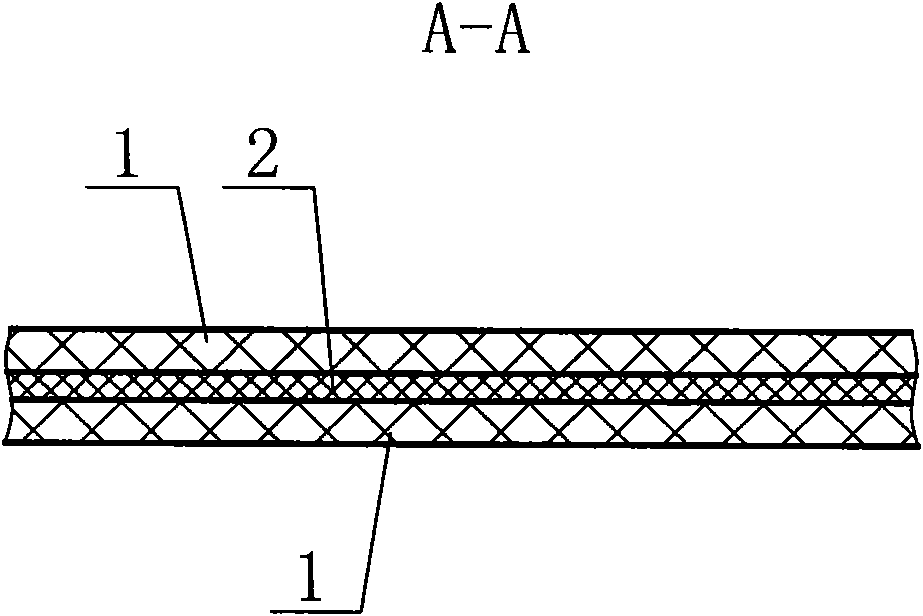

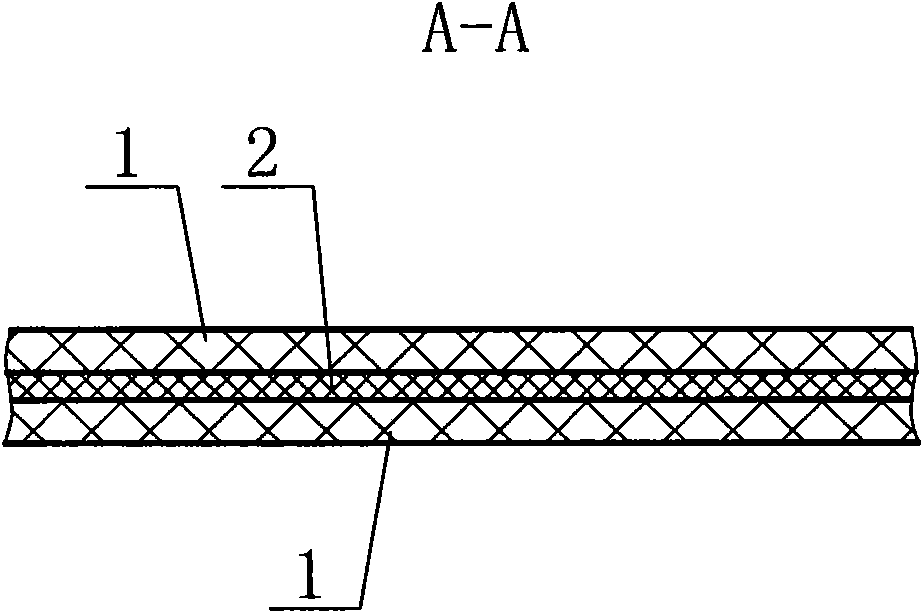

[0020] A high temperature resistant fiber layer composite filter material according to the present invention has a three-layer structure in section, the upper layer and the lower layer are mixed fiber layers 1, and the upper layer and the lower layer are PTFE base cloth layers 2, which are used in the mixed fiber layer 1 The raw materials are 60-80% of PPS fiber and 20-40% of PTFE fiber by weight percentage. Wherein PPS fiber has good thermal stability and chemical stability, and PTFE fiber has excellent chemical stability, corrosion resistance and good oxidation resistance, the present invention fully utilizes the advantage of PPS fiber and PTFE fiber self, solves the present problem There are problems in the anti-oxidation and corrosion resistance of the dust filter bags used in coal-fired power plants. The PTFE base cloth layer 2 can enhance the tensile strength and elasticity of the composite filter material itself, which is beneficial to prolong the service life of the com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com