Preparation and application of polyaniline nanowire/three-dimensional porous graphene electrode material

A graphene electrode, three-dimensional porous technology, used in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve problems such as poor structural stability, achieve high permittivity, improve cycle stability, and improve electrochemical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

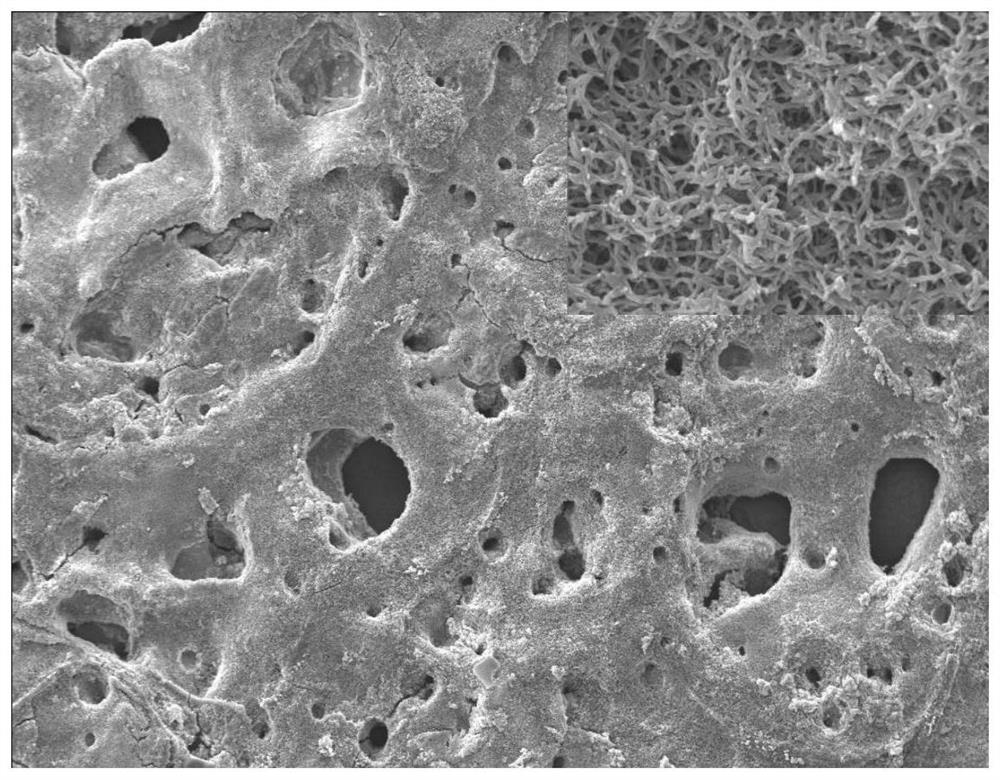

[0051] A preparation method of polyaniline nanowire / three-dimensional porous graphene electrode material, comprising the steps of:

[0052] (1) Hydrothermal reaction: Cut the foamed nickel sheet into 1cm×1cm as the substrate, put the foamed nickel sheet and 0.01moL / l graphene oxide aqueous solution 20mL together in a 50mL hydrothermal reaction kettle, and control the hydrothermal reaction temperature The temperature is 100°C, and the reaction time is 5h. After the reaction, the nickel-based three-dimensional graphene is placed in a vacuum drying environment at 80°C and dried for use;

[0053] (2) Electroplating: Dissolve 2g of aniline monomer into 100mL of dilute sulfuric acid with a mass concentration of 20%, and prepare an aniline electroplating solution; a three-electrode system is adopted, with nickel-based three-dimensional graphene as the working electrode, and Ag / AgCl as the counter electrode. The Pt electrode was used as a reference electrode, and was electroplated at ...

Embodiment 2

[0058] A preparation method of polyaniline nanowire / three-dimensional porous graphene electrode material, comprising the steps of:

[0059] (1) Hydrothermal reaction: Cut the foamed nickel sheet into 1cm×1cm as the substrate, put the foamed nickel sheet and 0.5mol / l graphene oxide aqueous solution 20mL together in a 50mL hydrothermal reaction kettle, and control the hydrothermal reaction temperature The temperature is 150°C, and the reaction time is 3h. After the reaction, the nickel-based three-dimensional graphene is placed in a vacuum drying environment of 80°C and dried for use;

[0060] (2) Electroplating: Dissolve 5g of aniline monomer into 100mL of dilute sulfuric acid with a mass concentration of 20%, and prepare an aniline electroplating solution; adopt a three-electrode system, nickel-based three-dimensional graphene is the working electrode, and Ag / AgCl is the counter electrode. The Pt electrode was used as a reference electrode, and was electroplated at a constant ...

Embodiment 3

[0065] A preparation method of polyaniline nanowire / three-dimensional porous graphene electrode material, comprising the steps of:

[0066] (1) Hydrothermal reaction: Cut the foamed nickel sheet into 1cm×1cm as the substrate, place the foamed nickel sheet and 1moL / l graphene oxide aqueous solution 20mL together in a 50mL hydrothermal reaction kettle, and control the hydrothermal reaction temperature. 300°C, the reaction time is 0.5h. After the reaction, the nickel-based three-dimensional graphene is dried in a vacuum drying environment at 80°C for use;

[0067] (2) Electroplating: Dissolve 8g of aniline monomer into 100mL of dilute sulfuric acid with a mass concentration of 20%, and prepare an aniline electroplating solution; adopt a three-electrode system, nickel-based three-dimensional graphene is the working electrode, and Ag / AgCl is the counter electrode. The Pt electrode was used as a reference electrode, and was electroplated at a constant voltage of 0.6V for 10 minutes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com