Reaction sintered ceramic bulletproof insert plate and preparation method of reaction sintered bulletproof ceramic

A technology of bulletproof inserts and sintered ceramics, which is applied in the field of inorganic non-metallic materials, can solve problems such as difficult removal, product performance degradation, and difficulty in residual silicon, so as to reduce labor intensity, facilitate industrialized large-scale production, and realize industrialized large-scale production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1) Mix the raw materials whose mass composition is 90% of silicon carbide powder, 3% of carbon black powder, and 7% of polyvinyl alcohol, spray dry and granulate, and then press and form in a mold to obtain a silicon carbide compact, Such as figure 1 , figure 2 shown;

[0022] 2) After mixing the mass composition of 70% silicon powder, 5% silicon carbide powder and 25% boron nitride powder evenly, press and form in a mold to obtain a compact of sintered infiltration agent;

[0023] 3) Stack the silicon carbide compact and the infiltration agent compact together in a vacuum of 4×10 -1 In a Pa vacuum furnace, heat up to 1550°C for sintering and heat preservation for 1 hour to obtain reaction sintered silicon carbide;

[0024] 4) Tapping and removing the infiltrating agent residue on the surface of the sintered silicon carbide to obtain a reaction sintered silicon carbide ceramic chip.

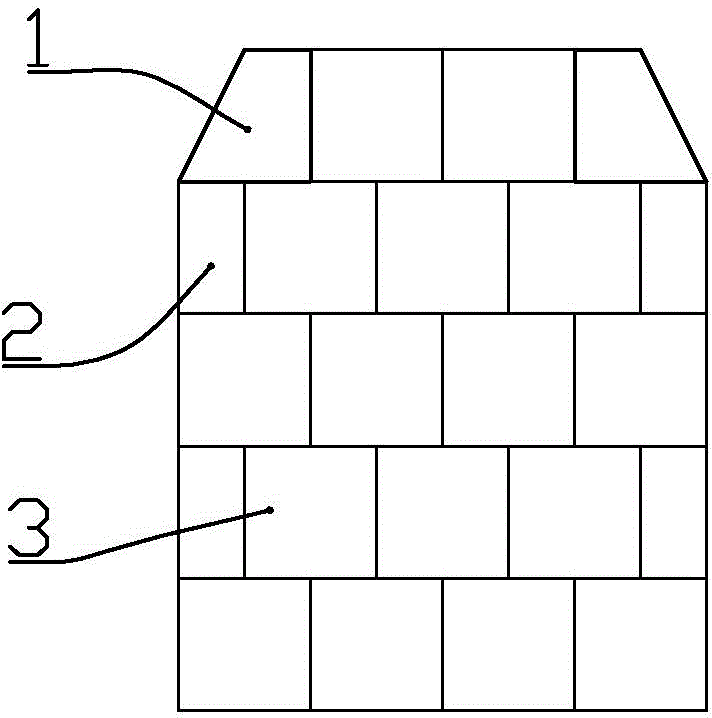

[0025] Such as image 3 As shown, a bulletproof board made of reaction sintered ...

Embodiment 2

[0027] 1) After mixing the raw materials whose mass composition is 85% of boron carbide powder, 5% of carbon black powder, and 10% of paraffin wax solution, they are spray-dried and granulated, and then pressed into a mold to obtain a boron carbide compact;

[0028] 2) After mixing the mass composition of 65% silicon powder, 3% silicon carbide powder and 32% boron nitride powder evenly, press and form in a mold to obtain a compact of sintered infiltration agent;

[0029] 3) Stack boron carbide compacts and infiltration agent compacts together in a vacuum of 1×10 -1 In a Pa vacuum furnace, heat up to 1550°C for sintering and heat preservation for 1 hour to obtain reaction sintered boron carbide;

[0030] 4) Tapping and removing the infiltrating agent residue on the surface of the sintered boron carbide to obtain a reaction sintered boron carbide ceramic chip.

Embodiment 3

[0032] 1) After mixing the raw materials whose mass composition is 80% of silicon carbide powder, 10% of carbon black powder, and 10% of phenolic resin solution, they are spray-dried and granulated, and then pressed into a mold to obtain a silicon carbide compact;

[0033] 2) After mixing the mass composition of 70% silicon powder, 8% silicon carbide powder and 22% boron nitride powder evenly, press and form in a mold to obtain a compact of sintered infiltration agent;

[0034] 3) Stack the silicon carbide compact and the infiltration agent compact together in a vacuum of 3×10 -1 In a Pa vacuum furnace, heat up to 1650°C for sintering and heat preservation for 3 hours to obtain reaction sintered silicon carbide;

[0035] 4) Tapping and removing the infiltrating agent residue on the surface of the sintered silicon carbide to obtain a reaction sintered silicon carbide ceramic chip.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com