Method for removing total nitrogen and ammonia nitrogen from blast furnace coal gas washing water

A blast furnace gas and washing water technology, which is applied in chemical instruments and methods, water/sewage treatment, water/sewage multi-stage treatment, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

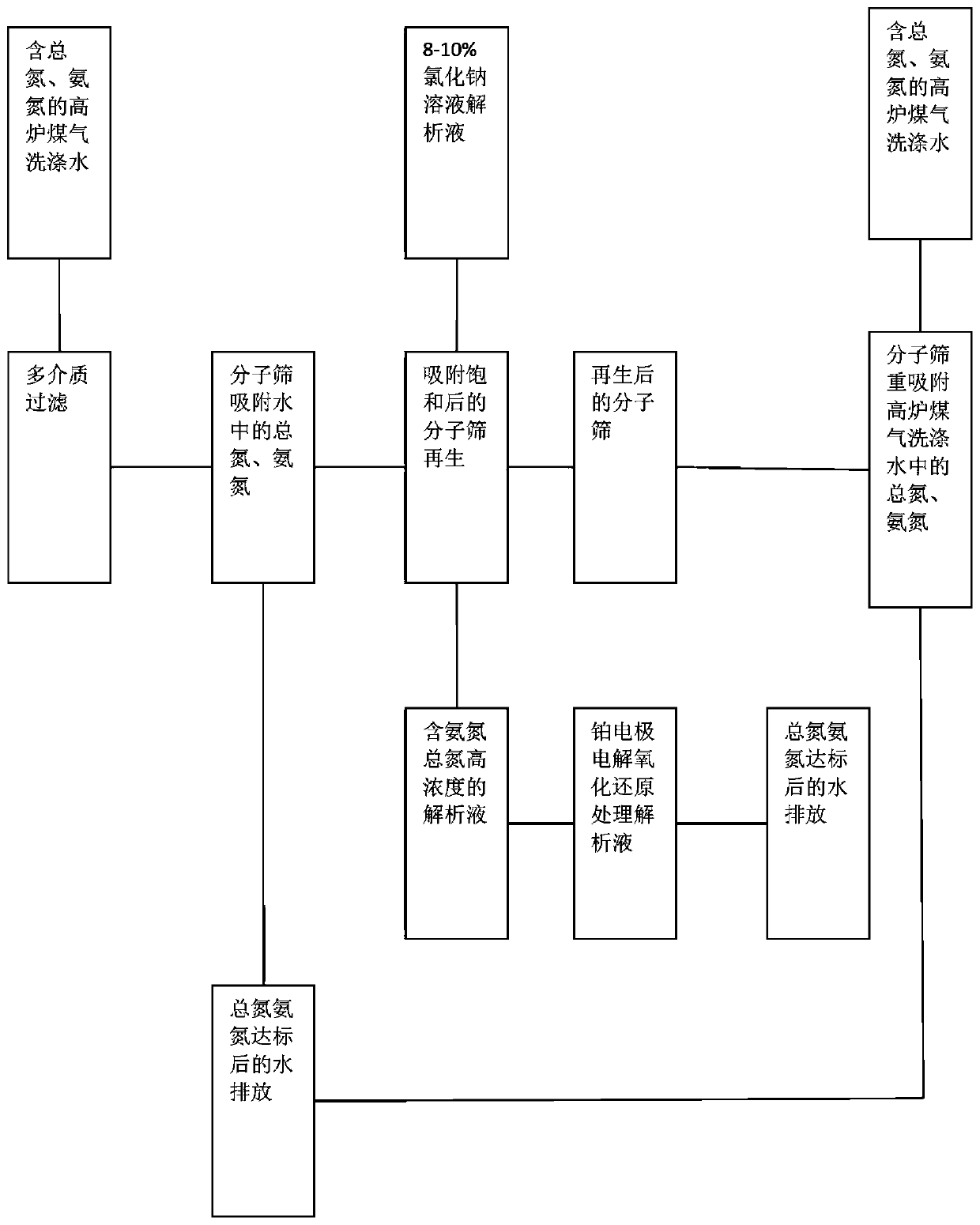

Image

Examples

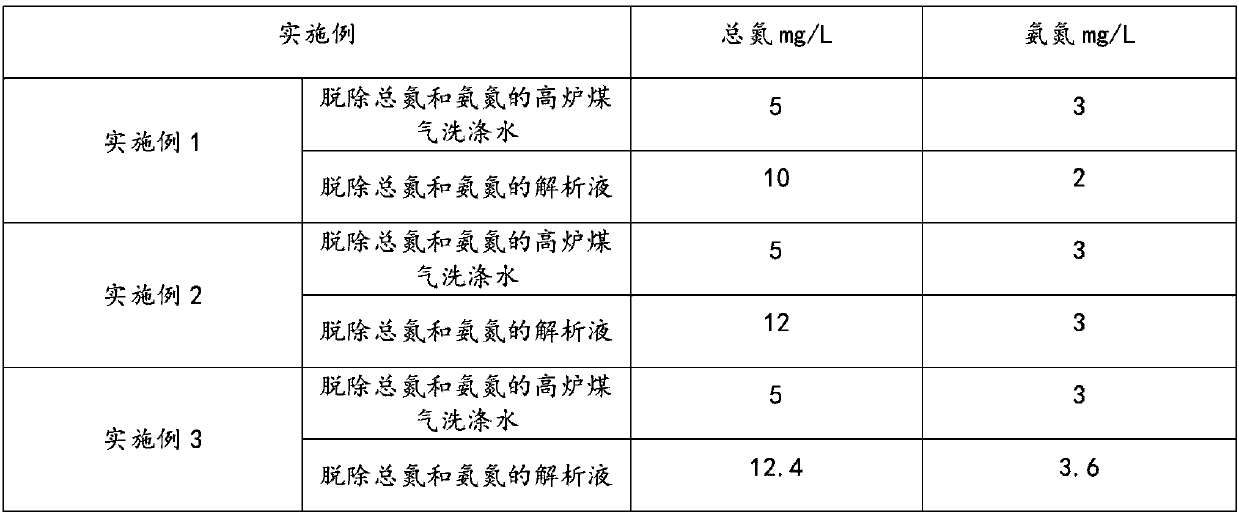

Embodiment 1

[0024] The method for removing total nitrogen and ammonia nitrogen in blast furnace gas washing water provided in this embodiment includes:

[0025] Filtrating blast furnace gas washing water containing total nitrogen and ammonia nitrogen to obtain filtered blast furnace gas washing water;

[0026] The filtered blast furnace gas washing water is subjected to molecular sieve adsorption treatment to obtain blast furnace gas washing water from which total nitrogen and ammonia nitrogen have been removed; the molecular sieve is mainly sodium 13X molecular sieve.

[0027] The filtration is carried out in a multimedia filter.

[0028] The filter material of the multimedia filter includes: pebbles, quartz sand and anthracite.

[0029] The filtering speed of the multimedia filter is 8-10m / h.

[0030] After the molecular sieve is adsorbed and saturated, the sodium chloride solution is used for regeneration to obtain the regenerated molecular sieve and an analysis solution containing t...

Embodiment 2

[0035] The method for removing total nitrogen and ammonia nitrogen in blast furnace gas washing water provided in this embodiment includes:

[0036] Filtrating blast furnace gas washing water containing total nitrogen and ammonia nitrogen to obtain filtered blast furnace gas washing water;

[0037] The filtered blast furnace gas washing water is subjected to molecular sieve adsorption treatment to obtain blast furnace gas washing water from which total nitrogen and ammonia nitrogen are removed; the molecular sieve is a 13X molecular sieve whose main cation is sodium.

[0038] The filtration is carried out in a multimedia filter.

[0039] The filter material of the multimedia filter includes pebbles, quartz sand and anthracite. :.

[0040] The filtering speed of the multimedia filter is 8-10m / h.

[0041] After the molecular sieve is adsorbed and saturated, the sodium chloride solution is used for regeneration to obtain the regenerated molecular sieve and an analysis solution...

Embodiment 3

[0046] The method for removing total nitrogen and ammonia nitrogen in blast furnace gas washing water provided in this embodiment includes:

[0047] Filtrating blast furnace gas washing water containing total nitrogen and ammonia nitrogen to obtain filtered blast furnace gas washing water;

[0048] The filtered blast furnace gas washing water is subjected to molecular sieve adsorption treatment to obtain blast furnace gas washing water from which total nitrogen and ammonia nitrogen are removed; the molecular sieve is a 13X molecular sieve whose main cation is sodium.

[0049] The filtration is carried out in a multimedia filter.

[0050] The filter material of the multimedia filter includes: pebbles, quartz sand and anthracite. .

[0051] The filtering speed of the multimedia filter is 8-10m / h.

[0052] After the molecular sieve is adsorbed and saturated, the sodium chloride solution is used for regeneration to obtain the regenerated molecular sieve and an analysis solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com