Patents

Literature

52results about How to "Uniform microporous structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

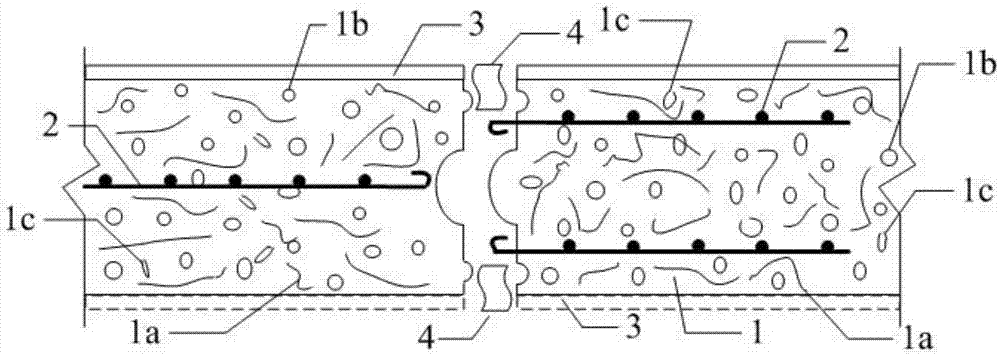

Light-weight concrete, multifunctional protective plate adopting concrete, and preparation method

ActiveCN103922668AGood flexibilityLarge specific surface areaSolid waste managementCeramicwareFiberFoam concrete

The invention belongs to the fields of building materials and construction technology. Light-weight concrete consists of a concrete base layer and waterproof surface layers, wherein the concrete base layer comprises the following components in parts by weight: 100 parts of cement, 0.1-10 parts of chrysotile fibers, 0.01-2 parts of water repellent, 10-30 parts of pulverized fuel ash, 0.1-6 parts of water reducer, 50-200 parts of water, and 1-20 parts of foaming agent or air entraining agent; the upper side and the lower side of the concrete base layer are coated with the waterproof surface layers which comprise the following components in parts by weight: 100 parts of penetrating type organosilicon waterproofing agent, 0.1-20 parts of nano TiO2, 0-2 parts of activity enhancer, 0.01-5 parts of dispersion stabilizer, and 50-200 parts of solvent. Correspondingly, the microporous structure of the foam concrete or air-entrained concrete is uniform, and the mechanical performance is improved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

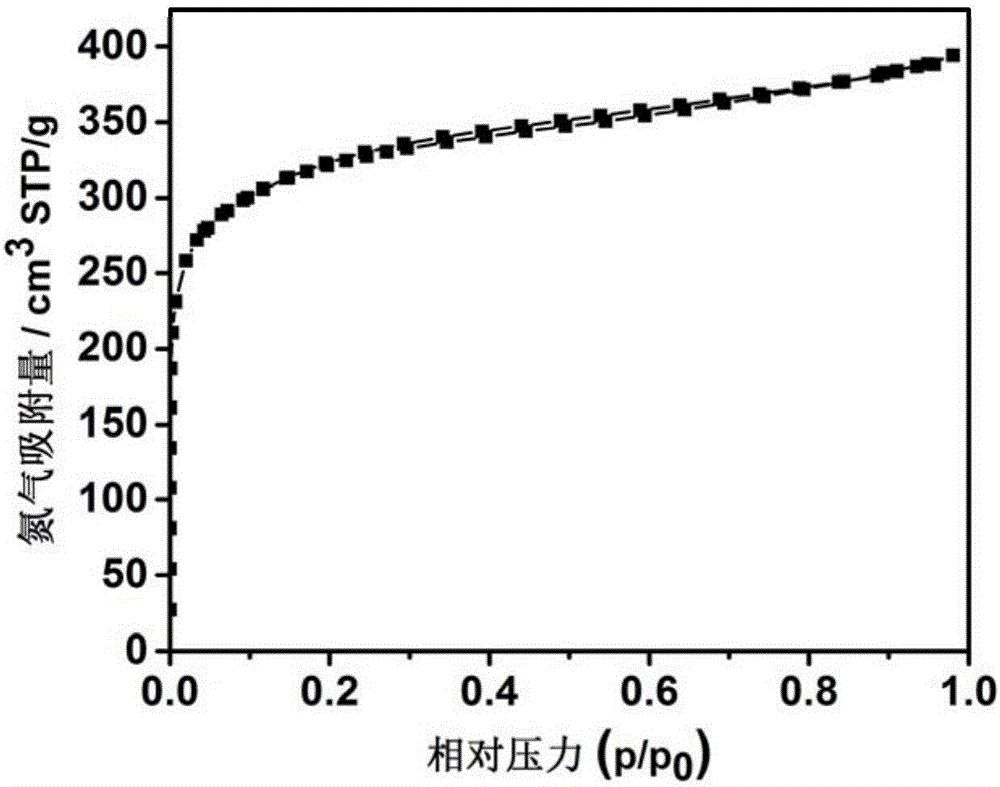

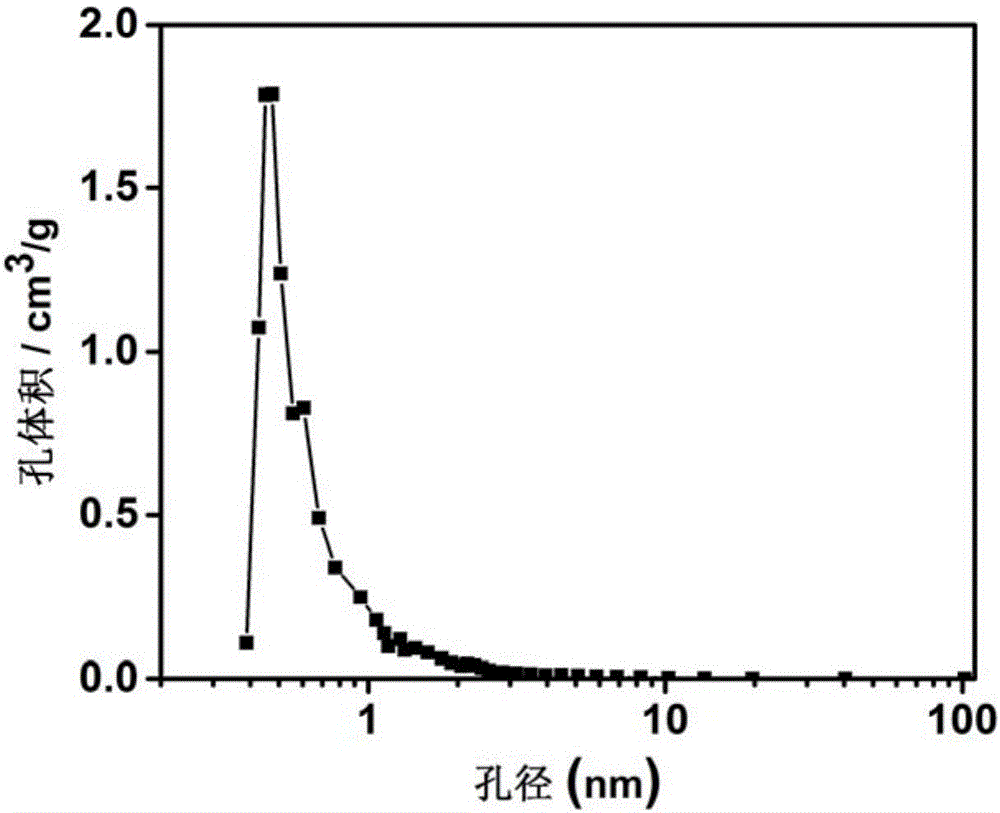

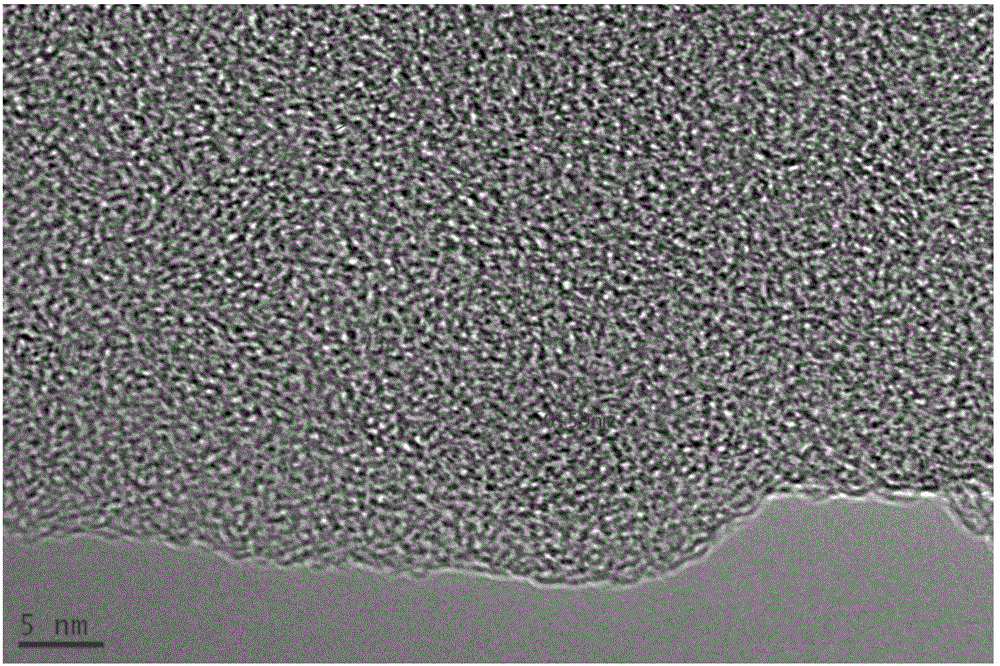

Preparation method of nitrogen doped porous carbon material and application of preparation method in supercapacitor

InactiveCN106587057ALarge specific surface areaUniform microporous structureCarbon compoundsHybrid capacitor electrodesDistillationSupercapacitor

The invention belongs to the fields of inorganic nano-materials and electrochemistry and particularly provides a preparation method of a nitrogen doped porous carbon material and application of the preparation method in supercapacitors. The preparation method comprises the following steps that a nitrogen-containing polymer and Lewis acid are dissolved in an acid solution in proportion, stirring is performed for 1-8 hours, then drying is performed by distillation, activation is performed under inert atmosphere protection at the temperature of 400-1000 DEG C for 1-24 hours, natural cooling is performed, then washing is performed by using the acid solution, then washing is performed with deionized water to make PH neutral, and drying is performed to obtain the nitrogen doped porous carbon material. Compared with the prior art, the preparation method of the nitrogen doped porous carbon material has low device requirement and is simple, and large-scale production is promoted. The prepared nitrogen doped porous carbon material is high in nitrogen content, has high specific surface area and uniform pore diameter distribution and has very high application value in the aspects such as batteries and capacitor electrode materials.

Owner:SHANGHAI INST OF TECH

Foam, production method for foam, and functional foam

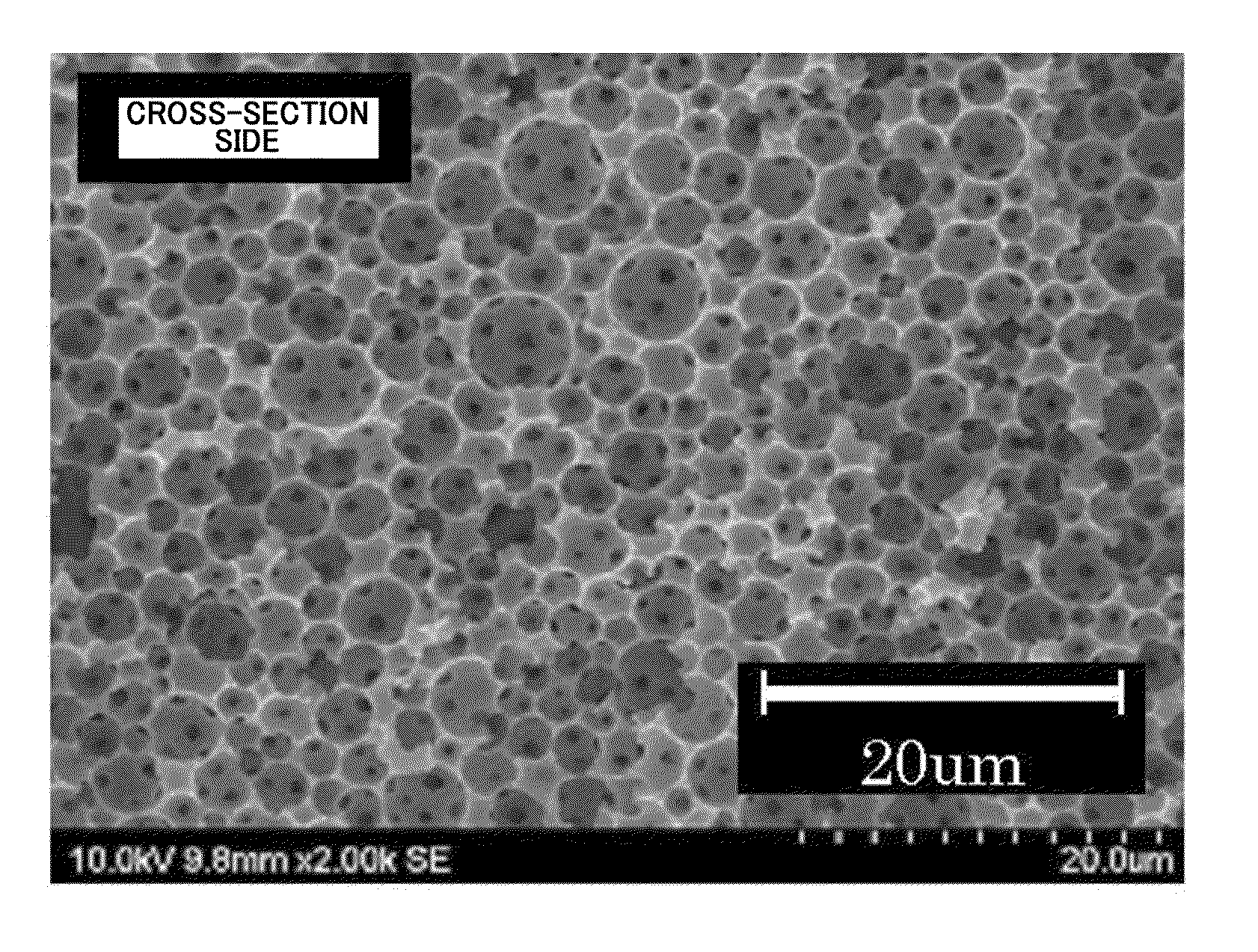

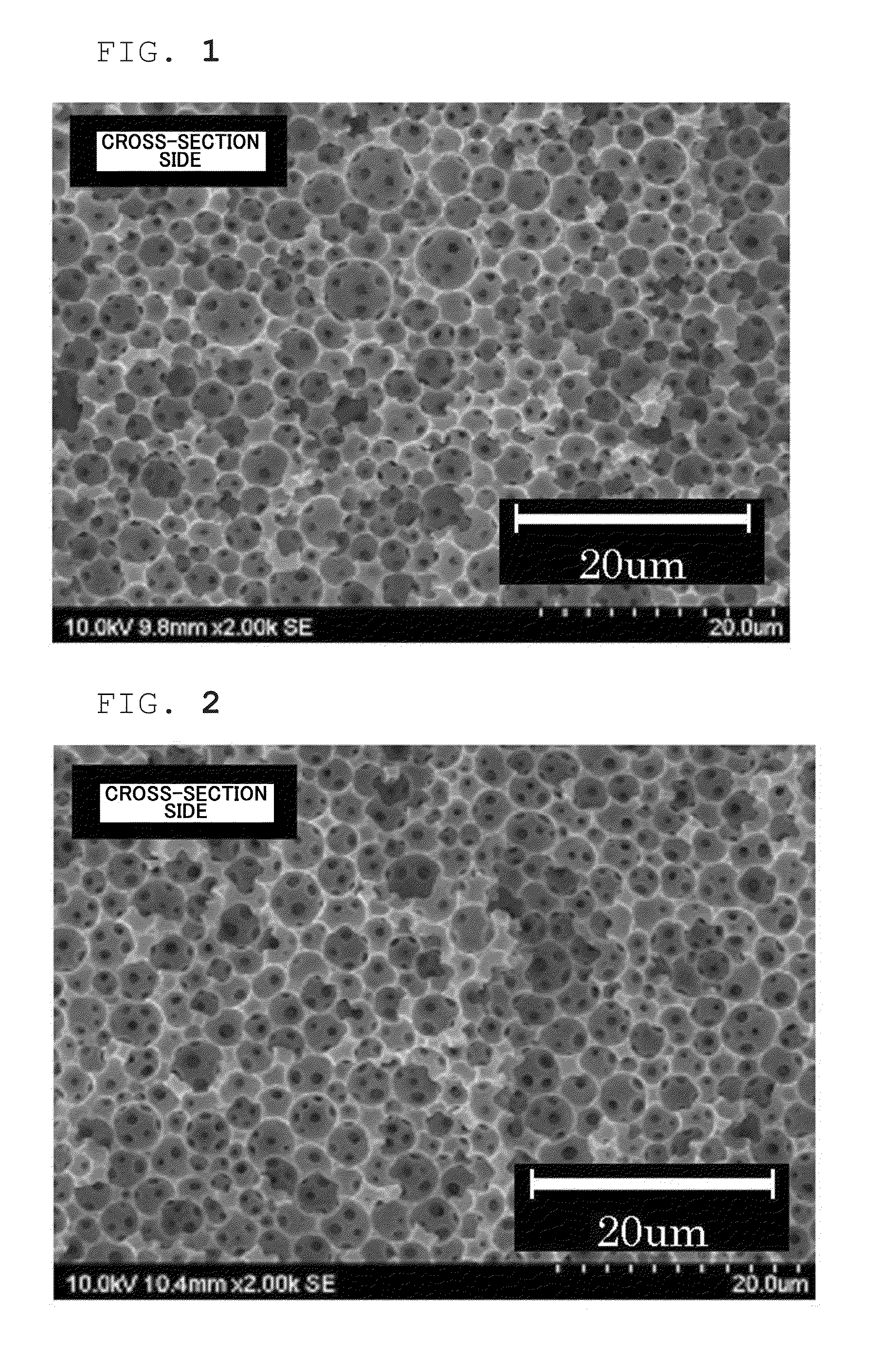

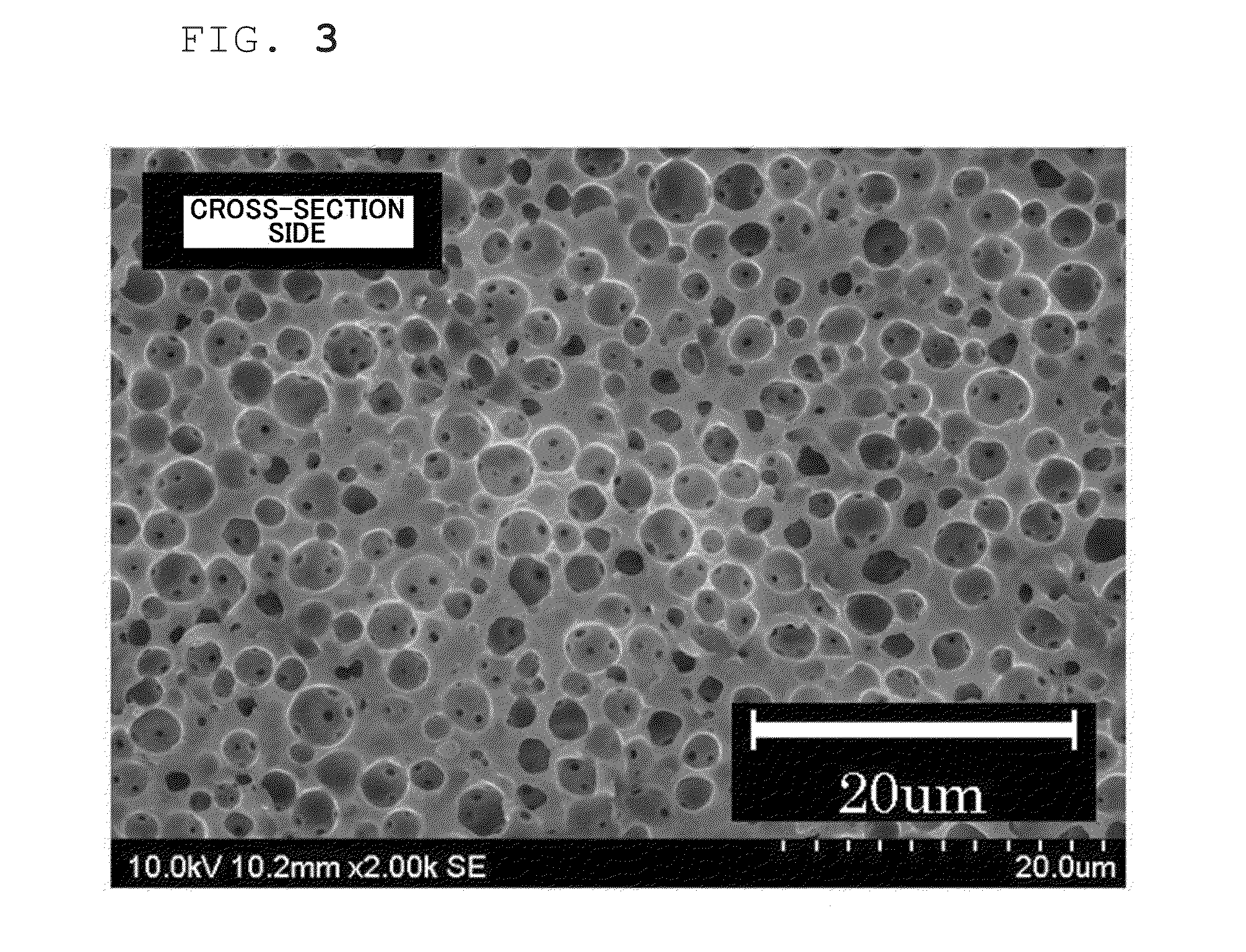

InactiveUS20130224467A1Improve heat resistanceImprove toughnessSynthetic resin layered productsAnimal housingHeat resistanceCrack free

Provided are a novel foam which has a uniform fine-cell structure and is excellent in toughness and heat resistance, and a production method therefor. Also provided is a functional foam which includes the above-mentioned foam and has imparted thereto various functions. The foam includes spherical cells, in which: the spherical cells each have an average pore diameter of less than 20 μm; the foam has a density of 0.15 g / cm3 to 0.9 g / cm3; and the foam is crack-free in a 180° bending test. The functional foam includes the foam.

Owner:NITTO DENKO CORP

Catalyst for coal liquefaction, preparation method and application thereof

InactiveCN101607208AHigh activityGood choiceMolecular sieve catalystsLiquid hydrocarbon mixture productionMolecular sieveMetal

The invention discloses a catalyst for coal liquefaction, a preparation method and an application thereof. The catalyst comprises the following raw materials in percentage by weight: 0.001-50 active catalyst components and 50-99.999 molecular sieve carriers, and the active catalyst components are VIB and / or VIII metal element oxides. The catalyst has the advantages of high catalytic activity, simple preparation method and mild reaction conditions for the direct coal liquefaction.

Owner:HANERGY TECH

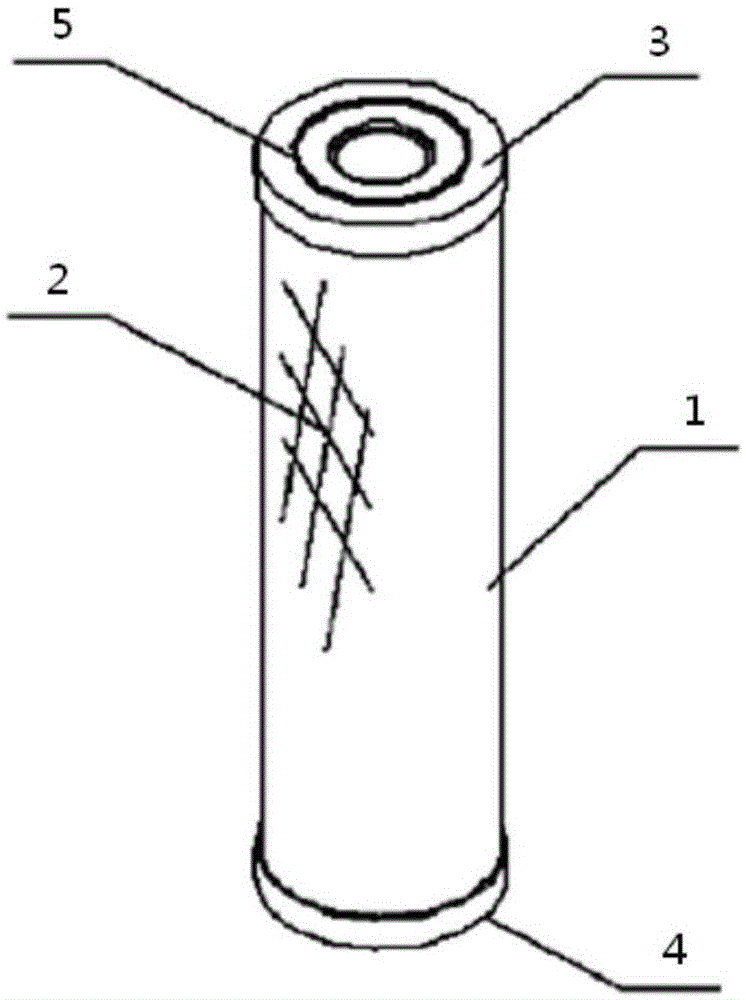

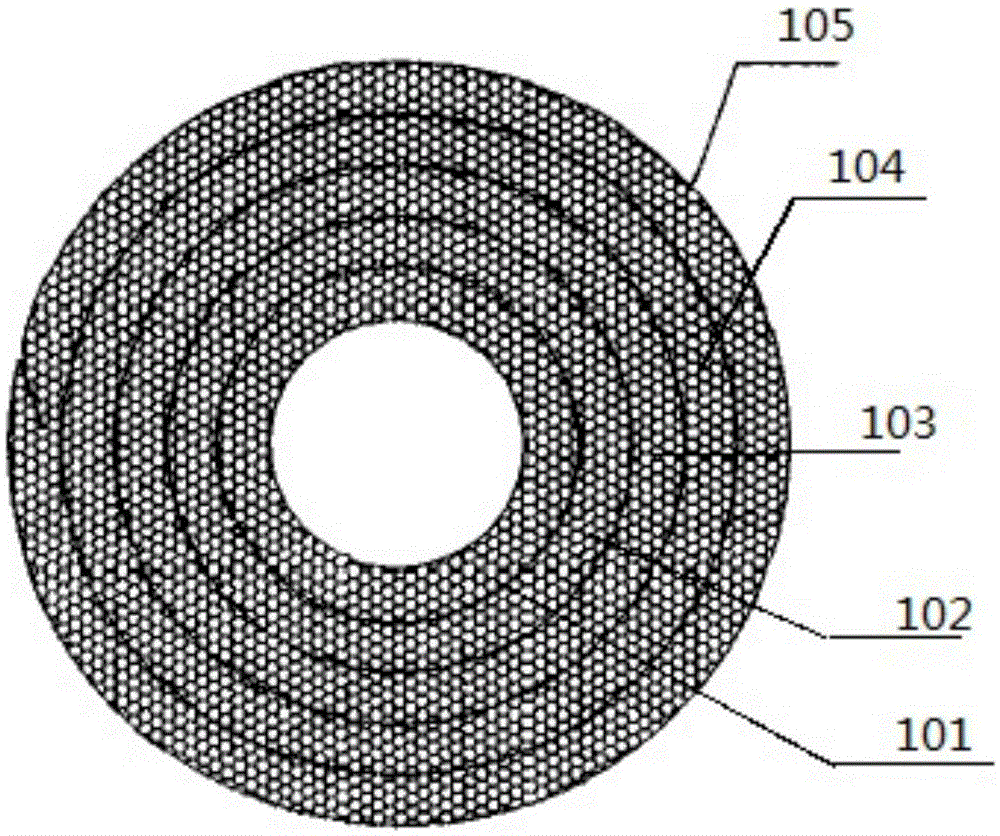

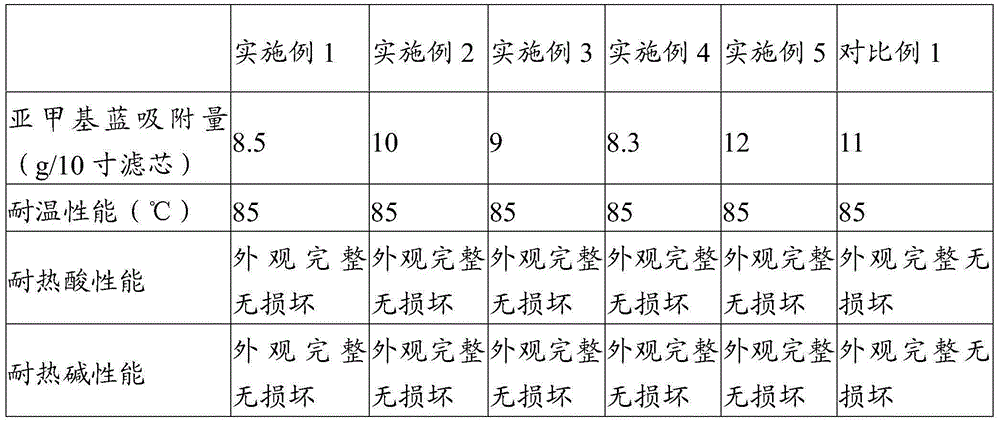

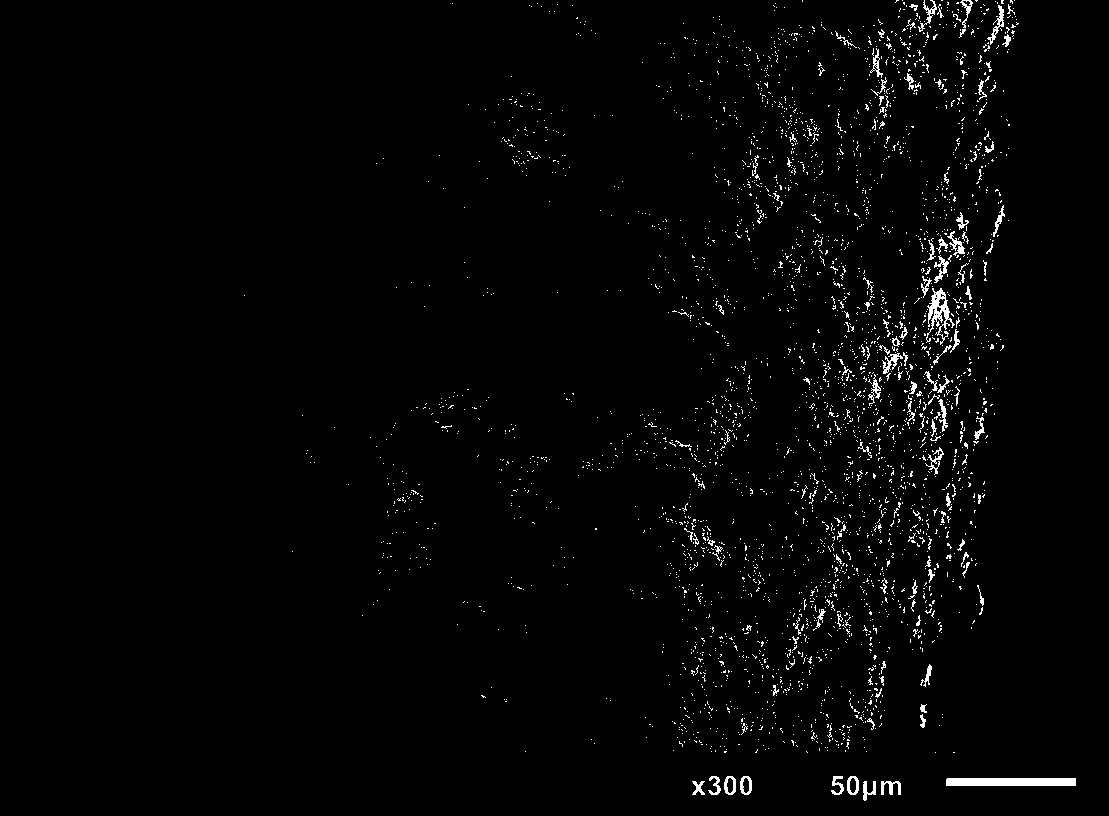

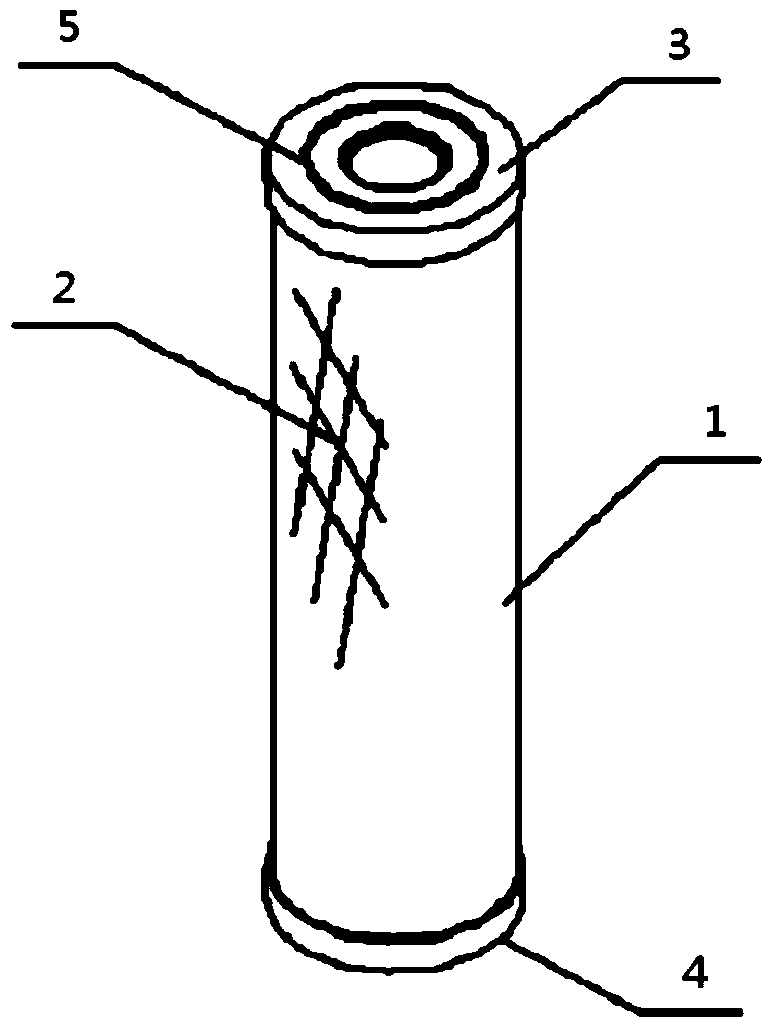

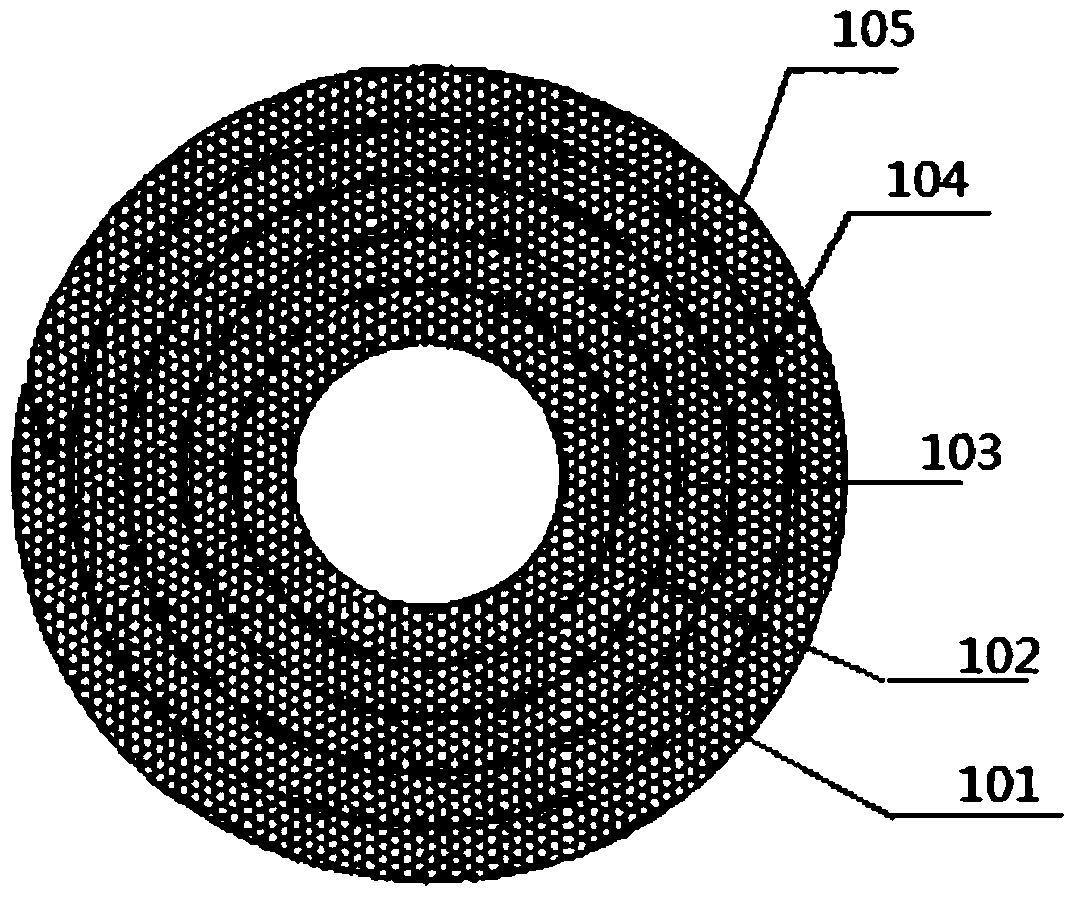

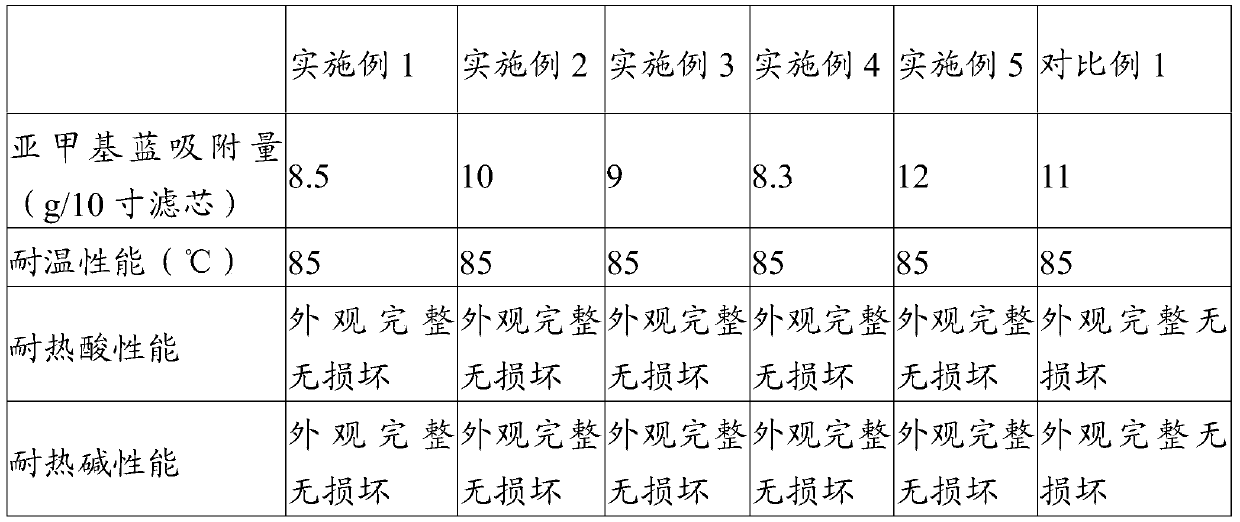

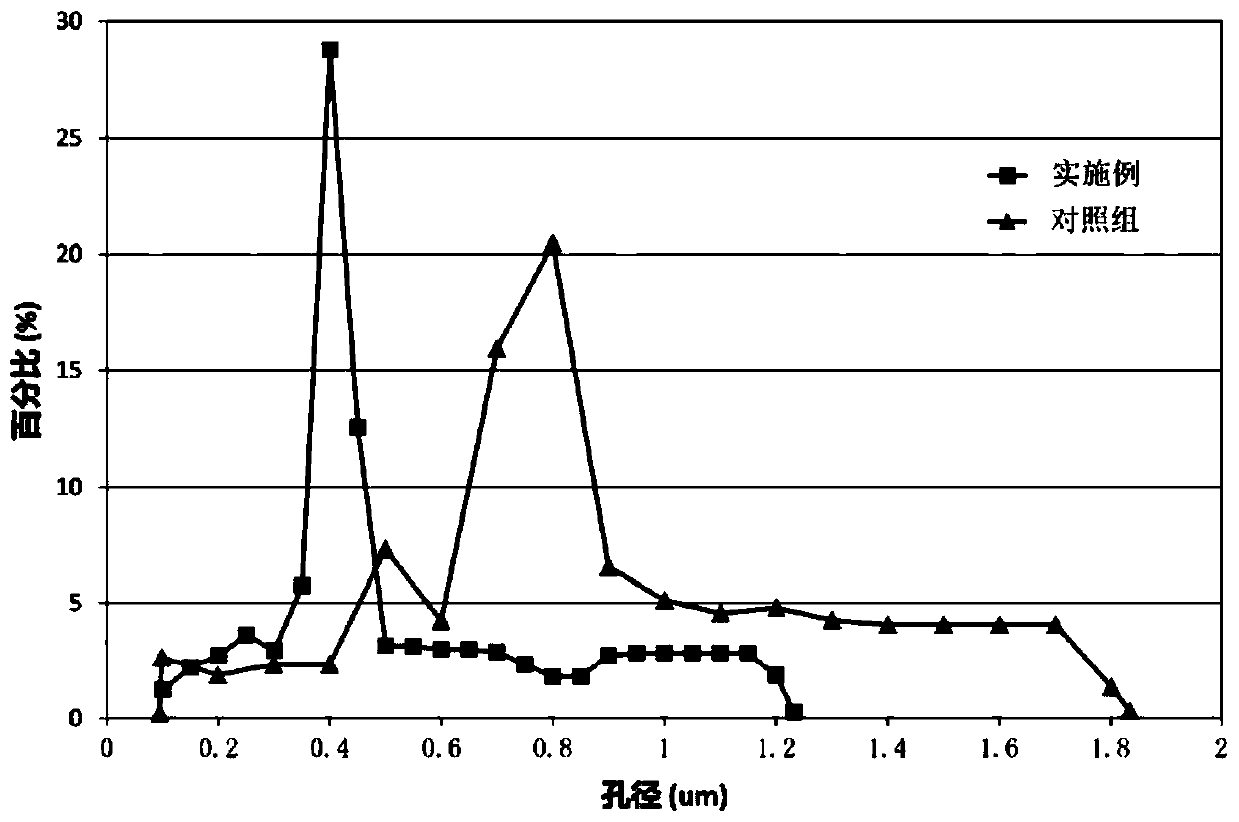

Activated carbon fiber composite material and preparation method thereof as well as activated carbon fiber composite filter element

InactiveCN105084572ARich microporous structureUniform microporous structureMultistage water/sewage treatmentComposite filterFibrous composites

The invention provides an activated carbon fiber composite material which is prepared from activated carbon fiber, staple fiber, powdered activated carbon, modified cellulose, processing aids and the like. As an adsorbing material of an efficient activated carbon filter element, the activated carbon fiber composite material overcomes the problems of poor intensity and easy slipping of lint of an activated carbon fiber felt, reserves the rich and uniform micro-pore structure of the activated carbon fiber and has all meso-pores of high-quality powdered and granular activated carbon, so that the activated carbon fiber composite material has large adsorption capacity and has a wide range of application for adsorbing organic matters. Moreover, the filter element prepared from the material is resistant to high temperature as well as acid and alkali and can be widely applied to electroplating production lines of the PCB (Printed Circuit Board) industry.

Owner:GUANGDONG ZHENGYE TECH

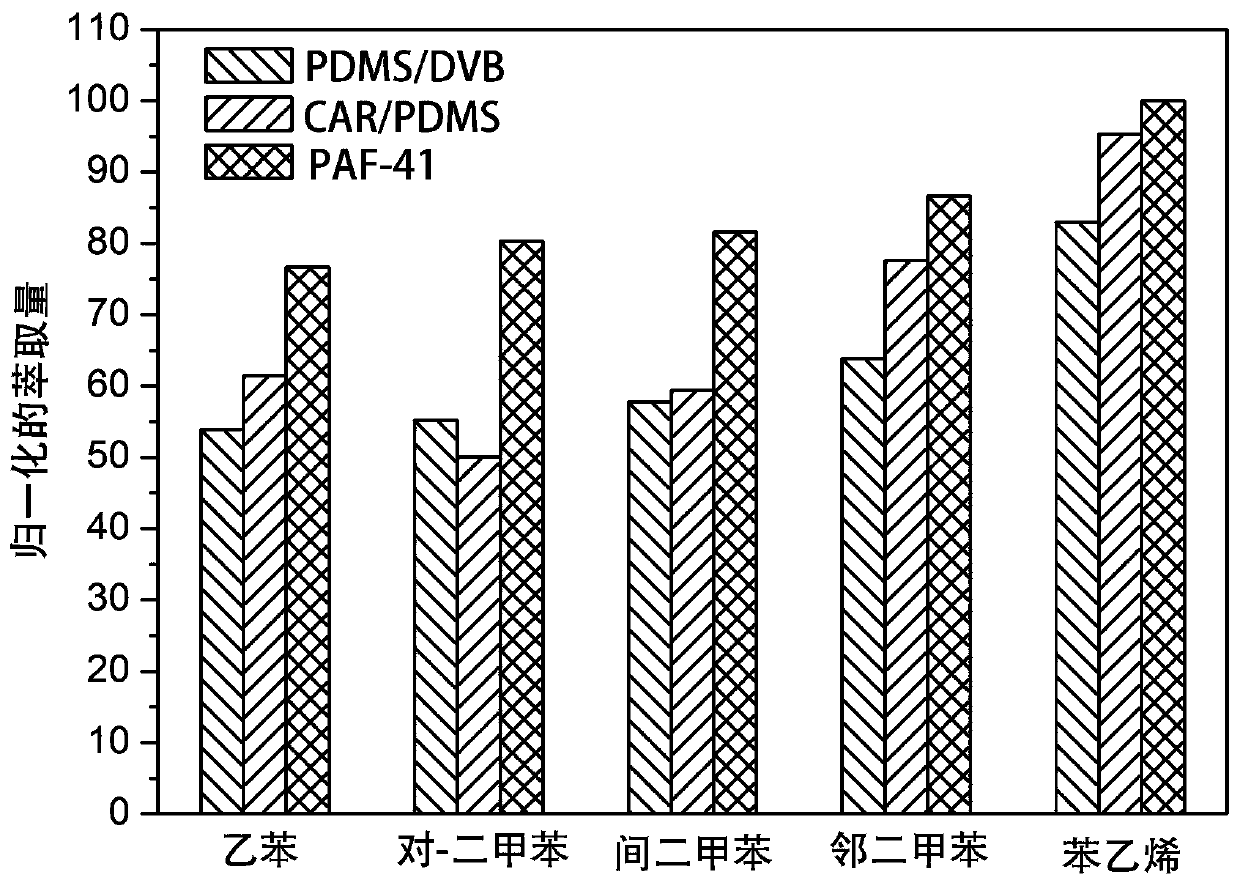

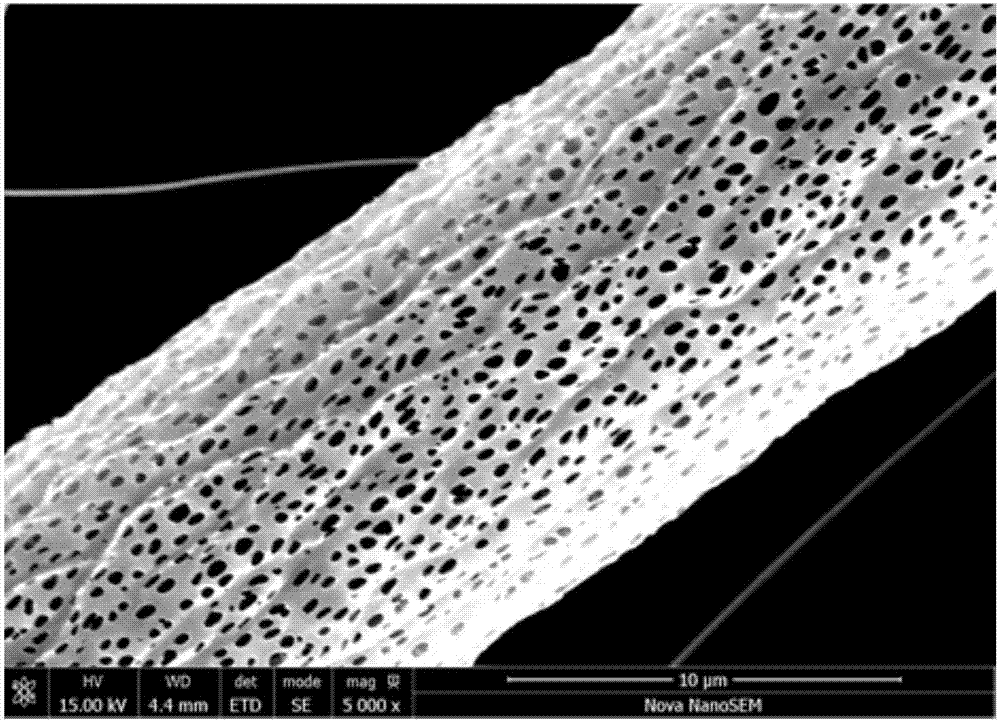

SPME extracting fiber of porous organic framework coating and preparation method of SPME extracting fiber

PendingCN109621911AHigh affinityUniform microporous structureIon-exchange process apparatusOther chemical processesFiberAromaticity

The invention relates to SPME extracting fiber of a porous organic framework coating and a preparation method of the SPME extracting fiber. The SPME extracting fiber comprises a fiber carrier and a coating attached to the surface of the carrier, carrier fiber is base fiber with the surface subjected to hydroxylation, one end of the carrier fiber is coated with a coating material, and the coating material is a mixture of PAF-41 and glue. The PAF-41 is a porous organic framework material with a uniform micropore structure, a high specific surface area and a high aromatic property, the structurecharacteristics of the porous organic framework material have good affinity to fragrant volatile substances, the extracting efficiency of SPME can be improved, and therefore the sensitivity of targetdetection is improved.

Owner:YANTAI UNIV

Method for preparing polyolefin microporous membranes with uniform structures

ActiveCN101724169AUniform microporous structureImprove breathabilityTubular articlesSurface coolingBlow molding

The invention provides a method for preparing polyolefin microporous membranes with uniform structures, comprising the following steps of: (1) mixing polyolefin resin with a thinner, wherein the weight ratio of the polyolefin resin to the thinner is 1-6 : 4-9; (2) extruding and cooling the mixture through a finish mold by adopting an extrusion blow molding mode to form a first membrane; (3) carrying out forming treatment after superimposed traction; (4) preheating, stretching and blowing the first membrane bubble to form a second membrane bubble; (5) carrying out forming treatment after the superimposed traction; (6) extracting the thinner and drying; (7) transversely stretching for forming treatment; and (8) rolling. In the invention, a double-bubble tube blow molding mode is adopted, the first membrane bubble is formed on the basis of extrusion cooling loop cooling of an extruding machine firstly, then the second membrane bubble is formed by carrying out blowing traction on the basis of prewarming, the polyolefin microporous membranes are prepared by adopting extracting agent extraction and heat forming treatment, the phenomenon of uneven structure caused by different cooling of two surfaces and skid in the vertical stretching process is avoided in the extruding casting process, and products with uniform microcellular structure and good ventilation property can be obtained.

Owner:SHENZHEN SENIOR TECH MATERIAL

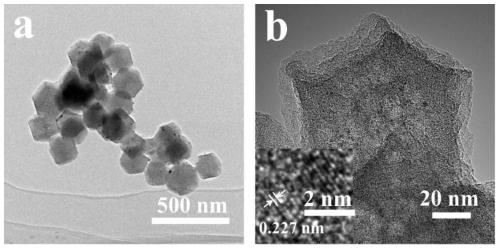

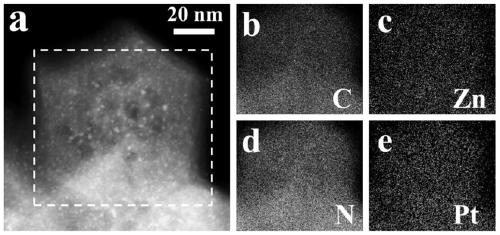

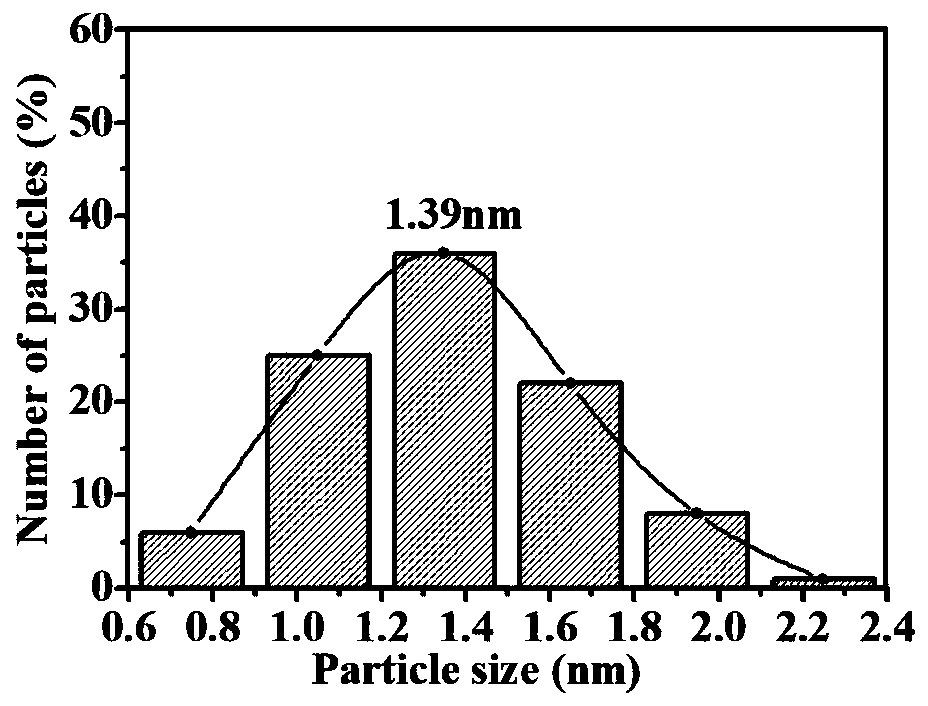

MOFs derived carbon-based material anchored high-dispersion metal Pt nanocluster, and preparation method and application thereof

ActiveCN111569928ATightly boundGood chemical stabilityPhysical/chemical process catalystsElectrodesPlatinumPhysical chemistry

The invention discloses an MOFs derived carbon-based material anchored high-dispersion metal Pt nanocluster as well as a preparation method and application thereof. The average particle size of Pt nanoclusters is 1-2nm; an MOFs derived carbon-based material is a nitrogen-doped MOFs derived carbon-based material; and the Pt nanoclusters are uniformly distributed in the MOFs derived carbon-based material. The preparation method comprises the following steps of: dissolving the nitrogen-doped MOFs derived carbon-based material loaded with high-dispersion metal Zn into a precursor solution of platinum; performing stirring to carry out an in-situ replacement reaction so as to reduce metal Pt from the precursor solution by the metal Zn; and carrying out post-treatment after the reaction is finished, so as to obtain the MOFs derived carbon-based material anchored high-dispersion metal Pt nanocluster. The preparation method is simple; and the obtained Pt nanocluster is small in nano size, highin dispersion, highly exposed in active center, excellent in HER catalysis performance and good in electrochemical stability.

Owner:WUHAN UNIV OF TECH

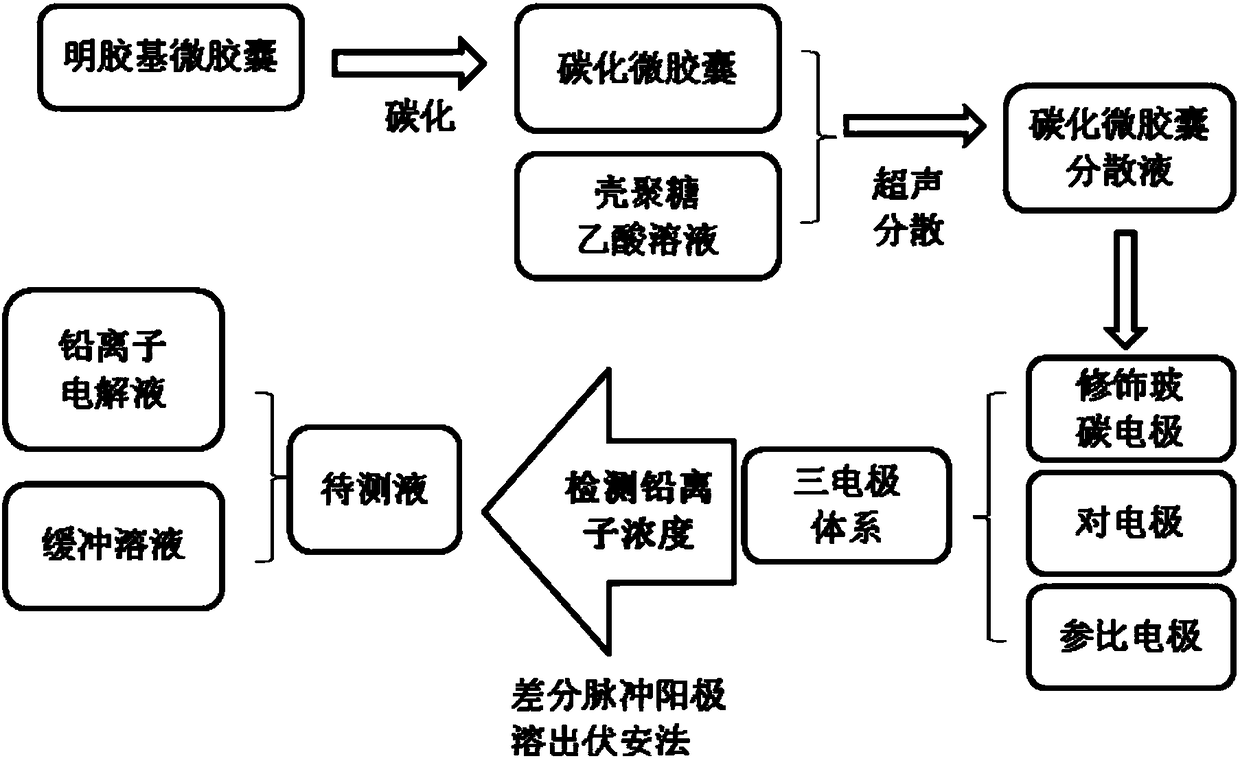

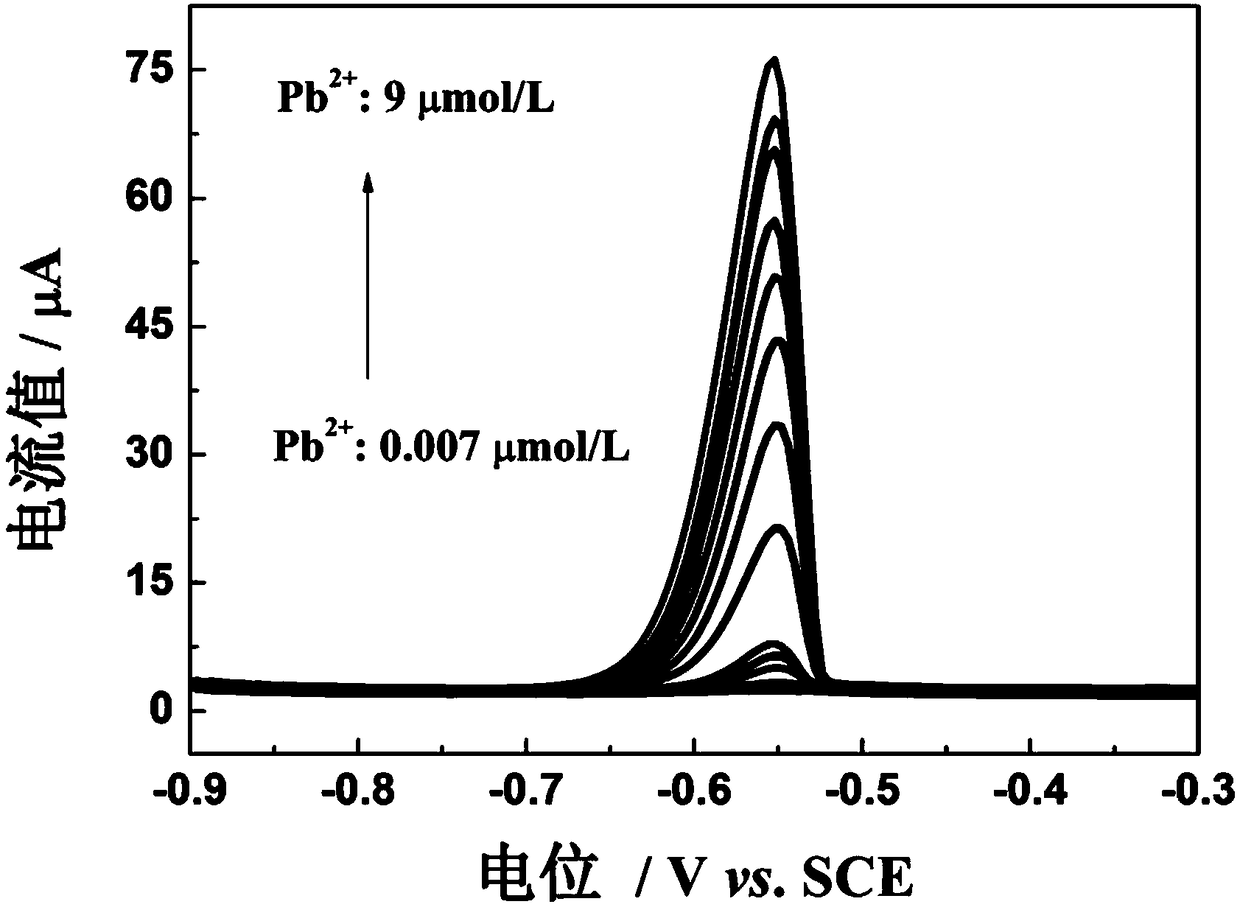

Preparation method of electrochemical sensor for trace lead ion detection

ActiveCN108982641AImprove adsorption capacityUniform microporous structureMaterial electrochemical variablesElectrochemical gas sensorPeak current

The invention discloses a preparation method of an electrochemical sensor for trace lead ion detection, belonging to the technical field of environmental detection and analysis. The method comprises the following steps: step 1: enabling gelatin-based microcapsules, which are prepared through a complex coacervation method, to be frozen and dried, and enabling carbonized microcapsule powder to be ultrasonically dispersed in a chitosan acetic acid solution; step 2: taking 5 mu L of carbonized microcapsule dispersion liquid, which is prepared in step 1, to serve as an electrode material so as to modify the surface of a glassy carbon electrode to act as a working electrode; step 3: adding different concentrations of lead ion electrolyte into a buffer solution to form 5 mL of a to-be-tested solution, inserting an electrode system in step 2 into the lead ion electrolyte, and enriching lead ions in the electrolyte at constant voltage; step 4: obtaining the standard curves of peak current values and lead ion concentrations by adopting a differential pulse anodic stripping voltammetry; and step 5: detecting lead ion concentrations in to-be-tested samples. The working electrode modification material prepared by the invention has the advantages of simple preparation, low cost, controllable structure, good repeatability and the like.

Owner:普瑞丰环保科技(武汉)有限公司

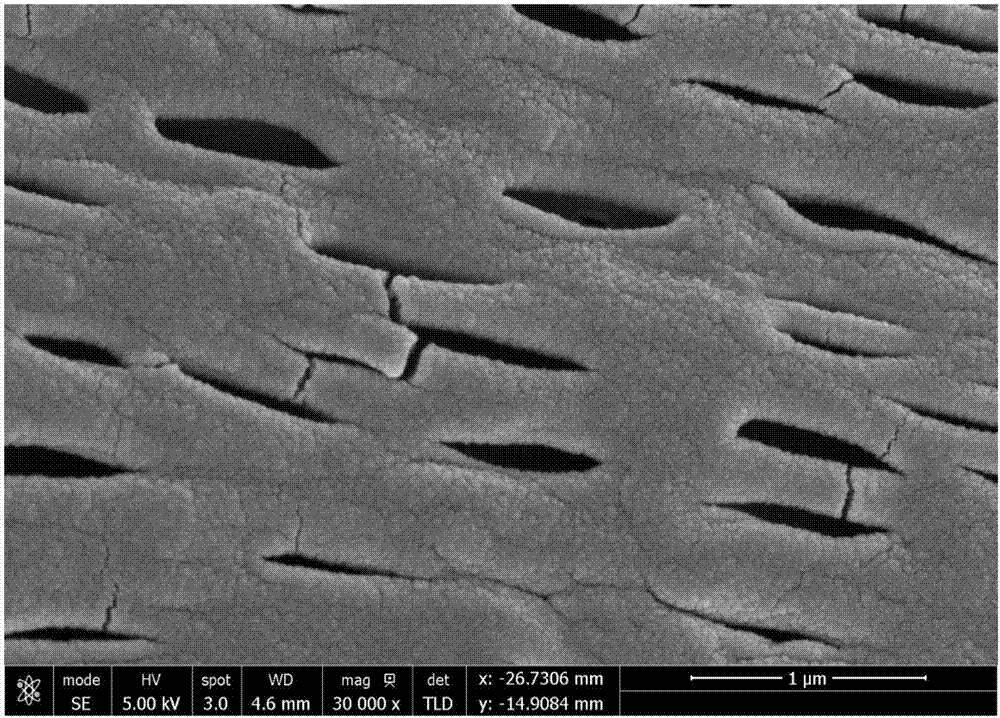

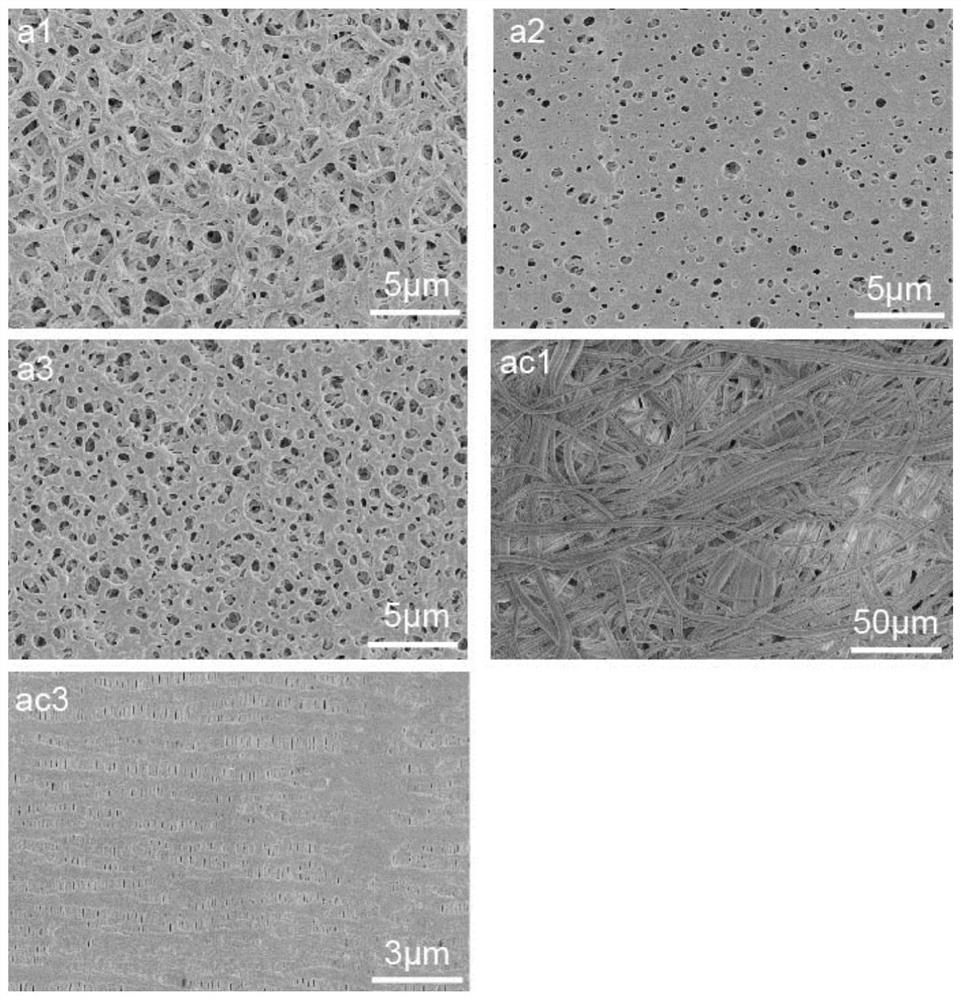

Preparation method of shape memory fiber membrane with adjustable fiber surface micropore structure and application of drug release of membrane

ActiveCN107974768ASimple preparation processAchieve drug loading and drug releaseHollow filament manufactureSurgeryElectrospinningChemistry

The invention discloses a preparation method of a shape memory fiber membrane with an adjustable fiber surface micropore structure and an application of drug release of the membrane, relates to a preparation method of a shape memory fiber membrane and an application of the membrane, and aims to solve the problems that the drug release process of an existing drug loading material cannot be controlled, and drug loading capacity is low. The preparation method of the shape memory fiber membrane includes the steps: dissolving polymer in an organic solvent to obtain polymer solution; transferring the polymer solution into electrostatic spinning forming. A drug release method includes the steps: preparing the drug-loading shape memory fiber membrane with the adjustable fiber surface micropore structure; performing stretching treatment and drug blocking; taking shape memory recovery measures to the drug-blocked shape memory fiber membrane to perform shape memory recovery. The fiber surface ofthe fiber membrane prepared by an electrostatic spinning process is provided with the uniform micropore structure, the drug loading capacity is high, the size and the shape of the fiber surface micropore structure can be adjusted by heating treatment or ultrasonic treatment, and drug loading and drug release are realized.

Owner:HARBIN INST OF TECH

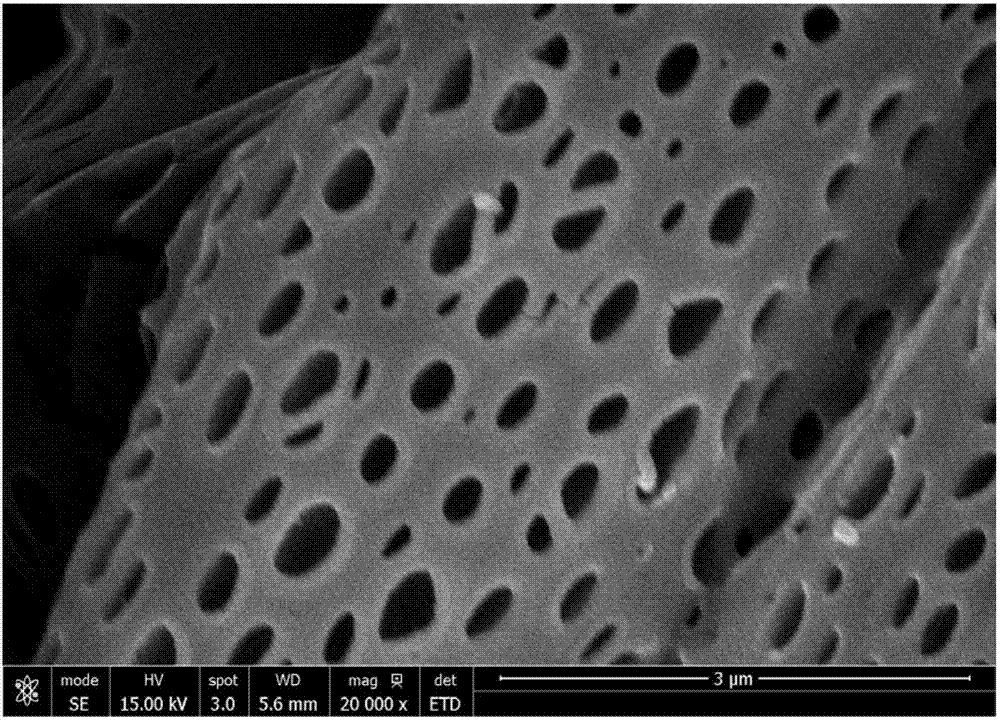

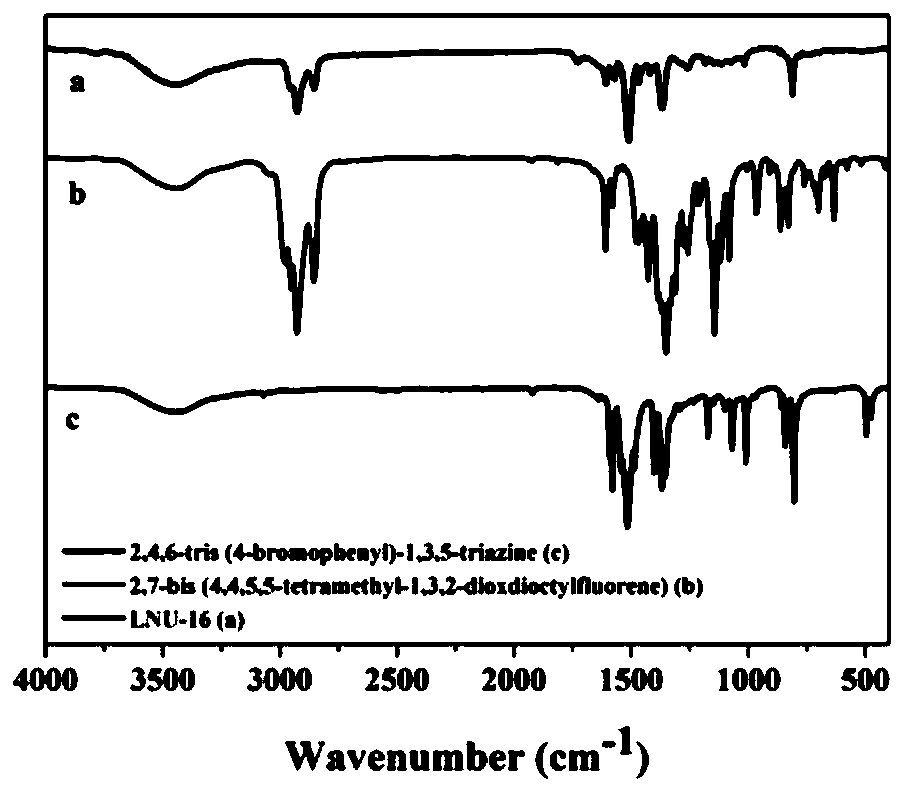

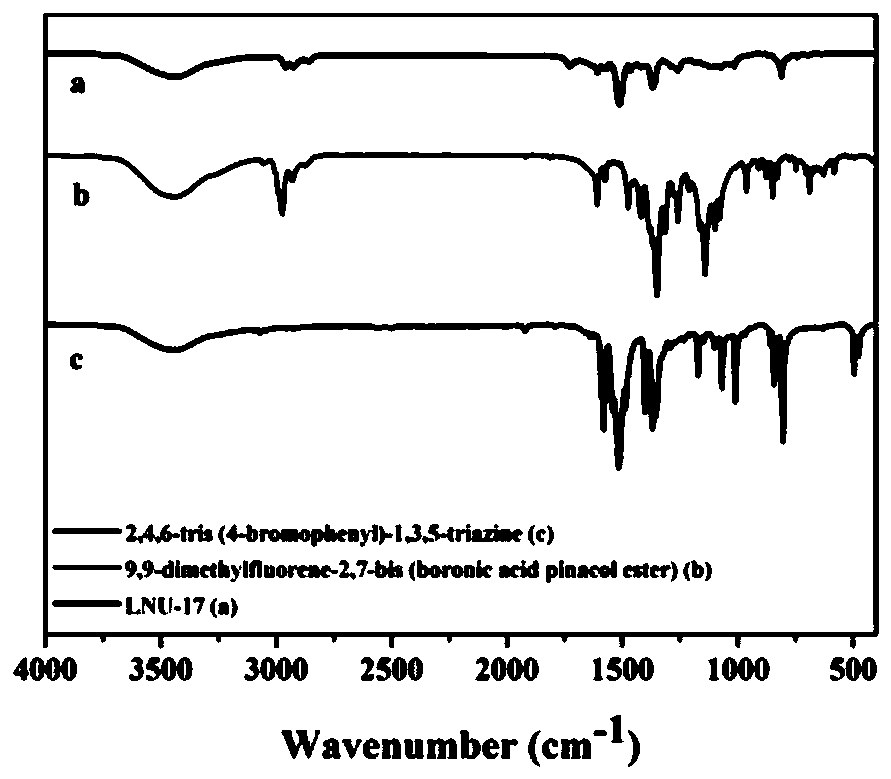

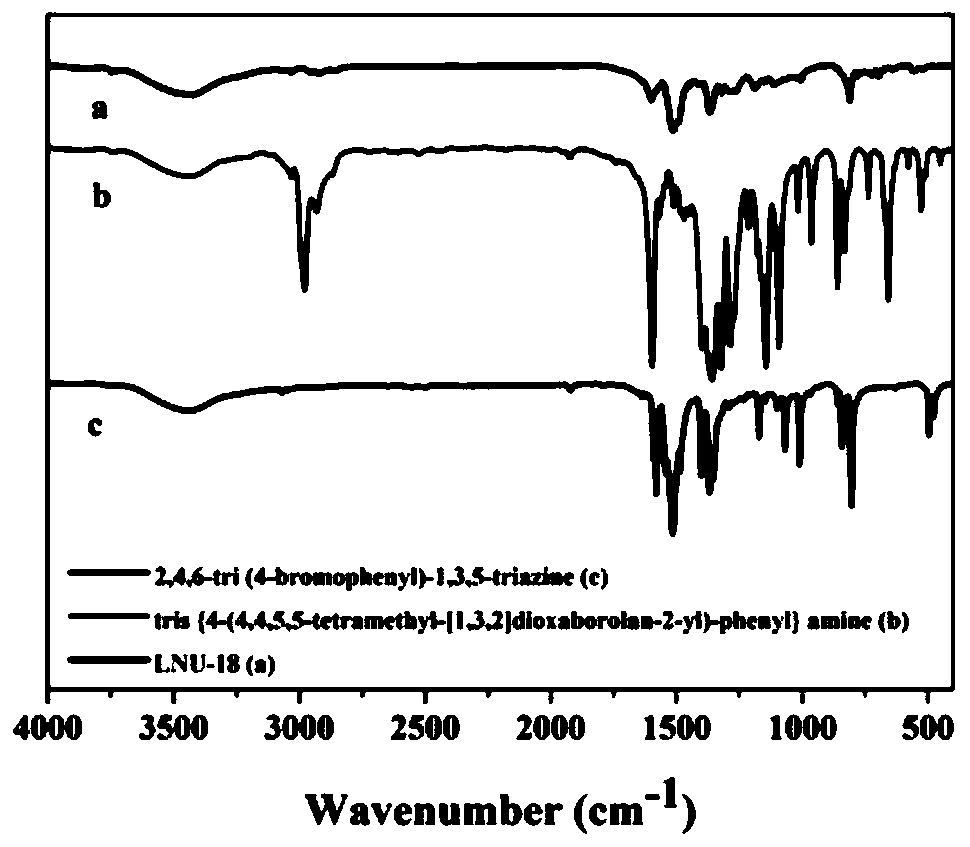

Porous carbon material based on porous organic polymer structure and preparation method and application thereof

ActiveCN109950058AMeet actual production needsUniform microporous structureHybrid capacitor electrodesPorous carbonNew energy

The invention belongs to the technical field of new energy materials, and particularly relates to a porous carbon material based on a porous organic polymer structure, which can be used for a supercapacitor electrode. The preparation method comprises the following steps: dissolving a boric acid organic monomer and 2,4,6-tris(4-bromophenyl)-1,3,5-triazine in DMF; freezing the mixture with liquid nitrogen, pumping air through an oil pump, unfreezing the mixture, and repeating the process for three times; rapidly adding a catalyst into a reaction system, freezing the catalyst by using liquid nitrogen, pumping air by an oil pump, performing unfreezing, repeatedly performing the step for three times, performing heating, carrying out a reflux reaction under a nitrogen condition for 2 days, performing cooling to room temperature after the reaction is finished, and repeatedly washing solids generated by the reaction by using an organic solvent for multiple times; carrying out vacuum drying toobtain the porous organic polymer LNUs; placing the polymer in a quartz boat, then horizontally placing the quartz boat in a tubular furnace, and performing heating under the protection of nitrogen toobtain a target product. The material has a good application prospect in an electrode material of a super capacitor.

Owner:LIAONING UNIVERSITY

Adsorbing material for capturing radioactive element iodine

ActiveCN112742346AGood adsorption performanceUniform sizeOther chemical processesNuclear energy generationSodium acid carbonateFilter cake

The invention belongs to the technical field of adsorbent preparation, and particularly relates to an adsorbing material for capturing radioactive element iodine. The material is prepared by the following steps: (1) dissolving mordenite in water to form turbid liquid; (2) preparing a 0.1-0.2 mol / L silver nitrate solution under a dark condition; (3) pouring the silver nitrate solution into the turbid liquid, and heating to boil in a stirring reflux state; (4) quickly adding a first complexing agent into the boiling liquid in the step (3); (5) preparing a sodium carbonate solution, and adding the sodium carbonate solution into the step (4); (6) adding a reducing agent into the solution obtained in the step (5), uniformly stirring, and heating in a water bath at 80 DEG C for 30 minutes; (7) performing suction filtration on the product obtained in the step (6); (8) preparing 0.01-0.3 mol / L of a copper sulfate solution; (9) dissolving a second complexing agent in deionized water; (10) adding the copper sulfate solution into the solution obtained in the step (9) in a stirring state, and adding a stabilizer and a reducing agent; (11) adding Ag-mordenite into the mixture obtained in the step (10); and (12) carrying out suction filtration on the mixture obtained in the step (11), and drying the filter cake at 110 DEG C for 24 hours.

Owner:UNIV OF JINAN +1

Preparation method of aluminum oxide porous material

ActiveCN109516831AImprove hydrophilicityImprove chemical reactivityCeramicwareMagnesium phosphateMagnesium orthophosphate

The invention discloses a preparation method of an aluminum oxide porous material. The preparation method comprises the following steps of modifying an aluminum oxide powder by a magnesium phosphate sol, adding a manganese oxide micropowder as a sintering additive, and reducing the firing temperature of the aluminum oxide porous material to the temperature of 1200 to 1400 DEG C. The preparation method has the advantage that the good pore structure can be obtained for the porous material within the wide firing temperature range. The aluminum oxide porous material prepared by the preparation method has excellent mechanical property.

Owner:浙江昕明环境科技有限公司

Environment-friendly soft porcelain preparation method

ActiveCN109437855ARealize comprehensive utilizationWith moisture control effectCeramic materials productionClaywaresFiberEmulsion

The invention relates to an environment-friendly soft porcelain preparation method which comprises the steps of preparing nano silver fiber, modifying boron nitride nanotubes, preparing phase change microcapsules, preparing soft porcelain and performing surface treatment. The environment-friendly soft porcelain is prepared from 30 to 50 parts of inorganic powder, 15 to 35 parts of cement, 10 to 15parts of phase change microcapsules, 10 to 30 parts of acrylic polymer emulsion, 0 to 2 parts of pigment, 0.5 to 2 parts of a coupling agent, 0.5 to 1.2 parts of montmorillonite, 0.5 to 1.2 parts ofkieselguhr and 0.8 to 1.5 parts of wood fiber. The environment-friendly soft porcelain prepared by the preparation method disclosed by the invention has the advantages of good breathability and antifouling, self-cleaning, temperature-regulating and moisture-control performance.

Owner:张凯

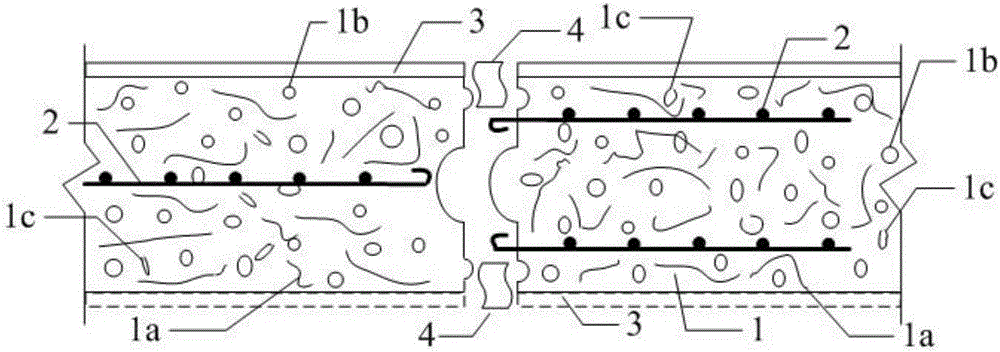

Hydrophilic diaphragm and battery containing hydrophilic diaphragm

InactiveCN112803117AImprove wettabilityExcellent ability to absorb aqueous electrolyteFinal product manufactureSecondary cellsElectrolytic agentPolyolefin

The invention discloses a hydrophilic diaphragm and a battery containing the hydrophilic diaphragm. The hydrophilic diaphragm is a microporous membrane containing a hydrophilic high polymer material; and the aperture of the hydrophilic diaphragm is 0.1-5 microns, the thickness of the hydrophilic diaphragm is 20-500 microns, and the porosity of the hydrophilic diaphragm is 30-90%. The hydrophilic diaphragm has the beneficial effects that the wettability of the hydrophilic diaphragm in a water-based electrolyte is obviously superior to that of commercial PP and PE microporous membranes and hydrophilic treated polyolefin diaphragms, the capacity of absorbing the water-based electrolyte is higher, and the conductivity of the diaphragm is higher; the hydrophilic diaphragm disclosed by the invention has a uniform microporous structure, the barrier capacity of the hydrophilic diaphragm is higher than that of non-woven fabric, fiber paper and a glass fiber membrane, and the risk of internal short circuit of the battery can be reduced; the hydrophilic diaphragm and electrolyte act together to induce regular growth of zinc dendrites, so that the cycle life of a metal zinc electrode is prolonged; and polarization overpotential of Zn dissolution / deposition is optimized, and the electrochemical performance of the zinc electrode is improved.

Owner:北京金羽新能科技有限公司

Method for preparing composite polypropylene microporous film by phase conversion method and product and application of composite polypropylene microporous film

ActiveCN110350131AAchieve preparationSimple production processSecondary cellsCell component detailsPhase conversionPorosity

The invention discloses a method for preparing a composite polypropylene microporous film by a phase conversion method and product and application of the composite polypropylene microporous film. According to the preparation method, a coating layer is introduced to surface(s) of one side or two sides of the film by a first mode (immersion precipitant phase conversion method) or a second mode (dryphase conversion method) during the fabrication process of bidirectionally stretching a polypropylene microporous substrate layer, the coating layer is only stretched in a longitudinal direction and atransverse direction or is only stretched in the transverse direction, and the preparation of the composite polypropylene microporous film is achieved. With the adoption of the method, the productionprocess of the composite polypropylene microporous film is simplified, the fabricated coating layer is high in porosity, the microporous structure is uniform, and the performance of the polypropylenemicroporous substrate layer can be improved very well. The composite polypropylene microporous film is applied into a lithium battery, the coating layer is a polymer or a composition capable for forming gel with an electrolyte, and thus, the cycle property and the safety of the lithium battery can be improved. The invention also provides a lithium battery diaphragm, and the lithium battery diaphragm comprises the composite polypropylene microporous film.

Owner:BEIJING NORMAL UNIVERSITY

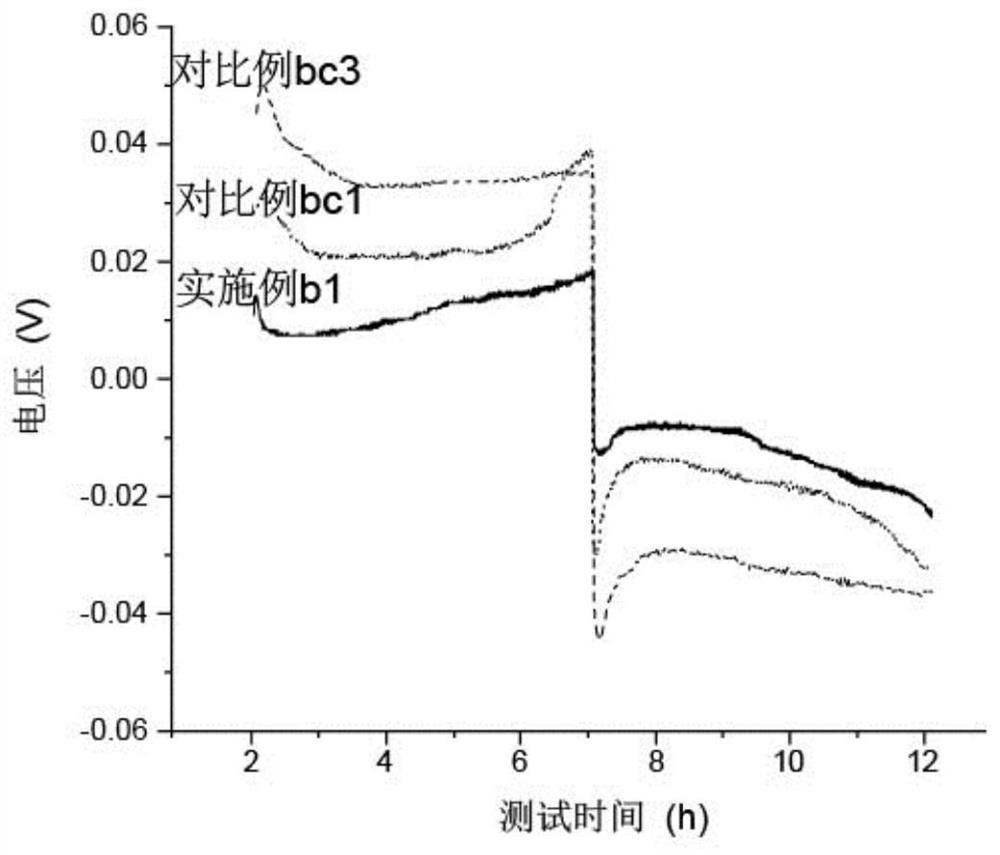

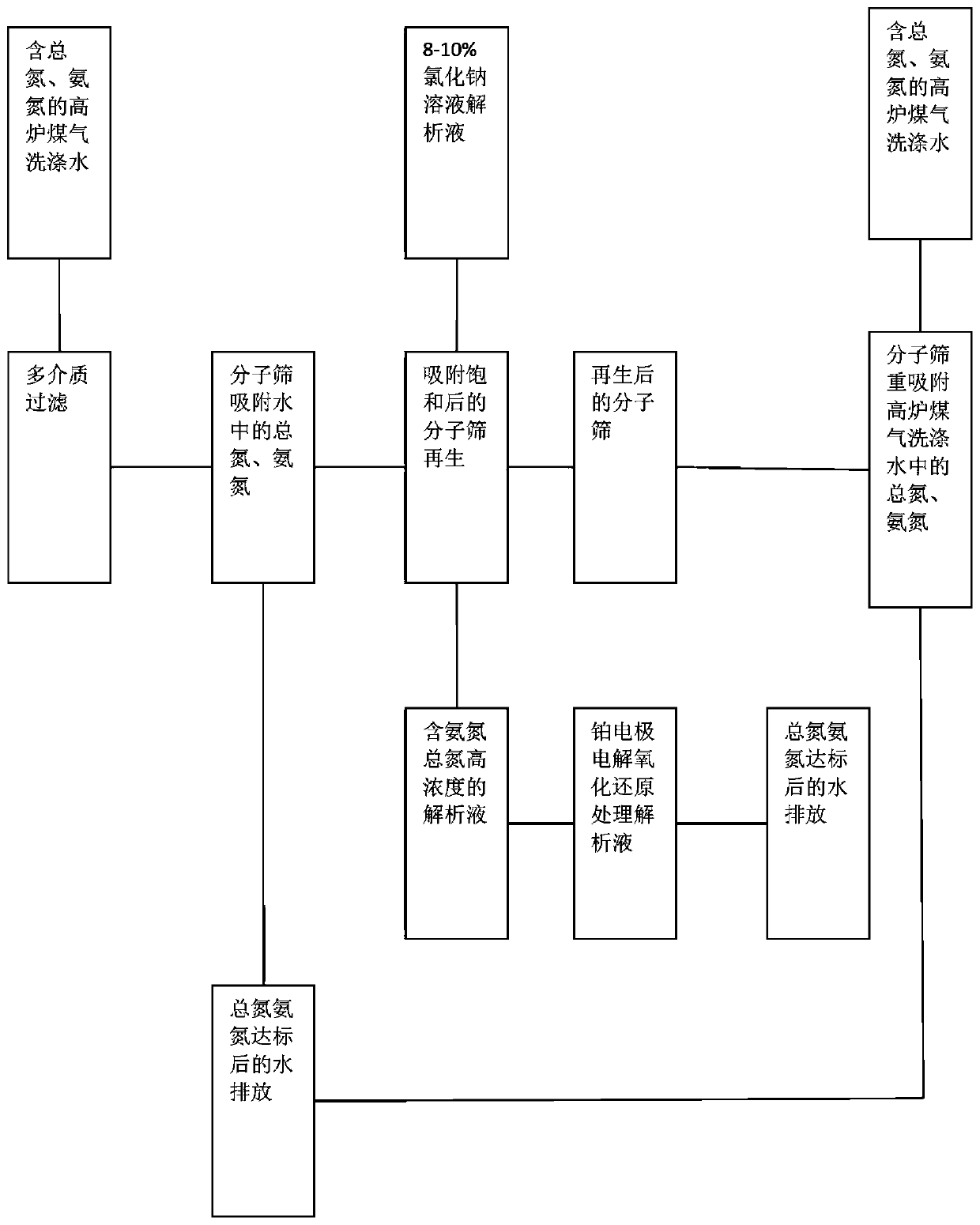

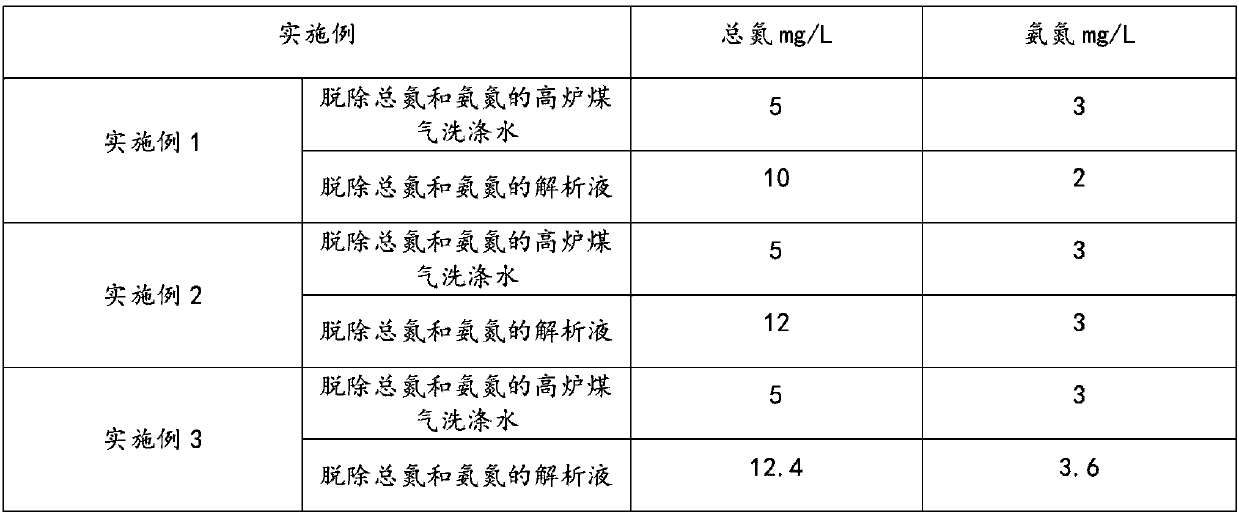

Method for removing total nitrogen and ammonia nitrogen from blast furnace coal gas washing water

InactiveCN110642437ANot tightly boundPromote exchangeTreatment involving filtrationMultistage water/sewage treatmentMolecular sieveFiltration

The invention relates to a method for removing total nitrogen and ammonia nitrogen from blast furnace coal gas washing water, and belongs to the technical field of wastewater treatment. The method includes the following steps: performing filtration treatment on the blast furnace coal gas washing water containing the total nitrogen and the ammonia nitrogen to obtain filtered blast furnace coal gaswashing water; and performing adsorption treatment on the filtered blast furnace coal gas washing water by using a molecular sieve to obtain blast furnace coal gas washing water without total nitrogenor ammonia nitrogen to meet the discharge requirements, wherein the molecular sieve is a 13X type molecular sieve with a main cation of sodium, after the molecular sieve adsorption is saturated, regeneration is performed by using a 10% sodium chloride solution, the regenerated desorption solution containing high-concentration total nitrogen and ammonia nitrogen is subjected to electroredox by using a platinum electrode (with a ruthenium coating) to remove the total nitrogen and the ammonia nitrogen, and the desorption liquid (the content of total nitrogen is less than 15 mg / l, and the contentof ammonia nitrogen is less than 5 mg / l) treated by electroredox treatment can reach a standard to be discharged.

Owner:BEIJING SHOUGANG CO LTD

Homodisperse method for lignocellulose

The invention provides a homodisperse method for lignocellulose, and belongs to the field of chemical engineering. The method comprises the steps of raw material smashing, alkali treatment, microwave acid treatment, polymerization treatment and regrinding. According to the lignocellulose treated through the method, powder is embrittled through acid and alkali treatment, the microcellular structure is enlarged and subjected to a grafting reaction with a polymer, on the basis of the physical refining technology, the obtained lignocellulose is good in cellulose dispersibility, the fineness can reach 300-800 meshes, and the microhole structure can still be kept; the lignocellulose can be uniformly dispersed after being added into the coating, the coating has the good heat preservation, heat insulation, sound insulation, insulation and gas permeability, thermal expansion is uniform, no flaking is caused, and the deep layer cracking resistance and scratch resistance are improved.

Owner:广西伯麟合纵科技有限公司

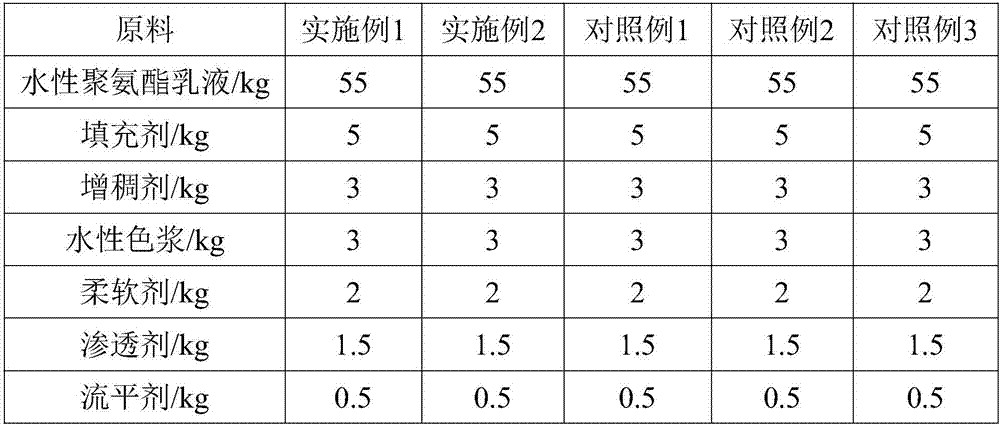

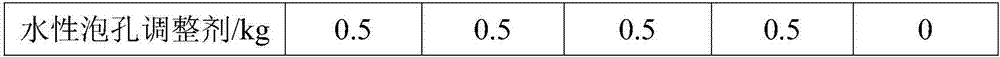

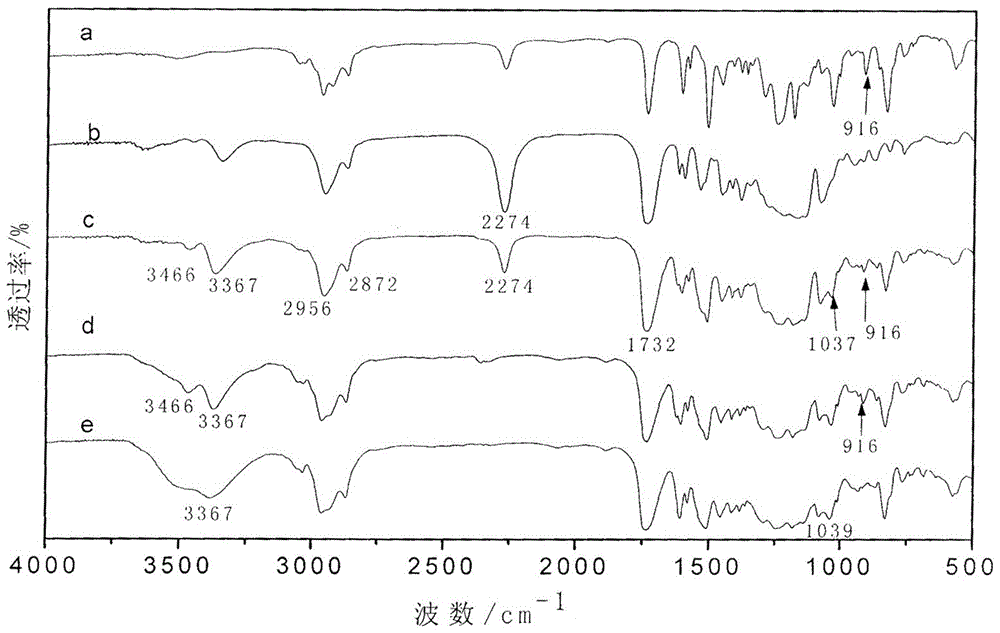

Water-based foaming pore regulator suitable for synthetic leather

InactiveCN106893242AEnhanced Immersion Penetration CapabilitiesIncrease the speed of solidificationPolyurea/polyurethane coatingsWater basedGluconic acid

The invention discloses a water-based foaming pore regulator suitable for synthetic leather and relates to the technical field of synthetic leather functional aids. The water-based foaming pore regulator suitable for the synthetic leather is prepared from the following raw materials in parts by weight: 15 to 20 parts of nano-titanium dioxide modified poloxamer, 5 to 10 parts of hydroxypropyl methyl cellulose, 3 to 5 parts of sodium polyacrylate, 2 to 3 parts of hydrolytic polymaleic anhydride, 1 to 2 parts of polyvinylpyrrolidone, 1 to 2 parts of sodium alginate, 0.5 to 1 part of N-hydroxymethyl acrylamide, 0.5 to 1 part of nano-ceramic adhesive powder, 0.1 to 0.3 part of sodium gluconate, 0.1 to 0.3 part of L-calcium aspartate, 0.05 to 0.1 part of amino trimethylene phosphonic acid, and 100 to 200 parts of water. The water-based foaming pore regulator provided by the invention can generate loose, uniform and fine micropore structures, and increase the thickness retention rate of products, so that the water-based foaming pore regulator is favorable for improving the embossed effect, enables the decorative patterns to be remarked and convex, and not to be deformed, and enhances the rebound resilience, the air permeability and the moisture permeability of a polyurethane film.

Owner:南平慧薇网知识产权营运有限公司

3D curved glass efficient polishing disk and preparation method thereof

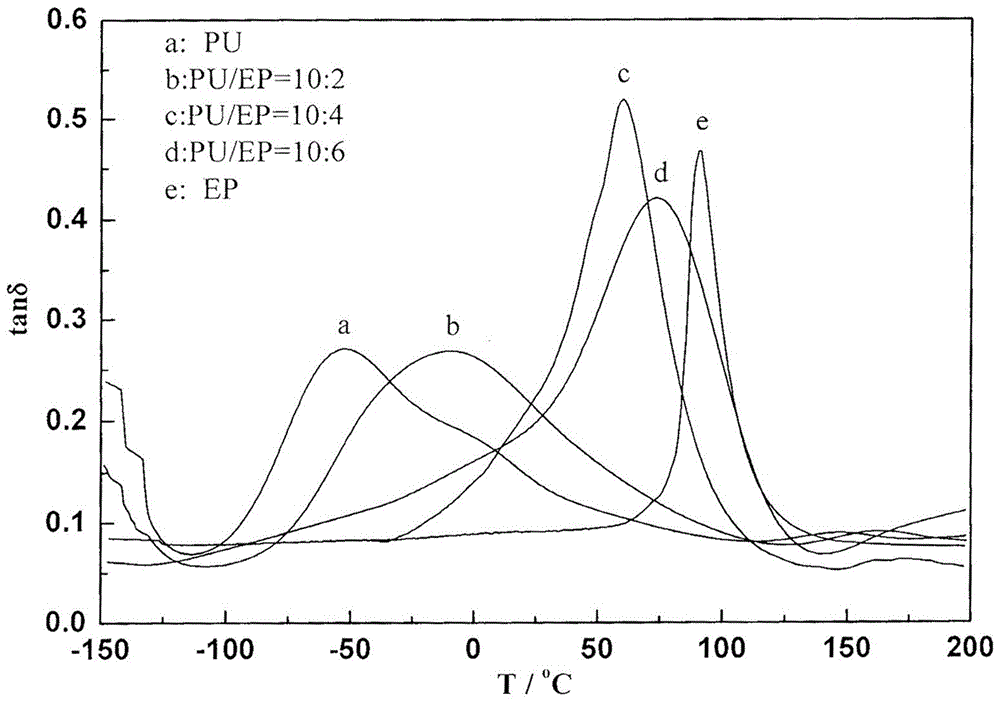

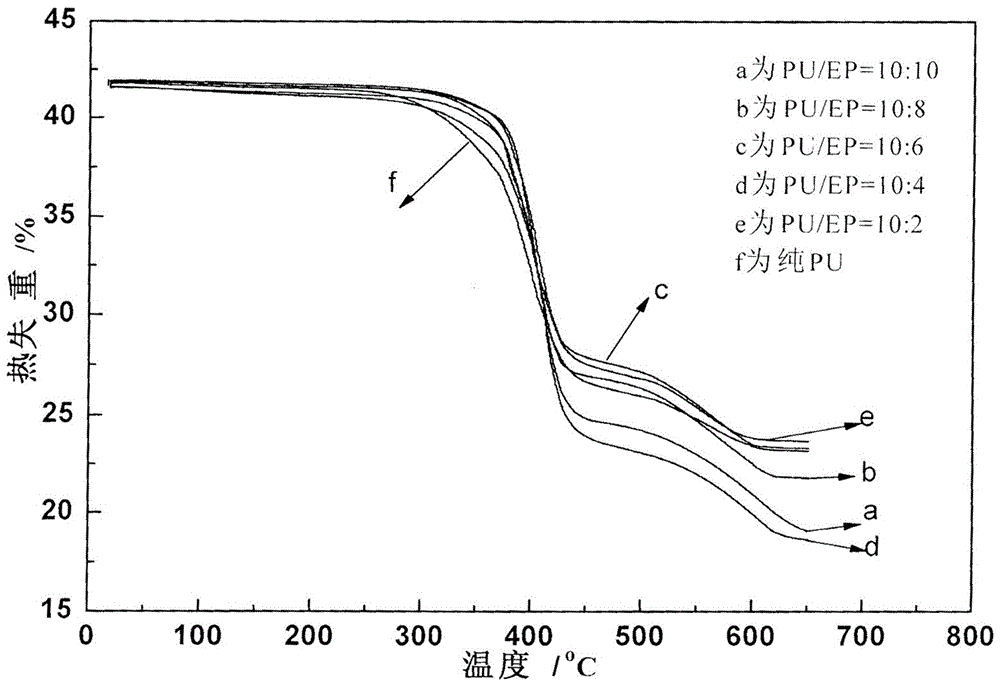

InactiveCN106695578AUniform microporous structureImprove cooling effectAbrasion apparatusGrinding devicesEpoxyHigh surface

The invention discloses a 3D curved glass efficient polishing disk and a preparation method thereof. The 3D curved glass efficient polishing disk is prepared from the following raw materials of, by weight, 45%-55% of polyurethane, 5%-15% of epoxy resin, 10%-15% of white corundum micro powder (W7), 5%-15% of ferric oxide, 5%-15% of cerium oxide powder and 0.5%-2% of foaming agents. According to the weight ratio, mixing and casting molding are conducted, the ultra-precise polished 3D curved glass soft foam elastic polishing disk with the Shore Hardness of 30-70 C is obtained. During polishing, the polishing disk only needs cooling water, a polishing solution does not need to be used, and thus high efficiency and environmental protection are achieved. Curved glass polished by the 3D curved glass elastic polishing disk prepared through the preparation method has high surface evenness, smoothness, light transmittance and precision and reaches the application standards of top grade mobile phone shells and other electronic products, and the advantages of high polishing efficiency and high yield are also achieved.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

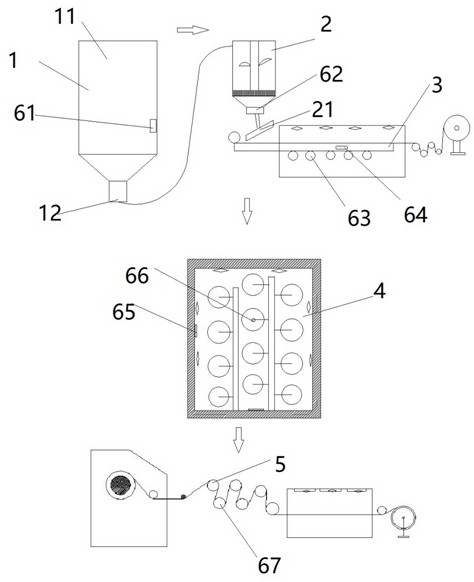

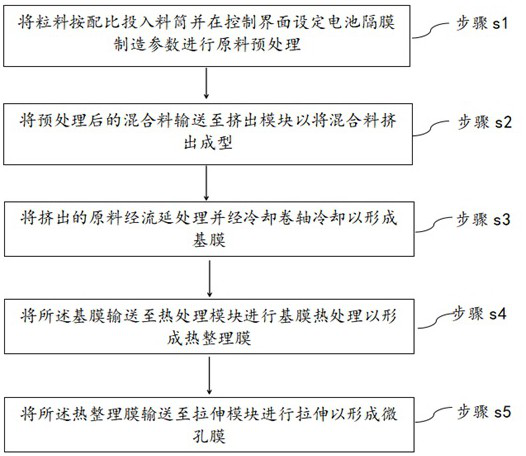

Battery diaphragm manufacturing system of rechargeable battery and manufacturing method thereof

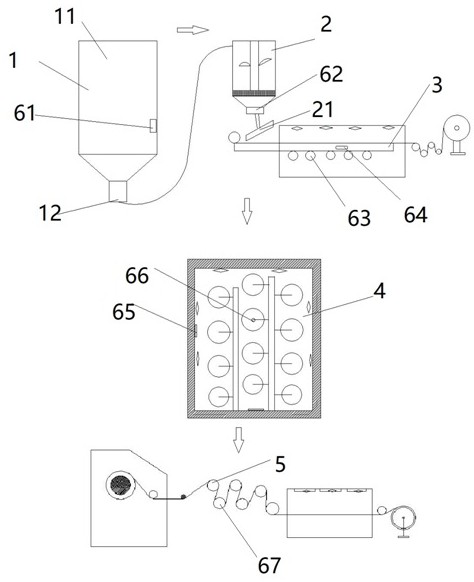

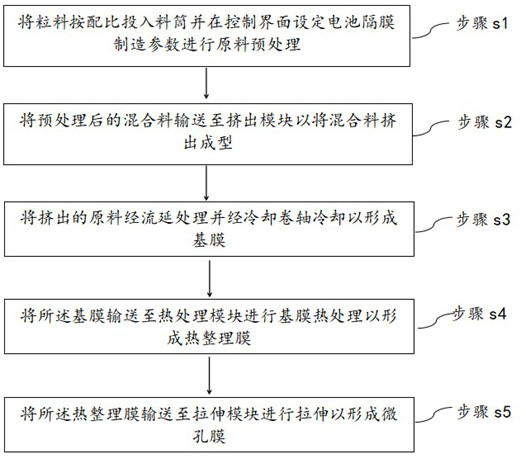

ActiveCN114179403AUniform microporous structureTemperature checkCell component detailsFlat articlesControl systemProcess engineering

The invention relates to the technical field of battery diaphragm preparation, in particular to a battery diaphragm temperature control system of a rechargeable battery and a manufacturing method thereof, the system comprises a raw material pretreatment module, an extrusion module, a casting module, a heat treatment module, a stretching module, a detection module and a control module, the manufacturing method comprises the following steps: step s1, feeding and raw material pretreatment; step s2, extrusion molding of the mixture; s3, carrying out curtain coating treatment and cooling to form a base film; s4, carrying out heat transfer treatment on the base film to form a heat finishing film; and s5, stretching the thermal finishing film to form the microporous film. The detection module and the control module are arranged to detect and adjust the temperature in the manufacturing process of the battery diaphragm, so that the temperature in each technological process in the processing and manufacturing process can be accurately controlled, and the battery diaphragm is effectively processed according to the set temperature in the processing process; and it is ensured that the battery diaphragm forms a uniform microporous structure at the preset temperature.

Owner:深圳市博盛新材料有限公司

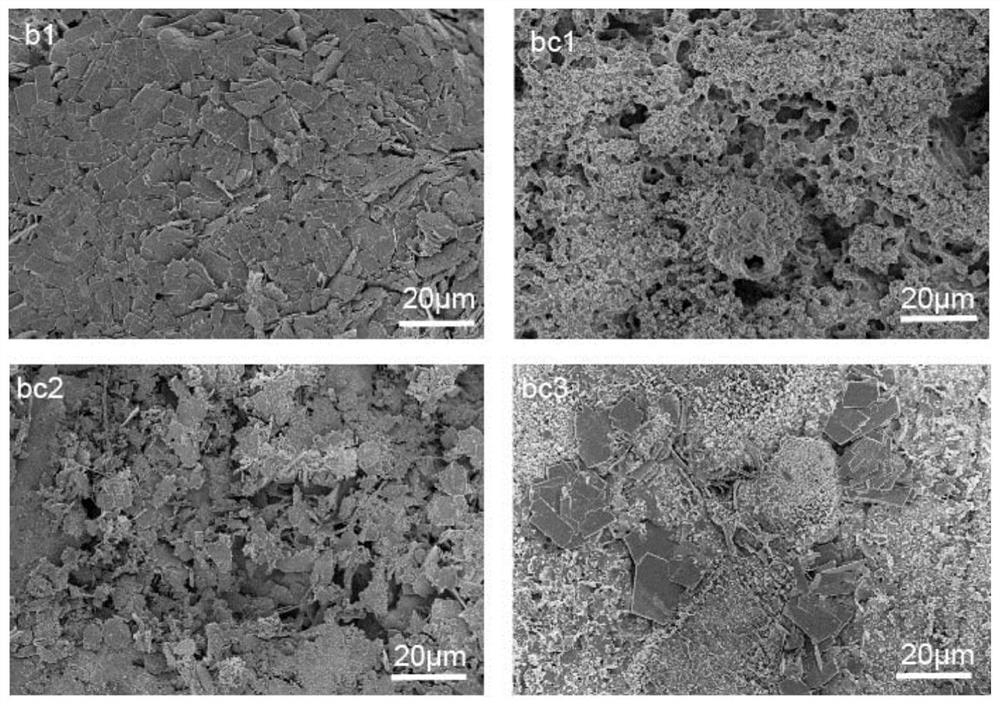

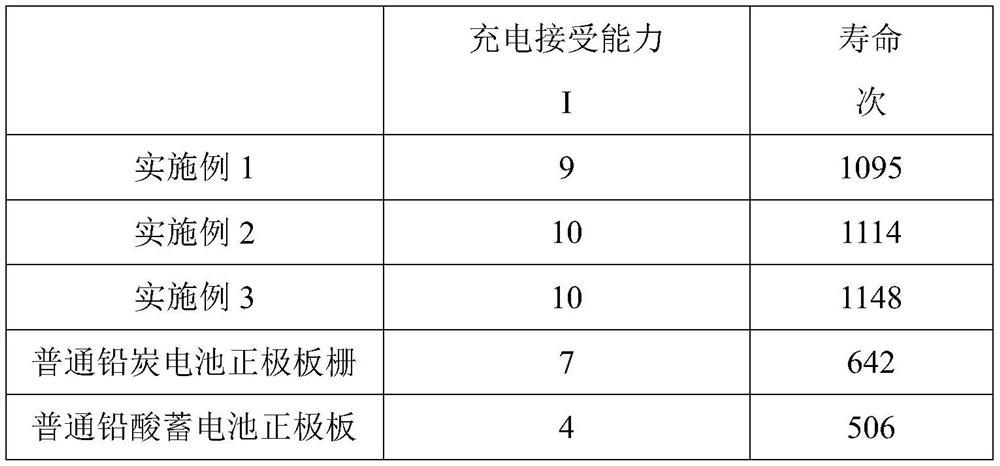

Graphene lead-carbon battery positive grid and preparation method thereof

ActiveCN112614980AStrong charge acceptanceExtended service lifeMaterial nanotechnologyElectrode carriers/collectorsCarbon fibersCarbon nanotube

The invention discloses a graphene lead-carbon battery positive grid and a preparation method thereof. The graphene lead-carbon battery positive grid comprises a lead grid green body and graphene lead plaster covering the surface of the lead grid green body, and the graphene lead plaster is prepared from the following raw materials in parts by weight: 750 to 820 parts of sponge lead, 10 to 14 parts of barium sulfate, 1.4 to 1.8 parts of graphene, 0.75 to 0.85 part of polyacrylonitrile-based carbon fiber, 0.9 to 1.2 parts of carboxylated carbon nanotube, 60 to 90 parts of waterborne polyurethane, 0.7 to 0.9 part of isocyanate, 80 to 95 parts of dodecanol, 40 to 50 parts of isoprene glycol and 0.2 to 0.3 part of polyoxyethylene lauryl ether. The graphene lead-carbon battery positive plate grid is high in charging acceptance and long in service life, is superior to a common lead-carbon battery positive plate grid, and is obviously superior to a common lead-acid storage battery positive plate.

Owner:QUANZHOU KAIYING POWER SUPPLY ELECTRICAL APPLIANCES

Preparation method of carbon-based composite adsorption material

PendingCN114768778ALower the temperature moderatelyReduce usageOther chemical processesWater contaminantsPhosphateSludge

The invention discloses a preparation method of a carbon-based composite adsorption material, which comprises the following steps: mixing pretreated kitchen waste, sewage plant sludge and rice hull powder, pretreating with hydrogen peroxide and sodium hydroxide, adding ferric trichloride and cationic polyacrylamide, conditioning, carrying out filter pressing dehydration, drying, and carrying out heat preservation and carbonization step by step to obtain the carbon-based composite adsorption material. According to the present invention, the common solid waste kitchen waste and sewage plant sludge in cities can be subjected to combined recycling treatment, and the prepared carbon-based composite adsorption material has excellent adsorption effect, and is especially suitable for the harmless treatment of phosphate-containing wastewater.

Owner:HEFEI BAIHE ENVIRONMENTAL PROTECTION TECH CO LTD

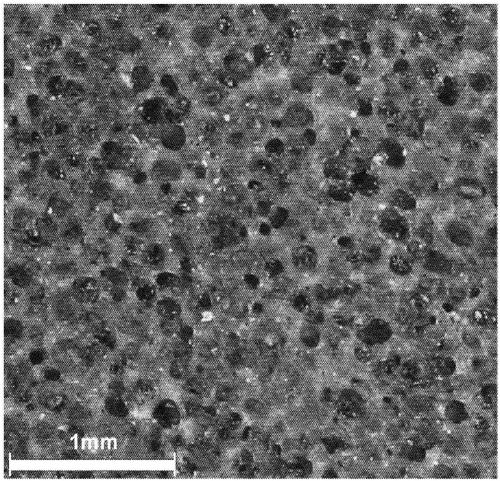

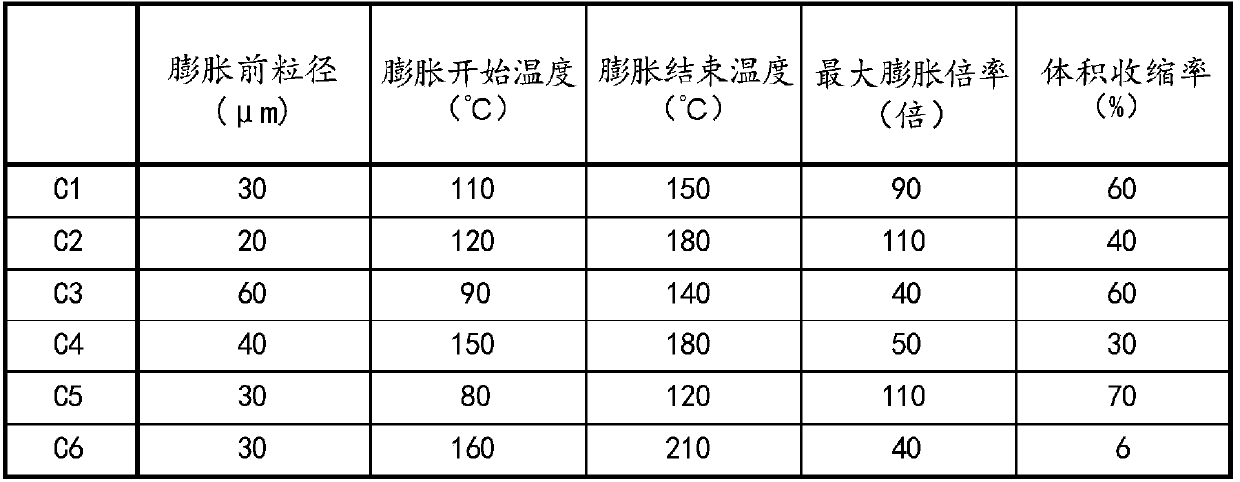

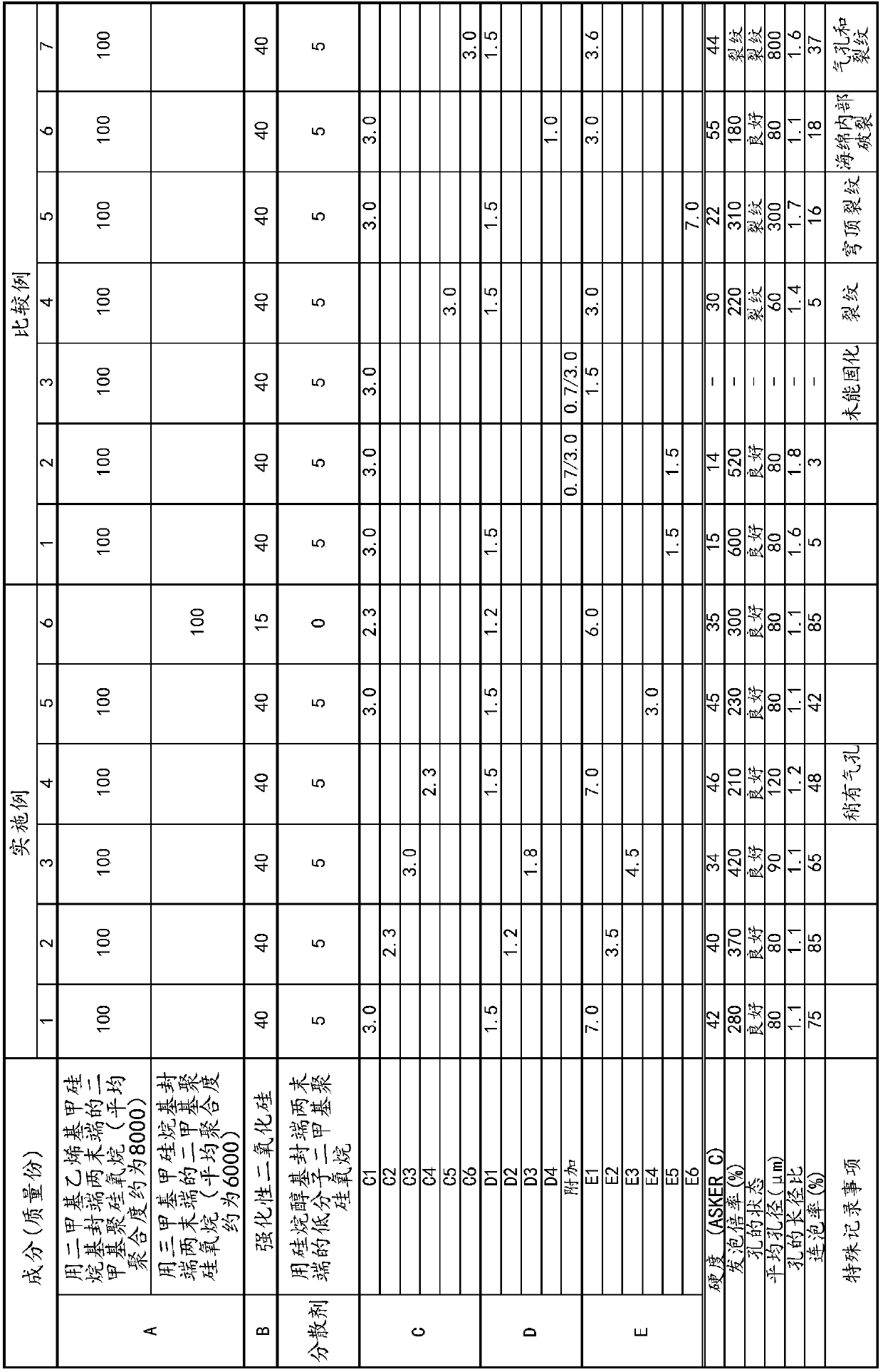

Millable silicone rubber composition, millable silicone rubber sponge, and method for producing said sponge

ActiveCN109563294AImprove surface smoothnessHigh dimensional accuracyAdhesivesSpecial door/window arrangementsPolymer scienceDecomposition

Owner:SHIN ETSU CHEM CO LTD

Method for preparing styrofoam

InactiveCN106398582ALarge ventilationUniform microporous structureNon-macromolecular adhesive additivesMacromolecular adhesive additivesPressure sensitiveChemistry

The invention provides a method for preparing a styrofoam. The method includes the following steps: preparing 100 parts by weight of pressure-sensitive adhesive; adding 0.5-2 parts by weight of an adhesion promoter, 0.1-1 part by weight of a wetting and dispersing agent, 0 .1-1 part by weight of thickener, 1-10 parts by weight of excipient, 10-30 parts by weight of filler, 10-50 parts by weight of water, 0.01-0.1 part by weight of tetramethylguanidine trifluoromethanesulfonate and 0.01-0.1 parts by weight of tetramethylguanidine lactate in the pressure-sensitive adhesive; adding the mixture in a foaming device commonly used in the field of styrofoam preparation, such as a foaming tank, a calender film suction foaming furnace, an extrusion lamination machine and a screw extruder; passing air through a microchannel reactor to the foaming device for foaming to obtain the styrofoam.

Owner:SHENYANG WANHE PLASTIC IND CO LTD

Battery separator manufacturing system for rechargeable battery and manufacturing method thereof

ActiveCN114179403BUniform microporous structureTemperature checkCell component detailsFlat articlesProcess engineeringBattery cell

The invention relates to the technical field of battery diaphragm preparation, in particular to a battery diaphragm temperature control system for rechargeable batteries and a manufacturing method thereof. The system includes a raw material pretreatment module, an extrusion module, a casting module, a heat treatment module, a stretching module, A detection module and a control module, the manufacturing method includes step s1, feeding and pre-processing of raw materials; step s2, extrusion molding of the mixture; step s3, casting treatment and cooling to form a base film; step s4, heat treatment of the base film to form heat-finishing the film; step s5, stretching the heat-finishing film to form a microporous film. The invention detects and adjusts the temperature in the manufacturing process of the battery diaphragm by setting the detection module and the control module, so as to accurately control the temperature of each technological process in the manufacturing process, and effectively realize that the battery diaphragm can be set according to the setting during the manufacturing process. The temperature is processed to ensure that the battery separator forms a uniform microporous structure at a preset temperature.

Owner:深圳市博盛新材料有限公司

Lightweight concrete, multifunctional protective board using the same and preparation method

ActiveCN103922668BImprove insulation effectImprove sound absorptionSolid waste managementCeramicwareFiberFoam concrete

The invention belongs to the fields of building materials and construction technology. Light-weight concrete consists of a concrete base layer and waterproof surface layers, wherein the concrete base layer comprises the following components in parts by weight: 100 parts of cement, 0.1-10 parts of chrysotile fibers, 0.01-2 parts of water repellent, 10-30 parts of pulverized fuel ash, 0.1-6 parts of water reducer, 50-200 parts of water, and 1-20 parts of foaming agent or air entraining agent; the upper side and the lower side of the concrete base layer are coated with the waterproof surface layers which comprise the following components in parts by weight: 100 parts of penetrating type organosilicon waterproofing agent, 0.1-20 parts of nano TiO2, 0-2 parts of activity enhancer, 0.01-5 parts of dispersion stabilizer, and 50-200 parts of solvent. Correspondingly, the microporous structure of the foam concrete or air-entrained concrete is uniform, and the mechanical performance is improved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

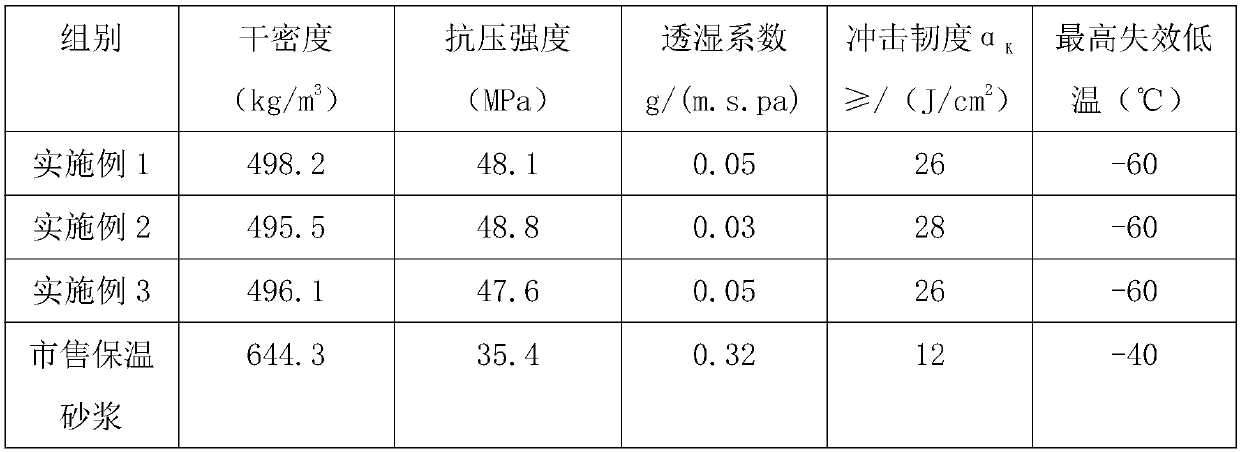

Insulating mortar for buildings and preparation method thereof

The invention discloses insulating mortar for buildings and a preparation method thereof, relating to the technical field of novel building materials. The mortar is prepared from the following raw materials: carbide slag, boric sludge, modified shale pottery sand, Zuoyun clay, sepiolite fibers, microcline powder, analcite powder, calcium nitrite, polydimethylsiloxane, dimethyl sulfoxide, woody sodium carbonate, dehydroacetic acid, a polyacrylate co-polymerized emulsion, a waterproof agent, an anti-freezing agent, a thickening time control agent and an air entraining agent. The preparation method comprises the following step of stirring, mixing and grinding raw materials. The insulating mortar for buildings is simple and convenient in preparation method, has the characteristics of being high in compressive strength, good in impact toughness and excellent in waterproof and anti-freezing property, is insulative and soundproof, weather-resistant and resistant to weather, long in service life and wide in application occasion, the safe reliability of the insulating mortar structural body for buildings is improved greatly, and the mortar is suitable for being popularized and applied.

Owner:HEFEI FANTENG ENVIRONMENTAL PROTECTION TECH CO LTD

A kind of activated carbon fiber composite material and its preparation method and a kind of activated carbon fiber composite filter element

InactiveCN105084572BRich microporous structureUniform microporous structureMultistage water/sewage treatmentFiberProduction line

The invention is made of activated carbon fiber, short fiber, powdered activated carbon, modified cellulose and processing aids, etc. to make activated carbon fiber composite material, as the adsorption material of high-efficiency activated carbon filter element, overcomes the disadvantages of poor strength of activated carbon fiber felt and easy shedding The problem is that the rich and uniform microporous structure of activated carbon fibers is retained, and there are a large number of mesopores (ie, mesopores) of high-quality powdered and granular activated carbons, so the adsorption capacity is large, and the range of applicable organic matter is wide, and the material is prepared. The filter element is resistant to high temperature, acid and alkali, and can be widely used in the electroplating production line of the PCB industry.

Owner:GUANGDONG ZHENGYE TECH

A kind of preparation method of aluminum oxide porous material

ActiveCN109516831BImprove hydrophilicityImprove chemical reactivityCeramicwareMagnesium phosphateMagnesium orthophosphate

The invention discloses a preparation method of an aluminum oxide porous material. The preparation method comprises the following steps of modifying an aluminum oxide powder by a magnesium phosphate sol, adding a manganese oxide micropowder as a sintering additive, and reducing the firing temperature of the aluminum oxide porous material to the temperature of 1200 to 1400 DEG C. The preparation method has the advantage that the good pore structure can be obtained for the porous material within the wide firing temperature range. The aluminum oxide porous material prepared by the preparation method has excellent mechanical property.

Owner:浙江昕明环境科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com