Lightweight concrete, multifunctional protective board using the same and preparation method

A technology of lightweight concrete and protective panels, applied in applications, ceramic products, household appliances, etc., can solve the problems of insufficient consideration of volume shrinkage resistance, heat insulation and shock resistance, reduction of pollutant degradation efficiency, and hygroscopicity. Large and other problems, to achieve the effect of good application prospects, good flexibility, and strong interface adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

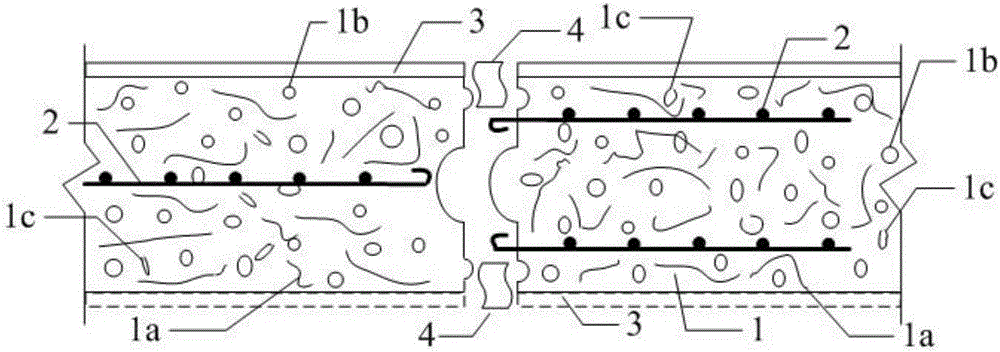

[0037] like figure 1 As shown, the lightweight concrete multifunctional protective plate product of the present invention includes a concrete base 1 and a nano-TiO-containing 2 Organosilicon waterproof layer 3, wherein the concrete base 1 includes the following components by weight ratio: 100 parts of cement, 0.1-10 parts of chrysotile fiber, 0.01-2 parts of water-repellent agent, 0.1-2 parts of quick-setting agent, 10- 30 parts of fly ash, 0.1-6 parts of water reducer, 50-200 parts of water, 1-20 parts of foaming agent or air-entraining agent; the upper and lower sides of the concrete base 1 are painted with a waterproof surface layer 3, and the waterproof surface Layer 3 includes the following components by weight: 100 parts of penetrating silicone waterproofing agent, 0.1-20 parts of nano-TiO 2 , 0-2 parts of activity enhancer, 0.01-5 parts of dispersion stabilizer, 50-200 parts of solvent. The steel wire grid skeleton 2 in the embedded multifunctional protective board pr...

Embodiment 2

[0046] The lightweight concrete used is air-entrained concrete obtained by adding 2% air-entraining agent. The steel wire mesh grid skeleton in the embedded multifunctional protective plate product in the middle of the lightweight concrete is before paving the nano-air-entrained concrete slurry. A single-layer wire mesh grid skeleton has been erected at the half-height in the middle of the protective plate. In addition to hardened concrete, the nano-foam concrete layer also includes chrysotile fibers, closed micro-bubbles and open micro-pores distributed therein. The preparation process and structure of lightweight concrete and Sandwich multifunctional protective board products are the same as in Example 1.

[0047] The dry density and volume water absorption of the corresponding nano-air-entrained concrete and Sandwich multi-functional protective board products are measured according to the methods specified in GB / T11969-2008, GB / T17671-1999, GB / T10294-2008, and JC / T603-2004 ...

Embodiment 3

[0049] The preparation process and structure of the nano-foam concrete and reinforced multi-functional protective board products are the same as in Example 1. The difference is: the foaming agent used is animal protein FP-6B, the water reducing agent is naphthalene-based high-efficiency water reducing agent FDN, the water-repellent agent used is silicone-based water-repellent agent, and the cement used is 625 type rapid hardening high-strength aluminum salt cement.

[0050] Respectively refer to GB / T11969-2008 "Autoclaved Air-entrained Concrete Performance Test Method", GB / T17671-1999 "Cement Mortar Strength Test Method", GB / T10294-2008 "Steady-state Thermal Resistance of Thermal Insulation Materials and Determination and Protection of Related Properties The dry density, volume water absorption, compressive strength and thermal conductivity of the corresponding nano-foam concrete and Sandwich multi-functional protective board products are measured by the method stipulated in "...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| drying shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com