Patents

Literature

106 results about "Chrysotile" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chrysotile or white asbestos is the most commonly encountered form of asbestos, accounting for approximately 95% of the asbestos in the United States and a similar proportion in other countries. It is a soft, fibrous silicate mineral in the serpentine subgroup of phyllosilicates; as such, it is distinct from other asbestiform minerals in the amphibole group. Its idealized chemical formula is Mg₃(Si₂O₅)(OH)₄. The material has physical properties which make it desirable for inclusion in building materials, but poses serious health risks when dispersed into air and inhaled.

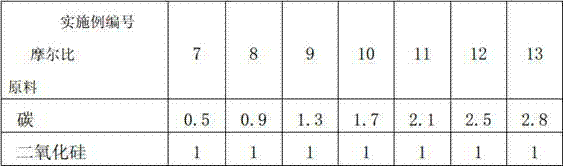

Preparation method of fibrous nano silicon carbide

InactiveCN103496703APlay the role of "template"High yieldMaterial nanotechnologySilicon carbideFiberRocket

The invention discloses a preparation method of fibrous nano silicon carbide. The preparation method is characterized by comprising the following steps: taking a carbon source and chrysotile asbestos of which the main chemical ingredient is silicon dioxide according to the molar ratio of carbon to silicon dioxide being (0.3-3):1; separately grinding the carbon source and chrysotile asbestos, evenly mixing to obtain a mixture; putting the mixture into a reaction device, vacuumizing, and continuously introducing argon in the reaction device; heating to 1350-2500 DEG C and carrying out thermal reaction for 0.2-6 hours; cooling to room temperature, stopping introduction of argon; collecting the reduction product, and grinding into fine powder which is the fibrous nano silicon carbide powder product. The preparation method has the advantages that raw materials are easily availably and equipment and technology are simple; moreover, the preparation method is friendly to environment and high in productivity. The prepared fibrous nano silicon carbide has good performances, can be widely applied to high-tech equipments such as nose cones of space shuttles, brakes of airplanes and racing bicycles, rocket nozzles, satellite antennas, guided missiles and the like, and also has broad use in nanometer microsystems.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Chrysotile tailing microcrystal glass and preparation method thereof

InactiveCN101891389AImprove impact resistanceGood chemical resistance and anti-corrosion functionWear resistantQuenching

The invention discloses chrysotile tailing microcrystal glass and a preparation method thereof and belongs to the technical field of chrysotile tailing control and comprehensive utilization. The chrysotile tailing microcrystal glass comprises the following raw materials in percentage by weight: 30 to 50 percent of chrysotile tailing, 27 to 50 percent of fly ash, 9 to 10 percent of limestone, 0 to 4 percent of industrial barium nitrate, 0 to 4 percent of industrial fluorite and 4 to 6 percent of industry pure alkali. The preparation method comprises the following steps of: 1) performing pre-homogenizing treatment on the chrysotile tailing; 2) preparing a mixture; 3) melting glass liquid; 4) performing water quenching and preparing powder; 5) performing press forming; 6) performing crystallization and sintering; and 7) performing demoulding and post-processing. The microcrystal glass prepared by the method is applicable to building, chemical anticorrosion, wear resistant lining for mine and the like. The chrysotile tailing microcrystal glass and the preparation method have a reasonable formula, can effectively improve the comprehensive utilization rate of the chrysotile tailing and reduce environment pollution, and, through harmless phase inversion to the chrysotile tailing, lower the cost for treating chrysotile tailing waste and are beneficial for popularization and application.

Owner:SOUTHWEAT UNIV OF SCI & TECH

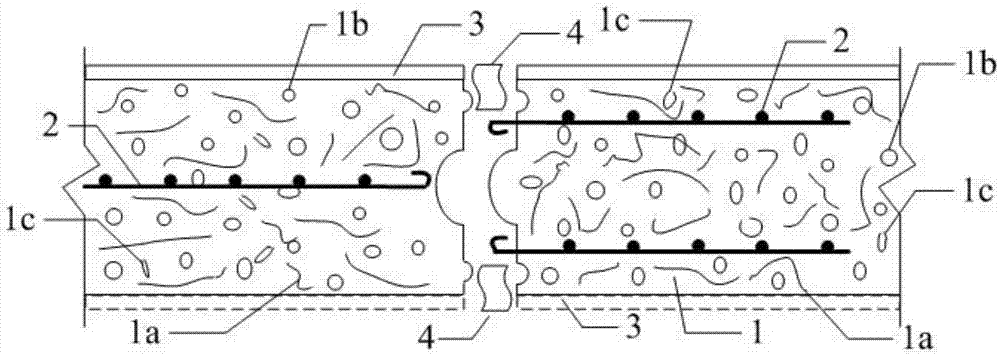

Light-weight concrete, multifunctional protective plate adopting concrete, and preparation method

ActiveCN103922668AGood flexibilityLarge specific surface areaSolid waste managementCeramicwareFiberFoam concrete

The invention belongs to the fields of building materials and construction technology. Light-weight concrete consists of a concrete base layer and waterproof surface layers, wherein the concrete base layer comprises the following components in parts by weight: 100 parts of cement, 0.1-10 parts of chrysotile fibers, 0.01-2 parts of water repellent, 10-30 parts of pulverized fuel ash, 0.1-6 parts of water reducer, 50-200 parts of water, and 1-20 parts of foaming agent or air entraining agent; the upper side and the lower side of the concrete base layer are coated with the waterproof surface layers which comprise the following components in parts by weight: 100 parts of penetrating type organosilicon waterproofing agent, 0.1-20 parts of nano TiO2, 0-2 parts of activity enhancer, 0.01-5 parts of dispersion stabilizer, and 50-200 parts of solvent. Correspondingly, the microporous structure of the foam concrete or air-entrained concrete is uniform, and the mechanical performance is improved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Fibrous nanosilicon preparation method

The invention discloses a fibrous nanosilicon preparation method. The method is characterized in that the method comprises the following steps: taking magnesium powder and silica-based chrysotile according to a magnesium: silica mole ratio of 0.3-3:1, and uniformly mixing to obtain a mixture; filling the mixture to a reaction apparatus, evacuating, continuously introducing argon to the reaction apparatus, heating to 500-800DEG C, carrying out a heat insulation reaction for 0.3-6h, cooling to room temperature, stopping the introduction of argon, and collecting a product obtained a combustion reaction; and mixing and reacting with dilute hydrochloric acid, filtering or centrifuging a material after the above reaction, washing the obtained solid precipitate with deionized water, drying, and milling to prepare fibrous nanosilicon. The preparation method has the advantages of easily available raw materials, simple apparatus and technology, and environmental protection, and the prepared fibrous nanosilicon has the advantages of excellent strength, excellent creep resistance and excellent high temperature resistance, and has good application prospects in the nanowire field, the switch field, the line field, the high-performance optical fiber field, the energy storage field, the environment treatment field, and the medical and health field.

Owner:SOUTHWEAT UNIV OF SCI & TECH

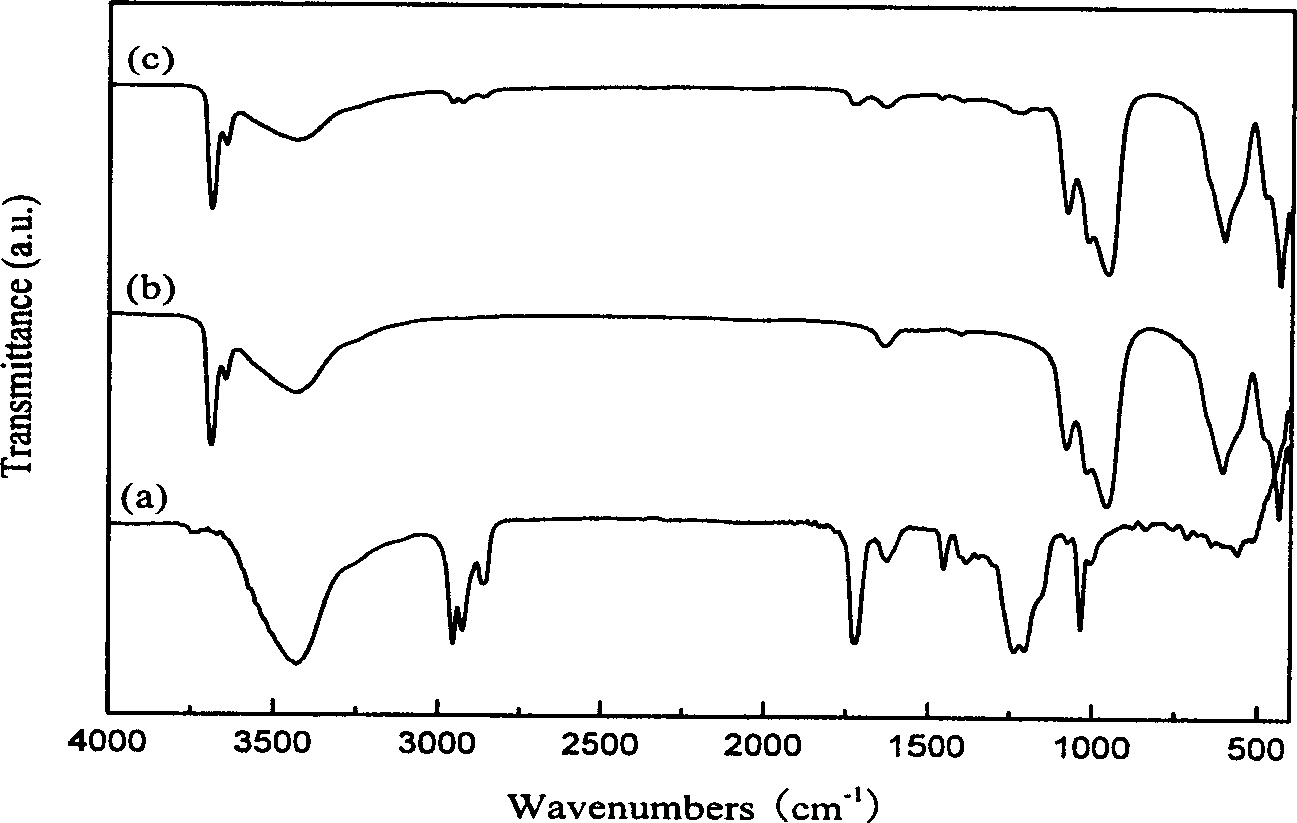

Curable Composition Containing as Constituent Material Silica Obtained by Decomposing Chrysotile and Cured Object

InactiveUS20080264302A1Mitigate the heat island effectEasy constructionSilicaCovering/liningsBiological bodyFiber

Chrysotile or chrysotile-containing serpentinite containing chrysotile is treated to convert the chrysotile contained therein into a non-asbestos material, so that the non-asbestos material is used as a material that can be recycled safely and is effective from the view point of environmental protection.[Means for Solving Problems] A curable composition characterized by containing at least a porous fibrous amorphous silica obtained by decomposing chrysotile or chrysotile-containing serpentinite with acid to substantially eliminate an influence of asbestos on living body, and a reinforcing fiber. The curable composition preferably contains a surfactant and a thickener and / or a filler and / or a colorant or an air-hardening material and / or water-hardening material and a thickener. The composition preferably contains 15 to 100% of the porous fibrous amorphous silica obtained by decomposing the chrysotile or the chrysotile-serpentinite with acid, 0 to 75% of a slaked line, 0 to 3% of a thickener, and 0 to 10% of a pulp.

Owner:NOZAWA CORP

Preparation method for porous silicon nanofiber/carbon composite material

ActiveCN104009211AHigh capacity densityExcellent rate performanceCell electrodesSecondary cellsCarbon compositesFiber

The invention relates to a preparation method for a porous silicon nanofiber / carbon composite material, and belongs to the technical field of lithium ion battery. The preparation method comprises the steps: firstly, carrying out acid dipping, water washing, filtration and drying on chrysotile asbestos to obtain a silica nanofiber having alkali metal oxide impurities removed; adding a reductive metal into the silica nanofiber, mixing evenly, then carrying out a reduction reaction to obtain a reduzate, carrying out pickling, water washing and drying on the reduzate to obtain a porous silicon nanofiber; and evenly mixing the obtained porous silicon nanofiber with a carbon precursor to obtain a mixed material, then dissolving the mixed material in a solvent, dispersing to obtain a mixed solution under an ultrasonic condition, and carrying out pyrolysis carbonization or hydrothermal carbonization of the dispersed mixed solution under the inert gas protection to obtain the porous silicon nanofiber / carbon composite material. The method takes natural minerals as raw materials, is low in cost and simple; and the porous silicon nanofiber / carbon composite material has the characteristics of large capacity density, high first-time Kulun efficiency, stable cyclic performance and the like.

Owner:KUNMING UNIV OF SCI & TECH

Oxide/silicate mineral fiber nano composite air-sensitive film and preparation method thereof

InactiveCN101609059AAvoid breakingEnhanced gas adsorption capacityMaterial resistanceFiberPalygorskite

The invention discloses an oxide / silicate mineral fiber nano composite air-sensitive film and a preparation method thereof, belonging to the technical field of functional composite material. The oxide / silicate mineral fiber nano composite air-sensitive film comprises silicate mineral fiber nano material substrate and a nano oxide powder layer coated on the surface of the silicate mineral fiber nano material substrate; wherein silicate mineral fiber nano material is any one in the minerals such as chrysotile, amphibole, meerschaum and palygorskite; and nano oxide powder is any one of nano stannic oxide, nano ferric oxide, nano zinc oxide and nano copper oxide. Compared with the prior art, the oxide / silicate mineral fiber nano composite air-sensitive film obtained by adopting the method has the tensile strength being improved from 10-50MPa to 100-3000MPa and the fracture toughness be enhanced from 3-5MPa.m1 / 2 to 100-500MPa.m1 / 2; the air-sensitive stability and the service life are improved by 80-100%.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Industrial sewage treatment agent

InactiveCN105948213AImprove securityFast flocculationWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionPhosphateThiourea

The invention discloses an industrial sewage treatment agent, which comprises the following raw materials by weight: 20-40 parts of chrysotile, 10-30 parts of diatomite, 10-30 parts of modified activated carbon, 10-20 parts of polymeric aluminum phosphate, 5-15 parts of polymeric phosphate-ferric chloried, 1-5 parts of aluminum potassium sulfate, 5-10 parts of bentonite, 1.5-2.5 parts of polyacrylamide, 1.4-2.5 parts of sodium hexametaphosphate, 1-3 parts of modified attapulgite, 10-30 parts of isopropanol, 5-15 parts of sodium nitrite, 2-10 parts of thiourea, and 2-4 parts of acrolein. The industrial sewage treatment agent provided by the invention can be used for industrial sewage treatment, and has the advantages of fast flocculation and purification speed, thorough sewage treatment, excellent stability and high safety.

Owner:林元文

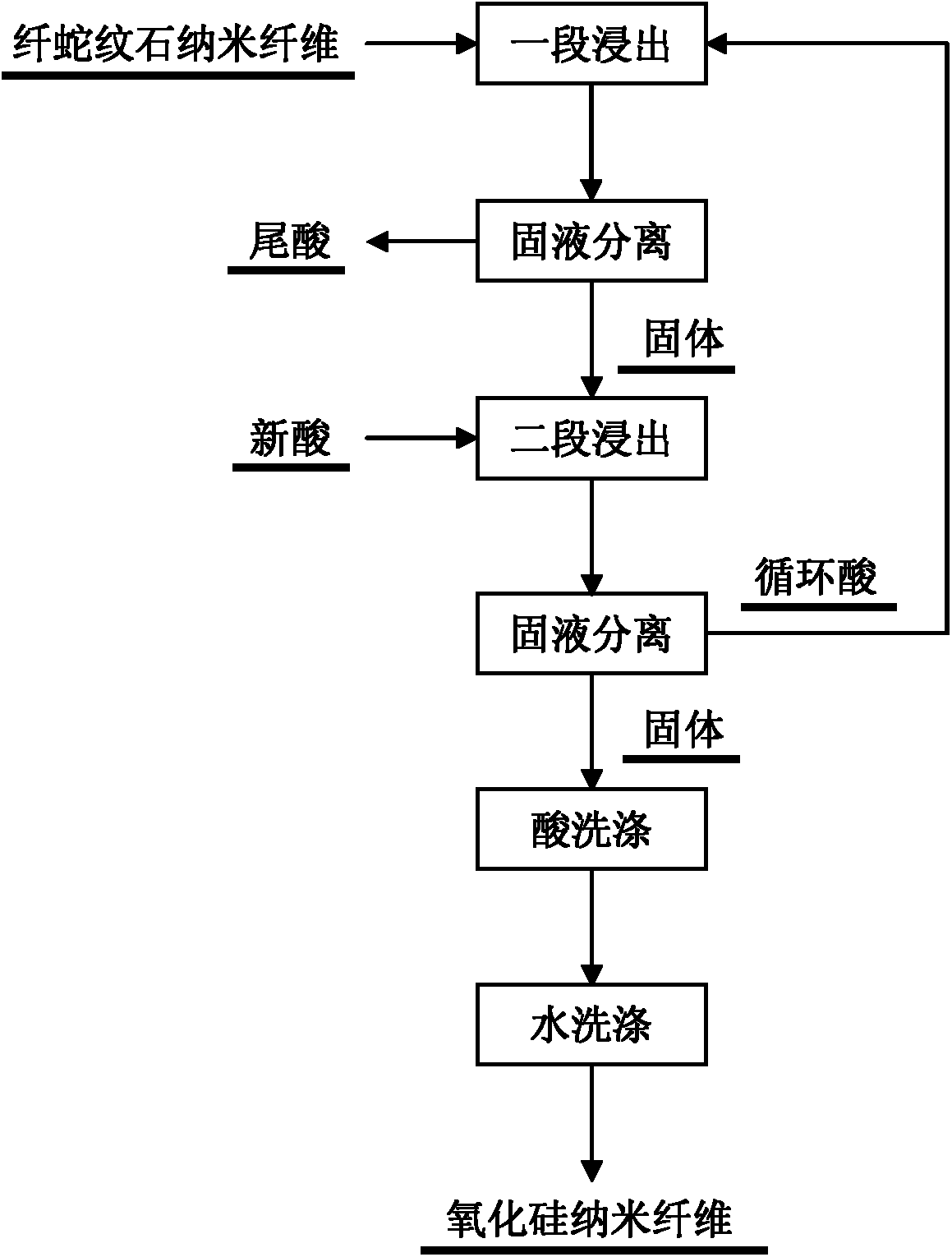

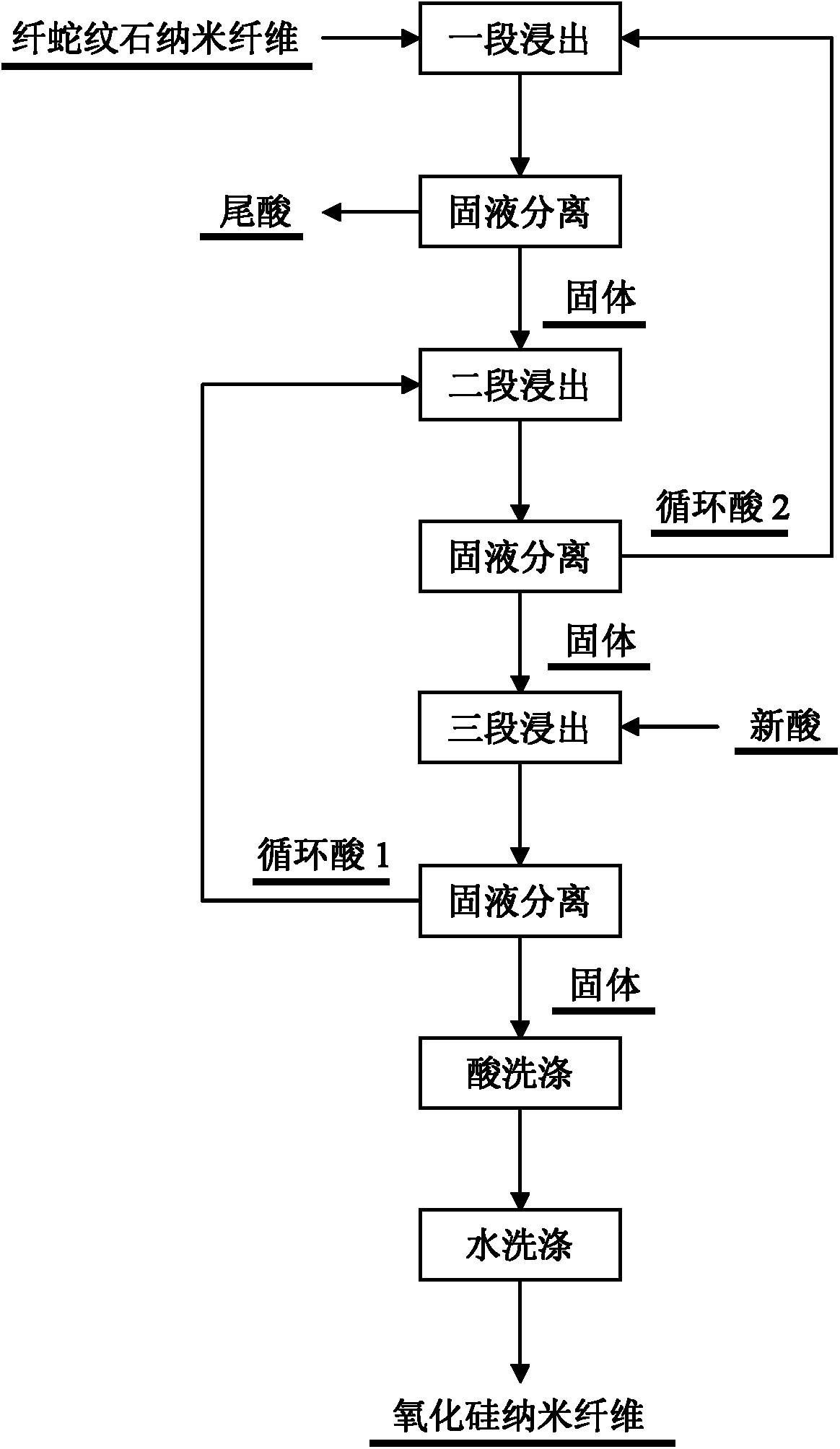

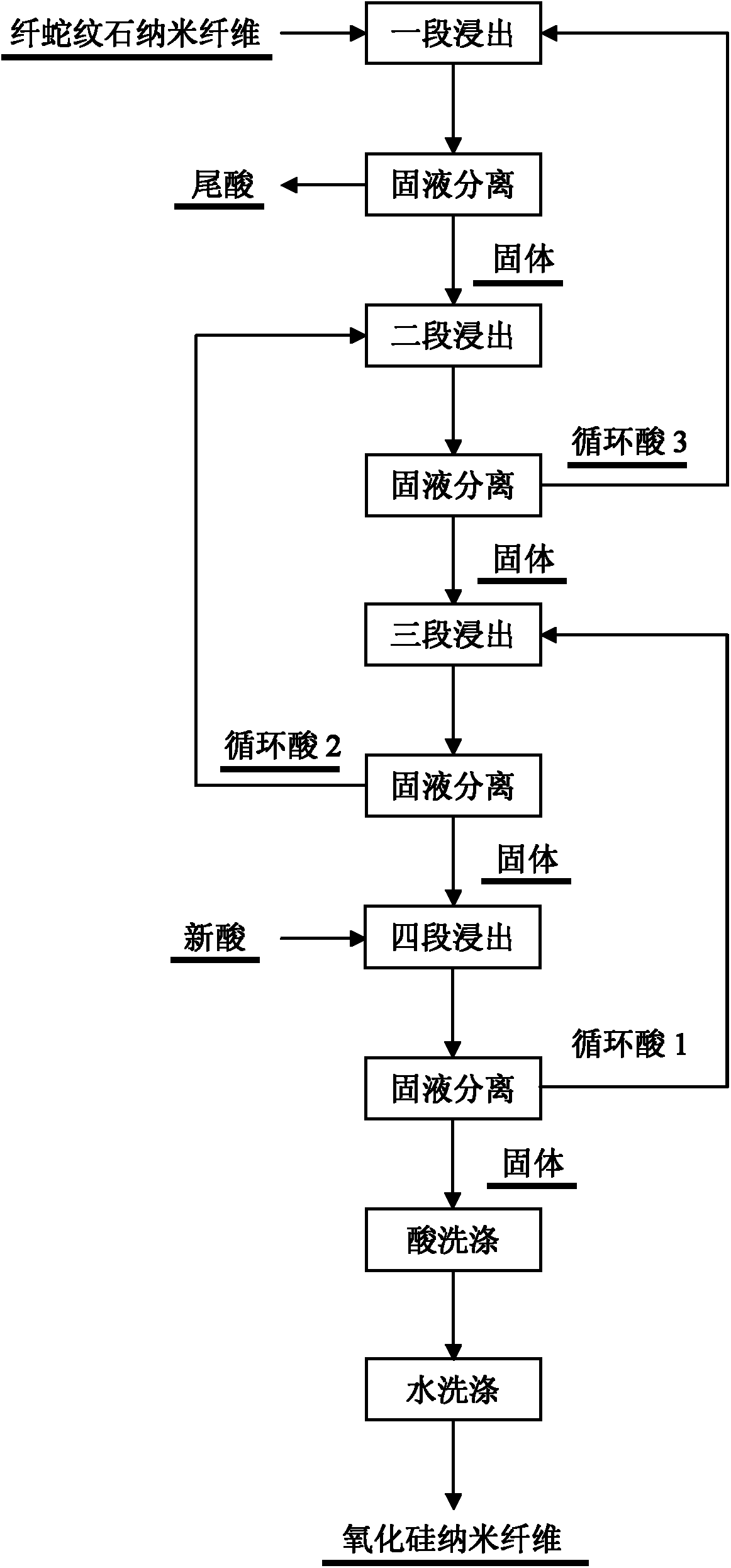

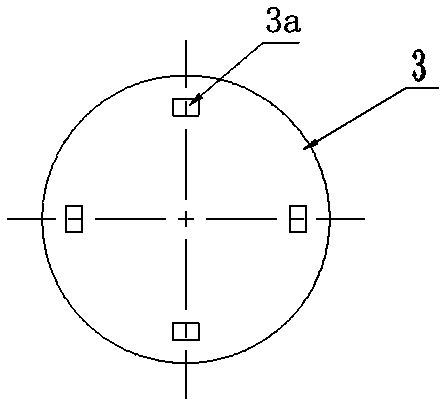

Efficient leaching technology of metal ions in chrysotile nanofiber

InactiveCN102352435AEfficient leachingHigh puritySilicaProcess efficiency improvementFiberSilicon oxide

The invention provides an efficient leaching technology of metal ions in chrysotile nanofiber and particularly relates to an efficient leaching technology of metal ions in silicon oxide nanofiber prepared from chrysotile, belonging to the fields of mineral materials and mineral processing. The efficient leaching technology uses chrysotile nanofiber as a raw material and one or more of low concentration sulphuric acid, hydrochloric acid and nitric acid as a leaching agent; and the countercurrent leaching technology with 2-4 sections is adopted, the efficient leaching of chrysotile nanofiber is performed for a proper time at the atmospheric pressure and at a proper temperature, the acid-leaching product is washed with dilute acid and water in sequence, and finally the silicon oxide nanofiber with higher purity can be obtained. By adopting the technology, the efficient leaching of metal ions can be effectively realized while the large length-diameter ratio of the product silicon oxide nanofiber can be maintained; and the equipment is simple, the operations are convenient, the acid consumption is extremely low, the pH value of the discharged tail acid is about 1 after the balance of the system, the subsequent magnesium extraction and neutralization treatment are performed easily and the environmental cost is reduced extremely.

Owner:CENT SOUTH UNIV

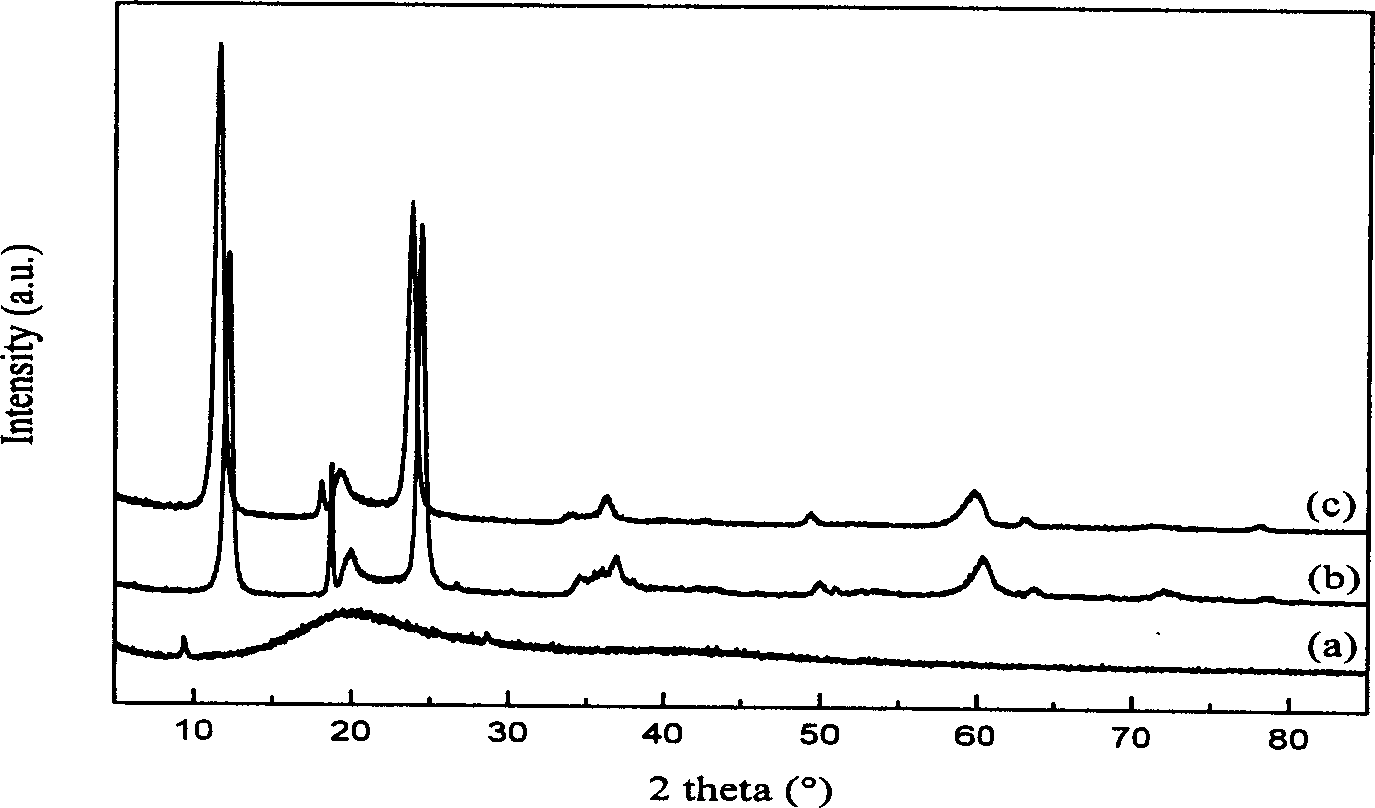

Method for preparing magnetic chrysotile nanotube

ActiveCN103466647AGood chemical stabilityStrong magnetismMagnesium silicatesMaterial nanotechnologyIron saltsAdditive ingredient

The invention discloses a method for preparing a magnetic chrysotile nanotube. The method comprises the following steps: adding amorphous silica, a magnesium compound, a bivalent iron salt and water into a reaction kettle under the protection of nitrogen, and uniformly mixing the ingredients to obtain a mixed solution, wherein the mass concentration of the amorphous silica in the mixed solution is 2-25%, the mass concentration of the magnesium compound is 1-20%, and the mass concentration of the bivalent iron salt is 0.2-15%; adding a sodium hydroxide solution into the mixed solution to regulate the pH value to 10-13.5, and then, transferring the solution into a high-pressure reaction kettle, reacting for 12-72 h at 180-240 DEG C under a sealed condition, filtering, washing and drying the product after the reaction to obtain the magnetic chrysotile nanotube. The magnetic chrysotile nanotube prepared by the method has strong magnetism, and the specific magnetism of the magnetic chrysotile nanotube is 12.78 A.M2.kg<-1>.

Owner:HEFEI UNIV OF TECH

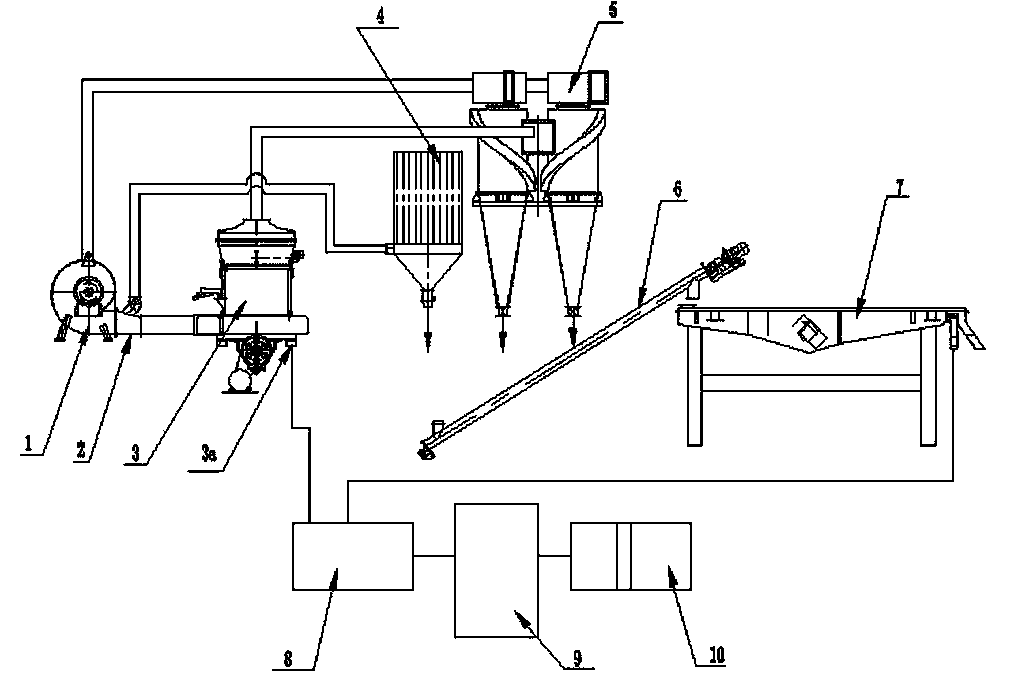

Breaking and separation integrated comprehensive recovery method of chrysotile tailings

InactiveCN103433137AReduce the delivery linkReduce lossesMagnetic separationGrain treatmentsRecovery methodMagnetic separator

The invention provides a breaking and separation integrated comprehensive recovery method of chrysotile tailings, which is characterized by comprising the steps of putting the dried chrysotile tailings in breaking and separation integrated equipment consisting of a pulverizer and a cyclone powder collector, achieving pulverizing and separation by adding 4-8 sand discharge ports on a pulverizing disc of the pulverizer, separating a chrysotile mixed material containing dust and tailing waste, conveying the chrysotile mixed material to a plane revolving screen or a plane shaking screen for classification and dedusting, removing fine sand and the dust, obtaining chrysotile products of different levels, roughing the tailing waste, the fine sand and the dust with a weak magnetic separator, obtaining magnetic middlings and tailings, and conveying the magnetic middlings into a ball mill for milling, and a wet weak magnetic separator for concentrating to obtain magnetite concentrates and tailings. According to the method, two production processes, grinding & asbestos fiber opening, and separation, of the chrysotile tailings are organically combined into a whole, effects of energy conservation and consumption reduction are achieved, and the chrysotile products of different levels and the magnetite concentrates are obtained simultaneously.

Owner:十堰源禹工贸有限公司

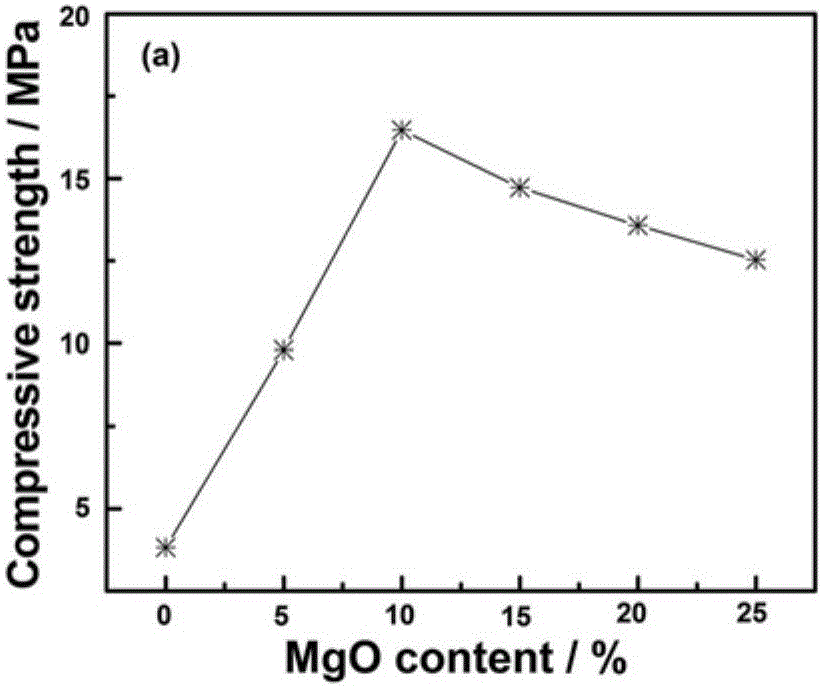

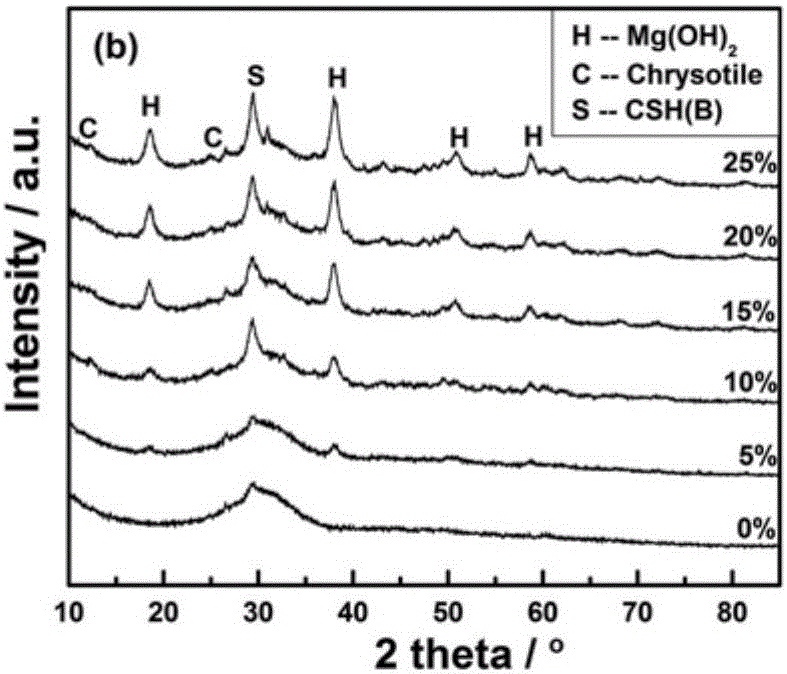

Method for synthesizing silicate building material from magnesium oxide and blast furnace slag

InactiveCN106045350AHigh mechanical strengthTechnically reasonableCement productionCalcium silicateSlag

The invention specifically relates to a method for synthesizing a silicate building material from magnesium oxide and blast furnace slag, belonging to the field of recycling of industrial waste residues. The method adopts a hydrothermal curing process, and a cured product has high mechanical strength and can be used as a wall material of a building, a brick for a pedestrian trail, etc. The method comprises the following steps: subjecting magnesium slag tailings to crushing, screening and roasting; then uniformly mixing the roasted tailings with a proper amount of blast furnace slag powder and water and carrying out compression molding; and allowing calcium silicate hydrate and chrysotile calcium silicate hydrate to be formed and aggregated in virtue of the slag activation effect of MgO in a high-temperature saturated water vapor environment so as to obtain the building material with usage performance like high mechanical strength. The prepared building material is applicable as a wall material of a building, a brick for a pedestrian trail, etc.; and the method is applicable to recycling of magnesium-containing mine tailings like low-grade magnesite, dolomite and brucite and residues of boric sludge and the like.

Owner:SHENYANG JIANZHU UNIVERSITY

Metal wear repairing agent and preparation method thereof as well as lubricating oil

ActiveCN104789297AFast productionReduce coefficient of frictionAdditivesAluminium chlorideIron(II) oxide

The invention provides a metal wear repairing agent and a preparation method thereof as well as lubricating oil. The metal wear repairing agent comprises the following components in part by weight: 2-6 parts of hydroxyl silicate ore, 0.3-0.7 part of apatite, 4.5-5.5 parts of vermiculite, 0.2-0.7 part of aluminum chloride, 0.2-1 part of chrysotile, 0.02-0.07 g of lanthanum oxide and 0.05-0.15 part of ferrous oxide; the preparation method of the metal wear repairing agent comprises the following steps: 1) pulverizing a mixture I of hydroxyl silicate ore, apatite, vermiculite, aluminum chloride, chrysotile into particles having a diameter smaller than or equal to 0.05 mm; 2) drying the pulverized particles, removing moisture and crystal water; 3) S03: adding lanthanum oxide and ferrous oxide powder to obtain a mixture II, grinding the mixture II again until a powdered mixture is obtained. According to the invention, the metal wear repairing agent can repair damaged surfaces, reduce the friction, and improve the abrasion resistance.

Owner:张涵

Polymer composite material slant wedge friction board for railroad cargo vehicle

InactiveCN1618873AMeet the requirements of heavy-duty high-speed operationIncrease transportation revenueFiberBogie

A wedged friction plate for the railway car is prepared from the high-molecular composite material, which is prepared from chrysotile fibres or sepiolite fibres or preoxidized fibres, copper (or steel) fibres, phenolic resin or the cashew shell oil (or nitrile rubber) modified phenolic resin, MoS2 and graphite. Its advantages are high stability of friction coefficient, and no damage to the vibration damper.

Owner:赵泽

Preparation method of chrysotile nanotube in direction arrangement

InactiveCN101607714AImprove crystal structureWith weak magneticMagnesium silicatesNano sio2Distilled water

The invention discloses a preparation method of chrysotile nanotubes in direction arrangement, comprising the following steps: 1) placing NaOH solution in a hydrothermal reaction kettle; 2) preparing water solution doped with magnetic ions, adding the water solution in the hydrothermal reaction kettle; 3) separately weighting active MgO and nano-SiO2 powder according to a molar ratio of 3 to 2, adding the active MgO and nano-SiO2 powder in the hydrothermal reaction kettle in turn, then adding distilled water in the reaction system, adjusting the pH value of the reaction system to 11-13.8; 4) sealing the hydrothermal reaction kettle and placing the kettle in a magnetic field; meanwhile, heating the hydrothermal reaction kettle and keeping temperature to perform a reaction for 15-80h, cooling; then opening the cooled hydrothermal reaction kettle, sucking up the upper clear liquid slowly and adding distilled water slowly for washing until the washing water which is sucked up is neutral; then heating and drying the product after opening the kettle to obtain the nanotubes of the invention. The method is simple, and the produced chrysotile nanotubes are pure with a perfect crystal structure so that the method is applicable to the nano-assembly and can be used in the preparation of nano-submicron devices.

Owner:SOUTHWEAT UNIV OF SCI & TECH

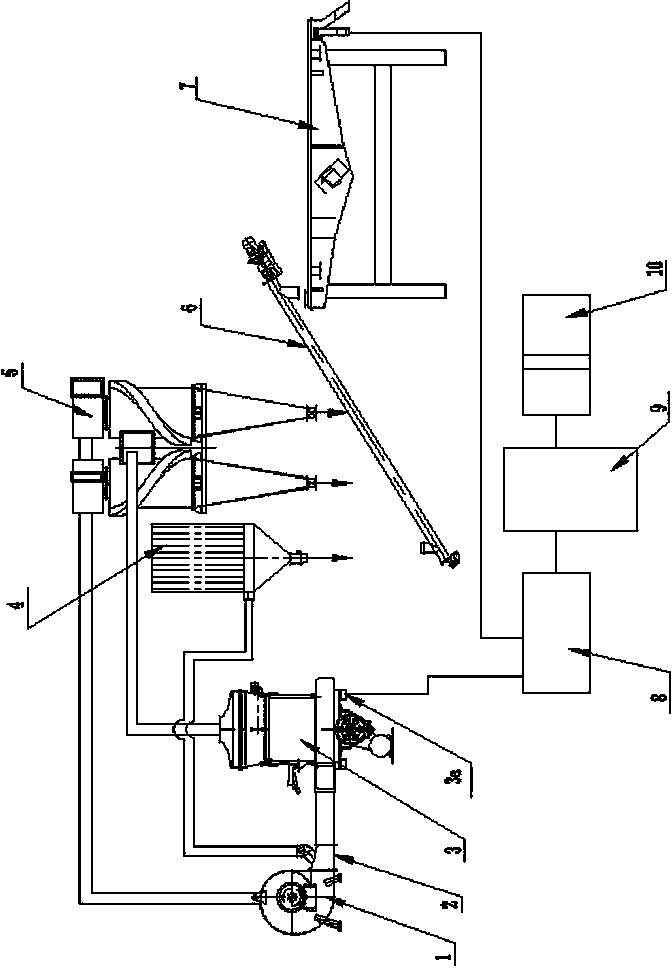

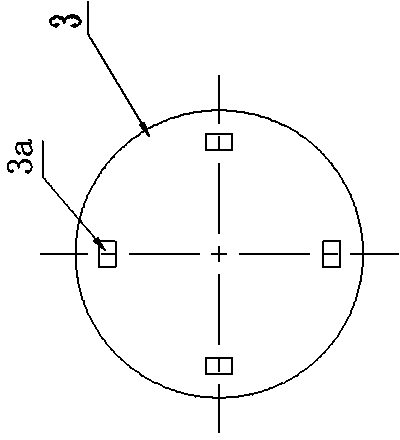

Breaking and separation integrated comprehensive recovery system of chrysotile tailings

InactiveCN103433138AReduce lossesProtection lengthMagnetic separationGrain treatmentsMagnetiteMagnetic separator

The invention provides a breaking and separation integrated comprehensive recovery system of chrysotile tailings, which is characterized in that a fan is connected with a pulverizing host and a duster respectively by a three-way valve; 4-8 sand discharge ports are annularly formed at the bottom of the pulverizing host; an outlet of the pulverizing host is connected with a cyclone collector by a pipeline; an inlet of a screw conveyer is connected with an outlet of the cyclone collector; an outlet of the screw conveyer is conveyed to a plane revolving screen or a plane shaking screen to achieve recovery of chrysotile; integrated functions of breaking and separation are achieved; a weak magnetic separator, a ball mill and a wet weak magnetic separator are connected sequentially to form a magnetic separating system of magnetite; and the magnetic separating system is used for magnetic separating of the magnetite from dust. According to the recovery system, the sand discharge ports in the pulverizing host separate tailing waste, two production processes of grinding & asbestos fiber opening and separation are organically combined into a whole, the production cost is lowered, the energy conservation and consumption reduction are achieved, and the magnetic separating system weakly separates the magnetite to produce iron ore concentrates.

Owner:十堰源禹工贸有限公司

Chrysotile asbestos tailings ceramsite and preparation method thereof

ActiveCN109553385AIncrease profitStable chemical propertiesCeramic materials productionCeramicwareExpanded clay aggregateSodium silicate

The invention discloses a chrysotile asbestos tailings ceramsite and a preparation method thereof, which relates to the technical field of comprehensive utilization of chrysotile asbestos tailings. The chrysotile asbestos tailing ceramsite comprises the following raw materials in parts by weight: 50-90 parts of chrysotile asbestos tailings, 5-40 parts of clay, 10-20 parts of pulverized coal, 10-20parts of limestone, 1-5 parts of industrial caustic soda, 1-10 parts of silica sand and 25-40 parts of 5-10 wt% aqueous sodium silicate solution. The chrysotile asbestos tailings ceramsite prepared by the invention has the advantages of light weight, high strength, stable chemical performance, environmental friendliness, no pollution, changing harm into benefit, and improving the comprehensive utilization rate of the chrysotile asbestos tailings.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Method for synthesizing lithium iron silicate positive electrode material by using chrysotile asbestos as raw material

InactiveCN104009224AAbundant resourcesSimple production processCell electrodesSecondary cellsFiberAlkali metal oxide

The invention relates to a method for synthesizing a lithium iron silicate positive electrode material by using chrysotile asbestos as raw material, and belongs to the technical field of lithium ion battery. The method comprises the steps: placing the chrysotile asbestos in an acidic solution, carrying out acid dipping, then carrying out water washing, filtering and drying to obtain a silica nanofiber having alkali metal oxide impurities removed; carrying out wet grinding and even mixing of a lithium salt, a ferrous salt and the silica nanofiber obtained in the above steps to obtain a precursor mixture, under a protective atmosphere, tabletting the obtained precursor mixture, then carrying out heat preservation for 7-13 h under a condition of the temperature of 650 DEG C-800 DEG C, cooling to the room temperature, and thus obtaining the lithium iron silicate positive electrode material. The method has the advantages of simple process and low cost, and provides conditions for cyclic utilization of asbestos tailings of an asbestos mine and achieving of sustainable development of enterprise and mineral resources.

Owner:KUNMING UNIV OF SCI & TECH

A kind of preparation method of porous silicon nanofiber/carbon composite material

ActiveCN104009211BHigh capacity densityImproved magnification performanceCell electrodesSecondary cellsCarbon compositesFiber

The invention relates to a preparation method for a porous silicon nanofiber / carbon composite material, and belongs to the technical field of lithium ion battery. The preparation method comprises the steps: firstly, carrying out acid dipping, water washing, filtration and drying on chrysotile asbestos to obtain a silica nanofiber having alkali metal oxide impurities removed; adding a reductive metal into the silica nanofiber, mixing evenly, then carrying out a reduction reaction to obtain a reduzate, carrying out pickling, water washing and drying on the reduzate to obtain a porous silicon nanofiber; and evenly mixing the obtained porous silicon nanofiber with a carbon precursor to obtain a mixed material, then dissolving the mixed material in a solvent, dispersing to obtain a mixed solution under an ultrasonic condition, and carrying out pyrolysis carbonization or hydrothermal carbonization of the dispersed mixed solution under the inert gas protection to obtain the porous silicon nanofiber / carbon composite material. The method takes natural minerals as raw materials, is low in cost and simple; and the porous silicon nanofiber / carbon composite material has the characteristics of large capacity density, high first-time Kulun efficiency, stable cyclic performance and the like.

Owner:KUNMING UNIV OF SCI & TECH

Method for preparing water glass through extracting silicon oxide from chrysotile tailings by strong-base roasting method

ActiveCN105502426AReduce dosageShorten roasting timeMagnesium carbonatesAlkali metal silicatesPotassium hydroxideSilicon oxide

The invention discloses a method for preparing water glass through extracting silicon oxide from chrysotile tailings by a strong-base roasting method. The method comprises the following steps: (1) carrying out processing, so as to obtain chrysotile tailing powder; (2) adding a strong base into the chrysotile tailing powder, carrying out uniform mixing, and carrying out a roasting reaction, so as to obtain a water glass containing active roasted product, wherein the strong base is sodium hydroxide or potassium hydroxide, and the chrysotile tailing powder and the strong base are weighed in a mole ratio of SiO2 to (Na / K) being (1: 0.5) to (1: 6); (3) proportioning the active roasted product and industrial water in a solid-liquid mass ration of being (1: 5) to (1: 30), and carrying out a water soaking reaction for 20 minutes to 2 hours, so as to obtain a water glass containing suspension; (4) subjecting the suspension obtained in the step (3) to filtrating and dehydrating, so as to obtain a water glass filtrate and filtrated residue; (5) subjecting the water glass filtrate to spray drying, thereby obtaining the water glass. According to the method, the strong base serves as a chemical adjuvant and reacts with silicon oxide in the chrysotile tailings, and then, leaching is carried out so as to prepare the water glass, thus, the process flow and roasting time are short, the energy consumption is low, and the method is green and environmentally friendly and is beneficial to popularization and application.

Owner:SOUTHWEAT UNIV OF SCI & TECH

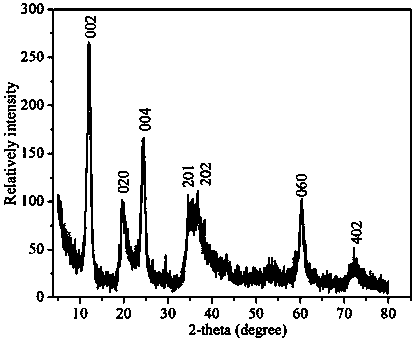

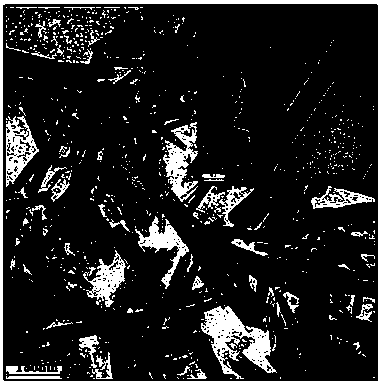

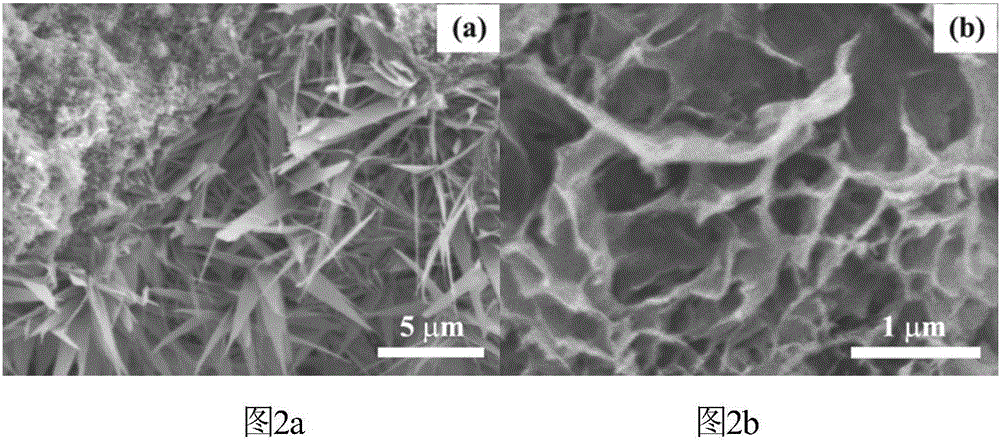

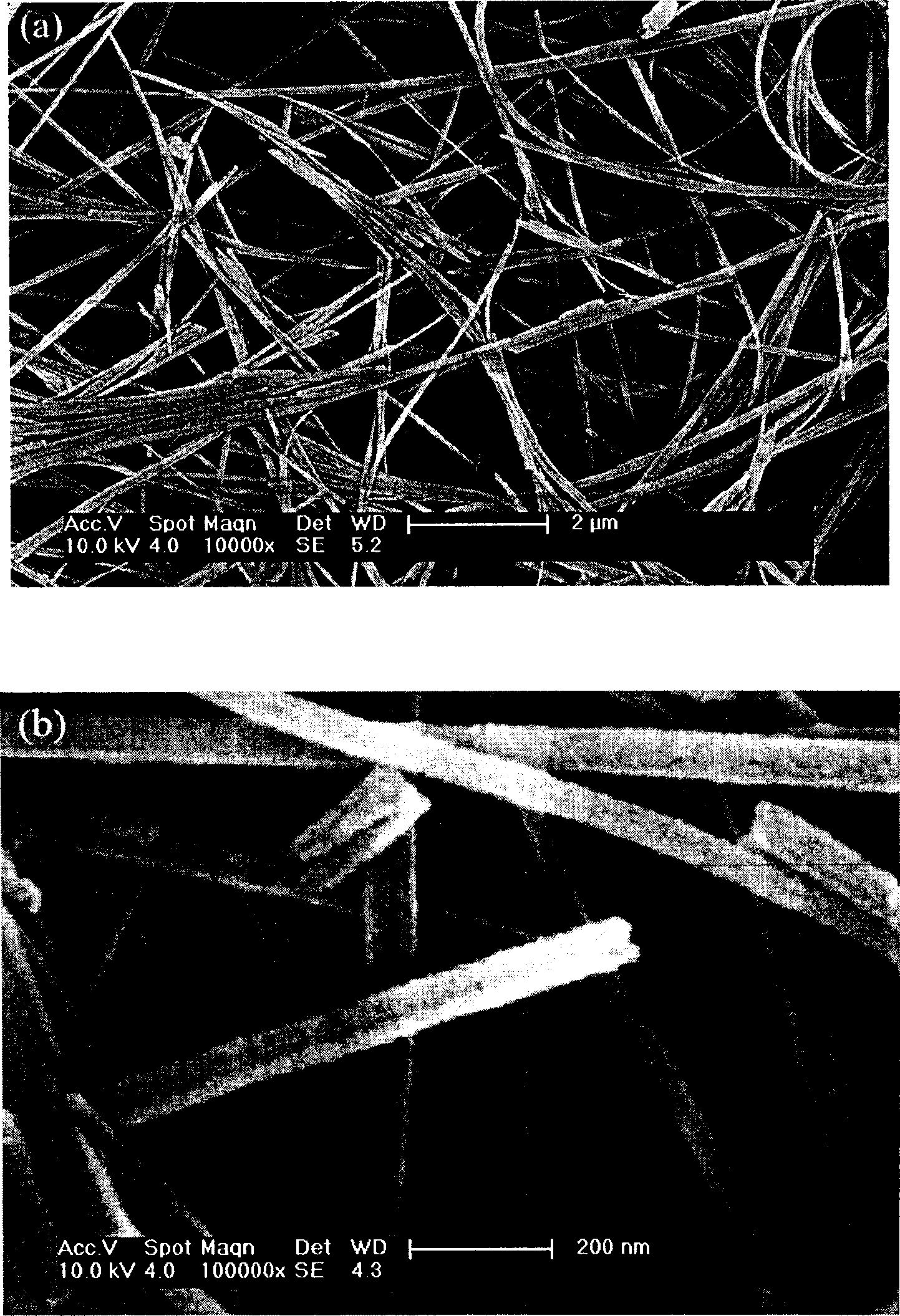

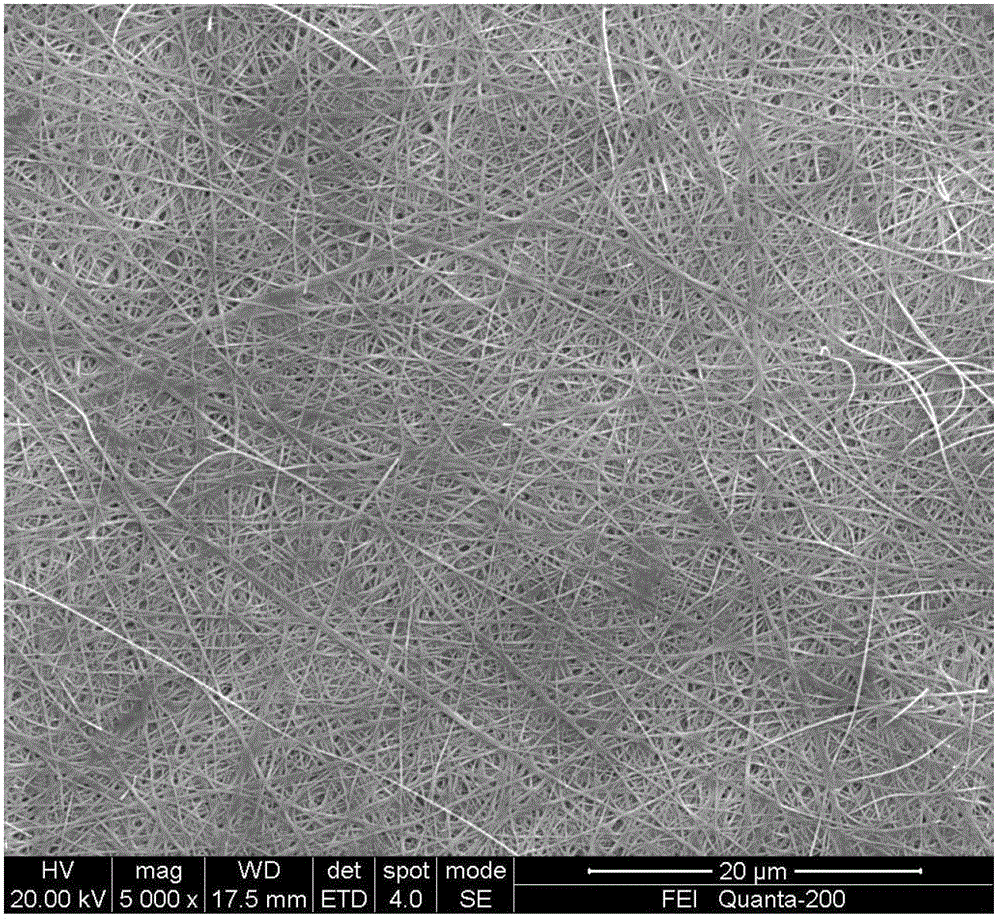

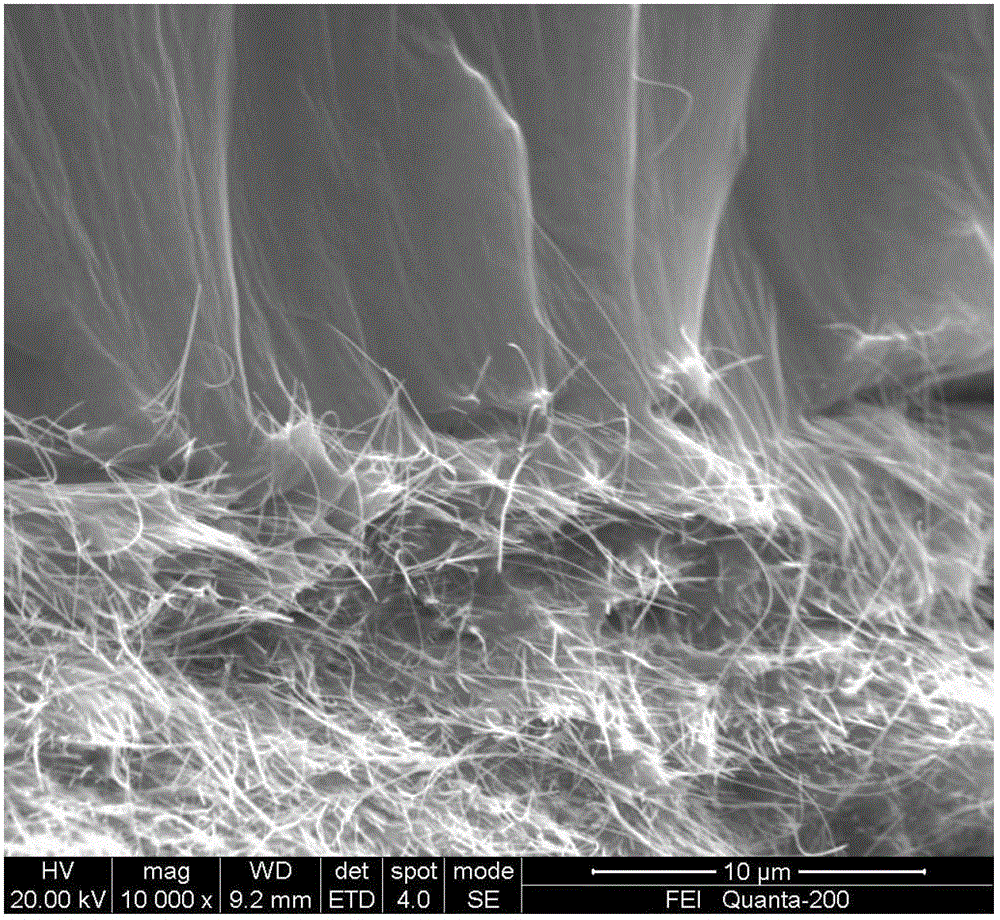

Method for preparing chrysotile nano fiber

The invention is a method for preparing a chrysotile nanofiber, comprising the steps of: using chrysotile commercial asbestos or asbestos gangue as raw materials, and purifying the raw material with water washing purification; mixing the purified raw material with anion surface active agent and water and soaking; dispersing; centrifugating and obtaining a white chrysotile nanofiber product by liquid-solid separation. And it can implement large-scale production and has a diameter generally 30-60 nm long, a length greater than 10 um, high purity, good crystallization degree, and relatively uniform appearance distribution.

Owner:CENT SOUTH UNIV

Scratch-resistant modified metal flashing coating for photo frame

The invention discloses a scratch-resistant modified metal flashing coating for a photo frame. The scratch-resistant modified metal flashing coating is prepared from 25-35 parts by weight of amino methyl ester-modified polymethacrylate, 5-15 parts by weight of modified cellulose acetate butyrate, 2-8 parts by weight of hydroxy acrylic resin, 3-9 parts by weight of an isocyanate curing agent, 1-5 parts by weight of organosilicone resin, 3-6 parts by weight of epoxy resin E-13, 2-5 parts by weight of aluminum powder, 1-4 parts by weight of nanometer silicon dioxide, 2-8 parts by weight of nanometer titanium dioxide, 3-6 parts by weight of chrysotile, 1-8 parts by weight of ceramic powder, 1-3 parts by weight of ethylene glycol monobutyl ether, 2-6 parts by weight of hexakis(methoxymethyl)melamine, 1-4 parts by weight of dimethyl ethanolamine, 2-4 parts by weight of isopropanol, 3-5 parts by weight of sodium hexametaphosphate, 1-4 parts by weight of butyl acetate, 2-5 parts by weight of a silane coupling agent KH-560, 3-6 parts by weight of a dispersant, 2-4 parts by weight of a levelling agent BYK-331, 1-4 parts by weight of a wetting agent, 3-6 parts by weight of an antifoaming agent, 1-4 parts by weight of xylene and 12-18 parts by weight of deionized water. The scratch-resistant modified metal flashing coating has excellent scratch resistance.

Owner:蚌埠市禹会区贵宾装饰材料商行

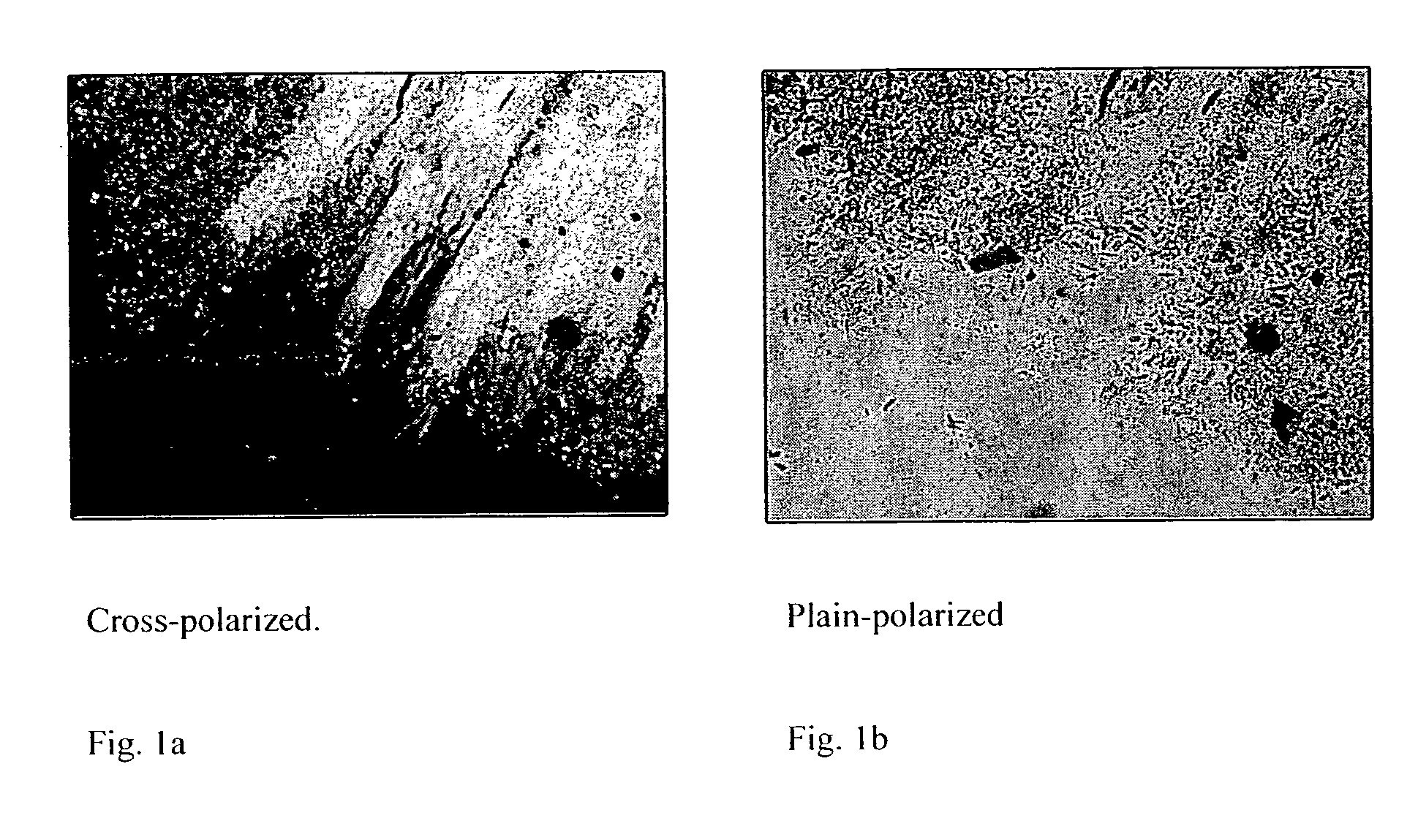

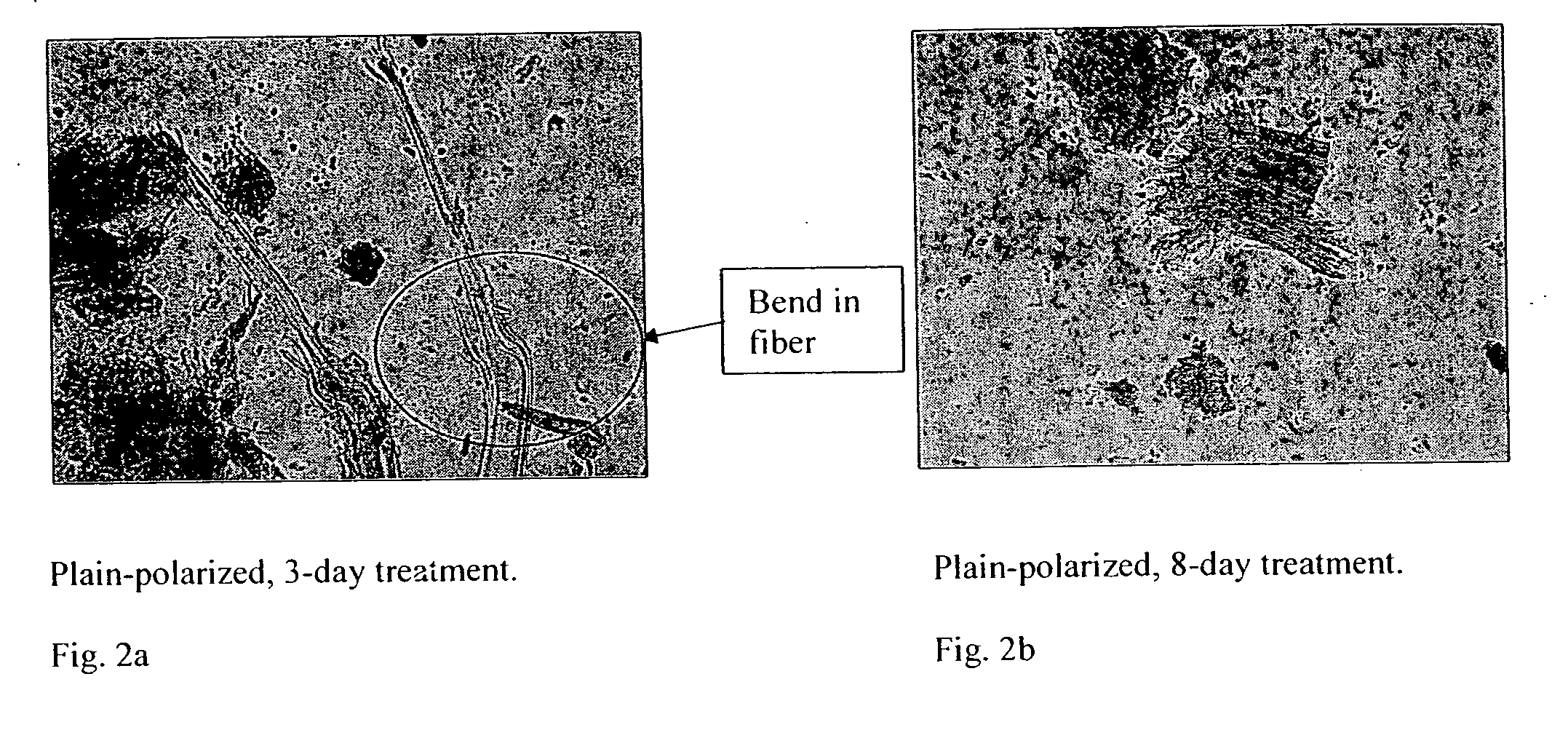

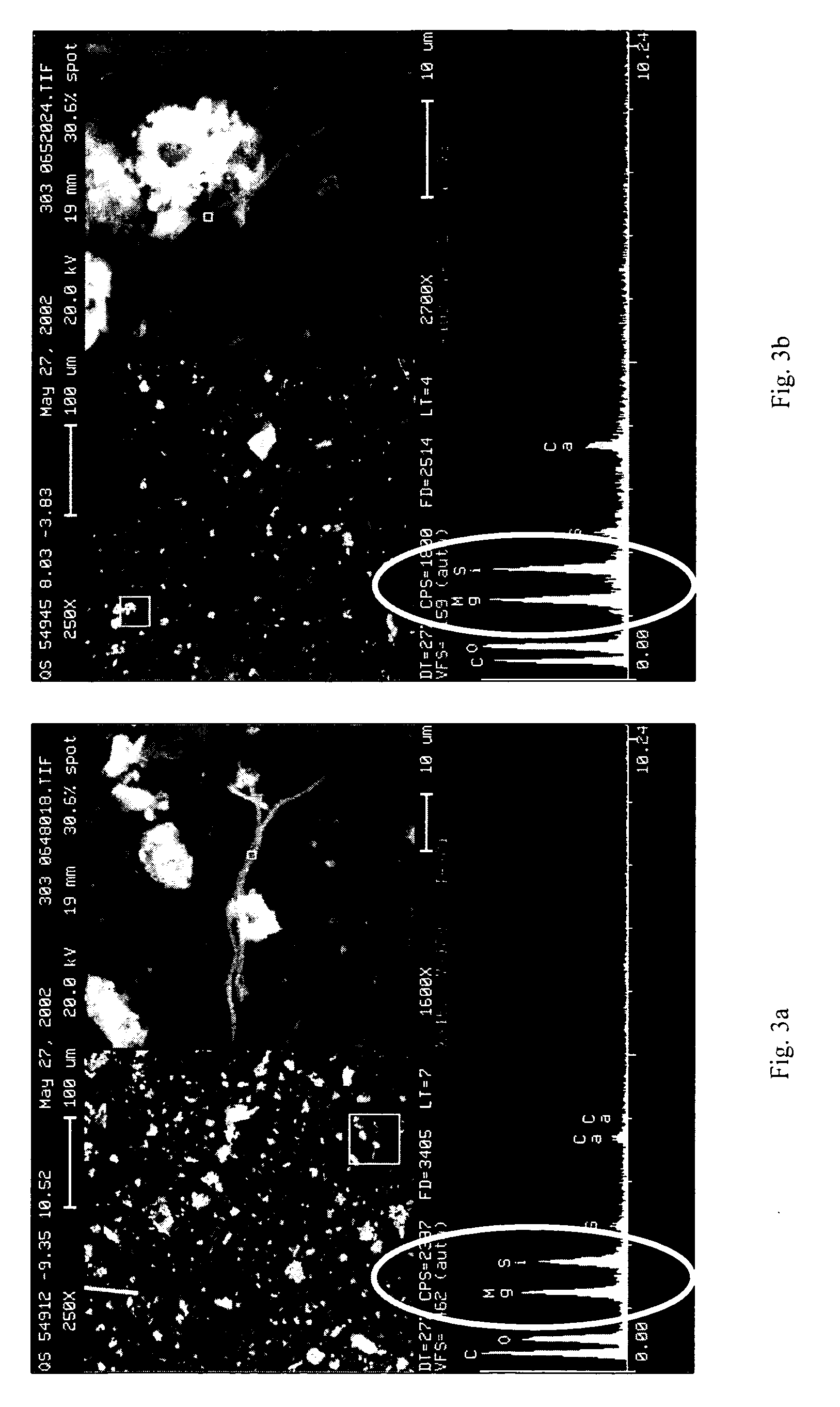

In-situ treatment of asbestos-containing material

InactiveUS20060106272A1Improve structural stabilitySafe removalSolid waste disposalFiberOXALIC ACID DIHYDRATE

The present invention relates to methods for the in-situ treatment of ACM containing chrysotile asbestos using a polycarboxylic acid such as oxalic acid. The polycarboxylic acid is introduced to the ACM while it remains substantially in place, or “in-situ,” and assists in converting the asbestos to a non-asbestos material. When the ACM is used as an insulating material, the asbestos fibers may be covered in gypsum that may be at least partially removed or dissolved away. The polycarboxylic acid may (1) directly attack the asbestos and / or (2) dissolve gypsum and form sulfuric acid capable of attacking the asbestos. Additional sulfuric acid may be introduced to assist in conversion of the asbestos to a non-asbestos form. Magnesium sulfate may be introduced to maintain the structural stability of the treated material thereby allowing it to substantially remain in place. Alternatively, the treated material may be safely removed for disposal.

Owner:352 EAST IRVIN AVENUE PARTNERSHIP

Scratch and heat resistant ceramic glaze

The invention discloses a scratch and heat resistant ceramic glaze. Raw materials of the ceramic glaze include pottery clay, polymethacrylate, hydroxyl-containing acrylic resin, organosilicon resin, epoxy resin E-13, aluminum powder, nano-silica, nanometer titanium dioxide, chrysotile, ceramic powder, ethylene glycol butyl ether, hexamethoxy methyl melamine, dimethylethanolamine, isopropanol, sodium hexametaphosphate, butyl acetate, a silane coupling agent KH-550, a scratch-resistant filler and a heat resistance modification additive. The ceramic glaze has excellent resistance to scratch and heat.

Owner:潘正龙

Cement permeation promoter for oil and gas well

The cement permeation promoter for oil and gas well is compounded with gum resin 25í½35 wt%, modified aluminum powder 8í½12 wt%, asphalt 35í½45 wt% and chrysotile fiber 16í½24 wt%. It is re-compounded through treating the aluminum powder with water solution of potassium permanganate to deactivate and stoving to obtain modified aluminum powder, and mixing the modified aluminum powder with other components in the said weight proportion to obtain the cement permeation promoter. The cement permeation promoter may be re-compounded with other admixtures to form a new type of permeating cement slurry system, which is cured in the stratum condition to form oil and gas passage with certain permeation rate, high strength, high heat and salt tolerance, oil phase permeation rate higher than water phase permeation rate, stable chemical performance and for cementing well, preventing sand, blocking water, etc.

Owner:SOUTHWEST PETROLEUM UNIV

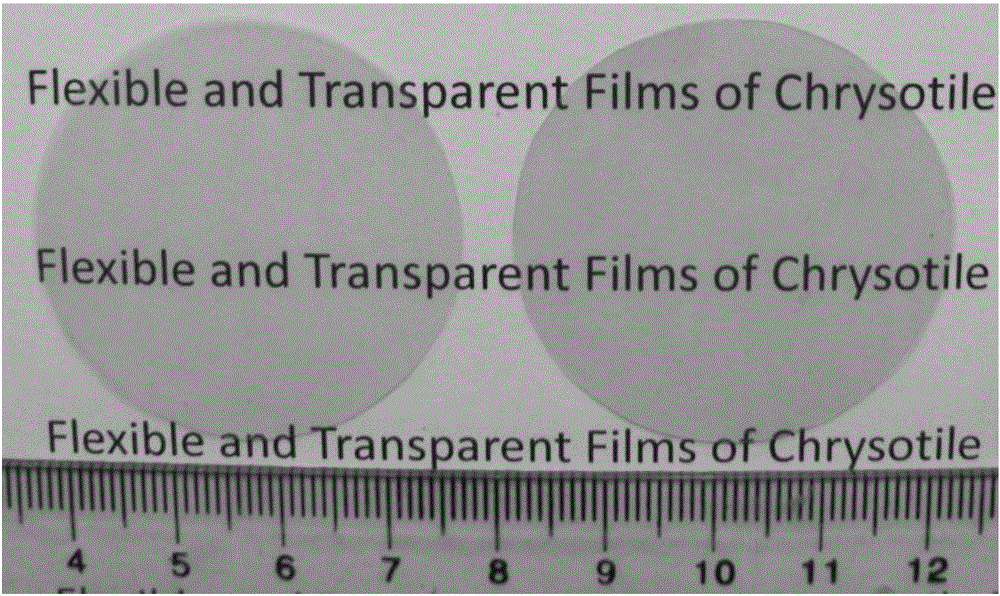

Method for regulating and controlling transmittance of chrysotile nano-fiber films by gap filling

InactiveCN105949359AImprove and control light transmittanceReduce Rayleigh scatteringMembranesSemi-permeable membranesFiberRayleigh scattering

The invention relates to a chrysotile nano-fiber film, in particular to a method for regulating and controlling transmittance of chrysotile nano-fiber films by gap filling. The method comprises the following steps: firstly, respectively soaking a plurality of chrysotile nano-fiber films in liquid solidifiable resins with different refractive indexes; after air in gaps of all the chrysotile nano-fiber films is discharged completely and the gaps are fully filled with the resin, taking out the chrysotile nano-fiber films; then removing residual resins on the surfaces of the chrysotile nano-fiber films; and finally solidifying to obtain the chrysotile nano-fiber films with different transmittances. The solidifiable resins with relatively high refractive indexes replace the air in the chrysotile nano-fiber films, namely, the resins with the different refractive indexes are used for filling the gaps among the chrysotile nano-fiber films, so that the Rayleigh scattering effect of an interface to visible light is reduced inordinately, and the purpose of improving, regulating and controlling the transmittance of the chrysotile nano-fiber films is achieved.

Owner:CENT SOUTH UNIV

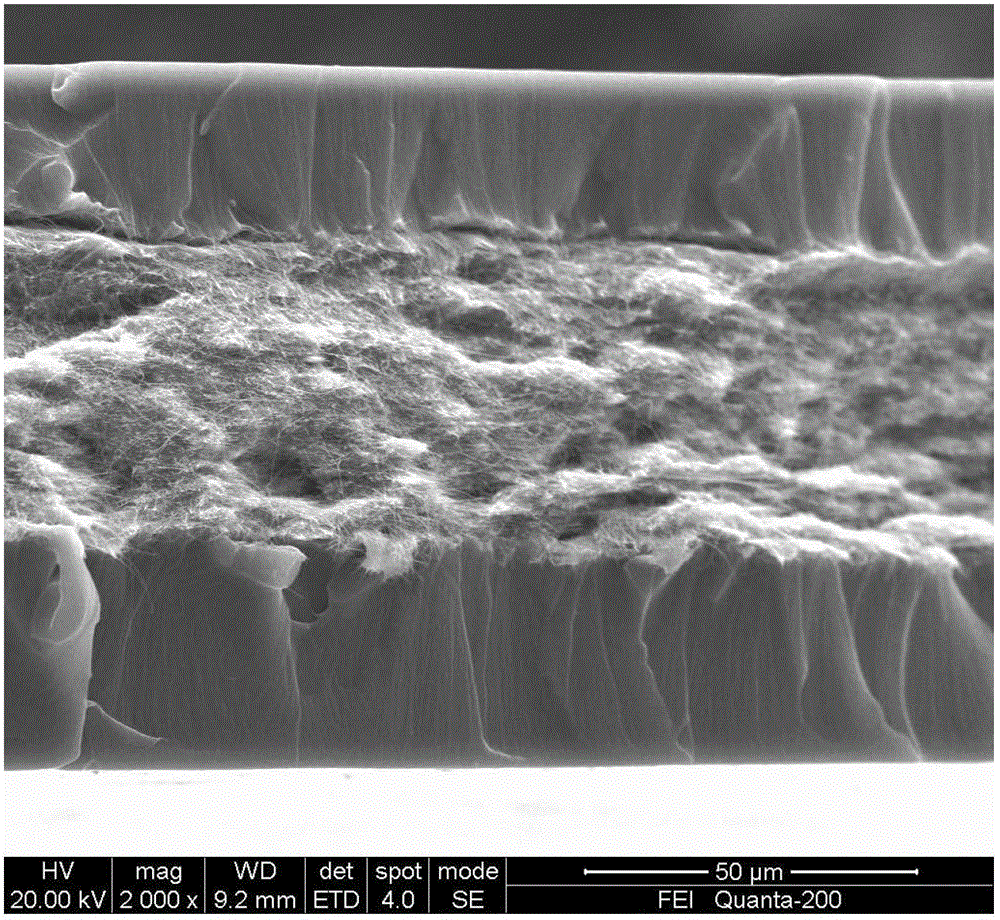

Chrysotile nanofiber and resin composite transparent film, and preparation method and application thereof

InactiveCN103331967ARefractive index adjustmentLow viscositySynthetic resin layered productsSolid-state devicesComposite filmUV curing

A chrysotile nanofiber and resin composite transparent film, and a preparation method and application thereof. The film includes a layer of chrysotile nanofiber layer with pores; the nanofiber layer is wrapped between an upper resin layer and a lower resin layer; and the resin is infiltrated into the pores of the fiber layer. The content of chrysotile nanofiber is 20wt%-75wt%, and the thickness of the transparent composite film is 70-150 mum. The method is as below: adding chrysotile nanofiber into water, adding a polymer binder, and forming a uniform colloidal solution through mechanical stirring and ultrasonic; filtering the colloidal solution with a microfiltration membrane, and drying the obtained filter membrane to form a white chrysotile nanofiber film; and impregnating the chrysotile nanofiber film in vacuum in a UV curing resin, taking out the film, leveling and forming, curing with the UV to obtain the chrysotile nanofiber and resin composite film. The composite transparent film can be applied to substrate materials of organic electroluminescent devices.

Owner:CENT SOUTH UNIV

Flame-retardant fiber non-woven fabric

The invention relates to a flame-retardant fiber non-woven fabric. The flame-retardant fiber non-woven fabric comprises a middle layer, and an upper surface layer and a lower surface layer which are located at two sides of the middle layer, wherein the middle layer is prepared from the following raw materials in parts by weight: 35 to 55 parts of modified cocoanut husk fiber, 5 to 8 parts of chrysotile, 10 to 15 parts of flame-retardant fiber, 3 to 5 parts of modified nano-sized pyrophyllite, 15 to 25 parts of an algae extract and 3 to 5 parts of zinc borate. The composite material non-woven fabric provided by the invention has the following advantages: normal production can be totally realized according to an original production process; and the non-woven fabric has good filtering performance and spinnability, no pulp dripping, good coloring performance, uniform lapping, normal gram weight, high tensile strength, good softening property, bacterium resistance, flame retardancy, good waterproof effect, no toxicity, no stimulation, non-directional strength, and similar vertical and horizontal strength.

Owner:浙江中宇节能科技有限公司

Sump oil filter aid composition

InactiveCN102580680AImprove adsorption capacityFilter aid is beneficialOther chemical processesFiberActivated carbon

The invention relates to sump oil filter aid composition, which is characterized by being composed of the following raw materials by weight part: 0.1 part to 10 parts of kieselguhr, 0.1 part to 10 parts of activated clay, 0.01 part to 0.05 part of graphite powder and 100 parts to 120 parts of sump oil filter aid composition filter sump oil. The sump oil filter aid composition further comprises the following raw materials by weight part: 0.1 part to 1 part of peralite, 0.1 part to 1 part of lignin fiber and 0.1 part to 1 part of chrysotile. The sump oil filter aid composition also comprises the following raw materials by weight part: 0.1 part to 1 part of magnesium oxide, 0.1 part to 3 parts of gypsum and 0.1 part to 1 part of active carbon. The sump oil filter aid composition has the advantages of being low in manufacture cost, convenient to use, quick in filter speed, clean in purification, good in quality of purified oil, convenient to deslagging and the like and has popularization value.

Owner:豆远奎

Paint, preparation method thereof and coating moulding method

InactiveCN102559041AExtended service lifePeeling offPretreated surfacesSpecial surfacesAlcoholAluminium powder

The invention provides a paint, comprising the following components: 35-60 parts by weight of organic silicon dried heat-resisting paint, 35-60 parts by weight of alcohol acid dried heat-resistant varnish, 25-35 parts by weight of crystalline flake graphite, 10-20 parts by weight of chrysotile asbestos, 30-50 parts by weight of air atomized aluminium powder and right amount of diluent, wherein the diluent is amino paint diluent or dimethylbenzene. The invention also provides a preparation method of the paint and a coating moulding method. The paint provided by the invention is formed by mixing the crystalline flake graphite, the organic silicon dried heat-resisting paint and the like, thus the paint has long life after being coated into a coating, no block stripping, foaming or layering phenomenon is caused, and product quality is greatly improved.

Owner:AVIC PST NANFANG GAS TURBINE COMPLETE MFG & INSTALLATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com