Metal wear repairing agent and preparation method thereof as well as lubricating oil

A metal wear and repair agent technology, applied in the direction of lubricating compositions, additives, petroleum industry, etc., can solve the problems of short service life of parts, and achieve the effects of cost reduction, fast production speed, and strong protective layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

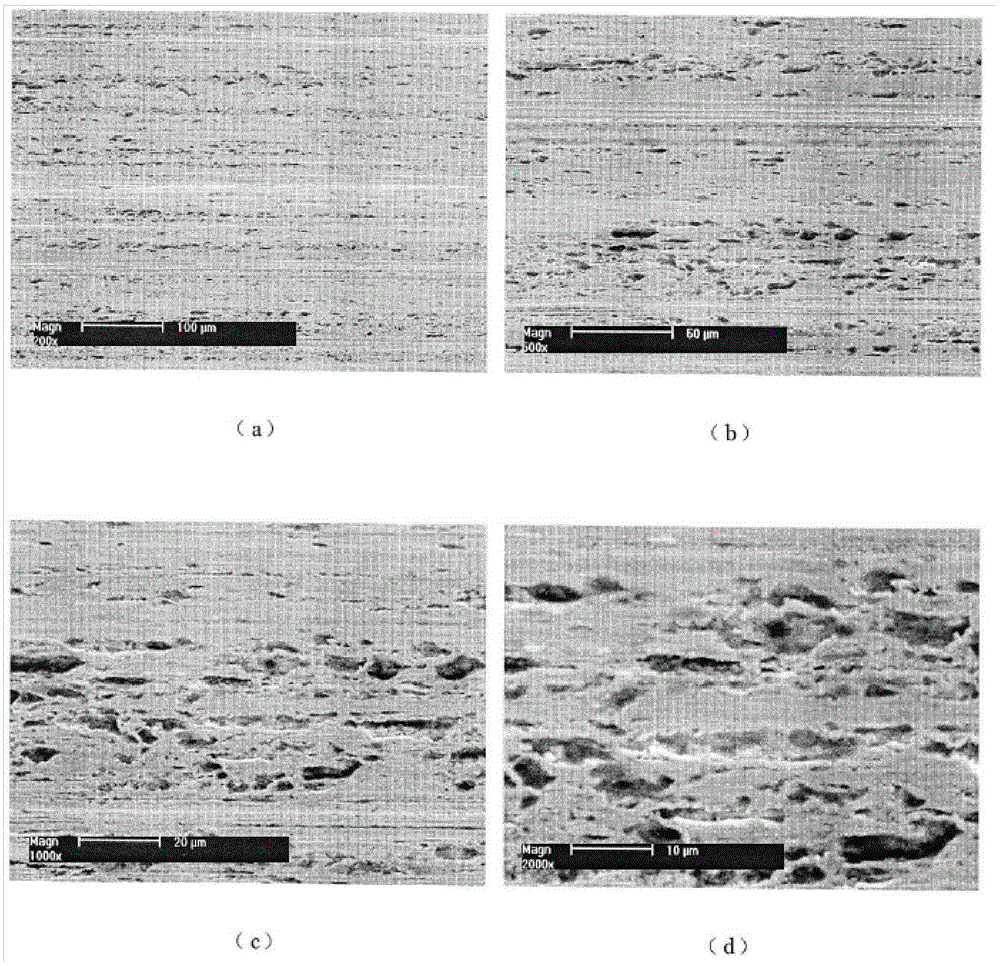

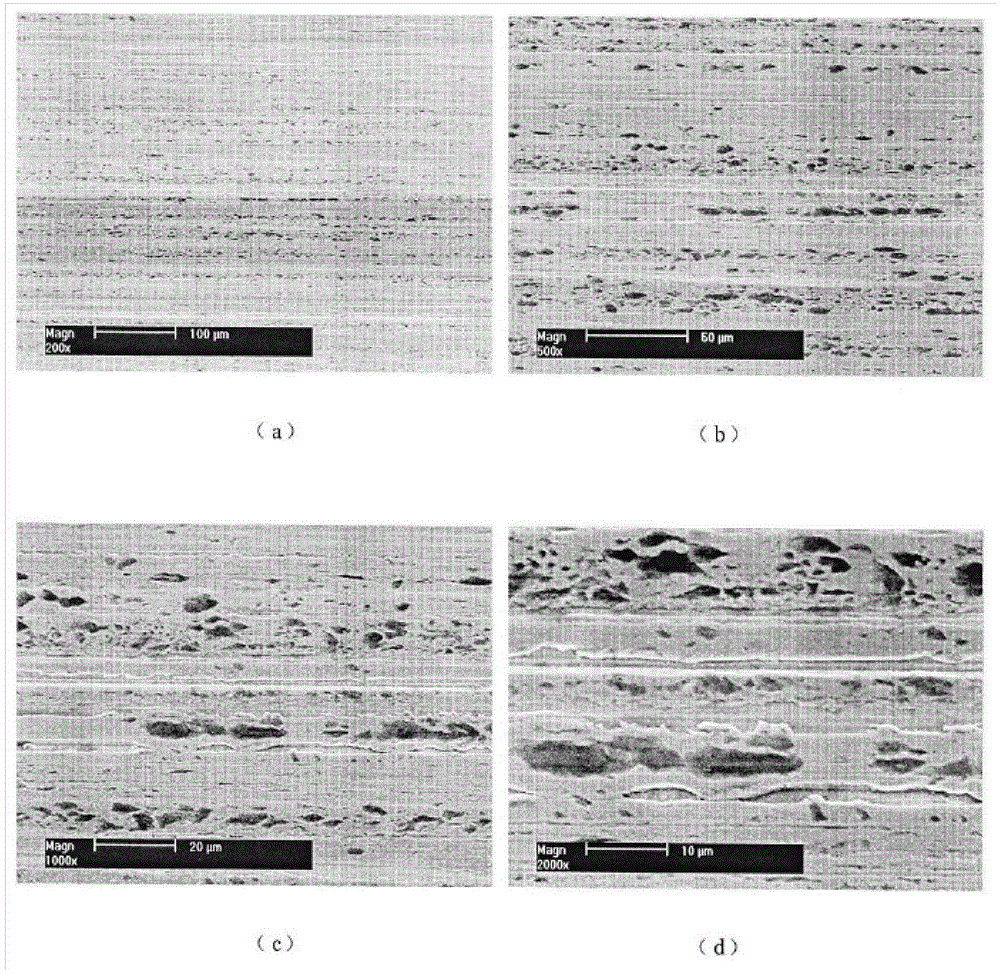

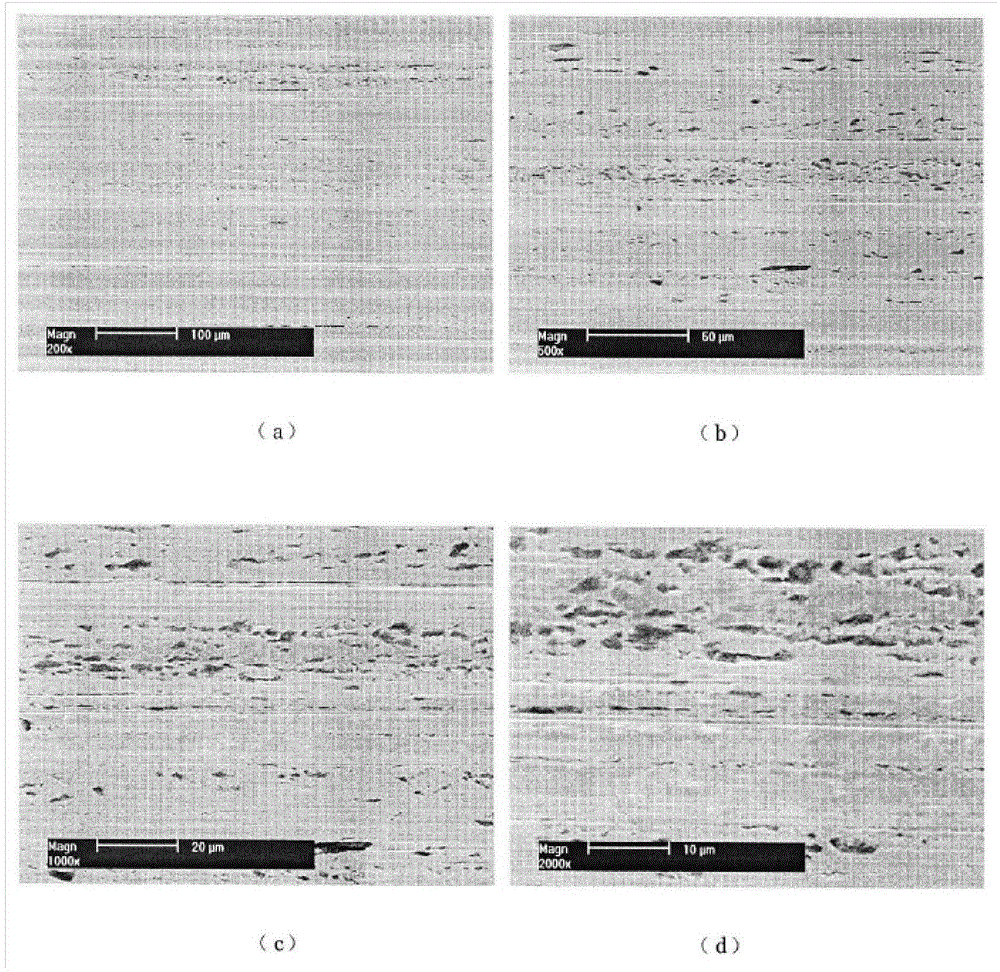

Image

Examples

preparation example Construction

[0051] The preparation method of the above-mentioned metal wear repairing agent comprises the following steps:

[0052] S01: Grinding hydroxysilicate ore, apatite, vermiculite, aluminum chloride, and chrysotile into particles with a diameter less than or equal to 0.05mm;

[0053] S02: Dry the above pulverized particles with a vacuum dryer at 120° for 3 hours to remove moisture and crystal water;

[0054] S03: After adding lanthanum oxide and ferrous oxide powder, grind again for 24 hours until a powdery mixture is obtained.

[0055]In order to improve the homogeneity of the repairing agent, as an improvement of the technical solution, before the pulverized particles are dried in the step S02, the unground large particles can be removed by flotation. Before adding lanthanum oxide and ferrous oxide powder in the step S03, the large iron particles present in the dried particles can be removed by magnetic separation, and of course the above two steps can also exist at the same ti...

Embodiment 1

[0059] A metal wear repairing agent, by weight, consists of the following components, 2 parts of hydroxysilicate ore, 0.7 parts of apatite, 4.5 parts of vermiculite, 0.2 parts of aluminum chloride, 0.2 parts of chrysotile, 0.07g of lanthanum oxide , 0.15 parts of ferrous oxide, which is prepared according to the above-mentioned method.

Embodiment 2

[0061] A metal wear repairing agent, by weight, consists of the following components, 6 parts of hydroxysilicate ore, 0.3 parts of apatite, 5.5 parts of vermiculite, 0.7 parts of aluminum chloride, 1 part of chrysotile, 0.02 g of lanthanum oxide , 0.05 part of ferrous oxide, which is prepared according to the above-mentioned method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com