Patents

Literature

920results about How to "Improve anti-wear performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lubricating oil additive based on single-layer or more-layer graphene

The invention relates to a lubricating oil additive based on single-layer or more-layer graphene, belonging to new high-tech materials and application field thereof and being mainly used for improving the property of lubricating oil. The lubricating oil additive is characterized in that single-layer or more-layer graphene and a dispersing agent are added into base oil, the content of the single-layer or more-layer graphene in the base oil is 0.0001-10 percent by mass, and the content of the dispersing agent in the lubricating oil is 0.001-2 percent by mass. The graphene has high specific surface area and thickness of 0.34-10 nanometers, is shaped as a sheet, is combined with the dispersing agent after being subjected to surface modification, and has excellent stability and dispersity in the base oil without easily precipitating like other additives. Under same filling amount, compared with the sheet graphite and the traditional graphite, more graphene can be absorbed on the secondary surface of the friction, the lubricating and anti-wear property of the base oil is improved, and the bearing capacity is enhanced.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

Lubricating oil composition

ActiveUS20070287643A1Improve wear resistanceEasy to keepOrganic compound preparationLiquid carbonaceous fuelsAniline pointAutomatic transmission

Owner:NIPPON OIL CORP

Lubricating oil compositions

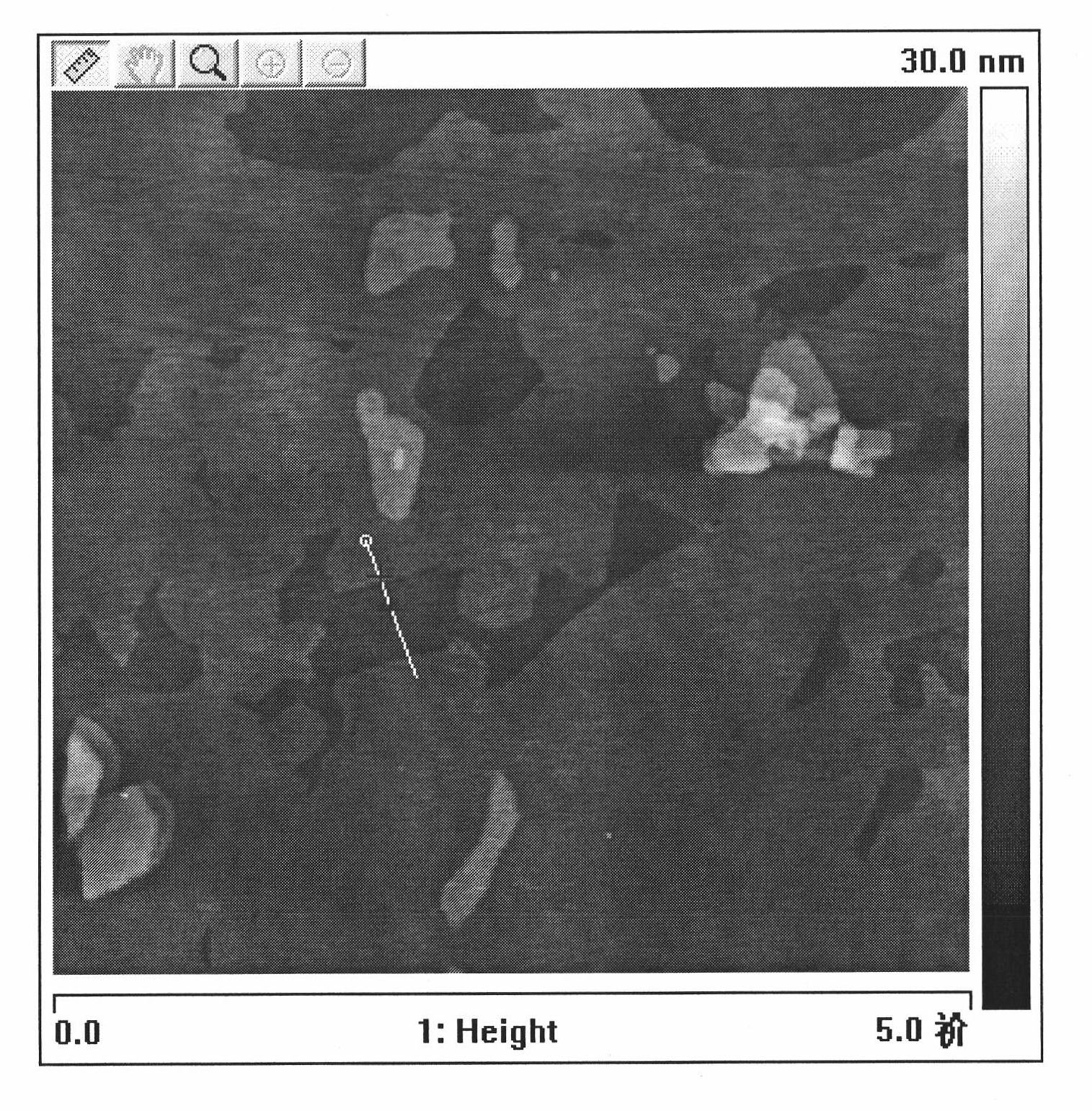

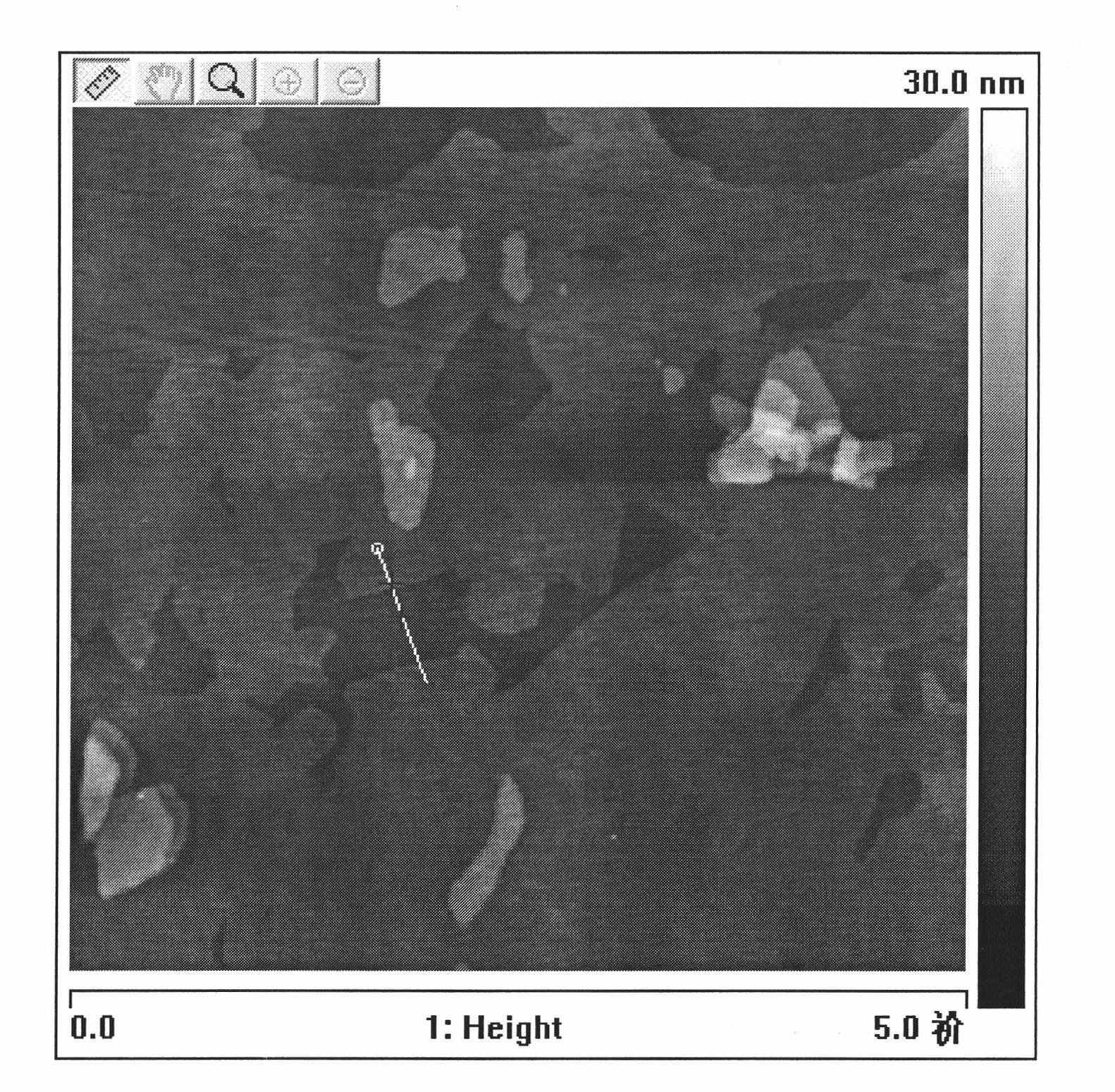

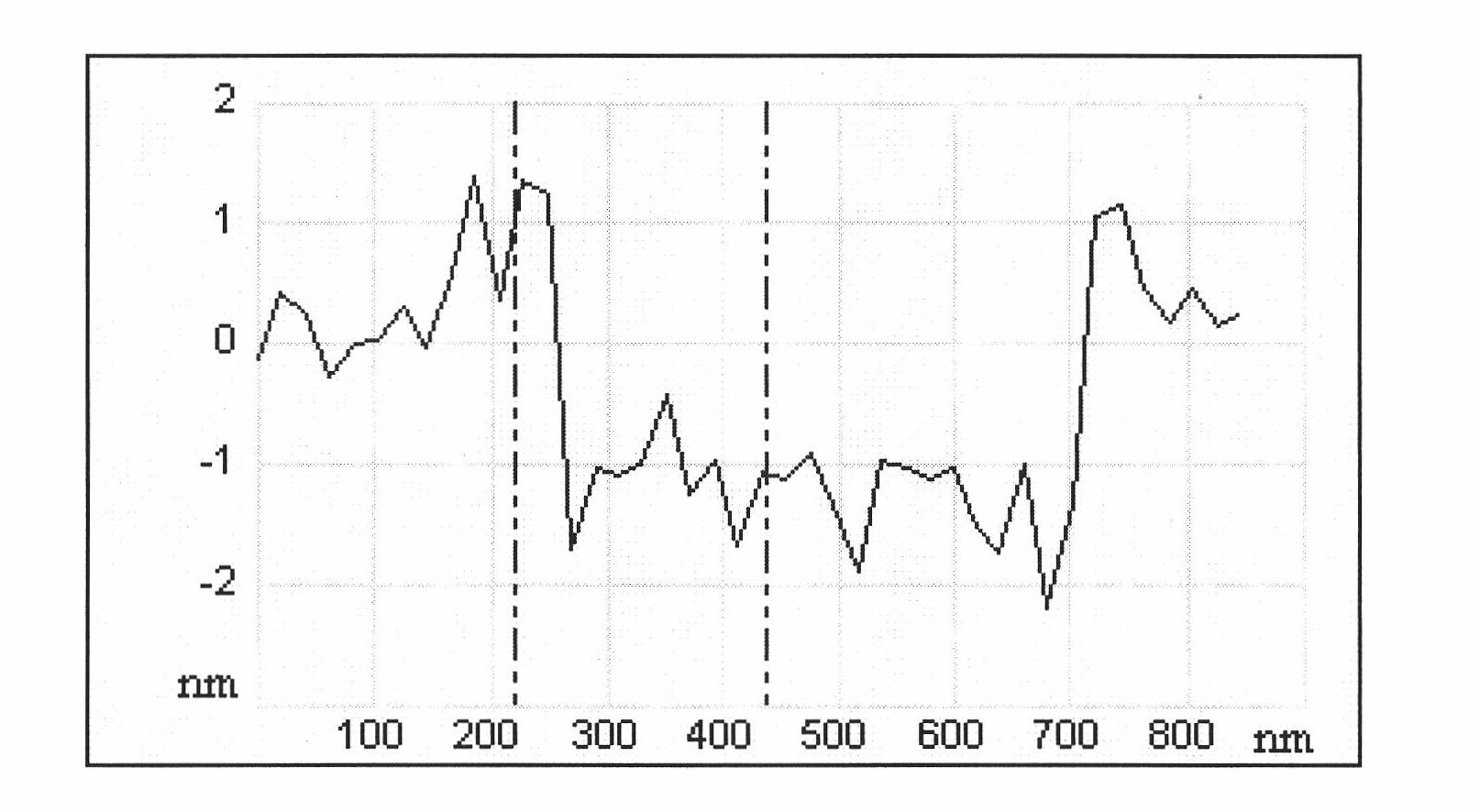

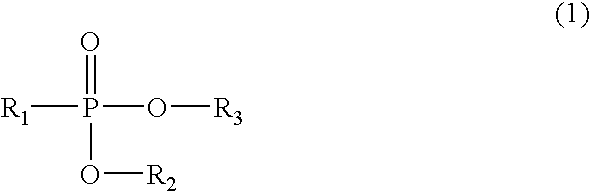

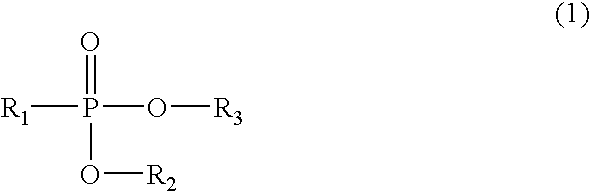

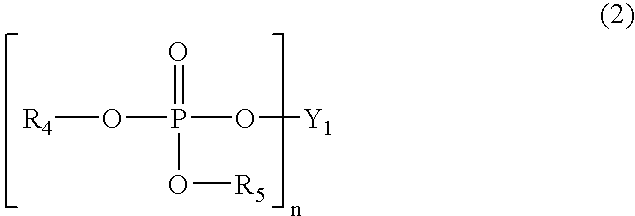

ActiveUS20050143266A1Improve anti-wear performancePhosphorus reductionAdditivesBase-materialsPhosphoric Acid EstersCompound (substance)

A lubricating oil composition is disclosed which comprises a lubricating base oil, (A) at least one type of compound selected from specific phosphoric acid esters and salts thereof or in combination with (B) at least one type of compound selected from specific metal salts of specific phosphoric acid esters, with excellent oxidation stability, base number retention properties, anti-wear properties, extreme pressure properties and anti-corrosion properties and thus can be suitably used, in particular, as a lubricating oil for an internal combustion engine.

Owner:NIPPON OIL CORP

Friction- and wear-reducing coating

InactiveUS20100028641A1Improve tribological propertiesImprove performanceSynthetic resin layered productsVacuum evaporation coatingAlloyHardness

A coating includes a first layer of a ceramic alloy and a second layer disposed on the first layer and including carbon. The coating has a hardness of from 10 to 20 GPa and a coefficient of friction of less than or equal to 0.12. A method of coating a substrate includes cleaning the substrate, forming the first layer on the substrate, and depositing the second layer onto the first layer to thereby coat the substrate.

Owner:EATON CORP

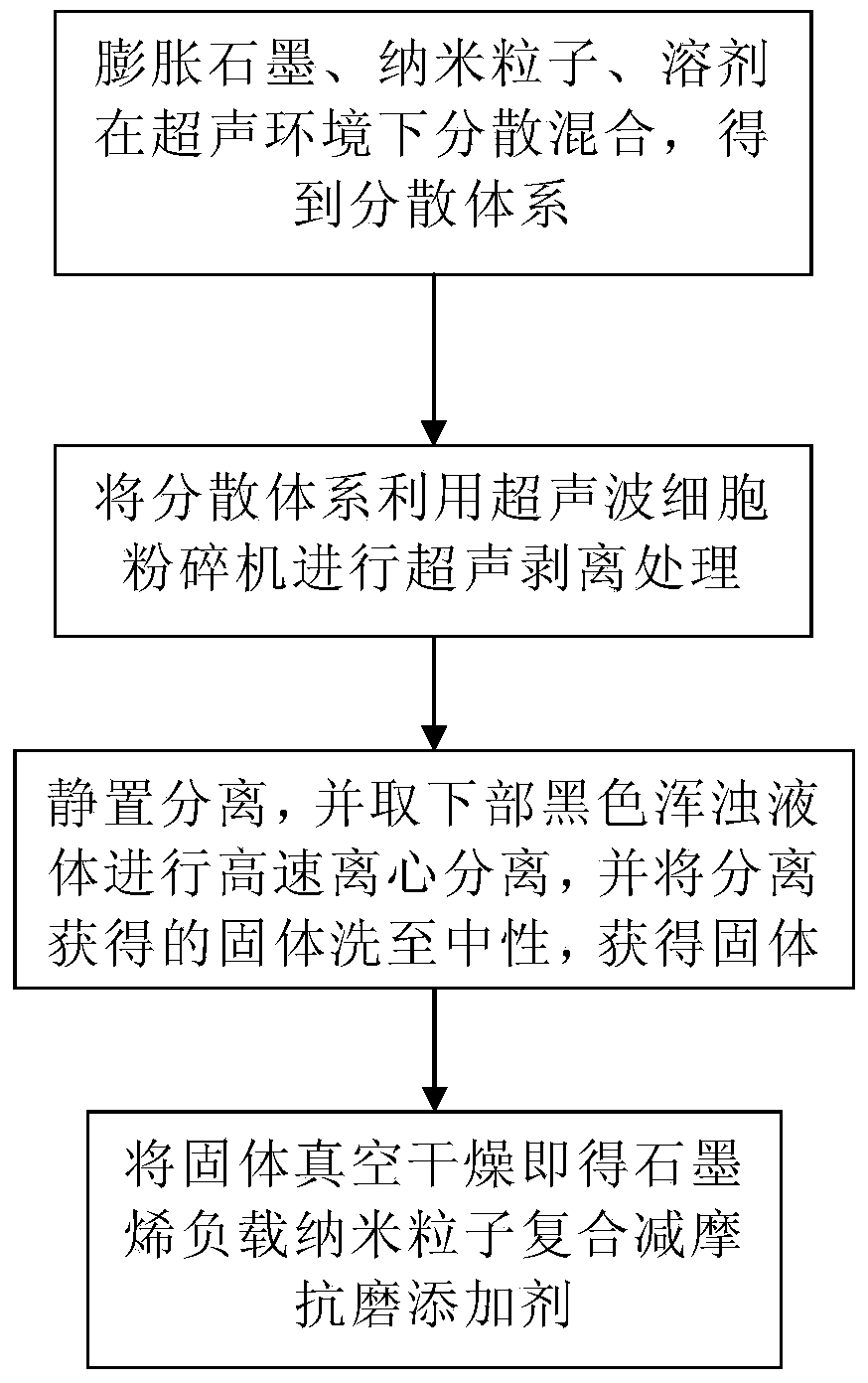

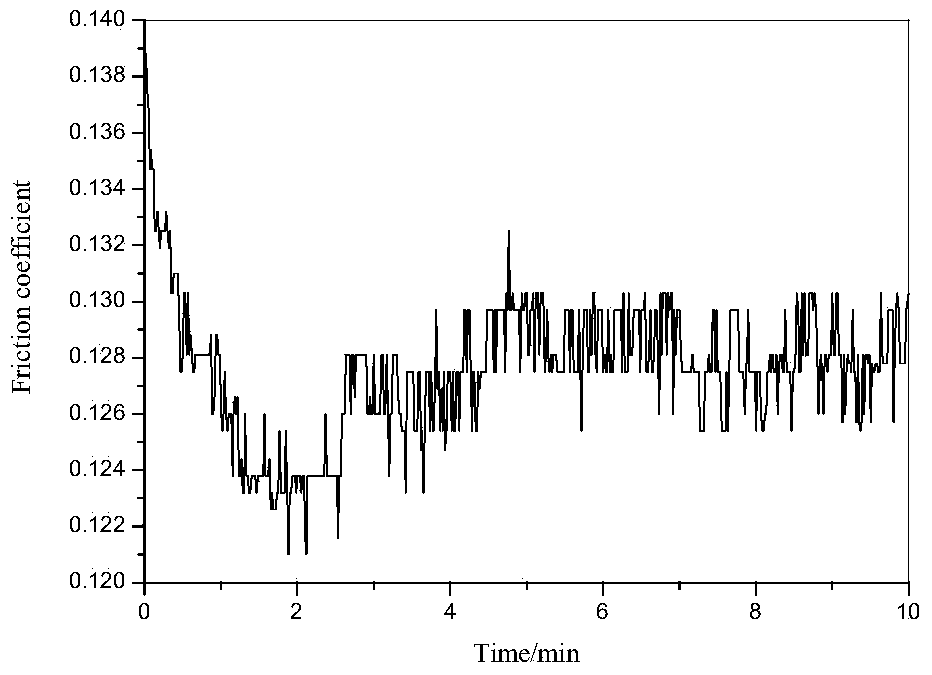

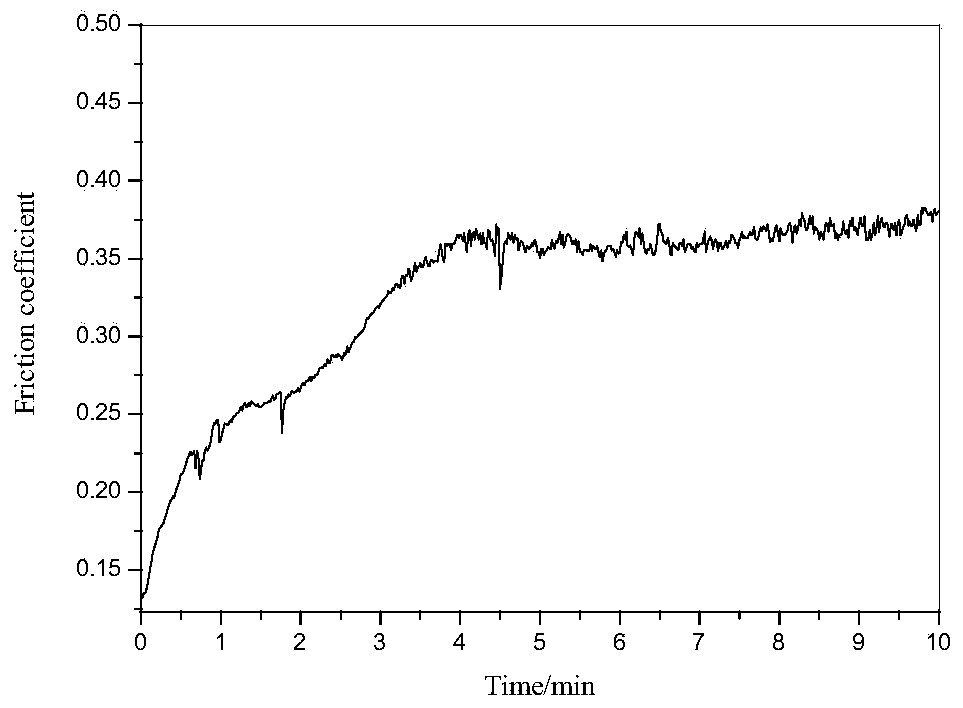

Method for preparing composite anti-friction and anti-wear additive of graphene-loaded nanoparticles

InactiveCN104017628AReduce coefficient of frictionImprove anti-wear performanceAdditivesSolventControllability

The invention discloses a method for preparing a composite anti-friction and anti-wear additive of graphene-loaded nanoparticles. The method comprises the following steps: carrying out ultrasonic dispersion on expanded graphite, nanoparticles and a solvent in an ultrasonic emulsification disperser to obtain an evenly mixed dispersion system A; putting the dispersion system A into an ultrasonic cell crusher to carry out ultrasonic stripping treatment, stripping the expanded graphite into multi-layer graphene sheets by ultrasonic action, and loading the multi-layer graphene sheets and the nanoparticles to obtain a dispersion system B after ultrasonic stripping is ended; standing and separating the dispersion system B, taking out a black troubled liquor at the lower part to carry out high-speed centrifugal separation, and washing the separated solid into neutral property, so as to obtain a solid C; putting the solid C into a vacuum drying oven to dry, so as to obtain the composite anti-friction and anti-wear additive of the graphene-loaded nanoparticles. The method disclosed by the invention is simple and convenient, simple in process, strong in controllability, and applicable to industrial production; the prepared composite anti-friction and anti-wear additive has the characteristics of good stability, low friction coefficient, excellent abrasion resistance and the like, and has a broad application prospect in the field of frictional wear.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Method for preparing graphene lubricating oil additive

The invention relates to a method for preparing a graphene lubricating oil additive and belongs to the technical field of lubricating oil. An oxidized graphene solution is subjected to centrifugal separation at low speed, supernatant is obtained, and the supernatant is dried at low temperature to obtain oxidized graphene powder; the oxidized graphene powder is heated in vacuum to be constantly dry, oxidized graphene powder is obtained and mixed with a dispersing agent and basic oil, after uniform mixing, the mixture is placed in a high-temperature high-pressure reaction kettle to be processed, oleophylic graphene is obtained, and the graphene lubricating oil additive is obtained by mixing the oleophylic graphene, the dispersing agent and the basic oil or mixing the oleophylic graphene with finished lubricating oil. The technology is simple and convenient, cost is reduced, all components have excellent dispersity and stability, and the problem about long-time stability of nano additives is solved. When lubricating oil where the additive is added is applied to mechanical operation, the abrasion resistance and bearing capacity of mechanical devices can be improved, and meanwhile the surfaces of the mechanical devices can be protected and highly repaired.

Owner:TANGSHAN XIRUN SCI TECH DEV CO LTD

Self-lubricating composite gasket for bearing and preparing method for gasket

InactiveCN102535167AEasy to pasteReduce coefficient of frictionFibre treatmentBearing componentsPolyesterPolymer science

The invention discloses a self-lubricating composite material gasket for a bearing and a preparing method for the gasket. A fiber mixed fabric is formed by weaving PTFE (polytetrafluoroethylene) fiber with at least one type of other fiber; an impregnated material is coated on the surface of the fiber mixed fabric; the final thickness of the fiber mixed fabric is 0.30 to 0.55 mm; the thickness of the gasket is 0.35 to 0.60 mm; the weight ratio of the PTFE fiber to the gasket is 0.3 to 0.7; and the other types of fibers can be any one or a few of aramid fiber, carbon fiber, high-strength polyester fiber and cotton fiber. The self-lubricating gasket has the characteristics of high strength and low friction coefficient, and is suitable to be used in heavy-duty occasions under the temperatures ranging from -50 to 180 DEG C.

Owner:JIANGSU CCVI BEARING

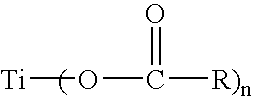

Titanium-containing lubricating oil composition

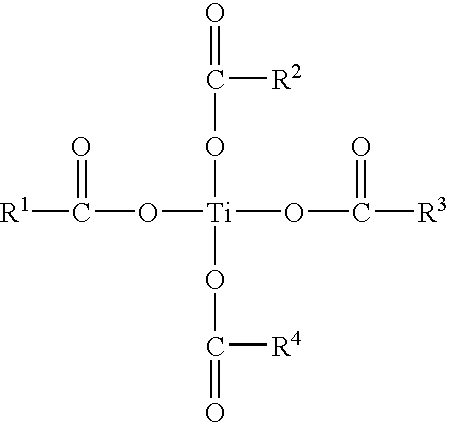

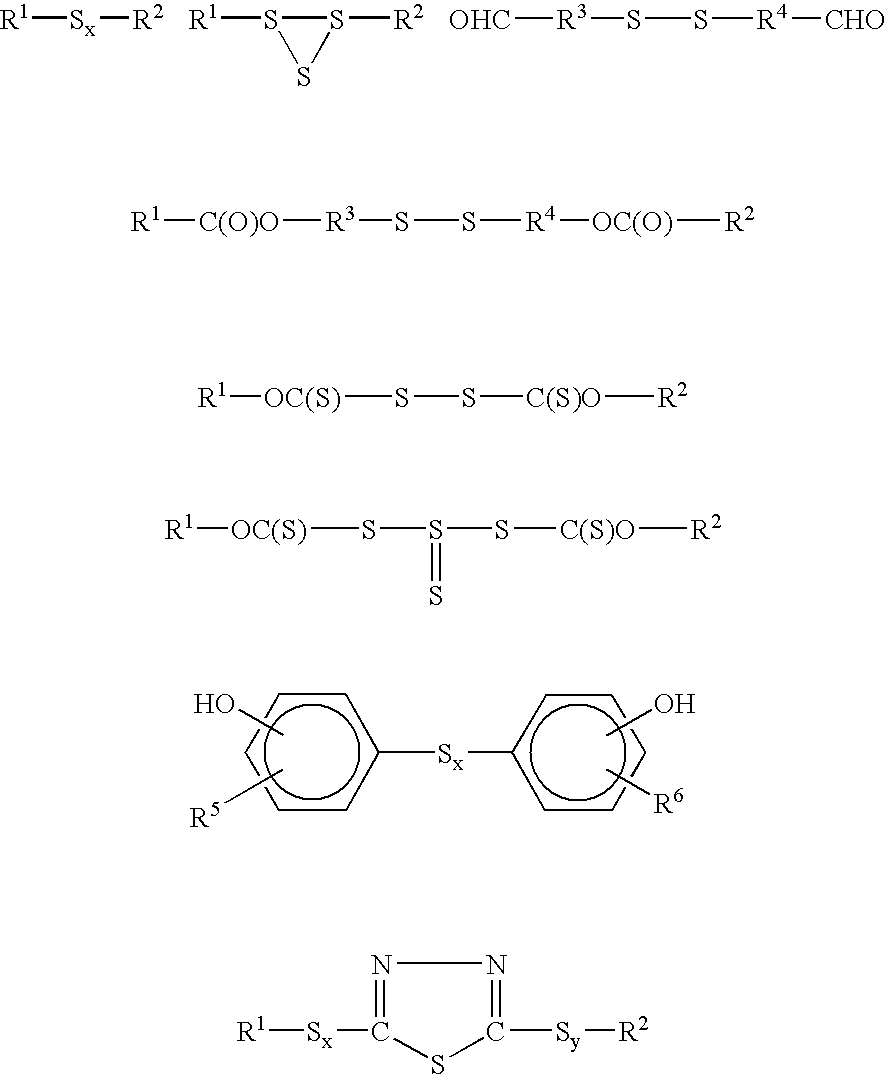

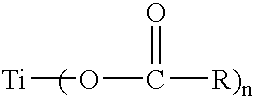

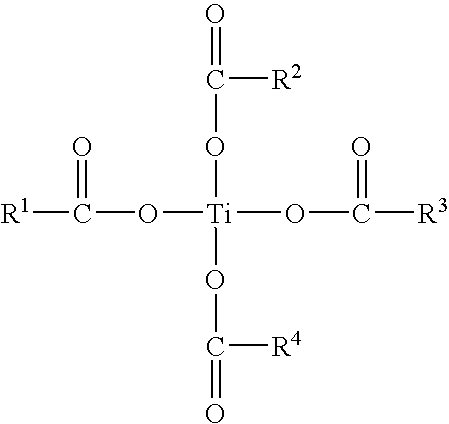

ActiveUS20070132274A1Improve fuel economyImprove wear characteristicsVehicle seatsWindowsTitanium metalPhysical chemistry

A lubricating oil composition comprising a) an oil of lubricating viscosity having a viscosity index of at least about 95; b) at least one calcium detergent; c) at least one oil soluble titanium compound; d) at least one friction modifier; and e) at least one metal dihydrocarbyldithiophosphate compound. The composition has a Noack volatility of about 15 wt. % or less, and contains from about 0.05 to about 0.6 wt. % calcium from the calcium detergent, titanium metal in an amount of at least about 10 ppm up to about 1500 ppm titanium from the titanium compound, and phosphorus from the metal dihydrocarbyldithiophosphate compound in an amount up to about 0.1 wt. %.

Owner:AFTON CHEMICAL

Titanium-containing lubricating oil composition

ActiveUS20070111908A1Improved performance characteristicsImprove featuresMixingAdditivesImideMolybdenum compounds

A fully formulated lubricating oil, lubricated surface, and lubricant additive concentrates for lubricants providing reduced sludge formation. The fully formulated lubricating oil composition has therein at least one succinimide dispersant derived from a polyalkylene compound having from about 50 to about 85% vinylidene double bonds in the compound, a metal containing detergent, at least one wear reducing agent, at least one antioxidant, and a hydrocarbon soluble titanium compound as a friction modifier. The lubricating oil composition is also substantially free of molybdenum compounds.

Owner:AFTON CHEMICAL

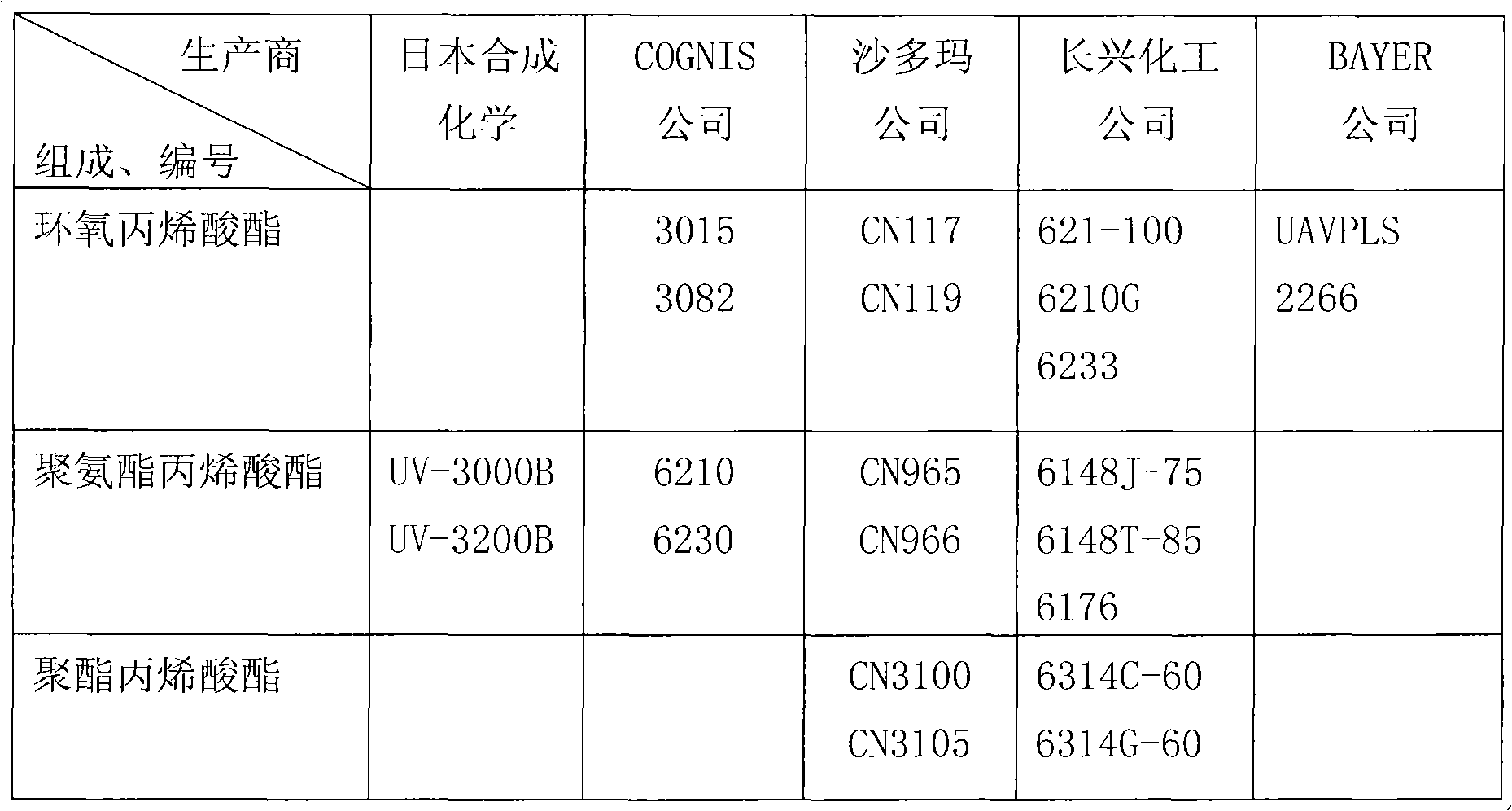

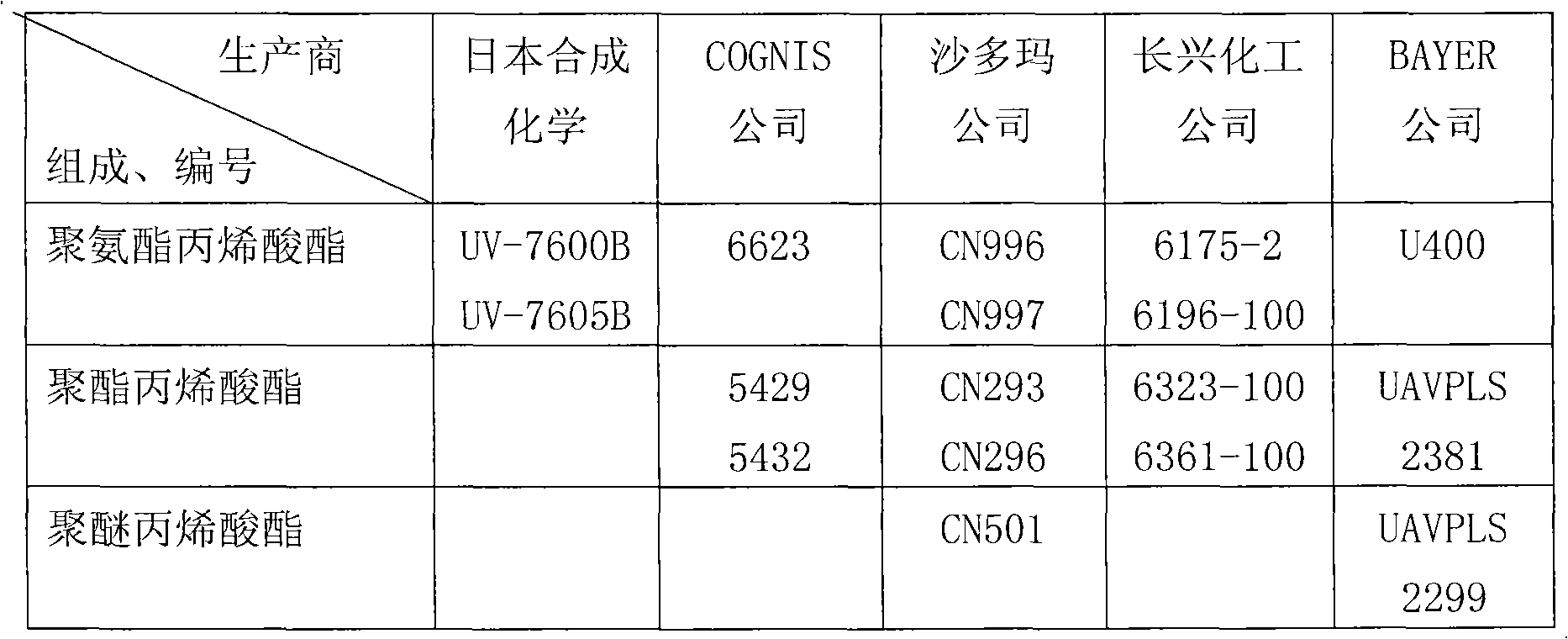

Ultraviolet cured coating and application thereof

InactiveCN101837667AImprove anti-wear performanceSurface Protection BenefitsLiquid surface applicatorsSynthetic resin layered productsAntioxidantUltraviolet

The invention belongs to the technical field of coating compositions and solves the problems of decreased adhesion of the coating to the magnesium alloy surface and easy ageing and cracking of the coating in the prior art. An ultraviolet cured coating comprises the following components in percentage by weight: a hardened first coat comprising 6 to 18 percent of low-functionality monomer, 30 to 51 percent of low-functionality prepolymer, 5 to 8 percent of alumina powder; 0.5 to 1.5 percent of antioxidant, less than 3 percent of auxiliary agent, 1 to 3 percent of photoinitiator and 18 to 35 percent of mixed solvent, an intermediate coat comprising 3 to 15 percent of low-functionality monomer, 35 to 57 percent of low-functionality prepolymer, 0.5 to 6 percent of transparent pigment, 1 to 4 percent of auxiliary agent, 1 to 3 percent of photoinitiator and 23 to 45 percent of mixed solvent, and a high-gloss cover coat comprising 1 to 8 percent of low-functionality monomer, 8 to 15 percent of low-functionality prepolymer, 10 to 22 percent of high-functionality monomer, 36 to 45 percent of high-functionality prepolymer, 1 to 4 percent of auxiliary agent, 3 to 5 percent of photoinitiator and 20 to 40 percent of mixed solvent.

Owner:惠州市嘉淇涂料有限公司

42CrMoE thermal treatment technique

ActiveCN101368275AHigh surface hardnessImprove surface wear resistanceSolid state diffusion coatingFurnace typesMiddle frequencyCase hardening

The invention belongs to a heat processing technique of 42CrMoE material used for a reciprocating compressor. The technique is suitable for the heat processing technique for the 42CrMoE piston rods used for all the reciprocating compressors and can also be applied to the mechanical devices which require high rigidity, wear resistance and corrosion resistance. The invention can solve the problems of cracks, low surface hardening rigidity as well as poor wear resistance, poor acid resistance and poor corrosion resistance generated when the traditional surface heating processing technique is applied to the 42CrMoE piston rod, and the like. The invention includes the forging and shaping, hardening and tempering, stabilizing, nitriding, middle frequency or high frequency quenching as well as low temperature annealing of the 42CrMoE material; a surface compounded heat processing technology combined with nitriding and middle frequency or high frequency quenching is adopted: the 42CrMoE material is arranged in a nitriding furnace; ammonia gas is pumped in after the treatments of temperature rising and pro-oxidation to carry out nitriding treatment; then the middle frequency or high frequency quenching on the surface is carried out. The heat processing technique can be adopted to completely prevent the quenching cracks generated during the traditional high frequency quenching, improve the surface rigidity to be more than HRC60, improve the wear resistance by 34 percent and improve the acid and corrosion resistance by 40 percent.

Owner:SHENYANG BLOWER WORKS GROUP CORP

Preparation method of high-strength and antioxidant rare-earth-based smoke denitration catalyst

ActiveCN104209117AReduce escape rateReduce productionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCeriumGlass factory

The invention discloses a preparation method of a high-strength and antioxidant rare-earth-based smoke denitration catalyst. The preparation method of the high-strength and antioxidant rare-earth-based smoke denitration catalyst comprises the following steps: by taking titanium dioxide and montmorillonite as carriers and ammonium metatungstate, cerous nitrate and lanthanum nitrate as active components, mixing, ageing, kneading, forming, drying and roasting with the accompanying of auxiliary materials. The auxiliary materials comprise ammonia water, lactic acid, citric acid, stearic acid, glass fiber, wood pulp, hydroxypropyl methyl cellulose, polyoxyethylene, monoethanolamine and water. The product prepared by the method is separated under a high SO2 smoke condition, nitric oxide in the smoke can be decomposed; meanwhile, the purpose of removing mercury and dioxin can be achieved. According to the preparation method of the high-strength and antioxidant rare-earth-based smoke denitration catalyst, the rare earth elements, namely cerium and lanthanum are used as the active components, so that the addition amount of vanadium is reduced, the toxicity of the product is reduced or the product is non-toxic product, the pressure of the post treatment of the product is reduced; the environmental protection pressure is reduced; the product is environmentally friendly; the product can be widely used in the field of thermal power plants, glass factories and chemical plants.

Owner:山东信义汽车配件制造有限公司

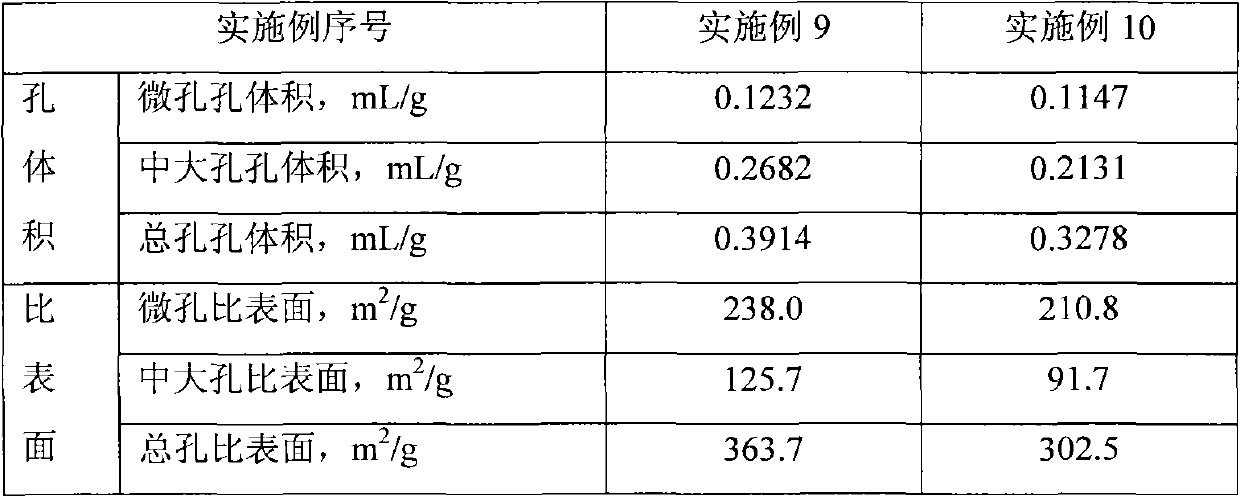

Method for improving pore structure of kaolin microsphere in-situ crystallization product

ActiveCN102019196AHigh molecular weightRegular structureMolecular sieve catalystsCatalyst activation/preparationPolyvinyl alcoholMicrosphere

The invention relates to a method for improving the pore structure of a kaolin microsphere in-situ crystallization product. The method comprises the following steps of: preparing kaolin spray microspheres with the particle sizes of between 20 and 110 mu m by using mixed kaolin grout by spray drying, wherein the mixed grout comprises kaolin, deionized water, a dispersant and an organic pore cannelforming template agent; the dispersant is sodium silicate or sodium pyrophosphate; and the organic pore cannel forming template agent is polyvinyl pyrrolidone or polyvinyl alcohol; baking the spray microspheres at the temperature of between 900 and 1,100 DEG C for 1 to 3 hours so as to obtain kaolin baked microspheres; mixing the kaolin baked microspheres with the mullite content of between 2 and12 percent, sodium silicate, a directing agent, solution of sodium hydroxide and deionized water; crystalizing the mixture at the temperature of between 90 and 95 DEG C for 16 to 36 hours; and filtering and drying so as to obtain a crystallization product which has a medium / large-pore structure and comprises a NaY molecular sieve. The crystallization product has a well-developed large-pore structure and the abrasion index of not more than 1.5 percent and comprises 20 to 50 percent of NaY molecular sieve.

Owner:PETROCHINA CO LTD +1

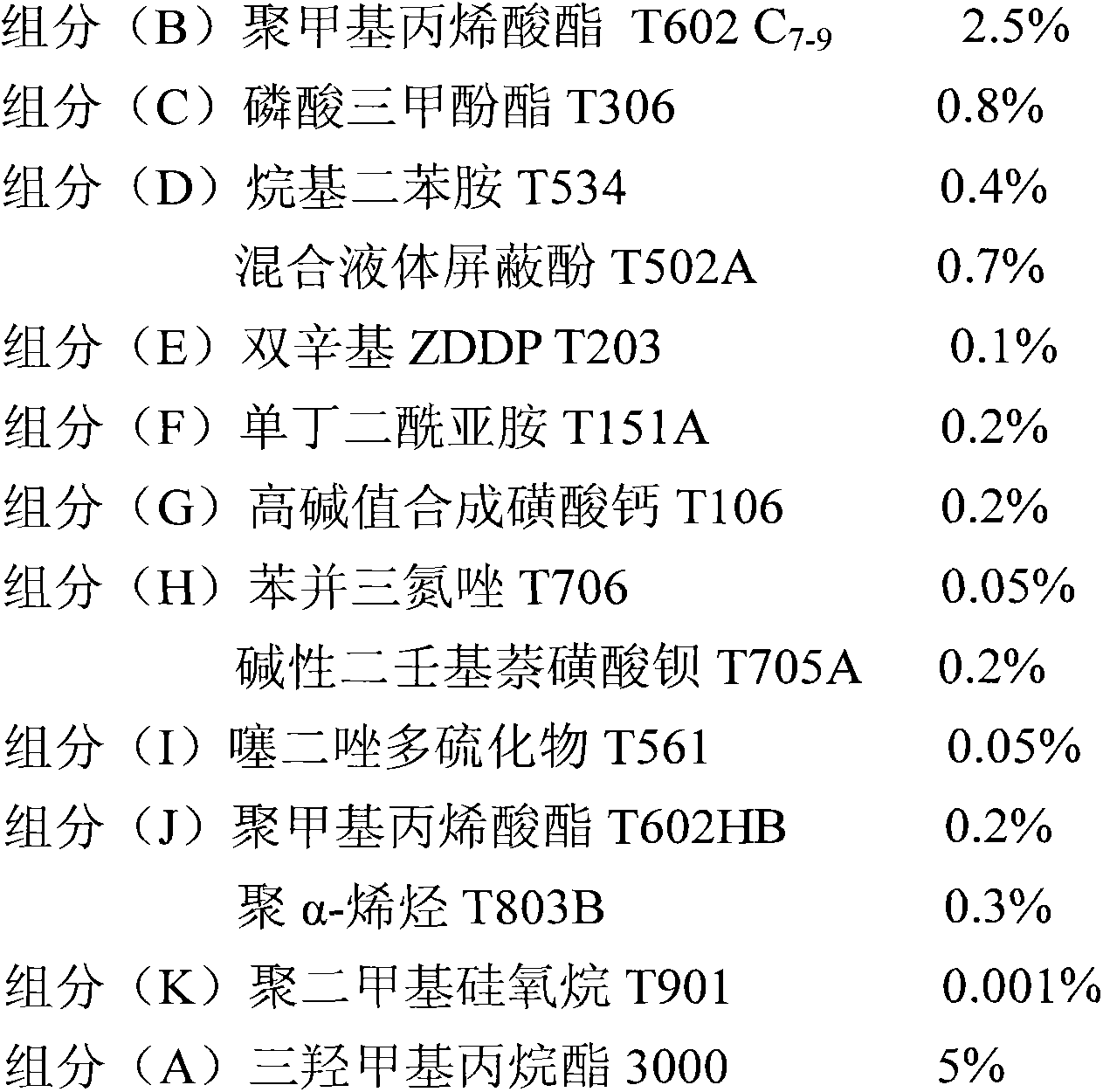

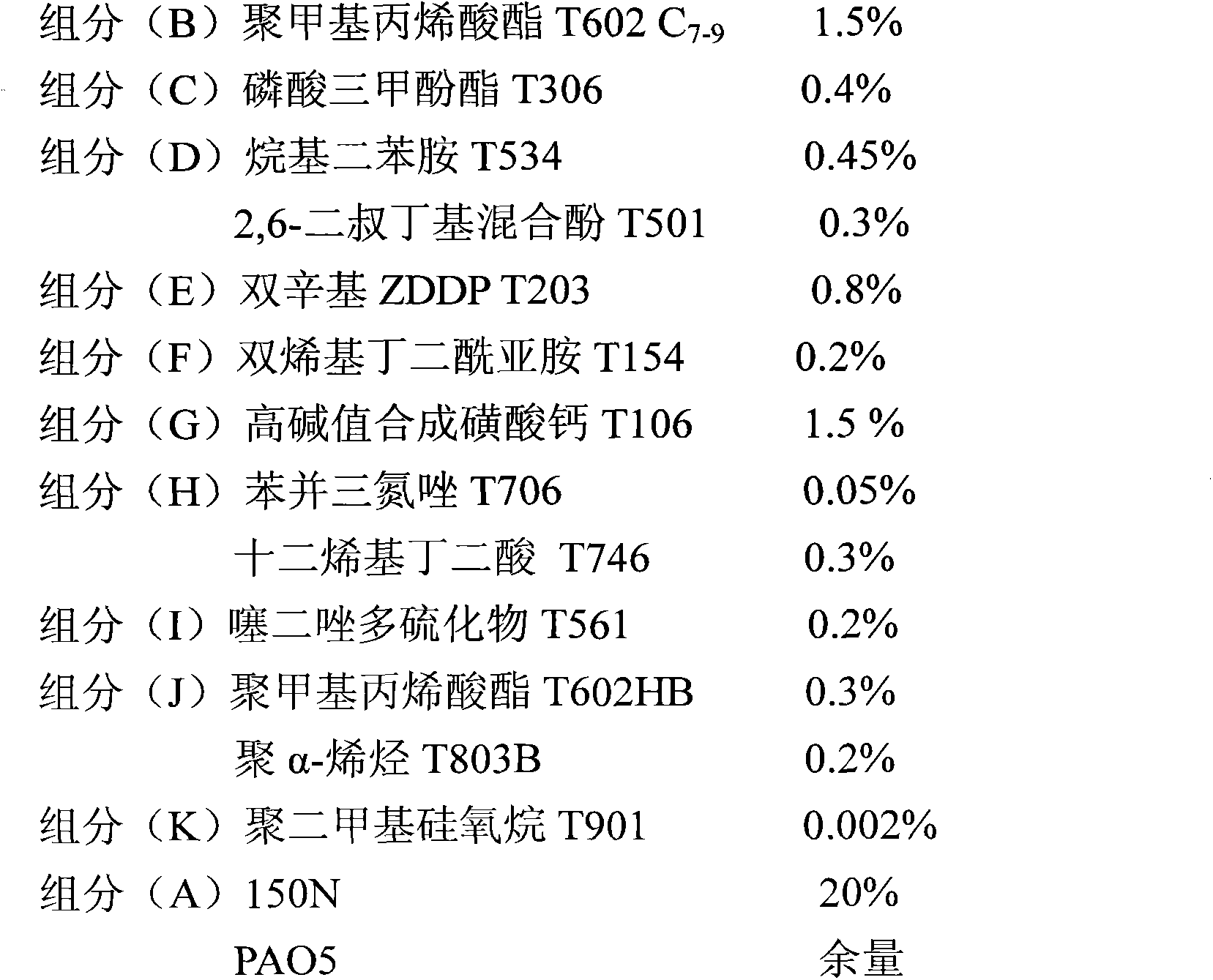

Automobile automatic transmission fluid

InactiveCN103980984AExcellent antioxidantImprove wear resistanceAdditivesAutomatic transmission fluidViscosity index

The invention relates to an automobile automatic transmission fluid, and mainly aims at solving the problems of non ideal wear resistance and antioxidant properties of automobile automatic transmission fluids in the prior art. The composition comprises base oil accounting for 85.0 to 97.0% of the total weight; a viscosity index improver accounting for 0.2 to 10.0% of the total weight; an anti-wear reagent at extreme pressure, accounting for 0.2 to 2.0% of the total weight; an antioxidant accounting for 0.05 to 2.0% of the total weight; an antioxidant anticorrosion anti-wear agent accounting for 0.02 to 1.0% of the total weight; a dispersant accounting for 0.1 to 3.0% of the total weight; a detergent accounting for 0.05 to 2.0% of the total weight; an anti rust agent accounting for 0.05 to 3.0% of the total weight; a metal deactivator accounting for 0.02 to 3.0% of the total weight; a pour point depressant accounting for 0.2 to 8.0% of the total weight; and an antifoaming agent accounting for 0.0001 to 0.02% of the total weight. The automobile automatic transmission fluid has the advantages of good antioxidant anticorrosion anti-wear properties.

Owner:LIAONING RUNDI AUTOMOTVE ENVIRONMENTAL PROTECTIONTECH

Waterproof high-gloss waterborne gloss oil for corrugated case and preparation method thereof

ActiveCN102517982AImprove waterproof performanceHigh glossDefoamers additionPaper coatingWaxPolymer science

The invention discloses a waterproof high-gloss waterborne gloss oil for a corrugated case and a preparation method thereof. The gloss oil is prepared from the following raw materials by mass: 50 to 69% of organosilicon modified styrene-acrylic acid ester emulsion, 16 to 30% of styrene-acrylate resin liquid, 3 to 8% of high gloss wax emulsion, 1 to 3% of waterproof wax emulsion, 5 to 10% of water and 0.1 to 0.3% of an antifoaming agent. The preparation method comprises the following steps: at normal temperature, adding the organosilicon modified styrene-acrylic acid ester emulsion at first, then at a rotating speed of 800 to 900 r / min, slowly adding the styrene-acrylate resin liquid, the high gloss wax emulsion, the waterproof wax emulsion and water in sequence under stirring, adjusting the rotating speed to be 400 r / min in 5 min, adding the antifoaming agent and carrying out dispersing for 5 min so as to allow all the raw materials in a system to be uniformly dispersed. The waterborne gloss oil has high water resistance, high gloss and wear resistance, is applicable to glazing of a variety of corrugated cases and enables the corrugated cases to meet requirements for beautiful appearance, moisture resistance and wear resistance.

Owner:GUANGDONG YINGKE GRP CO LTD

Nanometer fuel oil addition agent

ActiveCN1737090AReduce equipment wear and tearImprove lubricationLiquid carbonaceous fuelsFuel oilEngineering

Disclosed is a nanometer fuel oil addition agent, wherein the constituents comprises (by weight percent): rare earth powder 0.1-10%, fuel synergistic agent 1-10%, dispersing agent 1-20%, oleinic acid 1-10%, castor oil 1-20%, and balancing white oil.

Owner:上海集能化工有限公司

Wear-resisting ceramic coating for non-stick cookware and preparation method thereof

The invention discloses a wear-resisting ceramic coating for non-stick cookware and a preparation method thereof. The coating is composed of a component A and a component B, wherein the weight ratio of the component A to the component B is (2.8-3.2): (1.8-2.0); the component A is composed of silicon dioxide sol, aluminum oxide sol, zirconium oxide sol, water soluble polyester modified epoxy resin, ultrafine aluminum oxide powder processed by azeotropic distillation method, black iron oxides, ultrafine spherical ceramic powder, isopropyl alcohol, deionized water, hydroxyethyl cellulose acetate butyrate and fluorosilicon oil; and the component B is composed of methyl triethoxysilane, amino dimethyldiethoxylsilane, dimethyl dimethoxy silicane, isopropyl alcohol and alcohol. The preparation method comprises the following steps of: mixing the component A and the component B of the coating in a weight ratio of (2.8-3.2): (1.8-2.0); and hermetically stirring and curing the obtained mixture for at least 3 hours under the conditions of 35 DEG C and 800-1000 rpm, thereby obtaining the coating. According to the invention, through carrying out polycondensation reaction on metal oxide colloids and polysiloxane, the bonding strength of a film forming matter is improved.

Owner:JIANGMEN ANNUOTE COOKING UTENSILS MFG

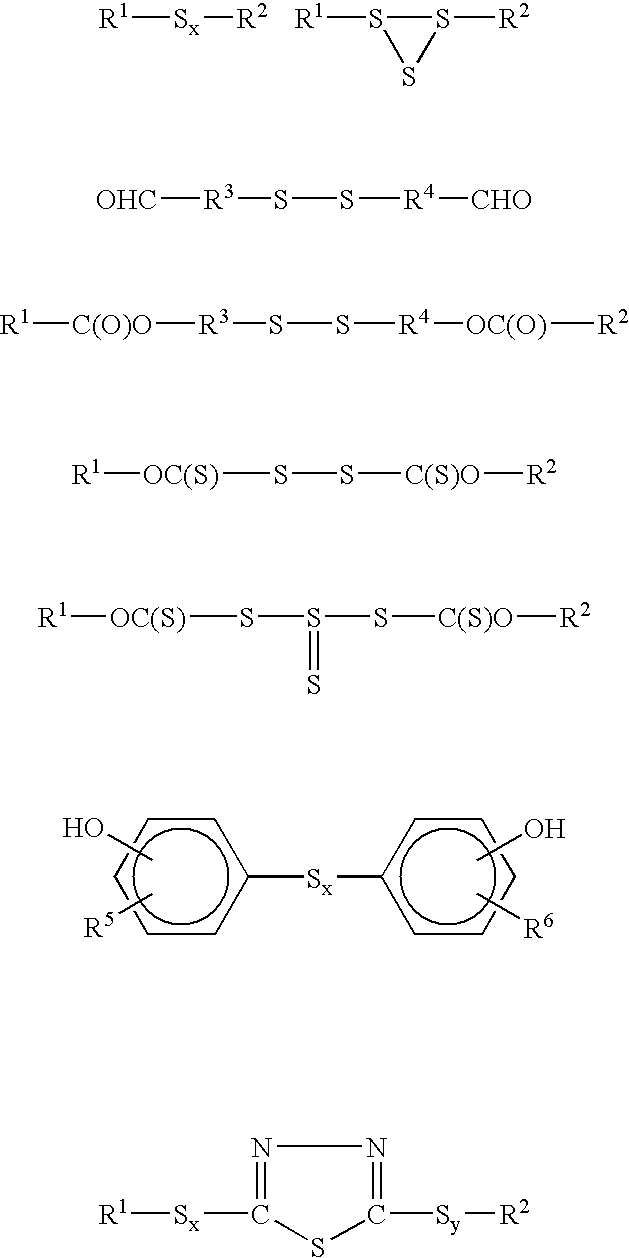

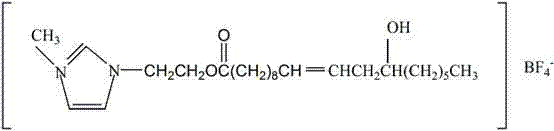

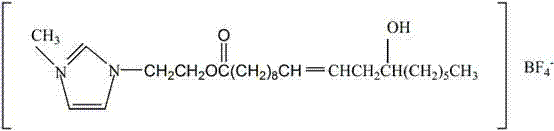

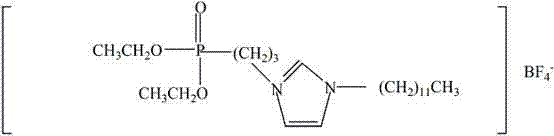

Composite extreme pressure anti-wear agent and total-synthesis anti-wear hydraulic oil containing same

ActiveCN102776053AExcellent friction reductionImprove wear resistanceAdditivesTetrafluoroborateBase oil

The invention discloses a composite extreme pressure anti-wear agent and total-synthesis anti-wear hydraulic oil containing the composite extreme pressure anti-wear agent, belonging to the field of production of lubricating oil. The hydraulic oil is mainly prepared by mixing aqueous base oil and the composite extreme pressure anti-wear agent, wherein the composite extreme pressure anti-wear agent is a compound of two kinds of imidazolyl tetrafluoroborate ion liquid. Compared with the prior art, the total-synthesis anti-wear hydraulic oil has the characteristics of excellent lubricating performance, energy saving, environment friendliness and the like and has high popularization and application values.

Owner:SHANDONG YUANGEN PETROLEUM CHEM

Process for producing formaldehyde-removing solid wood flooring

ActiveCN101804655AReduce energy consumptionTake advantage ofLiquid surface applicatorsWood compressionSolid woodWear resistant

The invention relates to a process for producing formaldehyde-removing solid wood flooring. The process comprises the following steps of: forming a solid wood flooring block, sanding the block, removing dust, coloring, coating UV putty coat I, solidifying I, sanding I, coating UV putty coat II, solidifying II, sanding II, coating wear resistant base coat, semi-solidifying I, coating transparent UV base coat, solidifying III, sanding III, coating UV finishing coat, semi-solidifying II, coating formaldehyde-removing UV wear resistant finishing coat, solidifying IV, and forming the finished product. The solid wood flooring produced by the process has the advantages of good colour and lustre, clear texture, high anti-bending static bending strength, good surface abrasion resistance, stable size, small deformation and special effects on adsorbing and degrading free formaldehyde in indoor air.

Owner:临江市宝健木业有限责任公司

Lubricating oil wear resistant additive, and preparation method and application thereof

InactiveCN104711077AImprove anti-wear performanceWith repair functionAdditivesMolybdateWear resistant

The invention discloses a lubricating oil wear resistant additive. The lubricating oil wear resistant additive comprises, by mass, 70-80% of base oil, 5-10% of organic molybdate, 1-3% of sorbitan monooleate, 0.7-0.8% of zinc diamyldithiocarbamate, 1-3% of nanometer graphene, and the balance of additives. The lubricating oil wear resistant additive has wear resistance and reduction effects on various lubricating oils, has a restoration function, can reduce the mechanical work noise and power loss, and is suitable for any brand of machine oils, gear oils, hydraulic oils, track oils and other lubricating oils. The invention also discloses a preparation method of the lubricating oil wear resistant additive. The method comprises the following steps: mixing nanometer graphene with sorbitan monooleate, carrying out ultrasonic dispersion, adding base oil, organic molybdate, zinc diamyldithiocarbamate and the additives, and uniformly stirring. The preparation method has the advantages of simple process steps, low cost, and suitableness for industrial production.

Owner:上海恒扬新能源科技发展有限公司

Self-crosslinking polyacrylate rubber latex, preparation method thereof and water-based paper printing ink

InactiveCN101870793APrevent sticking backFast dryingPaper coatingCoatingsWater basedHydrophilic monomer

The invention discloses self-crosslinking polyacrylate rubber latex, a preparation method thereof and water-based paper printing ink. The self-crosslinking polyacrylate rubber latex is prepared by the following steps: mixing an acrylic ester monomer, a hydrophilic monomer and ADH in a head tank A; mixing water, an emulsifier, the acrylic ester monomer and DAAM in a head tank B; adding water, the emulsifier and polymerizable self-emulsifying functional monomer, stirring the mixture, heating the mixture to 75 DEG C, and dripping a mixture in the head tank A and an initiator to prepare a protective colloid first; dripping the mixture in the head tank B and the initiator at 85 DEG C; and performing a constant-temperature reaction. The water-based paper printing ink is prepared by the following steps: dissolving a phenylethylene-acrylic acid polymer and a pH value regulator in water at 60 DEG C with stirring; adding a pigment and necessary assistant and mixing the mixture to prepare color paste; and uniformly mixing the color paste with the self-crosslinking polyacrylate rubber latex, a surface tension regulator and water. The water-based paper printing ink can be diluted by one or a mixture of two of water and ethanol, can be dried quickly and has high printing adaptability.

Owner:SUN YAT SEN UNIV +1

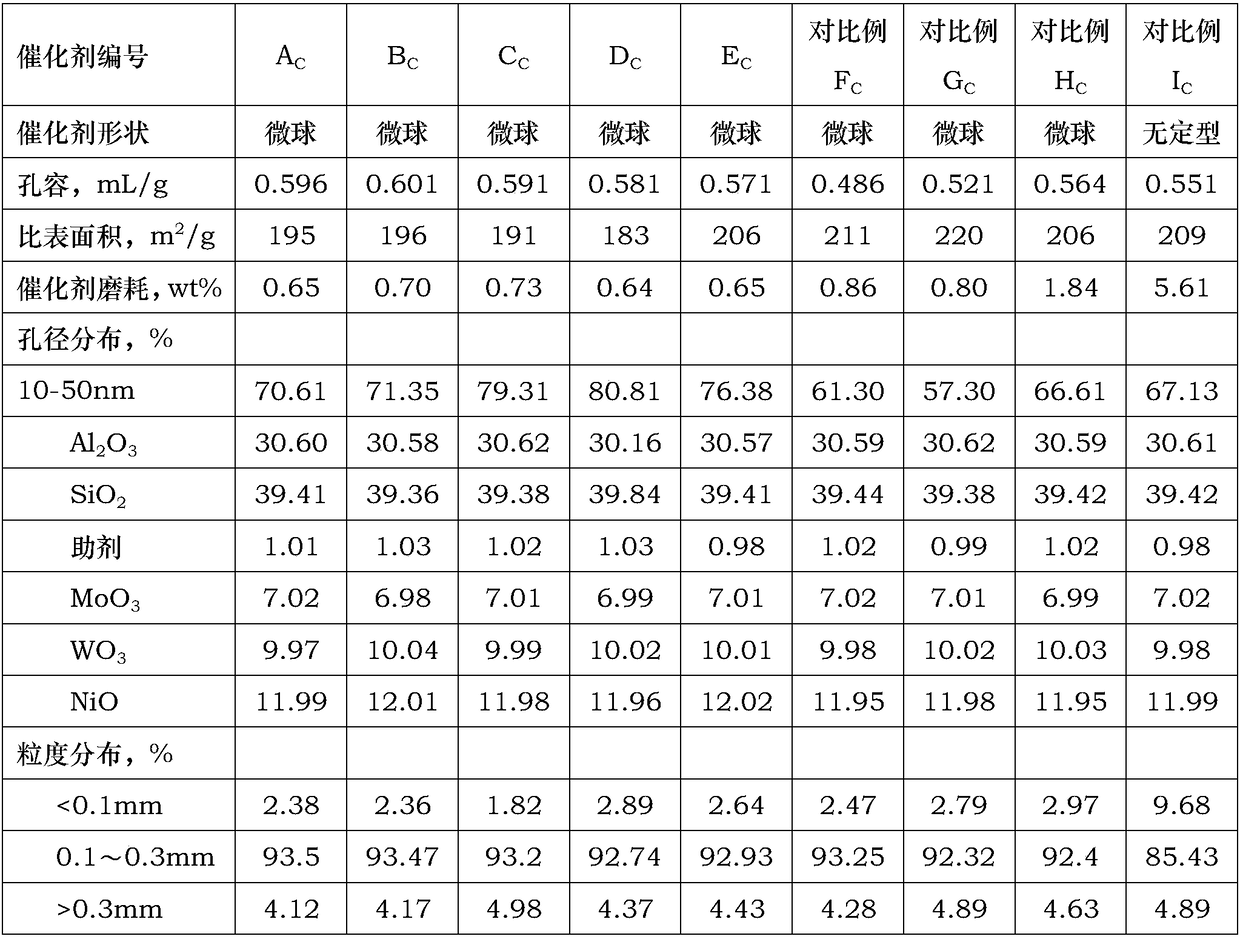

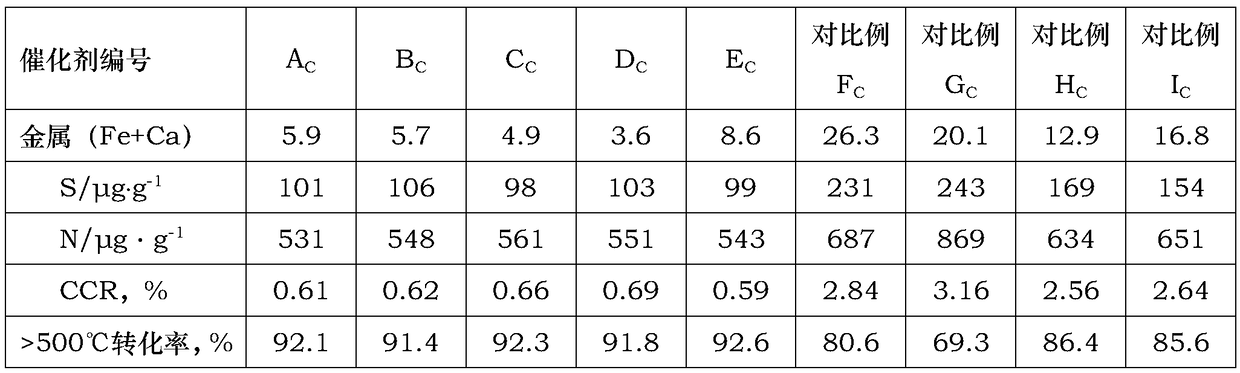

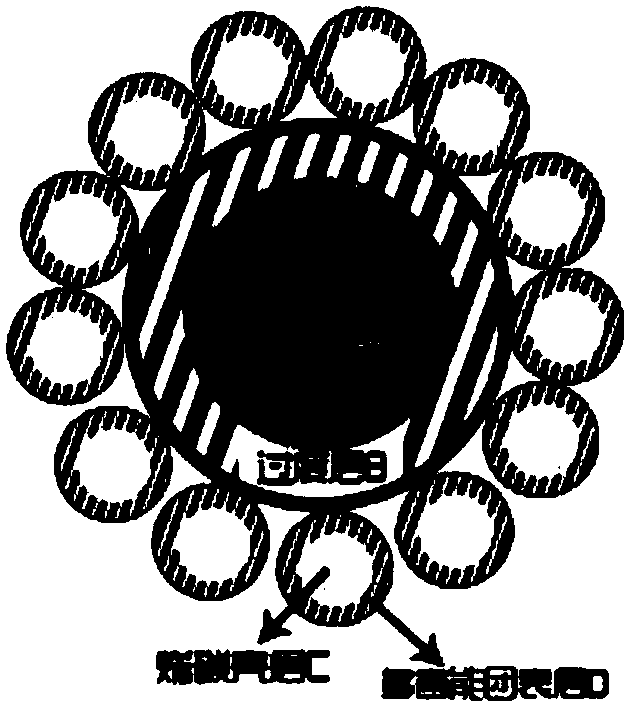

Boiling bed coal tar hydrotreating-hydrocracking composite catalyst and preparation method thereof

ActiveCN108686702ALarge hole volumeLarger than surfaceMolecular sieve catalystsHeterogenous catalyst chemical elementsMicrosphereSilicon oxide

The invention relates to a boiling bed coal tar hydrotreating-hydrocracking composite catalyst and a preparation method thereof. The boiling bed coal tar hydrotreating-hydrocracking composite catalystis prepared from the following components in percentage by mass: MoO3, WO3, NiO, aluminum oxide, silicon oxide molecular sieve and assistant. An acidized silicon-containing raw material and alkali gas react with each other, and the reaction product is cured to generate microsphere gel which has higher scale-accommodating capability and proper cracking performance. Active metal nickel, the assistant and a carrier raw material are prepared into slurry, the NiO is highly dispersed on the catalyst carrier, and nickel aluminum spinel is formed by a small amount of nickel and aluminum, so that thewater resistance and friction resistance of the catalyst are enhanced. Spray drying is performed, so that the grain distribution is concentrated, and high mechanical strength and abrasion resistance are achieved. A curing agent is added into the slurry, and the channel of the catalyst is enlarged in the escaping process of ammonia gas released in a drying process, so that the channel distributionis concentrated, and larger pore volume, larger specific surface area and higher abrasion resistance are achieved. The boiling bed coal tar hydrotreating-hydrocracking composite catalyst has higher hydrogenation activity, proper cracking activity and higher stability. The preparation method is simple and is low in cost.

Owner:一重集团大连工程建设有限公司

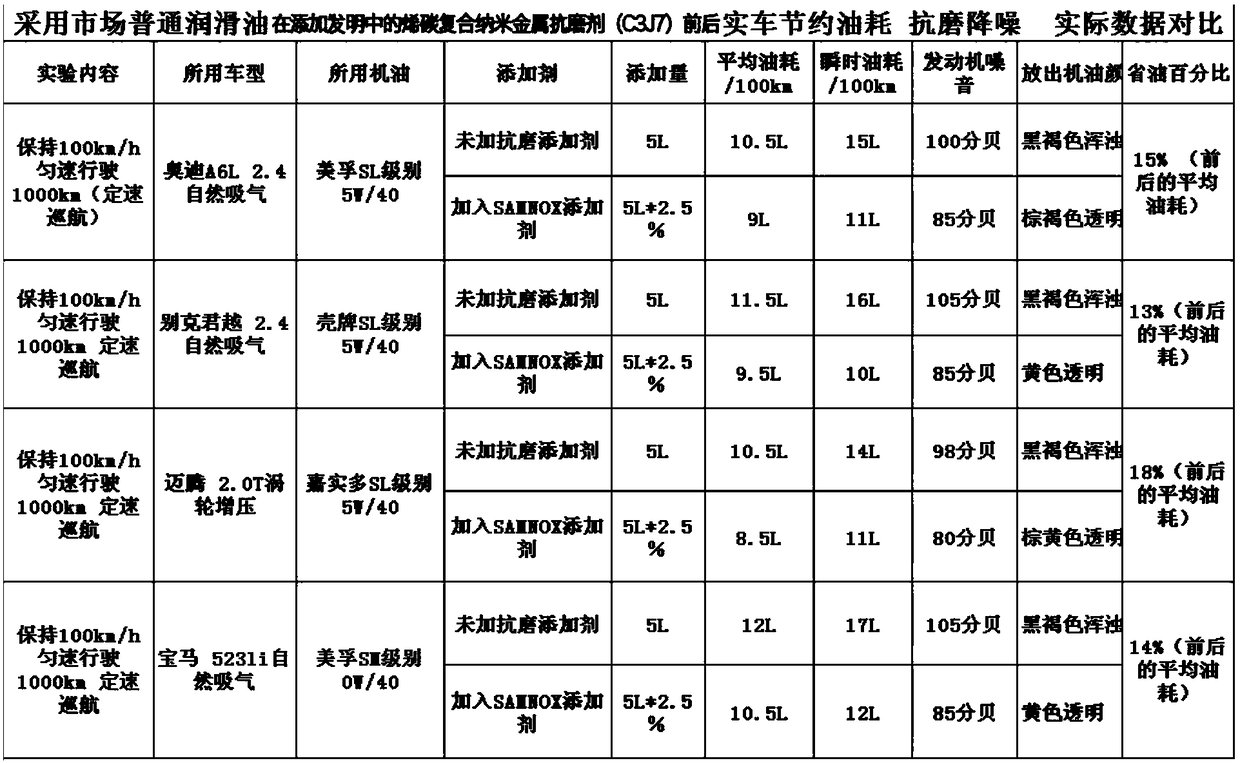

Olefinic carbon compound nanometer soft metal wear-resistant self-repairing material with surface modification, and preparation method thereof

ActiveCN108148652AImprove anti-wear performanceAchieve super lubricityAdditivesWear resistantLubrication

The invention relates to an olefinic carbon compound nanometer soft metal wear-resistant self-repairing material with surface modification, and a preparation method thereof. A nanometer olefinic carbon material with wear-resistant performance and a nanometer metal material with an abrasion repairing function are subjected to in-situ composite preparation with a sol-gel method, so that the materialhas dual functions of abrasion resistance and reduction and abrasion self-repairing, and the advantage complementation mechanism of the synergetic effect and the performance of different types of nanometer materials is performed. The olefinic carbon compound nanometer soft metal wear-resistant self-repairing material prepared with the preparation method can be used for realizing the breakthroughof 'exponential increase of wearing resistance under extreme pressure', 'zero abrasion of metal friction' under an extreme pressure situation is broken through, true super lubrication under the extreme pressure situation is realized, traditional sulfur-phosphorus-containing liquid lubrication performance and application technologies are subjected to revolutionary changes due to the occurrence of olefinic carbon compound wear-resistant energy-saving materials, the material does not contain caustic organic sulfur and phosphorus compound, wear-resistant performance is improved, and wear reductionenergy saving performance is also improved.

Owner:烟台华恒节能科技有限公司

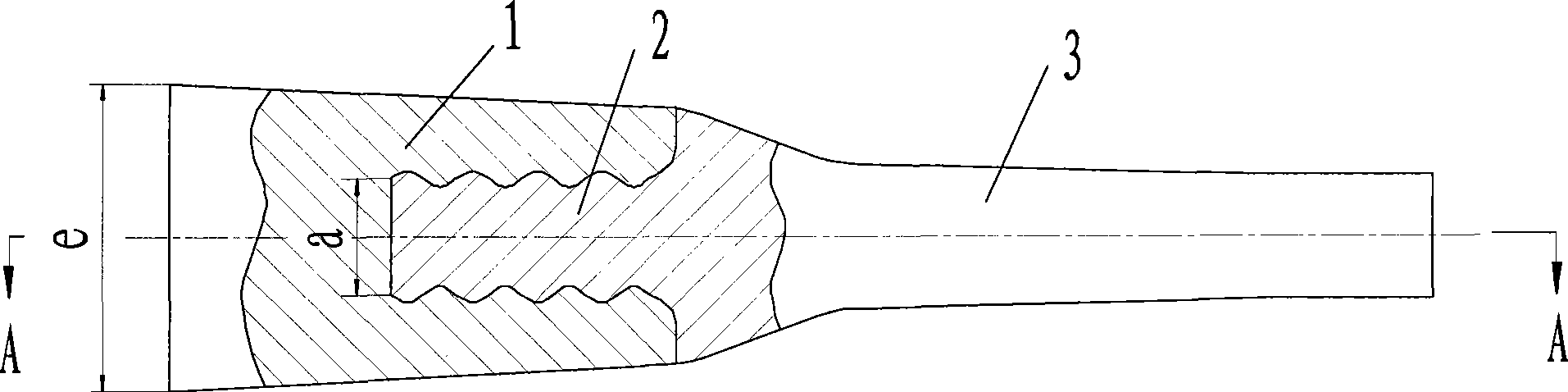

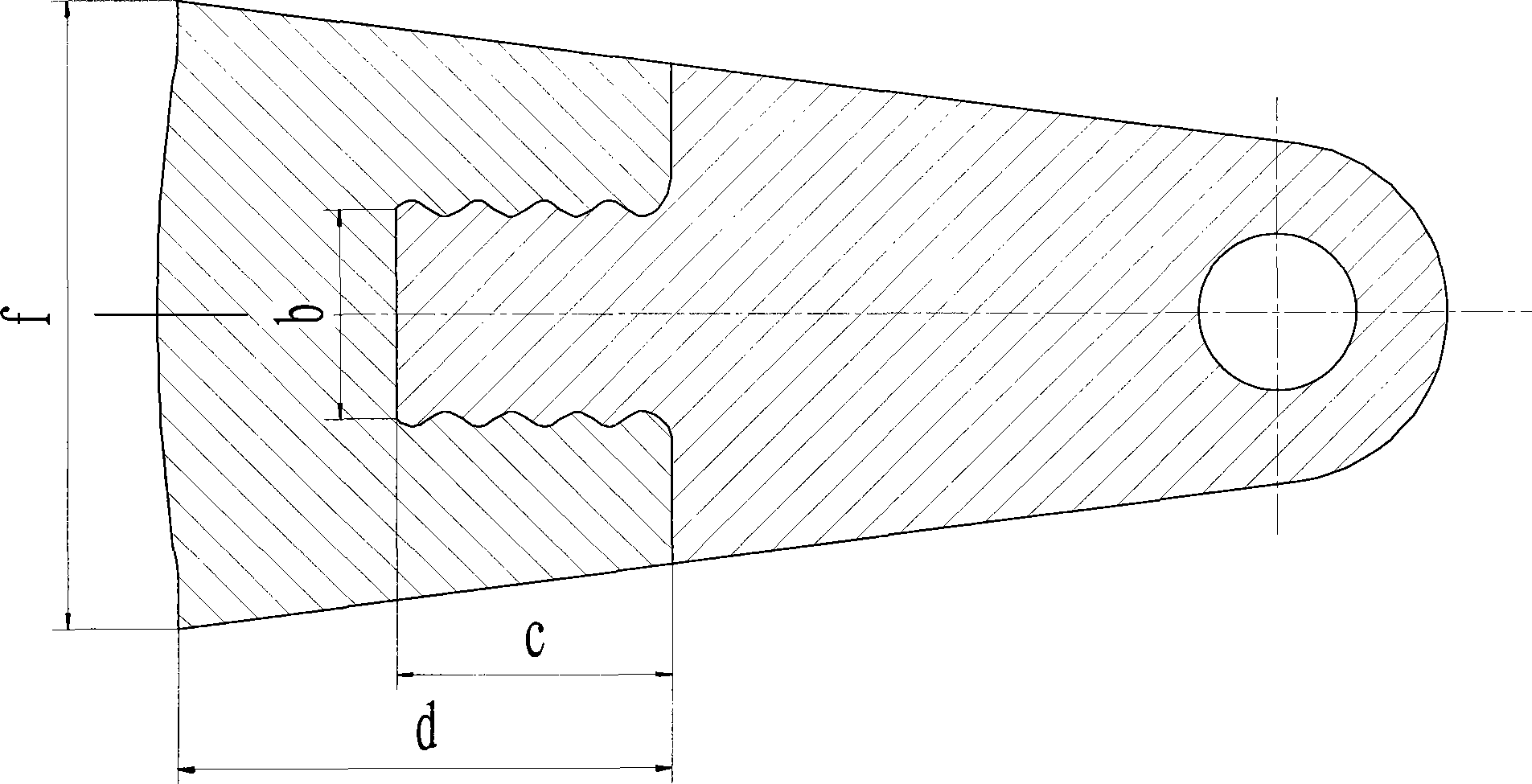

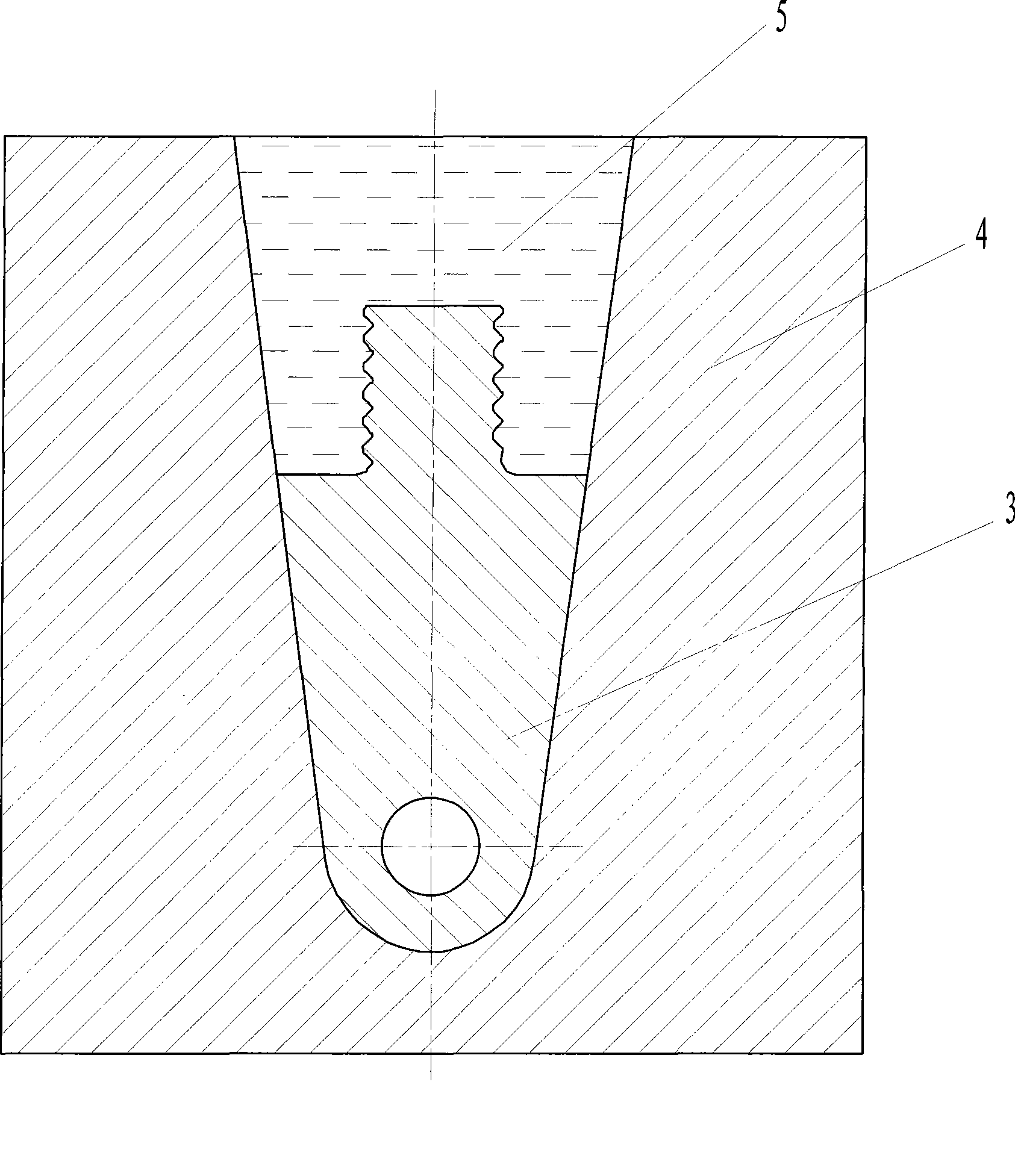

Bimetal composite hammer manufacture method and hammer handler precasting products

The invention relates to a method for preparing a double-metal composite hammer, which comprises the following steps: coating a thermal treatment protective paint on a hammer handle prefabricated member (3), and heating the hammer handle prefabricated member to be between 300 and 800 DEG C; coating casting paint on the surface of a cavity of a metal die (4), and preheating the metal die to be between 120 and 300 DEG C; putting the hammer handle prefabricated member into the cavity of the metal die, and pouring abrasion-resistant alloy melt (5) into the cavity of the metal die at a temperature of between 15 and 80 DEG C higher than a phase line temperature of the abrasion-resistant alloy melt; and within 10 seconds after pouring, pressurizing the hammer handle prefabricated member at 50 to 150MPa, keeping the pressure, and then taking out the hammer. Impact toughness of the hammer handle prefabricated member is more than or equal to 5 to 20 J / cm<2>, hardness is 25 to 40HRC, and the hammer handle prefabricated member is processed and shaped. The length of a connecting handle of the hammer handle prefabricated member is 1 / 4 to 4 / 5 of the length of the hammer head (1), and the thickness and the width of the connecting handle are 1 / 3 to 1 / 2 of the thickness and the width of the hammer respectively; and the surface of the connecting handle is provided with an annular groove. The method solves the problem that an embedded double-metal composite hammer is easy to fall off and a double-liquid double-metal composite hammer is easy to mix double liquids so as to reduce service performance.

Owner:BEIJING JIAOTONG UNIV +1

Self-crosslinked polyacrylate latex and preparation method thereof, and water-based paper ink

InactiveCN102304262APrevent sticking backFast dryingPaper coatingCoatingsHydrophilic monomerPolymer science

The invention discloses self-crosslinked polyacrylate latex and a preparation method thereof, and water-based paper ink. The preparation method for the self-crosslinked polyacrylate latex comprises the following steps of: mixing acrylate monomers, hydrophilic monomers and alcohol dehydrogenase (ADH) in a head tank A; mixing water, an emulsifier, acrylate monomers and diacetone acrylamide (DAAM) in a head tank B; adding water, an emulsifier and polymerization self-emulsification functional monomers into a normal-pressure reaction tank, stirring, heating to 75DEG C, dripping a mixture in the head tank A and an initiator, and preparing protective colloid; dripping a mixture in the head tank B and an initiator at 85DEG C; and reacting at constant temperature. The water-based paper ink is prepared by the following steps of: stirring and dissolving styrene-acrylate copolymer, a pH regulator and water at 60DEG C; adding pigments and necessary aids, and mixing to obtain color paste; and uniformly mixing the color paste, the self-crosslinked polyacrylate latex, a surface tension regulator and water. The water-based paper ink can be diluted by one of water and ethanol or a mixture of water and ethanol, and has high drying speed and good printing adaptability.

Owner:SUN YAT SEN UNIV +1

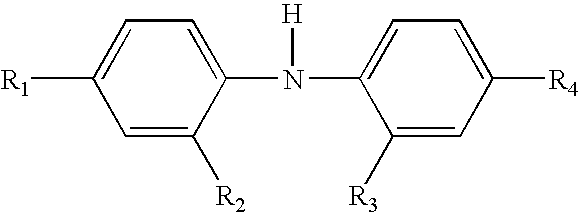

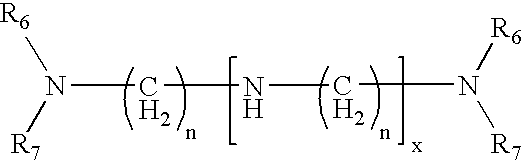

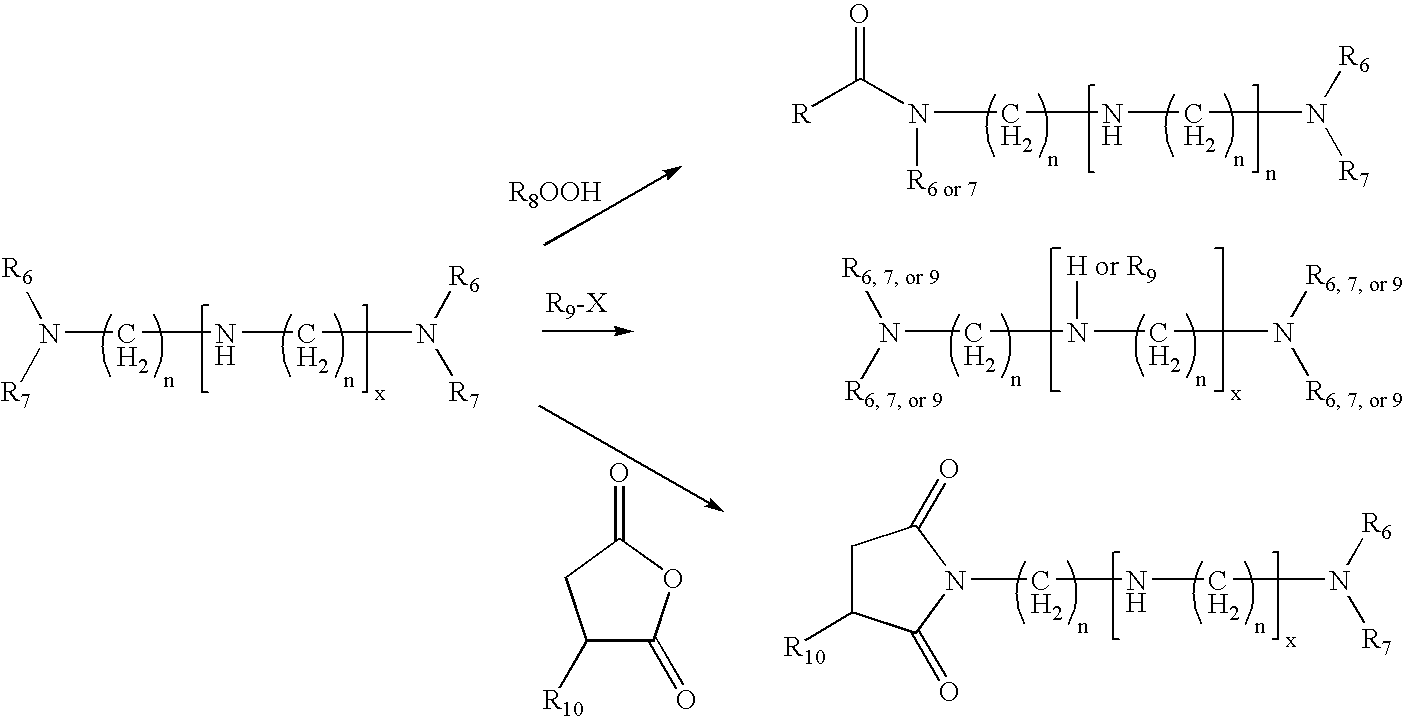

Antioxidant Synergist for Lubricating Compositions

ActiveUS20070254821A1Improve anti-wear performanceReduction in phosphorous and sulfur levelOrganic chemistryLiquid carbonaceous fuelsMonoglyceridePolyamine

Molybdenum-free lubricating compositions are provided, having an antioxidation additive composition based on a combination of (1) alkylated diphenylamine (APDA), (2) polyamine dispersant, and (3) monoglyceride, ethoxylated amide, or mixtures thereof. Further synergy is achieved when component (3) is borated, allowing a reduction in phosphorus levels to below 0.08% or even a phosphorus-free composition.

Owner:VANDERBILT CHEM LLC

Super-hard middle-chrome cast grinding ball and production process thereof

InactiveCN103060667ARefined grain sizeReduce in quantityFurnace typesQuenching agentsRare earthManganese

The invention discloses a super-hard middle-chrome cast grinding ball which consists of the following chemical ingredients: 1.8-3.0% of carbon, 0.3-1.5% of silicon, 0.2-1.5% of manganese, 7.0-10.0% of chrome, 0.02-0.1% of phosphorus, 0.02-0.1% of sulfur, 0.02-0.1% of copper, 0.02-0.1% of molybdenum, 0.02-0.1% of nickel, 0.02-0.1% of tungsten, 0.1-0.2% of rare earth yttrium and 80.1-87.2% of iron. The rare earth yttrium is adopted for evolution inoculation treatment, so that a carbide is changed in shape and distribution, furthermore a net is broken, and meanwhile crystal grains are refined, the texture is compact and the flexibility is improved. By adopting an oil medium annealing and tempering thermal treatment process, eutectic carbide with martensite with the broken net is obtained, the hardness of the middle-chrome grinding ball is HRC60-69, and the toughness and the abrasion resistance of a high-chrome grinding ball are remarkably improved. On premise that the abrasion resistance and the crushing resistance of the grinding ball are further improved, the content of the noble metal chrome is reduced, and relatively the manufacturing cost of the grinding ball is lowered, and significant social benefits are achieved.

Owner:NINGGUO ZHONGYI WEAR RESISTANT MATERIALS

Impact resistant high-efficiency wear-resistant material

The invention relates to an anti-impact efficient wear resistant material which is made of the following raw materials with the following weight ratio: 35 to 40 portions of ordinary Portland cement, 50 to 60 portions of quartz sand, 1.5 to 2 portions of sulpho-aluminate cement, 2 to 4 portions of coal ash, 0.4 to 1 portion of emulsion powders, 0.35 to 0.45 portion of dihydrate gypsum powder, 1.5 to 2.5 portions of silica dioxide powder, 0.35 to 0.45 portion of water reducing agent, 0.1 to 0.2 portion of cellulose ether and 0.1 to 0.2 portion of polypropylene staple. By adopting non-poisonous environmental protective raw materials, the anti-impact efficient wear resistant material has the advantages of impact resistance and high anti-compression strength, strong performance of high temperature resistance, good durability, long service life, environmental protection and low cost.

Owner:北京固瑞恩科技有限公司

Polyphenylene sulfide fiber spinning technology

ActiveCN102776601AHigh crystallinityGood light stabilityArtificial filament heat treatmentMonocomponent synthetic polymer artificial filamentPolymer scienceVacuum drying

The invention relates to a polyphenylene sulfide fiber spinning technology which comprises the steps as follows: (1) pre-processing materials: mixing graphite powder with a silane coupling agent to obtain modified graphite, and mixing the modified graphite and polyphenylene sulfide resin at a high speed so as to obtain a mixture, and finally pre-crystallizing and drying the mixture in a vacuum drying box to obtain dried powder with less than 50 ppm of water; (2) melting and spinning: feeding the dried powder into a double-screw extruder for melting and spinning so as to obtain a melt; (3) slowly cooling and cooling: thermally forming the smelt after forming silk through a spinneret plate, and then transferring to a slow cooling area, and finally transferring to a cooling area to solidify and form; and (4) drafting and finalizing: carrying out oil applying and silk guiding on the solidified and finalized fiber, and then drafting and finalizing at three times so as to obtain the short fiber with the linear density of 11 dte x. The polyphenylene sulfide fiber spinning technology is low in cost and easy in industrial production; and the fiber material prepared via the technology has good performance.

Owner:DUNHUANG XIYU MINING & CHEM

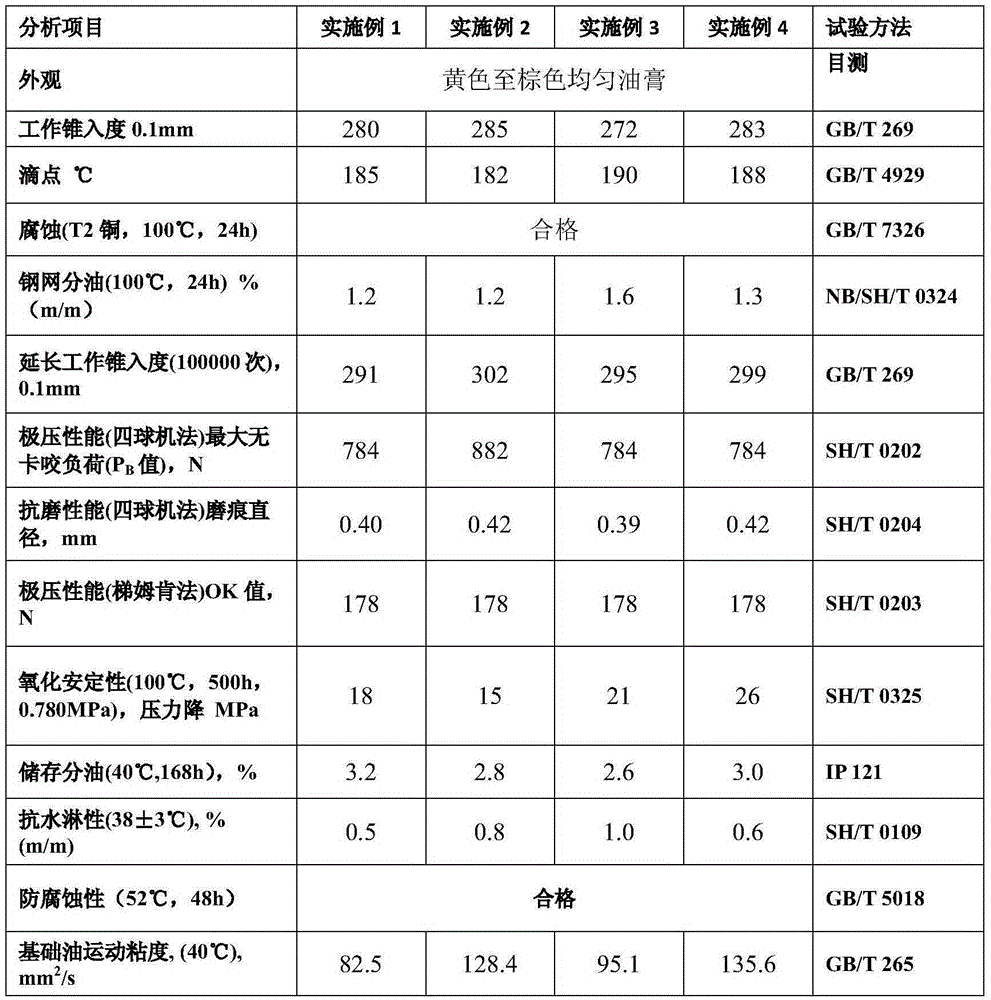

Anti-rust extreme pressure lithium lubricating grease composition and preparation method

InactiveCN105331426AImprove extreme pressure performanceImprove shear stabilityLubricant compositionAntioxidantLithium hydroxide

The invention relates to an anti-rust extreme pressure lithium lubricating grease composition and a preparation method thereof. The composition is prepared from 5.5%-12.5% of thickening agents, 72.8%-91.3% of base oil, 0.5%-3.8% of extreme pressure anti-wear agents, 0.28%-1.25% of antioxidants and 0.02%-1.05% of anti-rust anti-corrosion agents, wherein the base oil is high-viscosity mineral oil. The preparation method of the composition comprises the steps that one third of the base oil and 12-hydroxy stearin or a mixture of 12-hydroxy stearin and stearic acid are heated to the temperature ranging from 60 DEG C to 80 DEG C, a lithium hydroxide solution is added, the temperature is raised to range from 180 DEG C to 220 DEG C after a reaction is completed, one third of quenching oil is added, the extreme pressure anti-wear agents, the anti-rust anti-corrosion agents and the rest of the base oil are added after cooling is conducted, and the composition is prepared after grounding is conducted. The novel lubricating grease containing the extreme pressure components and the anti-rust anti-corrosion components has the excellent extreme pressure property and anti-corrosion property and can be widely applied to severer environment conditions with a medium or heavy load and water.

Owner:CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com