Ultraviolet cured coating and application thereof

A technology of curing coatings and ultraviolet light, which is applied in the direction of polyester coatings, polyether coatings, epoxy resin coatings, etc., and can solve problems such as large temperature differences, large differences in thermal expansion and contraction performance, and complex processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

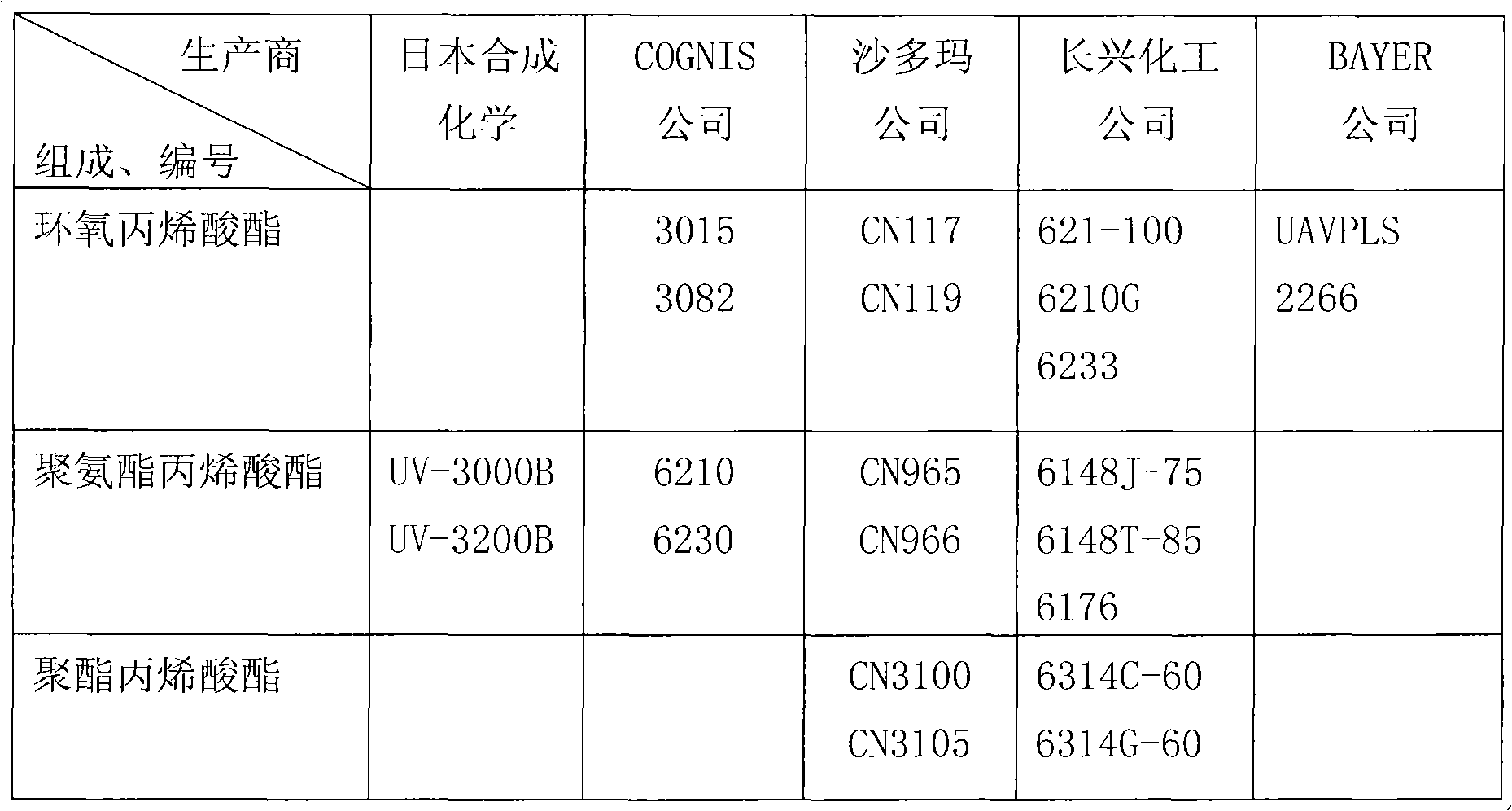

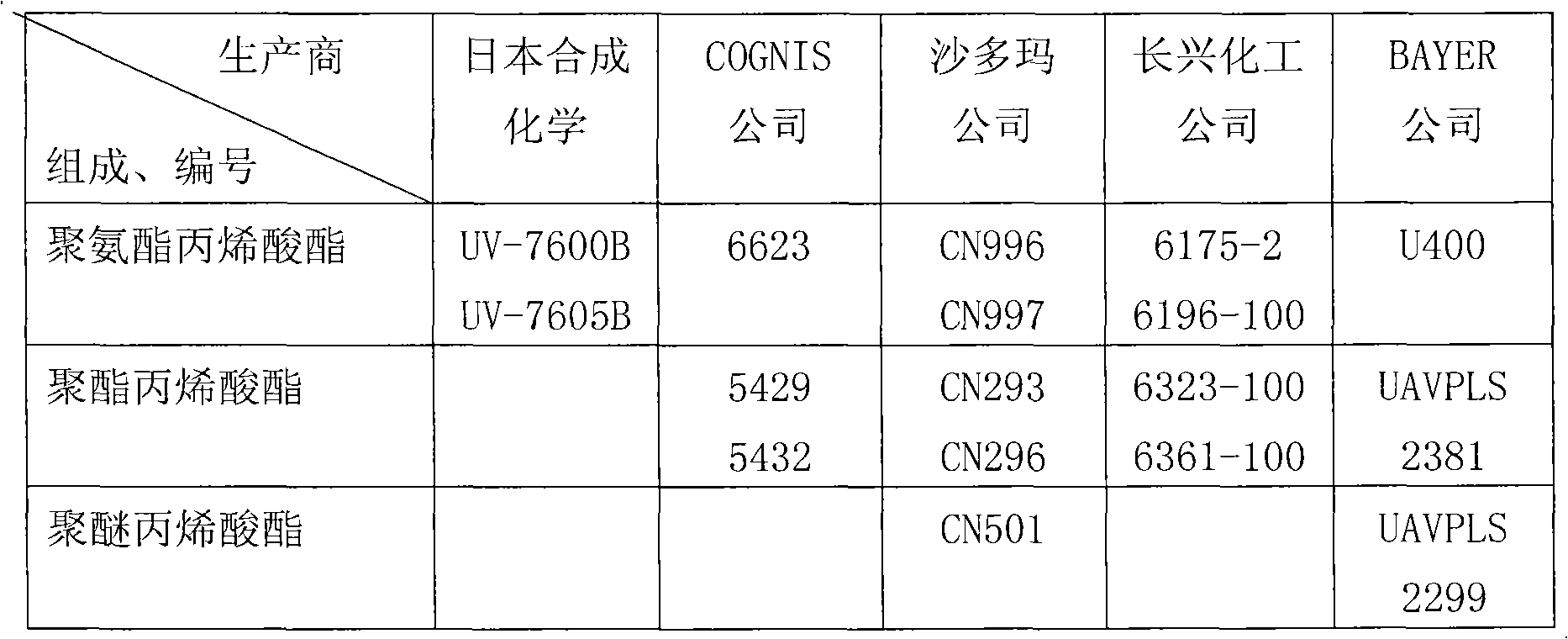

[0031] The percentage by weight of hard primer: Dipropylene glycol diacrylate (DPGDA) 8%, isobornyl acrylate (IBOA) 6%, polyurethane acrylate UV-3000B (Nippon Synthetic) 35%, epoxy acrylate 621-100 (Changxing Chemical) 15%, alumina powder 6%, antioxidant 1%, leveling agent 1%, dispersant 1%, adhesion promoter 1%, photoinitiator 2%, mixed solvent 24%.

[0032] The percentage by weight of the transparent colored intermediate coating is: dipropylene glycol diacrylate (DPGDA) 6%, 6-hexanediol diacrylate (HDDA) 3%, polyurethane acrylate 6176 (Changxing Chemical Industry) 25%, epoxy acrylate 621-100 (Changxing Chemical) 20%, transparent pigment 3%, leveling agent 1%, dispersant 1%, defoamer 1%, photoinitiator 2%, mixed solvent 38%.

[0033] The weight percentage of high-gloss surface coating is: 3,3,5-trimethylcyclohexyl acrylate (TMCHA) 2%, neopentyl glycol diacrylate (NPGDA) 3%, epoxy acrylate 621-100 (Changxing Chemical Industry) 13%, dipentaerythritol hexaacrylate (DPHA) 15%, u...

Embodiment 2

[0036] The percentage by weight of the hard primer: dipropylene glycol diacrylate (DPGDA) 6%, isodecyl acrylate (ISODA) 6%, polyurethane acrylate UV-3000B (Nippon Synthetic) 30%, epoxy acrylate CN117 (sand Dorma) 20%, alumina powder 6%, antioxidant 1%, leveling agent 1%, dispersant 1%, adhesion promoter 1%, photoinitiator 2%, mixed solvent 26%.

[0037] The percentage by weight of the transparent colored intermediate coating is: dipropylene glycol diacrylate (DPGDA) 4%, 6-hexanediol diacrylate (HDDA) 5%, polyurethane acrylate 6148T-85 (Changxing Chemical Industry) 30%, epoxy Acrylate 621-100 (Changxing Chemical) 15%, transparent pigment 3%, leveling agent 1%, dispersant 1%, defoamer 1%, photoinitiator 2%, mixed solvent 38%.

[0038] The weight percentage of high-gloss surface coating is: neopentyl glycol diacrylate (NPGDA) 5%, epoxy acrylate 621-100 (Changxing Chemical Industry) 11%, dipentaerythritol hexaacrylate (DPHA) 13%, polyurethane acrylate U400 ( BAYER company) 28%, p...

Embodiment 3

[0041] The percentage by weight of the hard primer: ethoxylated bisphenol A diacrylate (BPA4EODA) 7%, 3,3,5-trimethylcyclohexyl acrylate (TMCHA) 4%, polyurethane acrylate UV-3200B (Japanese synthetic ) 38%, epoxy acrylate 6210G (Changxing Chemical) 12%, alumina powder 8%, antioxidant 1%, leveling agent 1%, dispersant 1%, adhesion promoter 1%, photoinitiator 2% , mixed solvent 25%.

[0042] The percentage by weight of the transparent colored intermediate coating is: neopentyl glycol diacrylate (NPGDA) 5%, 6-hexanediol diacrylate (HDDA) 4%, polyurethane acrylate 6176 (Changxing Chemical Industry) 28%, epoxy Acrylate 3082 (COGNIS company) 25%, transparent pigment 4%, leveling agent 1%, dispersant 1%, defoamer 1%, photoinitiator 2%, mixed solvent 29%.

[0043] The weight percentage of high-gloss surface coating is: 3,3,5-trimethylcyclohexyl acrylate (TMCHA) 4%, 6-hexanediol diacrylate (HDDA) 2%, epoxy acrylate 3082 (COGNIS company) 15 %, dipentaerythritol hexaacrylate (DPHA) 12%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com