Olefinic carbon compound nanometer soft metal wear-resistant self-repairing material with surface modification, and preparation method thereof

A self-repairing material and surface modification technology, which is applied in the field of olefin-carbon composite nano-soft metal anti-wear self-repairing materials and its preparation, and anti-wear self-repairing materials, can solve problems such as corrosion of mechanical equipment, and achieve improved anti-wear performance and good Improvement of oil-soluble dispersibility, friction reduction and energy saving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

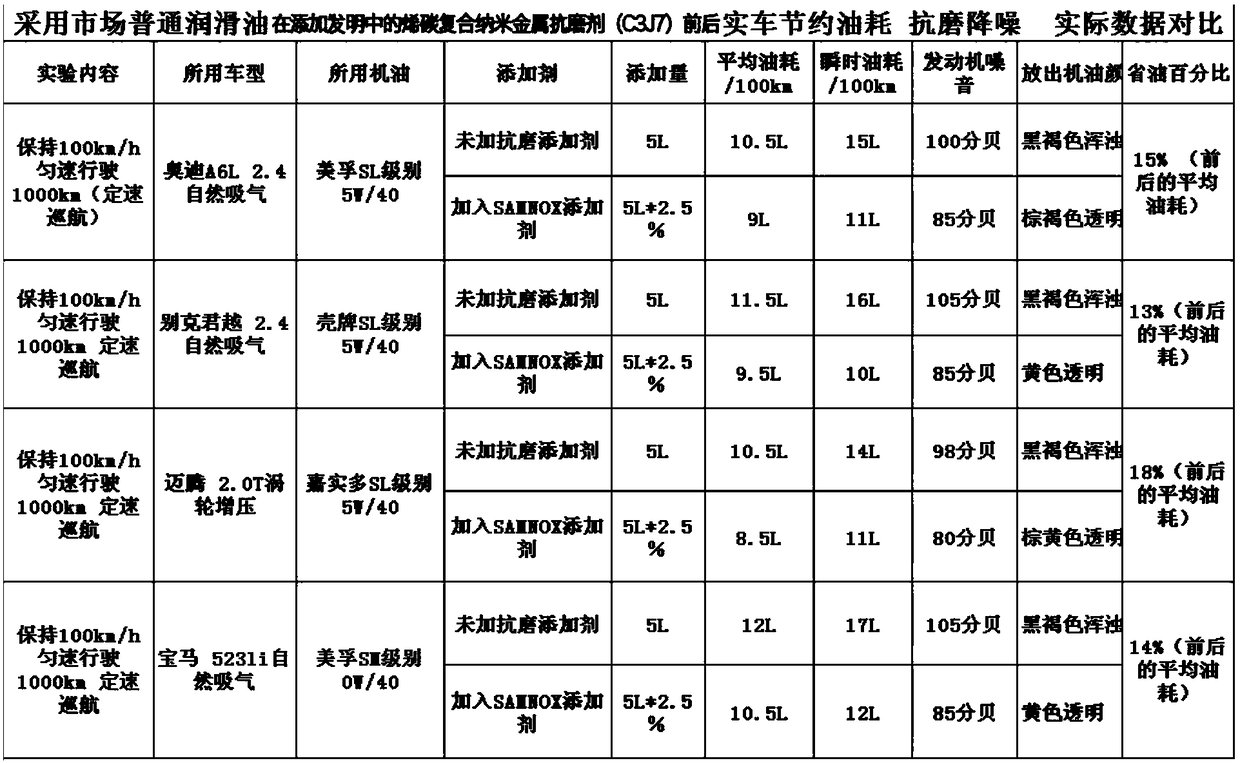

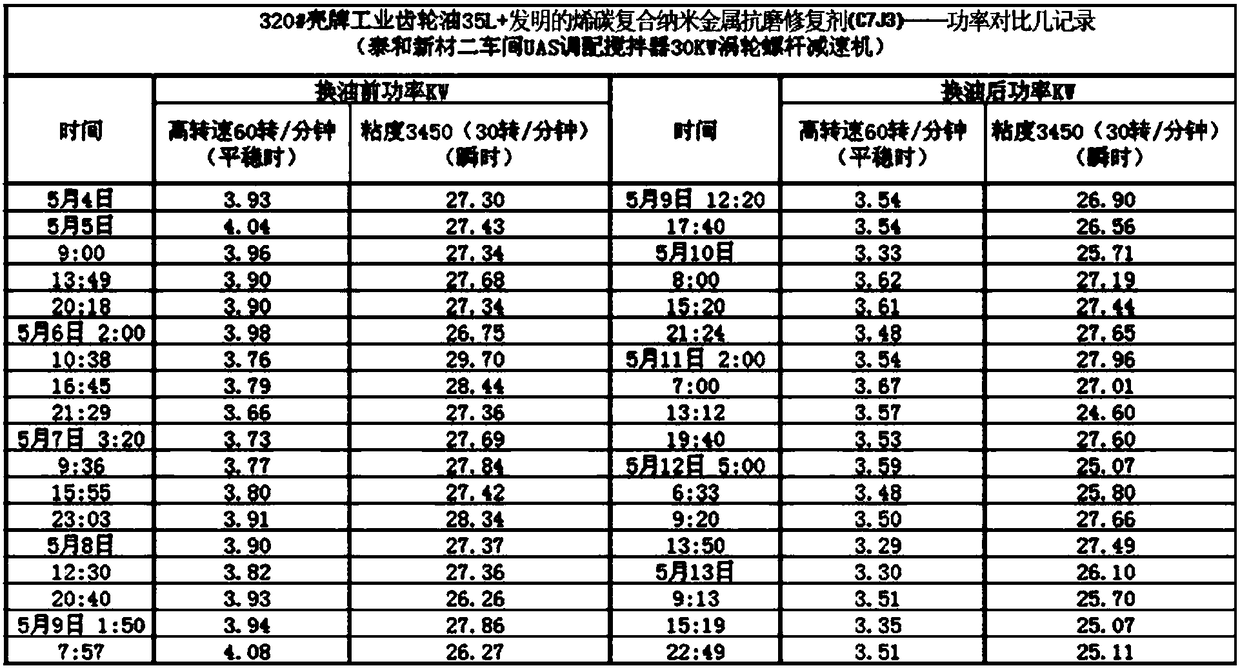

Examples

Embodiment 1

[0057] A preparation method of a graphene composite nano-silver anti-wear self-repairing material, the steps are as follows:

[0058] (1) Surface modification of nano-carbon particles

[0059] a. Soak 40g of nano-graphene oxide particles in 200g of amino-terminated silane coupling agent KH570, heat and stir in a water bath at 50°C for 30min, soak at 50°C for 8h, filter and wash with absolute ethanol for 3 times, and heat at 60°C Drying for 5h, the obtained nano-carbon particles are coated with lipophilic groups;

[0060] b. Transfer the surface-modified nano-graphene particles in step a to a reaction kettle, add 80 g of isotactic polyvinyl alcohol, 120 g of isooctyl sodium succinate and 120 g of 150SN base oil, heat and stir in a water bath at 50°C for 30 min , transferred to a 5000r / min high-speed disperser for 3 hours; then transferred back to the reactor, added 80g of succinimide T161B, 10g of polyisobutylene monosuccinimide and 30g of alkyl diphenylamine, in the reactor ...

Embodiment 2

[0074] A method for preparing a nano-diamond composite nano-copper anti-wear self-repairing material, the steps are as follows:

[0075] (1) Surface modification of nano-carbon particles

[0076] a. Soak 60g of nano-diamond particles in 150g of amino-terminated silane coupling agent KH570, heat and stir in a water bath at 50°C for 30min, soak at 50°C for 8h, filter and wash with absolute ethanol for 3 times, then dry at 60°C 5h, the obtained nano-diamond particles are coated with lipophilic groups;

[0077] b. Transfer the surface-modified nano-diamond particles in step a to a reaction kettle, add 80 g of isotactic polyvinyl alcohol, 120 g of isooctyl sodium succinate and 120 g of 150SN base oil, heat and stir in a water bath at 50° C. for 30 minutes, Transfer to a 5000r / min high-speed disperser and disperse for 3 hours; then transfer back to the reactor, add 80g of succinimide T161B, 10g of polyisobutylene monosuccinimide and 30g of alkyl diphenylamine, and stir in the react...

Embodiment 3

[0090] A preparation method of fullerene+silicon carbide (weight ratio 1:1) composite nano-titanium-silver (weight ratio 1:1) anti-wear self-repairing material, the steps are as follows:

[0091] (1) Surface modification of nano-carbon particles

[0092] a. Soak 20g of nano-fullerene particles and 20g of nano-silicon carbide particles in 180g of amino-terminated silane coupling agent KH550, heat and stir in a 50°C water bath for 30min, soak at 50°C for 8h, filter and wash with absolute ethanol for 3 After drying for 5 hours at 60°C, the obtained nano-carbon particles are coated with lipophilic groups;

[0093] b. Transfer the surface-modified nano-fullerene and silicon carbide particles in step a to a reaction kettle, add 60 g of isotactic polyvinyl alcohol, 140 g of isooctyl sodium succinate, and 150 g of 150SN base oil, at 50°C Heat and stir in a water bath for 30 minutes, transfer to a 5000r / min high-speed disperser and disperse for 3 hours; then transfer back to the react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com