Patents

Literature

30 results about "Glass factory" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Studio glass is the modern use of glass as an artistic medium to produce sculptures or three-dimensional artworks. The glass objects created are intended to make a sculptural or decorative statement. Their prices may range from a few hundred to hundreds of thousands of dollars (US). For the largest installations, the prices are in the millions.

Preparation method of high-strength and antioxidant rare-earth-based smoke denitration catalyst

ActiveCN104209117AReduce escape rateReduce productionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCeriumGlass factory

The invention discloses a preparation method of a high-strength and antioxidant rare-earth-based smoke denitration catalyst. The preparation method of the high-strength and antioxidant rare-earth-based smoke denitration catalyst comprises the following steps: by taking titanium dioxide and montmorillonite as carriers and ammonium metatungstate, cerous nitrate and lanthanum nitrate as active components, mixing, ageing, kneading, forming, drying and roasting with the accompanying of auxiliary materials. The auxiliary materials comprise ammonia water, lactic acid, citric acid, stearic acid, glass fiber, wood pulp, hydroxypropyl methyl cellulose, polyoxyethylene, monoethanolamine and water. The product prepared by the method is separated under a high SO2 smoke condition, nitric oxide in the smoke can be decomposed; meanwhile, the purpose of removing mercury and dioxin can be achieved. According to the preparation method of the high-strength and antioxidant rare-earth-based smoke denitration catalyst, the rare earth elements, namely cerium and lanthanum are used as the active components, so that the addition amount of vanadium is reduced, the toxicity of the product is reduced or the product is non-toxic product, the pressure of the post treatment of the product is reduced; the environmental protection pressure is reduced; the product is environmentally friendly; the product can be widely used in the field of thermal power plants, glass factories and chemical plants.

Owner:山东信义汽车配件制造有限公司

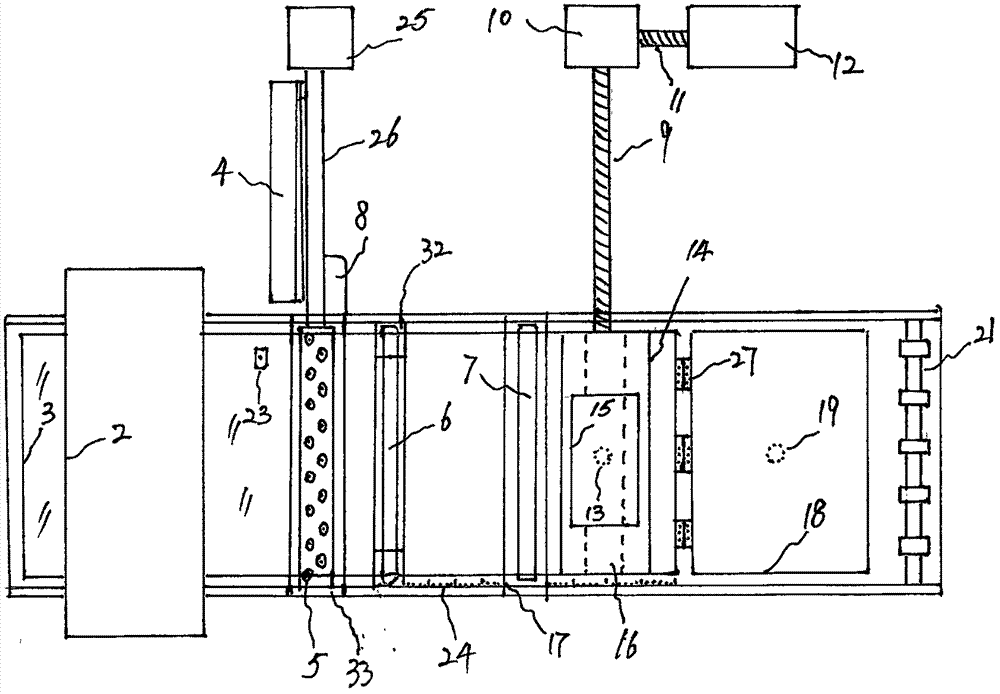

Rapid glass side edge grinding device applied to glass factory

ActiveCN106956181AChange angleImprove sanding qualityEdge grinding machinesGrinding carriagesEngineeringBolt connection

The invention relates to and particularly relates to a rapid glass side edge grinding device applied to a glass factory and aims to provide the rapid glass side edge grinding device which is relatively high in grinding quality, capable of saving time and effort in a grinding process and applied to the glass factory. The rapid glass side edge grinding device applied to the glass factory, provided by the invention, comprises a base plate, a first sliding rail, a first slider, a first motor, a first gear, an arranging table, a first gear rack, a baffle, a first fixing plate, a second sliding rail, a second slider and the like; the first sliding rail is installed at the right side inside the base plate in a bolt connection way; and the first slider is slidably connected within the first sliding rail. The rapid glass side edge grinding device provided by the invention realizes the effects of relatively high grinding quality and time-saved and effort-saved grinding process, and realizes grinding by adopting four tap position slots which form an angle of 90 degrees with one another to precisely move a glass side edge to make sure the glass side edge is parallel to the first sliding rail.

Owner:广东朗博玻璃实业有限公司

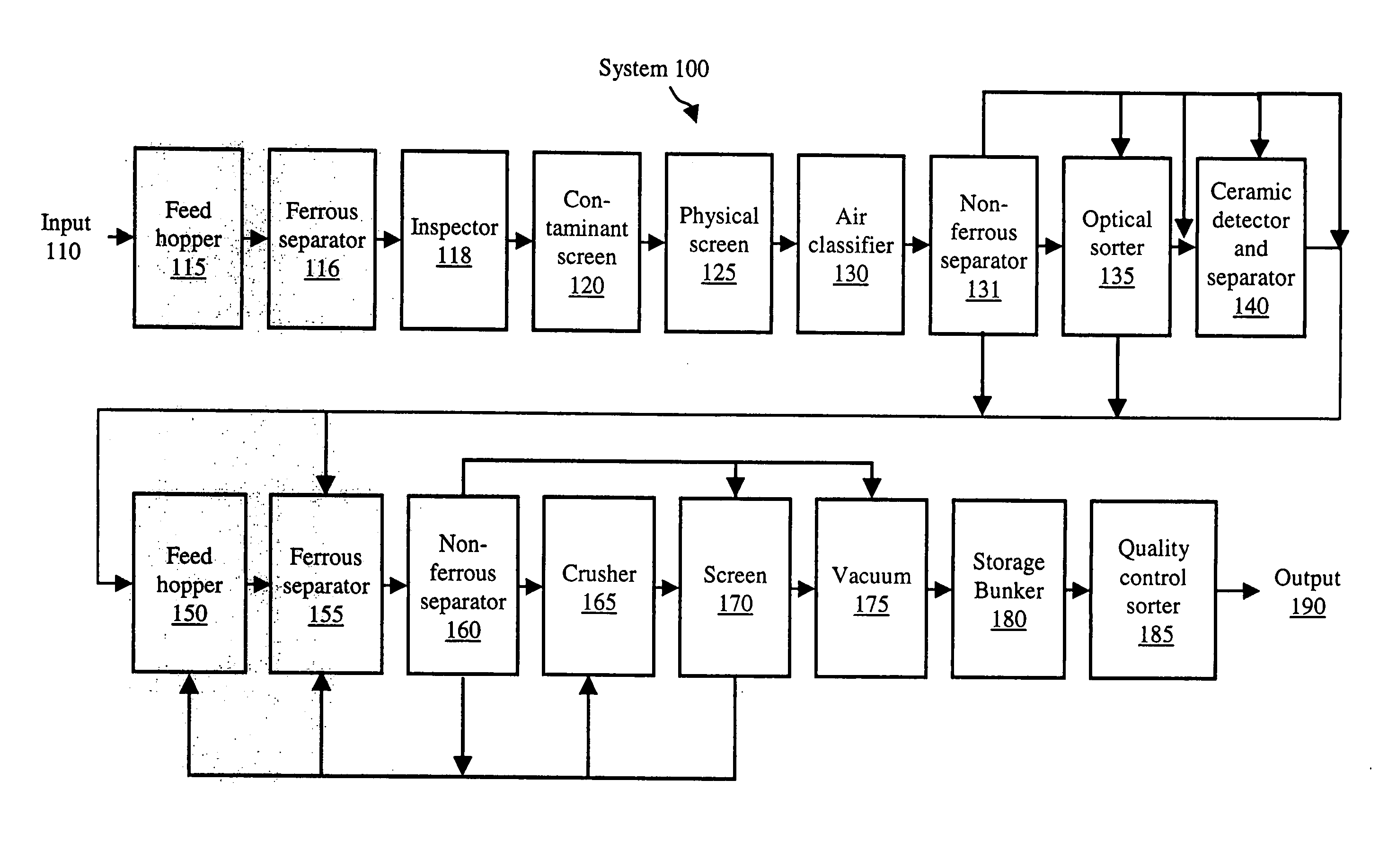

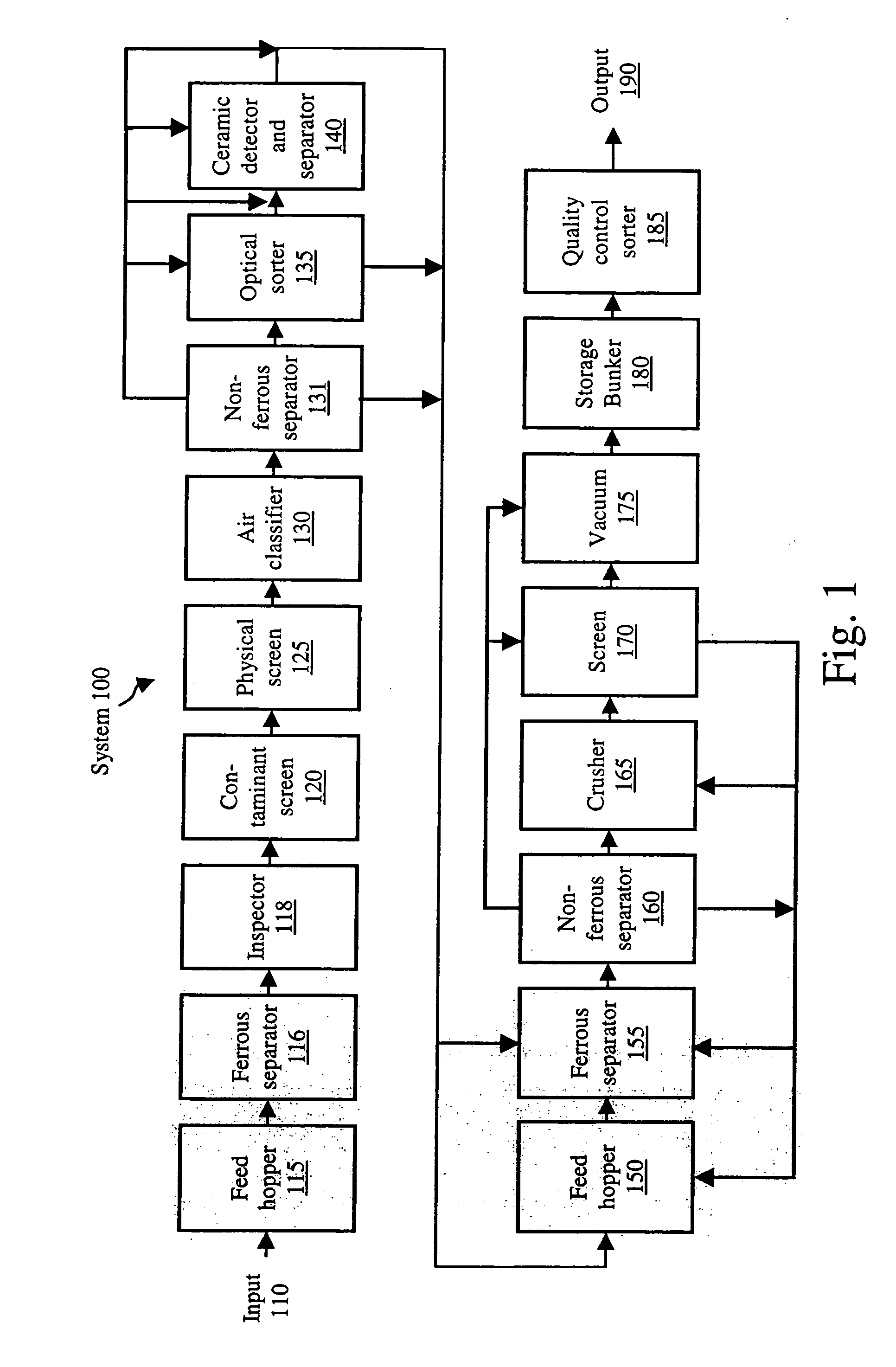

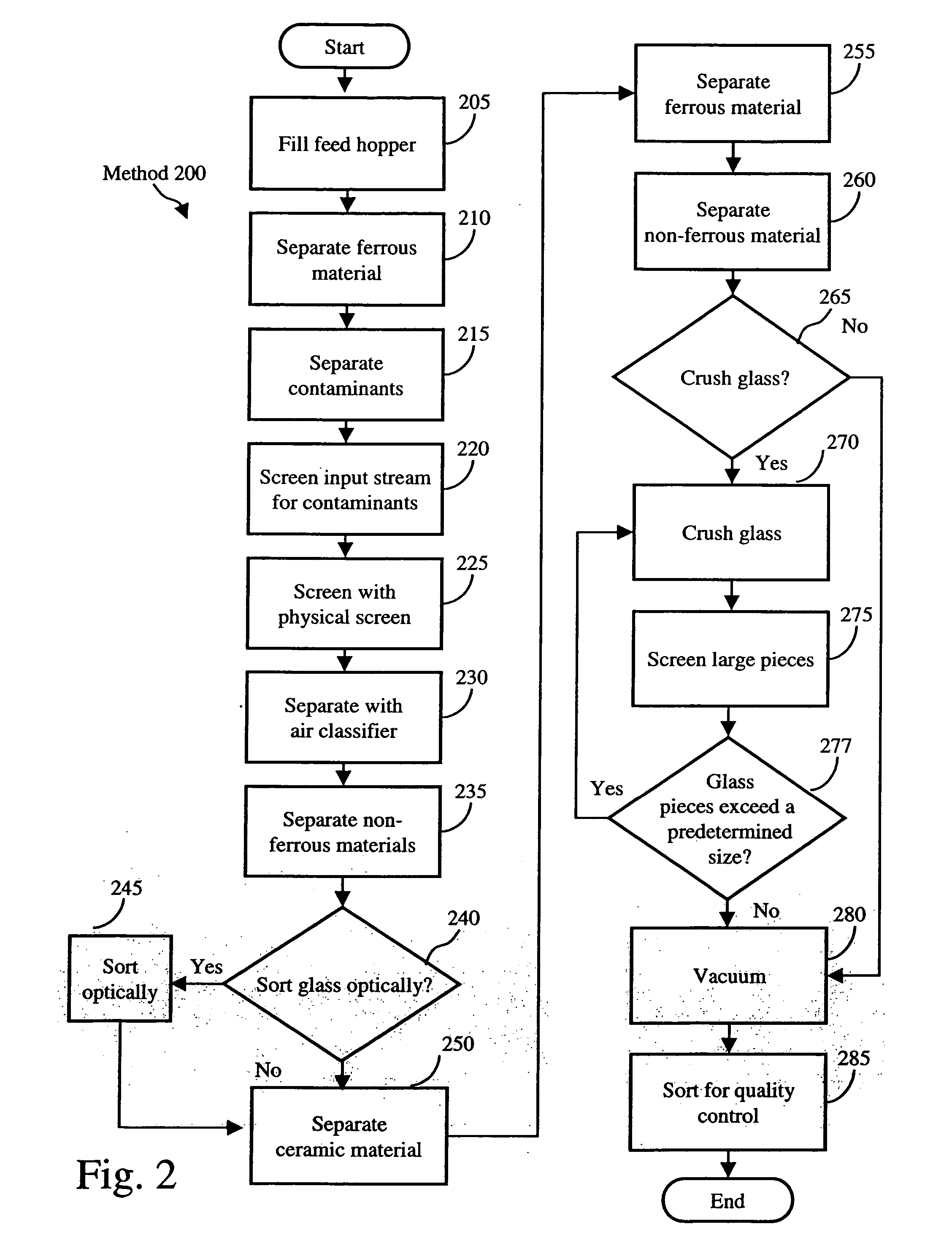

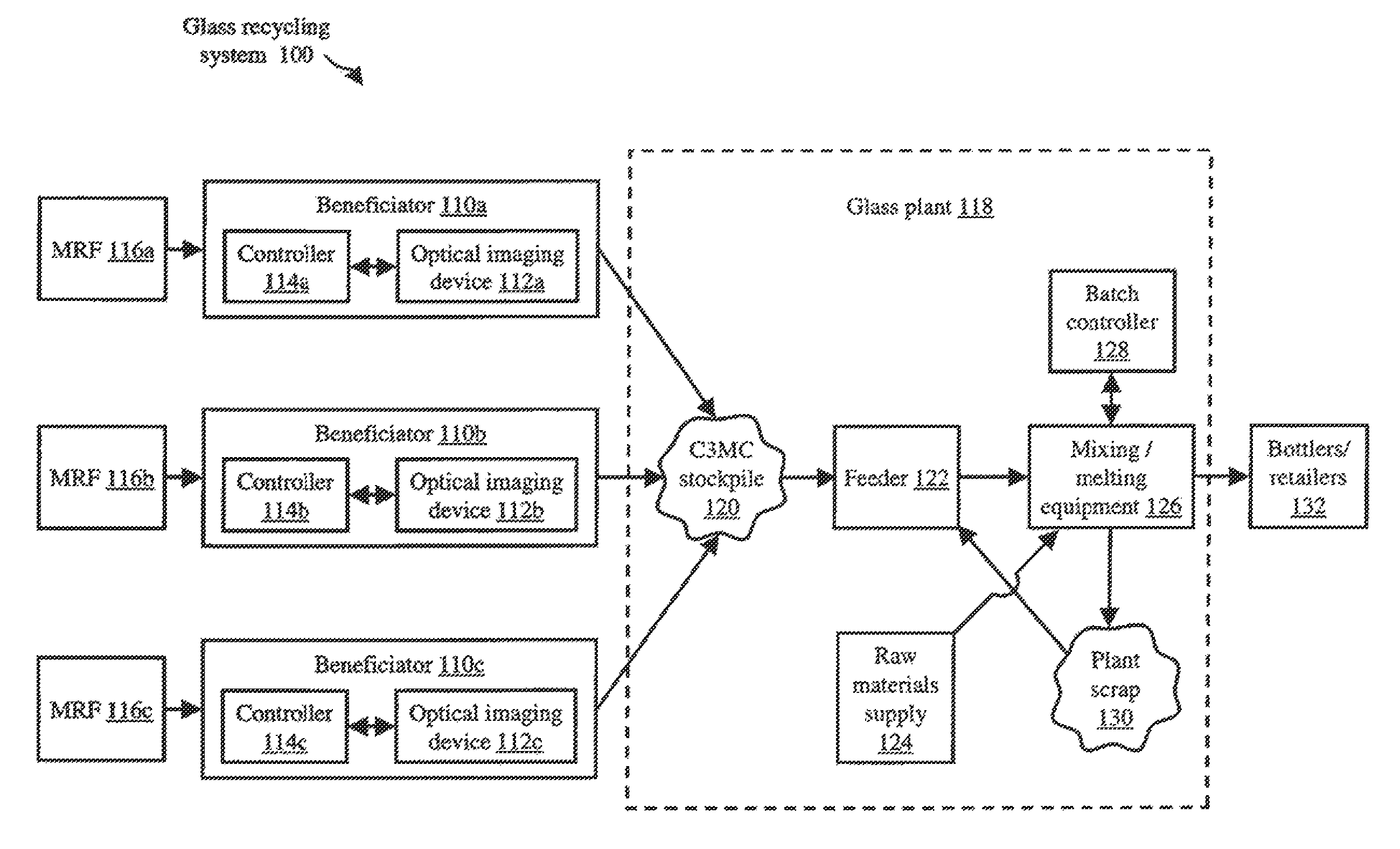

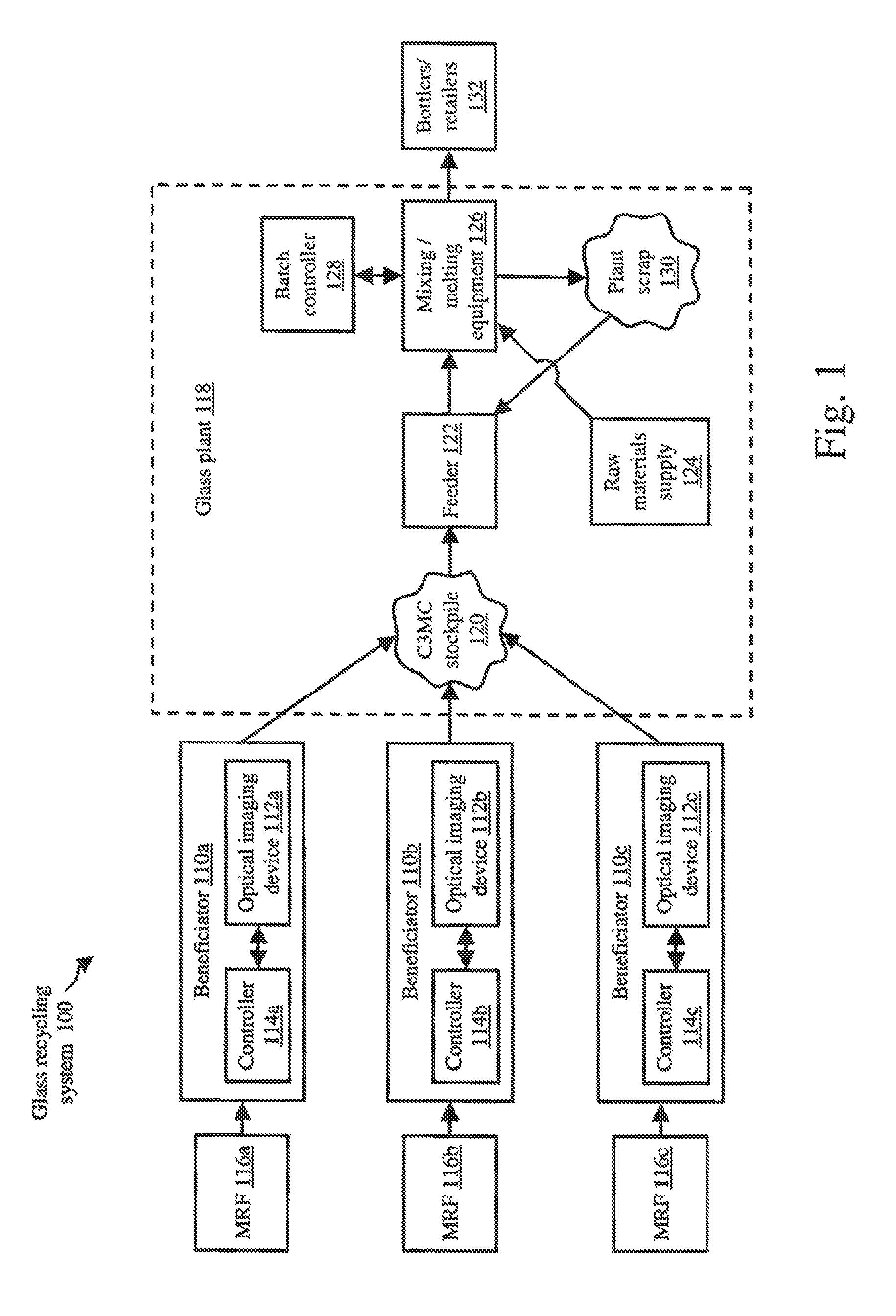

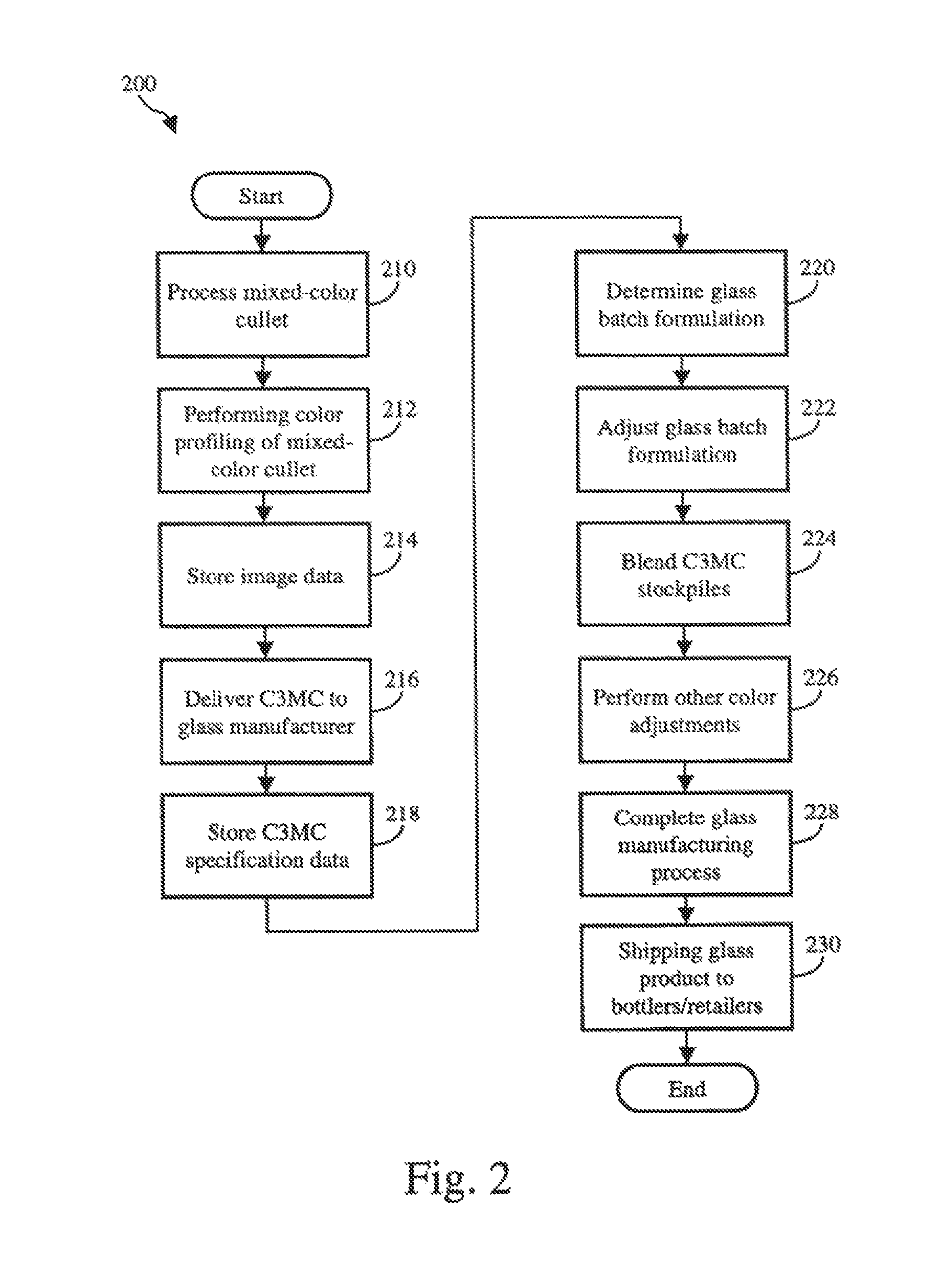

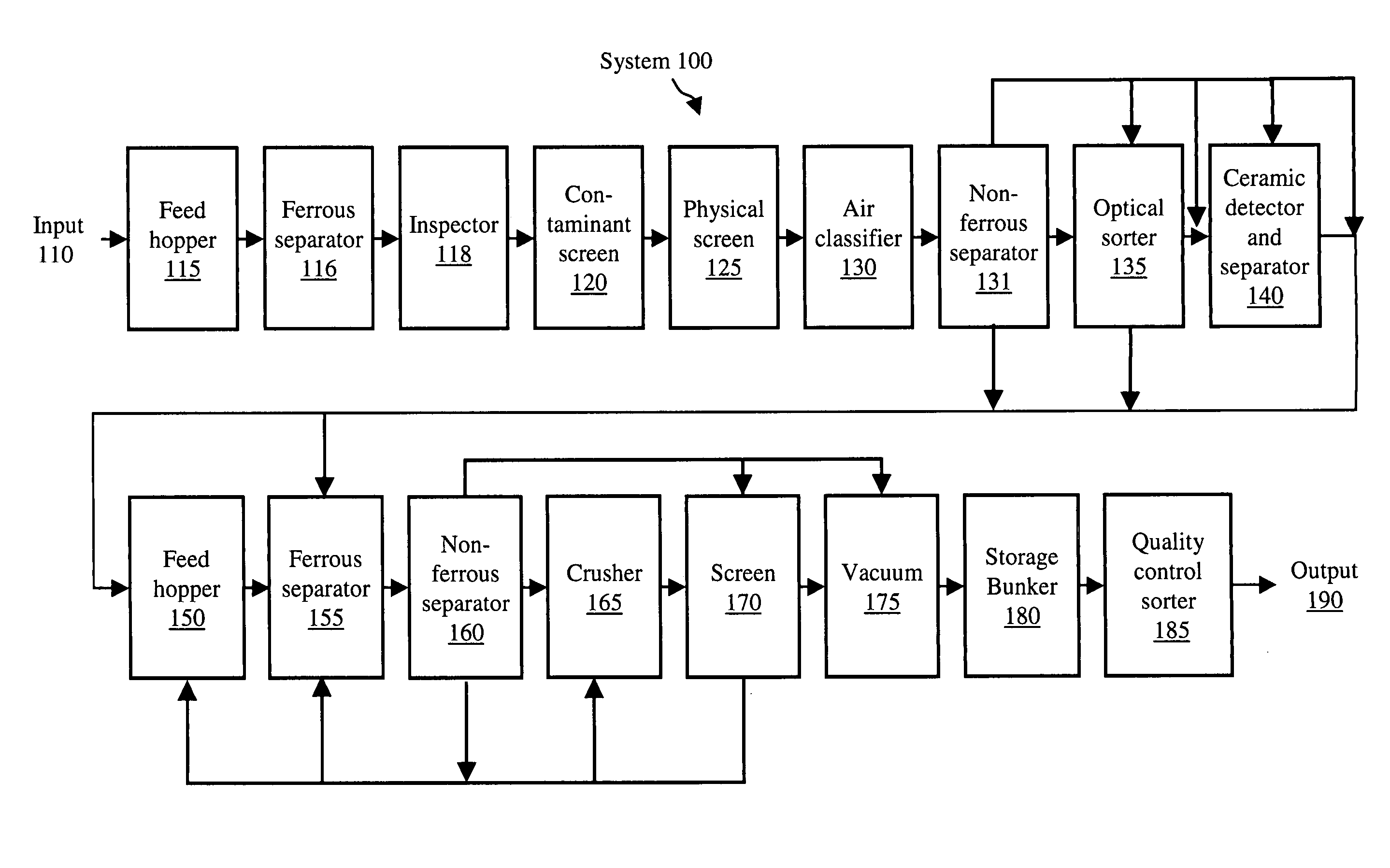

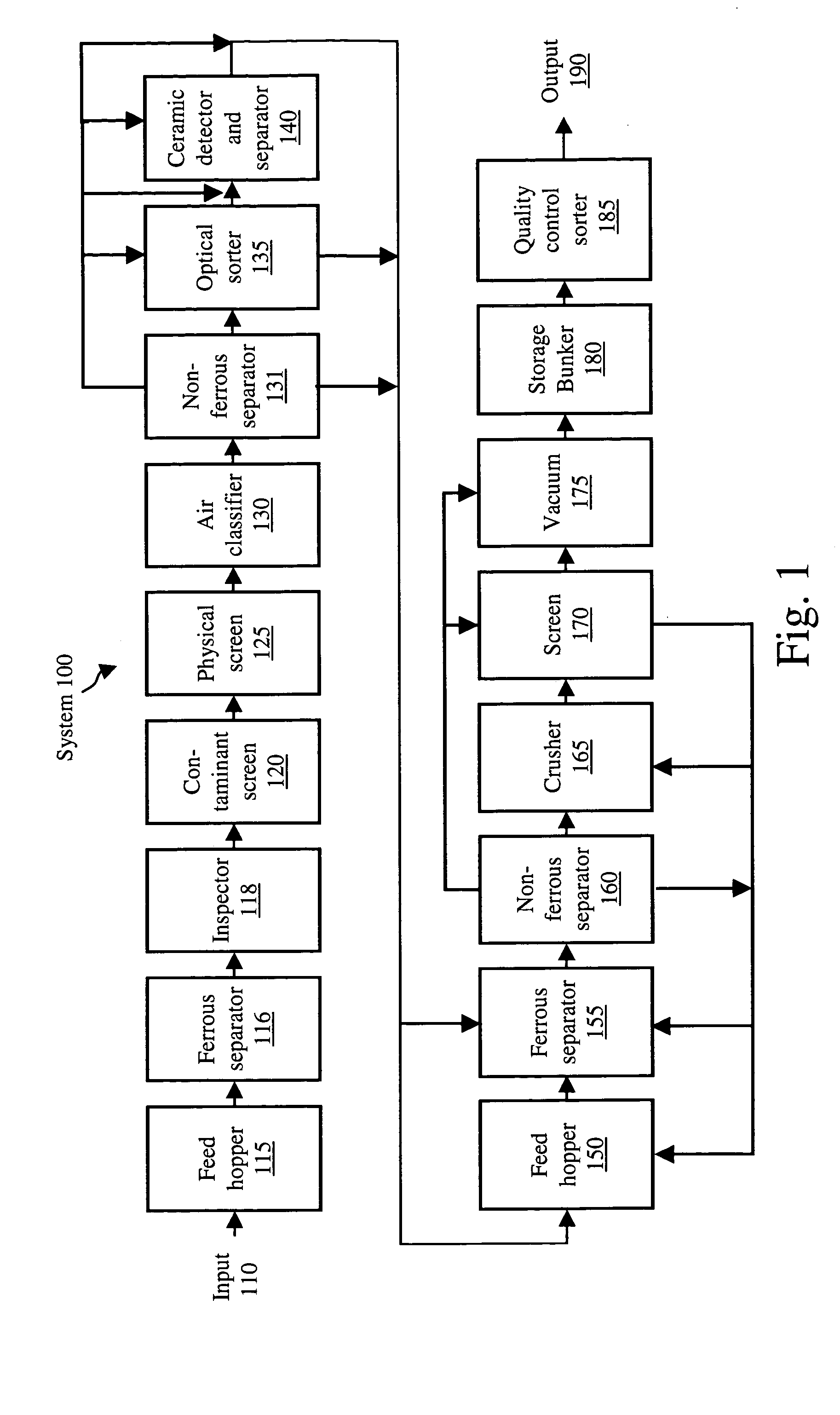

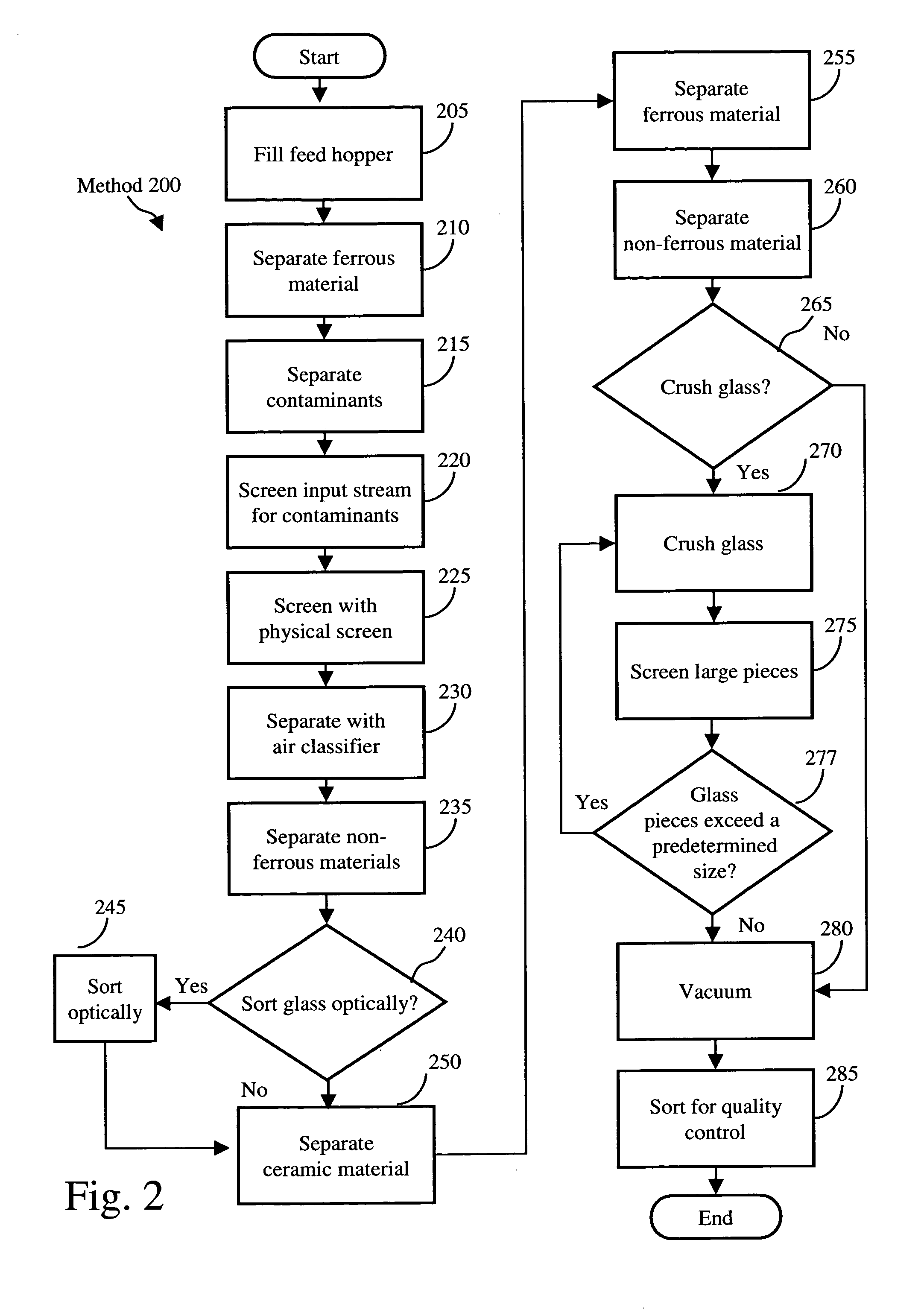

System and methods for glass recycling at a beneficiator

Owner:RE COMMUNITY HLDG II INC

Waterborne suede paint and preparation method thereof

The invention provides waterborne suede paint, which mainly comprises water, talc, light calcium, defoamer, ammonia water, styrene-acrylic emulsion, film-forming additives, glass beads and color paste. The invention also provides a method for preparing the waterborne suede paint. The paint has the advantages that the paint is outstanding in suede and stereoscopic sense, free from pollution, harmless to human body and free from incendivity, ensures strong water resistance and acid-alkali resistance of film, enables decorative surfaces to have high-grade nap-like effects, can be mixed to have dozens of soft colors, and is beneficial to waste utilization by utilizing waste glass beads of fly-ash glass factories.

Owner:上海奇想青晨新材料科技股份有限公司

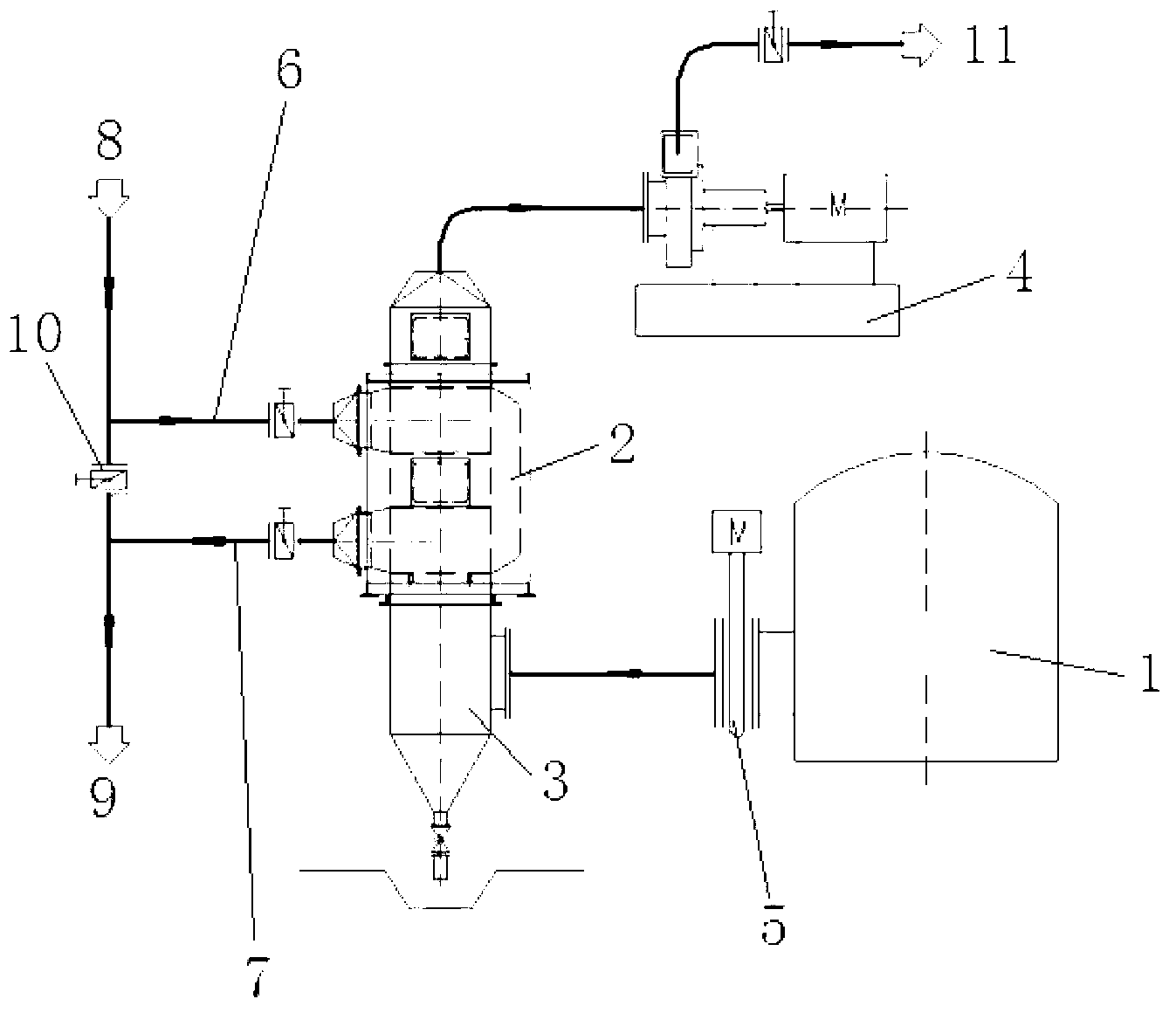

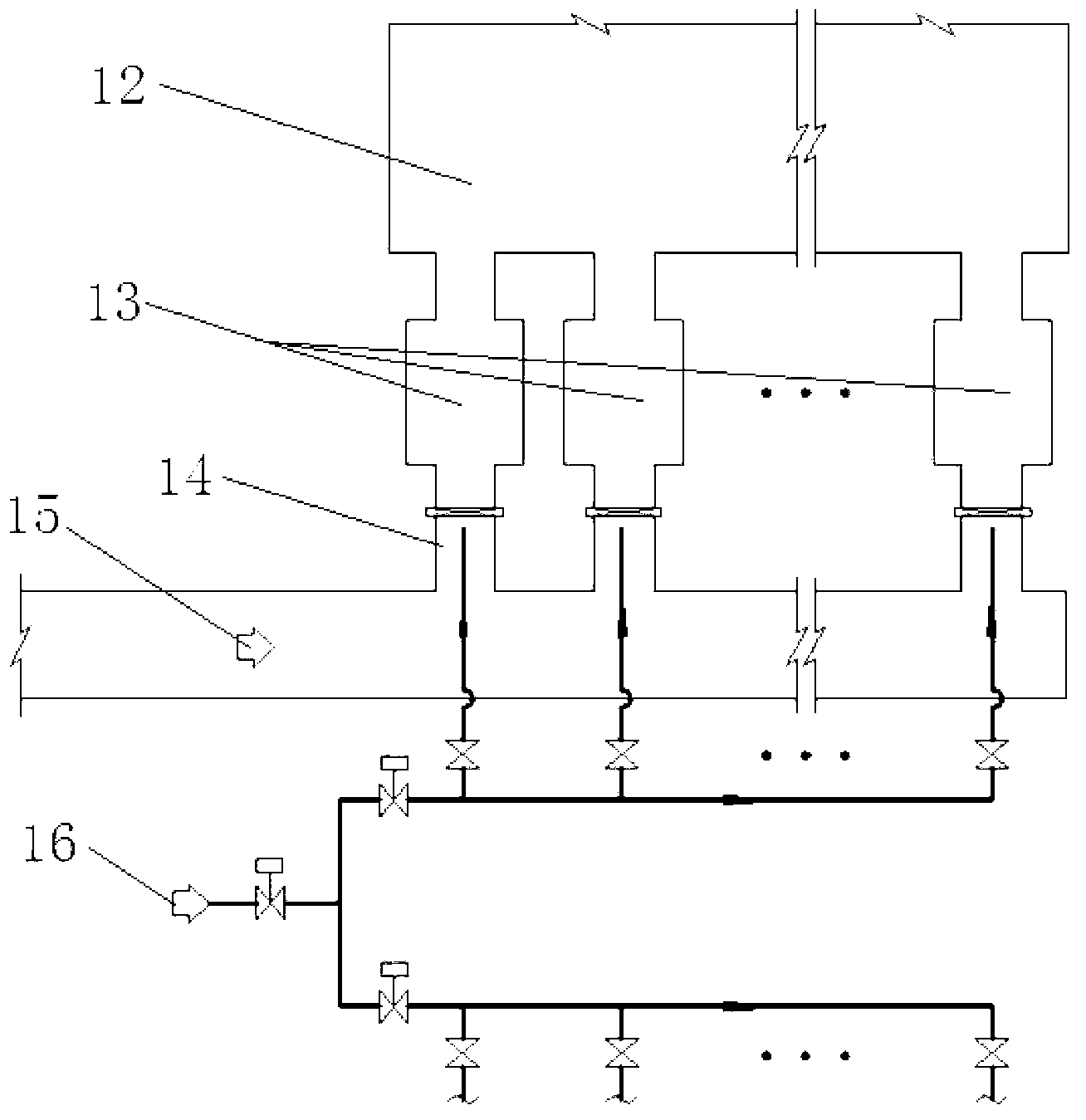

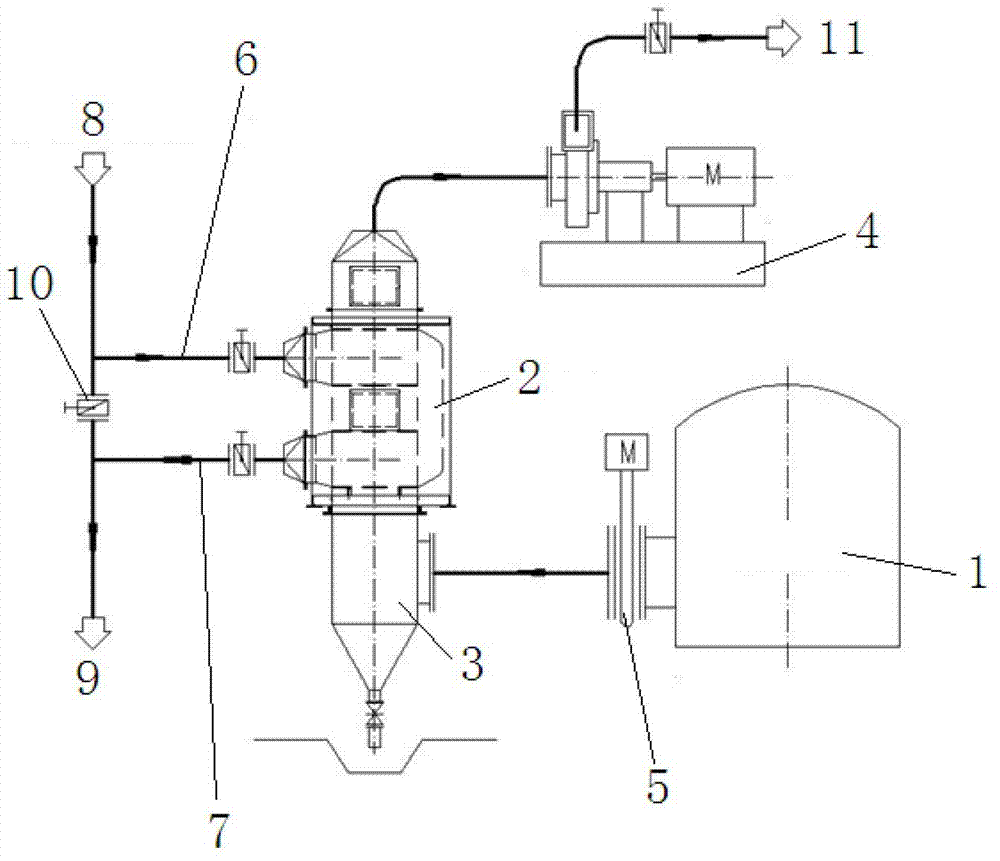

Fine particle polymerizer and high-efficiency dedusting defogging integrated system

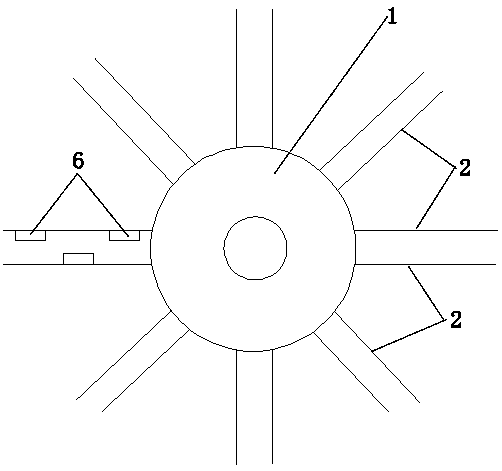

PendingCN106693590ASimple designLow investment costCombination devicesAuxillary pretreatmentParticulatesCyclone

The invention discloses a polymerizer for polymerization of fine particles; the polymerizer includes one or more cyclone devices, and each cyclone device comprises at least two rotational flow vanes; the rotational flow vanes are set to make a gas flow containing fine particles to form a rotary gas flow by the cyclone devices. The invention also provides a dedusting defogging integrated system comprising the polymerizer and an integrated dedusting defogging method. The high-efficiency dedusting defogging integrated system can effectively remove most of PM2.5 fine dust in the gas flow, and has quite high practical application value on governance of the fine particles in flue gas; moreover, the system is low device investment cost, low in energy consumption, and long-term running reliability, and can be used in the fields of flue gas purification of thermal power plants, steel plants, paper-making factories, glass factories, chemical plants and production workshops with particle emissions and the like.

Owner:DEMISTER SHANGHAI ENVIRONMENTAL TECH

System for and method of mixed-color cullet characterization and certification, and providing contaminant-free, uniformly colored mixed-color cullet

Methods of creating a batch of recycled glass from mixed color glass cullet. In one embodiment, the method includes receiving at a glass plant a weight and color composition percentage of a first batch of mixed color cullet. The glass plant also receives a weight and color composition percentage of a second batch of mixed color cullet. The weight and color composition percentage of the first batch and the second batch are combined to generate a combined weight and composition percentage. The combined weight and composition are percentage are used to generate, automatically at a glass plant, a formulation to produce glass of a desired color.

Owner:RE COMMUNITY HLDG II INC

Construction waste recycling technology

InactiveCN108527586AReduce consumptionReduce pollutionSolid waste managementBiofuelsEcological environmentRoad engineering

The invention discloses a construction waste recycling technology comprising the following treatment steps: S1, classifying construction wastes, clearing and screening relatively complete bricks and tiles which can be reused after being cleaned; S2, fully crushing waste bricks, tiles and concrete screened out, using crushed powder to prepare low-grade recycled aggregate concrete for foundation reinforcement, road engineering bedding, indoor floor and floor bedding, and production of non-load-bearing concrete hollow blocks, concrete hollow partition panels and autoclaved fly ash bricks; S3, enabling waste wood screened out in a construction project to pass a wood crushing machine; S4, conveying waste metal and steel materials screened out to a steel plant or a nonferrous metal smelter for remelting; and conveying waste glass screened out to a glass factory or a glass-ceramic factory as production raw materials. According to the construction waste recycling technology, urban traffic pressure and environmental pollution caused by transportation can be relieved, and the construction waste recycling technology benefits protection of cultivated land and ecological environment, and is ofenvironmental significance.

Owner:HUNAN ZHONGHONG HEAVY MACHINERY

Lithium silicate ceramic material absorbing high-temperature carbon dioxide and preparation method thereof

The invention relates to a lithium silicate ceramic material absorbing high-temperature carbon dioxide and a preparation method of the lithium silicate ceramic material absorbing high-temperature carbon dioxide. The lithium silicate ceramic material absorbing high-temperature carbon dioxide is characterized by comprising the raw materials by weight percent: 12.41-28.9% of SiO2, 30.52%-71.1% of Li2CO3 and 0-57.07% of K2CO3. The preparation method of the lithium silicate ceramic material absorbing high-temperature carbon dioxide comprises the following steps of: mixing the raw materials according to the proportion, putting in a mortar and grinding, putting the ground raw materials into a high-temperature resistor furnace, and calcining under high temperature of 600DEG C to 1000DEG C for 0.5h-8h to obtain the lithium silicate ceramic material absorbing high-temperature carbon dioxide, so that the potassium-doped lithium silicate ceramic material can be synthesized. The material provided by the invention can directly absorb a mass of high-temperature carbon dioxide discharged out by a tail gas fuel in the cement kiln, the glass factory and the like. Compared with the prior art, the potassium-doped lithium silicate ceramic prepared by the preparation method is higher in the carbon dioxide absorbing efficiency, and higher in the carbon dioxide use ratio.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD +1

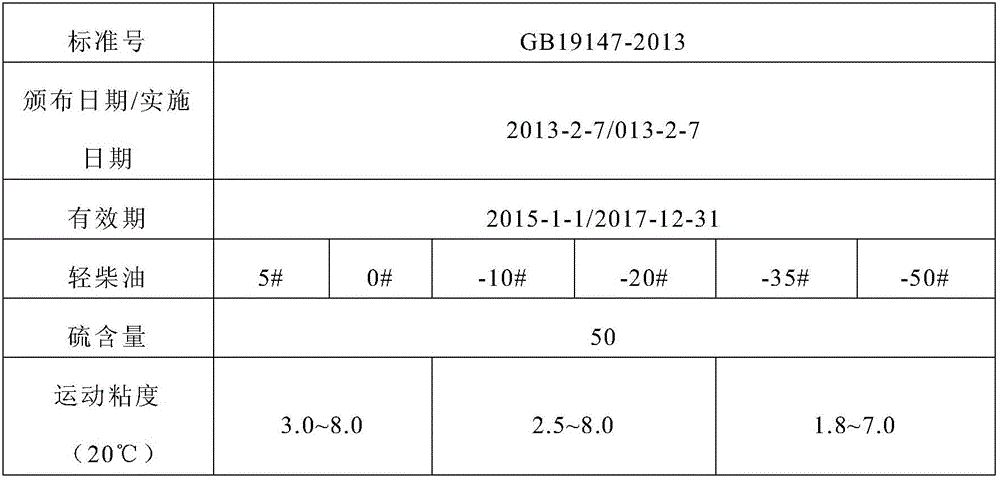

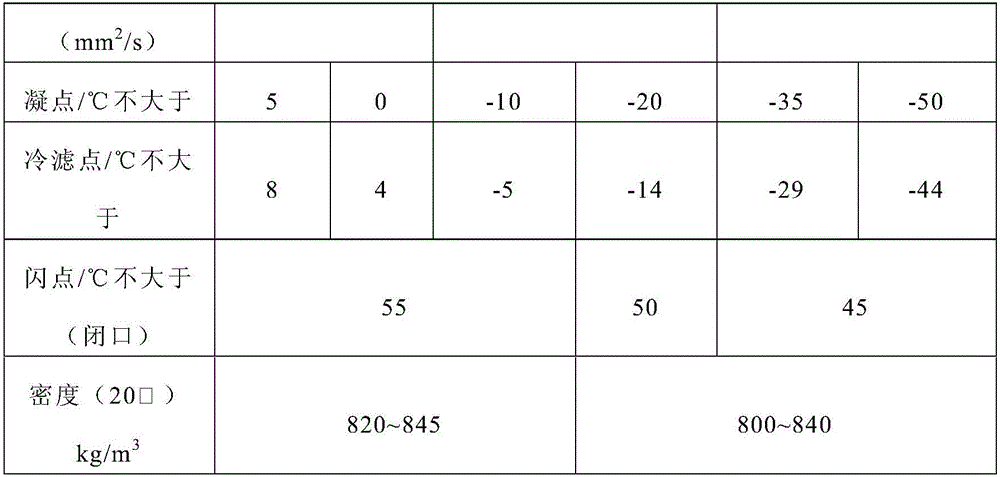

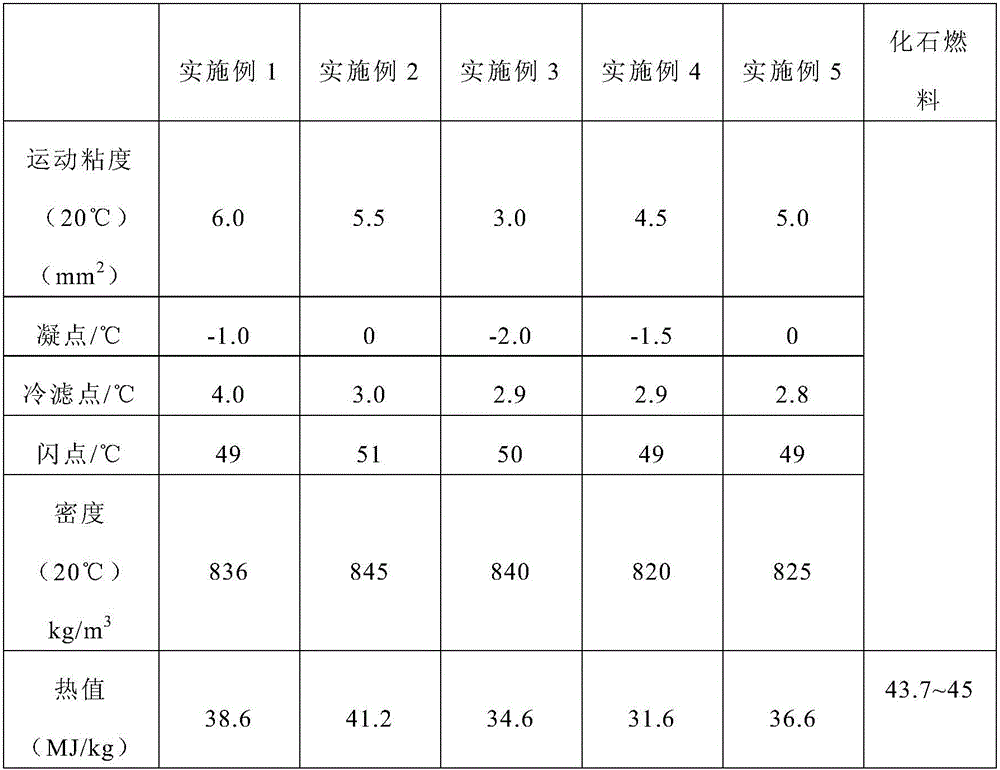

Renewable swill-cooked dirty fuel oil

InactiveCN102719284AReduce manufacturing costSolving Regulatory DifficultiesFatty oils/acids recovery from wasteLiquid carbonaceous fuelsFreezing Point TemperaturePetrochemical

Owner:深圳中兴新源环保股份有限公司

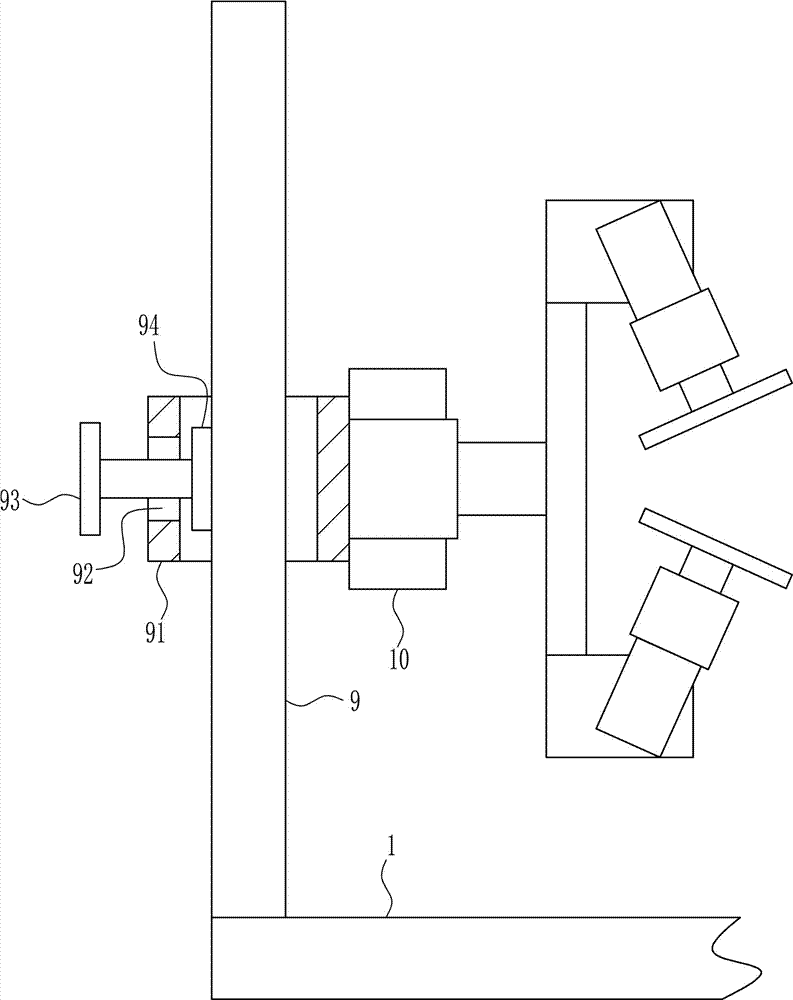

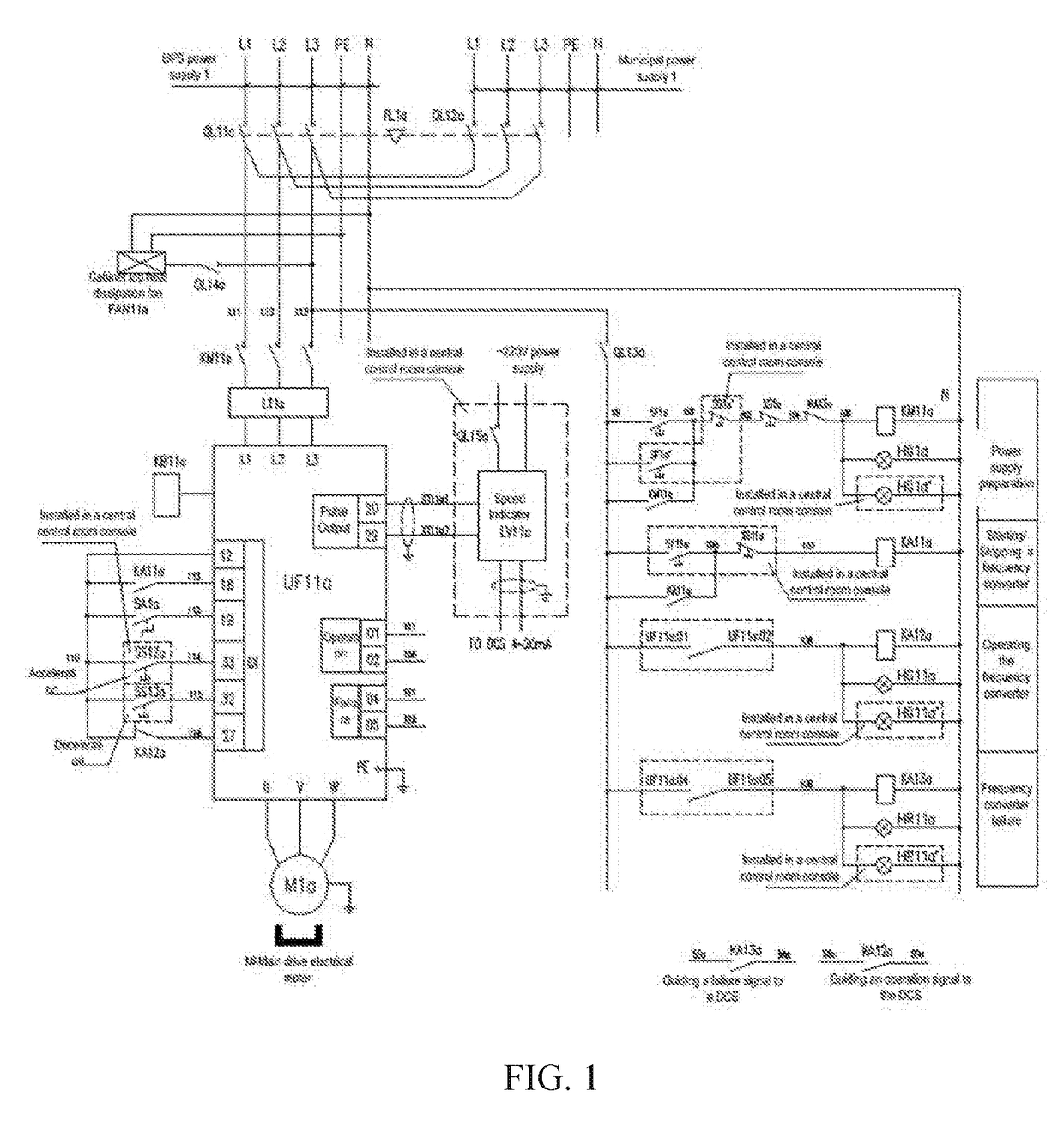

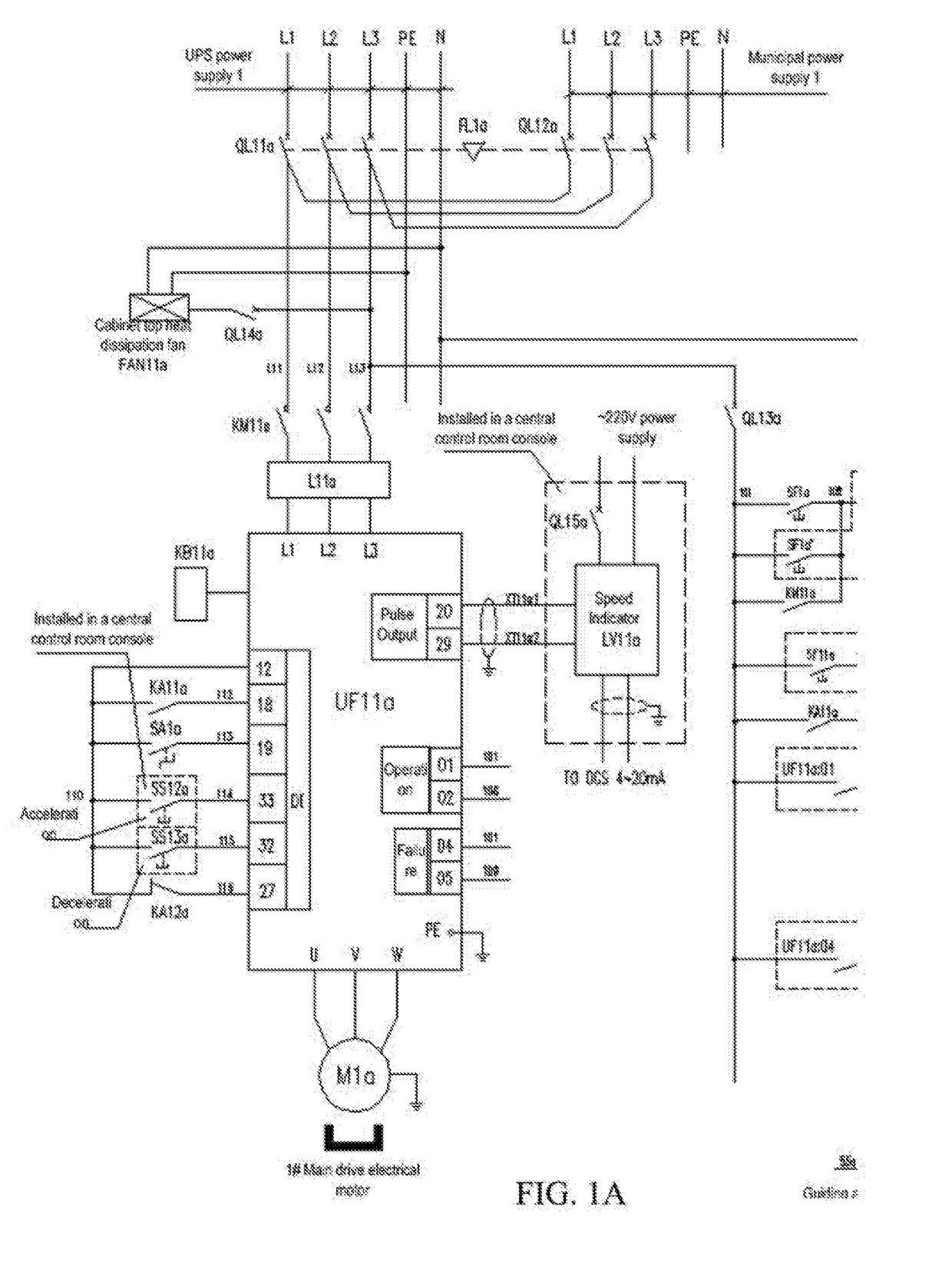

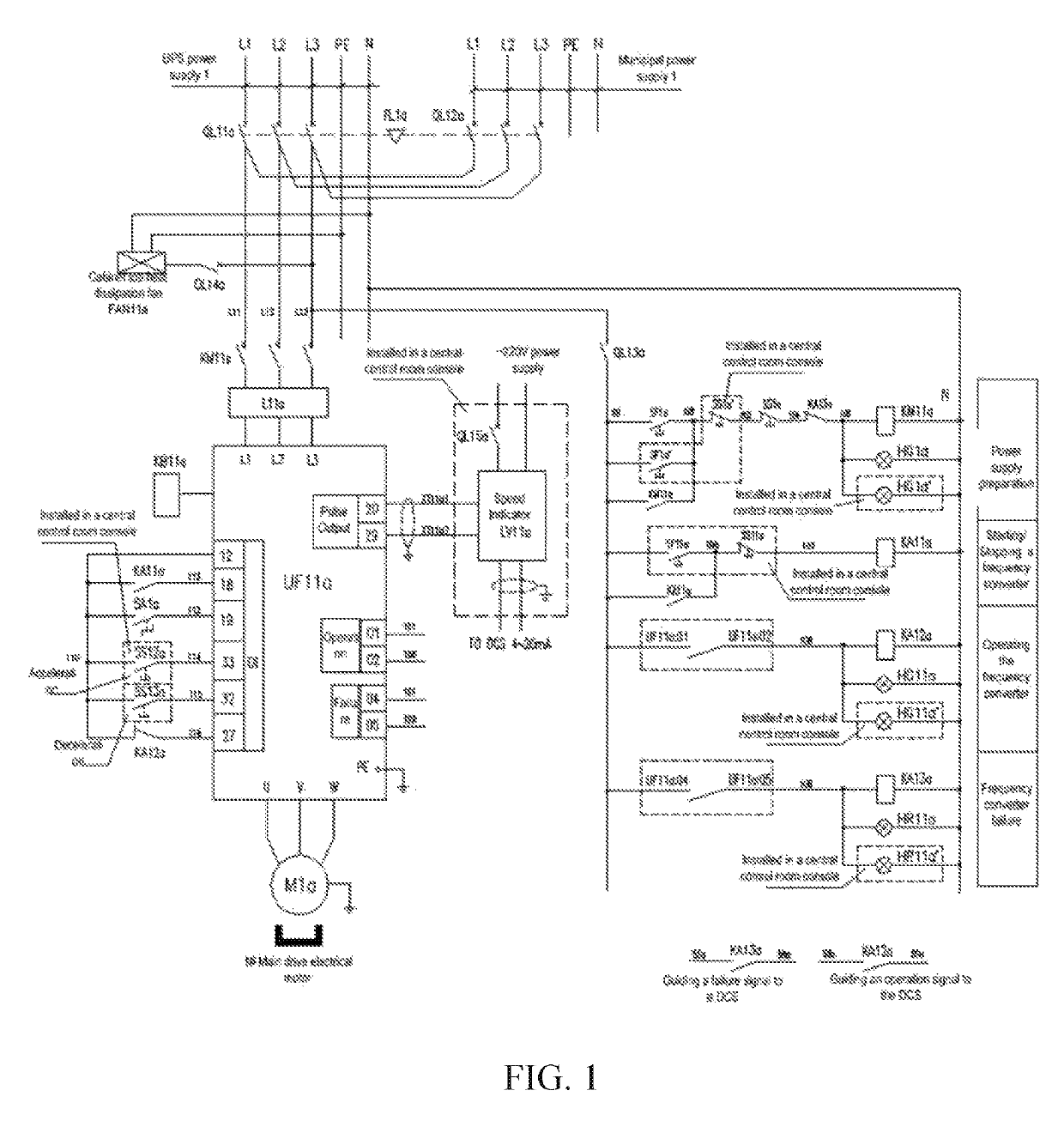

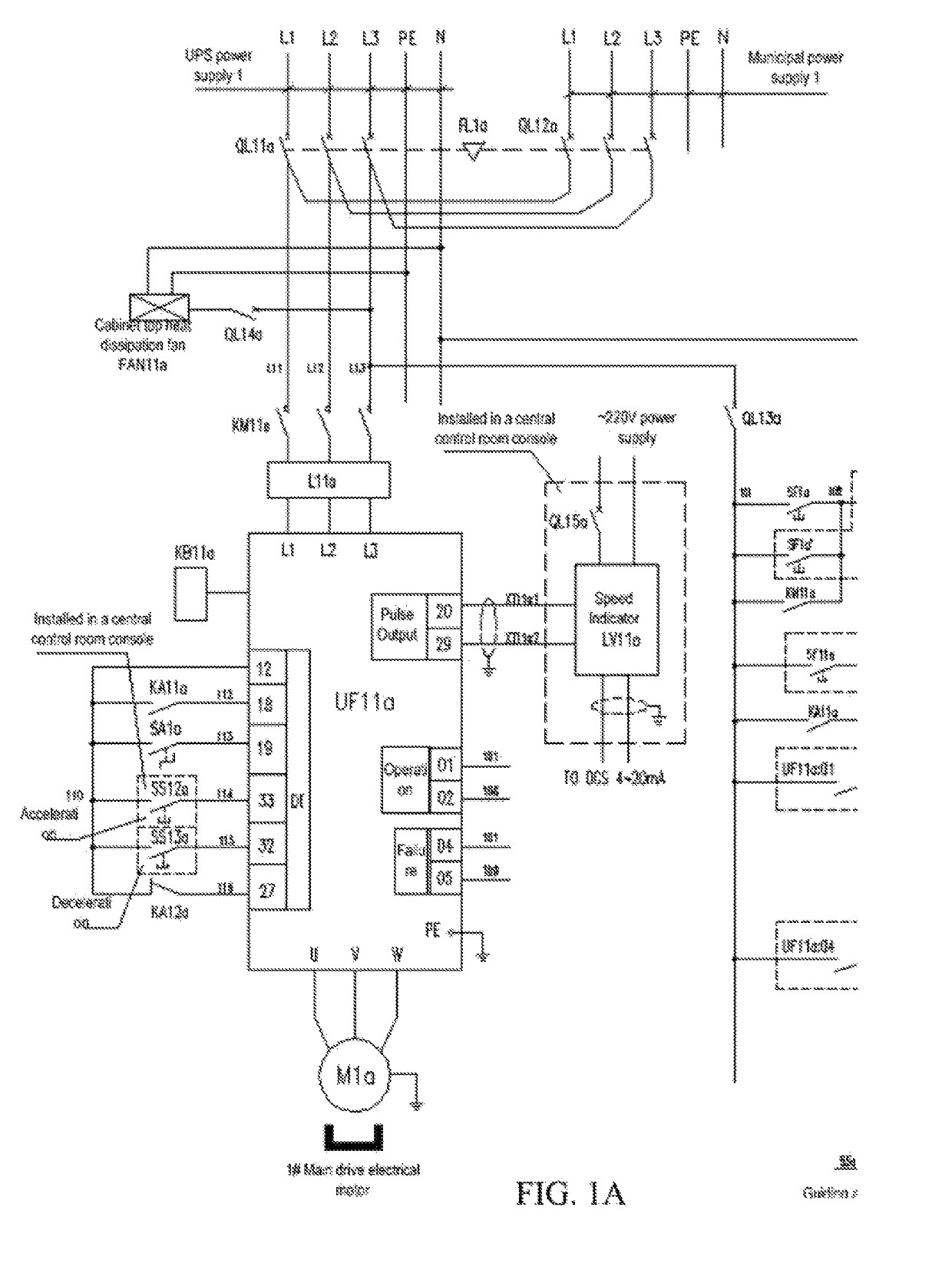

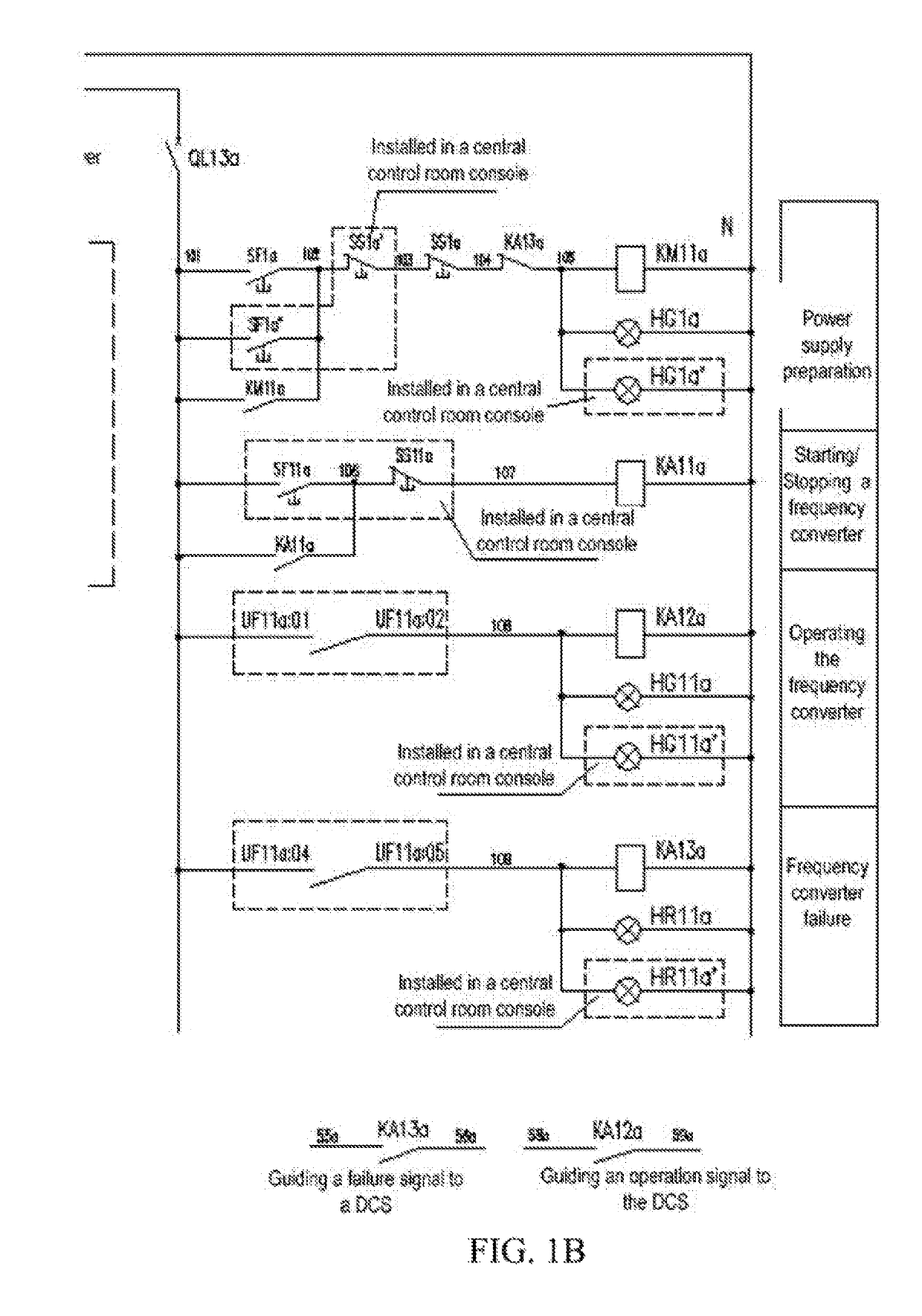

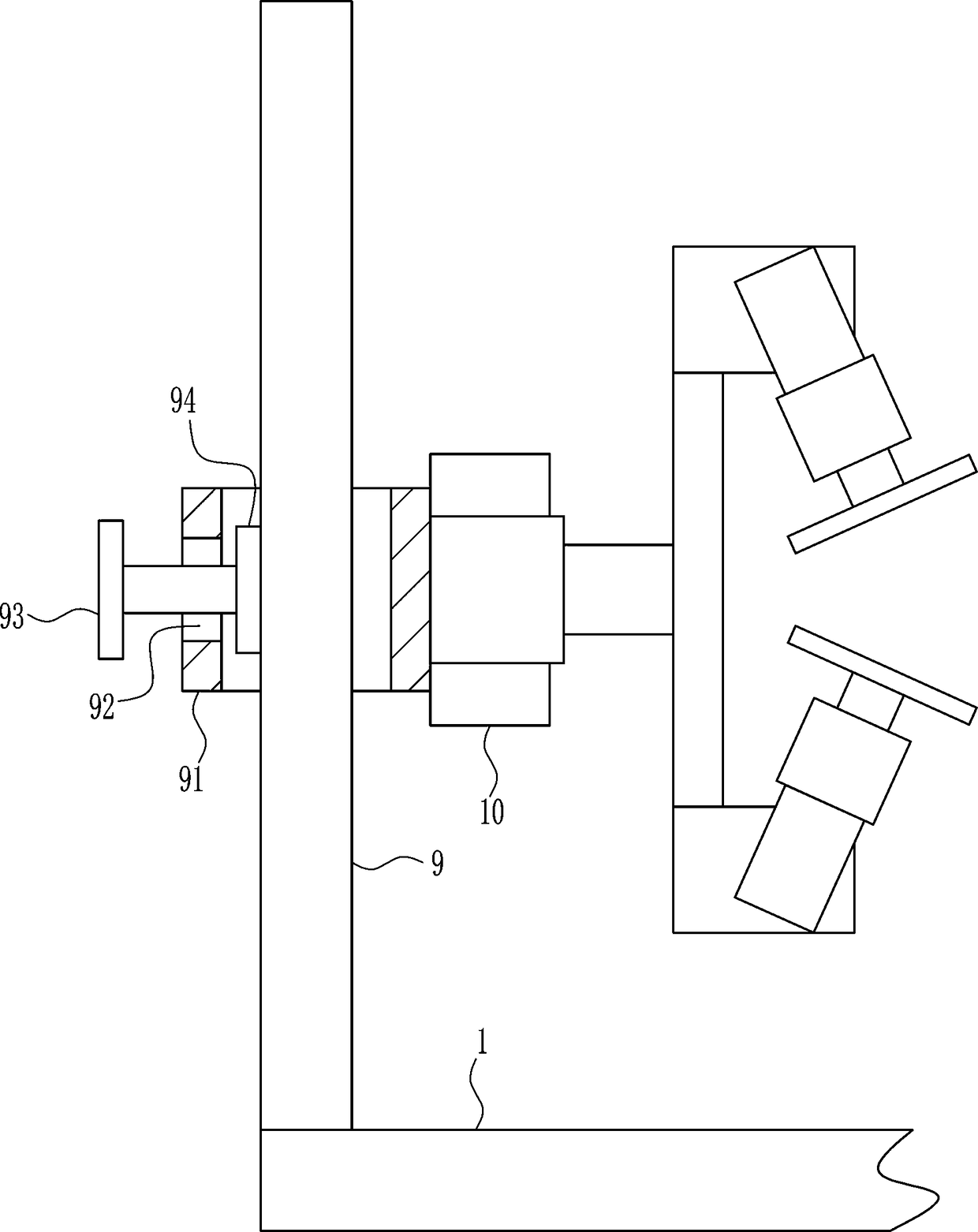

Main drive control method for glass factories

ActiveUS20170324355A1Avoid mistakesOvercome inaccuraciesAC motor controlPower network operation systems integrationEngineeringCircuit breaker

A main drive control method for glass factories, comprising the following steps: (a) providing a first circuit breaker and a second circuit breaker on a power supply loop of an electrical motor, wherein one end thereof is respectively connected to two main drive electrical motors; (b) enabling the first circuit breaker to be connected to a municipal power supply and the second circuit breaker to be connected to a UPS power supply; and (c) enabling the first circuit breaker and the second circuit breaker to be interlocked via a mechanical interlocking mechanism, so that only one of the circuit breakers can be switched on during a normal operation. The main drive control method for glass factories solves the problem that the rotation speed of a main drive electrical motor is incorrect due to the interference on a signal.

Owner:CHINA TRIUMPH INT ENG

Soldering tin material used for automotive glass hot-coating belts and application of soldering tin material

InactiveCN103273218AImprove performanceImpedance value suitable forWelding/cutting media/materialsSoldering mediaGlass factoryTensile shear

The invention discloses a soldering tin material used for automotive glass hot-coating belts and application of the soldering tin material. The soldering tin material is impact-resistant, temperature-resistant, proper in tensile-shear strength, low in welding temperature and melting point, capable of greatly reducing stress change among alloy materials and effectively preventing fatigue ageing and shedding of metals, excellent in performance and stable in quality, has all aspects to reach or exceed requirements of international similar products and is capable of providing high-quality service for automotive glass factories. The soldering tin material comprises tin, lead, silver and bismuth and is characterized by comprising, by weight, 20-30% of the tin, 58-68% of the lead, 4-14% of the bismuth and 0.3-5% of the silver.

Owner:DONGGUAN BEST ALLOYS

Systems and methods for glass recycling at a beneficiator

Owner:RE COMMUNITY HLDG II INC

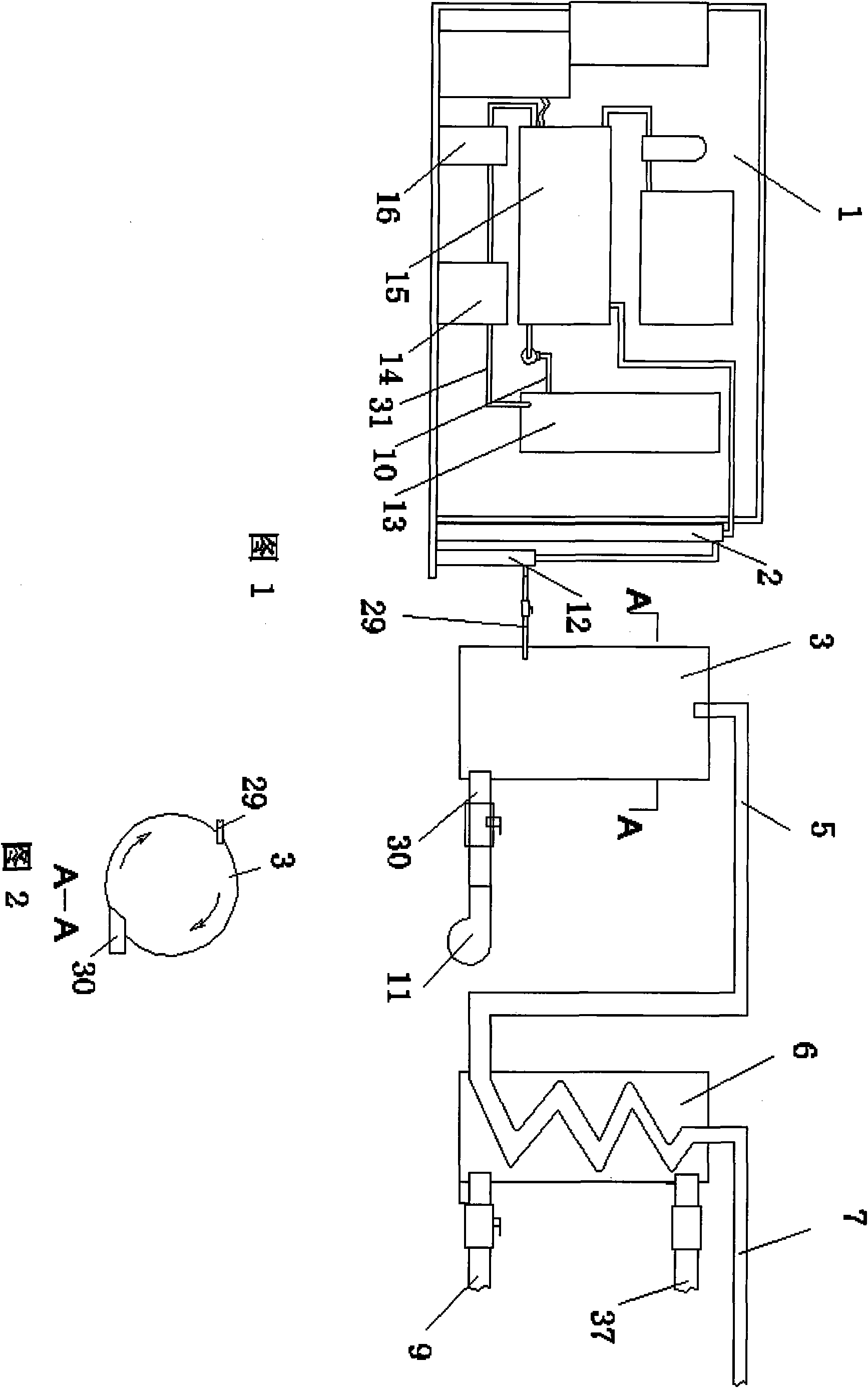

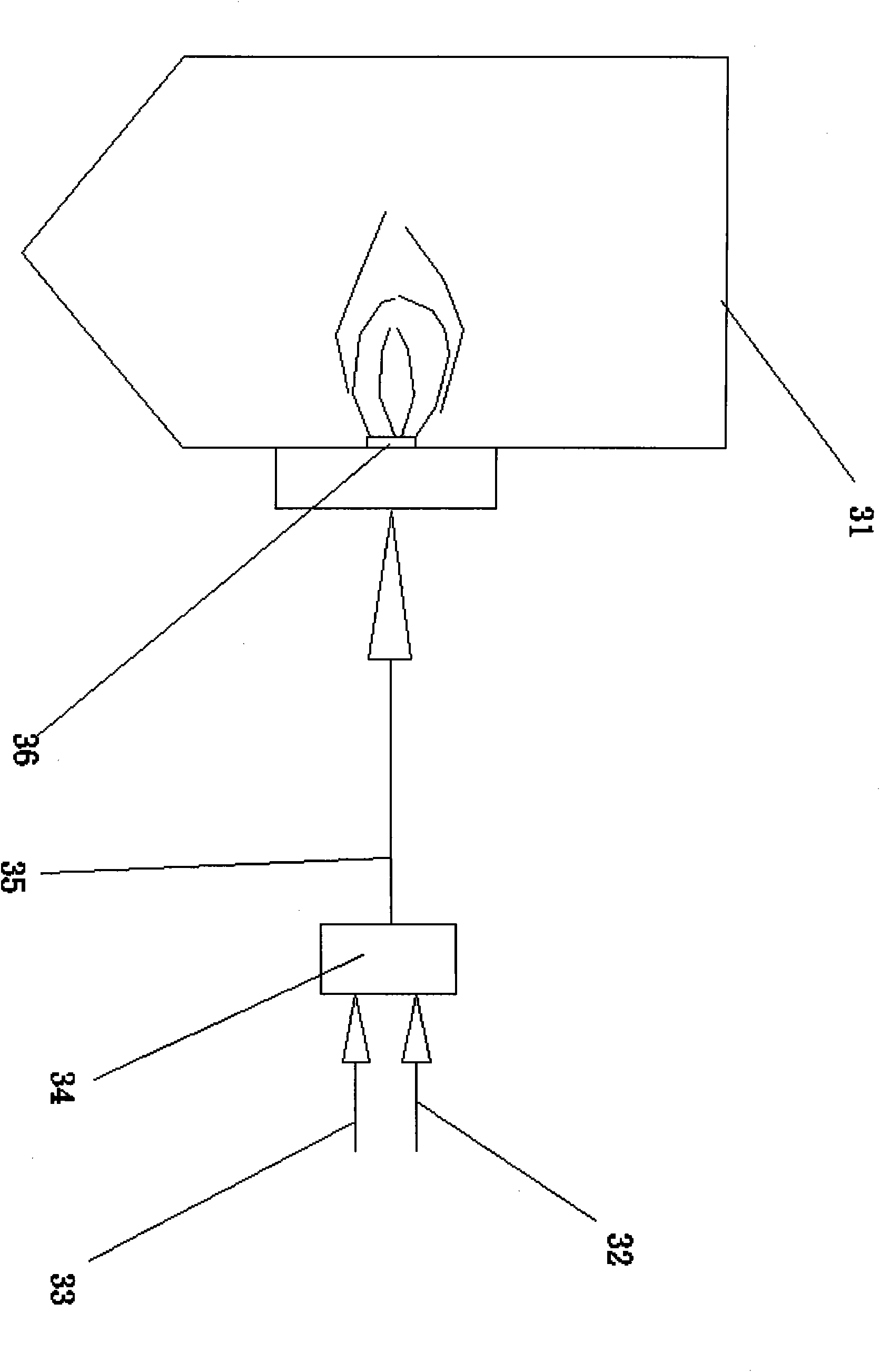

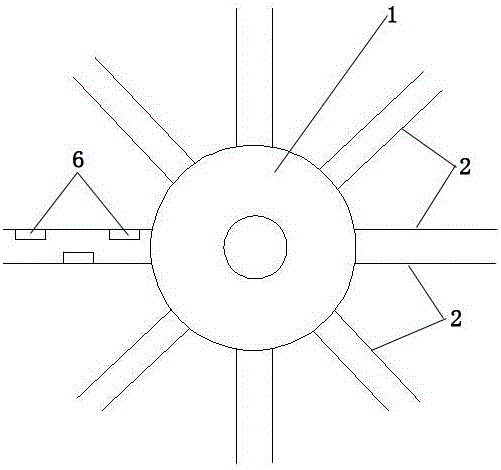

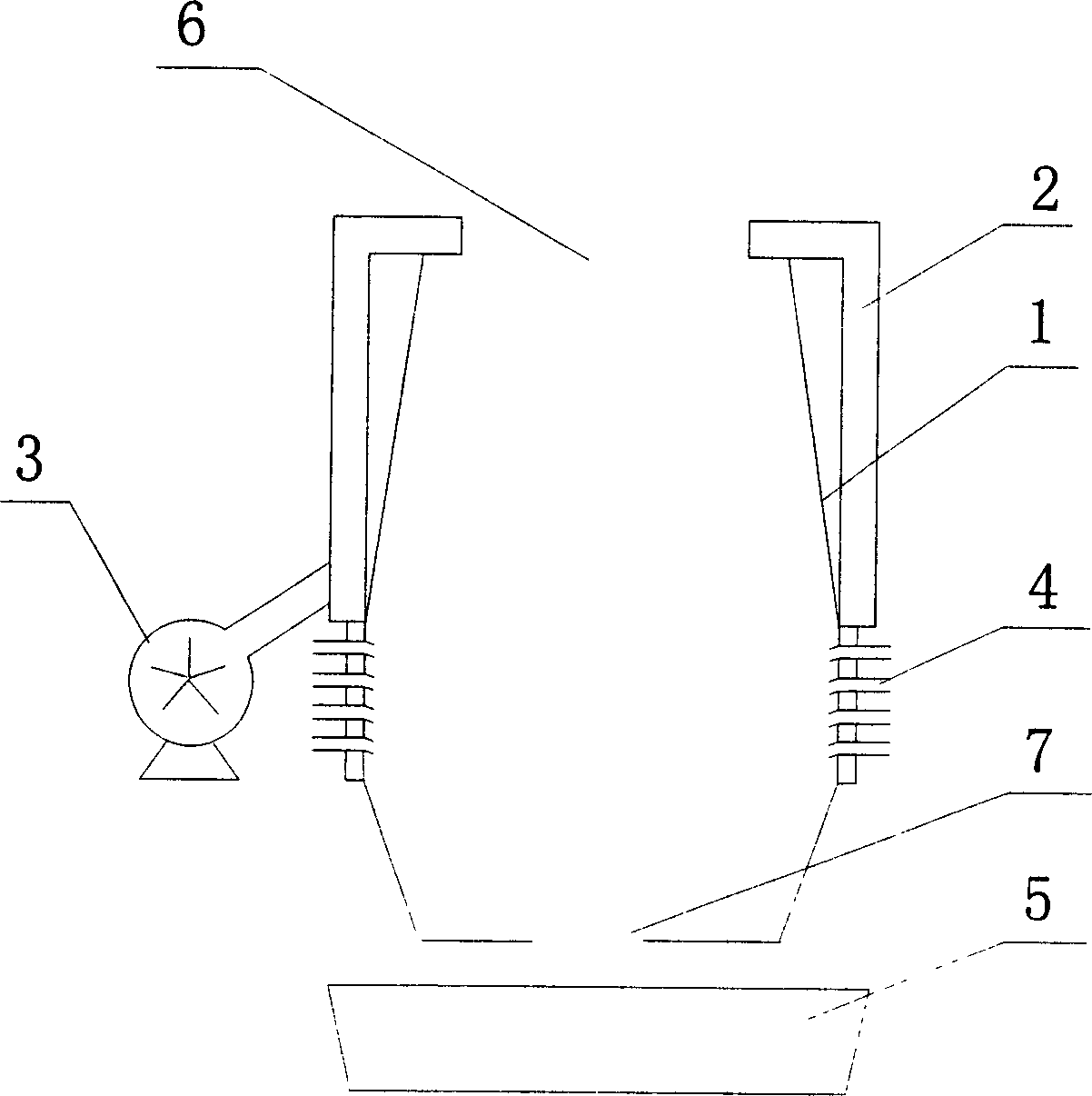

Hydrogen oxygen combustion-supporting device for improving combustion efficiencies of kiln in blown glass factory and boiler in power plant

InactiveCN101830630AReduce contentReduce pollutionGlass furnace apparatusNon-combustible gases/liquids supplyGlass factoryProcess engineering

The invention relates to a hydrogen oxygen combustion-supporting device for improving the combustion efficiencies of a kiln in a blown glass factory and a boiler in a power plant. The device comprises a hydrogen oxygen machine, a hydrogen oxygen mixing tank, a heating tank and a mixed fan; a gas outlet pipe of the hydrogen oxygen machine and the gas outlet pipe of the mixed fan are connected with the tangent line of a cylindrical wall on the inner side of the hydrogen oxygen mixing tank; the gas outlet pipe of the hydrogen oxygen mixing tank is connected with the heating tank; and an exhaust pipe of an annealing furnace is connected with the heating tank. A mixed gas of hydrogen and oxygen heated by the heating tank is introduced into the boiler or the kiln to support combustion, so a fuel can burn fully. The device has the advantages of effectively improving the heating efficiency of the fuel, lowering running cost, reducing smoke emission and contributing to environment protection.

Owner:佛山市铸顺金属材料有限公司 +1

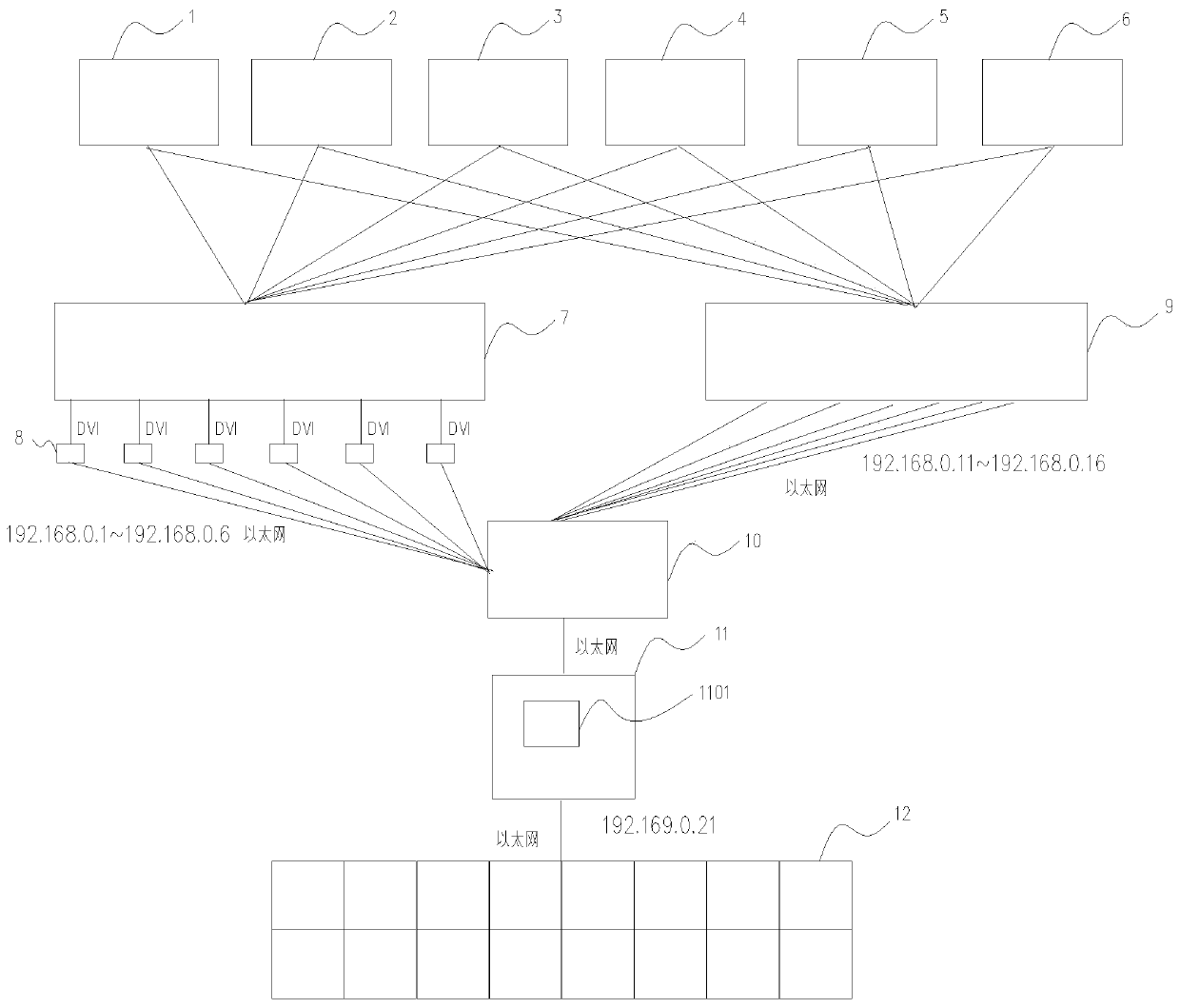

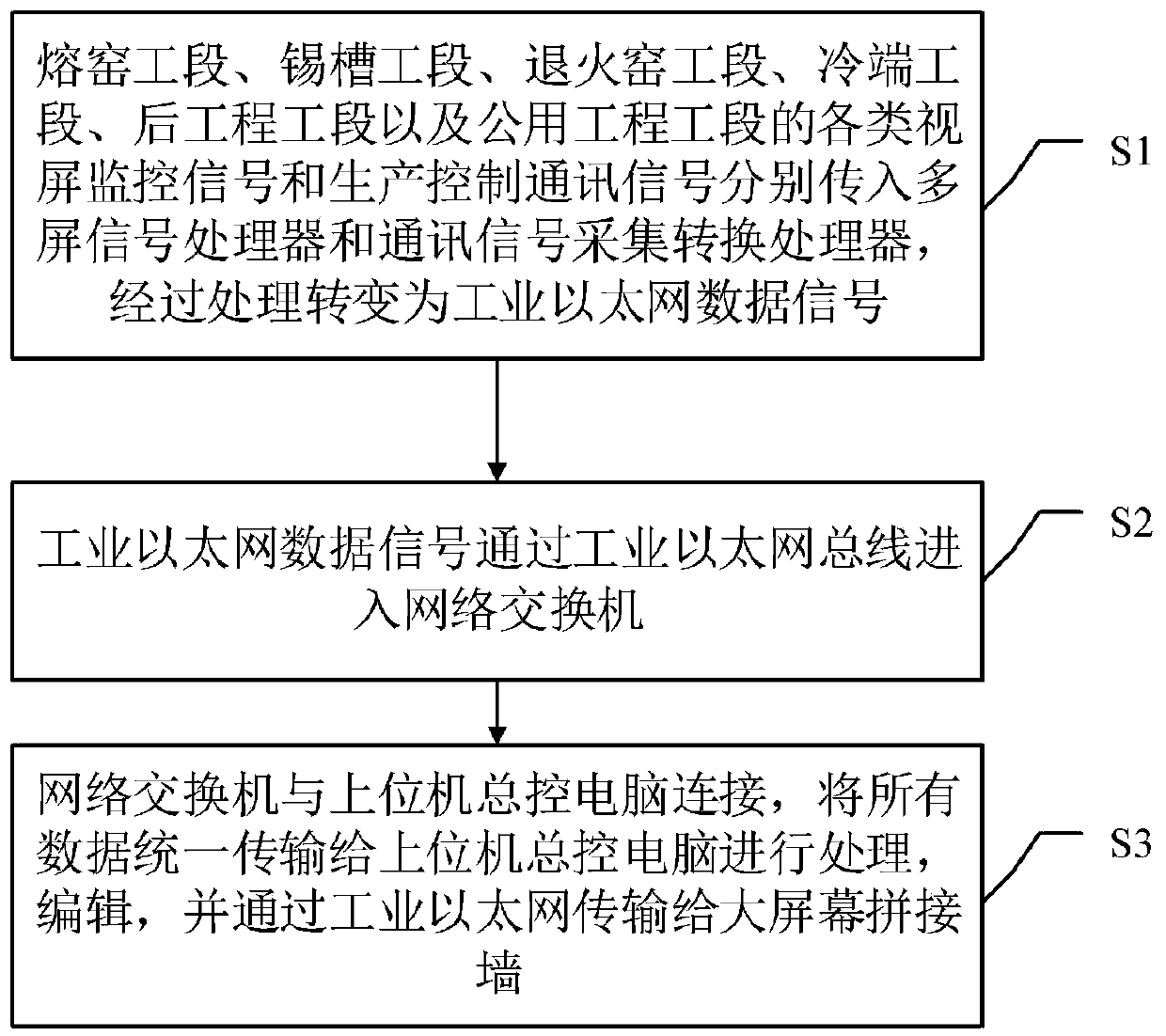

Glass factory multi-signal large-screen integrated control system and control method thereof

InactiveCN110083137AEasy to monitorReal-time centralized monitoring of production statusTotal factory controlProgramme total factory controlControl systemLarge screen

The invention discloses a glass factory multi-signal large-screen integrated control system and a control method thereof. The system comprises a multi-screen signal processor, decoding transmitters, acommunication signal acquisition and conversion processor, a network switch, an upper computer master control computer and a large screen splicing wall. The upper computer master control computer comprises a video signal large screen integration control unit. An input end of the multi-screen signal processor is connected to a melting furnace section, a molten tin bath section, an annealing furnace section, a cold end section, a rear engineering section and a public engineering section respectively. There are several decoding transmitters. Each section corresponds to one decoding transmitter.The input end of each decoding transmitter is connected to an output end of the multi-screen signal processor. The input end of the communication signal acquisition and conversion processor is connected with the melting furnace section, the molten tin bath section, the annealing furnace section, the cold end section, the rear engineering section and the public engineering section respectively. Thesystem and the method can be used to uniformly and integrally monitor production states of all the sections in a factory area.

Owner:BENGBU TRIUMPH ENG TECH CO LTD

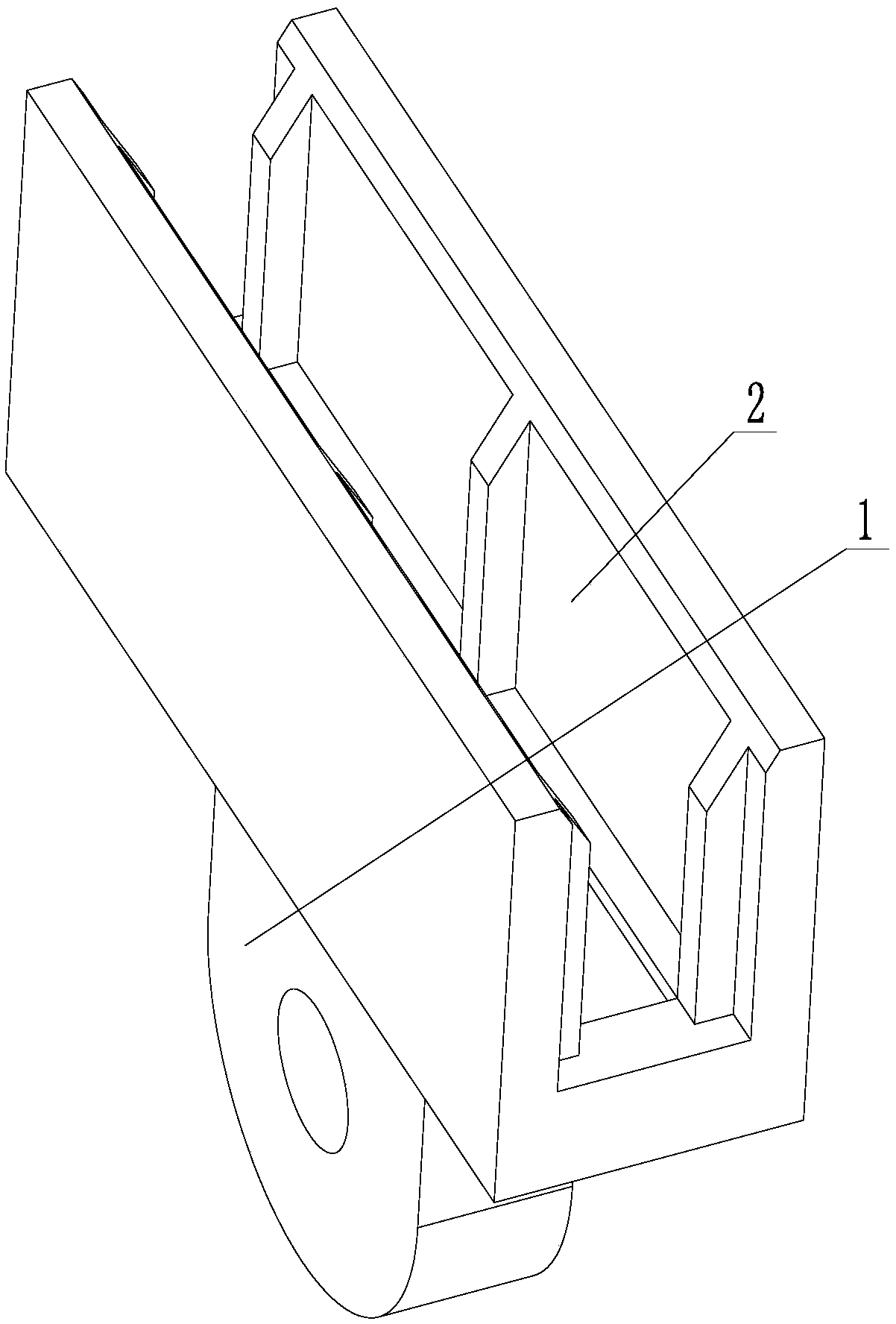

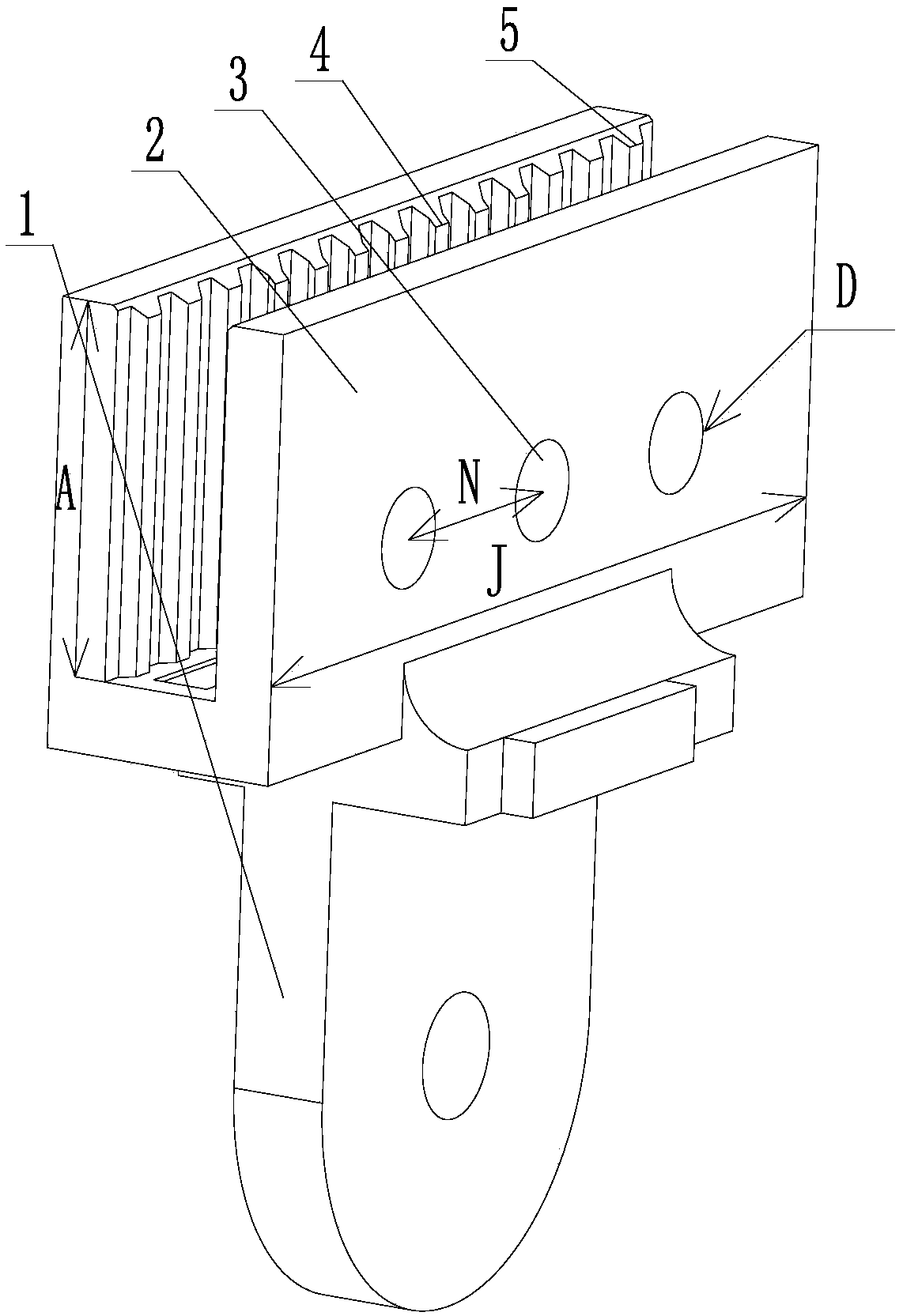

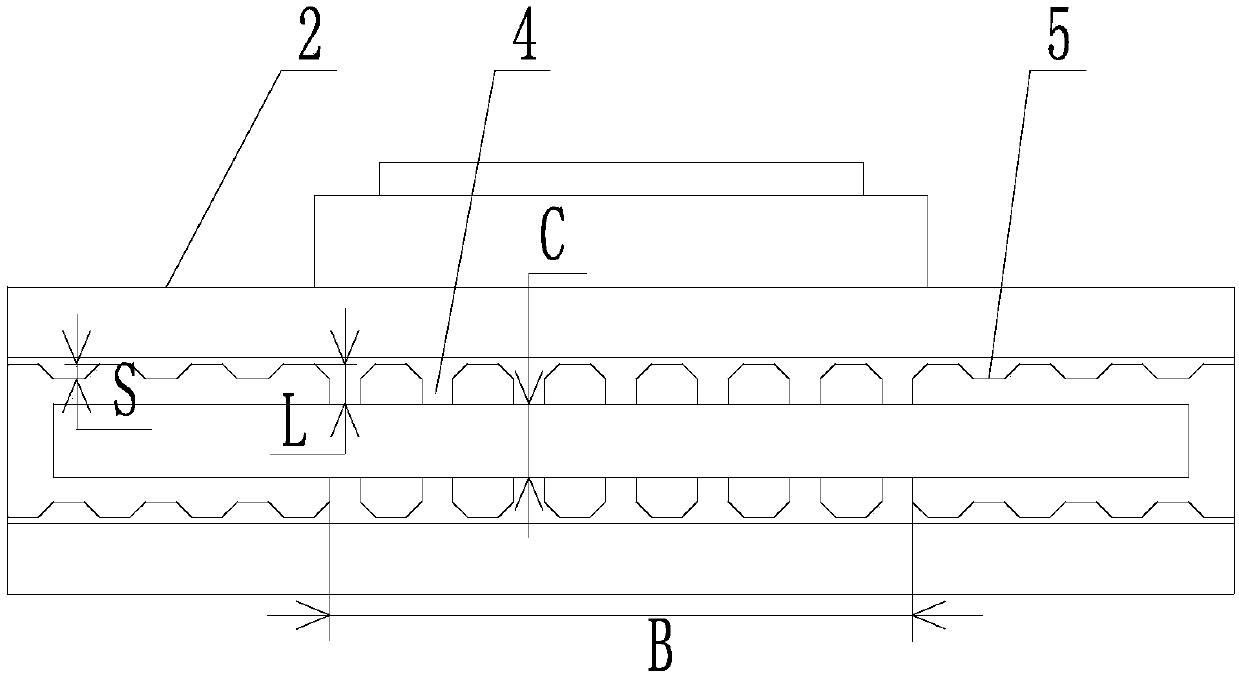

Bracket capable of quickly bonding and curing with window glass

PendingCN109555398AReduce manufacturing precisionReduce installation difficultyMan-operated mechanismPower-operated mechanismAdhesiveEngineering

The invention relates to a bracket capable of quickly bonding and curing with window glass, and belongs to the technical field of automobile accessories. The bracket includes a bracket body and a pairof clamping platesarranged atthe upper end of the bracket body, convex ribs are arranged on the inner walls of the clamping plates, a PU adhesive is arranged in grooves formed by the convex ribs andglass, a group of air holes are formed in the clamping plates at intervals, and the ratio of the length J of the clamping plates to the spacing distance N between the air holes is 3 to 6; and the convex ribs include a group of main ribs which is located in the middle sections of the clamping plates and in contact with the glass surface and a group of side ribs which is located at both ends of theclamping plates, the height L of the main ribs is greater than the height S of the side ribs, and the ratio of the depth A of the clamping plates to the thickness C of the glass is 3 to 5. According to the automobile window glass bracket, through the air holes formed in the clamping plates, coordination of the main ribs and the side ribs and control of the depth of the clamping plates, the curingefficiency of the PU adhesive is greatly improved while the strength of the bracket is ensured, the installation cycle of the glass and the bracket is effectively shortened, and then the promoting effect on reducing the cycle inventory in a glass factory is achieved.

Owner:HEBEI KELI AUTOMOBILE EQUIP CO LTD

Short-distance transporting device for small number of glass products

Owner:苏州市灵通玻璃制品有限公司

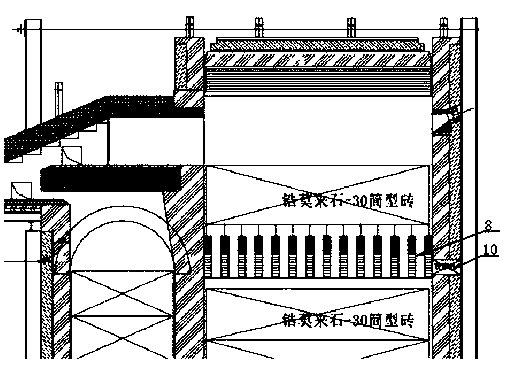

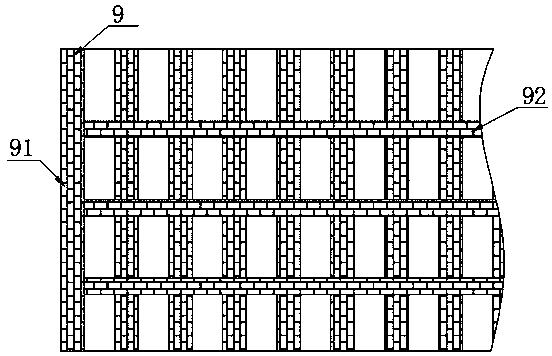

Method for applying low-heat value gas to combustion in melting furnace

ActiveCN102795757AReduce manufacturing costEmission reductionGlass furnace apparatusEngineeringMixed gas

The method relates to a gas supply manner for a glass production line, in particular relates to a mixed gas supply manner with producer gas as a fuel, and specifically relates to a method for applying low-heat value gas to combustion in a glass factory melting furnace. The method for applying the low-heat value gas to combustion in the glass factory melting furnace is characterized in that low-heat value coke oven gas low in cost exchanges heat with flue gas generated by the glass melting furnace, and then is mixed with the producer gas to generate a supplementary fuel for combustion in the smelting furnace; therefore, the dosage of one part of the producer gas is counteracted; as a result, the purposes of reducing energy consumption and saving glass production cost are achieved.

Owner:CHINA TRIUMPH INT ENG

Composite fuel oil

InactiveCN106010675AHigh viscosityImprove flash pointLiquid carbonaceous fuelsFuel additivesAntioxidantMass ratio

The invention discloses composite fuel oil and belongs to the technical field of petrochemical engineering. The composite fuel oil is prepared from, in percentage by mass, 40%-70% of fossil fuel oil, 20%-30% of solvent oil, 0-25% of gutter oil and 0-10% of coal tar, 1 permillage of an additive is further added to the composite fuel oil, and the additive is a mixture of a compatilizer, an anti-smoke agent, an anti-coking agent, an antioxidant and a pour point depressant in mass ratio being (1-10) : (1-10) : (1-10) : (0-1) : (0-1). High-viscosity and high-solidifying-point fossil fuel oil and low-viscosity and low-solidifying-point solvent oil are composited, the additive is added, and the combustion characteristics such as viscosity, flash points and the like of fuel oil are improved. The composite fuel oil is possibly applied to a power station, a cement plant, a glass factory and other industries to replace light diesel oil or heavy oil, is economical and realizes sustainable development.

Owner:WUHAN SIQI ENVIRONMENTAL PROTECTION TECH CO LTD

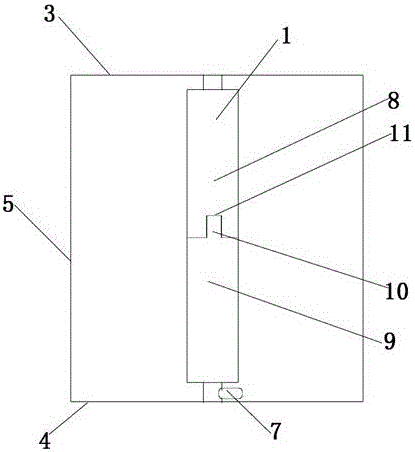

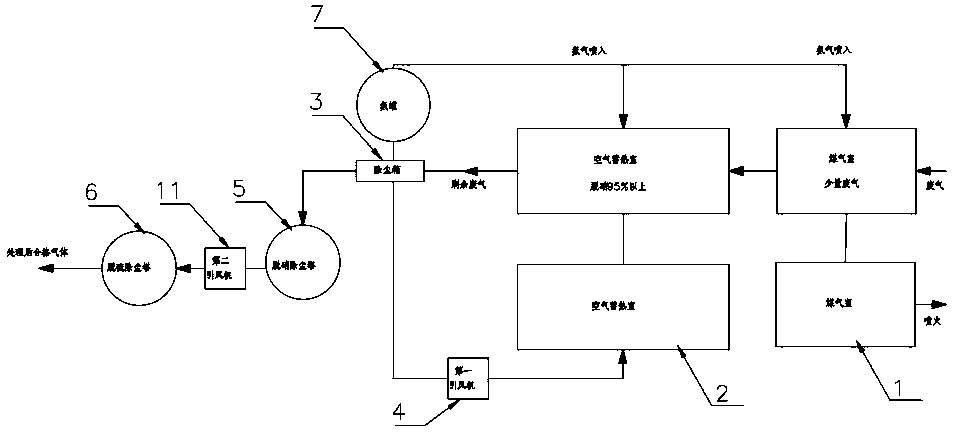

Glass factory waste gas denitration method

PendingCN110500603AReduce processing costsShort installation periodNitrous oxide captureGas treatmentEngineeringTreatment costs

The invention discloses a glass factory waste gas denitration method and belongs to the technical field of waste gas purification. A gas chamber is included. An air heat storage chamber is arranged onone side of the gas chamber, and a dust removing box is arranged at the output end of the air heat storage chamber. A gas return pipe is arranged between the dust removing box and the air heat storage chamber, a first induced draught fan is arranged at the middle portion of the gas return pipe, and a denitration dust removing tower is arranged at the output end of the dust removing box. By meansof the glass factory waste gas denitration method, a selective non-catalytic-reduction denitration method is adopted for conducting denitration on glass kiln waste gas, the treatment cost is reduced,great economic benefits and social benefits are achieved, ammonia gas and NOX are reacted to form N2 and H2O in the environment with the temperature being 850 DEG C to 1100 DEG C, the ammonia gas is sprayed evenly through a spray gun, the NOX can be reacted sufficiently in a mixed reaction space 8, in addition, the reaction speed is high, the denitration effect is good, and therefore the waste gasdischarged into the atmosphere reaches the environment-friendly requirement, the technology is simple, and use and popularization are facilitated.

Owner:山东郓城正华玻璃科技有限公司

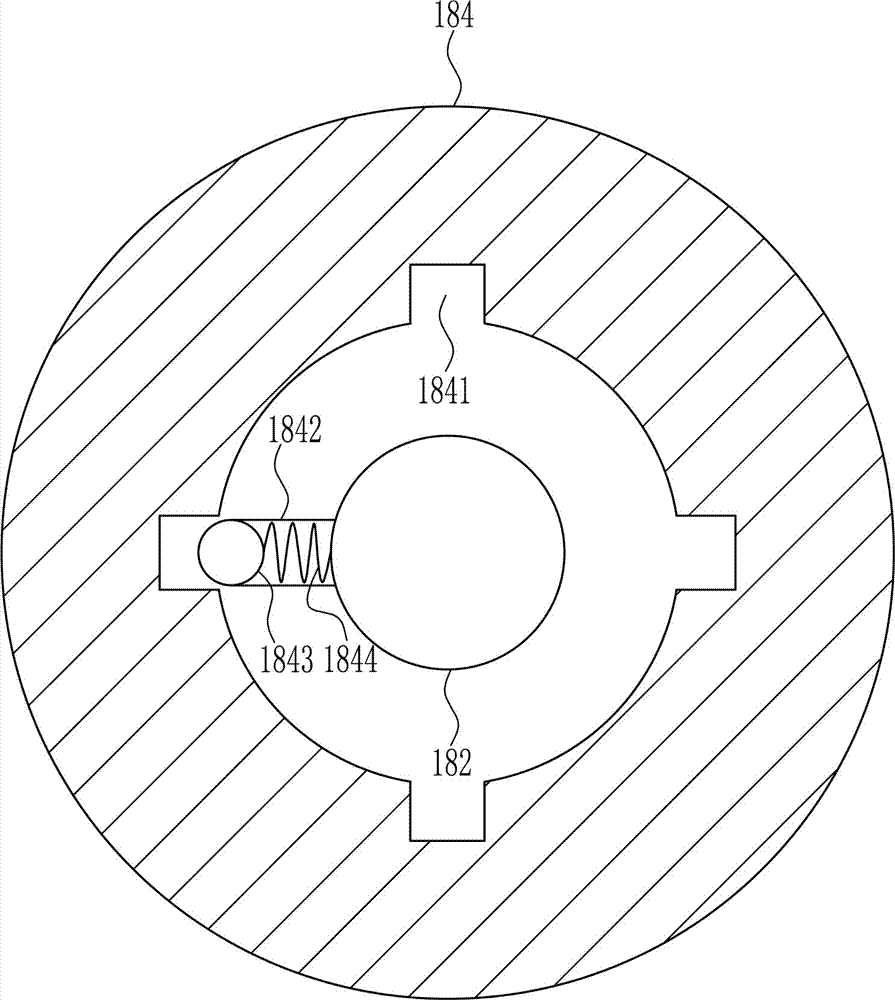

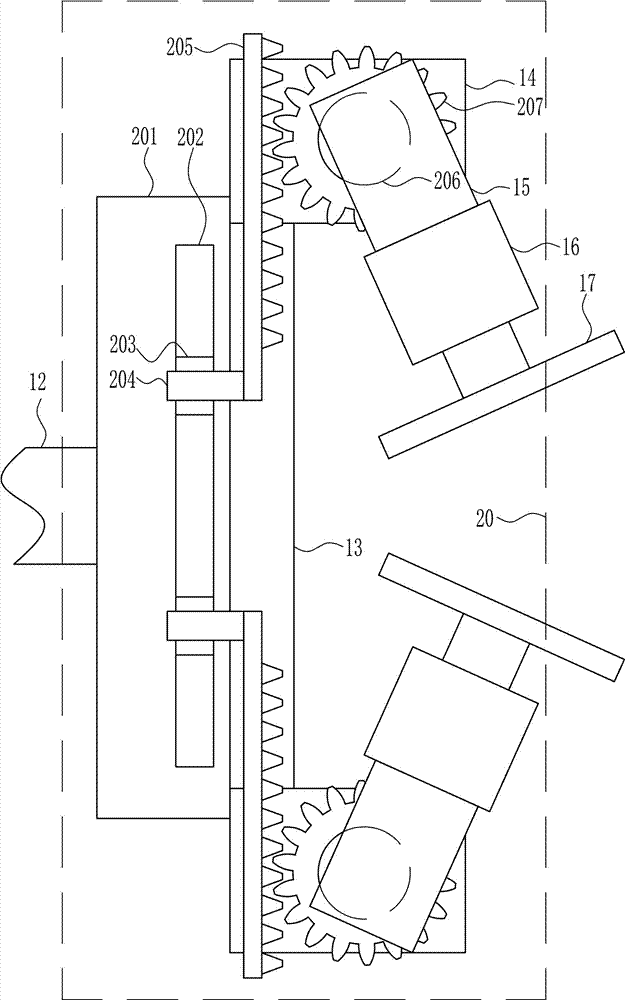

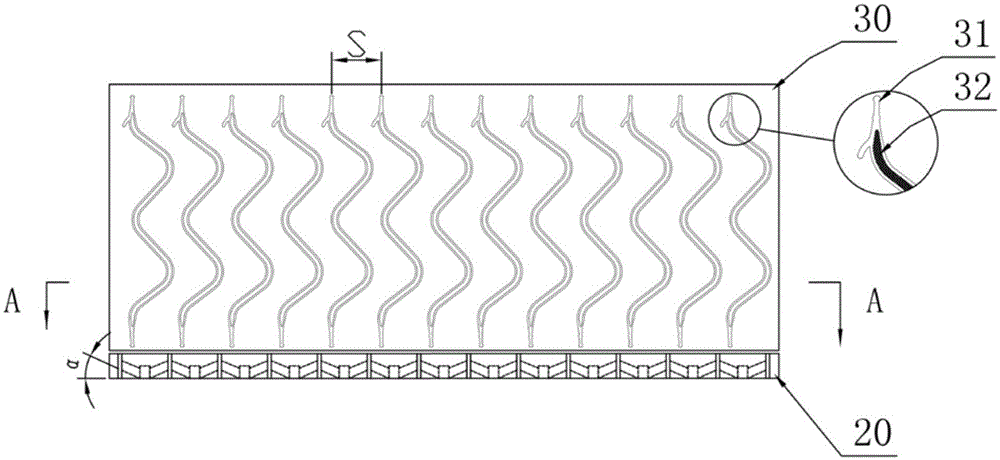

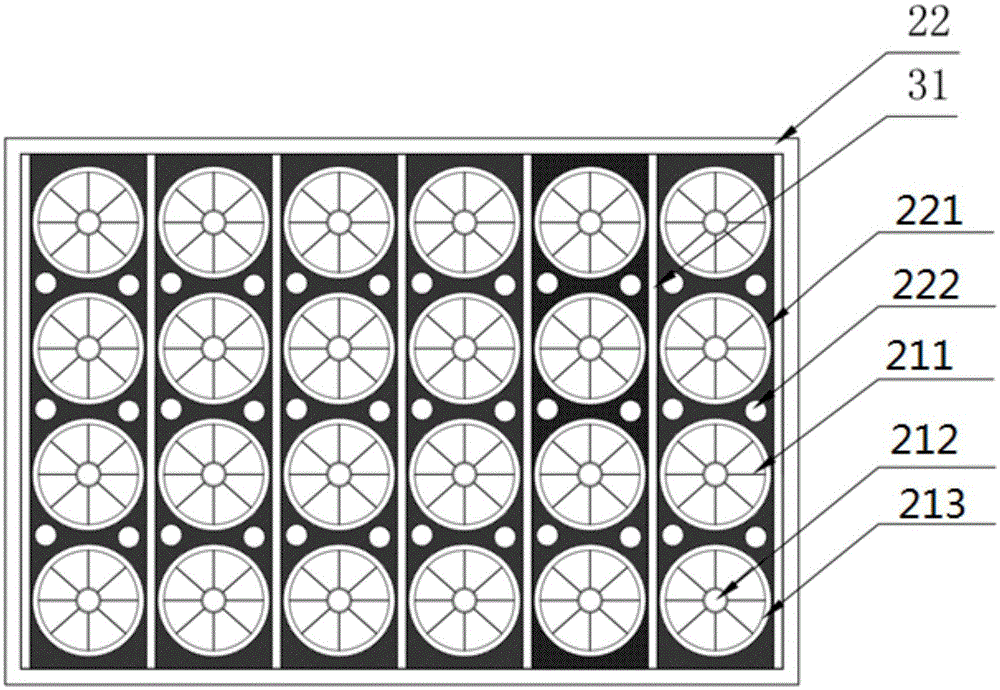

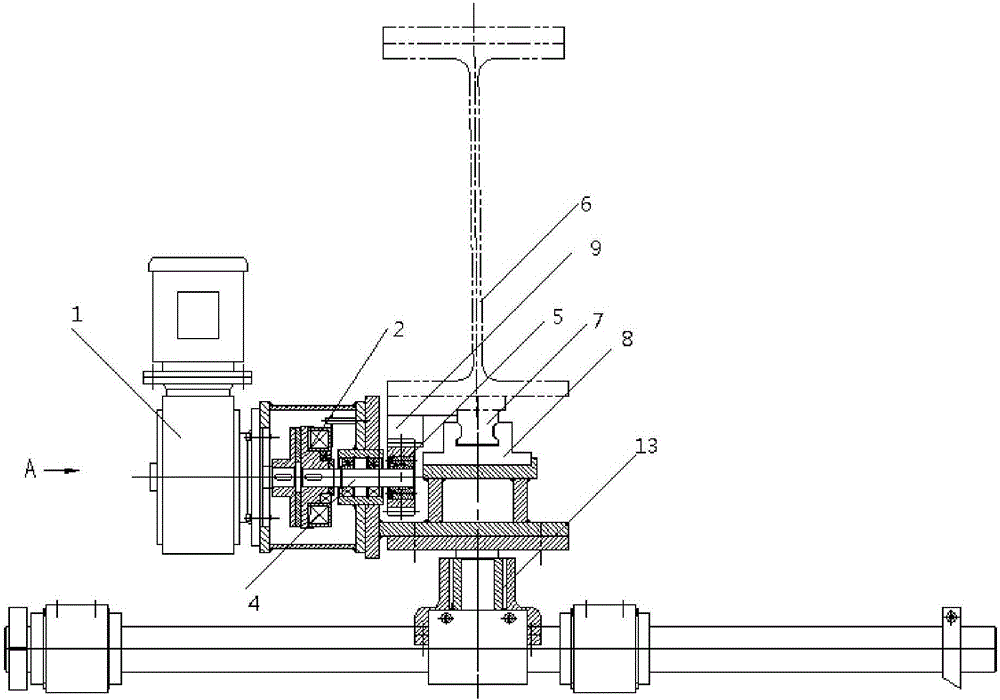

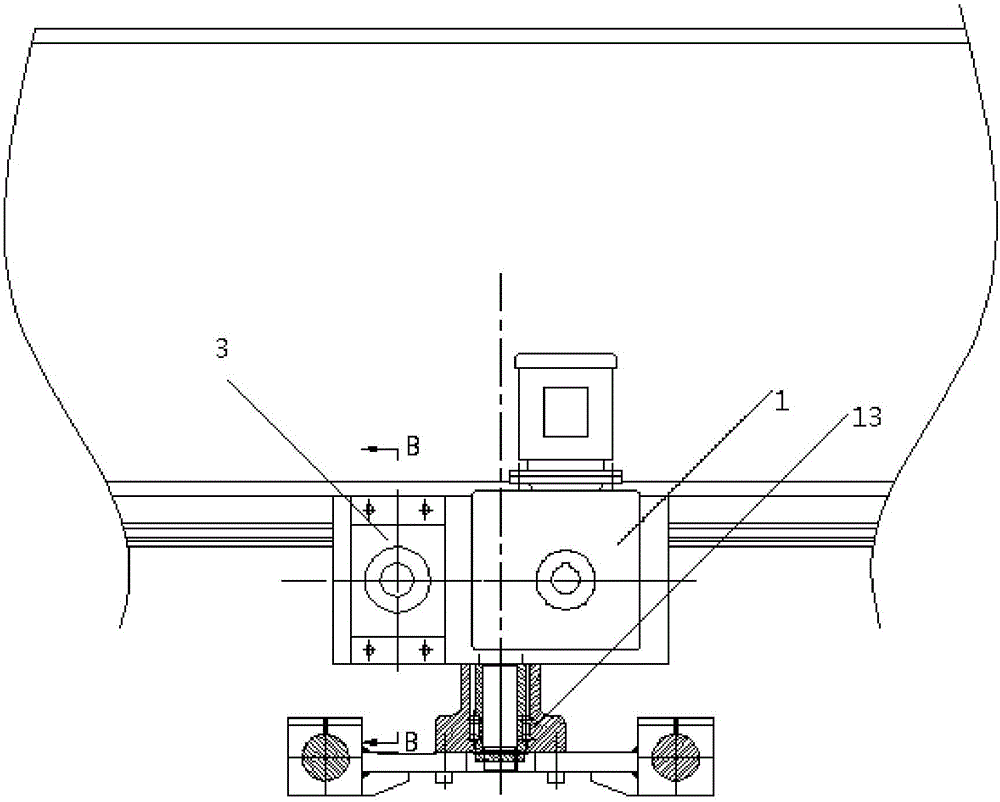

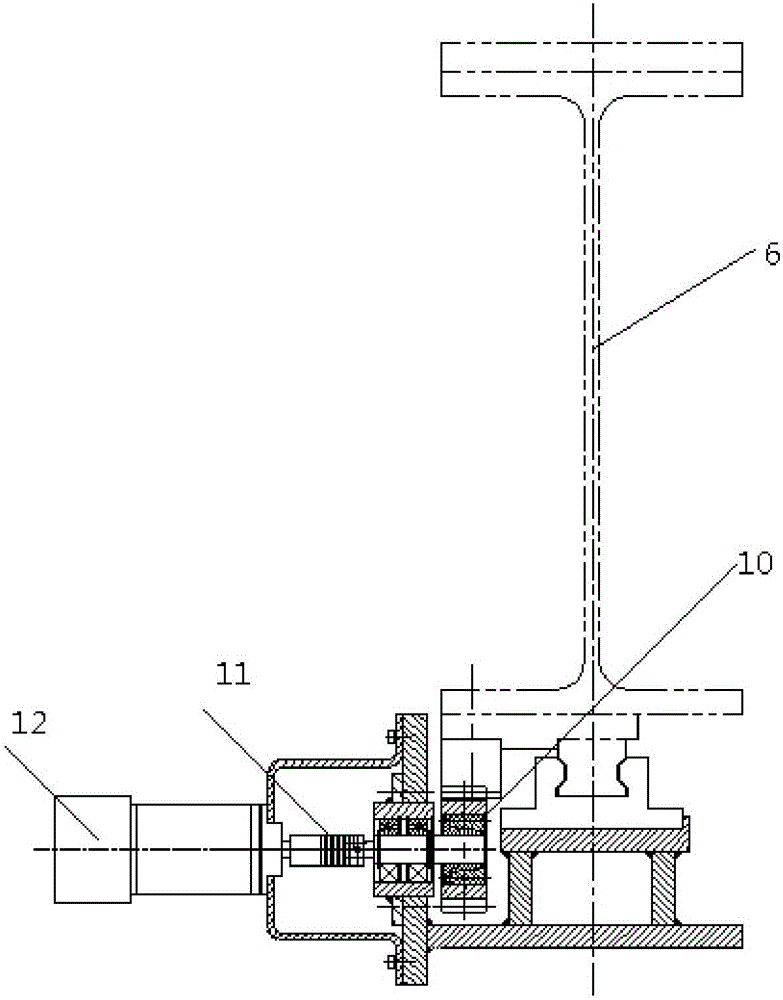

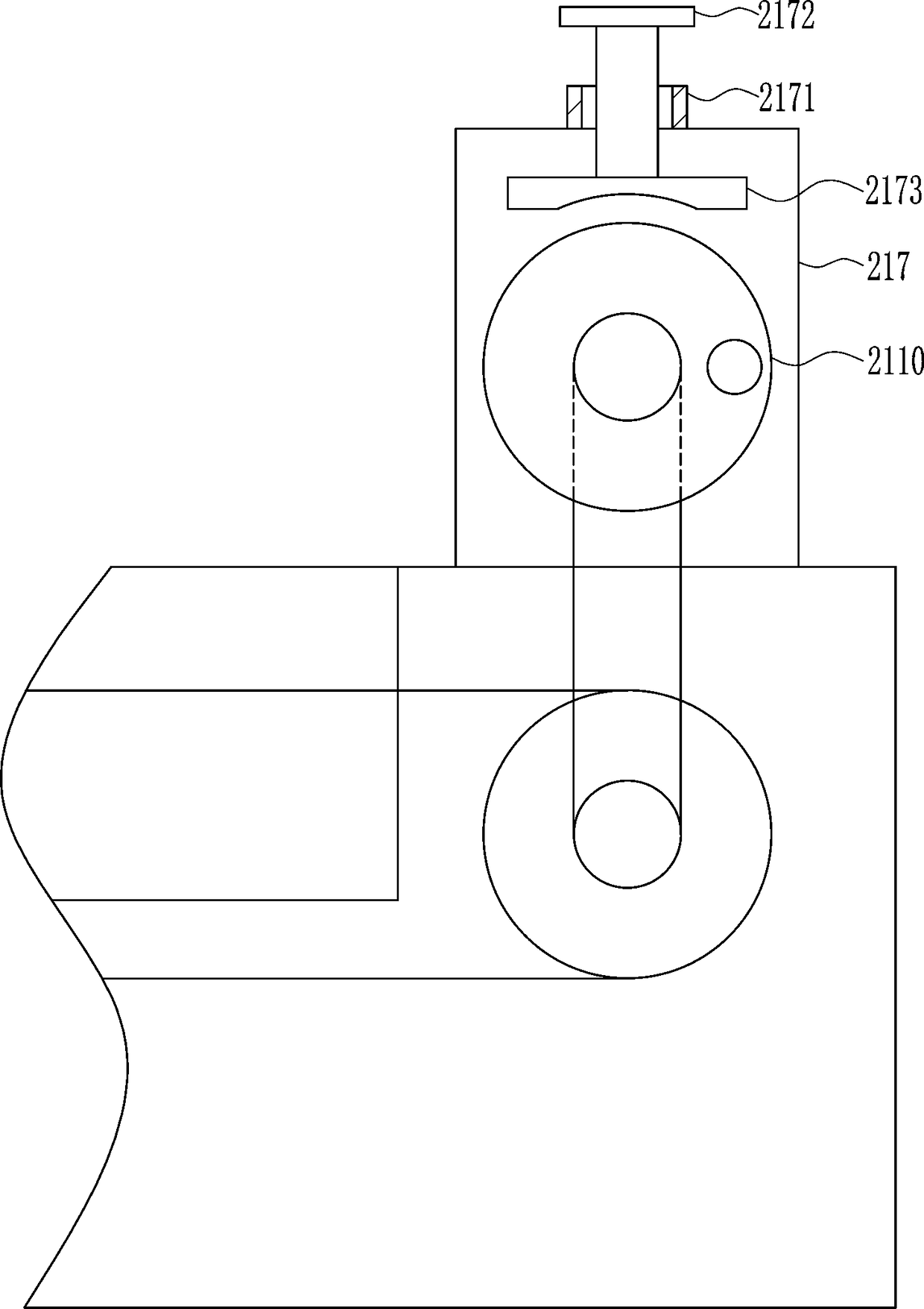

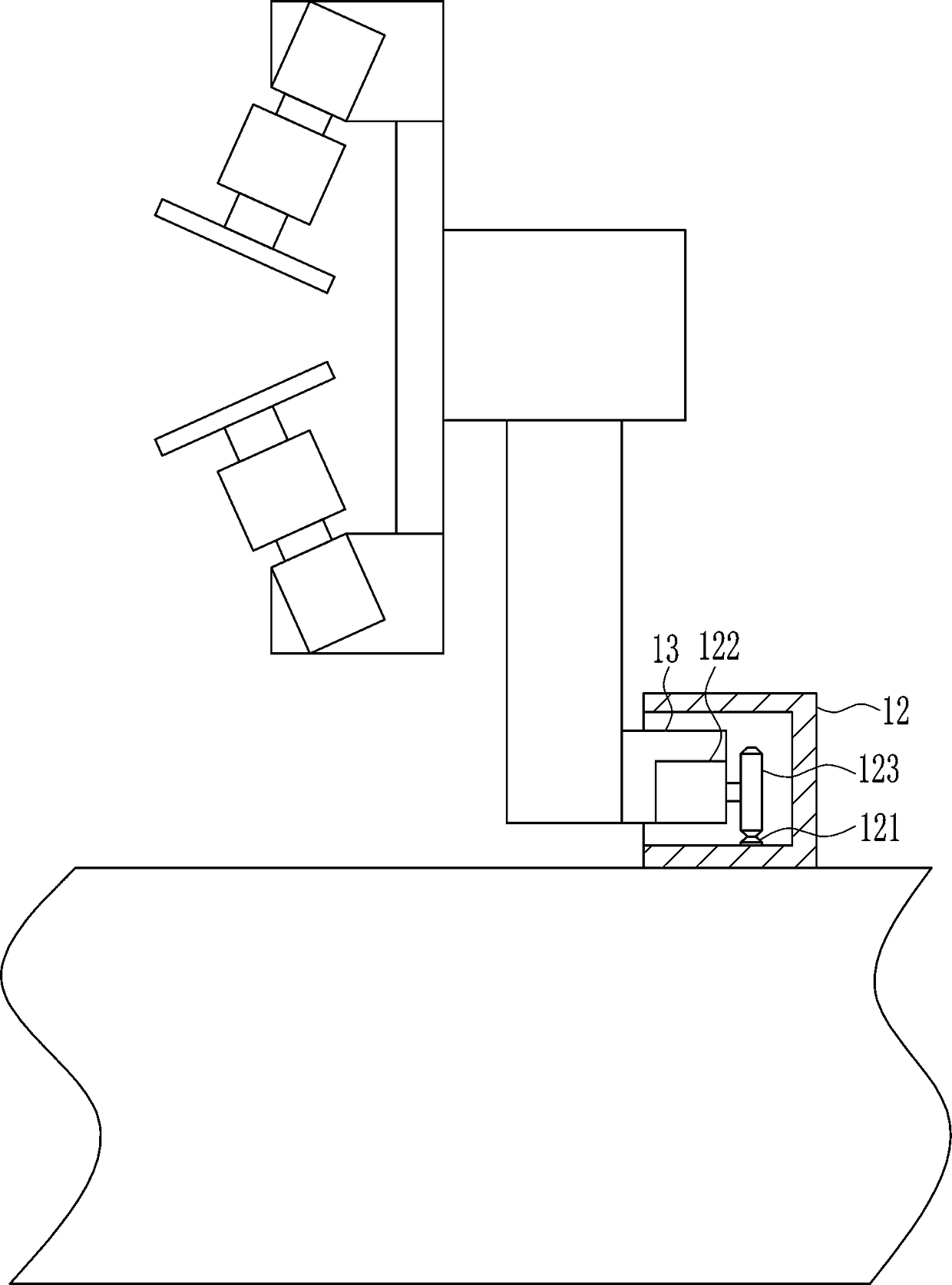

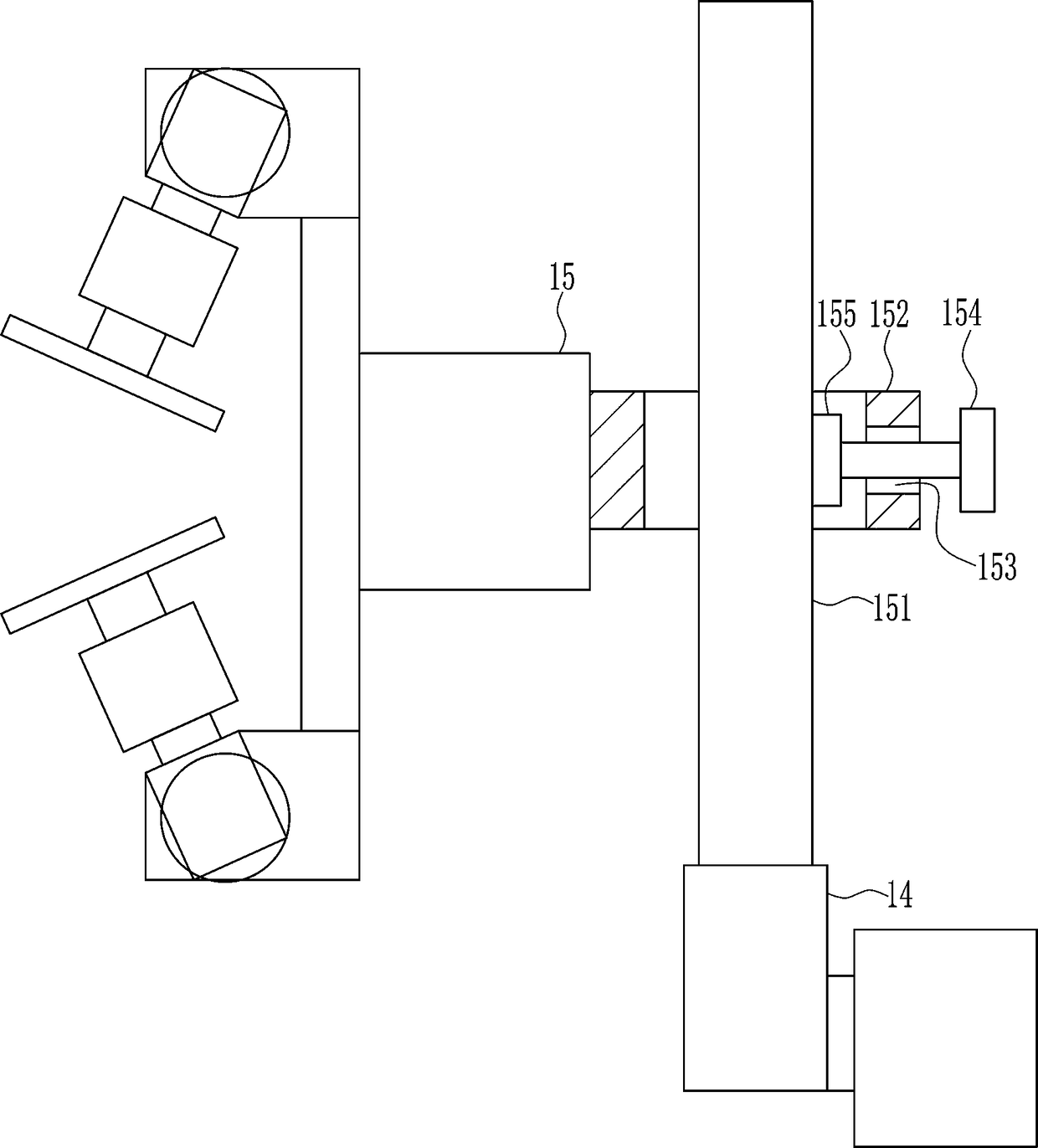

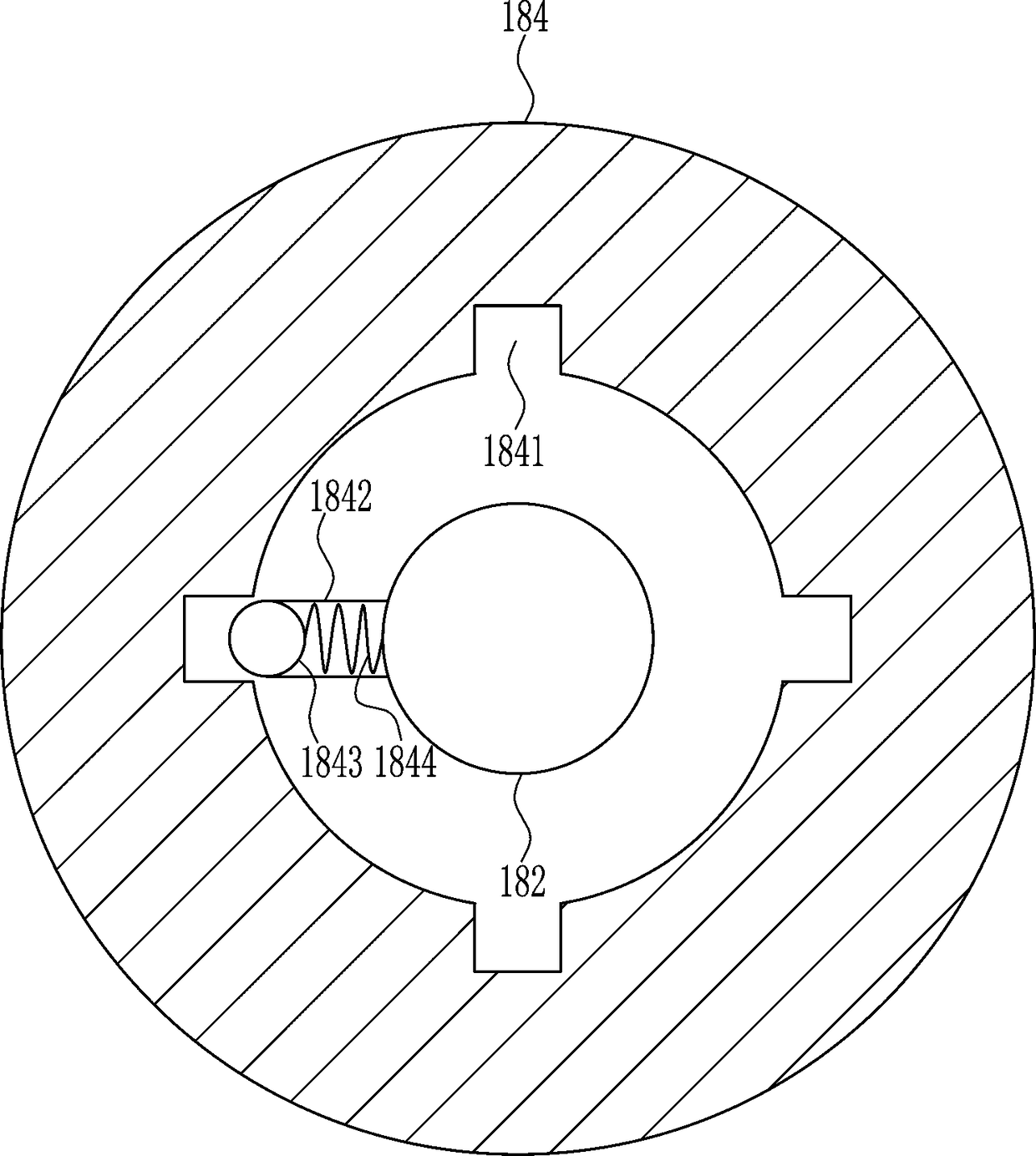

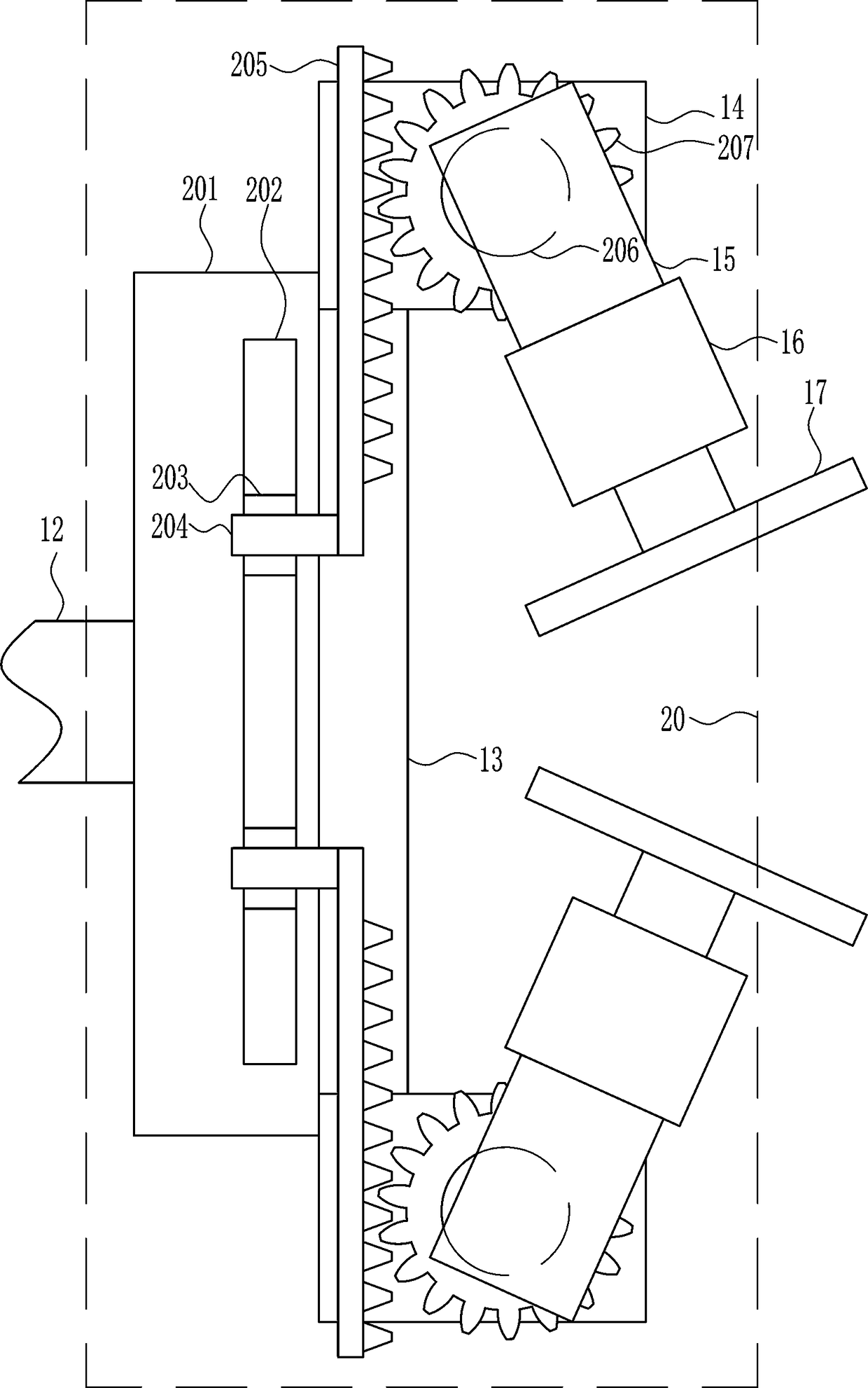

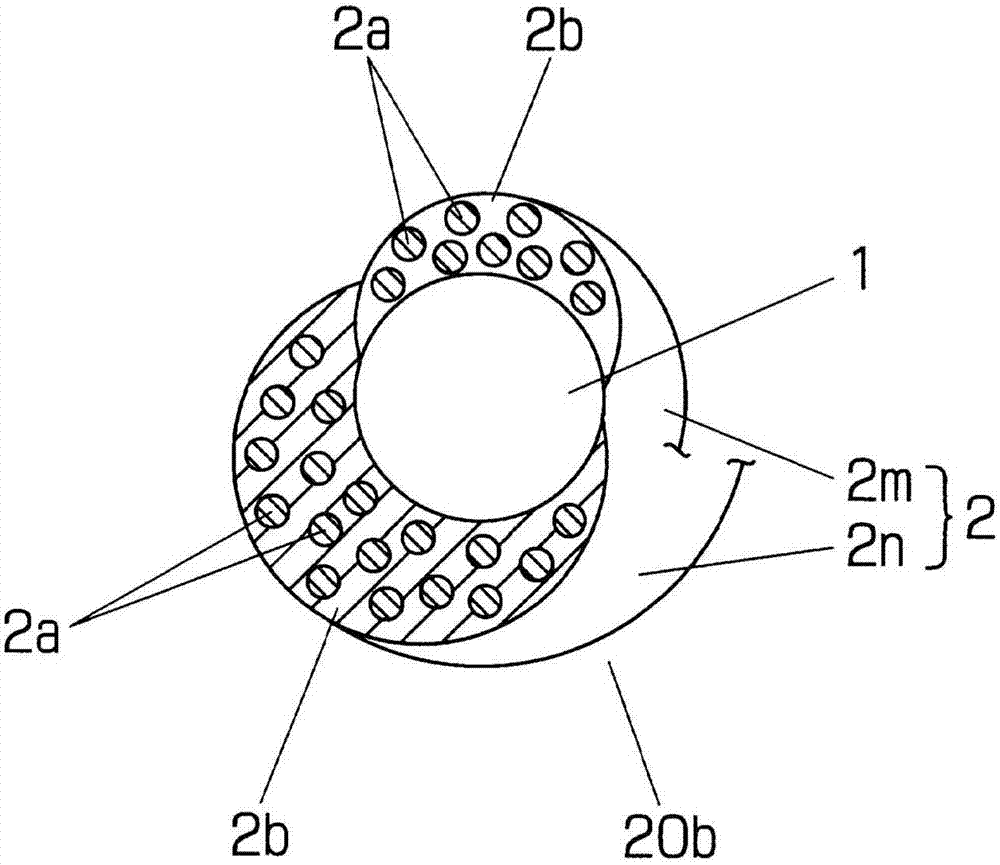

Rear suspension point swinging device for suspended edge roller

The invention discloses a novel rear suspension point swinging device for a suspended edge roller. The device comprises a motor speed reducer, an electromagnetic clutch and a position detector, wherein the electromagnetic clutch is mounted on a driving shaft, and a driving gear is mounted at the other end of the driving shaft; the bottom of a rear suspension point device is mounted on a stander of the edge roller in a sliding manner through a linear guide rail, and a rack is mounted on one side of the rear suspension point device and is matched with a driving gear; the position detector comprises a driven detection gear, an elastic coupling and a rotary decoder. The rear suspension point swinging device has the beneficial effects that the structure is simple and smart, parts required to be manufactured and machined are few, the mounting is convenient, and the operation precision and the regulation precision are high. Rear suspension points are now used in various glass factories, and the use effect is good.

Owner:BENGBU TRIUMPH ENG TECH CO LTD

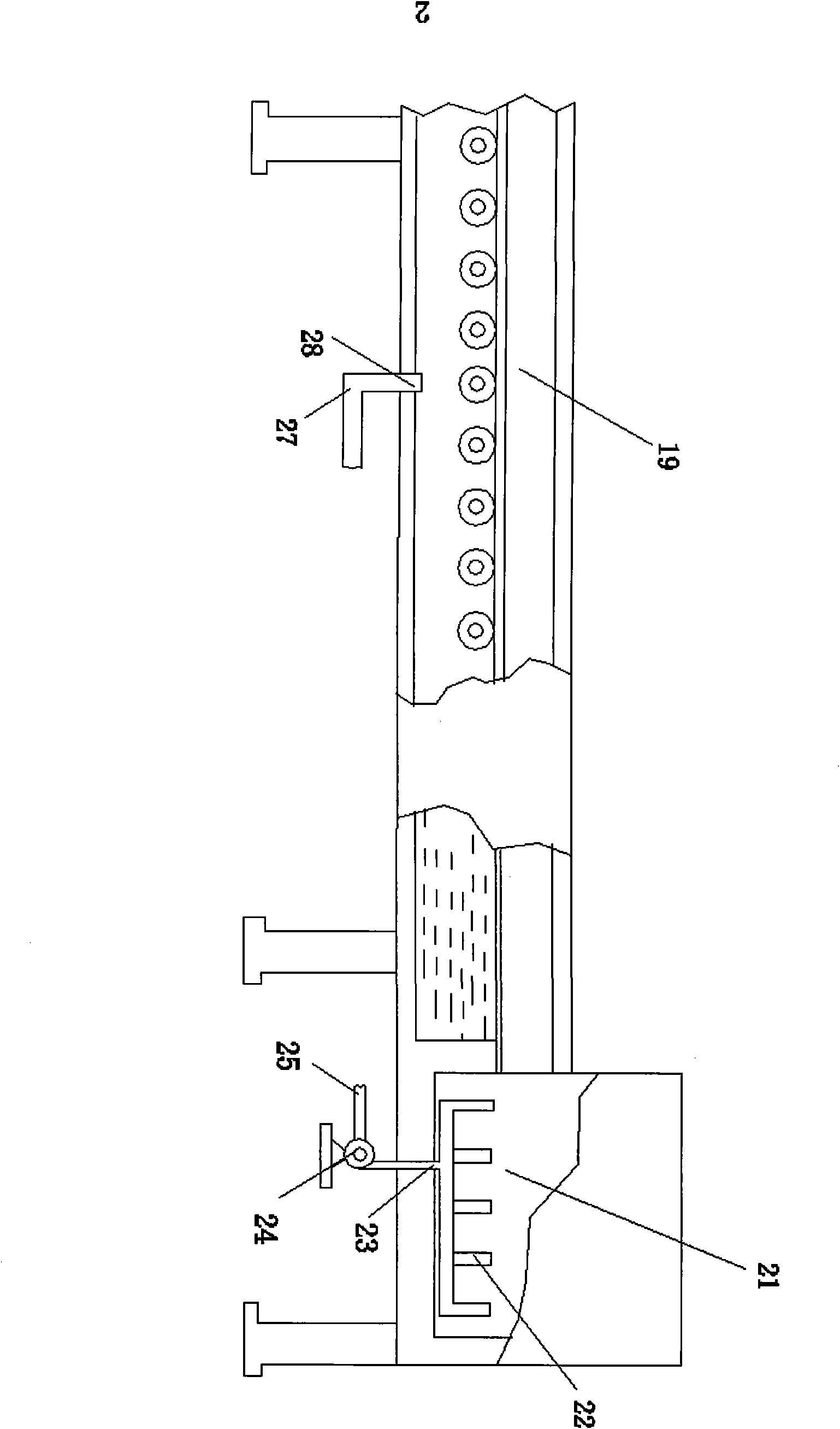

Glass side edge grinding equipment for a glass factory

ActiveCN106891221BReduce harmPrecision edgingEdge grinding machinesGrinding drivesEngineeringGlass fragment

The invention relates to glass processing equipment, in particular to glass side edge polishing equipment for a glass factory. The glass side edge polishing equipment for the glass factory is provided for achieving the technical effects that the equipment can conduct accurate edge polishing and save time and labor in the edge polishing process, and injuries of glass fragments produced in the edge polishing process to workers are small. In order to achieve the technical effects, the glass side edge polishing equipment for the glass factory, provided by the invention, comprises a bottom plate, a supporting plate, a carrying plate, a fixed plate, a fixed rod, a first push rod, a pressing plate, a first screw rod, a first pressing block, a first slide rail, a first sliding block and the like. The supporting plate is mounted in the middle of the upper side of the bottom plate in a welded mode. The carrying plate is mounted at the upper end of the supporting plate in a welded mode. The glass side edge polishing equipment for the glass factory achieves the effects that the equipment can conduct accurate edge polishing, time and labor are saved in the edge polishing process, and injuries of glass fragments produced in the edge polishing process to workers are small.

Owner:佛山市南海斯维雅玻璃有限公司

Method for applying low-heat value gas to combustion in melting furnace

ActiveCN102795757BReduce manufacturing costEmission reductionGlass furnace apparatusMixed gasGlass factory

The method relates to a gas supply manner for a glass production line, in particular relates to a mixed gas supply manner with producer gas as a fuel, and specifically relates to a method for applying low-heat value gas to combustion in a glass factory melting furnace. The method for applying the low-heat value gas to combustion in the glass factory melting furnace is characterized in that low-heat value coke oven gas low in cost exchanges heat with flue gas generated by the glass melting furnace, and then is mixed with the producer gas to generate a supplementary fuel for combustion in the smelting furnace; therefore, the dosage of one part of the producer gas is counteracted; as a result, the purposes of reducing energy consumption and saving glass production cost are achieved.

Owner:CHINA TRIUMPH INT ENG

Main drive control method for glass factories

A main drive control method for glass factories, comprising the following steps: (a) providing a first circuit breaker and a second circuit breaker on a power supply loop of an electrical motor, wherein one end thereof is respectively connected to two main drive electrical motors; (b) enabling the first circuit breaker to be connected to a municipal power supply and the second circuit breaker to be connected to a UPS power supply; and (c) enabling the first circuit breaker and the second circuit breaker to be interlocked via a mechanical interlocking mechanism, so that only one of the circuit breakers can be switched on during a normal operation. The main drive control method for glass factories solves the problem that the rotation speed of a main drive electrical motor is incorrect due to the interference on a signal.

Owner:CHINA TRIUMPH INT ENG

A transport device for short-distance small amount of glass products

Owner:苏州市灵通玻璃制品有限公司

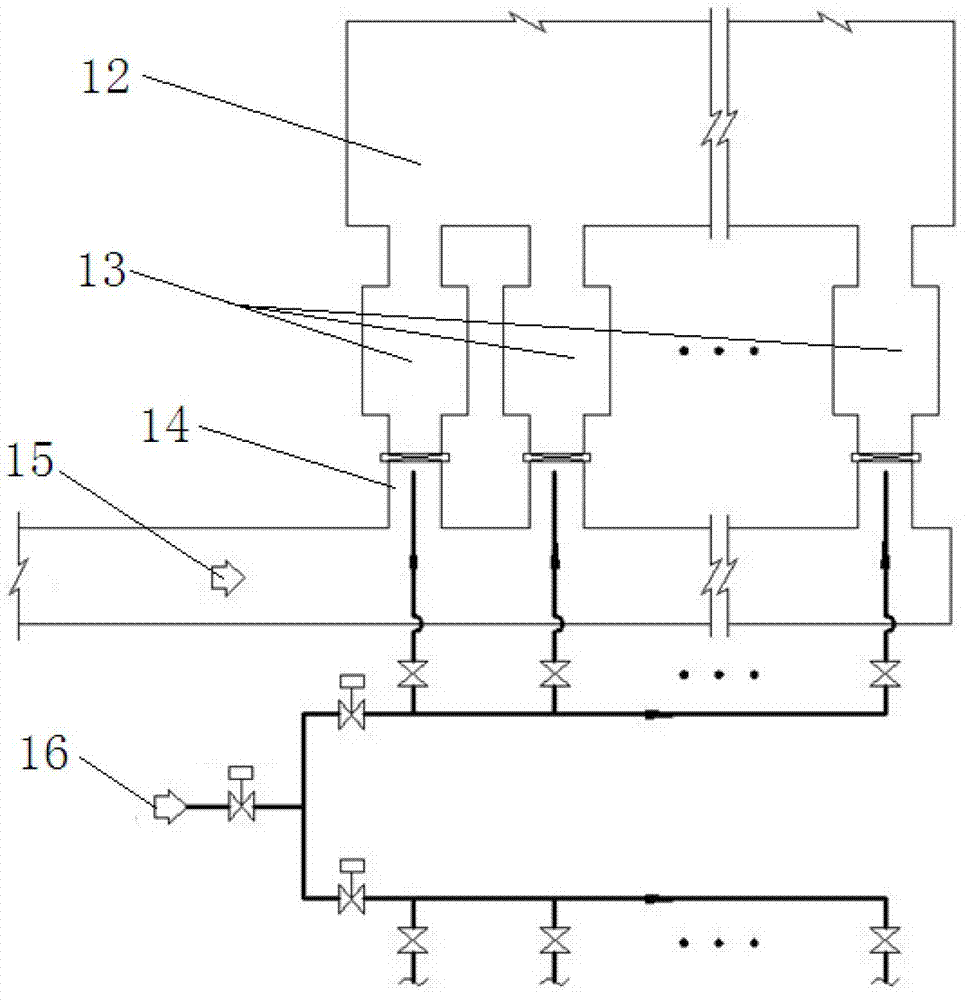

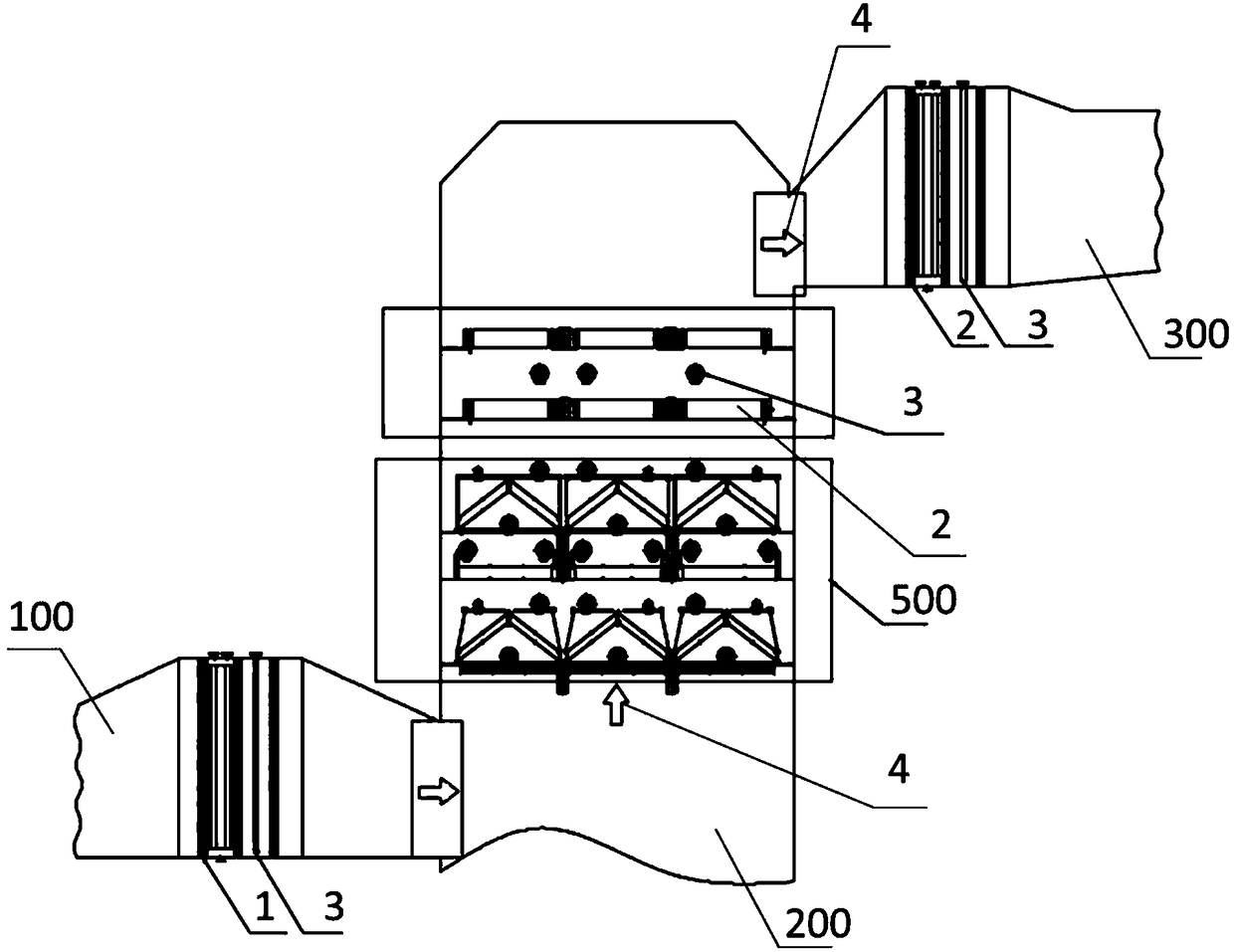

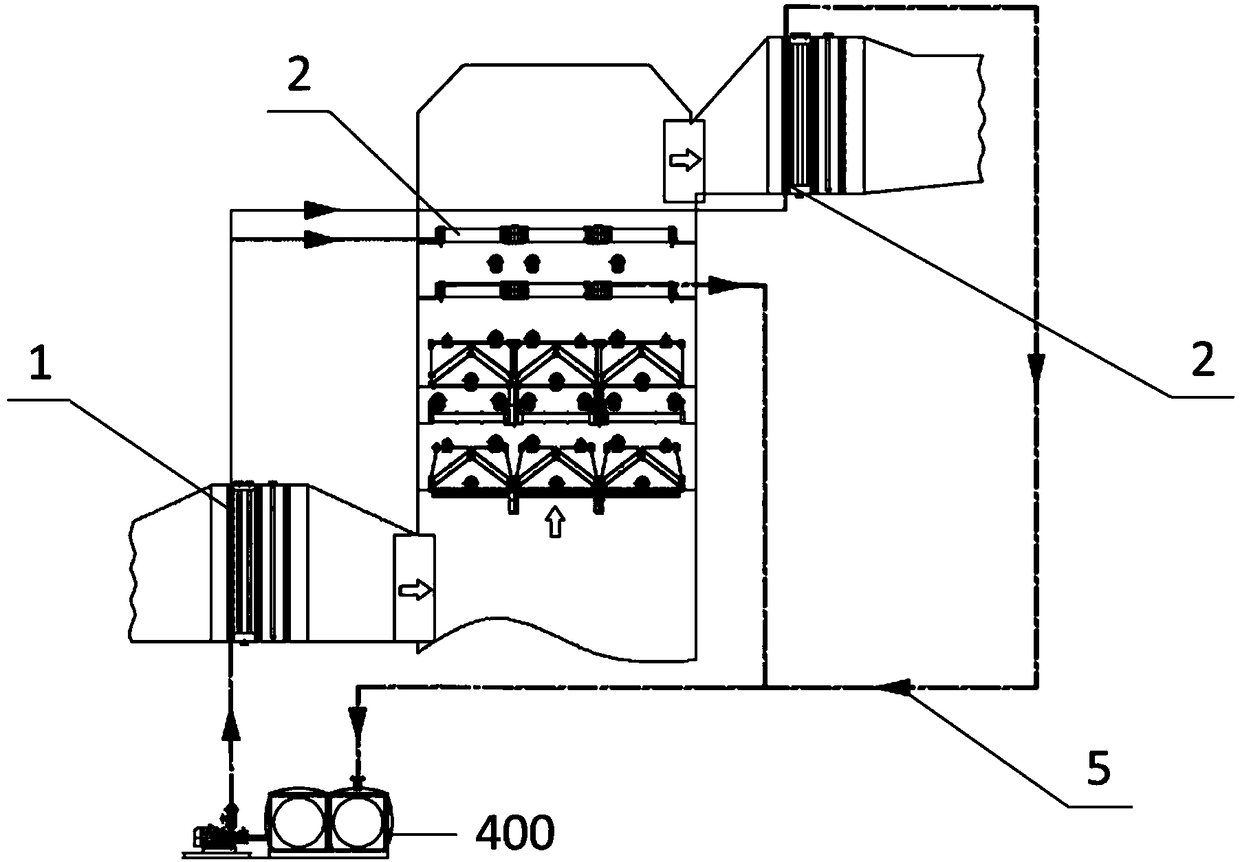

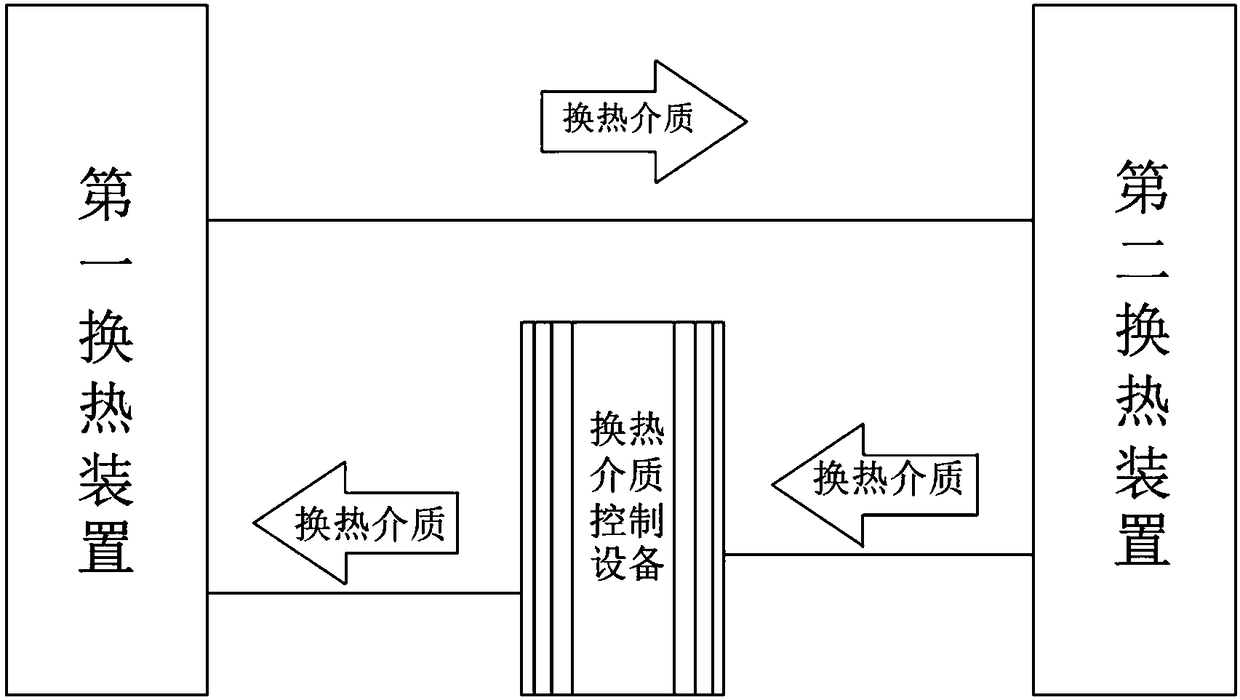

White smoke eliminating integrated system

PendingCN109282298AIncrease flow rateReduce the workload of capacity expansionEmission preventionPaper millEnergy consumption

The invention discloses a white smoke eliminating integrated system. The white smoke eliminating integrated system comprises heat exchange devices and heat exchange medium control equipment, wherein the heat exchange devices are configured to be capable of increasing the temperature of clean smoke through a heat exchange medium, and then the unsaturation degree of the clean smoke is increased, sothat the clean smoke is still in an unsaturated state when leaving a smoke discharging device to enter the atmosphere. The white smoke eliminating system further combines a dust removing and demistingdevice. The heat exchange medium is introduced into the heat exchange devices, absorbs heat at a raw smoke section and releases the heat at a clean smoke section, so that the temperature of the cleansmoke is increased, and then the phenomenon of white smoke generated during discharging through a chimney is eliminated; and moreover, the cost is low, the operation energy consumption is low, the reliability is high, and the white smoke eliminating integrated system can be used in the smoke cleaning fields such as a thermal power plant, a steel plant, a paper mill, a glass factory and a chemicalplant.

Owner:DEMISTER SHANGHAI ENVIRONMENTAL TECH

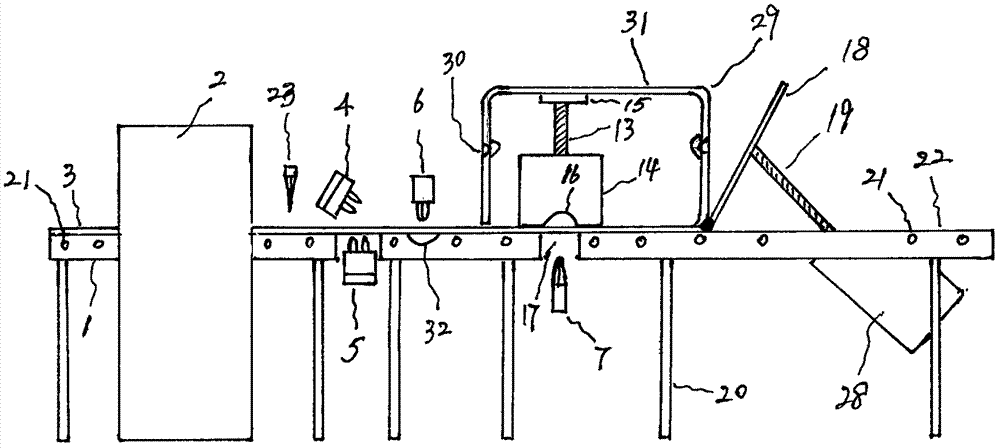

Bending-folding machine of sheet glass

InactiveCN106957142AIncrease added valueShort processGlass reforming apparatusGlass factoryVertical stabilizer

Flat glass bending and folding machine, let the flat glass (3) pass through the upper fire row (4) and the lower fire row (5) after being partially heated by the hot melting furnace (2) on the glass roller assembly line (1). During the high-temperature combustion process to soften again, the electric concave bar (6) is used to pre-thin three flat glass (3), which is beneficial to the movable bending plate (18) to carry out three 90-degree bending and shaping, and the vertical stability regulator ( 14) adjust the vertical support bar (13) on the top to adjust the height of the telescopic vertical support plate (15), and set up a horizontal plane two-dimensional mobile device to support the glass rectangular tube (31) without damage and deformation during processing. To prevent the three-dimensional large-area, hollow rectangular glass tube from collapsing after bending, it is sent to the product cooling exit area (22) by the electric roller (21). Due to the shortcomings of non-load bearing, it is suitable for glass machinery factories, flat glass processing factories and glass craft factories to process it into high value-added glass rectangular pipe wall products.

Owner:曹伟

A glass side quick grinding device for a glass factory

ActiveCN106956181BAvoid wastingImprove sanding qualityEdge grinding machinesGrinding carriagesEngineeringBolt connection

The invention relates to and particularly relates to a rapid glass side edge grinding device applied to a glass factory and aims to provide the rapid glass side edge grinding device which is relatively high in grinding quality, capable of saving time and effort in a grinding process and applied to the glass factory. The rapid glass side edge grinding device applied to the glass factory, provided by the invention, comprises a base plate, a first sliding rail, a first slider, a first motor, a first gear, an arranging table, a first gear rack, a baffle, a first fixing plate, a second sliding rail, a second slider and the like; the first sliding rail is installed at the right side inside the base plate in a bolt connection way; and the first slider is slidably connected within the first sliding rail. The rapid glass side edge grinding device provided by the invention realizes the effects of relatively high grinding quality and time-saved and effort-saved grinding process, and realizes grinding by adopting four tap position slots which form an angle of 90 degrees with one another to precisely move a glass side edge to make sure the glass side edge is parallel to the first sliding rail.

Owner:广东朗博玻璃实业有限公司

Method for preparing silicic acid-calcium fertilizer and its special furnace

InactiveCN1807360ANutritional diversityReduce silicon contentCalcareous fertilisersCalcium silicateSilicic acid

The invention relates to a preparation method for the calcium silicate with the special furnace, which comprises: 1) mixing and stirring the fine white sand discharged from glass factory and limewater slurry by weight ratio as 2: 1 to prepare fine white sand block; 2) putting the former product, CaCO3 carpolite and coke by weight ratio as 2: 1: 1 and total weight as 50~100kg into the high-temperature smelting furnace of 3000Deg or more every 8~12min, and obtaining continually the calcium silicate solution; 3) cooling the said solution to crush into particle and obtain the final product with 55~60% silicon and 35~40% calcium to increase food crop production up to 20~30% and the vegetable production up to 50%. This invention reduces the cost with simple process.

Owner:左明才

Preparation method for artificial insect amber glass craft

InactiveCN108725072AGuaranteed aestheticsNo effect on healthSpecial ornamental structuresHot meltPolyresin

The invention discloses a preparation method for an artificial insect amber glass craft. The preparation method comprises the following step (1) of collecting waste glass in a glass factory, cleaningthe waste glass with cleaning solutions, and then air-drying the waste glass naturally; the step (2) of grinding the air-dried glass into powder, and putting the powder into a required mould for finalizing after hot melting; blowing with argon gas under the negative pressure conditions, and quickly cooling to form a glass container with a cavity in the center; and the step (3) injecting resin mixtures into the glass container in the step up to 1 / 3-3 / 4 of the glass container (2) at normal temperature, putting treated insects, and continuing injecting the resin mixtures, so that the glass craftis obtained after curing. The method is easy to operate, and the surface of the finished amber glass craft is smooth, and not liable to burst.

Owner:ANHUI HONGFU CRAFTS

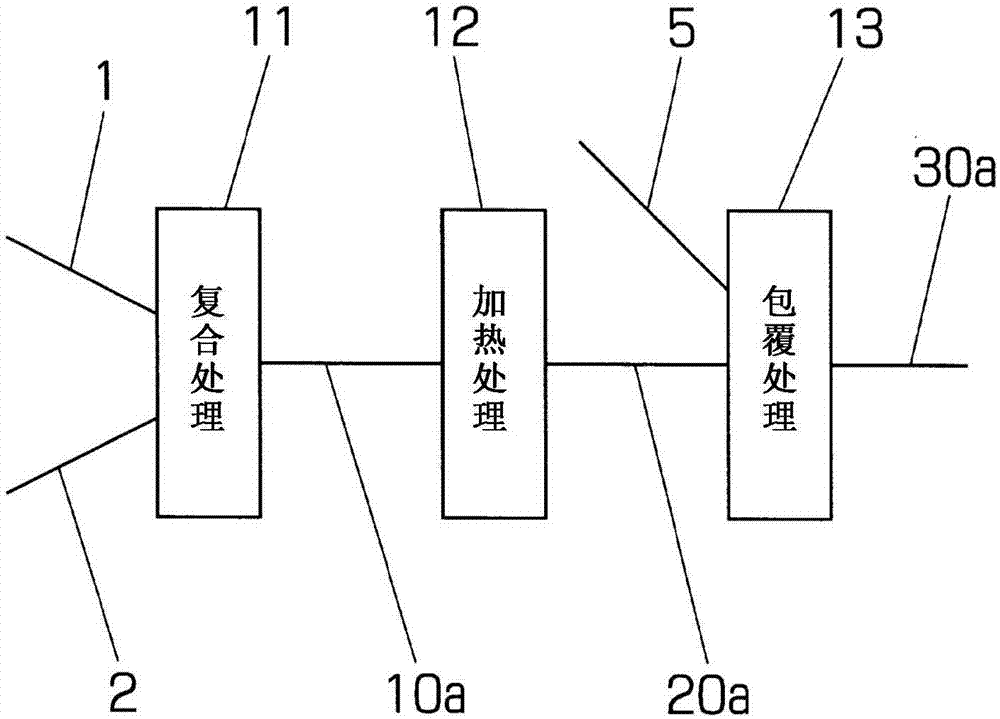

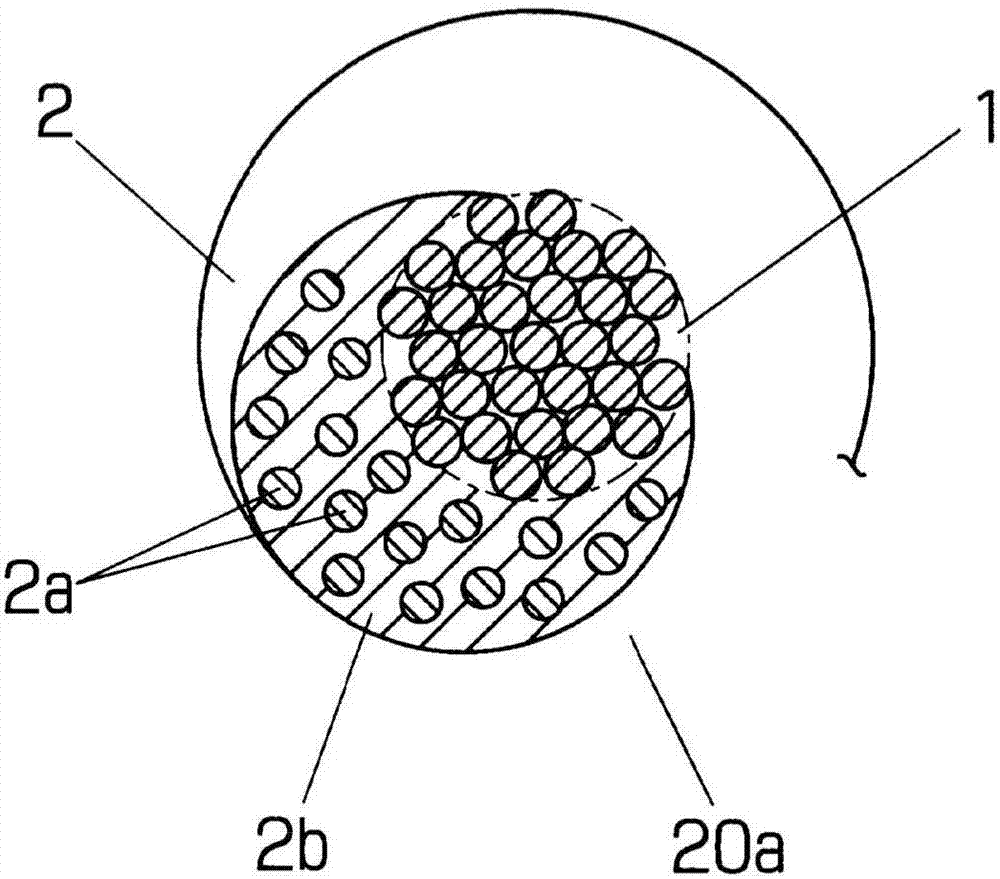

TOUGH THREAD, core yarn, braided fabric and glove

The invention provides a tough thread and a core yarn thereof, a braided fabric and a pair of gloves. The pair of gloves is suitable for the operator to wear at a work site, a steel plant, a plate glass factory or the like using a cutter, and is excellent in softness and economy, and does not cause the broken ends of the hard fiber to be exposed to the wearer's discomfort. A thread, a tough thread formed by winding by taking the thread as the core yarn, and the braided fabric and the pair of gloves yarn adding braiding, double-side braiding, and double-layer braiding to the tough thread and the braided fabric of other threads, the thread (20) has hard fibers (1) such as metal fibers and glass fibers and molten fibers (2), preferably, has the lower fibers (3) as the third fiber, and is formed by heating the molten fibers (2) to melt the molten fibers (2) and then welding with the hard fibers (1) and the lower fibers (3) into one body after the composite processing (twisting or cladding).

Owner:备酒聪

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com