Method for applying low-heat value gas to combustion in melting furnace

A low calorific value gas and glass factory technology, applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as inability to meet glass melting process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

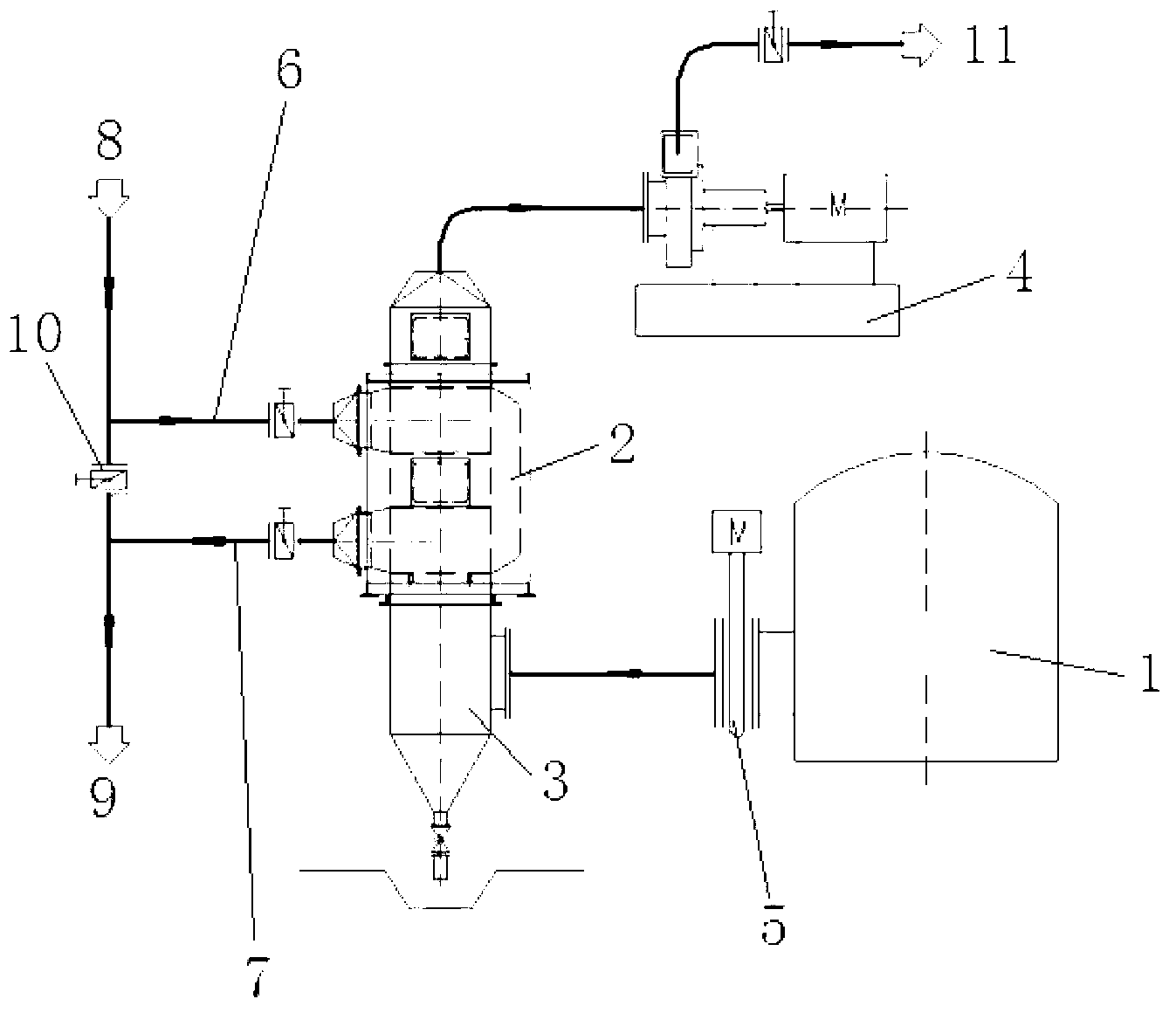

[0018] The present invention adopts following technical scheme:

[0019] The calorific value of the low calorific value coal gas adopted in the present invention is 1100~1600cal / Nm 3 range, the temperature is normal temperature, and there is no tar in the gas.

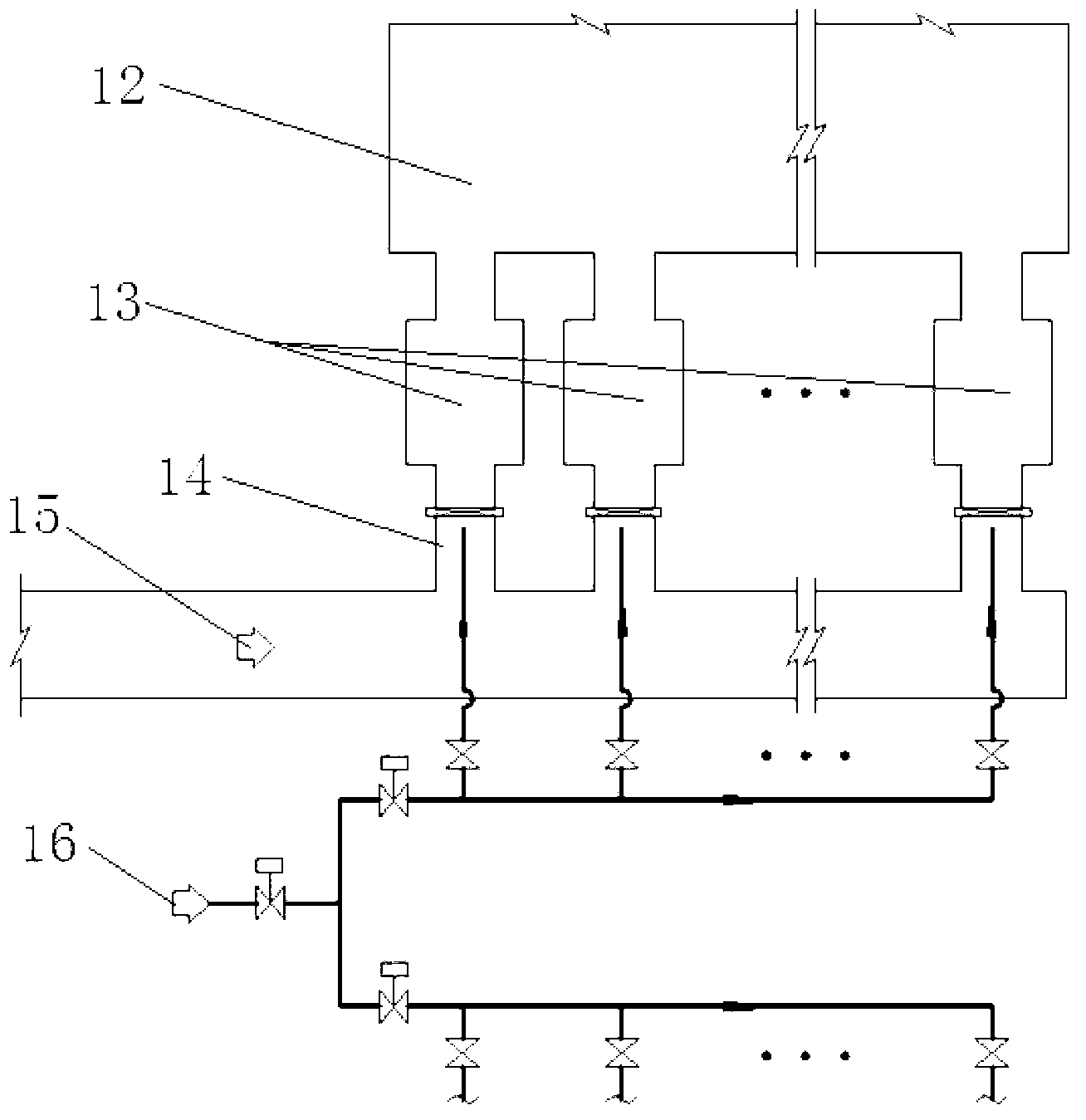

[0020] Use the flue gas produced by the glass melting furnace to heat the cold gas. The specific method is: a high-temperature gate valve is installed on the pipe of the outdoor flue of the joint workshop, and the other end of the high-temperature gate valve is provided with a pipe connected to the input port of a gas heat exchange platform. The platform is divided into upper, middle and lower floors. The lower floor is the ground, which is equipped with a heat exchanger to clean the drainage ditch, the middle floor is equipped with a gas plate heat exchanger, and the upper floor is equipped with a high-temperature induced draft fan. The high-temperature flue gas is extracted from the reserved opening on the outdoor f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com