White smoke eliminating integrated system

A white smoke and flue gas technology, applied in the field of flue gas purification, can solve the problems of corrosion of the heat exchanger body, unstable equipment operation, large blockage and scaling problems, saving energy and costs, reducing capacity expansion workload, reducing The effect of construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

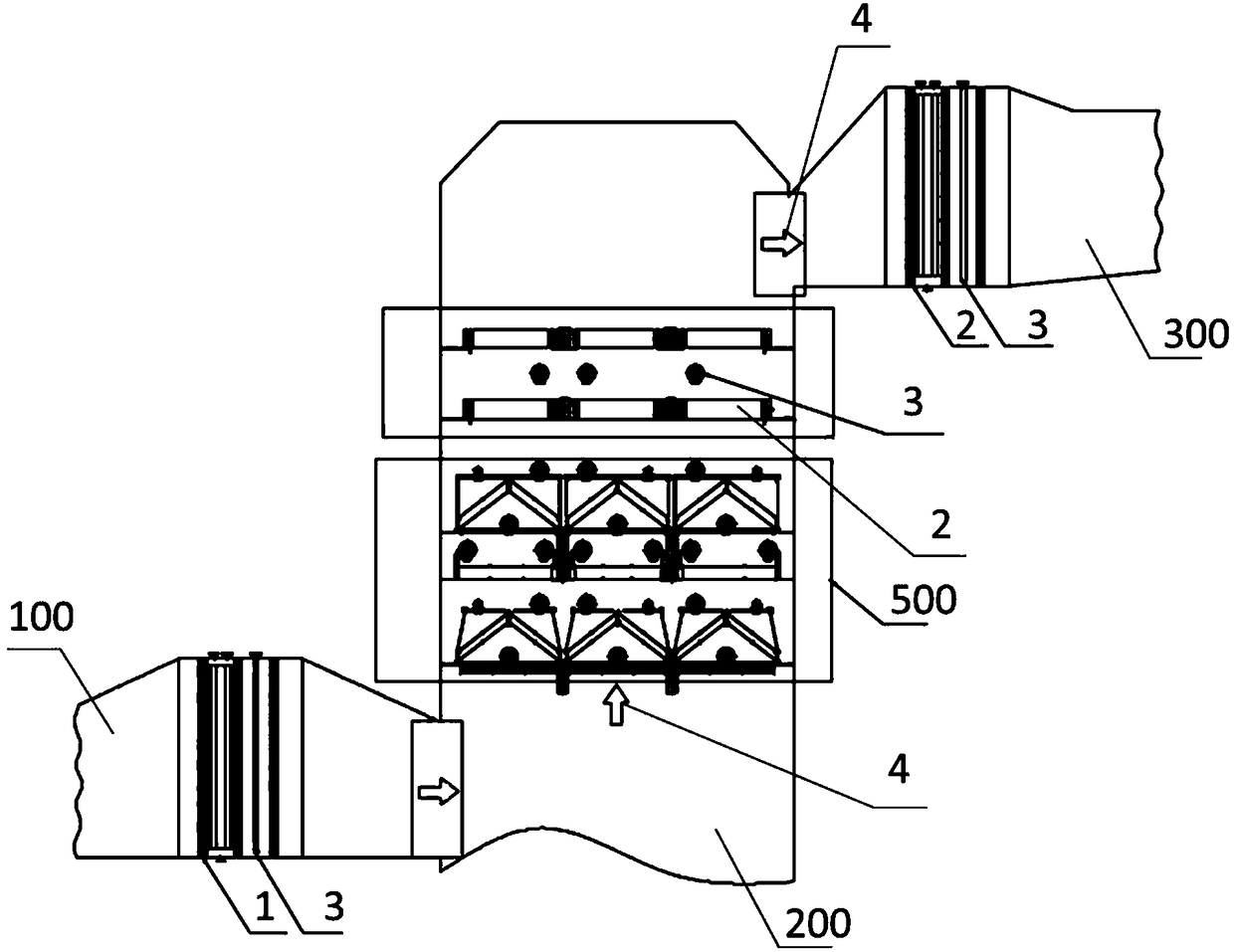

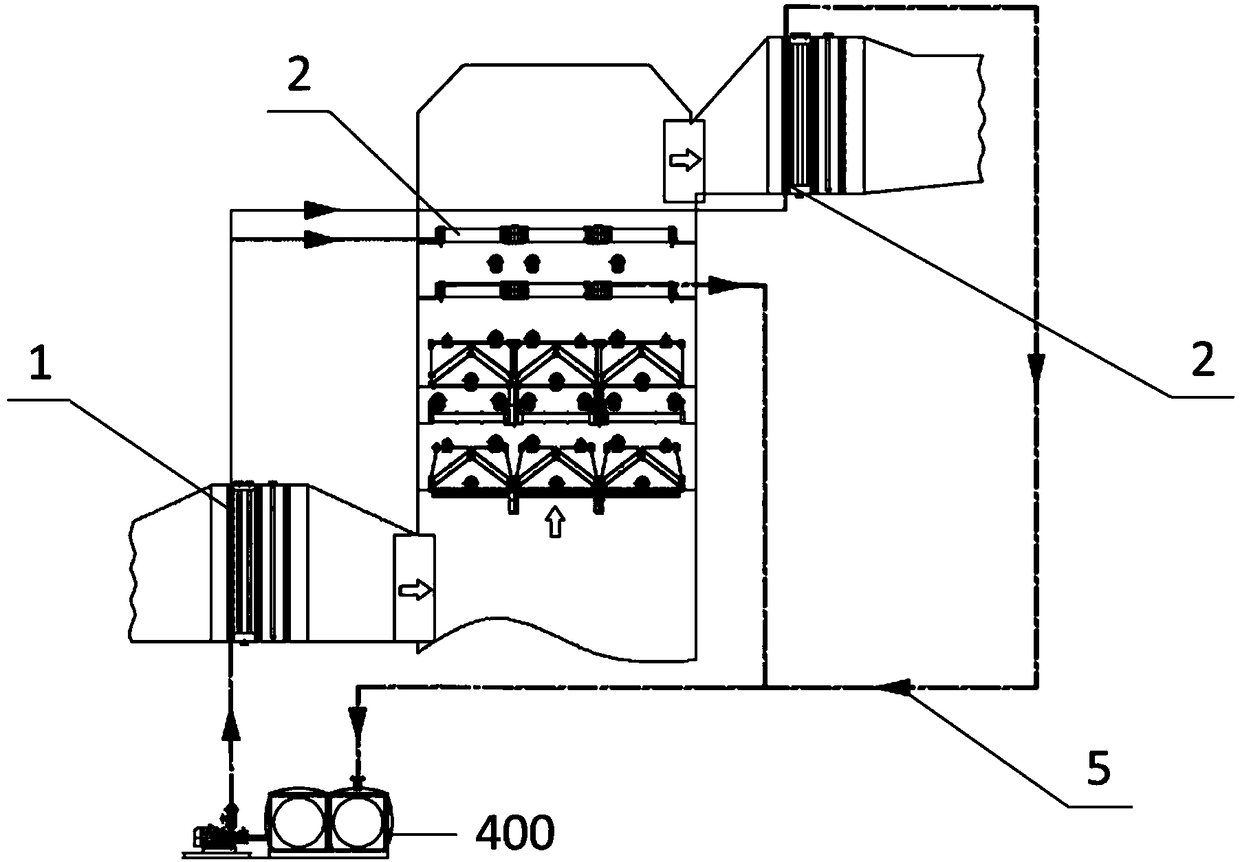

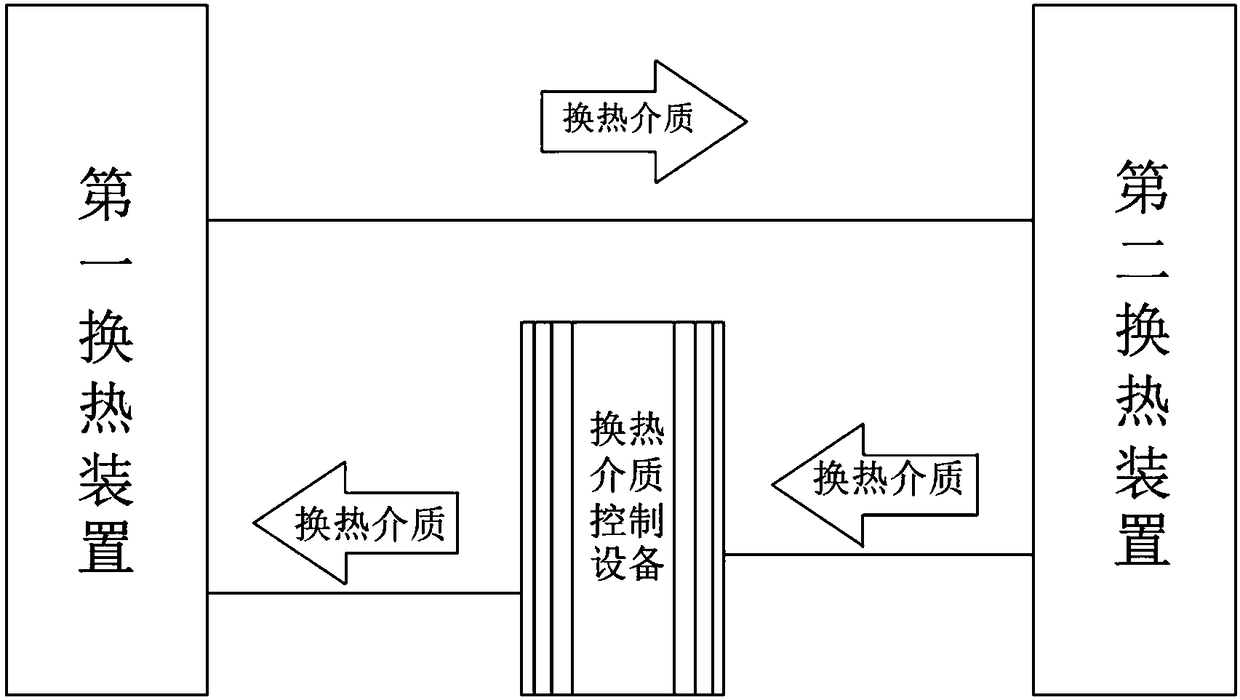

[0095] like Figure 1-22 As shown, a preferred embodiment of the present invention provides an integrated system for eliminating white smoke. The present invention provides an integrated system for eliminating white smoke, including a heat exchange device and a heat exchange medium control device 400, and the heat exchange medium The control device 400 is used for providing heat exchange medium to the heat exchange device. Among them, the heat exchange device is configured to increase the temperature of the net flue gas through the heat exchange medium, thereby increasing the degree of unsaturation of the net flue gas so that the net flue gas is still in an unsaturated state when it leaves the smoke exhaust device (such as a chimney) and enters the atmosphere . In this way, the temperature of the flue gas is lowered during the drifting process after leaving the smoke exhaust device, so that water is precipitated more slowly, and the purpose of eliminating white smoke is achie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com