Patents

Literature

230results about How to "No effect on health" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Modified silicate waterborne zinc-rich anticorrosive coating employing organic montmorillonite as anti-settling dispersant

The invention relates to an anticorrosive coating, and particularly relates to a modified silicate waterborne zinc-rich anticorrosive coating employing organic montmorillonite as an anti-settling dispersant. The modified silicate waterborne zinc-rich anticorrosive coating is prepared from components A and B, wherein the component A is prepared from 10-60% of flake zinc powder; the component B is prepared from 25-85% of silicone acrylic emulsion-modified potassium silicate solution, 0.1-5% of ricinate, 0.1-5% of organic montmorillonite, 0.1-5% of defoamer, and 0.01-2% of thickener, and the percent is weight percent. The modified silicate waterborne zinc-rich anticorrosive coating has the advantages that the dosage of zinc powder can be greatly reduced, and the cost of the coating is reduced. The water resistance of the coating is improved by the organic emulsion-modified potassium silicate solution; excellent painting hardness of the coating is achieved, the barrier property of the coating is improved, and meanwhile, the anticorrosive coating is almost zero in volatile organic compound (VOC) release property, and free of environmental pollution.

Owner:SHENYANG POLYTECHNIC UNIV

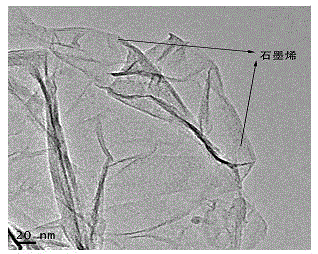

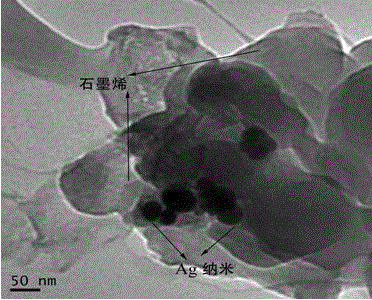

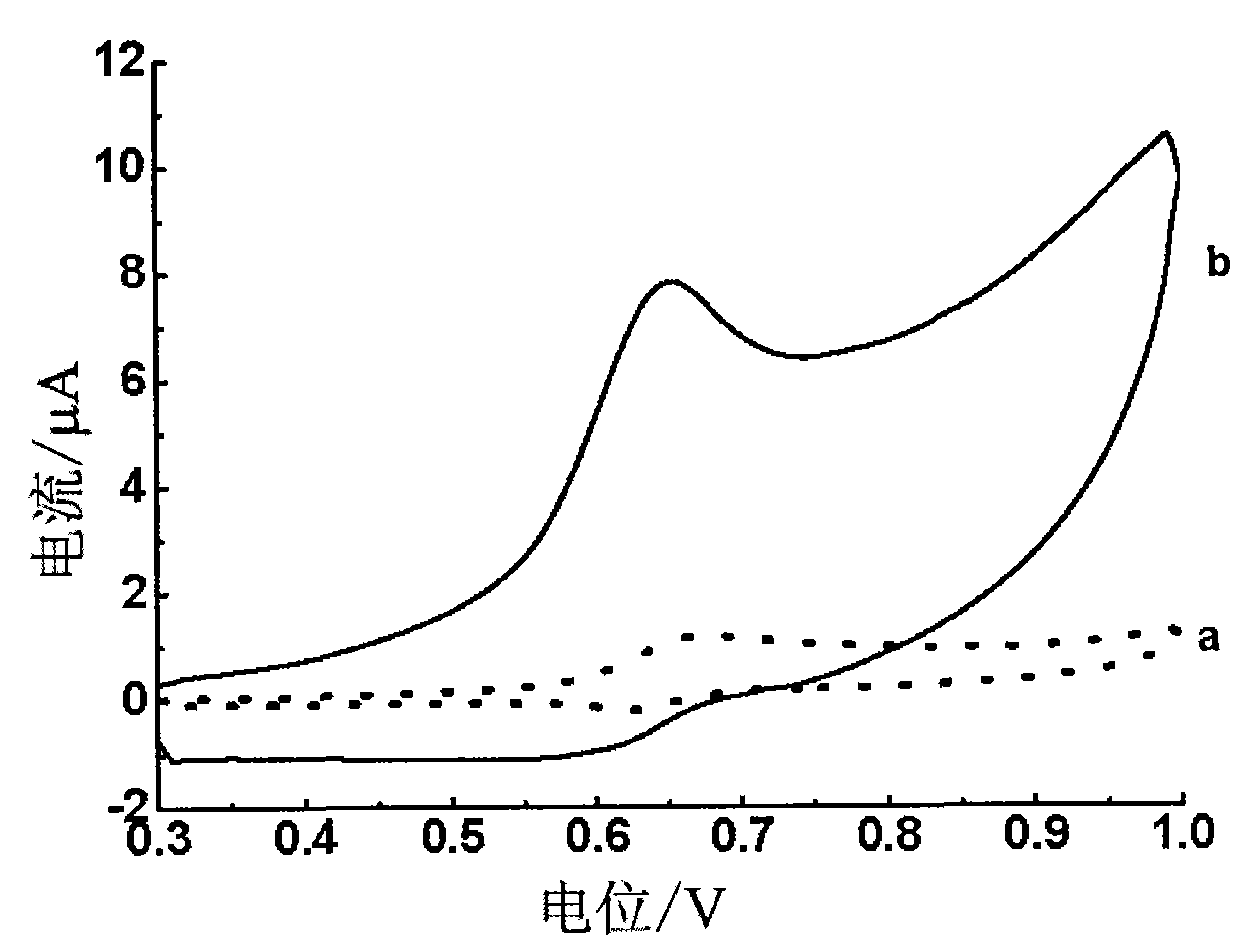

Silver-poly dopamine-graphene-modified electrochemical sensor and preparation method thereof

InactiveCN102914580AHigh sensitivityImprove conductivityMaterial electrochemical variablesGraphiteElectrochemistry

The invention discloses a silver-poly dopamine-graphene-composite-modified electrochemical sensor which is mainly characterized in that a silver-poly dopamine-graphene composite membrane is coated on the surface of a glassy carbon electrode. A preparation method of the silver-poly dopamine-graphene-composite-modified electrochemical sensor includes: adding silver-poly dopamine-graphene into dimethylformamide for uniform dispersing so that silver-poly dopamine-graphene dispersion liquid is obtained, then coating the dispersion liquid on the surface of the glassy carbon electrode, and evaporating solvent to obtain the needed sensor. A silver-poly dopamine-graphene composite is prepared only by mixing reactants and stirring at the room temperature. The preparation method is simple, mild in reaction conditions and low in cost. The prepared electrochemical sensor has the advantages of high sensitivity, low detection limit and the like, and is capable of achieving rapid sensitivity determination of guanine and adenine, simple to operate, green and environment-friendly.

Owner:XINYANG NORMAL UNIVERSITY

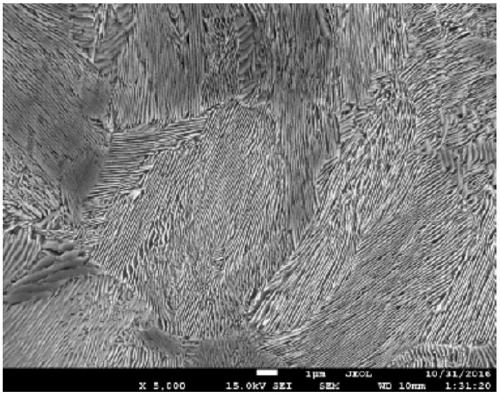

Hot-rolled steel wire rod for large bridge cable rope zinc-plated steel wire over 2000 MPa level and production method

ActiveCN109468530APlay a denaturing rolePlay a role in precipitation strengtheningProcess efficiency improvementWater bathsIngot

The invention relates to a hot-rolled steel wire rod for a large bridge cable rope zinc-plated steel wire over the 2000 MPa level. Chemical components of the steel wire rod comprise, by weight percentage, 0.90-1.10% of C, 0.20-0.60% of Si, 0.30-0.90% of Mn, smaller than or equal to 0.010% of P, smaller than or equal to 0.005% of S, 0.10-0.40% of Cr, 0.010-0.070% of Al, 0.02-0.15% of V, smaller than or equal to 0.05% of Cu, 20-40 ppm of Ca, 20-90 ppm of N and the balance Fe and inevitable residual elements. The content of sorbite texture of the steel wire rod is larger than or equal to 95%. Thethrough ring range of the tensile strength is smaller than or equal to 70 MPa (uniformity). After the steel wire rod is subjected to drawing and zinc plating, the tensile strength of the zinc-platedsteel wire is larger than or equal to 2000 MPa, and the number of torsions is larger than or equal to 12. According to the technical flow of the steel wire rod, pretreatment of molten iron is carriedout, steel is smelted through a converter or an electric furnace, LF refining is carried out, RH degassing treatment is carried out, continuous casting of 390*510 cogged ingot is carried out, a blankis reheated, the blank is rolled, the surface of an intermediate billet is subjected to finishing, the intermediate billet is reheated, the intermediate billet is rolled, the steel wire rod is subjected to EDC water bath toughening treatment, and the steel wire rod is collected and packed.

Owner:JIANGYIN XINGCHENG GOLD MATERIALS CO LTD

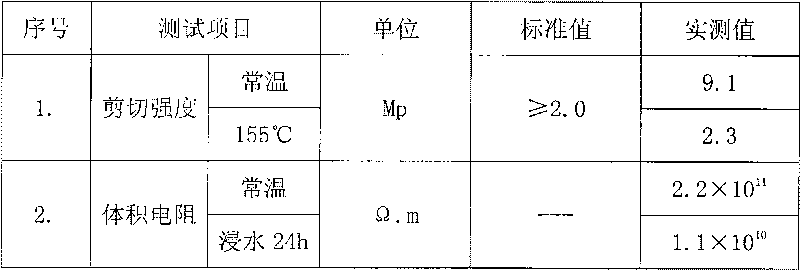

Adhesive, preparation method thereof, and epoxy glass fabric prepared from adhesive

ActiveCN101696349AFair priceNot easy to storePlastic/resin/waxes insulatorsFibre treatmentImidePolymer science

The invention discloses an adhesive, a preparation method thereof, and an epoxy glass fabric prepared from the adhesive. The adhesive comprises the following components in percentage by mass: 10 to 11 percent of tung oil, 2 to 3 percent of maleic anhydride, 38 to 40 percent of methylbenzene, 5 to 6 percent of bismaleimide resin, 17 to 19 percent of 601 epoxy, 11 to 12 percent of novolac epoxy and 15 to 16 percent of filler. The improvement on the formula design of the adhesive and the preparation method is carried out by adopting a plurality of technical means, and alkyd resin is mainly modified to improve the heat resistance; and a toughening agent, a cosolvent and a latent curing agent are selected, and all the selected component materials have moderate cost and are easy to purchase. The epoxy glass fabric product produced by the method is difficult to adhere and is easy to store in the storing process, does not fall off rubber powder or pollute environment, and has no influence on the health of operators.

Owner:CHINA XIDIAN GRP CO LTD

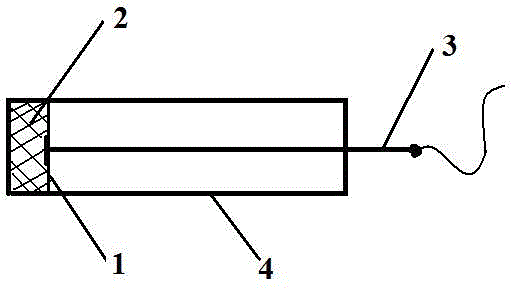

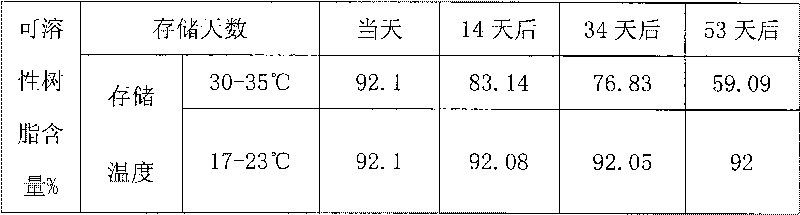

Three-laminated composite board type full-nutritional rice seedling breeding bedding and preparation method thereof

InactiveCN106542909AUniform textureQuality improvementGrowth substratesCulture mediaSurface layerUltimate tensile strength

The invention discloses three-laminated composite board type full-nutritional rice seedling breeding bedding and a preparation method thereof and relates to rice seedling breeding bedding and a preparation method thereof. The problems that existing seedling breeding bedding is poor in water-retaining property, fertilizer efficiency in the later period of seedling breeding is poor, strength is low, and the existing seedling breeding bedding is not suitable for being transported and carried are solved. The seedling breeding bedding is divided into three layers from top to bottom, the middle layer is a core layer, and the surface layers are located on the two sides of the core layer. The preparation method comprises the following steps that (1), straw is cut into sections; (2), steaming and softening are conducted; (3), the straw is ground and kneaded to be in a fiber shape and is dried; (4), mixing is conducted; (5), paving is conducted; and (6), hot-pressing is conducted. According to the three-laminated composite board type full-nutritional rice seedling breeding bedding (as shown in figure 1) produced through the preparation method, when no water is absorbed by the three-laminated composite board type full-nutritional rice seedling breeding bedding, the static bending intensity is 21-22.8 MPa, and the internal bonding strength is 0.35-0.40 MPa; and the three-laminated composite board type full-nutritional rice seedling breeding bedding is high in strength, not prone to breakage or damage and easy to cut and can be manufactured to be in different shapes.

Owner:刘越

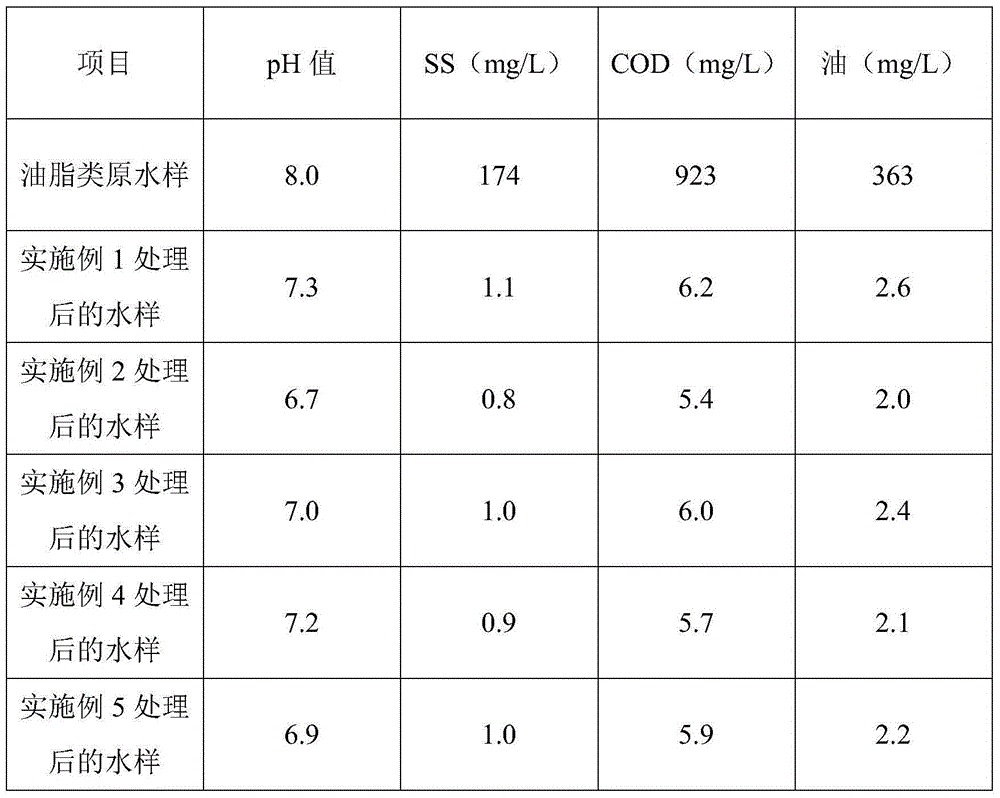

Grease sewage treatment agent

ActiveCN105174489AReduce moisture contentRapid precipitationScale removal and water softeningBiological water/sewage treatmentChemical oxygen demandPollution

The invention discloses a grease sewage treatment agent and belongs to the technical field of sewage treatment agent preparation. The grease sewage treatment agent comprises the following raw materials in parts by weight: 40 to 80 parts of enzyme preparation, 40 to 80 parts of demulsifier, 30 to 60 parts of flocculant, 30 to 60 parts of coagulant aids, 30 to 60 parts of foaming agent, 20 to 50 parts of flotation agent, 20 to 50 parts of bactericide, 10 to 20 parts of corrosion inhibition antisludging agent and 10 to 20 parts of deoxidant. The grease sewage treatment agent disclosed by the invention has the beneficial effects that existence forms of water-in-oil and oil-in-water in water can be broken to rapidly remove a large amount of SS (suspended solid), grease and COD (chemical oxygen demand); the grease sewage treatment agent is high in efficiency and has no corrosivity; secondary pollution cannot be caused to sewage in later stage, and the treatment cost is reduced.

Owner:江苏中丽新材料有限公司

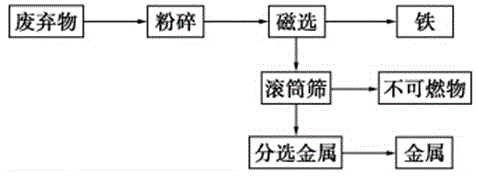

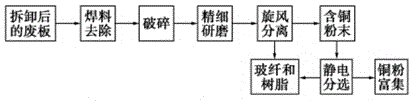

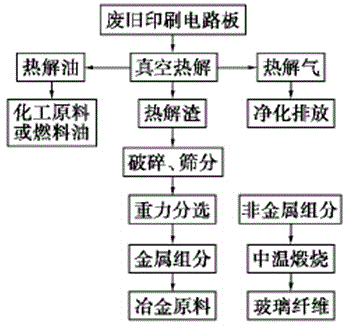

Energy-regeneration pollution-free disposal method for waste electrical appliance circuit board

ActiveCN104624611ASimple waste recycling processLess investmentWaste processingSolid waste disposalCatalytic oxidationDust control

The invention discloses an energy-regeneration pollution-free disposal method for a waste electrical appliance circuit board. The energy-regeneration pollution-free disposal method comprises the following steps: coarsely crushing the waste electrical appliance circuit board, performing alkalization and incineration at a temperature of 870-1400 DEG C to enrich multiple metals; cooling the incineration smoke in a hierarchical manner to coarsely separate the enriched metal oxides; collecting dust through a pipeline membrane process, removing dust through a dust collector, discharging after performing catalytic oxidative purifying, heating boiler stream through incineration heat energy to drive a steam turbine to generate power. The energy-regeneration pollution-free disposal method is simple and reliable, free of emission of harmful residues, waste gas and wastewater and free of secondary pollution; moreover, multiple metals in the waste circuit board can be completely enriched and recycled.

Owner:长沙紫宸科技开发有限公司 +1

Environment friendly coating

InactiveCN101397431ALow free formaldehyde contentHigh contrast ratioCoatingsAlkylphenolResidual monomer

The invention relates to interior wall paint, in particular to an environment-friendly paint which can be widely applied to the decoration of indoor walls, ceilings, plasterboards and the like, does not contain APEO (alkylphenol polyethenoxy ether), is scentless and has low free formaldehyde. The paint is prepared by mainly adopting the technology as follows: first, a dispersant, a wetting agent, a foam suppressor, a thickening agent and a mildew-proof algaecide are added into water sequentially under low speed; titanium pigment, a pH regulator, coarse whiting, calcined kaolin or washed kaolin, french chalk and a mildew-proof agent are added sequentially under medium speed; high-speed dispersion or sanding are carried out until the fineness of less than 50 Mum; and finally, a polystyrene-acrylic copolymer, a polyacrylic copolymer or a vinyl acetate copolymer-acrylic copolymer, a film-forming accessory agent, an antifreezing agent, a preservative, the foam suppressor, a rheology agent and H2O are added sequentially under low speed. The paint dose not contain APEO, thus having no effect on the reproductive system of human and animal; the paint has low odor, and no odor basically, reduces the harm of the residual monomer to human body, and has extremely good physical performances, thus being capable of meeting the requirements on indoor decoration.

Owner:SKSHU PAINT

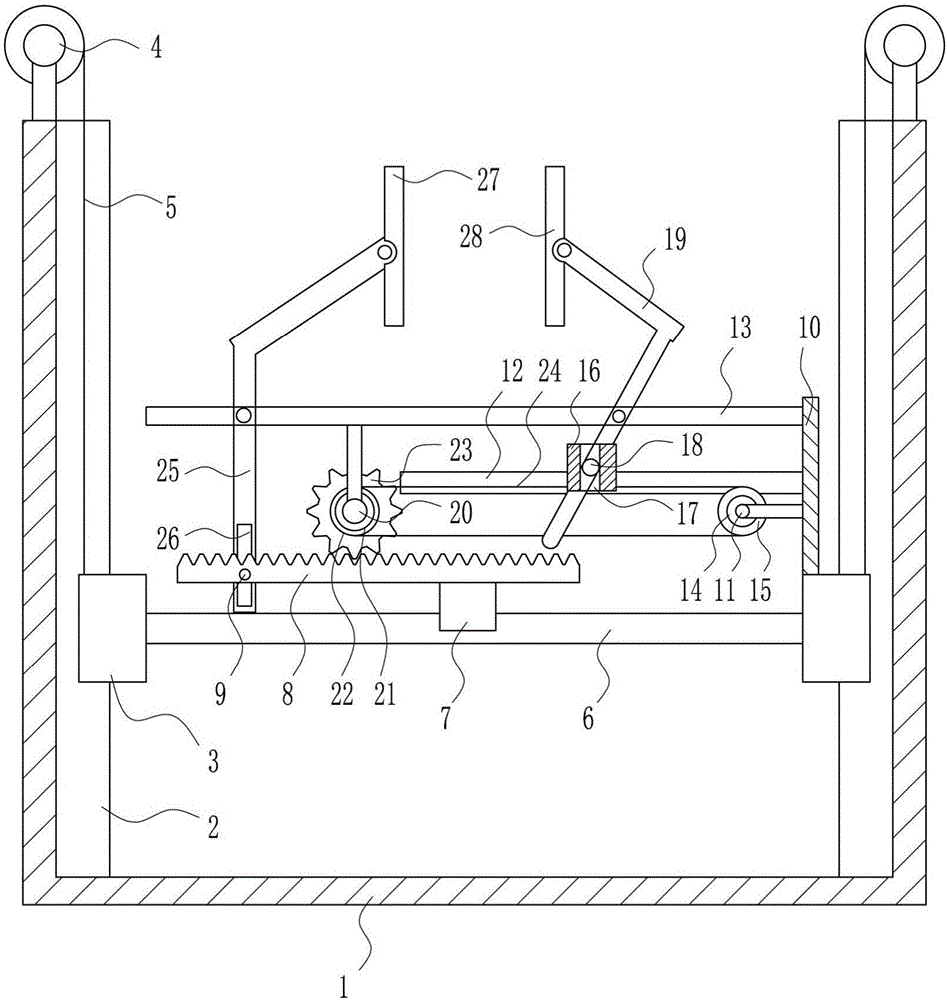

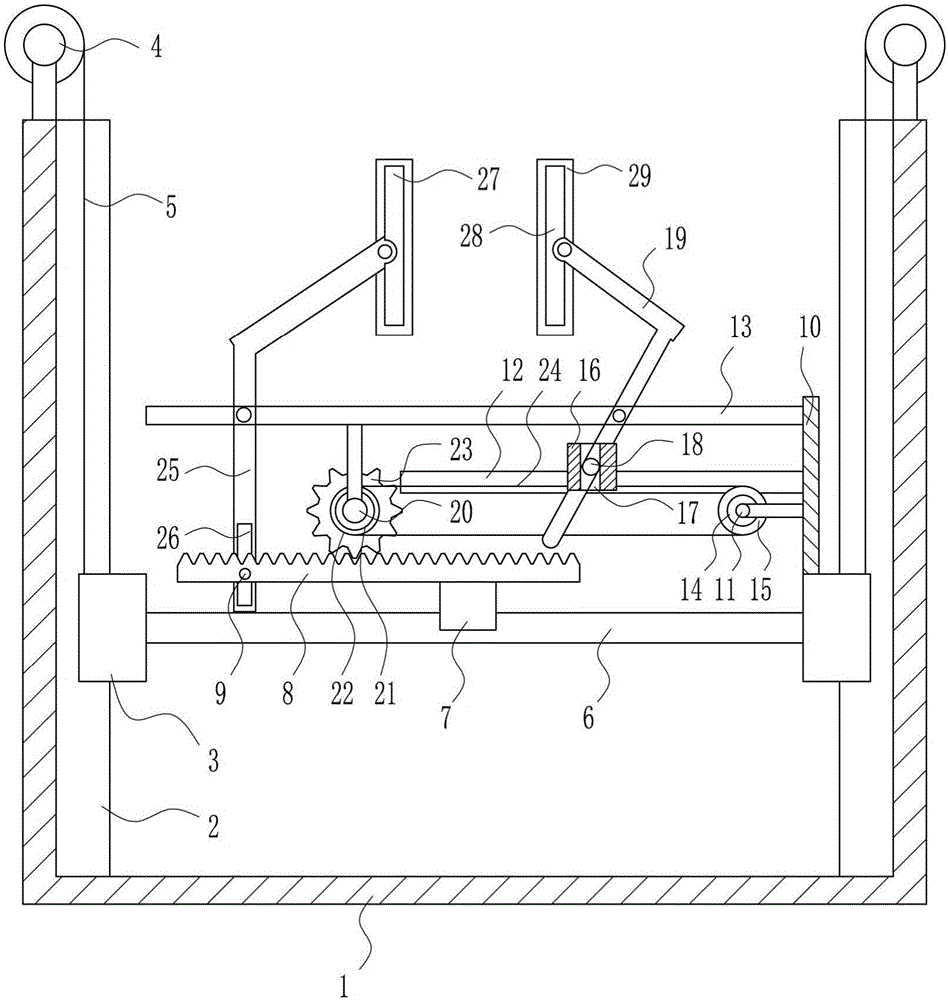

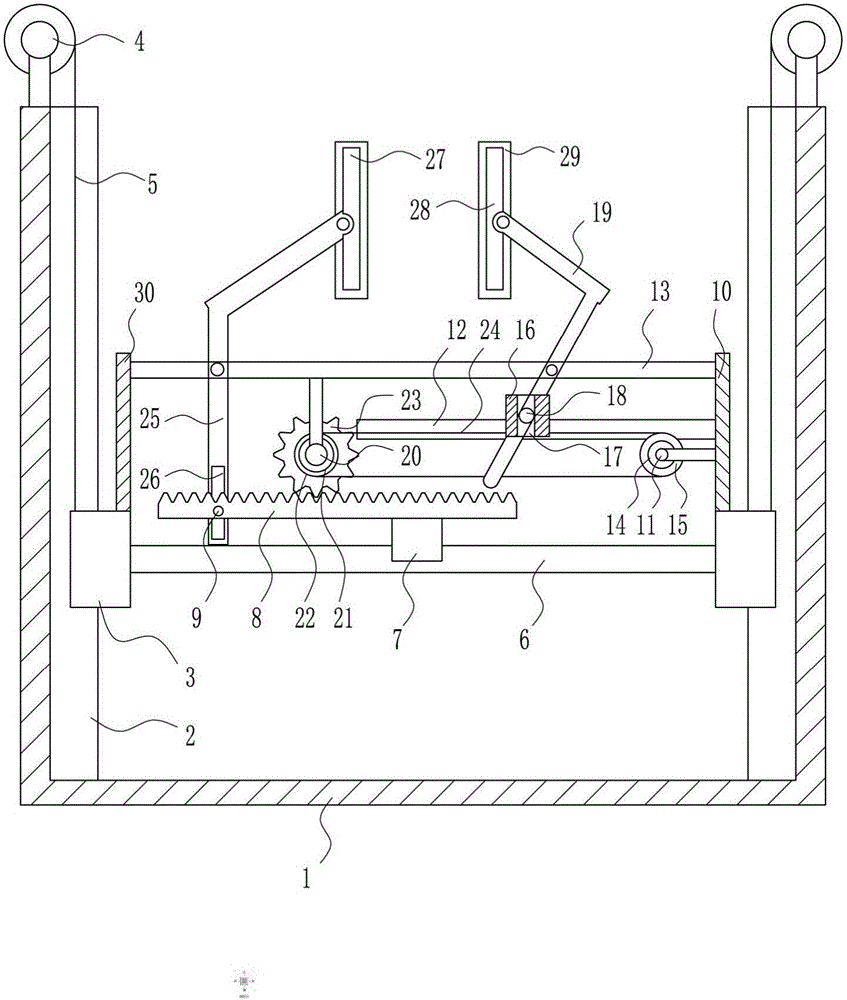

Display screen fixing and adjusting device for big data

ActiveCN106647938AEasy to fixImprove stabilityDigital data processing detailsEngineeringHuman health

The invention relates to the technical field of big data, in particular to a display screen fixing and adjusting device for the big data. In order to achieve the technical purpose that the height of the display screen can be adjusted without affecting the use of the display screen and no influence on the human health is caused, the display screen fixing and adjusting device for the big data is provided and comprises a U-shaped bracket, first sliding rails, first sliding blocks, electric wire wrapping wheels, pull ropes, a second sliding rail, a second sliding block, a rack, a first roller, a first supporting rod and the like. The first sliding rails are connected with the left side and the right side of the top in the U-shaped bracket respectively through bolts. The display screen is fixed through a left clamping plate and a right clamping plate so that the display screen is stabilized, and meanwhile, the lifting function of the display screen is achieved by means of the electric wire wrapping wheels on the two sides so that the height of the display screen is adjusted.

Owner:GUANGZHOU ZHONGCHANG KANGDA INFORMATION TECH

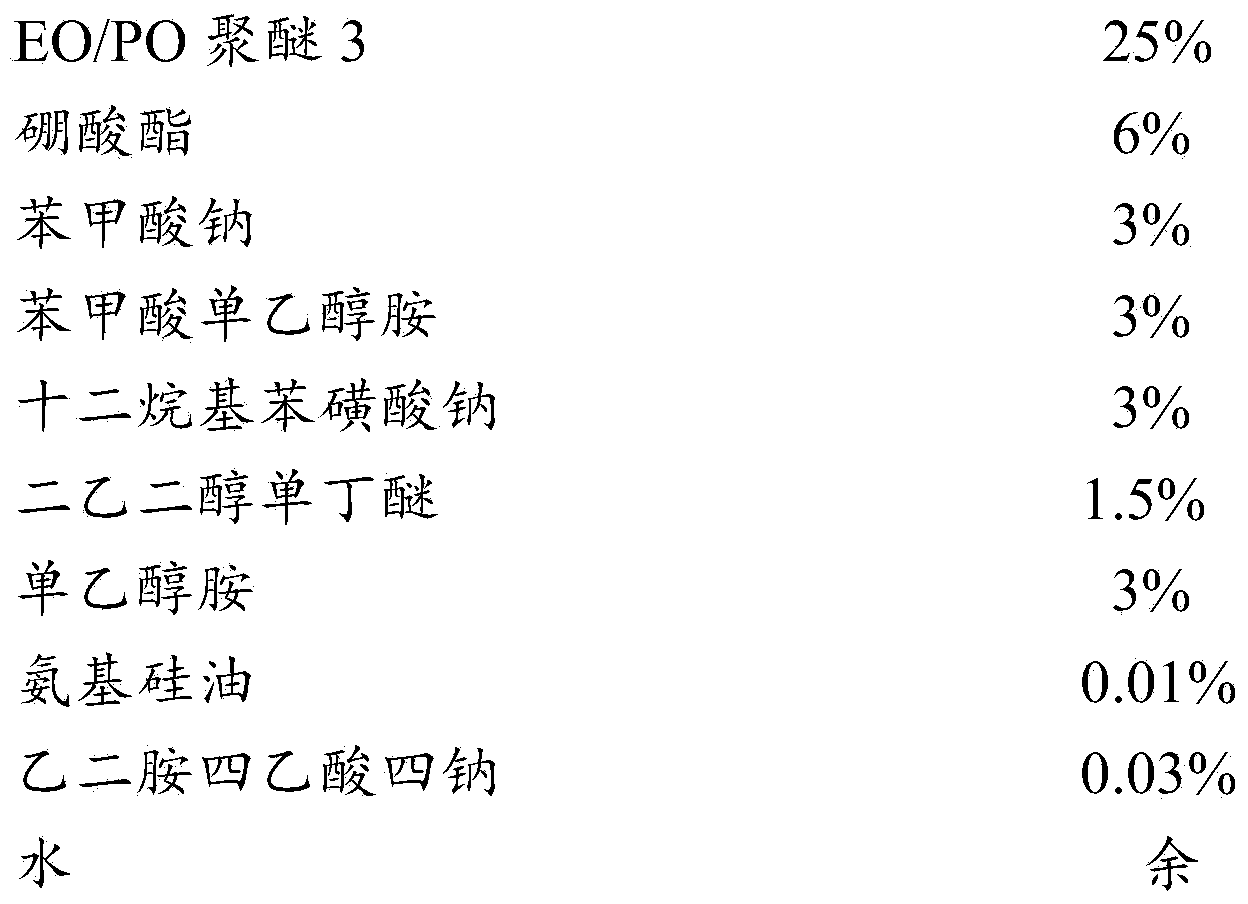

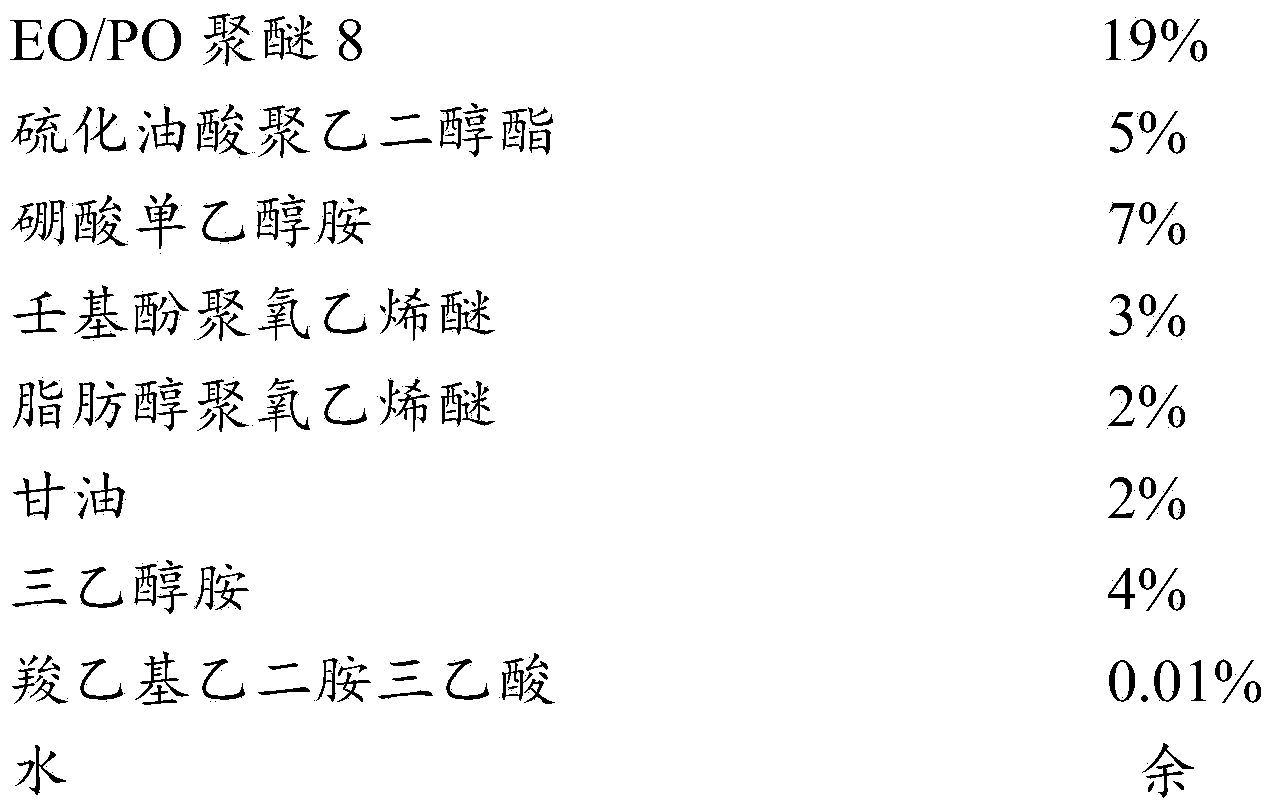

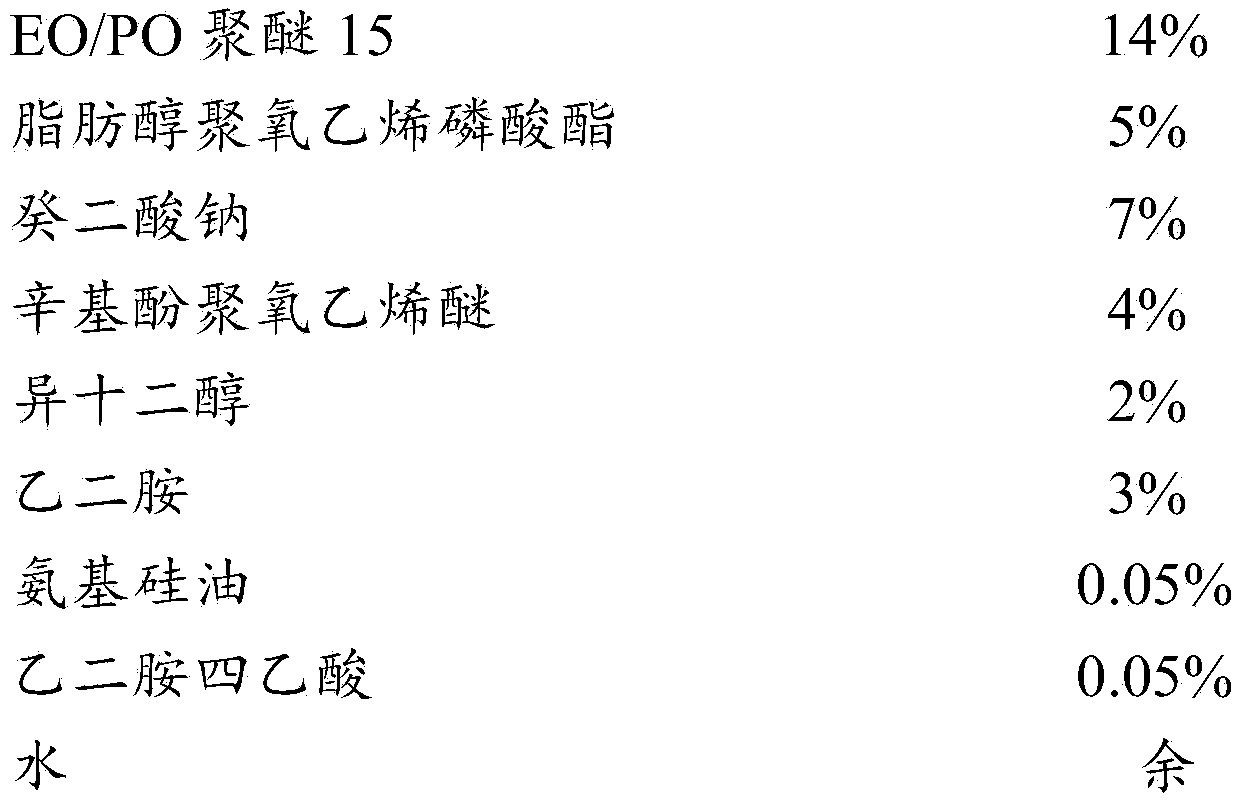

Fully synthetic stainless steel cold rolling mill compound and application thereof

InactiveCN104342274AExtended service lifeGood lubricating and cooling effectLubricant compositionWater solubleCleansing Agents

The invention relates to a fully synthetic stainless steel cold rolling mill compound and application thereof and mainly aims to solve the problems of poor lubricating extreme pressure property and short service life. The fully synthetic stainless steel cold rolling mill compound comprises the following components in parts by weight: a) 5-30 parts of water-soluble polyether; b) 1-10 parts of a water-soluble extreme pressure agent; c) 3-10 parts of a water-soluble antirust agent; d) 1-10 parts of a cleaning agent; e) 1-5 parts of a coupling agent; f) 0.01-0.5 part of a chelating agent; and g) 35-65 parts of water. With application of the technical scheme, the problems in the prior art are solved very well; and the fully synthetic stainless steel cold rolling mill compound can be applied to the stainless steel cold rolling process.

Owner:CHINA PETROLEUM & CHEM CORP

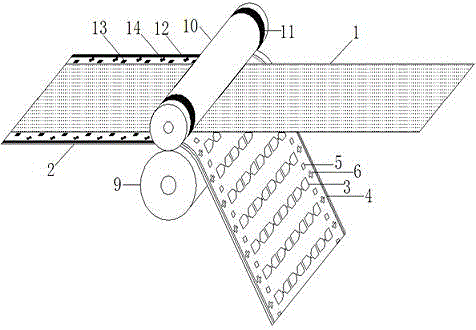

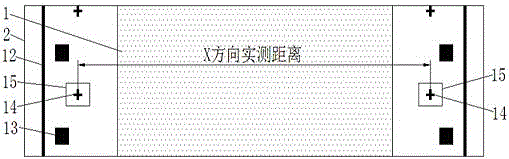

Laser production technology for radio frequency identification antenna capable of easily discharging waste

ActiveCN105789869ASolve the problem of waste dischargeGood waste discharge effectRadiating elements structural formsLaser beam welding apparatusAntenna designTime transformation

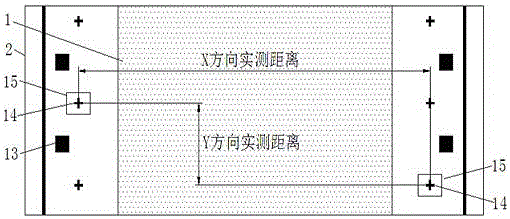

The invention discloses a laser production technology for a radio frequency identification antenna capable of easily discharging waste. In the laser production technology for the radio frequency identification antenna, changes of positions and dimensions of positioning marks at two sides of a radio frequency antenna substrate in X and Y directions are detected; real-time transformation is carried out on the shape, the dimension, the position and the angle of an engraved pattern through an adaptive algorithm according to the materials, the thicknesses, the composite temperatures, the environment temperatures and the humidities of a used metal film and the antenna substrate and the antenna design pattern and composition condition; meanwhile, laser engraving is compensated according to the monitored working temperature in a laser scanning system; and the influence of a temperature drift of the laser scanning system on the dimension and the position of the engraved pattern is reduced, so that the error of the system for overlapping positioning of the engraved pattern and a printed pattern is controlled within 20 microns or to be smaller than 1 / 2 laser spot size; the waste discharge technology is relatively easy to implement; the key problems of pattern positioning and edge tracking in the industrial process of the laser production technology for the radio frequency identification antenna are solved; and the industrialization process of the laser antenna production technology is pushed.

Owner:SUZHOU ZUENS IOT TECH CO LTD

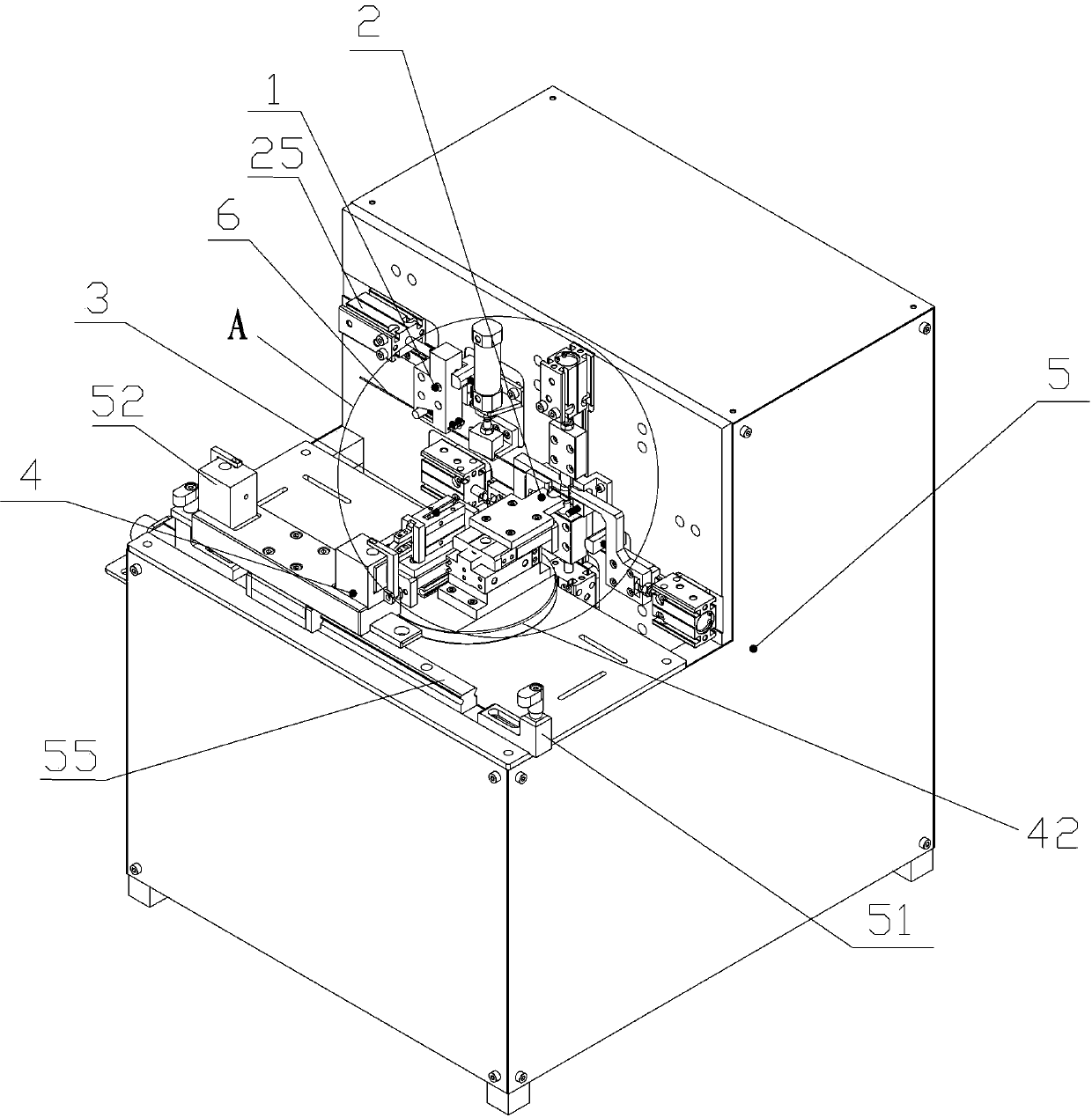

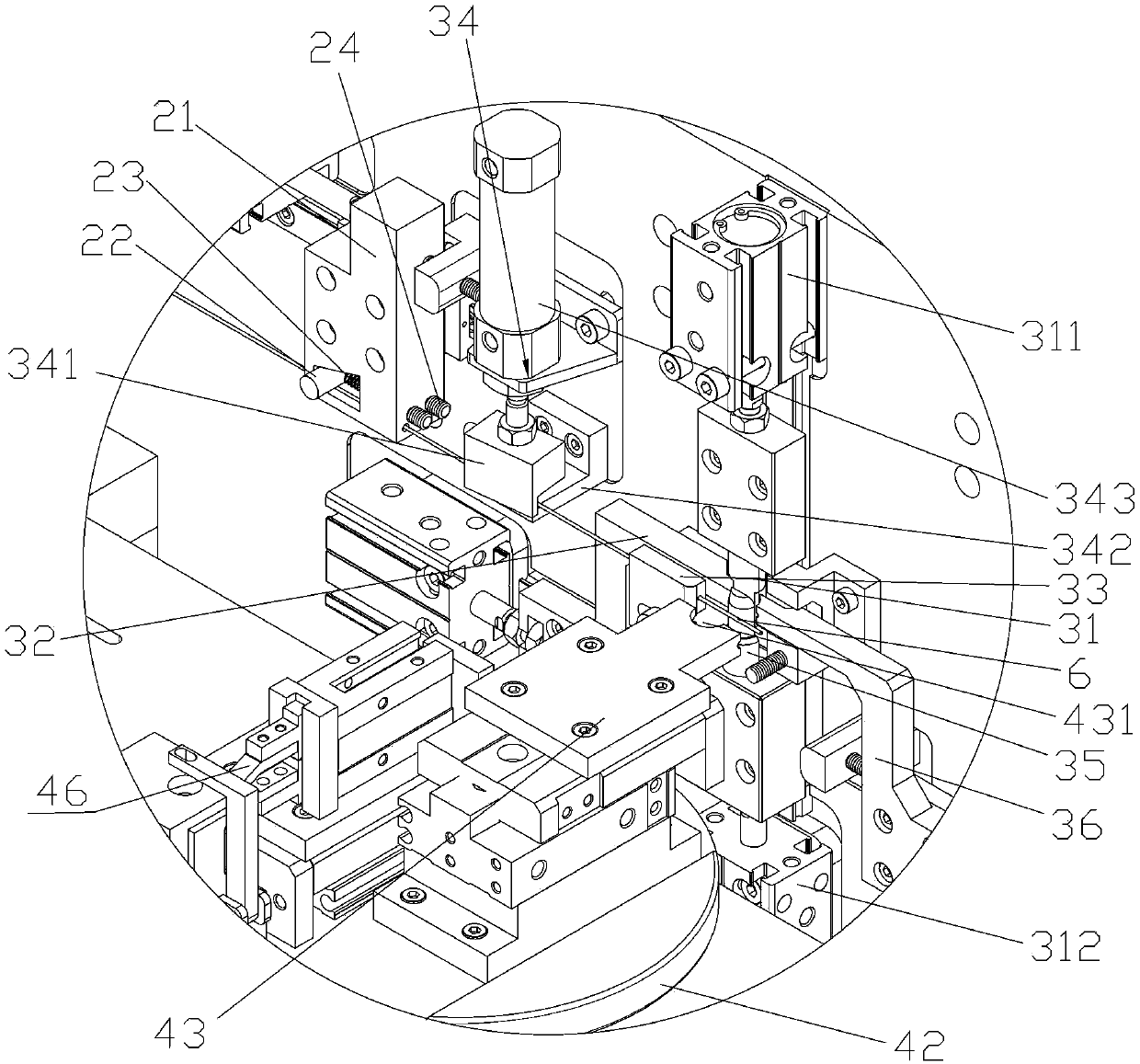

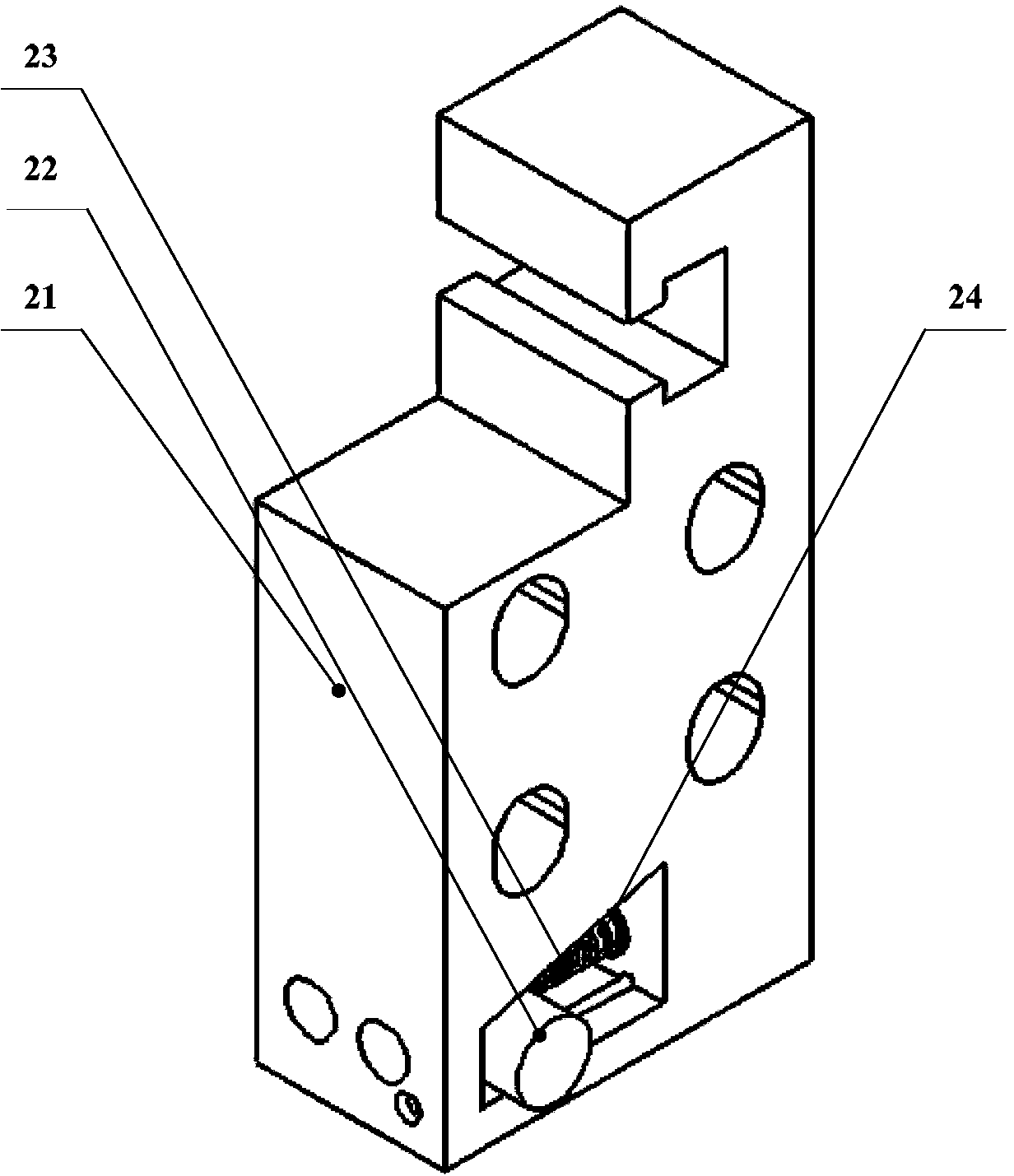

Forming and assembling equipment for decorative chain fastening members

ActiveCN103394923AQuality assuranceQuality improvementOther manufacturing equipments/toolsEngineeringSoldering

The invention belongs to the technical field of decoration processing equipment, and discloses forming and assembling equipment for decorative chain fastening members. The forming and assembling equipment for the decorative chain fastening members comprises a rack, a feeding device, a forming device, an assembling member clamping device and a fastening member clamping and transferring device, wherein the feeding device is used for feeding gold threads, the forming device is used for compressing the gold threads to form the fastening members, the assembling member clamping device is used for clamping assembling members, and the fastening member clamping and transferring device is used for clamping the fastening members and transferring the fastening members to the positions of the assembling members. The feeding device, the forming device, the assembling member clamping device and the fastening member clamping and transferring device are all arranged on the rack. The forming and assembling equipment for the decorative chain fastening members ensures the quality of decorative chains, the forming consistency of the fastening members is good, and assembling and soldering of the assembling members and the fastening members are easier to achieve. The degree of automation is high, and the complex degree of working of workers is reduced greatly. Further, time and labor are saved in a processing process, processing efficiency is high, a processing cycle is shortened, cost is lowered, and the forming and assembling equipment for the decorative chain fastening members can adapt to the modern production and manufacturing requirements of low cost, short cycles and high quality.

Owner:SHENZHEN INST OF ADVANCED TECH +1

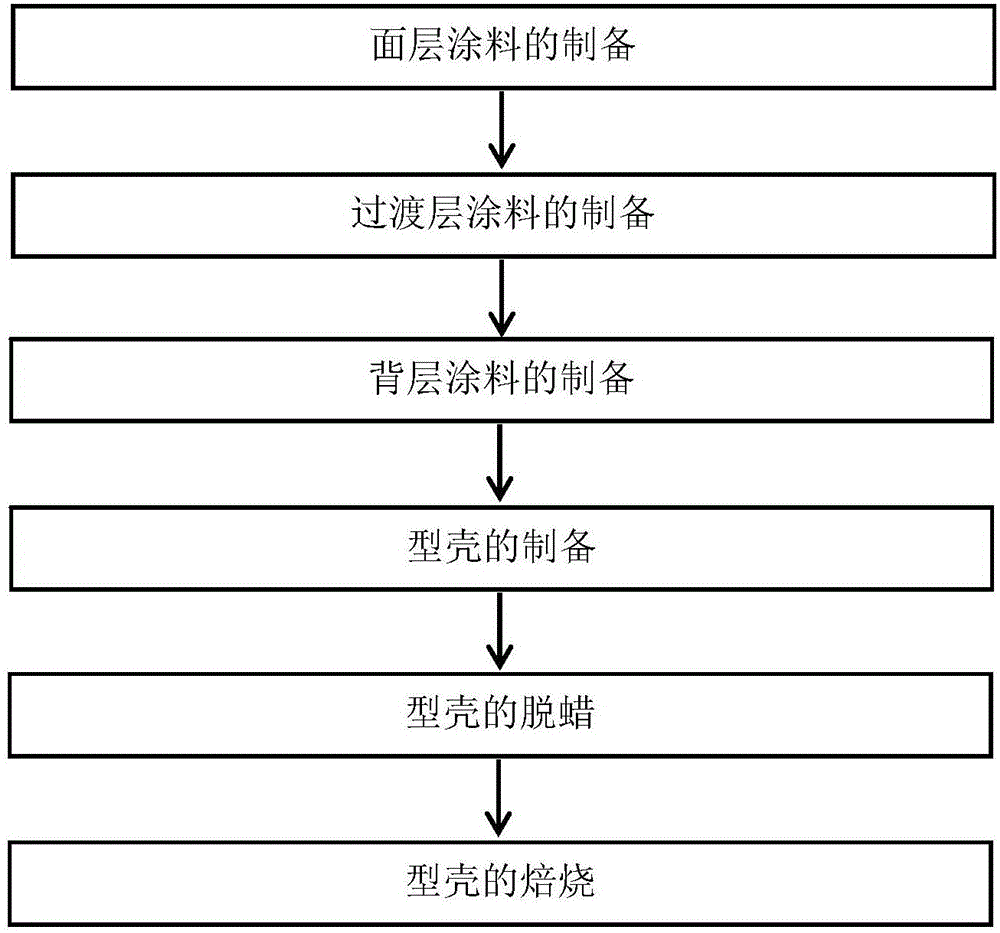

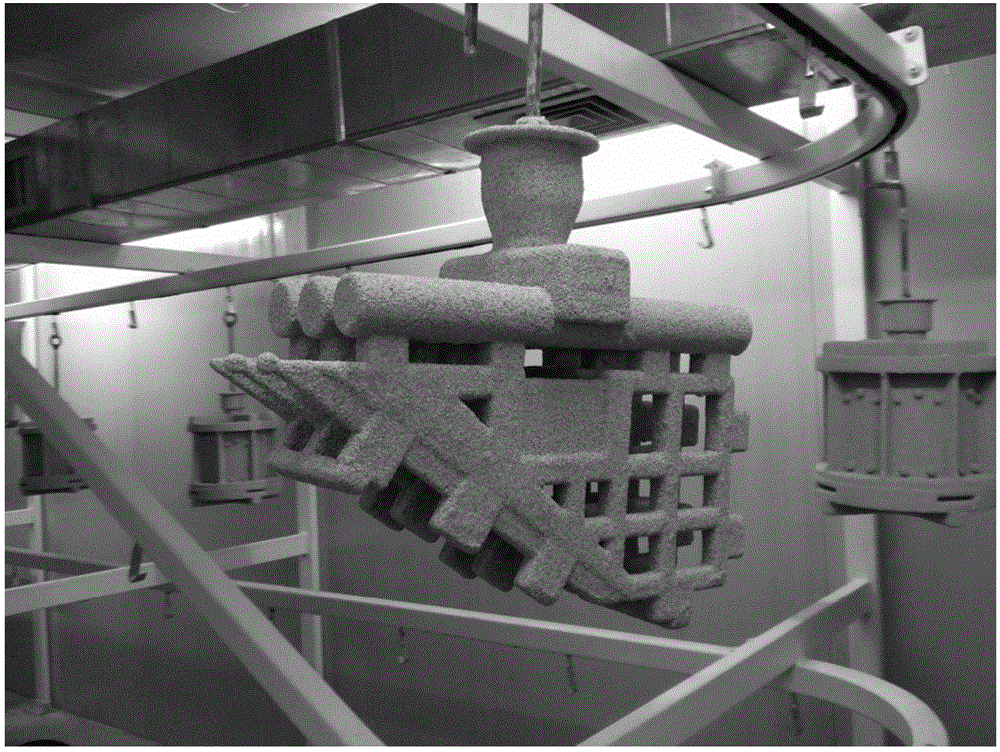

Preparation method of oxide surface layer shell for titanium alloy precision casting

The invention discloses a preparation method of an oxide surface layer shell for titanium alloy precision casting. The preparation method comprises the steps of preparation of binders, preparation of surface layer powdery material, preparation of surface layer coating, preparation of a surface layer shell, shell dewaxing, shell roasting and the like; the preparation method has the beneficial effects that: the used raw material has low price and is easily available, the traditional process is improved, the using amounts of zirconium oxide and yttrium oxide are greatly reduced, the process is simplified, the preparation flow is shortened, and the labor and raw material costs are reduced; adhesive adopts silicon sol and zirconium acetate as main raw materials and is added with n-caprylic alcohol and polyvinyl alcohol, so that the surface layer coating has good coating property, can be uniformly coated on a wax mold and has good compactness; the adhesive is added with zirconium oxide fireproofing ingredient, therefore, the surface layer shell is capable of resisting high temperature; steam dewaxing is adopted to achieve the effect of no environment pollution; the prepared surface layer shell has no influence on human health, has wide application range, small interface reaction layer with thickness 0.018-0.02mm, high precision and excellent performance and is easy to realize post-finishing.

Owner:QINGDAO RUNQIAN HI TECH CO LTD

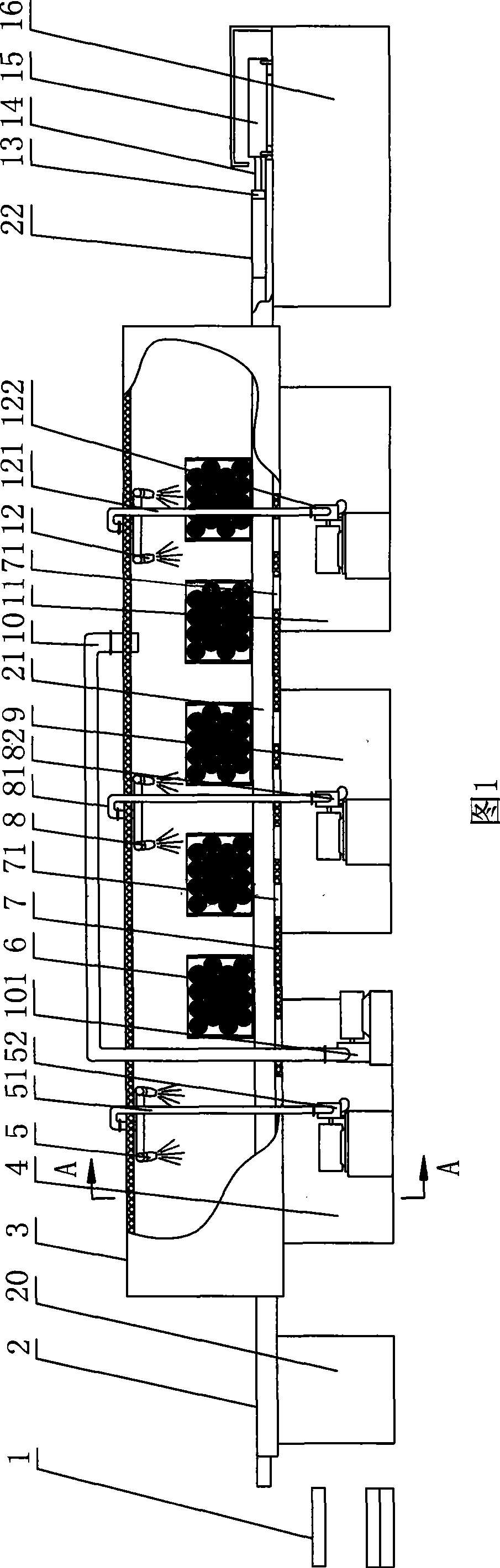

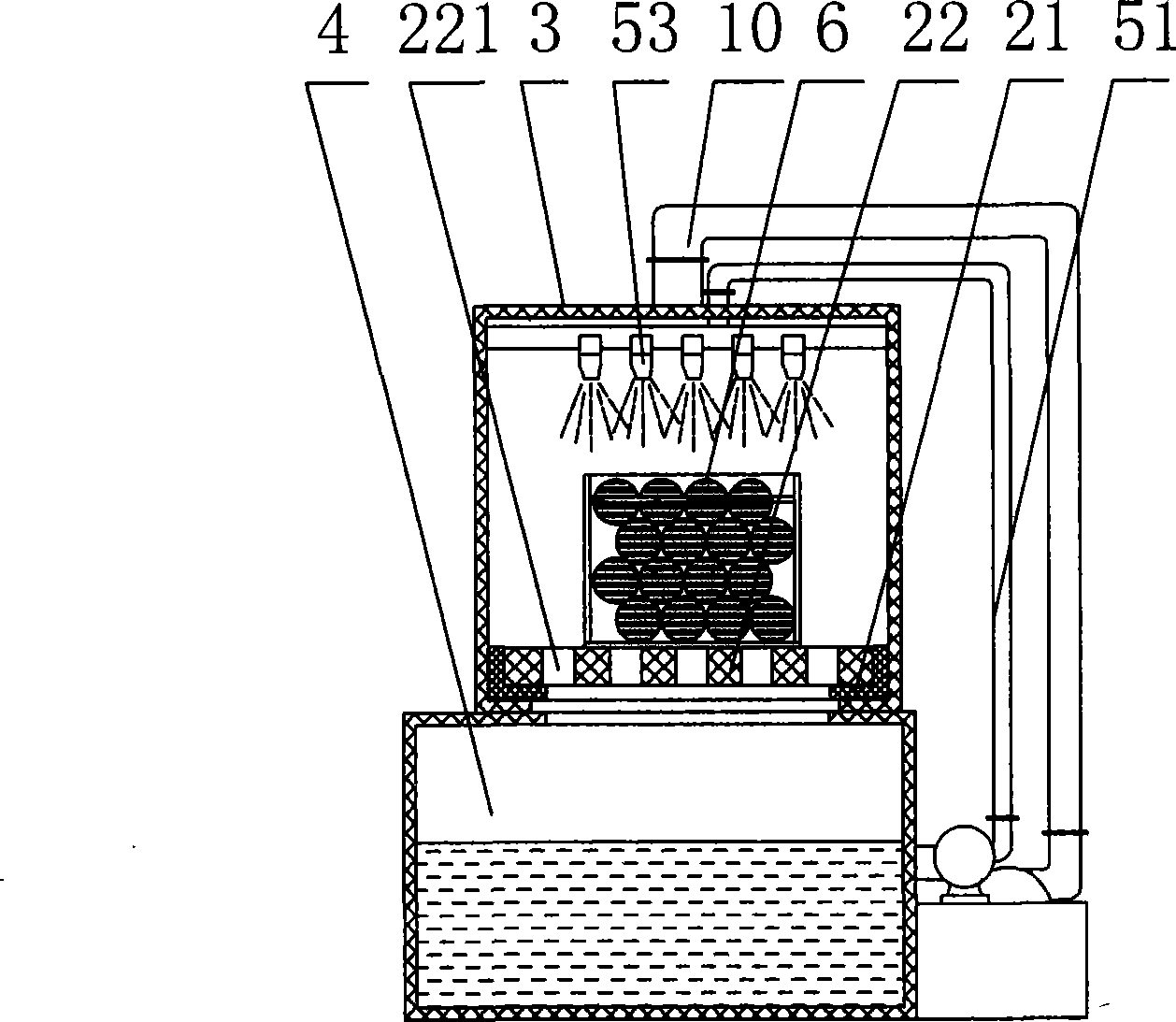

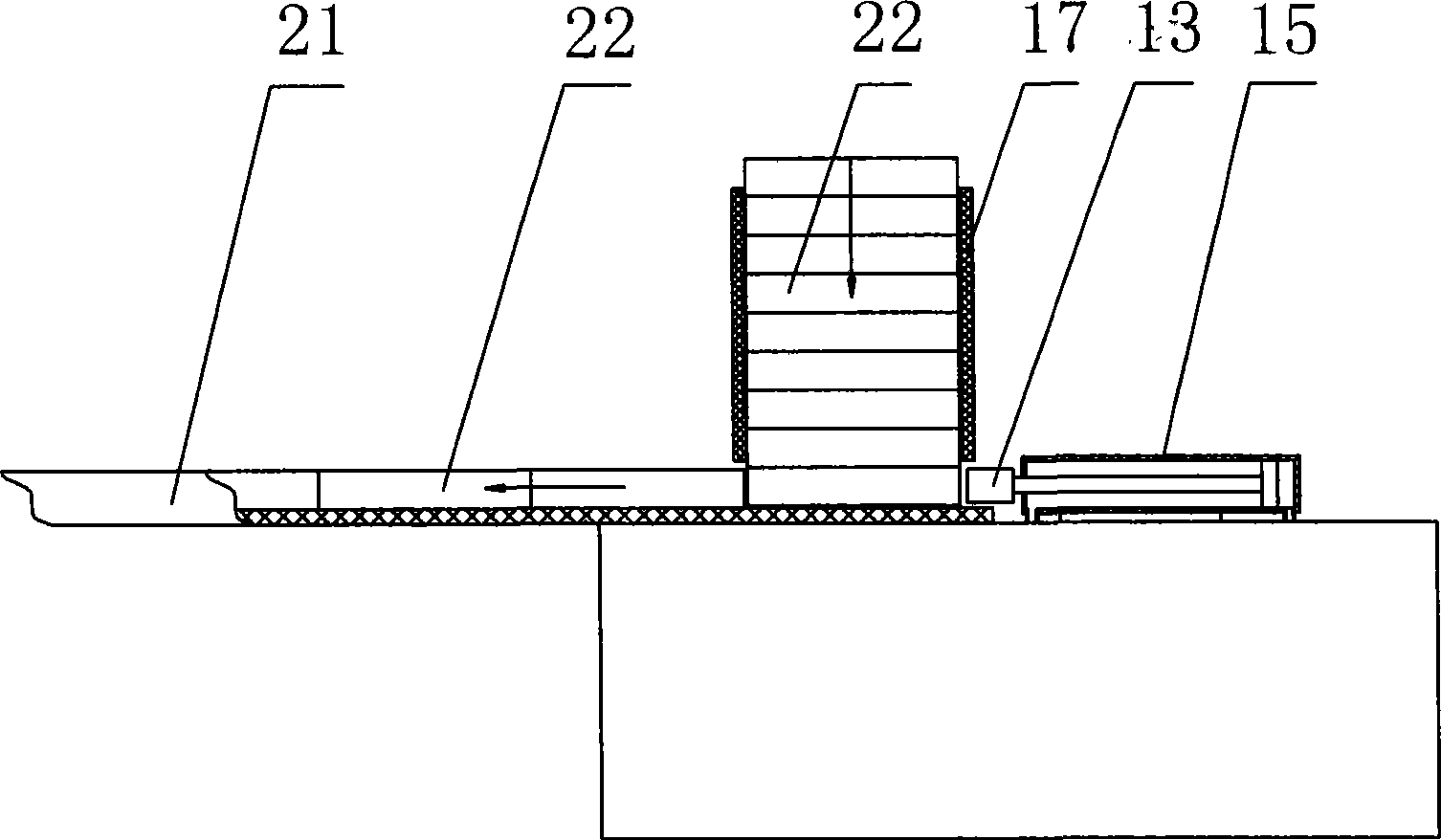

Device for cleaning vanadium-removing copper wire balls

ActiveCN101444781ANo effect on healthPhysical health effectsConveyorsCleaning using liquidsCopper wireSpray nozzle

A device for cleaning vanadium-removing copper wire balls comprises a tunnel, a copper wire ball conveying mechanism which is arranged at the bottom of the tunnel and passes through the entire tunnel, and a suction tube which is arranged at the top of the tunnel and connected with a vacuum pump. An acid cleaning spray nozzle set, a rough cleaning spray nozzle set and a fine cleaning spray nozzle set are sequentially arranged on the inner wall of the tunnel from the inlet of the tunnel, and an acid cleaning liquid storage tank, a rough cleaning liquid storage tank and a fine cleaning liquid storage tank are sequentially arranged below the copper wire ball conveying mechanism in the positions corresponding to the spray nozzle sets. The acid cleaning spray nozzle set, the rough cleaning spray nozzle set and the fine cleaning spray nozzle set are all connected with a high-pressure hydraulic pump via pipelines, and the high-pressure hydraulic pump is correspondingly connected with acid cleaning liquid storage tank, the rough cleaning liquid storage tank and the fine cleaning liquid storage tank. The entire cleaning process is enclosed and mechanized; and during the cleaning process, no irritant gases are discharged and an operator does not directly contact the copper wire balls, so as not to affect the health of the operator.

Owner:仙桃市中星电子材料有限公司

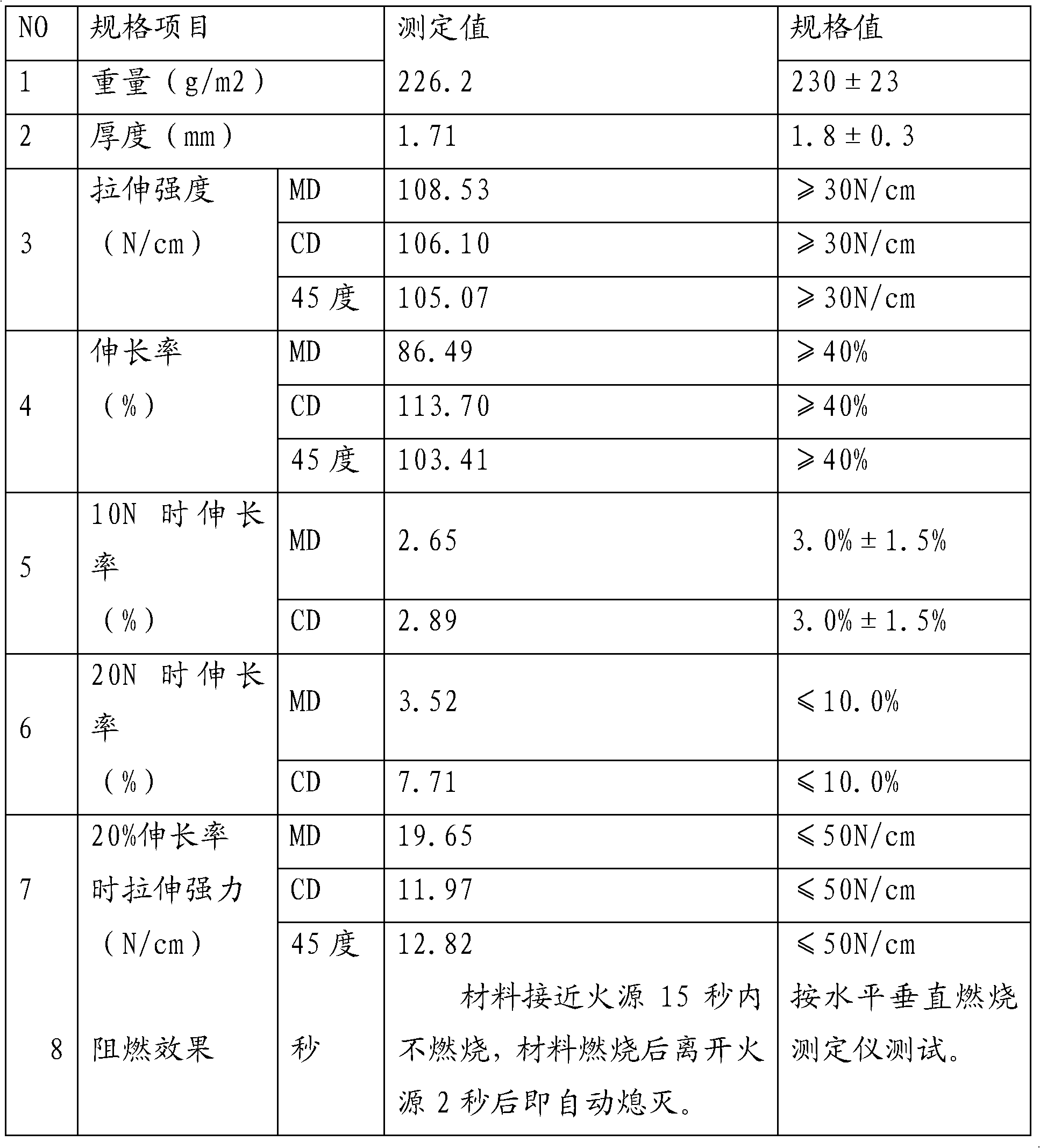

Environmentally friendly differential fiber non-woven automotive interior trim material and preparation method thereof

ActiveCN101851863AImprove spinnabilityAvoid it happening againFibre typesNeedling machinesFoam rubberEngineering

The invention belongs to automotive non-woven textiles, in particular to an environmentally friendly differential fiber non-woven automotive interior trim material and a preparation method thereof. The preparation method comprises the following steps of: preparing needle-punched grey cloth through feeding fibers, roughly opening, mixing fibers, fine opening, carding the fibers into a net, crosswise spreading the net and needling by using environmentally friendly colored flame retardant terylene short fibers as a raw material; and then carrying out foam gum dipping in flame retardant polyacrylate foaming rubber latex to obtain the differential fiber non-woven automotive interior trim material, wherein the adhesion quantity of the rubber latex is controlled to be 12-18g / m<2>. The environmentally friendly differential fiber non-woven automotive interior trim material has good property, high quality, environmental protection and high safety; and the preparation method provided by the invention has low energy consumption, no pollution and low cost.

Owner:福建福能南纺卫生材料有限公司

Trivalent chromium natural colour passivation solution for processing aluminium alloy

InactiveCN102002704ABright white surfaceNo effect on healthMetallic material coating processesCadmium CationChromic salt

The invention relates to a trivalent chromium natural colour passivation solution for processing an aluminium alloy, comprising the following components by contents: 1-2 g / L of chromic salt, 0.05-0.1 g / L of zirconium salt, 0.01-0.03 g / L of nickel sulfate NiSO4.6H2O, 0.4-0.8 g / L of film-forming agents, 0.4-0.6 g / L of trisodium citrate Na3C6H5O7.2H2O, and the balance of water. The trivalent chromium natural colour passivation solution does not contain harmful substances, i.e. hexavalent chromium, lead, mercury, cadmium, polybrominated diphenyl ethers, polybrominated biphenyl, and the like, can be recycled, realize the clean production, passivate at normal temperature and save the energy; in addition, the aluminium alloy processed by the trivalent chromium natural-colour passivation solution has white and bright surface colour and lustre, colour approximate to the natural colour of the aluminium alloy and film neutral salt spray corrosion property meeting the national standard and can realize the substitution of the trivalent chromium passivation solution for a hexavalent chromium passivation solution.

Owner:SOUTHWEST UNIVERSITY +1

Novel waterborne zinc-rich anti-corrosive paint

InactiveCN101418150AImprove anti-saggingImprove anti-settling performanceAnti-corrosive paintsWater basedMetasilicate

The invention discloses a novel water-based zinc-rich anti-corrosive paint, which consists of a component a and a component b; according to the total weight percentage of the paint, the component a comprises 50 to 56 percent of zinc powder and 10 to 15 percent of thixotropic agent, and the component b comprises 8 to 10 percent of potassium metasilicate, 17 to 20 percent of water, 1 to 2 percent of thickening agent and 4 to 7 percent of addition agent. When in use, the water-based zinc-rich anti-corrosive paint can be prepared by mixing the component a and component b. The paint system is a water-based system, does not contain organic solvent, has simple preparation method, saves materials, reduces the cost by 5 to 10 percent compared with like products, and has no environment pollution and no influence on constructors. The cured coating has the advantages of excellent ageing-resistant, radiation resistant and solvent resistant performance, good comprehensive performance and long-term corrosion resistance.

Owner:LANGFANG ZKYD ANTI RUST TECH

Controlled cooling and controlled rolling method for control over bearing steel wire network carbide

ActiveCN109402356APrevent precipitationUniform temperatureRolling contact bearingsShaftsWire rodWater baths

The invention relates to a controlled cooling and controlled rolling method for control over bearing steel wire network carbide. The controlled cooling and controlled rolling method is characterized by comprising the steps that a bar is quickly rolled into a wire with the specified specification to be subjected to spinning, scattered rolls are made, the final rolling temperature is controlled to be 780- 880 DEG C; the spitting temperature is controlled to be 750-850 DEG C; the continuous scattered rolls are subjected to on-line controlled cooling through EDC water bath isothermal quenching cooling, the cooling speed is controlled to be 2.0- 10 DEG C / s, and the final cooling temperature is controlled to be 620-630 DEG C; cover-adding slow cooling is conducted after EDC water bath isothermalquenching cooling, and the temperature when the scattered rolls are taken out from a cover is controlled to be 400-500 DEG C; and the rolls are collected after slow cooling, and air cooling is conducted to the room temperature. The disc rolls are subjected to controlled cooling through a mode of EDC water bath isothermal quenching cooling and cover-adding slow cooling, precipitation of the carbide in the cooling process can be effectively inhibited, a non-equilibrium microstructure is obtained, the small-strip-shaped or hemispheric carbide is formed, and finally, the network carbide is controlled.

Owner:JIANGYIN XINGCHENG GOLD MATERIALS CO LTD +1

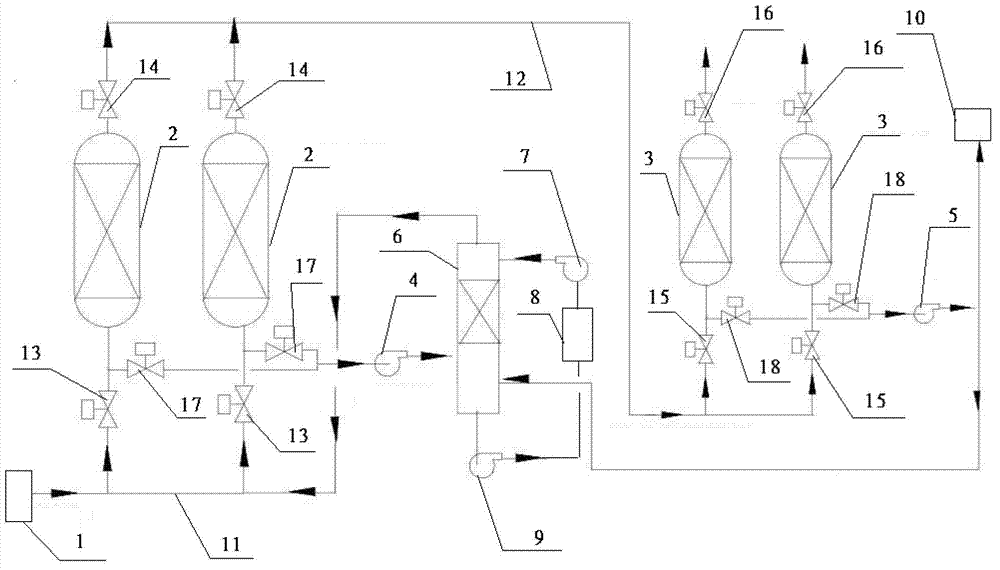

Absorption oil-gas recycling system and absorption oil-gas recycling process

The invention relates to an absorption oil-gas recycling system and an absorption oil-gas recycling process. The system comprises an absorption device, a desorption device, an intake device and a storage device, which are connected with one another. The absorption device and the desorption device are more first-staged. By the absorption oil-gas recycling system, the recycling process by combining multistage absorption and desorption is achieved, the problems of pollution and waste of hydrocarbon components in oil and gas are solved, external environment is protected effectively, and energy is utilized efficiently and economically. The absorption oil-gas recycling system is suitable for popularization and application in related oil-gas recycling fields, especially suitable for fields such as lean oil recycling and reusing and crude oil-gas recycling and reusing.

Owner:BAY ENVIRONMENTAL TECH BEIJING

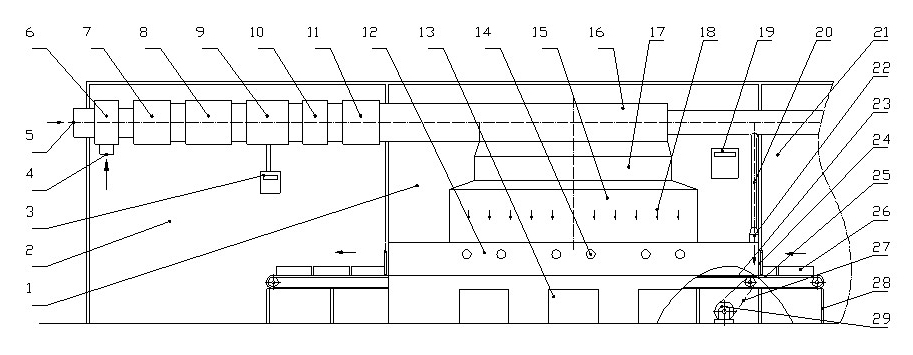

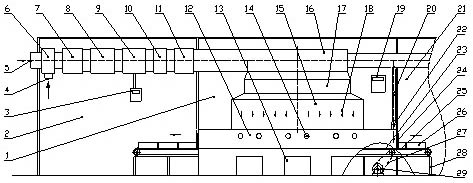

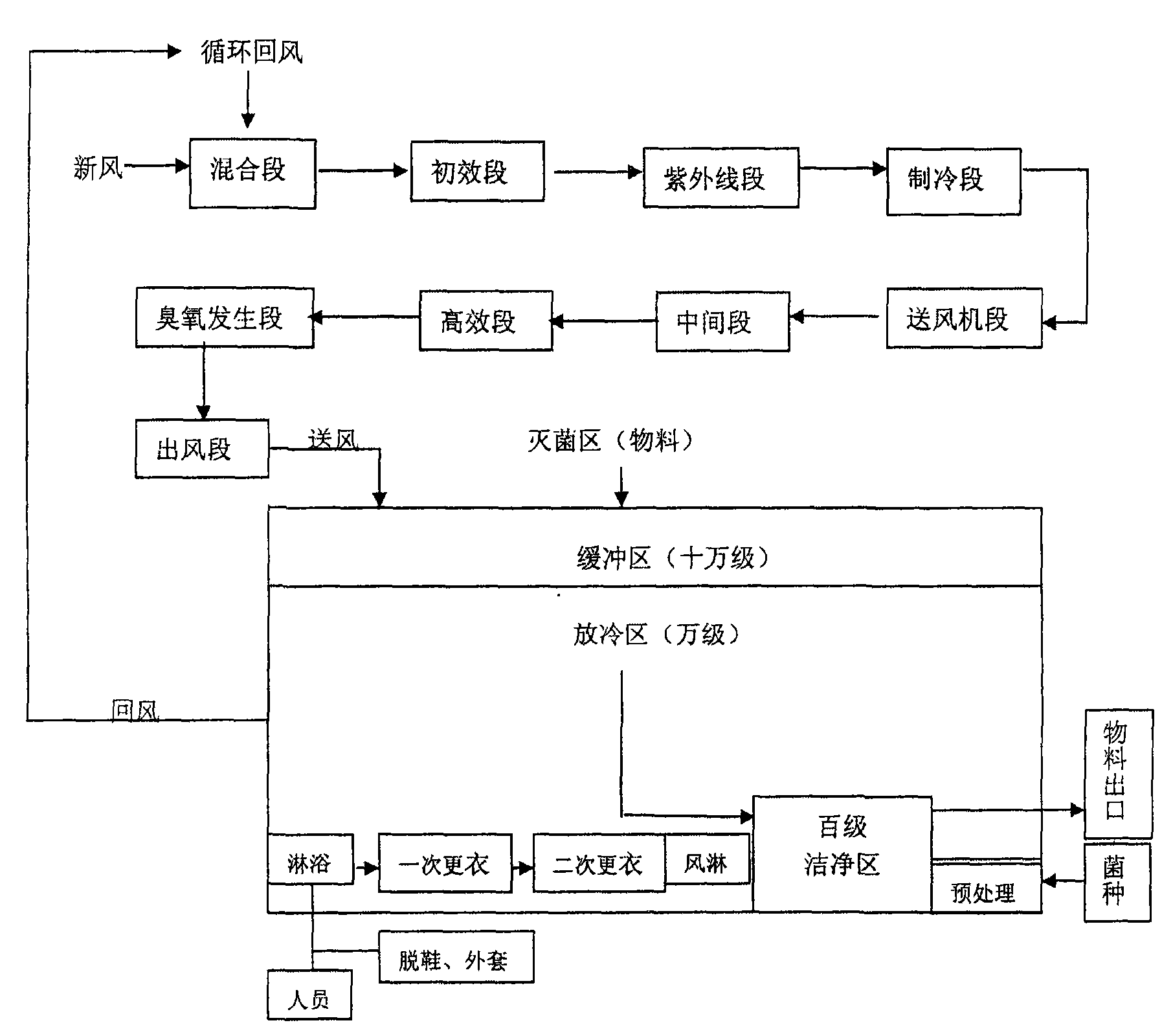

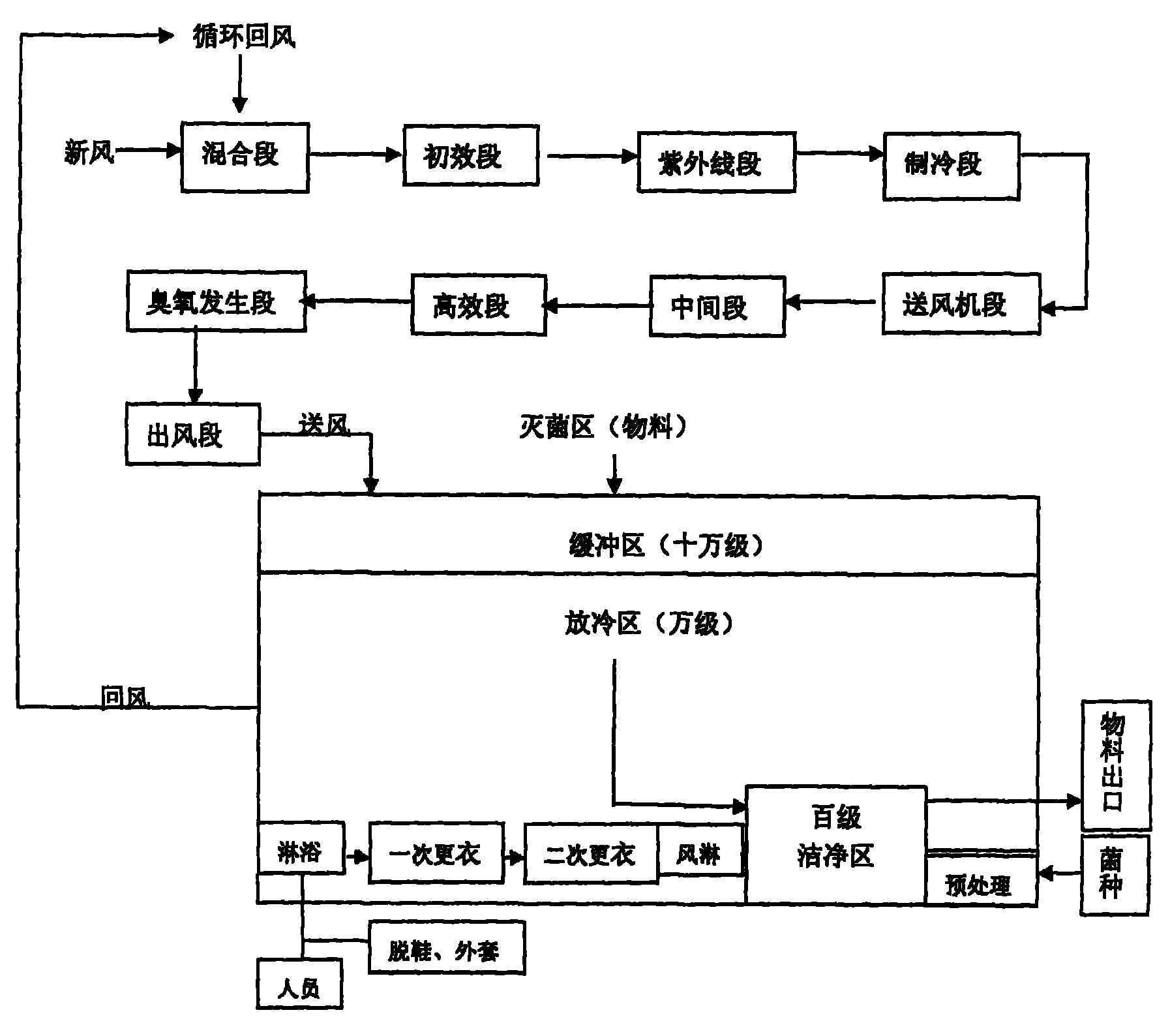

Edible fungus inoculation working system

Owner:INST OF SOIL & FERTILIZER FUJIAN ACADEMY OF AGRI SCI

Air purification system of edible fungus inoculation

InactiveCN101900386ANo effect on healthLower resistanceLighting and heating apparatusAir conditioning systemsAir filtrationAir filter

The invention relates to an air purification system of edible fungus inoculation. The air purification system is characterized by consisting of an air conditioning system, an air supply system, a return air system, an air exhaust system, an ozone system, ultraviolet lamp systems and an air filtering system, wherein the air conditioning system adopts a double operating mode refrigerating machine and is installed at the inlet air section of a dust free room, the air supply system utilizes a pipeline to supply air and is connected between the air outlet of the air conditioning system and the dust free room, the air exhaust system and the return air system are communicated with an air inlet through a return air wall and a return air pipeline, the air filtering system adopts an air filter and is installed at the air inlet, the ultraviolet lamp systems are respectively installed in an inlet air channel and the return air wall, and the ozone generating system is installed at a section where the cooled air enters the purification space. After the technical scheme is utilized, the cleanliness which cannot be achieved by fumigation of chemical medicines is realized, and the sedimentary number of static colony is zero; the air purification system does not influence inoculation environment and mechanical equipment and health of workers; and the microorganisms do not generate drug resistance. The system also has the advantages of convenient operation and low production cost.

Owner:STARWAY FOOD TECH DONG GUAN

Deoiling agent

InactiveCN1632094AScientific and reasonable compositionEasy to useNon-ionic surface-active compoundsSolventChemistry

The invention relates to an oil expelling agent, comprising the following raw material: water of small necless 300-400portions, fatty acid ethylene oxide addition compound penetrate, arene solvent, compound surface active agent. Its has scientific compounds, without toxicity and pungent odor, is water-soluble, has no pungency to the skin, no influence to people's health and no harm to the subject washed and paint protective film; it is safe, reliable, convenient, rapid and has good cleaning effect, can be widely applied in clearing in the fields such as aviation, train, ship army equipment, oil developing and processing, oil tank, oil pipeline, publishing machine, electric equipment, procession, manufacture and maintenance of chemical equipment the ground of garage and machine house .

Owner:ZIBO XIBEIZI CHEM

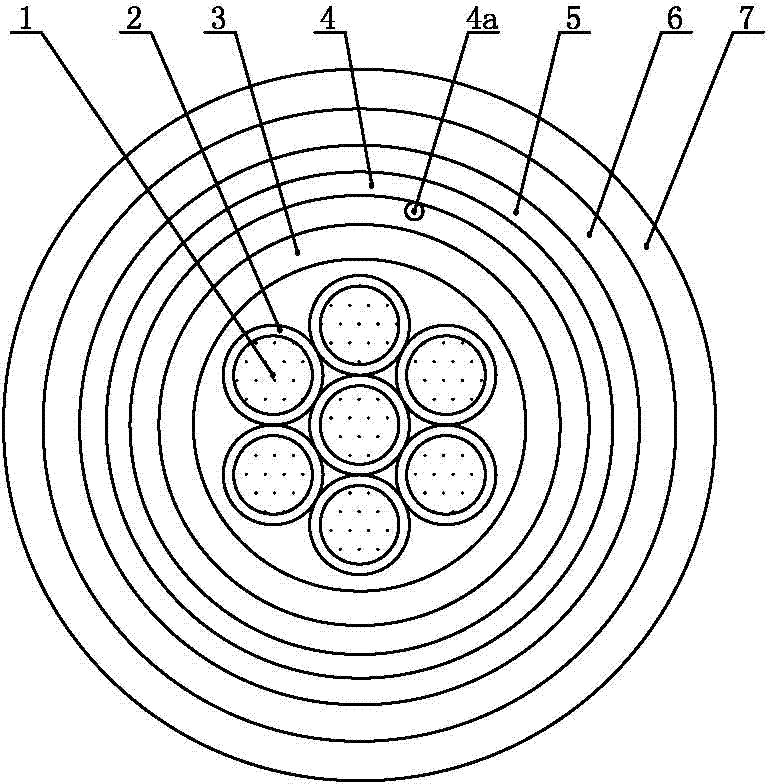

Hydrocarbon-ageing-resistant control cable for petrochemical unit and manufacturing method of hydrocarbon-ageing-resistant control cable

InactiveCN103578633AReduce the temperatureInsulation effectFlexible cablesCable/conductor manufactureCopper conductorPolyester

The invention relates to a hydrocarbon-ageing-resistant control cable for a petrochemical unit and a manufacturing method of the hydrocarbon-ageing-resistant control cable. The manufacturing method includes the steps that an insulating layer is evenly extruded on the periphery of each stranded copper conductor to form a control cable insulated wire core; a plurality of control cable insulated wire cores are stranded to form a control cable core. The periphery of the control cable core is sequentially wrapped by a flame-retardant fireproof longitudinal wrapping tape, an aluminum foil composite shielding tape, a hydrocarbon-ageing-resistant inside liner, a nylon inner sheath and a hydrocarbon-ageing-resistant outer sheath. The aluminum foil face of the aluminum foil composite shielding tape faces inwards and the inner side of the aluminum foil face of the aluminum foil composite shielding tape is provided with copper wire current steering wires. The components of the inside liner and the components of the outer sheath respectively comprise, by weight, 15 parts of PVC-SG2, 5 parts of NBR3305, 3-7 parts of adipic acid propylene glycol polyester,2-3 parts of epoxidized soybean oil, 0.6-1 part of barium stearate, 1-1.5 parts of lead sulfate tribasic, 0.05-0.1 part of diphenol propane, 3-5 parts of antimonous oxide, 0.1-0.5 part of chlorinated paraffin-52 and 0.3-0.5 part of dicyclopentadienyl iron. The hydrocarbon-ageing-resistant control cable is capable of resisting hydrocarbon ageing, small in external diameter and light in weight.

Owner:JIANGSU YUANYANG DONGZE CABLE

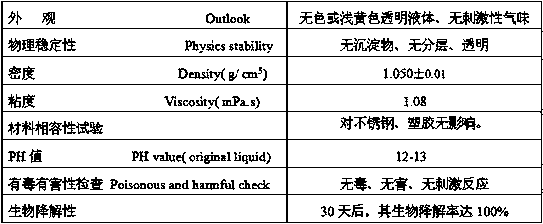

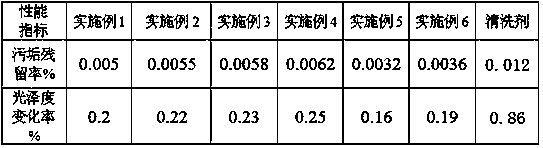

Environment-friendly water-based cleaning agent

InactiveCN109536294ALess foamLathers and rinses easilyOrganic detergent compounding agentsSurface-active detergent compositionsCarboxylateChemistry

The invention relates to an environment-friendly water-based cleaning agent, which includes: a non-ionic surfactant, organic alcohol, alkyl glycoside, organic sodium carboxylate, a corrosion inhibition additive, and water. The cleaning agent is suitable for precise cleaning on products made of stainless steel, plastic and glass and the like, can be completely dissolved, is residual-free, is low-foam and is easy to rinse, can remove oil dirt, dust and other dirt on the products, and is anti-static and has strong cleaning function and good cleaning effect. The cleaning agent is free of controlled harmful substances such as heavy metals, phosphorus and nitrites, etc, and also has corrosion inhibition effect on metals; biodegradability rate reaches 100%. The products cleaned with the cleaningagent hardly have residual dirt and change on glossiness; meanwhile, the products have service life. The cleaning agent is green, environment-friendly and toxic-free, is harmless, and is free of influence on body health and pollution on environment.

Owner:东莞市华启清洗剂科技有限公司

Preparation method of yttrium oxide moulding shell used for casting

ActiveCN106493287ASolve the problem of water back dissolutionSolve the breathability problemFoundry mouldsFoundry coresHuman healthTitanium alloy

The invention discloses a preparation method of an yttrium oxide moulding shell used for titanium alloy precision casting. A moulding shell surface layer coating comprises yttrium oxide refractory powder, ammonium zirconium carbonate binder, a wetting agent and a defoaming agent. The preparation method includes the steps of preparation of the surface layer coating, preparation of a back layer coating, preparation of the moulding shell, dewaxing, calcinations and the like. By means of the yttrium oxide moulding shell used for titanium alloy precision casting and the preparation method thereof, the problems that an existing moulding shell is prone to redissolution under the influence of water in the preparation and dewaxing processes, and steam dewaxing cannot be achieved are solved. The binder used for the coating is made of ammonium zirconium carbonate and is low in price, and the prepared coating is stable and reliable and cannot generate redissolution after being dried under the influence of water. The prepared surface layer coating is good in smearing performance and high in refractoriness, steam dewaxing is adopted, no pollution is caused to the environment, and the prepared surface layer moulding shell has no influence on the human health. The prepared yttrium oxide moulding shell is wide in application range, an interface reaction layer is small, titanium alloy casts are high in precision, performance is excellent, and later-period finishing is conducted easily.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

Method for producing water-soluble PTC functional conductive carbon paste

InactiveCN101407628AWide range of usesNo pollutionNon-conductive material with dispersed conductive materialSolubilityMonoglyceride

The invention relates to a preparation method of conductive carbon paste with water solubility and PTC function. The method comprises the following steps of: first step: carrying out preparation of the carbon paste; adding 40 percent to 60 percent of deionized water into 24 percent to 40 percent of bicomponent polyurethane, uniformly mixing, adding 10 percent to 20 percent of carbon powder, adding dispersing agent and uniformly stirring; second step: carrying out preparation of PTC functional material; taking 30 percent to 50 percent of deionized water, adding 2 percent to 4 percent of matrix wetting agent 500, 10 percent to 20 percent of ethylene glycol monomethyl ether and 3 percent to 5 percent of emulsifying agent; adding tween and uniformly mixing; then adding stearic acid, monoglyceride and glycerin, heating to 80 DEG C, uniformly stirring, homogenizing, emulsifying, reducing temperature to 35 DEG C, and filtering for spare; and third step: carrying out the preparation of conductive carbon paste with water solubility and PTC function, taking 100 parts by weight of conductive carbon paste and 30 to 60 parts by weight of PTC functional material, and mixing and stirring; and taking 0 percent to 4 percent of defoaming agent which is put into conductive carbon paste with PTC function in stirring and uniformly stirring. The method has simple operation, loose preparation conditions, wide material obtaining, no toxicity and no pollution; and the product thereof has excellent conductivity, safeness, reliability and wide application.

Owner:TIANJIN HUALIN WEIYE TECH DEV

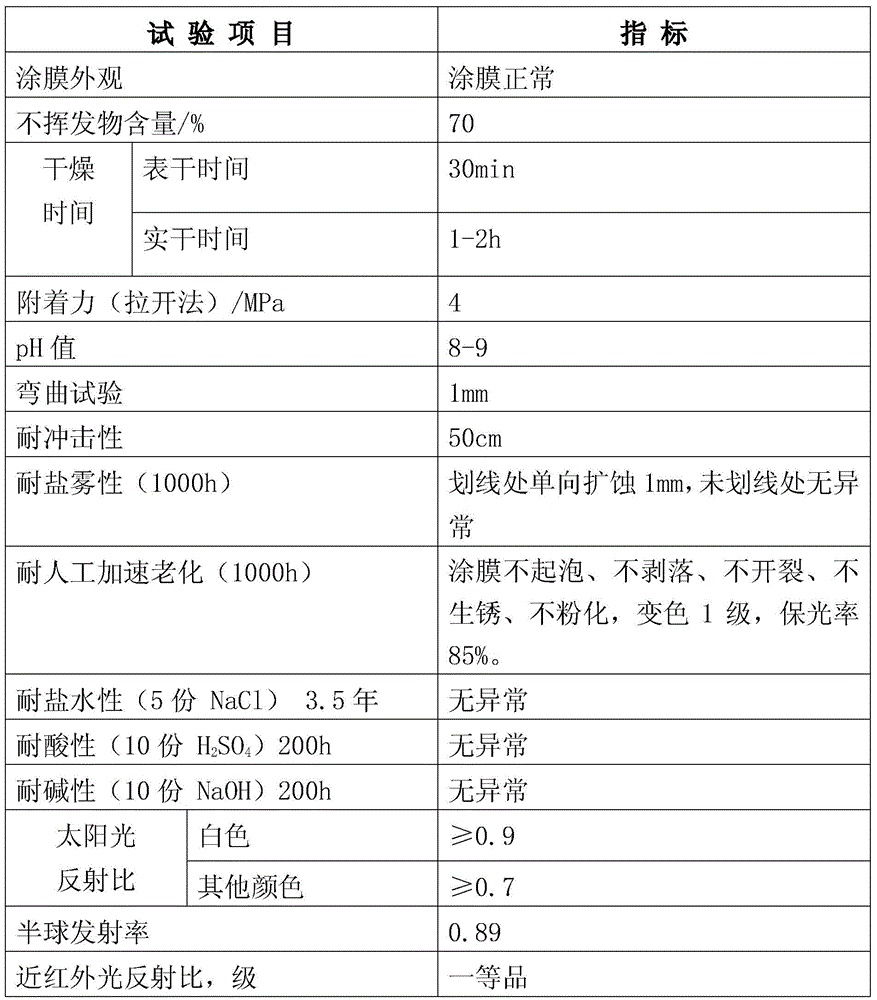

Heat-reflection thermal insulation anti-corrosion coating and preparation method thereof

InactiveCN105602329AGood thermal stabilityLow priceAnti-corrosive paintsReflecting/signal paintsThermal insulationZinc

Owner:SHENGYA TECH DALIAN

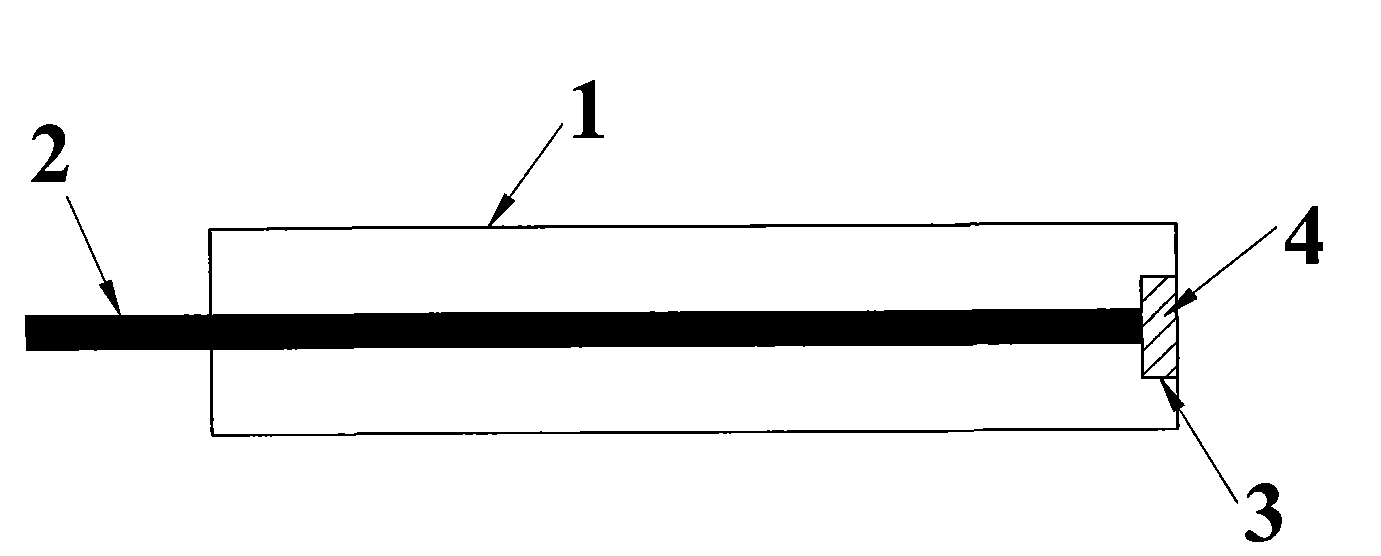

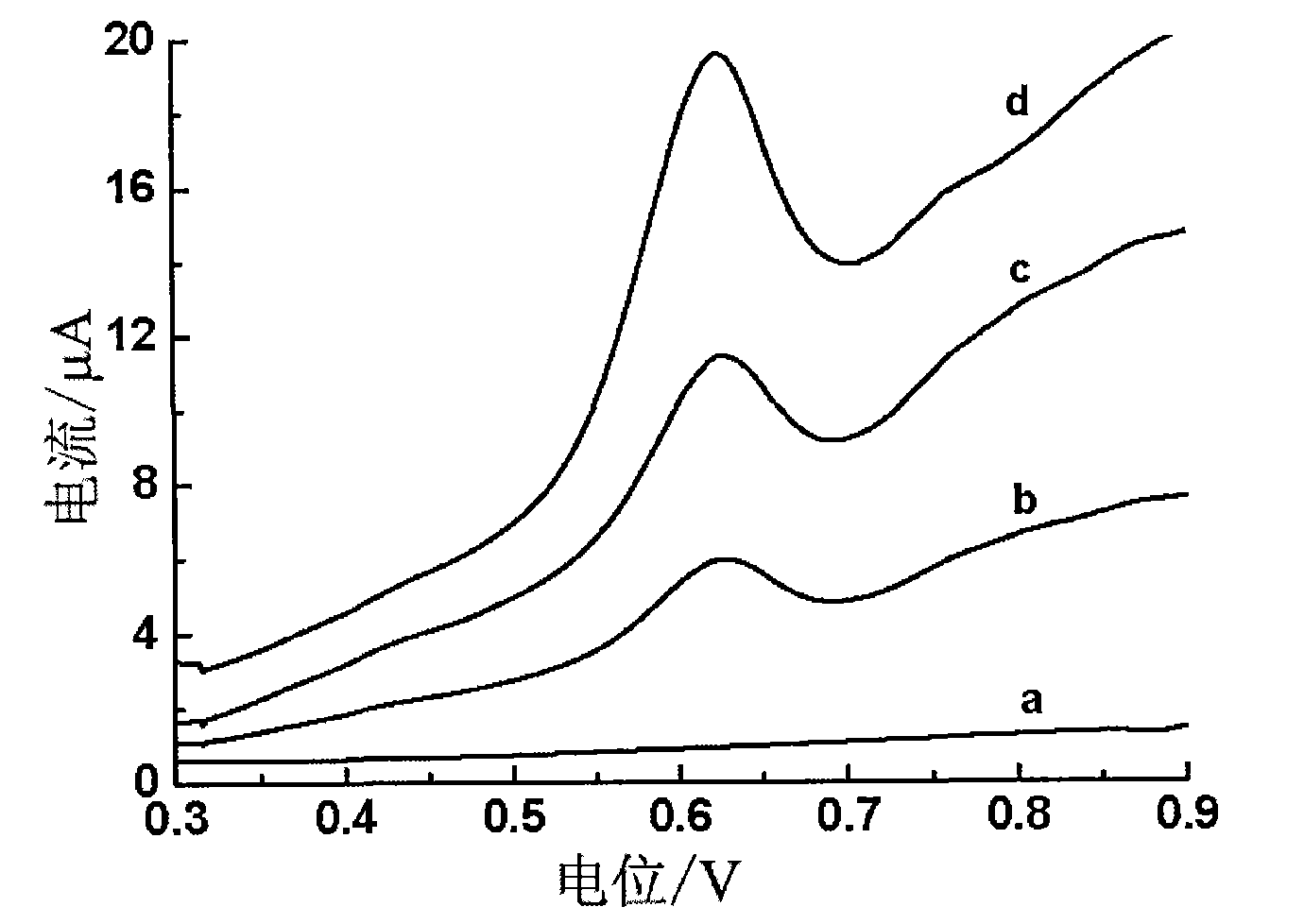

Electrochemical sensor for quickly detecting Sudan I in foods and preparation method thereof

InactiveCN101876645AHigh sensitivityIncrease concentrationMaterial electrochemical variablesElectrical conductorAdhesive

The invention discloses an electrochemical sensor for quickly detecting Sudan I in foods and a preparation method thereof. The preparation method of the sensor comprises the following steps of: uniformly mixing montmorillonite, conductive carbon powder and adhesive at a certain percentage to form a sensitive material; filling the sensitive material in a cavity on the front end of an insulating column and enabling the sensitive material contact with the end of a metal conductor inserted and fixed at the centre of the insulating column. The electrochemical sensor of the invention has the advantages of high sensitivity, low detection limitation, capability of realizing quick detection to the Sudan I in foods, simple and convenient operation, environment-friendliness, wide raw material sources and low cost; moreover, the preparation method is simple.

Owner:HUBEI INSPECTION & QUARANTINE TECH CENT

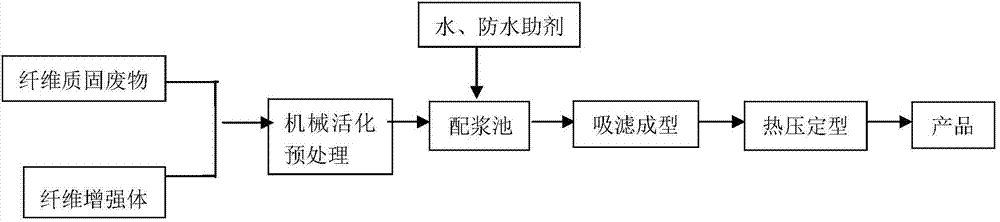

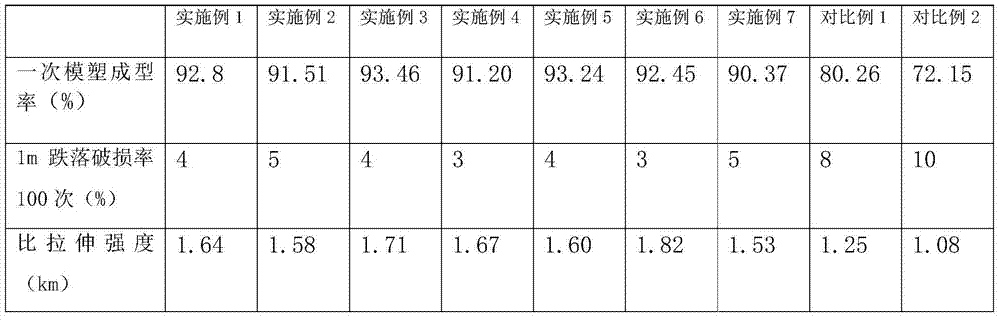

Method for producing seedling breeding container from fibrous solid wastes

InactiveCN104499380AExtensive sources of raw materialsReduce material consumptionFibrous raw materialsCultivating equipmentsPre treatmentHot press

The invention discloses a method for producing a seedling breeding container from fibrous solid wastes. The method sequentially includes the steps of (1), smashing raw materials, namely, drying the fibrous solid waste raw materials in the sun, smashing the raw materials and then mixing the smashed raw materials with reinforcements to obtain mixed materials; (2), subjecting the mixed materials to mechanical activating pretreatment to obtain modified fibers; (3), mixing pulp, namely, conveying the modified fibers into a pulp mixing pond, adding waterproof agents with stirring evenly and adding water to dilute to obtain pulp in a solid-to-liquid ratio of 1:(2-6); (4), performing suction filtering molding, namely, conveying the pulp into a mould cavity for suction filtering and dewatering pressing to obtain a wet blank product, wherein filtered water is delivered back to the pulp mixing pond for recycling; (5), performing hot-pressing shaping, namely, transferring the wet blank product into a hot-pressing mould, performing hot pressing under high pressure at a high temperature, and removing moisture generated during hot pressing to obtain the seedling breeding container. The method for producing the seedling breeding container from the fibrous solid wastes has the advantages of simple technology, zero pollution, low cost, high product molding ratio and the like.

Owner:GUANGXI UNIV +1

Novel non-corrosion fluoride solder and preparation method

InactiveCN101125398AWell formedUniform weld rootWelding/cutting media/materialsSoldering mediaChemical synthesisNitrogen gas

The present invention relates to a fluoride soldering flux without causticity of a soldering 6063 aluminum alloy and the method of preparation, which belongs to soldering material field of the aluminum and the aluminum alloy. The compounding ratio of the component by the weight percent is: the neutral QF soldering flux: 99.0 to 99.7 percent; ZnSiF6: 0.3 to 1.0 percent. The neutral QF soldering flux is prepared by adopting the chemical synthesis, and the ratio of K+ / A13+ is 1.9175, and the melting point of the soldering flux is 560 DEG C, and the soldering temperature is 580 to 620 DEG C. The soldering flux protects the soldering 6063 aluminum alloy in the stove by cooperating the AI-11.7Si eutectic soldering material nitrogen gas. The length of the clearance with the same clearance of the soldering material is more than 160 mm. The obverse and inverse surfaces of the soldering clearance are of good shaping with even welding root, and have no disadvantages of air holes on the surface and claming dregs. The cutting intensity for the soldering is more than 120 MPa. The soldering flux preparation art and the material of the present invention have low price, and do not absorb the damp. The present invention does not loose the efficiency when stored in the atmosphere for a long time, which is suitable for being widely applied.

Owner:JIANGSU UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com