Patents

Literature

169results about How to "Uniform gloss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Toner

ActiveUS9261806B2Excellent long-term storage stabilityEasy to fixDevelopersPolyester resinPolymer chemistry

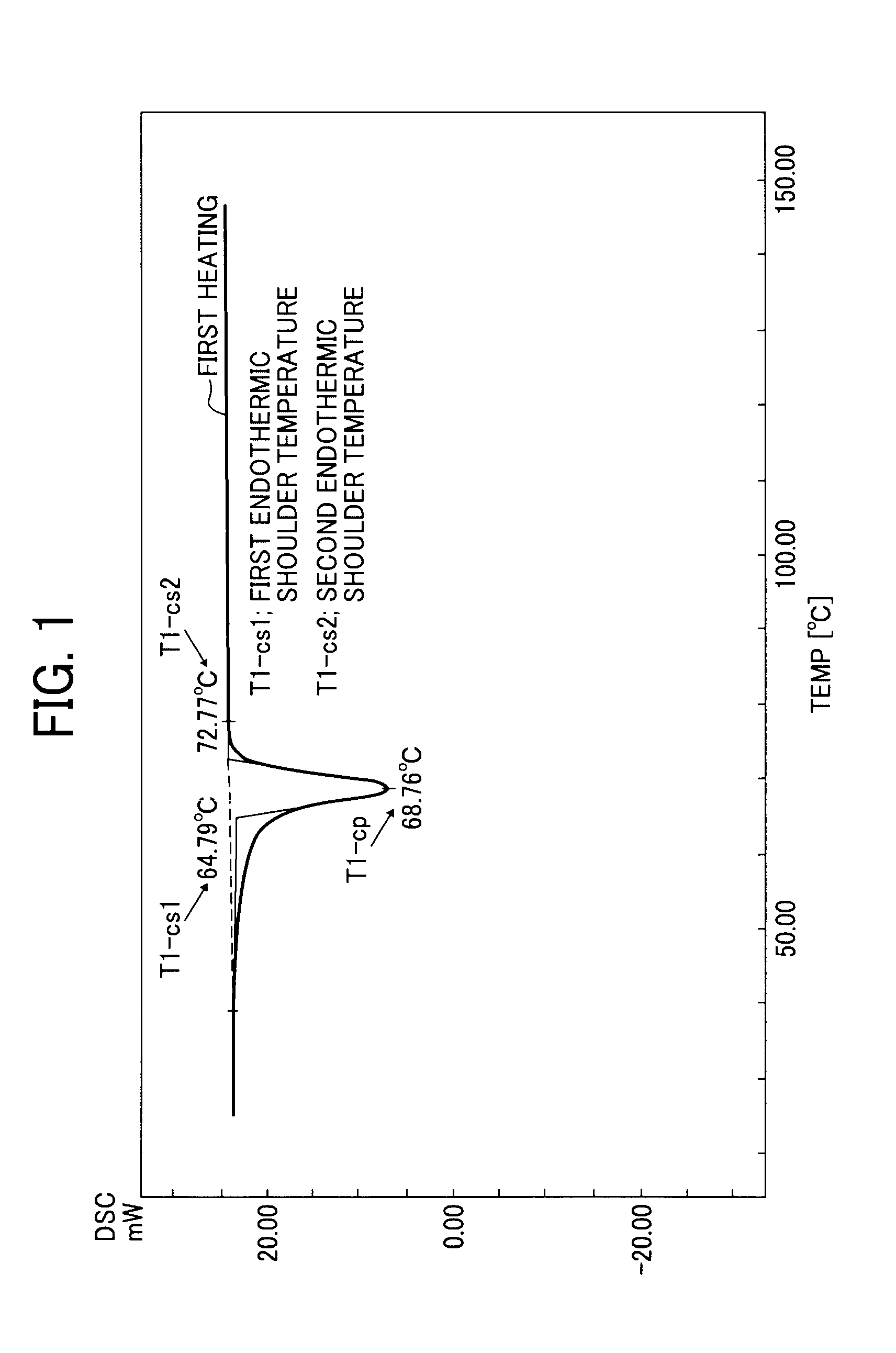

Provided is a toner having excellent long-term storage stability and exhibiting both low-temperature fixability and uniform gloss in high-speed printing. A toner has a toner particle that contains a crystalline polyester resin A, an amorphous polyester resin B and a colorant, wherein the crystalline polyester resin A has a polyester molecular chain having a nucleating agent segment at the terminal end thereof, and an SP value Sa ((cal / cm3)1 / 2) of the crystalline polyester resin A ranges from 9.00 to 11.50, and the amorphous polyester resin B has a specific functional group.

Owner:CANON KK

Dry toner for developing electrostatic images

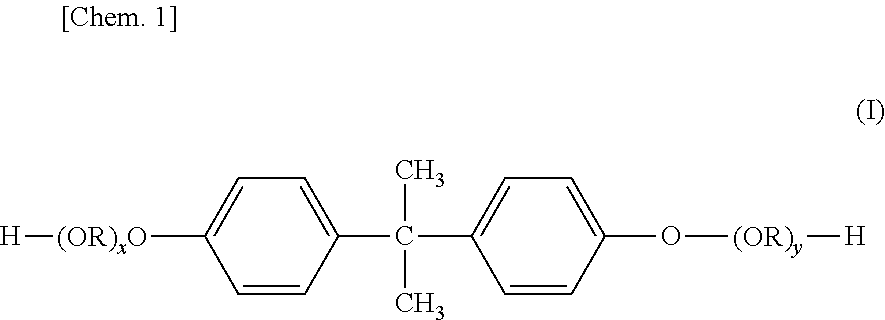

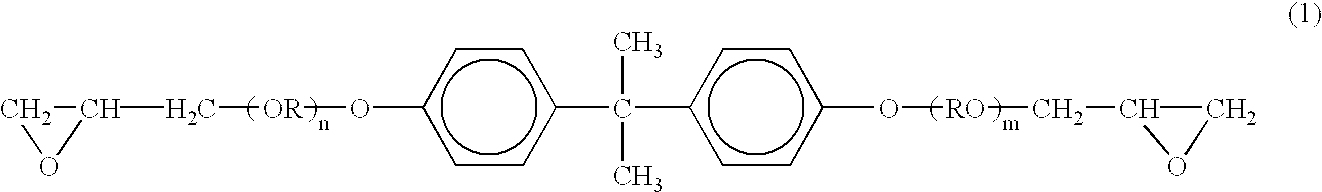

A dry toner for developing electrostatic images, including a colorant and a binder resin which comprises a copolymer resin having (A) a polyol resin moiety having a main chain of polyoxyalkylene and obtained by reaction of (a) an epoxy resin, (b) a dihydric phenol, and (c) an alkylene oxide adduct of a dihydric phenol or a glycidyl ether thereof; and (B) a polyester resin moiety obtained by reacting an alkylene oxide adduct of a dihydric phenol or a glycidyl ether thereof with a polycarboxylic acid, wherein the weight ratio of the epoxy resin of the polyol resin moiety (A) to the polyester resin moiety (B) is 95:5 to 60:40, wherein the epoxy resin includes at least two kinds of bisphenol epoxy resins having different number-average molecular weights, and wherein the binder resin has an acid value of not greater than 5.

Owner:RICOH KK

Toner, toner set, developer, developer set, image forming apparatus, image forming method, and process cartridge

InactiveUS20120082926A1Improve bindingIncrease resistanceElectrographic process apparatusDevelopersPolyesterOrganic solvent

A toner comprising an amorphous polyester, a crystalline polyester that is forming domains in the toner, and a colorant that is being dispersed at least in the domains of the crystalline polyester. The toner may be obtained by dispersing an oil phase including the amorphous polyester or a precursor capable of producing the amorphous polyester, the crystalline polyester, the colorant, and an organic solvent, in an aqueous medium to prepare an O / W dispersion, the oil phase; and removing the organic solvent from the O / W dispersion.

Owner:RICOH KK

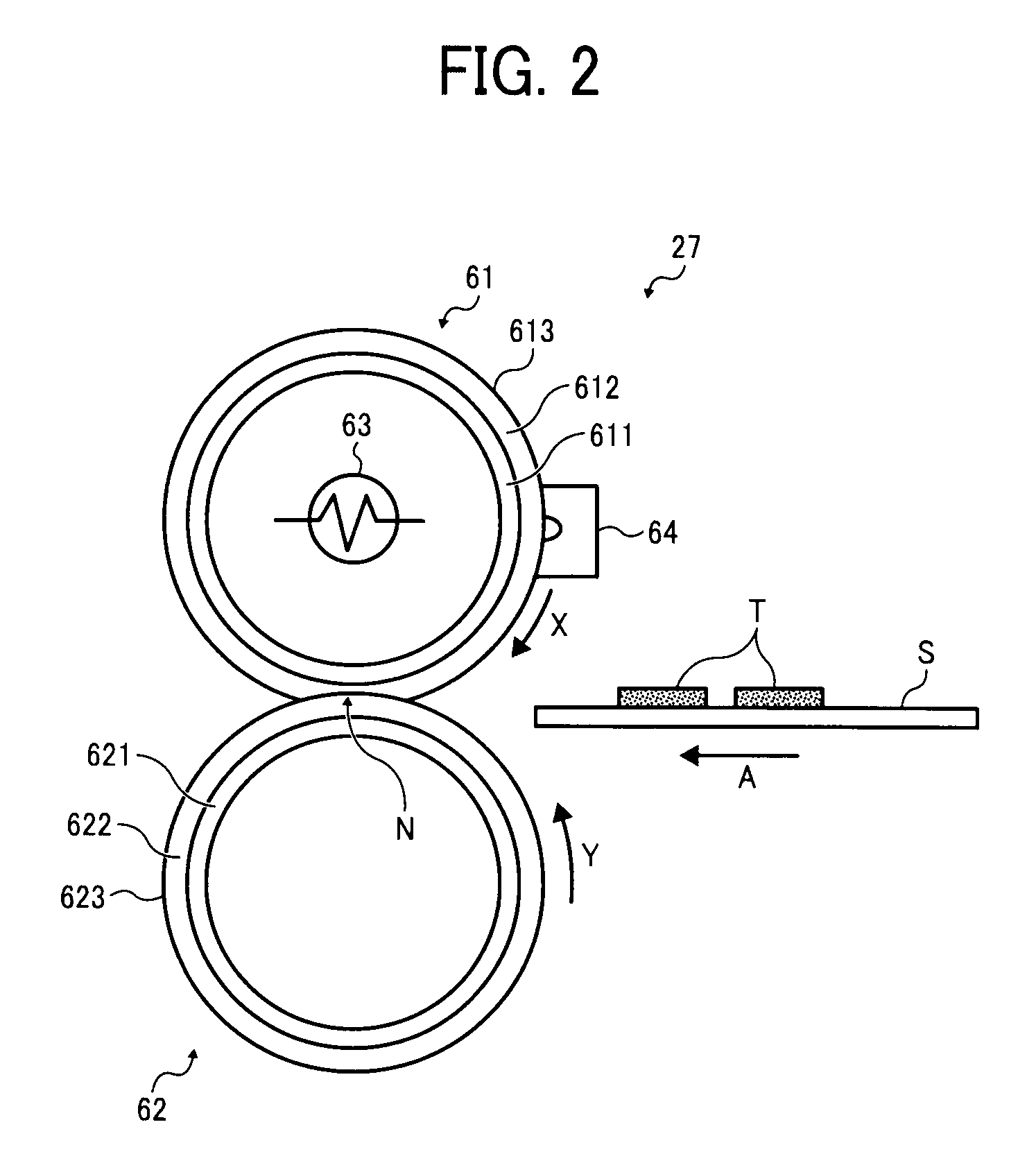

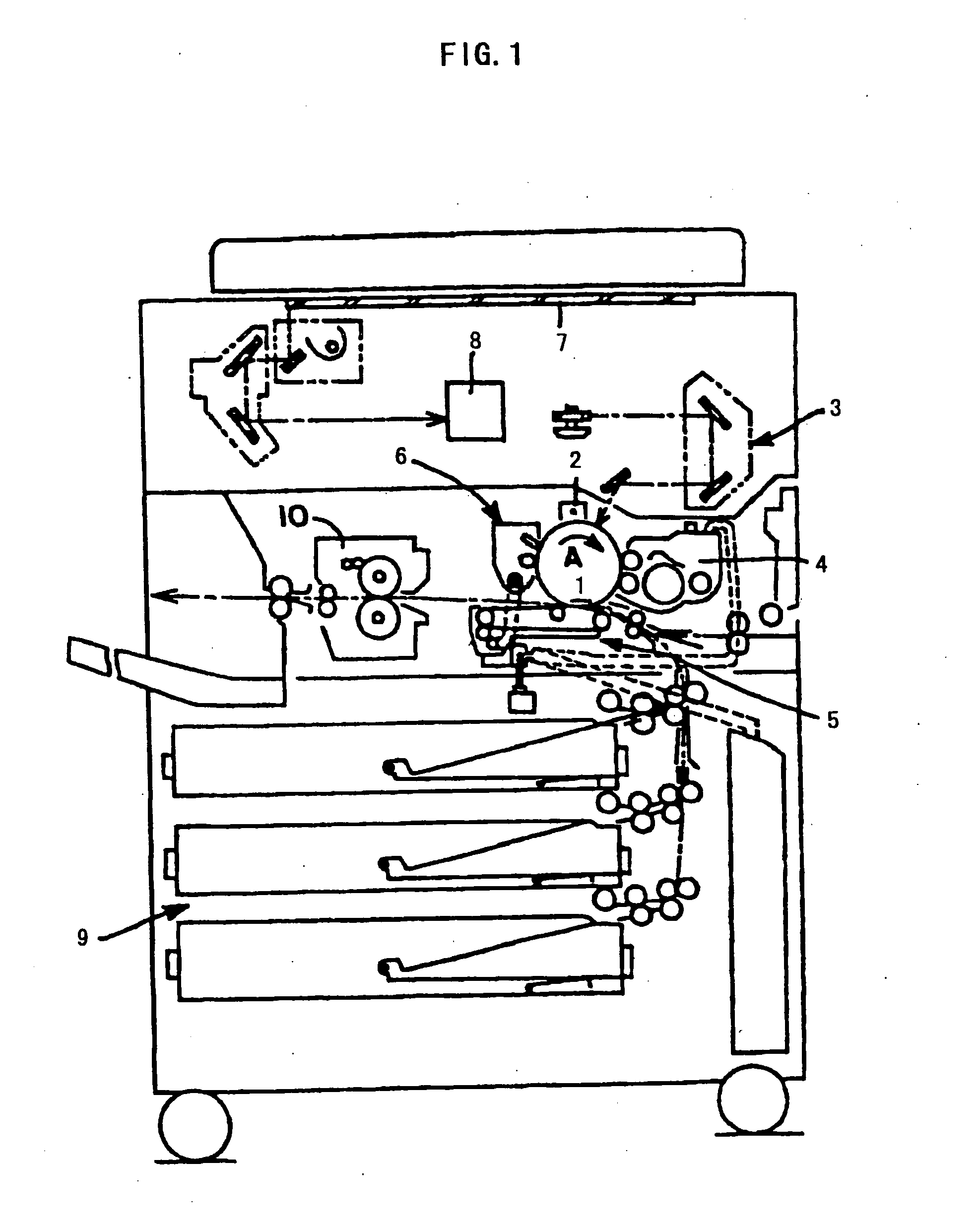

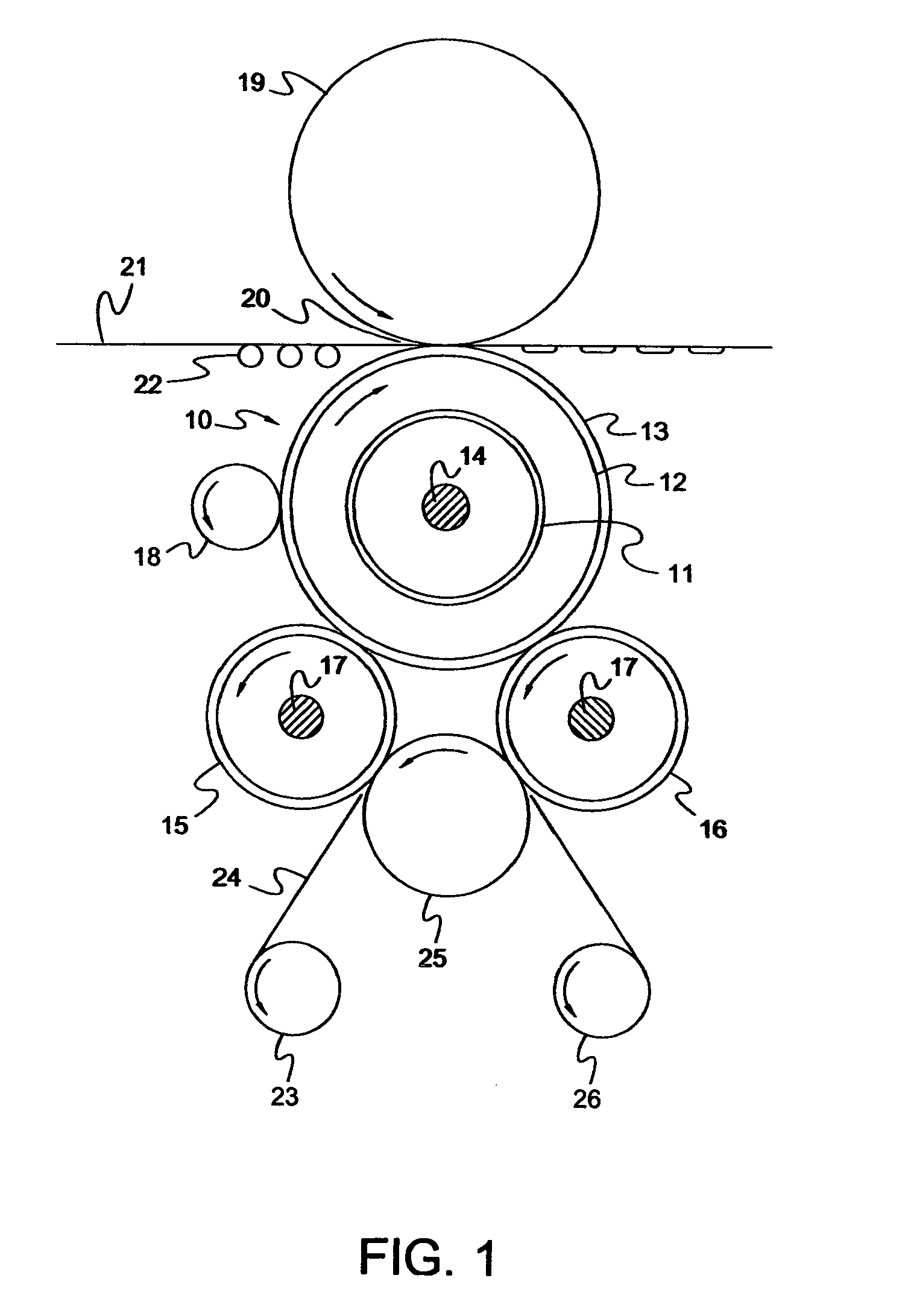

Durable electrophotographic prints

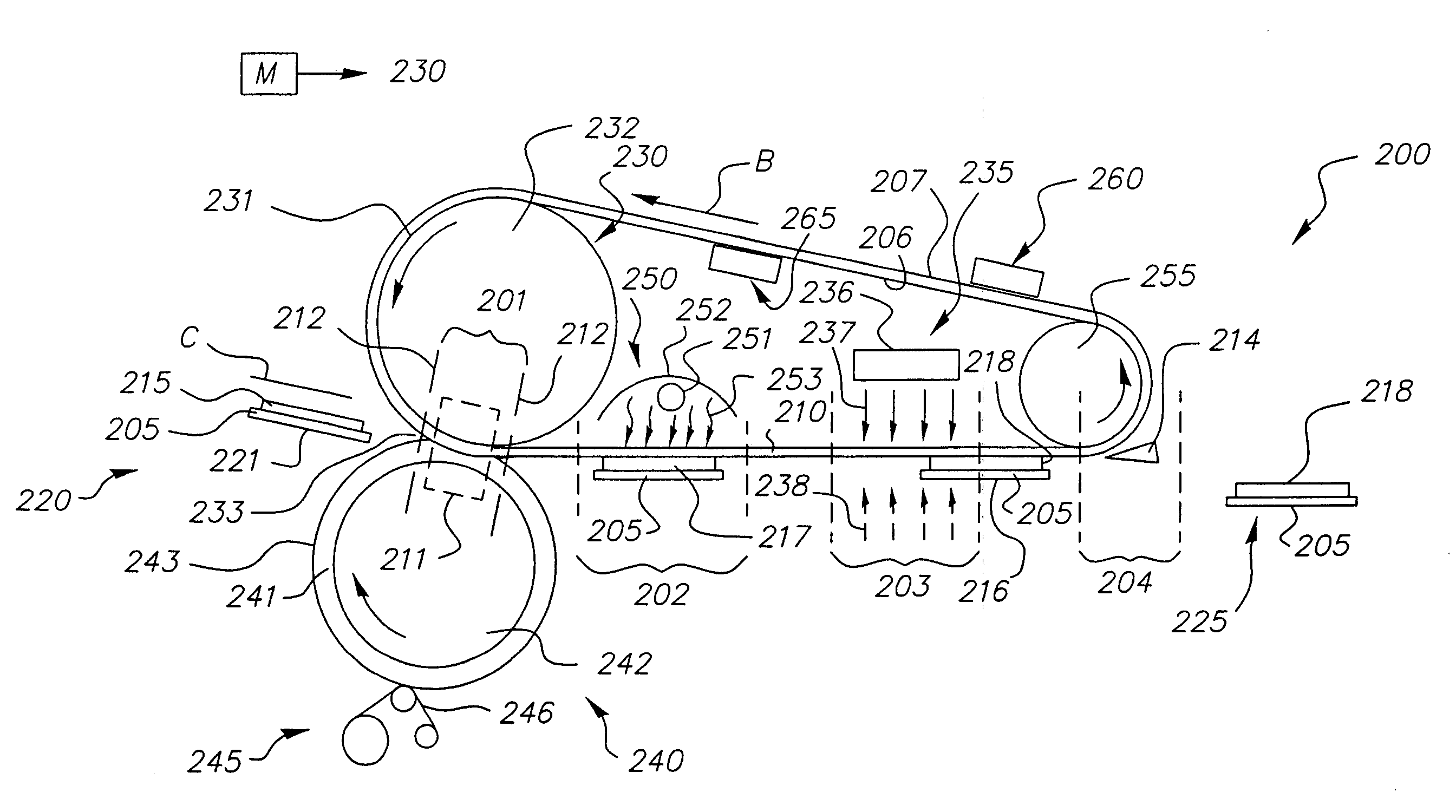

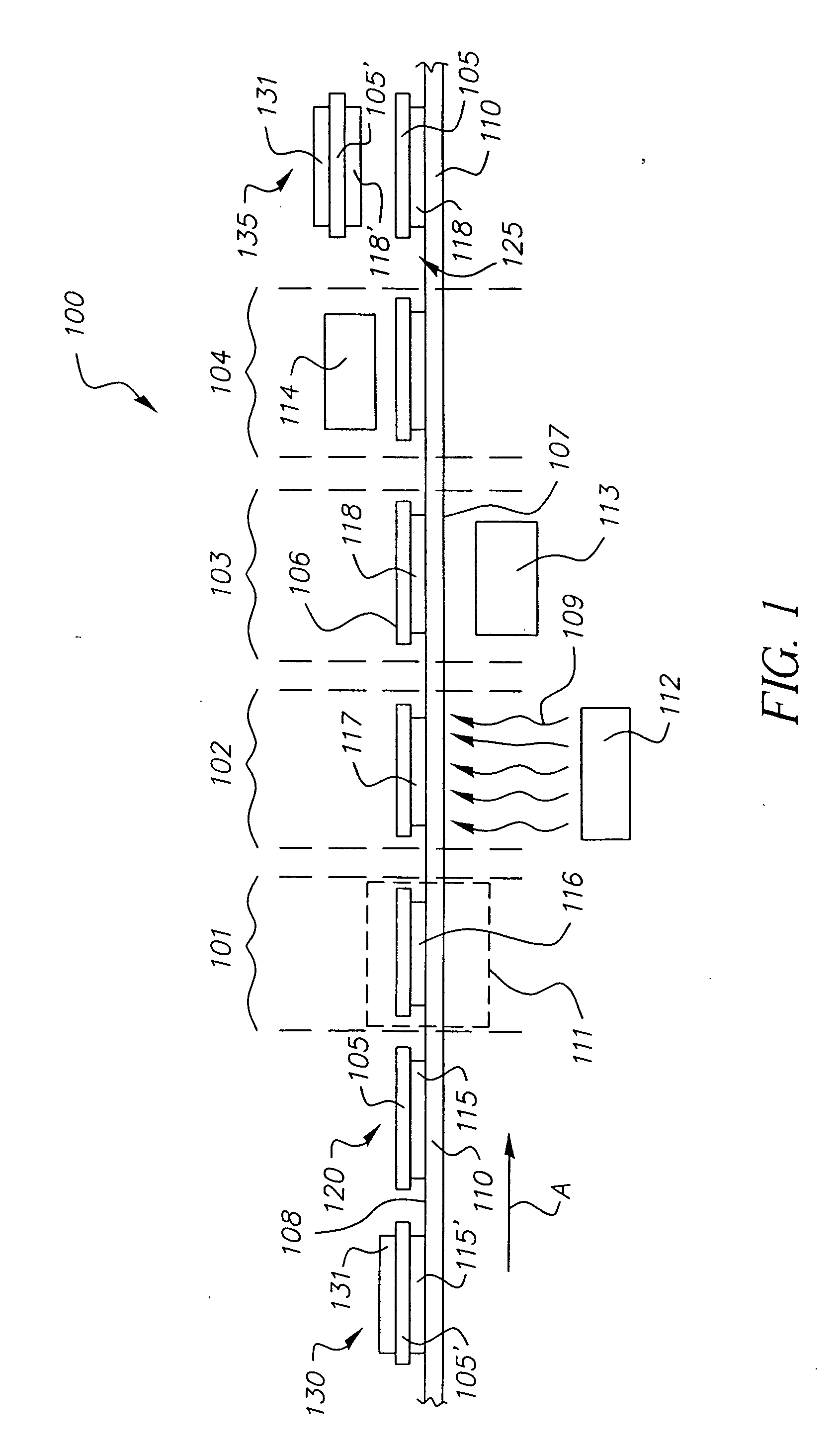

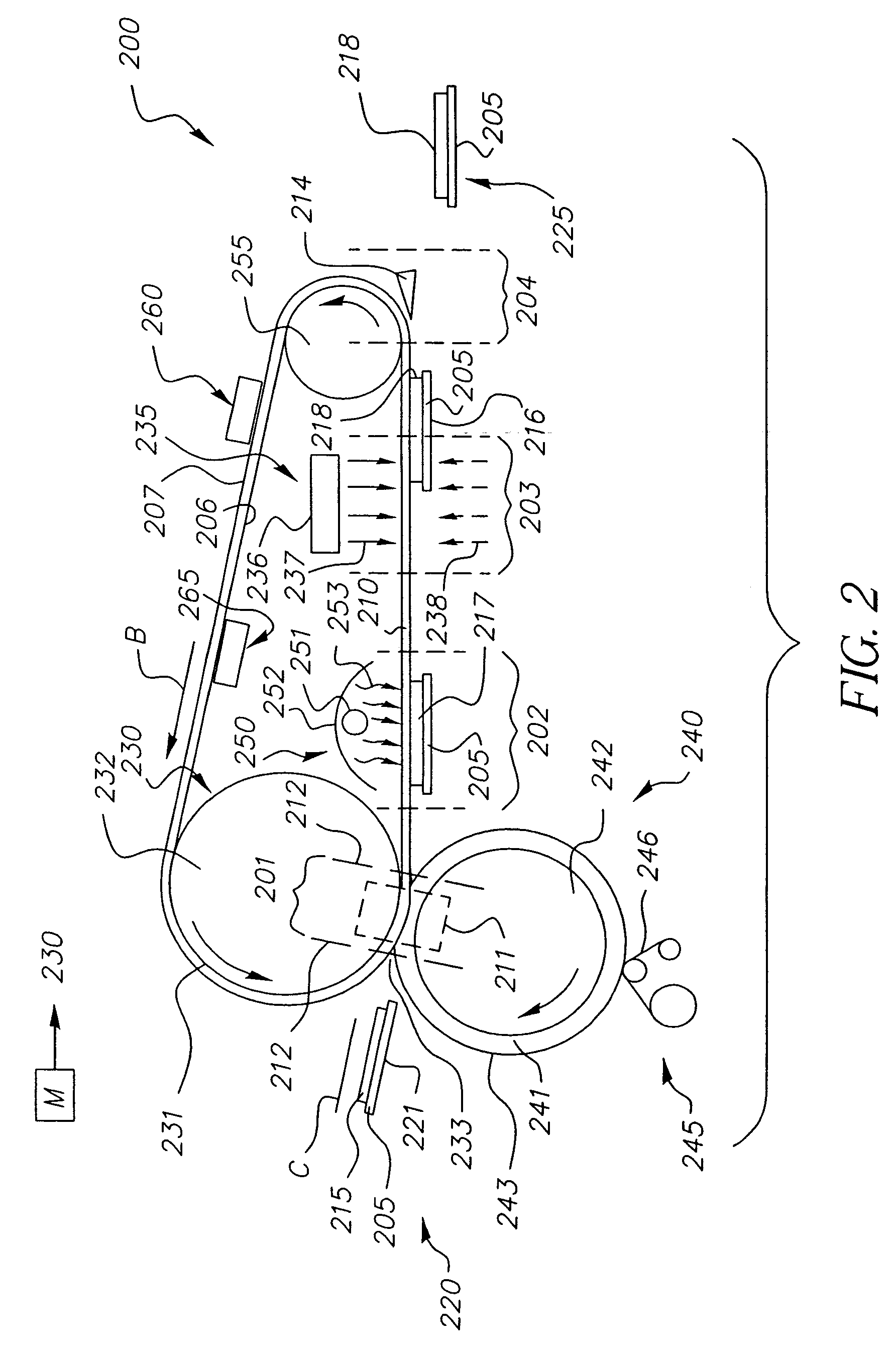

ActiveUS20050207807A1Uniform areaDurable surfaceElectrographic process apparatusMolten stateEngineering

UV-glossing for simplex and duplex prints, wherein an input member having thereon a pre-gloss toner image including UV-curable toner is moved, in non-slip association with a smooth UV-transparent web, jointly with the web through a plurality of process zones sequentially including a heating zone and an exposure zone, thereby producing an output member having a glossed, UV-cured, surface. In the heating zone, at least the outermost toner of the pre-gloss toner image is heated to a molten state in contact with the web. In the exposure zone, with the molten state being maintained, at least the outermost toner which contacts the web is cured by a flux of UV radiation transmitted through the web. In a preferred embodiment, the UV-curable toner is formed as an outer layer on the pre-gloss toner image.

Owner:EASTMAN KODAK CO

Modified silicate waterborne zinc-rich anticorrosive coating employing organic montmorillonite as anti-settling dispersant

The invention relates to an anticorrosive coating, and particularly relates to a modified silicate waterborne zinc-rich anticorrosive coating employing organic montmorillonite as an anti-settling dispersant. The modified silicate waterborne zinc-rich anticorrosive coating is prepared from components A and B, wherein the component A is prepared from 10-60% of flake zinc powder; the component B is prepared from 25-85% of silicone acrylic emulsion-modified potassium silicate solution, 0.1-5% of ricinate, 0.1-5% of organic montmorillonite, 0.1-5% of defoamer, and 0.01-2% of thickener, and the percent is weight percent. The modified silicate waterborne zinc-rich anticorrosive coating has the advantages that the dosage of zinc powder can be greatly reduced, and the cost of the coating is reduced. The water resistance of the coating is improved by the organic emulsion-modified potassium silicate solution; excellent painting hardness of the coating is achieved, the barrier property of the coating is improved, and meanwhile, the anticorrosive coating is almost zero in volatile organic compound (VOC) release property, and free of environmental pollution.

Owner:SHENYANG POLYTECHNIC UNIV

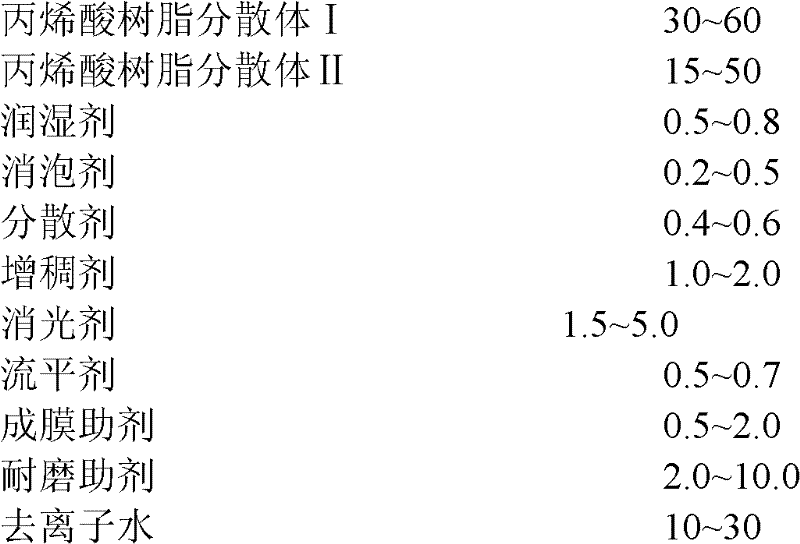

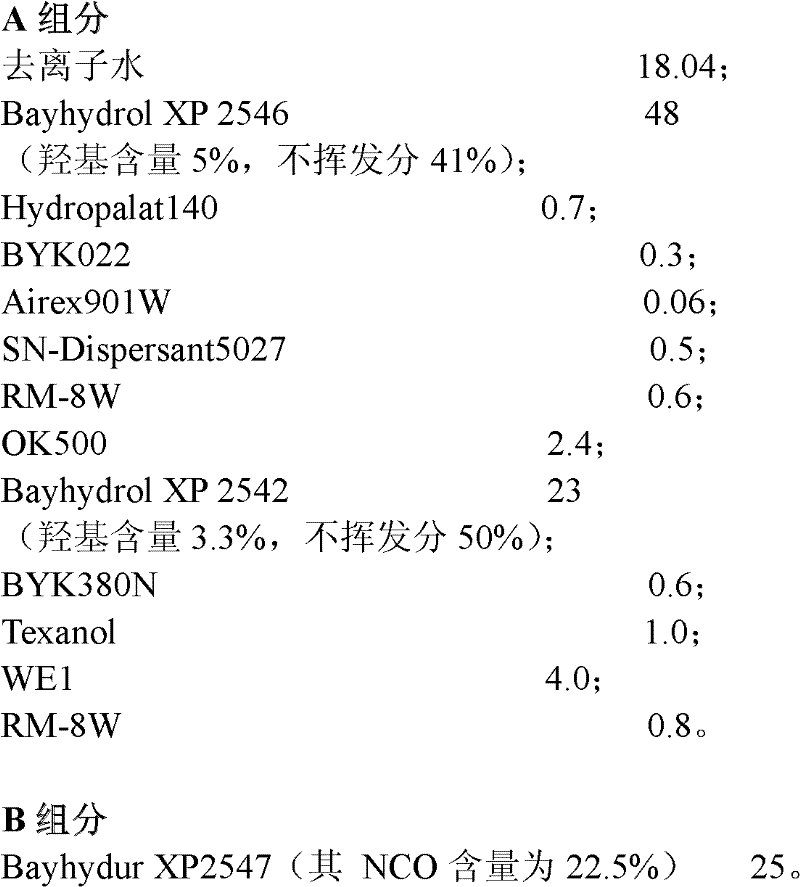

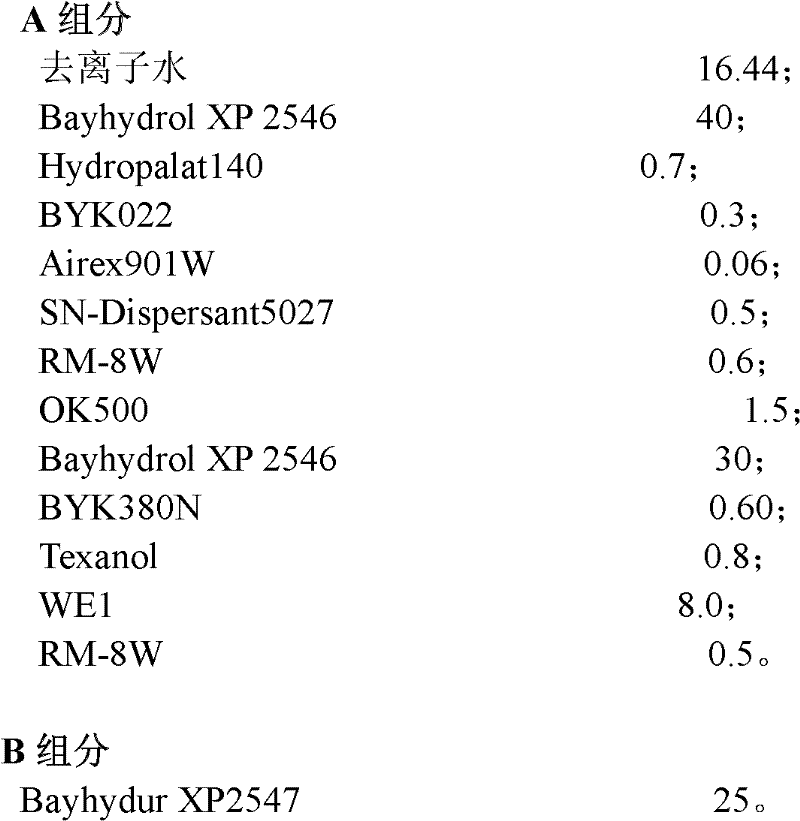

Double-component water-based polyurethane high-abrasion-resistance matte varnish and preparation thereof

InactiveCN102533077AReduce glossOvercome the disadvantage of uneven mattingPolyurea/polyurethane coatingsEpoxyAcrylic resin

The invention discloses a double-component water-based polyurethane high-abrasion-resistance matte coating and a preparation thereof. The coating comprises two components A and B, wherein the component A is prepared by using an acrylic resin dispersion body as a basic component and adding deionized water, a wetting agent, a defoaming agent, a dispersing agent, a thickening agent, a delustering agent, a leveling agent, a film forming additive and a water resistant additive to the acrylic resin dispersion body to disperse the acrylic resin dispersion body; and the component B is aliphatic polyisocyanate. The invention provides a water-based matte coating with low VOC (Volatile Organic Compounds), low gloss, good adhesion force, wear resistance and corrosion resistance; and the water-based matte coating can be very well combined with a water-based or solvent type epoxy resin floor coating and a polyurethane floor coating. The water-based matte coating disclosed by the invention has the advantages of low delustering agent adding quantity and stability in storage; the gloss of the coating system can be effectively reduced; and the comprehensive performance of the coating system is improved. By using the double-component water-based polyurethane high-abrasion-resistance matte coating disclosed by the invention, the water-based coating system solution with environment friendliness, high performance, stability in storage and low cost can be provided.

Owner:CENT SOUTH UNIV +1

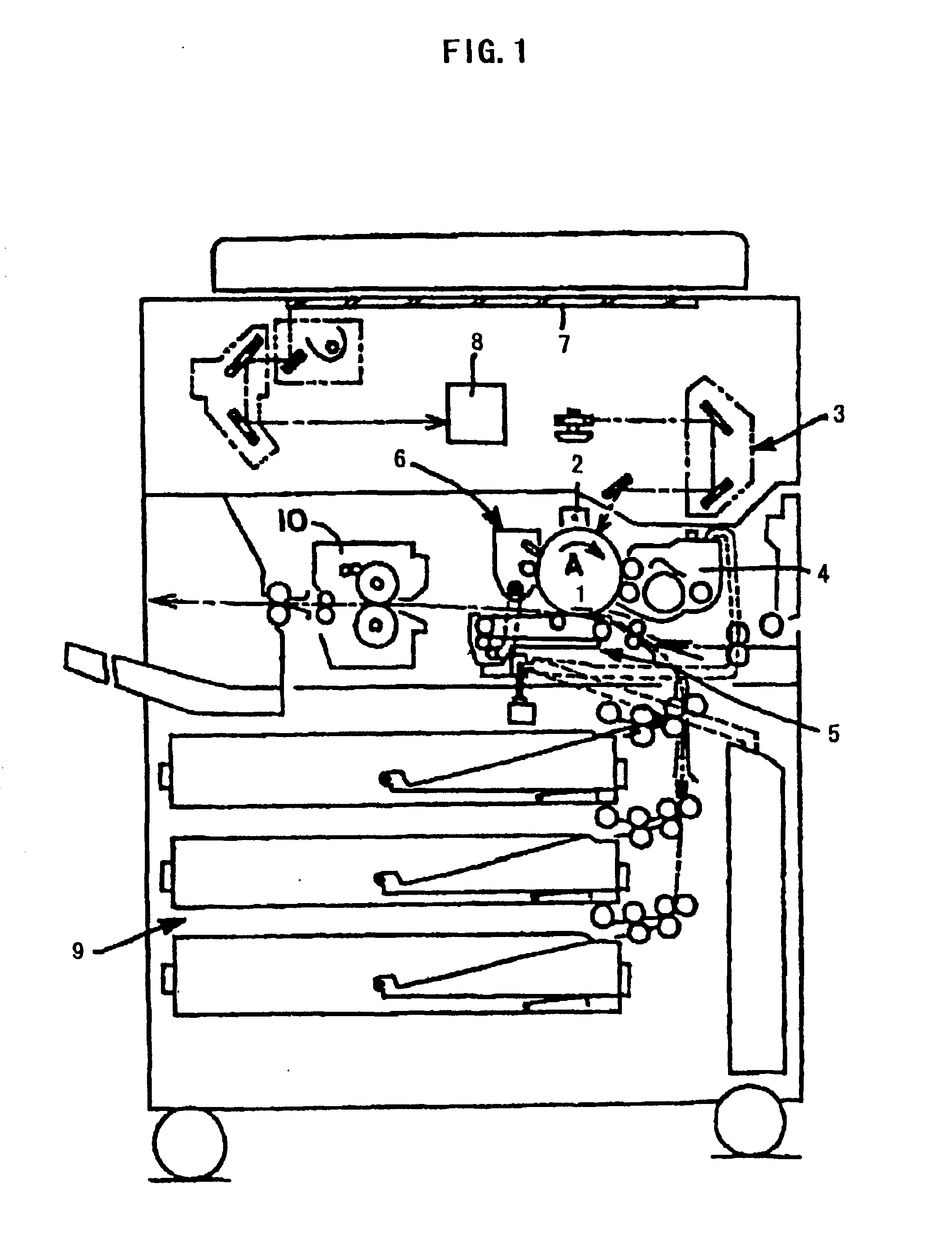

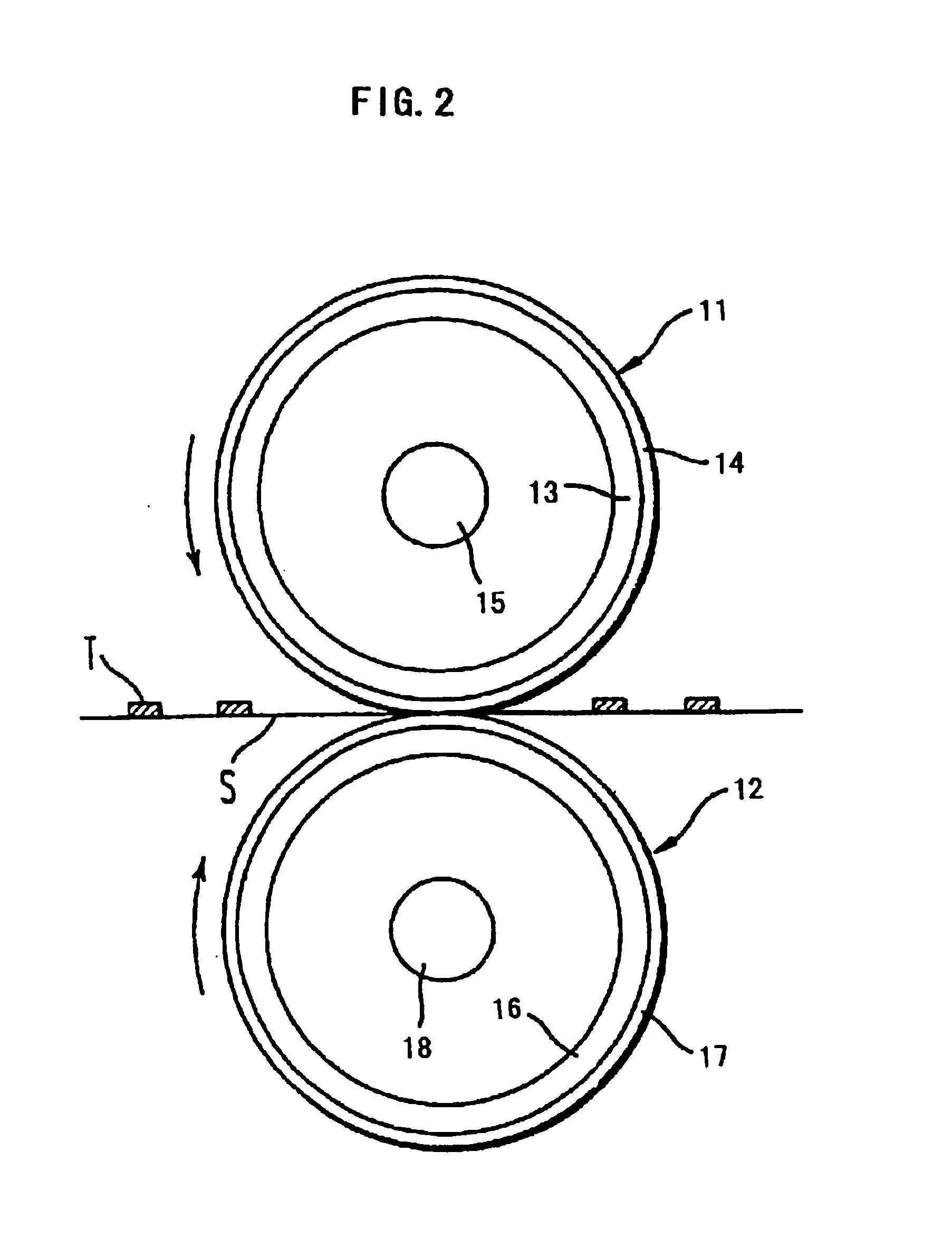

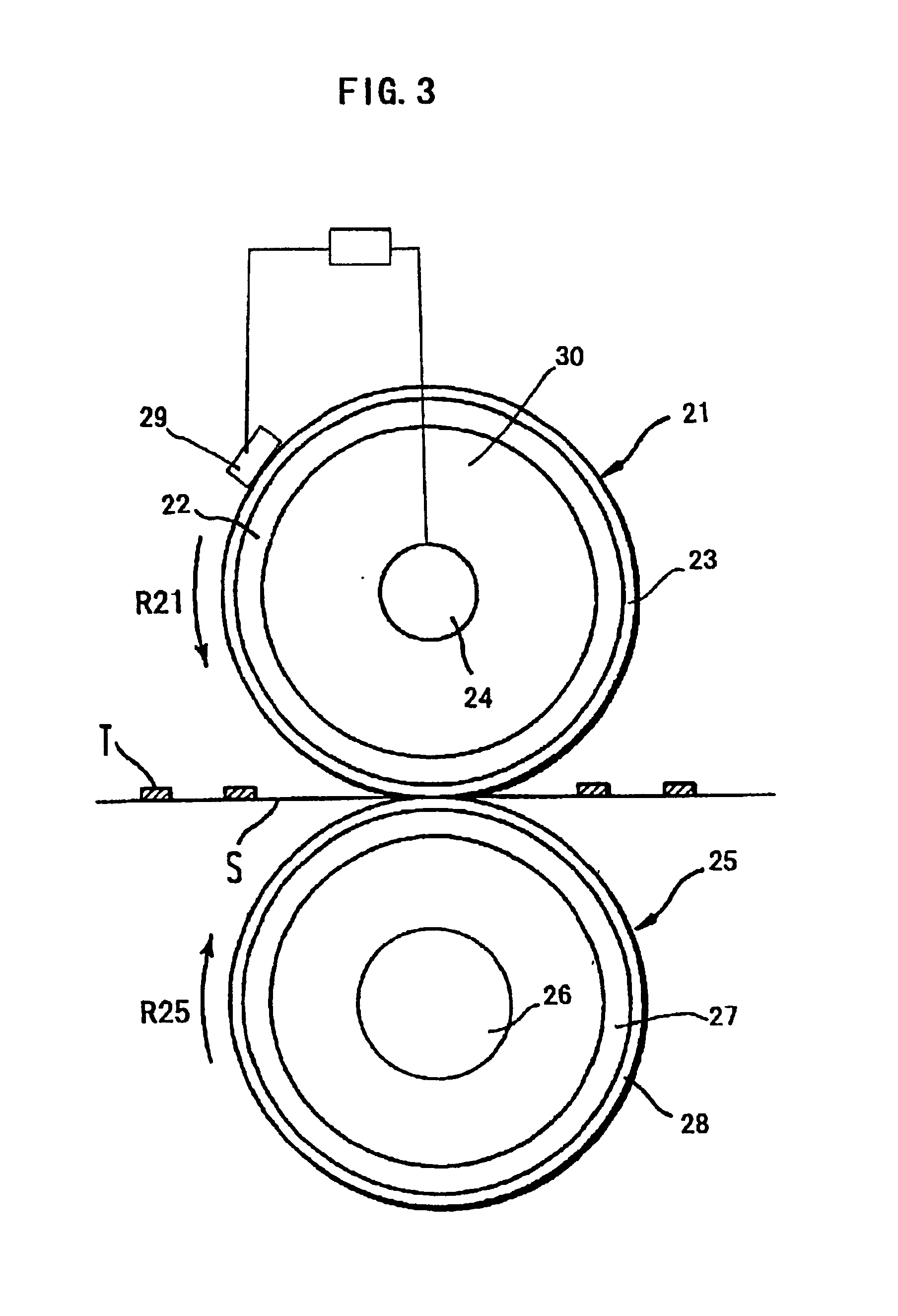

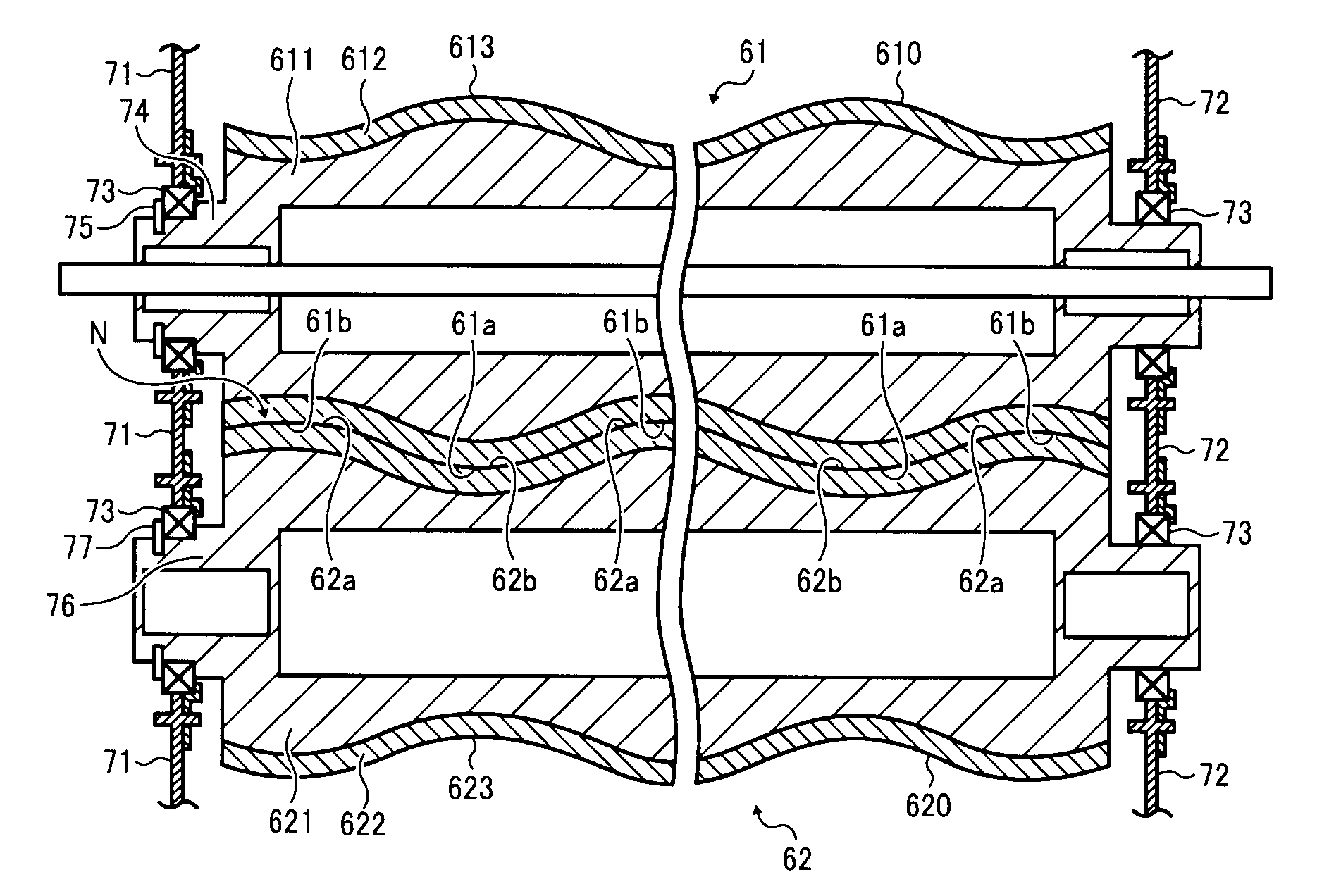

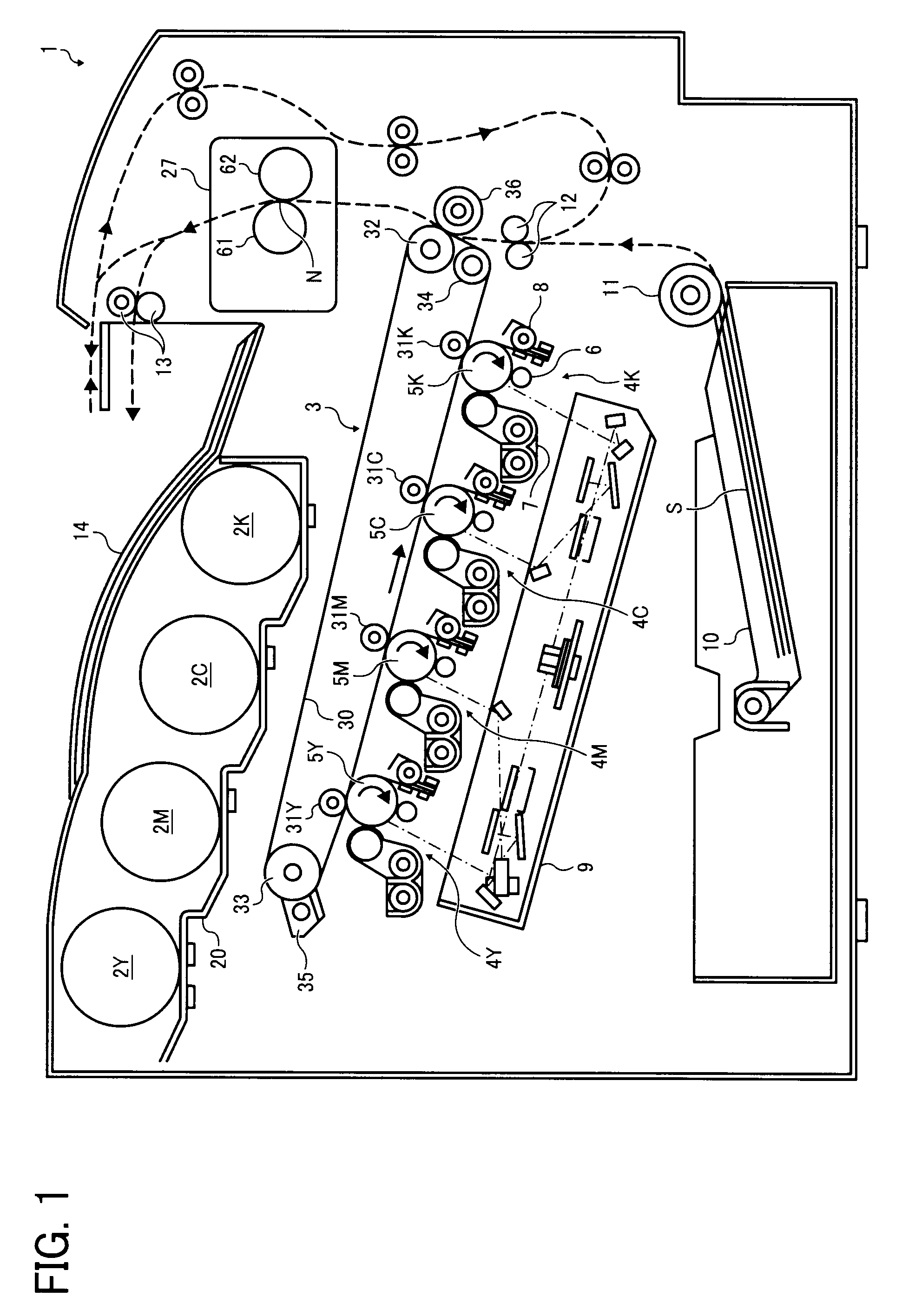

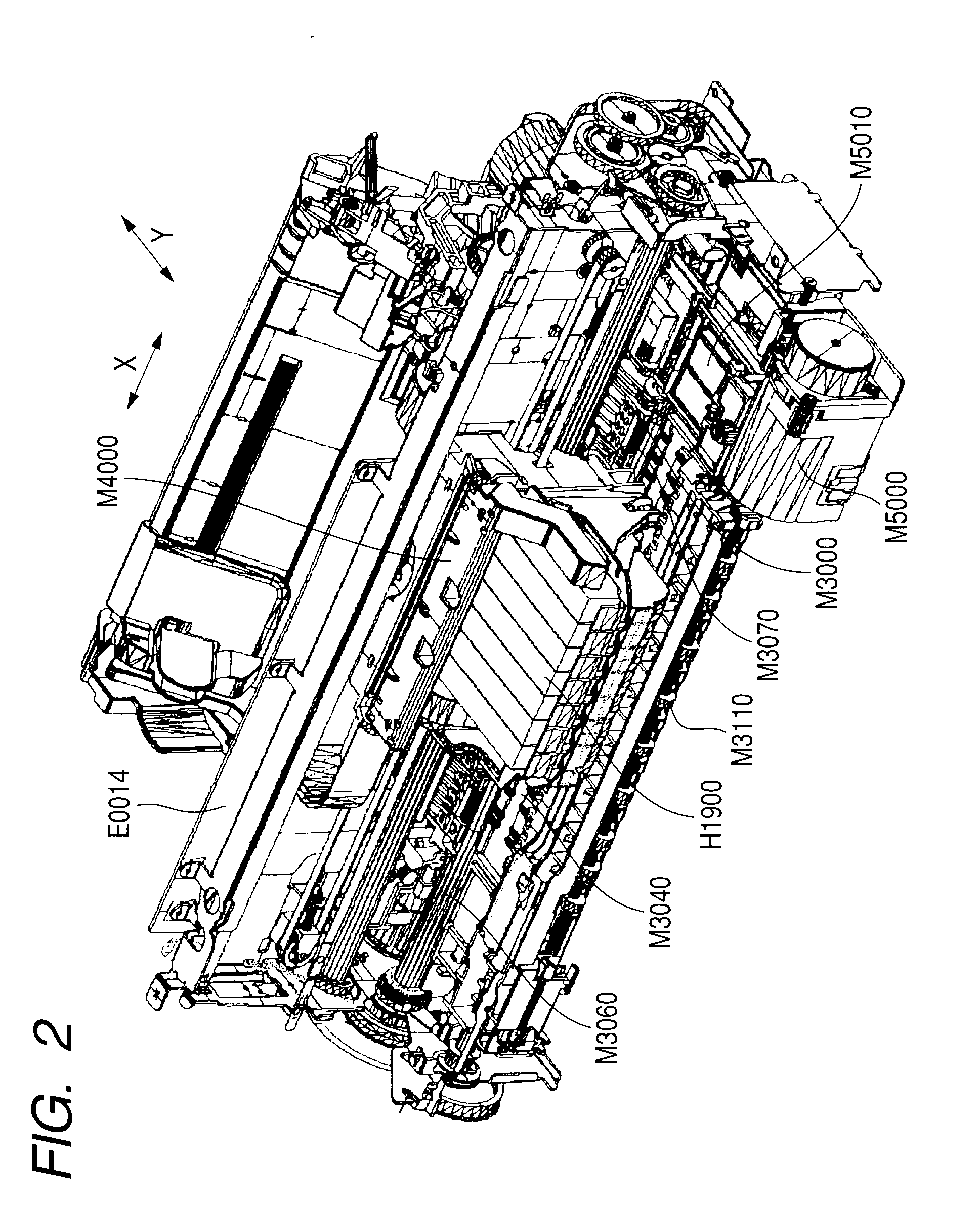

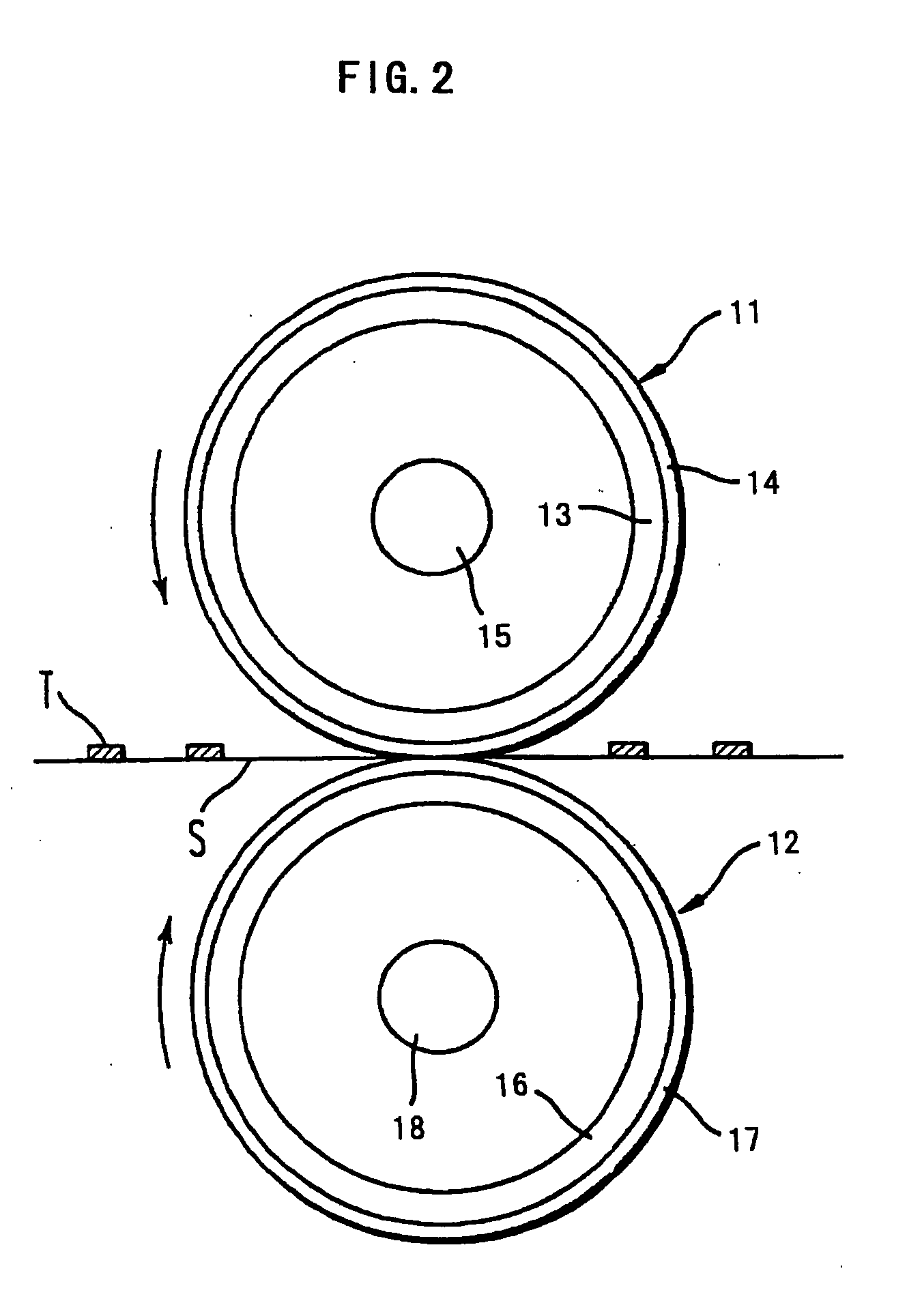

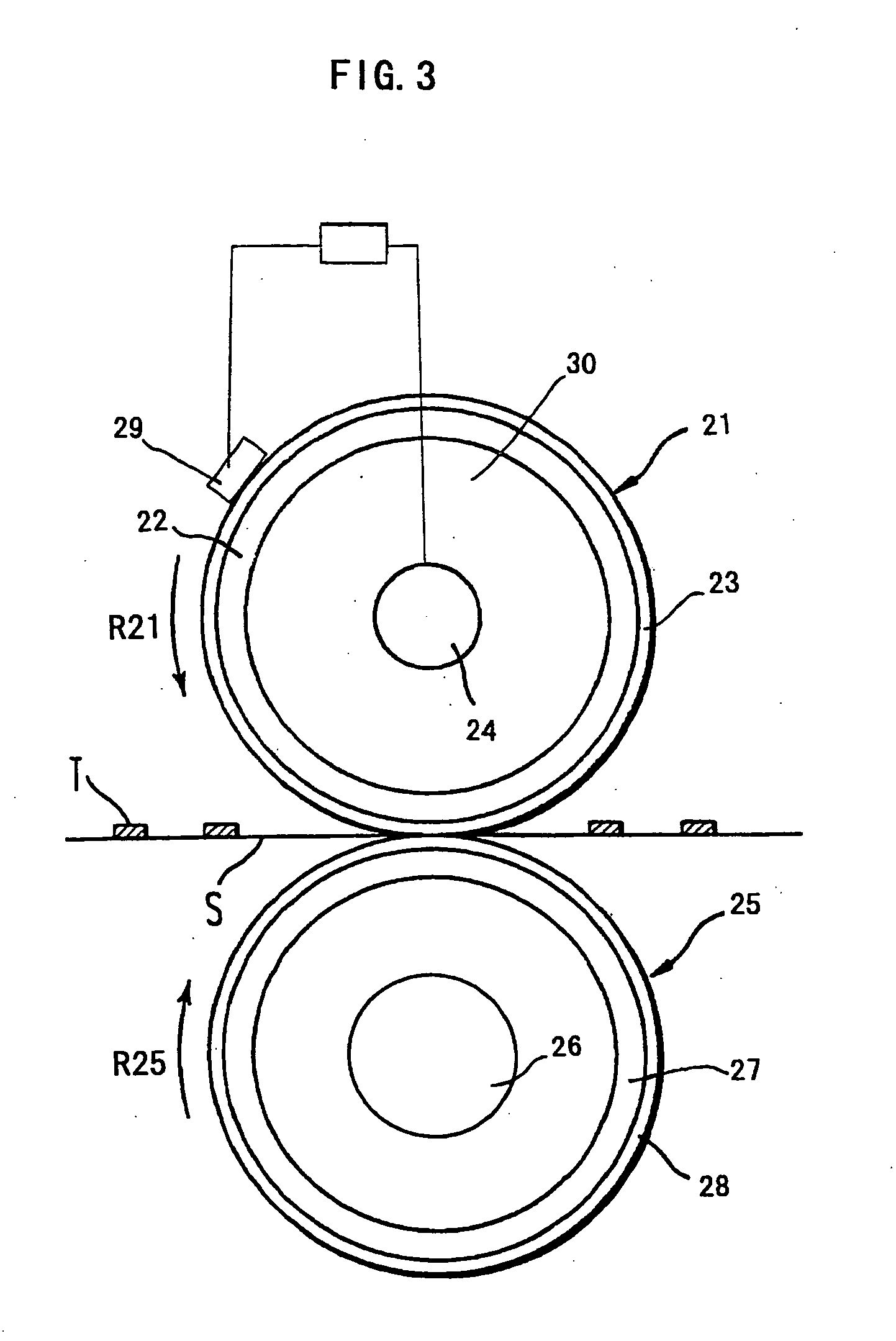

Image forming method and toner for use in the method

InactiveUS6899986B2High imagingFlat surfaceElectrographic process apparatusDevelopersImage formationSurface roughness

An image forming method, comprising passing a toner image-bearing sheet through a nip defined between two rollers including a heater roller to fix the toner image on the sheet, wherein the toner image is formed from a toner comprising a binder resin, and a colorant, wherein the toner image before the passage through the nip has a toner volume V1 and a toner image area S1, wherein the toner image after the passage through the nip has a toner volume V2 and a toner image area S2, and wherein a volume change Vt and an area change St defined by the formulas shown below are 30% or less and 20% or less, respectively:Vt(%)=(V1−V2) / V1×100St(%)=(S2−S2) / S1×100.Alternatively, the toner image before the passage through the nip has a surface roughness of 2.5 μm or less.

Owner:RICOH KK

Image forming method

InactiveUS20100296848A1High quality imagingUniform glossElectrographic process apparatusDevelopersImage formationMechanical engineering

Owner:RICOH KK

Cotton stalk pholeom fiber and degum processing method thereof

InactiveCN101298701ASoft toneUniform glossMechanical fibre separationFibre treatment to obtain bast fibrePre treatmentNatural fiber

The invention relates to a cotton-stalk hide fiber and a degumming method thereof. The technique process of the method comprises the following steps: cotton-stalk hide preparation, drying-softening, ultrasonic wave pre-treatment, pressing-drying, boiling-whitening, pressing-drying, washing with hot water, pressing-drying, oil-supply, pressing-drying, oven-drying, softening and obtaining of belt-form prepared dried fibers. The fiber of the obtained cotton-stalk hide prepared fiber appears as a smooth straight belt. The degumming process of the invention is so gentle and can preserve the physical capability and natural style of the cotton-stalk hide fiber to the most extent, and has the advantages of safety, high-efficiency, energy-conserving, low cost, low-pollution, simple operation and stable quality. The cotton-stalk hide prepared fiber of the invention appears as original coffee color (or white) with mild color tune, unified luster, flexible and loose state and smooth-straight belt form, and creats a better condition for further manufacturing. The original coffee color (without whitening) of the cotton-stalk hide fiber can be spun directly or spun with other natural fibers to weave out natural, healthy and environment-friendly novel products.

Owner:凌受明

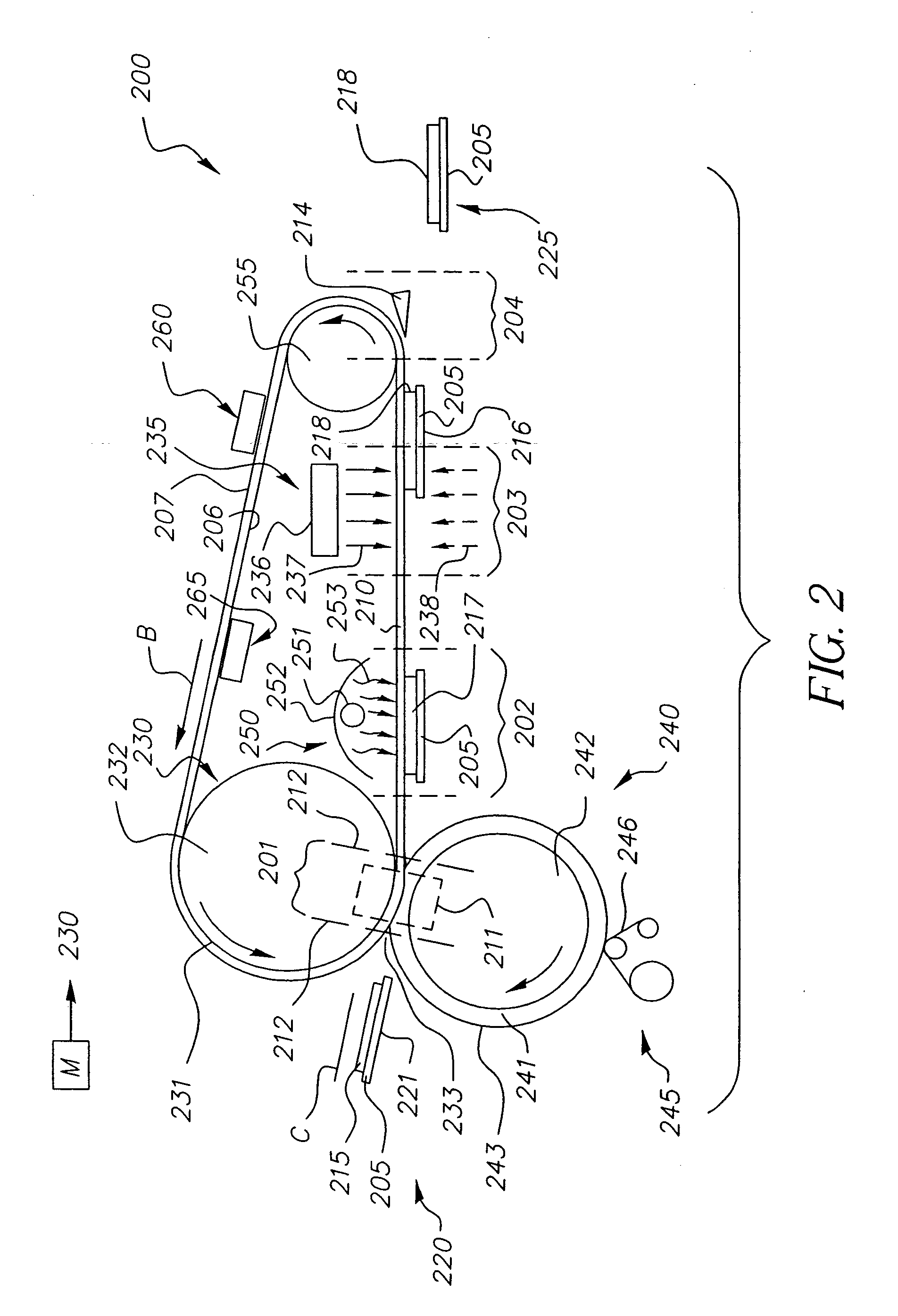

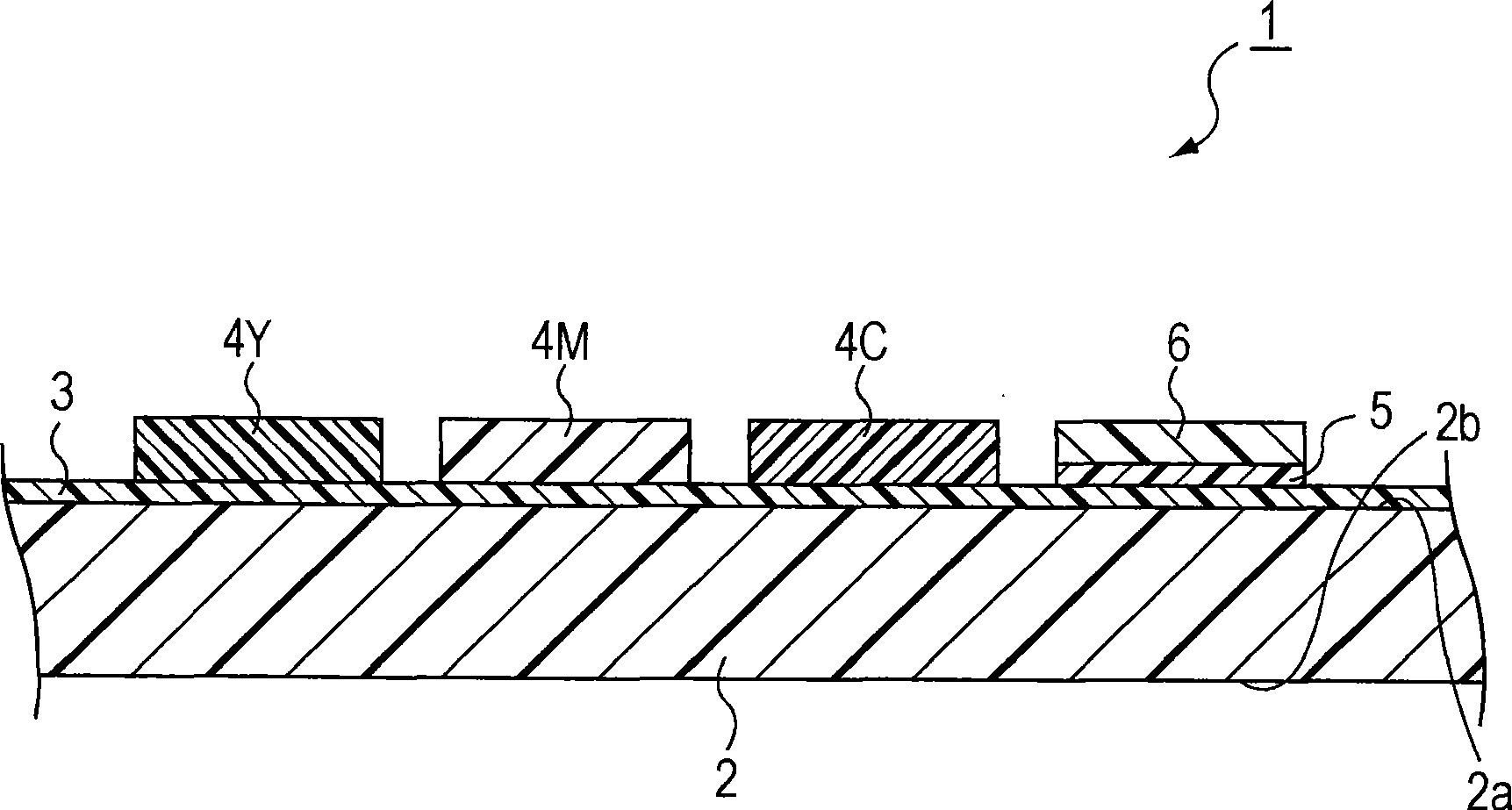

Durable electrophotographic prints

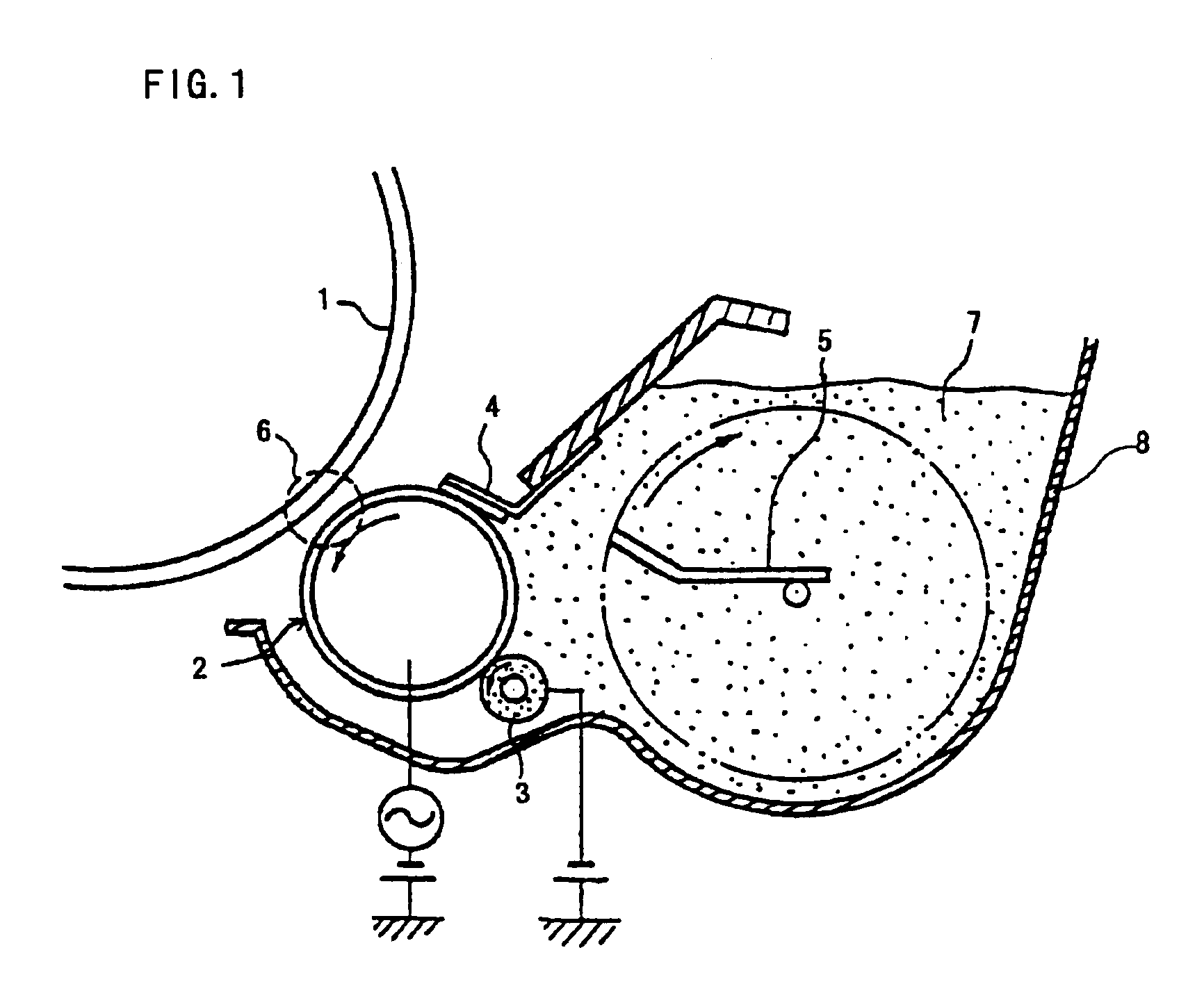

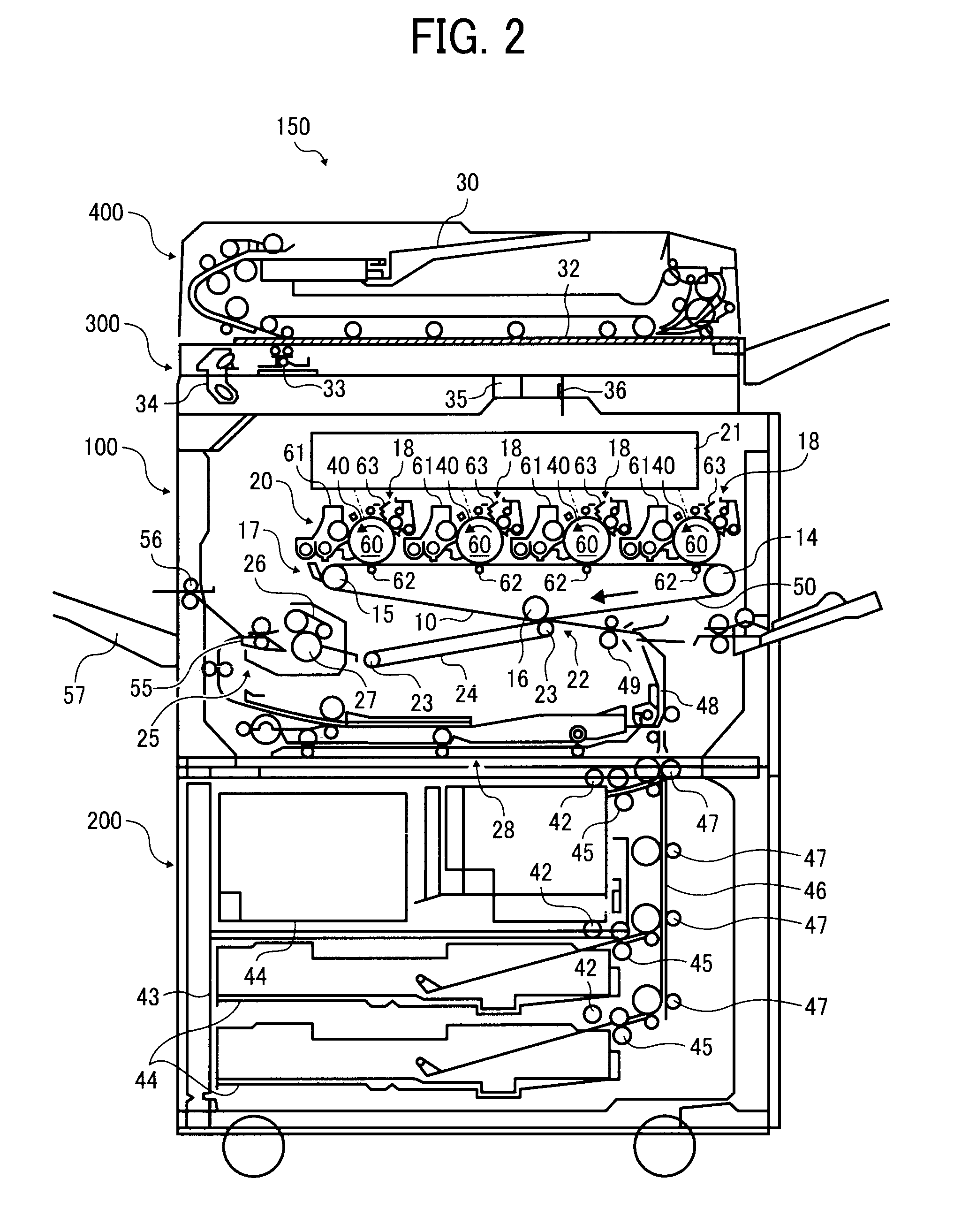

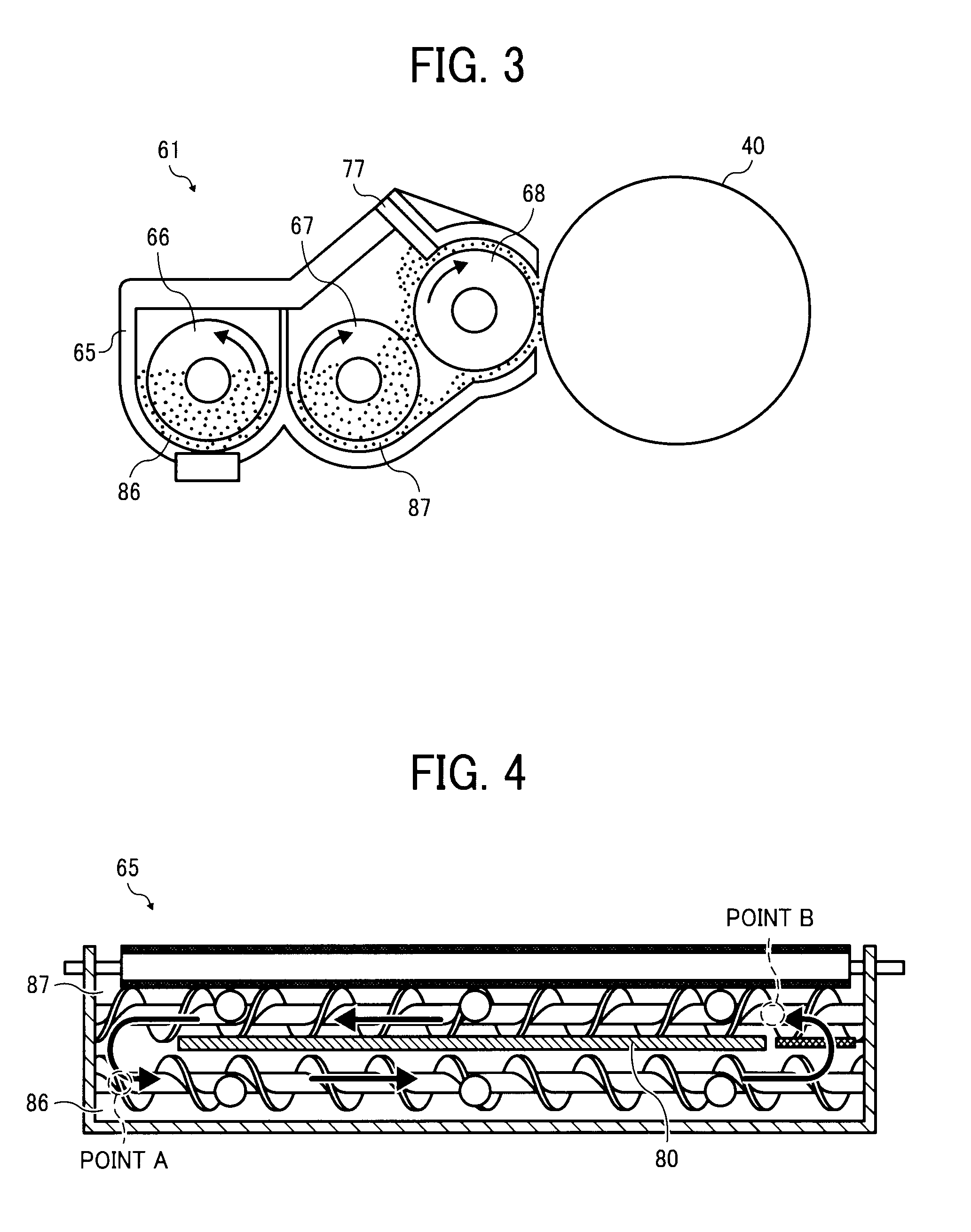

ActiveUS7184698B2Durable surfaceUniform glossElectrographic process apparatusMolten stateProcess zone

UV-glossing for simplex and duplex prints, wherein an input member having thereon a pre-gloss toner image including UV-curable toner is moved, in non-slip association with a smooth UV-transparent web, jointly with the web through a plurality of process zones sequentially including a heating zone and an exposure zone, thereby producing an output member having a glossed, UV-cured, surface. In the heating zone, at least the outermost toner of the pre-gloss toner image is heated to a molten state in contact with the web. In the exposure zone, with the molten state being maintained, at least the outermost toner which contacts the web is cured by a flux of UV radiation transmitted through the web. In a preferred embodiment, the UV-curable toner is formed as an outer layer on the pre-gloss toner image.

Owner:EASTMAN KODAK CO

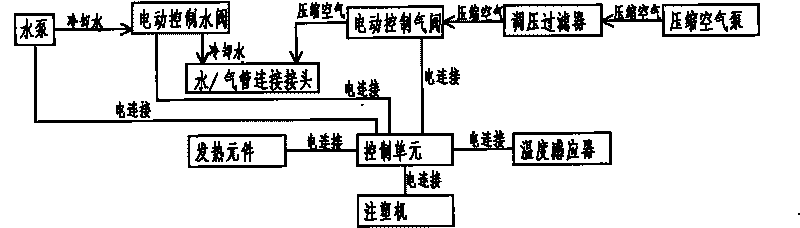

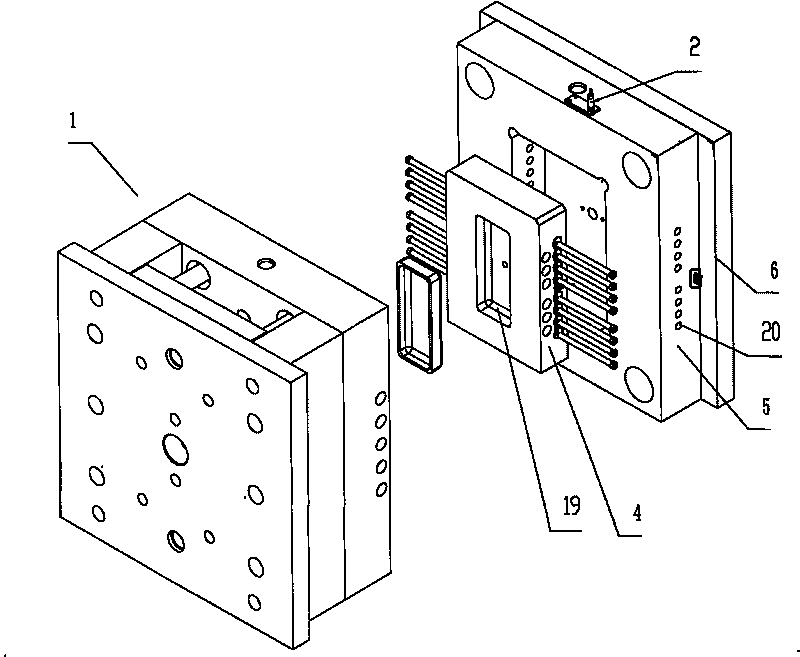

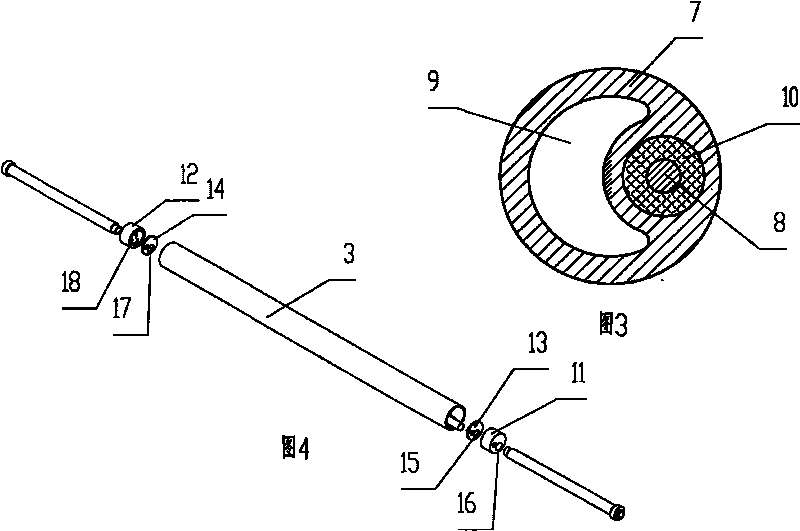

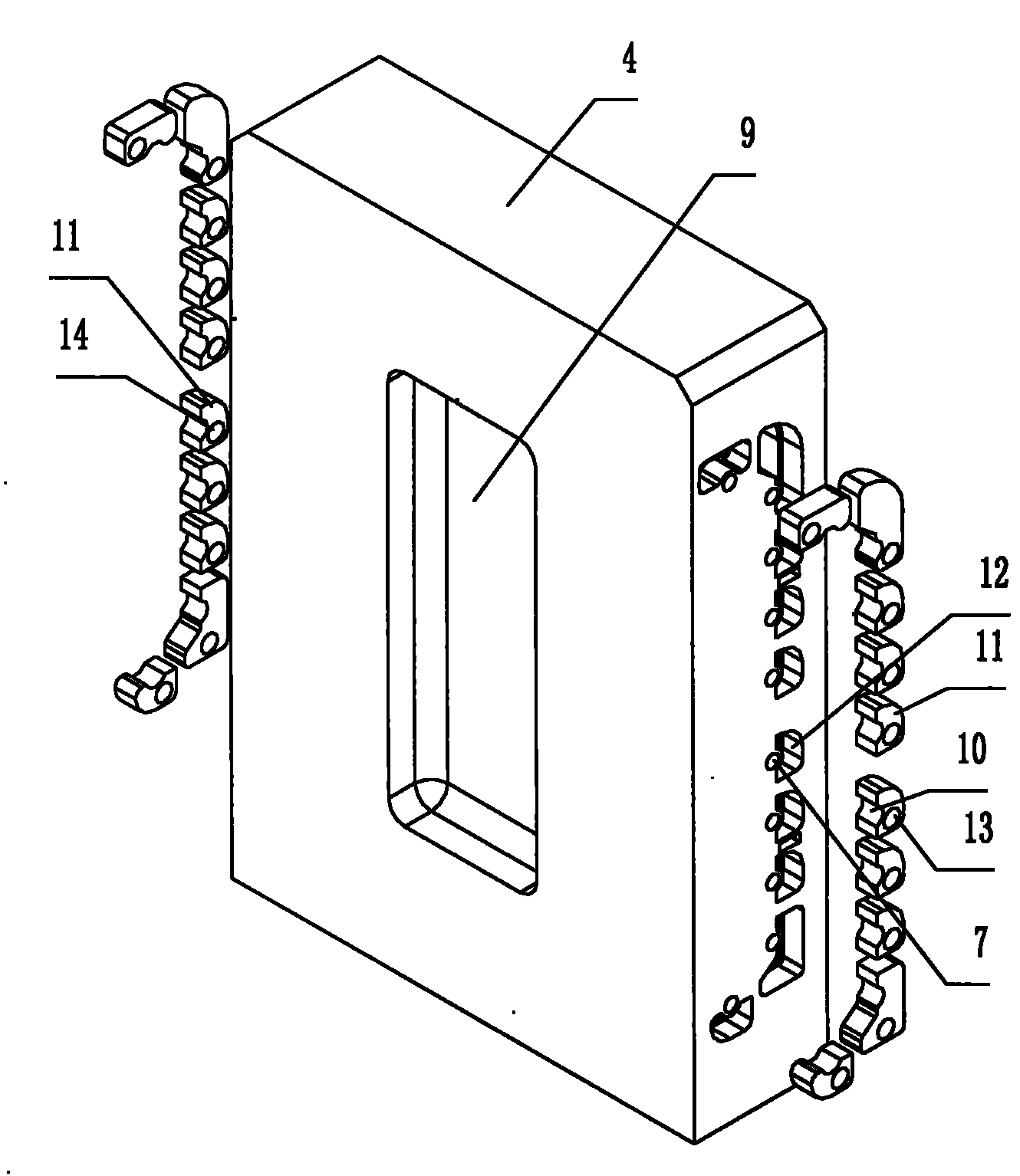

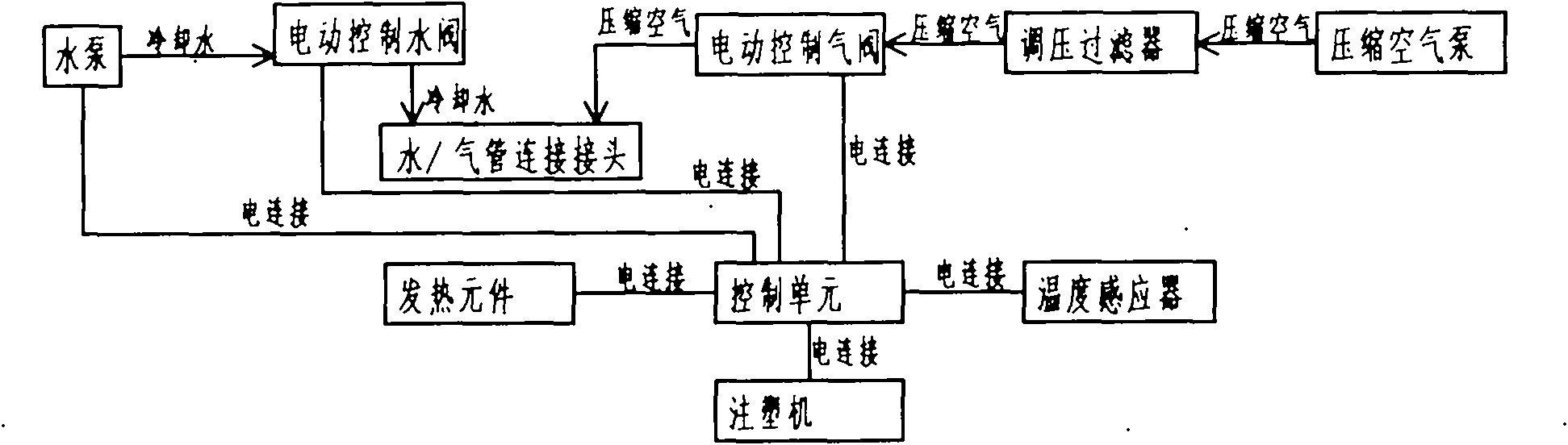

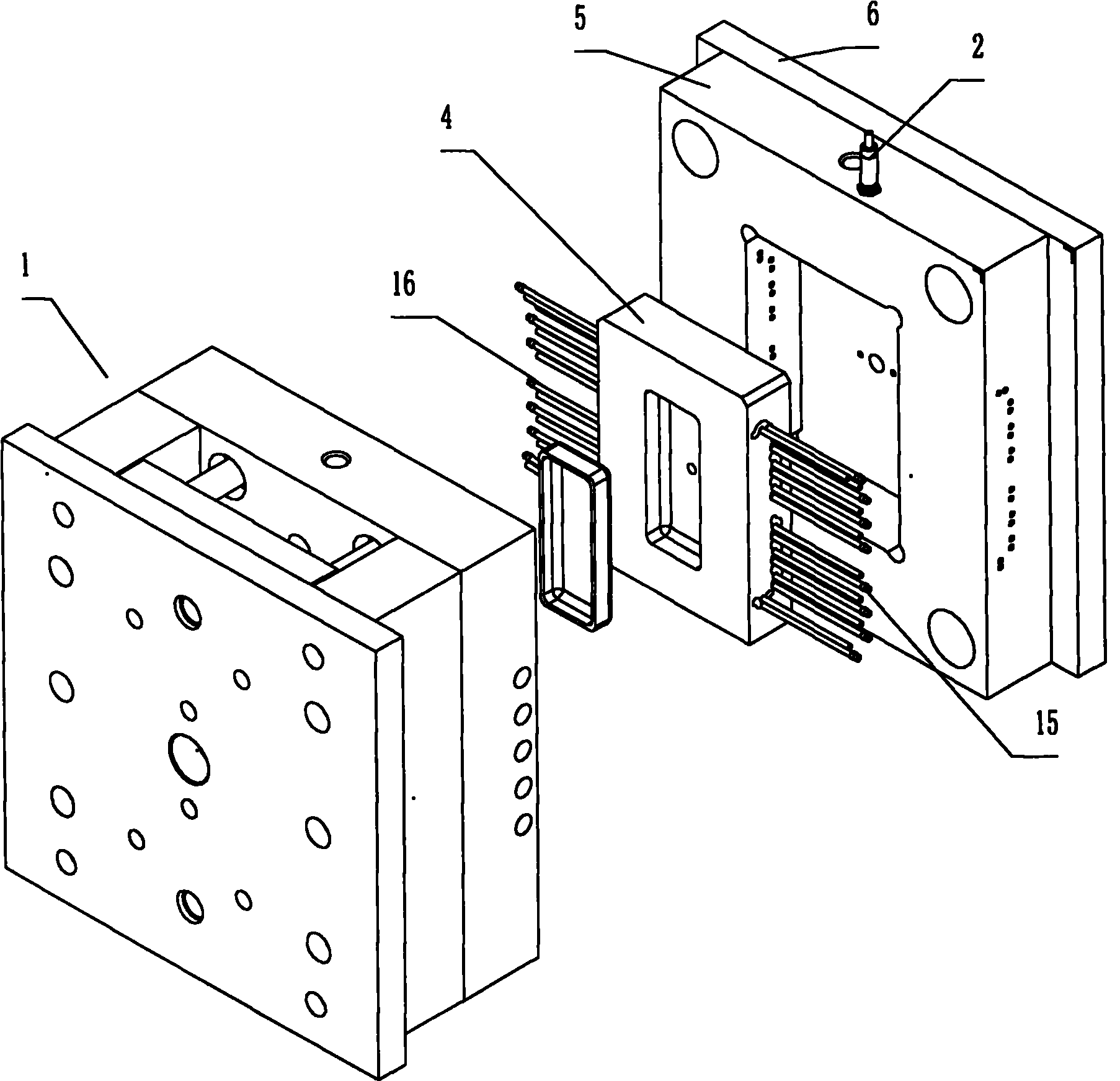

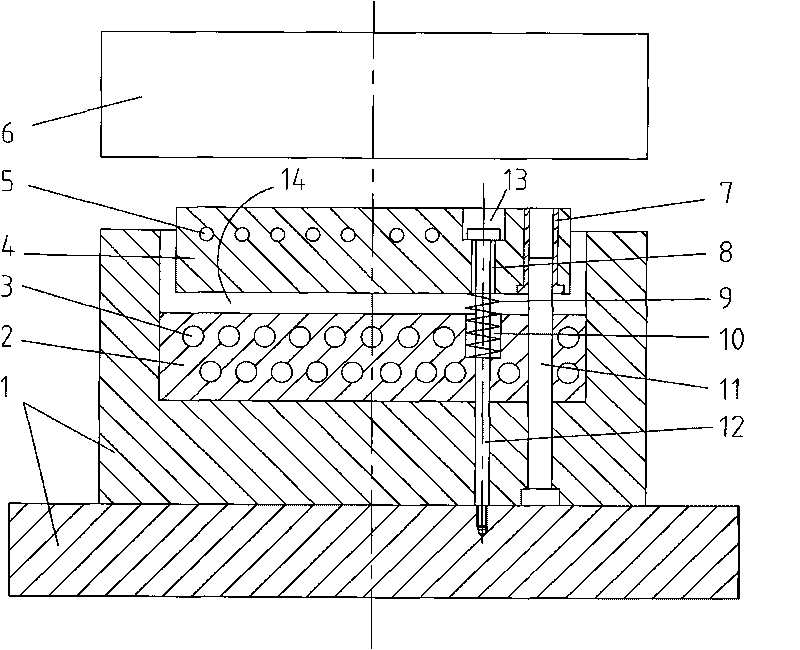

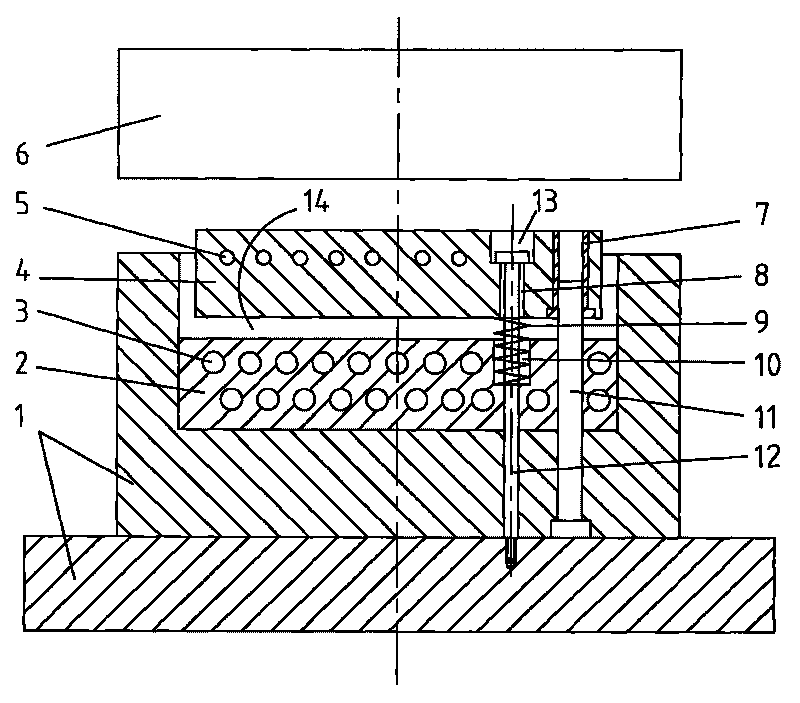

Mold heating and cooling rod and mold capable of realizing rapid cooling and rapid heating

The invention relates to a mold heating and cooling rod which comprises a heating and cooling rod body and a heating element, a cooling thermal insulation hole for introducing a cooling medium when a mold needs to be cooled and discharging the cooling medium when the mold needs to be heated and a heating element accommodating hole are arranged in the heating and cooling rod body along the axial direction, and the heating element is mounted in the heating element accommodating hole; the mold capable of realizing rapid cooling and rapid heating comprises a mold core and the heating and cooling rod, and the heating and cooling rod is in contact with the mold core; and one side of the heating and cooling rod which is provided with the heating element is near to a molding surface of the mold core. The advantages are that, as the molding surface can be rapidly and evenly heated and cooled and rapidly heated to the temperature which is near to or equal to that of melting materials, a molded product has the advantages of good quality, difficult production of weld marks, flow marks, surface bubbles and the like, even color and luster, even density of the product, small shrinkage and ability of reducing the injection pressure and the product deformation caused by residual stress after consolidating and molding the molten materials.

Owner:杨东佐

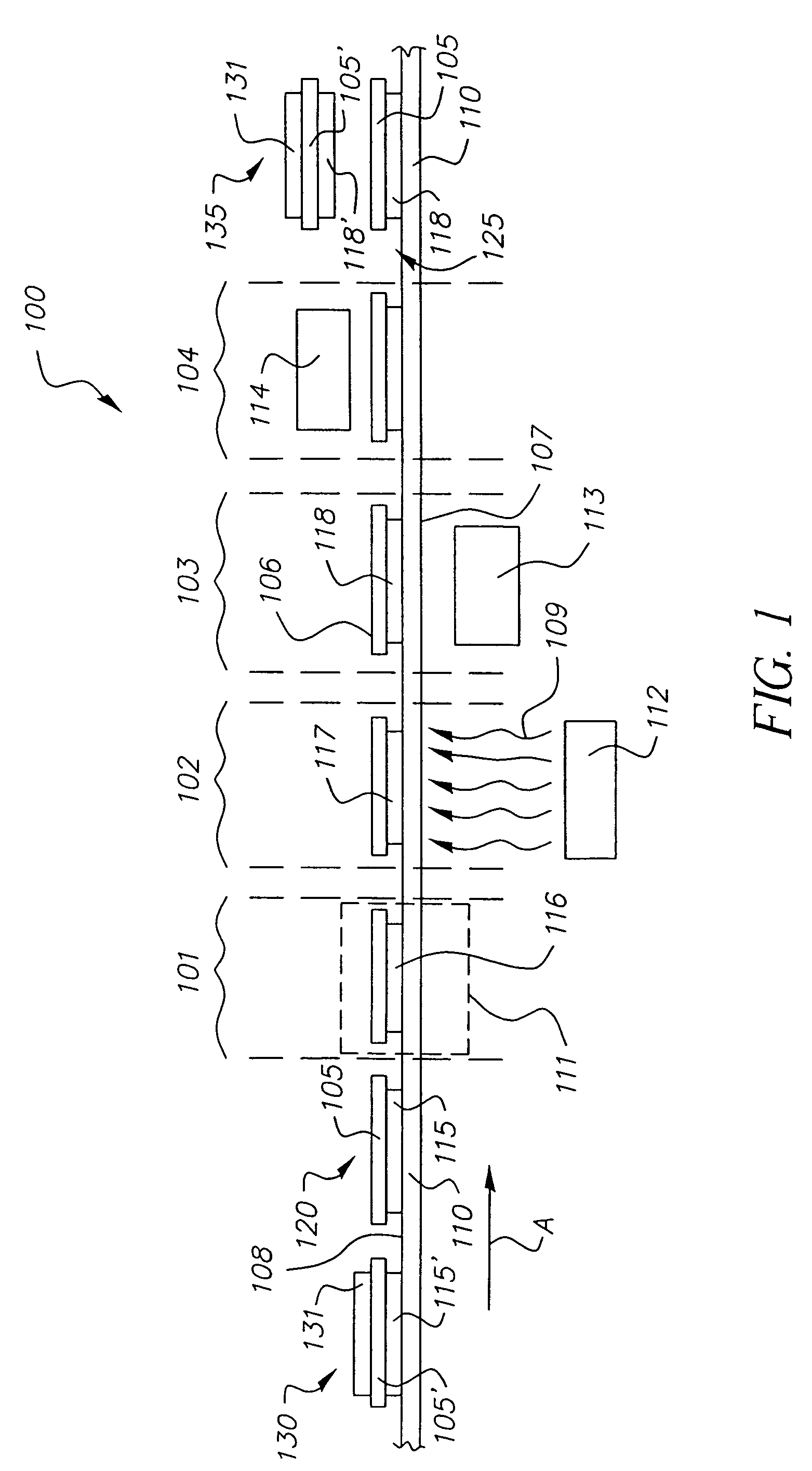

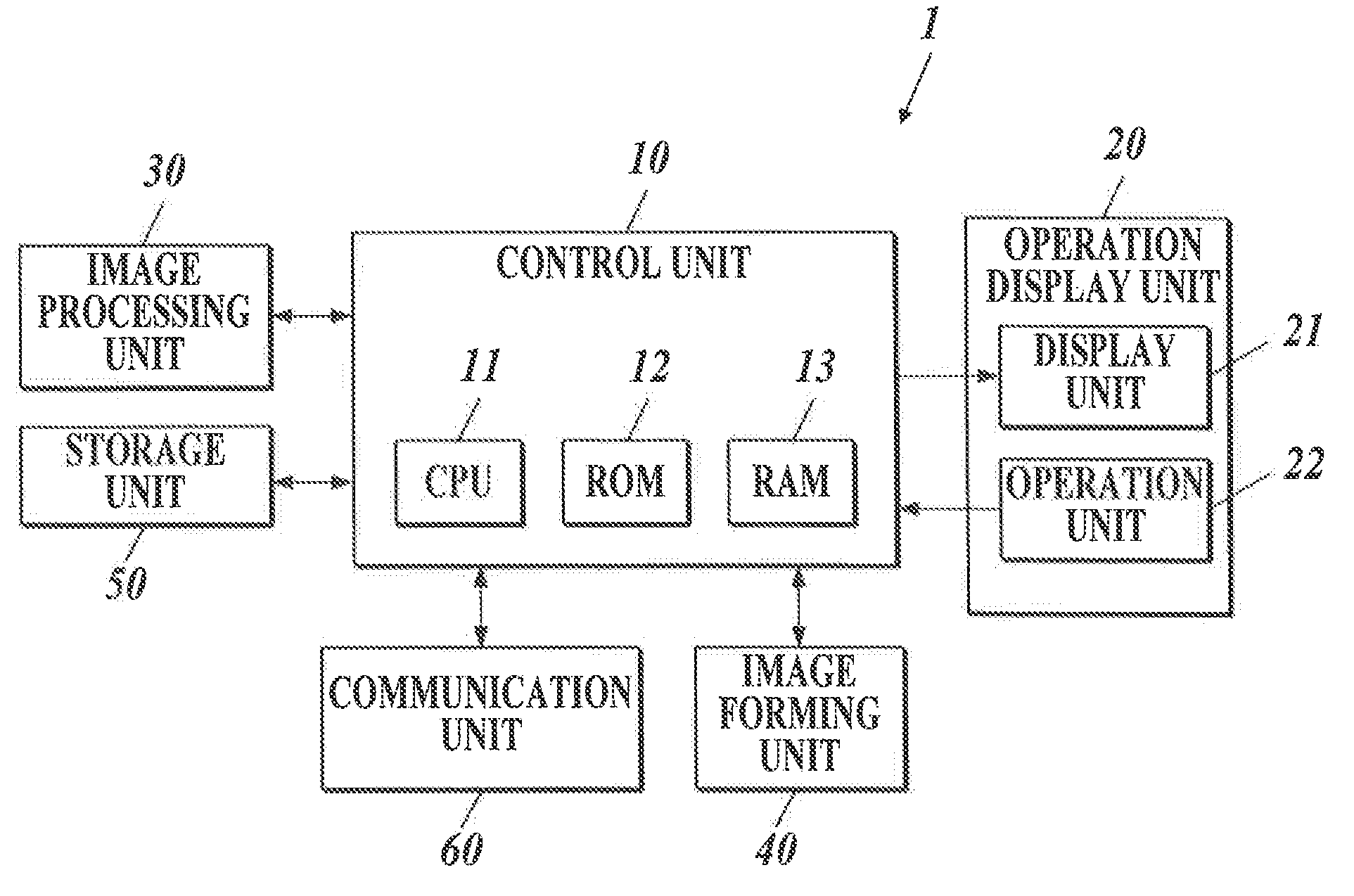

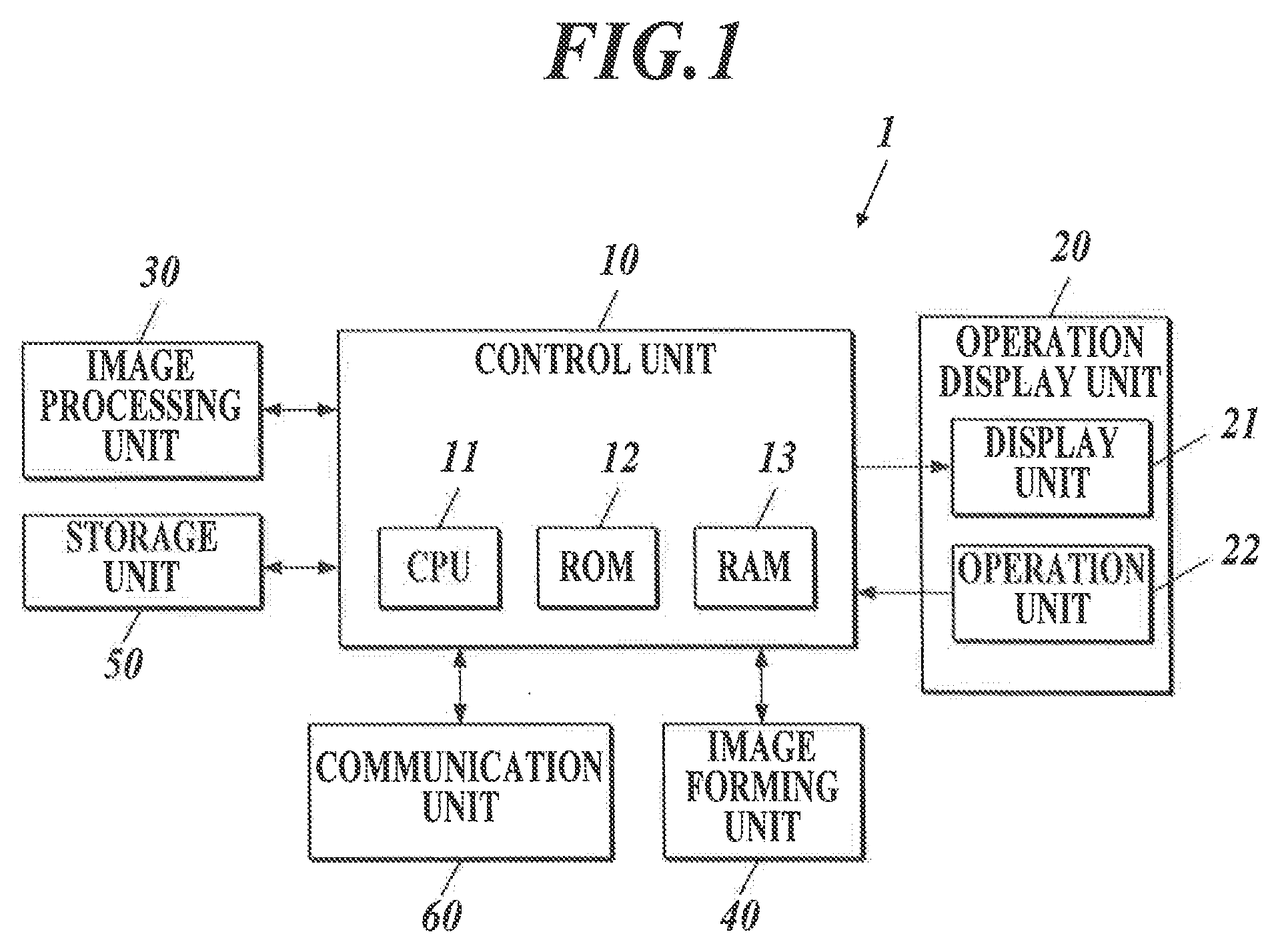

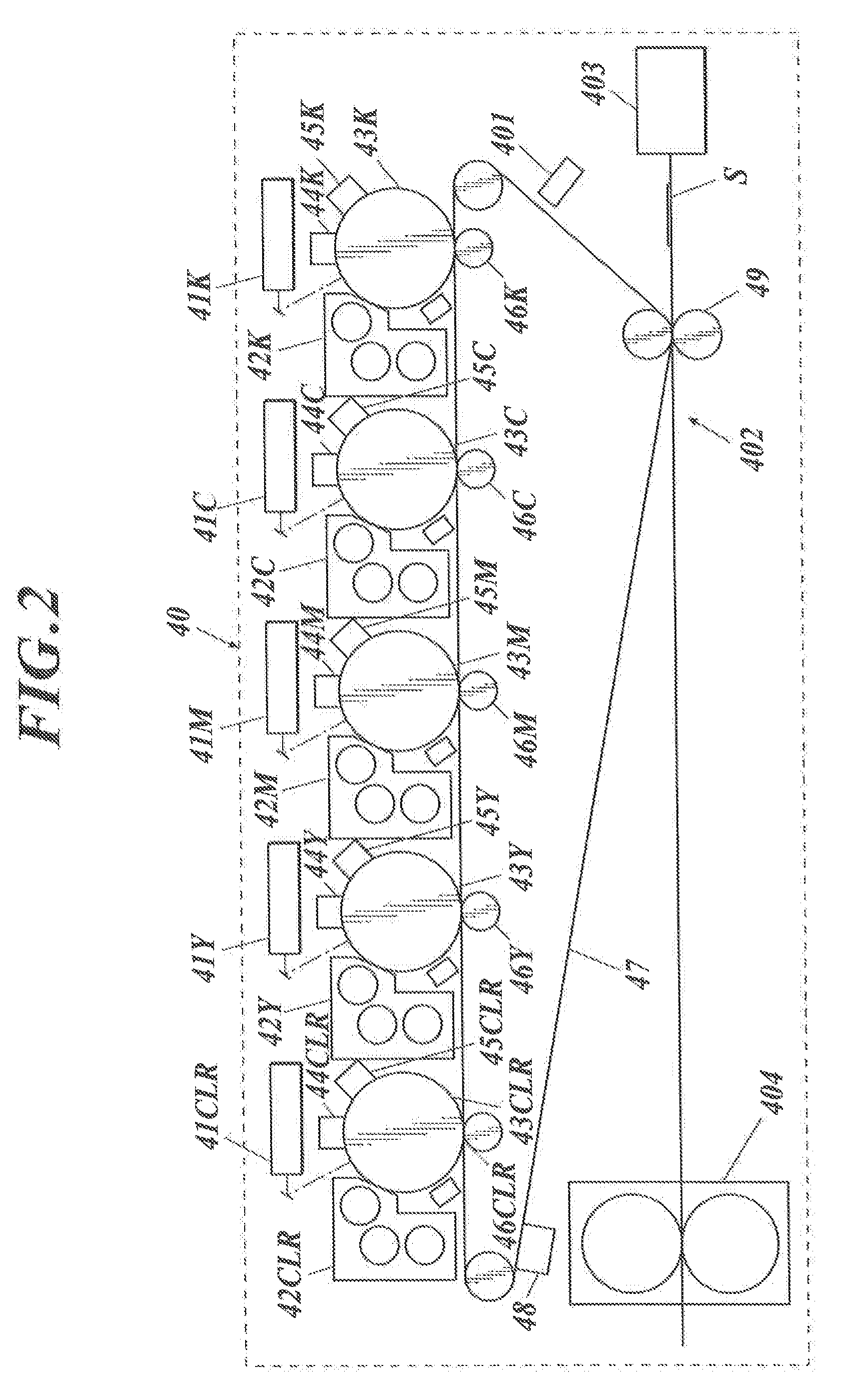

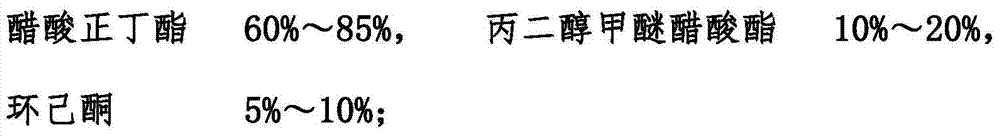

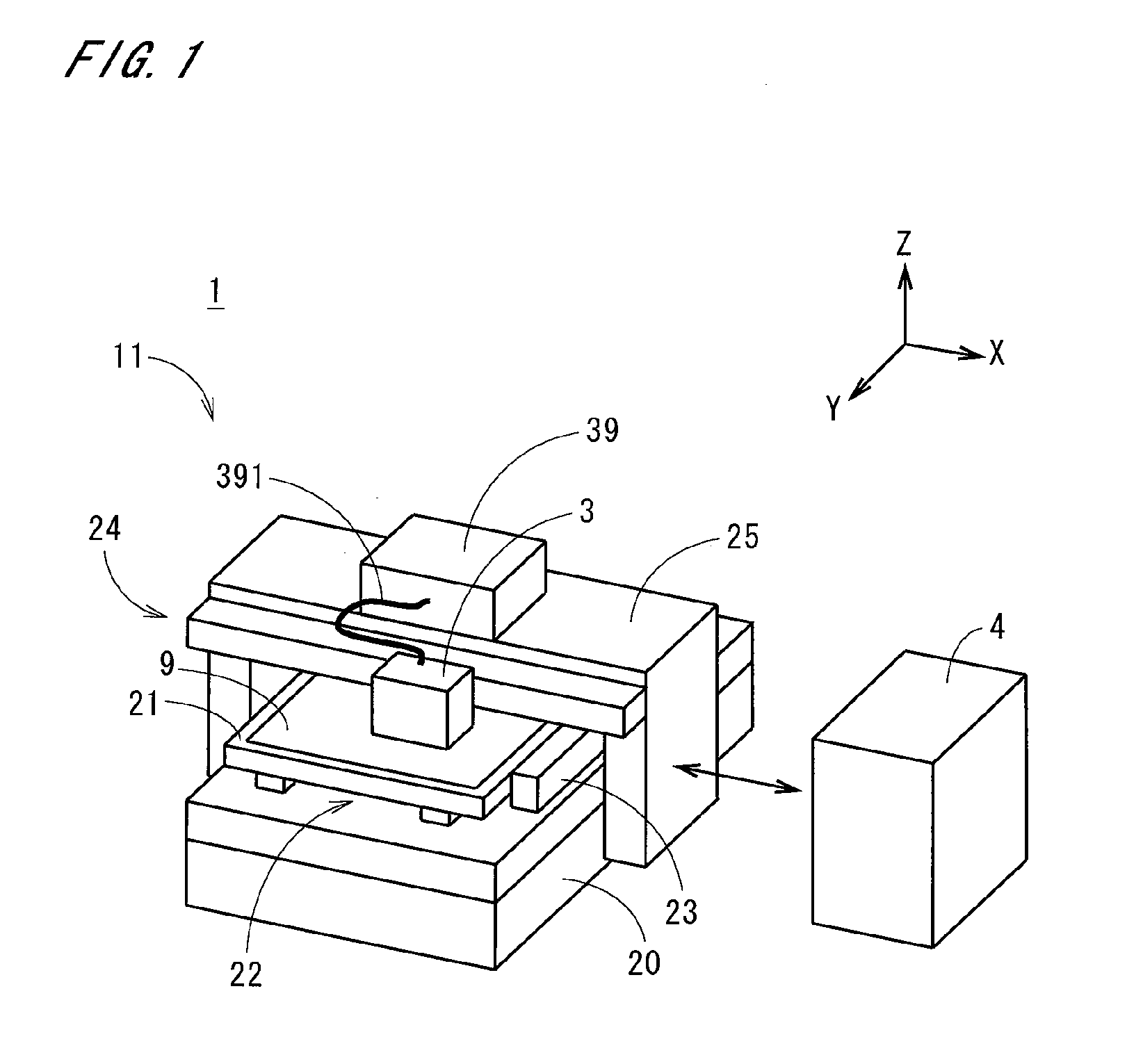

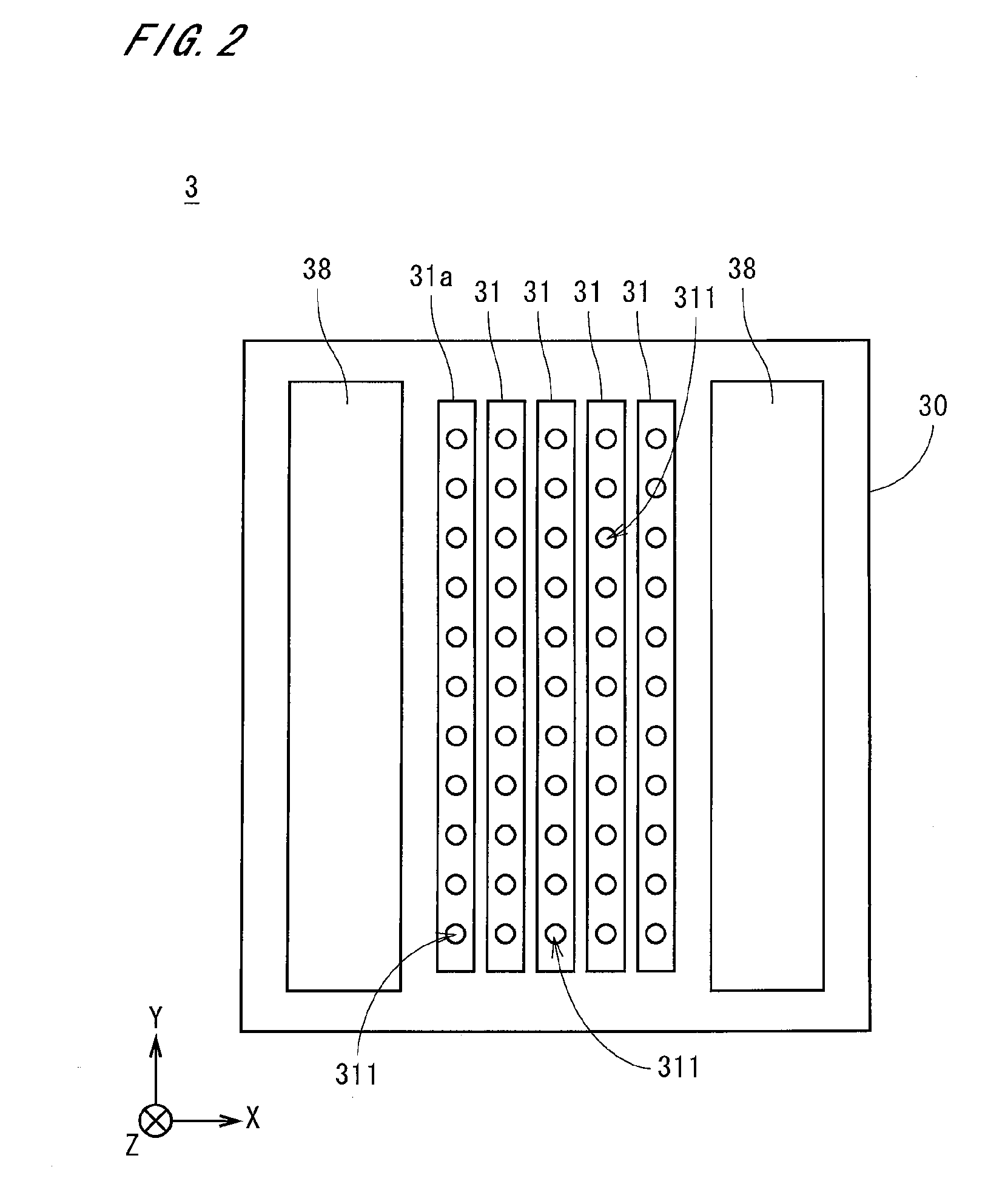

Image forming apparatus and image forming method

ActiveUS20130258367A1Gloss stableUniform glossDigitally marking record carriersDigital computer detailsImaging processingImage formation

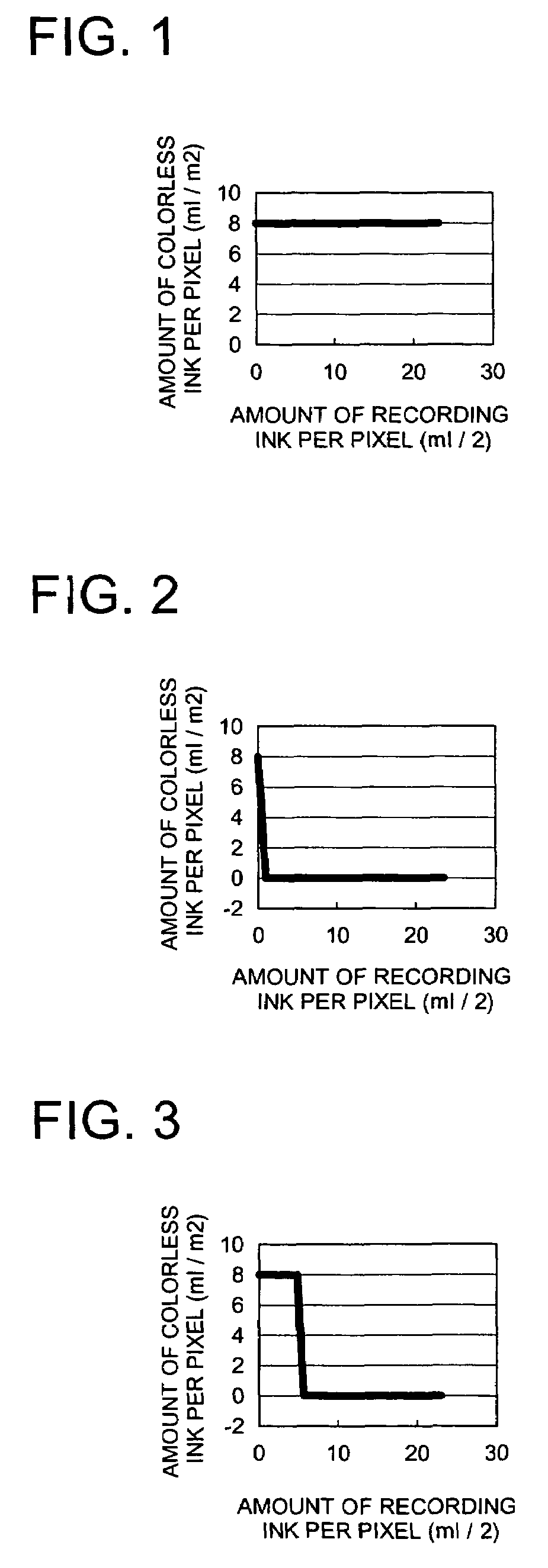

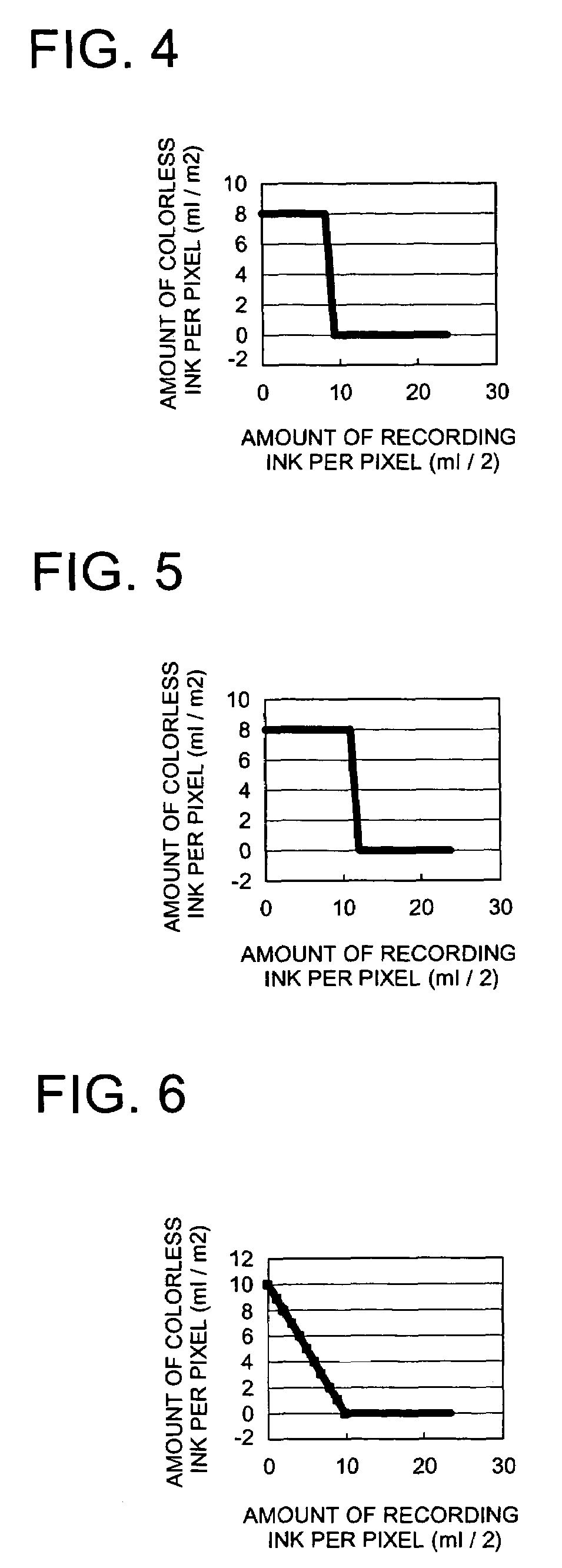

An image forming apparatus includes an image forming unit, a storage unit, an image processing unit and a control unit. The image processing unit (i) calculates a summed height of a color toner image formed on a sheet by summing up a height of the color toner image on the basis of input image data, (ii) calculates, on the basis of a target value for glossiness stored in the storage unit, a target total height of the color toner image and a clear toner image to realize the target value for glossiness, and (iii) calculates a height of the clear toner image by subtracting the summed height from the target total height. On the basis of the calculated height of the clear toner image, the control unit adjusts the height of the clear toner image formed on the sheet.

Owner:KONICA MINOLTA BUSINESS TECH INC

Ink jet ink, ink jet recording method, ink cartridge, recording unit, and ink jet recording apparatus

InactiveUS20100034972A1High glossUniform glossMeasurement apparatus componentsDuplicating/marking methodsEngineeringPolymer

Provided is an ink jet ink capable of recording an image having an unprecedentedly high level of scratch resistance and excellent glossiness while satisfying reliability of the ink such as ejection stability. The ink jet ink contains at least a pigment and a graft polymer, and is characterized in that the graft polymer includes at least a specific nonionic unit and a unit having a polysiloxane structure.

Owner:CANON KK

Image forming method and toner for use in the method

InactiveUS20050079430A1High grade tonerUniform densityDevelopersElectrographic process apparatusSurface roughnessImage formation

An image forming method, comprising passing a toner image-bearing sheet through a nip defined between two rollers including a heater roller to fix the toner image on the sheet, wherein the toner image is formed from a toner comprising a binder resin, and a colorant, wherein the toner image before the passage through the nip has a toner volume V1 and a toner image area S1, wherein the toner image after the passage through the nip has a toner volume V2 and a toner image area S2, and wherein a volume change Vt and an area change St defined by the formulas shown below are 30% or less and 20% or less, respectively: Vt(%)=(V1−V2) / V1×100 St(%)=(S2−S1) / S1×100. Alternatively, the toner image before the passage through the nip has a surface roughness of 2.5 μm or less.

Owner:RICOH KK

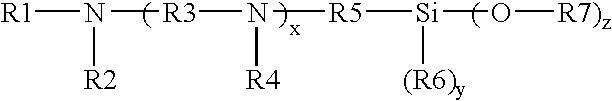

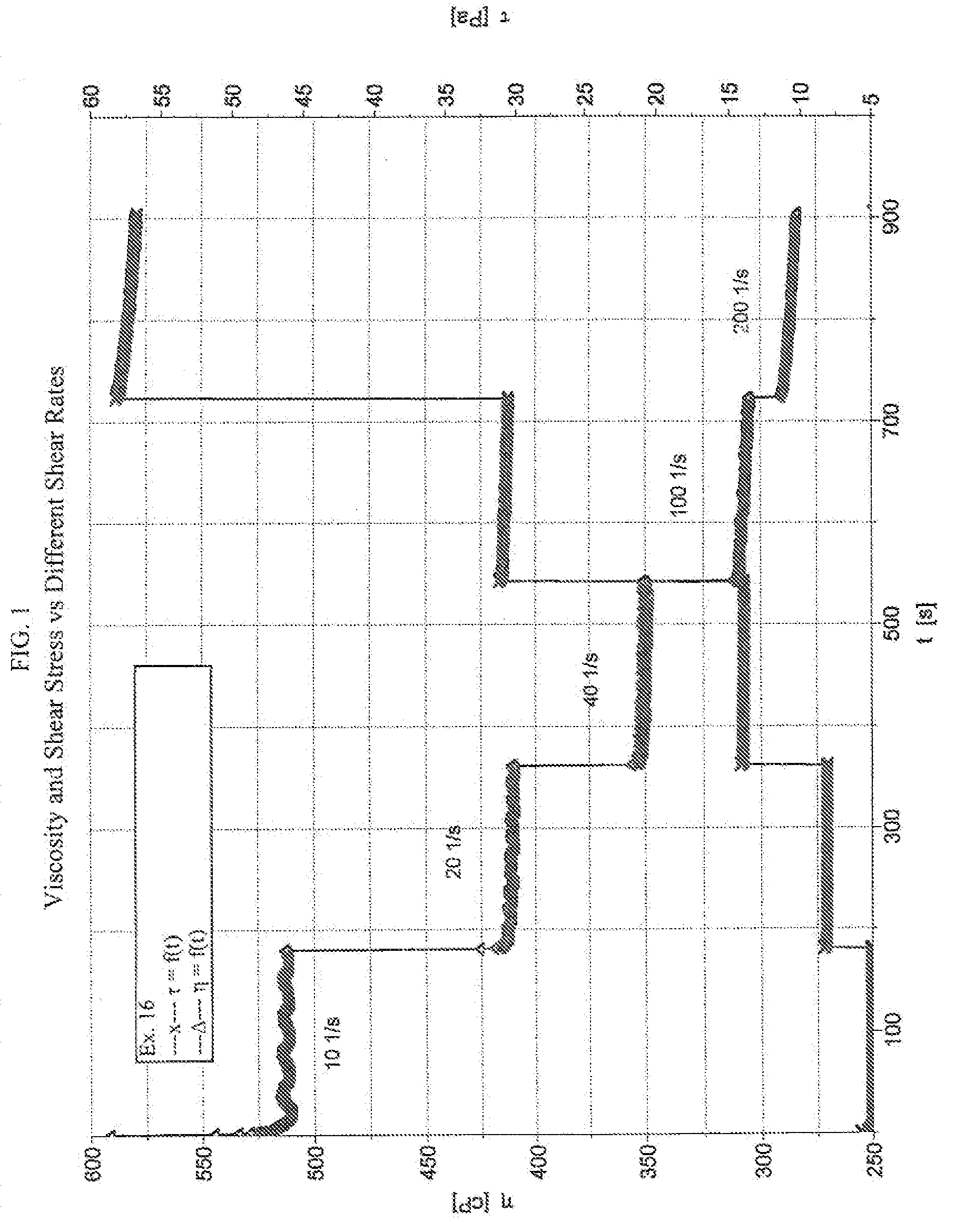

Automotive Protectant Compositions with Improved Vertical Cling

ActiveUS20100305260A1Uniform glossUniformity of protectionOther chemical processesPretreated surfacesAlkalinityUv absorber

The present invention relates generally to compositions, methods of use and kits for use as an automotive protectant composition and / or automotive cleaning composition. The protectant composition and / or cleaning composition comprises at least one surfactant and at least one rheology modifier, at least one silicone component, and water. The composition also optionally comprise, pH adjusters, builders, alkalinity sources, wetting agents, spreading agents, UV absorbers. The protectant composition has a viscosity of about 4000 to 6000 cps and exhibits a Vertical Cling parameter of between 1 and about 7 at a temperature of about 25° C. on automotive surfaces to which the compositions are applied.

Owner:ENERGIZER AUTO INC

PU anti-yellowing flat vanish sprayed on white finish for woodware

ActiveCN104497826AUniform glossStrong adhesionPolyurea/polyurethane coatingsChemistryWater resistance

The invention relates to PU anti-yellowing flat vanish sprayed on white finish for woodware. The PU anti-yellowing flat vanish comprises a component A, a component B and a component C for dilution, wherein the components A and B are separately stored and are mixed to react during use and then are diluted; the weight ratio of the component A, the component B and the component C for dilution is 1:(0.2-0.3):(0.4-0.6). The PU anti-yellowing flat vanish provided by the invention is uniform in gloss, strong in adhesive force, good in high-temperature resistance, water resistance and chemical resistance and good in light and color retaining property; the PU anti-yellowing flat vanish is good in flatting property and easy to spray, and particularly has an excellent effect in anti-yellowing and anti-weather performances.

Owner:GUANGDONG BADESE CHEM

Ink-jet recoding method and recorded matter

InactiveUS7261405B2Uniform glossMeasurement apparatus componentsDuplicating/marking methodsWater solublePolymer chemistry

Owner:KONICA MINOLTA INC

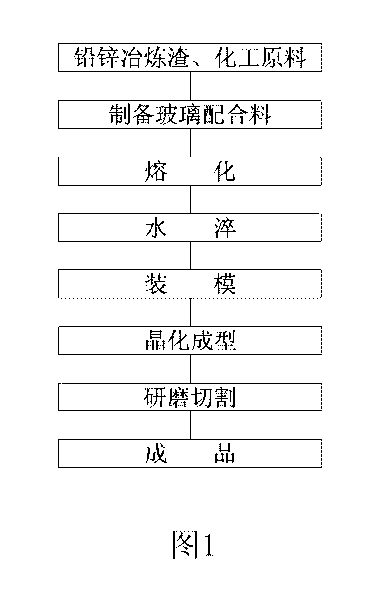

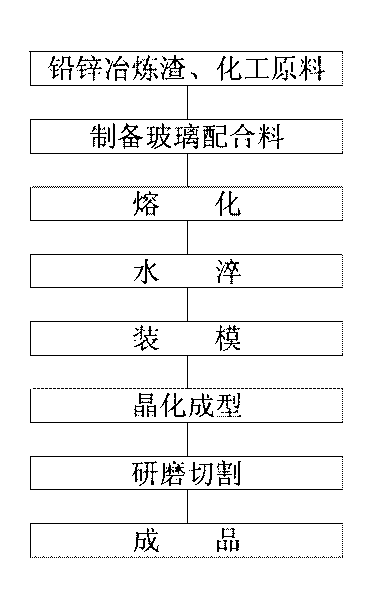

Green glass-ceramic plate made from lead-zinc smelting slag and manufacturing method thereof

The invention relates to a green glass-ceramic plate made from lead-zinc smelting slag and a manufacturing method thereof. The glass raw material is prepared from the following components in parts by weight: 40 to 60 parts of lead-zinc smelting slag, 26 to 38 parts of quartz, 15 to 24 parts of lithium feldspar, 2 to 4 parts of soda ash, 2 to 3 parts of zinc oxide, 2 to 5 parts of barium carbonate, 1 to 3 parts of borax, 2 to 2.5 parts of chromium oxide, 0 to 0.2 part of copper oxide and 0.04 to 0.2 part of carbon powder. The invention is not only in line with the common glass-ceramic produced by completely adopting industrial materials on the aspect of the performance, but also can realize waste utilization, reduce the environmental pollution, the product cost and the melting temperature of glass, improve the melting speed and the melting furnace efficiency of the glass, decrease the energy consumption and can be widely applied to building decoration materials, especially applied in various building decoration engineering, such as inside and outer walls, floors, pillars, table boards of the building, and the like.

Owner:FENGXIAN SANLIAN BUILDING MATERIALS

Mould capable of realizing rapid heat cycle

The invention discloses a mould capable of realizing a rapid heat cycle, which comprises a mould core provided with a moulding surface and heating rods with set number. Heating rod accommodating holes are formed at positions close to the moulding surface in the mould core and accommodate the heating rods; cooling insulation holes corresponding to the heating rods are formed at positions close to the heating rods in the mould core provided with the moulding surface, and are positioned on one side of the heating rods far from the moulding surface; the overall outline of the cross section of each cooling insulation hole is a closed curve; and one or more cooling insulation holes enclose corresponding heating rods in three directions. The mould has the advantages that: the moulding surface can be rapidly and uniformly heated and cooled, and can be rapidly heated to the temperature approaching to or equal to the temperature of a fused material, so the moulded products have good quality, weld marks, flow marks, surface bubbles and the like are not generated easily, the products have uniform luster and density and low shrinkage, and injection pressure and product deformation caused by residual stress after the fused material is solidified and moulded are reduced.

Owner:杨东佐

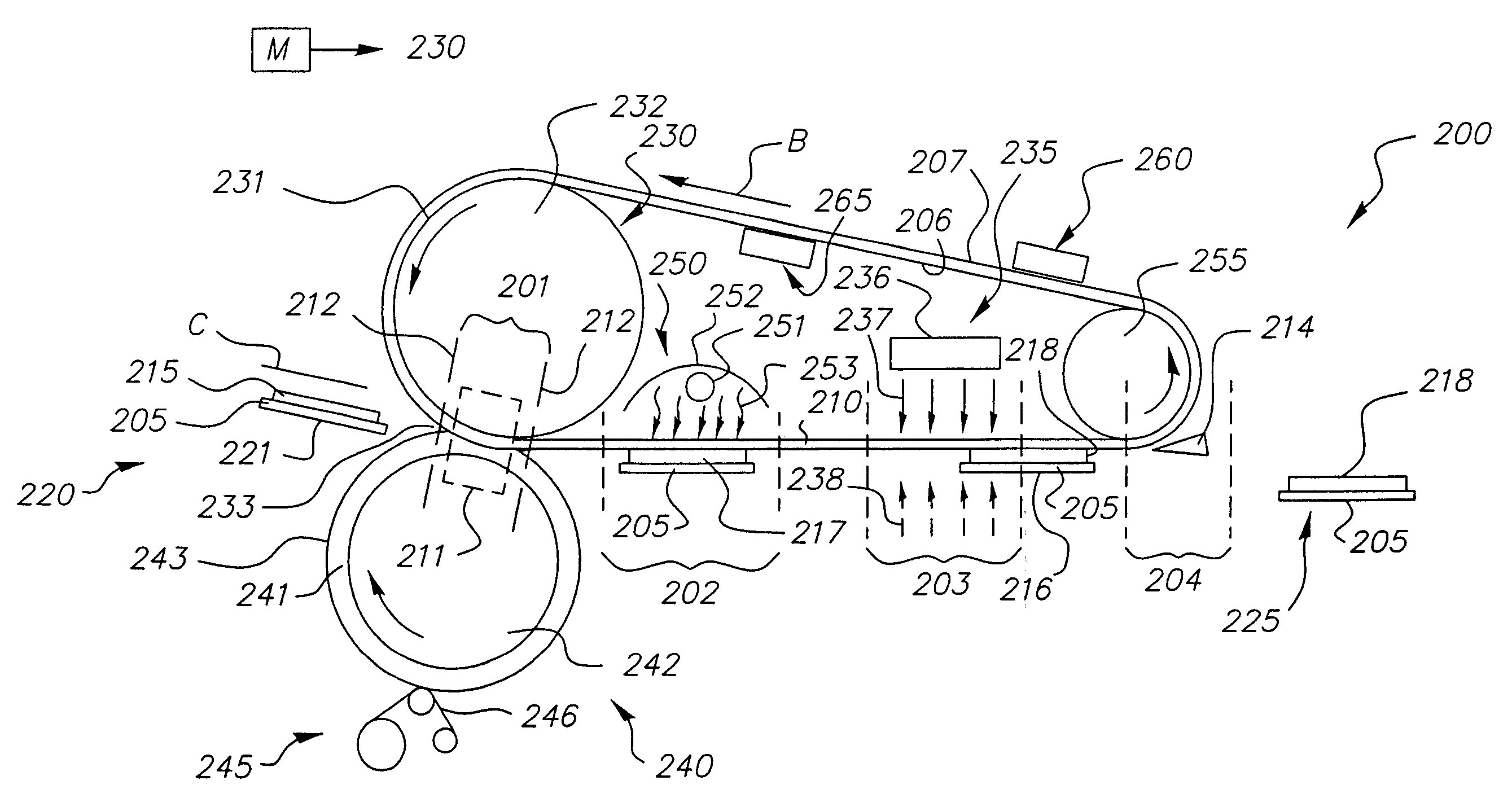

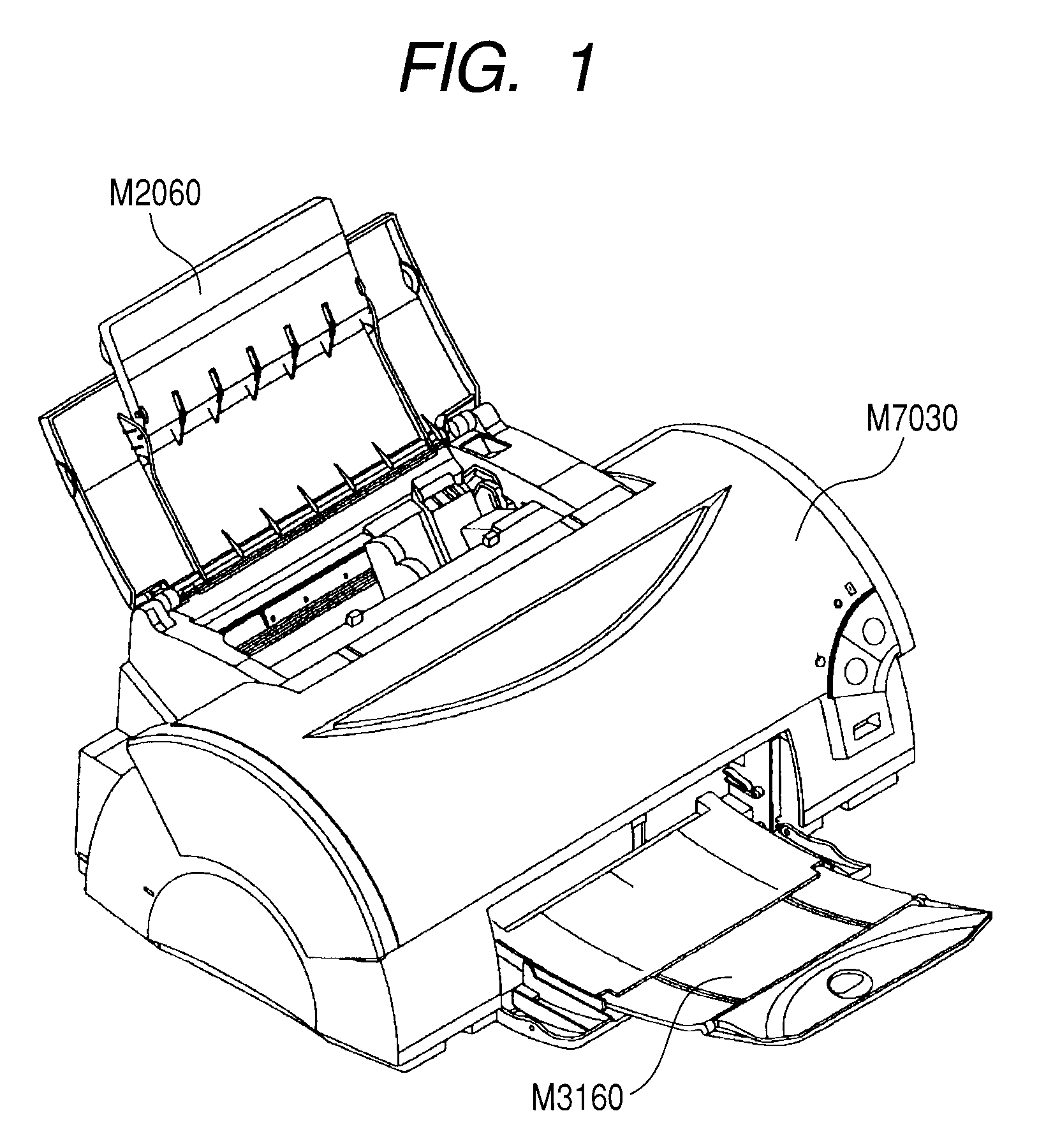

Method of printing and printer

InactiveUS20090174908A1Uniform glossSimple processTypewritersVisual presentationComputer visionColor tone

In an inkjet printer, a halftone image is generated from a grayscale original image with using a first threshold matrix, and the halftone image is printed with color inks having light curability on a base member with liquid repellency. A tint image with a dot area rate 1 to 40% is generated with a second threshold matrix where the number of halftone dots defined in a unit area in an image generated with the second threshold matrix is smaller than that in an image generated with the first threshold matrix, and the tint image is printed with clear ink having light curability. On the base member, halftone dots of the clear ink are distributed according to the tint image, and relatively large projections and depressions are macroscopically uniformly formed with lessening small projections and depressions of the color inks, to acquire a printed matter with uniform gloss.

Owner:DAINIPPON SCREEN MTG CO LTD

Coated photographic papers

InactiveUS6177222B1Uniform glossSmooth image surfaceDuplicating/marking methodsDevelopersPolyesterPhotographic paper

Owner:XEROX CORP

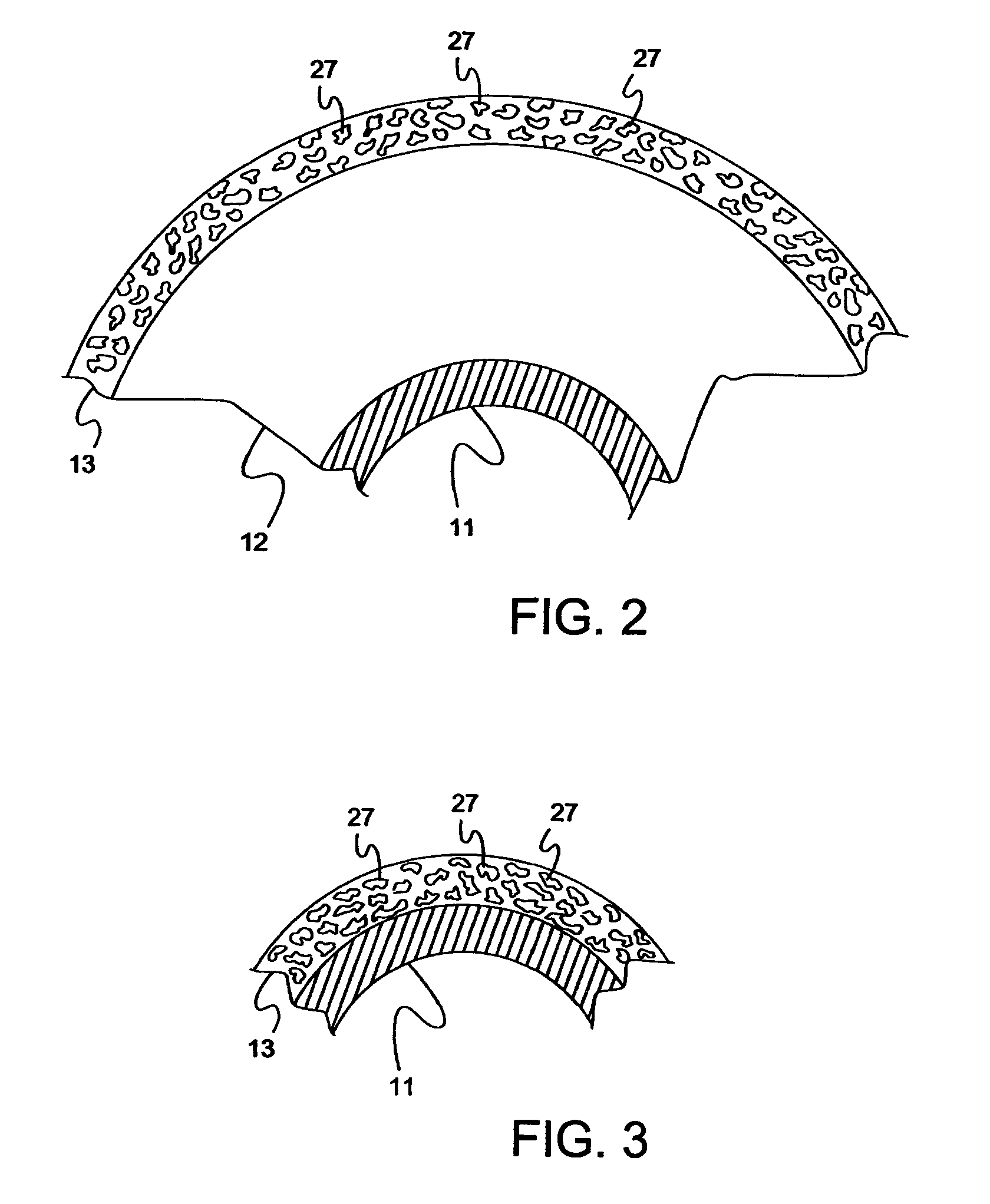

Process for electrostatographic reproduction

ActiveUS7195853B1Highly desirable low gloss imageLower surface energyDevelopersElectrographic process apparatusSurface layerEngineering

A process for fusing toner to paper. The toner fusing system for conducting this process includes a fuser roller consisting of a base, and a fusing surface layer that includes both a fluoroelastomer continuous phase, and also a discontinuous phase dispersed through the continuous phase in the form of domains.

Owner:EASTMAN KODAK CO +1

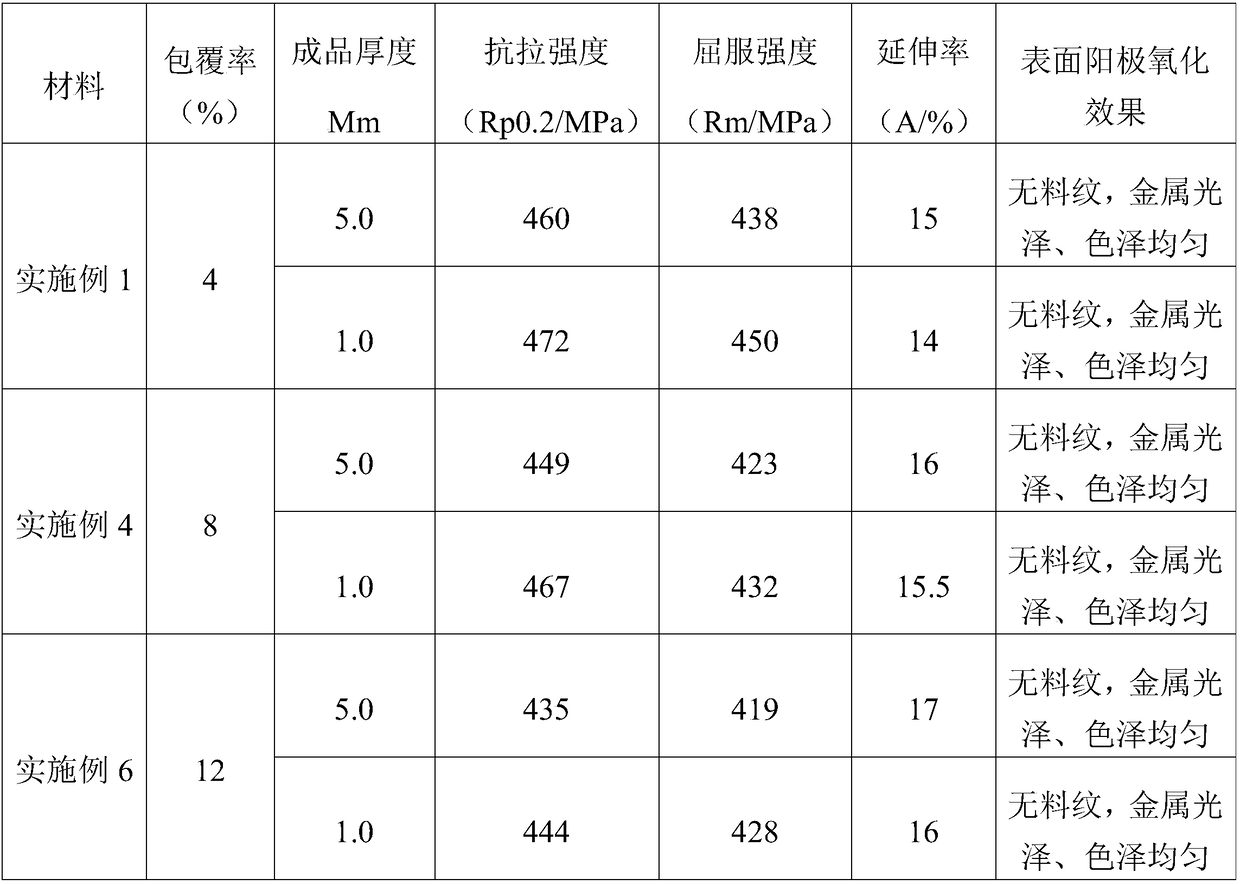

Preparation method of 1xxx/7xxx aluminium-alloy composite material

ActiveCN108909138AHigh hardnessHigh strengthLamination ancillary operationsLaminationHardnessAlloy composite

The invention discloses a preparation method of a 1xxx / 7xxx aluminium-alloy composite material. The preparation method comprises the following steps of: (1) preparation of a core-layer alloy casting plate and a coating-layer alloy casting plate; (2) surface treatment: respectively carrying out surface treatment on the core-layer alloy casting plate and the coating-layer alloy casting plate obtained in the step (1); (3) welding fixation: carrying out welding fixation on the core-layer alloy casting plate and the coating-layer alloy casting plate after surface treatment in the step (2) accordingto a coating-layer / core-layer combined mode; (4) preheating and hot rolling: preheating the alloy casting plate welded in the step (3), carrying out hot-rolling bonding and following machining according to the thickness of a finished product after the heating is finished to obtaining a product. The preparation method disclosed by the invention has the beneficial effects that two layers of aluminium-alloy composite plates have the characteristics of high hardness and high strength, meanwhile the anodic oxidation effect of an electronic product is obviously improved, so that after the anode ofthe electronic product is oxidized and colored, the surface has metallic luster and is uniform in color.

Owner:广西南南铝加工有限公司

Plastic floor surface treatment method

InactiveCN110053383AClear patternThree-dimensionalDuplicating/marking methodsSpecial surfacesLacquerEngineering

The invention discloses a plastic floor surface treatment method. A plastic floor comprises a base material, and the method comprises the following steps of firstly, base material surface treatment, wherein one or multiple UV paint is coated on the surface of the base material in a rolling manner to form the coating before printing; secondly, pattern layer setting, wherein through a digital printing device, pattern jet printing is carried out on the coating before printing, and if chamfers or irregular shapes appear on the edge of the floor, the printed pattern needs to cover the whole floor;thirdly, grain layer setting, wherein a registering or non-registering grain layer is arranged on the pattern layer, the printing device is directly used for printing stacked UV paint on the pattern,after curing, prominence operation is carried out to form grains, or a rubber roller with a grain path is used for roller coating of UV, and after curing, a concave and convex grain is formed; and fourthly, protection layer setting, wherein the roller coating, shower coating or spraying manner is used for coating of the protection paint or glue on the grain layer to form a wear-resisting layer. The plastic floor surface treatment method is clear in pattern, unified in luster and capable of achieving third dimension and durable appearing.

Owner:ZHEJIANG KINGDOM NEW MATERIAL GRP CO LTD

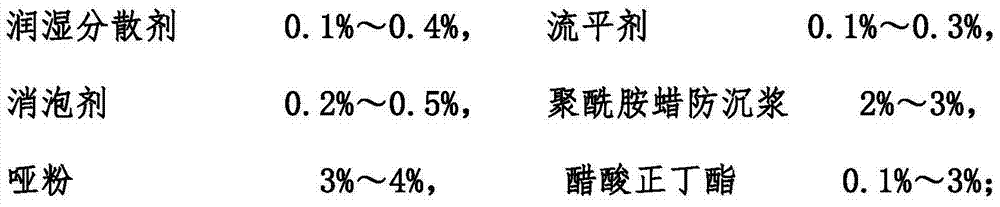

Environment-friendly curtaining odor-removing PU matted varnish and preparation method thereof

InactiveCN106349920AUniform transparencyUniform flatnessPolyurea/polyurethane coatingsCyclohexanoneFatty acid

The invention relates to an environment-friendly curtaining odor-removing PU matted varnish and a preparation method of the environment-friendly curtaining odor-removing PU matted varnish, and belongs to the technical field of wooden coating manufacturing. The environment-friendly curtaining odor-removing PU matted varnish is prepared by mixing component A, component B, and component C according to the weight ratio of 1: 0.5: 0.4-0.7; the component A is composed of fatty acid modified odor removal alkyd resin, short-oil castor oil alkyd resin, polyamide wax anti-sediment, wetting dispersant, flatting agent, antifoaming agent, modified polyethylene wax powder, matt powder, propylene glycol monomethyl ether acetate, cyclohexanone, ethylene glycol diacetate, 50% by mass of nitrocotton fluid, and n-butyl acetate; the component B is composed of aliphatic series polyisocyanate, TDI tripolymer curing agent, TDI prepolymer, and n-butyl acetate; the component C is composed of xylene, n-butyl acetate, propylene glycol monomethyl ether acetate, acetate, and ethylene glycol diacetate. The coating has strong adhesive force, good transparency, high fullness, good flexibility, good scratching resistance, uniform gloss, stability and impact-resistance, and good waterproof and chemical resistance.

Owner:山东巴德士新材料有限公司

Preparation method of natural vitamin E soft capsules

ActiveCN104095826ASame sizeUniform glossOrganic active ingredientsSenses disorderEngineeringVitamin E

The invention discloses a preparation method of natural vitamin E soft capsules. The method includes following steps: (1) material obtaining; (2) material weighing and preparing; (3) gelatin melting; (4) material proportioning; (5) a capsule-pressing process; (6) a drying process; (7) a capsule-picking process; (8) a polishing process; (9) a re-drying process; (10) an internally packaging process; and (11) an externally packaging process. According to the preparation method of the natural vitamin E soft capsules, two drying processes are carried out in the preparation method, wherein the first drying process is carried out after the capsule-pressing process to form the capsules and the further drying process is carried out after the polishing process so that the capsules are uniform in size and gloss and are high in rate of finished products and waste is reduced.

Owner:BRAVEIY BIOTECHNOLOGY (ANHUI) CO LTD

Thermal transfer recording medium

InactiveCN101486282AImprove adhesionEasy to separateThermographyOther printing apparatusFluorocarbonGlass transition

The application discloses a thermal transfer recording medium having at least one transferable protective layer arranged on a base with a non-transferable release layer provided therebetween, in which the protective layer is detached from the release layer at the interface between the at least one protective layer and the release layer during thermal transfer printing and then thermally transferred onto an image, includes a primer layer containing at least one fluorocarbon-based surfactant, the primer layer, the release layer, and the protective layer being stacked, in that order, on one surface of the base, in which the release layer has a glass transition temperature of 60 DEG C to 110 DEG C.

Owner:SONY CORP

Ultraviolet curable coating

InactiveUS20120015110A1Minimizing and eliminating gloss bandingUniform glossPolyurea/polyurethane coatingsUV curingUltraviolet

Ultraviolet curable compositions are disclosed that can be applied to achieve a uniform gloss after curing even under conditions of varying ultraviolet intensity during curing, that do not require continuous agitation to keep flattening agents and other additives suspended prior to application of the composition, and / or which do not exhibit a significant increase in viscosity over time in a roll coater application.

Owner:ARMSTRONG WORLD INDUSTRIES

Quick heating and quick cooling highlight molding die

Owner:CHINA HUALU PANASONIC AVC NETWORKS

Simple painted metal imitation fluorocarbon paint

The invention discloses a metal-like fluorocarbon paint for simple painting of outer wall, composed of components A, B and C packaged independently, and preparation method thereof; wherein, the component A (paint) comprises: fluorocarbon resin, anti-settling agent, flake cellulose vinyl acetate, anti-foam agent, butyl acetate, dimethylbenzene, fluorocarbon modified polyacrylic acid leveling agent, organic modified siloxane smoothening leveling agent, metal pigment paste, photo-stabilizer, and Ultraviolet absorber UV-1; the component B comprises: solidifier; the component C comprises: diluting agent; detailed proportion and preparation method thereof are referred to specification. The invention is provided with the following advantages of: 1, low cost; 2, easy to paint without surface paint glazing; 3, uniform color and luster; 4, extremely long weathering resistance; 5, excellent chemical resistance; 6, excellent pollution resistance. The invention is appropriate for painting and protecting outer wall surface.

Owner:GUANGDONG SANVO CHEM IND TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com