PU anti-yellowing flat vanish sprayed on white finish for woodware

A white finish and anti-yellowing technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of yellowing, aging, darkening, and color loss of the paint film, and achieve easy spraying and good gloss and color retention , good leveling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

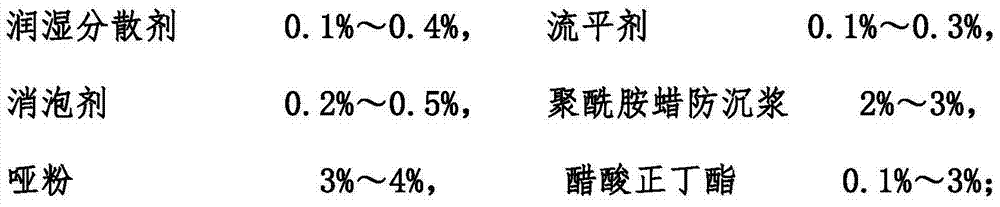

[0051] A kind of PU anti-yellowing matte varnish sprayed on the white finish paint for woodware, consists of the following components by weight percentage:

[0052] Component A:

[0053]

[0054] HDI curing agent 28%, dehydrated n-butyl acetate 72%;

[0055] Among them, component A and component B are stored separately. When using, mix component A and component B according to the weight ratio of 1:0.2 and then dilute.

[0056] Described cellulose acetate liquid is made up of following weight percent components:

[0057] Cellulose acetate 20%, n-butyl acetate 80%.

[0058] Described polyamide wax anti-settling slurry is made up of following weight percent components:

[0059] Polyamide Wax 30%, Xylene 70%.

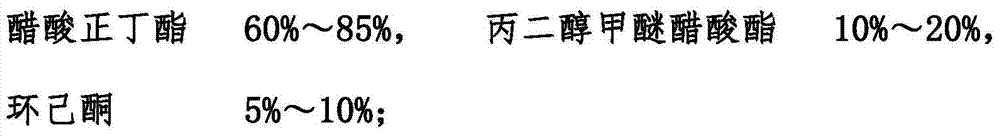

[0060] As a further improvement: the PU anti-yellowing matte varnish sprayed on the white topcoat for the described a kind of woodware also includes component C for dilution, and the component C is composed of the following components in percentage by weight :

[0...

Embodiment 2

[0082] A kind of PU anti-yellowing matte varnish sprayed on the white finish paint for woodware, consists of the following components by weight percentage:

[0083] Component A:

[0084]

[0085] Component B:

[0086] HDI curing agent 40%, dehydrated n-butyl acetate 60%;

[0087] The sum of the percentages of each component of component A meets 100%, and the sum of the percentages of each component of component B meets 100%;

[0088] Among them, component A and component B are stored separately. When using, mix component A and component B according to the weight ratio of 1:0.3 and then dilute.

[0089] As a further improvement: it also includes component C for dilution, and the component C is made up of the following components in percentage by weight:

[0090] n-butyl acetate 85%, propylene glycol methyl ether acetate 10%, cyclohexanone 5%;

[0091] The sum of the percentages of each component of component C satisfies 100%.

[0092] The weight ratio of the components ...

Embodiment 3

[0094] A kind of PU anti-yellowing matte varnish sprayed on the white finish paint for woodware, consists of the following components by weight percentage:

[0095] Component A:

[0096]

[0097] Component B:

[0098] HDI curing agent 30%, dehydrated n-butyl acetate 70%;

[0099] The sum of the percentages of each component of component A meets 100%, and the sum of the percentages of each component of component B meets 100%;

[0100] Among them, component A and component B are stored separately. When using, mix component A and component B according to the weight ratio of 1:0.2~0.3 and then dilute.

[0101] Described cellulose acetate liquid is made up of following weight percent components:

[0102] Cellulose acetate 20%, n-butyl acetate 80%.

[0103] Described polyamide wax anti-settling slurry is made up of following weight percent components:

[0104] Polyamide Wax 30%, Xylene 70%.

[0105] As a further improvement, it also includes component C for dilution, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com