Quick heating and quick cooling highlight molding die

A rapid cooling and rapid heating technology, which is applied in the field of molding molds for plastic products, can solve problems such as uneven gloss, flow marks, and influence on appearance quality of products, and achieve the effect of ensuring uniform appearance quality and gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

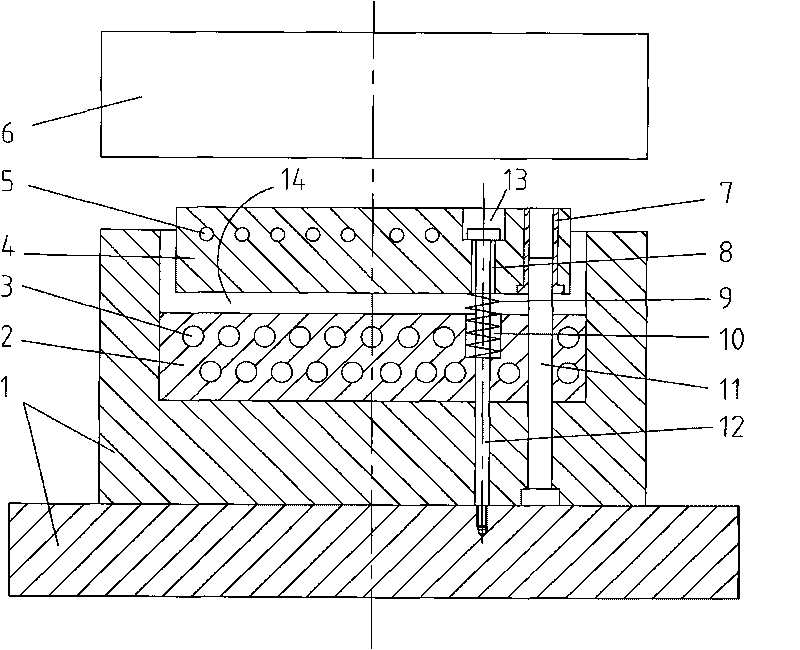

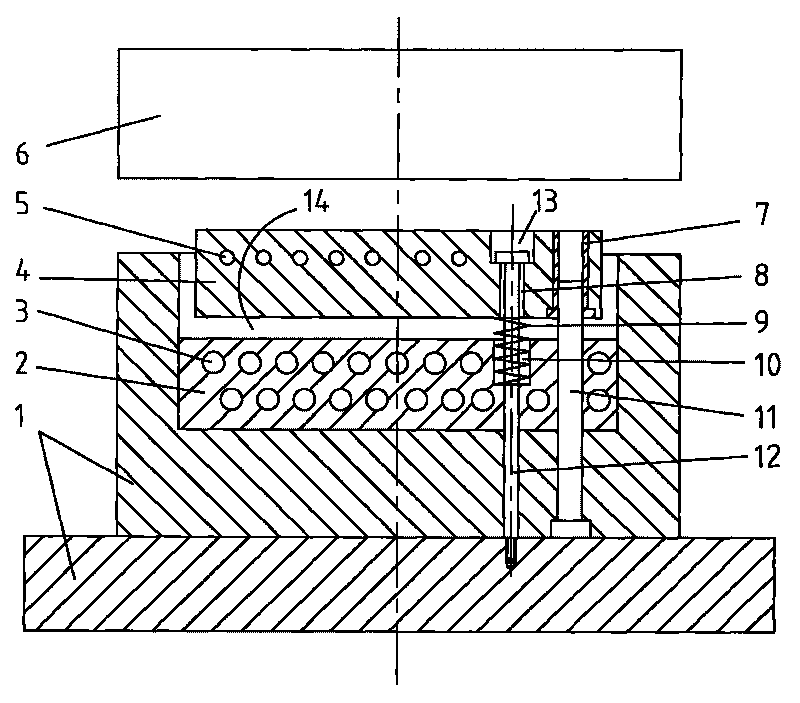

[0010] like figure 1 As shown: 1 is a fixed mold, which is located below; 6 is a movable mold, which is located above the lower mold 1.

[0011] A cooling block 2 with a cooling liquid channel 3 is fixedly installed on the inner side of the fixed mold 1, that is, at the bottom of the inner cavity. There is a floating insert 4 above the cooling block 2, and a workpiece cavity is formed between the floating insert 4 and the movable mold 6. .

[0012] A coaxial nut hole 13 and a limit hole 8 are processed on the floating insert 4. The diameter of the limit hole 8 is smaller than the diameter of the nut hole 13. The limit hole 8 is located below the nut hole 13. In the limit hole 8 and the junction of nut hole 13 form a step. A spring hole 10 is processed on the cooling block 2 .

[0013] There is an elastic piece between the floating insert 4 and the cooling block 2 to maintain the gap 14 between the two, the elastic piece is a spring 9, the spring 9 is located in the spring h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com