Simple painted metal imitation fluorocarbon paint

A technology of imitating metal and fluorocarbon paint, which is applied in the field of imitating metal fluorocarbon paint and its preparation, can solve the problems of poor fullness, uneven color and gloss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

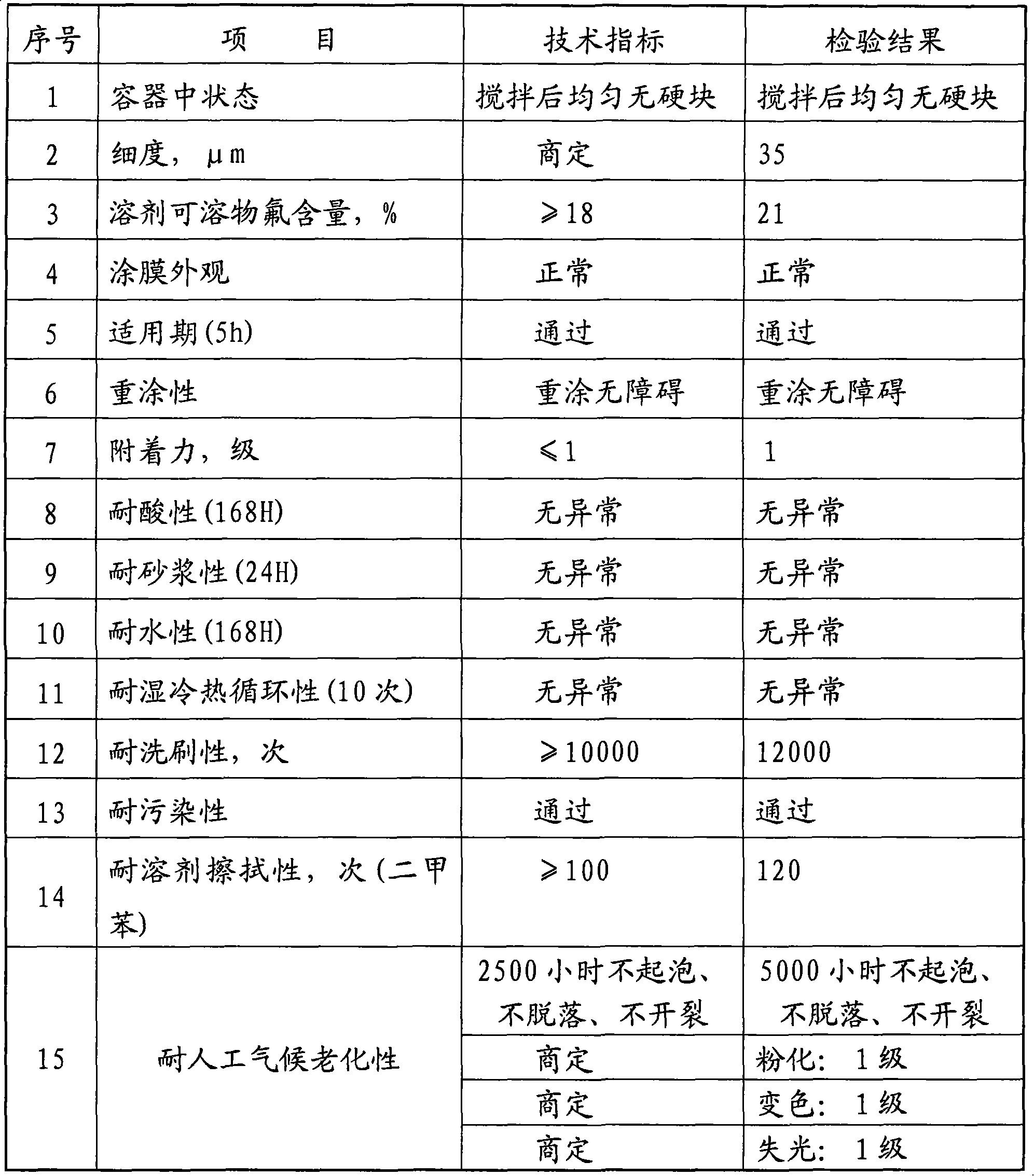

Examples

Embodiment 1

[0025] First, weigh the raw materials in proportion, put 65 parts of fluorocarbon resin into the dispersion tank, add 10 parts of anti-settling agent, 6 parts of vinyl acetate cellulose pulp, and 0.2 parts of defoamer, and stir for 5 minutes at a speed of 800 rpm , and then put in 6 parts of butyl acetate, 4.1 parts of xylene, 0.2 parts of fluorocarbon modified polyacrylic acid leveling agent, 0.1 part of organically modified silicone smoothing and leveling agent, 8 parts of metal pigment paste, light stabilizer 0.2 parts, ultraviolet absorber UV-10.2 parts, and then disperse at a high speed of 1000-1200 rpm for 10-15 minutes. After the metal pigment paste is completely dispersed and uniform, it is discharged after passing the test, and the finished component A is made. Component distribution ratio A (paint): B (curing agent): C (diluent) = 1: 0.1: 0.3-0.5.

Embodiment 2

[0027] First, weigh the raw materials in proportion, put 68 parts of fluorocarbon resin into the dispersion tank, add 11 parts of anti-settling agent, 6 parts of vinyl acetate cellulose pulp, and 0.2 parts of defoamer, and stir for 5 minutes at a speed of 800 rpm , and then put in 4 parts of butyl acetate, 2 parts of xylene, 0.2 parts of fluorocarbon modified polyacrylic acid leveling agent, 0.1 part of organically modified silicone smoothing and leveling agent, 8.1 parts of metal pigment paste, light stabilizer 0.3 parts, ultraviolet absorber UV-10.1 parts, and then disperse at a high speed of 1000-1200 rpm for 10-15 minutes. After the metal pigment slurry is completely dispersed and uniform, it is discharged after passing the test, and the finished component A is made. Component distribution ratio A (paint): B (curing agent): C (diluent) = 1: 0.1: 0.3-0.5.

Embodiment 3

[0029] First, weigh the raw materials in proportion, put 72 parts of fluorocarbon resin into the dispersion tank, add 9 parts of anti-settling agent, 5 parts of vinyl acetate cellulose pulp, and 0.2 parts of defoamer, and stir for 5 minutes at a speed of 800 rpm , then put in 3.1 parts of butyl acetate, 2 parts of xylene, 0.2 parts of fluorocarbon modified polyacrylic acid leveling agent, 0.1 part of organically modified silicone smoothing and leveling agent, 8 parts of metal pigment paste, light stabilizer 0.3 parts, 0.1 parts of ultraviolet absorber UV-1, and then disperse at a high speed of 1000-1200 rpm for 10-15 minutes, wait until the metal pigment slurry is completely dispersed and uniform, and the material is discharged after passing the test, that is, the finished product component A . Component distribution ratio A (paint): B (curing agent): C (diluent) = 1: 0.1: 0.3-0.5.

[0030] Names and technical indicators of main raw materials:

[0031] 1. Fluorocarbon resin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com