Patents

Literature

311results about How to "Improves stain resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

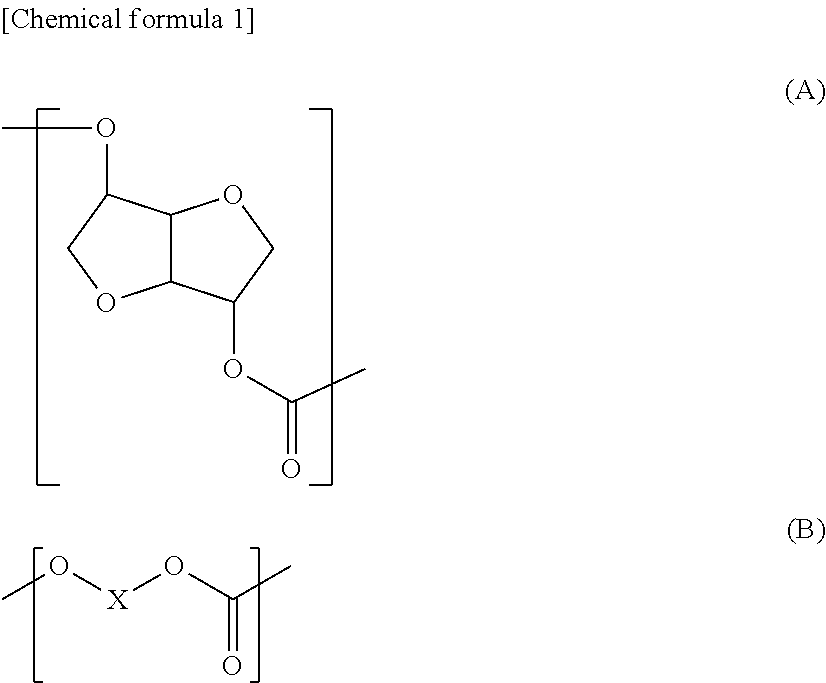

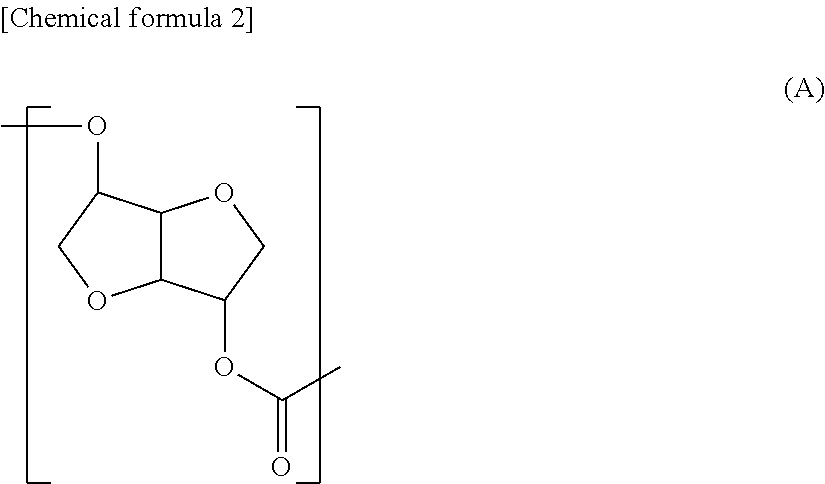

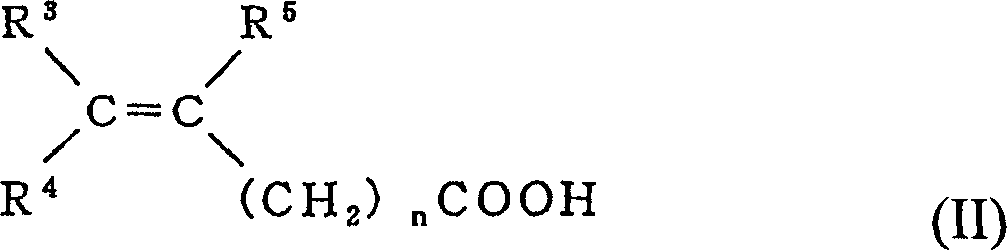

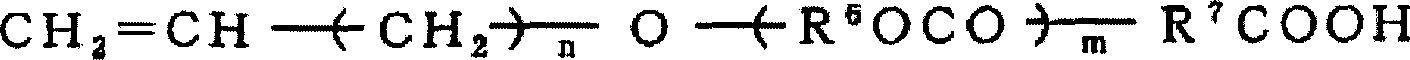

Polycarbonate diol and producing method thereof, and polyurethane and active energy ray-curable polymer composition both formed using same

ActiveUS20130109804A1Improves stain resistanceHigh hardnessOrganic chemistryPolyureas/polyurethane adhesivesMethacrylateElastomer

A novel polycarbonate diol is useful as a raw material for producing a polycarbonate diol-based polyurethane with a high degree of hardness, superior abrasion resistance, and superior hydrophilicity. The polyurethane is useful in paints, coating agents, synthetic leathers, artificial leathers, and highly-functional elastomers, or the like. The polycarbonate diol is also useful for producing an active-energy radiation curable polymer composition giving a cured film having superior contamination resistance and high degree of hardness. The curable polymer composition contains a urethane(meth)acrylate oligomer obtained from the polycarbonate diol. The polycarbonate diol is obtained, for example, by reacting two specific types of diols with diester carbonate in the presence of a transesterification catalyst. The catalyst has a metal of Group 1 or 2 on the periodic table. A metal content of the transesterification catalyst is 100 weight ppm or less.

Owner:MITSUBISHI CHEM CORP

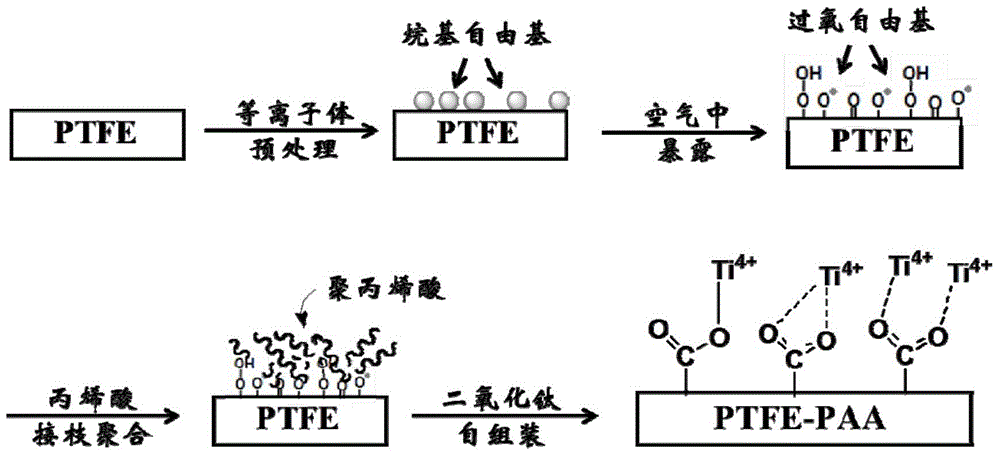

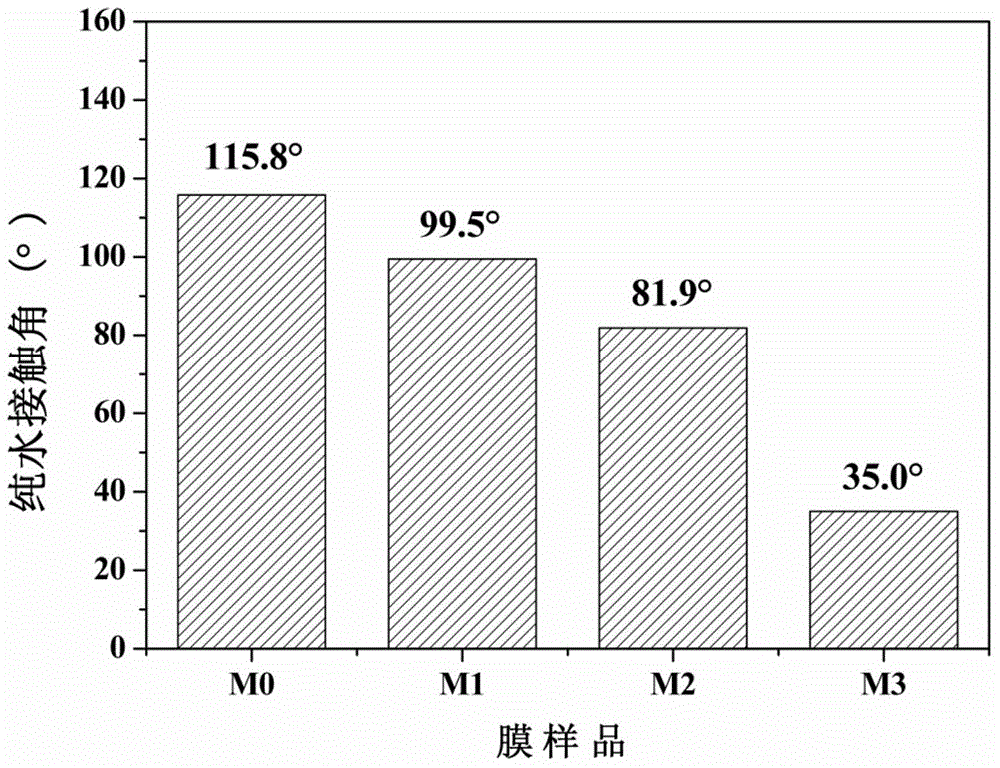

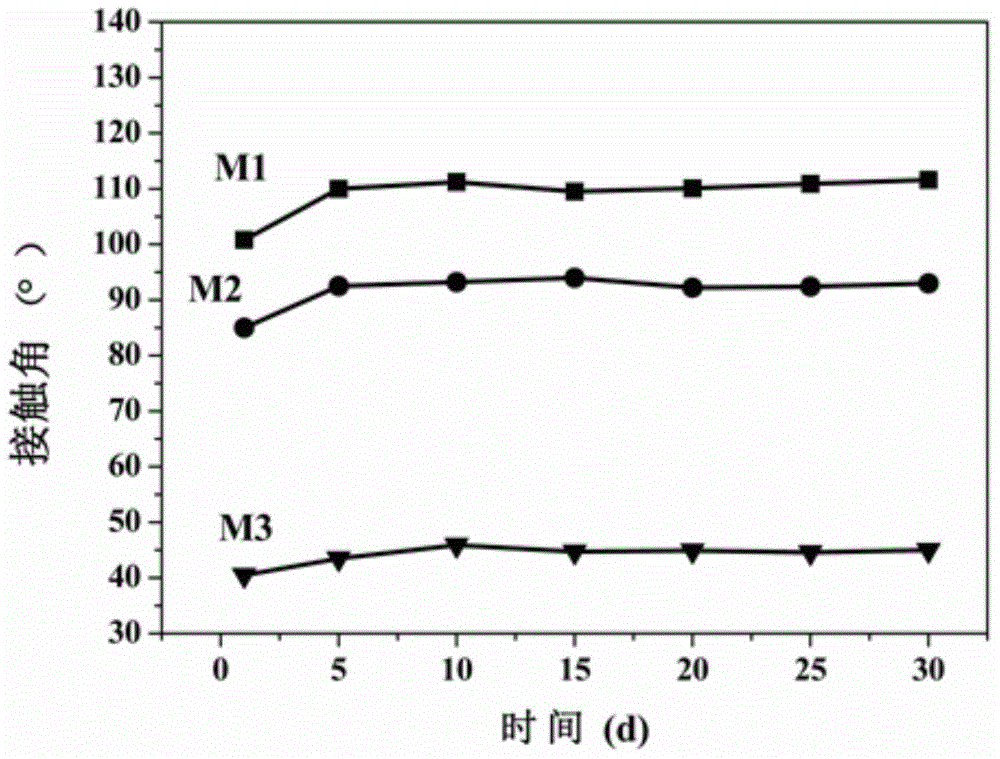

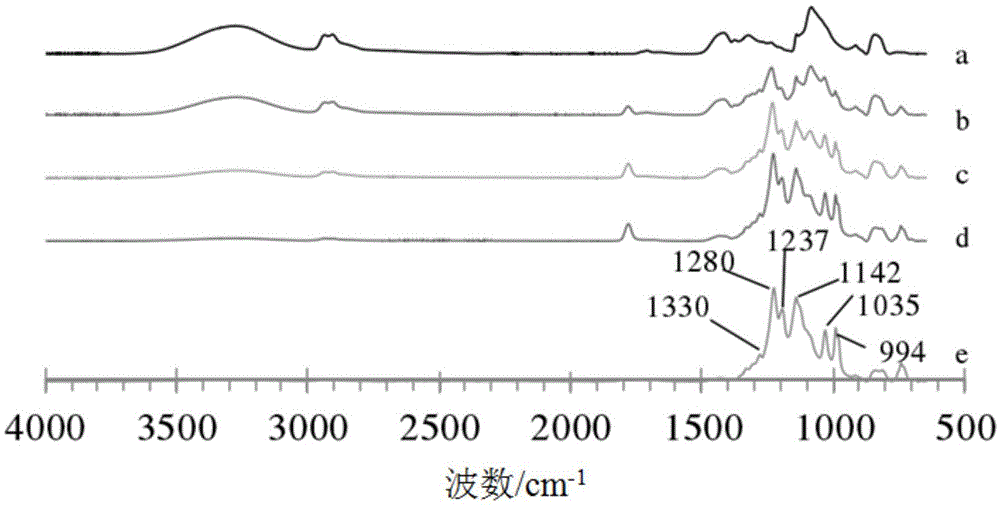

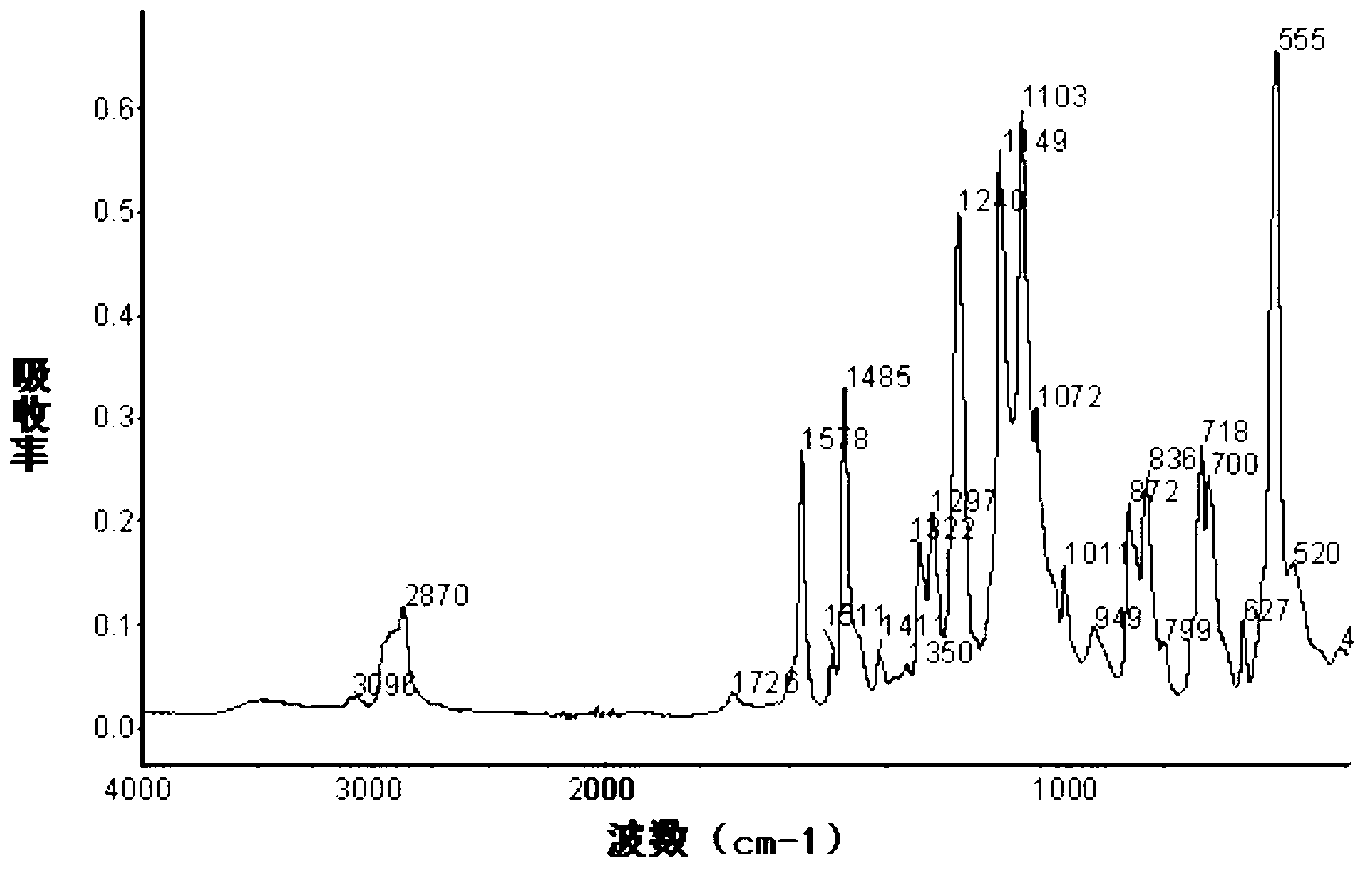

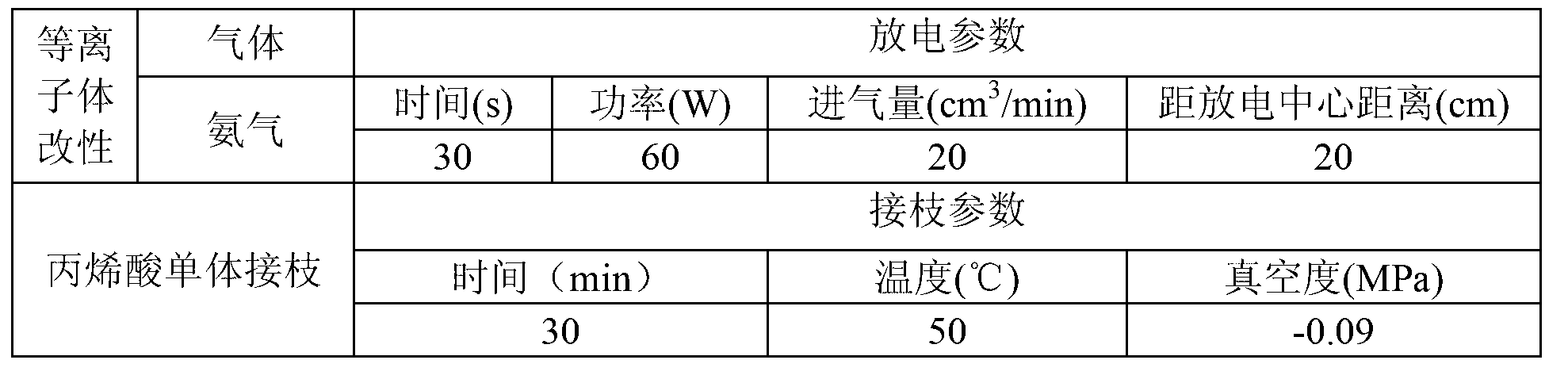

Hydrophilic modification method for polytetrafluoroethylene membrane

ActiveCN104998562AImprove featuresImprove filtering effectSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisGlass sheetVacuum drying

The inveniton provides a hydrophilic modification method for a polytetrafluoroethylene membrane. The method comprises the following steps: step 1, subjecting the polytetrafluoroethylene membrane to plasma treatment under a nitrogen atmosphere, and allowing the surface of the polytetrafluoroethylene membrane to generate relatively-stable free radicals and active sites; step 2, placing the polytetrafluoroethylene membrane into an acylic acid solution and carrying out static impregnation for a period of time, then taking the polytetrafluoroethylene membrane out of the solution and then placing the polytetrafluoroethylene membrane between two glase plates, and carrying out thermochemical polymerization in a vacuum drying oven so as to obtain the polytetrafluoroethylene membrane with the surface grafted with polyacrylic acid; and step 3, subjecting the polytetrafluoroethylene membrane to static impregnation in a titanium dioxide sol for a period of time, and allowing titanium dioxide to be assembled onto the surface of the polytetrafluoroethylene membrane through the coordination effect of metal titanium-ion Ti4+ and a carboxyl group on the polyacrylic acid so as to obtain a hydrophilic modified polytetrafluoroethylene membrane. The hydrophilic modified polytetrafluoroethylene membrane prepared by using the method in the invention retains excellent properties of a conventional polytetrafluoroethylene membrane and greatly improves filter performance, hydrophilic property, pollution resistant property and photocatalytic property of the polytetrafluoroethylene membrane.

Owner:深圳市新纳捷科技有限公司

Highly-flame-retardant modified acrylate coating

InactiveCN104263182AGood flame retardancyStrong heat resistanceFireproof paintsPolyurea/polyurethane coatingsAmmonium polyphosphateEmulsion

The invention discloses a highly-flame-retardant modified acrylate coating. The raw materials for preparing the coating comprise the following ingredients: 65-80 parts of phosphate ester modified acrylic emulsion, 5-10 parts of polysiloxane, 3-10 parts of waterborne polyurethane emulsion, 2-6 parts of resorcinol bis(diphenyl) phosphate, 0.5-1.8 parts of tri-isopropylphenyl phosphate, 10-30 parts of nanometer aluminum hydroxide, 15-32 parts of titanium dioxide, 5-20 parts of nano-silica, 19-35 parts of ammonium polyphosphate, 5-10 parts of dipentaerythritol, 3-10 parts of beta-cyclodextrin, 3-8 parts of an organic solvent, 3-5 parts of a film-forming additive, 2-5 parts of an auxiliary, and 30-60 parts of water. The highly-flame-retardant modified acrylate coating disclosed by the invention is good in flame retardancy, high in heat resistance, high in strength, and long in service life.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

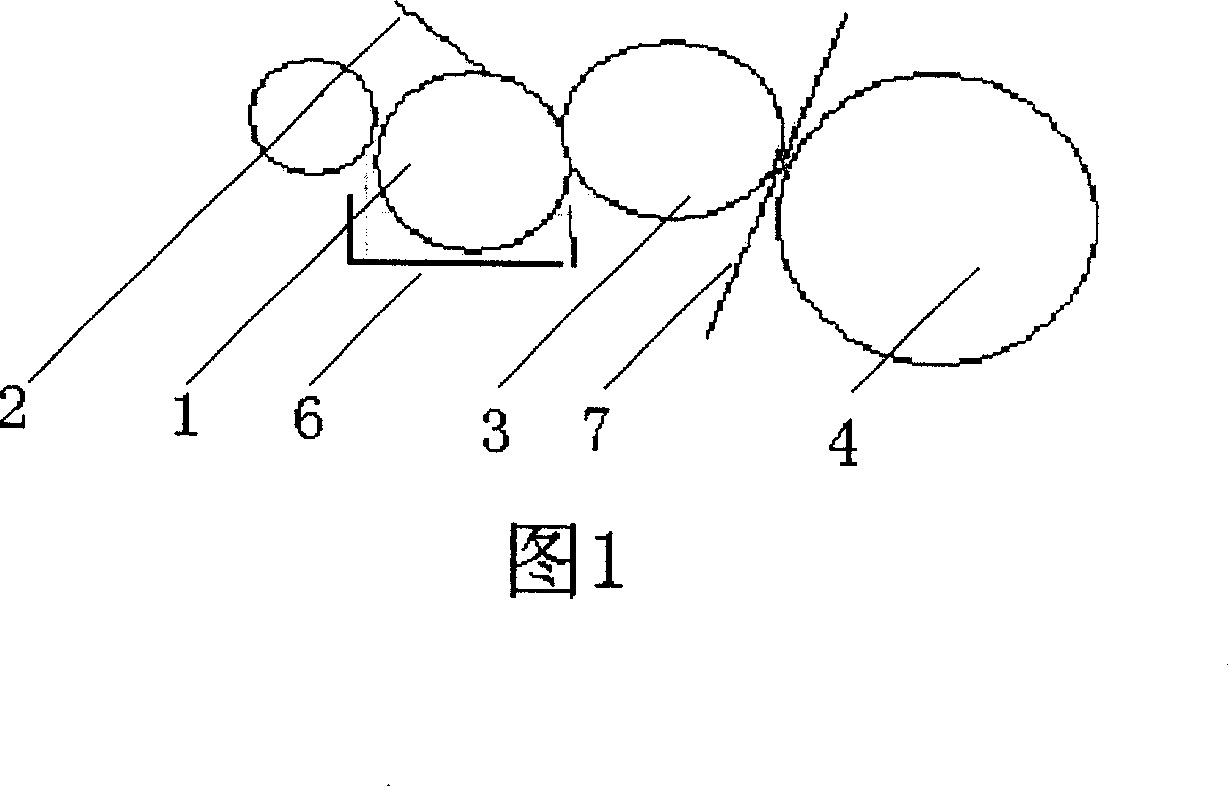

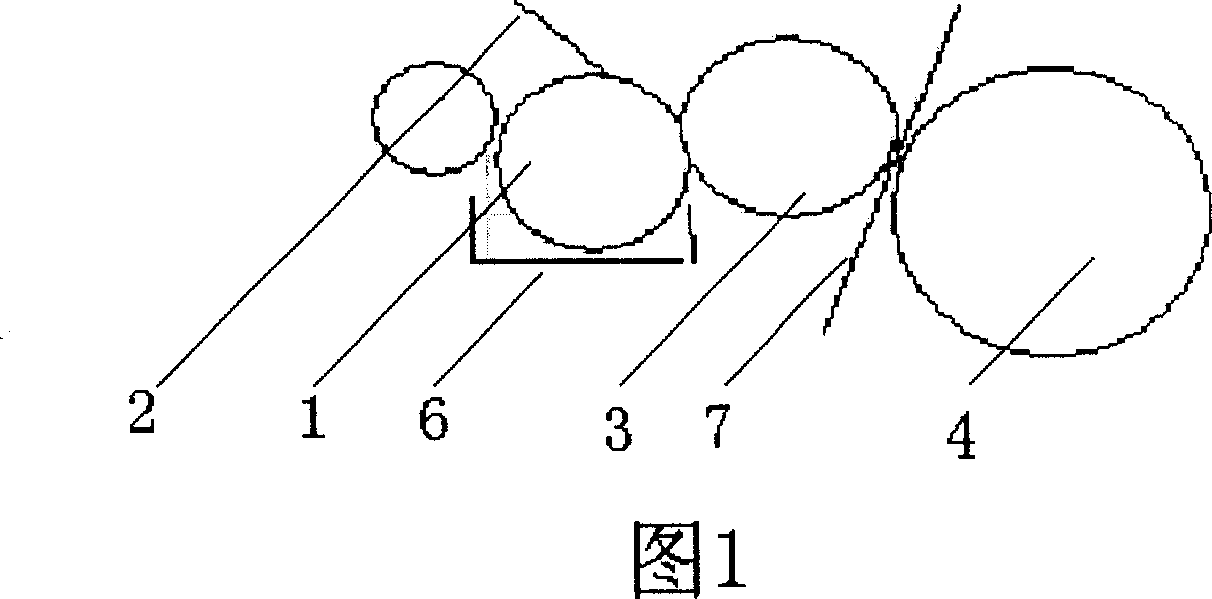

Printing decoration metallic plate capable of panel beating and manufacturing method thereof

ActiveCN101077676AGood decorative effectImprove product gradeSpecial ornamental structuresCoatingsSheet steelSurface tension

The present invention is printed metal plate and its making process. On the surface of coated steel sheet, patterns are first printed with ink fitting the surface coating of steel sheet and through intaglio offset printing, and high temperature cured paint or UV cured paint is then roller coated to the surface of the patterns. The printed metal plate has high decorating effect. Compared with available technology, the present invention has the advantages of environment friendship and low cost.

Owner:青岛河钢复合新材料科技有限公司 +1

Hydrophilic oleophobic polymer and preparation method thereof, and application thereof in humidity response oil and water separating membrane

InactiveCN103601826AGood water and solvent resistanceLow costSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisCarboxylationSewage

The invention discloses a hydrophilic oleophobic polymer and preparation method thereof, and application thereof in humidity response oil and water separating membrane. The preparation of the hydrophilic oleophobic polymer comprises the following steps: carrying out an esterification reaction of polyvinyl alcohol and perfluorocarboxylic acid or firstly carrying out a carboxylation of polyvinyl alcohol and then a neutralization reaction of the intermediate product and perfluorotertiary amine. When the product is used, a fabric silk screen is cleaned with ultrasonic sound; 10-50 parts of hydrophilic oleophobic polymer, 50-500 parts of nanometer sol, 1-5 parts of cross-linking agents and 1-5 parts of catalysts are dispersed uniformly; the mixed liquor is dip-coated or spray-coated on the surface of the membrane, and after drying and crosslinking, the humidity response super-hydrophilic and super-oleophobic oil and water separating net membrane. According to the invention, hydrophilic groups are distributed surrounding the hydrophobic chain segment on the surface of the net membrane with humidity responsiveness, and contact angle in the air of the product to water is reduced to 0 degree from more than 90 degrees, and the contact angle in air and water of the product to oil is above 150 degrees, so the product has a low adherence characteristic of droplet. The net membrane is used for separating oil and water mixture and processing oil-containing sewage.

Owner:SOUTH CHINA UNIV OF TECH

Normal-temperature multiple curing organic-inorganic hybridized aqueous nano polyurethane woodware coating and preparation method thereof

InactiveCN101798483ANo pollution in the processNon-flammablePolyurea/polyurethane coatingsIn situ polymerizationDouble bond

The invention discloses a normal-temperature multiple curing organic-inorganic hybridized aqueous polyurethane woodware coating and a preparation method thereof. The coating mainly contains organic-inorganic hybridized aqueous nano polyurethane latex, a film-forming assistant, a defoaming and foam inhibitor, a flatting agent, a base material wetting agent, a stable dispersing agent, a thickening agent and an aqueous photo initiator, wherein the organic-inorganic hybridized aqueous nano polyurethane latex is prepared by firstly obtaining a polyurethane prepolymer by pre-polymerizing, and then adding an inorganic nano material in an organic-inorganic hybridization way by an in-situ polymerization technology, and finally grafting a photo-curing end-capping agent containing active functional groups and C-C double bonds. The normal-temperature multiple curing organic-inorganic hybridized aqueous polyurethane woodware coating is obtained by adding and dispersing pigment fillings and an assistant evenly in the organic-inorganic hybridized aqueous nano polyurethane latex. The invention not only solves the pollution problem of a solvent-type VOC (Volatile Organic Compound) coating, but also solves the problem of aqueous coatings which have the defects of poor toughness and poor performances in weather resistance, aging resistance, acid resistance, alkaline resistance and solvent resistance.

Owner:SICHUAN UNIV +1

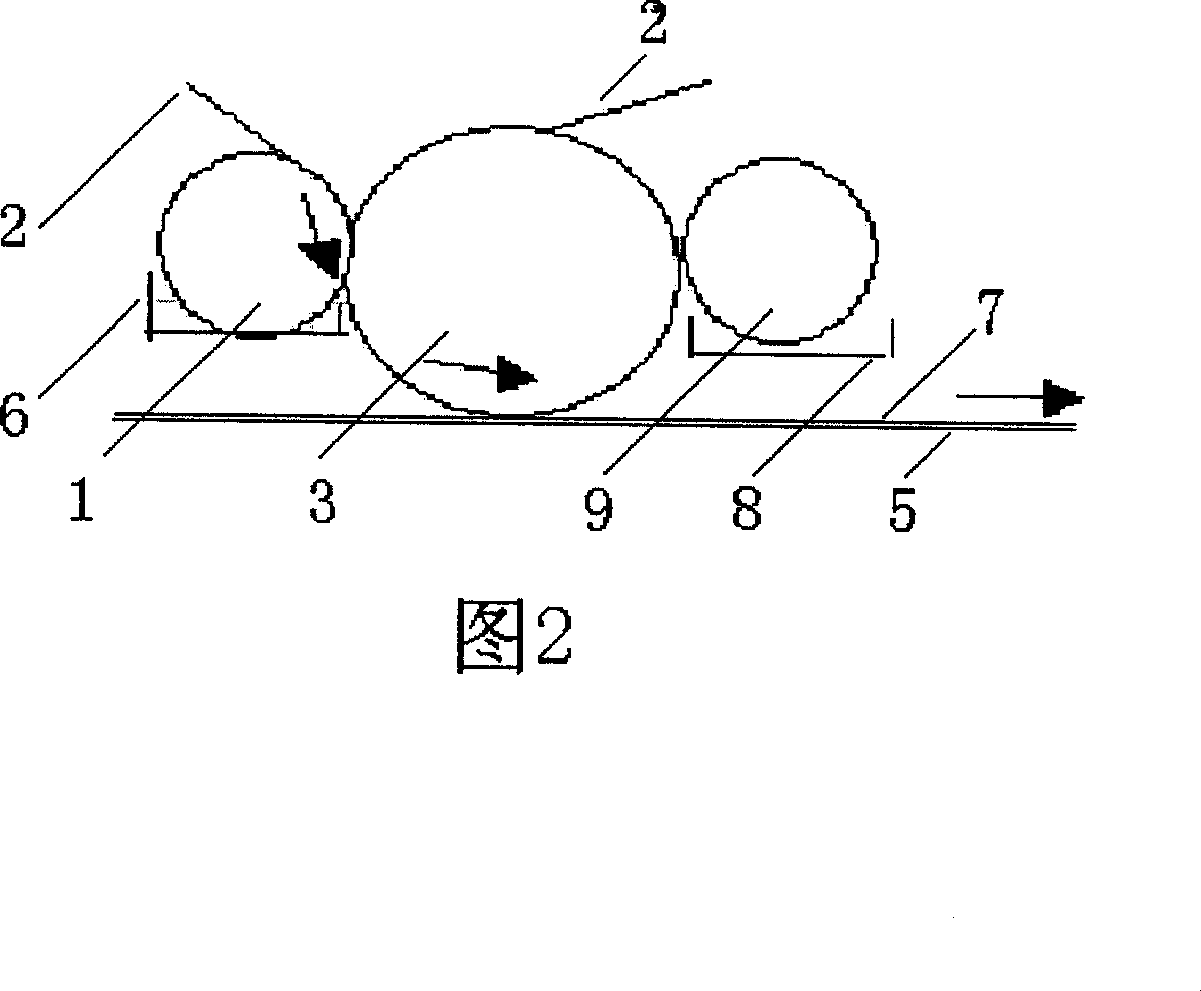

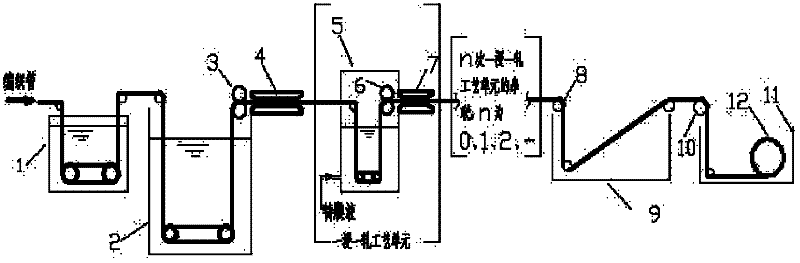

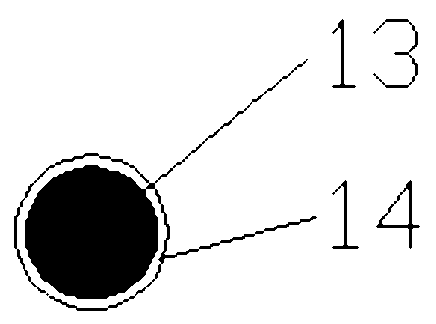

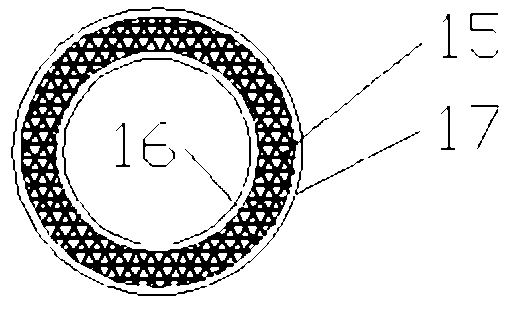

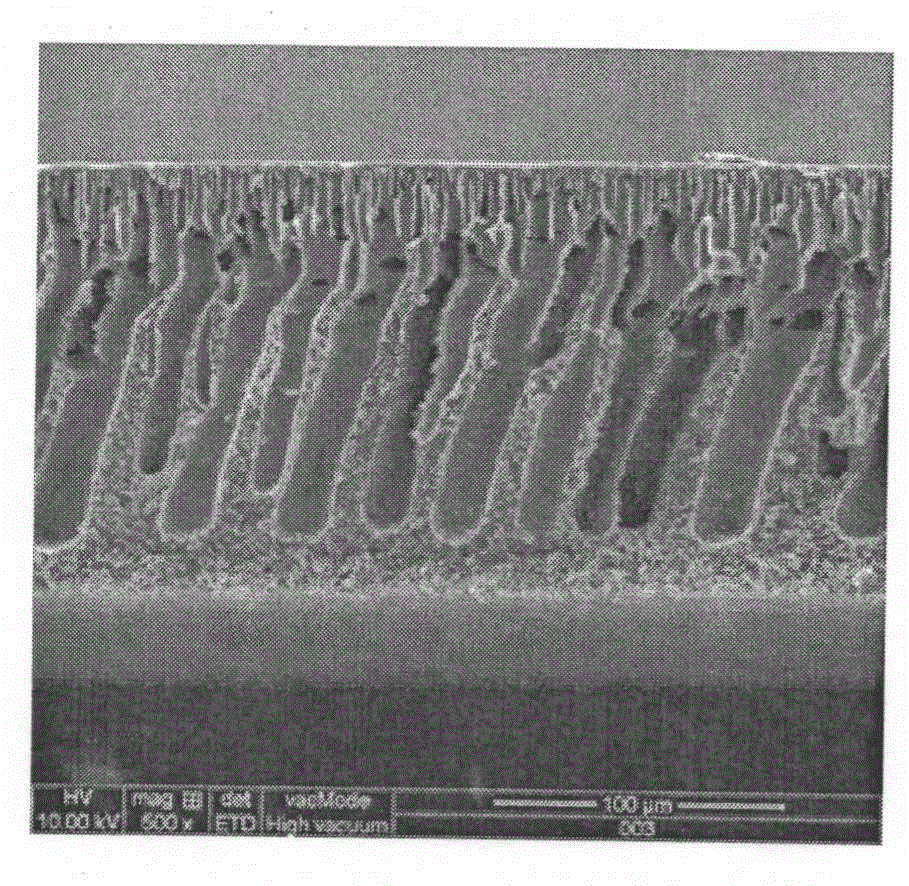

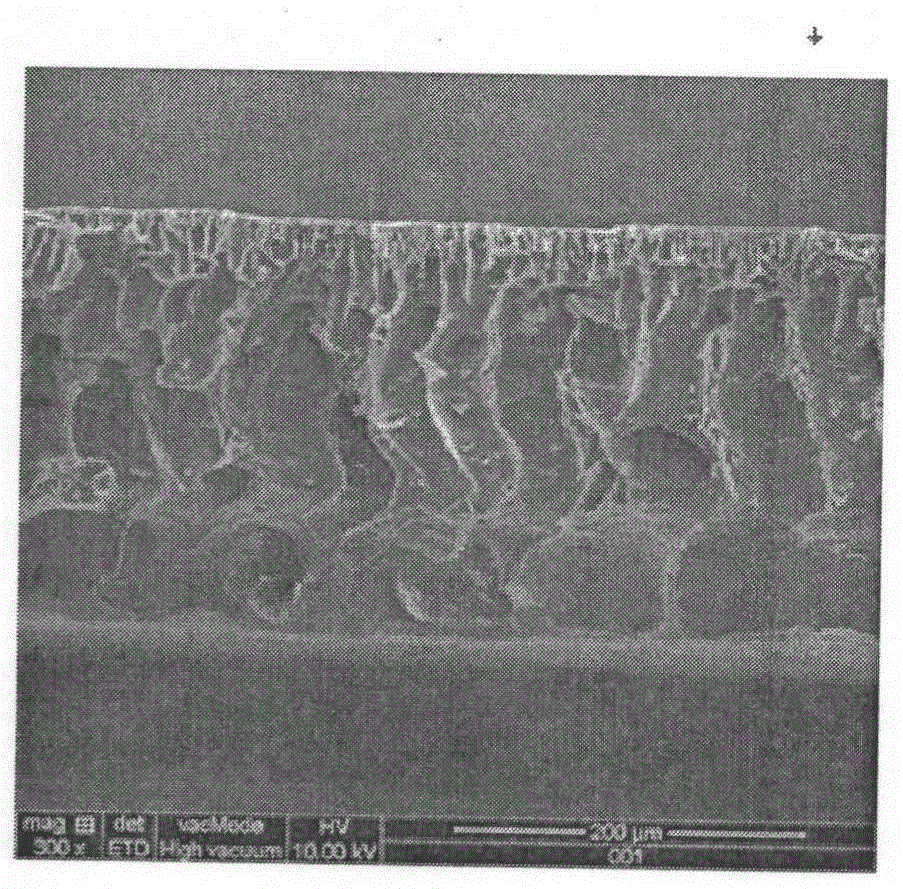

Preparation method of hollow fiber pipe in overlay film

The invention discloses a preparation method of a hollow fiber pipe in an overlay film, which comprises the following steps 1) preparing a high-molecular polymer, an organic solvent, an additive and a pore forming agent to a plurality of homogeneous casting solutions according to different proportions; 2) removing the PET fiber braiding tube surface spot objects; 3) using a modifier for modifying the PET fiber braiding pipe, fixing a circular pipe at high temperature; 4) using a multi-immersing multi-rolling (several primary immersing-technology in series) technology for cladding various homogeneous casting solutions to the internal and external walls of the PET fiber braiding pipe in order, carrying out a process of circular pipe heat fixing after each time of immersing and rolling, placing the obtained the composite braiding pipe in a gel bath for splitting the phase after the multi-immersing multi-rolling process is finished to obtain the hollow fiber pipe. According to the invention, the PET fiber braiding pipe is taken as a main body, the multi-immersing multi-rolling technology is used, the micro casting solution is coated to the internal and external walls of the braiding pipe, the anti-pollution capability of the braiding pipe can be improved, and a polymer coat layer is formed on the braiding tube surface which can ensure the effective porosity amount and interception effect of the hollow fiber tube.

Owner:SUZHOU CNPT SOURCETECH ENVIRONMENTAL TECH

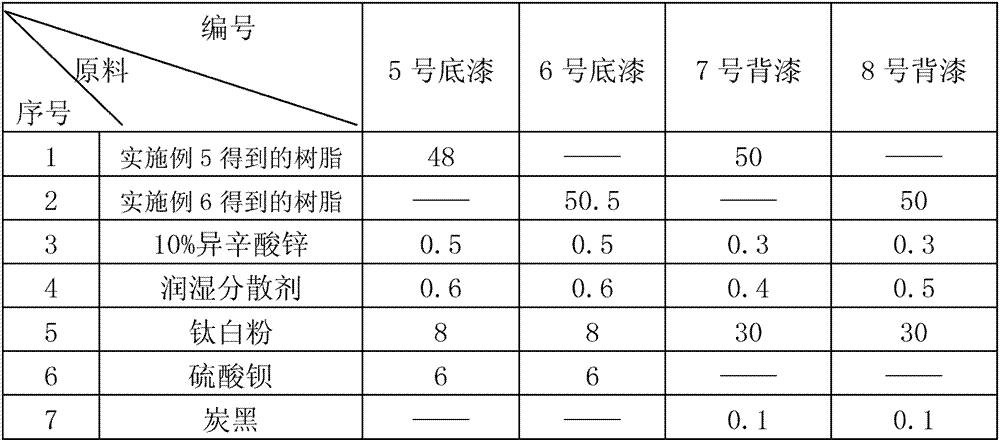

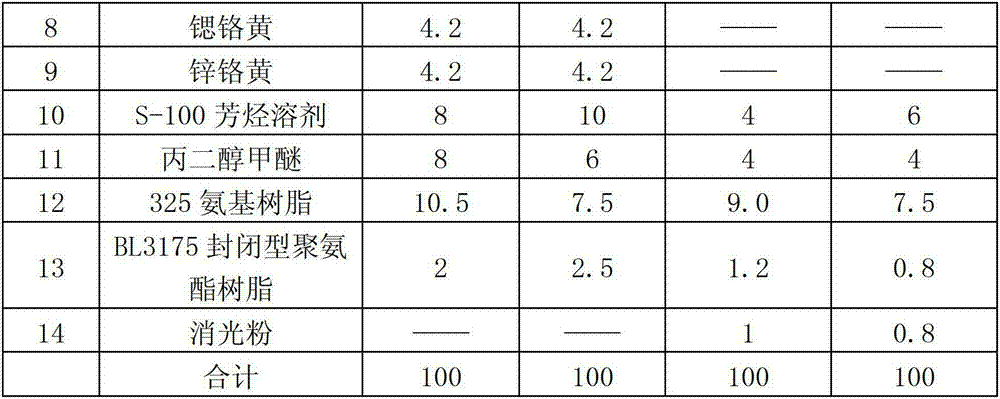

Paint used for coiled metal material

The invention discloses a paint used for a coiled metal material. The existing paint prepared by polyester resin has the disadvantages that the curing process needs high plate temperature, the energy consumption is high, the paint film is soft, and the scratch resistance, the chemical product resistance, the water resistance, the soiling resistance, the corrosion resistance and the friction resistance are poor. The paint used for the coiled metal material disclosed by the invention comprises the following components by weight percent: 40-55% of saturated polyester resin or epoxy modified saturated polyester resin, 15-35% of pigment, 0-10% of filler, 0-0.1% of de-foaming agent, 0.2-1.0% of wetting dispersant, 0-1.0% of flatting agent, 2-10% of ester solvent, 2-10% of aromatic hydrocarbon solvent, 2-15% of crosslinking agent, 0.1-1.0% of baked paint cooling catalyst, 0-1.5% of extinction powder, and 0.1-0.2% of wax powder. The paint disclosed by the invention has low curing temperature and high curing speed; and the painted film has excellent roughness and rigidity.

Owner:ZHEJIANG TRANSFER PAINT CO LTD

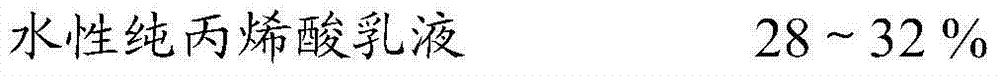

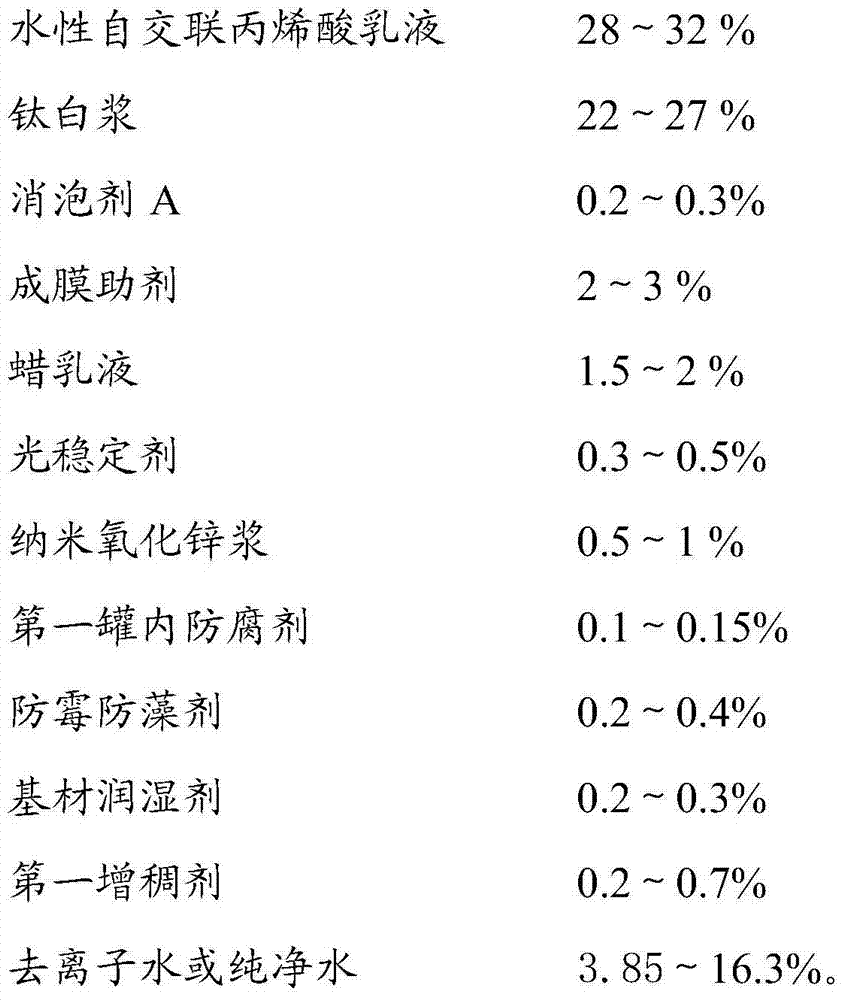

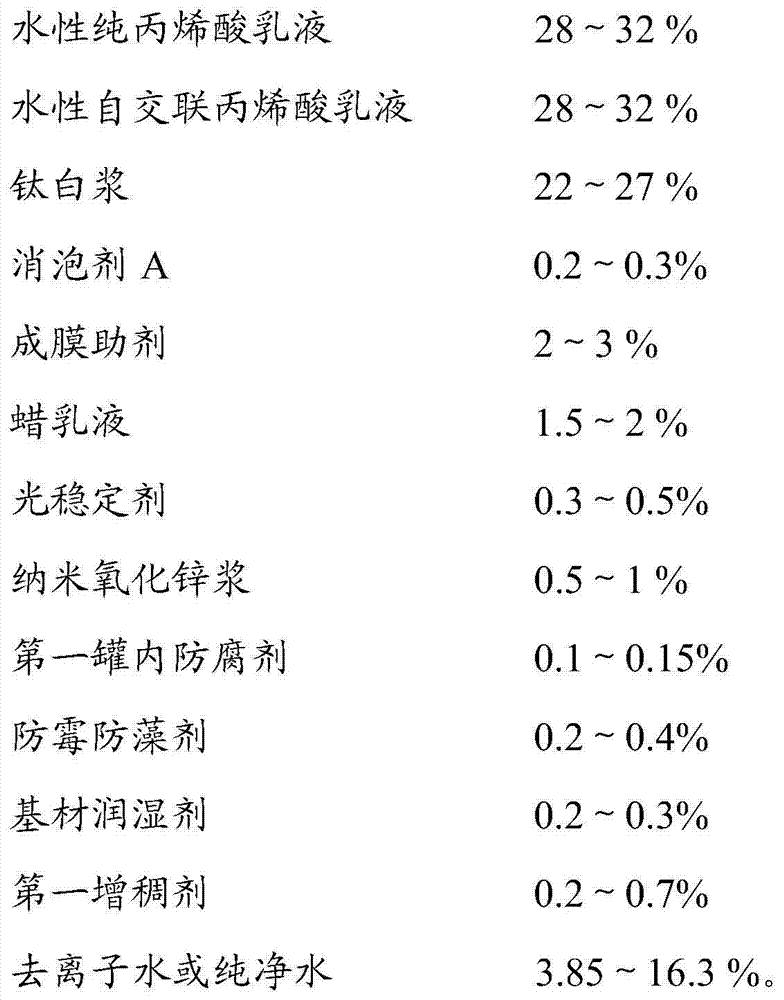

High-weather-resistance high-stain-resistance white paint for outdoor woodware and preparation method of paint

The invention discloses high-weather-resistance high-stain-resistance white paint for outdoor woodware and a preparation method of the paint. The high-weather-resistance high-stain-resistance white paint for the outdoor woodware comprises the following components in percentage by weight: 28-32% of water-based pure acrylic emulsion, 28-32% of water-based self-crosslinking acrylic emulsion, 22-27% of titanium dioxide pulp, 0.2-0.3% of a defoaming agent A, 2-3% of a film forming additive, 1.5-2% of wax emulsion, 0.3-0.5% of a light stabilizer, 0.5-1% of nanometer zinc oxide pulp, 0.1-0.15% of a first in-tank preservative, 0.2-0.4% of mildew-proof algaecide, 0.2-0.3% of a substrate wetting agent, 0.2-0.7% of a first thickening agent and 3.85-16.3% of deionized water or purified water. The high-weather-resistance high-stain-resistance white paint for the outdoor woodware is resistant to weather, stain and water, low in smell and VOC and excellent in environmental protection and safety comprehensive performances; the preparation method is simple in process and low in cost.

Owner:CHINA PAINT MFG CO SHENZHEN

Mfg. process and tech. of fluorine carbon emulsion for paint

A process for preparing the F-C emulsion used for paint to obtain the excellent coated film with high weatherability and resistance to dirt and water is prepared the emulsion polymerization reaction between fluorolefine, unsaturated vinyl monomer, vinyl carboxylate monomer and substituent cyclohexyl acrylate monomer in aqueous medium under the action of trigger.

Owner:青岛宏丰氟硅科技有限公司

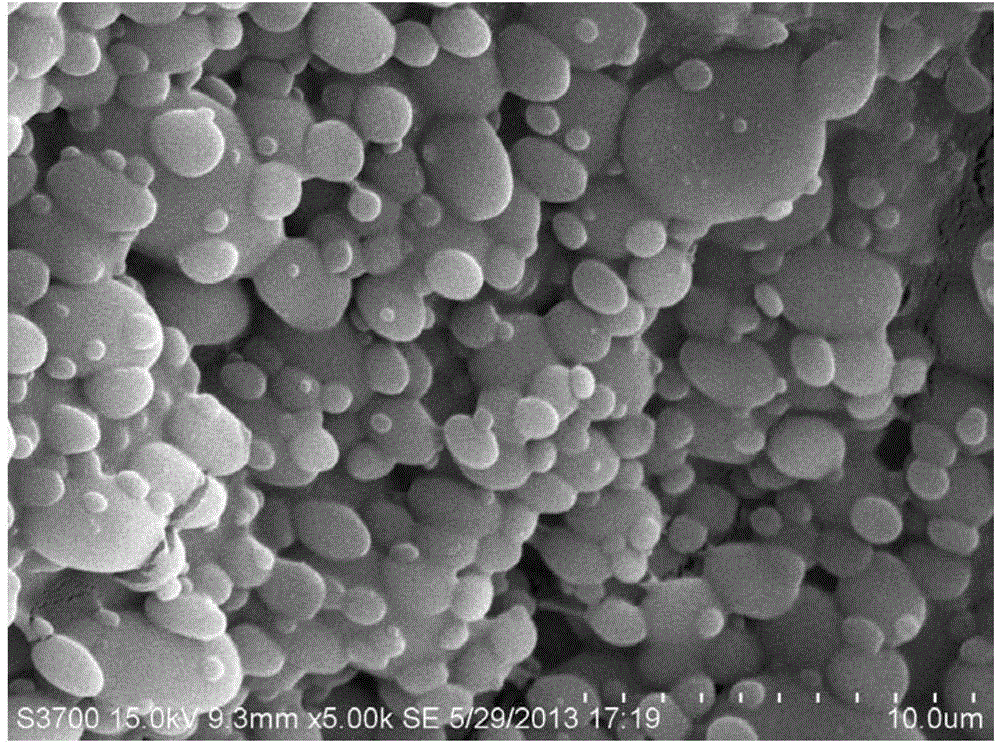

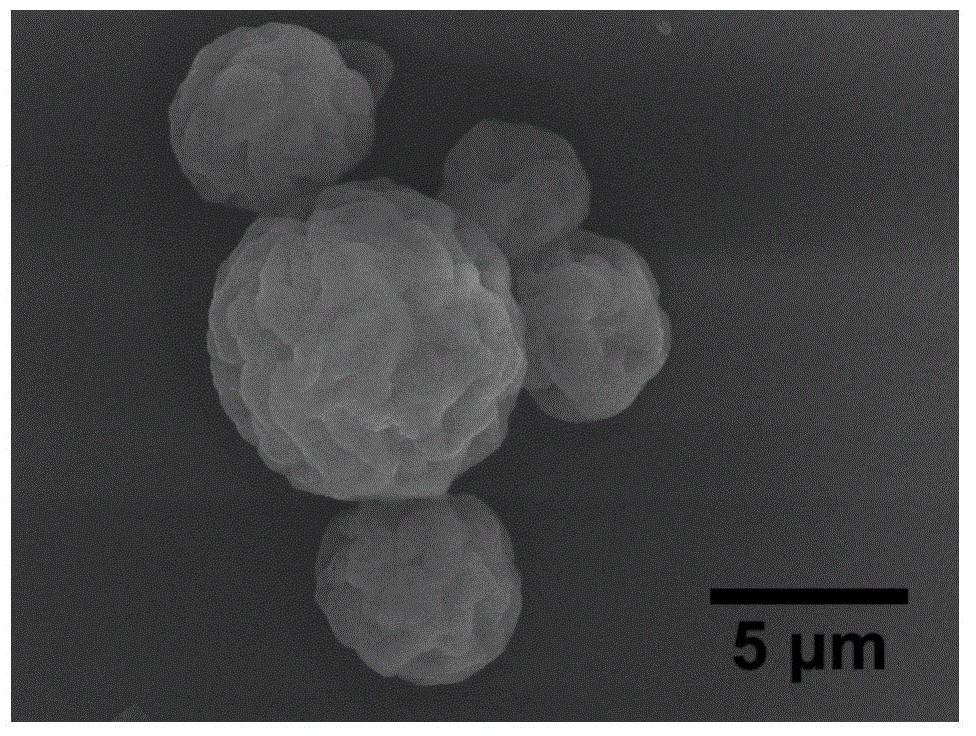

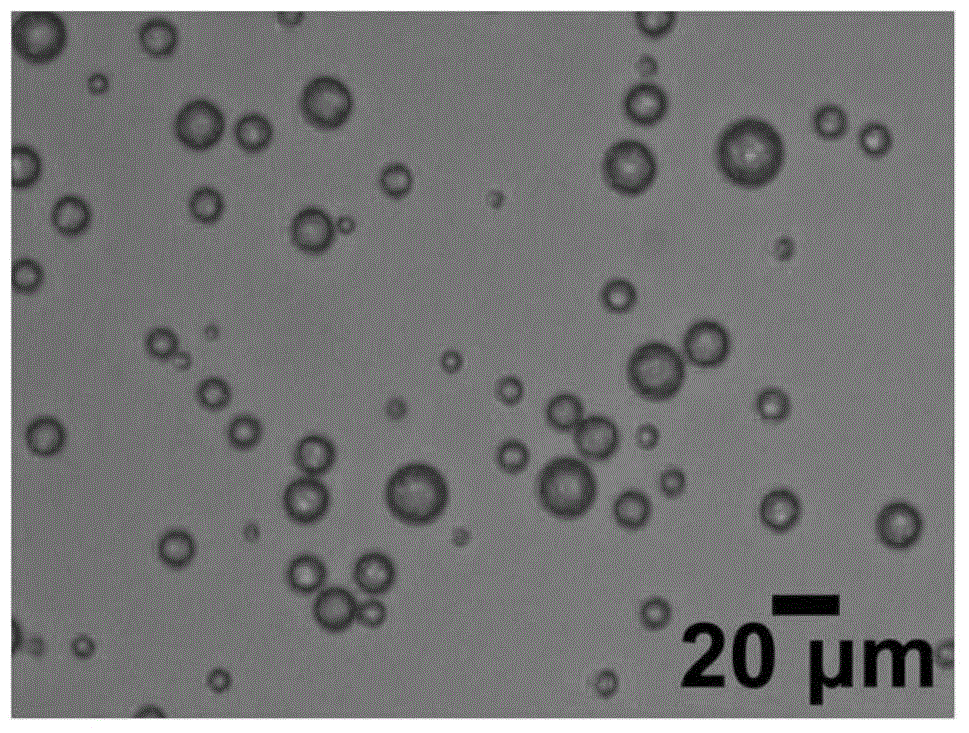

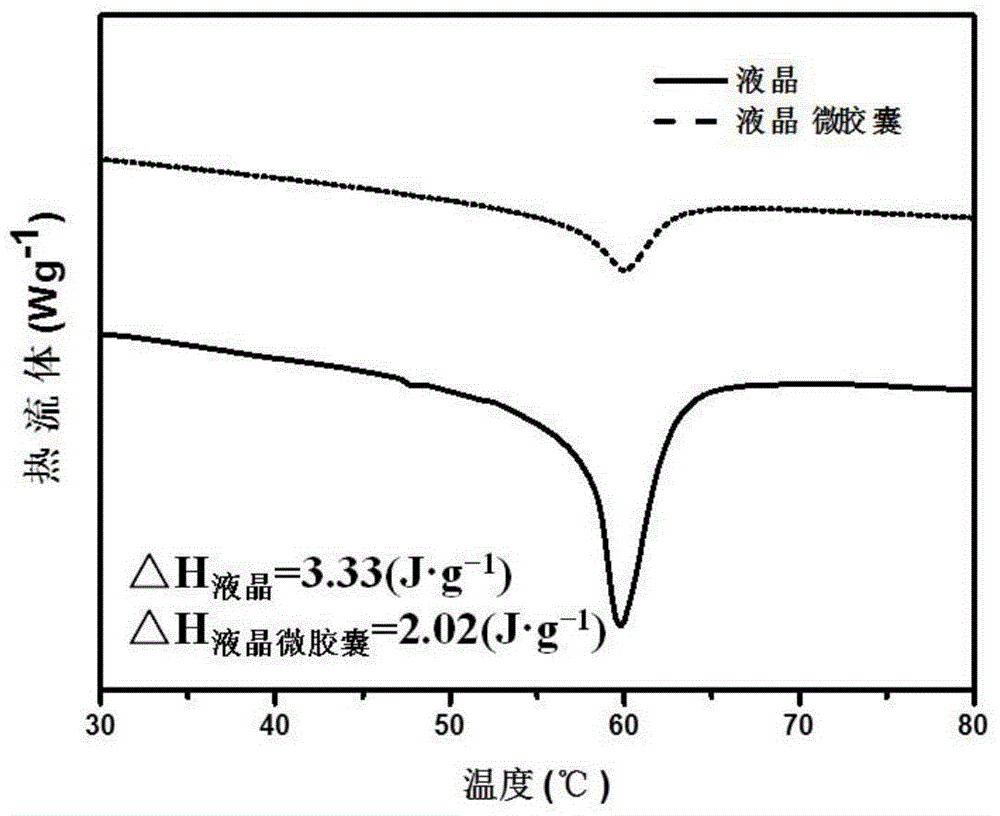

Liquid crystal microcapsule and preparation method thereof

InactiveCN104624124AIncrease coverageGood compatibilityMicroballoon preparationMicrocapsule preparationCrystallographyEmulsion polymerization

The invention provides a liquid crystal microcapsule and a preparation method thereof. The liquid crystal microcapsule preparation method comprises the following steps: 1, adding an emulsifier to water in order to obtain a dispersion used as a water phase; 2, uniformly mixing liquid crystal with a monoolefin monomer, a polyene cross-linking agent and an initiator to obtain a mixture used as an oil phase; 3, mixing the water phase with the oil phase, and emulsifying to obtain an oil-in-water emulsion; 4, polymerizing the emulsion to form the liquid crystal microcapsule with a core-shell structure; and 5, centrifuging the liquid crystal microcapsule, and carrying out spray drying to obtain liquid crystal microcapsule dry powder. The liquid crystal microcapsule prepared through the method has the advantages of uniform dimension, high cladding rate, short production period, simple process, no pollution to the liquid crystal, improved fusion with a microcapsule cladding material, long liquid crystal storage time, and improvement of the water resistance and the pollution resistance of the liquid crystal. The invention also provides the liquid crystal microcapsule with the core-shell structure prepared through the preparation method.

Owner:INST OF CHEM CHINESE ACAD OF SCI

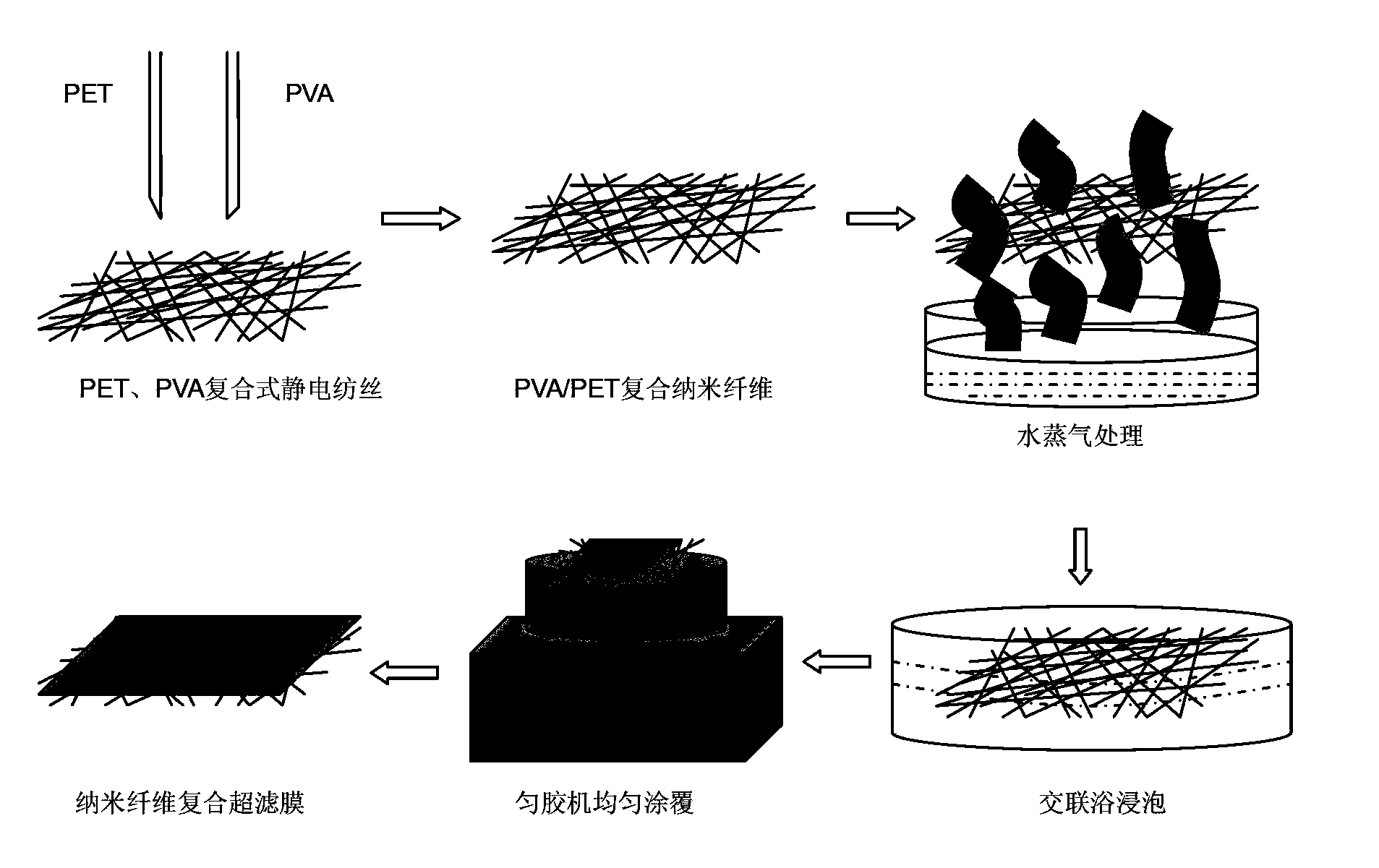

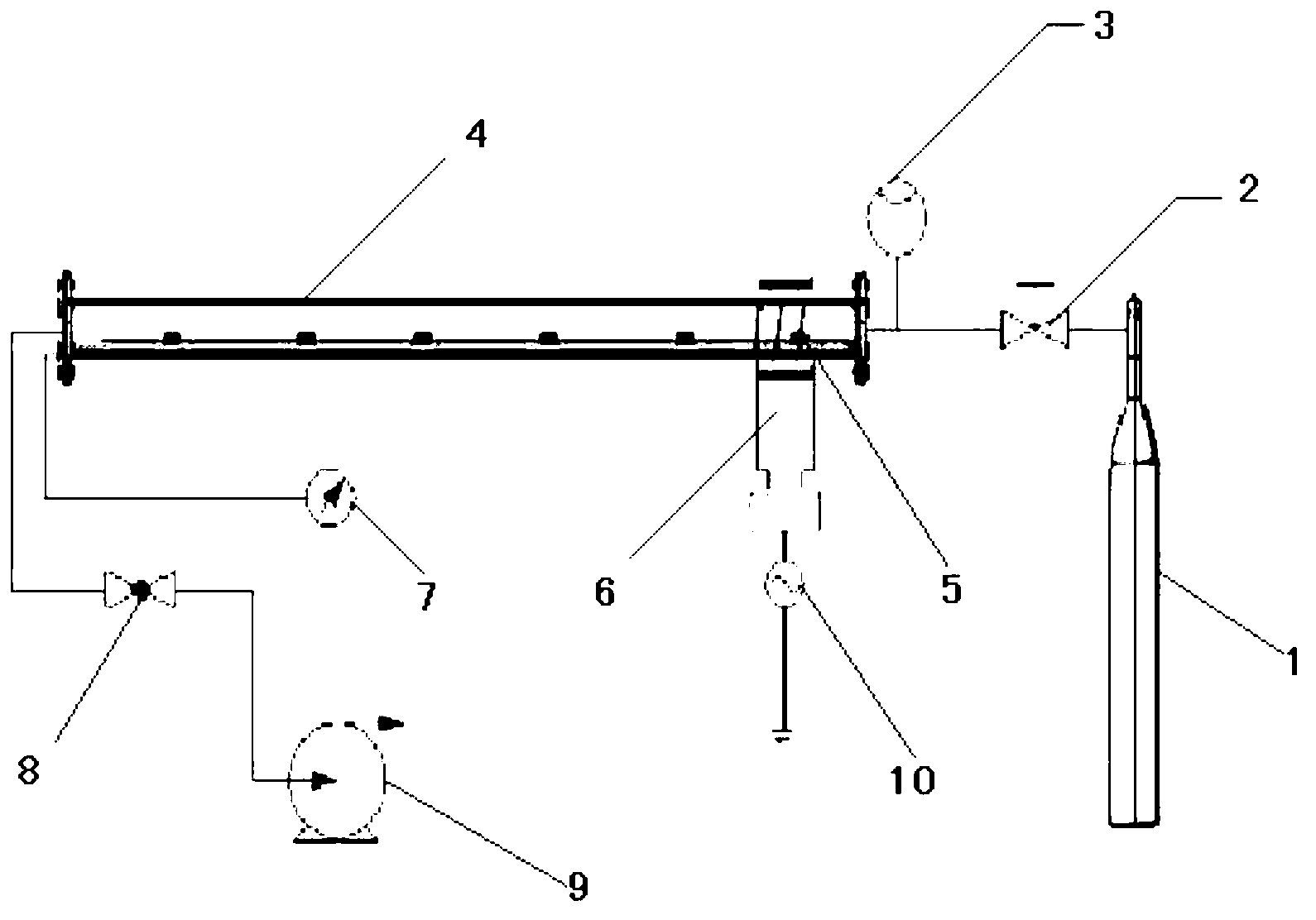

Nano-fiber composite ultrafiltration membrane preparation method based on electrostatic spinning technology

ActiveCN103386257AHigh water flux and retentionWide range of industrial applicationsSemi-permeable membranesUltrafiltrationIon

The invention relates to a nano-fiber composite ultrafiltration membrane preparation method based on an electrostatic spinning technology. According to the invention, a high-molecular polymer used for spinning is dissolved in a solvent, such that a spinning solution A with a concentration of 10-30wt% is obtained; a PVA spinning solution with a mass percentage of 7-10% is prepared; a PVA water solution with a mass concentration of 1-6% is prepared; through crosslinking treatment, a PVA coating liquid is obtained; the spinning solution A and the PVA spinning solution is subjected to composite electrostatic spinning, such that a nano-fiber composite membrane is obtained; the membrane is processed under water vapor, and is soaked with a crosslinking bath; the PVA coating liquid is used for coating by using a spin coater; a sealed reaction is carried out under room temperature; the membrane is soaked by using deionized water, and is suspended and air-dried, such that the ultrafiltration membrane is obtained. The surface of the prepared nano-fiber composite ultrafiltration membrane comprises large amounts of hydrophilic groups and active groups. The membrane has good mechanical performances and anti-pollution performances, and is especially suitable for ultrafiltration under ultra-low pressure or even no power. The membrane has high flux and retention rate under low pressure.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

Fluorine water-base paint

The present invention relates to paint industry technology, and is especially one kind of fluoric water-base paint. The fluoric water-base paint consists of fluorocarbon emulsion 20-90 wt%, supplementary emulsion 1-25 wt%, pigment 5-20 wt%, stuffing 1-31 wt%, dispersant 0.1-1.4 wt%, defoaming agent 0.1-0.3 wt%, wetting agent 0.3-0.5 wt%, bactericidal anti-mildew agent 0.1-0.3 wt%, filming assistant 0.01-13.5 wt%, thickener 0.01-1.1 wt% and multifunctional assistant 0.3-0.5 wt% except water. The paint has high weather resistance, high chemical corrosion resistance, antifouling property, high performance / cost ratio and other advantages.

Owner:SHANGHAI HENGFENG FLUOROCARBON MATERIAL

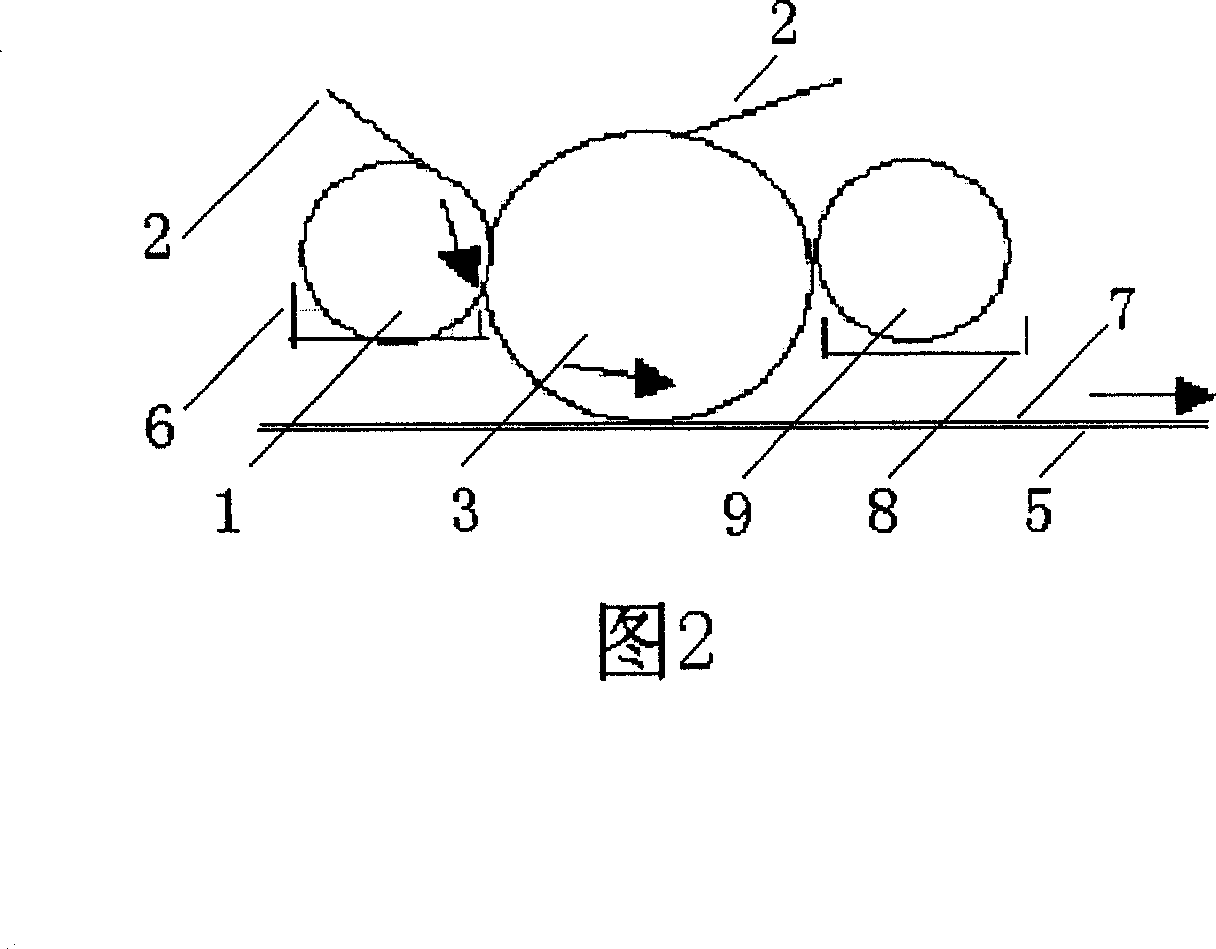

Gravure rubber wheel directly transfer printing pattern metallic plate

InactiveCN101077677AImprove protectionReduce usageSpecial ornamental structuresSpecial surfacesPolyvinyl chlorideEngineering

The present invention is printed metal plate with intaglio offset transfer printed patterns and its making process. On the surface of coated steel sheet, patterns are first printed with ink fitting the surface coating of steel sheet and through intaglio offset printing, and high temperature cured paint or UV cured paint is then roller coated to the surface of the patterns. The printed metal plate has high decorating effect. Compared with available technology, the present invention has the advantages of environment friendship and low cost.

Owner:HAIER GRP CORP +1

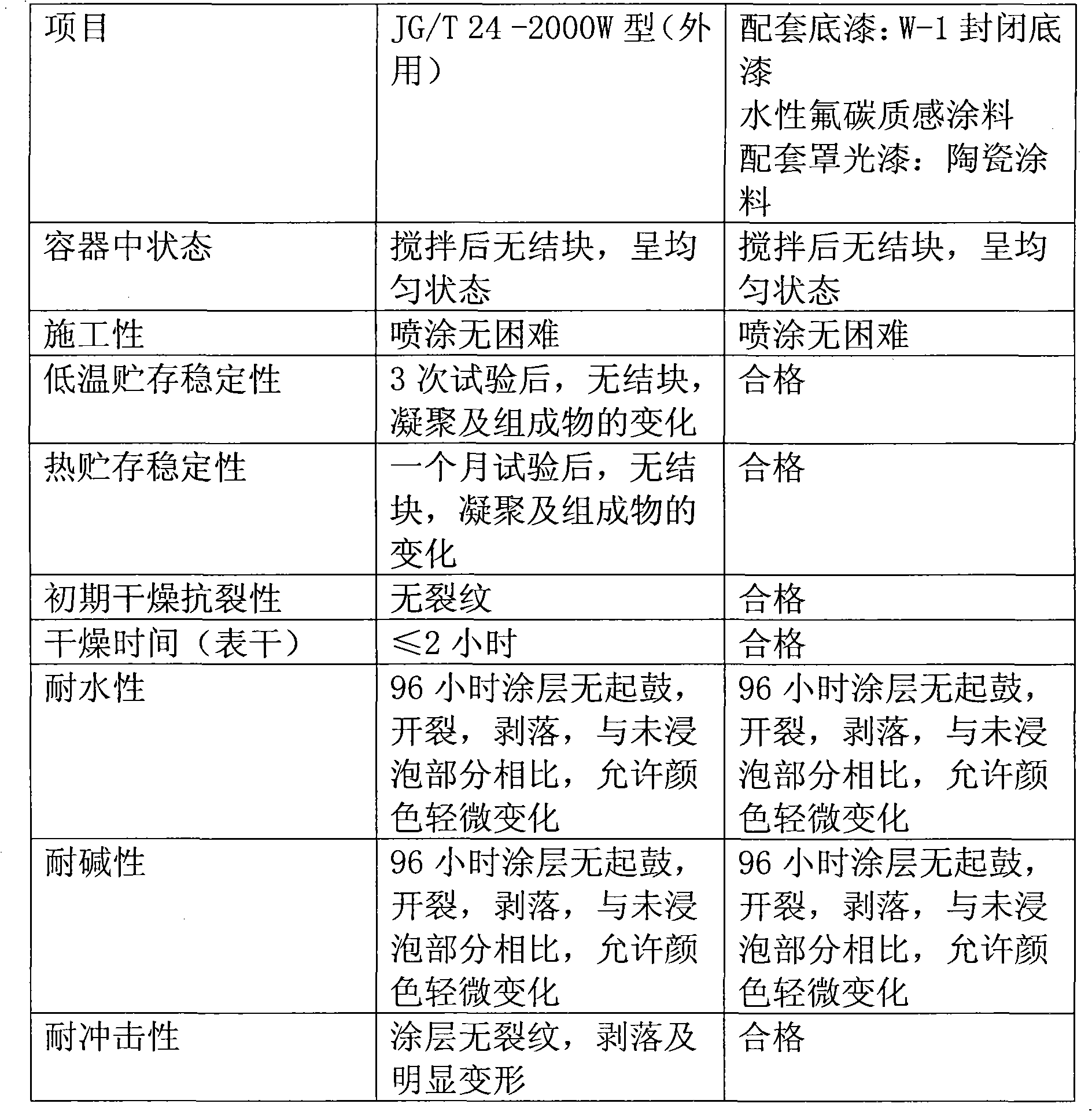

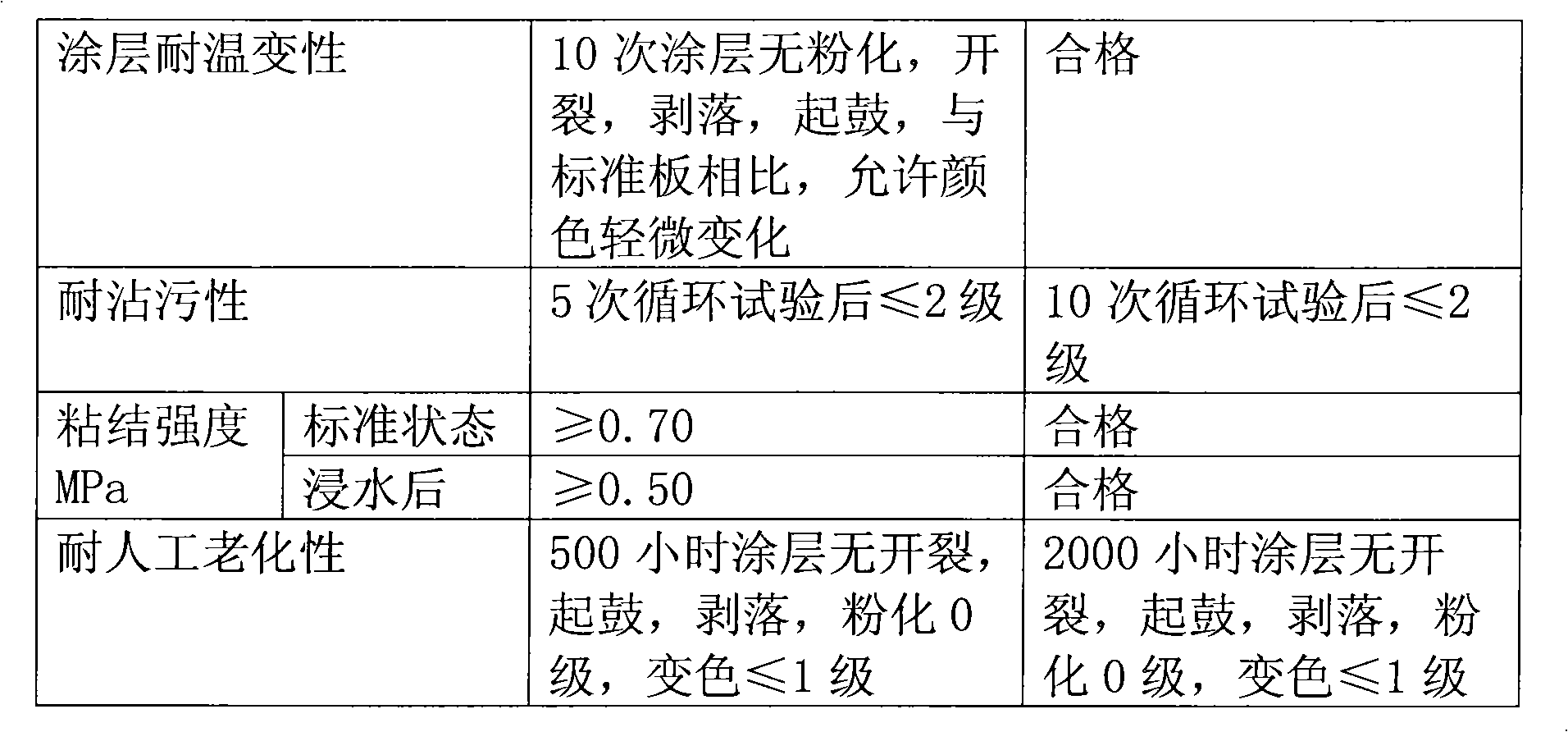

Waterborne fluorocarbon texture coating and preparation method and application thereof

InactiveCN101851450AImprove water resistancePollution resistantBuilding constructionsCoatingsLow speedWeather resistance

The invention discloses a waterborne fluorocarbon texture coating and a preparation method and application thereof. The coating comprises the following components in part by weight: 141 to 180 parts of fluorocarbon emulsion, 5 to 12 parts of film-forming aid, 5 to 6 parts of cosolvent, 80 to 100 parts of water, 1 to 2 parts of antifoaming agent, 3 to 6 parts of disinfectant, 1 to 3 parts of mildew preventive, 2 to 3 parts of pH regulator, 5 to 10 parts of thickening agent, 600 to 1,000 parts of color sand, and 0 to 89 parts of sheet. The preparation method comprises the following steps of: under the stirring at a high speed, adding the film-forming aid, the cosolvent, the antifoaming agent, the disinfectant, and the mildew preventive in turn, stirring at the high speed and reducing the stirring speed; adding the fluorocarbon emulsion, regulating the pH value, and regulating the viscosity by using the thickening agent to obtain pulp; stirring the pulp at a low speed, adding the color sand and sheet, and mixing to obtain the waterborne fluorocarbon texture coating. The waterborne fluorocarbon texture coating applied to a coated outer wall surface has good protection functions of water resistance, weather resistance, smudge resistance, and the like, and makes the wall surface have elegant, harmonious and serious aesthetic feeling.

Owner:SHANGHAI HENGFENG FLUOROCARBON MATERIAL

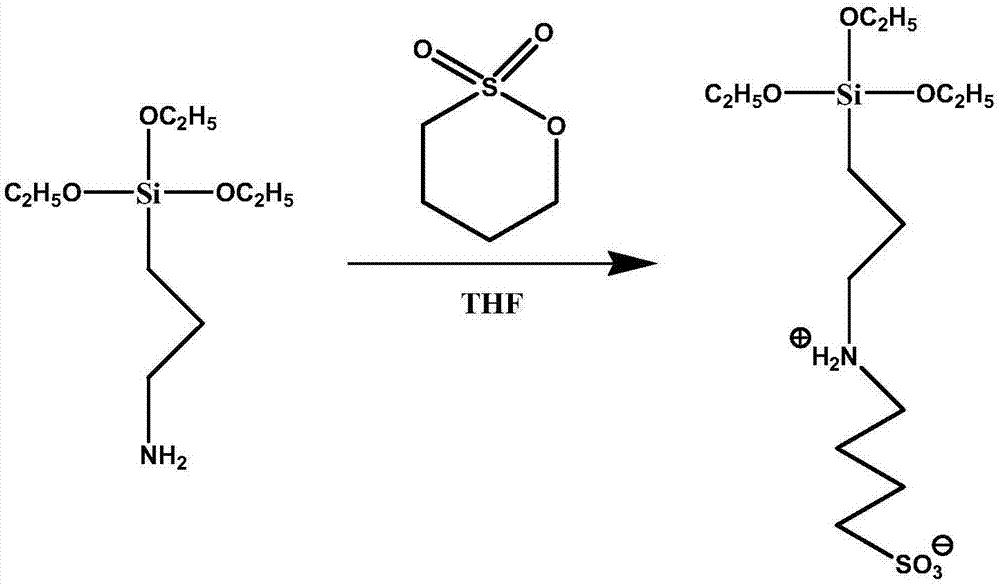

Method for forming amphoteric ion structure on surface of separation membrane and separation membrane

InactiveCN104226128AMild reaction conditionsSimple stepsSemi-permeable membranesPhysical chemistryGrafting

The invention discloses a method for forming an amphoteric ion structure on the surface of a separation membrane. The method comprises the following steps: (1) immersing the separation membrane in a solution containing positively charged substances, wherein the positively charged substances react with active groups on the surface of the separation membrane to realize the grafting of the positively charged substances onto the surface of the separation membrane; and (2) washing the separation membrane with the surface being grafted with the positively charged substances, and immersing the separation membrane in a solution containing negatively charged substances, wherein the negatively charged substances have Michael addition reaction with the positively charged substances on the surface of the separation membrane so as to be grafted to the surface of the separation membrane to obtain an ampphoteric ion modified separation membrane. The invention also discloses a modified membrane prepared by the method. The method for forming the amphoteric ion structure on the surface of the separation membrane is carried out under the normal temperature and normal pressure, only the separation membrane needs to be immersed in the positively charged substance solution and the negatively changed substance solution, the reaction conditions are moderate, the preparation steps are simple, and therefore industrialization can be achieved easily.

Owner:ZHEJIANG UNIV

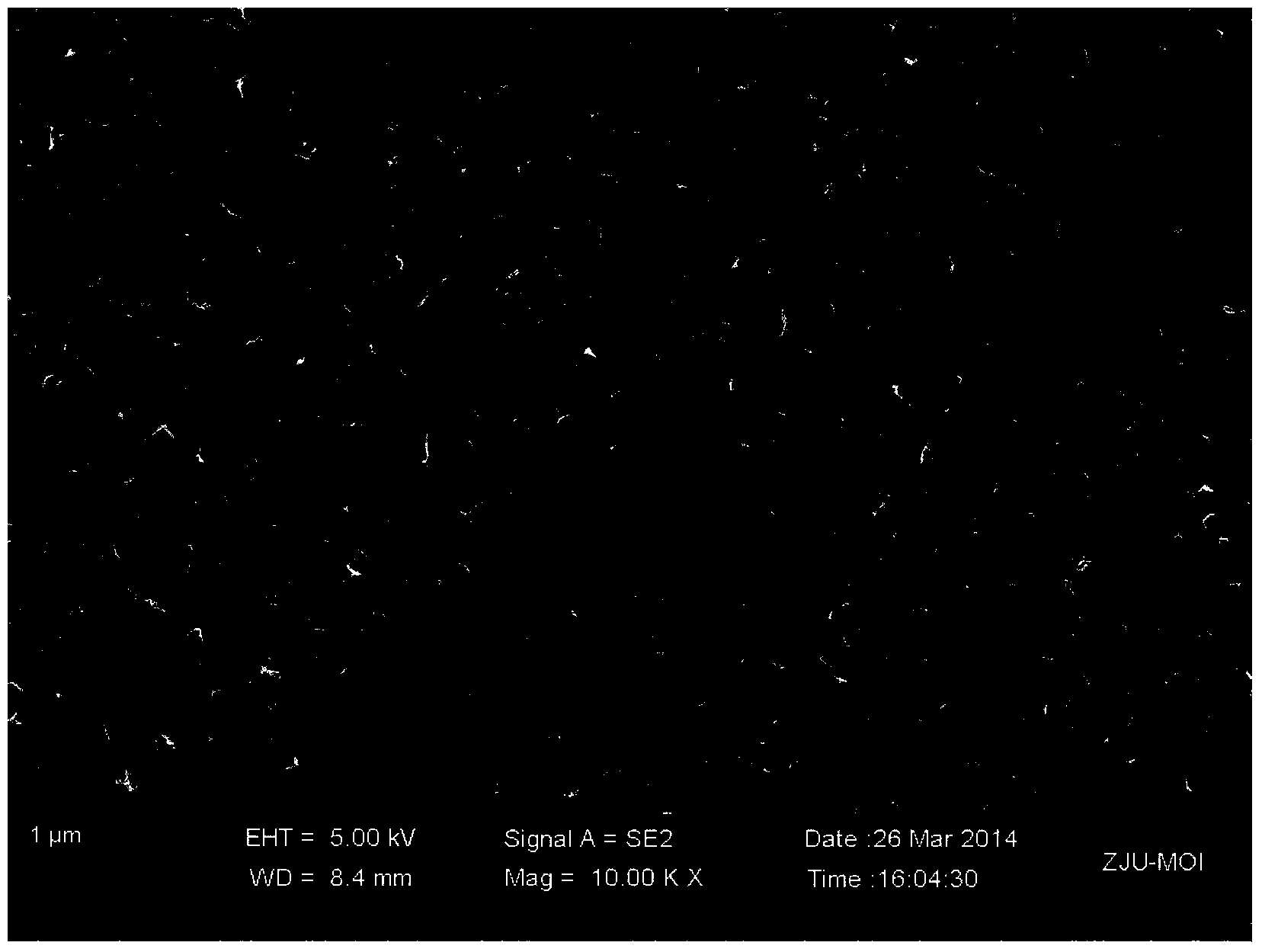

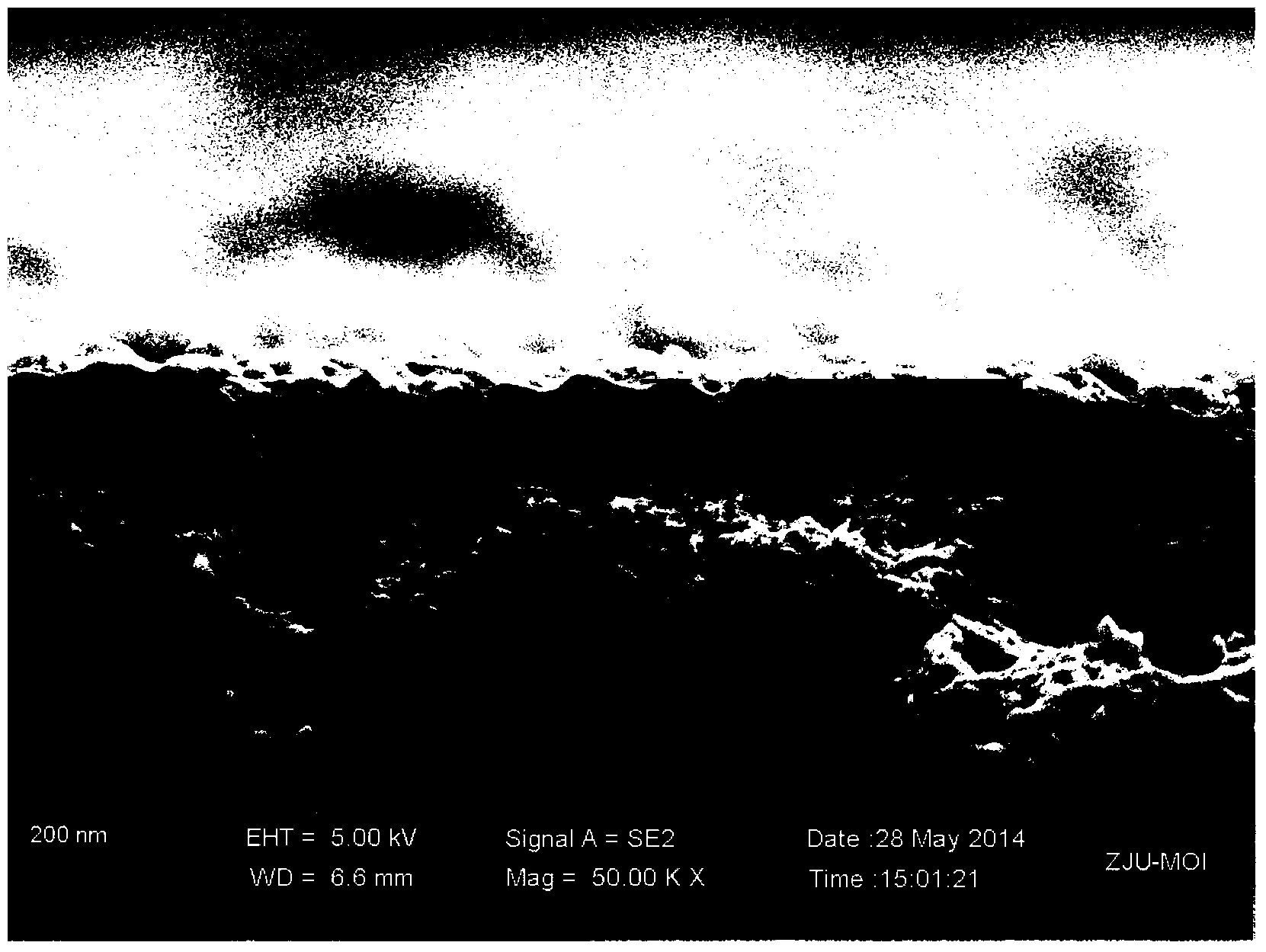

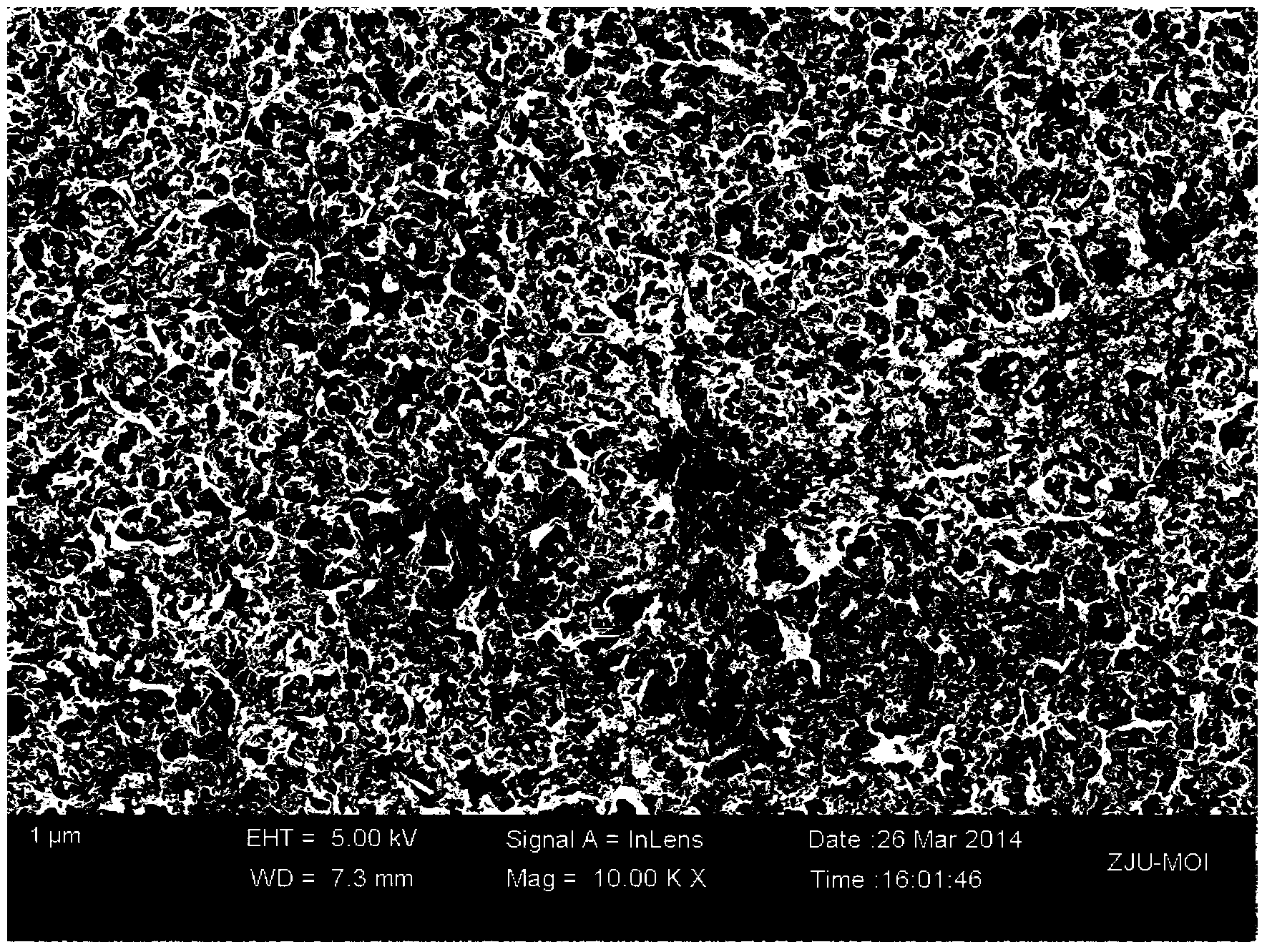

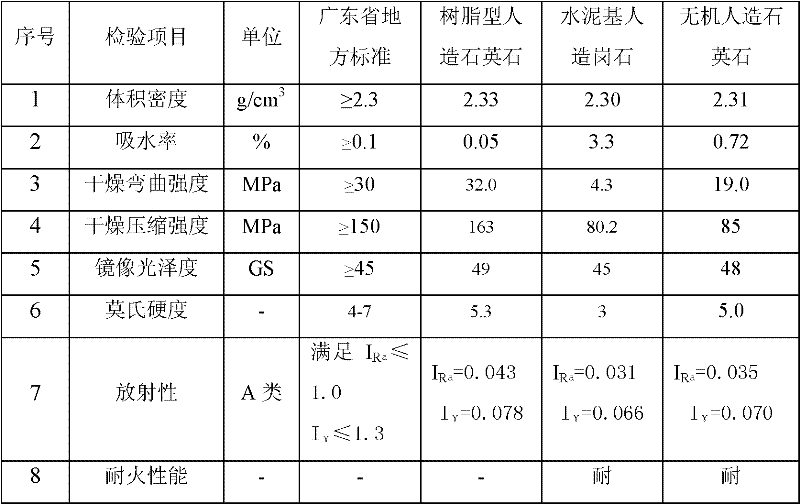

Novel inorganic artificial quartzite and preparation method thereof

InactiveCN102503345AAdvantages of preparation methodNo room temperature maintenanceHardnessMaterials science

The invention discloses a novel inorganic artificial quartzite and a preparation method thereof and belongs to the field of building decorative materials. The novel inorganic artificial quartzite provided by the invention comprises the following raw materials by weight parts: 2-20 parts of inorganic polymer A components, 4-20 parts of inorganic polymer B components, 50-90 parts of aggregates and 0.1-1.0 part of additives. The preparation method provided by the invention comprises the following steps: uniformly stirring the components, such as inorganic polymers, pigments, aggregates, and additives, according to a certain technology, and then performing the processes of distributing materials, vacuumizing, vibrating, pressing and forming, fixing thickness, curing, polishing, cutting, protecting and the like, thereby obtaining the inorganic artificial quartzite. The production technology for the inorganic artificial quartzite is simple; during the production process, a plate surface is free from being cracked and warped; the mechanical property is excellent, the glossiness is high and the hardness is high; and the novel inorganic artificial quartzite belongs to a novel environment-friendly product which can be widely applied to various indoor and outdoor decorative and fitting-out projects.

Owner:GUANGZHOU INSTITUTE OF BUILDING SCIENCE CO LTD

Membranes having antibiotic and hydrophilic properties and preparation method thereof

ActiveCN106457161AMaintain antimicrobialHigh mechanical strengthSemi-permeable membranesMembranesOrganic compoundNanometre

The present invention relates to a separation membrane having both antibiotic and hydrophilic properties for water treatment and a preparation method thereof. In the separation membrane of the present invention, since an organic compound (antimicrobial and / or hydrophilic compound) is chemically conjugated to non-metal inorganic nanoparticles or metal nanoparticles, the nanoparticles are not eluted from the separation membrane even when the separation membrane is used for water treatment for a long period of time, so that the separation membrane may continuously maintain antimicrobial properties and high water permeability, is safe to the human body even when used for the treatment of drinking water, such as water purification, and exhibits characteristics in which stain resistance is also significantly enhanced due to antimicrobial and hydrophilic properties, which have been continuously imparted. Furthermore, high mechanical strength is exhibited by a metal or inorganic nanofiller introduced.

Owner:LG ELECTRONICS INC

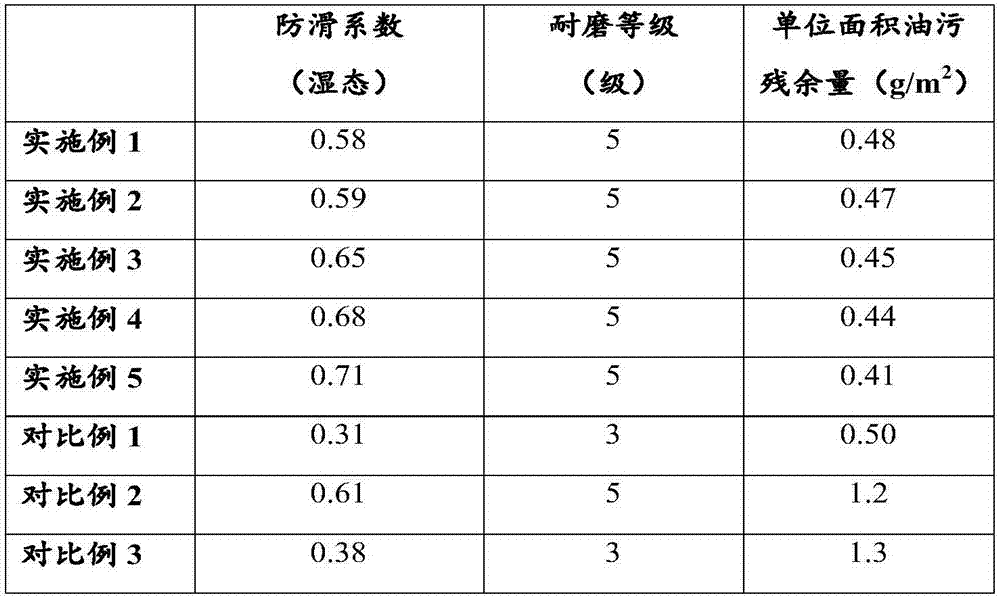

Preparation method for antiskid and anti-wear easily-cleaned ceramic tiles

ActiveCN107265861AImprove wear resistanceNot easy to wearCeramic shaping apparatusFlooringCeramic glazeCeramic tiles

The invention provides a preparation method for antiskid and anti-wear easily-cleaned ceramic tiles, and relates to the technical field of building ceramics. The antiskid and anti-wear easily-cleaned ceramic tiles are prepared from the following successive steps: preparing a green body layer by pressing, spreading an overglaze layer, preparing a decoration layer by ink jet printing, printing an antiskid and anti-wear layer, preparing an easily-cleaned dry layers, conducting burning, conducting burnishing and polishing edges. Technical problems commonly existing in ceramic archaized tiles in present markets that surface anti-wear strength is not enough, wearing is easy, the antiskid factor is low, cleaning is difficult, dirt hiding is easy and the like are relieved, and technical effects that the prepared antiskid and anti-wear easily-cleaned ceramic tiles have high anti-wear strength, uneasiness to wear and a high antiskid factor, people are effectively prevented from falling, the security of the tiles is improved, meanwhile, the contamination resistance is excellent, dirt is not easy to hide, cleaning is easy, and convenience is provided for daily cleaning are achieved.

Owner:GUANGDONG KITO CERAMICS GROUP CO LTD +2

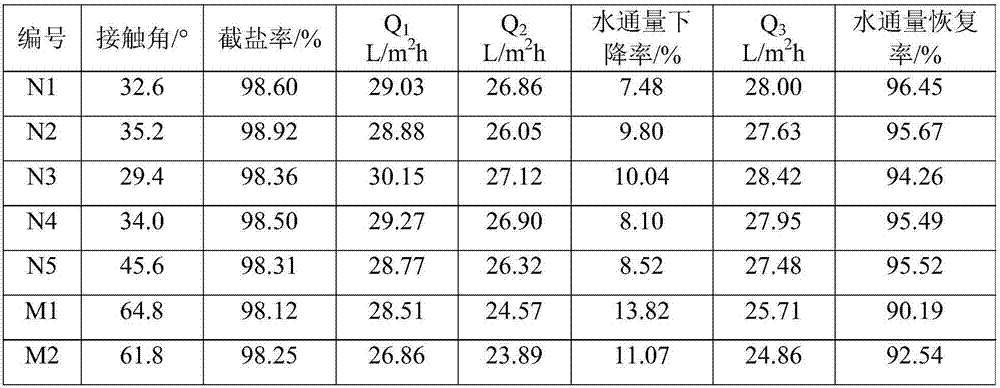

Preparation method of ultra-low pressure contamination-resistance composite reverse osmosis membrane

InactiveCN101450290AImprove hydrophilicityImproves stain resistanceSemi-permeable membranesPolymer sciencePolyvinyl alcohol

The invention discloses a method for preparing an ultralow pressure fouling resistant composite reverse osmosis membrane. A layer of hydrophilic matter is coated onto an ultralow pressure polyamide membrane. The method comprises the following steps: preparing and mixing a polyvinyl alcohol solution, a polyethylene imine solution and a crosslinking agent solution; spreading the mixture onto a polyamide carrier membrane; and obtaining the ultralow pressure fouling resistant composite reverse osmosis membrane after drying. The reverse osmosis membrane has high water flux, a high salt rejection capability and good fouling resistance under the ultralow pressure operation.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Method for preparing ultra-low pressure contamination-resistance composite reverse osmosis membrane using chitosan

InactiveCN101450289AImprove hydrophilicityImproves stain resistanceSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisCrosslinked chitosanAcetic acid

The invention discloses a method for preparing an ultralow pressure fouling resistant composite reverse osmosis membrane through chitosan. The method comprises the following steps: dissolving chitosan with the deacetylation degree above 90 percent in acetic acid, and preparing solution A with the mass concentration of 1 to 10 percent after removing solid impurities in the solution; mixing crosslinking agent solution and hydrochloric acid through stirring to form solution B; and finally mixing solution A and solution B, spreading a mixed solution onto a polyamide carrier membrane, and preparing the ultralow pressure fouling resistant composite reverse osmosis membrane after drying. The obtained ultralow pressure fouling resistant composite reverse osmosis membrane has a crosslinked chitosan layer formed on a polyamide layer, thereby improving the hydrophilicity of the reverse osmosis membrane and the fouling resistance of the reverse osmosis membrane, and saving a great amount of power consumption during the operation with ultralow pressure.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Low-gram weight white impregnated bond paper and producing method thereof

The present invention relates to a production method of titanium white paper. Said production method includes the following steps: mixing the titanium white powder and adhesive B to obtain titanium white powder mixed adhesive B; mixing the titanium white powder and adhesive A to obtain titanium white powder mixed adhesive A; impregnating base paper with adhesive; spray-coating titanium white powder mixed adhesive B on one side or two sides of base paper impregnated with adhesive; drying said base paper; then spray-coating the titanium white powder mixed adhesive A on two sides of the base paper coated with titanium white powder mixed adhesive B; drying said base paper; cooling and cutting so as to obtain the invented low-gum white impregnated adhesive film paper finished product.

Owner:张志利

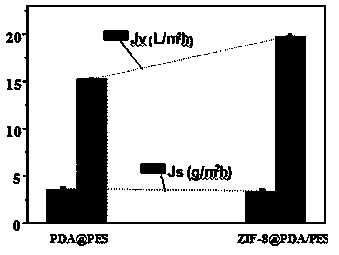

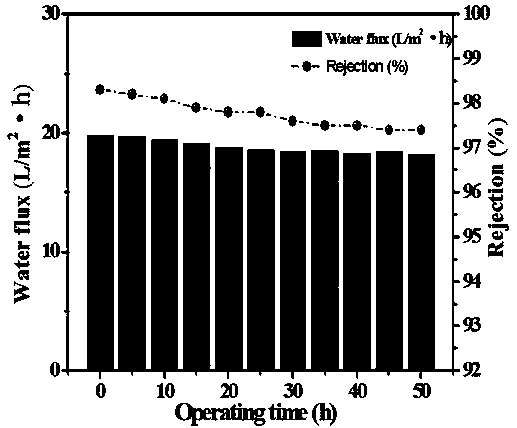

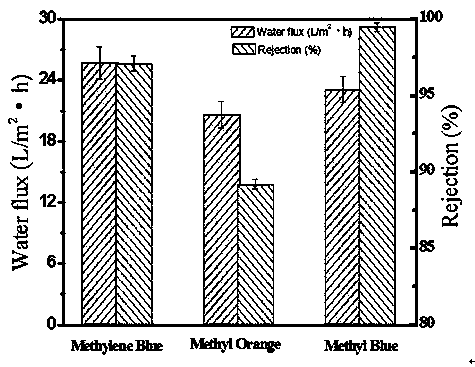

Method for modifying polyethersulfone forward osmosis membrane through ZIF-8 in-situ growth and obtained membrane

InactiveCN109499370AImproves stain resistanceImprove performanceSemi-permeable membranesMembranesSolventHigh pressure

The invention discloses a method for modifying a polyethersulfone forward osmosis membrane through ZIF-8 in-situ growth and an obtained membrane and belongs to the technical field of water treatment membranes. The method comprises the following steps: modifying a polyethersulfone based basement membrane with dopamine, so as to obtain a modified membrane; subjecting the modified membrane to a reaction in ZIF-8 mother liquor, and obtaining a continuous and dense ZIF-8 membranous layer on the surface of the membrane by using an in-situ growth method, thereby obtaining the membrane. The technicalscheme of the invention is the simplest and effective technology for modifying the polyethersulfone forward osmosis membrane through in-situ method growth, the entire process has no need of high pressure and high temperatures, an aqueous solvent is used and is non-toxic and pollution-free, and thus, the method is an environment-friendly synthesis process.

Owner:QINGDAO UNIV OF SCI & TECH

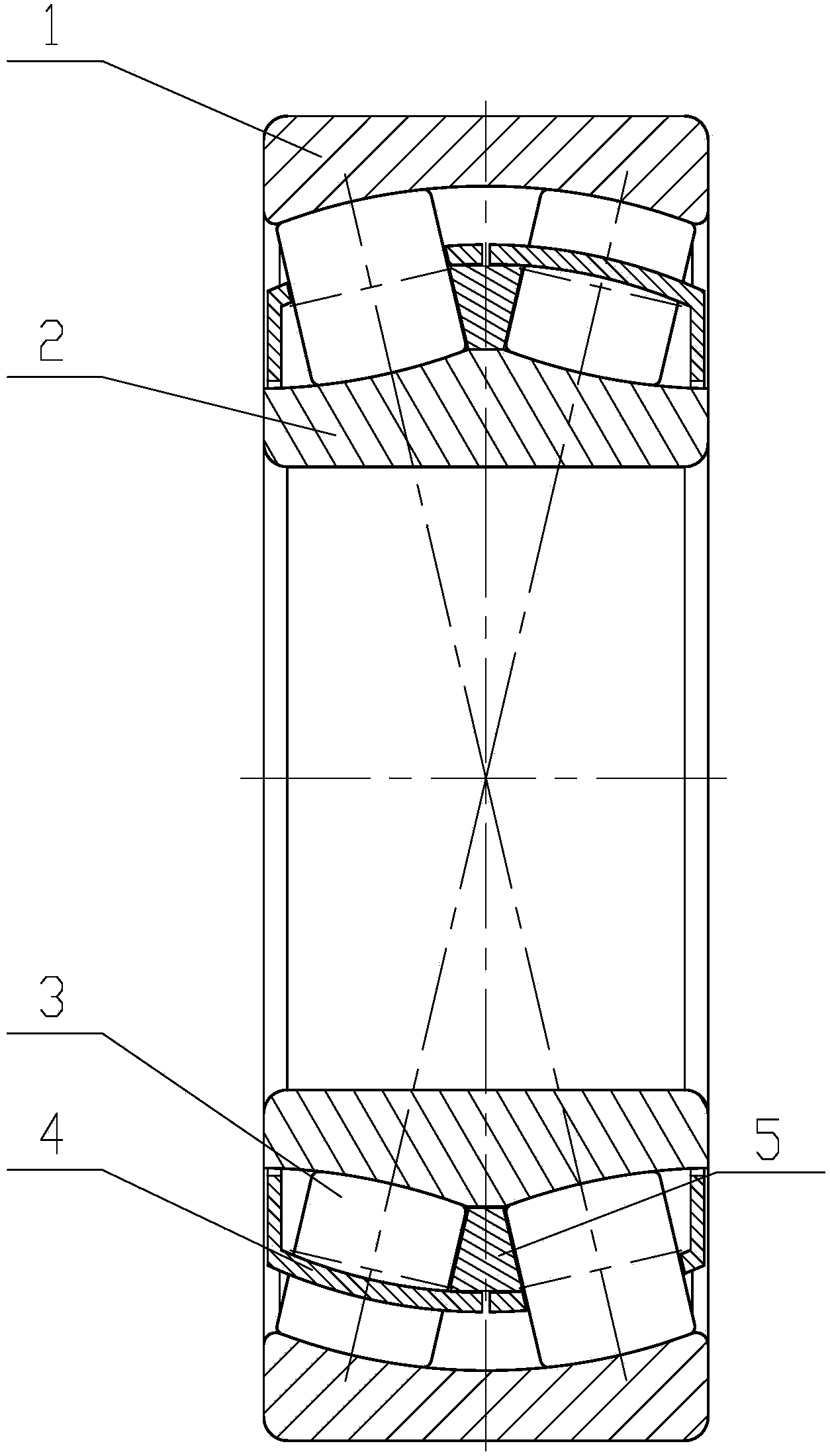

Sealed self-aligning roller bearing for high-speed rail and repair method thereof

InactiveCN103836067AImprove carrying capacityImproves stain resistanceRoller bearingsBearing componentsGlass fiberNylon 66

The invention relates to a sealed self-aligning roller bearing for a high-speed rail and a repair method thereof. The bearing comprises an inner ring, an outer ring, a roller, a holder and a sealed housing, wherein the holder is formed by integral injection moulding of a glass fiber enhanced nylon 66 material and is located on a middle line between the inner and outer rings; the holder is integrally cone-shaped, and the axial section of the single side wall of the holder is / -shaped; roller installation parts are uniformly distributed in the periphery of the holder, and the side face of each roller installation part is a spherical face; the included angle beta between the connecting line of the widest part of each roller installation part and the center of the bearing and the radial section of the bearing is equal to a nominal contact angle. The invention further discloses the repair method of the bearing. According to the structural design, the repaired bearing can be continuously used, so that the maintenance cost of the high-speed rail is effectively lowered, and the service life of the bearing is remarkably prolonged.

Owner:SHANDONG KAIMEIRUI BEARING TECH CO LTD

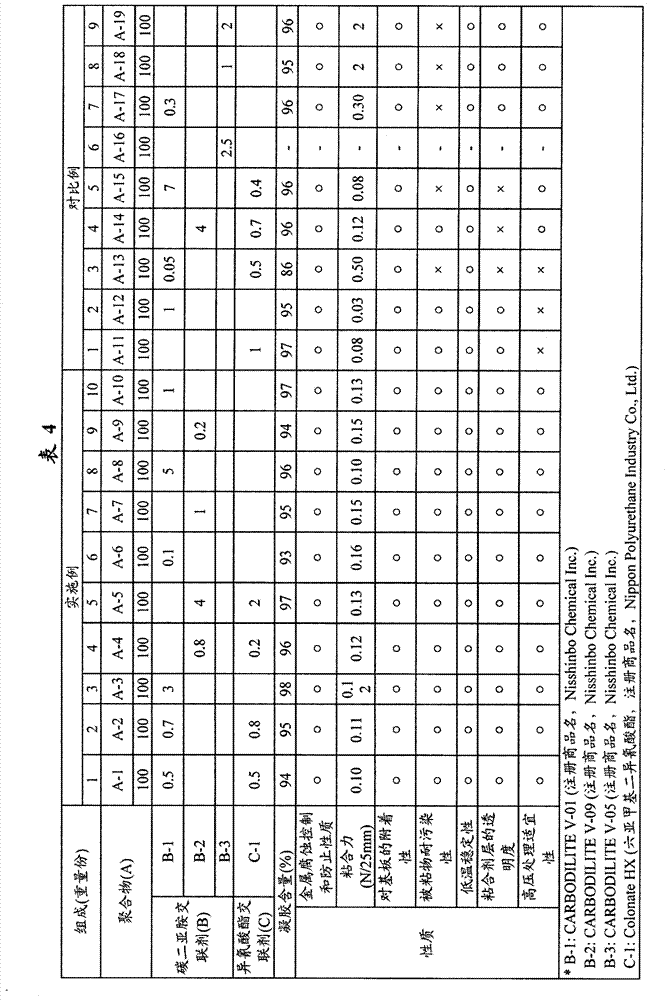

Adhesive composition, and surface protection film using it

ActiveCN102816547AImproves stain resistanceHigh transparencyFilm/foil adhesivesEster polymer adhesivesAdhesiveMethyl group

The invention provides an adhesive composition controlling the pollution of an adherend and making an adhesive have an excellent transparency. The adhesive composition comprises 100 parts by weight of a (methyl) acrylate copolymer and 0.1-5 parts by weight of a carbodiimide crosslinking agent, wherein the (methyl) acrylate copolymer comprises 0-0.5 parts by weight of a carboxyl-containing monomer, 0.6-9 parts by weight of a hydroxy-containing (methyl)acrylic monomer, and 90.5-99.4 parts by weight of a (methyl) acrylate monomer, and has a weight average molecular weight of 100,000-1,000,000g / mol.

Owner:CHEIL IND INC

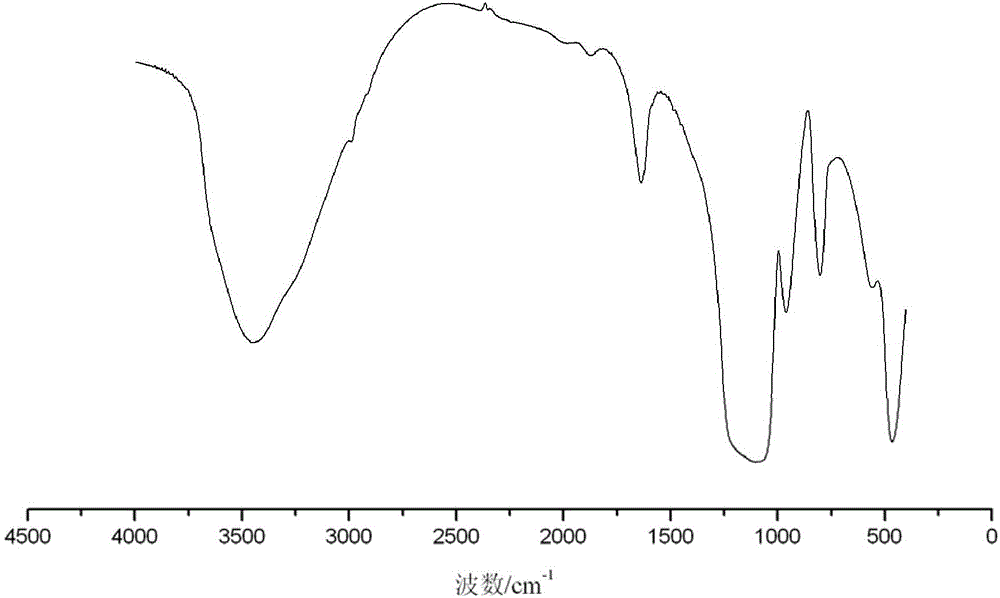

Preparation and catalytic regeneration of functionalized graphene oxide/polyether sulfone blended ultrafiltration membrane

The invention provides preparation and catalytic regeneration of a functionalized graphene oxide / polyether sulfone blended ultrafiltration membrane. The preparation method of the functionalized graphene oxide / polyether sulfone blended ultrafiltration membrane is characterized by comprising the following specific steps: dispersing cobaltosic oxide-loaded graphene oxide and a pore-foaming agent into an organic solvent with an ultrasonic wave; adding polyether sulfone to a dispersion liquid, and stirring and dissolving at 75-85 DEG C; standing and defoaming to obtain a casting liquid; scraping the casting liquid at room temperature when the environment humidity is 50%-55% to prepare a liquid membrane; and putting into a water bath at 10-25 DEG C, after the membrane falls off, taking out the membrane, washing, soaking, freezing and drying to obtain the functionalized graphene oxide / polyether sulfone blended ultrafiltration membrane.

Owner:DONGHUA UNIV

Preparation method of amphoteric polyether sulphone separation membrane

InactiveCN103263863AEasy to prepareMild preparation conditionsSemi-permeable membranesUltrafiltrationCarboxylic group

The invention discloses a preparation method of an amphoteric polyether sulphone separation membrane. The preparation method specifically comprises the following steps of: 1, taking a polyether sulphone flat ultrafiltration membrane, and removing an additive contained in the polyether sulphone flat ultrafiltration membrane to obtain a clean polyether sulphone flat ultrafiltration membrane; 2, performing plasma modification on the polyether sulphone ultrafiltration membrane obtained in the step 1 by using a controllable low-temperature plasma discharge device to obtain a modified polyether sulphone ultrafiltration membrane; and 3, taking an acrylic monomer, and grafting the modified polyether sulphone ultrafiltration membrane with the acrylic monomer to obtain the amphoteric polyether sulphone separation membrane. The polyether sulphone separation membrane prepared by the preparation method is an amphoteric membrane of which the surface contains amine groups and carboxyl, and the surface hydrophilicity is enhanced, so that the pollution resistance of the membrane is improved; and while the retention rate is increased, the pure water flux is greatly improved, so that the filtration efficiency is improved.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Fluorine-containing aqueous coating composition

InactiveCN1738878AGood chemical resistanceImprove water resistancePolyurea/polyurethane coatingsSolventChemistry

A fluorine-containing aqueous coating composition composed of (A) an aqueous emulsion of a functional group-containing fluororesin obtained by dispersing, in water, a fluoroolefin copolymer having a functional group that is obtained through solution polymerization and (B) a water-dispersible unblocked isocyanate compound is disclosed. The fluororesin aqueous coating composition can be cured at ordinary temperature, and a coating formed therefrom is excellent in chemical resistance, water resistance, solvent resistance, contamination resistance, hardness, weathering resistance and durability.

Owner:DAIKIN IND LTD

Composite reverse osmosis membrane as well as preparation method and application thereof

InactiveCN107297158AImprove mechanical propertiesHigh desalination rateMembranesSemi-permeable membranesCross-linkReverse osmosis

The invention relates to the field of water treatment and discloses a composite reverse osmosis membrane as well as a preparation method and application thereof. The composite reverse osmosis membrane comprises a supporting layer, a separation layer and a hydrophilic and pollution-resisting layer, which are stacked in sequence, wherein the separation layer is a layer formed by cross-linked polyamide; and the hydrophilic and pollution-resisting layer is a layer formed by carrying out a crosslinking reaction on a polymer containing hydroxyl and a silane coupling agent containing zwitterions. The reverse osmosis membrane provided by the invention not only has relatively high water flux and desalting rate, but also has relatively strong pollution-resisting performance; and the preparation method of the reverse osmosis membrane is simple and has an extremely good industrial application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Pollution-resistant separation membrane with mixed charge layer on surface and preparation method thereof

InactiveCN108295676AWide range of optionsMild reaction conditionsReverse osmosisCharge layerPollution

The invention discloses a pollution-resistant separation membrane with a mixed charge layer on the surface and a preparation method thereof. The surface of the pollution-resistant separation membranecontains an equal number of reverse charged groups at the same time, and the surface of the membrane shows local charge balance. The preparation method comprises the following steps: immersing the separation membrane containing a reaction site on the surface into a mixed solution containing an anionic compound and a cationic compound, and simultaneously grafting the anions and cations onto the surface of the separation membrane through a Michael addition reaction to obtain the pollution-resistant separation membrane with the mixed charge layer on the surface. By the preparation method, the selection ranges of raw materials are wide, the process is simple and mild, designability is strong, industrialization is easy, and the prepared pollution-resistant separation membrane has a significantly improved pollution-resistant effect and is stable in structure.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com