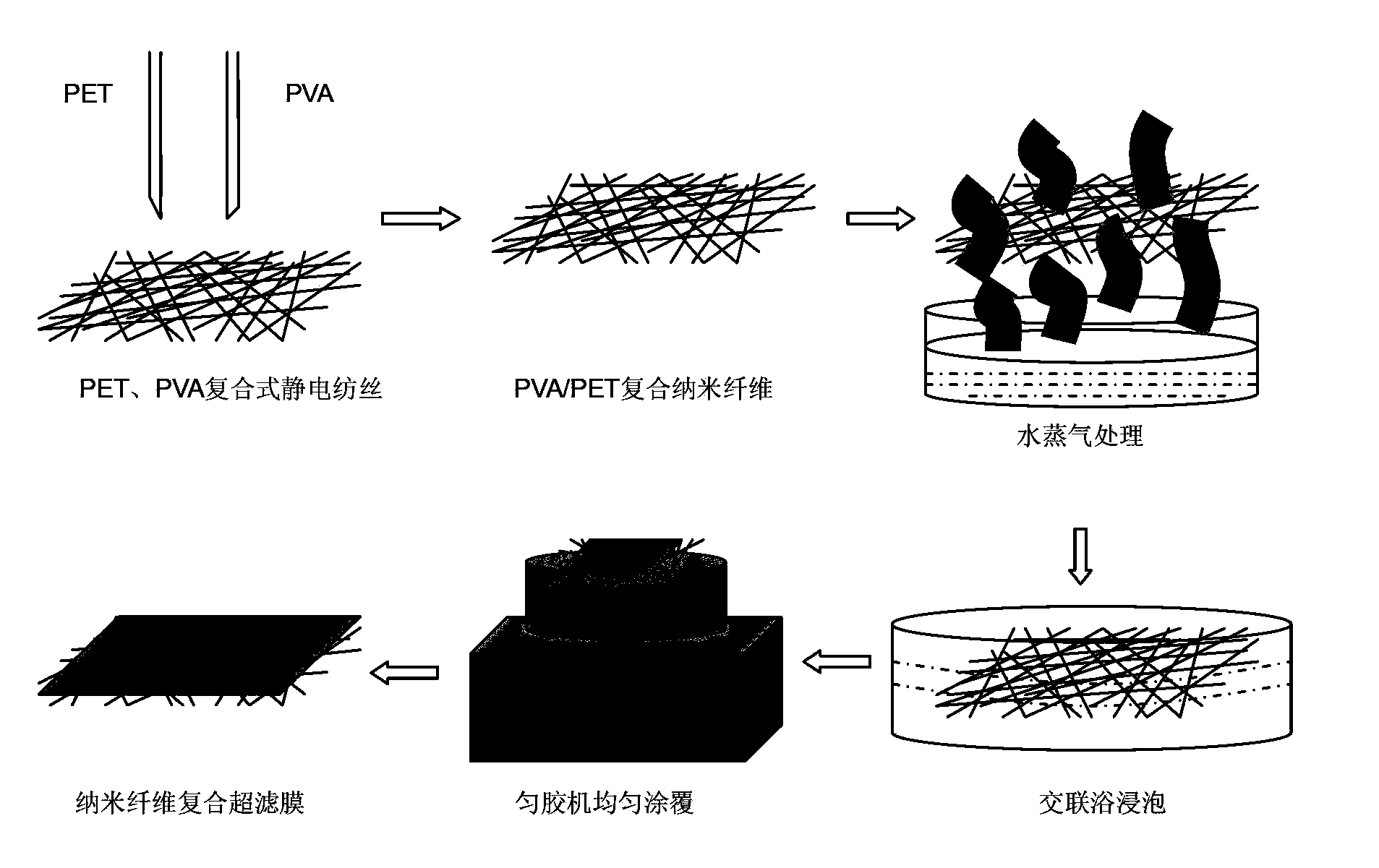

Nano-fiber composite ultrafiltration membrane preparation method based on electrostatic spinning technology

An electrospinning technology, a nanofiber technology, is applied in the field of preparation of nanofiber composite ultrafiltration membranes, which can solve the problems of limiting the flux and retention rate of the filtration membrane, low porosity, and large pore size on the membrane surface, and achieves wide industrial application. , the effect of high water flux and retention rate, good pollution resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Weigh a certain amount of PET and dissolve it in a mixed solution of trifluoroacetic acid (TFA) / dichloromethane (DMC) (4:1 (v:v)) to make a solution with a concentration of 20wt%, and let it stand After completely dissolving, stir it with magnetic force for one hour to obtain PET spinning solution (spinning solution A) for use.

[0034] (2) Prepare a PVA aqueous solution with a mass fraction of 7%, fully swell for 24 hours, and then heat in a water bath for 3 hours. Cool to room temperature to obtain PVA spinning solution; in addition, prepare a uniform PVA aqueous solution with a mass fraction of 1%, and then process it with a glutaraldehyde crosslinking agent, that is, add glutaraldehyde and make its content in the PVA solution be 1wt%, to obtain a PVA coating solution, wherein the content of glutaraldehyde is 1wt%.

[0035] (3) Add the prepared PET spinning solution to one nozzle, and PVA spinning solution to another nozzle to perform composite electrospinning t...

Embodiment 2

[0041] (1) Weigh a certain amount of PET and dissolve it in a mixed solution of trifluoroacetic acid (TFA) / dichloromethane (DCM) (2:1 (v:v)) to make a solution with a concentration of 25wt%, and let it stand for After complete dissolution, magnetically stir for two hours and set aside.

[0042] (2) Prepare a PVA aqueous solution with a mass fraction of 7wt%, fully swell for 24 hours, and then heat in a water bath for 5 hours. Cool to room temperature to obtain a PVA spinning solution; in addition, prepare a uniform PVA aqueous solution with a mass fraction of 2%, and process it with a glutaraldehyde crosslinking agent to obtain a PVA coating solution, wherein the content of glutaraldehyde is 1wt%.

[0043] (3) Put the prepared PET spinning solution (spinning solution A) into one nozzle, and PVA spinning solution into another nozzle to perform composite electrospinning to obtain a nanofiber composite film. The basic parameters of electrospinning are: : Voltage 19kV, nozzle ape...

Embodiment 3

[0048] (1) Prepare a trifluoroacetic acid (TFA) solution with a mass fraction of 28% of PET, let it stand until it is completely dissolved, and then stir it magnetically for one hour to obtain a PET spinning solution (spinning solution A).

[0049] (2) Prepare a PVA aqueous solution with a mass fraction of 8%, fully swell for 24 hours, and then heat in a water bath for 3 hours. Cool to room temperature to obtain PVA spinning solution; in addition, it is formulated into a uniform PVA aqueous solution with a mass fraction of 2%, and treated with a terephthalaldehyde crosslinking agent to obtain a PVA coating solution, wherein the content of terephthalaldehyde is 1wt%.

[0050] (3) Add the prepared PET spinning solution to one nozzle, and PVA spinning solution to another nozzle to perform composite electrospinning to obtain a nanofiber composite film. The basic parameters of electrospinning are: voltage 20kV, nozzle aperture 0.8mm, the flow rate of spinning solution (spinning so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com