Preparation method of composite membrane containing oxidized graphene

A composite membrane and graphene technology, applied in the field of membrane separation, can solve the problems of limiting the structural properties of graphene oxide, unfavorable application in the field of separation membrane preparation, long preparation time, etc., to improve water flux and retention rate, and the preparation method is simple. , The effect of high preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

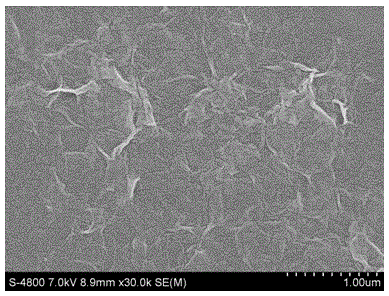

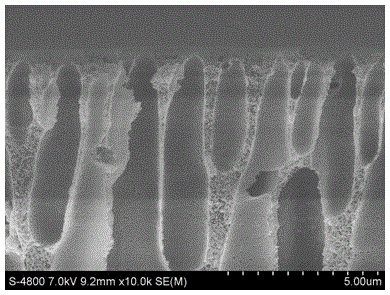

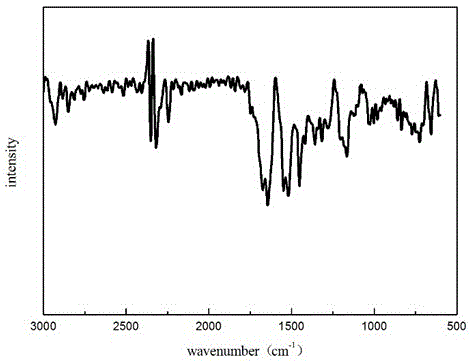

[0029] In the embodiment of the present invention, the polyacrylonitrile (PAN) base film was immersed in a 0.5 mol / L NaOH solution for alkali treatment for 1.5 h to obtain a charged H-PAN base film with a surface charge. The prepared charged base film was placed in the middle of an electric field composed of two graphite plates, and a distance of 2 cm was kept between the charged base film and the two electrodes. Add 1g / L positively charged polyetherimide to the electric field, turn on the power supply, and keep it energized at 5V for 3 minutes to obtain a composite film with a positively charged surface, and place the composite film in the air for 5 minutes until drained. Put the composite film in the middle of the electric field again, change the direction of the positive and negative poles of the power supply, add 1g / L negatively charged graphene oxide in the electric field, turn on the power supply, and keep it powered on for 3min at a current of 5V, so that the negatively ...

Embodiment 2

[0032] In the embodiment of the present invention, the base film of polyacrylonitrile (PAN) was immersed in a 0.5 mol / L NaOH solution for 1.5 hours of alkali treatment to obtain a charged H-PAN base film with a surface charge. The prepared charged base film was placed in the middle of an electric field composed of two graphite plates, and a distance of 4 cm was kept between the charged base film and the two electrodes. Add 1g / L positively charged polyallylamine hydrochloride to the electric field, turn on the power supply, and keep electrifying at 3V for 3min to obtain a positively charged composite film on the surface, and place the composite film in the air for 10min until Drain. Put the composite film in the middle of the electric field again, change the direction of the positive and negative electrodes of the power supply, add 0.025g / L negatively charged graphene oxide into the electric field, turn on the power supply, and keep electrifying at a current of 3V for 3min to m...

Embodiment 3

[0035]In the embodiment of the present invention, a positively charged polyamideimide (PAI) base film is placed in the middle of an electric field composed of two copper electrode plates, and a distance of 2 cm is maintained between the base film and the two electrodes. Add 1g / L negatively charged graphene oxide in the electric field, turn on the power supply, and keep it on for 3 minutes at 5V to obtain a composite film with a negatively charged surface, and place the composite film in the air for 10 minutes until drained. Put the composite film in the middle of the electric field again, change the direction of the positive and negative poles of the power supply, add 1g / L positively charged cationic acrylamide into the electric field, turn on the power supply, and keep electrifying at a current of 5V for 3min to make the positively charged cationic acrylamide Amides are enriched around the composite membrane and deposited on the surface of the composite membrane through electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com