Inorganic-organic hybrid film based on Cu2O nano wire, and preparation method and application thereof

A technology of organic hybridization and nanowires, applied in the field of inorganic-organic hybrid membranes and its preparation, can solve the problems of low mechanical properties and poor stability, and achieve the effect of good mechanical properties, good stability, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) 250ml 10mM CuSO 4 Solution, mix 250mL NaOH (28mM) solution and 500mL glucose (0.8mM) solution, stir evenly, place in a 1L flask, heat on a heating mantle, keep at 85-90°C for 40 minutes, the solution will be seen It turns from blue to yellow-green and finally orange, which proves the progress of the reduction reaction. After the reaction solution is cooled, it is washed with deionized water, and the solid is collected by filter membrane filtration. It is dried and stored at 60 ° C to obtain yellow-green cuprous oxide nanowires, which are recorded as Cu. 2 O NWs.

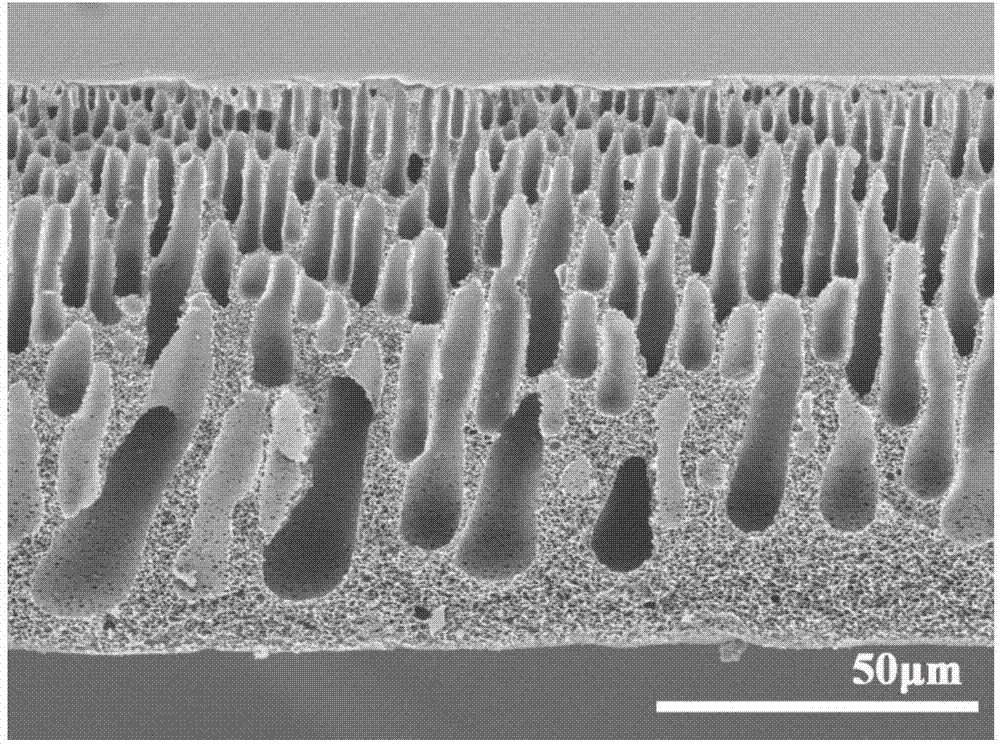

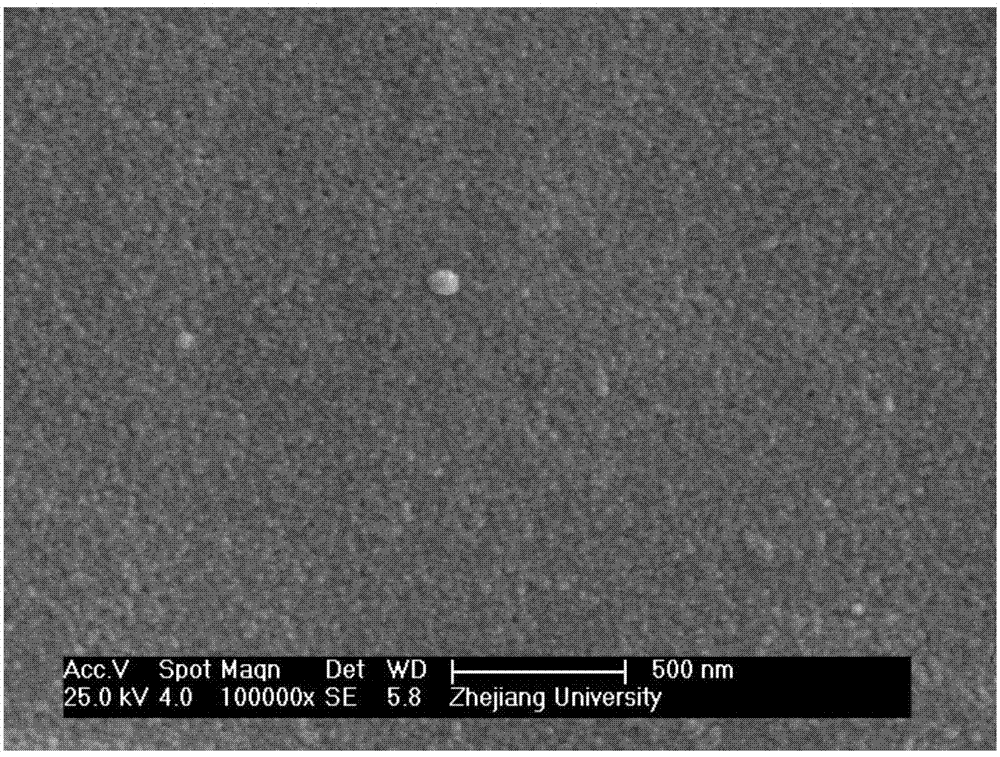

[0025] (2) 3.657g dry PSF and 0.023g Cu 2 O NWs(Cu 2 The mass of O NWs is PSF, Cu 2 (0.1wt% of the total mass of O NWs and DMAC) was dissolved in 20.6mL organic solvent DMAC, stirred for 12h to a uniform and stable casting solution, and then the casting solution was left to stand for 24h and ultrasonically degassed; adjust the ambient humidity ( 60-65%rh) and temperature (20-25°C), cast the casting sol...

Embodiment 2

[0036] (1) 250ml 2mM CuSO 4 Solution, mix 250mL NaOH (50mM) solution and 500mL glucose (0.4mM) solution, stir evenly, place in a 1L flask, heat on a heating mantle, keep at 85-90°C for 40 minutes, the solution will be seen It turns from blue to yellow-green and finally orange, which proves the progress of the reduction reaction. After the reaction solution is cooled, it is washed with deionized water, and the solid is collected by filter membrane filtration. It is dried and stored at 60 ° C to obtain yellow-green cuprous oxide nanowires, which are recorded as Cu. 2 O NWs.

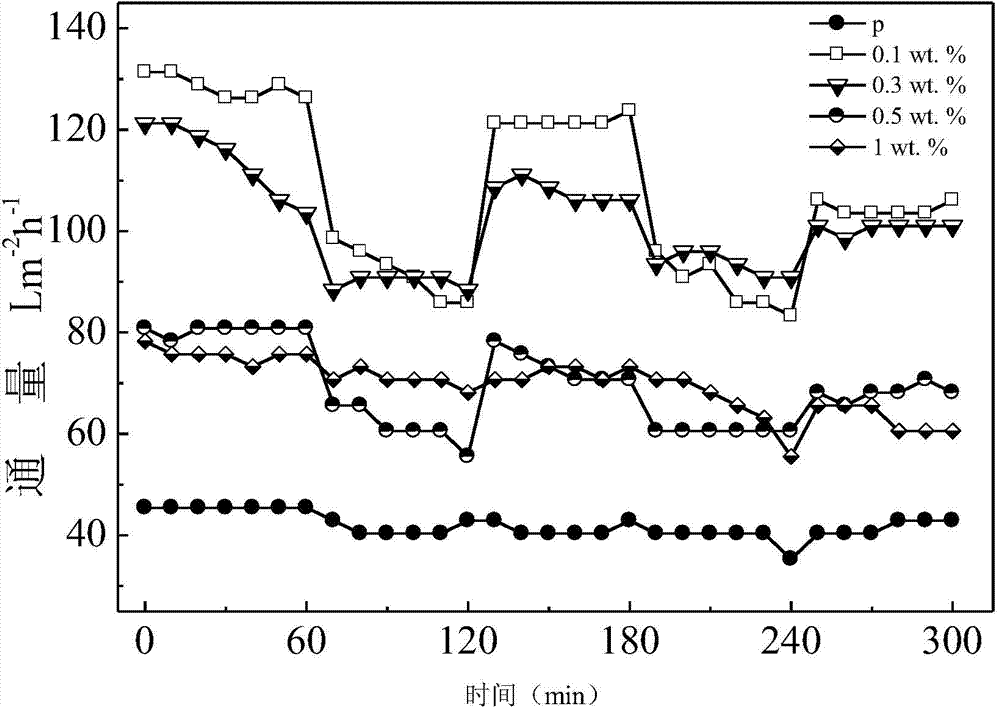

[0037] (2) operate according to the step (2) of embodiment 1, the difference is that PSF is changed into PVDF, and the Cu prepared by adding different amounts of steps (1) 2 O NWs, making Cu 2 The masses of O NWs are PVDF, Cu 2 0 of the total mass of O NWs and DMAC (i.e. no Cu 2 O NWs, pure PVDF organic film), 0.1%, 0.3%, 0.5%, 1wt%, prepared different Cu 2 O NWs content of Cu 2 O NWs / PVDF membrane. ...

Embodiment 3

[0040] Cu in Example 1 2 O NWs and dry PES are blended and dissolved in the organic solvent DMAC, and are operated according to the step (2) of Example 1 to make Cu 2 The masses of O NWs are PES, Cu 2 0 of the total mass of O NWs and DMAC (i.e. no Cu 2 O NWs, pure PES organic film), 0.1%, 0.2%, 0.5%, 1wt%, prepared different Cu 2 O NWs content of Cu 2 O NWs / PES film.

[0041] to Cu 2 O NWs / PES also carried out the measurement of the flux of pure water and BSA filtration experiments, the results show that the flux of the hybrid membrane is the largest when the addition amount is 0.2wt.%: the initial flux is 126.1L m -2 h -1 , after two 1-hour BSA filtrations, the pure water flux was maintained at 100.2L m -2 h -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume usage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com