Patents

Literature

96results about How to "Smooth and dense surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wolframium (W) doped diamond-like coating and preparation method thereof

InactiveCN103451608AHigh coating hardnessImprove bindingVacuum evaporation coatingSputtering coatingChemical stabilityMaterials science

The invention provides a wolframium (W) doped diamond-like coating and a preparation method thereof. The coating comprises a Cr bottom layer, a CrC transition layer and a W doped diamond-like layer, wherein the Cr bottom layer is deposited on the surface of a substrate, the CrC transition layer is prepared on the Cr bottom layer, and the W doped diamond-like layer is prepared on the CrC transition layer. The preparation method comprises the following steps: firstly carrying out plasma cleaning on the substrate, opening a column electric arc Cr target to prepare the Cr bottom layer on the surface of the substrate, opening a plane magnetron sputtering C target to prepare the CrC transition layer on the Cr bottom layer, and finally closing the column electric arc Cr target and opening a plane magnetron sputtering W target to prepare the W doped diamond-like layer on the CrC transition layer. According to the preparation method provided by the invention, the electric arc and magnetron sputtering composite coating technology is adopted, so that the prepared coating is smooth and compact in surface, high in hardness, high in film bonding strength, low in friction coefficient and good in oxidization resistance and chemical stability, and can meet relatively high requirements for oxidization resistance, wear resistance and antifriction performance, therefore the coating has wide application prospects.

Owner:XI AN JIAOTONG UNIV

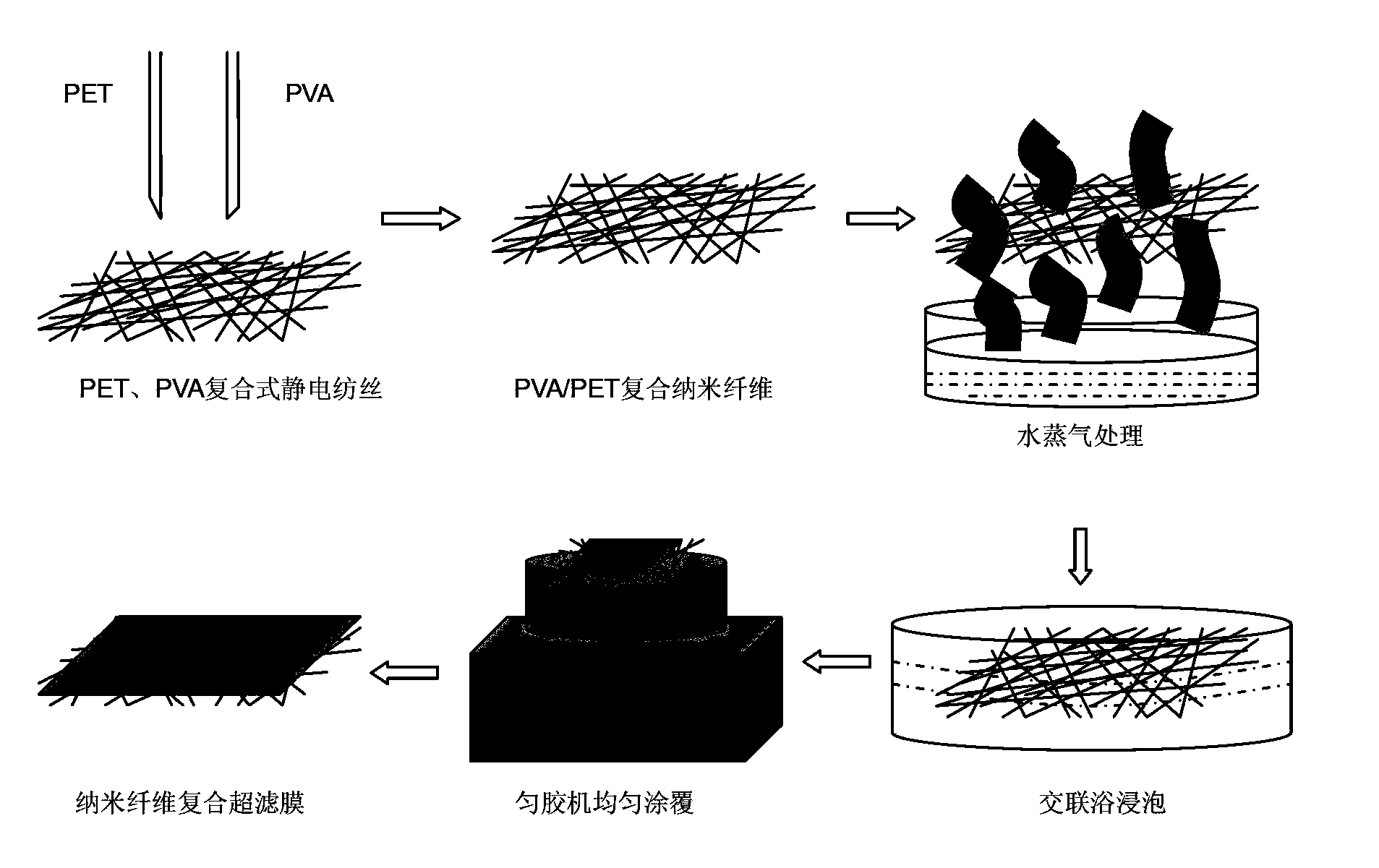

Nano-fiber composite ultrafiltration membrane preparation method based on electrostatic spinning technology

ActiveCN103386257AHigh water flux and retentionWide range of industrial applicationsSemi-permeable membranesUltrafiltrationIon

The invention relates to a nano-fiber composite ultrafiltration membrane preparation method based on an electrostatic spinning technology. According to the invention, a high-molecular polymer used for spinning is dissolved in a solvent, such that a spinning solution A with a concentration of 10-30wt% is obtained; a PVA spinning solution with a mass percentage of 7-10% is prepared; a PVA water solution with a mass concentration of 1-6% is prepared; through crosslinking treatment, a PVA coating liquid is obtained; the spinning solution A and the PVA spinning solution is subjected to composite electrostatic spinning, such that a nano-fiber composite membrane is obtained; the membrane is processed under water vapor, and is soaked with a crosslinking bath; the PVA coating liquid is used for coating by using a spin coater; a sealed reaction is carried out under room temperature; the membrane is soaked by using deionized water, and is suspended and air-dried, such that the ultrafiltration membrane is obtained. The surface of the prepared nano-fiber composite ultrafiltration membrane comprises large amounts of hydrophilic groups and active groups. The membrane has good mechanical performances and anti-pollution performances, and is especially suitable for ultrafiltration under ultra-low pressure or even no power. The membrane has high flux and retention rate under low pressure.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

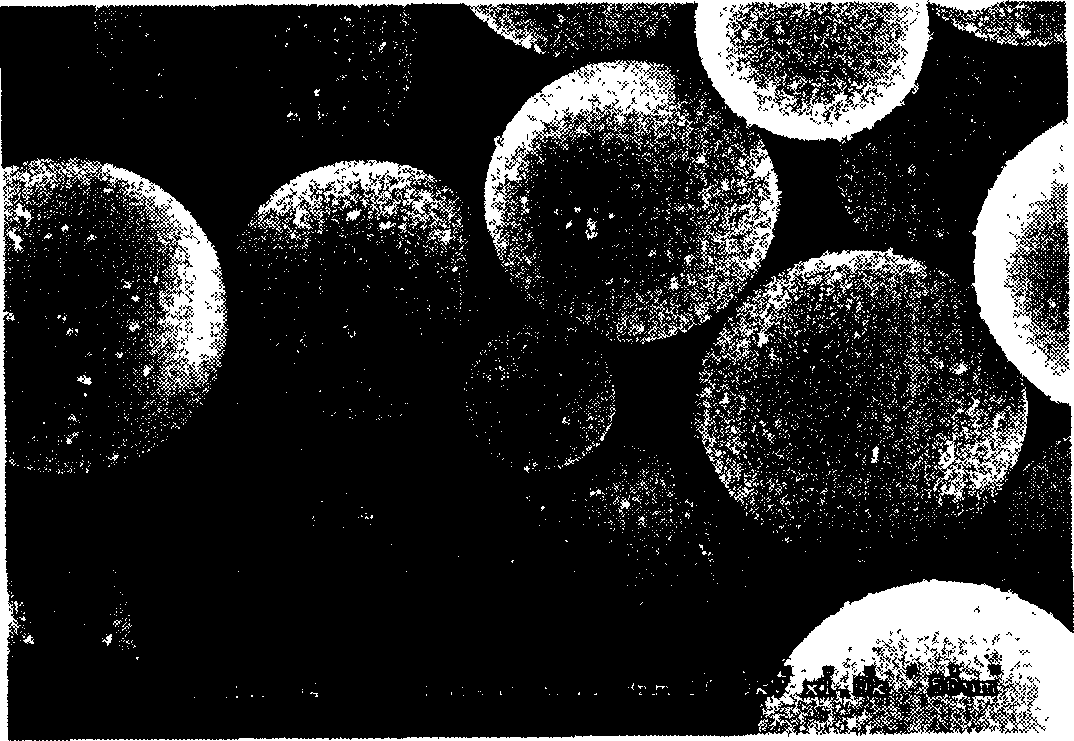

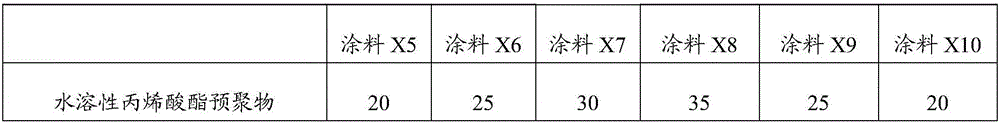

Phase change energy storage microcapsule of composite shell and its making method

InactiveCN1570014ASmooth and dense surfaceComplete appearanceHeat-exchange elementsMicroballoon preparationHexadecaneComposite construction

The invention discloses a phase change energy storage microcapsule of composite shell and its making method, wherein the core material of the microcapsule employs tetradecane, pentadecane or hexadecane, the shell layer has a composite construction, the inner layer is melamine resin, the outer layer is PEG200 modified melamine resin, or PEG200 modified melamine, or copolycondensation resin of methyl poultry manure amine, acetyl poultry manure amine or benzene substituted melamine.

Owner:TIANJIN UNIV

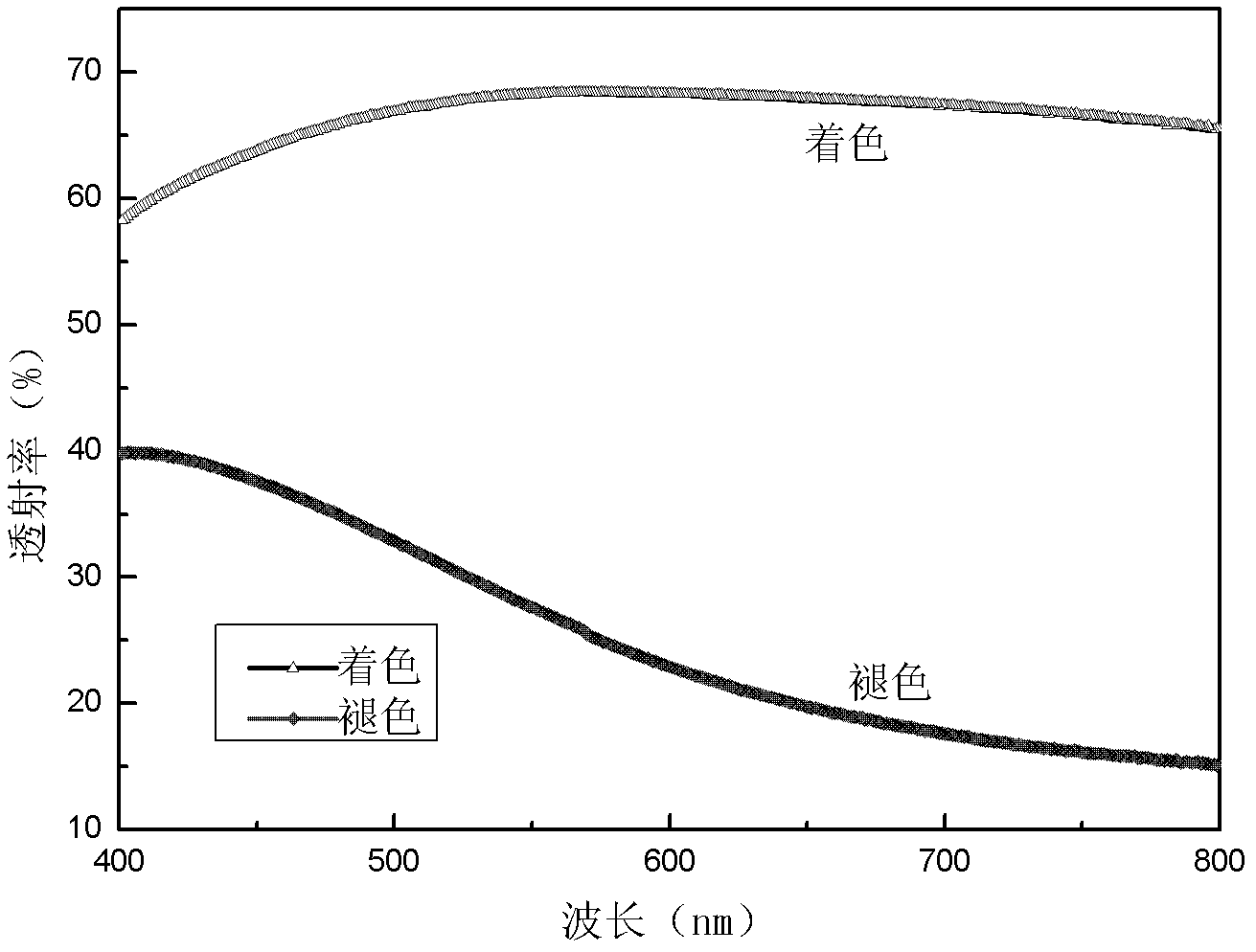

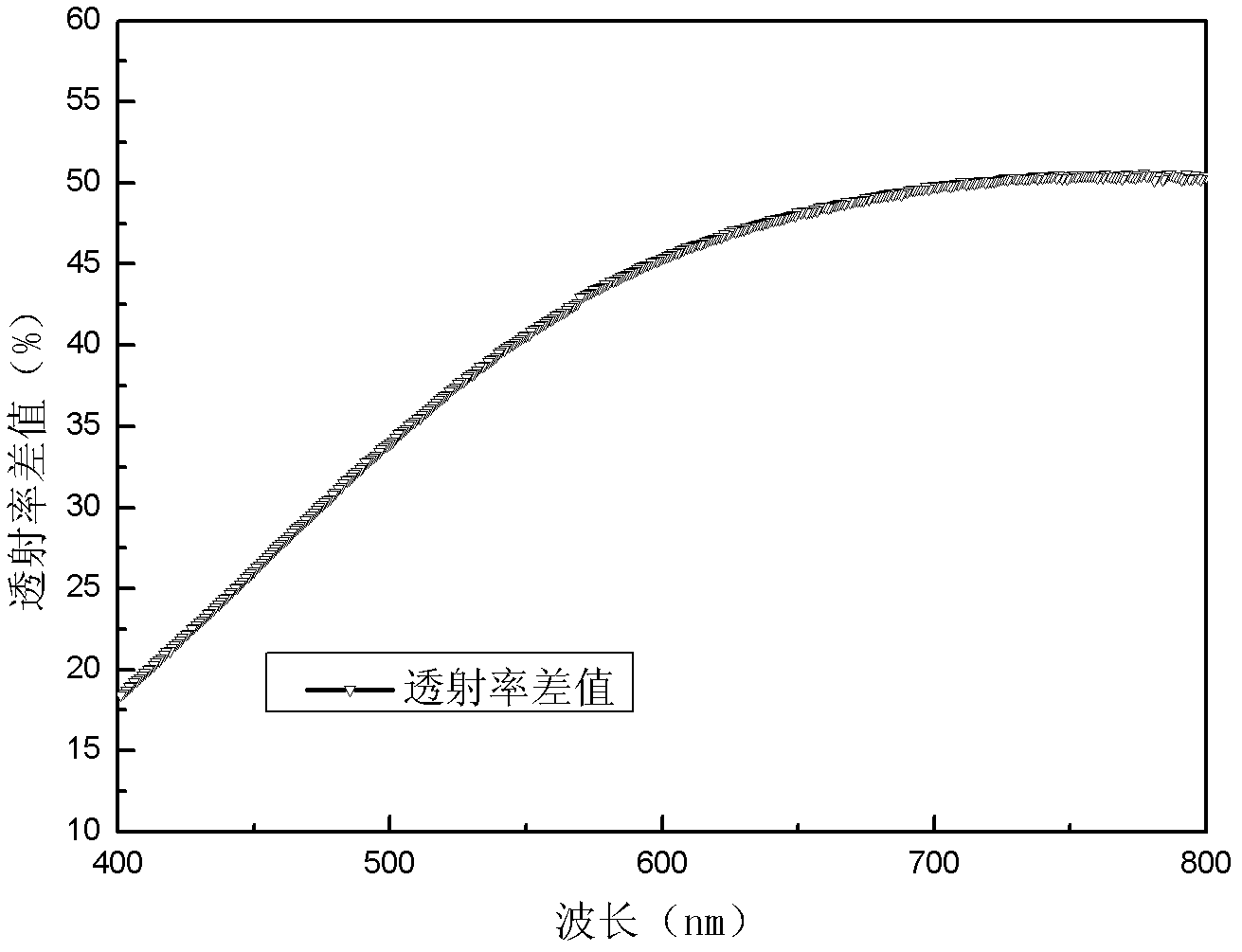

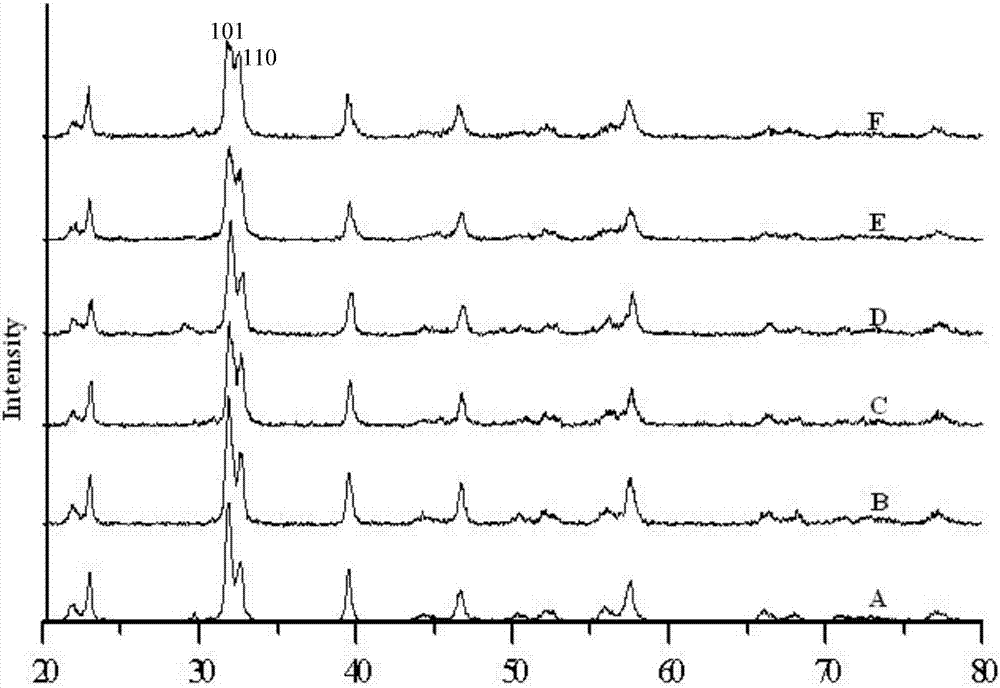

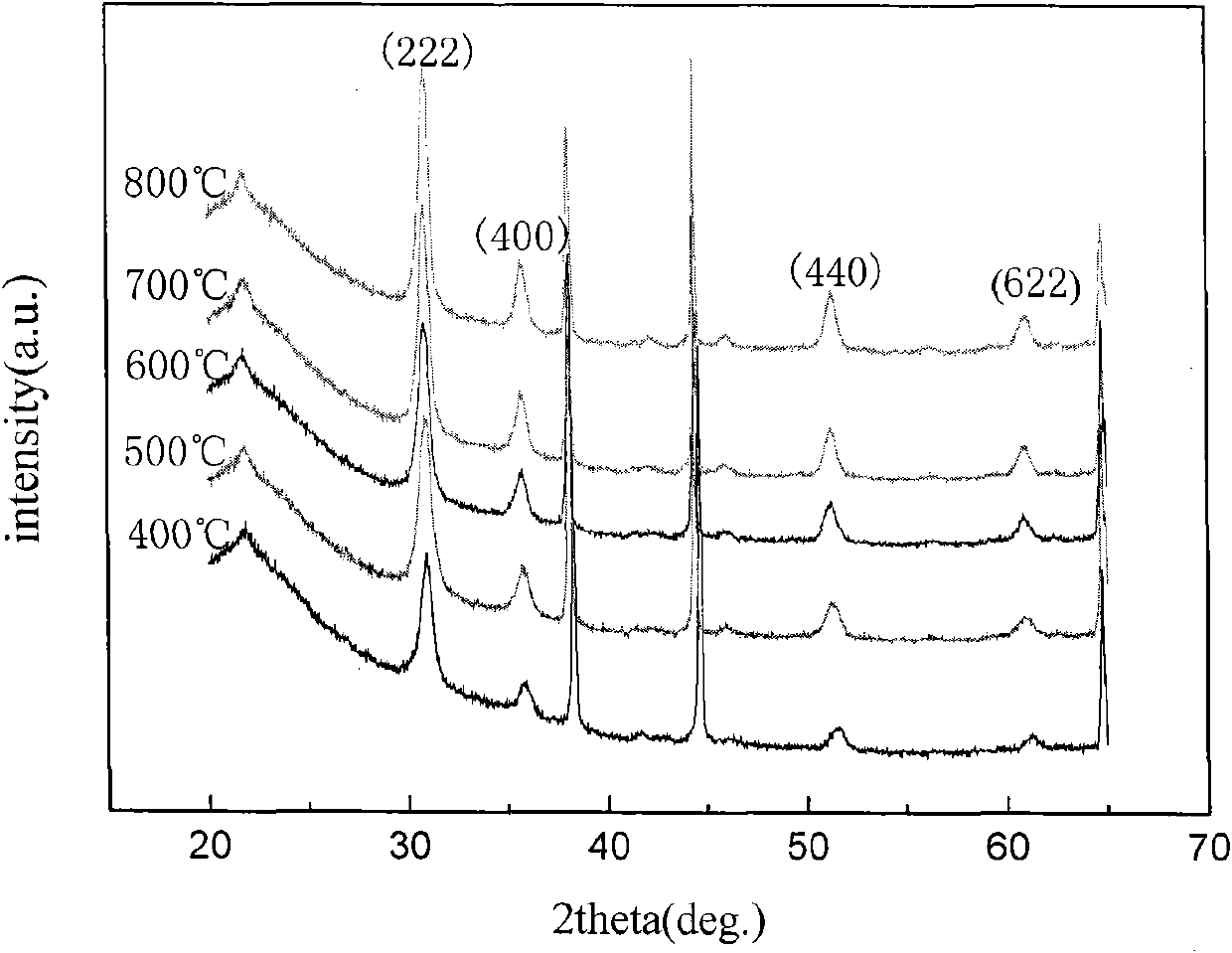

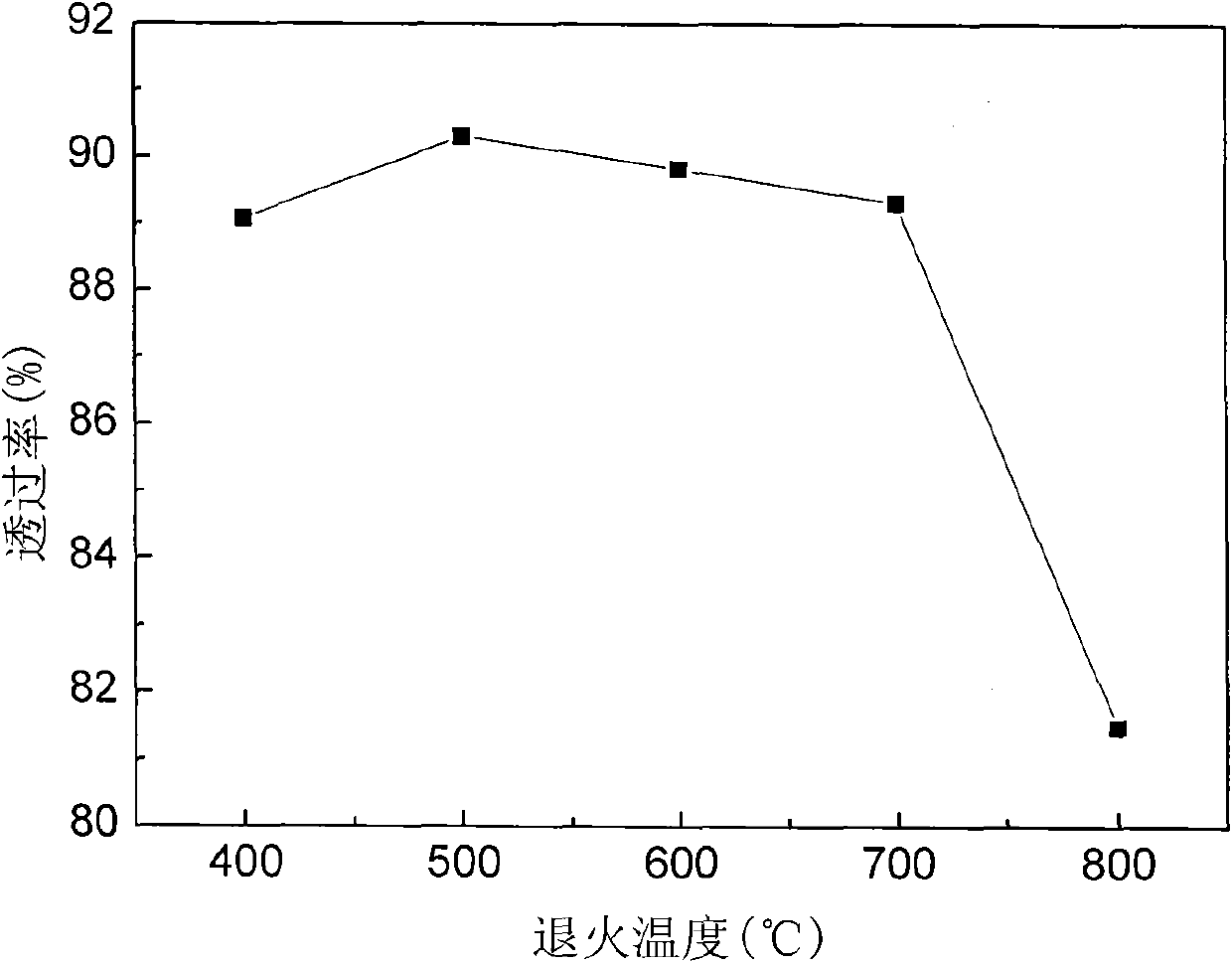

Method for preparing WO3 film

ActiveCN102849963AEasy to manufactureExcellent electrochromic performanceWater bathsRoom temperature

The invention relates to a method for preparing a WO3 film, comprising the following concrete steps of: (1) dissolving a tungsten powder in hydrogen peroxide in water bath to prepare a solution X, and reacting in water bath at room temperature for 3-4 h, wherein the ratio of the tungsten powder to hydrogen peroxide is (10-25 g) to (100 ml); (2) stirring the solution X to react at the temperature of 51-55 DEG C for 25-30 min, and filtering; (3) adding anhydrous ethanol into the solution X with the ratio of hydrogen peroxide to anhydrous ethanol being 2: 0.9-1.1, stirring for reaction at the temperature of 75-85 DEG C for 28-30 min, and allowing an orange transparent sol to stand for 4-5 hours; (4) dipping a cleaned ITO or FTO glass substrate in the sol for 100-140s, and pulling for film forming at the speed of 4.5-5 cm / min; and (5) drying the obtained substrate at the temperature of 75-85 DEG C for 20-30 min, and annealing at the temperature of 180-220 DEG C for 50-70 min so as to obtain the WO3 film. The WO3 film prepared by the method has advantages of good electrochromic property, good cycle stability and smooth and compact surface.

Owner:ZHANGZHOU KIBING GLASS

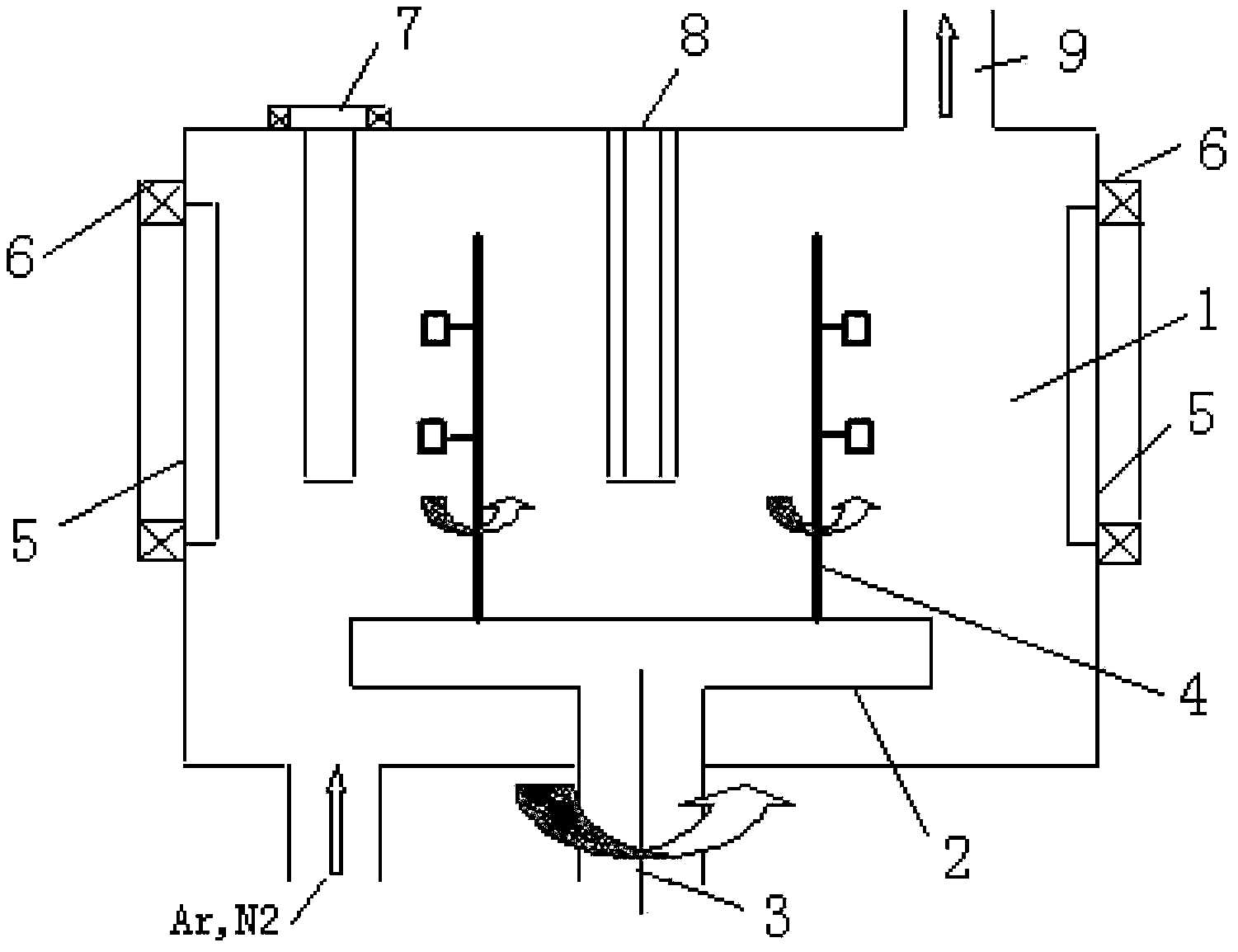

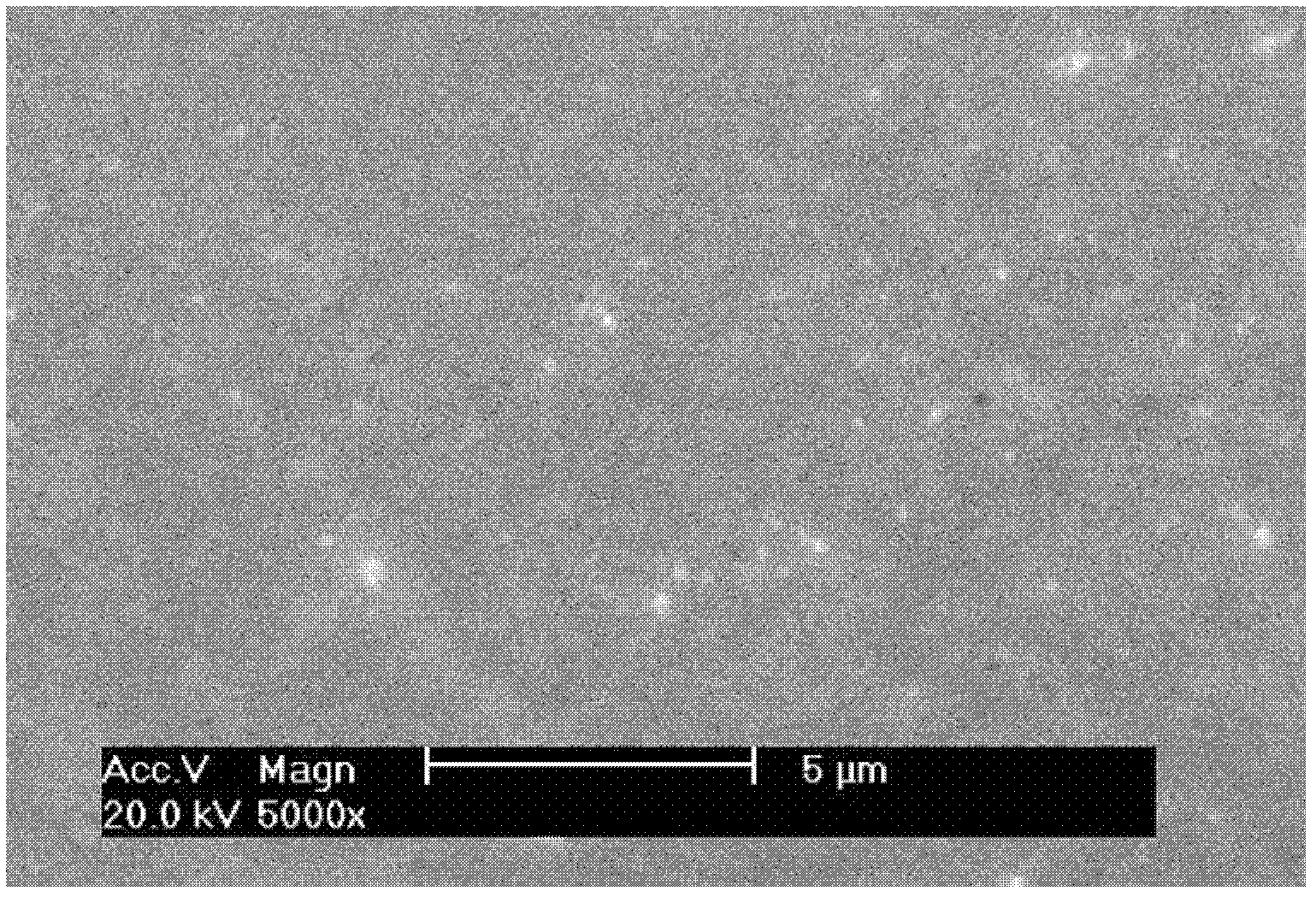

Cr-doped DLC (diamond-like carbon) coating with anticorrosion and antifriction properties and preparation method

InactiveCN102912298AImprove bindingSmooth and dense surfaceVacuum evaporation coatingSputtering coatingDlc coatingSputtering

The invention discloses a method for preparing a corrosion-resistant antifriction Cr-doped DLC (diamond-like carbon) coating. The method comprises the steps of placing a pretreated substrate on a rotating stand rod of arc and magnetron sputtering composite deposition equipment, taking a post arc Cr target as a Cr source and three pairs of flat targets C targets as C sources, and installing the three pairs of flat targets C on the inner wall of a furnace body in an opposite manner; adopting high-purity Ar as a main ionization gas to guarantee an effective glow discharge process; and adopting high-purity N2 as a reacting gas, ionizing the reacting gas and combining the reacting gas with Cr and C elements to deposit on the surface of the substrate so as to form the Cr-doped DLC coating. The prepared Cr-doped DLC coating has a smooth and compact surface, hardness of 20 GPa, binding force with the substrate of 80N, coating thickness of 2.0 micrometers, and excellent corrosion resistance and antifriction performance.

Owner:XIAN HAOYUAN COATING TECH

Handicraft clay sculpture material and preparation method thereof

InactiveCN104261794AGuaranteed patch improvementsThe formula is scientific and reasonableOperabilityChloride

The invention discloses a handicraft clay sculpture material. The handicraft clay sculpture material is prepared from the following raw materials in parts by weight: 2-3 parts by weight of borax, 1-2 parts by weight of ammonium dihydrogen phosphate, 4-6 parts by weight of magnesium oxide, 0.5-1 part by weight of aluminum chloride, 0.5-1 part by weight of sodium humate, 50-60 parts by weight of kaolin, 10-20 parts by weight of calcium carbonate, 30-40 parts by weight of quartz powder, 10-20 parts by weight of white mica powder, 1-3 parts by weight of gypsum, 0.5-1 part by weight of hydroxyethyl cellulose and water, wherein the total amount of the water is the required amount for realizing a dough-like plastic state of a product. The handicraft clay sculpture material disclosed by the invention can be used under any conditions, has the advantages of reasonable and scientific formula, easiness in obtainment of the raw materials, low cost and easiness in dispersion and stirring, the surface of a work is less prone to cracking in a hardening process and is dense and smooth, and the handicraft clay sculpture material can be widely used in the fields of sculptures, clay sculptures, models and the like. The invention further discloses a preparation method of the handicraft clay sculpture material, and the preparation method has the advantages of simple process steps and strong operability.

Owner:HUANGHE S & T COLLEGE

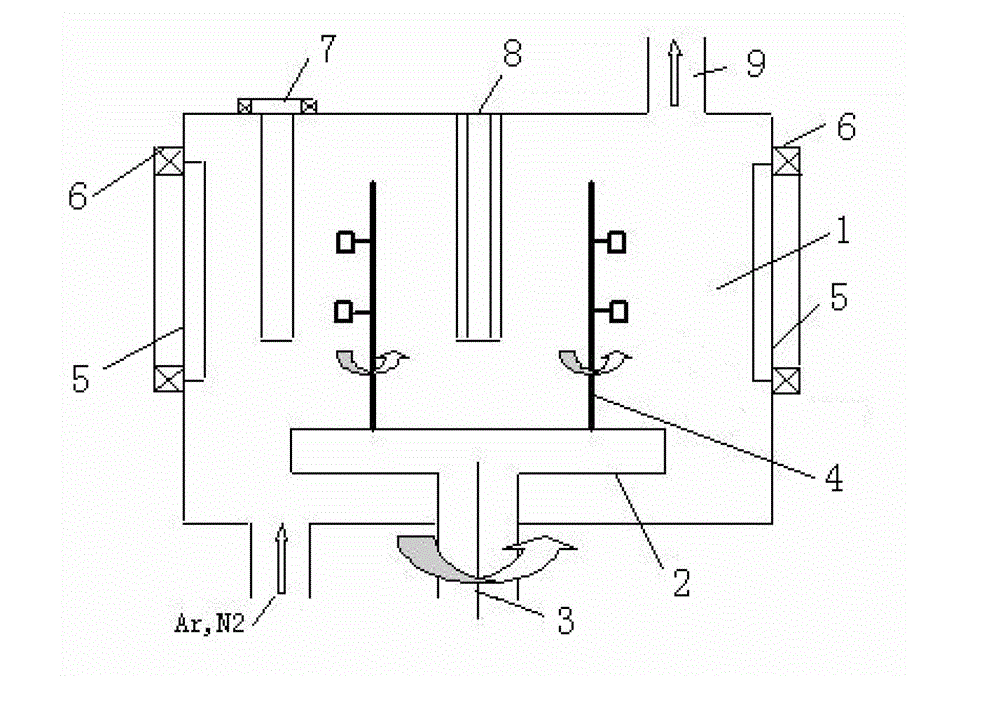

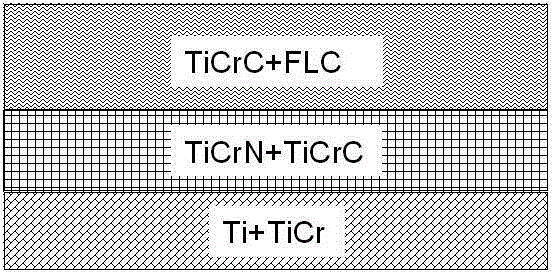

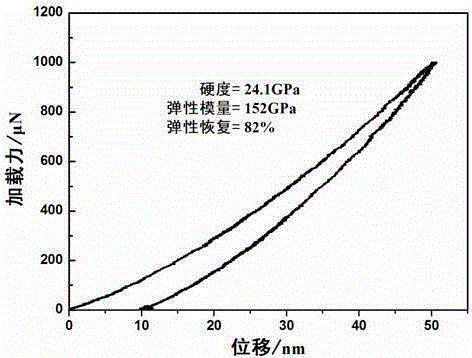

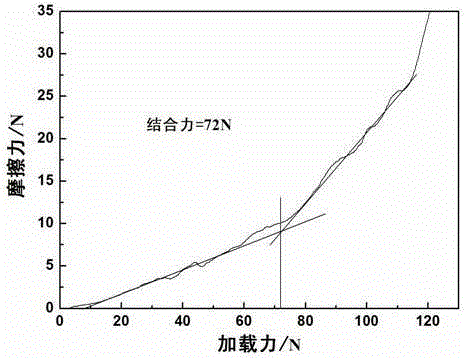

Method for achieving industrialization of multi-layer composite fullerene-like film on automotive engine

ActiveCN105220120ARealize industrial productionSimple processVacuum evaporation coatingSputtering coatingSputteringPlasma density

Disclosed is a method for achieving industrialization of a multi-layer composite fullerene-like film on an automotive engine. According to the invention, industrialization of the multi-layer composite fullerene-like film on the automotive engine is achieved through the cooperation between an integration technology with the combination of cathodic arcs and unbalanced magnetron sputtering and a technology which utilizes a high-power pulse ion source to increase the plasma density of a region with a coating film. The prepared multi-layer composite fullerene-like film has excellent comprehensive performance of the low friction coefficient, low abrasion, high elastic recovery and high binding force, the quality of the engine can be substantially improved, and the service life of the engine can be substantially prolonged.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing rose hip seed oil microcapsules

ActiveCN104982933ADispersed without stickingSmooth and dense surfaceLipidic food ingredientsFood preparationPolymer scienceRose hip

The invention relates to a method for preparing rose hip seed oil microcapsules, and belongs to the technical field of microcapsule preparation. According to the preparation method, rose hip seed oil is used as a core material, and the following wall material composition is used as a wall material. The dosage of the core material is 20%-30% of the total mass of the core material and the wall material composition, and the wall material composition is composed of alkenyl succinic acid starch ester and maltodextrin according to the mass ratio of 1-4:1. According to the method, the maltodextrin and the alkenyl succinic acid starch ester are mixed according to the mass ratio of 1:1-4 and then are used as the wall material, the performance of the alkenyl succinic acid starch ester serving as the wall material can be improved, and thus the rose hip seed oil microcapsules without obvious sunken parts on the surfaces and with even particles are prepared.

Owner:CHINA AGRI UNIV

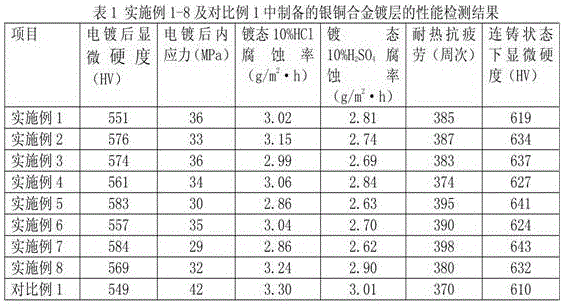

Repairing method of scrapped continuous casting crystallizer copper plate

ActiveCN105780063AImprove performanceExtended service lifeElectroforming processesSand blastingPre treatment

The invention discloses a repairing method of a scrapped continuous casting crystallizer copper plate. The repairing method comprises the steps of (1) pretreatment: carrying out degreasing treatment, mechanical sand blasting scuffing treatment, electrolytic degreasing treatment, ultrasonic degreasing treatment and acid spraying activating treatment on a copper plate base material subjected to machining, so as to obtain a to-be-cast copper plate base material; (2) electroforming solution injection: injecting an electroforming solution into an electroforming tank, adjusting the pH, and heating the electroforming solution till the temperature reaches a set value; and (3) electroforming: putting the to-be-cast copper plate base material adopted as a cathode into the electroforming tank, putting an anode into the electroforming tank, switching on the power, and stopping electroforming till the thickness of a silver-copper alloy plating reaches a set value. According to the repairing method, the crystallizer copper plate base material at the scrapping limit is repaired and reutilized through adopting an easy and feasible preparation method, the obtained crystallizer copper plate is excellent in performance, the service life of the crystallizer copper plate is prolonged through the silver-copper alloy plating, the production cost is improved, and the sustainable development property is high.

Owner:XIXIA LONGCHENG SPECIAL MATERIALS CO LTD

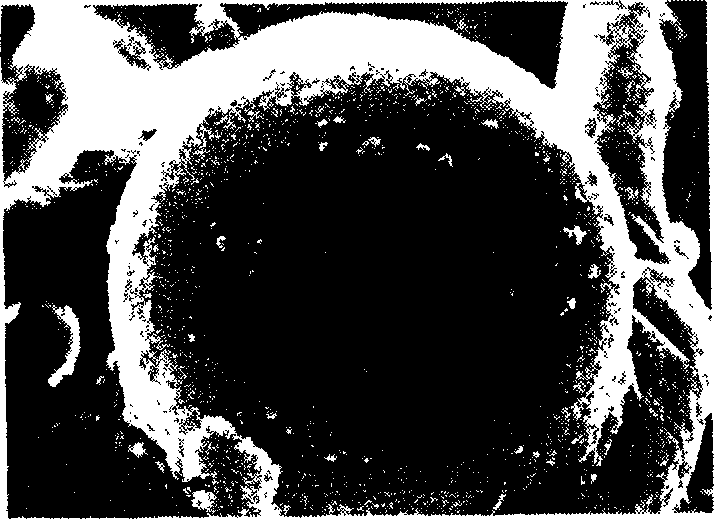

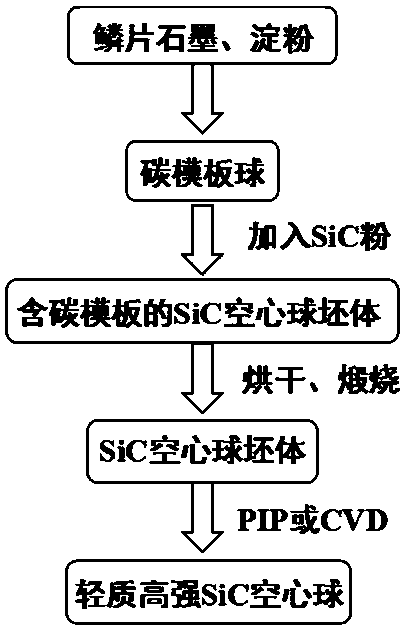

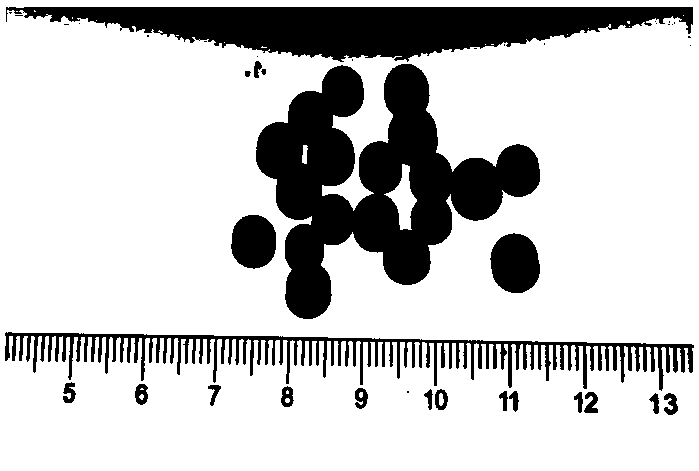

SiC hollow sphere and preparation method of same

The invention discloses a SiC hollow sphere and a preparation method of same. The preparation method includes the steps of: 1) mixing raw materials, including flake graphite, starch and water, and forming carbon template spheres in a pelletizing machine, placing the carbon template spheres in a roll-forming machine, adding SiC powder, in several batches, into the roll-forming machine to form a SiChollow sphere green body internally coated with the carbon template sphere, and drying and calcining the green body to remove the carbon template sphere to obtain a SiC hollow sphere green body; 2) compacting the surfaces of the SiC hollow sphere green body in the step 1) through a precursor vacuum impregnation pyrolysis process or a chemical vapor deposition process. The light-weight and high-strength SiC hollow sphere has high density and high compression resistance, has uniform and controllable size and smooth and compact surface, can reach 10-50 MPa in compression resistance, and can be widely applied to light packing, catalysis materials, heat preservation and insulation materials, fire-proofing and water-proofing materials, anti-radiation materials, etc.

Owner:NAT UNIV OF DEFENSE TECH

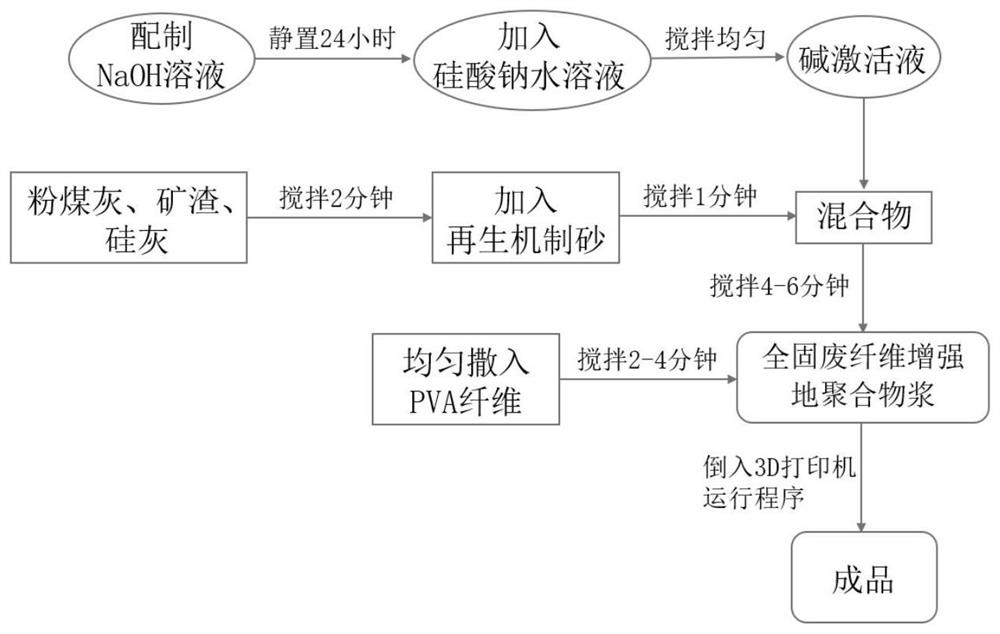

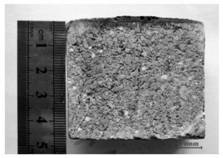

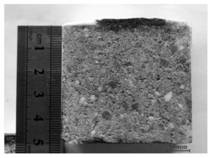

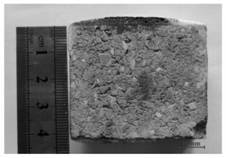

All-solid waste fiber reinforced geopolymer composite material suitable for 3D printing technology

ActiveCN113754359AImprove sustainabilityEasy to handleAdditive manufacturing apparatusCement productionIndustrial constructionAggregate (composite)

The invention relates to the technical field of solid waste resource utilization and geopolymer concrete preparation, in particular to an all-solid waste fiber reinforced geopolymer composite material suitable for a 3D printing technology. The all-solid waste fiber reinforced geopolymer composite material comprises the following raw materials in parts by mass: 20-30 parts of aggregate, 70-80 parts of a cementing material, carbon nanotubes, PVA fibers and an alkali activator, wherein the cementing material comprises the following components in percentage by mass: 15-30% of fly ash, 55-65% of slag and 10-25% of silica fume; and the aggregate is regenerated machine-made sand. The all-solid-waste ultra-high-performance geopolymer concrete provided by the invention can reach initial setting within 10-25 minutes after being discharged, and meets the 3D printing requirement. Besides, the fly ash, the slag and the regenerated machine-made sand are all derived from industrial building solid wastes, so that the waste of the solid wastes can be effectively reduced, the sustainability of the building is improved, and an efficient, environment-friendly and energy-saving solution is provided for treatment after the building is demolished.

Owner:无锡初如企业管理合伙企业(有限合伙)

NdFeB zinc series phosphating solution and application method thereof

InactiveCN105695974AImprove corrosion resistancePrevent precipitationMetallic material coating processesSaline waterTime range

The invention discloses an NdFeB zinc series phosphating solution. The NdFeB zinc series phosphating solution is composed of Zn2+, PO43-, NO3-, F-, an accelerant and Ni2+, wherein the amount-of-substance concentration ratio of Zn2+ to PO43- to NO3- to F- to the accelerant is (54-74) :(163-183) :(126-146) :(50-70) :(3-5), the concentration of the accelerant ranges from 0.1 g / L to 1.3 g / L, and the concentration of Ni2+ ranges from 0.01 g / L to 0.2 g / L. The phosphating solution and water are prepared into a work solution according to the ratio of 1:10. According to work parameters, the free acidity ranges from 5% to 8%, the total acidity ranges from 30% to 40%, the phosphating temperature ranges from 50 DEG C to 55 DEG C, the phosphating time ranges from 10 minutes to 15 minutes, NdFeB is treated to generate a light grey or grey phosphating film, the soaking time of 3% neutral saline water is three hours or above, the cross-cut test of a paint film obtained after cathode electrophoresis is the degree 0, and the time of the neutral salt spray test of the paint film obtained after cathode electrophoresis is 550 hours or above. The phosphating solution is high in film-forming thickness and fine in film layer crystallization on treated workpieces, the surface is smooth and dense, the corrosion resistance is excellent, the solution is stable, less sediment is generated, and the time of the salt spray test is longer; and meanwhile no organic complexing agent is included in the formula, the enterprise cost is reduced, and the environment is protected.

Owner:QINGDAO XINPURUI DETECTION TECH CO LTD

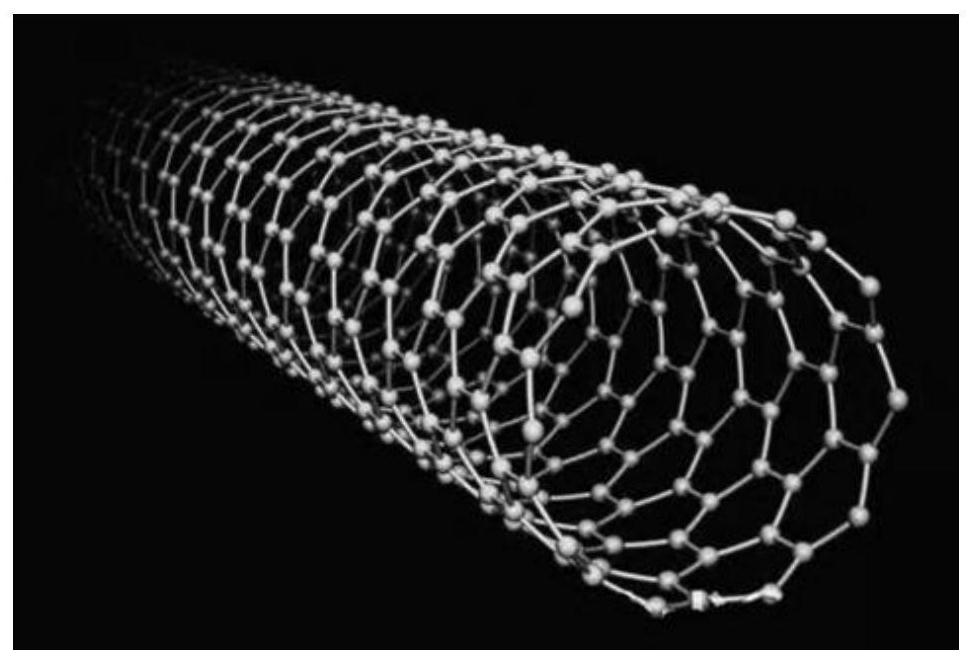

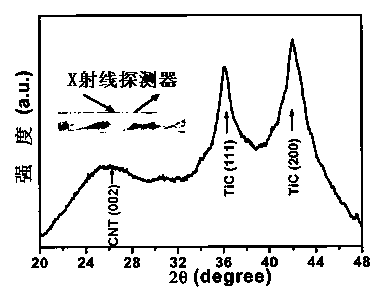

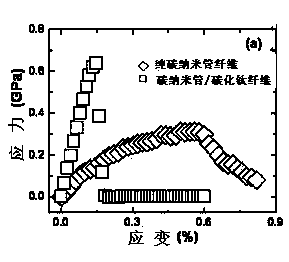

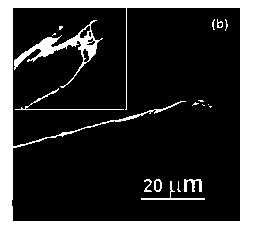

Preparation method of carbon nano-tube composite material with enhancing characteristics

InactiveCN103395772AHigh tensile modulusHigh mechanical strengthMaterial nanotechnologyCarbon compoundsFiberComposite film

The invention discloses a preparation method of a carbon nano-tube composite material with enhancing characteristics. The composite materials of carbon nano-tubes (CNTs) and a metal carbide include spiral carbon nano-tubes / metal carbide composite fiber and film. According to the composite fiber, carbon nano-tubes are drawn or twisted from a carbon nano-tube array, such that spinning fiber is formed; the spinning fiber is immersed into a metal precursor solution; and the mixture is heated in a reductive gas comprising carbon-source gas, such that the composite material is prepared. Compared with direct-spinning fiber, the carbon nano-tube composite material with enhancing characteristics has the advantages that: the composite has higher tensile strength, conductivity, and tensile modulus; 2, a parallel tape composite structure comprising carbon nano-tube array embedded in an NbC film shows enhanced conductivity and improved superconductivity along a CNT axial direction; 3, enhanced upper critical magnetic field of a NbC / CNT composite film shows that the NbC coherence length is reduced with the CNTs content in the NbC array; and 4, a nano-mechanical test also proofs the potential application of the material in enhancing the fracture toughness of the NbC / CNT composite film.

Owner:常熟苏大低碳应用技术研究院有限公司

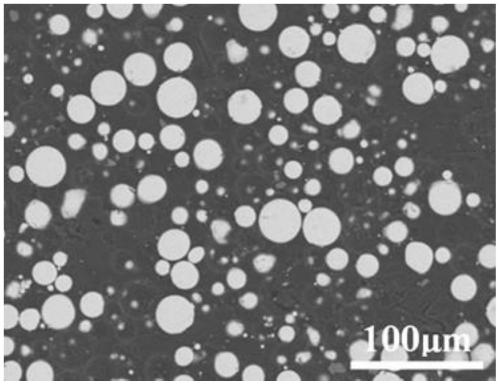

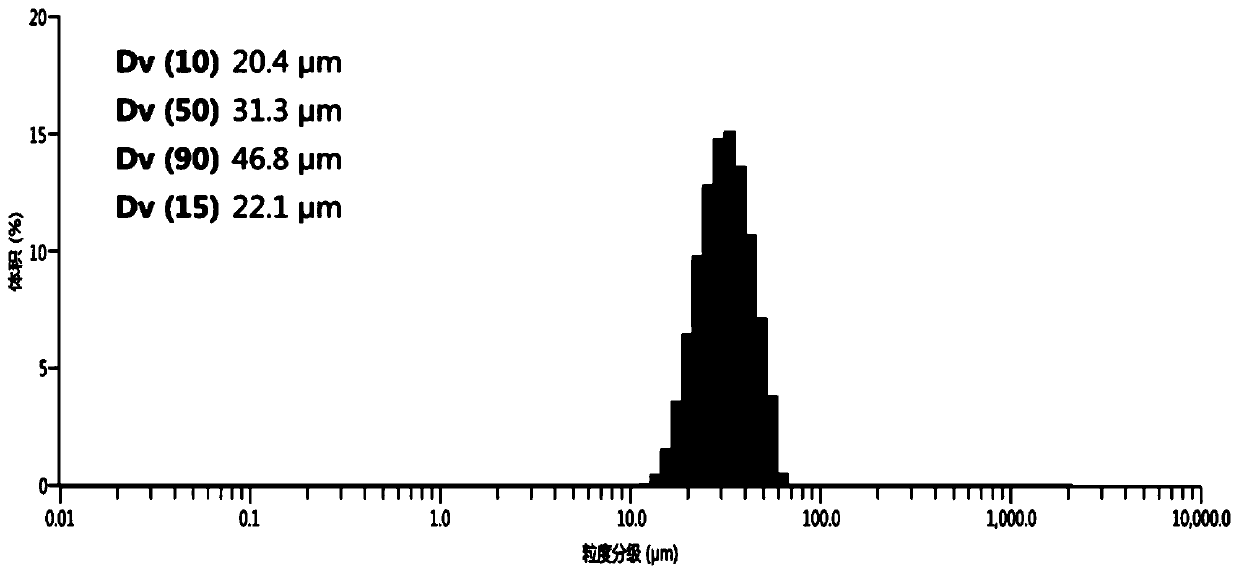

Organic phase-change material microcapsules in narrow particle size distribution and preparation method thereof

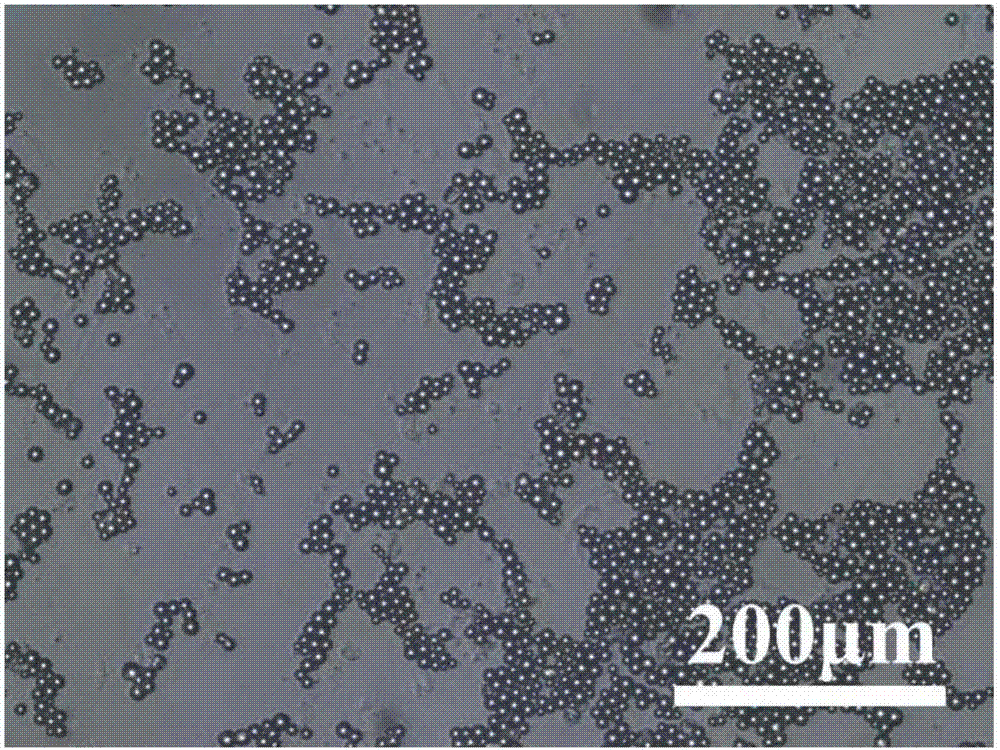

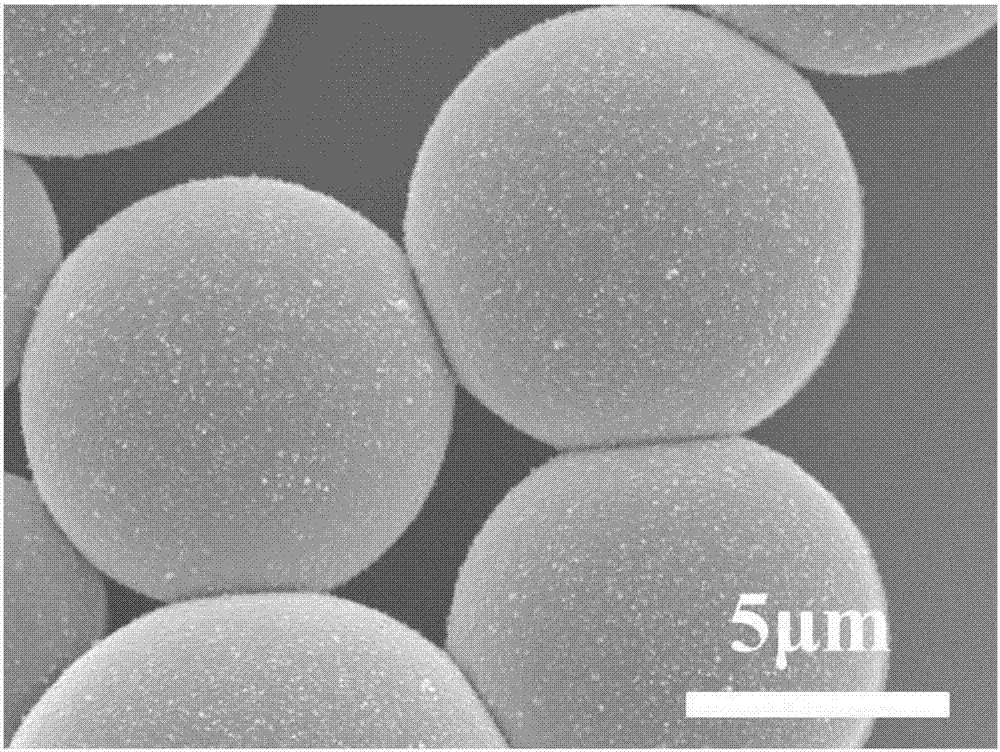

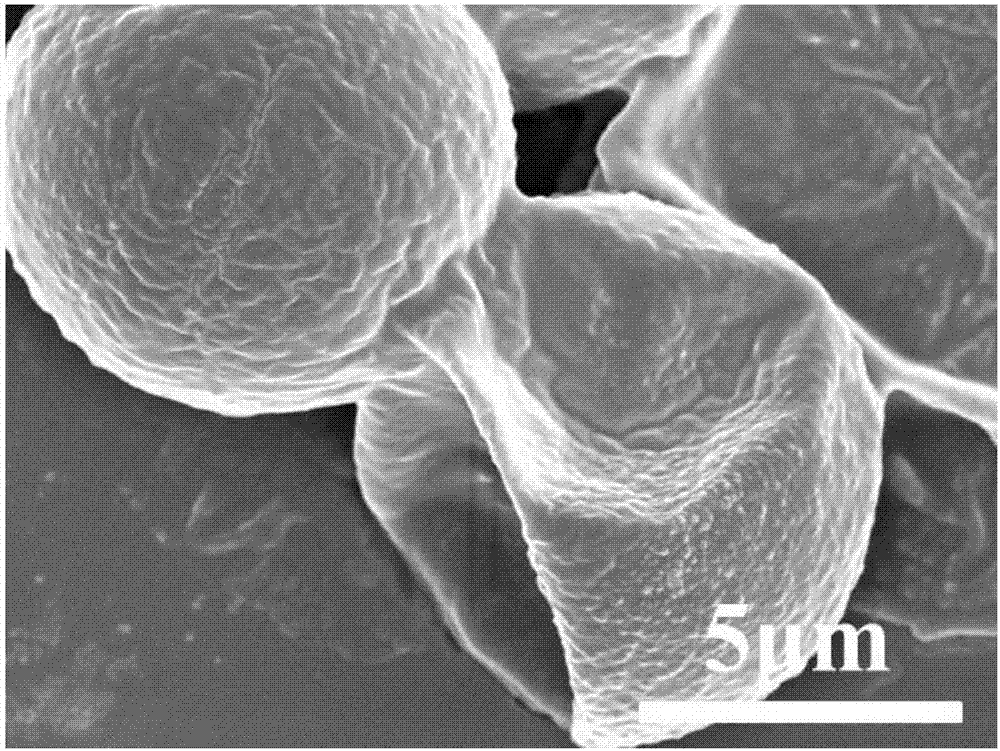

ActiveCN107418519AMeet particle size requirementsSmooth and dense surfaceHeat-exchange elementsMicroballoon preparationFiberMicro devices

The invention provides organic phase-change material microcapsules in narrow particle size distribution and a preparation method thereof. The method sequentially comprises an emulsion emulsifying stage and a microencapsulation stage, wherein the emulsion emulsifying stage comprises the following steps: (1) preparing a pre-emulsion; (2) pressing the pre-emulsion obtained in the step (1) through a porous membrane to obtain emulsion drops. According to the organic phase-change material microcapsules provided by the invention, the range of particle size distribution is narrow, and the average particle size is controllable, thereby facilitating industrial production; the organic phase-change material microcapsules can be applied to the heat preservation and energy storage in building as well as the fields such as temperature regulating fiber, heat transfer fluid, electronic element cooling and thermal protection on biomedical micro devices with higher requirements on particle size, and solve the problems that uniform heat transfer is hard to realize by existing microcapsule particles in non-uniform distribution and the temperature control and heat storage properties of the phase-change material are not realized fully.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Diamond-like coating with insulating performance and preparing method

InactiveCN105039908AIncrease ionization rateImprove bindingVacuum evaporation coatingSputtering coatingDlc coatingMetal

The invention discloses a diamond-like coating with insulating performance and a preparing method. The diamond-like coating is a DLC coating with megohm-level insulating performance and is obtained by regulating and controlling the contents of Sp3 bonds and Sp2 bonds in the coating; the content of the Sp3 bonds is larger than 70%, and the content of the Sp2 bonds is smaller than 30%; the coating has the megohm-level insulating performance as well as the wear-resisting performance, the friction-reducing performance and the corrosion-resisting performance. According to the preparing method, in the DLC coating not doped with metal, the contents and the proportions of the Sp3 bonds and the Sp2 bonds in the coating are regulated and controlled through an innovative technical measure, and thus the DLC coating with the excellent megohm-level insulating performance is obtained.

Owner:XI AN JIAOTONG UNIV

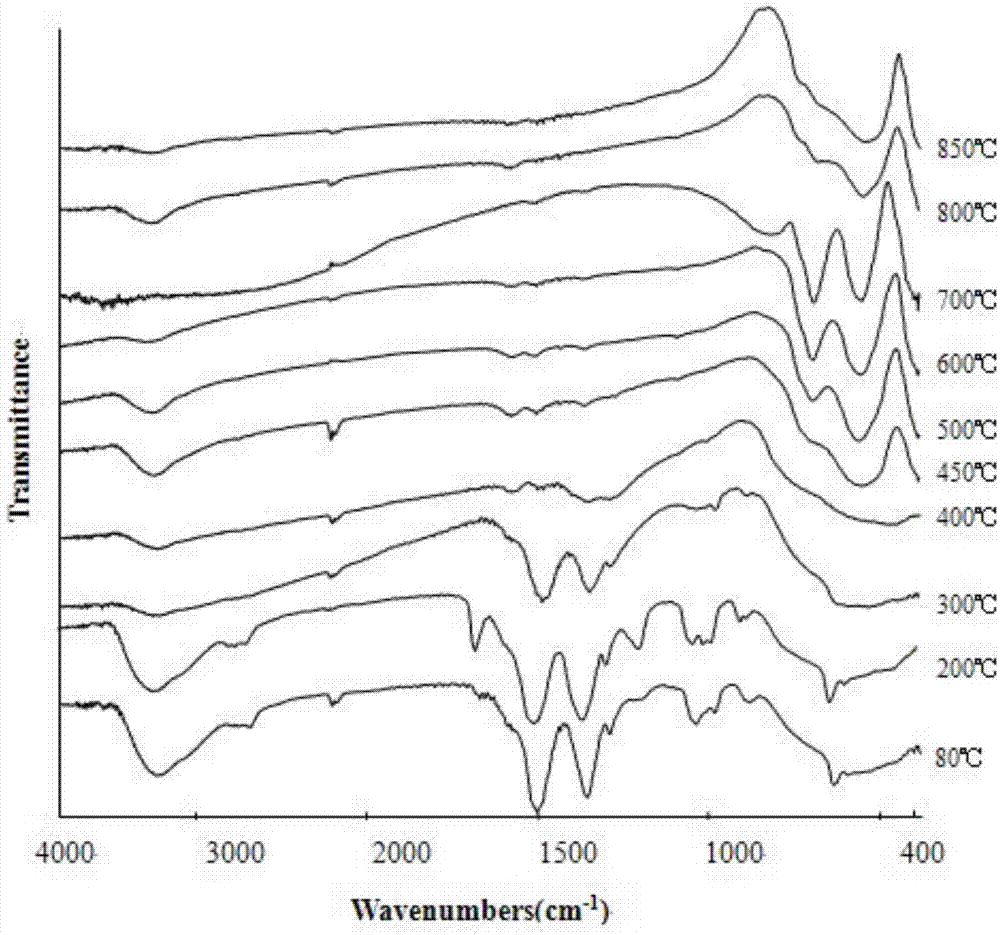

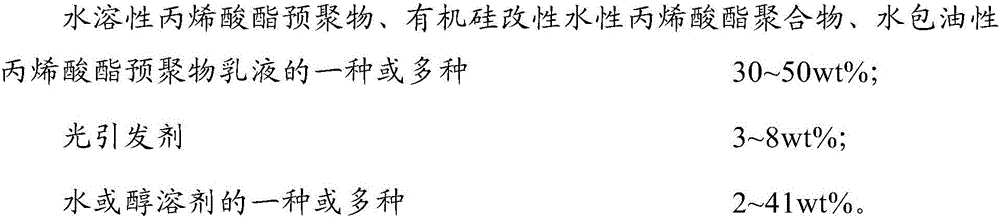

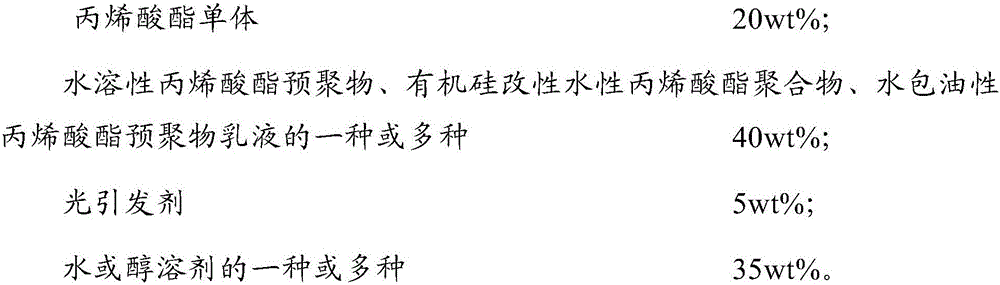

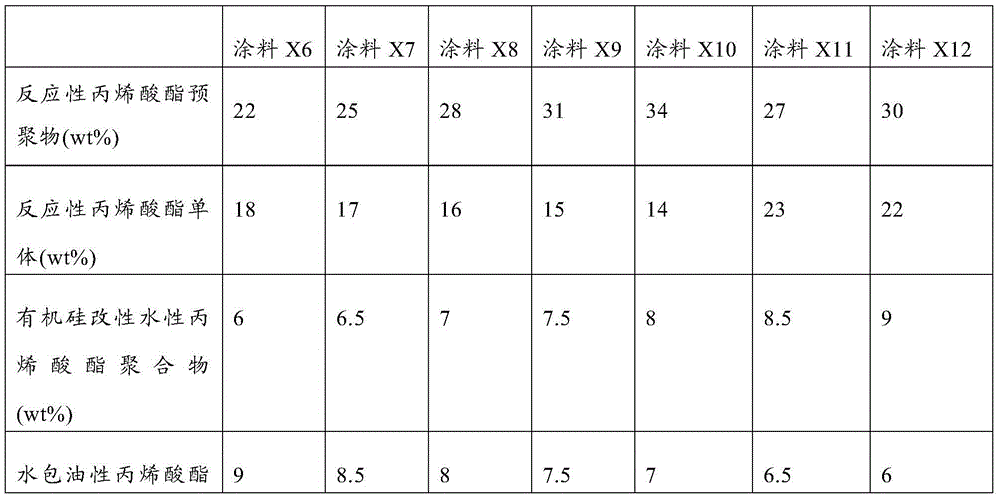

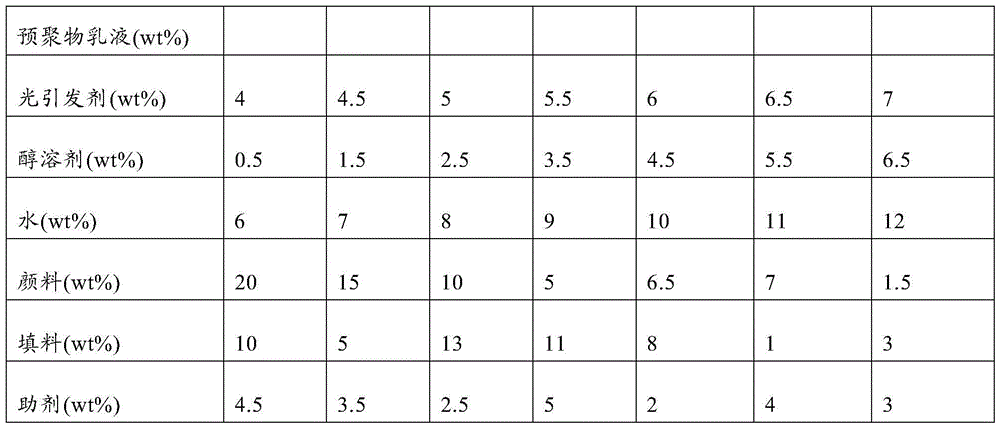

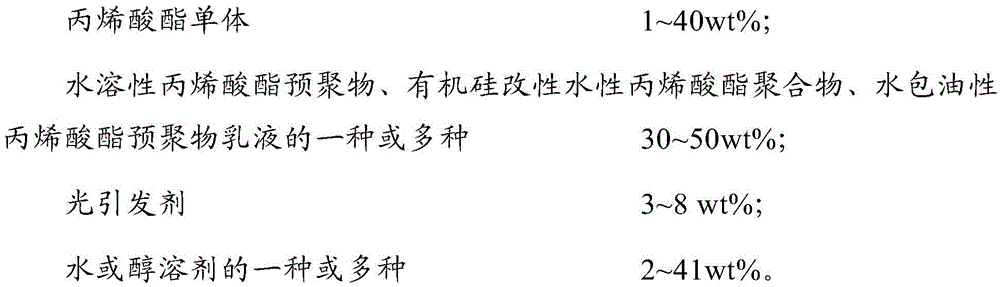

Waterborne radiation curing coating decorating plate and preparation method thereof

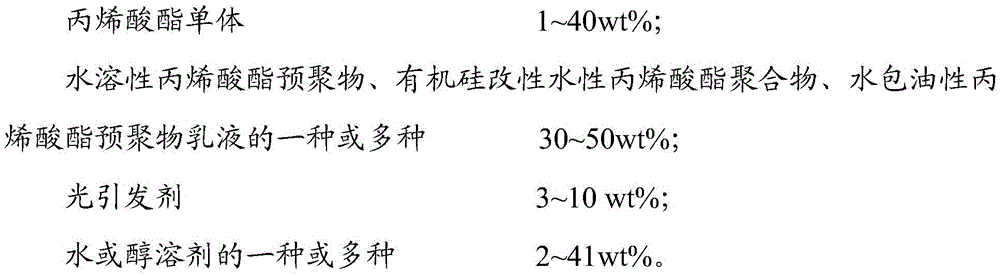

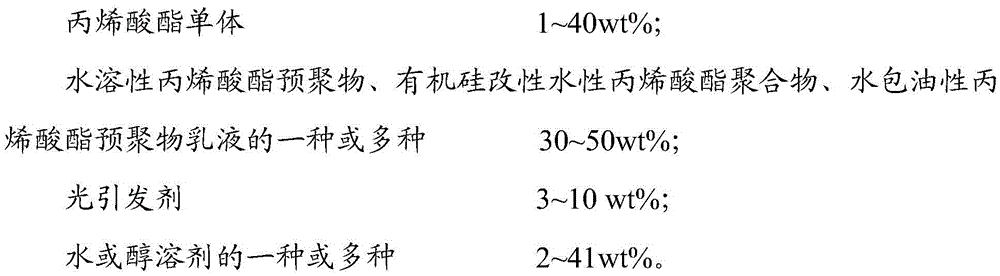

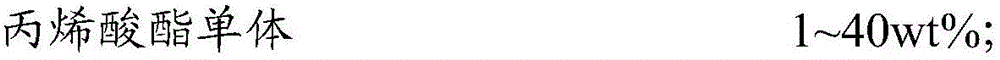

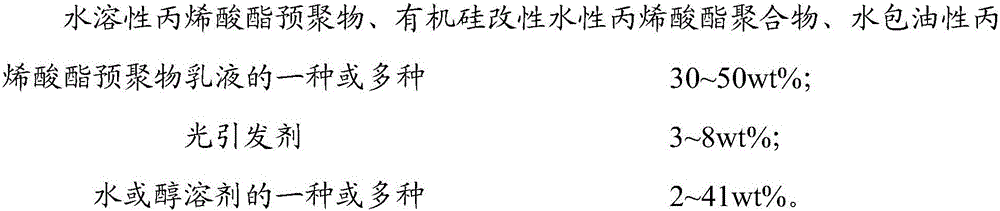

ActiveCN105670471AImprove color expressionSmooth and dense surfaceFireproof paintsAntifouling/underwater paintsEnvironmental resistanceSolvent

The invention provides a waterborne radiation curing coating decorating plate and a preparation method thereof. The waterborne radiation curing coating decorating plate comprises a bamboo grass wood baseplate and a closed layer and / or a white closed layer and a finish layer which are sequentially coated on the surface of the bamboo grass wood baseplate, each of the closed layer and / or the white closed layer and the finish layer comprises a waterborne radiation curing coating, and the waterborne radiation curing coating is composed of, by weight, 1-40 wt% of acrylate monomer, 30-50 wt% of one ore multiple of water-soluble acrylate prepolymer, organosilicon modified waterborne acrylate polymer and oil-in-water acrylate prepolymer emulsion, 3-10 wt% of photoinitiator and 2-41 wt% of one or multiple of water or alcohol solvent. The waterborne radiation curing coating decorating plate is environment-friendly, has better mechanical performance, good antibacterial performance, fouling resistance and heat resistance and is high in color and pattern expressiveness.

Owner:ZHUHAI JIAWEILI ENVIRONMENTAL PROTECTION SCI & TECH

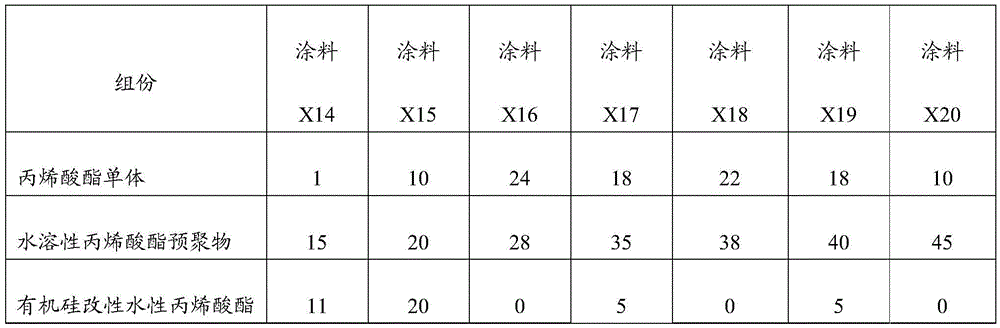

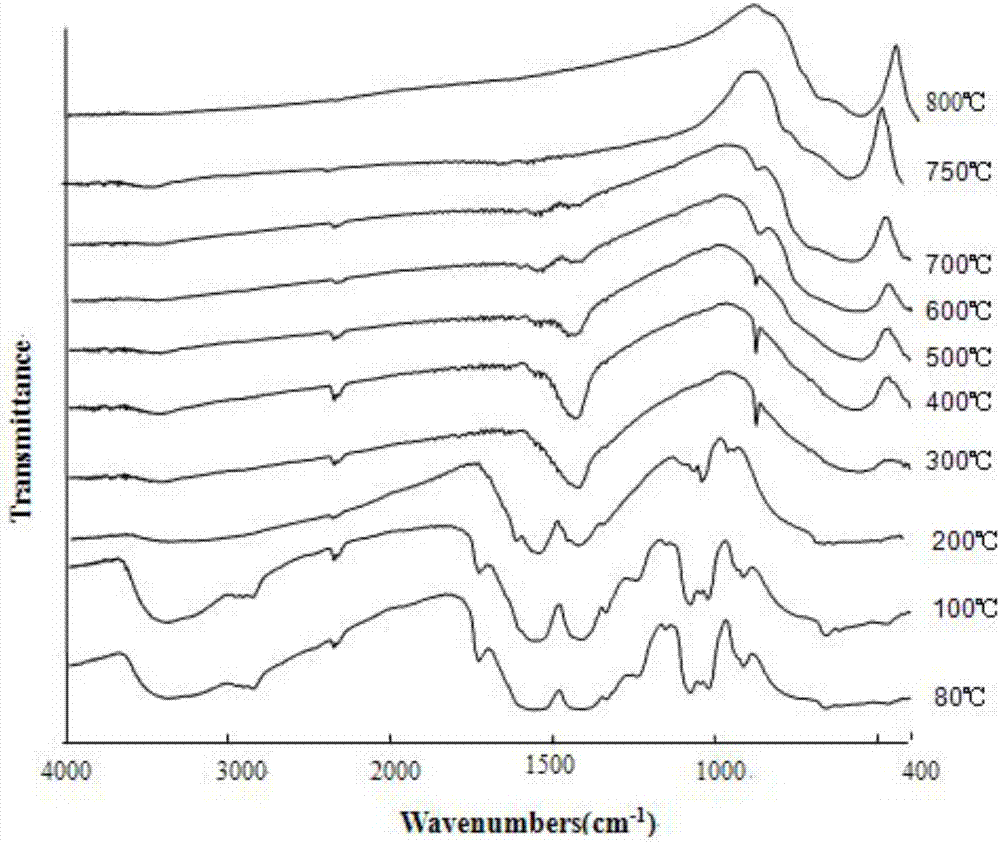

Preparation method of calcium doped lead titanate ceramic fiber

InactiveCN107164841AImprove uniformityMicrostructure is easy to controlFibre chemical featuresFiberHigh density

The invention relates to a preparation method of calcium doped lead titanate ceramic fiber, and the preparation method is characterized by comprising the following specific steps: (1) preparation of stable sol; (2) drawing and drying; (3) decomposition of dry gel fiber; and (4) sintering. The sintering conditions are as follows: the sintering temperature is 750 DEG C, the sintering time is 60min, and the heating rate is 2 DEG C / min. The preparation method has scientific and reasonable design, simple process, easy operation, low cost, and other advantages, the ceramic fiber prepared by the method has high strength, superior performance, smooth surface, high density, low tendency to fragmentation and other advantages, and the method has the advantages of convenient operation and easy implementation, and is a highly innovative preparation method of the calcium doped lead titanate ceramic fiber.

Owner:HEBEI CHEM & PHARMA COLLEGE

Coating agent for thermally insulating material and laminate for thermally insulating material using the same

ActiveCN101163756AImprove dust resistanceImprove oxidation resistanceFireproof paintsThermal insulationCarbonizationGraphite

Provided are a coating agent for a thermally insulating material which can form a laminate for a thermally insulating material having a coating layer of a surface being smooth and lustrous, being excellent in the prevention of generation of a dust, exhibiting high mechanical strength as a laminate and which further exhibits excellent workability in a coating operation; and a carbonized laminate and a laminate for a thermally insulating material using the above coating agent. A coating agent for a thermally insulating material, which comprises (1) a carbonized material having a carbonization degree of 40 % or more, (2) a vein graphite, (3) a paste and (4) a liquid agent which dissolves the paste and disperses or dissolves the carbonized material; and a laminate which is formed by applying the above coating agent for a thermally insulating material on the surface of a carbonized formed article having a bulk density of 0.1 to 0.8 g / cm3, followed by carbonizing.

Owner:KUREHA KAGAKU KOGYO KK

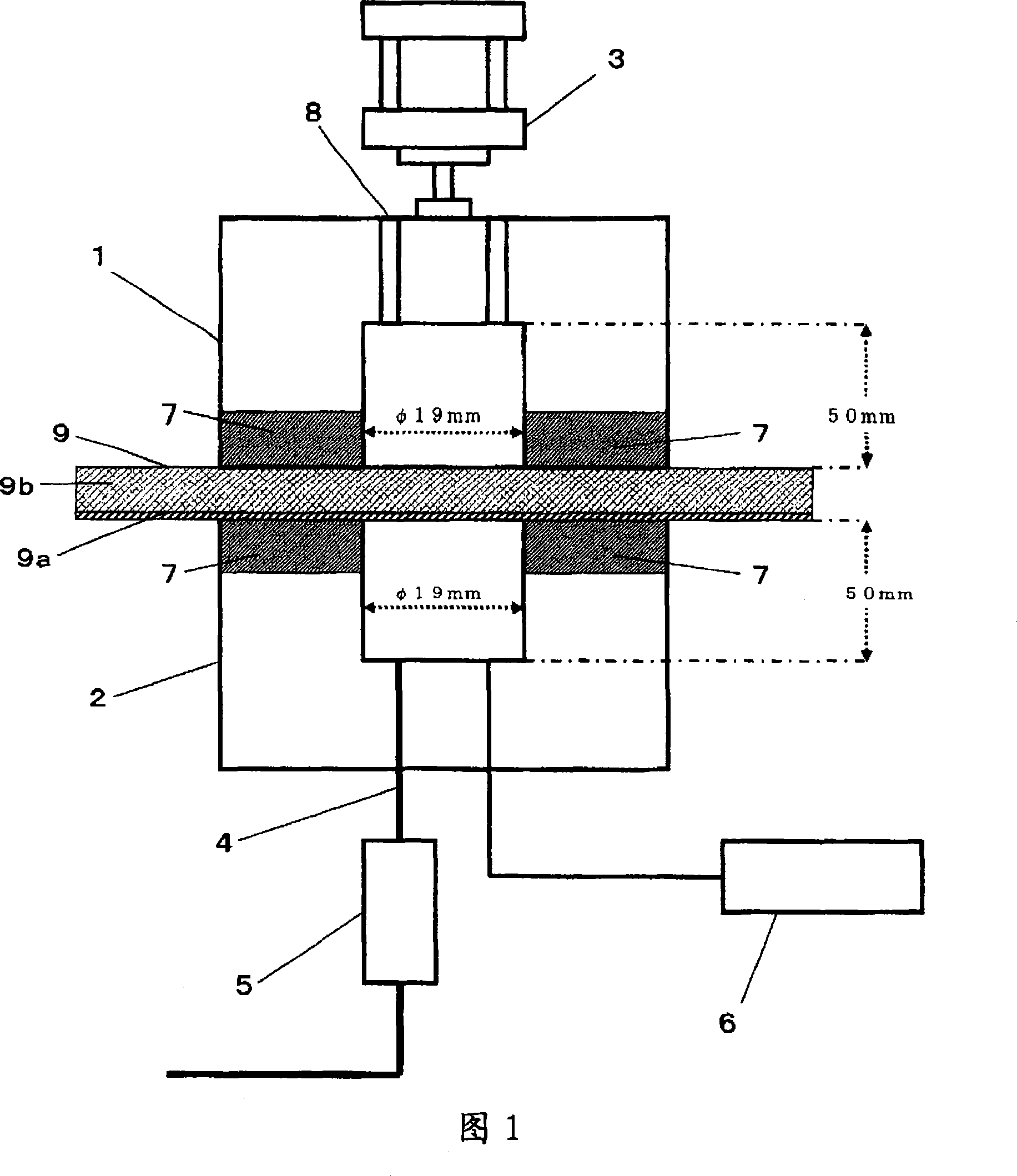

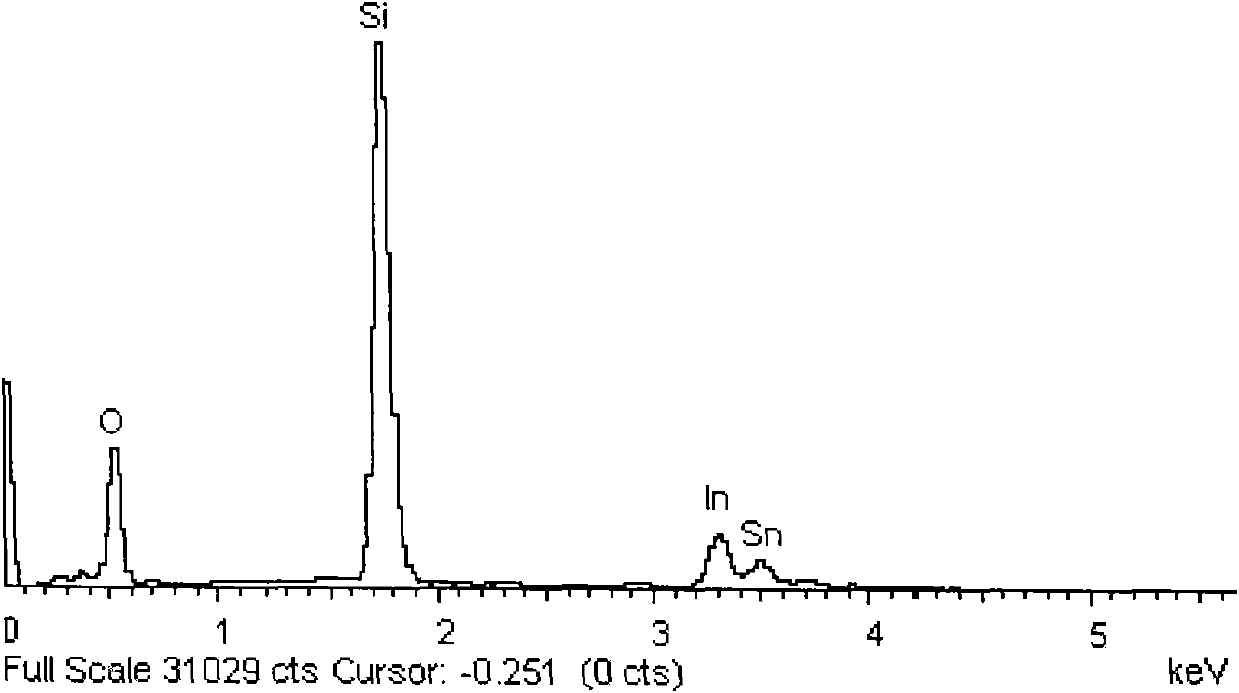

ITO film loaded silica optical fiber and preparation method thereof

ActiveCN101950043AWith light guideConductiveCladded optical fibreOptical waveguide light guideFiberSurface binding

The invention relates to silica optical fiber modification, aiming at providing an ITO film loaded silica optical fiber and a preparation method thereof. The silica optical fiber is taken as base body, and indium tin oxide transparent and conductive film is coated on the surface. In the invention, simple and feasible pre-treatment is carried out on the silica optical fiber, so that ITO film obtained by sol-gel method is firmly combined with the surface of the silica optical fiber, crystallization of film is complete, surface is smooth and compact, and photoelectric properties are good, thus preparing an ITO film loaded silica optical fiber and giving both light guiding property and electrical conductivity to the fiber. The invention can be widely applied to the fields of infrared transmission, current sending and photoelectric response devices, thus greatly widening respective application field.

Owner:ZHEJIANG SCI-TECH UNIV

Aerated brick demolding oil and preparation method thereof

The invention relates to aerated brick release oil and a preparation method thereof, and belongs to the technical field of chemical raw materials and preparation methods thereof. A demoulding oil for aerated bricks, made of the following raw materials in parts by weight: 20-30 parts of pine oil, 5-10 parts of glycerin, 10-15 parts of sodium petroleum sulfonate, and 2-6 parts of sodium nitrate , 2-5 parts of stearic acid, 5-9 parts of sodium hydroxide, 10-15 parts of triethanolamine, 20-30 parts of carboxymethyl cellulose, 5-10 parts of emulsifier, 5-10 parts of saponin, 5 parts of ethanol -10 parts, 10-20 parts of bentonite, 5-9 parts of waste engine oil, 3-8 parts of β-hydroxymalonic acid, 50-100 parts of water. The release oil for aerated bricks of the present invention is based on pine oil as the main raw material, and added glycerin, saponin, etc., and also fully utilizes industrial waste engine oil, so that the final product release oil can ensure the quality of aerated bricks. It is easier to separate from the mold, and ensure that the surface of the aerated brick is smooth and tight after demoulding.

Owner:苗娥

Waterborne radiation curing coating decorative plate and preparation method thereof

ActiveCN105802482AGood patternImprove color expressionFireproof paintsAntifouling/underwater paintsSolventAcrylate polymer

The invention provides a waterborne radiation curing coating decorative plate and a preparation method thereof. The waterborne radiation curing coating decorative plate comprises an inorganic plate and finish with which the surface of the inorganic plate is coated. The finish comprises a waterborne radiation curing coating. The waterborne radiation curing coating comprises 1-40 wt% of acrylate monomers, 30-50 wt% of one or more of a water-soluble acrylate prepolymer, an organosilicone modified water-soluble acrylate polymer and oil-in-water acrylate prepolymer emulsion, 3-8 wt% of photoinitiator and 2-41 wt% of one or more of water or alcohol solvents. The waterborne radiation curing coating decorative plate has good patterns and color expressive force, the surface is smooth and compact, good antimicrobial performance, anti-fouling performance, anti-scratching performance, water-proof performance, mould-proof performance and heat-resistant performance are achieved, and the decorative plate can be widely applied to various decoration materials. The waterborne radiation curing coating decorative plate is simple in preparation process, suitable for batch production and good in environment friendliness and energy conservation.

Owner:ZHUHAI JIAWEILI ENVIRONMENTAL PROTECTION SCI & TECH

Ultrathin bamboo-wood fiber board with bio-based non-formaldehyde adhesive and manufacturing method thereof

The invention discloses an ultrathin bamboo-wood fiber board with bio-based non-formaldehyde adhesive and a manufacturing method thereof. The manufacturing method sequentially comprises the proceduresof peeling, slicing, washing with water or air, cooking and hot grinding, adhesive application and drying, spreading for pre-pressing, hot pressing, cooling for curing, sanding and sawing, inspectionfor classification, and packaging. The ultrathin bamboo-wood fiber board does not contain toxic substances such as formaldehyde, benzene and xylene, and the problem of formaldehyde pollution cauasedby boards is effectively solved. The texture is uniform in all directions, the surface is smooth and dense, the mechanical property is good, the dampproof property is good, the size is stable, the application and field of the fiber board are extended and stretched, and the board is a novel product beneficial for environment protection, energy saving and comprehensive utilization of regenerative resources.

Owner:NANNING KETIAN SHUIXING TECH LTD CO

Waterborne radiation-curable coating decorative plate and preparation method thereof

ActiveCN105860778AImprove color expressionSmooth and dense surfaceCovering/liningsAntifouling/underwater paintsSolventAcrylate polymer

The invention provides a waterborne radiation-curable coating decorative plate and a preparation method thereof. The decorative plate comprises a metal substrate and a finishing coat layer coating the metal substrate. The finishing coat layer contains a waterborne radiation-curable coating. The waterborne radiation-curable coating comprises, by weight, 1 to 40% of acrylate monomer, 30 to 50% of one or more selected from a group consisting of water-soluble acrylate prepolymer, organosilicon-modified waterborne acrylate polymer and oil-in-water acrylate prepolymer emulsion, 3 to 10% of a photoinitiator and 2 to 41% of one or more selected from a group consisting of water or alcoholic solvents. The waterborne radiation-curable coating decorative plate has good pattern and color expressive force, smooth and compact surface and good antibacterial, anti-pollution, anti-scrape, waterproof, mildew-resistant and heat-resistant properties and is widely applicable to a variety of decoration environments; and the preparation method is simple, applicable to batch production, and good in environmental protection and energy saving performance.

Owner:ZHUHAI JIAWEILI ENVIRONMENTAL PROTECTION SCI & TECH

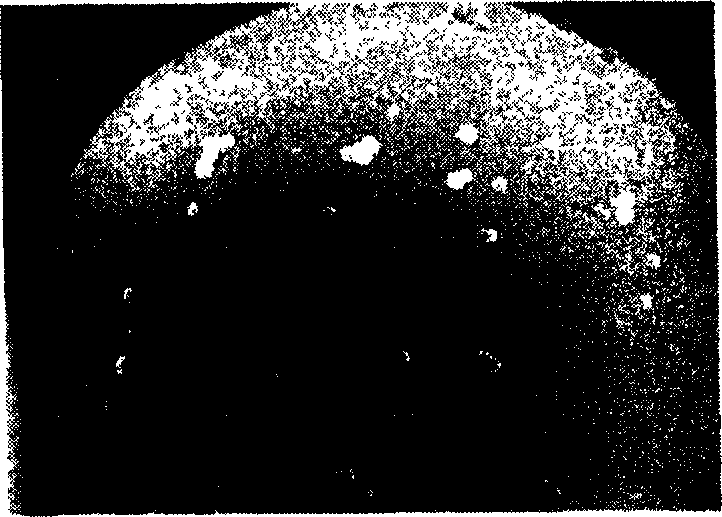

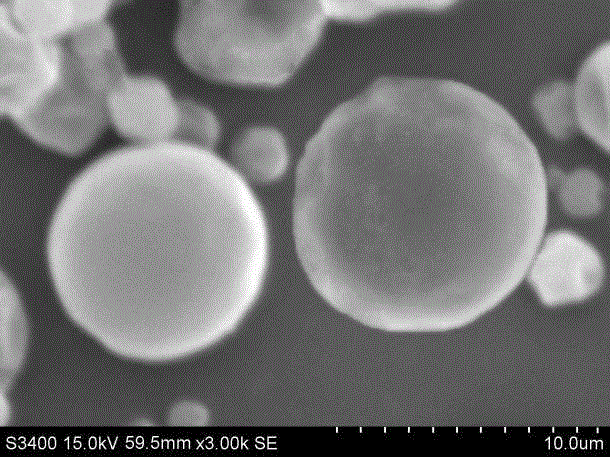

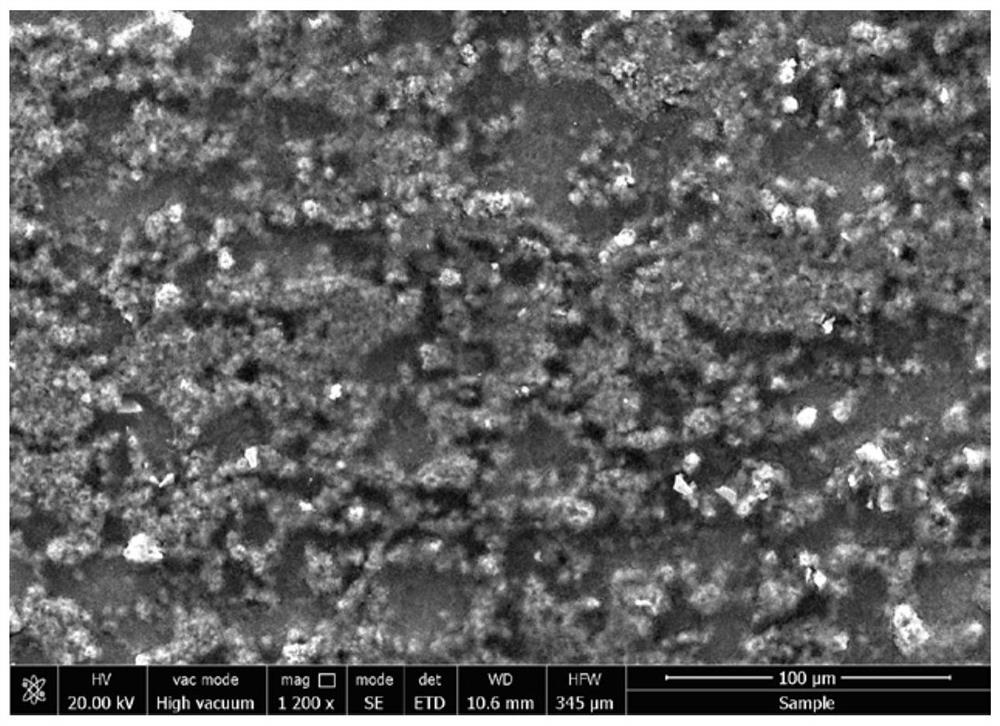

High-entropy alloy spherical powder for molten additive manufacturing of powder bed and preparing method and application thereof

ActiveCN111318716AGuaranteed purityAvoid introducingAdditive manufacturing apparatusTransportation and packagingPlasma jetHigh entropy alloys

The invention discloses a high-entropy alloy spherical powder for molten additive manufacturing of a powder bed and a preparing method and application thereof, and belongs to the technical field of additive manufacturing. The preparing method of the high-entropy alloy spherical powder for molten additive manufacturing of the powder bed comprises the following steps of high-entropy alloy wire preparing, preparing before atomizing, plasma atomizing, powder granularity grading and mixing. A plasma atomizing method is adopted, a plasma jet flow is used for melting a high-entropy alloy wire, impurity introducing caused by manners of crucible smelting and the like can be avoided, purity of a high-entropy alloy melt can be ensured, the plasma jet flow serves as atomizing media, the spheroidizingtime of broken liquid drops can be greatly prolonged, the metal liquid drops can be promoted to be solidified to form spherical powder particles, the prepared high-entropy alloy powder is high in sphericity degree, smooth and compact in surface, free of satellite balls and hollow powder, good in powder fluidity, low in oxygen content and few in impurity, and the property requirement of molten additive manufacturing of the powder bed for the high-property metal powder can be met.

Owner:SOUTH CHINA UNIV OF TECH

Slag-corrosion-resistant coating for steel ladle carbon-free tank lining and preparation method of slag-corrosion-resistant coating

The invention relates to a slag-corrosion-resistant coating for a carbon-free ladle lining of a steel ladle and a preparation method of the slag-corrosion-resistant coating. The slag-corrosion-resistant coating comprises the following raw materials in parts by weight: 50-70 parts of magnesium aluminate spinel; 1-20 parts of zirconium dioxide; 1-5 parts of boride; 10-30 parts of silica sol; 1-10 parts of a micromolecular organic carboxylic acid solution; 0.1-2 parts of an oxysilane coupling agent; 0.1-2 parts of a water reducing agent; the silica sol is acidic silica sol, the pH value is 2-6, and the content of SiO2 in the silica sol is 20-40%. The slag-corrosion-resistant coating has the advantages that the slag-corrosion-resistant coating is suitable for steel ladle carbon-free tank lining bricks, and a coating layer coated with the slag-corrosion-resistant coating is smooth and compact in surface, low in porosity, uniform in quality, stable in performance, good in bonding performance with base bricks at normal temperature and high temperature, good in thermal shock resistance and good in anti-scouring performance, and the slag-corrosion-resistant effect is remarkably improved; the good slag-resistant protection effect can be achieved on the refractory material of the carbon-free tank lining, and the repairing frequency of the carbon-free tank lining is reduced.

Owner:UNIV OF SCI & TECH LIAONING +1

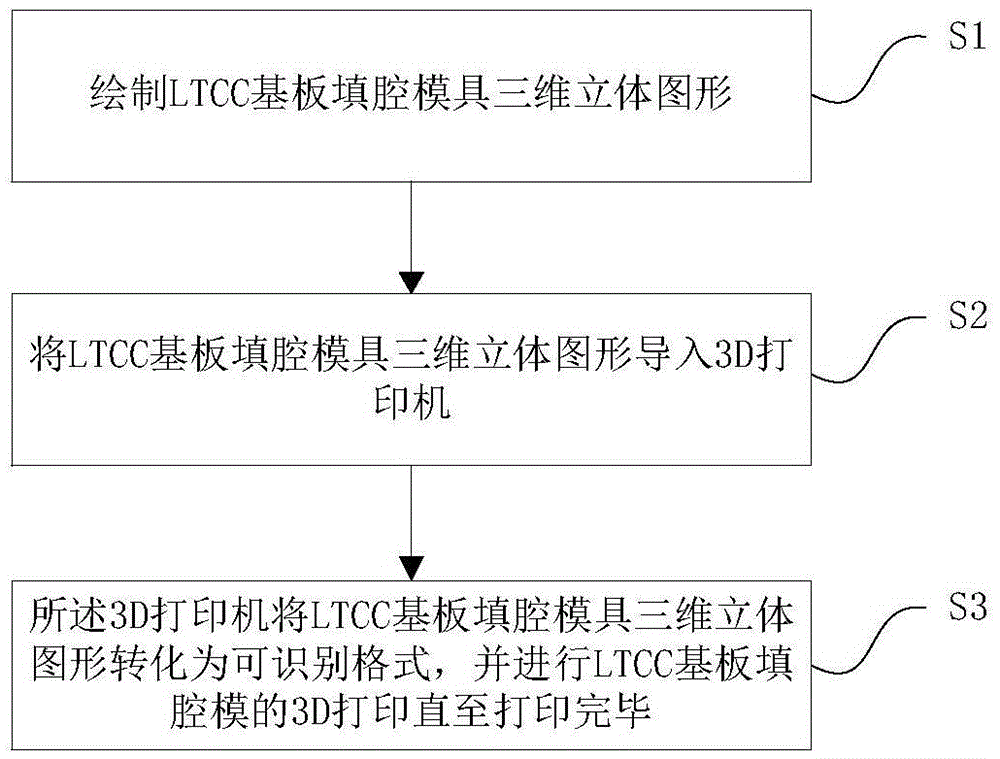

3D printing processing technology of LTCC substrate cavity filling mold

InactiveCN105599299AGood consistencySmooth and dense surfaceAdditive manufacturing apparatusThree-dimensional graph3D printing

The invention relates to a 3D printing processing technology of an LTCC substrate cavity filling mold. The technology comprises the steps that a three-dimensional graph of the LTCC substrate cavity filling mold is drawn; the three-dimensional graph of the LTCC substrate cavity filling mold is imported into a 3D printing machine; the three-dimensional graph of the LTCC substrate cavity filling mold is converted into a recognizable format through the 3D printing machine, and 3D printing of the LTCC substrate cavity filling mold is carried out till printing is finished. According to the 3D printing processing technology of the LTCC substrate cavity filling mold, the problems that a traditional preparation method of a cavity filling mold is low in yield, not high enough in size precision and poor in consistency and durability are solved, the formed LTCC substrate cavity filling mold which is good in consistency, smooth and tight in surface, uniform in internal structure and high in size precision can be manufactured, and the 3D printing processing technology is applicable to high-performance LTCC substrate with a cavity.

Owner:BEIJING INST OF RADIO MEASUREMENT

Preparation method for an inorganic ceramic coating with high heat resistance

ActiveCN102225864ASmooth and dense surfaceImprove waterproof performanceAluminium chlorideCeramic coating

The invention relates to a preparation method for an inorganic ceramic coating with high heat resistance. The method is characterized by comprising the following steps: respectively dissolving lithium carbonate, aluminum nitrate nonahydrate and rare earth oxide in water, and carrying out stirring until a clear transparent solution a is obtained; dissolving barium chloride and aluminum chloride inwater, and carrying out stirring until a clear transparent solution b is obtained; adding ethyl orthosilicate and anhydrous ethanol into distilled water, adding an acid catalyst, and carrying out stirring until a clear solution c is obtained; respectively obtaining clear sol ac and sol bc, carrying out the process of gelation on sol ac and sol bc at a constant temperature being in a range of 60 to 90 DEG C so as to obtain gel ac and gel bc; calcining gel ac and gel bc to obtain ceramic powder ac and ceramic powder bc; calcining ceramic powder ac and ceramic powder bc into frits; preparing thefrits, a binder and distilled water into slurry, and spraying the slurry onto the surface of a substrate, and calcining the substrate so as to obtain the inorganic ceramic coating with high heat resistance. The obtained inorganic ceramic coating has a fine and smooth surface, good waterproof performance, excellent mechanical properties and high strength, well couples with the substrate, and produces an effect of expanding bandwidth.

Owner:ZHONGCAI HIGH NEW MATERIAL +1

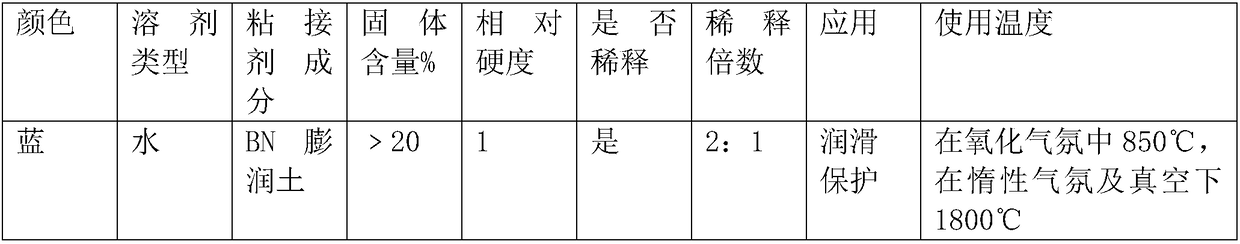

High-temperature lubricating anti-penetration nano environmental protection coating and preparation and use methods thereof

ActiveCN109439040AHigh solid contentIncrease temperatureAlkali metal silicate coatingsSodium BentoniteSoft clay

The invention discloses a high-temperature lubricating anti-penetration environmental protection coating, which is prepared from the following components in percentage by weight: 25 to 40 percent of boron nitride, 0.5 to 10 percent of nano alumina, 10 to 15 percent of silica sol, 1 to 5 percent of liquid sodium silicate, 10 to 15 percent of aluminum sol, 1 to 5 percent of nano silica, 0.5 to 2.5 percent of bentonite, 0.5 to 1.0 percent of soft clay and 35 to 50 percent of pure water. The coating disclosed by the invention has high temperature resistance and can be widely applied to surfaces ofrefractory materials such as a launder, a distribution plate, a distribution flow tank, a filter box, an adapter plate, a skimmer and a casting table lining, which are in contact with aluminum alloyliquid, thereby protecting the refractory material from scouring, erosion and penetration of the aluminum alloy liquid, and more importantly, protecting the aluminum alloy liquid from pollution of thealuminum alloy liquid; meanwhile, the materials selected by the invention are all inorganic materials, so that the coating is an environmental protection coating. The invention further discloses a preparation method and a use method of the coating.

Owner:贵阳联合高温材料有限公司

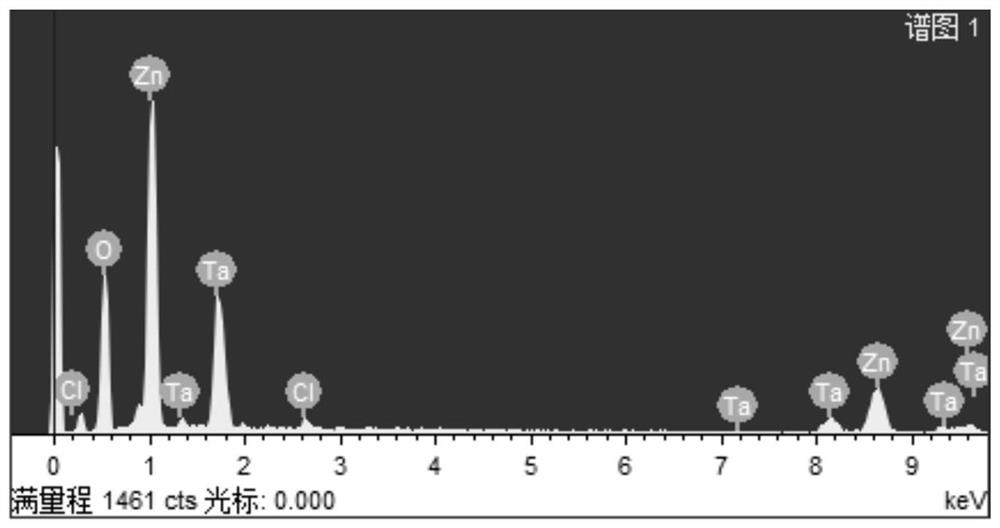

Method for preparing zinc-tantalum alloy by solvating ionic liquid

The invention provides a method for preparing zinc-tantalum alloy by solvated ionic liquid, and belongs to the technical fields of metallurgy. The method for preparing zinc-tantalum alloy by the solvated ionic liquid specifically comprises the following steps that 1, ZnCl2 as a precursor is dissolved in 1,3-dimethyl-2-imidazolinone, and TaCl5 is continuously added in the mixture to form the solvated ionic liquid; 2, a beaker is used as an electrolytic cell, and the obtained solvated ionic liquid is used as an electrolyte to form an electrolytic cell system, and a three-electrode system is usedfor electrodeposition; and 3, after electrodeposition, a cathode is removed, the electrolyte adhering to the surface is cleaned, and the zinc-tantalum alloy is obtained on the surface after drying. The zinc-tantalum alloy prepared by the method has the characteristics of uniform particles, compact and smooth surface and excellent adhesion. The method can realize the rapid preparation of thick zinc-tantalum alloy coatings and has the advantages of simple equipment, low cost, safety and environmental protection and easy achieving, and the practicability is greatly improved.

Owner:NORTHEASTERN UNIV

Waterborne radiation curable coating decorative plate and preparation method thereof

ActiveCN105623337AMake up for the problem of high surface tension and easy shrinkage cavityMake up for the shrinkage problemCovering/liningsPolyurea/polyurethane coatingsEnvironmental resistanceWater soluble

The invention provides a waterborne radiation curable coating decorative plate and a preparation method thereof. The decorative plate comprises a composite material plate and a finish paint coating the surface of the composite material plate; the finish paint contains a waterborne radiation curable coating; the waterborne radiation curable coating contains the following components: 1-40 percent by weight of acrylate monomer, 30-50 percent by weight of one or more of water-soluble acrylic prepolymer, organic silicone modified waterborne acrylate polymer and oil-in-water acrylate prepolymer emulsion, 3-8 percent by weight of photoinitiator and 2-41 percent by weight of one or more of water or alcohol solvent. The waterborne radiation curable coating decorative plate provided by the invention is good in design and color expressive force, smooth and dense in surface, simple in manufacturing process, suitable for mass production and good in environmental friendliness.

Owner:ZHUHAI JIAWEILI ENVIRONMENTAL PROTECTION SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com