Preparation method of carbon nano-tube composite material with enhancing characteristics

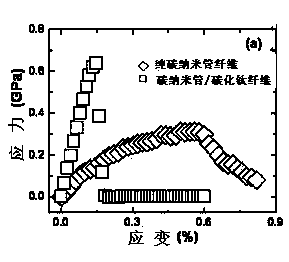

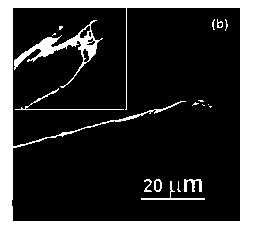

A technology of carbon nanotubes and composite materials, applied in the fields of nanotechnology, carbon compounds, nanotechnology for materials and surface science, and can solve the problems of low mechanical strength and electrical conductivity of fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

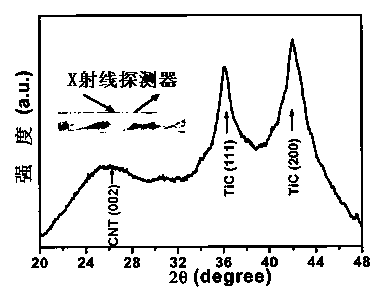

[0071] The preparation process of the precursor solution of TiC-embedded CNT composite fiber is as follows: 12 g of hexafluorotitanic acid (H 2 TiF 6 , ALDRICH, 99.9%, 60%) was added to 40 mL of pure water (18 MΩ, MILLI-Q water treatment system) dissolving 7.5 g of polyethyleneimine (PEI, BASF Company, Clifton New Jersey, without further treatment) in solution. The resulting solution was filtered using an Amicon ultrafiltration system with an ultrafiltration membrane under 60 psi argon pressure to remove impurities with a molecular weight less than 3000 g / mol. And through HORIBA JOBIN YVON ULTIMA II inductively coupled plasma-atomic emission spectrometer (ICP-AES) and standard SW846 EPA (Environmental Protection Agency) method 6010 procedure for titanium content analysis, the results show that the final precursor solution has a titanium content of 496 mM.

Embodiment 2

[0073] The preparation process of the precursor solution of the composite fiber with niobium carbide embedded in CNT is as follows: NbCl 5 (purity>99%), NH 4 OH and 20% HF are dissolved in pure water treated by Milli-Q water treatment system. The resulting solution was subjected to ultrafiltration using an Amicon ultrafiltration system under 60 psi argon pressure to remove impurities with a molecular weight less than 3000 g / mol. The details are as follows: by adding ammonia water dropwise, 2g NbCl 5 Convert to Nb(OH) 5 Afterwards, dissolve in 30 mL of deionized water, and then add 7.5 mL of 20% HF. Add 31 parts (3.0 g in total) of PEI one by one, and mix and stir. The solution was placed in an Amicon ultrafiltration system with an ultrafiltration membrane for filtration to remove impurities with a molecular weight less than 3000 g / mol. Then the solution was diluted 3 times to 200mL, and then subjected to ultrafiltration to obtain a concentrated solution of 35mL. The ICP ...

Embodiment 3

[0075] The preparation process of the precursor solution of the composite fiber with tantalum carbide embedded in CNT is as follows: dissolve tantalum chloride in water, and then add ammonia water to produce tantalum hydroxide (Ta(OH) 5 )precipitation. Wash with plenty of deionized water to remove chloride ions in the precipitate. The precipitate was then dissolved in 20% HF to form a tantalum fluoride complex. PEI was added, and the resulting solution was filtered using an Amicon ultrafiltration system under 60 psi argon pressure to remove impurities with a molecular weight less than 3000 g / mol. ICP results indicated that the final precursor solution had a tantalum content of 214 mM.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com