Patents

Literature

75 results about "Hexafluorotitanic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hexafluorotitanic acid (systematically named oxonium hexafluoridotitanate(2-)) is an inorganic compound with the chemical formula (H₃O)₂[TiF₆]. As with most oxonium salts, it is not stable when undissolved, or under neutral to basic conditions, tending to decompose in those conditions to titanium fluorides or oxyfluorides. Under highly acidic conditions, it decomposes to titania, which accelerated by fluoride scavengers. Under highly basic conditions, it is hydrolysed to titanium hydroxide. A related salt, is the anhydrous fluoronium hexafluoridotitanate(2-) or (H₂F)₂[TiF₆].

Rare-earth modified Ti-Zr chemical passivation solution for surface treatment of aluminium profiles and using method of rare-earth modified Ti-Zr chemical passivation solution

ActiveCN103103512AImprove compactnessImprove performanceMetallic material coating processesCerium nitratePotassium fluoride

The invention discloses a rare-earth modified Ti-Zr chemical passivation solution for surface treatment of aluminium profiles and a using method of the rare-earth modified Ti-Zr chemical passivation solution. The rare-earth modified Ti-Zr chemical passivation solution is characterized in that the passivation solution is a main salt for auxiliary film-formation, which takes rare-earth compounds as a Ti-Zr passivation treatment solution, and a passivation film is light yellow in appearance and has field judgement property on the quality of a formed film. A formula of the rare-earth modified Ti-Zr chemical passivation solution is as follows: each litre of solution contains 0.5g.L<-1>-10g.L<-1> of potassium fluotitanate (hexafluorotitanic acid), 0.5g.L<-1>-10g.L<-1> of potassium fluozirconate (fluozirconic acid), 0.5g.L<-1>-5g.L<-1> of cerium nitrate (ceric sulfate and ammonium ceric nitrate), 2g.L<-1>-10g.L<-1> of potassium nitrate, 0.5g.L<-1>-3g.L<-1> of sodium fluoride (potassium fluoride), 0.5g.L<-1>-1g.L<-1> of sodium dodecyl benzene sulfonate or OP-10, 0.2mL-5mL.L<-1> of nitric acid and 1g.L<-1>-5g.L<-1> of boric acid. The using method of the rare-earth modified Ti-Zr chemical passivation solution comprises the following steps of: (1) clearing dirt, such as dirt attached to an aluminium alloy; (2) pretreating the surface of the aluminium alloy; (3) carrying out passivating treatment on the surface of the aluminium alloy by using the rare-earth modified Ti-Zr chemical passivation solution; and (4) washing the aluminium alloy by using water and drying the aluminium alloy. The rare-earth modified Ti-Zr chemical passivation solution disclosed by the invention has the advantages of light yellow appearance, high film formation speed, simple process, uniformity in film layer, strong corrosion resistance, low environment pollution and the like.

Owner:GUANGDONG XINGFA ALUMINUM

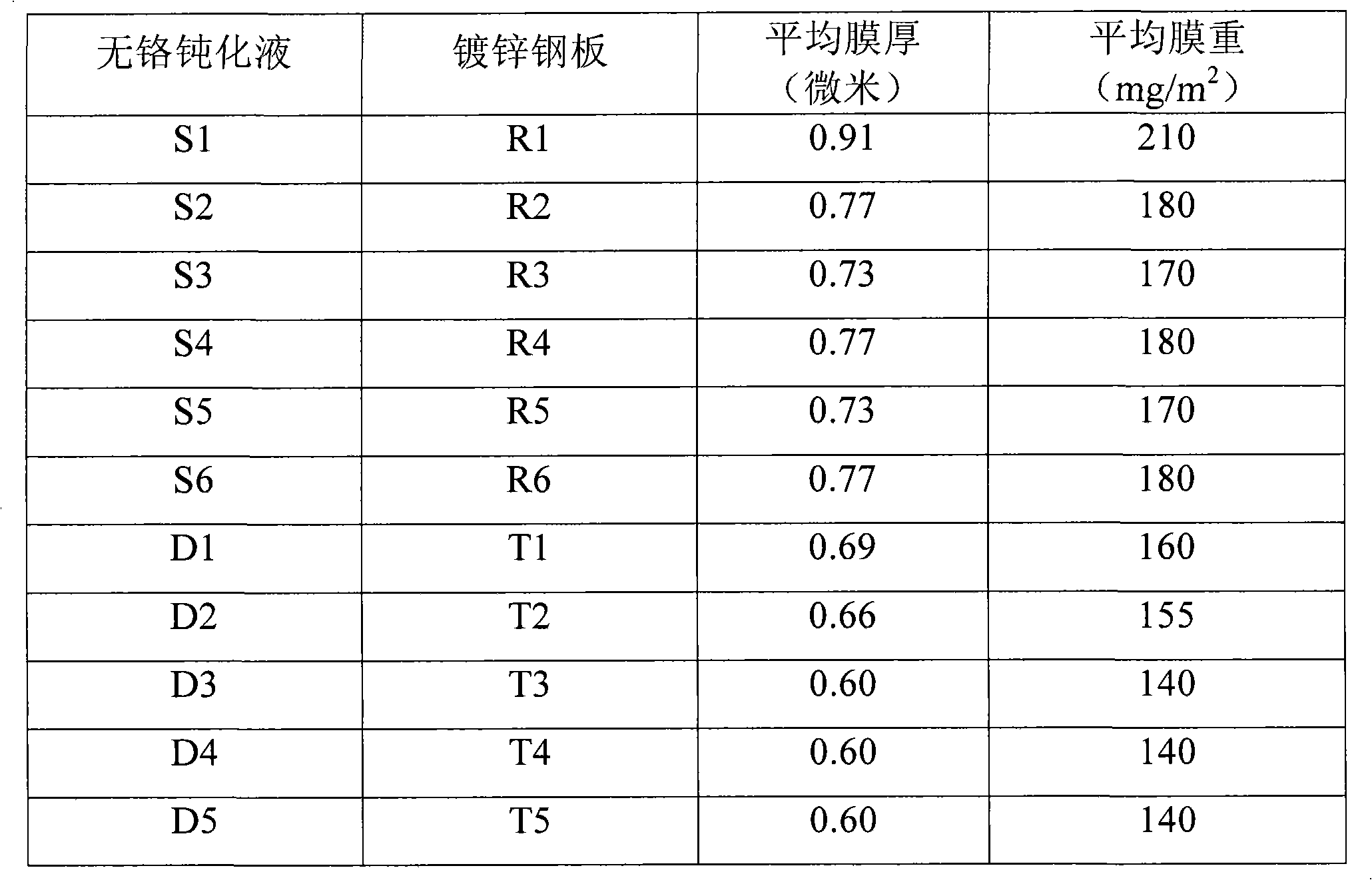

Chromium-free passivation solution and hot-dip galvanized metal material

InactiveCN102373453AImprove corrosion resistanceImprove water resistanceHot-dipping/immersion processesChromium freeSilanes

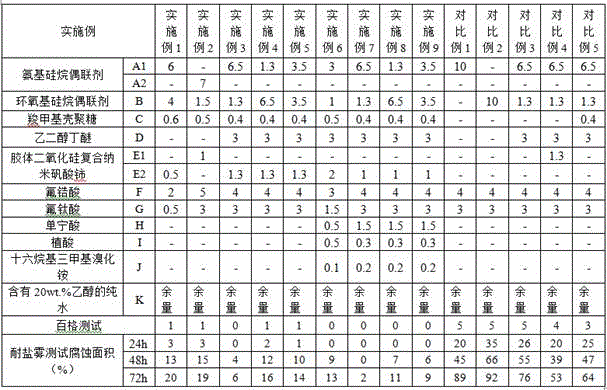

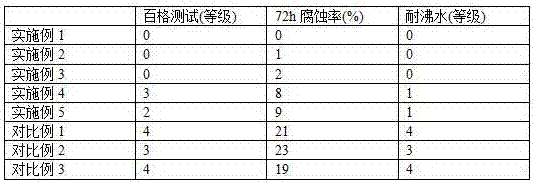

The invention relates to a chromium-free passivation solution and a hot-dip galvanized metal material. The chromium-free passivation solution is prepared from a raw material mixture through uniform mixing. The raw material mixture contains one or more silane coupling agents and water. The chromium-free passivation solution is characterized in that the raw material mixture also contains one or more titanium compounds, one or more inorganic silicon compounds, one or more water-soluble film-forming agents and tannic acid or phytic acid, wherein the one or more titanium compounds are selected from hexafluorotitanic acid, ammonium hexafluorotitanate, potassium hexafluorotitanate, metatitanic acid and titanyl sulfate and the one or more inorganic silicon compounds are selected from nanoscale silica powder, silica sol and sodium silicate. The chromium-free passivation solution has good corrosion resistance, good water resistance, good heat resistance, good fingerprint resistance and excellent roller coating performances. A passivation method adopting the chromium-free passivation solution can greatly shorten treatment time, can be utilized for passivation plate production in a spray mode or a roller coating mode, and also can avoid an oiling process in galvanized plate production.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

Addition product, production and use thereof as corrosion inhibitor

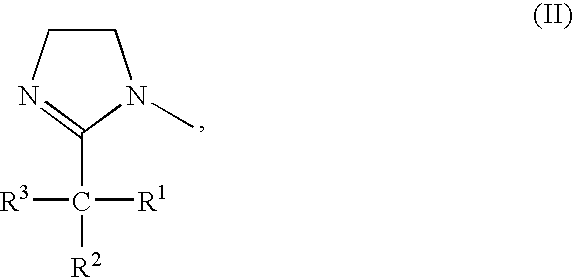

InactiveUS20040168748A1Rapid and lasting inhibitionOrganic chemistrySolid state diffusion coatingHexafluorotitanic acidHexafluorosilicic acid

The invention relates to an addition product that can be produced from hexafluorosilicic acid, hexafluorotitanic acid, and / or hexafluorozirconic acid by an acid-base reaction with one or several organic bases and a method for production and use thereof. The addition products according to the invention guarantee a rapid and lasting inhibition of corrosion processes; they are in particular suitable for inhibiting the corrosion of light metals.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

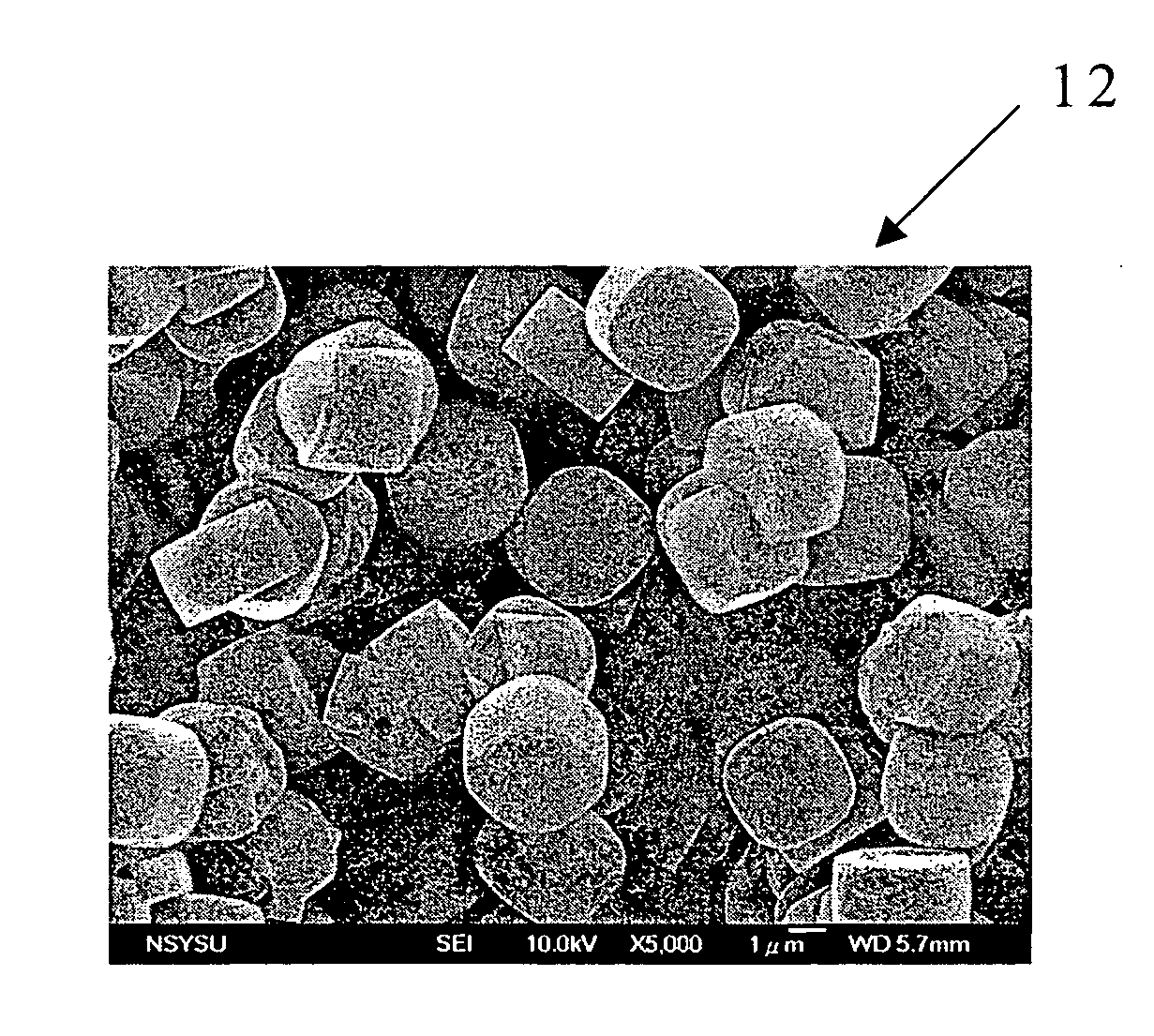

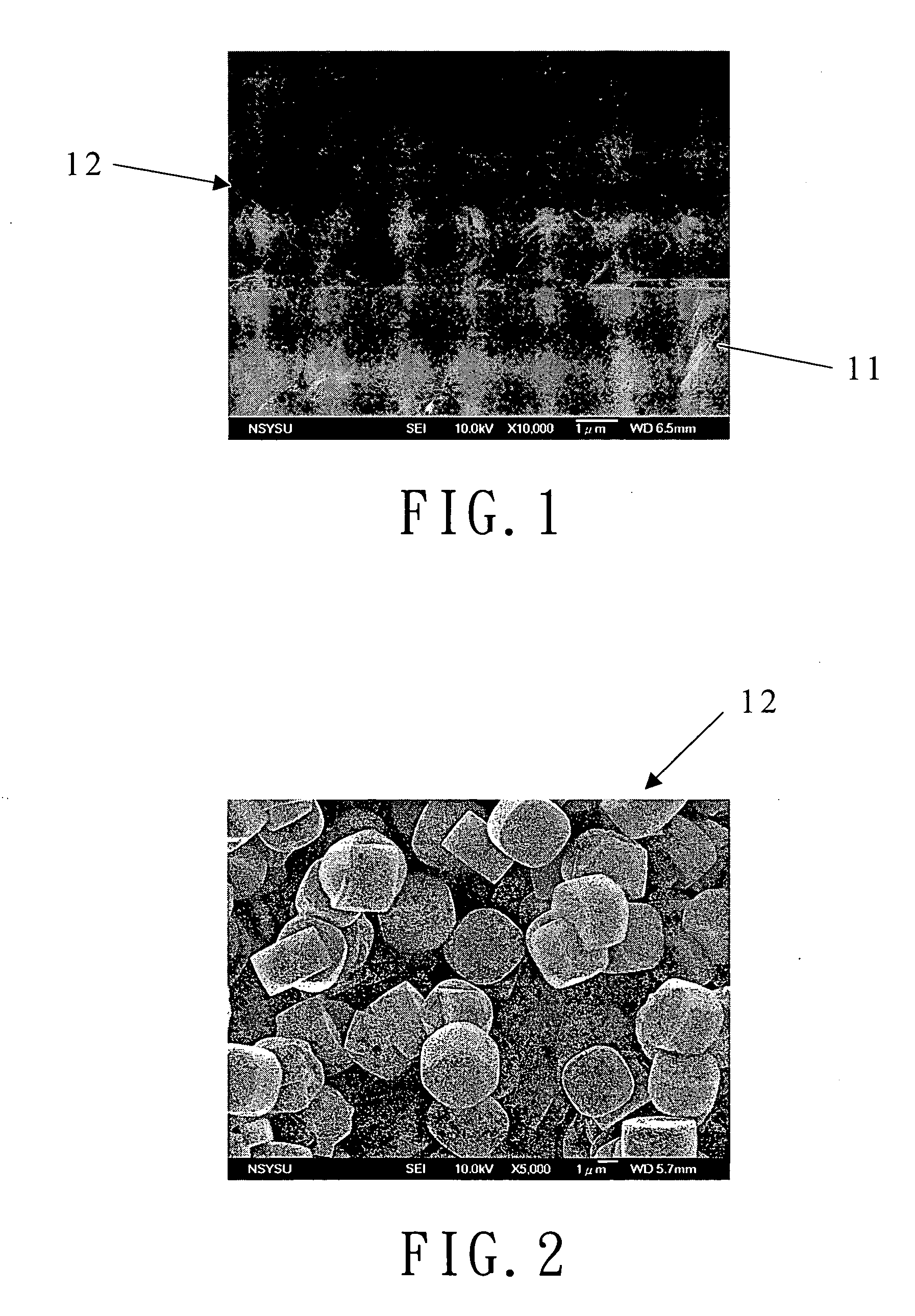

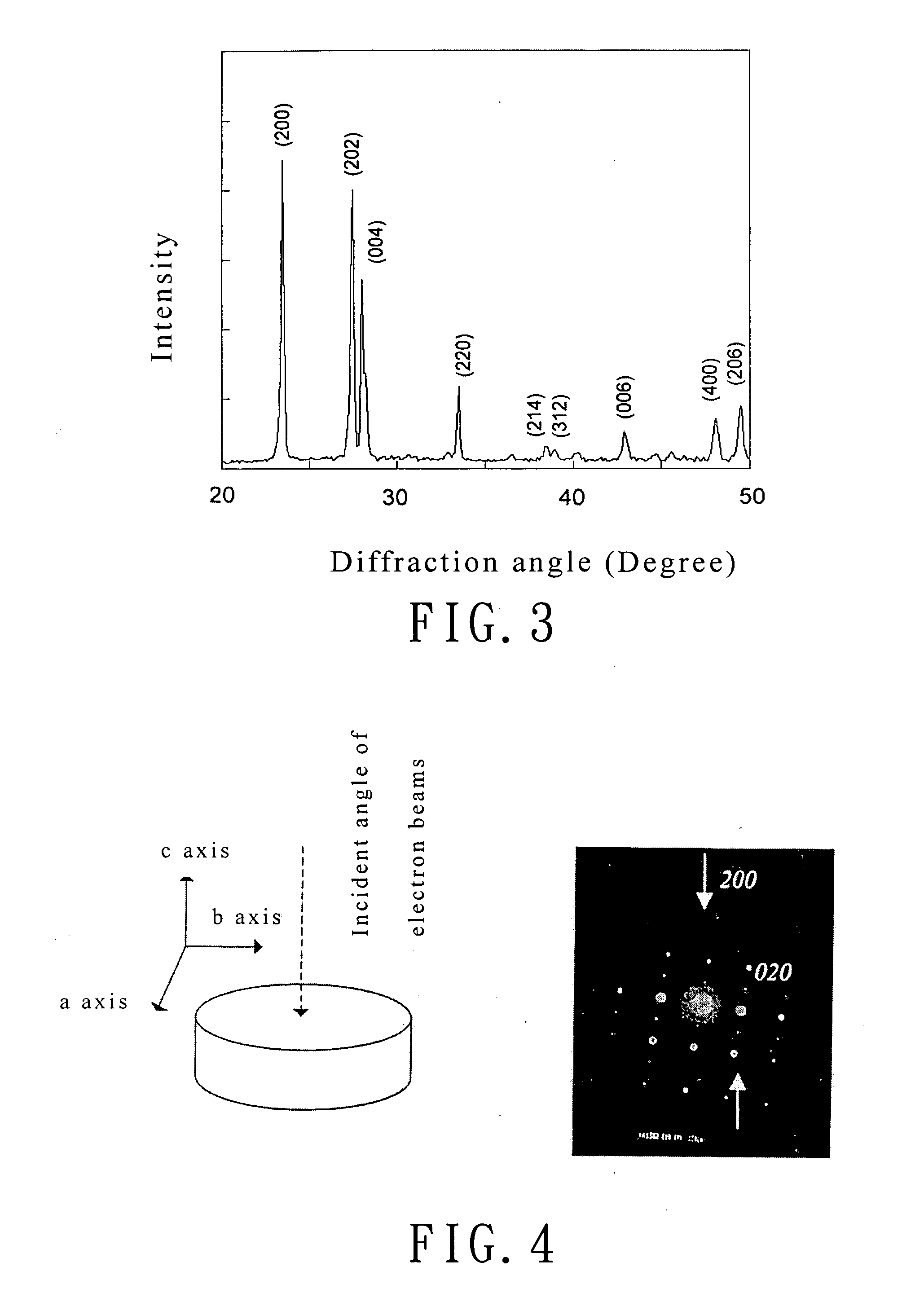

Titanate-containing material and method for making the same

InactiveUS20070099003A1Pretreated surfacesCatalyst activation/preparationHexafluorotitanic acidCompound (substance)

A titanate-containing material includes: a silicon-containing layer; and a crystalline layer of ammonium oxotrifluorotitanate formed on the silicon-containing layer. A method for making a titanate-containing material includes: immersing a silicon-containing substrate into an aqueous solution containing hexafluorotitanate radicals; and reacting the hexafluorotitanate radicals with water so as to form a crystalline layer of an oxotrifluorotitanate compound on the silicon-containing substrate.

Owner:NAT SUN YAT SEN UNIV

Method for preparing insulated iron powder used by soft magnetic composite materials

ActiveCN102528024AImprove high temperature resistanceImprove the problem that the heat treatment temperature is too lowInorganic material magnetismIron powderHexafluorotitanic acid

A method for preparing insulated iron powder used by soft magnetic composite materials belongs to the technical field of magnetic function materials and powder metallurgy. The process is that a cladding process includes: adding high-purity iron powder with concentration of 0.1-5g / ml for industrialized production into hexafluorotitanic acid or hexafluorozirconic acid cladding solution with concentration of 0.002-0.05g / ml, stirring for 5-60 minutes for reacting at temperature of 20-70 DEG C, filtering and washing, and drying at 50-120 DEG C to obtain insulated iron powder. The method for preparing insulated iron powder used by soft magnetic composite materials has the advantages of being simple in preparing process, high in efficiency and complete in cladding. An insulated cladding layer onthe surface of the iron powder can effectively reduce magnetic loss of powder cores of the soft magnetic composite materials, and comprehensive performance of the powder cores can be regulated by controlling thickness of the insulated layer.

Owner:CENT IRON & STEEL RES INST

Antibacterial and mouldproof aluminum alloy chromium-free passivation agent and preparation method thereof

InactiveCN105349988APrevent mildewHigh strengthMetallic material coating processesChromium freeCoconut diethanolamide

The invention discloses an antibacterial and mouldproof aluminum alloy chromium-free passivation agent. The antibacterial and mouldproof aluminum alloy chromium-free passivation agent is prepared by the following raw materials in parts by weight: 5-10 of 30-40% hexafluorotitanic acid, 5-10 of 40-45% hexafluorozirconic acid, 0.1-0.2 of borax, 1-2 of sodium fluoride, 1-2 of 65-70% nitric acid, 0.5-1 of coconut diethanolamide, 1-2 of sodium benzoate, 0.3-0.5 of chitosan, 5-10 of ethylenediaminetetraacetic acid disodium salt, 50-100 of film coalescing aid, and 800-1000 of water. The aluminum alloy passivation agent can form a compact film having a netty structure on the surface of an aluminum alloy, is excellent in strength, toughness, adhesive ability and corrosion resistance, has antibacterial and mouldproof effects, can prevent the moulding of the aluminum alloy to guarantee the surface smoothness and the color durability of the aluminum alloy, can reduce the environmental pollution, and is excellent in economic benefit and social benefit.

Owner:安徽家园铝业有限公司

Environment-friendly metal surface treating agent and preparation method thereof

ActiveCN105734547AGood adhesionImprove corrosion resistanceMetallic material coating processesHexafluorotitanic acidSilanes

The invention provides an environment-friendly metal surface treating agent which comprises a first film forming agent and a second film forming agent, wherein every 1 l of the first film forming agent comprises 1 to 10 g of silane coupling agents, 0.2 to 0.6 g of carboxymethyl chitosan, and the balance being water; every 1 l of the second film forming agent comprises 0.5 to 3 g of colloidal silicon dioxide composite nano ceriumvanadate, 0.1 to 6 g of hexafluorozirconic acid, 0.1 to 5 g of hexafluorotitanic acid, and the balance being water; the silane coupling agents comprise an amino silane coupling agent and an exposy silane coupling agent; and the colloidal silicon dioxide composite nano ceriumvanadate is colloidal silicon dioxide containing nano ceriumvanadate. According to the metal surface treating agent, a stable and compact composite protective covering film can be formed on the surface of a metal material, and excellent adhesiveness and corrosion resistance are achieved.

Owner:上海丰野表面处理剂有限公司

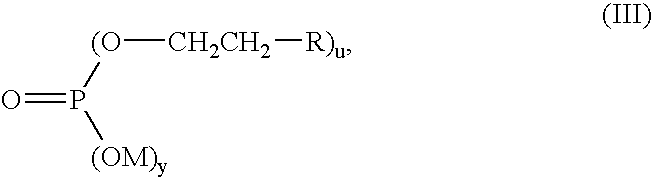

Colored conversion layers on metal surfaces

InactiveUS20060173099A1Solid state diffusion coatingMetallic material coating processesTungstate ionChromium free

Chromium-free conversion coating treatment solutions and processes for depositing a colored layer on zinc or galvanized steel, aluminum, magnesium or their alloys, are provided comprising: hexafluorotitanate and / or hexafluorozirconate ions; molybdate and / or tungstate ions; one or more chelating complex formers; and a copolymer of alkylene phosphonic or alkylene phosphinic acid and one or more unsaturated carboxylic acids.

Owner:HENKEL KGAA

Aluminum passivator and preparation method thereof

InactiveCN104611688ANormal pHGood effectMetallic material coating processesAcetic acidHexafluorotitanic acid

The invention discloses an aluminum passivator which is prepared from the following raw materials in parts by weight: 5-8 parts of silica sol, 1-3 parts of citric acid, 1-3 parts of glacial acetic acid, 2-5 parts of hexafluorotitanic acid, 3-5 parts of hexafluorozirconic acid, 2 parts of L-tartaric acid, 4-5 parts of ammonia water and 69-82 parts of water. The invention aims at providing a preparation method which is good in effect and free of pollution, for the aluminum passivator.

Owner:杭州美立尔表面处理技术有限公司

Colored conversion layers on metal surfaces

Chromium-free conversion coating treatment solutions and processes for depositing a colored layer on zinc or galvanized steel, aluminum, magnesium or their alloys, are provided comprising: hexafluorotitanate and / or hexafluorozirconate ions; molybdate and / or tungstate ions; one or more chelating complex formers; and a copolymer of alkylene phosphonic or alkylene phosphinic acid and one or more unsaturated carboxylic acids.

Owner:HENKEL KGAA

Colored chromium-free passivation solution

ActiveCN107236946AImprove passivation effectEasy to understandMetallic material coating processesChromium freeHexafluorotitanic acid

The invention relates to a colored chromium-free passivation solution. The colored chromium-free passivation solution is an aqueous solution, and is prepared from, by weight, 1-5 parts of a hexafluorozirconic acid solution, 2-8 parts of hexafluorotitanic acid, 1-3 parts of ammonium metavanadate, 0.1-2 parts of tannic acid and 80-100 parts of water; the hexafluorozirconic acid solution is an aqueous solution containing 30-60wt% of hexafluorozirconic acid; and the hexafluorotitanic acid solution is an aqueous solution containing 30-60wt% of hexafluorotitanic acid. The prepared colored chromium-free passivation solution has very good passivation performance.

Owner:上海釜强智能科技有限公司

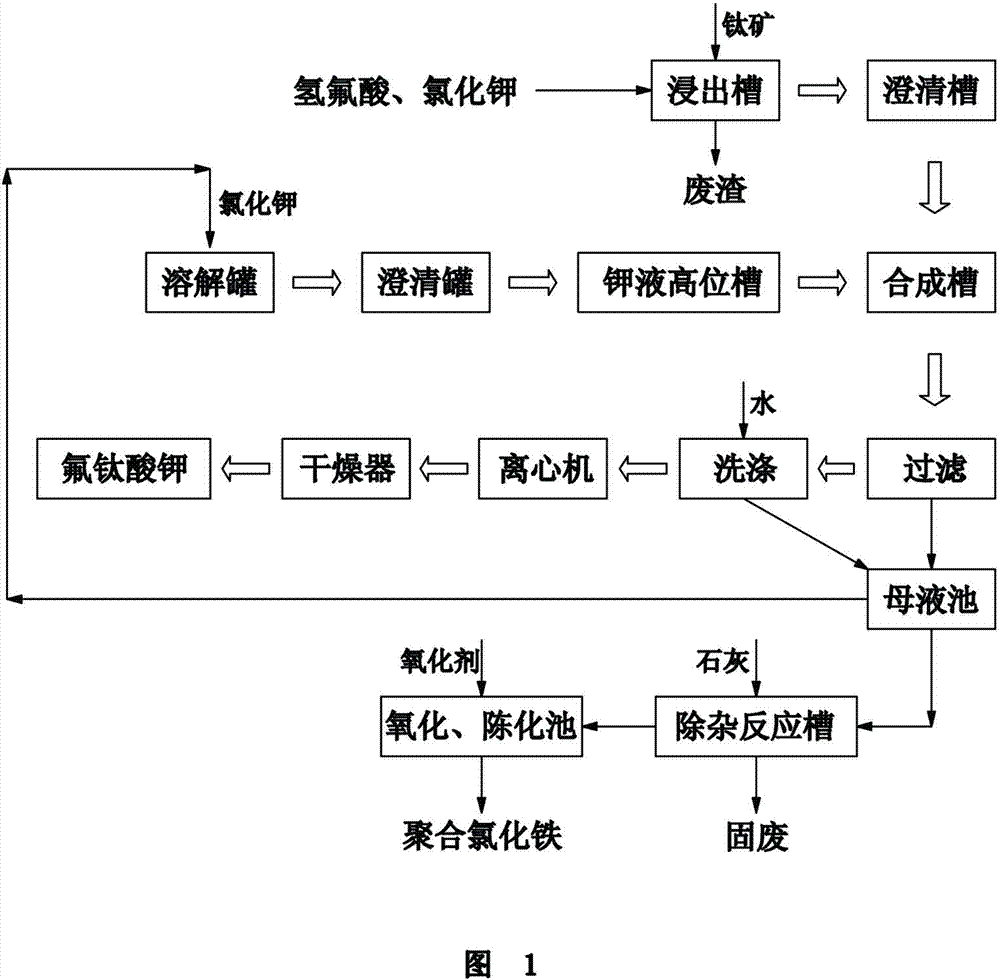

Production process for cogeneration of polymerization ferric chloride water purification agent by using potassium fluotitanate

ActiveCN102951688ALow volume of mother liquorReduce mother liquor lossIron halidesWater/sewage treatment by flocculation/precipitationPotassiumCogeneration

The invention discloses a production process for cogeneration of polymerization ferric chloride water purification agent by using potassium fluotitanate. The production process comprises the following steps: adding hydrofluoric acid and potassium chloride in a leaching tank; opening the leaching tank to stir; adding a theoretical amount of titanium ore; heating to 90-105 DEG C and leaching; sealing to react to obtain hexafluorotitanic acid iron slurry; settling the leached slurry to obtain a hexafluorotitanic acid iron clear liquid for later use; dissolving the potassium chloride by using a hexafluorotitanic acid potassium mother liquid; filtering to obtain a clear liquid for later use; adding metered potassium chloride liquid into a certain amount of hexafluorotitanic acid iron clear liquid while stirring; continually reacting and crystallizing to obtain the hexafluorotitanic acid potassium; carrying out solid-liquid separation on the hexafluorotitanic acid potassium slurry; washing the hexafluorotitanic acid potassium, wherein a part of wastewater enter the potassium chloride for dissolving and recycling; and the other part of wastewater enter an impurity-removing reaction tank; adding metered fine lime in the impurity-removing reaction tank; filter pressing and adding quantified oxidizing agent and stabilizing agent; and standing to obtain polymerization ferric chloride. With the adoption of the production process, the hexafluorotitanic acid potassium mother liquid is recycled, the concentration of the hexafluorotitanic acid potassium mother liquid is improved, and the impurities in the hexafluorotitanic acid potassium mother liquid are removed; and the ferric element is oxidized, alkalified, aged and polymerized to obtain the polymerization ferric chloride.

Owner:福建省漳平市九鼎氟化工有限公司

Preparation method of water-phase cerium fluoride microparticle and application thereof

InactiveCN106865594AImprove photocatalytic reactivityPromote growthWater/sewage treatment by irradiationWater treatment compoundsNitrateHexafluorotitanic acid

The invention relates to a preparation method of a water-phase cerium fluoride microparticle and application thereof, and belongs to the technical field of photocatalysis. The preparation method has the advantages that by using ceric ammonium nitrate or cerous nitrate as a cerium source, and using ammonium hexafluorotitanate or ammonium fluoride as a fluorine source, the water-phase cerium fluoride microparticle with good dispersivity is prepared by a simpler and mild preparation technology; the good phtocatalysis property is realized under the visible light condition, and the application field of cerium fluoride is widened.

Owner:KAIFENG UNIV

Pre-coating non-chrome ceramic filming agent of aluminum alloy profile and sheet workpiece

InactiveCN103668154AReduce consumptionLow priceMetallic material coating processesHydrofluoric acidNitrate

The invention discloses a pre-coating non-chrome ceramic filming agent of an aluminum alloy profile and a sheet workpiece. The pre-coating non-chrome ceramic filming agent is characterized by being prepared from the following raw materials in percentage by mass: 4.5 to 6.5% of hexafluorozirconic acid with mass concentration of 50%, 0.1 to 1% of hexafluorotitanic acid with mass concentration of 40%, 0.1 to 1% of tannic acid, 0.1 to 0.5% of nitric acid with mass concentration of 65%, 0.1 to 0.5% of phytic acid, 0.1 to 0.5% of citric acid, 0.1 to 1% of hydrofluoric acid, 2 to 3% of nickel nitrate, 4 to 6% of ammonium bicarbonate, and the balance of water. The pre-coating non-chrome ceramic filming agent can be prepared under normal temperature without heating, so that the energy consumption can be decreased; the pre-coating non-chrome ceramic filming agent has the same film treating performance for the aluminum alloy profile and the sheet workpiece as imported products, accompanying with lower cost.

Owner:DALIAN SANDAAOKE CHEM

Environment-friendly metal surface treatment agent

InactiveCN105039950ANo smellAccelerated corrosionMetallic material coating processesMetallic materialsHydrolysis

Provided is an environment-friendly metal surface treatment agent. The metal surface treatment agent can form an even and compact chemical conversion coating with superior corrosion resistance and coating adaptation on the surface of metal. The metal surface treatment agent is used for iron, aluminum and zinc type metal materials and comprises (A) hexafluorozirconic acid or fluorozirconate thereof; (B) hexafluorotitanic acid or fluotitanate thereof; (C) 1,2-Bis(trimethoxysilyl)ethane or Bis(triethoxysilyl)ethane hydrolysis products; (D) molybdate; and (E) one or more of nitrate of beryllium, nitrate of magnesium, nitrate of calcium, nitrate of strontium, nitrate of aluminum, nitrate of vanadium, nitrate of manganese, nitrate of copper and nitrate of zinc.

Owner:抚顺克立恩清洗有限公司

Aluminum profile chromate-free passivation agent

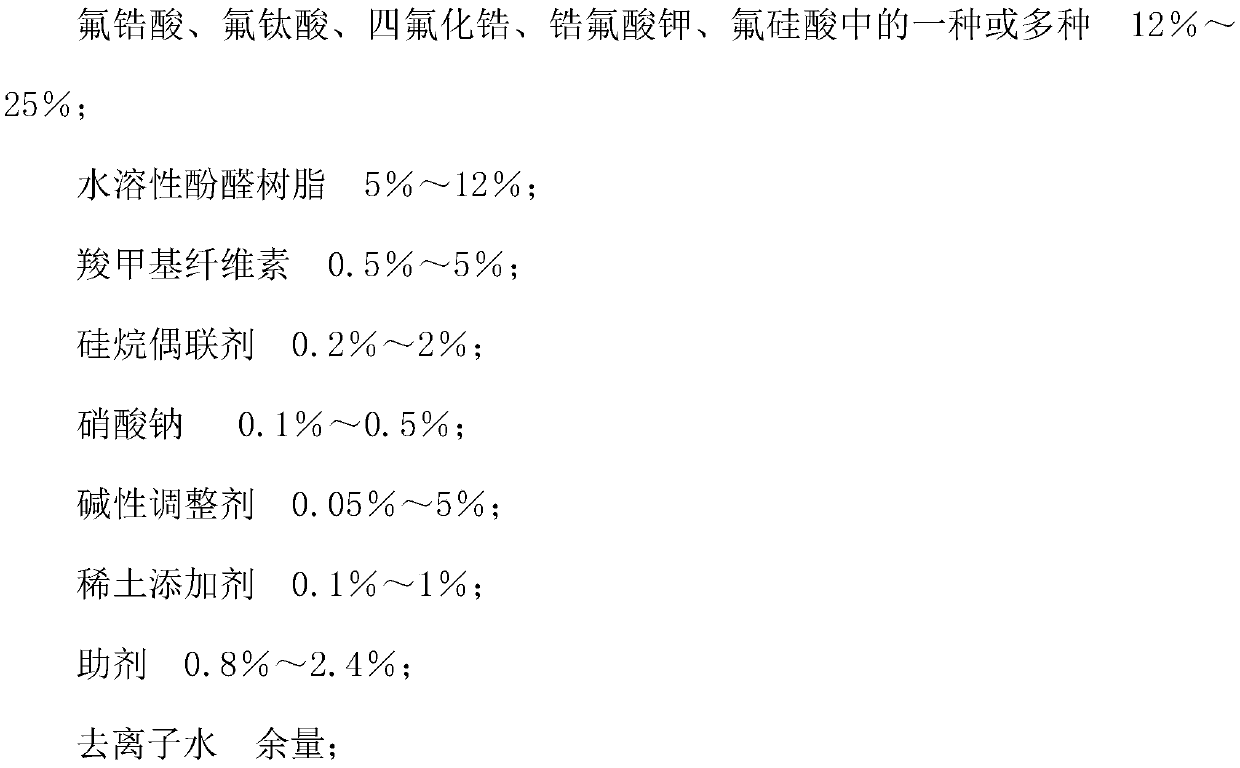

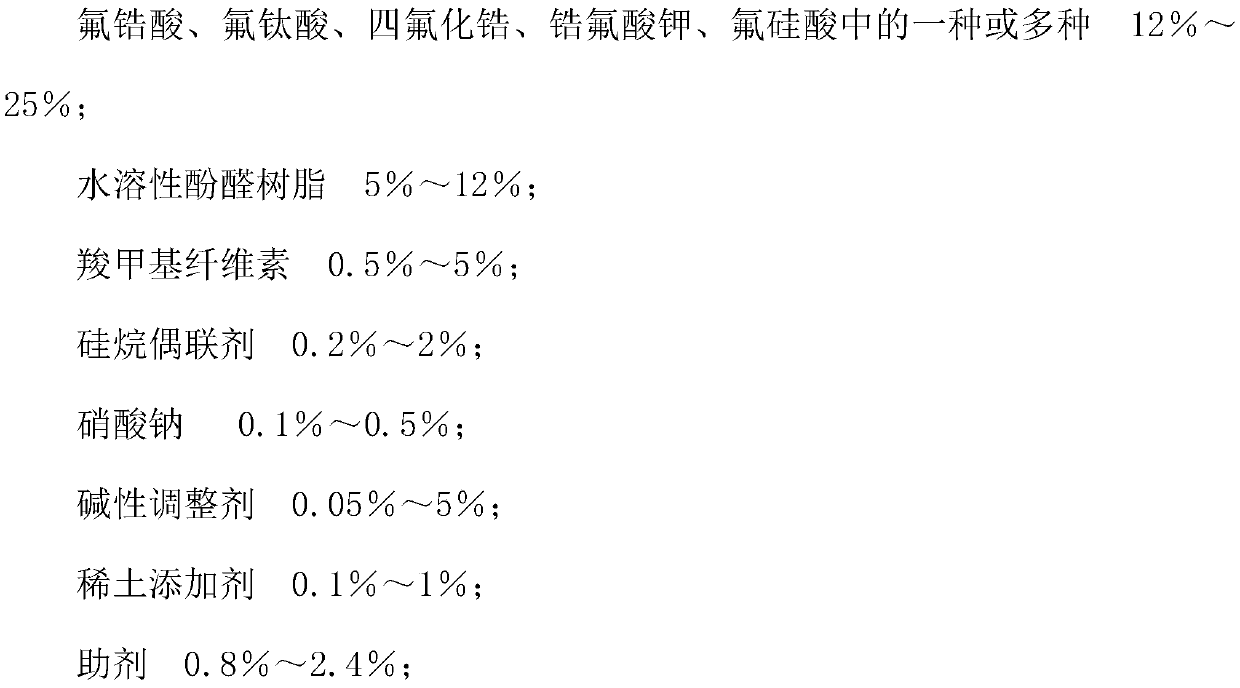

PendingCN110257809AImprove rust resistanceLow costMetallic material coating processesAntioxidantRare earth

Owner:浙江九合环保科技有限公司

Environment-friendly low-cost metal surface treatment agent and preparation method thereof

ActiveCN104294260AEnvironmentally friendlyNo toxic heavy metal ionsMetallic material coating processesSlagSilicon dioxide

The invention provides an environment-friendly low-cost metal surface treatment agent. The treatment agent is composed of the following raw materials, by weight, 10-20 parts of 3-aminopropyl triethoxysilane, 10-20 parts of dispersed nano-silica, 10-40 parts of hexafluorozirconic acid, 0-25 parts of hexafluorotitanic acid, 5-10 parts of oxalic acid, 8-15 parts of hydrogen peroxide, 887-950 parts of water and 2-5 parts of ammoniacal liquor. In comparison with traditional phosphatization, the invention has advantages of environmental protection property (no toxic heavy metal ion), low energy consumption (use at normal temperature), low use-cost (handling capacity per kilogram is 5-8 times higher than common phosphatization), no slag and the like.

Owner:江苏鸿捷环保设备有限公司

High-corrosion-resistance marine aluminum alloy surface metal-organic skeleton film treatment liquid and using method thereof

ActiveCN108330475AAccelerated corrosionGood adhesionMetallic material coating processesChromium freeEnvironmental resistance

The invention relates to the technical field of metal surface treatment, in particular to a high-corrosion-resistance marine aluminum alloy surface metal-organic skeleton film treatment liquid and a using method thereof. The treatment liquid is prepared from the following components of 25-1600 ppm of hexafluorozirconic acid with the concentration being 45%, 12.5-1000 ppm of hexafluorotitanic acidwith the concentration being 50%, 5-120 ppm of manganese difluoride, 25-600 ppm of glucose, 5-40 ppm of sodium sulfate with the concentration being 50%, and the balance water. The aluminum alloy surface is coated with the treatment liquid to form a metal-organic skeleton film. According to the metal-organic skeleton film treatment liquid, metal ions are provided through the hexafluorozirconic acidand the hexafluorotitanic acid, organic unsaturated bonds are provided through the glucose and combined with the metal ions to form a skeleton, adhesion precipitation of aluminum oxides is facilitated, film forming is easy, the corrosion resistance and the adhesion of the skeleton film are improved advantageously, meanwhile, chromium-free raw materials are adopted, and the environmental protection and pollution-free effects are achieved.

Owner:广东省珠海市质量计量监督检测所

Environment-friendly chromium-free rust-proof passivation solution and preparation method thereof

InactiveCN107699883AImprove the effect of surface treatmentImprove adhesionMetallic material coating processesCerium nitrateCerium nitrate hexahydrate

The invention discloses an environment-friendly chromium-free rust-proof passivation solution. The rust-proof passivation solution is prepared from the raw materials of, by weight, 100 parts of deionized water, 2-10 parts of salicylic acid, 4-10 parts of benzotriazole, 3-10 parts of sodium citrate, 2-10 parts of 2-chlorine-4,5-dihydro-1H-imidazole sulfonate, 1-10 parts of hexafluorotitanic acid, 1-5 parts of sodium gluconate, 1-5 parts of zinc oxide, 4-10 parts of cerium nitrate, 3-10 parts of silane-modified polyphosphazene-polyethersulfone block copolymers, 5-10 parts of silver nitrate, 1-10parts of n-butanol, 1-5 parts of sodium silicate, 1-5 parts of 2-mercapto benzimidazole-5-sodium sulfonate dehydrate, 1-10 parts of oxalic acid, 1-5 parts of ethyl alcohol and 1-5 parts of 3-[(methylol)methylamine] ethanesulfonic acid. The obtained environment-friendly chromium-free rust-proof passivation solution can be used for low-temperature surface treatment, is high in surface treatment efficiency, environmentally friendly and good in rust-proof performance and has good market prospects.

Owner:JINGMEN TUODA TECH CO LTD

Abrasion-resistant and scraping-resistant aluminum alloy chromium-free passivating agent and preparation method thereof

InactiveCN105316665AReduce wearLess scratchesMetallic material coating processesChromium freeSodium gluconate

The invention discloses an abrasion-resistant and scraping-resistant aluminum alloy chromium-free passivating agent and a preparation method thereof. The passivating agent is prepared from, by weight, 5-10 parts of 30-40% hexafluorotitanic acid, 5-10 parts of 40-45% hexafluorozirconic acid, 1-2 parts of polyepoxysuccinic acid, 4-6 parts of sodium gluconate, 1-2 parts of sodium fluoride, 1-2 parts of 65-70% nitric acid, 1-2 parts of Turkey red oil, 1-2 parts of simethicone, 50-100 parts of 40-50% polyethylene wax emulsion, 50-100 parts of coalescing agents and 800-1000 parts of water. According to the aluminum alloy passivating agent, a compact film of a net structure can be formed on the surface of aluminum alloy, excellent strength, tenacity and adhesive capacity are achieved, and the corrosion resistance is good; meanwhile, good abrasion resistance is achieved, abrasion and scraping on the surface of the aluminum alloy can be reduced, environment pollution can be reduced, and good economic benefits and social benefits are achieved.

Owner:HEFEI HAIYUAN MACHINERY

Aluminum alloy natural color chromate-free passivation treatment agent and preparation method thereof

ActiveCN109609944AImprove corrosion resistanceSimple processMetallic material coating processesPotassium persulfateAluminium alloy

The invention discloses an aluminum alloy natural color chromate-free passivation treatment agent. The aluminum alloy natural color chromate-free passivation treatment agent is prepared from, by weight percentage, 5-10% of potassium persulfate, 1-5% of sorbitol, 0.5-1.5% of ammonium metavanadate, 0.1-0.5% of sodium diisobutyl naphthyl sulfonate, 0.1-0.5% of potassium zirconium carbonate, 0.05-0.08% of polyoxyethylene 10 lauryl ether, 0.01-0.05% of sodium pyrrolidone carboxylate, 0.05-0.1% of cerium salt, 3-10% of inorganic acid, 0.5-2% of organic acid and the balance water. The cerium salt isone or a mixture of cerium oxalate, cerium zincate, cerium formate and cerium acetate. The inorganic acid is one of hexafluorozirconic acid and hexafluorotitanic acid or a mixture of both. The organicacid is one of formic acid, acetic acid and oxalic acid. According to the chromate-free passivation treatment agent, a chromate-free passivation film formed on the surface of aluminum alloy is colorless and transparent, and the natural color of the aluminum alloy is not changed; and after treatment is conducted through the aluminum alloy natural color chromate-free passivation treatment agent, the corrosion resistance of the aluminum alloy is greatly improved, and the treatment agent can be applied to occasions without surface coating.

Owner:LINYI JINHU COLOR COATING ALUMINUM IND

Environment-friendly emission reduction washing-free type metal surface treatment agent

InactiveCN108754480AReduce generationEmission reductionMetallic material coating processesRare earth metal compoundsHydrolysate

The invention discloses an environment-friendly emission reduction washing-free type metal surface treatment agent. The environment-friendly emission reduction washing-free type metal surface treatment agent comprises zirconium / titanium compounds, rare earth metal compounds, silane, alcohol amine, resin and the like. The zirconium / titanium compounds are mixed compounds with one or a plurality of types of hexafluorozirconic acid, hexafluorotitanic acid, potassium fluozirconate, sodium fluozirconate, ammonium fluozirconate, potassium fluotitanate, sodium fluotitanate, ammonium fluorotitanate, organic zirconium and organic titanium compounds and derived structure compounds of the mixed compounds, the rare earth metal compounds are compounds with one or a plurality of types of rare earth chloride, rare earth nitrate, rare earth hydrate, rare earth carbonate, rare earth acetate and rare earth sulfate, the rare earth chloride, the rare earth nitrate, the rare earth hydrate, the rare earth carbonate, the rare earth acetate and the rare earth sulfate contain one or a plurality of types of rare earth elements including cerium, lanthanum and neodymium, and the silane is a mixture of organicsilane coupling agents and one or a plurality of types of derivatives, hydrolysate and premixes of the organic silane coupling agents. The environment-friendly emission reduction washing-free type metal surface treatment agent has the advantages that the environment-friendly emission reduction washing-free type metal surface treatment agent which is a washing-free environment-friendly metal surface pretreatment agent does not contain phosphorus, is free of heavy metal, little in wastewater discharge, excellent in corrosion resistance and low in cost and is environmentally friendly.

Owner:上海优梓新材料科技有限公司

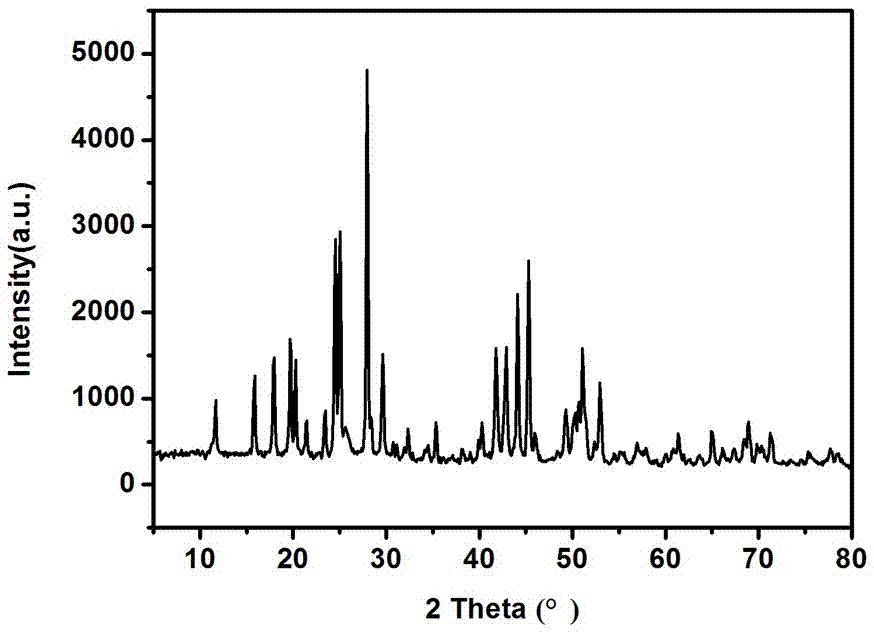

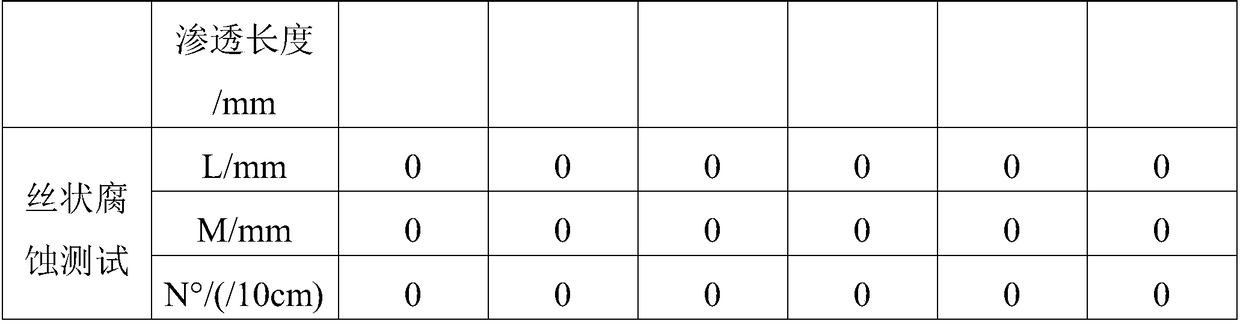

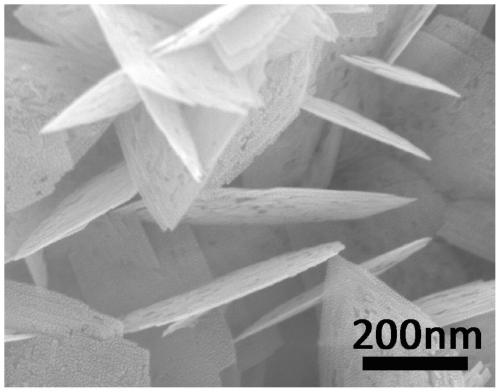

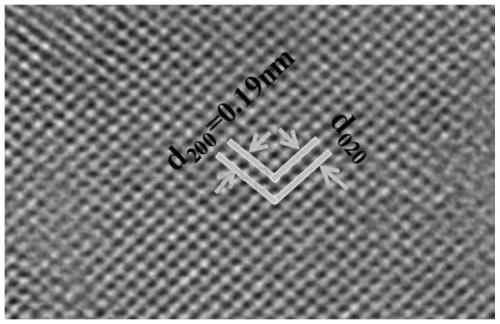

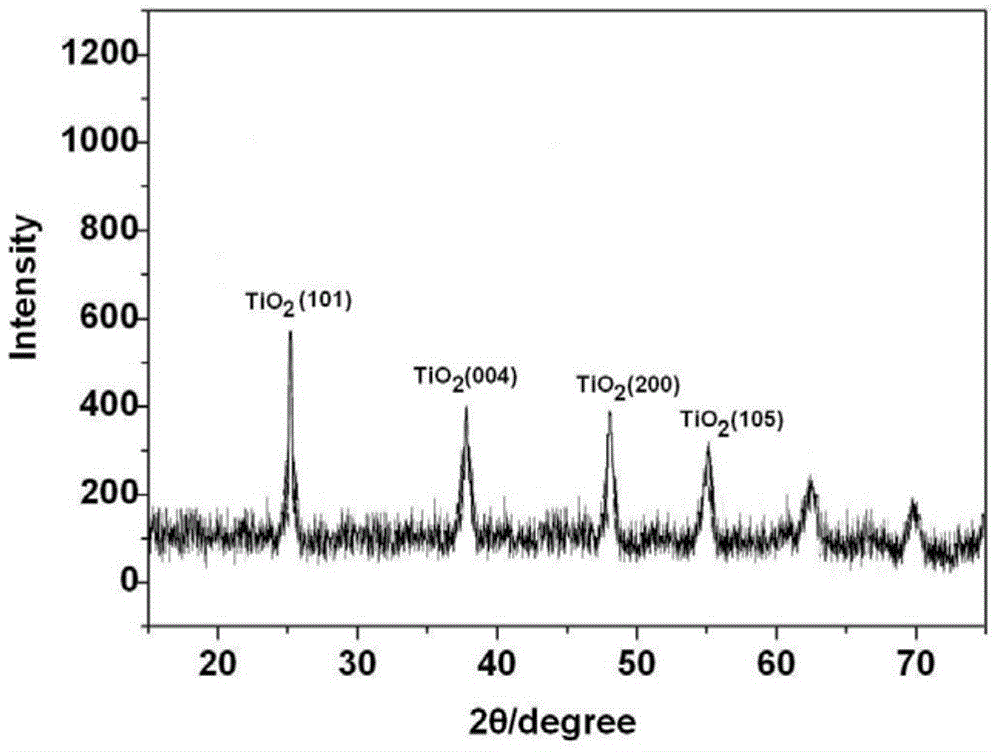

Preparation method and application of {001} crystal face exposed porous titanium dioxide nanosheet

ActiveCN111268725AGood dispersionHigh purityPhysical/chemical process catalystsNanotechnologySemiconductor materialsMaterials science

The invention discloses a preparation method and application of a {001} crystal face exposed porous titanium dioxide nanosheet, and belongs to a preparation method and application of a semiconductor photocatalytic material. The invention specifically relates to a method for preparing a {001} crystal face exposed porous titanium dioxide nanosheet in a cyclohexanol-hexafluorotitanic acid-tetrabutyltitanate reaction system, and application of the {001} crystal face exposed porous titanium dioxide nanosheet as a semiconductor material in the aspect of hydrogen evolution reaction of photocatalyticdecomposition of water. The method comprises the following steps: dissolving hexafluorotitanic acid and tetrabutyl titanate in cyclohexanol; adding the obtained solution into a closed homogeneous reaction container for reaction; and after the reaction is finished, quickly cooling the reaction product, and separating, washing and drying the reaction product to obtain a target product. The method is simple and convenient in process and good in repeatability, and the obtained product is high in purity, good in dispersity and uniform and controllable in size distribution, has a nano-porous structure and a high {001} crystal face exposure ratio, and is expected to be produced on a large scale. The titanium dioxide nanosheet is used as a photocatalytic material and has excellent hydrolysis hydrogen evolution performance, so that the titanium dioxide nanosheet has good economic benefits and a relatively wide market prospect.

Owner:CHINA UNIV OF MINING & TECH

Chromium-free passivating pretreatment method for mirror aluminum board

InactiveCN103866308AChange structureImprove adhesionMetallic material coating processesChromium freePretreatment method

The invention relates to a chromium-free passivating pretreatment method for a mirror aluminum board. The pretreatment method comprises the following steps: degreasing, washing with water, surface conditioning, washing with water, chromium-free passivating, and pure water washing, wherein a degreasing solution comprises the following components: 1-4wt% of potassium hydroxide, 0.5-1.6wt% of potassium metasilicate, 0.3-1.2wt% of potassium tetraborate, 0.5-2wt% of alkoxy ether fatty alcohol and 0.1-0.8wt% of compound corrosion inhibitor; a surface conditioning solution comprises the following components: 1-4% of phosphoric acid and 0.15-0.3wt% of hydrofluoric acid; a chromium-free passivating solution comprises the following components: 0.2-0.6wt% of hexafluorozirconic acid, 0.05-0.2wt% of hexafluorotitanic acid, 0.5-1.6wt% of magnesium nitrate, 0.03-0.07wt% of hydrofluoric acid, 0.02-0.05wt% of sodium sulfate, 0.1-0.3% of 3-amino propyl ethoxy silane and 0.006-0.01wt% of lanthanum rare earth compound. When the mirror aluminum board is processed by using the chromium-free passivating pretreatment method disclosed by the invention, the mirror surface does not lose light, the passivating film is colorless and transparent, and a hexavalent chromium passivation method for the mirror aluminum board at present can be replaced.

Owner:SHANGHAI REAL INDAL

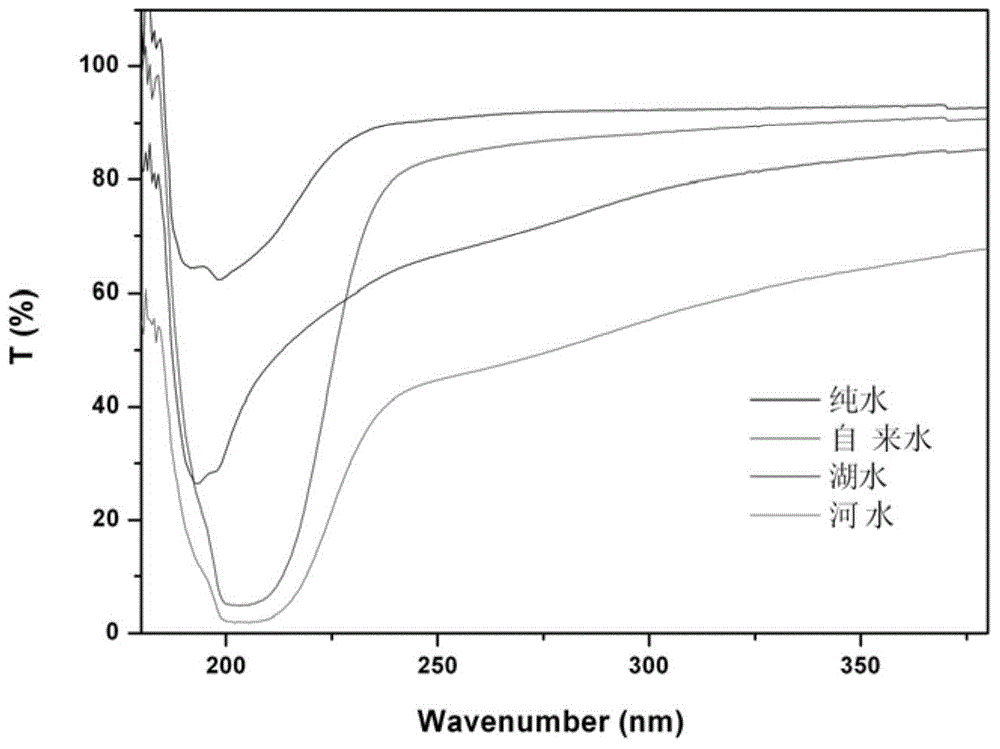

Method for effectively degrading algal toxin in water

InactiveCN104944512AImprove mechanical propertiesGood UV transmittanceWater/sewage treatment by irradiationWater/sewage treatment by sorptionSolventMicro spheres

The invention relates to a method for effectively degrading algal toxin in water. The method comprises the following processing steps: (1) adding MC(Microcystin)-LR into an alcohol-water mixed solvent, oscillating to enable the MC-LR to be completely dissolved, adding ammonium hexafluorotitanate, boric acid and ammonium hexafluorosilicate, reacting for 15-25 hours at the constant temperature of 35 DEG C, immersing a quartz fiber filter band into substances generated through the reaction, taking out and airing the quartz fiber filter band, calcining the quartz fiber filter band at the temperature of 400 DEG C for 2-2.5 hours with the temperature increasing rate of 10 DEG C / min, cooling, and taking out the quartz fiber filter band, so as to obtain the quartz fiber filter band loaded with titanium dioxide porous micro-spheres with the molecular imprinting function; (2) sewing the prepared quartz fiber filter band loaded with the titanium dioxide porous micro-spheres with the molecular imprinting function into a filter sleeve capable of sleeving an ultraviolet lamp tube according to the profile of the ultraviolet lamp tube; (3) inserting the ultraviolet lamp tube capable of being immersed into water into the filter sleeve, and then, placing the filter sleeve into a photoreaction container filled with microcystin polluted water. Through the adoption of the method, the efficiency for degrading algal toxin in water is relatively high.

Owner:张易祥

Dehydrofluorination catalyst

ActiveCN101637732AHigh selectivityHigh activityPreparation by hydrogen halide split-offCatalyst activation/preparationChromium CompoundsHigh activity

The invention discloses a dehydrofluorination catalyst aiming at solving the problems of low activity of the catalyst and low selectivity to Z-type fluoroolefin. The precursor of the catalyst consistsof 40-80 percent of trivalent chromium compound and 20-60 percent of fluoride of metal ammonium by mass percent, wherein the trivalent chromium compound is chromic oxide or chromium hydroxide, and the fluoride of metal ammonium is hexafluoro ammonium metatitanic, hexafluoro ammonium antimonite or hexafluoro ammonium stannate. The catalyst is prepared by the following method: evenly mixing the trivalent chromium compound and the fluoride of metal ammonium by mass percent, pressing and shaping the mixture, and then baking and activating hydrogen fluoride. The dehydrofluorination catalyst has high activity and selectivity to the Z-type fluoroolefin, and is mainly used for preparing corresponding Z-type fluoroolefin by dehydrofluorination using hydrofluorocarbon as the material under the condition of gaseous phase reaction.

Owner:XIAN MODERN CHEM RES INST

Method for synthesizing pyrroloquinoline quinone

InactiveCN108329313ARaw materials are cheap and easy to getImprove reaction speedOrganic chemistrySolubilityHexafluorotitanic acid

The invention relates to a method for synthesizing pyrroloquinoline quinone. By the method, ethyl pyruvate is used as a starting synthesizing raw material to prepare the pyrroloquinoline quinone. In the synthesizing method, a step of synthesizing a compound 4 into a compound 5 is a key step of the synthesizing route, in the key step (5), Lewis acid ionic liquid such as hexafluoroantimonate ionic liquid, hexafluorotitanate ionic liquid and hexafluoroborate ionic liquid is creatively used, the ionic liquid has functions of a reaction medium and a catalyst, and therefore, the reaction speed and yield of the steps can be increased. In addition, [BMIm]SbF6 ionic liquid is used optimally, [BMIm]SbF6 ionic liquid and Sc(OTf)3 can form [Sc(OTf)3-x][SbF6] with high catalytic activity, the reactionefficiency can be greatly improved, the solubility of the obtained reaction product in the [BMIm]SbF6 ionic liquid is low, the reaction product precipitates out easily, and therefore, the reaction yield (which can reach 96%) is improved.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Passivation composition and process for zinciferous and aluminiferous surfaces

InactiveUS20050072495A1Solve the lack of corrosion resistanceSolve the lack of resistanceSolid state diffusion coatingHexafluorotitanic acidPhosphate ion

In at least one embodiment, the present invention relates to a process for the temporary anti-corrosive treatment of a metal surface that consist predominantly of aluminum and / or zinc, said process comprising a) placing the surface of the metal in contact with an anti-corrosive composition comprising 2.0-400 g / L phosphate ions, 0.5-400 g / L fluorometallate ions, and having a pH of between 1.0-4.0, for a time period of between 0.1-200 seconds, b) drying the anti-corrosive treatment composition on the metal surface to form a primary passivating coating on the metal surface, c) removing the primary passivating coating from the metal surface, and d) conversion coating the metal surface. In certain embodiments, the phosphate solution comprises phosphoric acid and the fluorometallate solution comprises hexafluorotitanic acid.

Owner:HENKEL KGAA

Polyving akohol chrome-free corrosion-resistant silane passive film

InactiveCN106756953AImprove corrosion resistanceGood self-lubricating performanceMetallic material coating processesMethacrylateSilanes

The invention discloses a polyving akohol chrome-free corrosion-resistant silane passive film. The polyving akohol chrome-free corrosion-resistant silane passive film is prepared from, by weight, dodecafluoroheptyl methacrylate, hexafluorobutyl methacrylate, a silane coupling agent KH560, azodiisobutyronitrile, a silane coupling agent KH570, a proper quantity of a silane coupling agent KH858, imvite, triethoxy methyl silane, aluminum acetylacetonate, polyether amine, ammonium metavanadate, hexafluorotitanic acid, sodium molybdate, trisodium phosphate, silica sol, polyving akohol, a proper amount of absolute ethyl alcohol, a proper amount of tetrahydrofuran, a proper amount of isopropanol, a proper amount of dilute hydrochloric acid, a proper amount of dilute nitric acid and a proper amount of deionized water. Prepared passivating liquid can form a film layer on the surfaces of various kinds of substrates, the adhesive force is high, the compactness is good, the film is high in abrasion resistance, oil resistance, salt mist resistance and alkali resistance, and the film is free of pollution to the environment, harmless to human bodies and worthy of popularization.

Owner:张庆

Metal surface treatment agent for gelatinous film and preparation method of metal surface treatment agent

InactiveCN104988478AIncrease contact angleImprove stabilityMetallic material coating processesElectrochemical responseSilanes

The invention discloses a metal surface treatment agent for a gelatinous film. The surfaces of acrylate adhesive solution particles in the metal surface treatment agent contain a large amount of carboxyls; aniline is added into the acrylate adhesive solution; aniline monomers diffuse to the inside of a micelle first, and are then doped with the carboxyls; subsequently, under the action of an oxidant, the aniline generates a polymerization reaction on the surfaces of emulsion particles, so that a contact angle of a polyaniline coating to water is increased, and the adhesive force and the water resistance are improved; according to the coating, the surface of metal is passivated to form a protecting action under the actions of electron transfer and oxidation reduction; an inorganic component Ti<4+> introduced by silanization-modified hexafluorotitanic acid forms TiO2 particles in a heating and curing process, and the TiO2 particles are uniformly filled in the gaps of a silane film, so that the whole film layer is more uniform and compact, a micro electrochemical reaction on the surface of the film layer can be effectively inhibited, and further the corrosion resistance is greatly improved.

Owner:HEFEI ZHENGHAO MECHANICAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com