Method for effectively degrading algal toxin in water

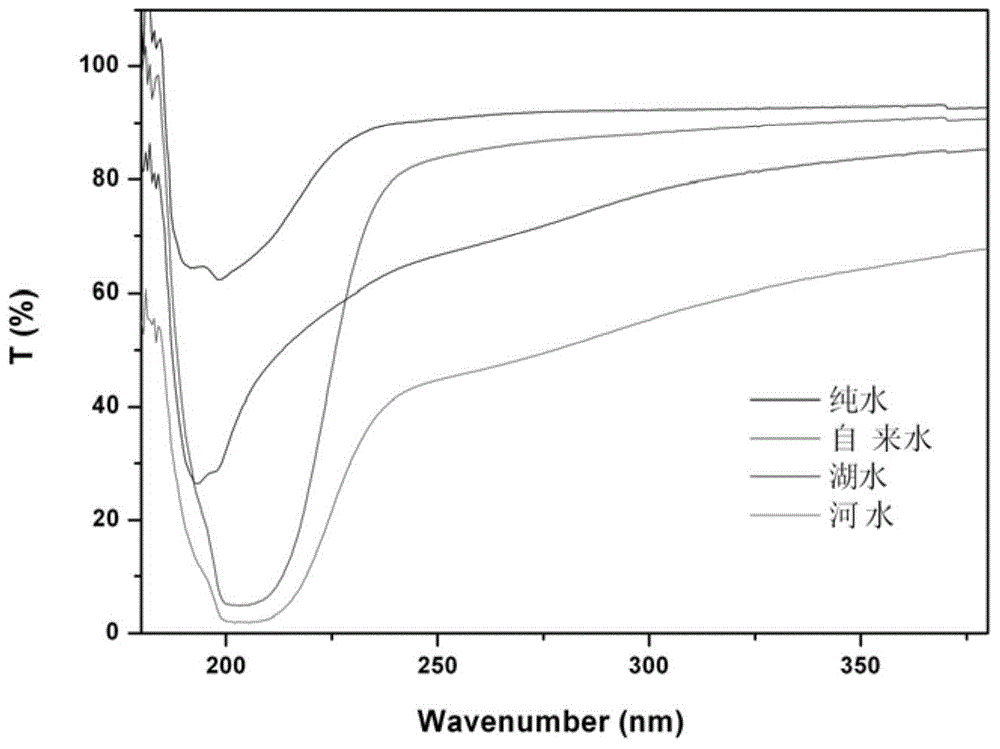

A technology of algae toxins and microcystins, applied in the direction of light water/sewage treatment, adsorption water/sewage treatment, etc., can solve the problems of low reaction efficiency and energy waste, achieve efficient use of ultraviolet radiation, reduce ineffective absorption, The effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

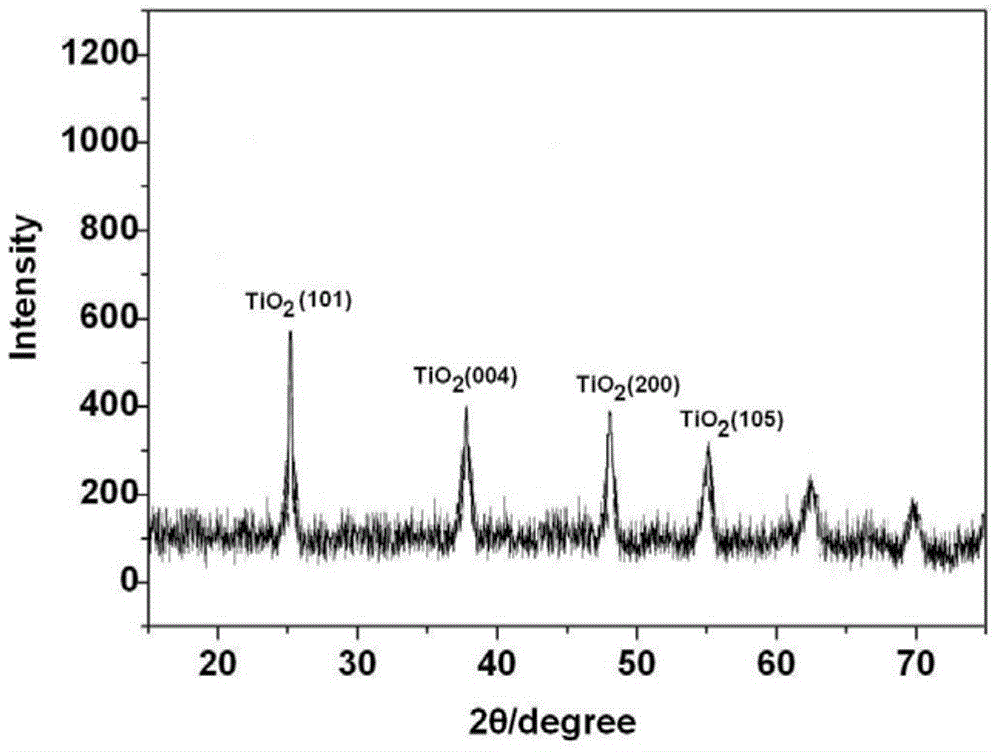

[0027] Add 2 mg (2 μM) of microcystin MC-LR to 100 mL of alcohol-water mixed solvent, dissolve, and the alcohol is methanol or ethanol, and the volume ratio of alcohol to water is 0.5:10 to 1.0:10. Then, 1.98g (0.05M) of ammonium hexafluorotitanate, 0.78g (0.12M) of boric acid and 0.36g (0.01M) of ammonium hexafluorosilicate were added, stirred thoroughly, and reacted for 15 hours at a constant temperature of 35°C. The powder particles generated by the reaction were evenly coated on a quartz fiber filter belt with a length of 30 cm and a width of 25 cm, and dried, and then calcined at a temperature of 400 ° C for 2 to 2.5 hours, with a heating rate of 10 ° C / min, and taken out after cooling. , to obtain a quartz fiber filter belt loaded with titania porous microspheres with molecularly imprinted function.

[0028]The obtained quartz fiber filter tape loaded with titania porous microspheres with molecular imprinting function was sewn into a filter sleeve with a length of 30cm a...

Embodiment 2

[0033] Add 200 mg, (0.2 mM) of the extract of natural cyanobacterial microcystins to 200 mL of alcohol-water mixed solvent, dissolve, the alcohol is methanol or ethanol, and the volume ratio of alcohol to water is 0.5:10 to 1.0:10. Then, 1.98g (0.05M) of ammonium hexafluorotitanate, 0.78g (0.12M) of boric acid and 0.36g (0.01M) of ammonium hexafluorosilicate were added, stirred thoroughly, and reacted at a constant temperature of 35°C for 15 hours. The powder particles generated by the reaction are evenly coated on a quartz fiber filter belt with a length of 30 cm and a width of 25 cm, and dried, and then calcined at a temperature of 400 ° C for 2 to 2.5 hours at a heating rate of 10 ° C / min, and taken out after cooling. , to obtain a quartz fiber filter belt loaded with titania porous microspheres with molecularly imprinted function.

[0034] The obtained quartz fiber filter belts loaded with titania porous microspheres with molecular imprinting function were sewn into filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com