Patents

Literature

81 results about "Ammonium hexafluorosilicate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ammonium fluorosilicate (also known as ammonium hexafluorosilicate, ammonium fluosilicate or ammonium silicofluoride) has the formula (NH4)2SiF6. It is a toxic chemical, like all salts of fluorosilicic acid.

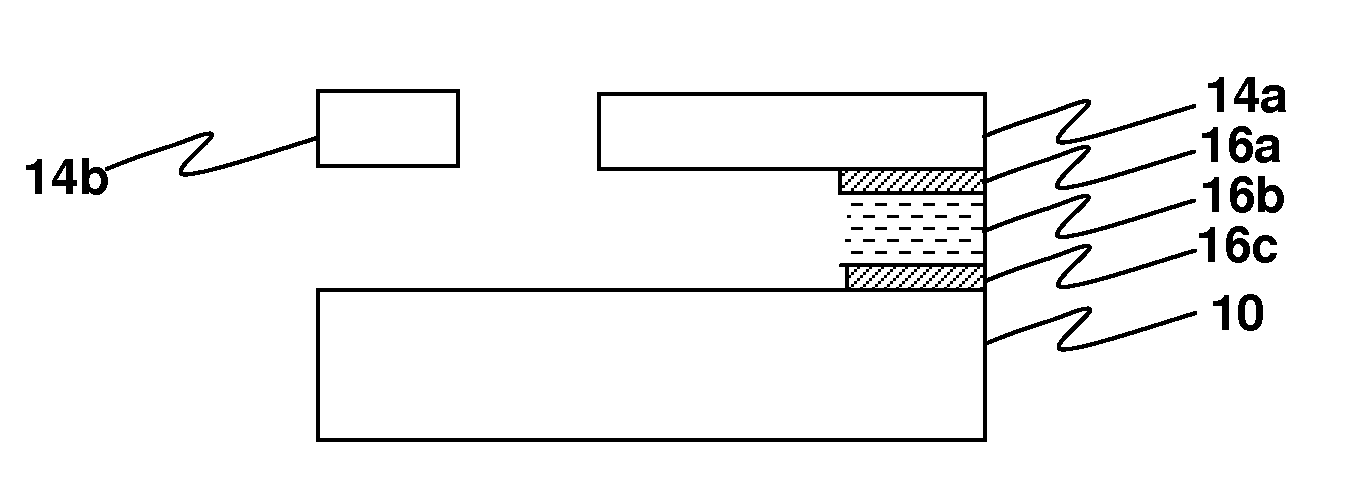

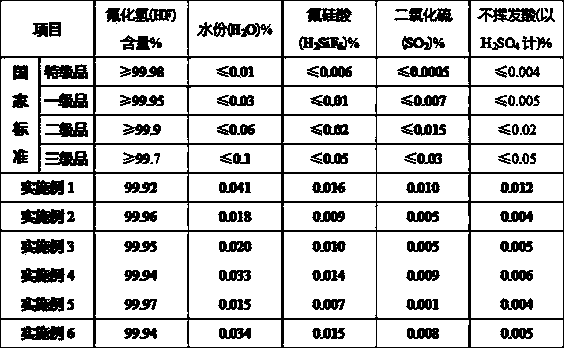

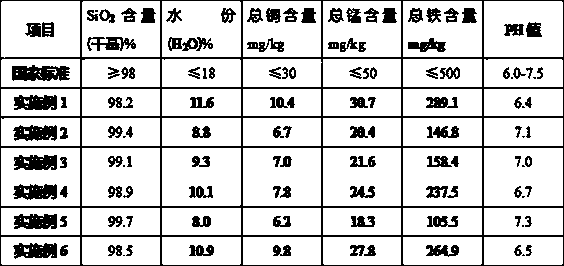

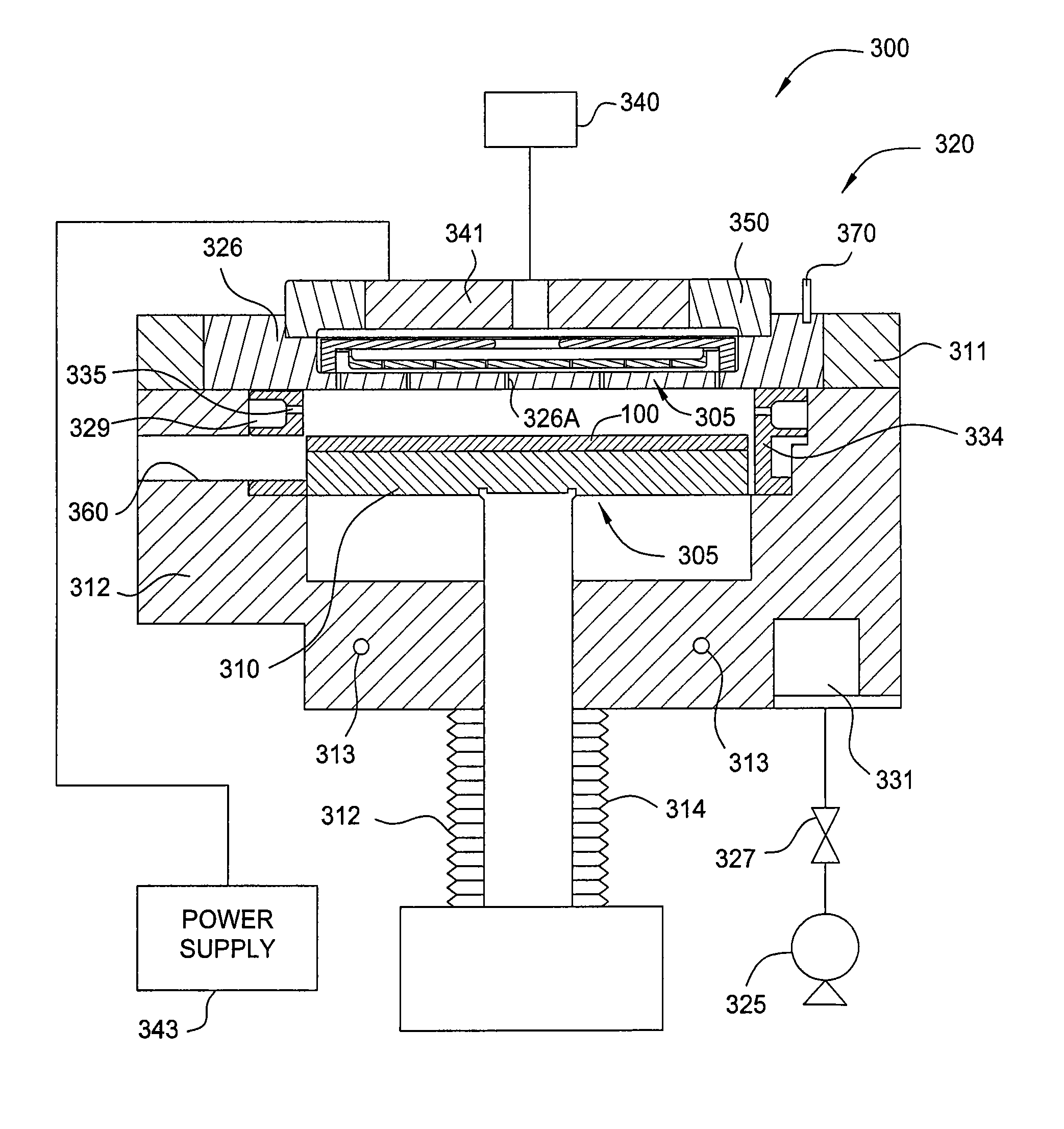

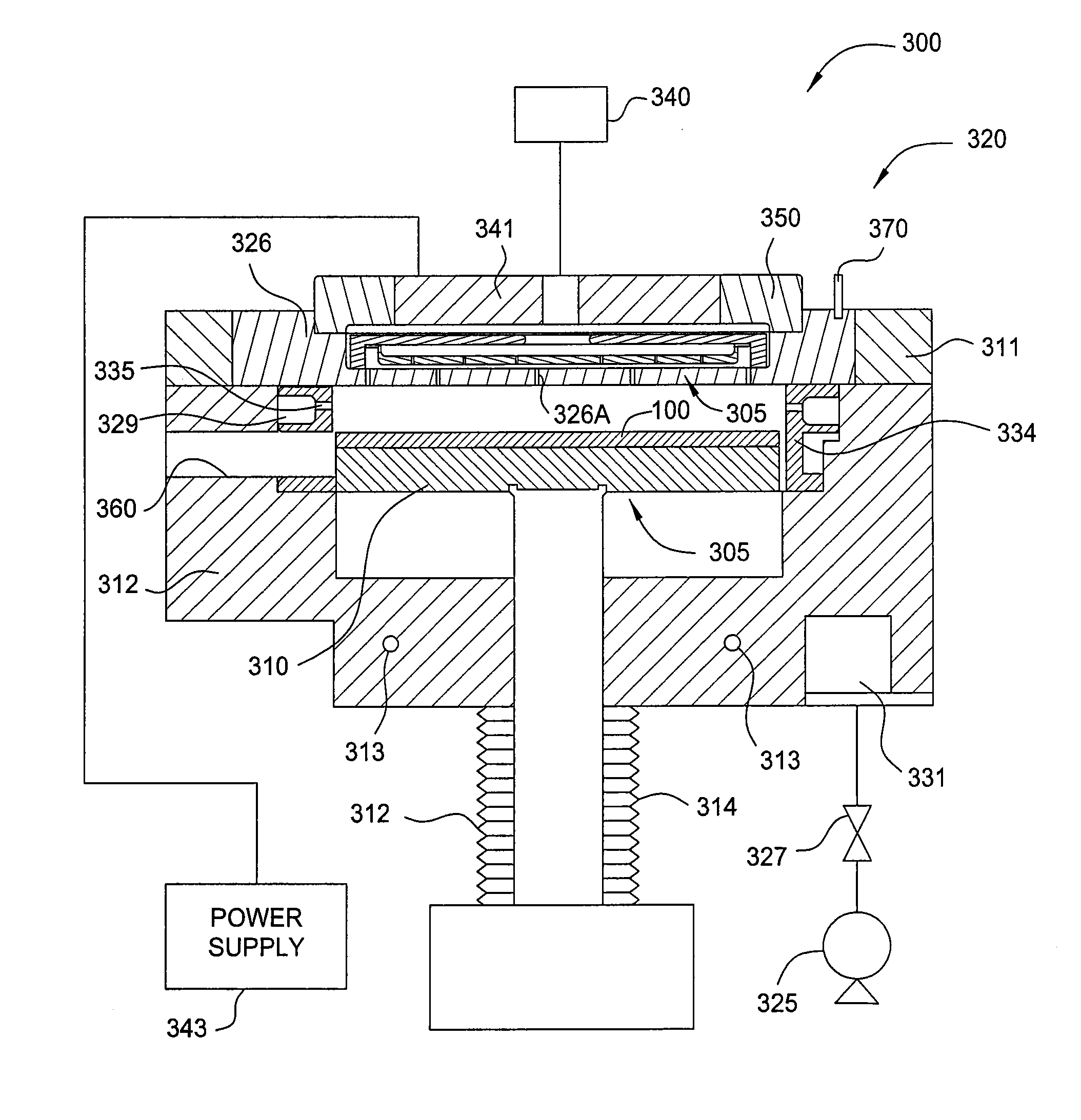

Passivation layer formation by plasma clean process to reduce native oxide growth

ActiveUS20080160210A1Format be limitLighting and heating apparatusVacuum evaporation coatingAmmoniaSubstrate surface

Embodiments described herein provide methods for removing native oxide surfaces on substrates while simultaneously passivating the underlying substrate surface. In one embodiment, a method is provided which includes positioning a substrate containing an oxide layer within a processing chamber, adjusting a first temperature of the substrate to about 80° C. or less, generating a cleaning plasma from a gas mixture within the processing chamber, such that the gas mixture contains ammonia and nitrogen trifluoride having an NH3 / NF3 molar ratio of about 10 or greater, and condensing the cleaning plasma onto the substrate. A thin film, containing ammonium hexafluorosilicate, is formed in part, from the native oxide during a plasma clean process. The method further includes heating the substrate to a second temperature of about 100° C. or greater within the processing chamber while removing the thin film from the substrate and forming a passivation surface thereon.

Owner:APPLIED MATERIALS INC

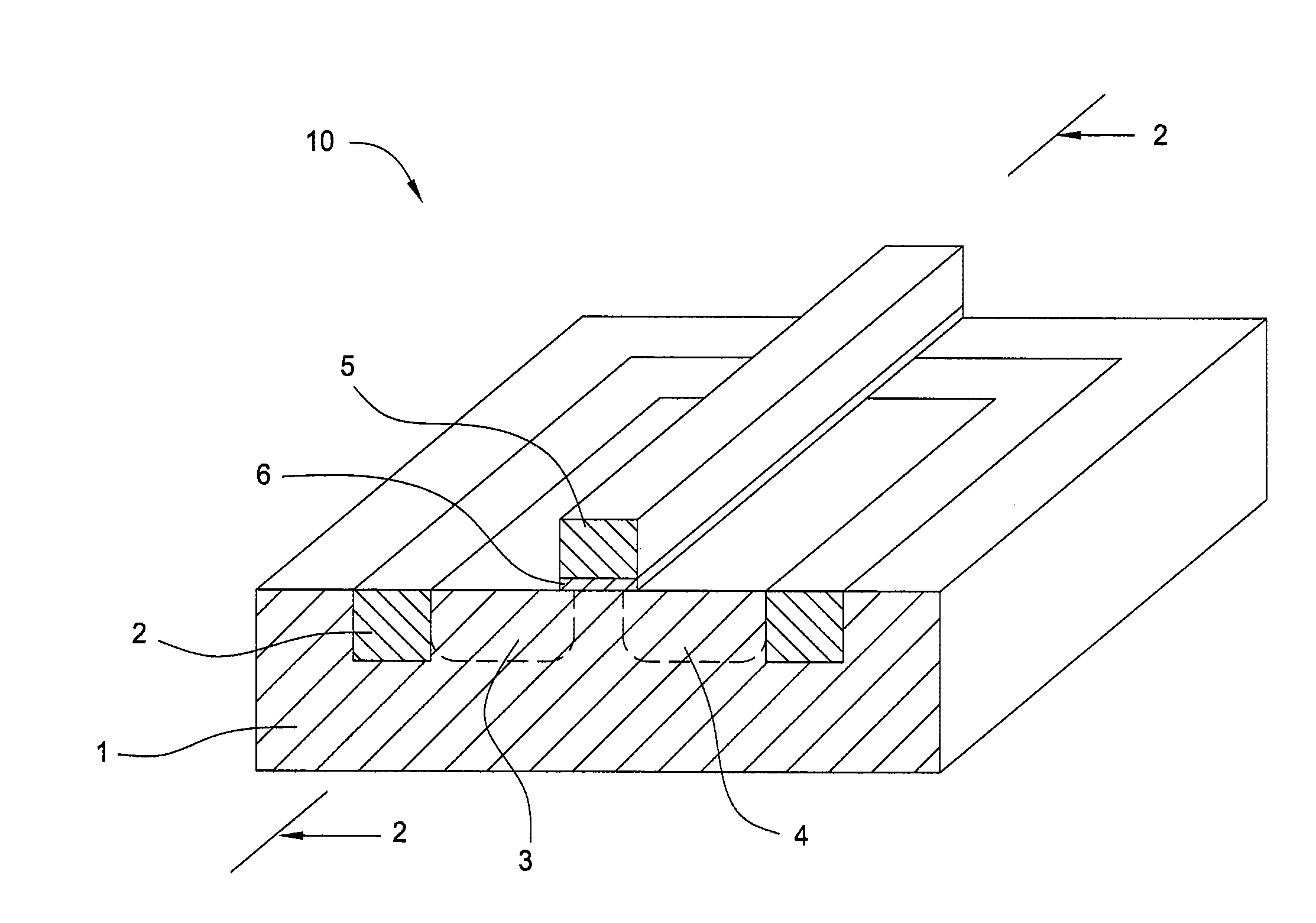

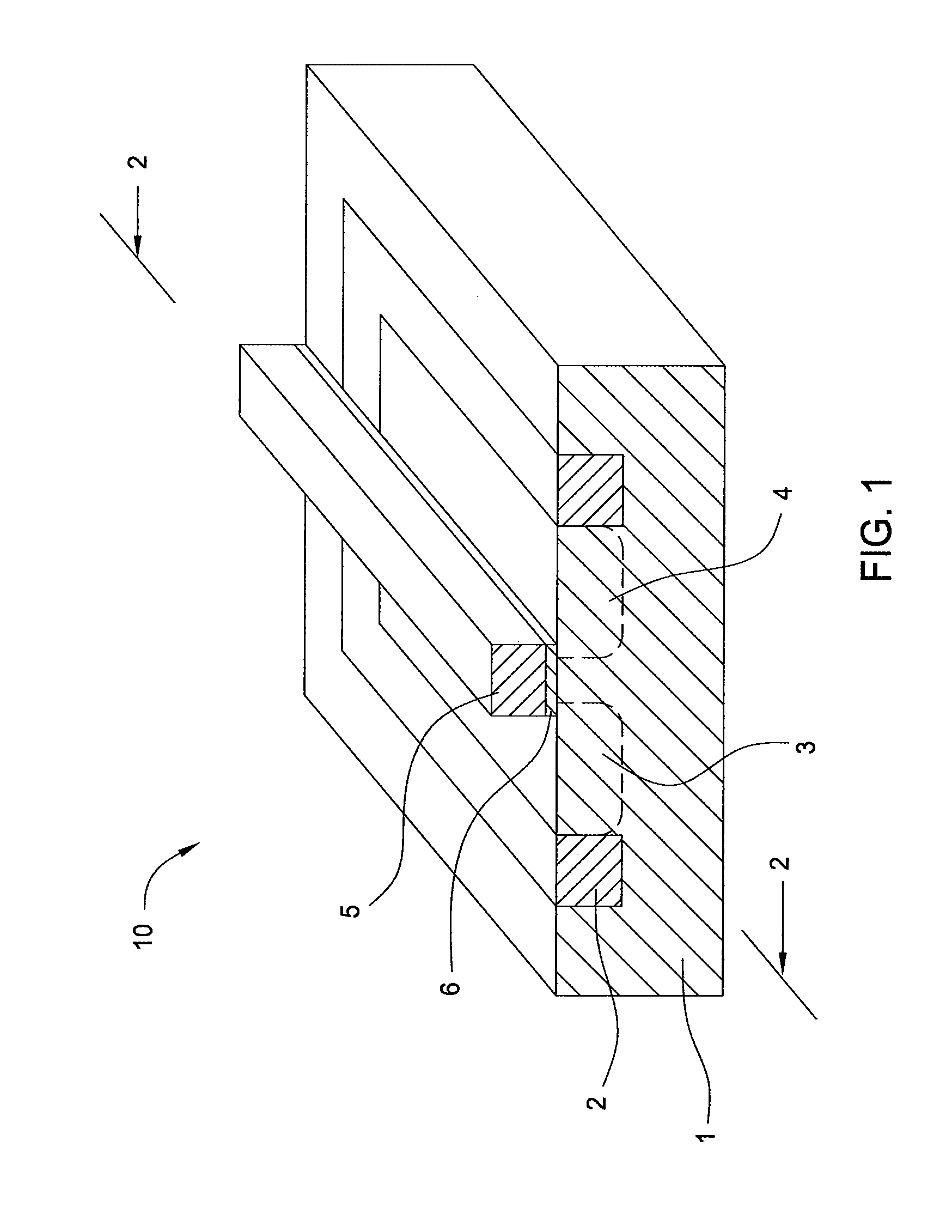

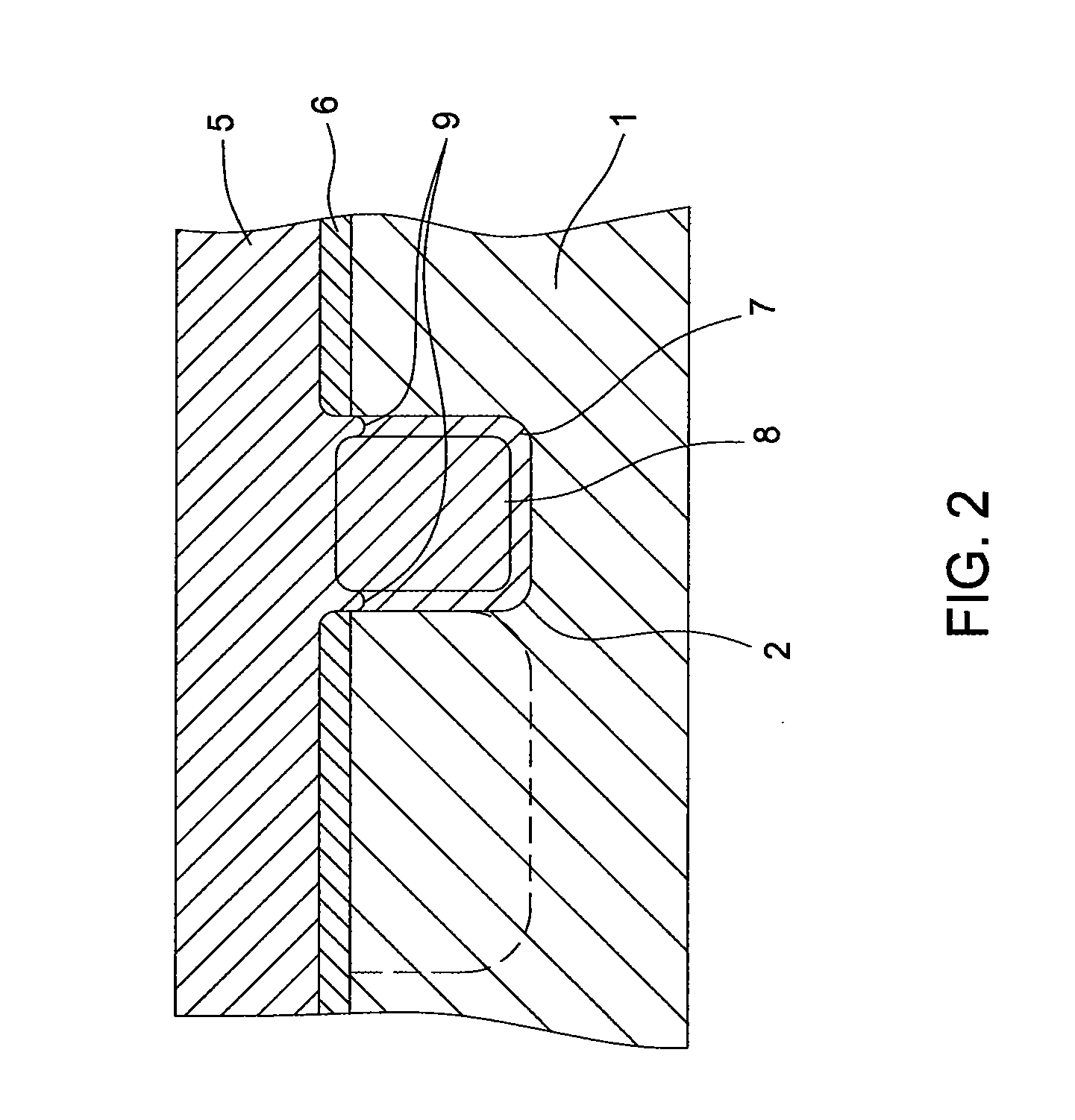

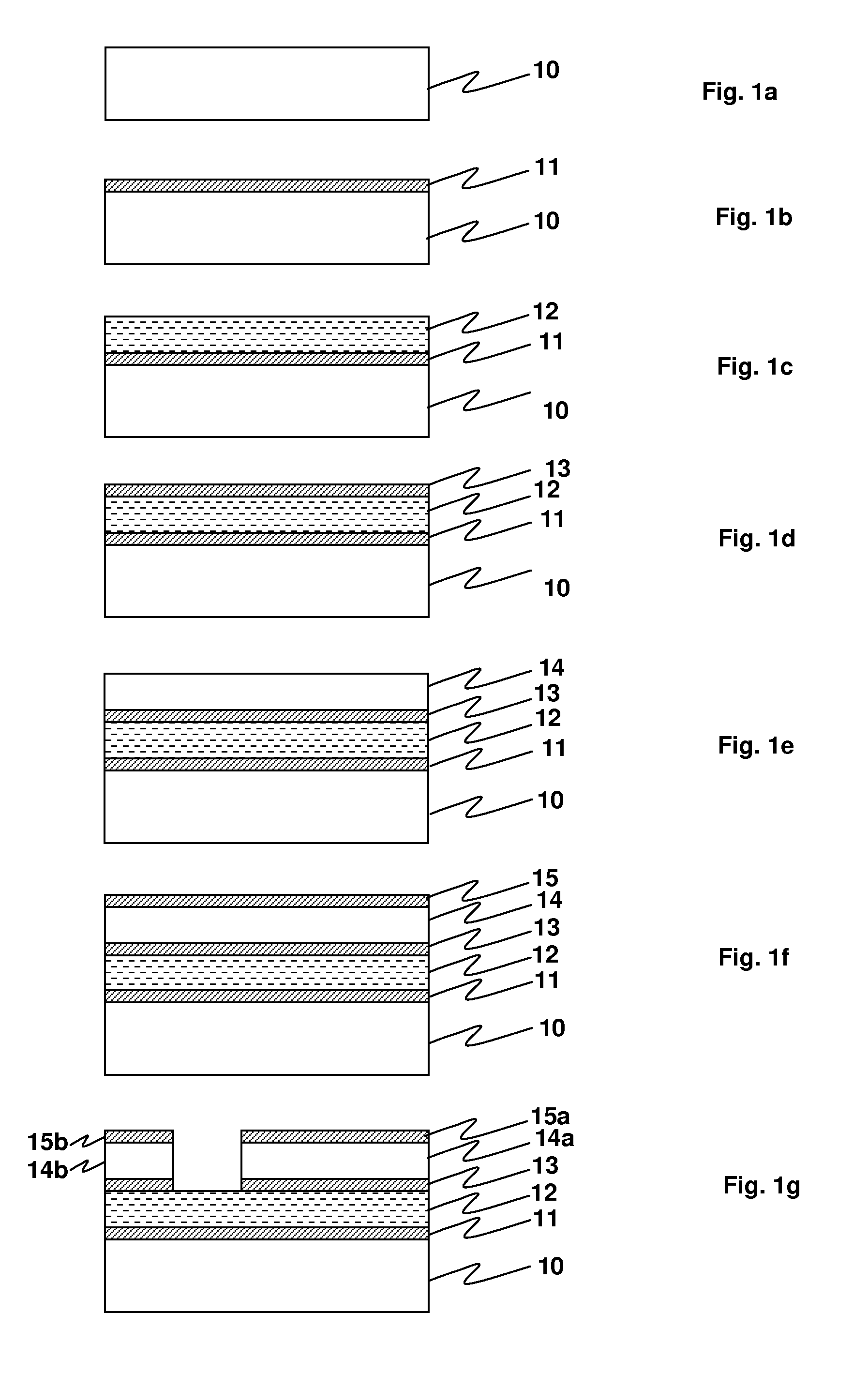

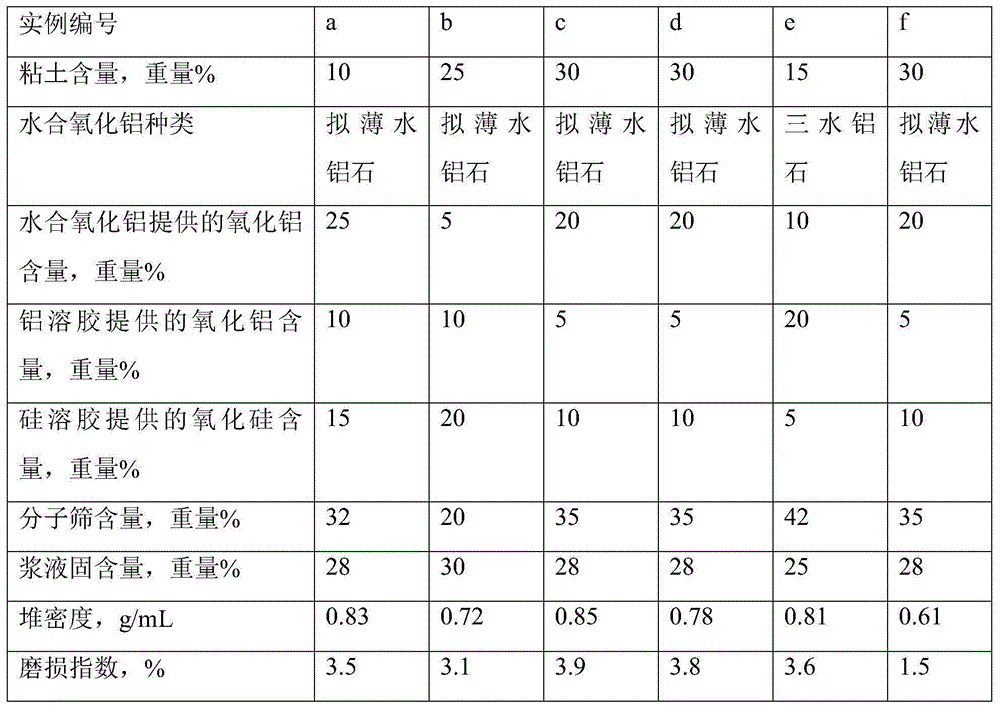

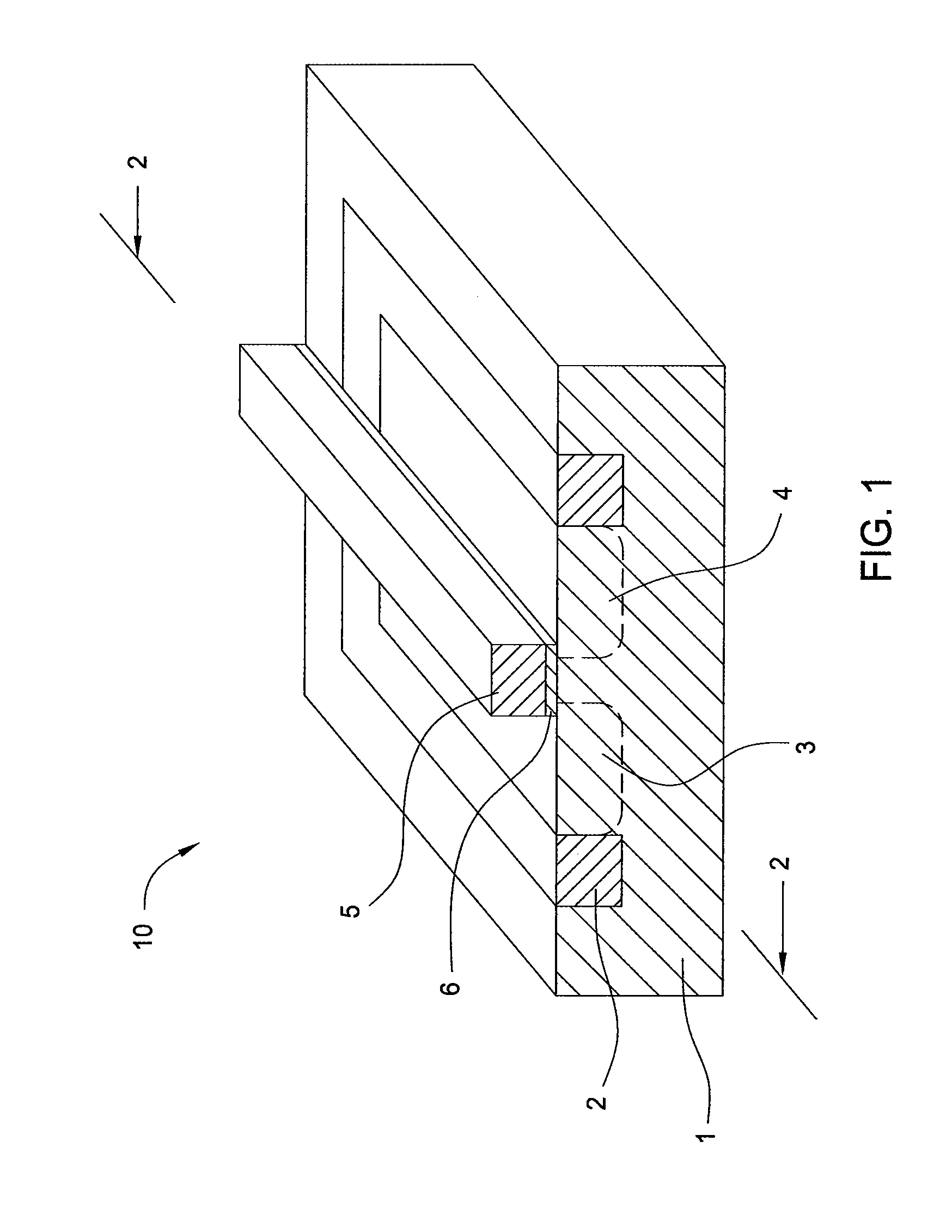

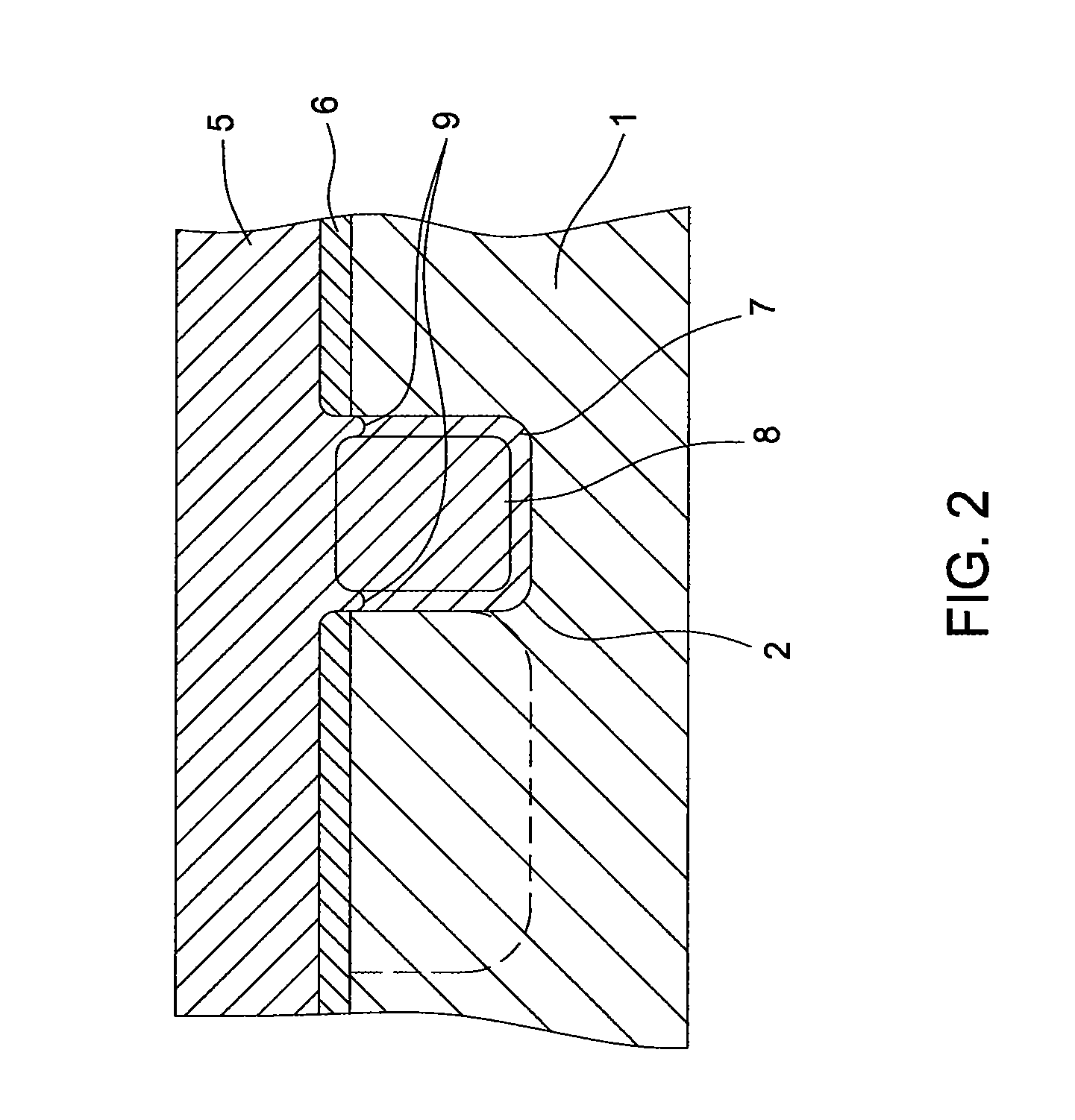

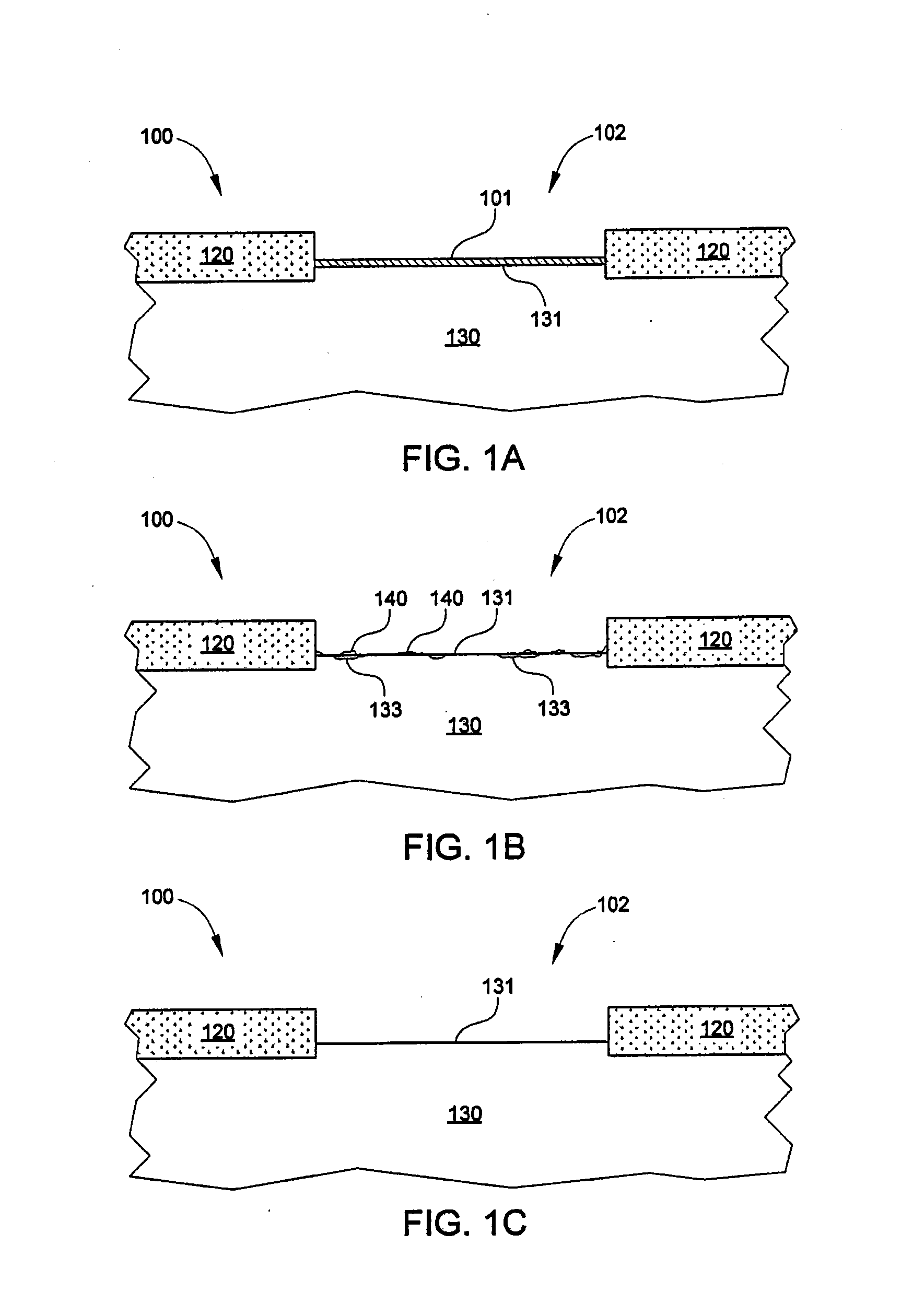

Process for manufacturing electro-mechanical systems

ActiveUS9139425B2Minimizing and eliminating effectReduce fluxTransducer detailsDecorative surface effectsEngineeringStiction

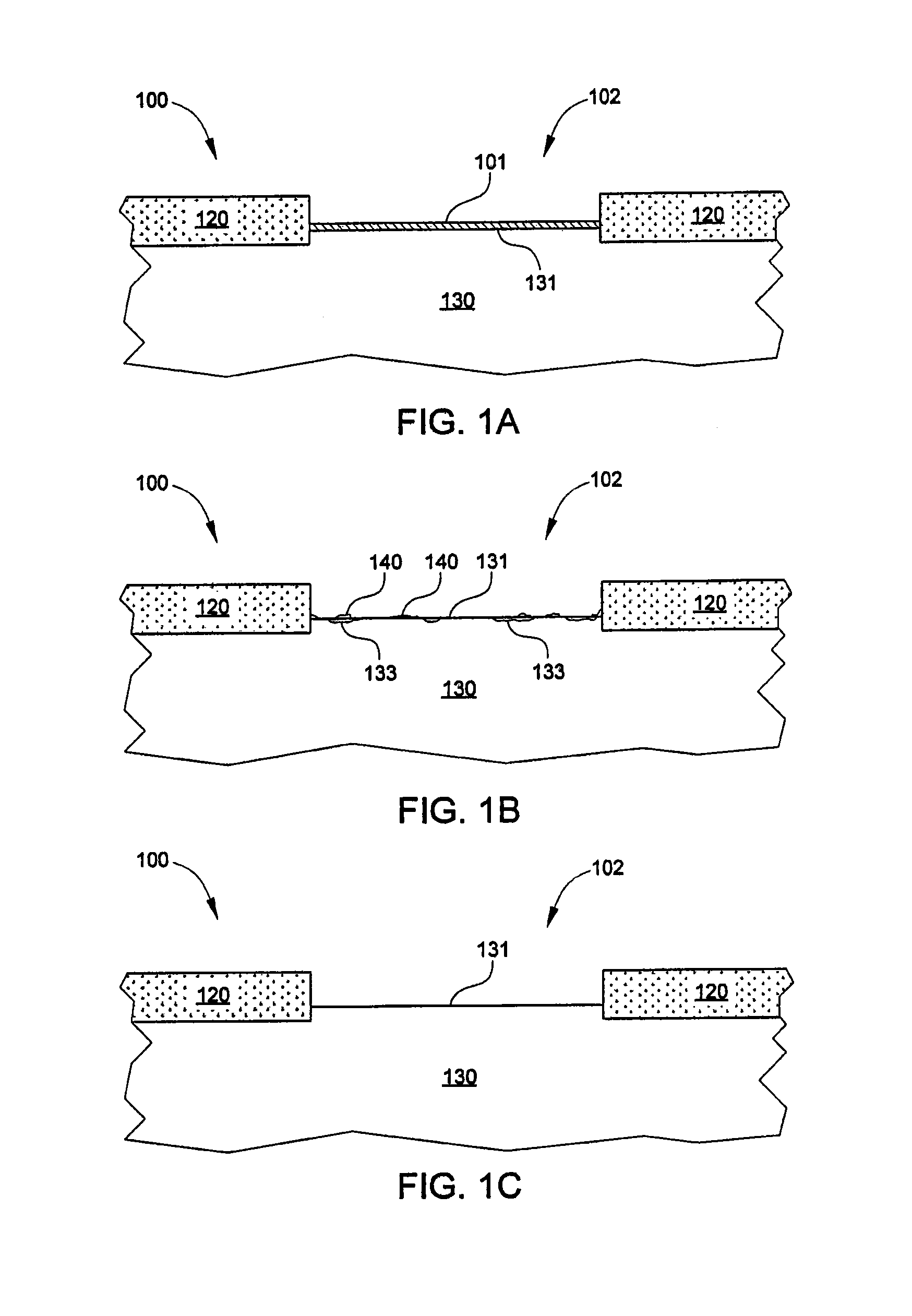

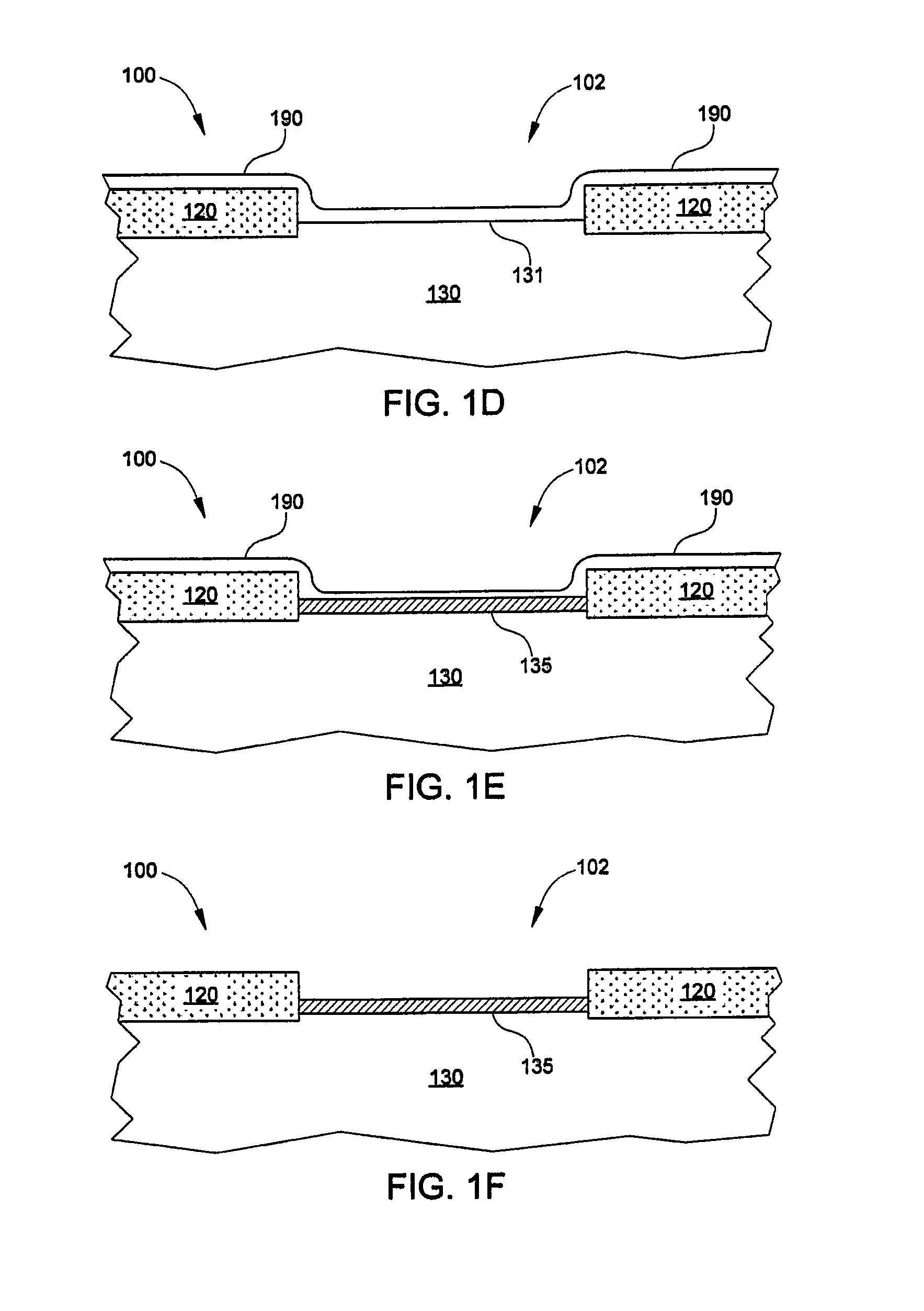

A method of avoiding stiction during vapor hydrofluoride (VHF) release of a microelectromechanical system (MEMS) or nanoelectromechanical system (NEMS) composed of a mechanical device and a substrate is described. A silicon nitride layer is provided between the substrate and a sacrificial oxide layer and / or between a device layer and the sacrificial oxide layer, and / or on a side of the device layer facing away from the sacrificial oxide layer, and converted to thicker ammonium hexafluorosilicate with VHF while simultaneously removing a portion of the sacrificial oxide. The ammonium hexafluorosilicate acts as a temporary support, shim, wedge, or tether which limits device movement during fabrication and is later removed by sublimation under heat and / or reduced pressure.

Owner:SPTS TECH LTD

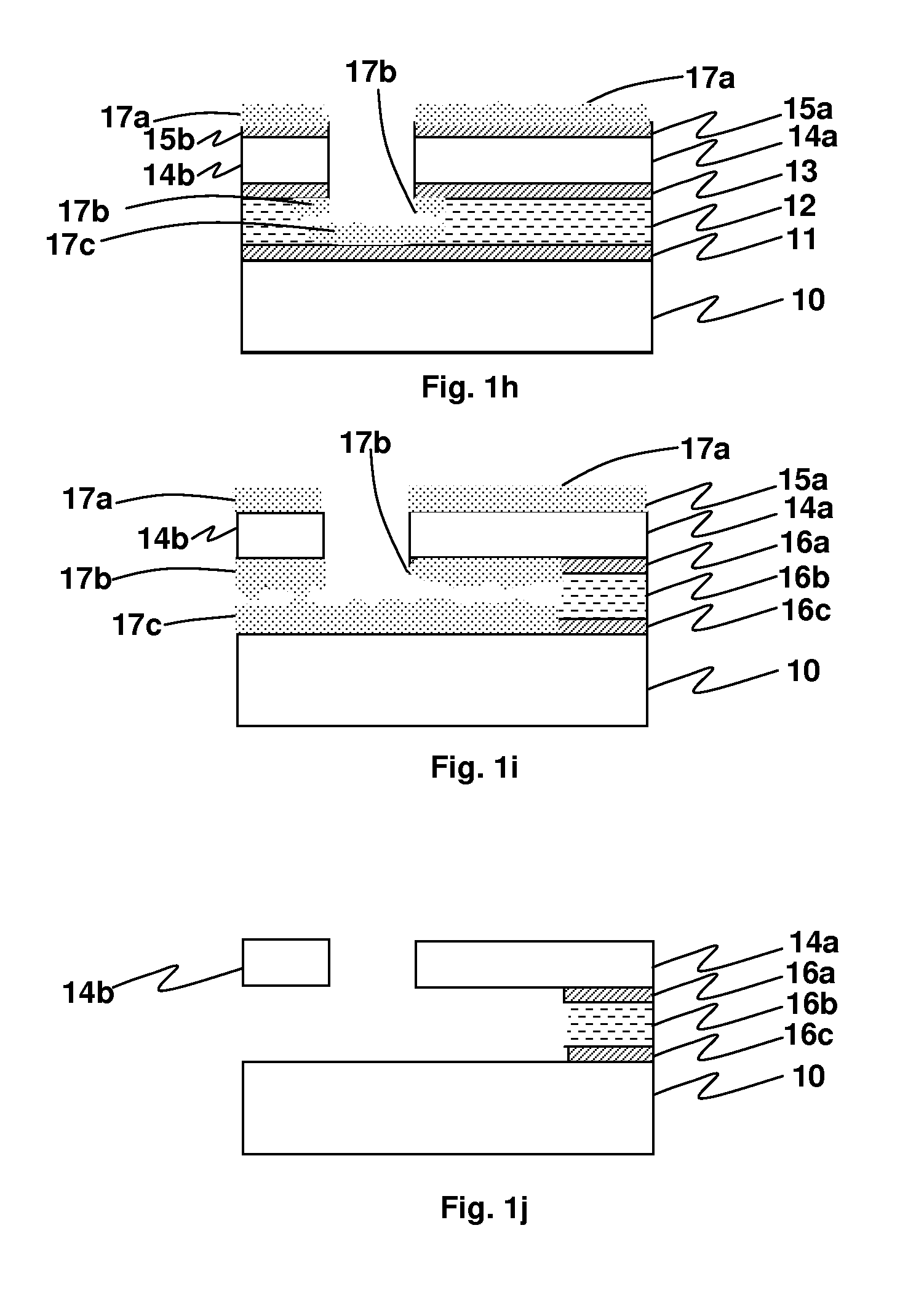

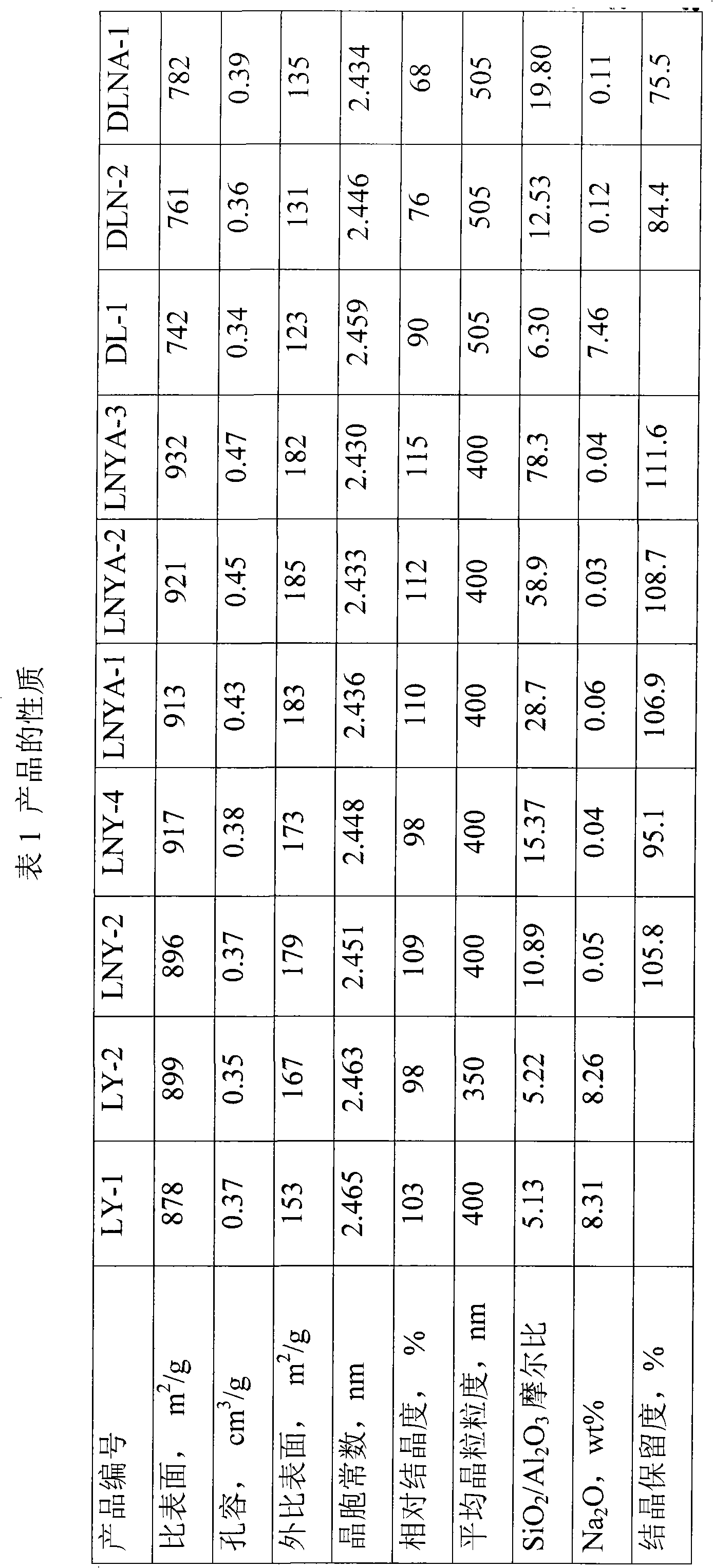

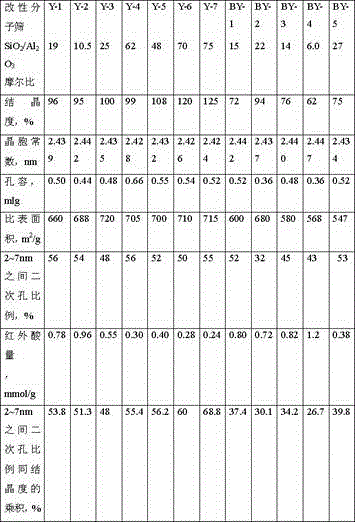

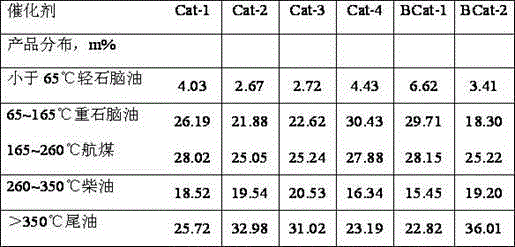

Modified Y catalyst containing rare earth and phosphorus

The invention relates to the field of catalysts, and provides a fine-grain modified Y catalyst containing rare earth and phosphorus and a preparing method. Y-molecular-sieve raw powder before being modified is directly synthesized through a non-template agent, the average grain ranges from 400 nm to 700 nm, and the crystal reservation degree is larger than 90%. After Y-molecular-sieve constituent elements are subjected to ammonium exchanging, hydrothermal aging and ammonium-hexafluorosilicate dealumination and silicon reinsertion, the obtained molecular sieve and a rare-earth solution are subjected to an exchanging reaction, then a phosphorus compound is led into the exchanged slurry liquid, reacting is further carried out, the mixture is filtered and washed, and a filtered bake is roasted under the water vapor condition; the molecular sieve, aluminum oxide, clay, acid and water are pulped, mixed to be even, sprayed, formed and roasted, and then a microsphere with the bulk density of 0.6 g / mL to 0.9 g / mL is obtained. The fine-grain modified Y-molecular-sieve cracking catalyst containing rare earth and phosphorus prepared with the method has the high heavy-oil conversion capacity and the good coke selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

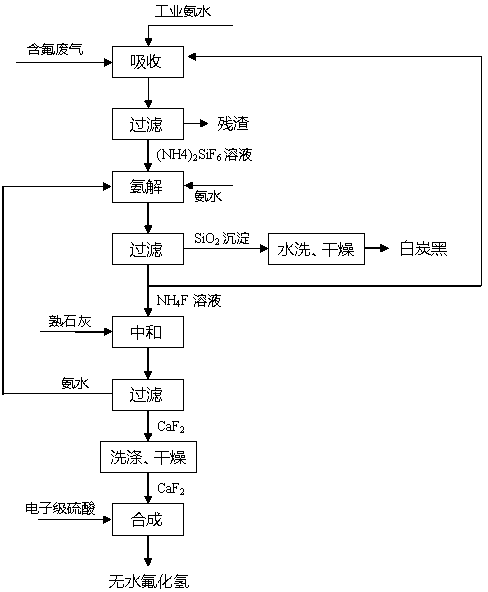

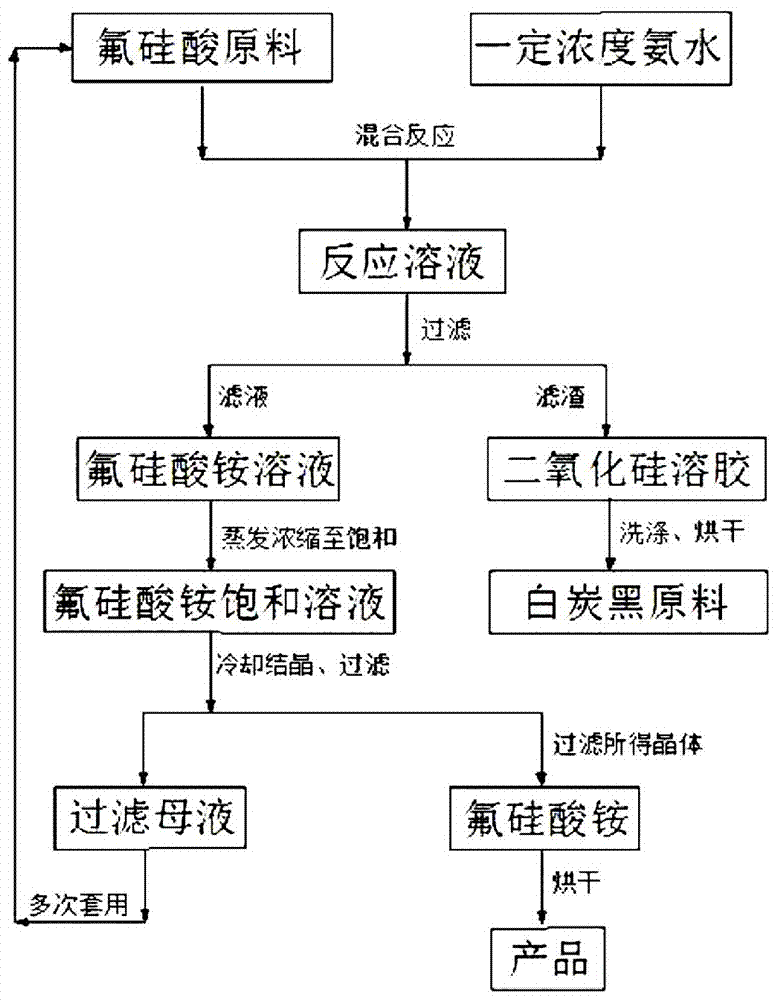

Method for linked producing ammonium fluoride and white carbon black

A process for preparing ammonium fluoride and white carbon black simultaneously includes such steps as fast reaction between fluorosilicic acid (or ammonium fluorosilicate) and ammonia water to obtain the crystal seeds of white carbon black, adding water, fluorosilicic acid (or ammonium fluorosilicate) and ammonia water, reacting while controlling pH=8-9 to obtain the slurry of white carbon black deposit and ammonium fluoride solution, filtering, washing to obtain white carbon black paste and ammonium fluoride solution, and respectively preparing white carbon black and ammonium fluoride from them.

Owner:DO FLUORIDE CHEM CO LTD

Passivation layer formation by plasma clean process to reduce native oxide growth

Embodiments described herein provide methods for removing native oxide surfaces on substrates while simultaneously passivating the underlying substrate surface. In one embodiment, a method is provided which includes positioning a substrate containing an oxide layer within a processing chamber, adjusting a first temperature of the substrate to about 80° C. or less, generating a cleaning plasma from a gas mixture within the processing chamber, such that the gas mixture contains ammonia and nitrogen trifluoride having an NH3 / NF3 molar ratio of about 10 or greater, and condensing the cleaning plasma onto the substrate. A thin film, containing ammonium hexafluorosilicate, is formed in part, from the native oxide during a plasma clean process. The method further includes heating the substrate to a second temperature of about 100° C. or greater within the processing chamber while removing the thin film from the substrate and forming a passivation surface thereon.

Owner:APPLIED MATERIALS INC

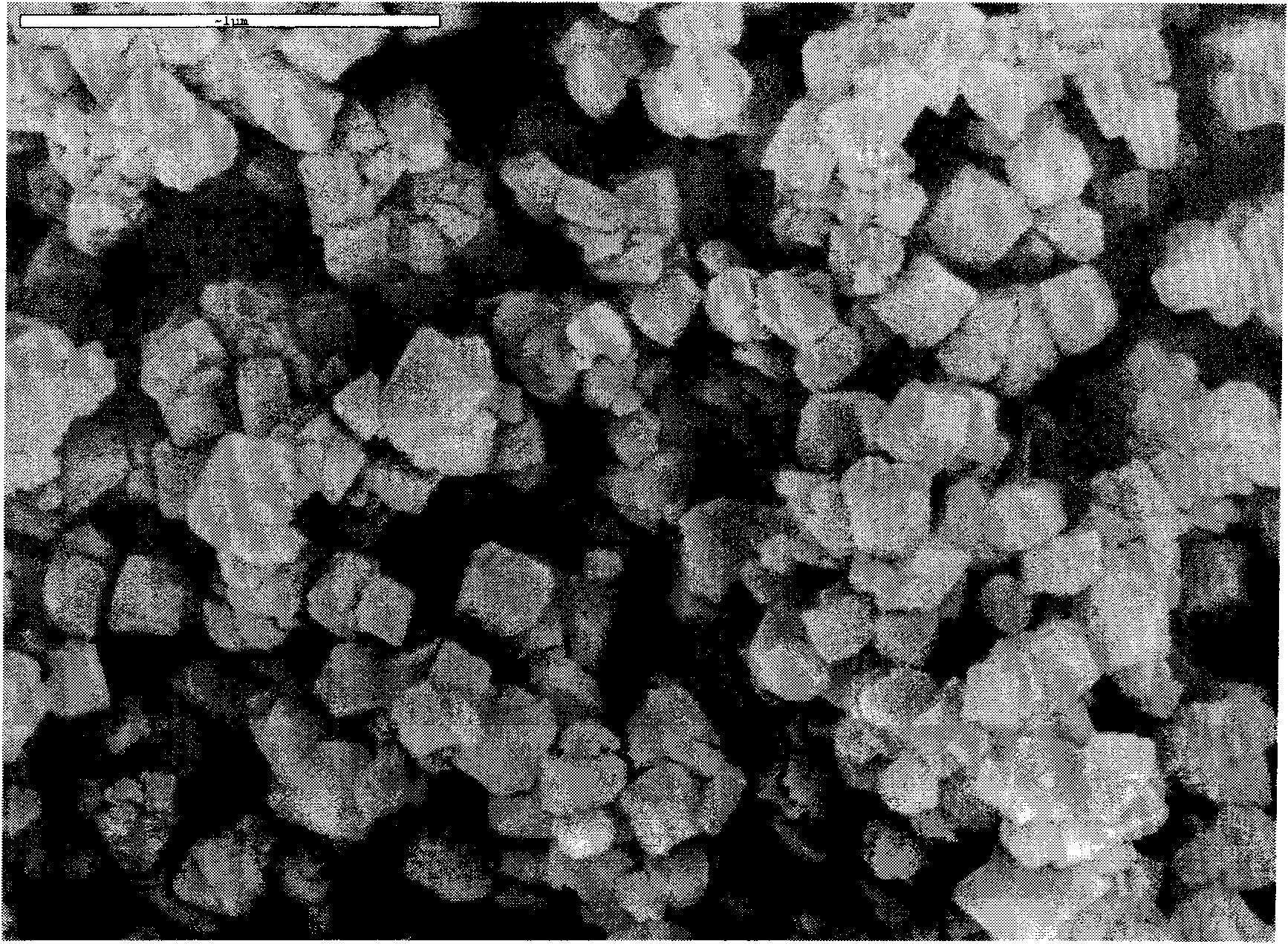

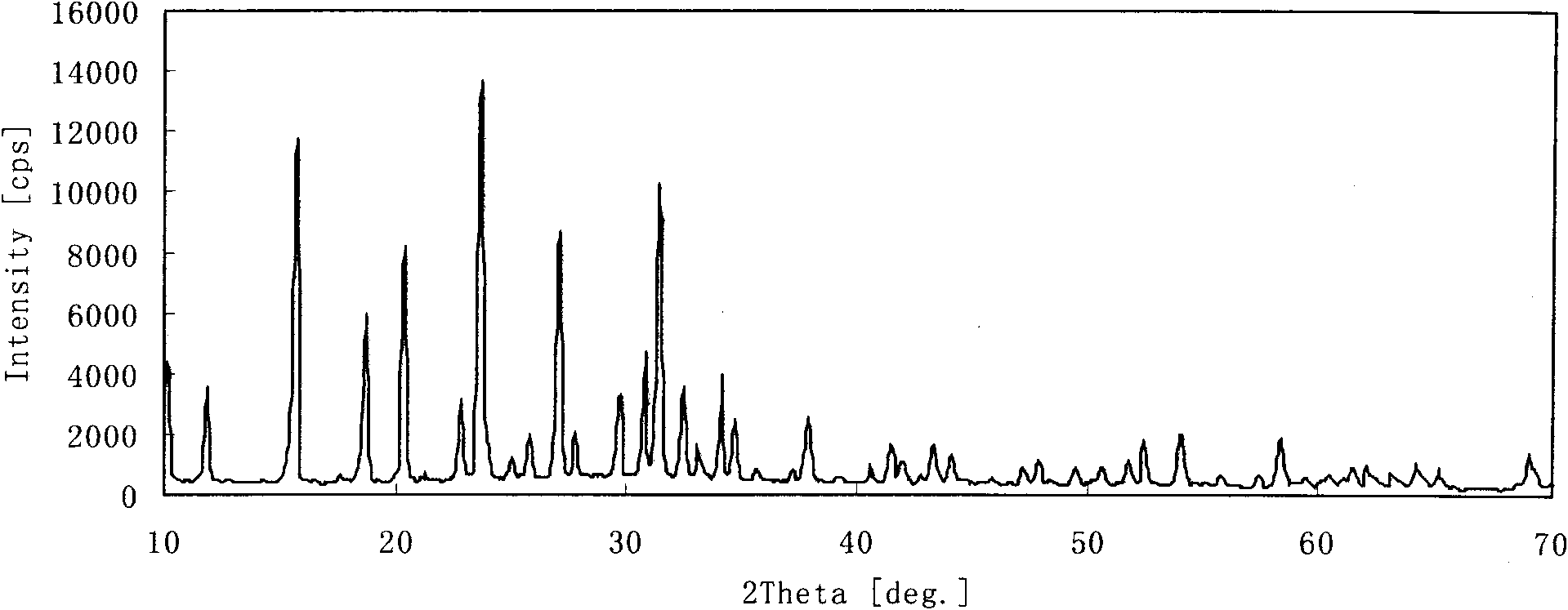

Small-grain high-Si Y-type molecular sieve and preparation method thereof

ActiveCN101941713AHigh crystallinityPreserve integrityFaujasite aluminosilicate zeoliteOxygenRaw material

The invention discloses a small-grain high-Si Y-type molecular sieve and a preparation method thereof. The small-grain high-Si Y-type molecular sieve is a product prepared by using a small-grain NaY molecular sieve as a raw material and selecting proper modification processes, namely ammonia exchange, ammonium hexfluorosilicate for dealuminzation and silicon supplement, hydro-thermal treatment and aluminum salt aqueous solution treatment. The small-grain NaY molecular sieve used by the method can guarantee the skeleton continuity of the molecular sieve product, reduce the collapse possibilityof skeleton structure and maximally retain the integrity of Si-Al-O structure of the product during the subsequent medication treatments due to the high thermal and hydrothermal stabilities, high Si-Al ratio, high stability and uniform skeleton Si-Al structure; therefore, the product still has a crystalline retention degree as high as above 95 percent while having the greatly improved Si-Al ratio. The Y-type molecular sieve can be used as the active component for the hydrocracking catalysts to improve the activities of the catalysts, selectivity of the target product and the quality of the product.

Owner:CHINA PETROLEUM & CHEM CORP +1

Modified Y-type molecular sieve and preparation method thereof

ActiveCN106672995AReduce Na contentImprove processing efficiencyFaujasite aluminosilicate zeoliteMolecular sieveIon exchange

The invention discloses a modified Y-type molecular sieve and a preparation method thereof. The preparation method comprises: (1) carrying out ammonium salt ion exchange in an ammonium salt solution by using NaY zeolite as raw powder to achieve a Na2O weight content of less than 3.0%; (2) carrying out hydrothermal treatment on the Y molecular sieve obtained in the step (1); (3) carrying out sodium ion exchange on the Y molecular sieve obtained in the step (2) in a sodium salt solution; and (4) carrying out ammonium hexafluorosilicate dealuminzation silicon supplementing treatment on the Y molecular sieve obtained in the step (3), filtering, drying, and calcining to obtain the final modified Y-type molecular sieve. According to the present invention, with the method, the high-silicon and high-crystallinity modified Y molecular sieve being rich in mesoporous structure can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

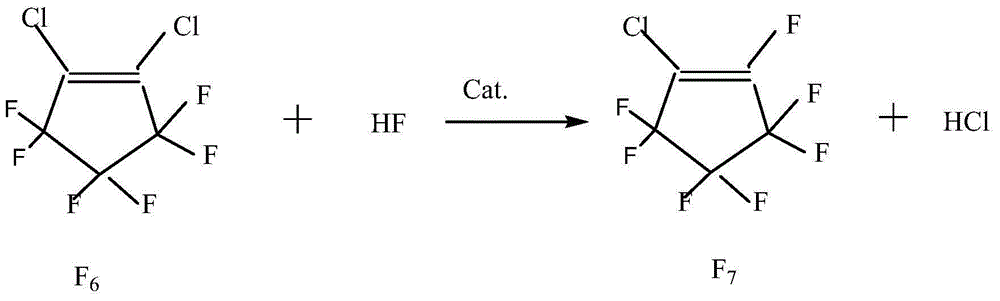

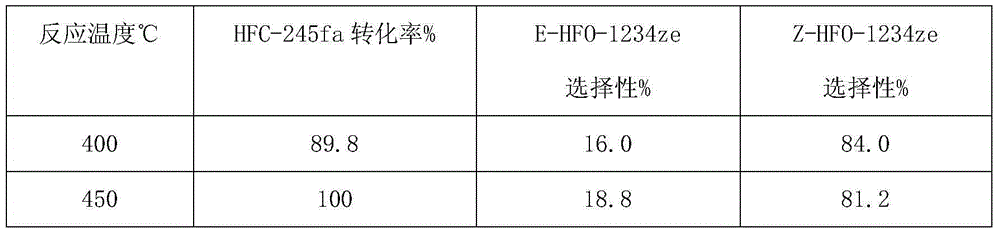

Chromium base catalyst, and preparation method and use thereof

InactiveCN104907063AInhibit carbon depositionCatalytic activity unchangedPreparation by hydrogen halide split-offPreparation by halogen replacementCalcium silicateChemical synthesis

The invention discloses a chromium base catalyst, and a preparation method and a use thereof, and belongs to the field of chemical synthesis. The precursor of the catalyst is composed of 90-99.9mass% of a trivalent chromium compound and 0.1-10mass% of a silicon-containing compound, wherein the trivalent chromium compound is chromic oxide or chromium hydroxide, and the silicon-containing compound can be zinc silicate, nickel silicate, magnesium silicate, aluminum silicate, zirconium silicate, barium silicate, bismuth silicate, ammonium fluorosilicate, nickel hexafluorosilicate, zinc fluorosilicate, magnesium fluorosilicate, aluminum fluorosilicate or calcium fluorosilicate The chromium base catalyst has the advantages of large specific surface area, effective inhibition of carbon formation, and long service life, is mainly used for gas phase catalysis of reactions for preparing hydrofluorocarbons or fluorinated alkenes from halogenated hydrocarbons or halogenated alkenes at a high temperature, and can also be used for gas phase catalysis of reactions for preparing hydrofluoroalkenes through hydrogen fluoride removal of hydrofluorocarbons at a high temperature.

Owner:BEIJING YUJI SCI & TECH

Method for recycling fluorine-containing waste gas in phosphorus chemical industry production

InactiveCN103803561AEfficient recyclingWon't clogSilicaFluorine/hydrogen-fluorideChemical industryFiltration

The invention discloses a method for recycling fluorine-containing waste gas in phosphorus chemical industry production. Originally, industrial ammonium hydroxide is utilized to absorb fluorine-containing waste gas to prepare ammonium fluosilicate solution which is soluble to water and high in stability, then ammonolysis reaction is carried out between ammonium hydroxide and ammonium fluosilicate solution and silicon dioxide sediment and ammonium fluoride solution are obtained after filtration; and the silicon dioxide sediment is washed with water and dried to obtain a white carbon black product. The prepared ammonium fluoride solution is partly fed to an absorption system for circulation, neutral reaction is carried out on the rest of prepared ammonium fluoride solution with industrial-grade slaked lime to prepare water-insoluble calcium fluoride and ammonium hydroxide, the ammonium hydroxide is fed to an aminolysis section for circulation, and finally, the high-purity calcium fluoride reacts with electronic-grade sulfuric acid obtained after twice rectification to prepare high-purity anhydrous hydrogen fluoride. The method is simple in process and low in investment and pollution, can be used for effectively recycling fluorine-containing waste gas, thereby solving the problem of environmental pollution, obtaining anhydrous hydrogen fluoride and white carbon black with high economic value; therefore, the method can be put into industrial application easily.

Owner:武汉工程大学邮电与信息工程学院 +1

Method for removing native oxide and associated residue from a substrate

InactiveUS8455352B1Electric discharge tubesSemiconductor/solid-state device manufacturingSilicon tetrafluorideAmmonia

Native oxides and associated residue are removed from surfaces of a substrate by sequentially performing two plasma cleaning processes on the substrate in a single processing chamber. The first plasma cleaning process removes native oxide formed on a substrate surface by generating a cleaning plasma from a mixture of ammonia (NH3) and nitrogen trifluoride (NF3) gases, condensing products of the cleaning plasma on the native oxide to form a thin film that contains ammonium hexafluorosilicate ((NH4)2SiF6), and subliming the thin film off of the substrate surface. The second plasma cleaning process removes remaining residues of the thin film by generating a second cleaning plasma from nitrogen trifluoride gas. Products of the second cleaning plasma react with a few angstroms of the bare silicon present on the surface, forming silicon tetrafluoride (SiF4) and lifting off residues of the thin film.

Owner:APPLIED MATERIALS INC

Glass frosting powder for processing anti-dazzle glass and preparation method thereof

The invention discloses glass frosting powder for processing anti-dazzle glass and a preparation method thereof. The glass frosting powder is prepared by mixing the following raw materials in percentage by weight: 44-48% of ammonium bifluoride, 10-14% of ammonium bifluoride, 6-10% of ammonium fluosilicate, 6-10% of potassium fluoborate, 3-7% of calcium fluoride, 3-7% of precipitated barium sulphate, 3-7% of barium carbonate, 1-5% of polyethylene glycol, 0.5-1.5% of Arabic gum, 1-3% of starch and 3-7% of organic acid. The preparation method comprises the steps of grinding the raw materials into powder respectively, then pouring the fine powder into a mixer, and uniformly mixing.

Owner:LONGYAN HEDA MACHINERY

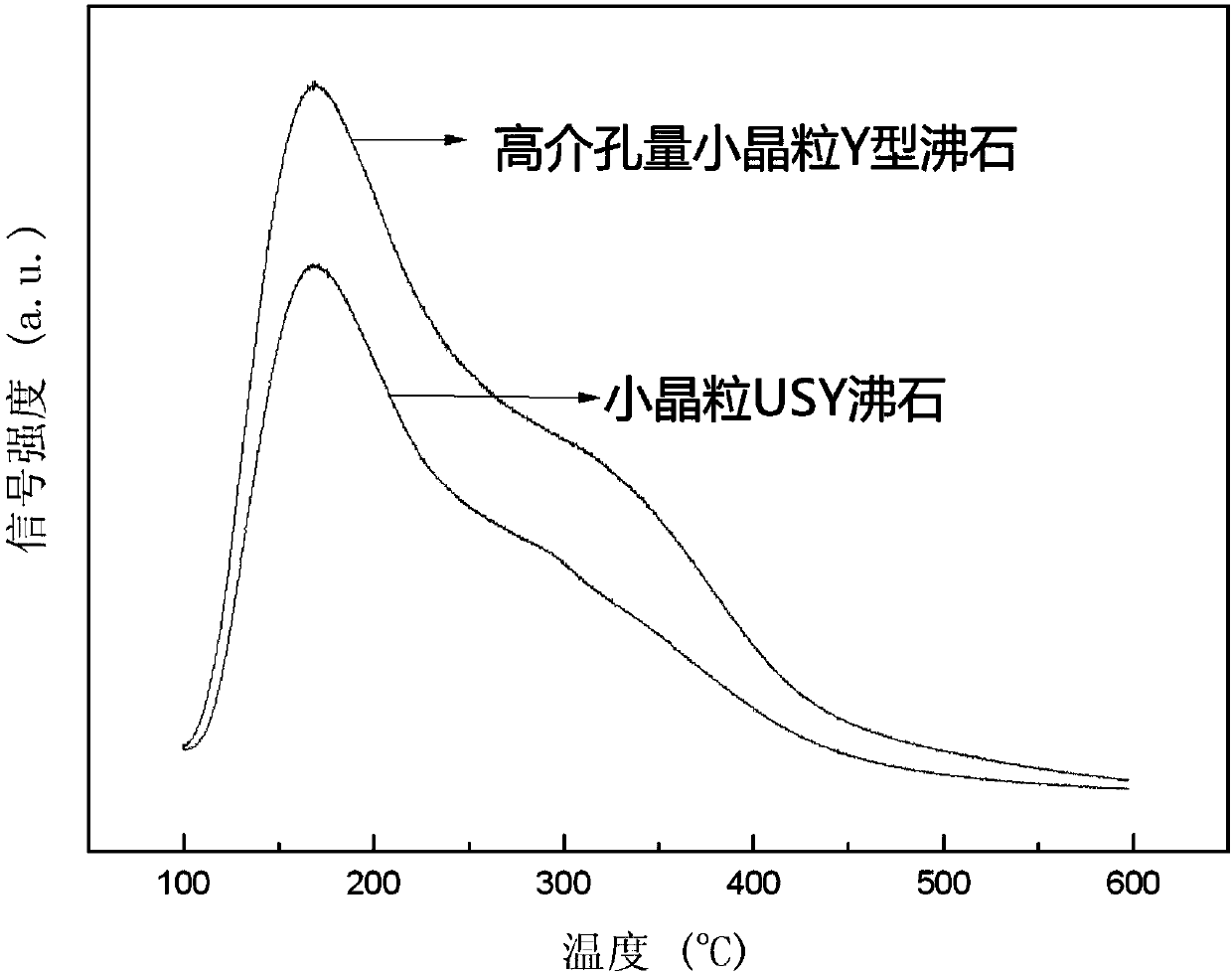

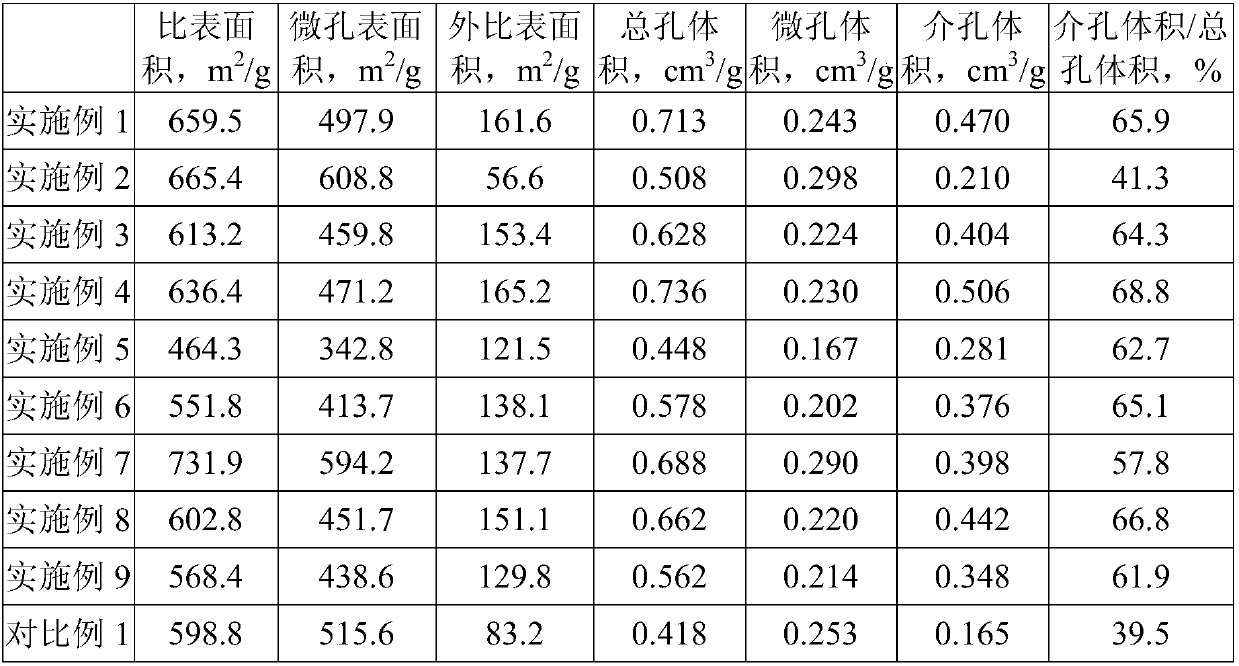

High-mesopore-amount Y type zeolite and preparation method thereof

ActiveCN107758684AEasy to prepareRelaxed experimental conditionsFaujasite aluminosilicate zeoliteIon exchangeChemistry

The invention provides a preparation method of high-mesopore-amount Y type zeolite. The preparation method comprises: carrying out ammonium ion exchange treatment on Y type zeolite at a temperature of50-120 DEG C to obtain NH4Y zeolite; adding the NH4Y zeolite to a buffer solution with a concentration of 0.1-1 M, and beating to a slurry; slowly adding an ammonium fluorosilicate solution with a concentration of 0.01-1 M to the slurry in a dropwise manner, and stirring for 0.1-5 h at a temperature of 20-120 DEG C to obtain a crude product; directly carrying out alkali treatment on the crude product or carrying out alkali treatment after washing and drying, wherein the crude product is treated for 0.1-5 h at a temperature of 30-120 DEG C with an alkaline solution with a concentration of 0.01-3.0 M, and a mass ratio of the alkaline solution to the crude product is 1-50:1, preferably 5-40:1; and carrying out ammonium ion exchange on the obtained crude product at a temperature of 50-120 DEGC, calcining for 1-8 h at a temperature of 300-800 DEG C, washing, and drying to obtain the high-mesopore-amount Y type zeolite.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Calcined uzm-22 and uzm-22hs aluminosilicate zeolites

Crystalline microporous zeolites designated calcined UZM-22 and UZM-22HS have been synthesized. The calcined UZM-22 is represented by the empirical formula:M1′mn+Al1-xExSiyOz and UZM-22HS has an empirical formula of:M1an+Al(1-x)ExSiy′Oz″where M1 and M1′ are exchangeable cations such as lithium or strontium and E is a framework element such as gallium. Both zeolites are obtained from an as synthesized microporous crystalline composition having an empirical formula of:Mmn+RrAl1-xExSiyOz either by calcination for UZM-22 or by various treatments such as ammonium hexafluorosilicate treatment for UZM-22HS.M is an alkali, alkaline earth, or rare earth metal such as lithium and strontium, R is a singly charged organoammonium cation such as the choline cation and E is a framework element such as gallium.

Owner:UOP LLC

Beta-molecular sieve and preparation method thereof

ActiveCN104671251AUniform structureSuitable for acidityCatalyst carriersMolecular sieve catalystsMolecular sievePtru catalyst

The invention discloses a beta-molecular sieve and a preparation method thereof as well as a hydrogenation catalyst containing the beta-molecular sieve. The beta-molecular sieve has the following properties: the molar ratio of SiO2 to Al2O3 is 30 to 150, the non-skeleton aluminum accounts for less than 2% of total aluminum, and the silicon atoms for coordination in a Si(0Al) structure accounts for more than or equal to 95% of the silicon atoms in the skeleton structure. The preparation method comprises the steps of connecting the raw powder of the beta-molecular sieve with normal-pressure dynamic vapor and then contacting with ammonium fluorosilicate. The beta-molecular sieve is suitable for serving as an acidic component in a diesel oil hydrogenation modification catalyst and a hydrogenation cracking catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

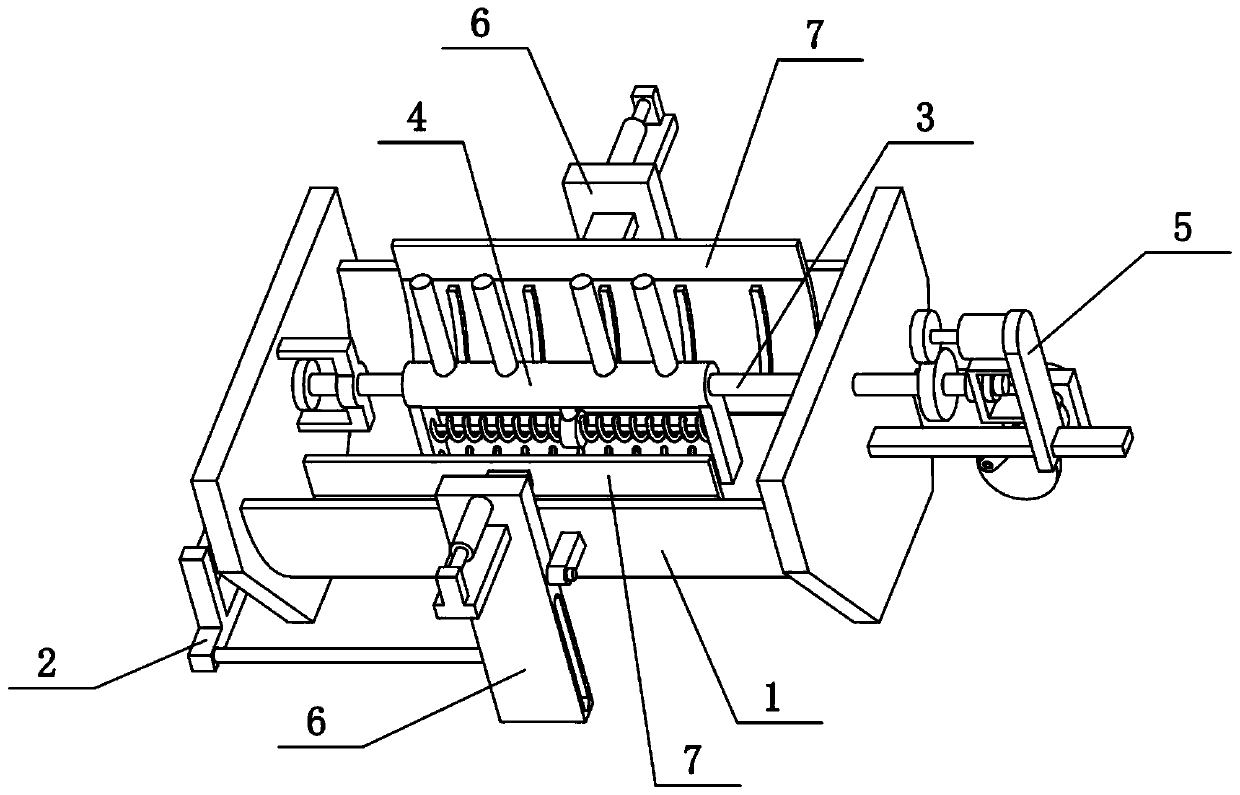

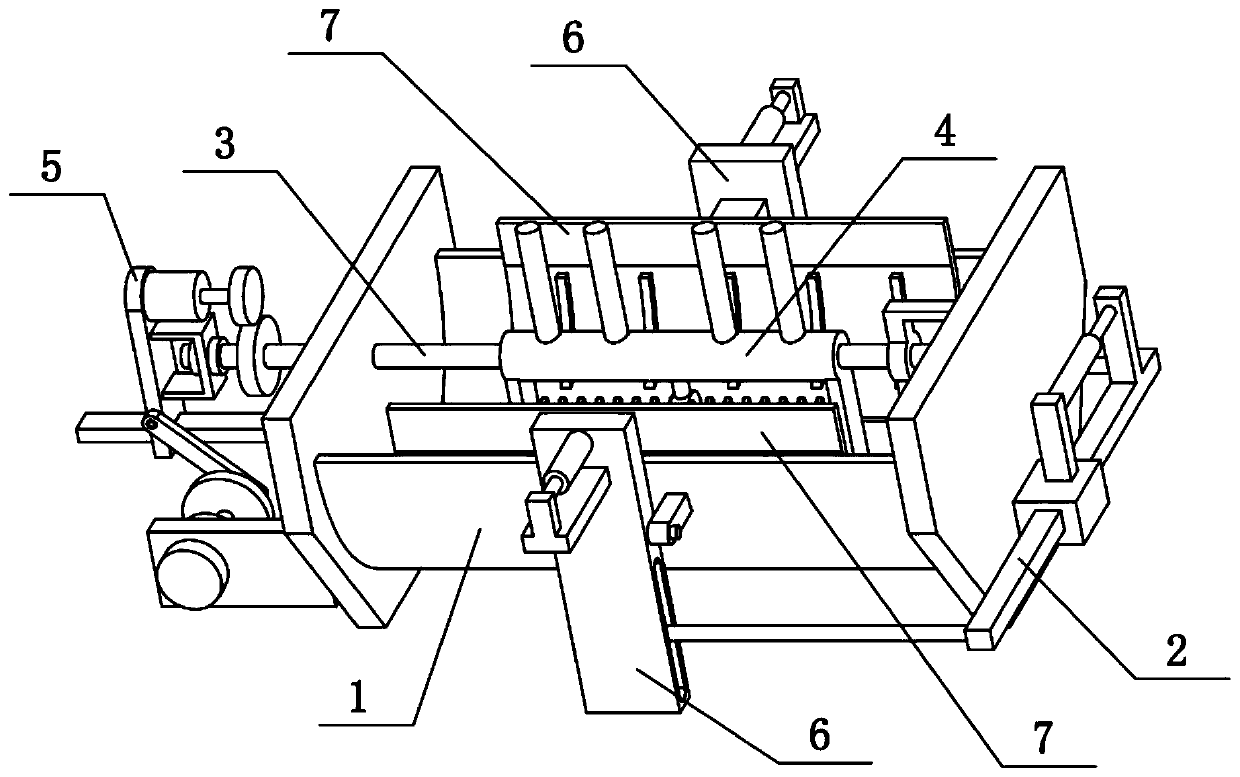

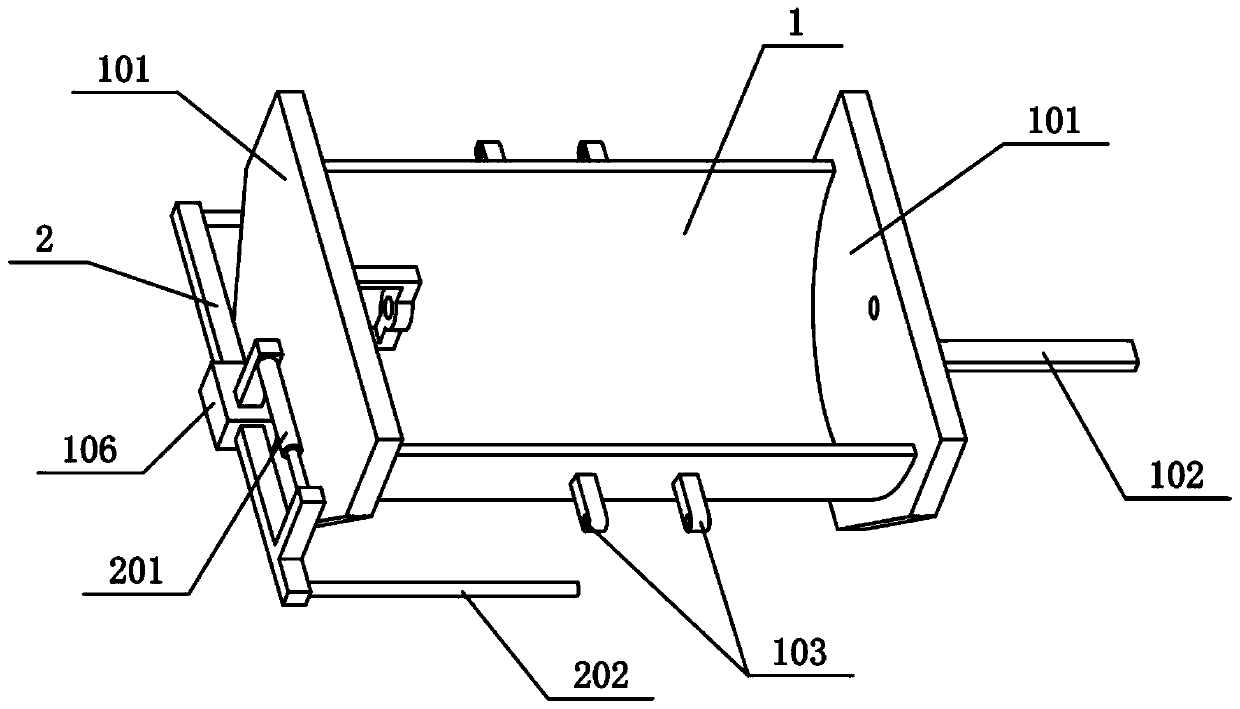

Ceramic glaze, processing device, and ceramic glaze processing method

ActiveCN110841543AImprove the mixing effectTransportation and packagingMixer accessoriesCelluloseHexafluorosilicic acid

The invention discloses a ceramic glaze, a processing device, and a ceramic glaze processing method. The ceramic glaze is composed of following raw materials in parts by weight: 10 parts of carboxymethyl cellulose, 5 parts of ammonium dichromate, 1 part of ammonium borofluoride, 2 parts of boric acid powder, 1 part of ochre, 1 part of potassium nitrate, 10 parts of green glass, 7 parts of ammoniumfluorosilicate, 3 parts of tin frit, 8 parts of copper oxide, and 1 part of ferric oxide. The processing method comprises following steps: step one, adding raw materials of ceramic glaze into a semi-cylinder container; step two, starting a motor (I) and a motor (II), wherein the motor (I) drives a horizontal shaft to rotate around the axis of the horizontal shaft, the motor (II) drives the horizontal shaft to reciprocate left to right, a compression spring (I), a compression spring (II), a spring sleeve column (I), and a spring sleeve column (II) horizontally stir the raw materials of the ceramic glaze, and multiple stirring rods vertically stir the raw materials of the ceramic glaze; and step three, closing the motor (I) and the motor (II), wherein when an electric telescoping rod (II) extends or retracts, arc plates are driven to move front to rear, and two arc plates evenly heat the raw materials of the ceramic glaze.

Owner:佛山意达加精密陶瓷科技有限公司

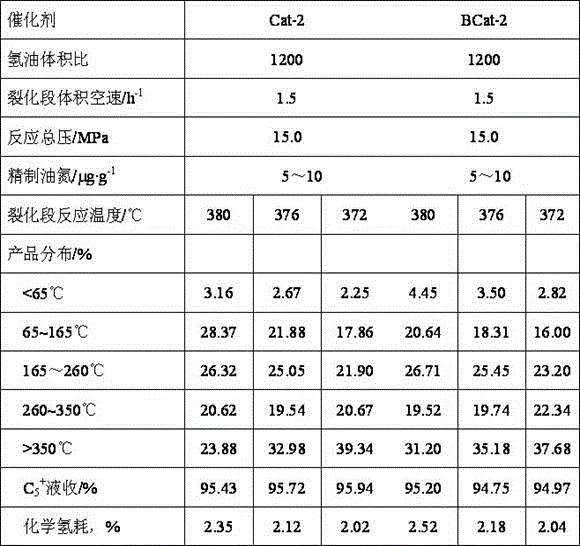

Method for preparing hydro-cracking catalyst composition

ActiveCN105618113AReduce the ratio of silicon to aluminumImprove heat sensitivityMolecular sieve catalystsHydrocarbon oil crackingPtru catalystOrganosolv

The invention discloses a method for preparing a hydro-cracking catalyst composition. The method comprises the following steps: 1, modified Y type molecular sieve, amorphous silica-alumina and / or aluminum oxide are well mixed according to a certain ratio; dilute nitric acid is added, such that a slurry is formed; extrusion molding is carried out; and drying and roasting are carried out, such that a silica-alumina carrier containing the modified Y type molecular sieve is obtained; and 2, the carrier obtained in the step 1 is impregnated with an impregnation solution containing active metals; after impregnation, the carrier is dried and the dried carrier is roasted, such that the hydro-cracking catalyst is obtained. A preparation method of the modified Y type molecular sieve comprises the following steps: NaY zeolite is adopted as raw powder; ammonium salt ion exchange, ammonium fluorosilicate dealumination and silicon reinsertion treatment, hydrothermal treatment, and aluminum salt solution treatment are carried out; impregnation is carried out in organic solvents; and fast drying, alkali desilication, drying and roasting treatments are carried out, such that the modified Y type molecular sieve is obtained. The hydro-cracking catalyst composition provided by the invention has good temperature increase sensitivity and operation flexibility. The composition can be widely used in hydro-cracking reaction processes.

Owner:CHINA PETROLEUM & CHEM CORP +1

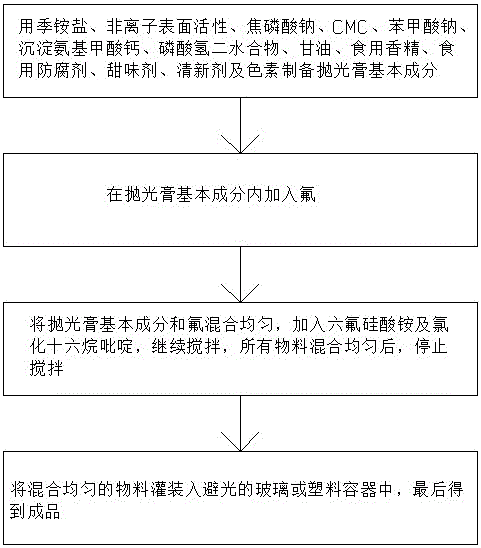

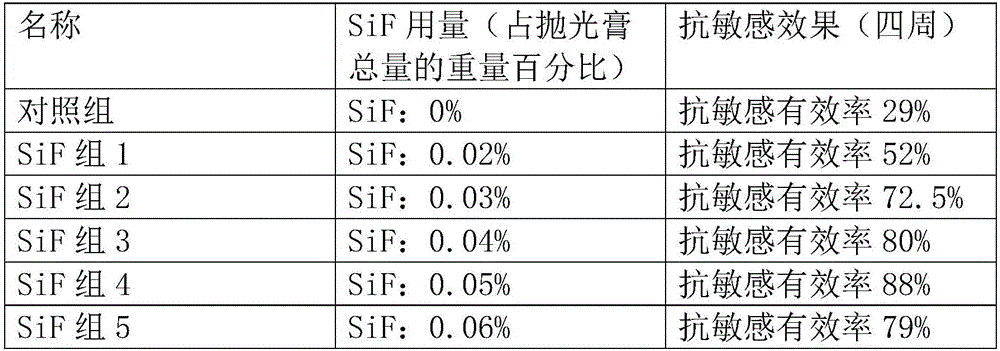

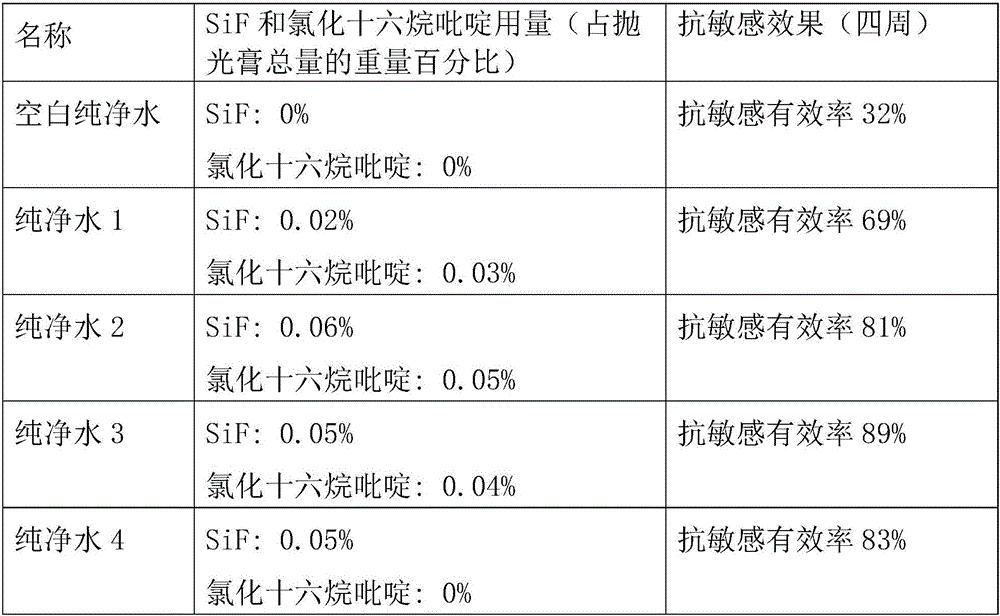

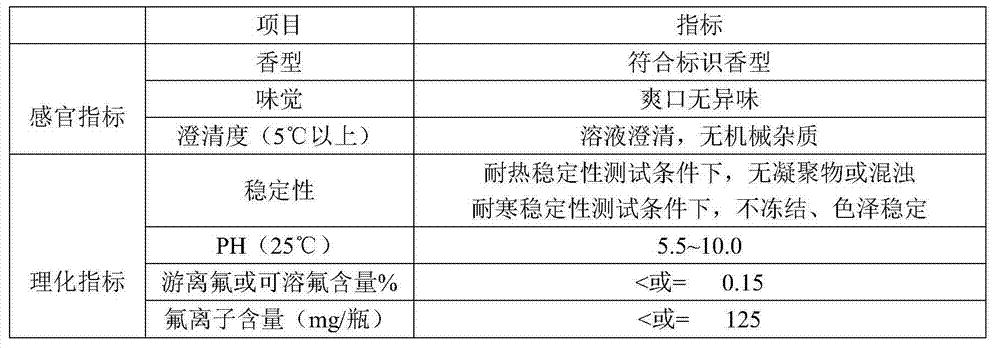

Anti-caries and anti-allergy polishing paste and preparation method thereof

InactiveCN106539697AReduce cancer riskSignificant anti-sensitivity effectCosmetic preparationsToilet preparationsSide effectCalcium formate

The invention discloses anti-caries and anti-allergy polishing paste and a preparation method of the anti-caries and anti-allergy polishing paste. The anti-caries and anti-allergy polishing paste is prepared from the following components in percentage by weight: 0.5% of quaternary ammonium salt, 2% of a nonionic surfactant, 0.25% of sodium pyrophosphate, 0.85% of CMC, 0.5% of sodium benzoate, 5% of sediment amino calcium formate, 45% of hydrogen phosphate dehydrate, 22% of glycerol, 0.1-0.3 % of edible essence, 0.1-0.3 % of an edible preservative, 0.2% of a sweetening agent, 0.08-0.2 % of a refreshing agent, and 0.0001-0.0002% of a pigment. Ammonium hexafluorosilicate is taken as the functional material and added into the polishing paste, compared with the existing anti-allergy toothpaste, the anti-caries and anti-allergy polishing paste provided by the invention has the more obvious anti-allergy efficacy, in addition, the anti-caries and anti-allergy polishing paste is good in mouthfeel and contains no alcohol, so that the risk of cancer caused by the alcohol is reduced, and thus the product is safe; no side effects including teeth color change are caused; meanwhile, the anti-caries and anti-allergy polishing paste has the effects of preventing caries and killing bacteria, and can well maintain the health of the oral cavity.

Owner:南通上水电子科技有限公司

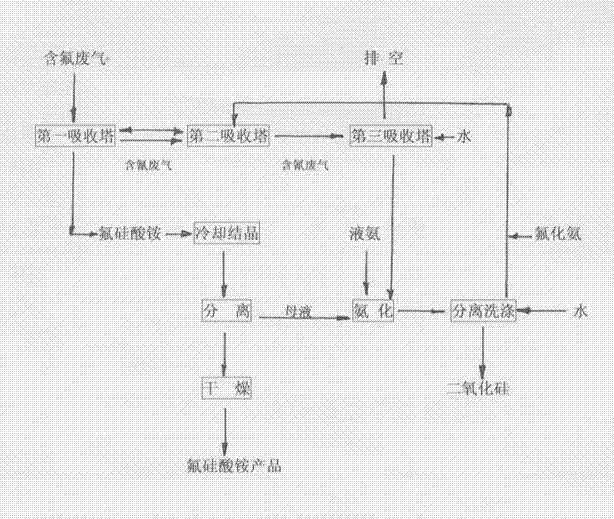

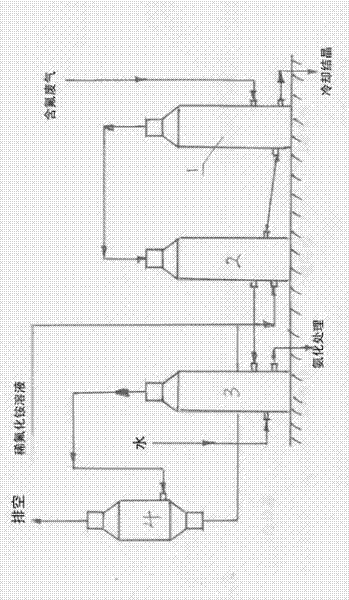

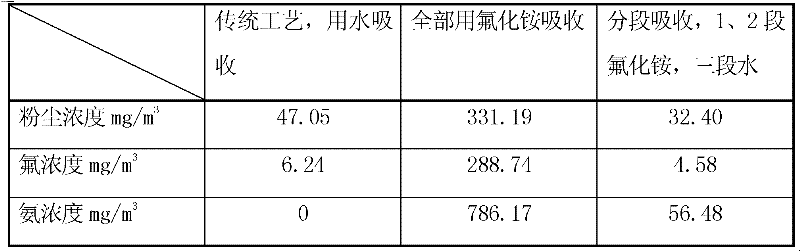

New method for processing fluorine-containing tail gas in production of calcium superphosphate

InactiveCN102380303AGuaranteed qualifiedNo emissionsSilicon halogen compoundsPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesWastewaterTower

The invention discloses a mew method for processing a fluorine-containing tail gas in the production of calcium superphosphate, which considers practical cases of the production of calcium superphosphate and needs of the environmental protection processing of the tail gas and adopts a tail gas segment absorption mode to process wastewater and waste gases. The method of the invention is characterized in that: the fluorine-containing tail gas generated in the production process of calcium superphosphate is processed in a three-segment absorption mode; ammonium fluoride is adopted as an absorption liquid in the first segment and the second segment, and water is adopted as an absorption liquid in the third segment; ammonium fluorosilicate which is well absorbed in the first segment and the second segment is cooled and crystallized to obtain an ammonium fluorosilicate product, and can also be directly ammonified as needed to obtain an over 40% ammonium fluoride solution which can be evaporated and concentrated to obtain an ammonium fluoride product or can be used to prepare other fluorine chemical engineering products; and water is used as an absorption washing liquid in the third segment, and an obtained mixed solution is added with a mother solution (a dilute ammonium fluorosilicate solution) according to the needed concentration amount when the fluorine-containing tail gas which is not completely absorbed in a first absorbing tower and a second absorbing tower or ammonia, or volatilized ammonium fluoride and an ammonium fluorosilicate liquid foam which escape because of the over high temperature of the first absorbing tower and the second absorbing tower is absorbed and washed by water.

Owner:云南氟业化工股份有限公司

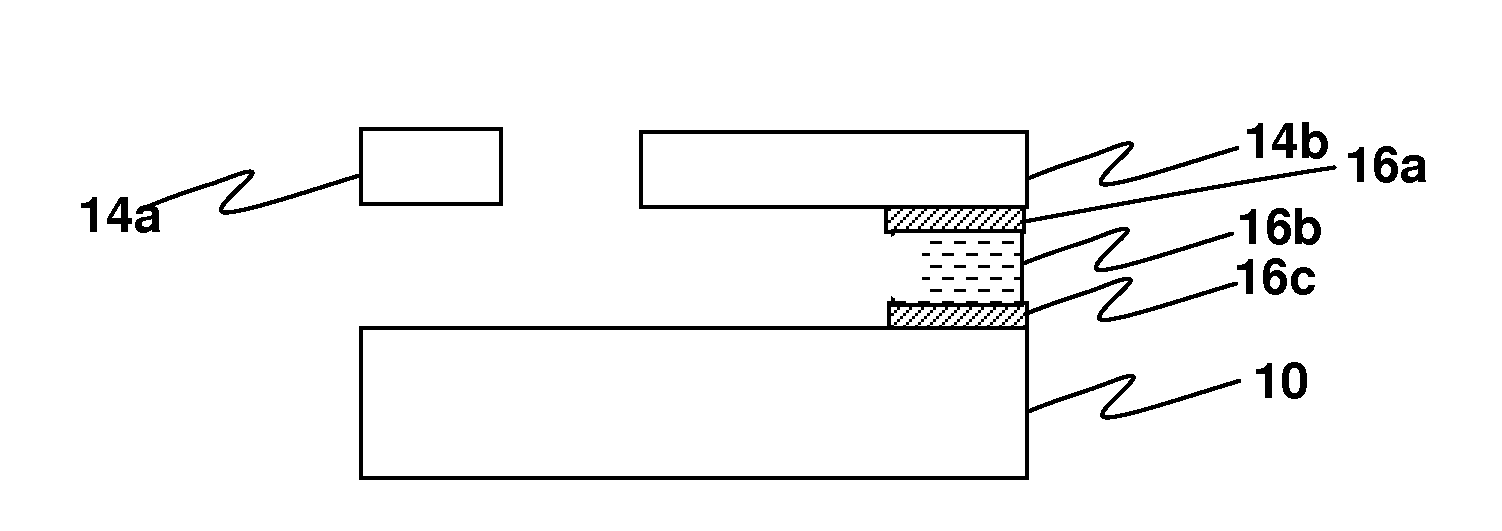

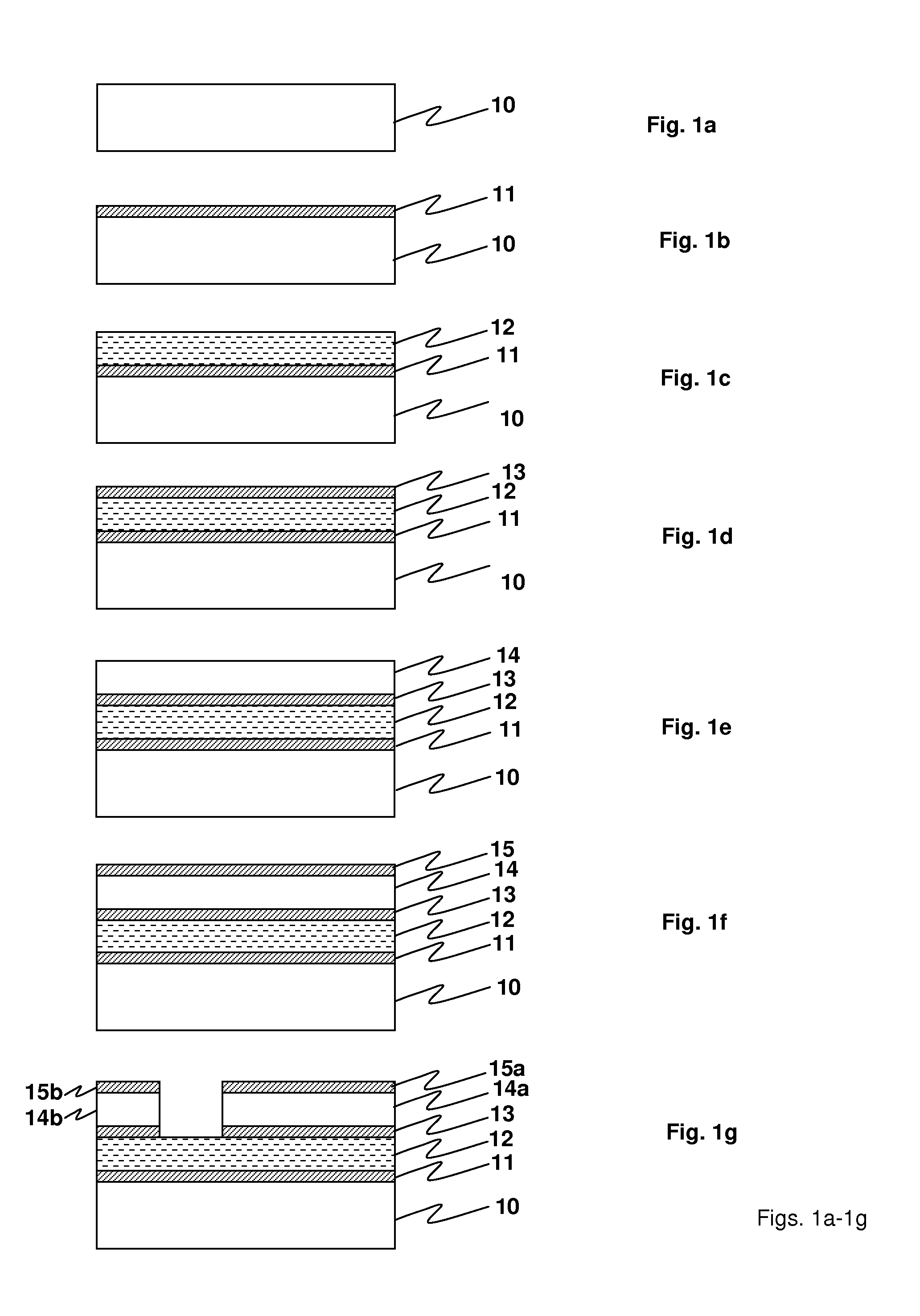

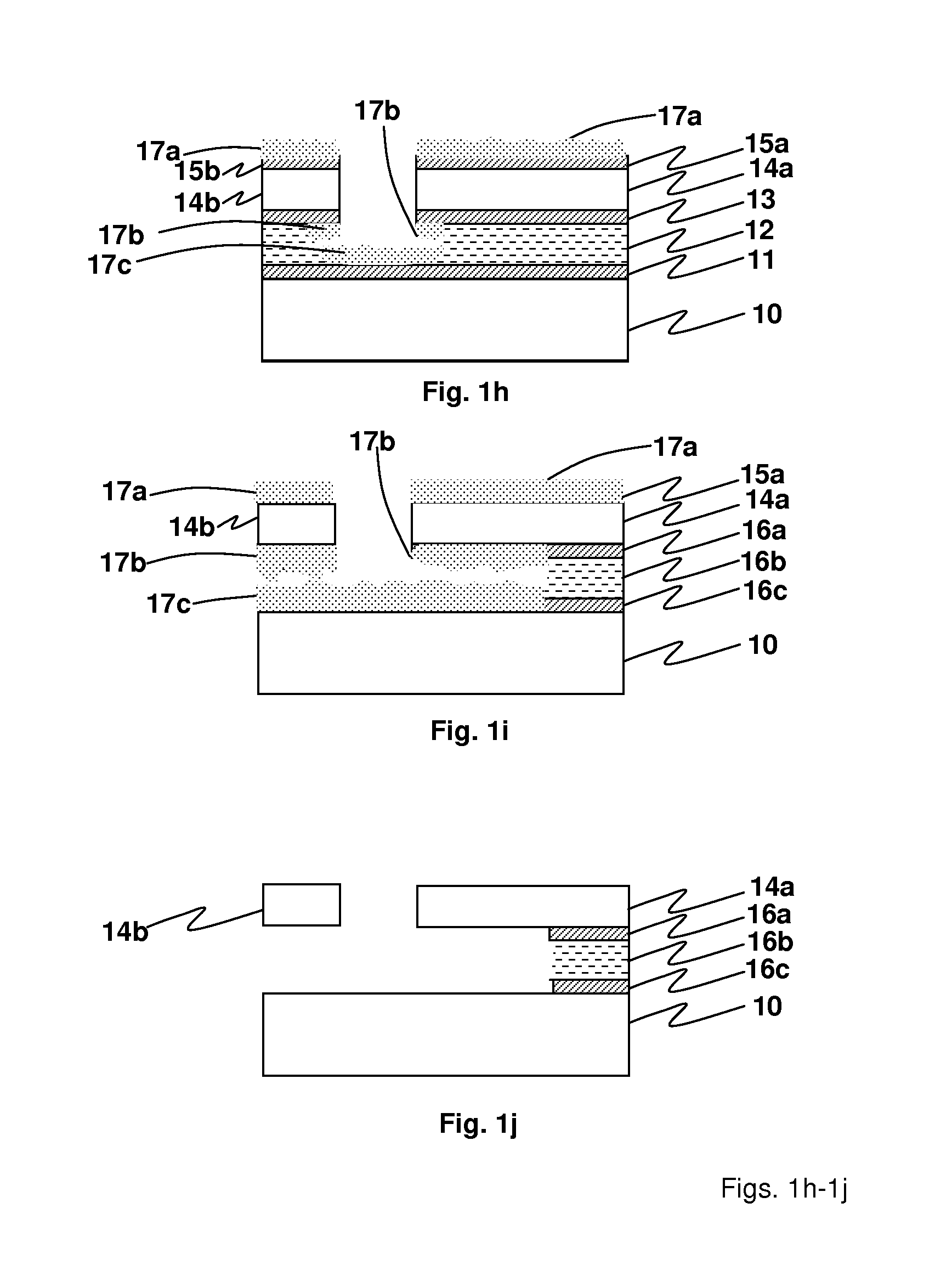

Process for manufacturing electro-mechanical systems

ActiveUS20130334628A1Minimizing and eliminating effectReduce fluxTransducer detailsDecorative surface effectsManufacturing technologyEngineering

A method of avoiding stiction during vapor hydrofluoride (VHF) release of a microelectromechanical system (MEMS) or nanoelectromechanical system (NEMS) composed of a mechanical device and a substrate is described. A silicon nitride layer is provided between the substrate and a sacrificial oxide layer and / or between a device layer and the sacrificial oxide layer, and / or on a side of the device layer facing away from the sacrificial oxide layer, and converted to thicker ammonium hexafluorosilicate with VHF while simultaneously removing a portion of the sacrificial oxide. The ammonium hexafluorosilicate acts as a temporary support, shim, wedge, or tether which limits device movement during fabrication and is later removed by sublimation under heat and / or reduced pressure.

Owner:SPTS TECH LTD

Method of separating and recycling SiO2 and ammonium fluorosilicate from fluorine-containing dust

ActiveCN108928825AGuaranteed qualityFull circulationSilicaFluosilicic acidPregnant leach solutionSlurry

The invention provides a method of separating and recycling SiO2 and ammonium fluorosilicate from fluorine-containing dust, which includes: 1) independently adding two types of fluorine-containing dust, which are sorted according to whiteness of 80%, respectively to different leaching troughs, adding water, circulating washing liquid or crystallization mother liquid for dissolution, wherein the solution is heated during the process with complete stirring, thus leaching the substance; 2) filtering or press-filtering the leached slurry while hot, and separating a leachate and filter residue; 3)adding the leachate into a crystallization kettle for cooling crystallization, and after the substance is completely crystallized, separating the crystal and the crystallization mother liquid; 4) carrying out heat-leaching to the filter residue with the crystallization mother liquid again and performing secondary cooling crystallization; 5) performing multistage countercurrent washing to the filter residue, produced from the material with whiteness being higher than 80%, and drying and crushing the product to obtain SiO2; 6) mixing the crystallization mother liquid and primary concentrated washing liquid of the filter residue, and performing evaporative concentration-cooling crystallization to a part of the solution to obtain the ammonium fluorosilicate.

Owner:SHENZHEN SHENTOU ENVIRONMENT TECH CO LTD

Method for removing native oxide and associated residue from a substrate

InactiveUS20130316533A1Electric discharge tubesElectrostatic cleaningPhysical chemistrySilicon tetrafluoride

Owner:APPLIED MATERIALS INC

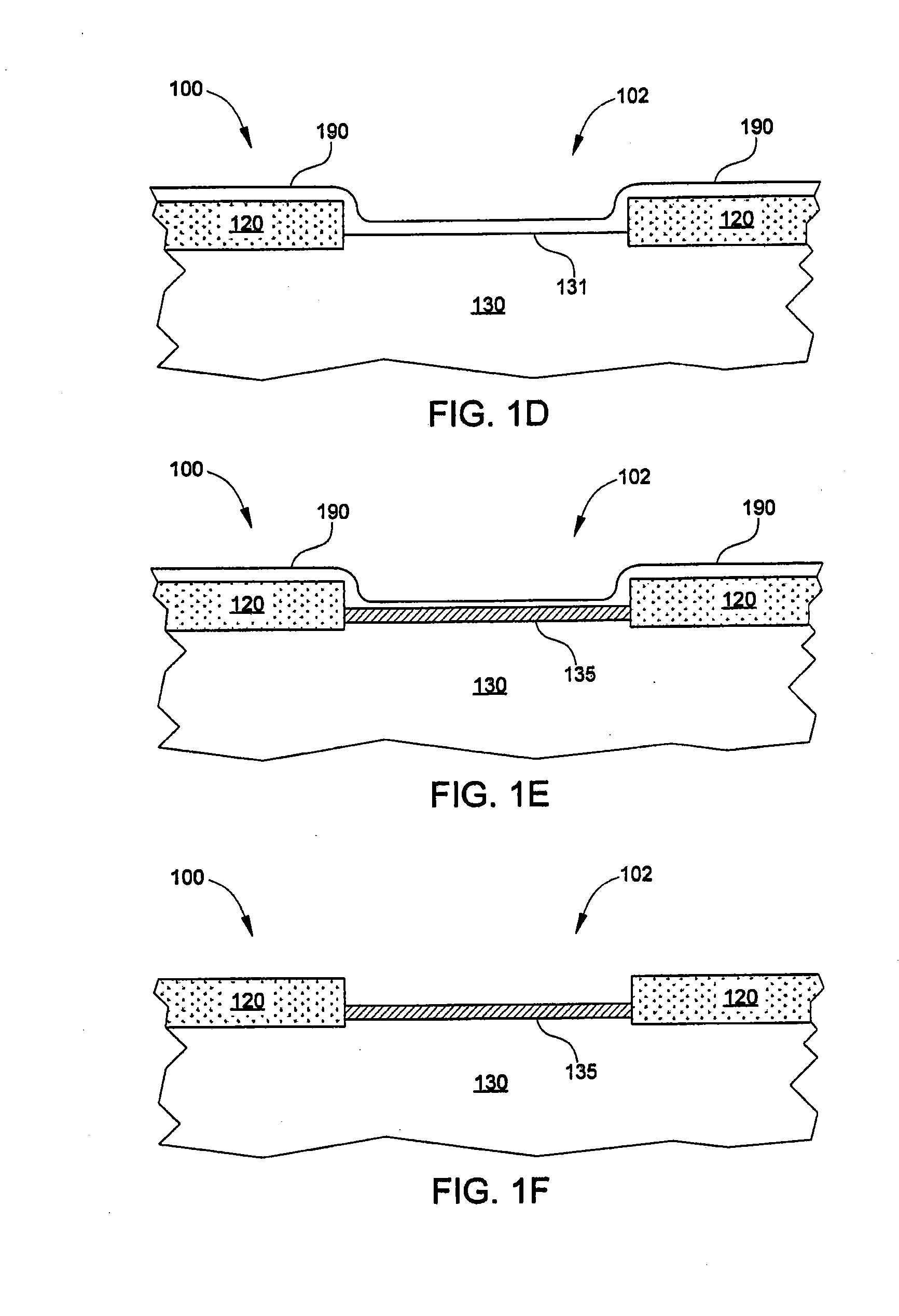

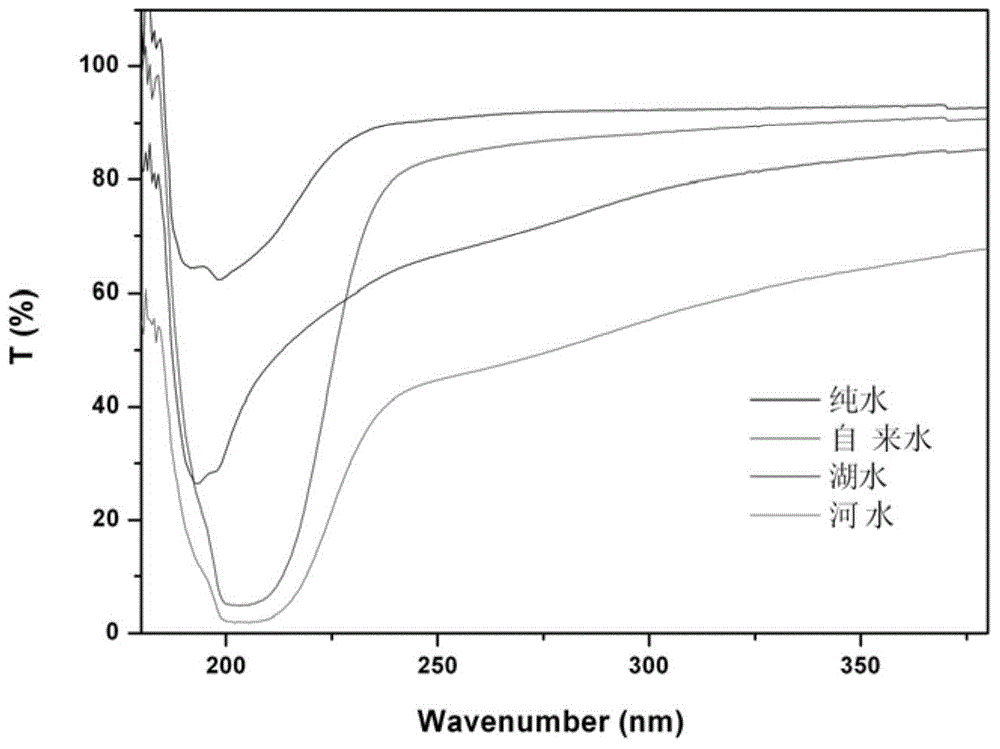

Method for effectively degrading algal toxin in water

InactiveCN104944512AImprove mechanical propertiesGood UV transmittanceWater/sewage treatment by irradiationWater/sewage treatment by sorptionSolventMicro spheres

The invention relates to a method for effectively degrading algal toxin in water. The method comprises the following processing steps: (1) adding MC(Microcystin)-LR into an alcohol-water mixed solvent, oscillating to enable the MC-LR to be completely dissolved, adding ammonium hexafluorotitanate, boric acid and ammonium hexafluorosilicate, reacting for 15-25 hours at the constant temperature of 35 DEG C, immersing a quartz fiber filter band into substances generated through the reaction, taking out and airing the quartz fiber filter band, calcining the quartz fiber filter band at the temperature of 400 DEG C for 2-2.5 hours with the temperature increasing rate of 10 DEG C / min, cooling, and taking out the quartz fiber filter band, so as to obtain the quartz fiber filter band loaded with titanium dioxide porous micro-spheres with the molecular imprinting function; (2) sewing the prepared quartz fiber filter band loaded with the titanium dioxide porous micro-spheres with the molecular imprinting function into a filter sleeve capable of sleeving an ultraviolet lamp tube according to the profile of the ultraviolet lamp tube; (3) inserting the ultraviolet lamp tube capable of being immersed into water into the filter sleeve, and then, placing the filter sleeve into a photoreaction container filled with microcystin polluted water. Through the adoption of the method, the efficiency for degrading algal toxin in water is relatively high.

Owner:张易祥

Oral medicine composition for resisting radiation, preventing dental caries and diminishing inflammation and preparation thereof

InactiveCN104491840ASpecial regulationEnhance immune functionOrganic active ingredientsPeptide/protein ingredientsTectorial membraneOral medicine

The invention discloses an oral medicine composition for resisting radiation, preventing dental caries and diminishing inflammation and a preparation thereof, and belongs to the technical field of oral medicine preparations. The composition is prepared from the following components in parts by mass: 100-500 parts of white hyacinth bean extract, 100-2000 parts of grape seed proanthocyanidin extract, 300-3000 parts of tea polyphenol, 0.01-0.1 part of epidermal growth factor EGF, 10-200 parts of triclosan and 2-6 parts of ammonium hexafluorosilicate. The oral medicine composition and the preparation thereof disclosed by the invention have a durable antibacterial effect, can be attached to the surface of teeth or oral cavity for a long time to form a protective film, can be used for tenderly protecting the oral cavity, has an excellent taste, and is safe to human bodies.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

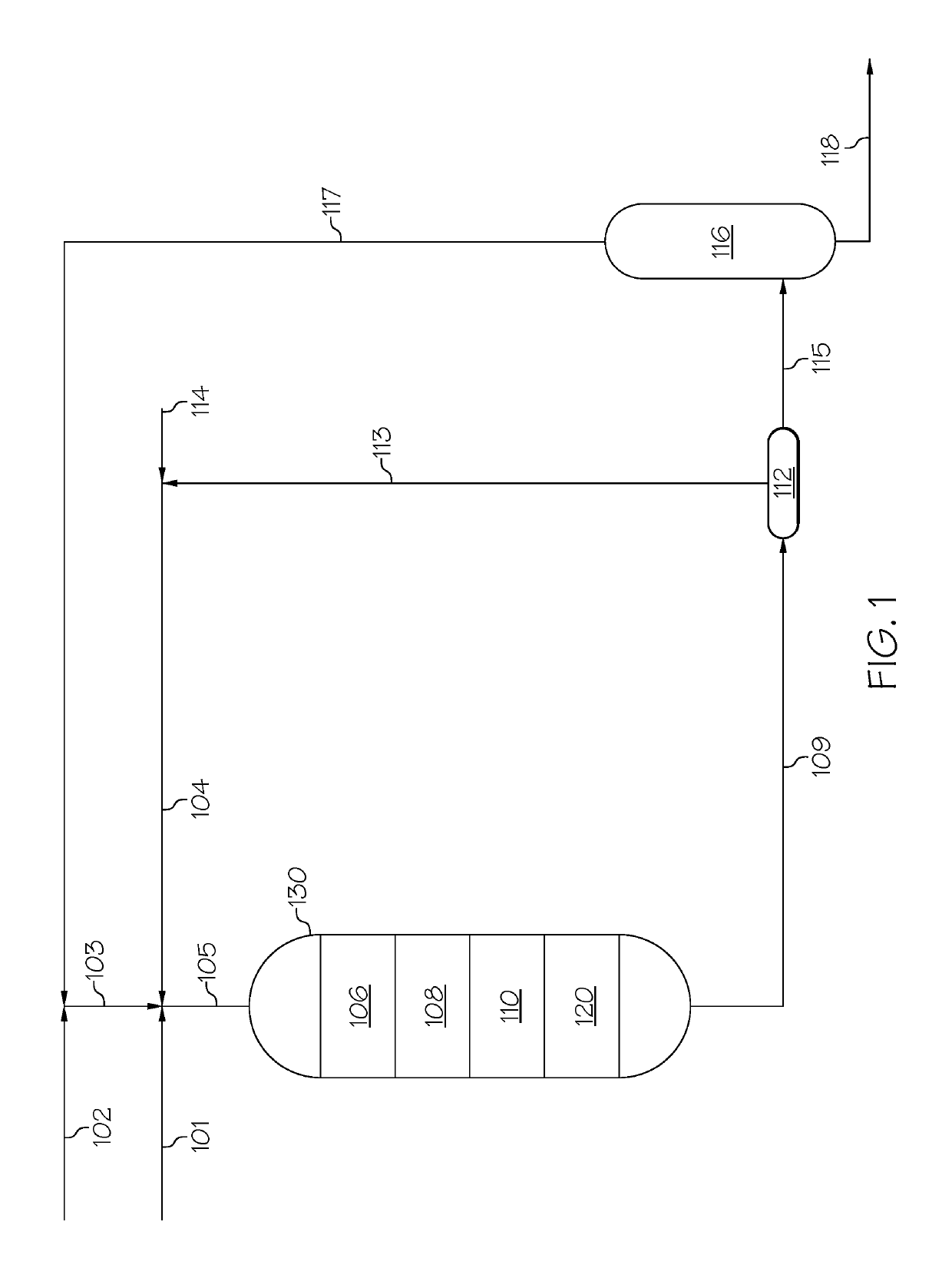

Zeolites, the production thereof, and their uses for upgrading heavy oils

ActiveUS10407311B2Low costLess expensiveMolecular sieve catalystsCatalyst activation/preparationFuel oilModified zeolite

According to one or more embodiments disclosed herein, a mesoporous zeolite may be made by a method comprising contacting an initial zeolite material with ammonium hexafluorosilicate to modify the framework of the initial zeolite material, and forming mesopores in the framework-modified zeolite material. The contacting may form a framework-modified zeolite material. The mesoporous zeolites may be incorporated into catalysts.

Owner:SAUDI ARABIAN OIL CO

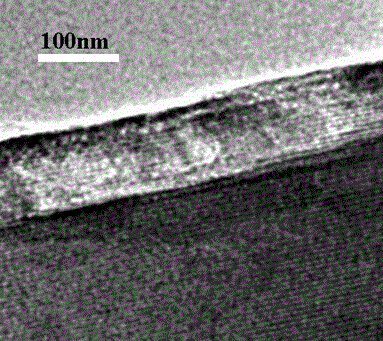

Large-mode-field triple-clad optical fiber, preparation method thereof and optical fiber laser

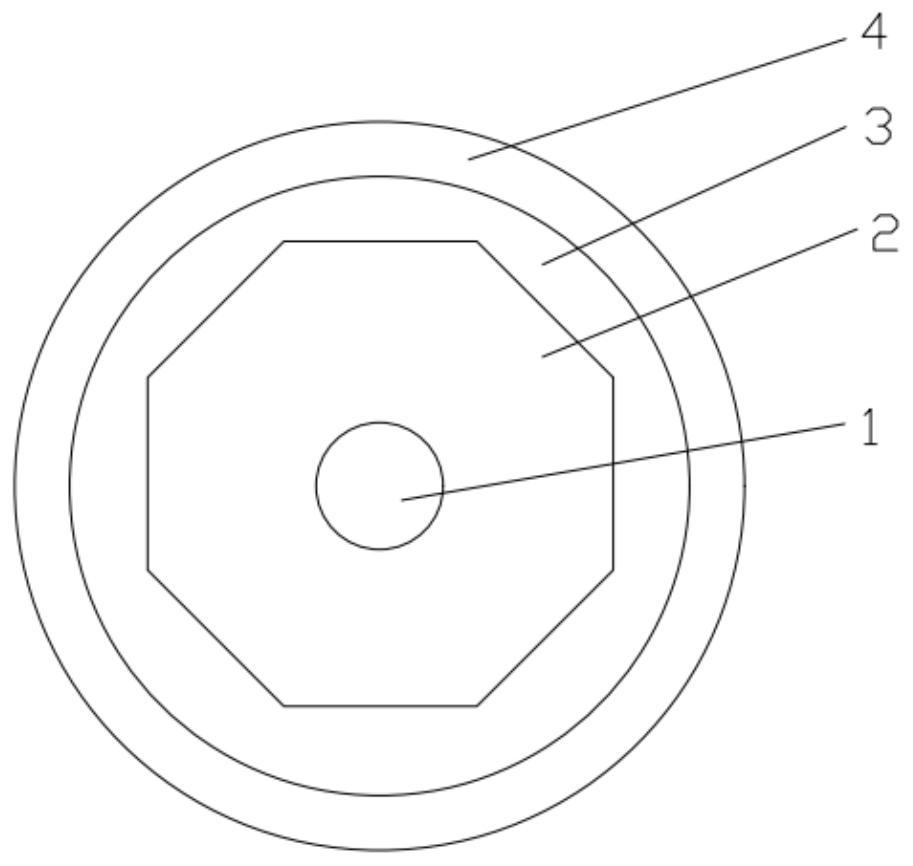

ActiveCN112068243ATake advantage ofIncrease concentrationGlass optical fibreOptical fibre with multilayer core/claddingAluminium chlorideHigh concentration

The invention discloses a large-mode-field triple-clad optical fiber, a preparation method thereof and an optical fiber laser. The large-mode-field triple-clad optical fiber comprises a fiber core, afirst cladding wrapping the fiber core and a second cladding wrapping the first cladding. The fiber core is porous glass sintered after being doped with a co-dopant, and the co-dopant is a mixture ofytterbium ions and at least one of aluminum chloride, ammonium dihydrogen phosphate and cerous nitrate; the first cladding is porous glass that is obtained by doping with at least one of germanium oxide and ammonium hexafluorosilicate and then performing sintering; and the second cladding is porous glass sintered after heavily doping ammonium hexafluorosilicate. Porous glass is adopted as a matrixmaterial, high-concentration and high-uniformity doping of rare earth ions and fluorides can be achieved by fully utilizing the characteristic that the porous glass has nanoscale pore channels whichare communicated with one another, and the refractive indexes of the first cladding and the second cladding are controlled by adjusting the concentration of doping ions; therefore, the laser is effectively bound in the fiber core, and the transmission efficiency and stability of the optical fiber are effectively improved.

Owner:创昇光电科技(苏州)有限公司

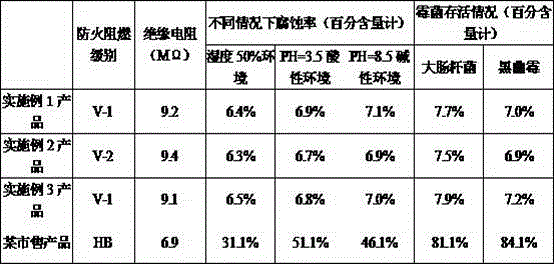

Art design packaging film material

InactiveCN106519713AExcellent flame retardantGood acid and alkali resistanceFlexible coversWrappersROSIN POWDERChromium trioxide

The present invention relates to an art design packaging film material, which comprises rosin pentaerythritol ester, an ethylene-vinyl acetate copolymer, an epichlorohydrin rubber, isobutyl propionate, epichlorohydrin, butyl acetate, glyceryl monostearate, diethanolamine, dimethyl fumarate, bromohexadecane, imidazoline, ammonium fluorosilicate, diantimony trioxide powder, chromium trioxide powder, quick lime powder, limestone powder, asbestos fiber, graphite fiber, disodium octaborate tetrahydrate, rosin powder, hexabromocyclododecane, triphenyl phosphate, sodium stannate, trichloroethyl phosphate, sodium methylenebisnaphthalenesulphonate, tert-butyl peroxybenzoate, benzoyl peroxide, oxidized polyethylene, polyvinyl formal-acetal, and n-oxydiethylidene-2-benzothiazole sulfamide. The product of the present invention has advantages of excellent fire retardation, excellent acid resistance, excellent alkali resistance, excellent anti-mildew property, excellent antibacterial property, and product performance improving.

Owner:安陆市万众创新智能科技有限公司

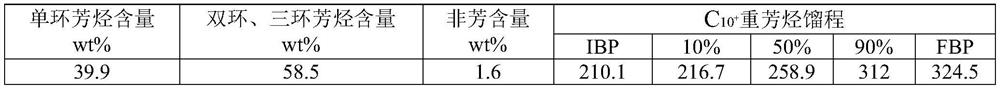

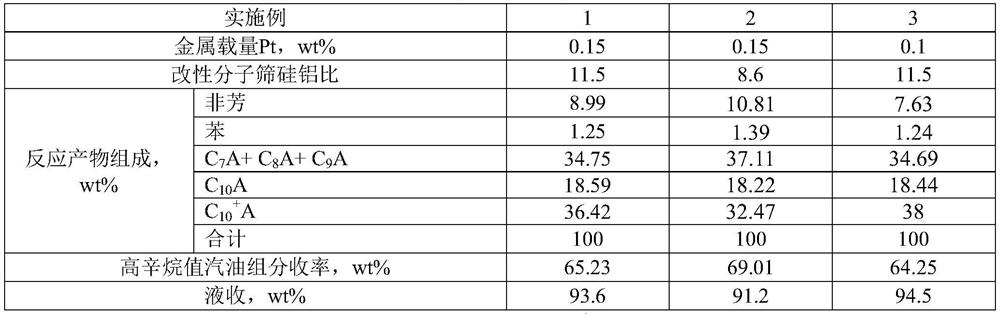

a c 10 + Ring-opening catalyst for selective hydrogenation of heavy aromatics and preparation method thereof

ActiveCN108940354BGood dispersionHigh activityMolecular sieve catalystsHydrocarbon oils refiningHigher alkanesMolecular sieve

The invention discloses a C 10 + A catalyst for selective hydrogenation ring-opening of heavy aromatics and a preparation method thereof. The catalyst of the present invention, based on the mass of the catalyst, consists of the mass percentage of each component: HY molecular sieve 50-80%, platinum metal 0.05-0.35%, and the balance is alumina; the SiO of the catalyst 2 / A1 2 o 3 The molar ratio is 8~13, and the specific surface area is 450~600m 2 / g, the pore volume is 0.35~0.7cm 3 / g; the catalyst is HY molecular sieve first modified by ammonium fluorosilicate and platinum-containing solution, then extruded with alumina, dried and roasted, and finally modified by equal volume impregnation with platinum-containing solution, dried, Made after roasting. The catalyst of the present invention has higher activity and stability for lightening heavy aromatics, and is especially suitable for selective hydrogenation ring-opening of inferior macromolecular heavy aromatics to produce more light BTX aromatics or high-octane gasoline.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

Preparing method of high-selectivity anti-carbon benzene alkylation catalyst

ActiveCN108043449AReduce active center densityClear the channelMolecular sieve catalystsHydrocarbonsHydrolysateIon exchange

The invention belongs to the technical field of petrochemical engineering catalysts, and discloses a preparing method of a high-selectivity anti-carbon benzene alkylation catalyst. The preparing method comprises the steps of 1, selecting a high silica-alumina-ratio MFI zeolite molecular sieve to serve as a parent of the catalyst; 2, mixing acidized silicone grease hydrolysate with the high silica-alumina-ratio MFI zeolite molecular sieve to be subjected to extrusion forming, and then using an aqueous solution of ammonium hexafluorosilicate to treat the formed strip-shaped product; 3, using separating mother liquor which is obtained by using hydration heat to crystallize the high silica-alumina-ratio MFI zeolite molecular sieve to treat the formed strip-shaped product of the high silica-alumina-ratio MFI zeolite molecular sieve; 4, adopting an ion exchange method to convert the formed strip-shaped product of the high silica-alumina-ratio MFI zeolite molecular sieve which is treated by the mother liquor into a hydrogen-form alkylation catalyst. By means of the preparing method of the high-selectivity anti-carbon benzene alkylation catalyst, the mother liquor which is generated duringhydro-thermal synthesis of the high silica-alumina-ratio MFI zeolite molecular sieve is used for treating the formed strip-shaped catalyst, useful ingredients in the mother liquor are recycled, poresof the catalyst are unblocked, and the environmental pollution in the whole production chains of the alkylation catalyst is also reduced.

Owner:DALIAN UNIV OF TECH

Method for preparing ammonium fluorosilicate and coproducing white carbon black from fluorine-containing tail gases of phosphoric acid device

The invention discloses a method for preparing ammonium fluorosilicate and coproducing white carbon black from fluorine-containing tail gases of a phosphoric acid device. The method comprises the following steps: 1) absorbing the fluorine-containing tail gases of the phosphoric acid device by using water or a solution to obtain a solution of which the fluosilicic acid concentration is 9% or more;then, adding ammonia water to neutralize the solution until the pH of the solution is 2 or more, then, stopping adding the ammonia water, carrying out uniform stirring and mixing, and then, discharging the solution; 2) filtering the solution obtained in the step 1), washing and drying the filter residue to prepare white carbon black, and reserving the filtrate for later use; and 3) performing evaporating concentration on the filtrate to a saturated state, and then, carrying out cooling crystallization and filtration to obtain a filter residue, namely ammonium fluorosilicate. By using the method, not only is the treatment problem of the fluorine-containing tail gases solved, but also the utilization value of a fluorine-containing resource is increased, the application field of the fluorine-containing resource is widened, and the social and economic benefits are remarkably increased.

Owner:HUBEI LIUGUO CHEM IND

Controllable synthesis method of all-silicon and high-silicon CHA molecular sieve membrane

ActiveCN111530302AEasy to synthesizeReduce consumptionSemi-permeable membranesProductsMolecular sieveHexafluorosilicic acid

The invention relates to a controllable synthesis method of an all-silicon and high-silicon CHA molecular sieve membrane. The method comprises the following steps: taking N, N, N-trimethyl-1-adamantylammonium hydroxide (TMAdaOH) as a template agent, taking ammonium hexafluorosilicate, or a common silicon source and fluoride as silicon sources, and synthesizing the all-silicon and high-silicon CHAmolecular sieve membrane in a dilute solution with H2O / SiO2 of about 30. Meanwhile, an atomic economic synthesis method is developed and is also called sol-free synthesis, so that the use of a largeamount of mother liquor in traditional hydrothermal synthesis is avoided, the utilization rate of raw materials is greatly increased, and the cost for preparing the membrane is reduced. The thicknessof the prepared all-silicon and high-silicon CHA molecular sieve membrane is less than 1 micron, and the all-silicon and high-silicon CHA molecular sieve membrane has excellent CO2-CH4 separation performances.

Owner:SHANGHAI UNIV OF ENG SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com