New method for processing fluorine-containing tail gas in production of calcium superphosphate

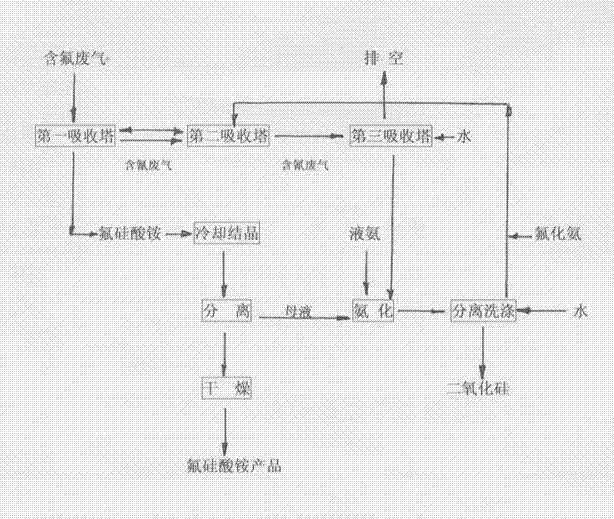

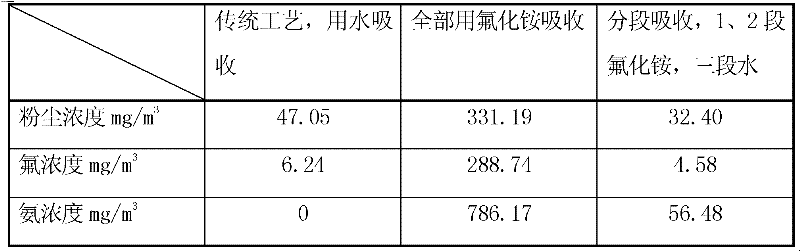

A technology of calcium superphosphate and a new method is applied in the new field of treating fluorine-containing tail gas in the production of calcium superphosphate, which can solve the problems of increasing pollutants such as ammonia, nitrogen emission, easy escape of ammonium fluorosilicate, etc., and achieve an environment-friendly environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: produce 1000Kg ammonium fluorosilicate product, by weight percentage

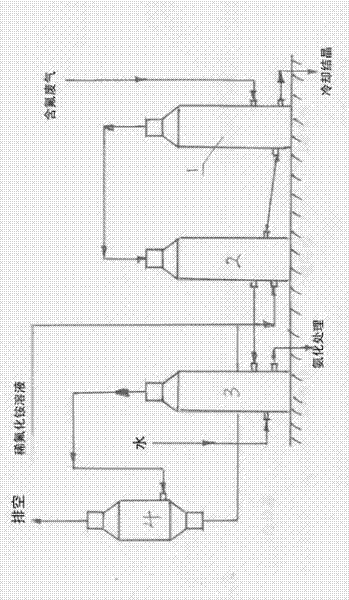

[0031]1. The silicon tetrafluoride gaseous waste gas escaped in the superphosphate production process is absorbed by the ammonium fluoride solution of 18%-20% with a concentration (the first two stages of absorption process), and the temperature of the first absorption tower 1 is controlled to be 80°C, The temperature in the second absorption tower 2 is 60°C, when the pH value of the solution in the first absorption tower 1 and the second absorption tower 2 reaches 3.0-3.5, react ammonium fluoride with silicon tetrafluoride gas to generate fluorosilicic acid 4000Kg of ammonium is discharged from the bottom of the first absorption tower (1) into the cooling crystallization tank, under continuous stirring, to prevent the crystals from blocking the pipeline, and naturally cool to room temperature in the crystallization tank, at this time, a large amount of ammonium fluorosilicate crystals a...

Embodiment 2

[0038] Taking the calcium superphosphate plant with an annual output of 300,000 tons as the implementation plan, put 6 tons of ammonium fluoride solution with a concentration of 20.5% into the first absorption tower 1 and the second absorption tower 2 of the tail gas absorption system respectively, The third absorption tower 3 still uses water as the absorption washing liquid. At this time, send the fluorine-containing waste gas generated in the production process of superphosphate to the first absorption tower 1, control the temperature of the first absorption tower 1 to 60°C, and the inside of the second absorption tower to 80°C, and the pH value in the first absorption tower 1 When reaching 3.5, more than 99% of ammonium fluoride has been converted into ammonium fluorosilicate. From the first absorption tower 1, this solution is all put into the tank with stirring paddles, and allowed to cool naturally. When the ammonium fluorosilicate solution discharged from the first ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com