Whole process variable pressure controlled carburation method

A variable voltage control, whole process technology, applied in metal material coating process, coating, solid diffusion coating and other directions, can solve the problems affecting the comprehensive mechanical properties of parts, large fluctuations in product quality, grain growth, etc. Achieve the effect of shortening the production process cycle, considerable economic benefits, and reducing carburizing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

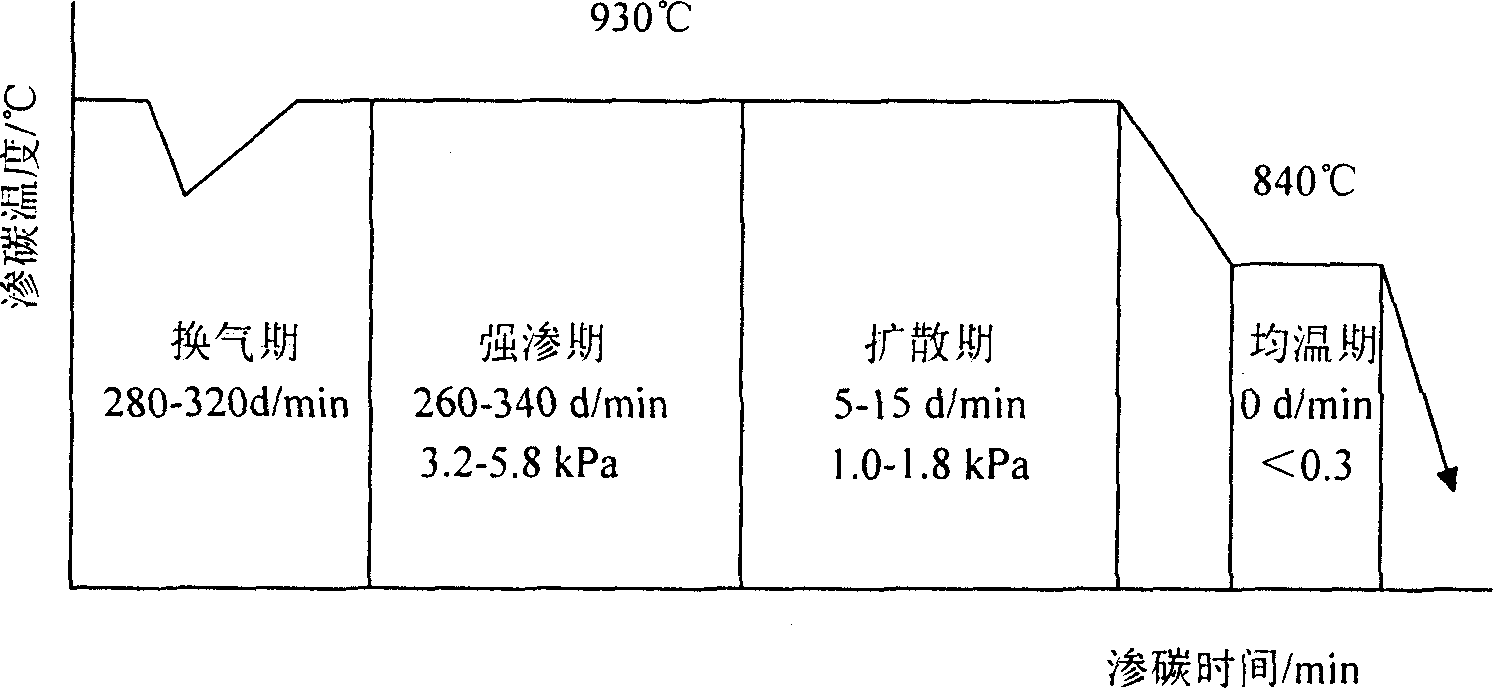

[0011] Such as figure 1 As shown, the whole process of carburizing in the present invention includes a ventilation stage, a strong infiltration stage, a diffusion stage, and a cooling and quenching maintenance stage. The figure shows the process parameters and pressure value control range of each stage.

[0012] The carburizing technology operation steps of the whole process pressure change control of the present invention: as shown in the pressure change carburizing process curve of the accompanying drawing:

[0013] 1. During the ventilation period, after the parts are installed in the furnace, the temperature is raised to 880°C, and the amount of kerosene drops is increased, and the sample hole and the exhaust hole valve are opened at the same time to speed up the ventilation process.

[0014] 2. In the strong infiltration period, when the carbon potential (CP value) of the atmosphere reaches above 1.1, close all exhaust valves, adjust the drop rate of kerosene to 260-340d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com