Method for manufacturing reinforced concrete basement external wall

A technology of reinforced concrete and production methods, which is applied to the processing of walls, building materials, and building components, and can solve problems such as increased construction costs, hidden dangers of external wall waterproofing, and unsatisfactory production methods for reinforced concrete external walls in basements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

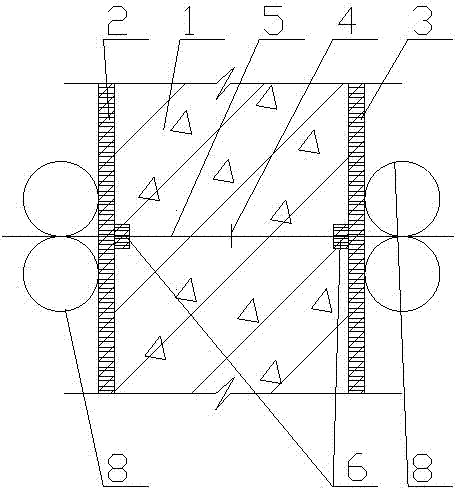

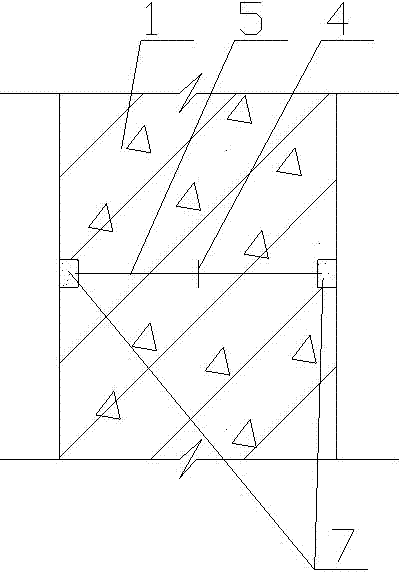

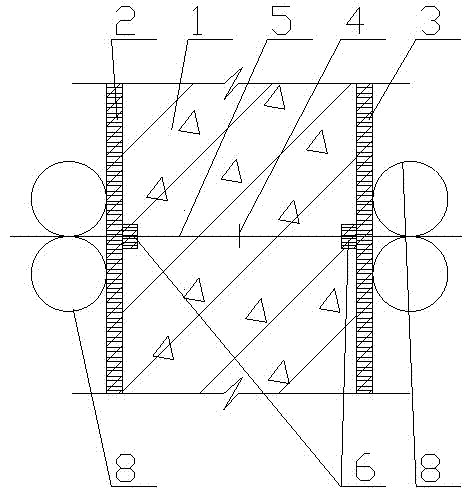

[0011] The present invention will be further described below in conjunction with the drawings and embodiments.

[0012] The embodiment of the present invention: when the basement reinforced concrete external wall construction is carried out, especially when the basement reinforced concrete external wall construction of the high-rise building is carried out, the construction method of the basement reinforced concrete external wall of the present invention is adopted. The method includes pre-connecting a pair of pull screws 5 with a water-stop iron sheet 4 between the inner formwork 2 and the outer formwork 3 used for pouring the basement reinforced concrete outer wall 1. When the opposite drawing screw 5 is connected with the inner template 2 and the outer template 3, a wooden stopper 6 is installed at both ends of the opposite drawing screw 5, and the wooden stopper 6 can be made into a cylindrical shape or a rectangular column shape. The height of the wooden stopper 6 It can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com